Patents

Literature

302 results about "Diisononyl phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diisononyl phthalate (DINP) is a phthalate used as a plasticizer. DINP is typically a mixture of chemical compounds consisting of various isononyl esters of phthalic acid, and is commonly used in a large variety of plastic items.

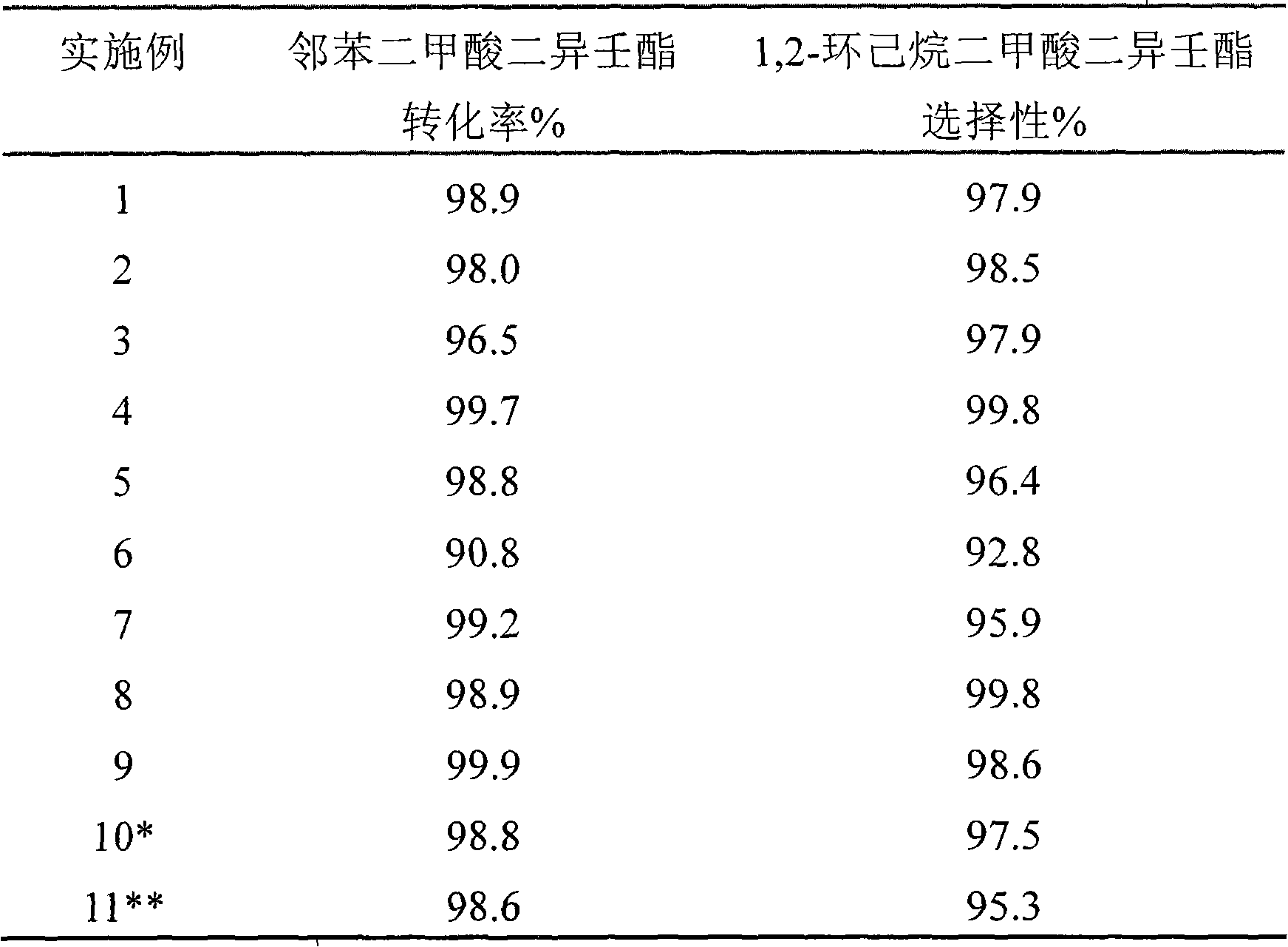

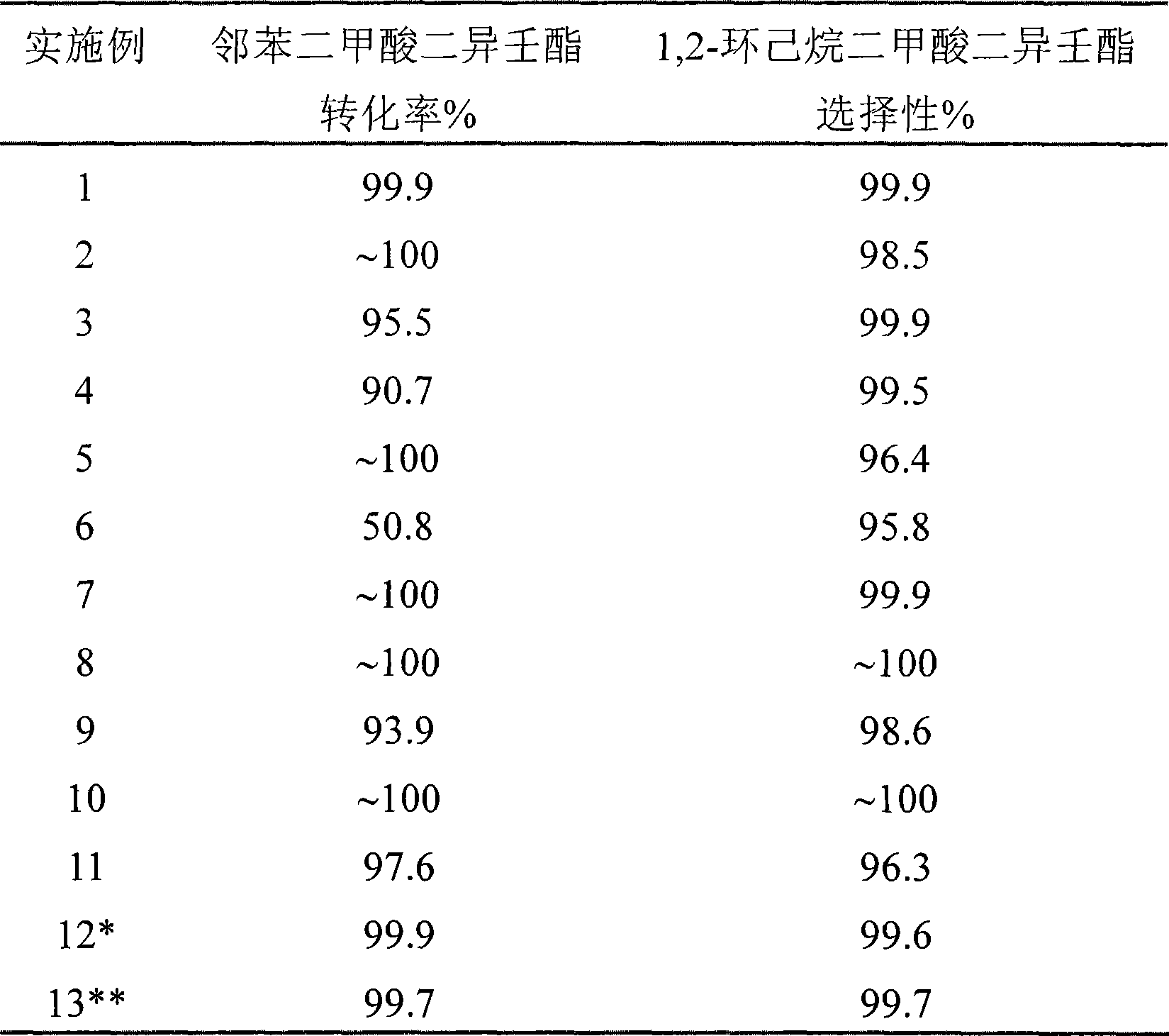

Catalyst for producing 1,2-cyclohexane dicarboxylic acid diesters

InactiveCN101406840AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention provides a catalyst for converting diisononyl phthalate, diisooctyl phthalate, dibutyl phthalate and other long-chain esters into corresponding 1, 2-cyclohexane dicarboxylic acid binary ester through hydrogenation. The catalyst for converting the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters into corresponding the 1,2-cyclohexane dicarboxylic acid binary ester through the hydrogenation consists of main active ingredients, additives and carriers, wherein the main active ingredients are noble metal Ru and Pd; the additives are Fe, Co, Ni, Cu and other metals or oxides; and macroporous Al2O3, ZrO2, TiO2 and the like are selected as the carriers. Under certain temperature, certain hydrogen pressure and the action of the catalyst, the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters in a trickle bed reactor can be converted into the corresponding the 1, 2-cyclohexane dicarboxylic acid binary ester with high activity and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

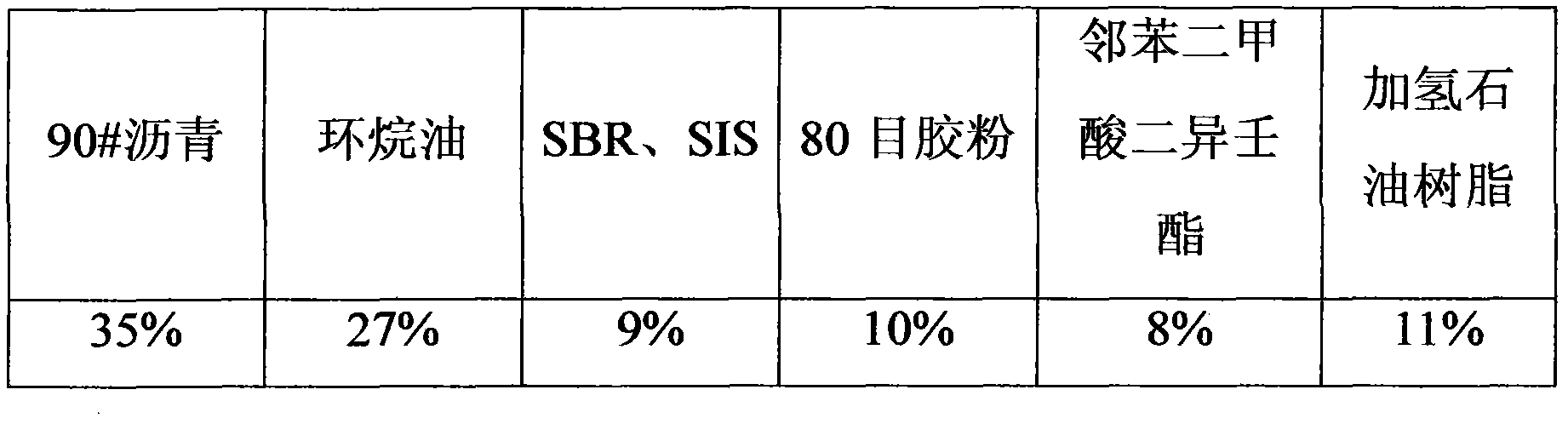

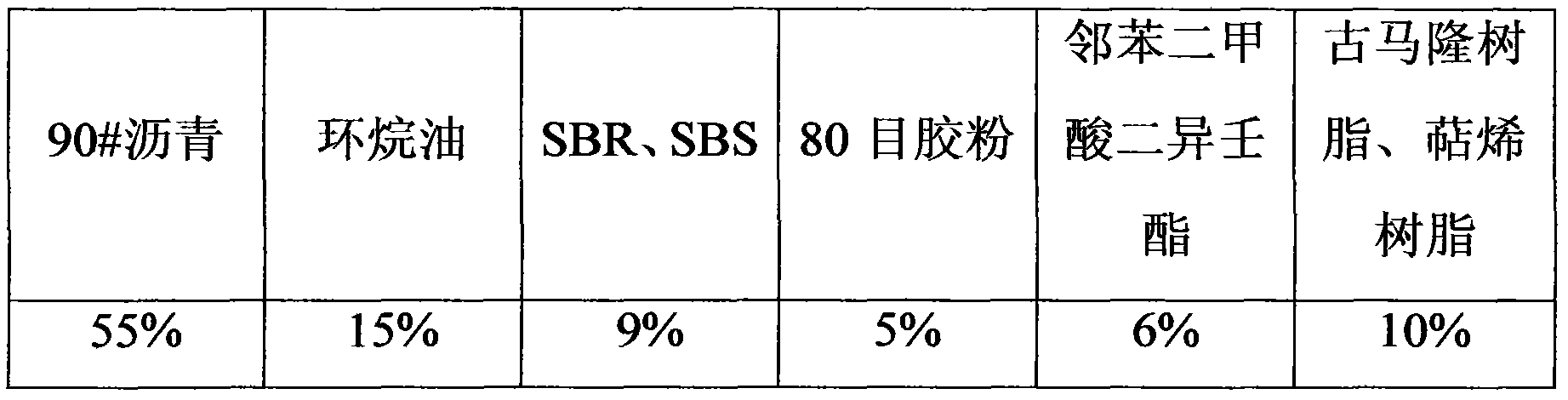

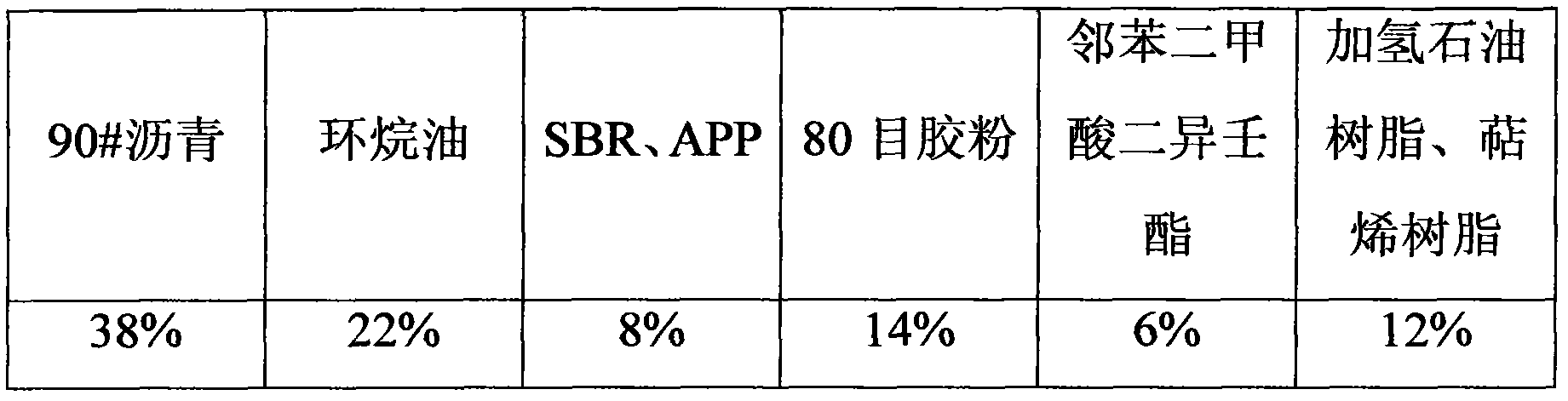

Non-cured asphalt mastic

The invention requests to protect non-cured asphalt mastic comprising the following components in percentage by weight: 35-55 asphalt, 15-30 naphthenic oil, 3-10 polymer modifying agent, 55-20 gelatin powder, 3-10 diisononyl phthalate and 10-20 tackifying resin. The non-cured asphalt mastic can be independently used or can be used with the matched coil to form a waterproof system and can effectively solve the problem of water leakage caused by the crack of a waterproof layer due to the deformation of a base layer.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

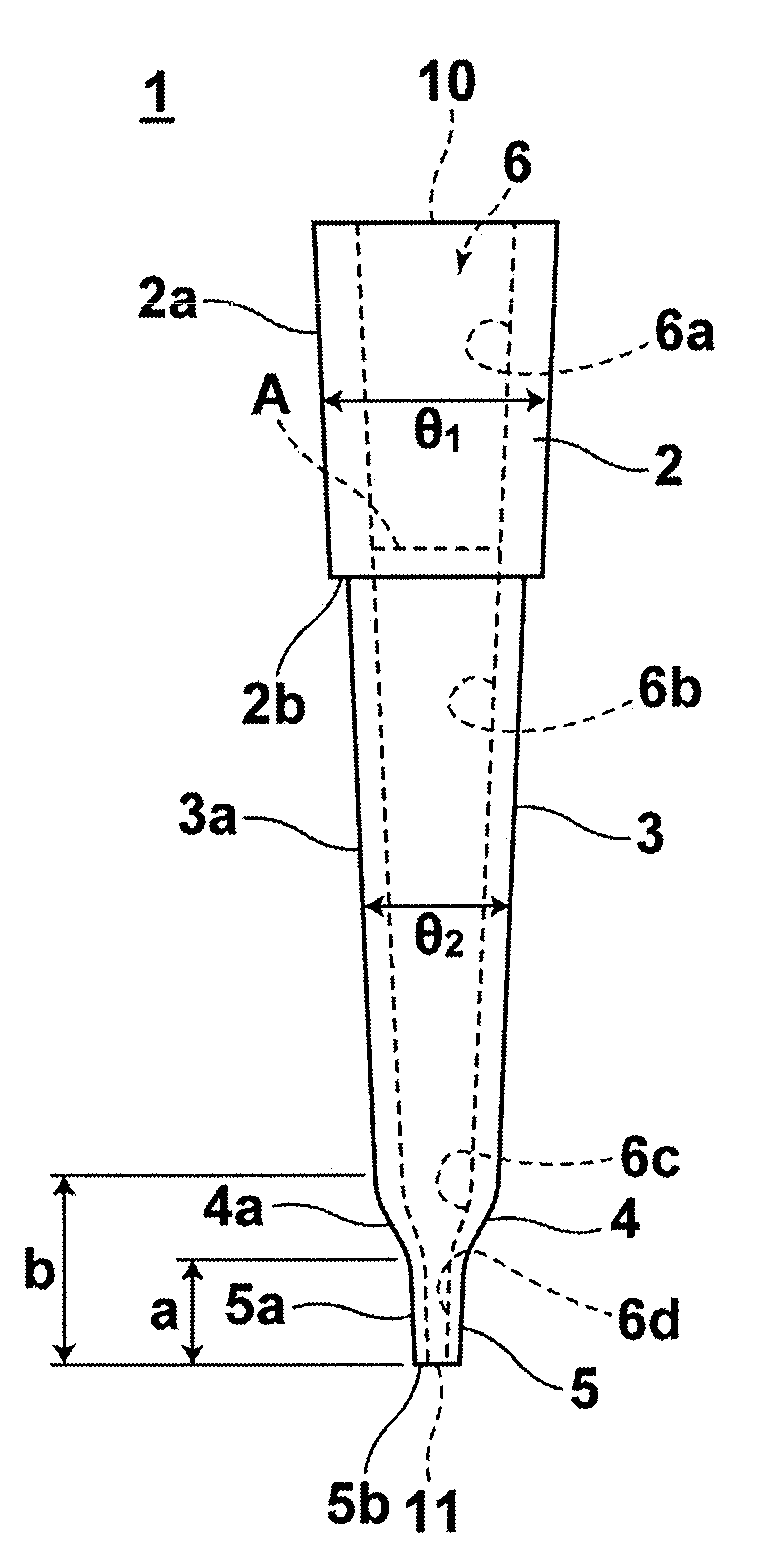

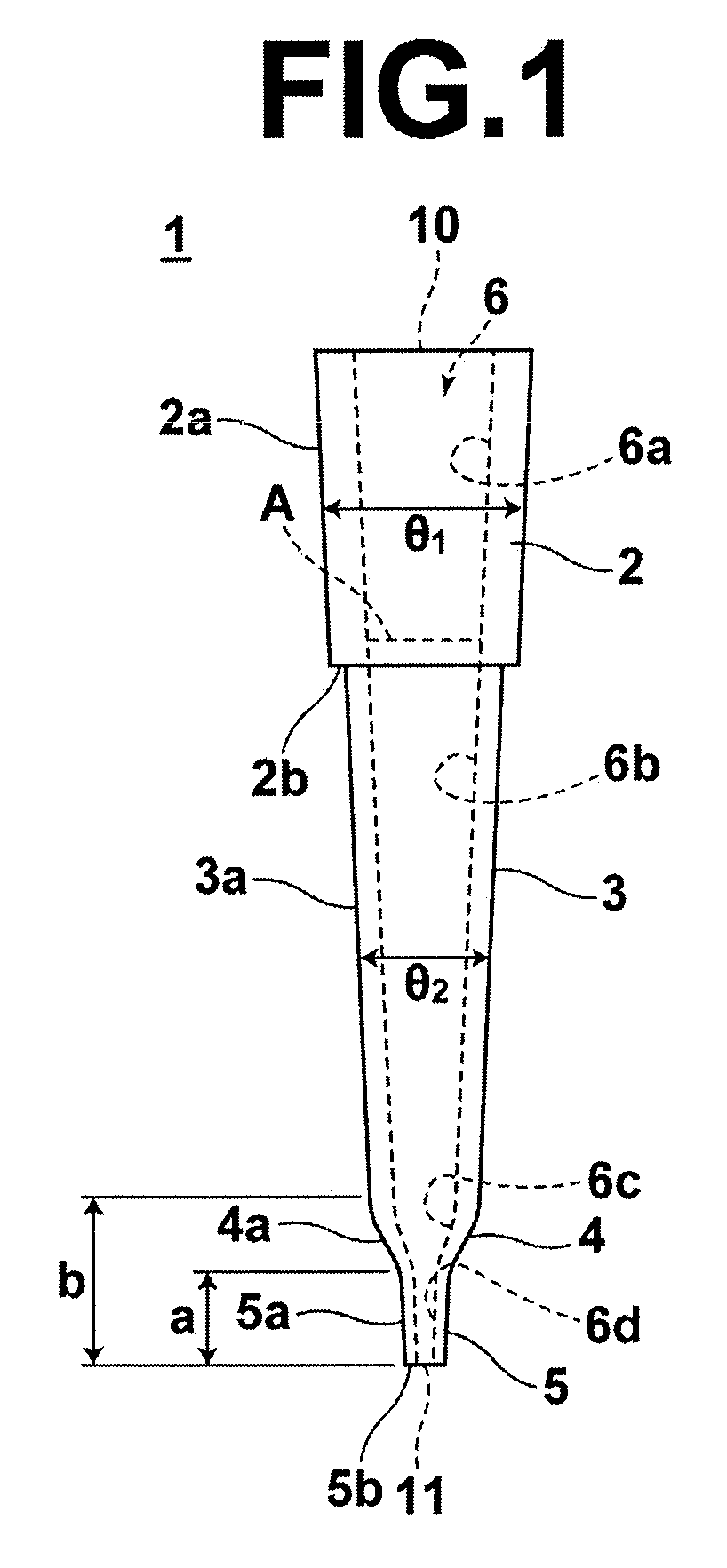

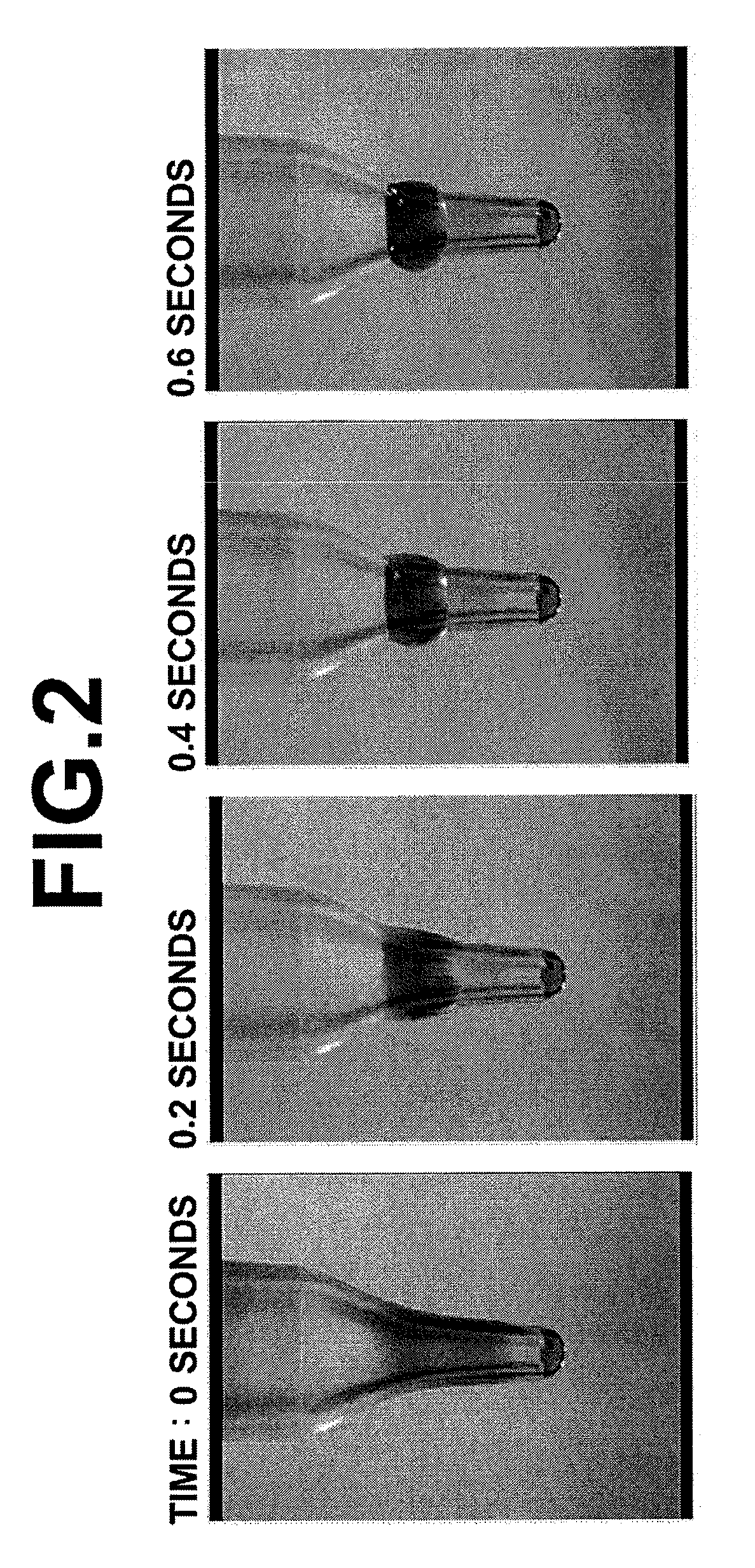

Pipette tip

InactiveUS20090202392A1Reliable distributionAnalysis using chemical indicatorsAnalysis by subjecting material to chemical reactionPipette1,3-Butanediol

A pipette tip formed by a polypropylene substrate coated with a water repellent agent. The water repellent agent contains a silicone resin containing at least one specific substance selected from the group consisting of diisononyl phthalate, diisodecyl phthalate, trioctyl trimellitate and poly (1,3-butanediol adipate). The total mass of the specific substance is 1-30 mass % of the silicone resin.

Owner:FUJIFILM CORP

Plasticiser compositions

C9 to C11 alkyl benzoates are used as plasticisers for polyvinyl chloride in particular in combination with plasticisers such as di-2-ethyl hexyl phthalate, diisononyl phthalate, di-2-propyl heptyl phthalate, diisodecyl phthalate or di-2-ethyl hexyl terephthalate. The use of the C9 to C11 alkyl benzoates provides low viscosity low volatility plasticisers, which are fast fusing with lower hot bench gelation temperature and which can be used to reduce the staining problems associated with use of di-2-ethyl hexyl phthalate and diisononyl phthalate. The low viscosity of the C9 to C11 alkyl benzoates allows the formulation of solvent free flexible PVC formulations meeting stringent VOC limitations.

Owner:EXXONMOBIL CHEMICAL CO INC

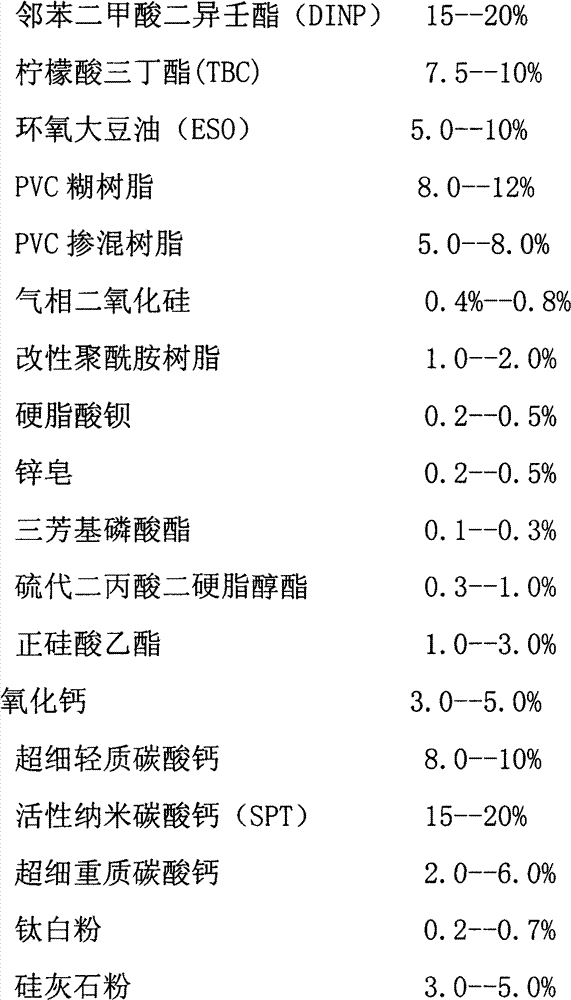

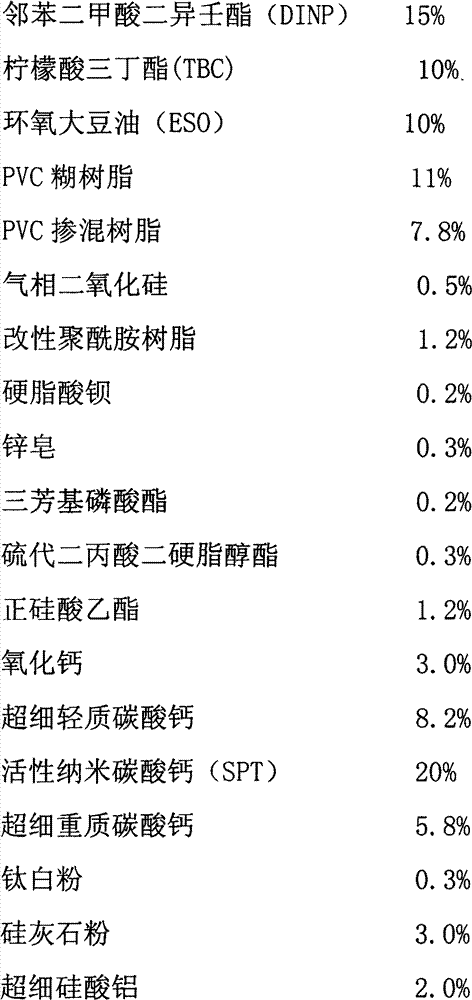

Environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for vehicle

ActiveCN102757746AGood compatibilityReduce usageNon-macromolecular adhesive additivesOther chemical processesPhosphateTributyl citrate

The invention relates to an environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for a vehicle. The environment-friendly PVC weld joint sealant mainly comprises the components of diisononyl phthalate (DINP), tributyl citrate (TBC), epoxidized soybean oil (ESO), PVC paste resin, PVC blend resin, fumed silica, modified polyamide resin, barium stearate, zincsoap, triaryl phosphate, thiodipropionic acid distearate alcohol ester, tetraethoxysilane, calcium oxide, ultrathin light calcium carbonate, active nano-calcium carbonate (SPT), ultrathin heavy calcium carbonate, titanium dioxide, wollastonite in powder, ultrathin aluminium silicate and the like. According to the environment-friendly PVC weld joint sealant provided by the invention, the technologies of raw material compounding, nontoxic additive adding and the like are adopted so as to reduce the curing temperature of the sealant; and a 'wet-to-wet' technology is achieved during coating the vehicle. Through the adoption of the environment-friendly PVC weld joint sealant, the energy consumption is reduced, and the volatizing of harmful gases is reduced. The environment-friendly PVC weld joint sealant has the characteristics of nontoxicity, environmental protection, fireproof performance, energy conservation, easiness in construction and the like The environment-friendly PVC weld joint sealant is an energy-conservation environmental-protection PVC weld joint sealant.

Owner:SHAANXI DADI IND CO LTD OF CHINA NAT NUCLEAR

Sheath material for data transmission cable

InactiveCN102492240AImprove thermal stabilityImproved color stabilityPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chlorideHeat stability

The invention discloses a sheath material for a data transmission cable, which is mainly prepared by, by weight, 100 parts of polyvinyl chloride resin, 40-60 parts of plasticizer, 0<parts<=15 parts of epoxidized soybean oil, 2-10 parts of stabilizing agent, 0<parts<=2 parts of pigment, 0<parts<=2 parts of polyethylene wax and 5-60 parts of calcium carbonate, wherein the plasticizer is diisononyl phthalate, the stabilizing agent is a Ca / Zn composite stabilizer, and the polyethylene wax is high-melting-point polyethylene wax with melting point higher than 105 DEG C. The heat stability of the sheath material for the data transmission cable is improved obviously in the production process compared with the existing polrvinyl chloride sheath materials, and color stability of the sheath material for the data transmission cable is good in the production process. Simultaneously, the production cost is reduced, environmental pollution caused by usage of lead salt stabilizers is further avoided, current environment-friendly requirement is met, and the sheath material has wide application prospect.

Owner:SUZHOU HENGLI COMM MATERIAL

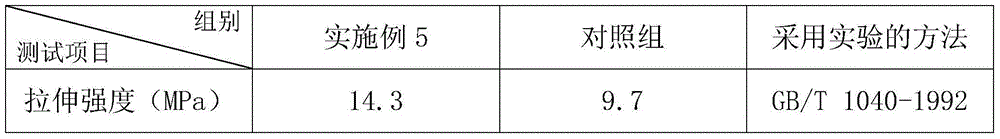

High-elasticity environment-friendly PVC modified material and preparation method thereof

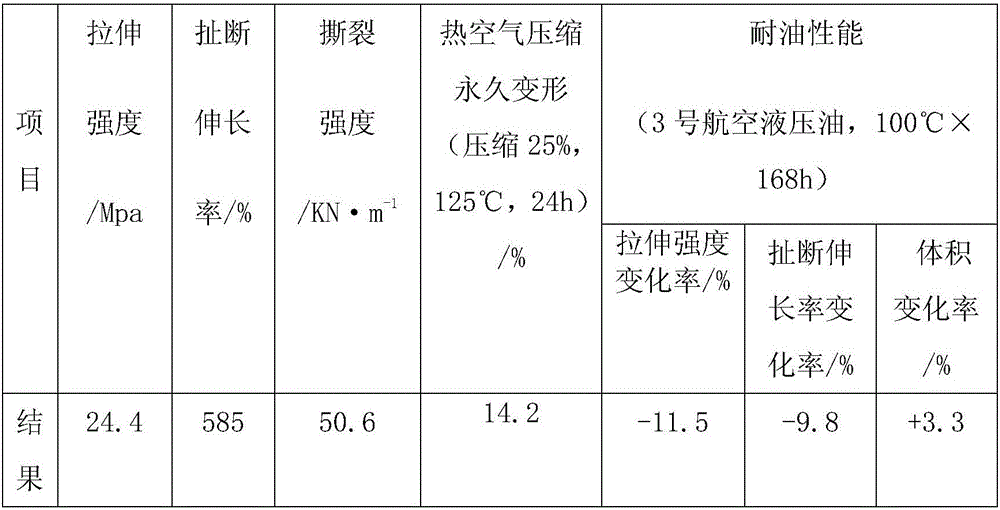

The invention relates to the technical field of PVC modified materials, in particular to a high-elasticity environment-friendly PVC modified material and a preparation method of the high-elasticity environment-friendly PVC modified material. The high-elasticity environment-friendly PVC modified material comprises 80-120 parts of PVC resin, 10-15 parts of filler agents, 40-60 parts of plasticizers, 2-6 parts of heat stabilizers, 10-15 parts of impact modifiers and 15-35 parts of elasticity modifiers, wherein the plasticizers are a mixture composed of diisononyl phthalate and epoxidized soybean oil according to the weight ratio of 8-10:1, the elasticity modifiers are expanded polystyrene, the glass transition temperature of the expanded polystyrene ranges from 80 DEG C to 90 DEG C, and the density of the expanded polystyrene ranges from 1.04 g / cm<3> to 1.06 g / cm<3>. All properties of the prepared high-elasticity environment-friendly PVC modified material exceed national standards, elasticity is high, the maximum tensile strength is 24.6 MPa, and the maximum elongation at break is 567 percent, and the PVC modified material is environmentally friendly. The preparation method of the high-elasticity environment-friendly PVC modified material is simple in process, convenient to implement and control, stable in quality, high in production efficiency and applicable to large-scale industrial production.

Owner:广东祺龙科技有限公司

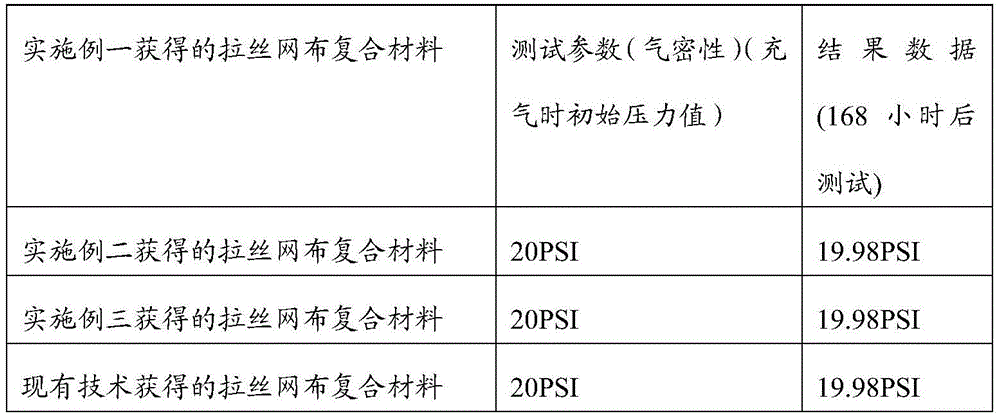

Wire-drawing screen cloth composite material and preparing method thereof

InactiveCN105666963APrevent penetrationSolve sticking problemsSynthetic resin layered productsCoatingsPolyvinyl chlorideEngineering

The invention relates to a wire-drawing screen cloth composite material which comprises a PVC layer, a wire-drawing screen cloth layer, a first coating and a second coating. The first coating and the second coating are arranged on the two side faces of the wire-drawing screen cloth layer respectively so as to form a pre-compositing layer. The two side faces of the pre-compositing layer are attached to the PVC layer respectively to form the wire-drawing screen cloth composite material. The first coating and the second coating are each prepared from, by weight, 60-80 parts of diisononyl phthalate or dioctyl phthalate, 95-105 parts of polyvinyl chloride and 2-4 parts of a stabilizer. Viscosity of the first coating and viscosity of the second coating each range from 10000 cps to 12000 cps. The invention further relates to a preparing method of the wire-drawing screen cloth composite material. The wire-drawing screen cloth composite material can effectively solve the problem of bonding of the wire-drawing screen cloth and has the advantage of effectively improving air tightness.

Owner:FUJIAN SIJIA ENVIRONMENTAL PROTECTION MATERIAL TECH

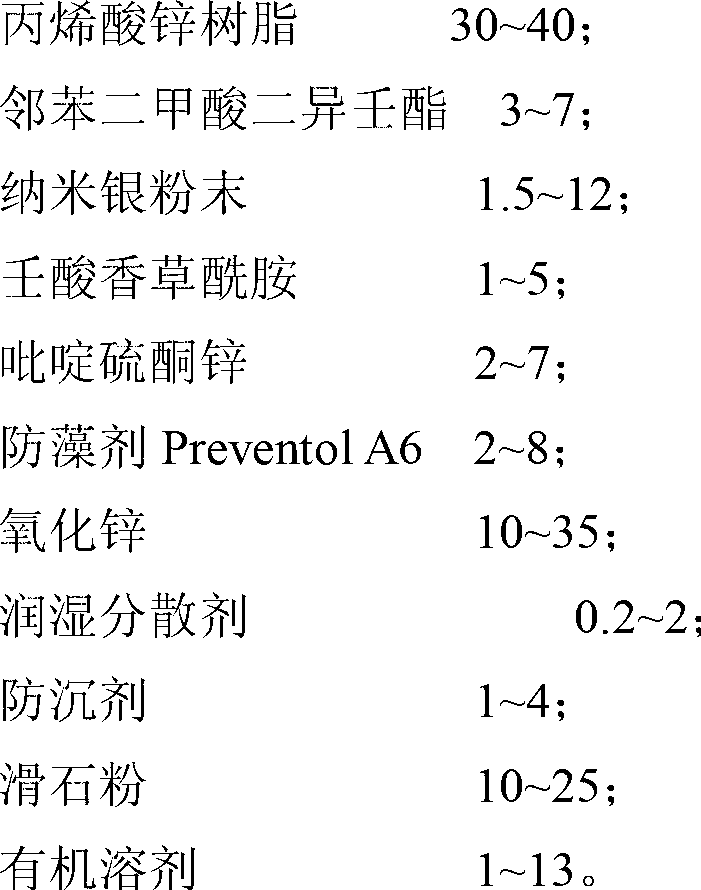

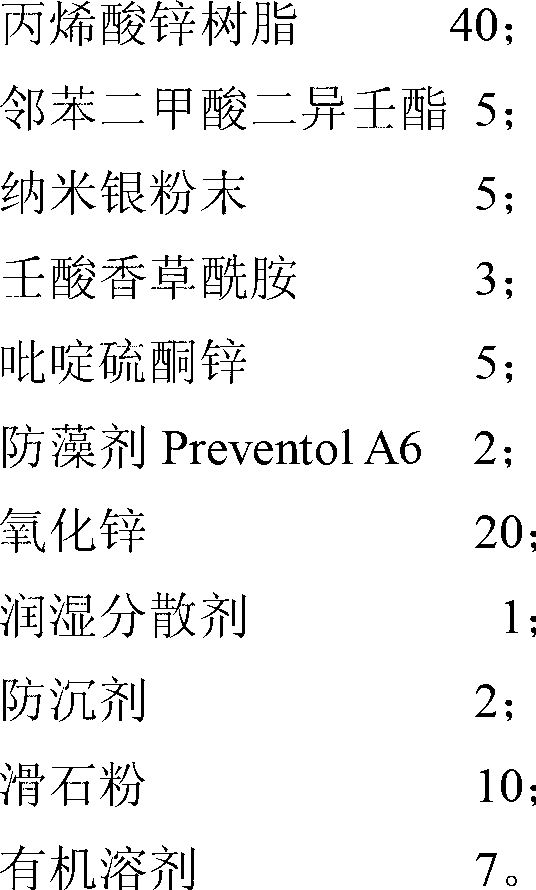

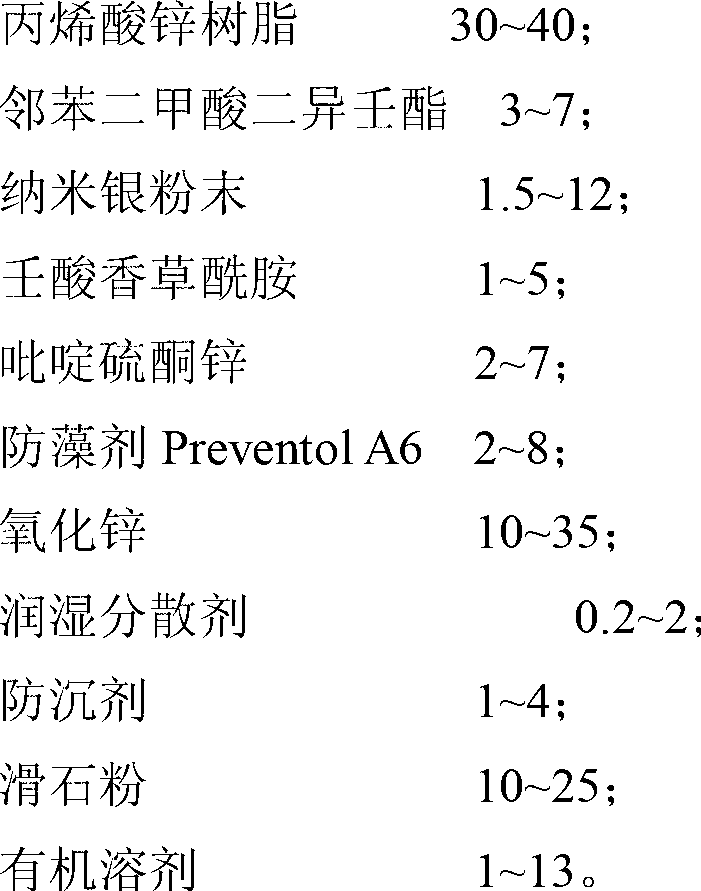

Aquaculture net cage antifouling paint and preparation method thereof

ActiveCN103013265ALow toxicityGood killing effectAntifouling/underwater paintsPaints with biocidesSodium PyrithionePliability

Aquaculture net cage antifouling paint comprises the following components of zinc acrylate resin, diisononyl phthalate, nano-silver powder, nonanoic acid vanillyl amide, zinc pyrithione, algaecide preventol A6, 10-35 parts of zinc oxide by weight, wetting dispersant, anti-settling agent, talcum powder and an organic solvent. The invention further discloses a preparation method of the antifouling paint. Compared with the prior art, the antifouling paint and the preparation method thereof have the advantages that the compounded antifouling agent has complementary advantages, the existing antifouling agent system is widened, excellent killing property for a plurality of marine fouling animals and algae is brought, no poison and no residue properties are realized. An antifouling coating has certain flexibility, and improves the adhesion, the mechanical performance and the durability.

Owner:ZHEJIANG FEIJING PAINT

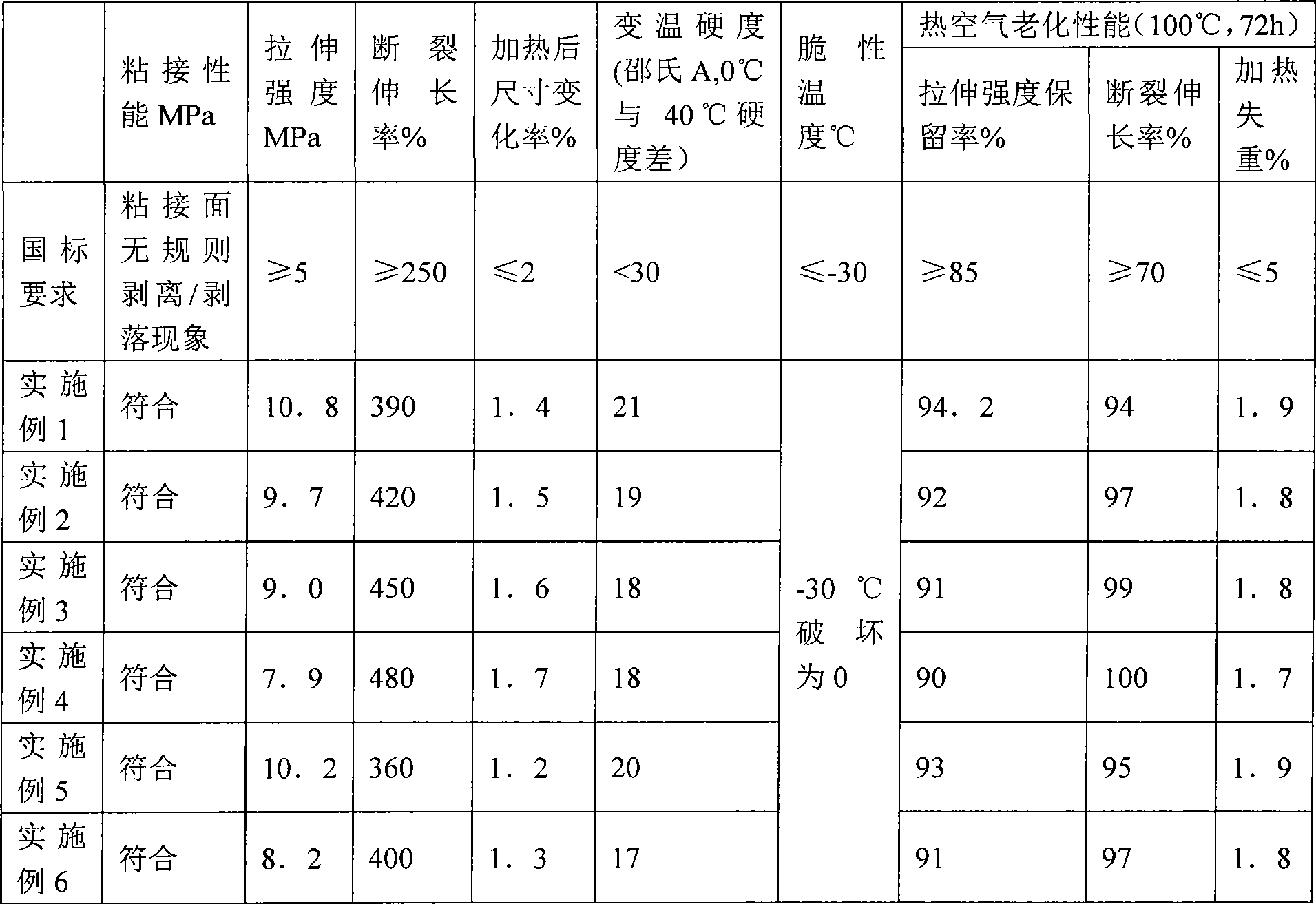

Production method of hard polychloroethylene section bar soft-hard coextrusion rubber strip

The invention provides a production method for a sealing joint strip used for co-extrusion with hard PVC profile materials. The produced sealing joint strip has good adhesive property, tensile property and low-temperature flexibility. The materials less fluctuates with the temperature; the variance ratio of the size of the sealing joint strip after being heated is close to that of the PVC profile materials; therefore, the separation phenomena of the sealing joint strip and the PVC profile materials caused by different shrinkage factors does not appear, thus ensuring the long-term sealing function of plastic doors and windows. The production method comprises the steps of material proportioning, mixing, pelleting, drying and extrusion. The components of ingredients are as follows according to the parts by weight: 100 parts of PVC, 10-15 parts of calcium carbonate, 60-90 parts of diisononyl phthalate, 10-15 parts of titanium pigment and 1-4.5 parts of calcium zinc stabilizing agent.

Owner:南京皇家聚锋建筑材料有限公司

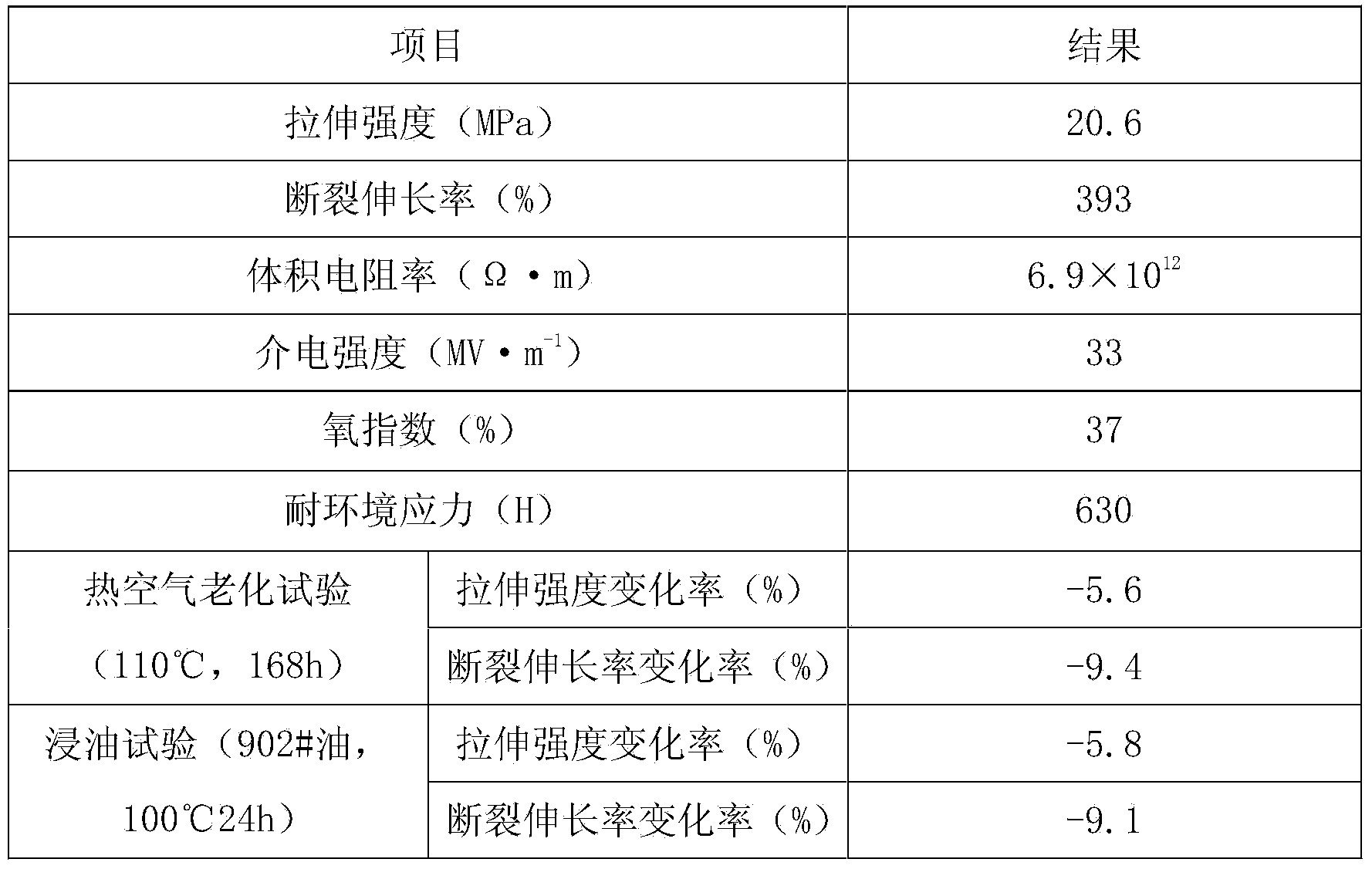

Black weather-stress-cracking-resistant polyethylene cable sheath material and preparation method thereof

ActiveCN103509232AImprove high temperature resistanceGood oil resistancePlastic/resin/waxes insulatorsInsulated cablesPolyesterLinear low-density polyethylene

The invention discloses a black weather-stress-cracking-resistant polyethylene cable sheath material and a preparation method thereof. The black weather-stress-cracking-resistant polyethylene cable sheath material is prepared from the following raw materials in parts by weight: 55-75 parts of linear low-density polyethylene , 20-30 parts of high-density polyethylene, 15-20 parts of EVA resin, 10-15 parts of diisononyl phthalate, 8-12 parts of propanediol sebacate polyester, 5-10 parts of epoxidized linseed oil, 10-15 parts of antimony trioxide, 5-10 parts of zinc stannate, 5-10 parts of ,nanometer zeolite powder, 3-5 parts of straw ash, 4-6 parts of a composite filling material, 8-12 parts of nanometer dolomite, 20-30 parts of channel black, 2-3 parts of dibutyltin dilaurate, 1-2 parts of calcium stearate, 1-2 parts of zine stearate, 3-5 parts of oxidized polyethylene wax, 0.5-1 part of antioxidant DLTP and 1-2 parts of antioxidant 1010. The cable material of the invention has excellent performances comprising environment stress cracking resistance, high temperature resistance, oil resistance, cold resistance, acid-base resistance, weathering aging resistance, wear resistance and the like, has good running in a working environment of -40 DEG C to 95 DEG C without deformation and cracking, and is safe, reliable and durable in use.

Owner:安徽天民电气科技有限公司

Environment-friendly plastic material

The invention discloses an environment-friendly plastic material which comprises the following raw materials in parts by weight: 20-25 parts of polycaprolactone PCL, 65-70 parts of modified poly-beta-hydroxybutyric acid PHB, 13-18 parts of peanut protein flour, 1.5-1.8 parts of jute fiber, 3-4 parts of wood fiber, 1.1-1.3 parts of a silane coupling agent KH, 2-3 parts of sodium lactate, 1.1-1.6 parts of sodium diacetate, 2-2.2 parts of diisononyl phthalate, 5-7 parts of epoxy tall oil acid butyl ester, 2-4 parts of oxidized starch, 20-23 parts of nano white carbon black, 6-8 parts of light calcium carbonate, 3-5 parts of sea-foam stone powder and 1-1.4 parts of an antioxidant 1010, wherein the modified poly-beta-hydroxybutyric acid PHB is prepared by blending and modifying poly-beta-hydroxybutyric acid PHB and high cis-butadiene rubber. The environment-friendly plastic material can be degraded by microbes and is low in decomposition rate, high in oxidation resistance and impact resistance and low in water-absorbing quality.

Owner:汕头市纳川塑胶制品有限公司

Degradable plastic and method for preparing same

The invention discloses a degradable plastic. The degradable plastic is made of, by weight, 60-65 parts of starch, 50-55 parts of polycaprolactone, 70-75 parts of poly butylenes succinate, 75-80 parts of polyhydroxyalkanoate, 20-30 parts of polyvinyl alcohol, 4-6 parts of chitin, 7-15 parts of polyaspartate acid, 15-20 parts of celluloses, 10-15 parts of polypropylene, 13-16 parts of phenolic resin, 2-4 parts of diatomaceous earth, 20-30 parts of asbestos, 15-20 parts of carbon black, 8-10 parts of phthalate, 35-40 parts of silicone rubber, 12-14 parts of diisononyl phthalate, 5-8 parts of zinc chromate and 12-16 parts of organic tin. The degradable plastic has the advantages that the degradable plastic is good in thermoplastic property and can be sufficiently degraded, and good anti-aging effects can be realized.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

Plasticiser Compositions

C9 to C11 alkyl benzoates are used as plasticisers for polyvinyl chloride in particular in combination with plasticisers such as di-2-ethyl hexyl phthalate, diisononyl phthalate, di-2-propyl heptyl phthalate, diisodecyl phthalate or di-2-ethyl hexyl terephthalate. The use of the C9 to C11 alkyl benzoates provides low viscosity low volatility plasticisers, which are fast fusing with lower hot bench gelation temperature and which can be used to reduce the staining problems associated with use of di-2-ethyl hexyl phthalate and diisononyl phthalate. The low viscosity of the C9 to C11 alkyl benzoates allows the formulation of solvent free flexible PVC formulations meeting stringent VOC limitations.

Owner:EXXONMOBIL CHEM PAT INC

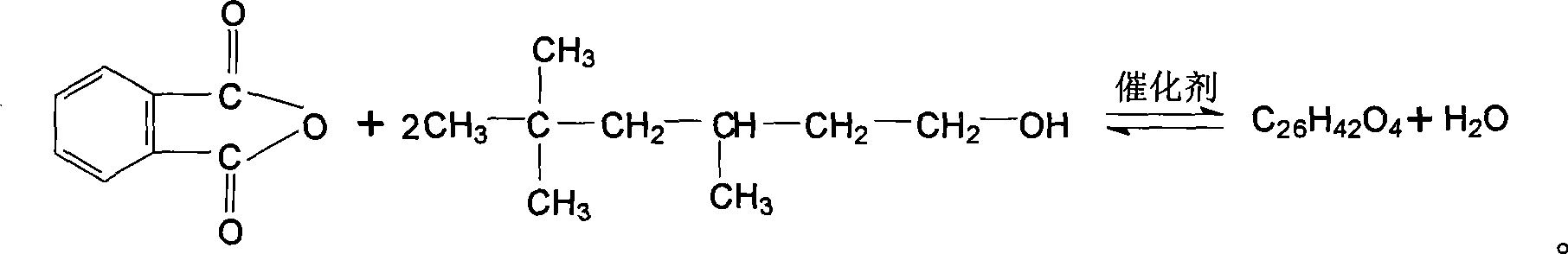

Method for producing plasticizer phthalic acid dinonyl

InactiveCN101157615AWon't happenShorten the production cycleOrganic compound preparationCarboxylic acid esters preparationIsononyl alcoholAcid catalysis

The invention relates to a production method for organic chemical product plasticizer, in particular to a production method for plasticizer phthalic acid diisononyl. The method comprises the steps as follows that: firstly, 3 to 4 portions of isononyl alcohol and one portion of bengan are filled into a reaction kettle, and then the solution is heated up when being stirred to carry a single-etherifying reaction; secondly, 0.001 to 0.002 parts of compound catalyst are filled in the solution after heating the solution to 150 to 180 DEG C; thirdly, the solution is continuously heated to 225 to 235 DEG C, and the solution is remained in the same temperature for 2 to 3 hours to carry a double-etherifying reaction, so that the in-kettle solution can be reacted fully and completely; fourthly, the solution is cooled down to 190 to 195 DEG C, and rude product of the plasticizer phthalic acid diisononyl is gained after traditionally depressurizing and dealcoholizing the solution; fifthly, the plasticizer phthalic acid diisononyl is obtained after traditionally discoloring and filtering the rude product. The invention has the advantages of avoiding the environment pollution due to acid catalysis method and decreasing the energy consumption.

Owner:无锡双象新材料有限公司

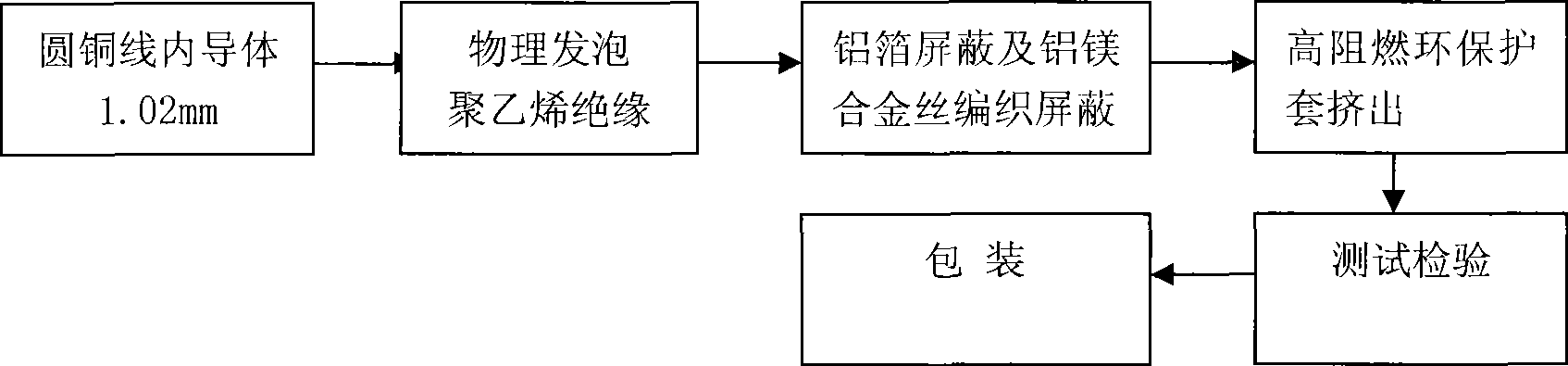

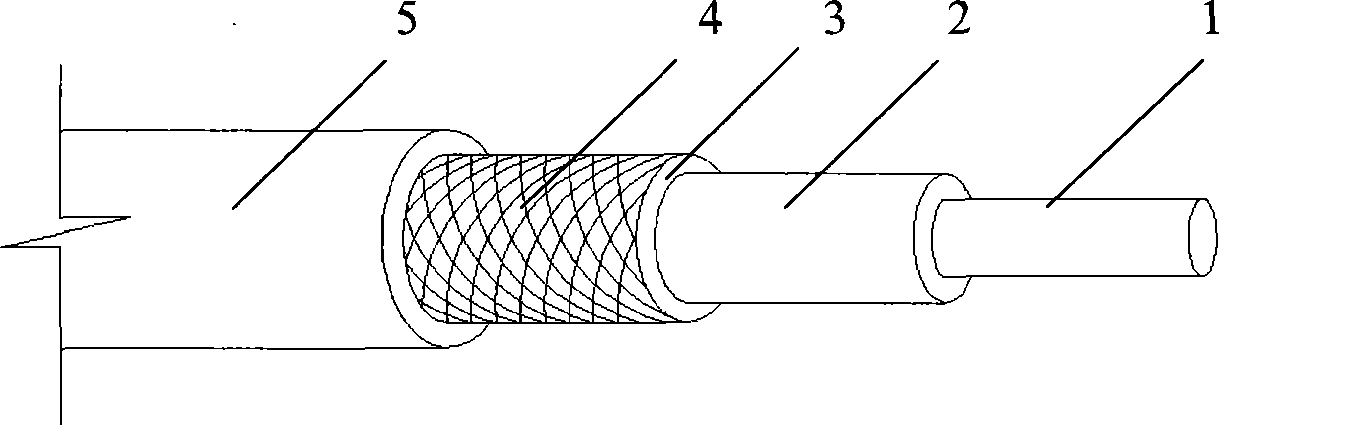

Highly flame-retardant environment friendly sheath material and co-axial cable composed thereof

InactiveCN101475724AImprove flame retardant performanceEnvironmental protection is goodCoaxial cables/analogue cablesInsulated cablesSystems designPolyvinyl chloride

The invention provides a high fire-resistance environment-friendly sleeve material, which is prepared from the following substances in portion by weight: 100 portions of polyvinyl chloride, 20 to 25 portions of diisononyl phthalate, 15 to 20 portions of tributyl 2-acetylcitrate, 4 to 5 portions of a calcium-zinc complex stabilizing agent, 2 to 3 portions of epoxidized soybean oil, 1 to 2 portions of a lubricant, 8 to 10 portions of diantimony trioxide, 10 to 15 portions of zinc borate, 20 to 25 portions of activated light calcium carbonate, 8 to 10 portions of decabromodiphenyl oxide, and 2 portions of non-hydroscopic black carbon. The high fire-resistance environment-friendly sleeve material greatly improves fire resistance and hygroscopicity resistance of a product with strong practicality, establishes a raw material foundation for design and development of environment-friendly and flame retardant cables; and an environment-friendly CMR grade flame retardant coaxial cable integrated with environmental protection and high fire resistance is successfully developed based on the high fire-resistance environment-friendly sleeve material, thereby overcoming the defects existing in the prior coaxial cable for a building cabling system, greatly improving environmental protection performance and fire resistance of the product, and meeting strict requirements on design and application of building horizontal and vertical cabling systems with significant social benefit.

Owner:王一群 +1

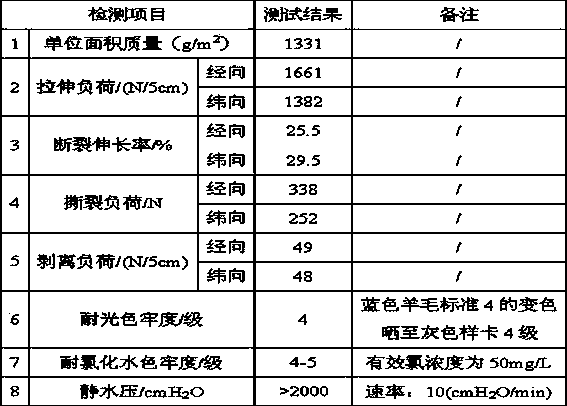

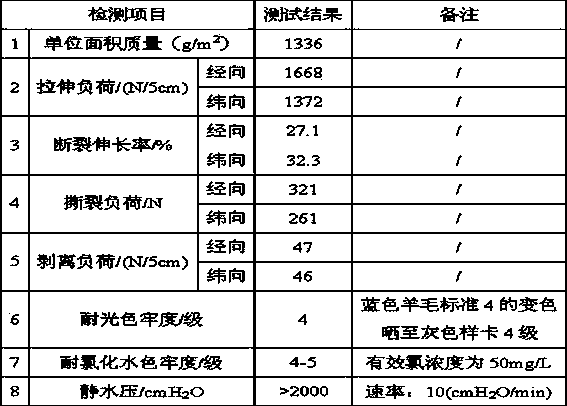

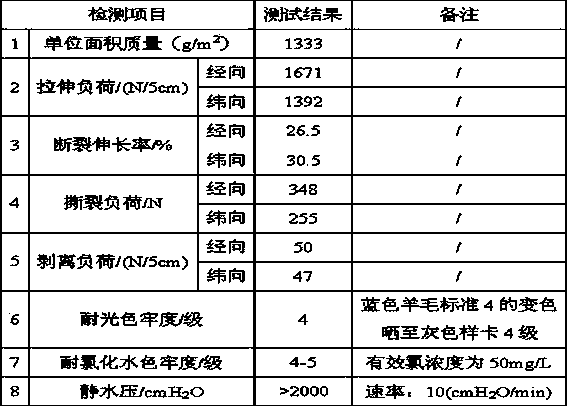

Environment-friendly single-spray mosaic swimming pool cloth and production process thereof

ActiveCN103481605AReduce dosageImprove anti-agingSynthetic resin layered productsSpecial ornamental structuresEnvironmental resistanceYarn

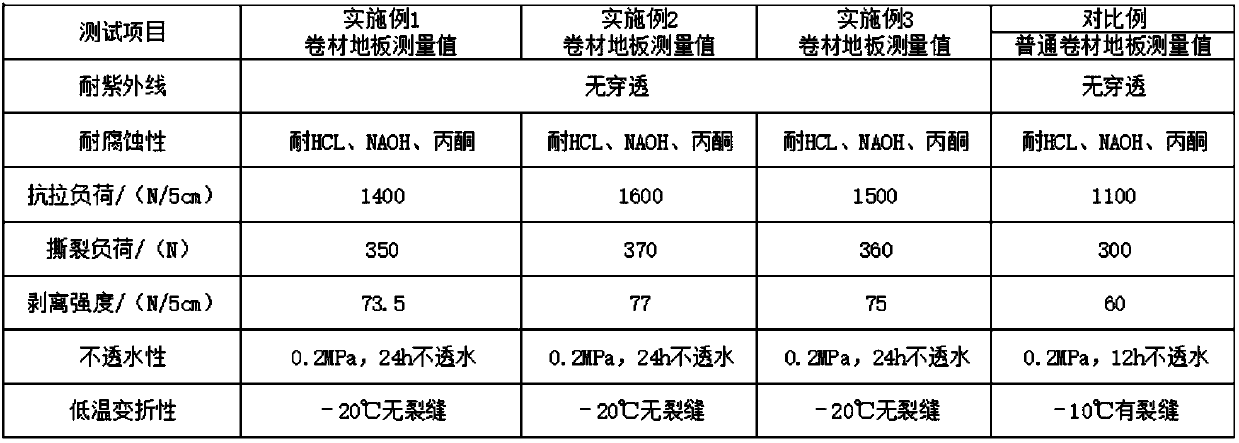

The invention relates to environment-friendly single-spray mosaic swimming pool cloth and a production process thereof. The swimming pool cloth is formed by taking terylene warp knitted biaxial screen cloth as the base cloth and binding PVC (Polyvinyl Chloride) films on two surfaces, wherein the terylene warp knitted biaxial screen cloth is 1000D*1000D in linear density, 9*9 per inch in density and 66D / 24F in binding yarn; and the PVC film is prepared from the following raw materials in parts by weight: 100 parts of PVC resin powder, 45-55 parts of diisononyl phthalate, 1-5 parts of epoxidized soybean oil, 15-25 parts of nanometer calcium powder, 3-5 parts of barium-zinc stabilizer, 0.5-3 parts of antibacterial agent, 0.1-0.5 part of anti-UV agent, and 8-10 parts of rutile titanium dioxide. The environment-friendly single-spray mosaic swimming pool cloth disclosed by the invention has excellent chlorination colour resistant fastness and light colour resistant fastness and good tension load, tear load, peeling load, breaking elongation and hydrostatic pressure; simultaneously, the environment-friendly single-spray mosaic swimming pool cloth disclosed by the invention is flat and generous in appearance and has mosaic simulative effect, and therefore, the environment-friendly single-spray mosaic swimming pool cloth is welcomed by customers and has wide mark prospect.

Owner:ZHEJIANG BOTAI PLASTIC

Formula of modified polymethyl methacrylate

The invention discloses a formula of modified polymethyl methacrylate. The formula of the modified polymethyl methacrylate comprises polymethyl methacrylate and additives, wherein the additives include a shock resistance modifying agent, a plasticizer, a filling agent, a wear-resistant agent and a lubricant, the shock resistance modifying agent is a methacrylic acid-butadiene-styrol copolymer, the plasticizer is diisononyl phthalate, the filling agent is talcum powder, the wear-resistant agent is silicon dioxide, and the lubricant is fatty acid amide. According to the formula of the modified polymethyl methacrylate, multiple additives are added in the polymethyl methacrylate, the hardness of the modified polymethyl methacrylate is increased, the surface snags are avoided, the shock strength is improved, and the forming flowing property is good.

Owner:TAICANG CHENZHOU PLASTIC

Phthalate-free medical polrvinyl chloride (PVC) plastic

The invention discloses phthalate-free medical polrvinyl chloride (PVC) plastic. The plastic is prepared by blending the following components in part by weight: 100 parts of PVC resin, 25 to 95 parts of eco-friendly plasticizer, 0.1-8 parts of polyolefin and chloroethylene function modifier, 4.5-9 parts of high-efficiency heat stabilizer and 0.3-1.5 parts of lubricant, wherein the eco-friendly plasticizer is cyclohexane1,2-diisononyl phthalate, SOFT-N-SAFE, EPN or acetyl tributyl citrate; the polyolefin and chloroethylene function modifier is more than two of styrene, maleic anhydride, diethyl maleate and chloroethylene; the chloroethylene is more than one of powdery, pasty and liquid calcium and zinc heat stabilizer; and the lubricant is butyl stearate or oxidized polyethlene wax. The phthalate-free medical PVC plastic is used for producing disposable medical supplies and is safe because the plastic is phthalate-free.

Owner:欧阳伟

Cantharias specimen and making method thereof

InactiveCN103299985ASimple preparation processFast preparation processSpecial ornamental structuresDead animal preservationAcetic acidPolyethylene glycol

The invention discloses a making method of an artificial cantharias specimen which is made by taking urea-formaldehyde resin as a main raw material and sodium hydroxide and glacial acetic acid as auxiliary raw materials. The making method comprises the following steps of: synthesizing a urea-formaldehyde resin raw monomer, pre-treating insects, preparing a ripe monomer, preparing a mould, fixing and embedding an insect sample, demoulding and polishing, wherein the raw monomer is formed by adding sodium hydroxide and glacial acetic acid into formaldehyde and urea as raw materials and then polymerizing, and the proportion of the formaldehyde to the urea is equal to 55:18 to 50:22; the urea-formaldehyde resin has the shrinking percentage of 5-20%, the hardening time of 2-5d and the bubbling number of 0-5; and the ripe monomer is prepared by mixing the liquid urea-formaldehyde glue of the raw monomer and an extension agent, adding glacial acetic acid and stirring, wherein the extension agent is selected from polyethylene glycol 600, DEHP (Di 2-Ethyl Hexyl Phthalate) and DINP (Diisononyl Phthalate). The making method disclosed by the invention is simple and rapid in process, low in cost and the raw materials are easy to purchase; and a sample is high in strength and good in toughness, glossiness and transparency.

Owner:NORTHWEST A & F UNIV

High-elasticity environmentally-friendly flame-retardant rubber material

The present invention discloses a high-elasticity environmentally-friendly flame-retardant rubber material comprising the raw materials of hydrogenated nitrile rubber, EPDM rubber, butadiene styrene rubber, vinyl chloride thermoplastic elastomers, ABS resin, di-tert-butyl peroxide DTBP, sulfur, divinylbenzene, accelerator DM, modified clay, carbon masterbatch, magnesium oxide, stearic acid, a modified flame retardant, polyphenyl ether, diisononyl phthalate DINP, antioxidant D-50, antioxidant SP and epoxy soybean oil. The high-elasticity environmentally-friendly flame-retardant rubber material has excellent flame retardant properties, and is halogen-free, low in toxicity, environmentally-friendly, good in elasticity and other mechanical properties and processing performances, and suitable for a variety of production and living areas.

Owner:宁国市开源橡塑汽车零部件有限公司

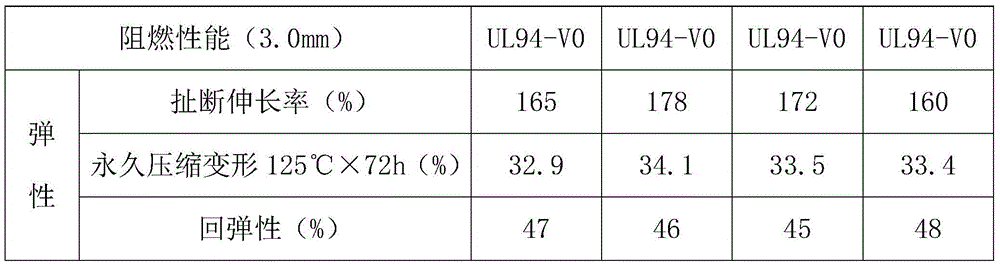

Preparation method and application method of phthalates molecular imprinted magnetic materials through dual-virtual template

ActiveCN109092254AEasy to prepareLow costOther chemical processesWater contaminantsCross-linkFunctional monomer

The invention relates to a preparation method and application method of a phthalates molecular imprinted magnetic material through dual-virtual template. The preparation method comprises the followingsteps of preparing graphene oxide by a modified Hummer method; loading Fe3O4 granules to the surfaces; adding cetyl trimithyl ammonium bromide and tetraethylorthosilicate to obtain a magnetic graphene oxide-Meso-PS compound; using the compound as a carrier, using dipropyl phthalate and diisononyl phthalate as a virtual template, using Phenyltrimethoxysilane and 3-aminopropyl triethoxy silane as functional monomers, using tetraethylorthosilicate as a cross-linking agent, performing vibrating for stirring at room temperature, and performing sol-gel surface molecular imprinting; and eluting template molecules with a mixed solution of methyl alcohol and acetic acid, performing magnetic separation, and then performing vacuum drying to obtain the phthalates molecular imprinted magnetic materialthrough dual-virtual template. The material has favorable adsorptive selectivity on 6 priority-controlled phthalates, can be quickly separated from aqueous phases, is short in balance time and high in adsorbing capacity, can be reused for 6 times, can realize selective removal and enrichment of various PAEs in water, and has high practical application value.

Owner:GUANGDONG UNIV OF TECH

Military ground cloth and preparation method thereof

ActiveCN105951469AWaterproofAging resistantLiquid surface applicatorsCoatingsPolyvinyl chlorideUltraviolet lights

The invention provides military ground cloth and a preparation method of the military ground cloth, and solves the technical problems that the existing tent cloth is too simple in structure, has no features of resisting flame and ultraviolet light, is poor in functionality, and has no preparation method. The military ground cloth comprises a base cloth layer, wherein each of the upper side and the lower side of the base cloth layer is provided with a PVC (polyvinyl chloride) coating; the PVC coating is prepared from the following components in parts by weight: 68 to 84 parts of PVC paste resin, 30 to 40 parts of plasticizer DINP (Diisononyl phthalate), 6 to 10 parts of calcium carbonate, 2 to 8 parts of chlorinated paraffin, 1 to 6 parts of stabilizing agent, 12 to 18 parts of flame retardant, 4 to 10 parts of bonding agent and 0.1 to 0.5 part of anti-UV (anti-ultraviolet) agent. The military ground cloth has the advantage of strong functionality.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

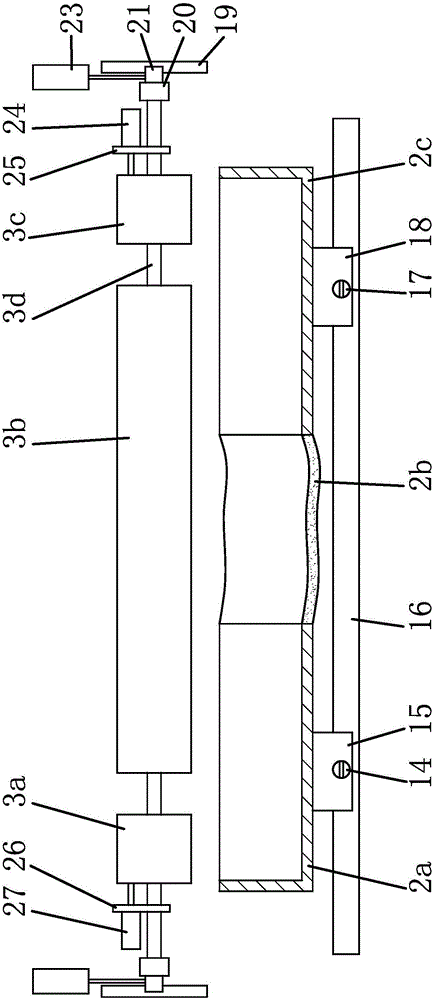

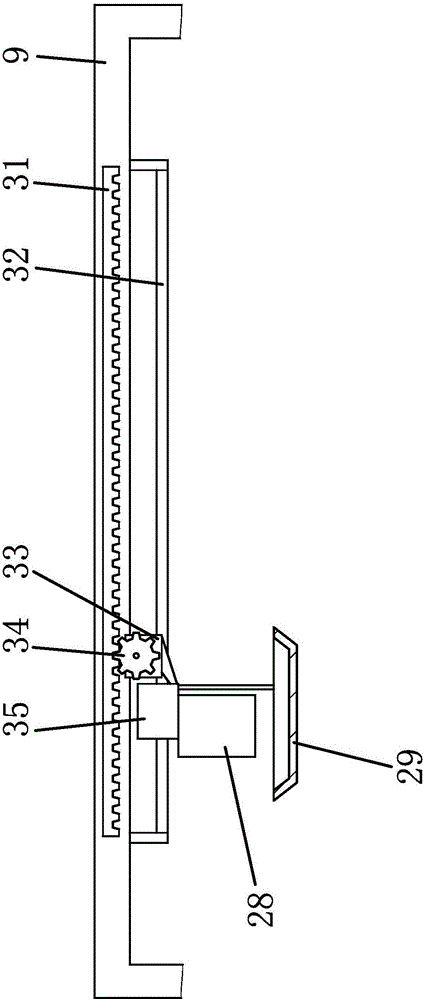

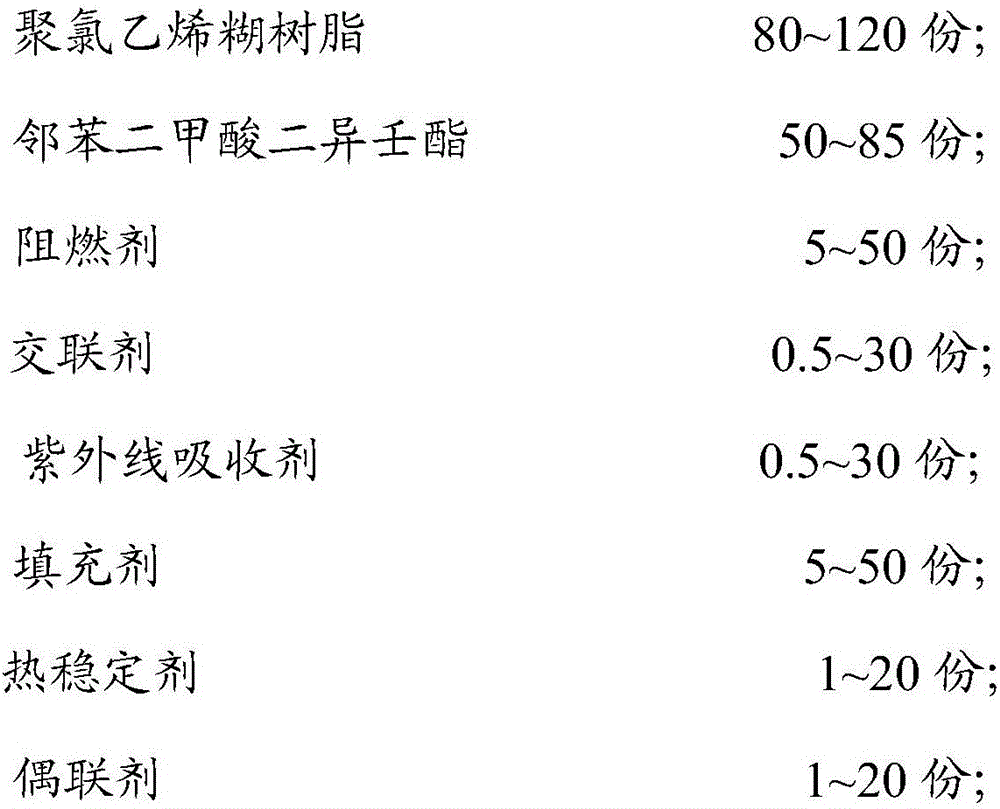

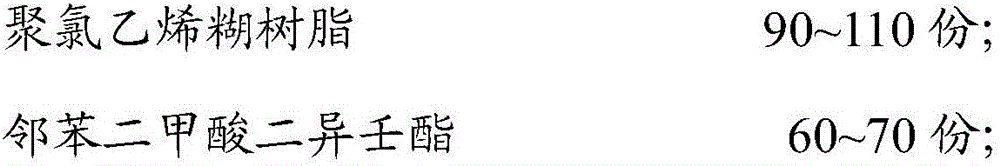

Flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material

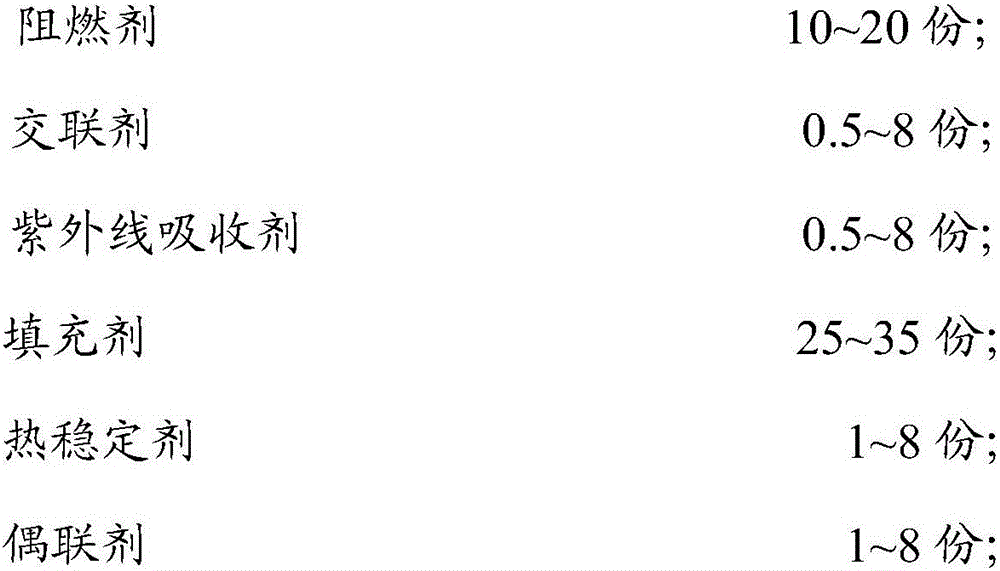

The invention relates to a flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material.The material is prepared from, by mass, 80-120 parts of polyvinyl chloride paste resin, 50-85 parts of diisononyl phthalate, 5-50 parts of fire retardant, 0.5-30 parts of a cross-linking agent, 0.5-30 parts of ultraviolet light absorber, 5-50 parts of filler, 1-20 parts of heat stabilizer and 1-20 parts of a coupling agent, wherein the fire retardant is zinc stannate-molybdenum trioxide or zinc stannate-ammonium molybdate.According to the flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material, an efficient flame-retarding and smoke-suppressing agent is added to polyvinyl chloride, so that flame retardation performance, heat resistance and smoke suppression performance of the material are improved.

Owner:ZHEJIANG UNIFULL IND FIBER

Pressure-resistant and abrasion-resistant wire PVC (Poly Vinyl Chloride) material

InactiveCN102212236AStrong pressure and wear resistancePlastic/resin/waxes insulatorsPolyvinyl chlorideDiisononyl phthalate

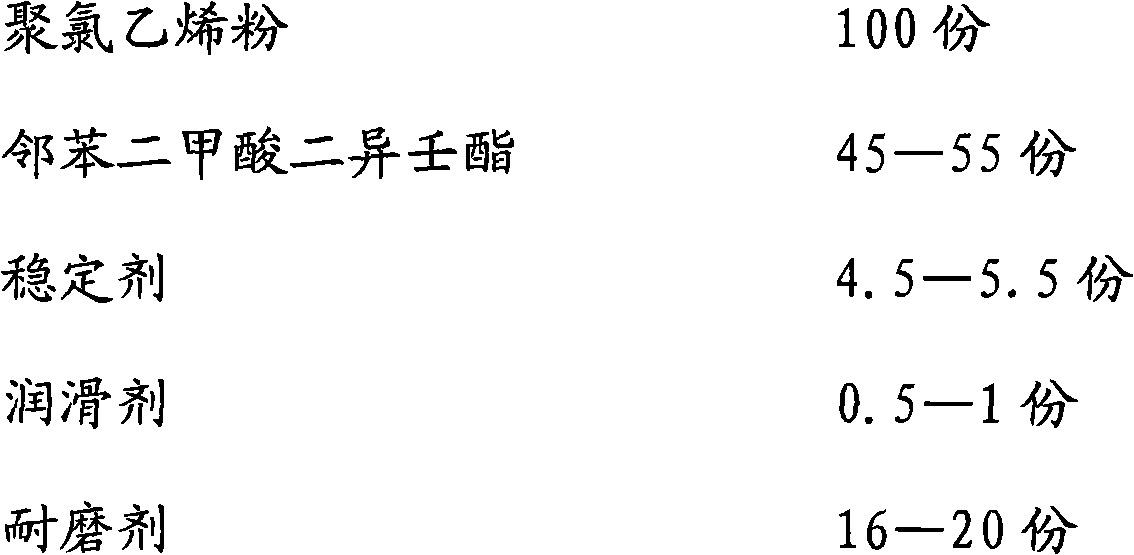

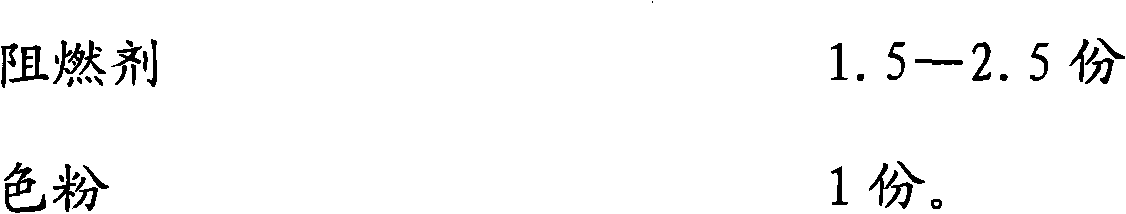

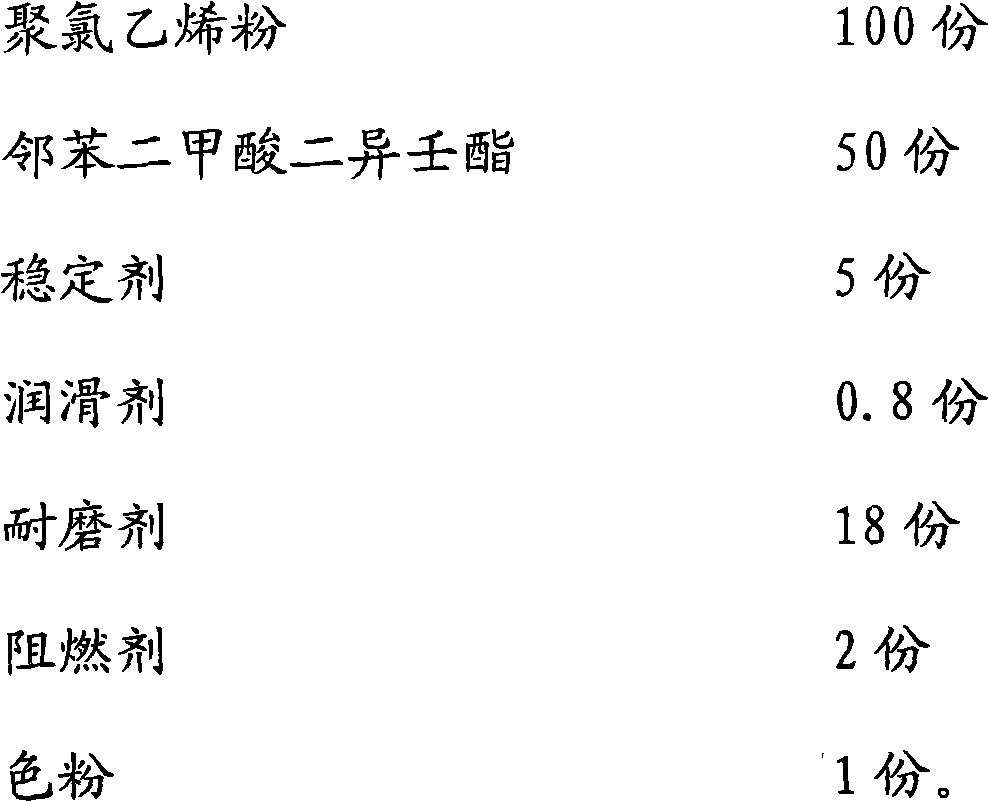

A pressure-resistant and abrasion-resistant wire PVC (Poly Vinyl Chloride) material provided by the invention mainly relates to the field of polymer materials, particularly to a functional material for electric wires and cables, and more particularly to a pressure-resistant and abrasion-resistant functional material. The pressure-resistant and abrasion-resistant wire PVC (Poly Vinyl Chloride) material comprises the following components in parts by weight: 100 parts of polyvinyl chloride powder, 45-55 parts of diisononyl phthalate, 4.5-5.5 parts of stabilizing agent, 0.5-1 part of lubricant, 16-20 parts of abrasion-resistance agent, 1.5-2.5 parts of flame retardant agent and 1 part of toner powder. A pressure-resistant and abrasion-resistant wire produced by the formula has stronger performances of pressure resistance and abrasion resistance because of compatibly preparing the composite wear-resisting agent with other addition agents.

Owner:DONGGUAN QUANSHENG PLASTIC

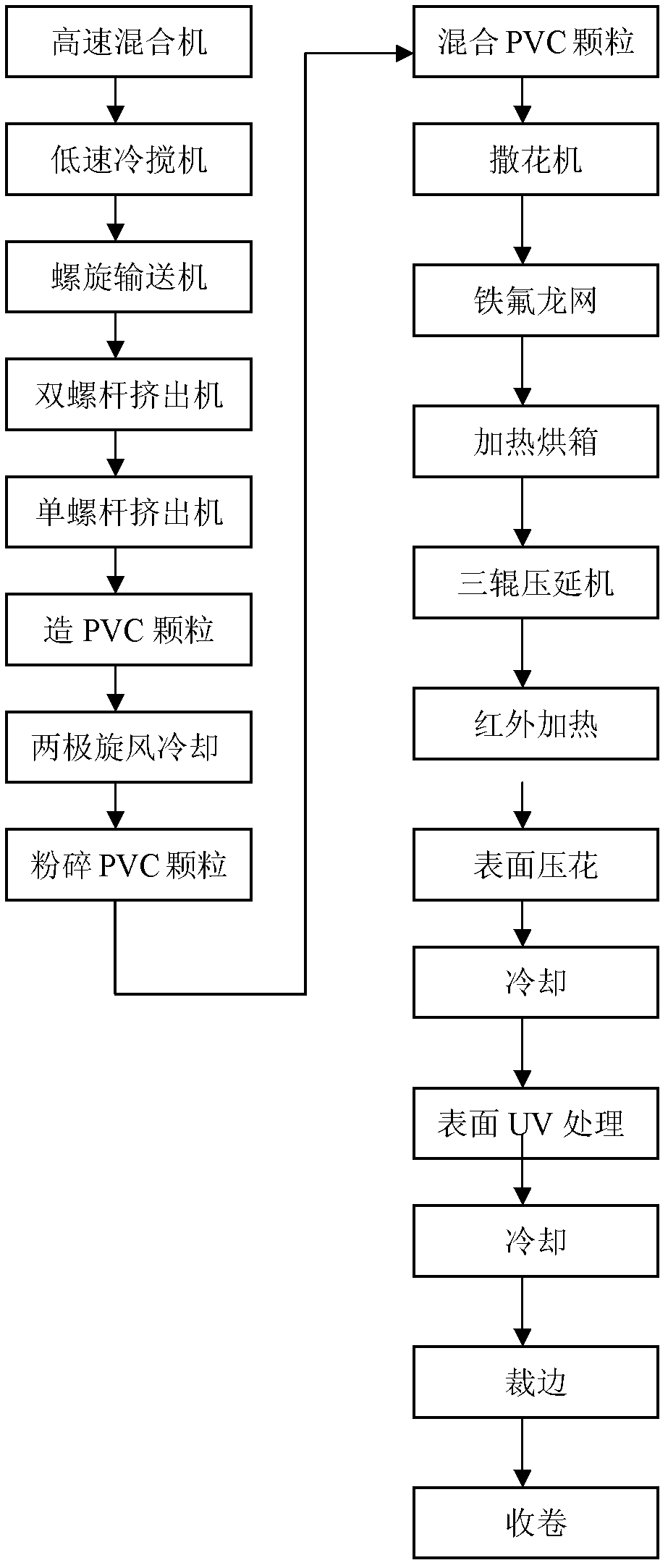

PVC granule-spread permeable coiled floor, and its preparation method

The invention relates to a PVC granule-spread permeable coiled floor, and its preparation method. The floor material comprises (by weight parts) polyvinyl chloride (PVC) resin 100, diisononyl phthalate 30-35, calcium carbonate 100, thermal stabilizer 4-6, modifier 2-4, and color masterbatch 8-10. The floor is prepared by PVC granulating, PVC granule crushing, PVC granule spreading, three-roller calendering, and post-treatment. The product has high density and wear resistance, clear pattern, wide applicability, and environmental friendliness. The floor has high plastification, uniform material, high permeability, and stable size stability.

Owner:上海大巨龙蓬盖新材料有限公司

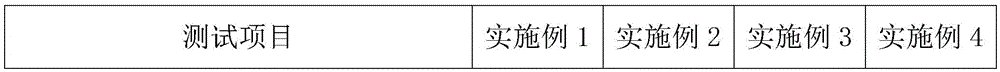

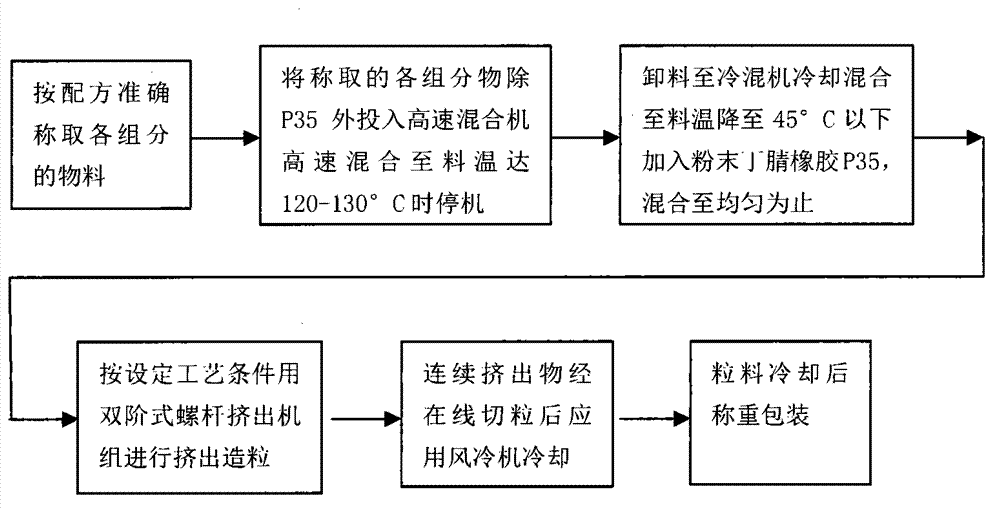

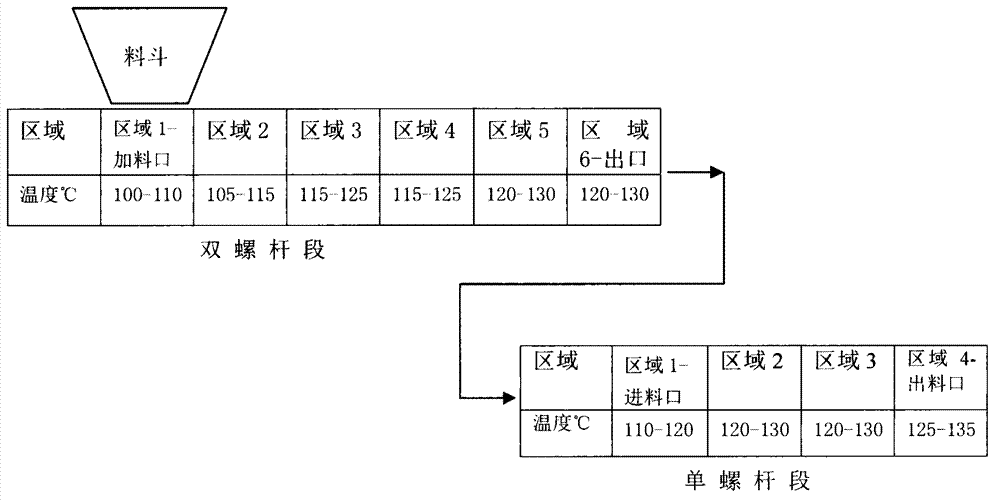

PVC pellet composition with low compression set, and preparation method and application thereof

The invention provides a PVC pellet composition with low compression set, and a preparation method and application thereof. The PVC pellet composition comprises PVC resin, an elasticity modifier full cross-linking type powdery butadiene-acrylonitrile rubber P35, a plasticizer diisononyl phthalate, another plasticizer epoxidized soybean oil, a Ca / Zn composite heat stabilizer, a colloidizing aid acrylate copolymer, an outer lubricant polyethylene wax, an inner lubricant butyl stearate, an antiseptic and a weather-resisting agent. The PVC pellet composition substantially improves durability and service life of finished products and is especially applicable to manufacturing of automobile window sealing strips or building door-and-window sealing strips with high requirements on elastic recovery.

Owner:NINGBO TAIYONG AUTOMOTIVE PARTS

Nitrile butadiene rubber gasket used for sealing high-pressure lubricating oil and preparation method thereof

The invention discloses a nitrile butadiene rubber gasket used for sealing high-pressure lubricating oil and a preparation method thereof. The nitrile butadiene rubber gasket is prepared from the following raw materials in parts by weight: 25-40 parts of carboxylated nitrile butadiene rubber, 16-27 parts of thermoplastic polyester elastomer, 12-23 parts of chlorohydrin rubber, 4-8 parts of C9 petroleum resin, 10-15 parts of white corundum micro powder, 1-2 parts of accelerator NS, 0.5-1 part of accelerator ZDBP, 5-10 parts of 1,2-polybutadiene, 2-3 parts of 1,1-di(tert-butylperoxy)cyclohexane, 1-2 parts of tetra-chloro-benzoquinone, 2-3 parts of ethylene thiourea, 3-5 parts of triallyl trimellitate, 1-2 parts of zinc stearate, 1-2 parts of anti-aging agent RD, 0.5-1 part of anti-aging agent TMDQ, 6-12 parts of diisononyl phthalate, 10-15 parts of tungsten disulfide and 6-12 parts of modifier. The nitrile butadiene rubber gasket has excellent comprehensive properties, and not only has higher mechanical strength but also has excellent pressure, oil, wear, impact and fatigue resistance.

Owner:ANHUI JINGYI GLASS MACHINERY

Anti-slip PVC printing register swimming pool coil floor

ActiveCN109594805AEasy to cleanResistance to frictionLamination ancillary operationsSynthetic resin layered productsFiberPolyester

The invention relates to a coil floor, in particular to an anti-slip PVC printing register swimming pool coil floor which comprises a high-strength polyester fiber mesh and PVC adhesive films, whereinthe top surface and the bottom surface of the high-strength polyester fiber mesh are respectively hot-pressed and compounded with a layer of the PVC adhesive film, and the PVC film comprises the following raw materials in parts by weight: 45-55 parts of suspension method-polyvinyl chloride resin powder, 24-28 parts of diisononyl phthalate, 4.5-7.0 parts of dioctyl adipate, 1.0-2.5 parts of epoxidized soybean oil, 1.0-2.5 parts of a bismuth zinc liquid stabilizer, 10-15 parts of light active calcium carbonate, 0.15-0.25 part of a mildewproof agent and 1.5-2.2 parts of organic toner. The surface of the coil floor is coated with a self-cleaning surface treatment agent to form a layer of protective film which is resistant to pollution, easy to clean, and resistant to friction, acid, alkali and ultraviolet rays; a physical embossing technology is introduced, a register embossing technology is adopted for printed patterns with different patterns, and a concave structure formed by embossed patterns is utilized to improve the three dimension and anti-slip effect of the printed patterns.

Owner:GUANGZHOU PLATO PLASTIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com