Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

A technology of cyclohexanedicarboxylic acid dibasic ester and phthalic acid dibasic ester is applied in the field of preparing 1,2-cyclohexanedicarboxylic acid dibasic ester, which can solve problems such as harm to human health and reduce reaction pressure. and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

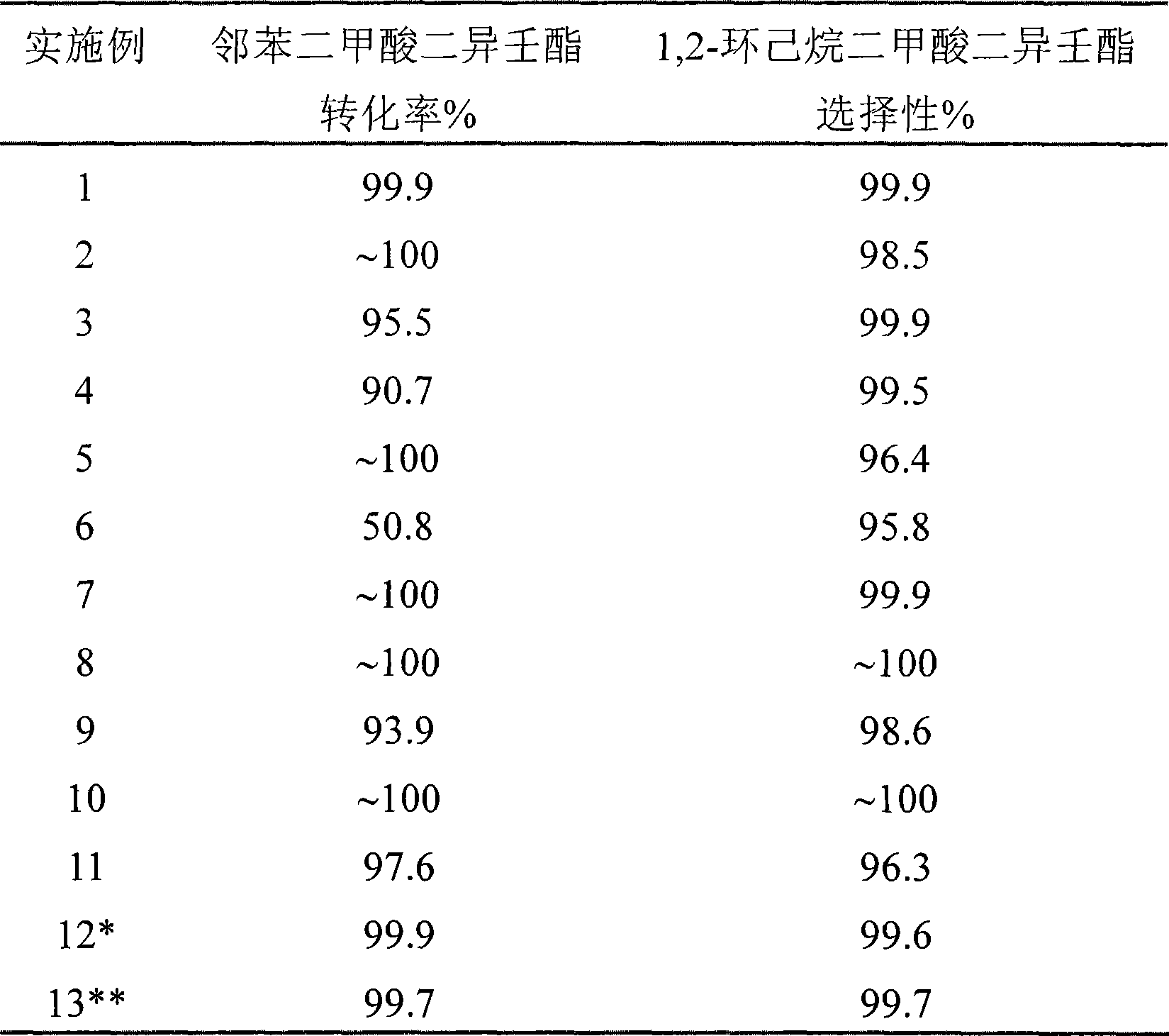

Examples

Embodiment 1

[0018] The catalyst used is Pd-Ru-ZrO 2 / Al 2 o 3 . Catalyst weight composition is: Pt=1%, ZrO 2 =2%, Ru=0.03%, the rest is the carrier Al 2 o 3 . Carrier Al 2 o 3 Using the product Al from Tianjin Research Institute of Chemical Industry 2 o 3 , and the catalyst active component Pd and additives Ru and ZrO were added by conventional impregnation method 2 Carried on the carrier Al 2 o 3 (Al 2 o 3 The particle size is 20-40 mesh). 5.0 grams of catalyst were activated by hydrogen before the reaction, the activation conditions are: GHSV=1200~2400h -1 , Atmospheric pressure ~ 1.0MPa, 200 ~ 400 ℃, reduction time 5 ~ 12 hours. A trickle bed reactor is used. The reaction temperature is 200°C, the hydrogen pressure is 5.0MPa, and the H 2 The / ester molar ratio is 150, and the weight space velocity of diisononyl phthalate is 0.5h -1 , the reaction time is 20h, sampling analysis. The analysis of fatty dibasic acid dibasic esters and phthalic dibasic acid dibasic ester...

Embodiment 2

[0020] The weight space velocity of diisononyl phthalate is 0.3h -1 , other conditions are identical with embodiment 1.

Embodiment 3

[0022] The weight space velocity of diisononyl phthalate is 0.8h -1 , other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com