Cable for automobiles

A cable and automobile technology, which is applied in the field of automotive cables, can solve the problems of flammability, heat resistance, solution resistance, fire performance not meeting the requirements, and fire, etc., to achieve improved flexibility, good physical and mechanical properties, and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

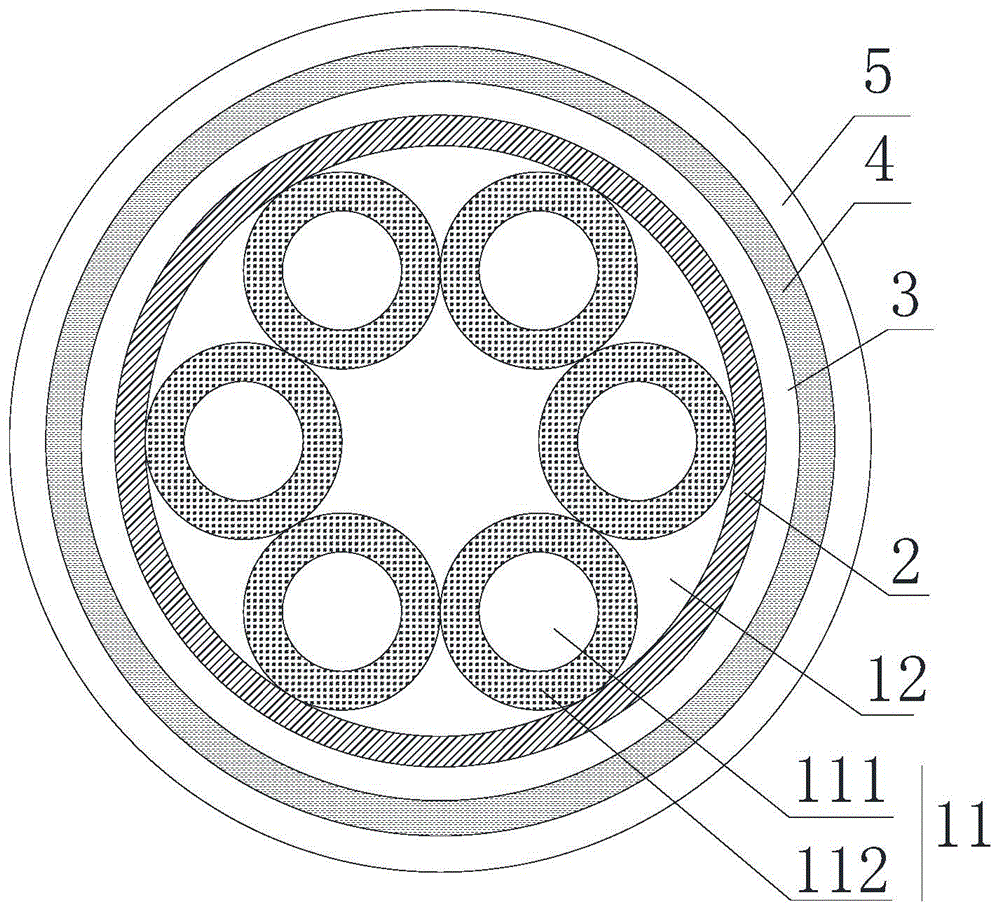

Image

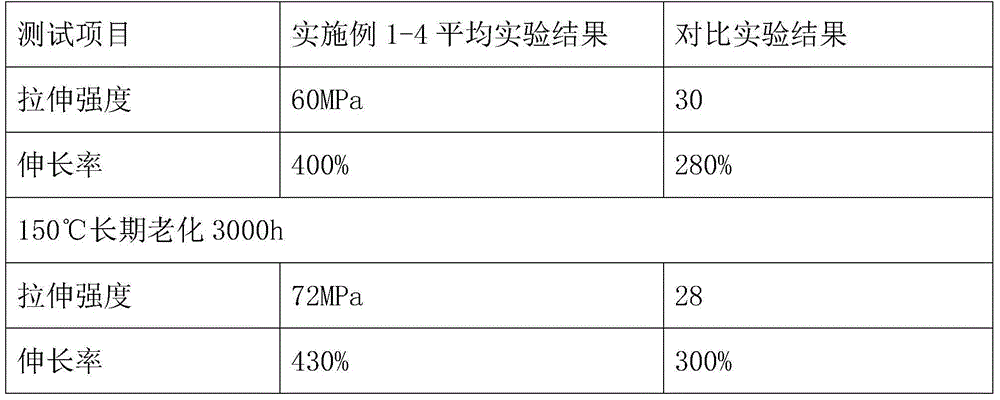

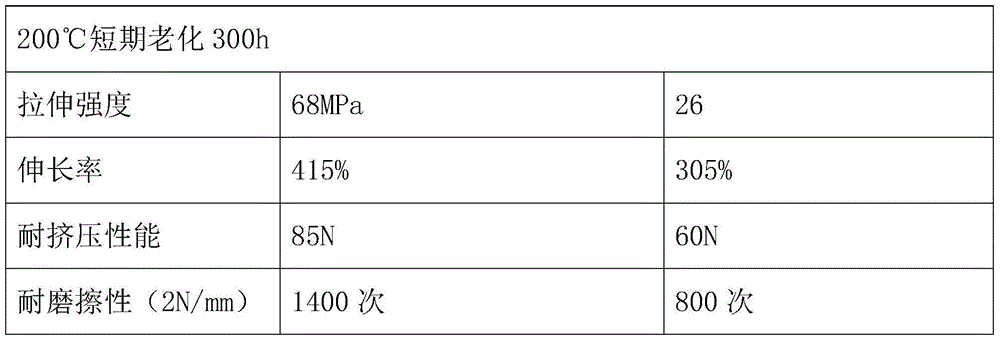

Examples

Embodiment 1

[0020] A kind of automobile cable that the present invention proposes, its sheath material comprises by weight: 30 parts of nitrile rubber, 10 parts of 2,4-toluene diisocyanate dimer, 20 parts of isocyanate-terminated polyurethane prepolymer, 2 parts of butyl phthalate, 0.4 parts of octyl phthalate, 0.6 parts of dioctyl terephthalate, 30 parts of carbon black, 14 parts of calcium carbonate, 10 parts of kaolin, 12 parts of modified mica, liquid ring 5 parts of oxygen resin, 4 parts of polyethylene vinyl ester, 1 part of tetrafluoroethylene, 1 part of antioxidant 1010, 0.8 part of antioxidant 1035, 2 parts of antioxidant 1076, 2 parts of vulcanization system, wherein the vulcanization system is by weight Including: 2 parts of stearic acid, 0.5 parts of manganese dioxide, 2 parts of antimony dioxide, 0.8 parts of dicumyl peroxide, and 1.4 parts of tetramethylthiuram monosulfide.

[0021] The synthesis process of the isocyanate-terminated polyurethane prepolymer is as follows: hea...

Embodiment 2

[0026] A kind of automobile cable that the present invention proposes, its sheath raw material comprises by weight: 50 parts of nitrile rubber, 5 parts of 2,4-toluene diisocyanate dimer, 30 parts of isocyanate-terminated polyurethane prepolymer, 1 part of butyl phthalate, 0.8 parts of octyl phthalate, 0.2 part of dioctyl terephthalate, 40 parts of carbon black, 10 parts of calcium carbonate, 20 parts of kaolin, 5 parts of modified mica, liquid ring 8 parts of oxygen resin, 2 parts of polyethylene vinyl ester, 3 parts of tetrafluoroethylene, 0.5 part of antioxidant 1010, 1.2 parts of antioxidant 1035, 1 part of antioxidant 1076, 3 parts of vulcanization system, wherein the vulcanization system is by weight Including: 1 part of stearic acid, 0.8 parts of manganese dioxide, 1 part of antimony dioxide, 1.4 parts of dicumyl peroxide, and 0.5 parts of tetramethylthiuram monosulfide.

[0027] The synthesis process of isocyanate-terminated polyurethane prepolymer is as follows: heat a...

Embodiment 3

[0032] A kind of automobile cable that the present invention proposes, its sheath raw material comprises by weight: 40 parts of nitrile rubber, 8 parts of 2,4-toluene diisocyanate dimer, 22 parts of isocyanate-terminated polyurethane prepolymer, 1.8 parts of butyl phthalate, 0.5 parts of octyl phthalate, 0.5 parts of dioctyl terephthalate, 34 parts of carbon black, 12 parts of calcium carbonate, 14 parts of kaolin, 10 parts of modified mica, liquid ring 5.2 parts of oxygen resin, 3.8 parts of polyethylene vinyl ester, 1.2 parts of tetrafluoroethylene, 0.95 parts of antioxidant 1010, 0.8 part of antioxidant 1035, 1.8 parts of antioxidant 1076, 2.3 parts of vulcanization system, wherein the vulcanization system is by weight Including: 1.8 parts of stearic acid, 0.6 parts of manganese dioxide, 1.8 parts of antimony dioxide, 0.9 parts of dicumyl peroxide, and 1.3 parts of tetramethylthiuram monosulfide. The thickness of the modified mica sheet is 0.005-0.014 microns, and the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com