Conductive coating of anti lightning stroke and method for preparing the same

A kind of conductive paint and anti-lightning technology, applied in the direction of conductive paint, coating, etc., can solve the problems of increasing aircraft load, cumbersome, complex lightning protection devices, etc., to achieve improved electrical conductivity, good electrical conductivity, good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

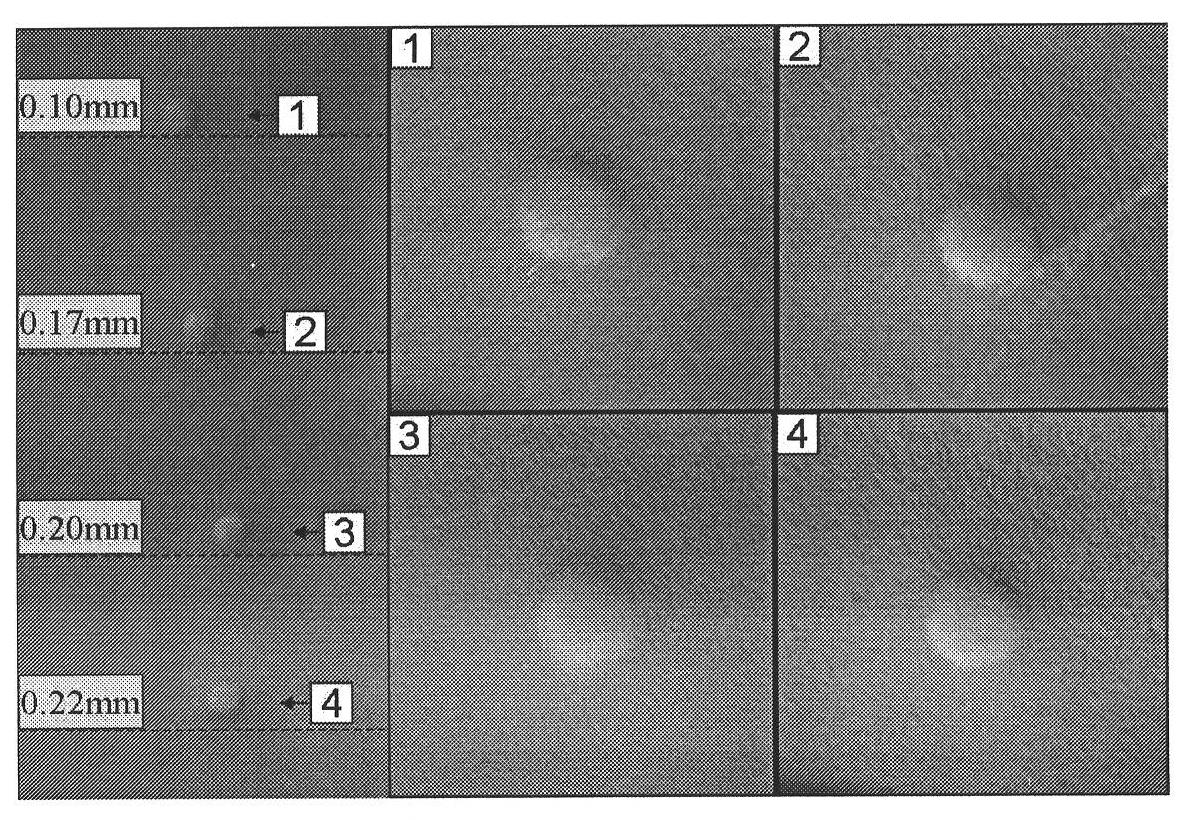

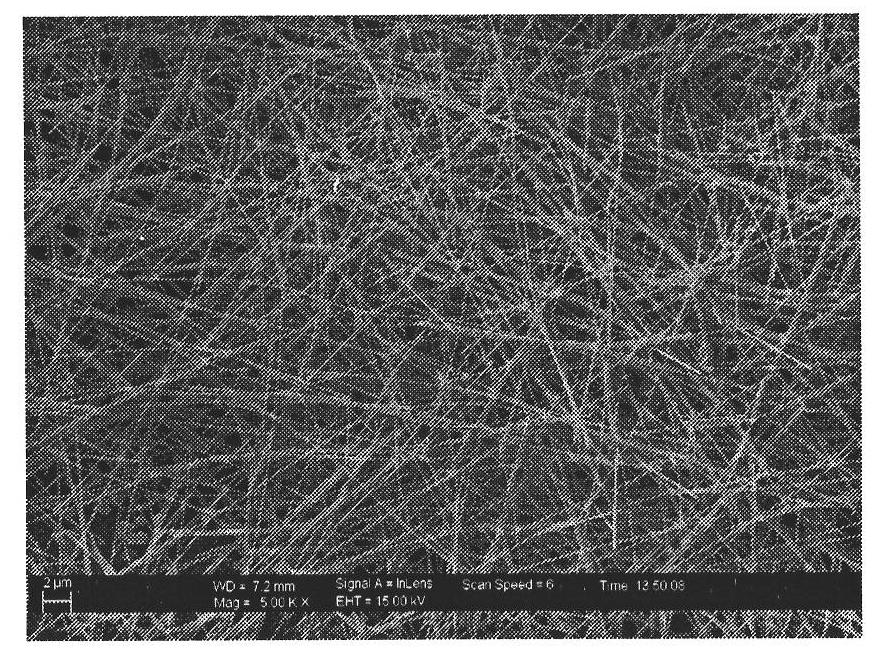

Image

Examples

preparation example Construction

[0020] The preparation steps of anti-lightning strike conductive coating are as follows:

[0021] 1) In terms of mass percentage, 35% to 70% of silver powder, 2.1% to 4.2% of cellulose acetate butyrate, 1.1% to 2.1% of dispersant, 12.7% to 33.1% of silicone resin, 1.9% ~5.0% dibutyl phthalate and 1.1%~3.0% defoamer are mixed, and then diluted with butyl acetate to a solid content of 40wt%~60wt%, and then fully ground to disperse the filler evenly;

[0022] 2) Add 7.9% to 20.7% of hexamethylene diisocyanate biuret polyurethane curing agent into the uniformly ground mixture, and continue to grind evenly to obtain a lightning-resistant conductive coating.

Embodiment 1

[0025] Weigh 8.5884g spherical silver powder, 5.1585g 10wt% cellulose acetate butyrate CAB-20 solution, 0.5535g Deqian 904s dispersant, 5.0085g Dow Corning 840 silicone resin, 0.4715g dibutyl phthalate and 0.0506 g Deqian 6800 defoamer, mix them with each other, and then dilute it with butyl acetate until the solid content is within the range of 40wt% to 60wt%, and then grind it sufficiently to make the filler disperse evenly. Then weigh 2.4925g of 75wt% Bayer N75 curing agent solution and add it to the homogeneously ground mixture, and continue grinding. After the pre-curing reaches the construction viscosity, the prepared anti-lightning strike conductive coating is applied to the surface of the sample. After fully drying, the mass percentage of the spherical silver powder in the coating is about 60%, and the measured resistivity of the coating is about 0.11 Ohm·cm. At the same time, the conductive paint pre-cured to meet the construction viscosity requirement was brush-coat...

Embodiment 2

[0027] Take by weighing 0.6438g spherical silver powder, 0.3845g 10wt% cellulose acetate butyrate CAB-20 solution, 0.0223g Deqian 904s dispersant, 1.0123g Dow Corning 840 silicone resin, 0.0987g dibutyl phthalate and 0.0530g Deqian 6800 defoamer, mix them with each other, and then dilute it with butyl acetate until the solid content is within the range of 40wt% to 60wt%, and then grind it sufficiently to make the filler disperse evenly. Then weigh 0.5013g of 75wt% Bayer N75 curing agent solution and add it to the homogeneously ground mixture, and continue grinding. After pre-curing reaches the construction viscosity, apply the prepared anti-lightning strike conductive coating on the surface of the sample. After fully drying, the mass percentage of the spherical silver powder in the coating is about 35%, and the measured resistivity of the coating is about 102.47 Ohm·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com