Patents

Literature

203 results about "Drafting machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drafting machine is a tool used in technical drawing, consisting of a pair of scales mounted to form a right angle on an articulated protractor head that allows an angular rotation. The protractor head (two scales and protractor mechanism) is able to move freely across the surface of the drawing board, sliding on two guides directly or indirectly anchored to the drawing board. These guides, which act separately, ensure the movement of the set in the horizontal or vertical direction of the drawing board, and can be locked independently of each other.

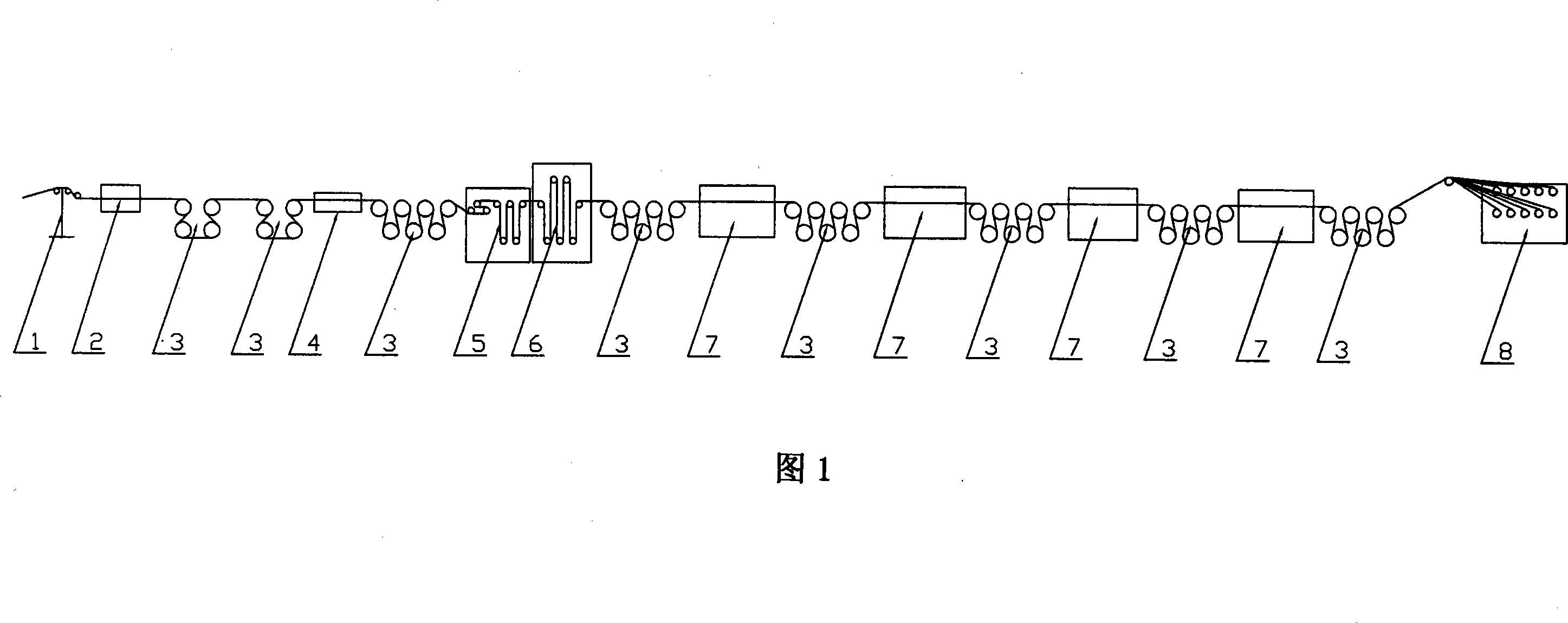

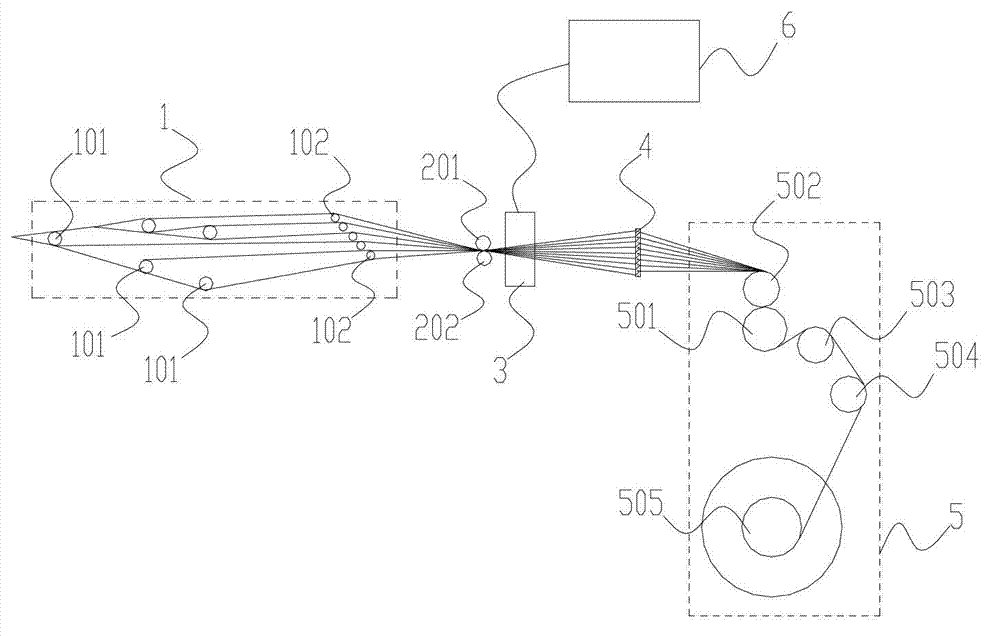

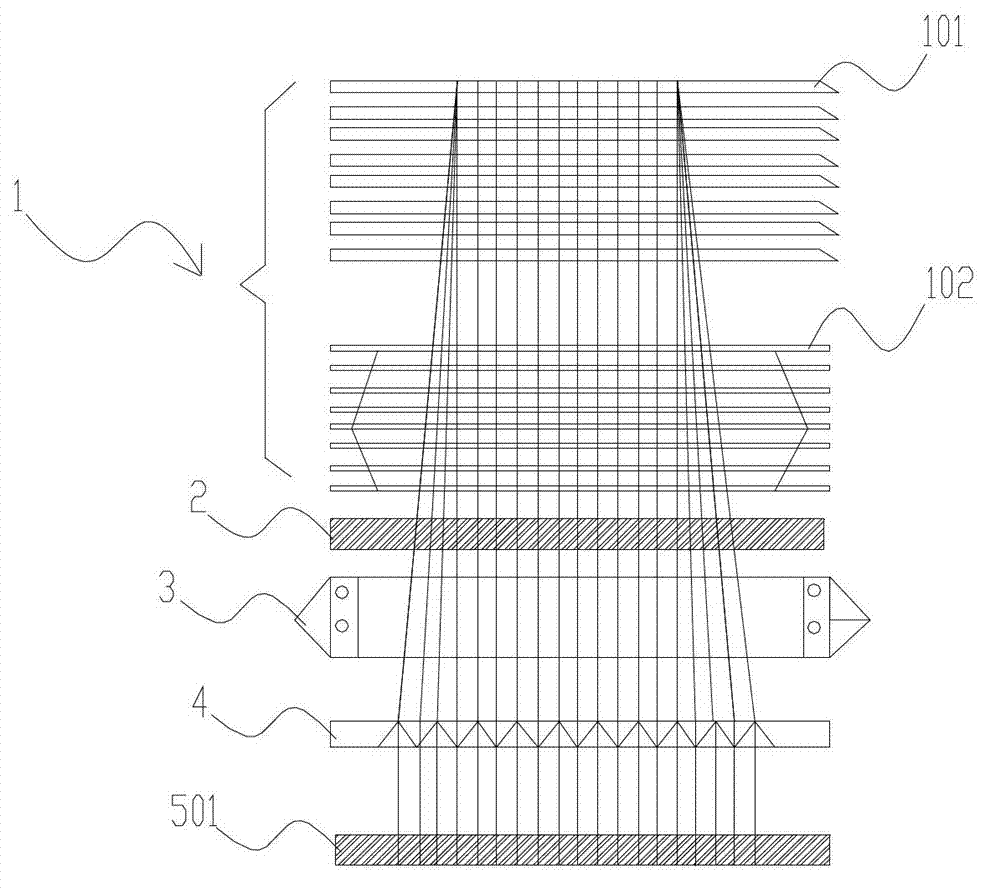

Method and apparatus for producing high strength, high modulus polyethylene filament by melt drawing

ActiveCN101476170AImprove featuresHigh strengthArtificial thread manufacturing machinesArtificial filament heat treatmentPolymer scienceHigh intensity

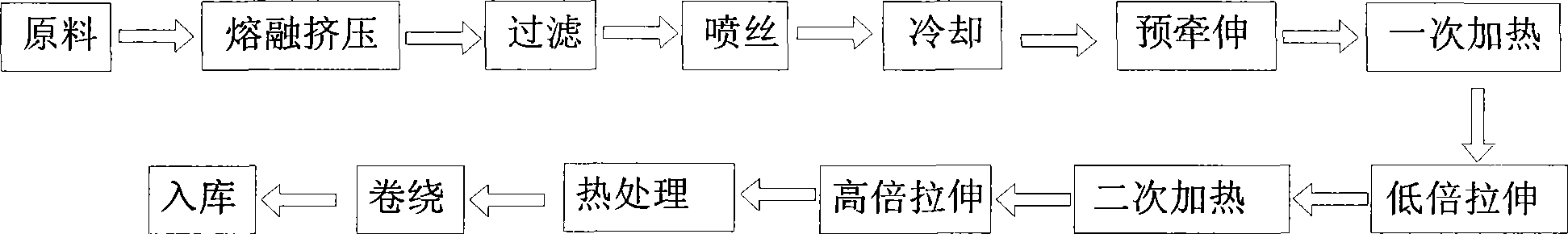

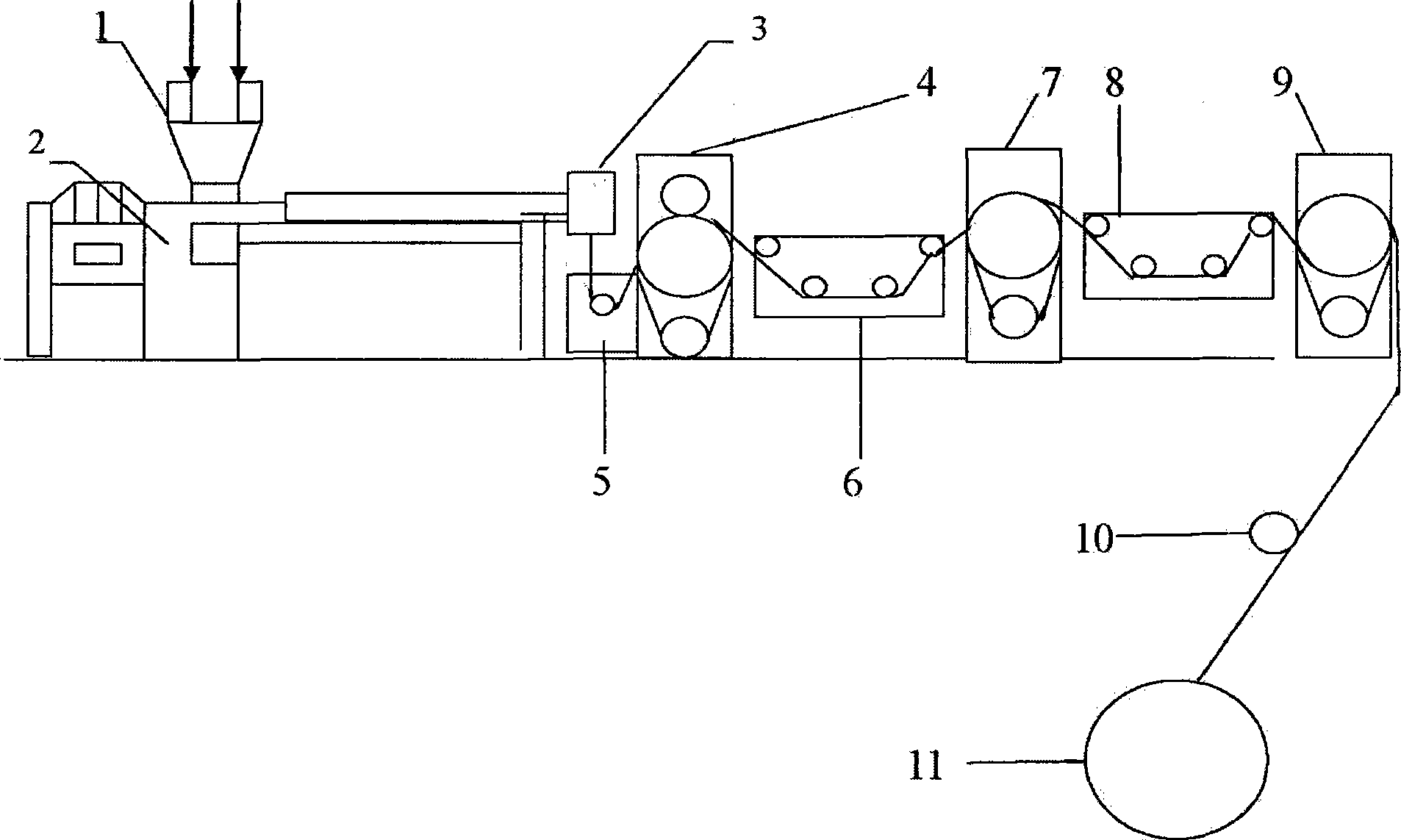

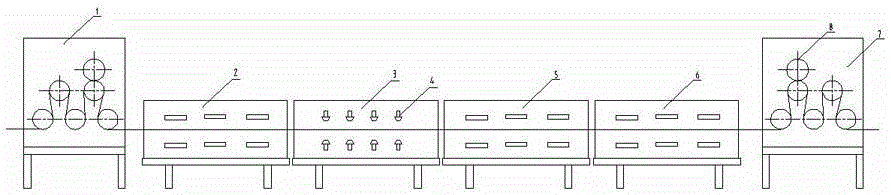

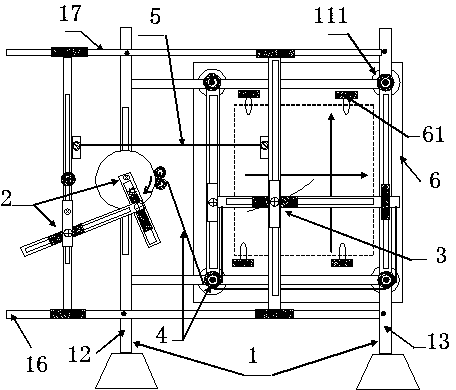

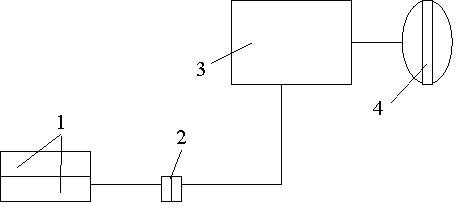

The invention discloses a method for producing polythene fiber with high strength and high modulus by melting fiber drawing and a device thereof. The method includes steps as follows: blend composition of polythene with super high molecular weight and three element blend composition of polythene with super high molecular weight are used as raw material, the raw material is spout fibre adobe after melted through a screw extruder, the fibre adobe is preset drafted after cooling, then low power drafted after once heating, then high power drafted after twice heating, finally is processed heat processing for obtaining polythene fiber with high strength and high modulus. The screw extruder, a cooling mechanism, a drafting machine processing preset drafting, an once heating mechanism, a low power drafting machine, a twice heating mechanism, a high power drafting machine, a heat processing mechanism, a winding reeling machine are arranged in the device orderly. The invention provides a producing method with simple technique, short producing flow, low cost and no pollution aiming at problem that UHMWPE melting spout fibre process has difficult to spin, and provides a device with compact equipment and easy to operate.

Owner:闫镇达

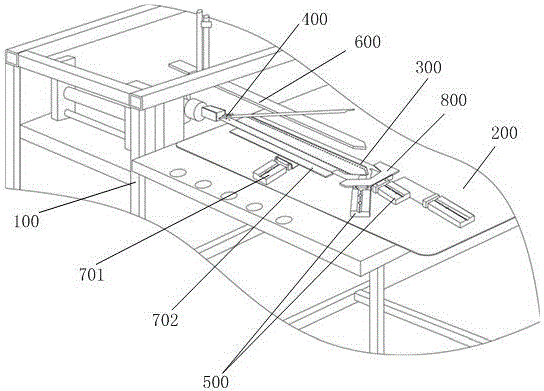

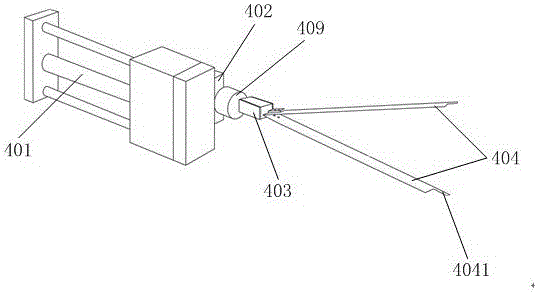

Cuff opening machine and cuff opening folding device of same

The invention provides a cuff opening machine and a cuff opening folding device of the same. The cuff opening folding device of the cuff opening machine comprises a base plate mounted on a rack, an induced draft plate mounted on the base plate and equipped with a groove and induced draft holes, an induced draft machine communicated with a plurality of induced draft holes, a side folding device mounted on the base plate and folding a cuff opening strip cut part, and an angle breaking device mounted on the base plate and breaking an angle of one end of the cuff opening strip. The cuff opening strip cut part can be quickly folded via the cuff opening machine, so a procedure of manually ironing the cuff opening strip cut part folded side can be avoided; and labor intensity can be reduced and production efficiency can be improved.

Owner:广东明德科技有限公司

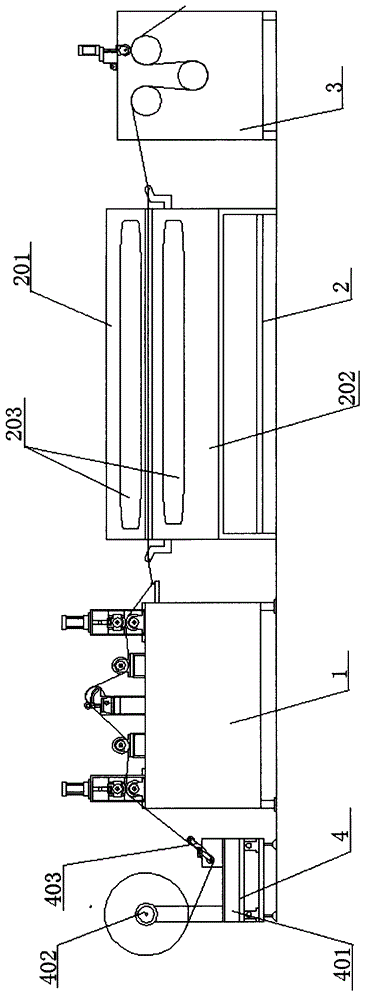

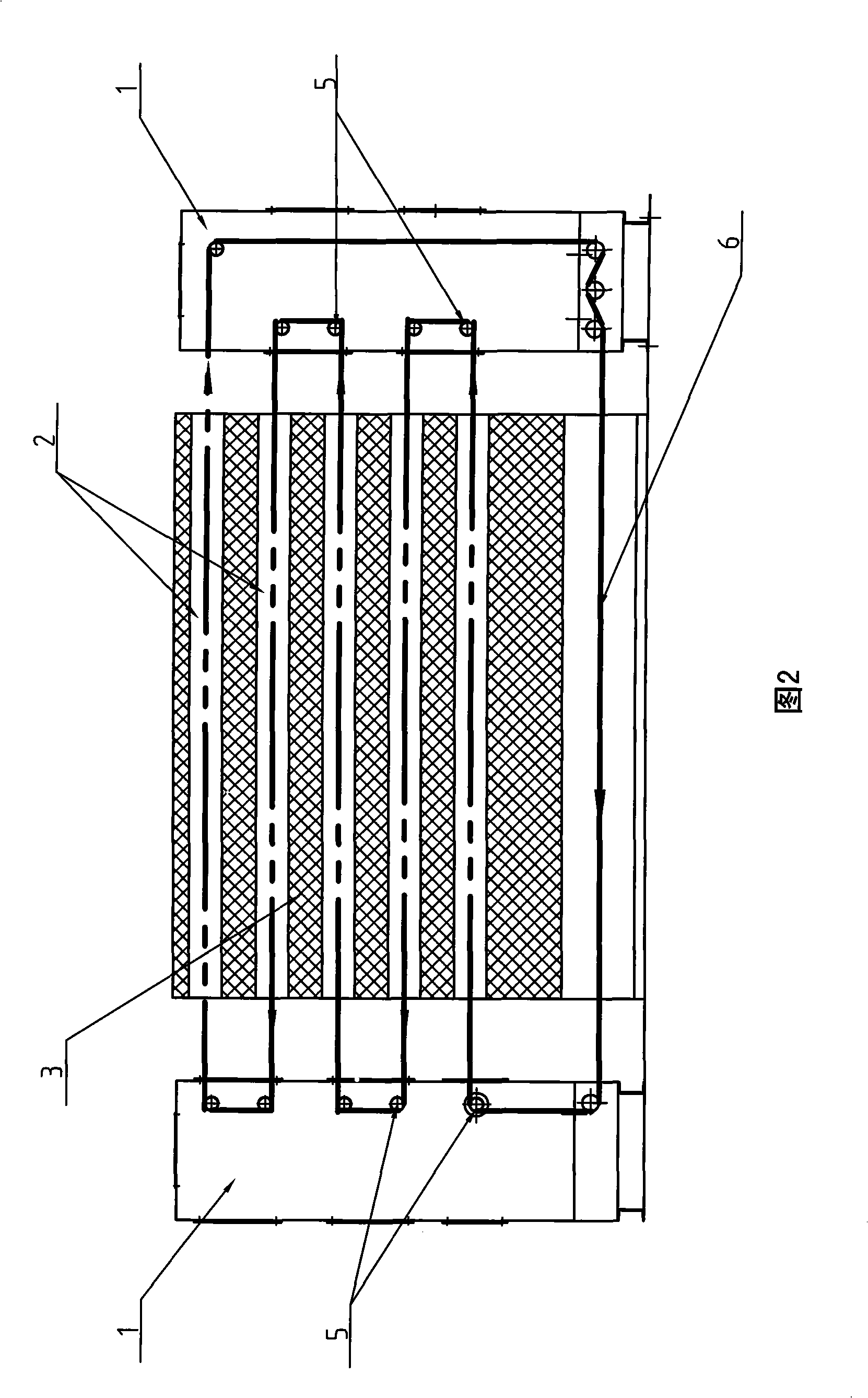

High-modulus high-strength polyvinyl fibre abstraction drafting production line

ActiveCN101135069AReasonable designShorten the production cycleArtificial thread manufacturing machinesFilament manufactureWinding machineProduction line

The high modulus and high strength polyethylene fiber extracting and drafting production line includes one godet frame, one first drafting machine, one water washing machine, one second drafting machine, one extracting machine, one hot blast drying box, one third drafting machine, one drafting and heating box, one fourth drafting machine and one winding machine connected successively. The drafting machines are hot roller ones, the drafting and heating box is one double air duct one, and the extracting machine is one multistage or multilayer one. The present invention has reasonable first, short production period, high extracting efficiency, high drafting power, low production cost, high operation efficiency and high product quality.

Owner:JIANGSU SHENTAI SCI & TECH DEV

Industrialized polyimide fiber drafting method

ActiveCN102943331ASmall impact heat loadImproved physical-mechanical propertiesTextiles and paperYarnPart type

Disclosed is an industrialized polyimide fiber drafting method. The method includes that a certain deniers of polyimide yarn sheets with uniform tension are placed in a four-part type hotbox environment and clamped by a rubber roller, under a certain feeding speed, the yarn sheets achieve a certain multiple drafting through a speed difference between a front drafting machine and a rear drafting machine, and the four-part type hotbox is a combination of a prehearing section hotbox, a superheated steam humidifying section hotbox, a high temperature drafting hotbox and a setting hotbox. During the process of the fiber treatment, the temperature changing gradient is reasonable, the impact thermal load which is stressed on the fibers is small, and the probability that the yarn sheets generate broken filaments is remarkably reduced. The fibers are subjected to superheated steam humidifying treatment before the high temperature drafting, the static electricity in the yarn sheets is eliminated, the drafting force of the same number of fibers is reduced by 25%, the draft multiple is increased by 30%, and the strength of the fibers is increased 40%. After the polyimide fibers are subjected to the drafting and high temperature setting, the internal stress of the polyimide fibers is eliminated, the stability of the fiber structure is improved, and the shrinking rate of the polyimide fibers is maintained about 2%.

Owner:JIANGSU AOSHEN HI TECH MATERIALS CO LTD

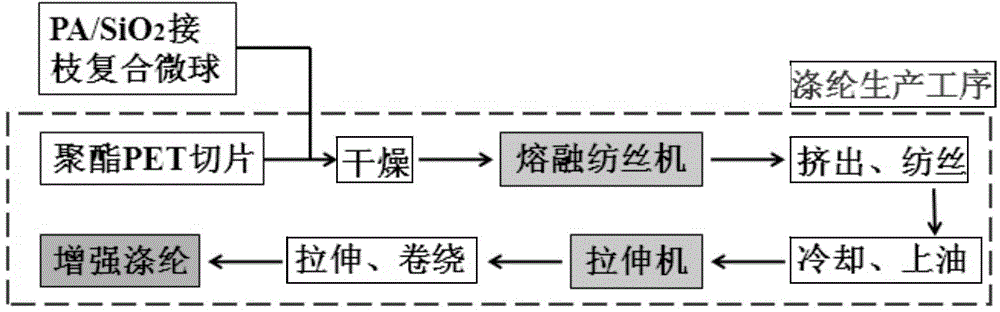

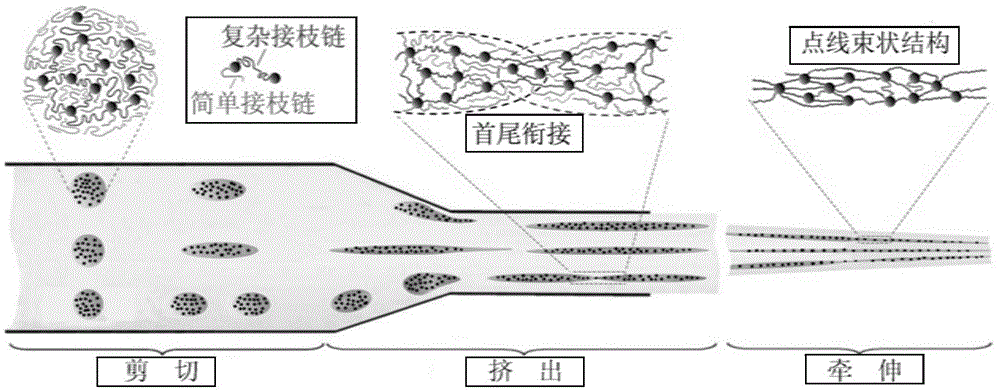

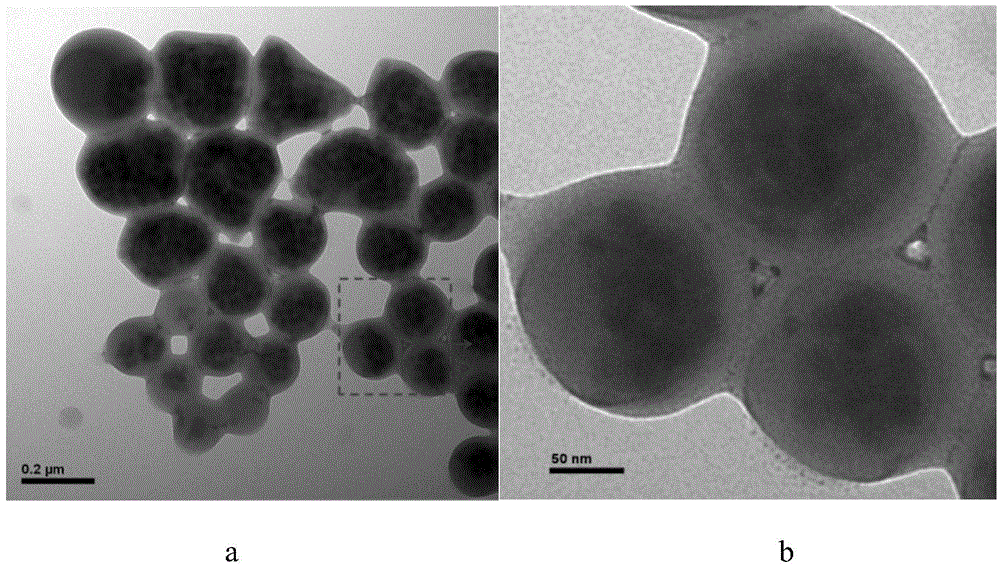

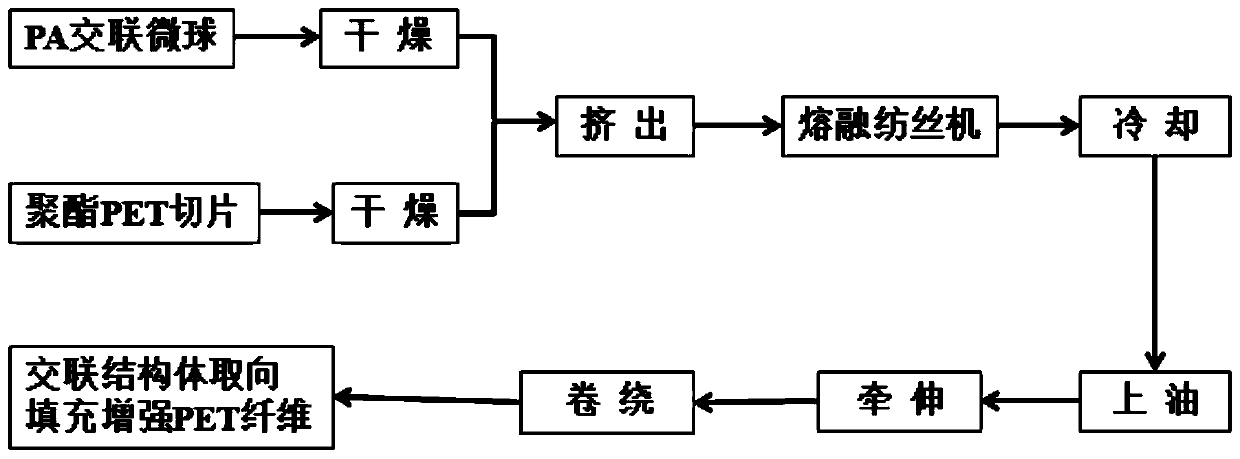

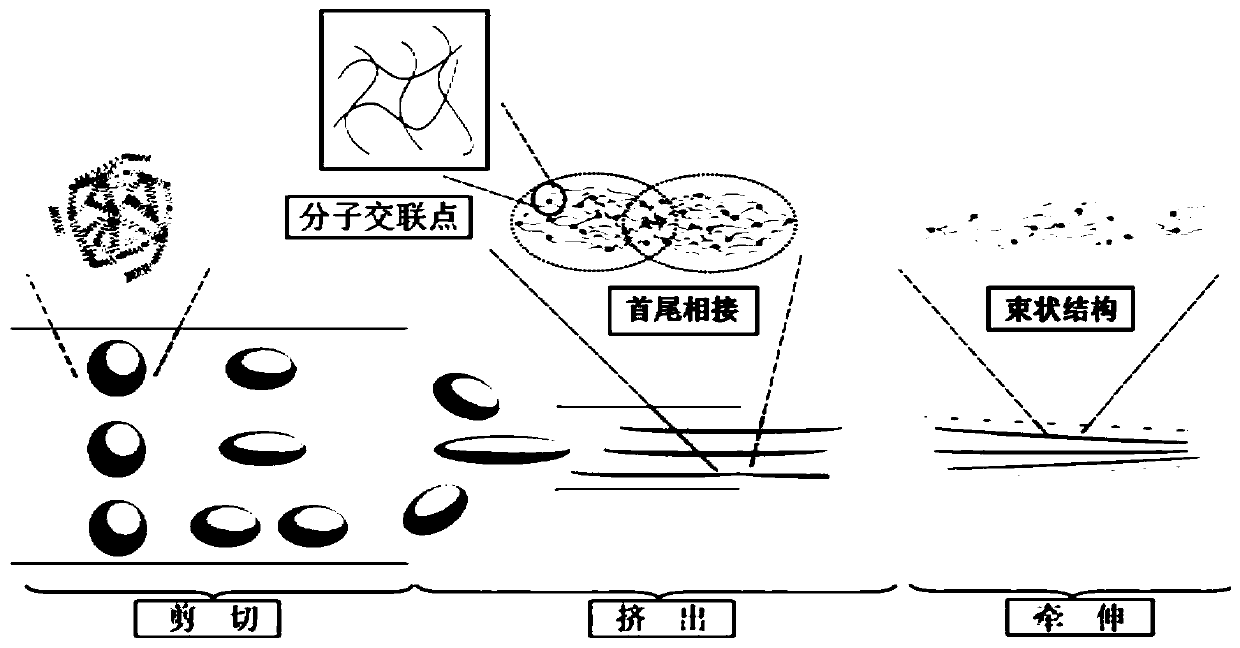

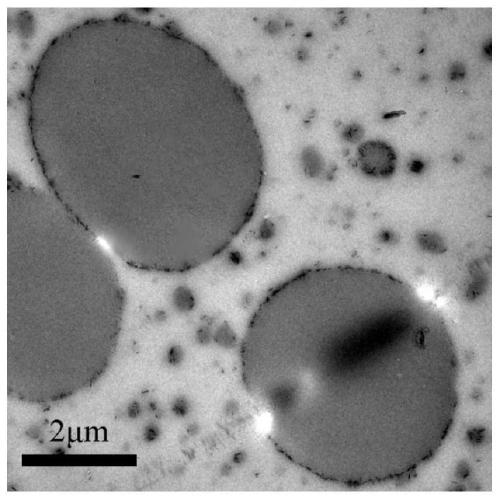

Preparation method of grafted SiO2 particle cluster orientation reinforced polyester fiber

ActiveCN104695043AAvoid mass reunionsEasy to passMelt spinning methodsMonocomponent polyesters artificial filamentPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a preparation method of grafted SiO2 particle cluster orientation reinforced polyester fiber. The method comprises the steps of carrying out vacuum drying on a polyethylene terephthalate (PET) chip and pomegranate-shaped polymethyl methacrylate (PMMA) / SiO2 graft composite microspheres; mixing the dried PET chip granules and the dried PMMA / SiO2 graft composite microsphere powder, feeding the mixture into a melt spinning machine, and carrying out melt extrusion; cooling, oiling, and carrying out spinning draft in a drawing machine to obtain the grafted SiO2 particle cluster orientation reinforced polyester fiber. According to the method, the grafted SiO2 particle clusters in the composite microspheres are sequentially arranged and regularly oriented along the axial direction of the fiber and the oriented SiO2 particles are connected front and back by carrying out melt blending, extrusion and drawing on the composite microspheres and polyester PET resin in the melt spinning machine and a spinning draft machine, so that a beam-shaped arrangement structure which takes the SiO2 particles as crosslinking points and PMMA graft chains as connecting lines can be built in PET fiber, and the polyester fiber finally has better mechanical strength.

Owner:ZHEJIANG SCI-TECH UNIV

Method for preparing fishing flexible blended and modified polyethylene monofilaments

ActiveCN101851797AImprove product qualityFeel goodSpinning head liquid feederFilament manufactureElastomerWinding machine

The invention discloses a method for preparing fishing flexible blended and modified polyethylene monofilaments, relates to a method for preparing fishing polyethylene monofilaments and aims to provide a method for preparing the fishing flexible blended and modified polyethylene monofilaments. A stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments with high-pressure air current after the total drafting multiple is controlled to be between 9.63 and 9.87 times and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the fishing flexible blended and modified polyethylene monofilaments by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for processing high-performance modified polyethylene monofilaments for manufacturing fishing net

InactiveCN101851795AIncrease heat treatment temperatureHigh breaking strengthSpinning head liquid feederFilament manufactureWinding machineElastomer

The invention discloses a method for processing high-performance modified polyethylene monofilaments for manufacturing a fishing net, relates to a method for processing polyethylene monofilaments for manufacturing a fishing net and aims to provide a method for processing the high-performance modified polyethylene monofilaments for manufacturing the fishing net. In the technical scheme of the invention, a stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry HDPE resin, a dry VERSIFYTM 6002 elastomer, white oil or a turpentine aid; uniformly mixing the materials to obtain an HDPE / VERSIFYTM 6002 elastomer blend and fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PE monofilaments by using the winding machine; and separating the modified PE monofilaments into the high-performance modified polyethylene monofilaments for manufacturing the fishing net by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Anti-tangent, cotangent, secant and cosecant function demonstrating and graph drawing instrument

ActiveCN104332085AEasy to operateImprove applicabilityNon-circular curve drawing instrumentsEducational modelsRectangular coordinatesEngineering

The invention discloses an anti-tangent, cotangent, secant and cosecant function demonstrating and graph drawing instrument which is made according to a rectangular coordinate definition of an anti-trigonometric function and by combining pushing-turning principles with slider-connecting rod characteristics. The instrument comprises a support, a demonstrating device, a drawing mechanism and a drawing board, the demonstrating device is mounted on a lower slideway and an upper slideway of uprights, and the drawing mechanism is connected with the uprights, the lower slideway, the upper slideway and a guide rod, and connected with the demonstrating device through a soft rope and a pull rod. The above components are combined by adopting different assembly modes, anti-tangent, cotangent, secant and cosecant function relations can be demonstrated visually by only pushing a handle on the push rod, continuous and accurate function graphs can be drawn on the drawing board, paper or any fixed planes, and type forms of anti-tangent, cotangent, secant and cosecant can be demonstrated while corresponding graphs can be drawn. The drawing instrument can be used in a classroom, a drawing room, a construction site and a self-study place for students and is high in drawing efficiency, clear and accurate in graph, simple to operate, convenient to carry and complete in function.

Owner:润桐(苏州)技术服务有限公司

Method for weaving pure China hemp high-count weak strength yarn home textile fabric

The invention discloses a method for weaving a pure China hemp high-count weak strength yarn home textile fabric, which comprises the following steps of: performing micro tension control on China hemp high-count weak strength yarns on a warping machine, wherein the open length of a warp beam is 2,400 millimeters, the tension of a tension rod is 4 to 10 grams, the number of the total warps is 18,338 to 23,520, the number of single shaft heads is 750 to 1,040, the number of parallel cylinders is 20 to 28 and the volume of filling cylinders is 750 to 1,040; performing sizing, wherein the tension is 4,000 to 4,100N, the sizing mode is single immersion and single pressing, the size force is 18 to 24KN, the wet elongation is 0.1 to 0.2 percent, sheet yarns are prevented from being twisted, the backing-off tension of the warp beam is 650 to 750N, the volume of a size tank is 320 liters and the size immersion length is 60 to 80 centimeters; performing up and down alternated lease by adopting a STAUBLI OPAL-3600 automatic lease machine made in Switzerland, and performing drafting by adopting a STAUBLI DELTA 110-3600 automatic drafting machine made in Switzerland; and performing low-tension weaving by using a broad-breadth single weaving shaft loom, wherein the feeding tension is 3,000 to 4,000N, the speed is 450n / min, the height of a rear beam is less than 4 centimeters, the temperature of a weaving workshop is 25 to 30 DEG C, and the relative humidity is 68 to 72 percent. According to the method, the efficiency of a fabric machine is improved, the discharge quality is ensured, the yarns are well enhanced, the weaving broken ends of the fabric machine are reduced, and the fabric quality is good.

Owner:JIANGSU YUEDA HOME TEXTILE

Technology for manufacturing PTFE sewing threads with film splitting method

InactiveCN105887264AGuaranteed uniformityGuaranteed StrengthFilament/thread formingYarnWinding machineYarn

The invention discloses a technology for manufacturing PTFE sewing threads with a film splitting method. The technology comprises the following steps that firstly, a wide PTFE film blank is drafted, wherein the wide PTFE film blank is drafted into a narrow film with a film drafting device; secondly, film splitting drafting of the narrow PTFE film is carried out, wherein the narrow PTFE film manufactured in the first step is cut into 30-40 pieces of narrow yarns with a film splitting device on a film splitting and drafting device, and then the narrow yarns are drafted to be thin with a drafting machine and manufactured into PTFE sewing threads; thirdly, winding is carried out, wherein the PTFE sewing threads manufactured in the second step are wound with a multi-head winding machine. The technology is simple in process, equipment used in the manufacturing procedures is simple in structure and easy to use and operate, the product quality can be easily controlled, labor intensity is relieved, manpower input is reduced, the production efficiency is improved, the manufactured PTFE sewing threads are not likely to crack and long, and the uniformity, strength and the qualified rate of the PTFE sewing threads are ensured.

Owner:陈路

Method for preparing fishing poly-blended and modified polypropylene monofilaments

InactiveCN101851798AHigh breaking strengthHigh glossSpinning head liquid feederFilament manufactureWinding machineAquatic product

The invention discloses a method for preparing fishing poly-blended and modified polypropylene monofilaments, relates to a method for preparing fishing polypropylene monofilaments in the technical field of aquatic products and aims to provide a method for preparing the fishing poly-blended and modified polypropylene monofilaments. A stirring machine, a double-screw extruder, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry T30S type PP resin, a spinning-grade dry HEPE resin, a spinning-grade dry PA1010 resin, a dry PP-G-MAH resin, dry zinc stearate and a spinning turpentine aid; extruding the mixture twice by using the double-screw extruder and pelletizing to obtain poly-blended particles; fusing and extruding the poly-blended particles by using a charging barrel of the single-screw extruder, pre-drafting extruded primary filaments, thermally drafting the pre-drafted filaments twice and winding monofilaments by using the filament winding machine of a torque motor; and separating the monofilaments by using the filament separating machine to obtain the fishing poly-blended and modified PP monofilaments.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Method for preparing modified polypropylene monofilaments for processing small-size fishing rope

InactiveCN101851794AImprove roundnessFeel goodArtificial filament physical treatmentSpinning head liquid feederElastomerWinding machine

The invention discloses a method for preparing modified polypropylene monofilaments for processing a small-size fishing rope, relates to a method for preparing monofilaments for a small-size fishing rope and aims to provide a method for preparing the modified polypropylene monofilaments for processing the small-size fishing rope. A stirring machine, a single-screw extruder, a twice-drafting electrical heating drafting machine, a filament winding machine and a filament separating machine are adopted. The method is characterized by comprising the following steps of: mixing a sieved spinning-grade dry T30P type resin, a dry VERSIFYTM 6002 elastomer and a turpentine aid; uniformly mixing the materials to obtain a PP / VERSIFYTM 6002 elastomer blend; fusing and extruding the blend by using the single-screw extruder; cooling and pre-drafting the fused and extruded primary filaments, thermally drafting the pre-drafted filaments twice, rapidly cooling the thermally-drafted filaments from which oil is removed with high-pressure air current and winding modified PP monofilaments by using the winding machine; and separating the modified PP monofilaments into the modified polypropylene monofilaments for processing the small-size fishing rope under filament separating tension by using the filament separating machine.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Elastic nonwoven and preparing method thereof

InactiveCN106637681AAchieve a sense of drapeAchieve resilienceMelt spinning methodsNon-woven fabricsElastomerPolymer science

The invention relates to elastic nonwoven, and belongs to the technical field of nonwoven. The elastic nonwoven is prepared from, by weight, 50-80% of ethyl propylene coelastomer, 17-49% of polypropylene chips and 1-3% of flexibility modifier. The preparing method comprises the steps of mixing the polypropylene chips, the flexibility modifier and ethyl propylene coelastomer in proportion, and stirring and mixing the mixture to be uniform; feeding the mixture into a screw extruder and conducting melting plastification mixing through heating, then conveying the material into a spinning die to be subjected to spinning, and adopting narrow-gap positive pressure drafting and sideblowing cooling to form strands; after the strands cool down, making the strands sucked into a drafting machine under the negative pressure of the inlet of the drafting machine, and conducting cross lapping with the subsidiary of a suction ventilator below a web curtain to form a fluffy fiber layer; using a sealing roller to conduct prepressing and sizing on the fluffy fiber layer, afterwards using a hot mill to conduct hot milling adhesion reinforcing to form the elastic nonwoven. According to the elastic nonwoven and preparing method thereof, the problem that the nonwoven is low in ductility is solved; meanwhile, flexibility and elasticity of the nonwoven are improved.

Owner:ZHANGJIAGANG JUNMA NON WOVEN CO LTD

Production method of polyphenyl thioether filament

InactiveCN101280465AHigh breaking strengthLow elongation at breakHeating/cooling textile fabricsMonocomponent synthetic polymer artificial filamentFiberHigh fracture

Disclosed is a polyphenylene sulphide PPS filament production method. After the precrystallization the PPS resin slice is sent to a filled-drying tower, the drying is proceeded with the use of the dehumidifying high purity nitrogen. The drying temperature is controlled at 165 DEG C, and the drying time is 6 hours. After the drying, the PPS resin slice relies on the dead weight to enter a screw extruder for the meltdown. The controlling temperature of each zone of the screw extruder is 260 / 310 / 318 / 325 / 322 DEG C, and then after the meltdown through the screw extruder the PPS resin slice enters a spinning manifold to spin. The filament spraying pressure is 220kg / cm2. After heated through a heater, the as-spun fiber sprayed through a spraying plate is in cooling molding through a lateral blow in which the temperature is controlled at 22 DEG C. The cooled fibers are in winding shaping through a winding head with the winding speed of 1000m / min. After the fiber winding, a parallel drafting machine is adopted for the processing of the drafting setting with the drafting speed of 500m / min, the drafting temperature of 105 DEG C and the setting temperature of 140 DEG C. Therefore, the fiber produced through the method of the invention has the advantages of high fracture strength, low fracture growth, high thermal stability, chemical resistance and so on.

Owner:梅艳芳

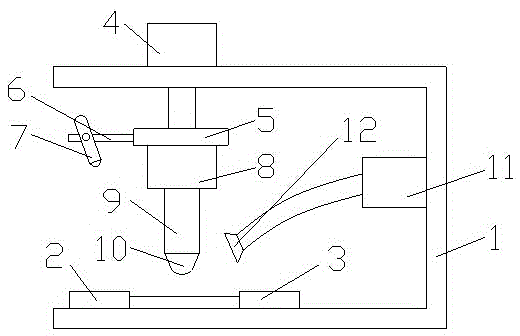

Building board drilling device

InactiveCN105583913APrecise drillingEasy to operateStationary drilling machinesBark-zones/chip/dust/waste removalFree stateDrill bit

The invention provides a building board drilling device. A clamping device comprises a left clamping piece and a right clamping piece, and the left clamping piece and the right clamping piece are arranged on a rack in a sliding manner and matched with each other to fix a board to be drilled; a first driving device is arranged on the rack and located above the clamping device and can drive a supporting plate to vertically move, a positioning rod is arranged at the upper portion of the rack, and a laser sighting device is hinged to the positioning rod; a second driving device is arranged below the supporting plate and can drive a drill rod to rotate, a drill bit is arranged on the drill rod, and in the free state, a projection of the drill bit on the bottom face of the rack coincides with a sighting point of the laser sighting device; and an air drafting machine is arranged on the rack and located on one side, far away from the laser sighting device, of the supporting plate, an air drafting cover is connected to the air drafting machine through an air drafting hose, and the air drafting cover faces the drill bit. By means of the building board drilling device, operation is convenient, accurate drilling on the board can be achieved, and wood bits are not prone to splashing in the drilling process.

Owner:王永志

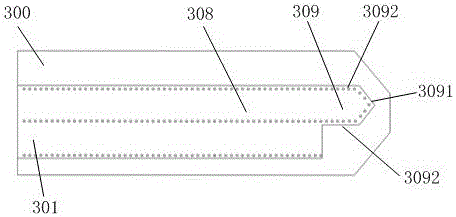

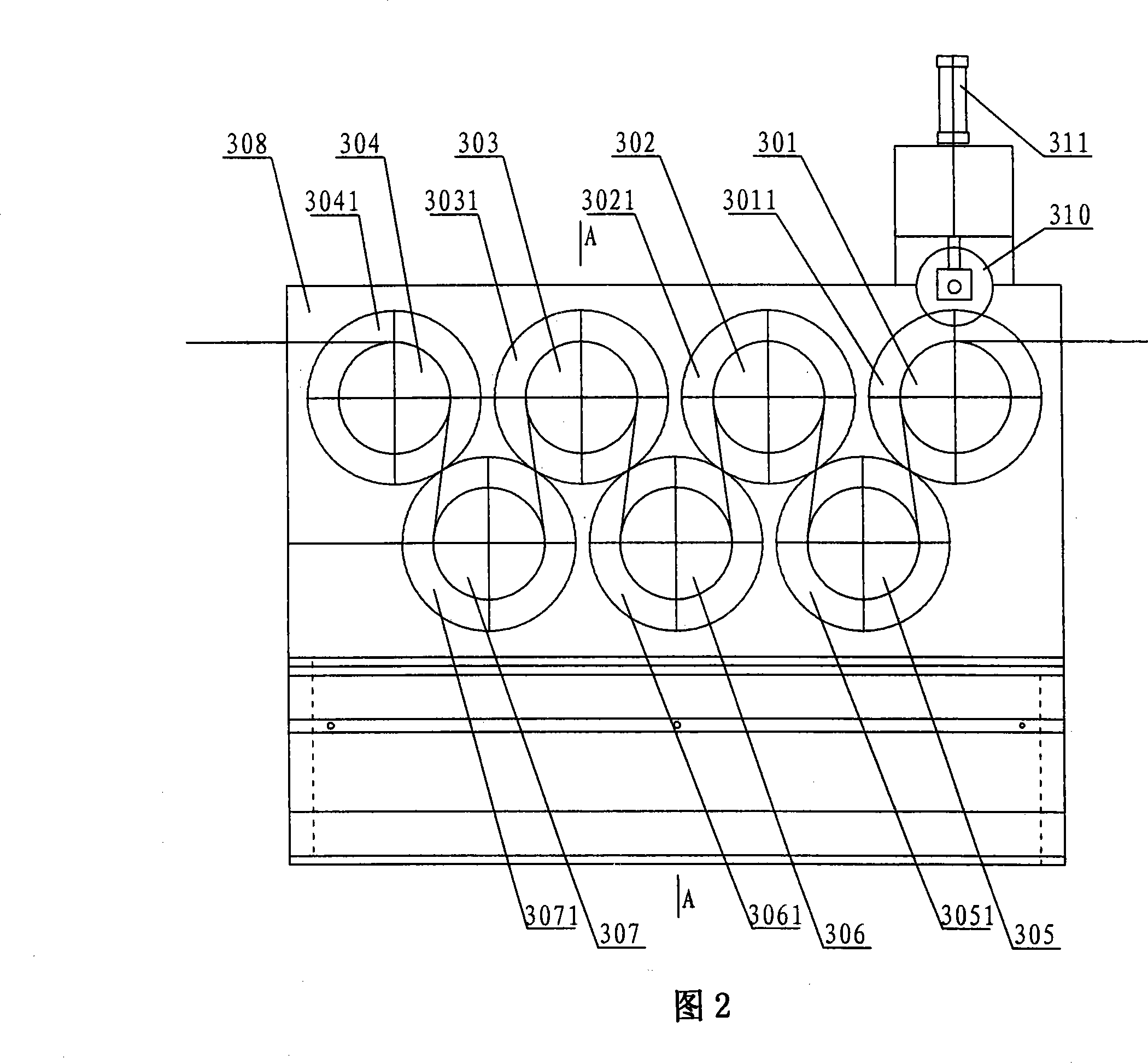

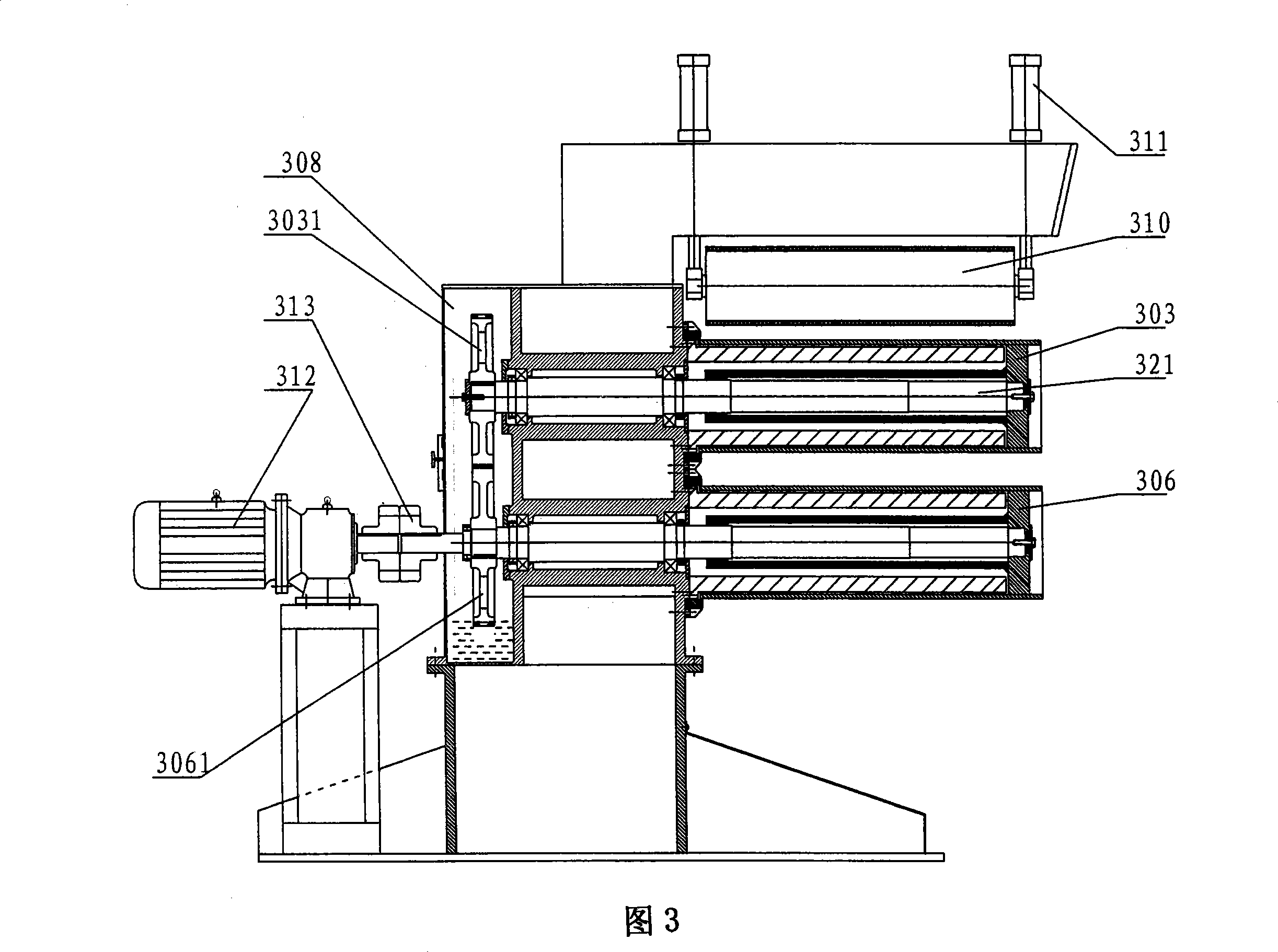

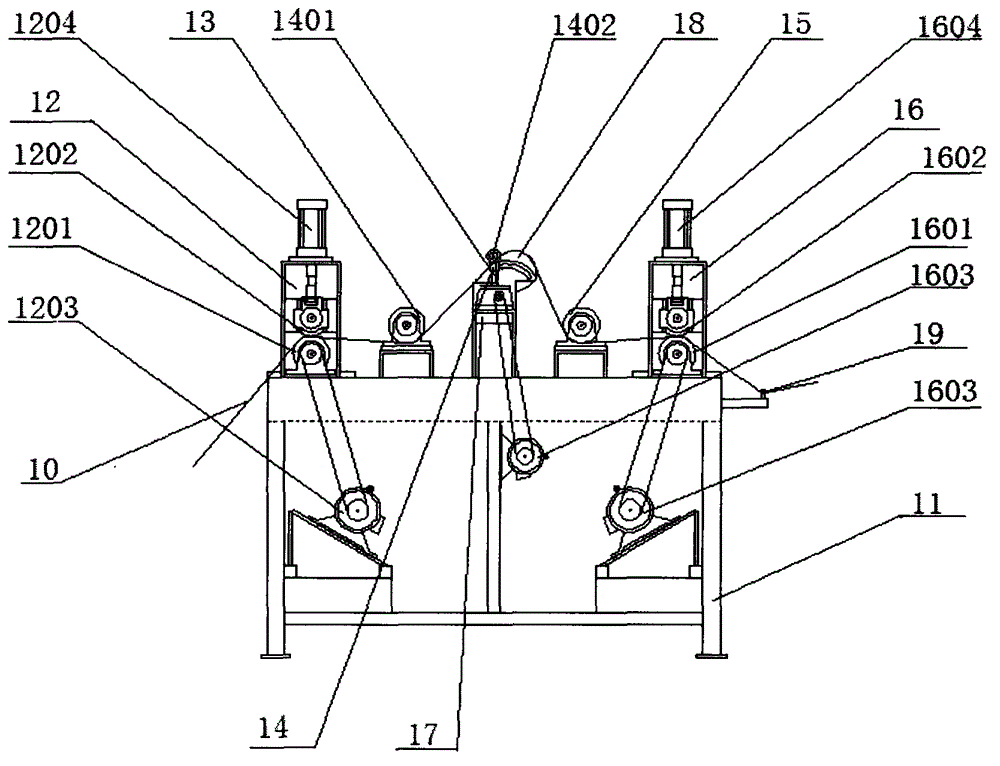

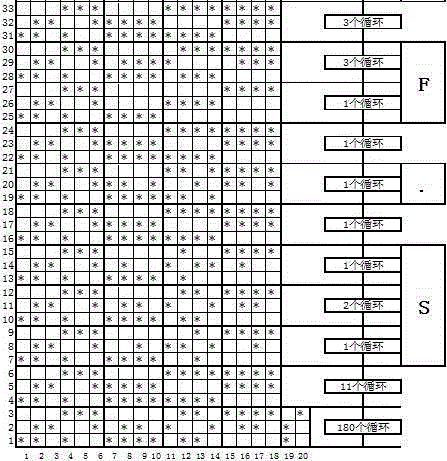

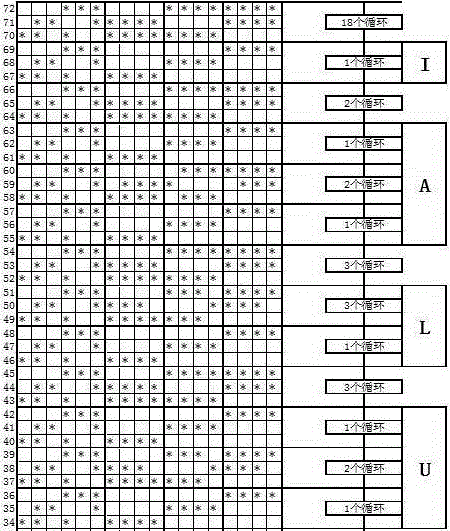

Carbon fiber drafting machine

The invention relates to production equipment for carbon fiber, in particular to a carbon fiber drafter. The drafter comprises two drafting units which are respectively arranged at two sides of a preoxidation furnace with multiple layers of heating channels; each drafting unit comprises multiple groups of drafting rollers which are distributed from down to up, each group of drafting rollers corresponds to the multiple layers of heating channels of the preoxidation furnace, and the carbon fiber can pass through the layers of heating channels one by one in reciprocation through the groups of drafting rollers sequentially. The drafter can ensure the carbon fiber to pass through the multiple layers of heating channels of the preoxidation furnace one by one in reciprocation, make full use of vertical space of the equipment and greatly reduce the length and occupying area of the production line; as each drafting roller group has a separate driving device, the rotational speed of the drafting roller group can be regulated by frequency conversion according to tension requirement of the process and center-controlled by a computer, thus improving the processing effect of the carbon fiber.

Owner:镇江奥立特机械制造有限公司

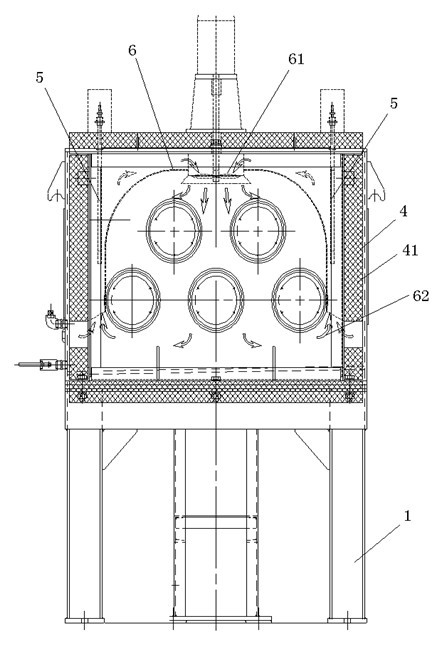

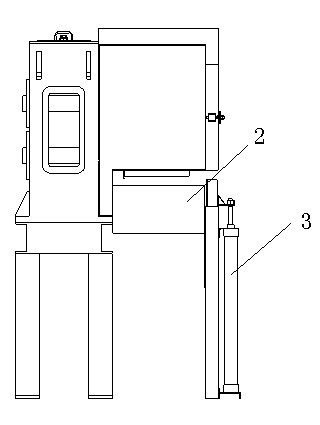

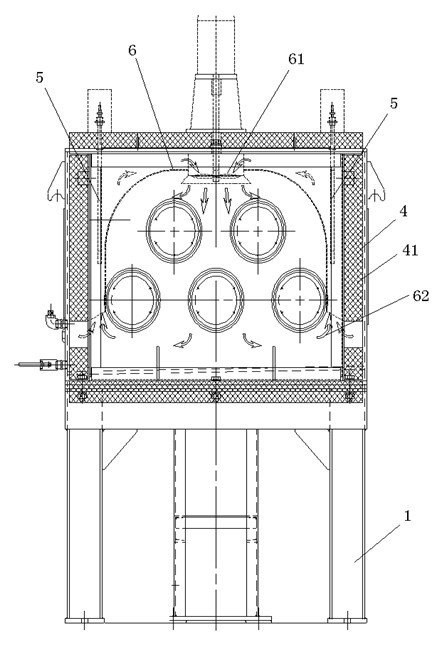

Heat holding furnace for drafting machine

The invention discloses a heat holding furnace for a drafting machine. The heat holding furnace comprises a shell, a furnace door, a furnace door lifting mechanism, a furnace lining, heat elements and a hot wind circulating system, wherein the furnace door is arranged on the shell and connected with the furnace door lifting mechanism; the furnace lining is fixed on the shell; a heat insulating layer is arranged on the furnace lining; the heat elements are arranged in the shell and positioned at two sides of a hearth; and the hot wind circulating system comprises a circulating fan and an air flue in the furnace, and the circulating fan blows the heat of the heat elements to a work area through the air flue in the furnace. The heat holding furnace has good heat and insulation effect, safety, reliability and long service life.

Owner:南京际华三五二一环保科技有限公司

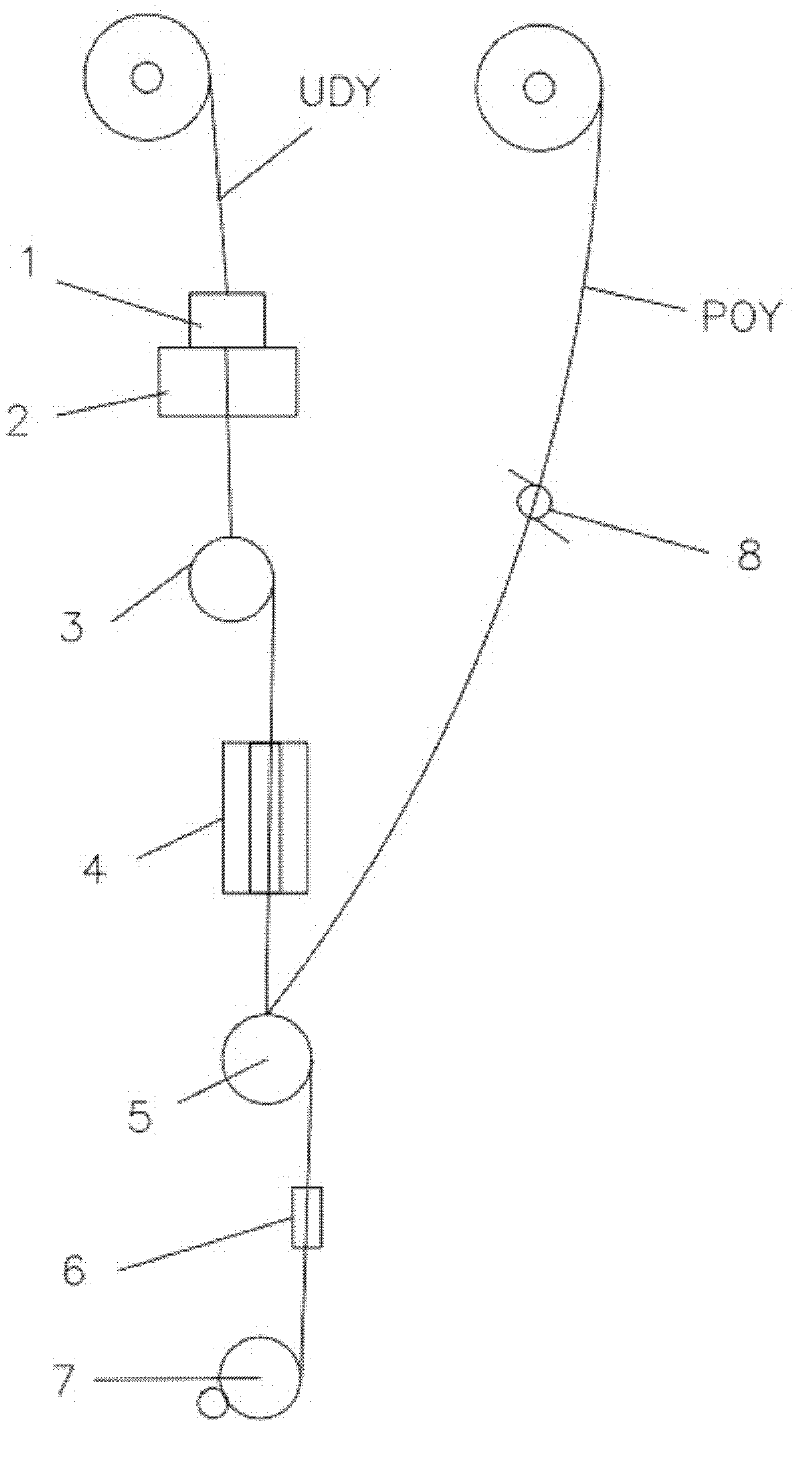

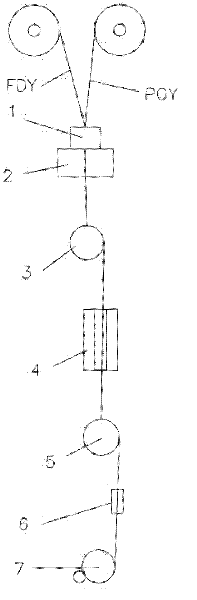

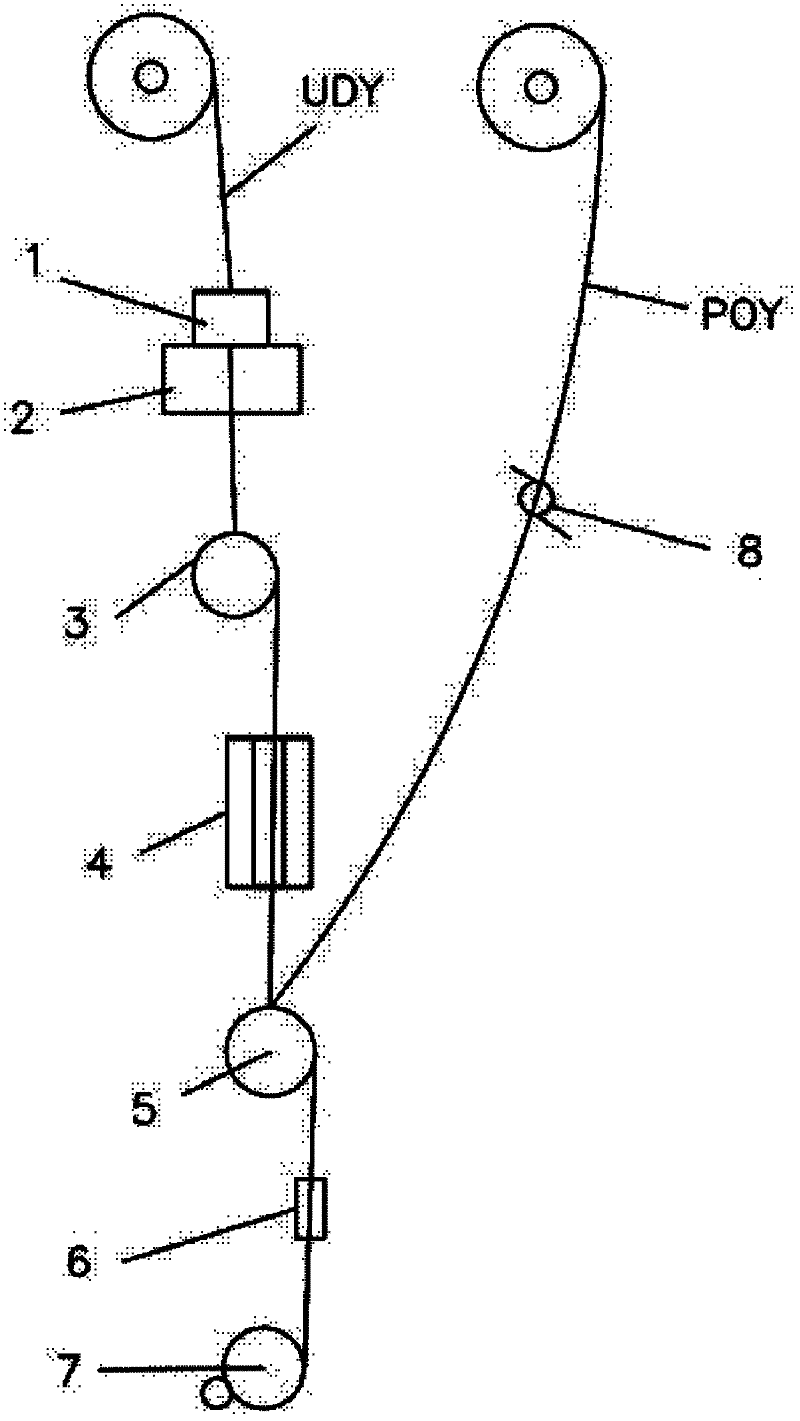

Method for producing polyester ITY (Interlaced Texture Yarn) through flat drafting

The invention discloses a method for producing polyester ITY (Interlaced Texture Yarn) through flat drafting. The method adopts a drafting machine to mix and combine FDY (Full Drawn Yarn) and POY (Polyester Pre-Oriented Yarn); the drafting machine comprises a yarn feeding pressure roller, a yarn feeding tension controlling roller, a first drafting disc, a hot plate, a second drafting disc, an interlacer and a winding roller; the yarn feeding pressure roller is pressed on the yarn feeding tension controlling roller; the method is characterized in that the finished FDY is produced by one stage process, the FDY and the POY together pass through the yarn feeding pressure roller and the yarn feeding tension controlling roller to realize yarn feeding, and together pass through the first drafting disc, the hot plate, the second drafting disc and the network device in sequence to finish the winding finally; and during the process, the first drafting disc is in a heating state, the hot plate and the second drafting disc are in a non-heating state. The ITY produced by the method has the advantages that the interlacing degree is high; the boiling water shrinkage is low and can be adjusted as needed; and the dyeing uniformity is good. Therefore, the ITY can be used to produce high-grade fabrics products, particularly knitted fabrics.

Owner:TONGKUN GRP

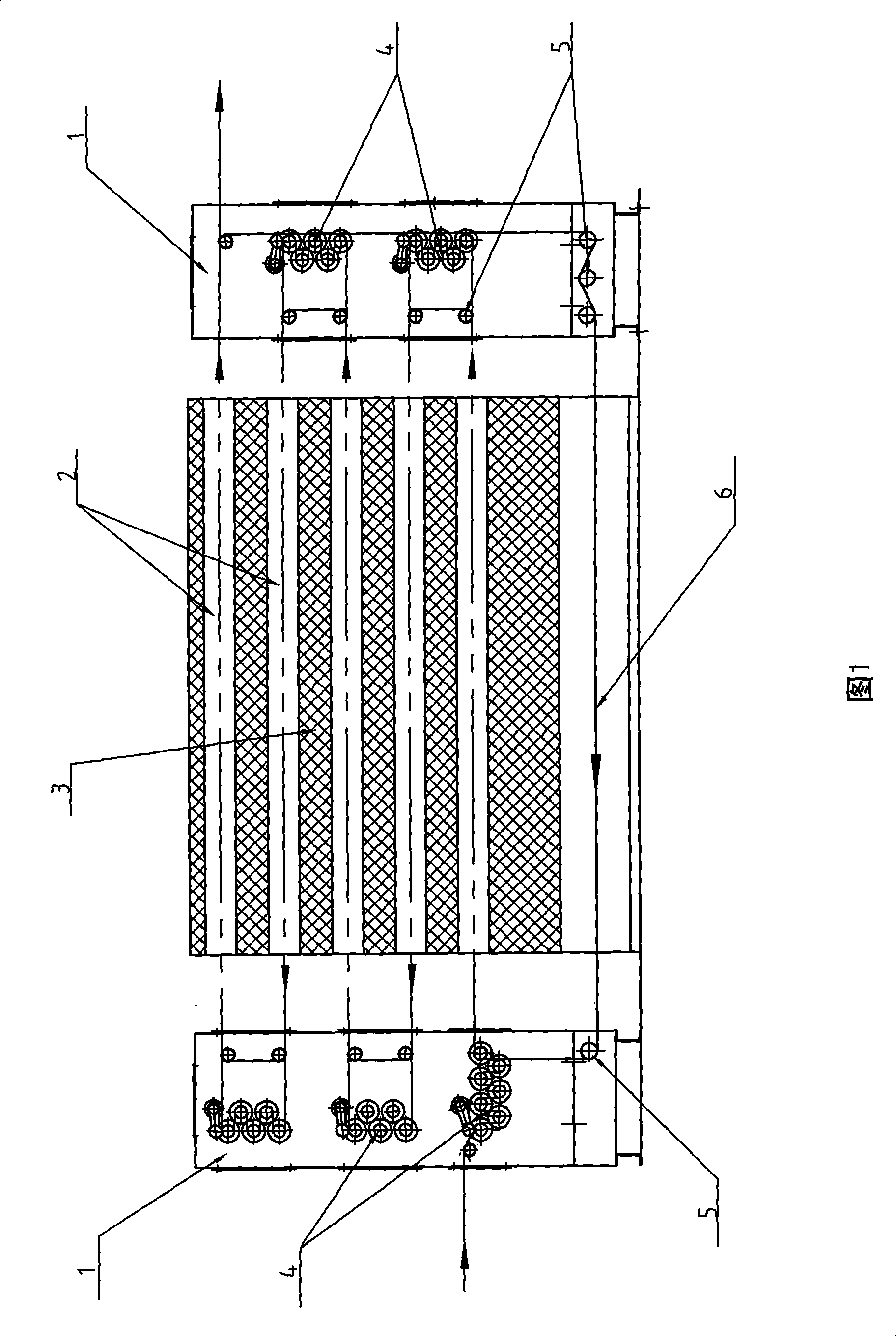

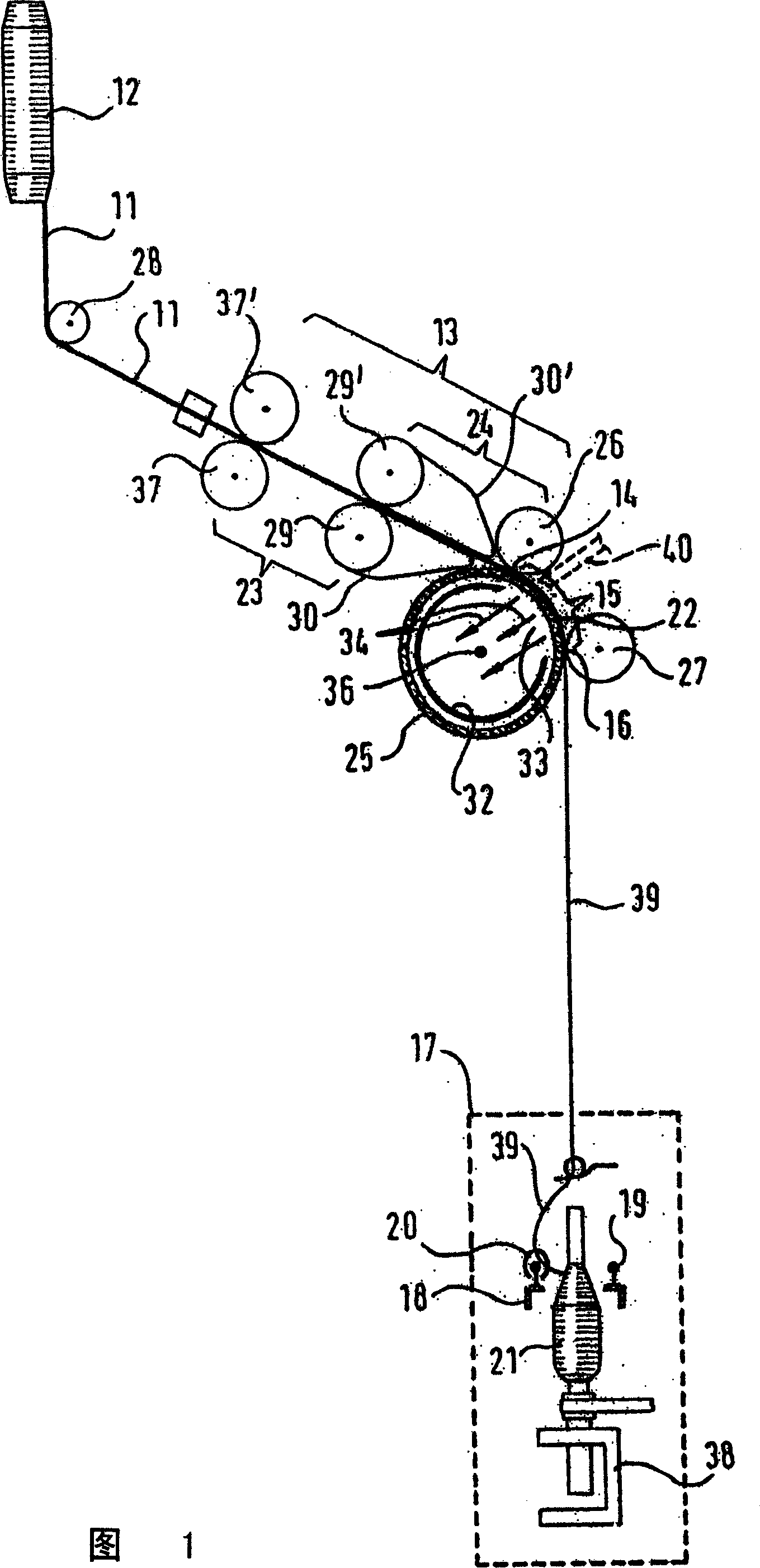

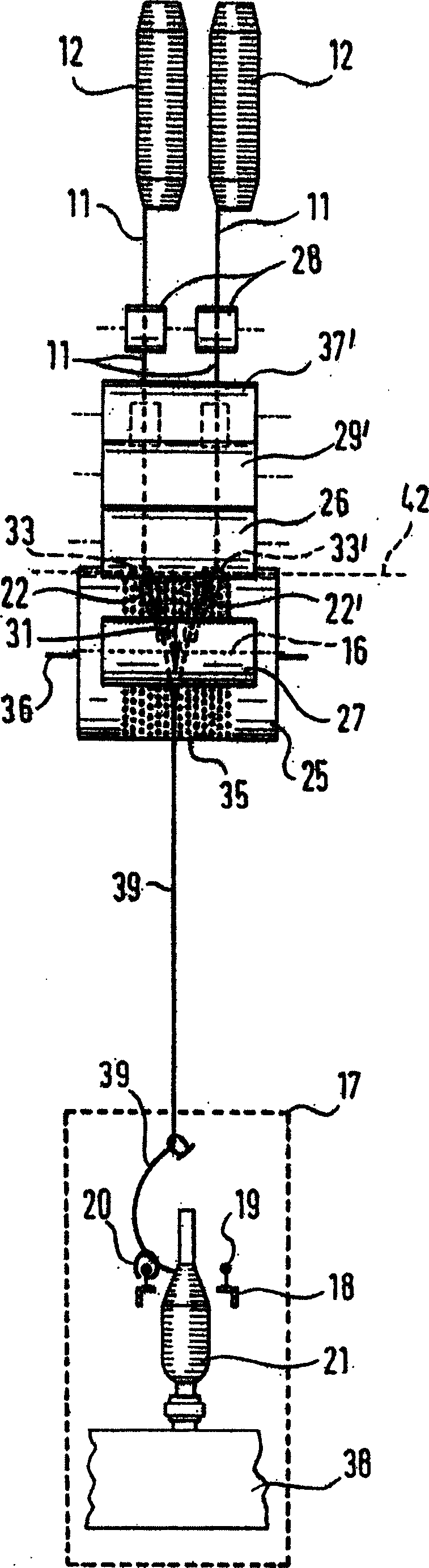

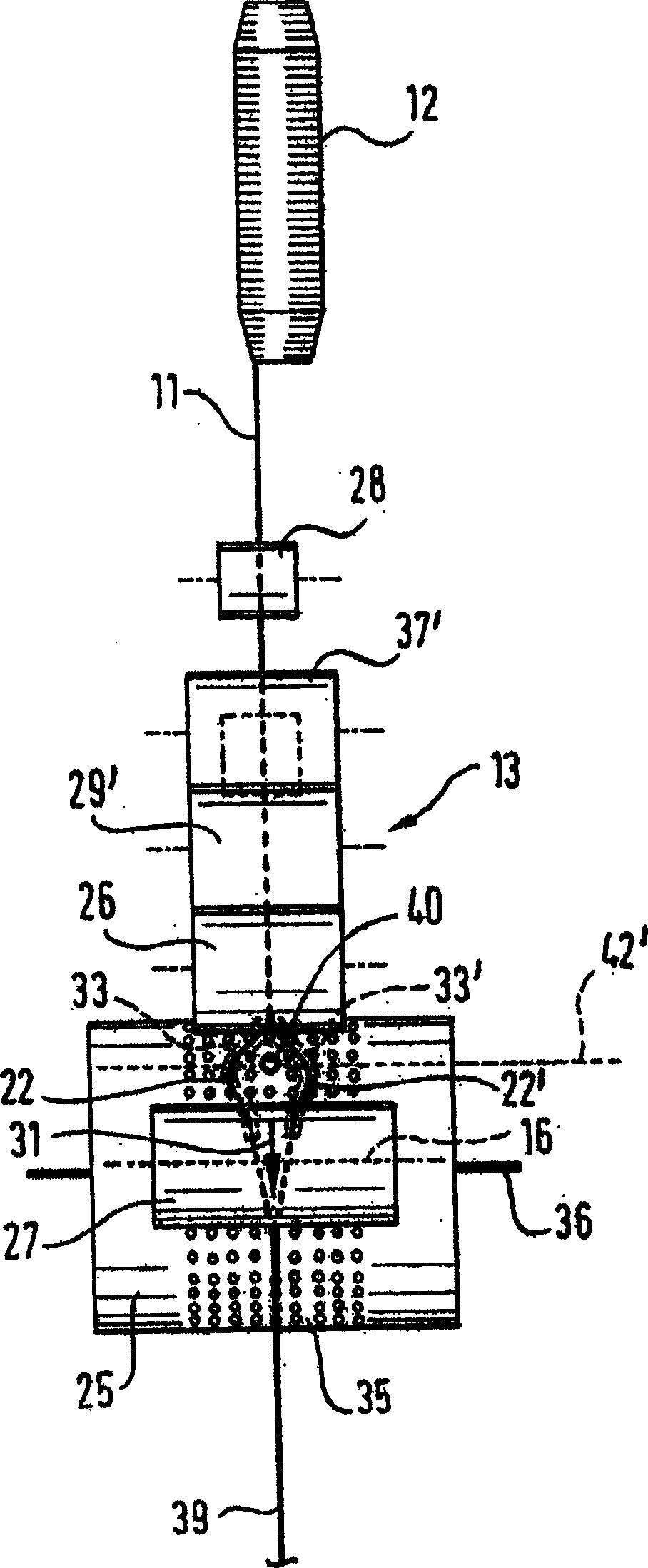

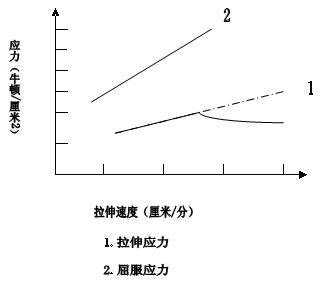

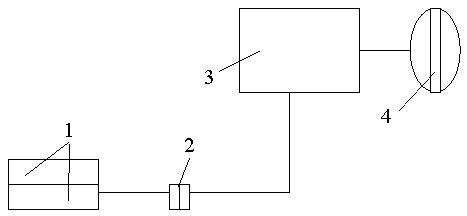

Spinning frame having multi-stage condensation draft unit

InactiveCN1483870AFull spinning twistHigh strengthDrafting machinesContinuous wound-up machinesFiberMaterial Perforation

The frame is equipped with a suction device 25 equipped with a perforation range 35 on a pair of exit rollers of a multi step drafting machine 13, and the suction device 25 provides a guiding plane for sliver to form a condensing step, set to form compact fiber strands by condensing the slivers in the condensing step, and a revolution changing device 52d is equipped on a drafting device 13 or a driving mechanism for drafting device, and revolutions of the individual roller pairs 29 become free from each other in relation to time that induces the compact fiber strands 22, 22' to receive a variable draft in time.

Owner:MASCHINENFABRIK RIETER AG

Technology for reprocessing waste silk in polyester staple fiber production process

InactiveCN102691139AImprove qualityGood mechanical propertiesNew-spun product collectionArtificial filament washing/dryingPolyesterWater baths

The invention relates to a technology for reprocessing waste silk in the polyester staple fiber production process. The technology comprises the following steps of: a) feeding head and tail silk and abnormal silk into a silk guide device; b) feeding generated silk into an oil immersion tank; c) feeding the silk subjected to oil immersion into a first drafting machine, a water bath and a second drafting machine; d) feeding the processed silk into a steam heating box to be heated and then feeding the heated silk into a tension-setting machine; e) feeding the processed silk into a third drafting machine, a silk folding machine, three rollers and a tension roller in sequence; f) feeding the processed silk into a crimping and heating box and a crimping machine; g) feeding the processed silk into a relaxation heat setting machine; and h) finally carrying out cutting off and packing. The technology has the following advantages that the waste silk generated in the production process can be effectively recycled, thus saving the production cost and improving the product competitiveness; and the technology is simple to implement and is considerable in benefits.

Owner:FUJIAN JINLUN FIBER SHAREHOLDING CO LTD

Mono-LOGO yarn-dyed mini-jacquard fabric

ActiveCN106637598AIncrease added valueGood value for moneyFibre treatmentSwivel-woven fabricsHigh concentrationFiber

The invention relates to mono-LOGO yarn-dyed mini-jacquard fabric. A processing technique comprises the specific steps of selecting specifications: warp density of 571 / 10 cm, weft density of 244 / 10 cm, breadth of 106 inches, cotton compact spinning 40 S for warps, and copper fiber 32 S for wefts; (1), designing patterns, to be specific, designing patterns in CAD (computer-aided design), wherein the patterns are mono-patterns and pattern repeat is equal to width; (2), making a pattern card; (3), sizing, to be specific, sizing mainly by using starch size, and using 'high-concentration low-viscosity' size-mixing process; (4), drafting, to be specific, drafting with Staubli automatic drafting machine; (5), weaving, to be specific, weaving with 19 out of 20 healds of Sliver rapier loom, under opening 76 mm, semi-clear openings, back rest 20 mm, opening time 310 degrees, and weft insertion time 90 degrees; (6), after-finishing. The wefts of the fabric are of colored copper fiber, the patterns are highlighted, and the grade of the fabric is increased.

Owner:JIANGSU YUEDA HOME TEXTILE

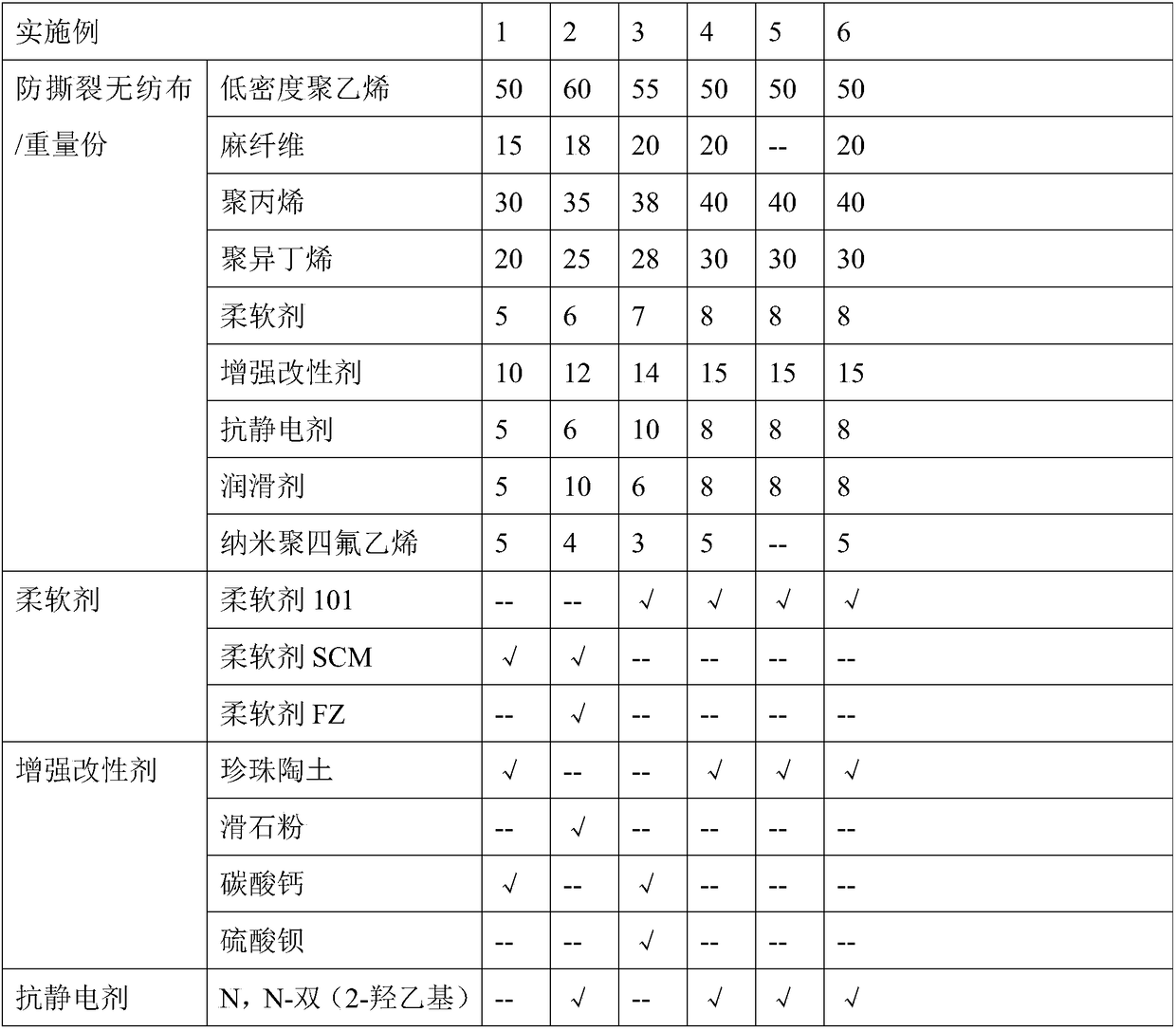

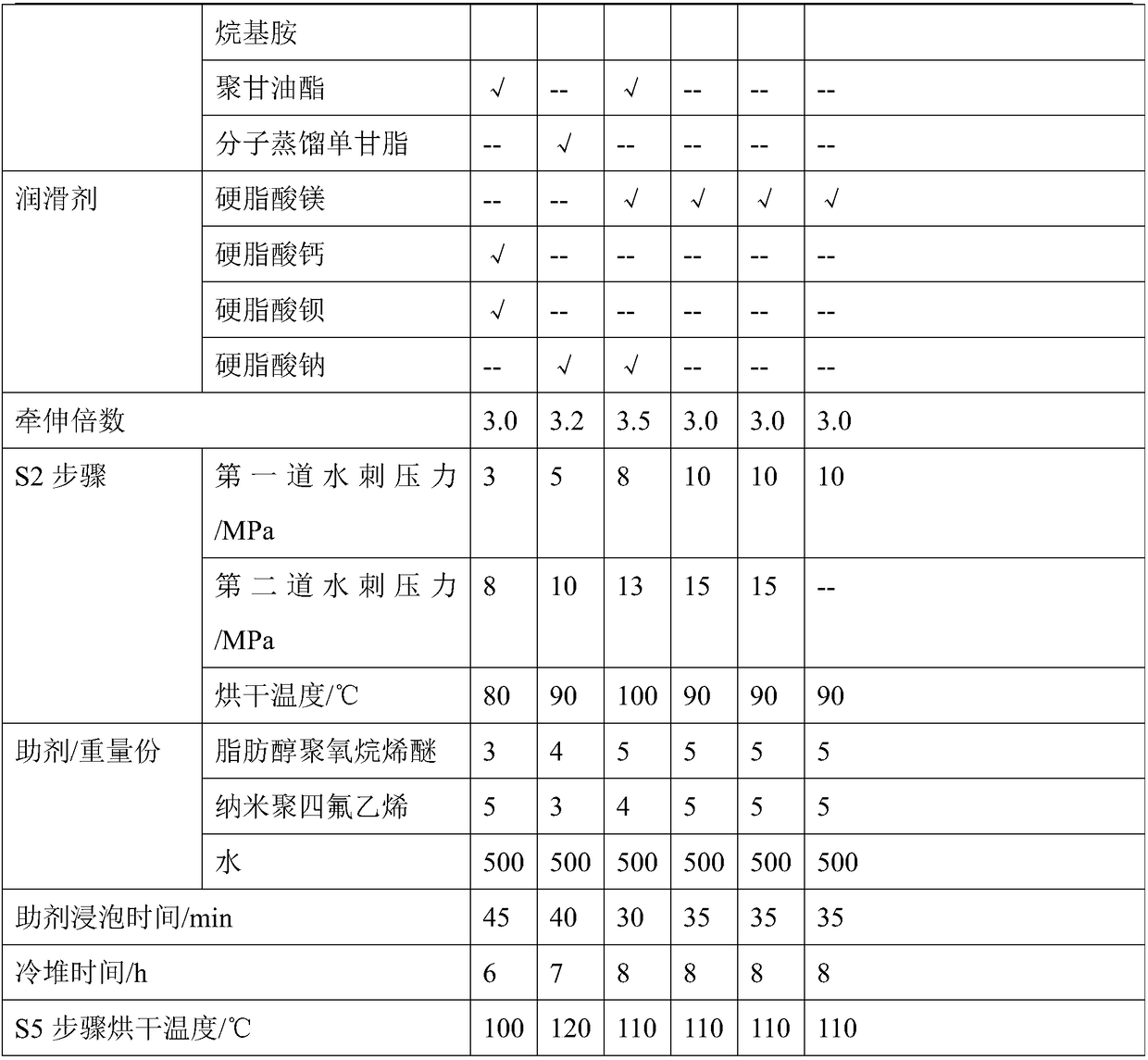

Anti-tearing non-woven fabric and preparation method thereof

ActiveCN108950866AReduce breakage rateGood touchNon-woven fabricsVegetal fibresLow-density polyethyleneNonwoven fabric

The invention relates to anti-tearing non-woven fabric and a preparation method thereof, and belongs to the technical field of non-woven fabric and preparation thereof. The anti-tearing non-woven fabric is prepared from, by weight, 50-60 parts of low-density polyethylene, 15-20 parts of fibrilia, 30-40 parts of polypropylene, 20-30 parts of polyisobutene, 5-8 parts of softening agent, 10-15 partsof reinforced modifier, 5-10 parts of antistatic agent, 5-10 parts of lubricating agent and 3-5 parts of nano polytetrafluoroethylene. The preparation method comprises the following steps of fiber webpreparation, wherein raw materials are subjected to fusion, mixing and opening and then are carded by a carding machine to form a web to obtain a fiber web, and a drafting machine carries out drafting on the fiber web; spunlacing, wherein the drafted fiber web is fed into a spunlacing area for primary spunlacing and secondary spunlacing to form the non-woven fabric; drying, cold bleaching, washing and drying. The anti-tearing non-woven fabric and the preparation method thereof have the advantages that the breaking strength is high, the hydrostatic pressure is high, and the molding rate is high.

Owner:FUJIAN GUAN HONG IND

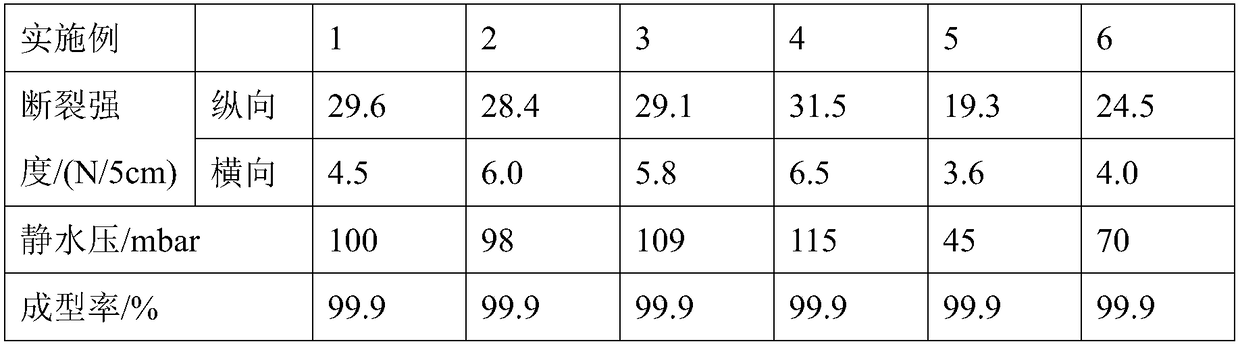

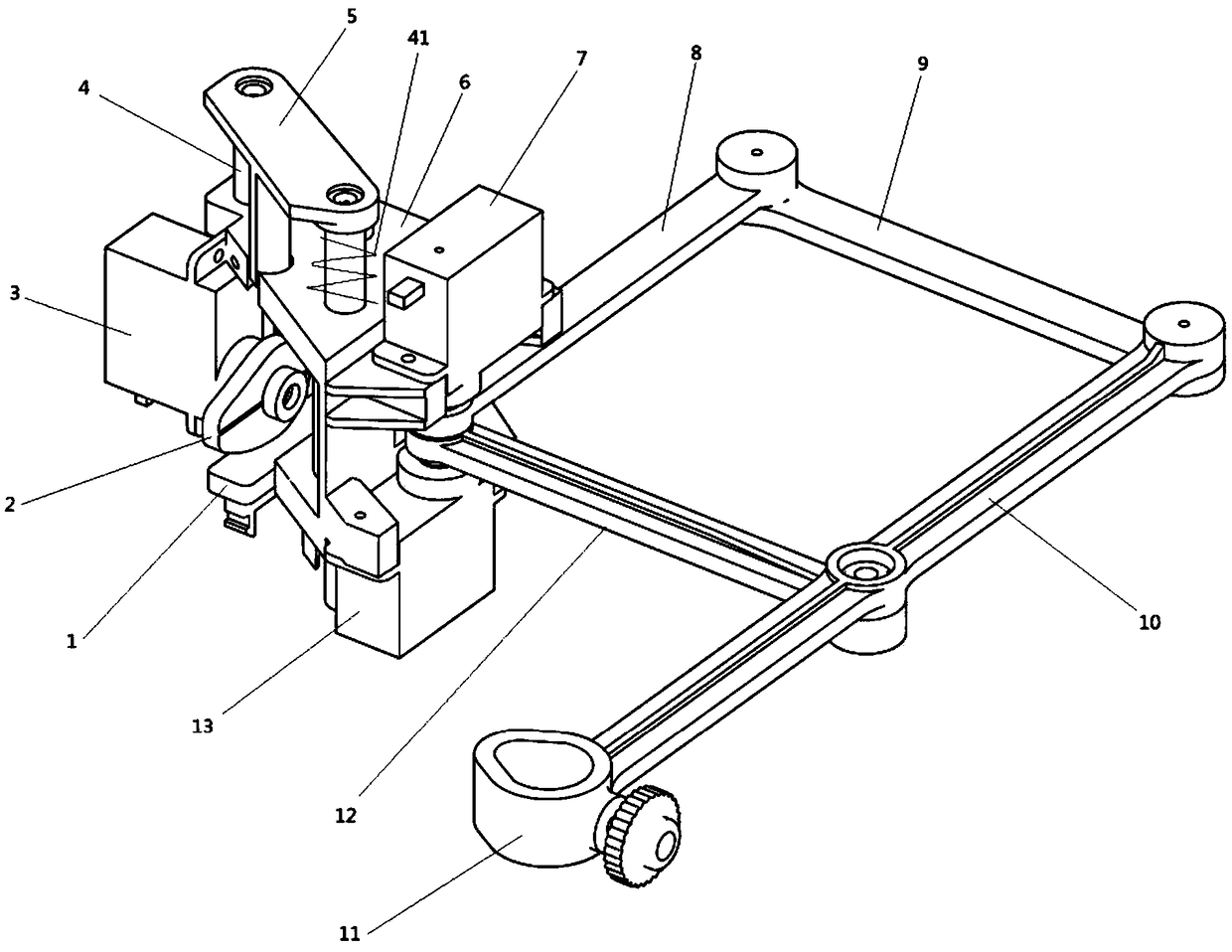

Drawing mechanical arm and control system thereof

The invention discloses a mechanical arm drawing mechanism. The mechanical arm drawing mechanism includes a supporting platform and a lifting platform, and the lifting platform and the supporting platform are connected by a lifting mechanism. The lifting platform is provided with an upper motor and a lower motor separately, the lower motor is connected with a main arm, and the upper motor is connected with an auxiliary arm. A connecting rod is hinged to the other end of the auxiliary arm, and a working arm is hinged to the other end of the connecting rod. A pen clamp is arranged at the other end of the working arm, and the other end of the main arm is hinged to the working arm. Firstly, the defects of a steering engine are solved by means of linear compensation, curvature speed regulation,virtual compensation and graphic feedback compensation for the steering gear, and then through the cooperation of the upper motor and the lower motor, the pen clamp at the front end of the working arm can be placed at any position of a drawing board. The whole mechanical arm drawing mechanism is low in cost, simple in structure, small in size and wide in application range.

Owner:LITTLE MONSTER EDUCATION TECH CO LTD

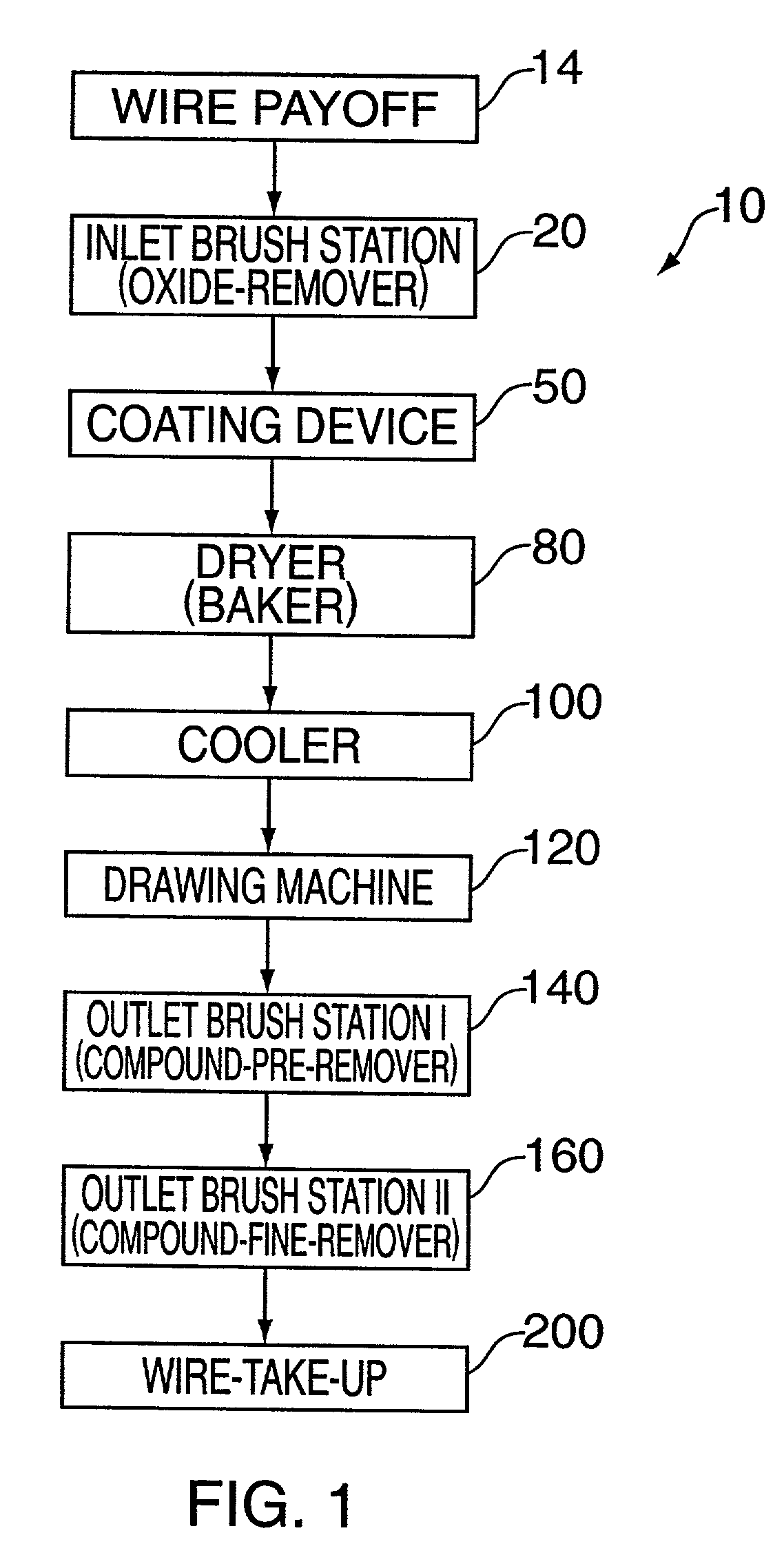

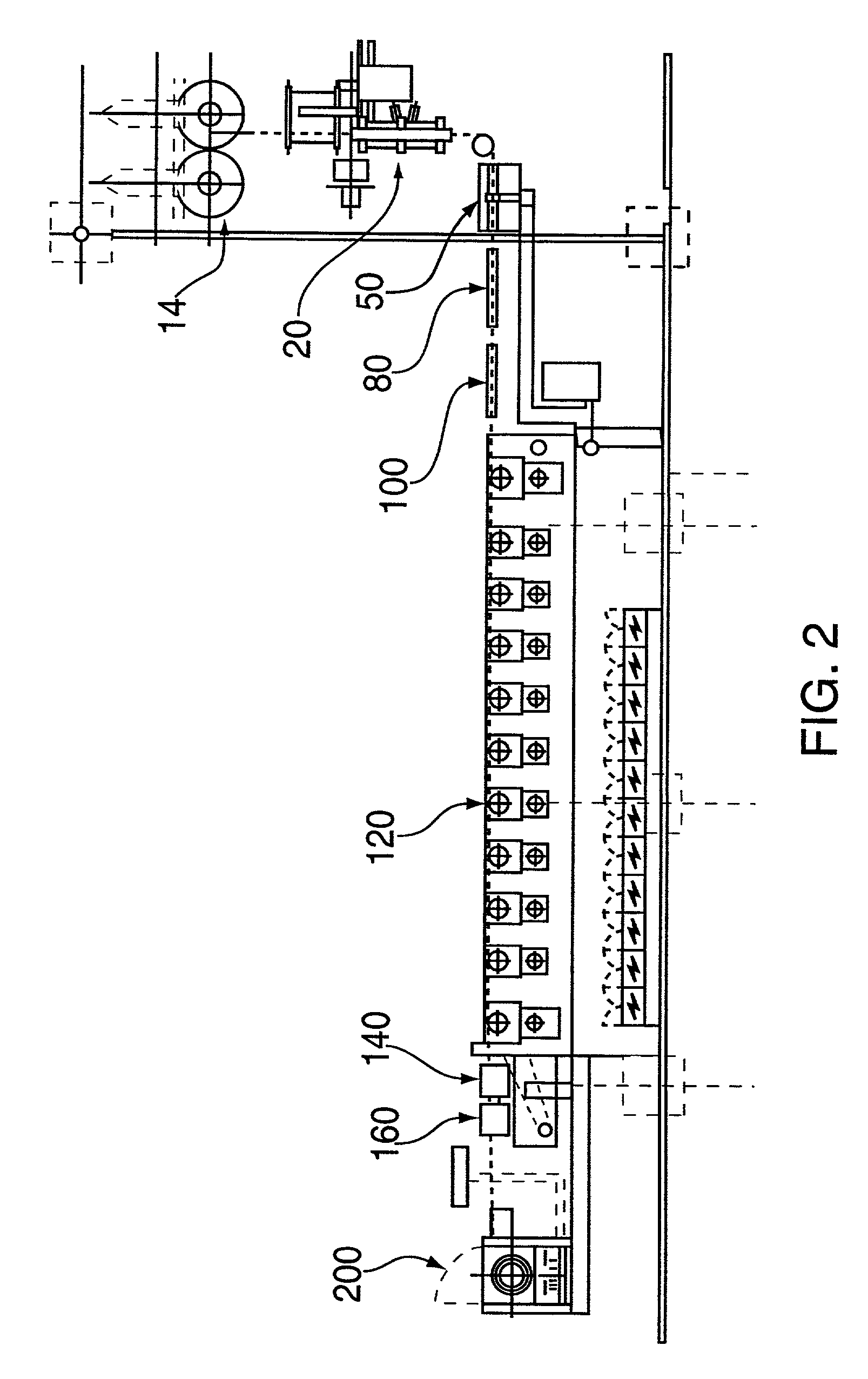

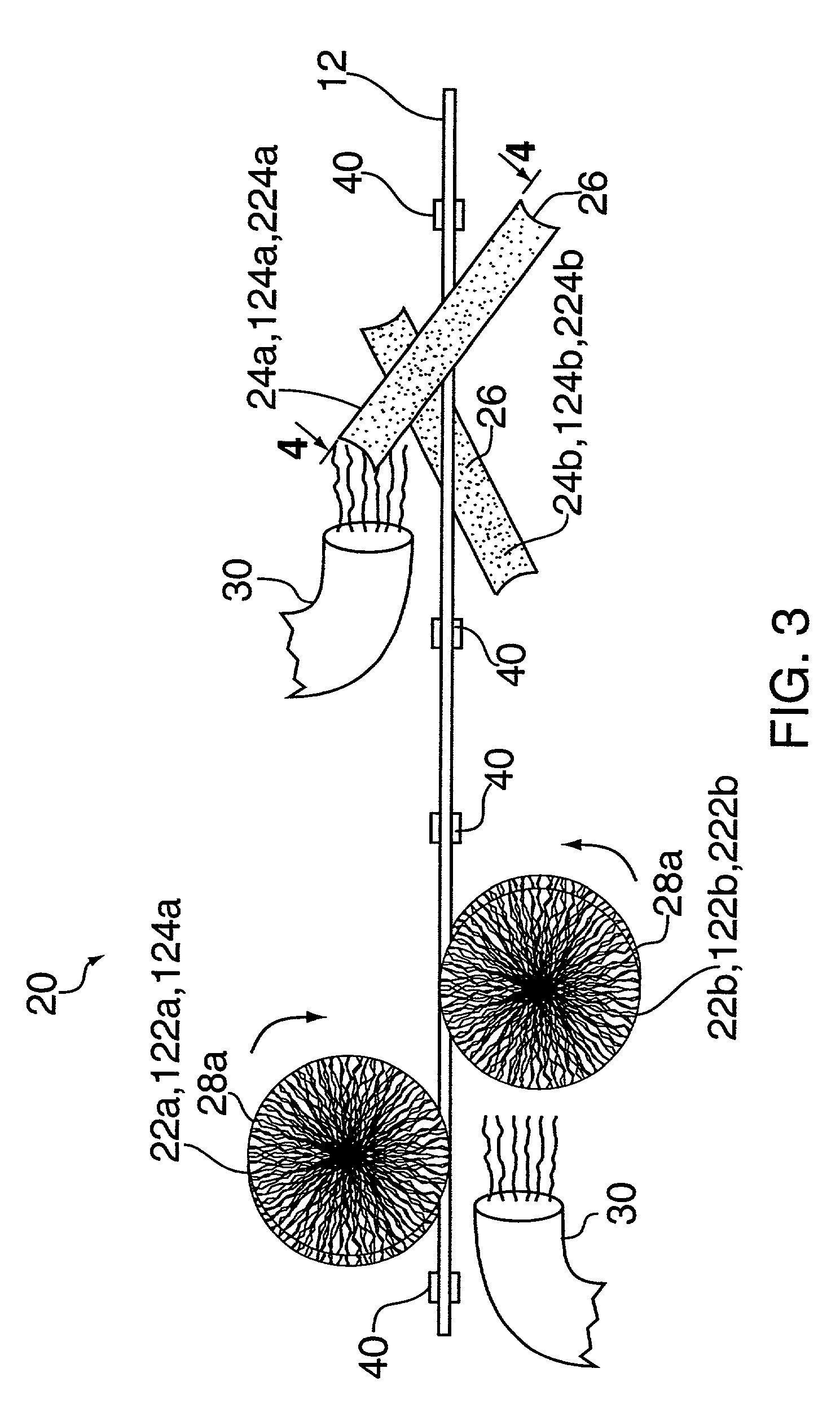

In-line wire drawing continuous treatment process

InactiveUS20010028954A1Work treatment devicesExtrusion cleaning devicesMetal filamentStainless steel wire

A continuous in-drawing line process and system for drawing stainless steel wire is provided wherein wire is (1) brushed in an inlet brush station to remove oxide film from the wire surface; (2) coated with a lubricant carrier coating which is dried then subsequently cooled; (3) drawn through a drawing machine using a lubricant; and (4) brushed to remove residual carrier compounds from the surface of the drawn wire. The system for carrying out this process includes a wire payoff; an inlet brush station having two pairs of brushes that rotate in a direction opposite to that of the wire to remove oxide film therefrom; a coating device; a dryer; a cooler; a drawing machine; first and second outlet brush stations each having two pairs of brushes that rotate in a direction opposite to that of the wire to remove residual drawing compounds therefrom; and a wire take-up device.

Owner:AMERICAN PRECISION STEEL COMPANY L P WHOSE GENERAL PARTNER IS IE E W P S 1

Needle-punched non-woven base fabric

The invention relates to a needle-punched non-woven base fabric, belonging to the technical field of a needle-punched non-woven base fabric production technology. The needle-punched non-woven base fabric takes sea-island fiber as a raw material and is made according to the steps of: (1) opening and pre-processing the raw material; (2) performing rough opening; (3) feeding into a primary cotton box; (4) performing fine opening; (5) feeding into a secondary cotton box; (6) feeding into an air pressure cotton box; (7) feeding into a carding machine; (8) feeding into a lapping machine; (9) feeding into a drafting machine; (10) feeding into a pre-needling machine; (11) feeding into an upper needling machine; (12) feeding into a lower needling machine; (13) feeding into a single-sided needling machine; (14) feeding into a double-sided needling machine; (15) feeding into a winding machine; (16) feeding into an ironing machine; and (17) feeding into the winding machine. The needle-punched non-woven base fabric has good air permeability and high wear resistance, and is soft and comfortable.

Owner:ZHEJIANG MEISHENG IND

A kind of preparation method of cross-linked structure orientation filling reinforced chemical fiber

ActiveCN107435171BAvoid damageGood orientationMelt spinning methodsConjugated synthetic polymer artificial filamentsPolymer scienceMicrosphere

The invention discloses a preparation method of crosslinking structure oriented filling enhanced chemical fiber. The method comprises the following steps: preparing PAcr crosslinked microsphere containing a molecular crosslinking point as a junction point and a PAcr molecular chain as a junction line; uniformly mixing the dried PET chips and the dried PAcr crosslinked microsphere powder, feeding a mixture into a melt spinning machine, and carrying out melt extrusion, cooling, oiling, extension and reeling to obtain the crosslinking structure oriented filling enhanced chemical fiber. According to the invention, in the melt spinning machine and a spinning draft machine, through the effect of a shearing field, an extrusion field and a stretching field during a melt blending process, the PAcr crosslinked microsphere and polyester resin realize oriented arrangement of the crosslinking structure in microsphere along the fiber axis and successive connection of an oriented structure, so that in the PET fiber, a bunched enhanced structure which is characterized in that the molecular crosslinking point is taken as the junction point and the PAcr molecular chain is taken as the junction line is constructed, and the provided polyester fiber has better mechanical properties.

Owner:ZHEJIANG SCI-TECH UNIV

Slasher capable of realizing automatic pattern arrangement and automatic pattern arranging method

ActiveCN103046266AWith automatic flower arrangement functionImprove accuracyBeaming machinesTextile treatment carriersData processing systemYarn

The invention discloses a slasher capable of realizing automatic pattern arrangement and an automatic pattern arranging method. The slasher comprises a yarn distributing device and a headstock winding device, wherein the yarn distributing device is arranged in front of the headstock winding device, a compression roller device, an automatic pattern arranging device and an expansion reed are arranged between the yarn distributing device and the headstock winding device and are sequentially arranged along moving direction of yarns, and the automatic pattern arranging device is connected with a data processing system. By the aid of the automatic pattern arranging method, automatic pattern arranging function of the slasher is realized, thus labor force is saved, accuracy rating of sizing pattern arrangement is greatly increased, and producing efficiency and utilization rate of an automatic warp drafting machine during drafting process are greatly improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

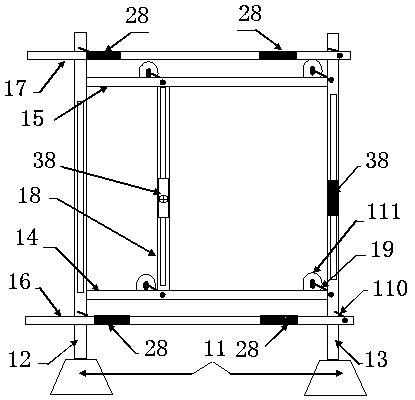

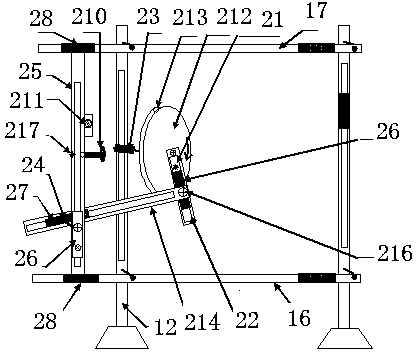

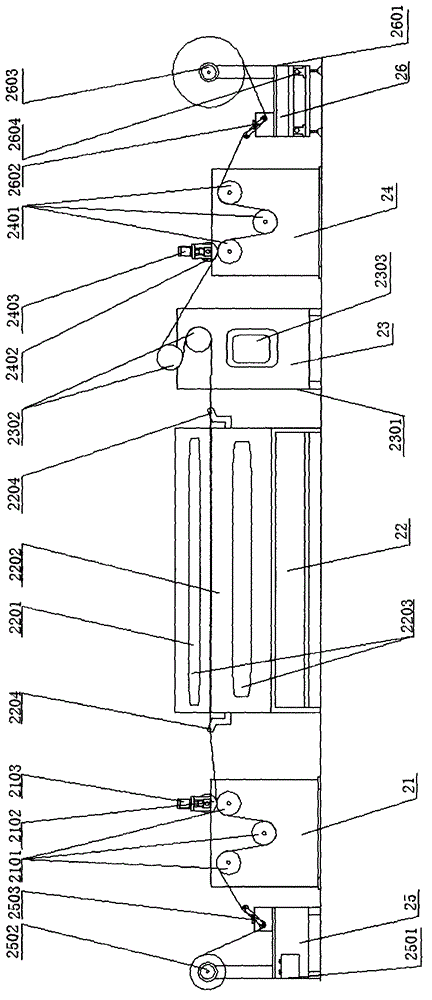

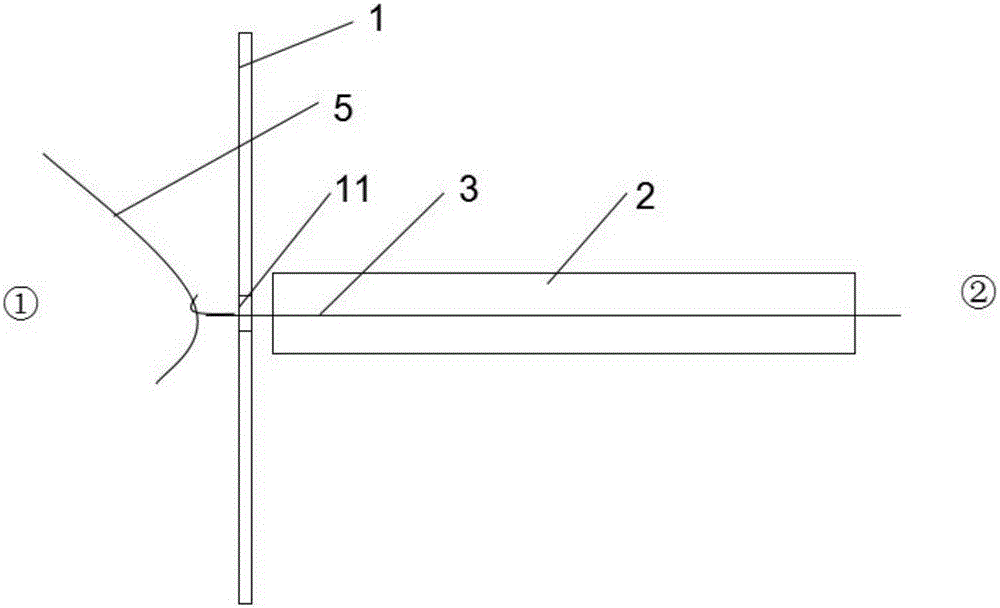

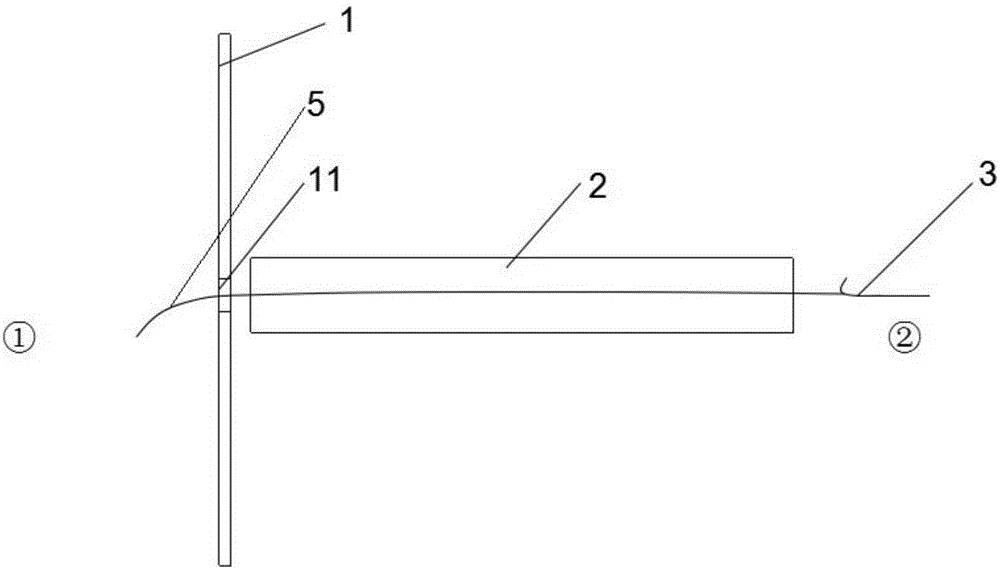

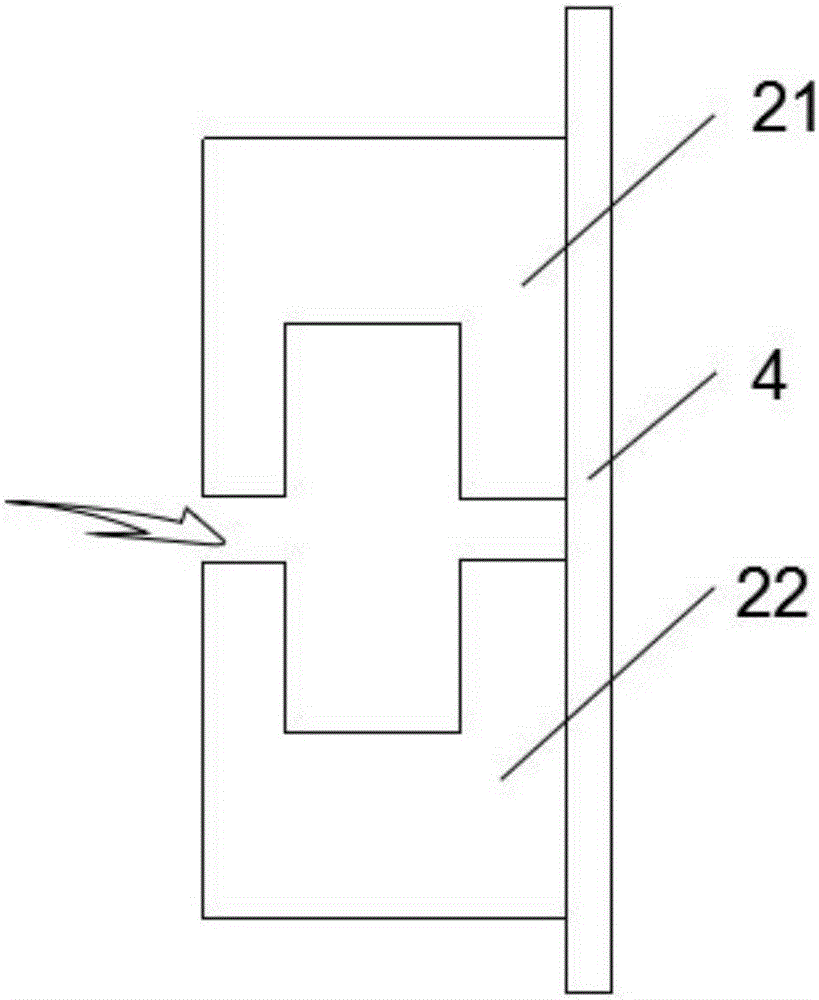

Automatic drafting machine and drafting method thereof

The invention discloses an automatic drafting machine and a drafting method thereof. The machine comprises a heddle, a rail, a crochet hook and a wallboard. The rail is half-enclosed, is composed of an upper concave block and a lower concave block which are oppositely arranged, and one side of the rail is fixed to the wallboard. The heddle is arranged on one side of the rail. A heddle eye is arranged at the position, corresponding to the position of the rail, of the heddle. After the crochet hook hooks a warp yarn, the crochet hook passes through the heddle eye and the rail, and then the drafting is completed. Nozzles are uniformly distributed in the length direction of the rail. The beneficial effects of the machine are that the nozzles are uniformly mounted in the rail through which the crochet hook passes; the nozzles are connected to an external air compression device, and the nozzles inject air in the rail; and when the crochet hook normally hooks the yarn and passes through the rail, the yarn which is attached on the surface of the rail as static electricity is generated due to friction can be blown out of the rail, so that mistakes can be reduced.

Owner:TORAY SAKAI WEAVING & DYEING NANTONG CO LTD

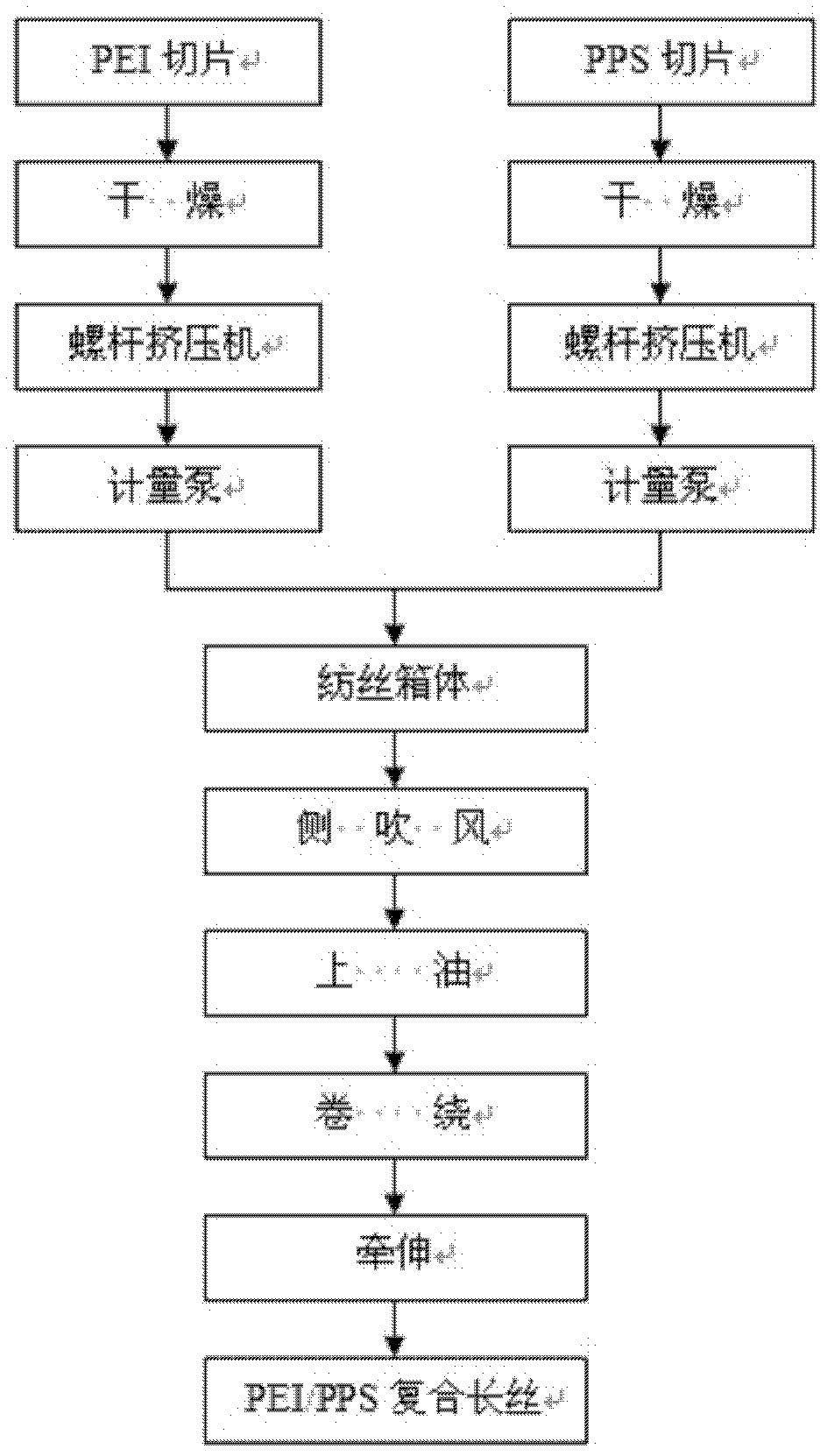

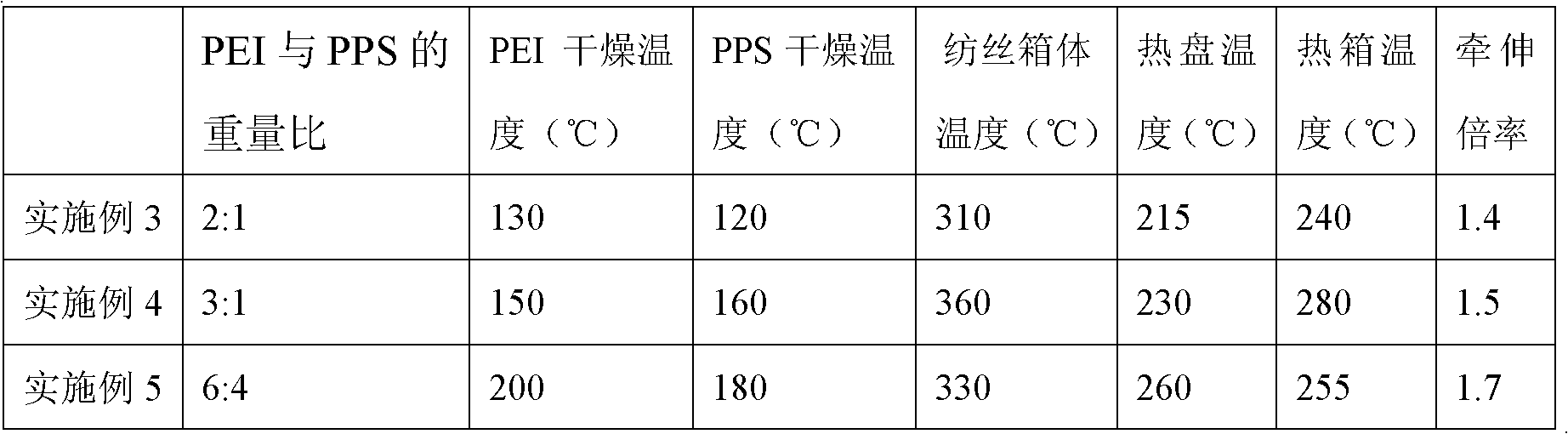

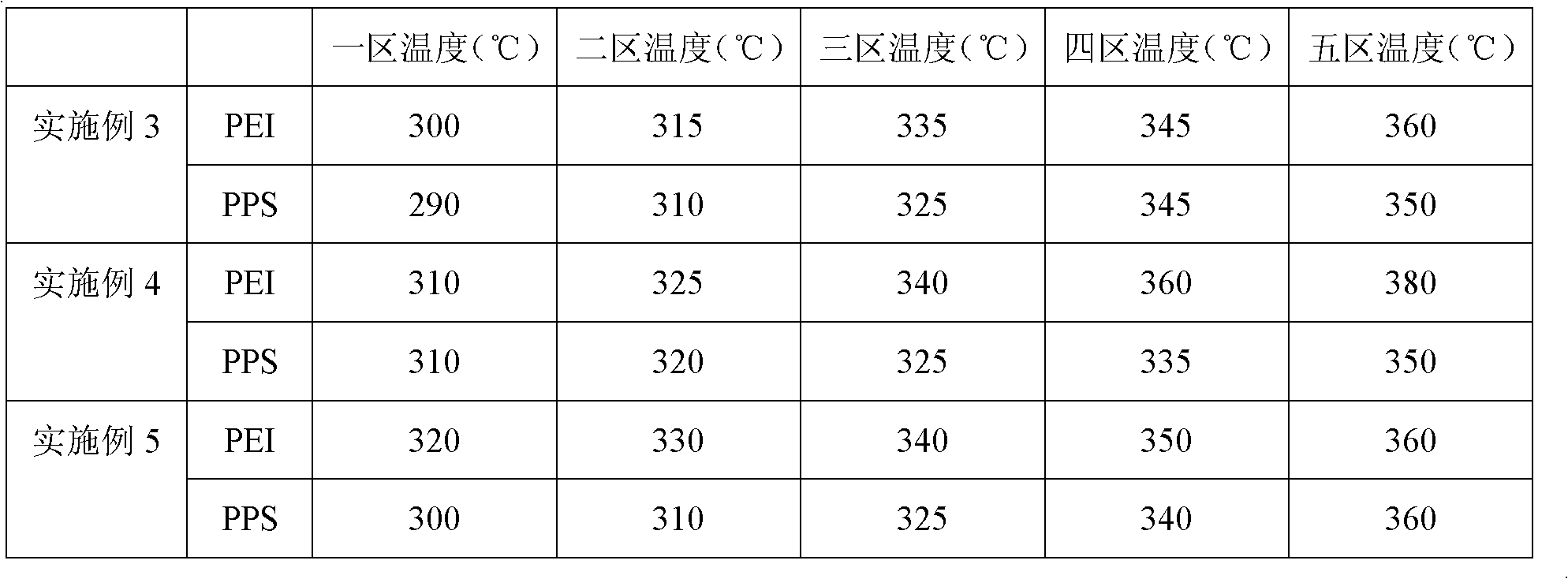

Polyetherimide/polyphenylene sulfide composite filament preparation method

ActiveCN102995161AHigh strengthReduce manufacturing costConjugated synthetic polymer artificial filamentsStretch-spinning methodsPolyetherimideWorking environment

The invention discloses a PEI / PPS composite filament preparation method, which comprises the following steps: slicing two raw materials of PEI and PPS and respectively drying, respectively performing melted extrusion through a screw extruder and discharging to form a PEI melt and a PPS melt; respectively metering the PEI melt and the PPS melt by a metering pump; mixing to form a mixed melt, extruding a filamentous melt from a spinneret hole of a spinning casing under the effect of the spinning casing, extruding the filamentous melt from the spinneret hole of the spinning casing, cooling under side blowing wind and solidifying and then forming, and then oiling, performing winding formation with high speed on a winding head, and drafting by a parallel drafting machine to obtain the PEI / PPS composite filament. The fabric prepared by the obtained PEI / PPS composite filament can be used for a protective clothing under the special work environment such as fire-fighting, high temperature or chemical attack, the production cost is low, and the obtained PEI / PPS composite filament can be used for the filtering materials in the fields such as garbage burning factories, and has high strength and oxidative resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of self-extensional polyester fibre

InactiveCN1354289ANo swayExcellent self-extensibilityArtificial filament heat treatmentYarnPolyester

The production method of self-extending polyester fibre is simplemented by using polyester POY grey yarn whose spinning speed is 3000 m / min-3500 m / min through the process of drawing-heat forming procedure on the general flat drafting machine. It is characterized by that it sdrafting temp. must be controlled in 80 deg.C-110 deg.C, heat-forming temp. must be controlled in 110 deg.C-140 deg.C, and the drafting multiple is 1.0-1.2, and heat-forming time is 0.2 sec.-0.4 sec. Said invented method can be used for producing fibre whose self-extending rate is 0%-5%, and its performance is stable, and can be stored for a long period.

Owner:BALING PETRO CHEM CO LTD SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com