Nitrile butadiene rubber gasket used for sealing high-pressure lubricating oil and preparation method thereof

A technology of nitrile rubber and carboxylated nitrile rubber, which is applied in the field of rubber gaskets, can solve the problems that the comprehensive performance cannot meet the market demand, etc., and achieve improved heat resistance and chemical stability, improved mechanical properties, and excellent pressure resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

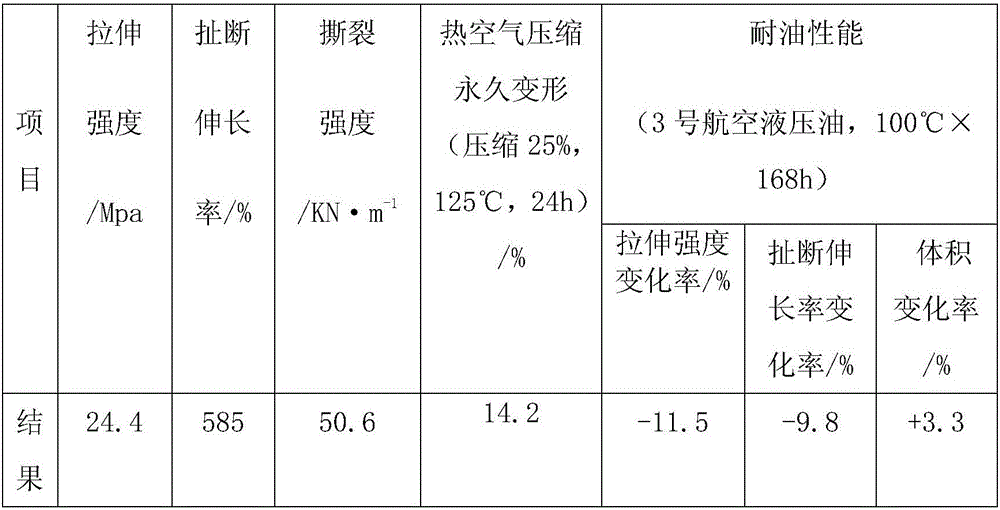

Image

Examples

Embodiment Construction

[0014] A kind of nitrile rubber gasket for high-pressure lubricating oil sealing, made of the following raw materials in weight (kg): carboxylated nitrile rubber 35, thermoplastic polyester elastomer 24, chlorohydrin rubber 19, C9 petroleum resin 6, white corundum powder 12. Accelerator NS 1.5, accelerator ZDBP 0.8, 1,2-polybutadiene 7, 1,1-di-tert-butylperoxycyclohexane 2.5, tetrachlorobenzoquinone 1.5, ethylenethiourea 2.5, partial Triallyl trimellitate 4, zinc stearate 1, antioxidant RD 1, antioxidant TMDQ 0.5, diisononyl phthalate 8, tungsten disulfide 12, modifier 9;

[0015] The preparation method of the modifier is as follows: (1) take the following raw materials in weight (kg): sea ball stone 17, needle coke 11, polymerized ferrophosphorus powder 13, nanometer aluminum titanate 10, methylene dinaphthalene sulfonate Sodium sulfosuccinate 3, sodium dioctyl sulfosuccinate 2, cetearyl glucoside 2, polypropylene glycol 200 6, tri-n-butylamine 5, octyldodecyl mescemate 4; (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com