Processing technology of needle-punched non-woven fabric

A technology of needle-punched non-woven fabrics and processing technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor strength and durability, and achieve the effects of small elongation, high strength and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

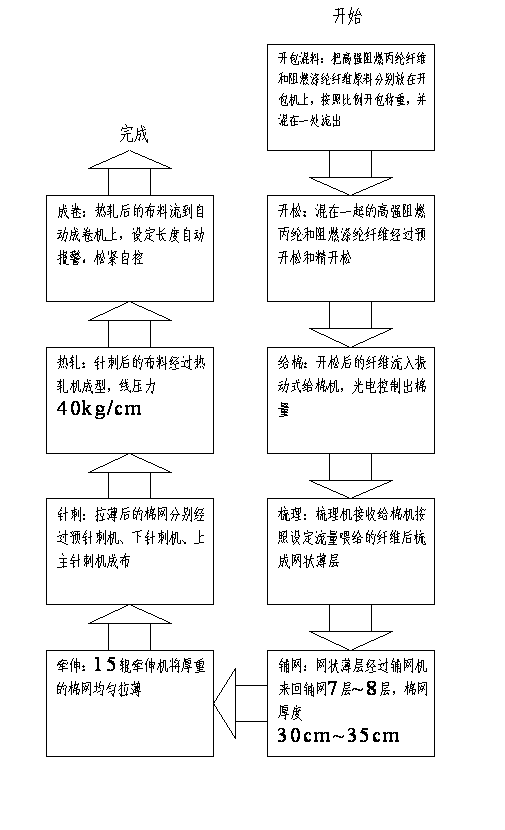

[0036] Take the high-strength flame-retardant polypropylene fiber and flame-retardant polyester fiber raw materials with a weight ratio of 4:1 and put them into the bale unpacking machine for automatic unpacking and mixing. 950 rpm, followed by fine opening and loosening. The fine machine used is equipped with 7 nail chisel plates, and the speed is set at 950 rpm.

[0037] The fiber raw material after opening is quantitatively flowed into the carding machine through the vibrating cotton feeder to be carded into a net shape. The carding machine contains double cylinders and double doffers. The fluffy mesh fiber flows into the cotton laying machine and lays 8 layers back and forth, with a thickness of 30cm~35cm, and then sent to the drafting machine for uniform thinning to 10cm.

[0038] The thinned cotton web is first pre-acupunctured. The frequency of the pre-acupuncture machine is set at 500 punctures / minute, the needle density is 4000 pieces / m, the diameter of the needle hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pinhole diameter | aaaaa | aaaaa |

| Pinhole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com