Patents

Literature

694 results about "Oil immersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In light microscopy, oil immersion is a technique used to increase the resolving power of a microscope. This is achieved by immersing both the objective lens and the specimen in a transparent oil of high refractive index, thereby increasing the numerical aperture of the objective lens.

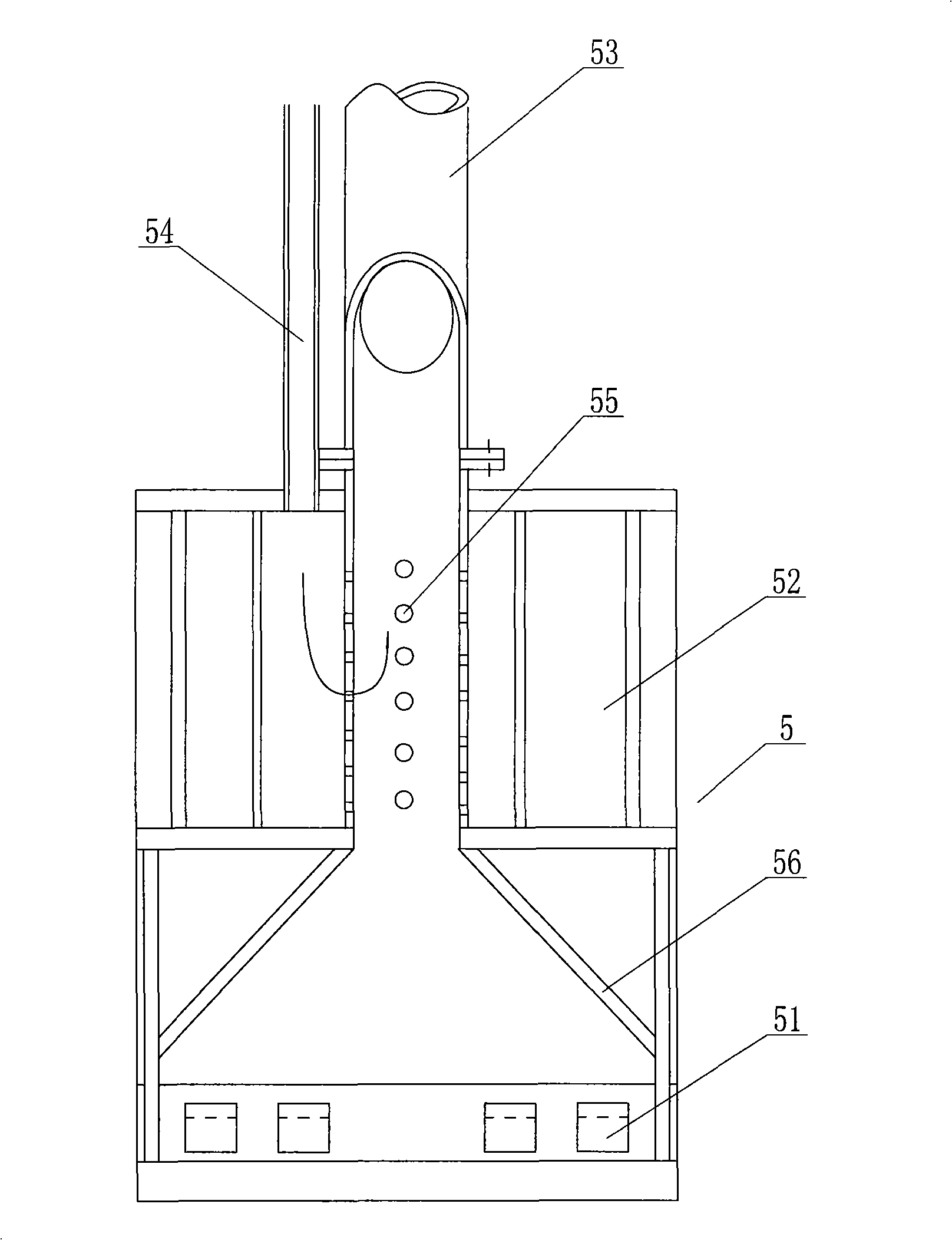

Oil paper insulated electrothermic aging test and local discharge integrated detection device of transformer

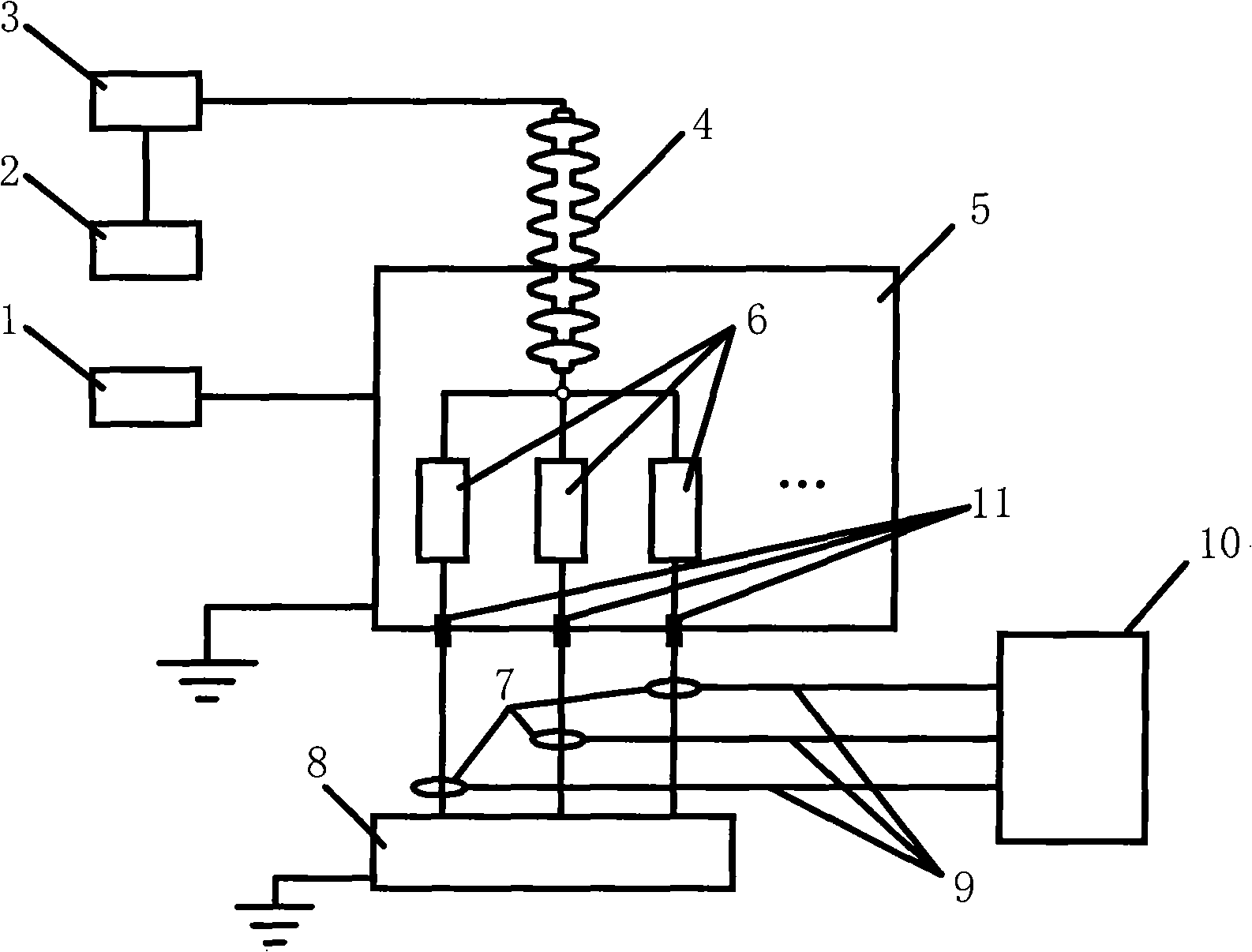

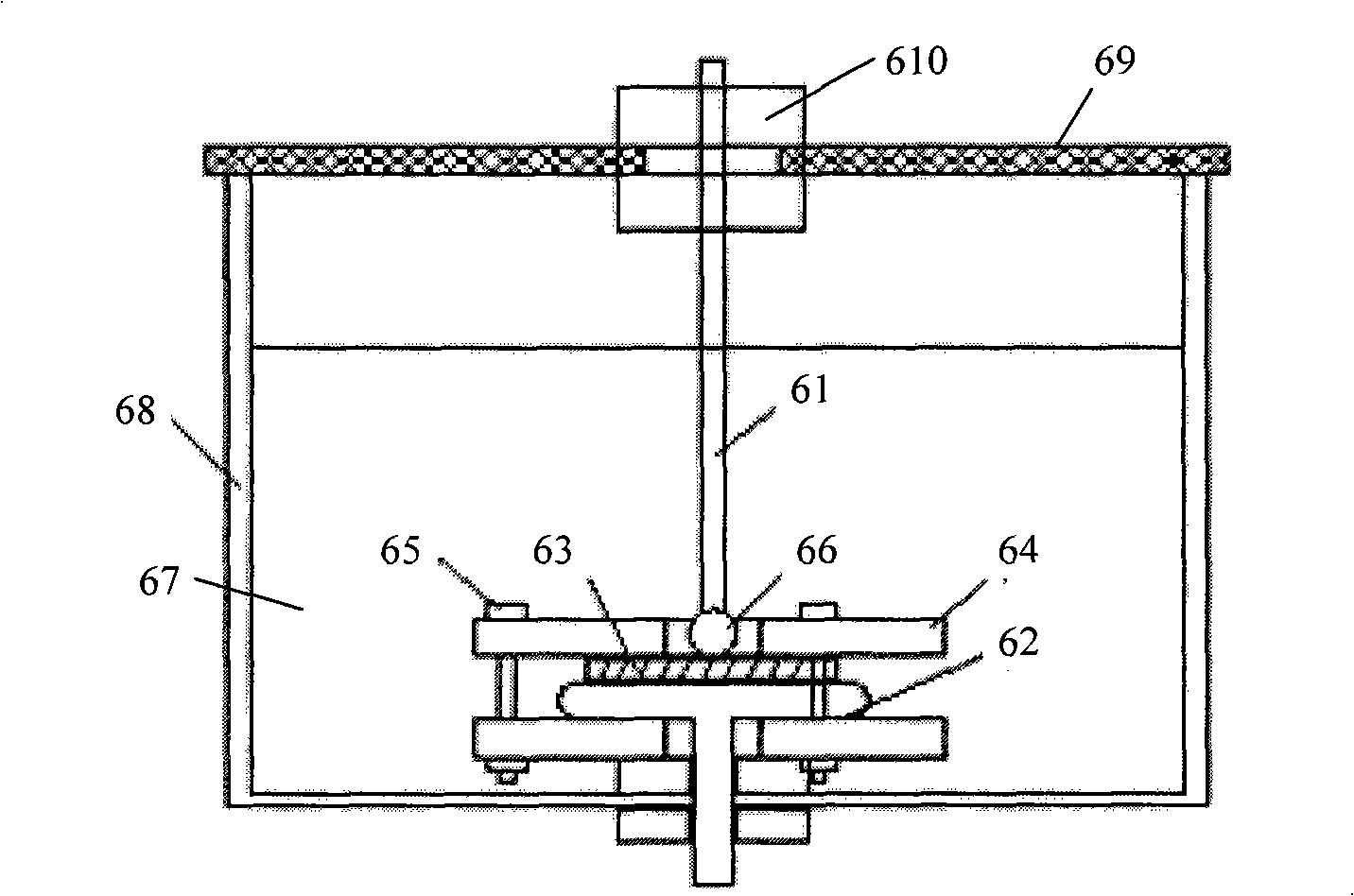

The invention provides an integrated testing device used in local discharge detection for oil immersion power transformer paper oil insulation electric heating ageing study, comprising an electric heating ageing oven, a test object electrode system and a high-voltage alternating current power supply system. The test object electrode system is arranged in the electric heating ageing oven and connected with the high-voltage alternating current power supply system. The testing device also comprises a local discharge signal acquisition system which comprises a local discharge signal transducer, a signal transmission cable and a data acquisition processing device. The input end of the signal transducer is connected with the test object electrode system, the output end is connected with the data acquisition processing device through the signal transmission cable; the testing device can acquire the local discharge parameter in the electric heating ageing process of paper oil insulation, provides data for the electric heating ageing study and can further realize the on-line monitoring of transformer paper oil insulation electric heating ageing state on the basis of the study.

Owner:CHONGQING UNIV

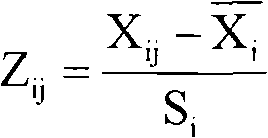

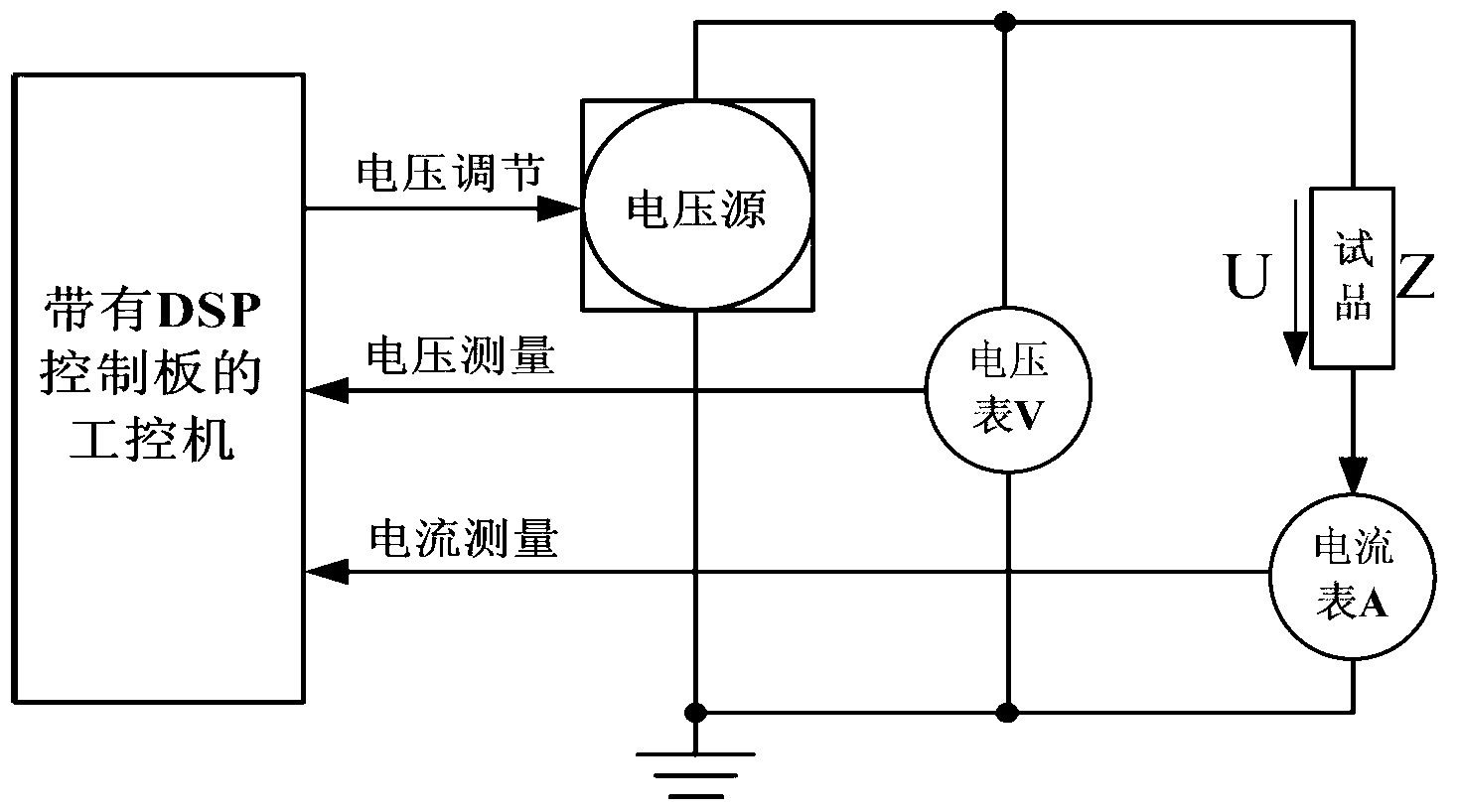

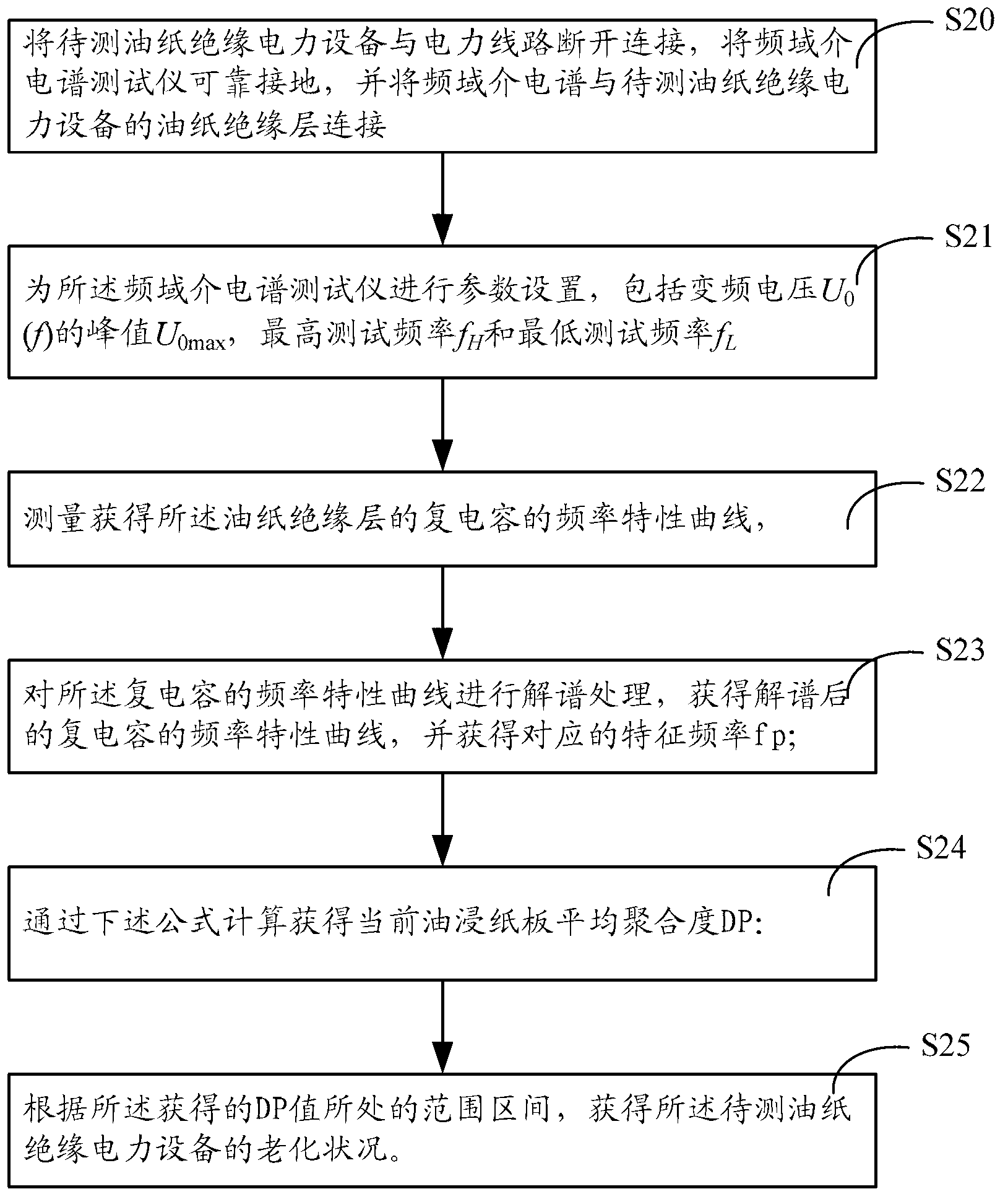

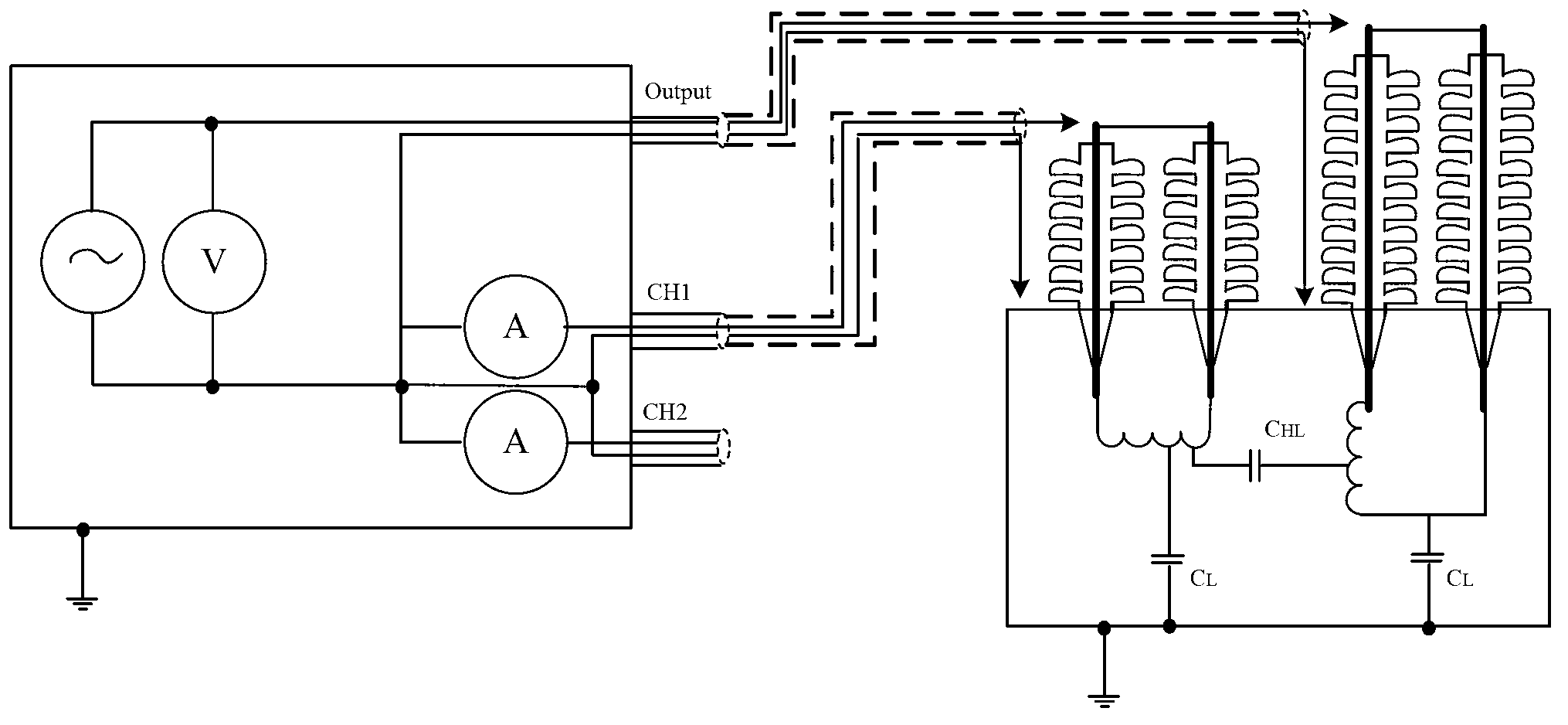

Method for evaluating insulation aging state of oil paper insulation electrical equipment on basis of frequency domain spectroscopy

A method for evaluating insulation aging state of oil paper insulation electrical equipment on the basis of frequency domain spectroscopy comprises the following steps of: disconnecting the oil paper insulation electrical equipment to be tested from a power circuit, reliably grounding a frequency domain spectroscopy tester and connecting the frequency domain spectroscopy tester with the oil paper insulation electrical equipment to be tested; measuring and obtaining the frequency characteristic curve of an oil paper insulation layer complex capacitor; performing spectrum unfolding processing to the frequency characteristic curve of the complex capacitor, thereby obtaining the frequency characteristic curve of the spectrum-unfolded complex capacitor and obtaining a corresponding characteristic frequency (fp); calculating by the following formula to obtain the current average degree of polymerization (DP) of an oil immersed paper plate; and obtaining the aging situation of the oil paper insulation electrical equipment to be tested according to the range zone of the obtained DP value. According to the embodiment of the invention, the average degree of polymerization (DP) of the insulation paper can be exactly evaluated and the insulation aging state of the oil paper can be judged without lifting a core, damaging the insulation material or sampling.

Owner:SHENZHEN POWER SUPPLY BUREAU

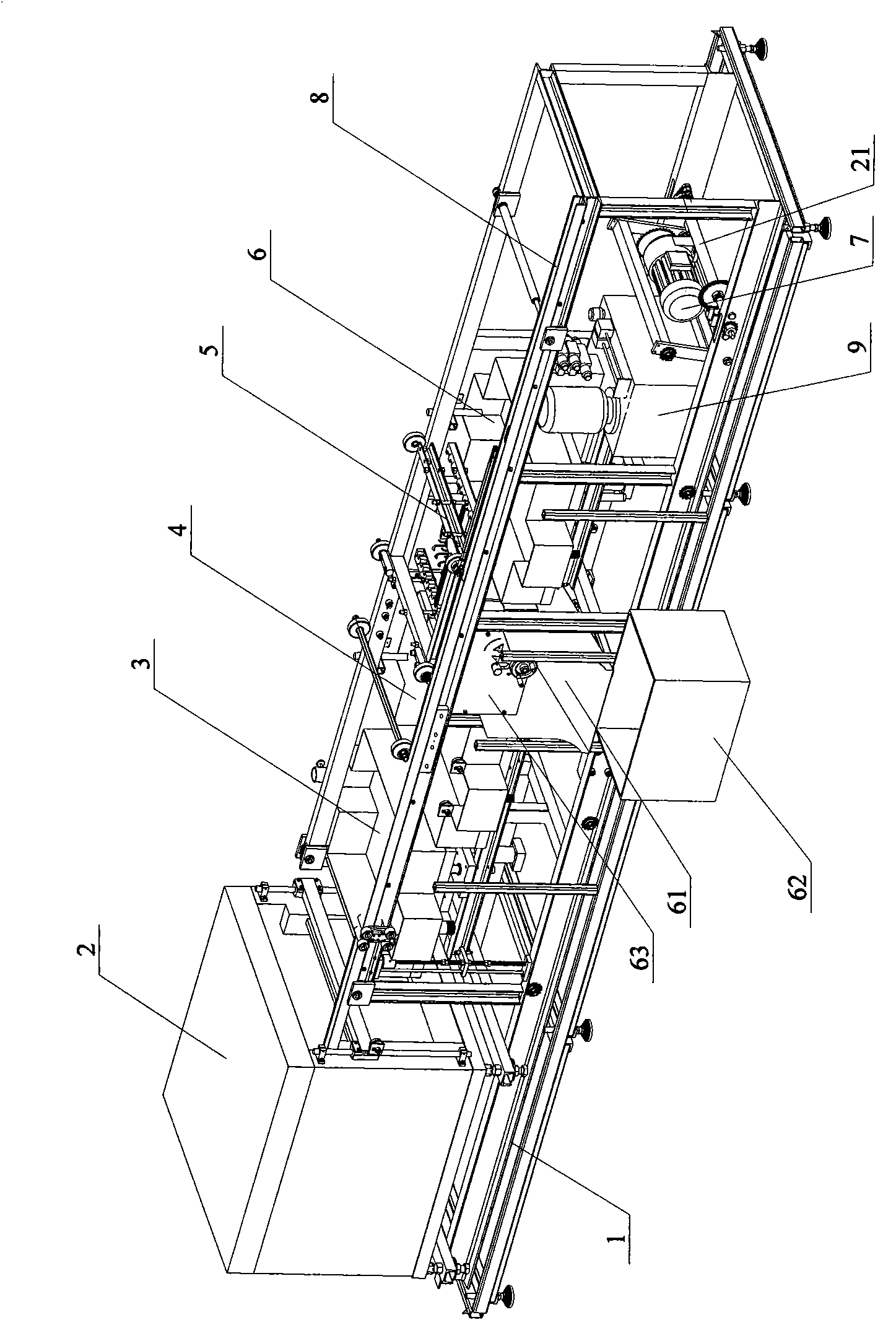

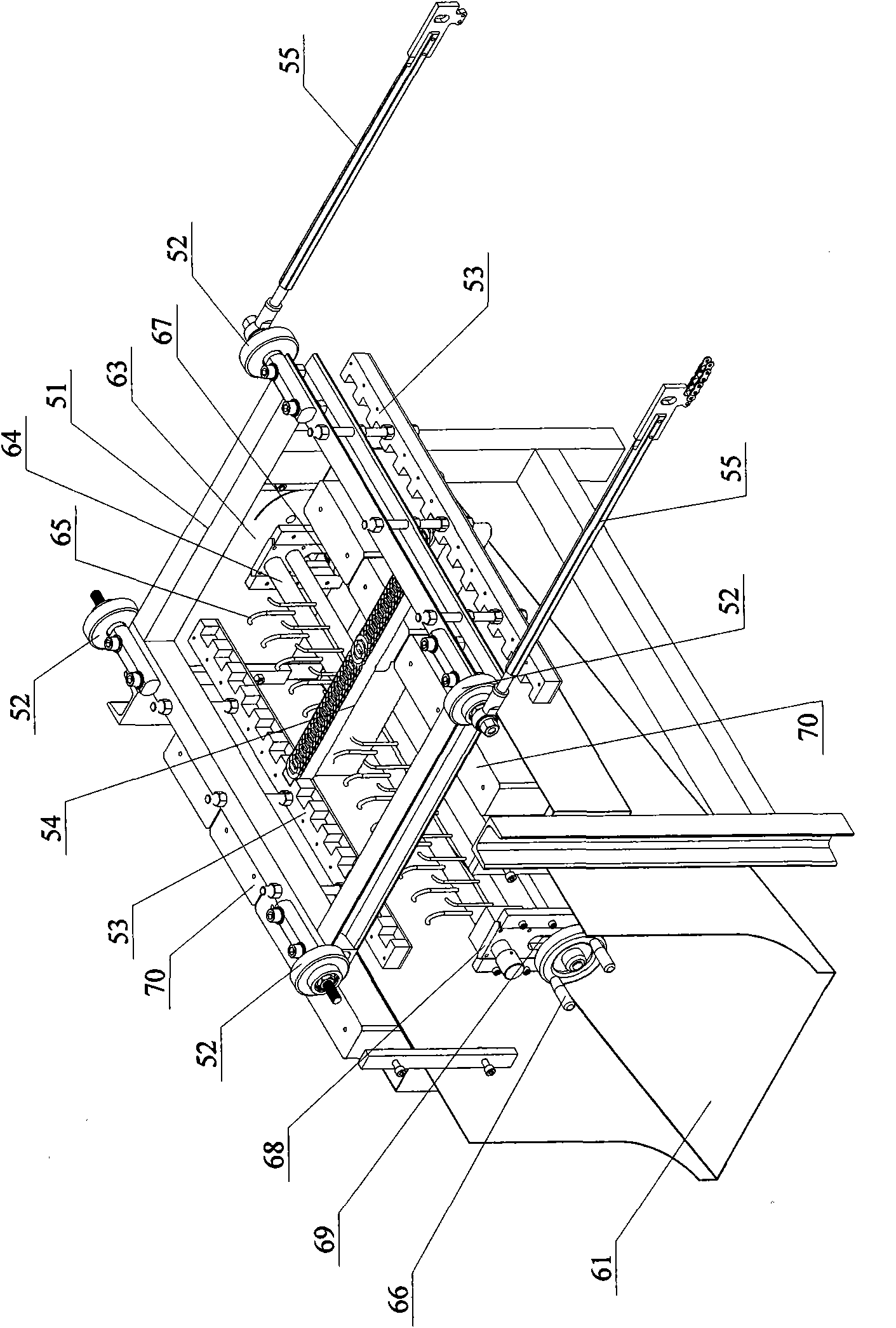

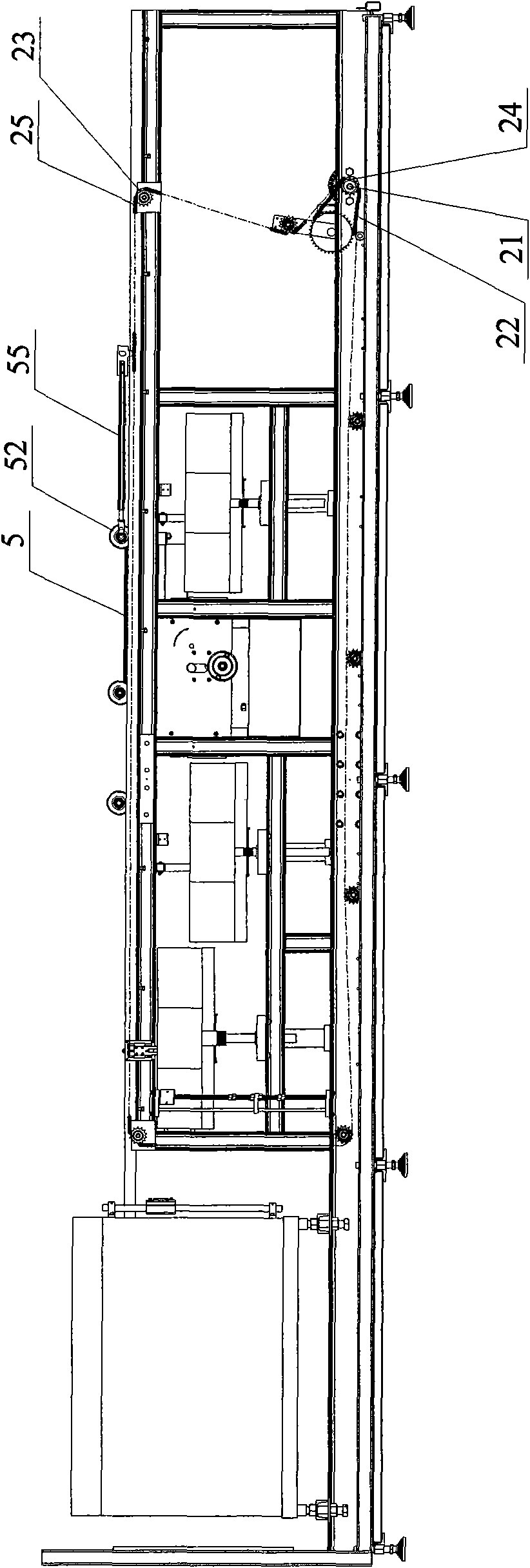

Full-automatic plastic dipping production line

ActiveCN101797784AReduce health impactRealize fully automatic productionLiquid surface applicatorsCoatingsProduction lineEngineering

The invention discloses a full-automatic plastic dipping production line, which comprises a frame, and a movable mold frame, a raw material box, a cooling box, a discharge device and an oil immersion box which are arranged on the frame, wherein the movable mold frame is driven by a drive device and is controlled by a control unit to move left and right along the from to realize oil immersion, plastic dipping, cooling and discharge. The full-automatic plastic dipping production line realizes the full-automatic plastic dipping production, has high control precision, greatly reduces the influence on the health of an operator, improves the production efficiency, and saves labor and resources.

Owner:浙江珠城科技股份有限公司

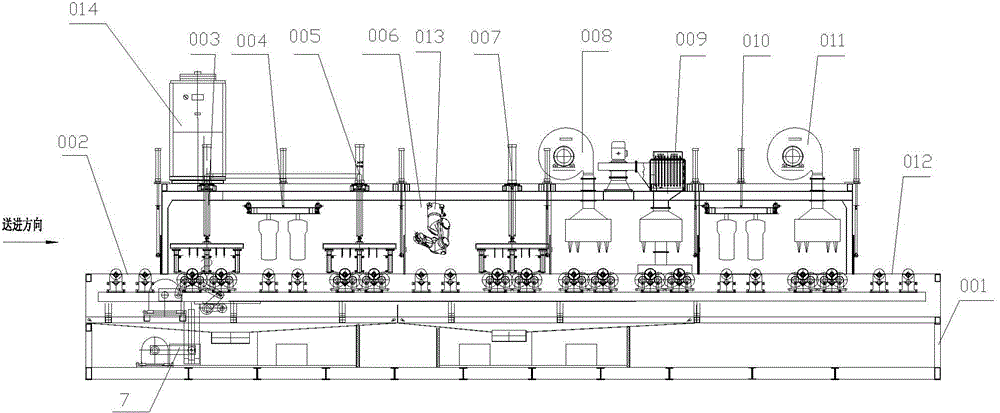

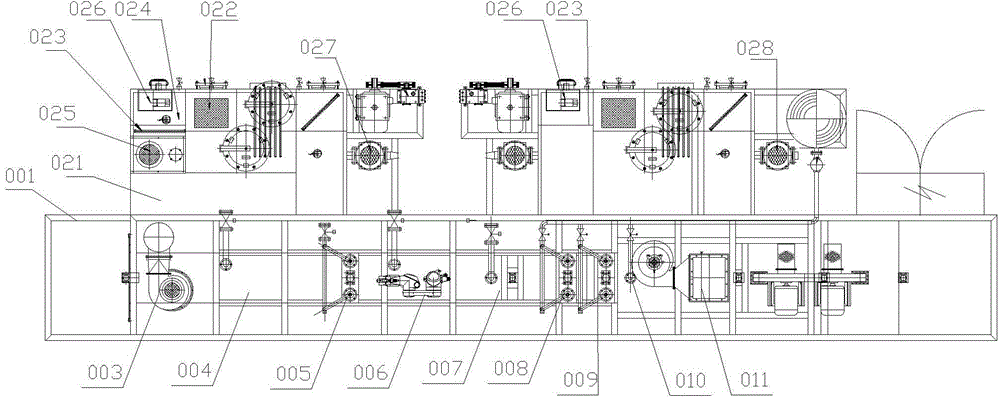

Crankshaft cleaning machine

ActiveCN105312269ASolve cleaningSolve productivityLiquid surface applicatorsCoatingsSurface cleaningWind shear

The invention provides a crankshaft cleaning machine. The crankshaft cleaning machine comprises a rack as well as a first surface cleaning system, a surface ultrasonic cleaning system, a second surface cleaning system, an oil duct cleaning system, a surface rinsing system, a surface blow-drying system, a hot air drying system, an ultrasonic oil immersion system and a wind-shear oil blowing system which are arranged on the rack sequentially, a workpiece conveying system for conveying workpieces is further arranged on the rack and comprises a lifting and conveying mechanism and a tool adjusting mechanism. The crankshaft cleaning machine is designed for cleaning an automobile crankshaft and integrates advanced combined means such as ultrasonic waves, high-pressure spray, ultrahigh-pressure spray, rotation, flexible robot hole alignment, ultrasonic oil immersion, oil blowing and the like so as to be applied to crankshaft cleaning, drying and rustproofing processes, and the tool adjusting mechanism of the conveying system can adjust the width automatically to adapt to cleaning of products in various specifications.

Owner:CHONGQING KEBEN TECH

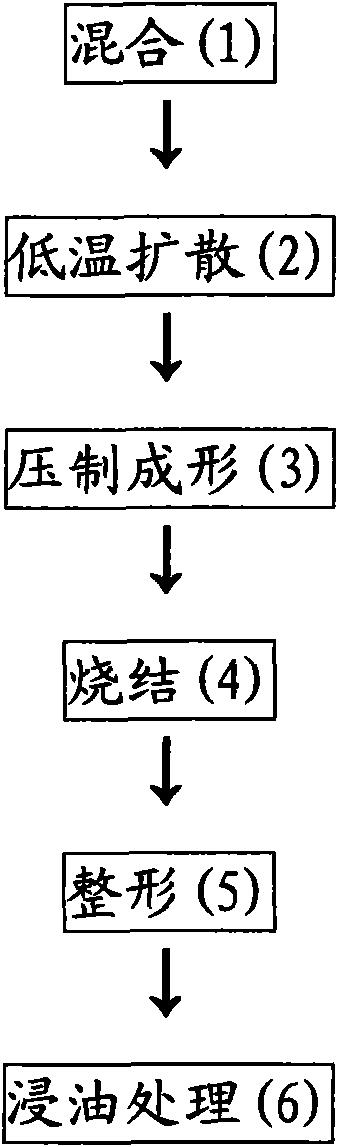

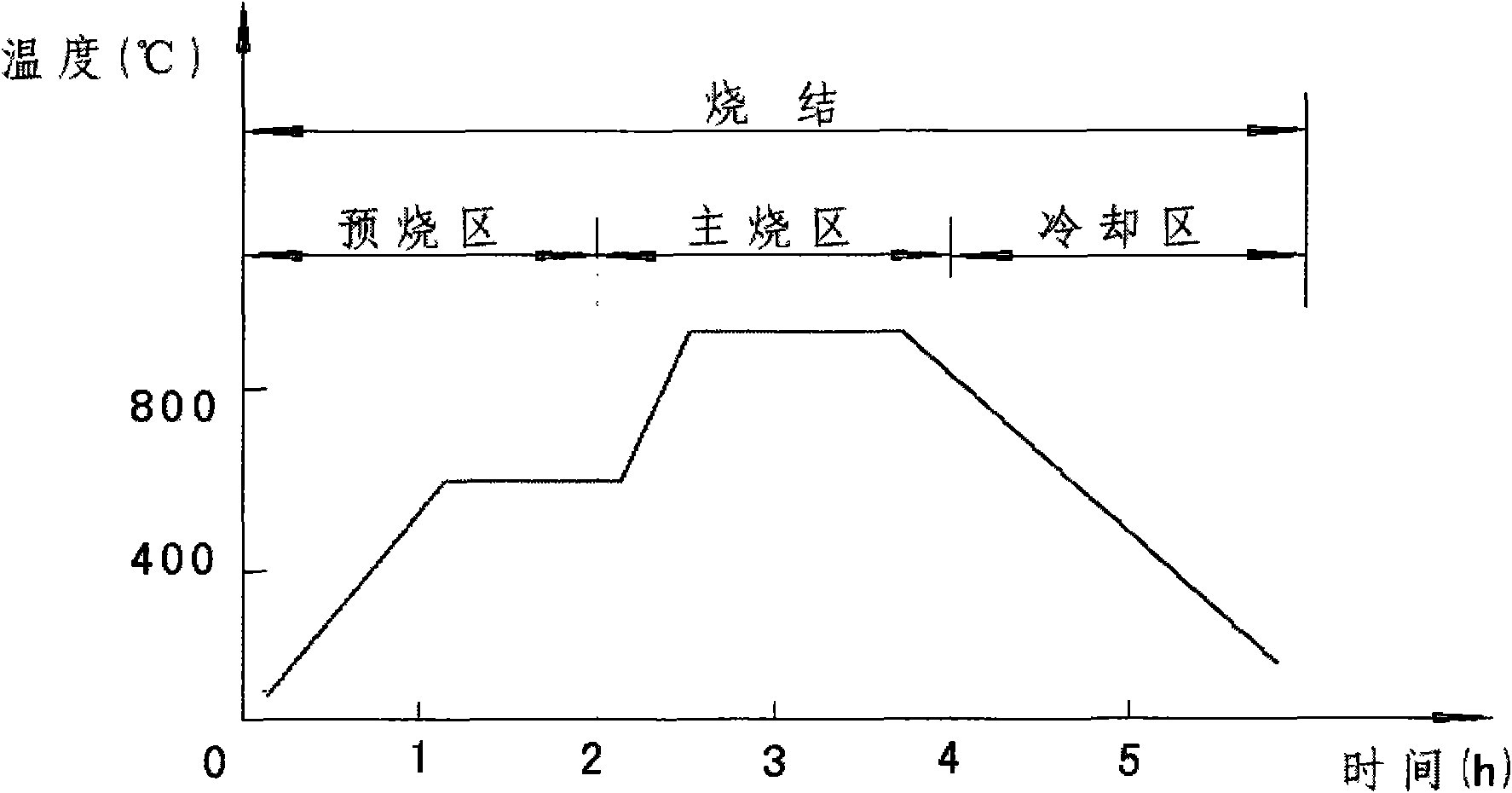

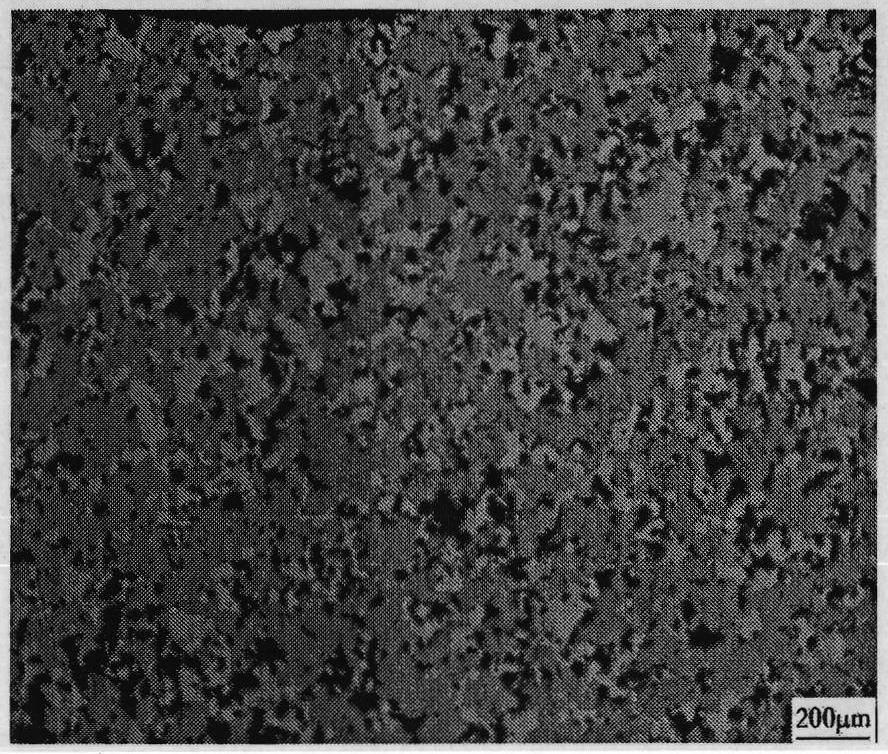

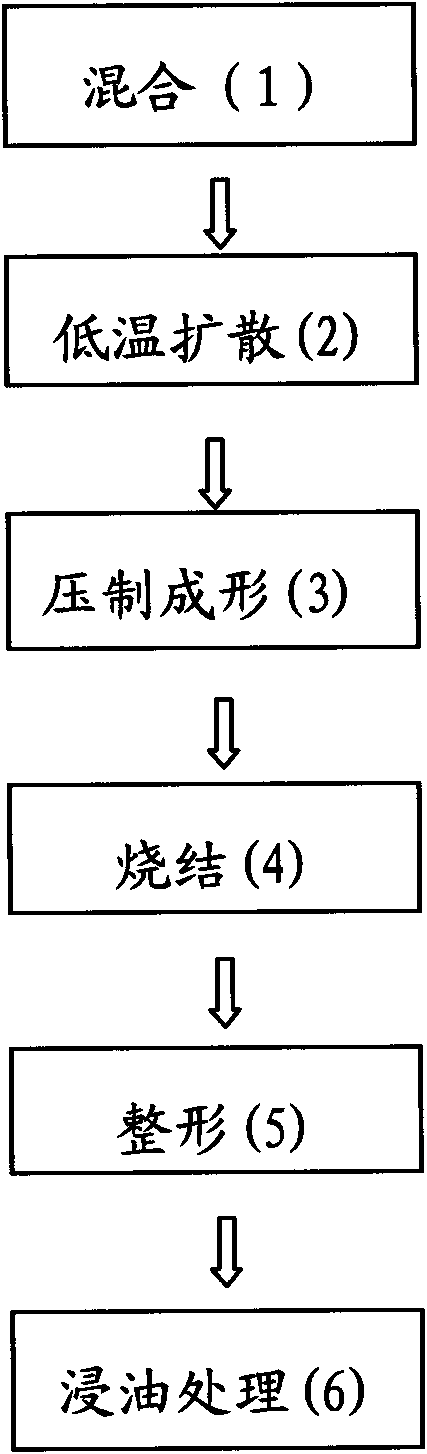

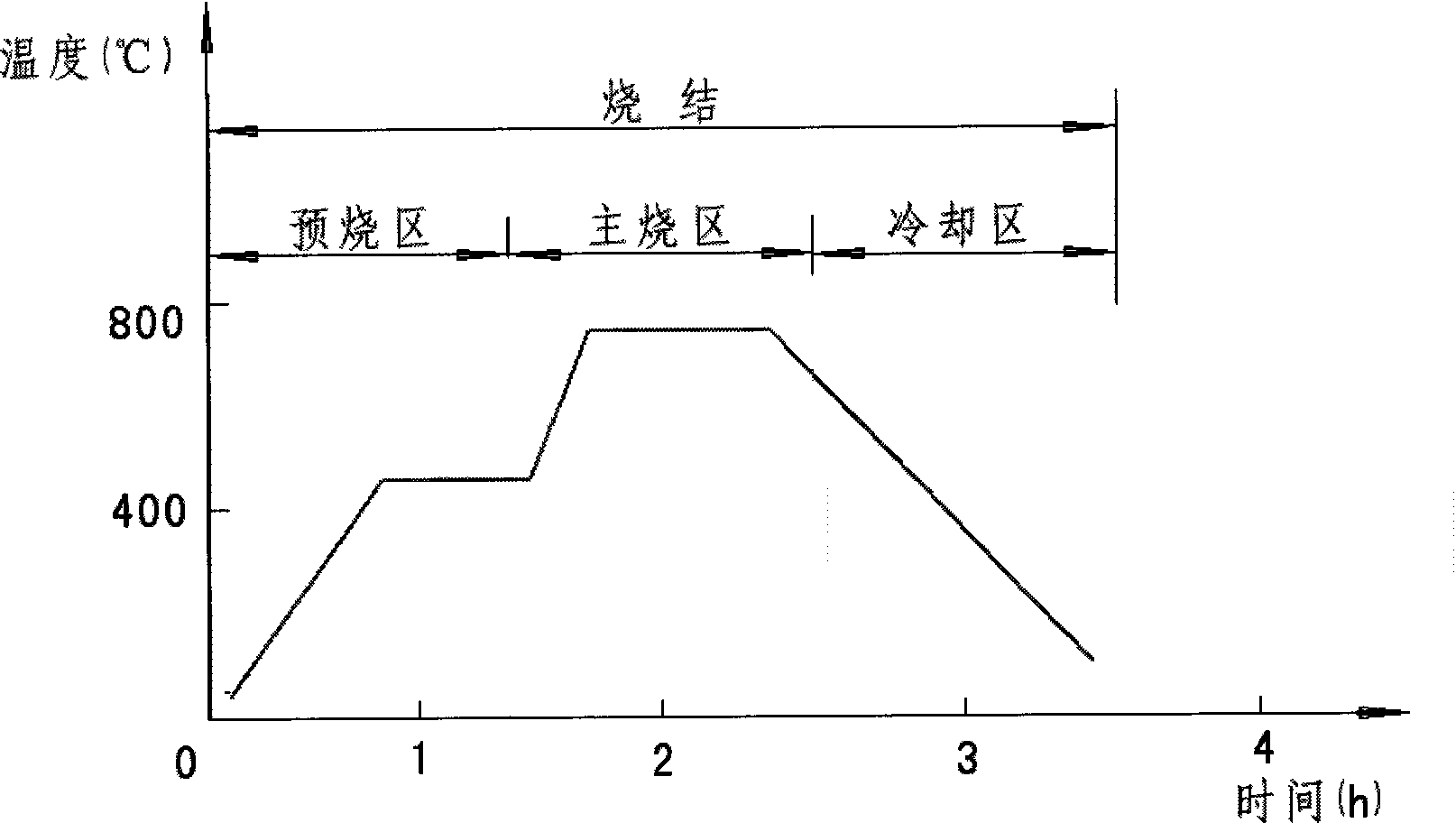

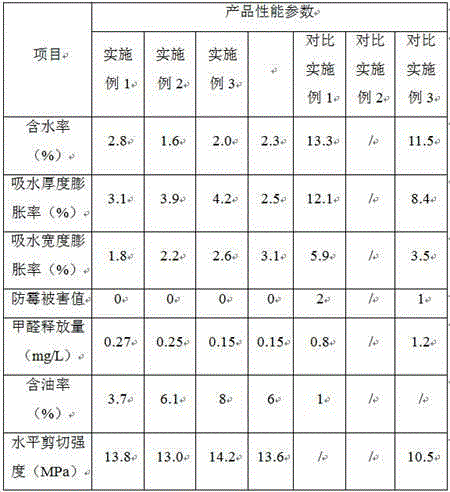

Ultrahigh rotating speed oil bearing for powder metallurgy and manufacturing method thereof

The invention discloses an ultrahigh rotating speed oil bearing for powder metallurgy and a manufacturing method thereof. The bearing comprises the following components in percentage by weight: 27-54% of Cu, 3-6% of Sn, 2.2-6% of MoS, 0.2-2% of La or Ce and the balance of Fe and inevitable impurities. The bearing is manufactured by carrying out processes of mixing, low-temperature diffusion, press forming, sintering, reshaping and oil immersion treatment on mixture formed by proportionally mixing the powders. Solid lubricant and rare earth which are used as an active catalyst and an enhancer for a basis material of the bearing are added to the bearing, thereby being benefical to grain refinement; and weeny through holes are generated on a sintering body, and the connectivity rate is more than 95 percent. When the bearing rotates at a high speed, an oil film is formed on the inner wall of the bearing by the lubricating oil, and the bearing is applicable to an ultrahigh rotating speed motor with the rotating speed being more than 34000 rpm.

Owner:JIANGSU YINGQIU GRP CO LTD

Micro-arc oxidation process for reducing surface friction coefficient of titanium alloy

InactiveCN101280450AImprove bindingHigh hardnessSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

Disclosed is micro-arc oxidation process to reduce the friction coefficient of titanium alloy surface, which has the process steps of (1) the chemical degreasing, (2) the micro-arc oxidation that the basic parameters are trisodium phosphate of 1-30g / L, tungsten sodium of 0-10g / L, sodium silicate of 0-50g / L, tartaric acid of 0-20g / L, glycerol of 0-10g / L and sodium hydroxide of 5-10g / L, (3) the post-processing that the hot oil immersion treatment is proceeded for the film after the oxidation. Through the invention, the high-performance ceramic membrane with strong cementing property, high hardness and low coefficient friction can be obtained on the titanium surface. Through the testing of a high-temperature friction and wear testing machine of MM-U5G screen material end surface, the friction coefficient of the titanium micro-arc oxidation film is 0.1 to 0.5. During the observation of the oxidation film after the experiment, the shedding and wear phenomenon is not found.

Owner:NANCHANG HANGKONG UNIVERSITY

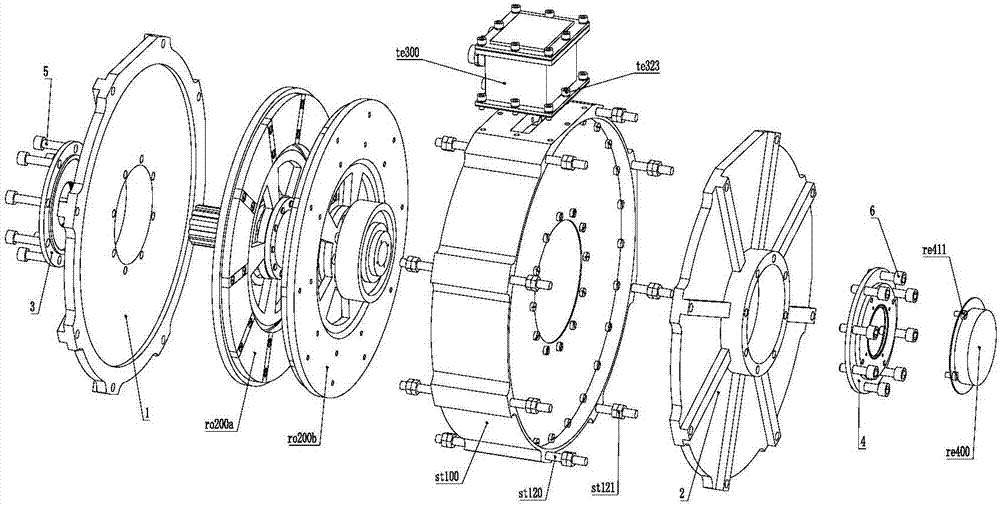

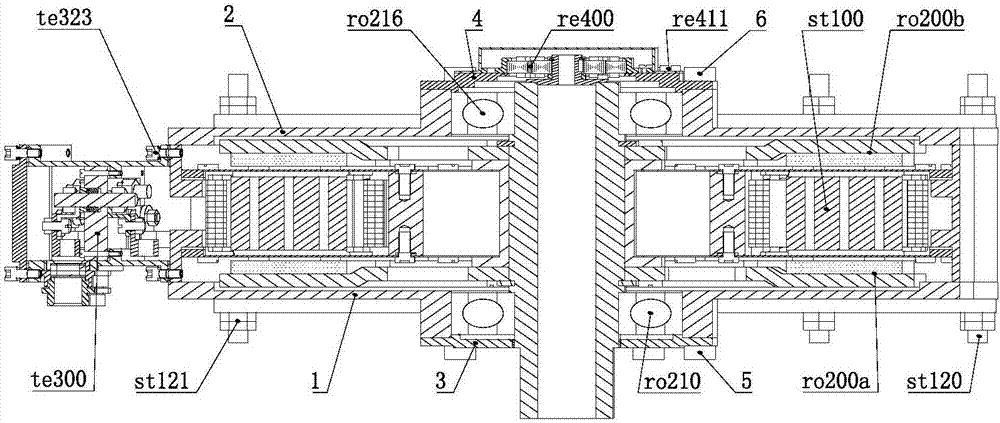

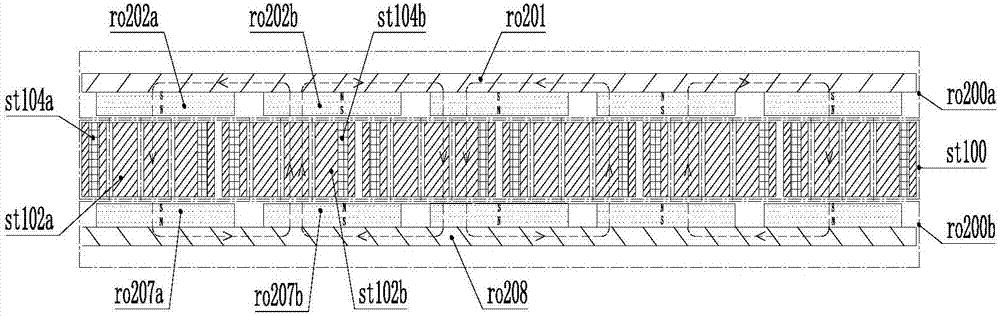

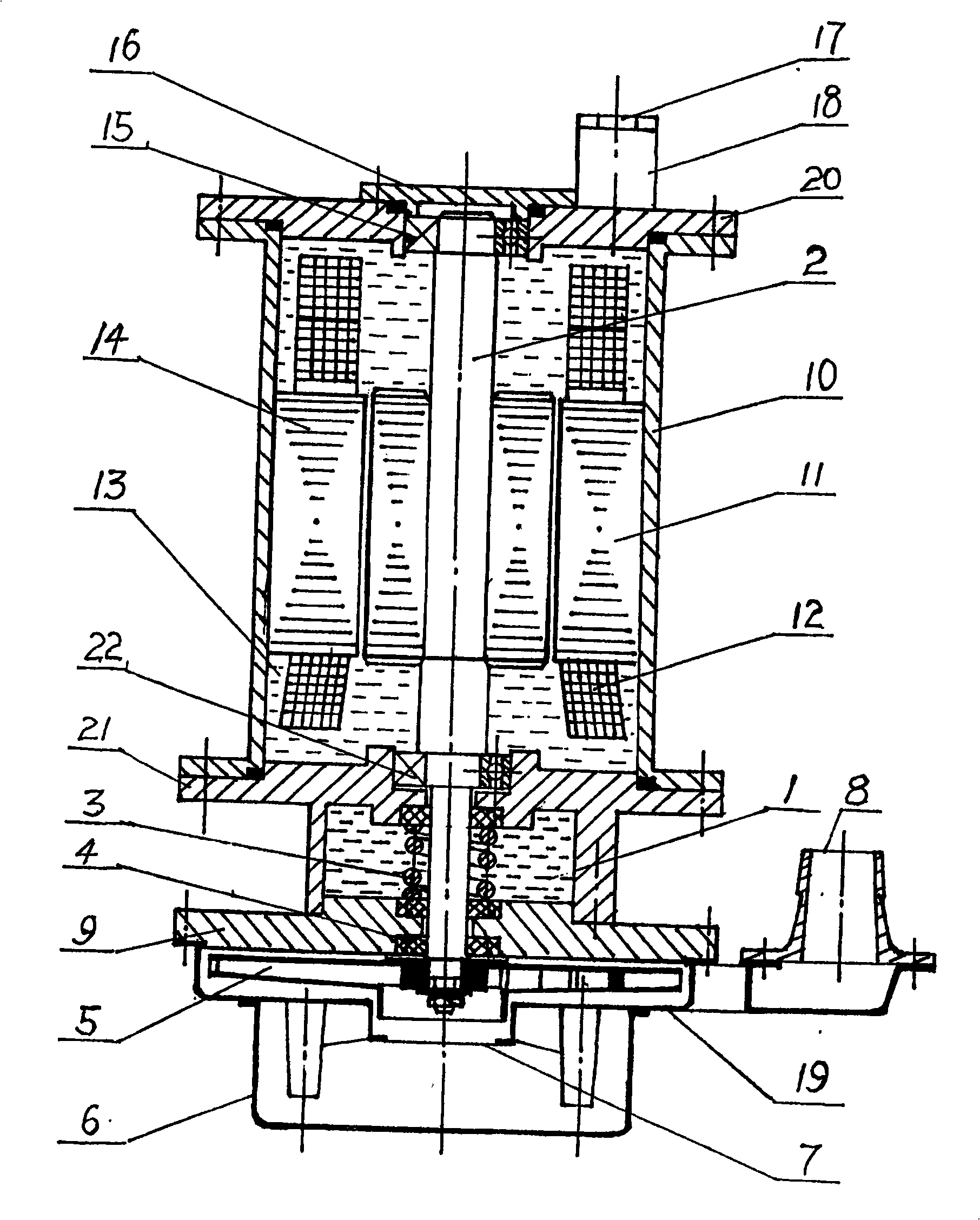

Disc type axial-flux motor with oil-immersed circularly cooled stator and segmented armatures

InactiveCN107196480AImprove power densityIncreased torque densityStructural associationCooling/ventillation arrangementSurface mountingTorque density

The invention discloses a disc type axial-flux motor with an oil-immersed circularly cooled stator and segmented armatures. A framework with double rotors and single stator is adopted; and a main shaft is designed. Each rotor adopts a magnetic steel surface-mounting type structure; and a whole stator oil-immersion circulation cooling and heat dissipation mode is adopted for temperature rise management. The disc type axial-flux motor with the oil-immersed circularly cooled stator and the segmented armatures comprises a stator assembly, a driving end rotor assembly, a non-driving end rotor assembly, a wire outlet box assembly and a rotary transformer assembly. An engine base is provided with an oil inlet joint and an oil outlet joint, both of which can carry out oil-immersion circulation cooling for the stator and have the advantages such as high convective heat transfer efficiency, big heat exchange area and fast heat transfer speed. The disc type motor adopting such a heat dissipation structure can achieve higher power density and higher torque density, is more compact in structure and is suitable for the occasions with strict requirements on the motor mounting space in future.

Owner:XI AN JIAOTONG UNIV

Intelligent temperature adjustment textile and making method thereof

The invention relates to an intelligent temperature adjustment textile and a making method thereof. The intelligent temperature adjustment textile is obtained through wrapping a phase change microcapsule by a coating adhesive, and coating the surface of a textile fabric. The above coating comprises 30-35wt% of the phase change microcapsule, 20-40wt% of an emulsion, 0.2-2wt% of a dispersant, 0.1-1wt% of an antifoaming agent, 2-8wt% of a thickener, 0.1-0.5wt% of a net removal agent and 20-30wt% of deionized water. The method comprises the steps of beating, pre-finishing, coating, baking and cooling rolling. The phase change material adopts the phase change microcapsule, so no oil immersion like negative effects of the fabric do not appear during endothermic melting; the textile adopting pint-like uniform coating has soft handle and good ventilating performance; and the temperature of a last stage hot air oven is controlled in a range of 150-180DEG C, so a cross-linking reaction of maleic anhydride and the phase change material is carried out, thereby the intelligent temperature adjustment textile coating has good fastness and water washing resistance.

Owner:YANCHENG CHAOYANG CLOTHING ACCESSORIES

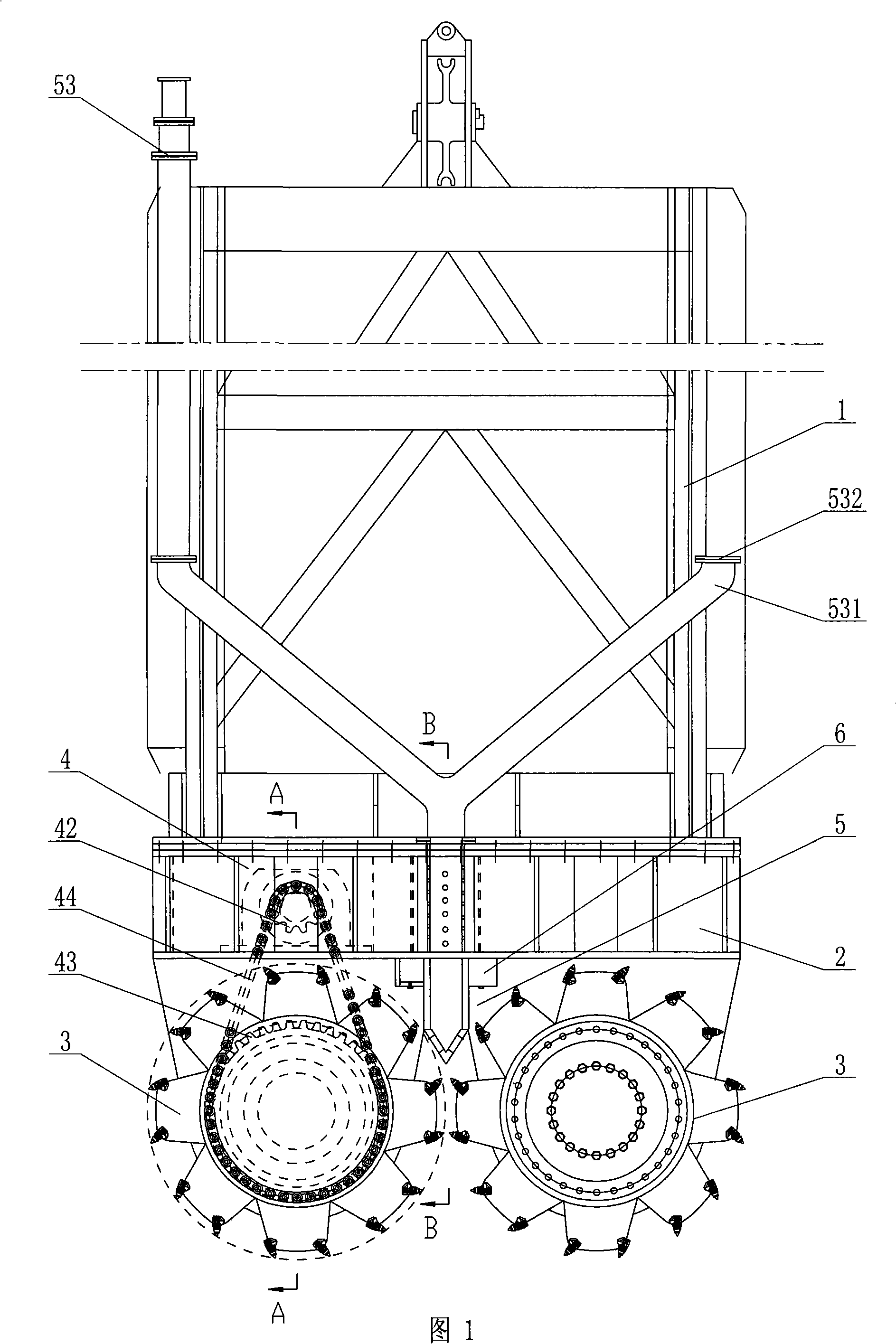

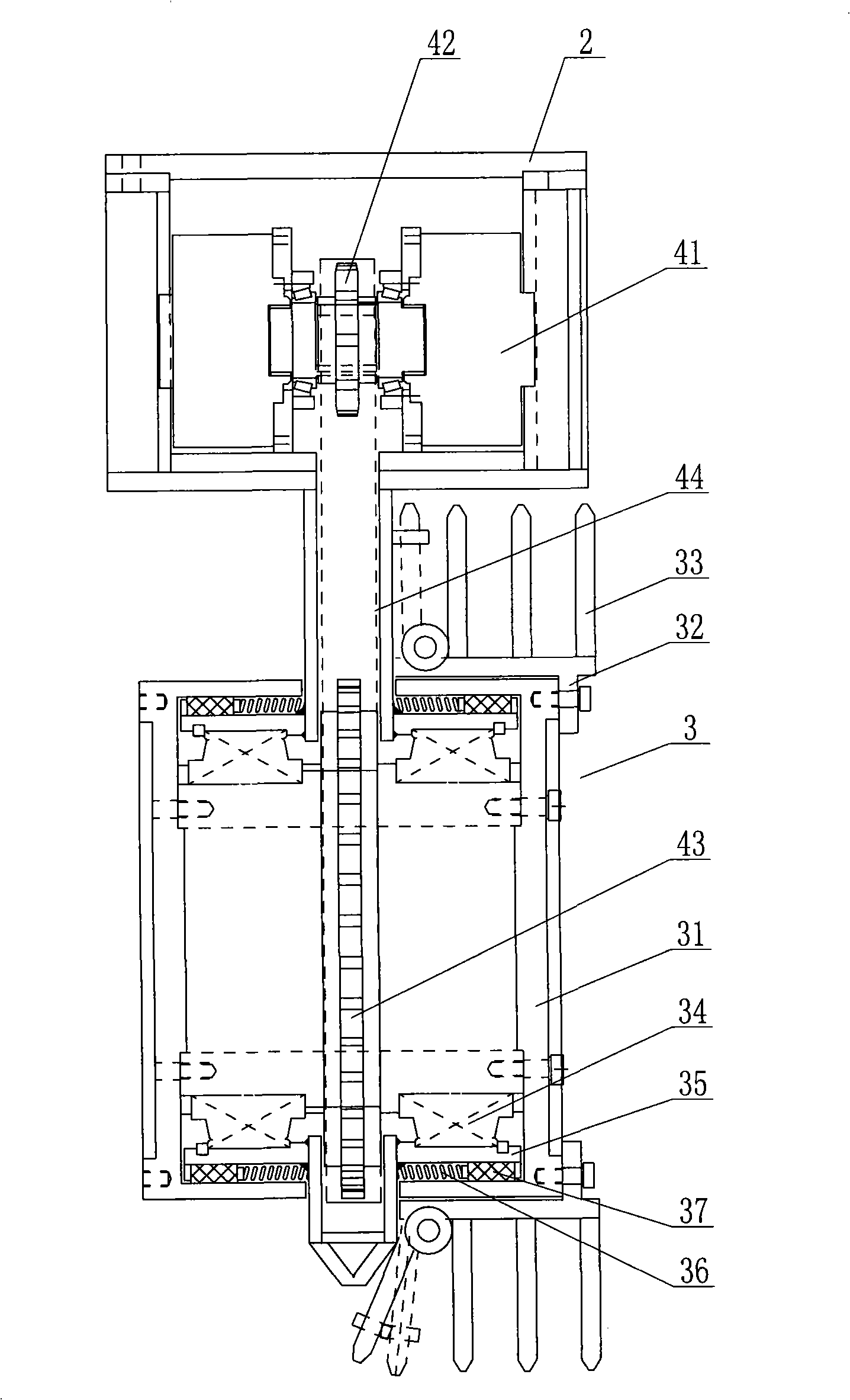

Two-wheel slotter

InactiveCN101285310ASecurity buildEfficient constructionSoil-shifting machines/dredgersExcavationsHydraulic motorMilling cutter

The invention provides a dual wheel slot milling machine, comprising a guide frame, a sealing box body, a driving device and at least one milling wheel which is arranged on the lower part of the sealing box body and provided with a plurality of milling heads along the periphery of the milling wheel and can positively or negatively milling-dig soil layer and rock layer, wherein the driving device comprises a hydraulic motor with low rotary speed and big torque arranged in the sealing box body by the oil immersion lubrication sealing, and a variable speed transmission mechanism consisting of a small chain wheel arranged on an output shaft of the hydraulic motor, a big chain wheel used to drive the milling wheel to turn and a chain used to connect the small chain wheel and the big chain wheel. Due to the adoption of the structure of the driving device with the combination of the hydraulic motor with low rotary speed and big torque and the chain transmission, the slot milling machine is safe and highly efficient, and can perfectly construct the continuous wall with flattening, same thickness and big width, and the work efficiency, rotating speed and torque of the slot milling machine are almost the same as the imported equipment; moreover, the slot milling machine has the advantages of simple and reliable structure, low manufacturing cost, convenient assembly, disassembly and maintenance, low maintenance cost, energy conservation, environmental protection and easy popularization.

Owner:谢沃林

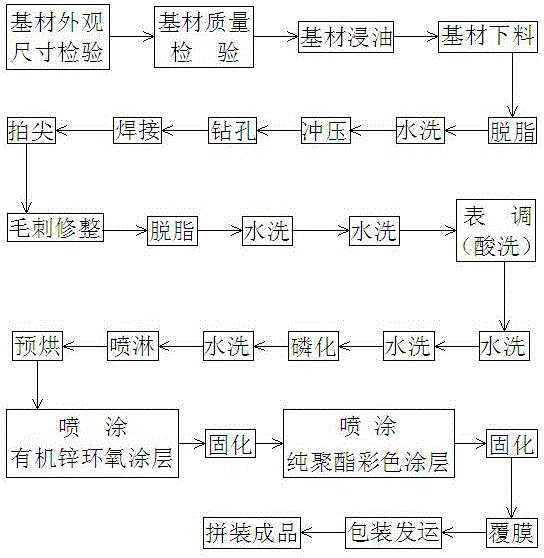

Production technical process of zinc-steel guardrails

The invention relates to the field of machining of guardrails, in particular to a production technical process of zinc-steel guardrails. The production flow is as follows: (1) inspection of external dimension of a substrate; (2) inspection of quality of the substrate; (3) oil immersion of the substrate; (4) substrate blanking; (5) degreasing; (6) washing; (7) stamping; (8) drilling; (9) welding; (10) tip forming; (11) burr trimming; (12) degreasing; (13) washing; (14) washing; (15) surface conditioning (pickling); (16) washing; (17) washing; (18) phosphating; (19) washing; (20) spraying; (21) pre-heating; (22) spraying of an organic zinc epoxy coating; (23) solidifying; (24) spraying of a pure polyester color coating; (25) solidifying; (26) laminating; (27) packaging and forwarding; and (28) assembling to produce a finished product.

Owner:CHUZHOU BOHAO DOOR MFG CO LTD

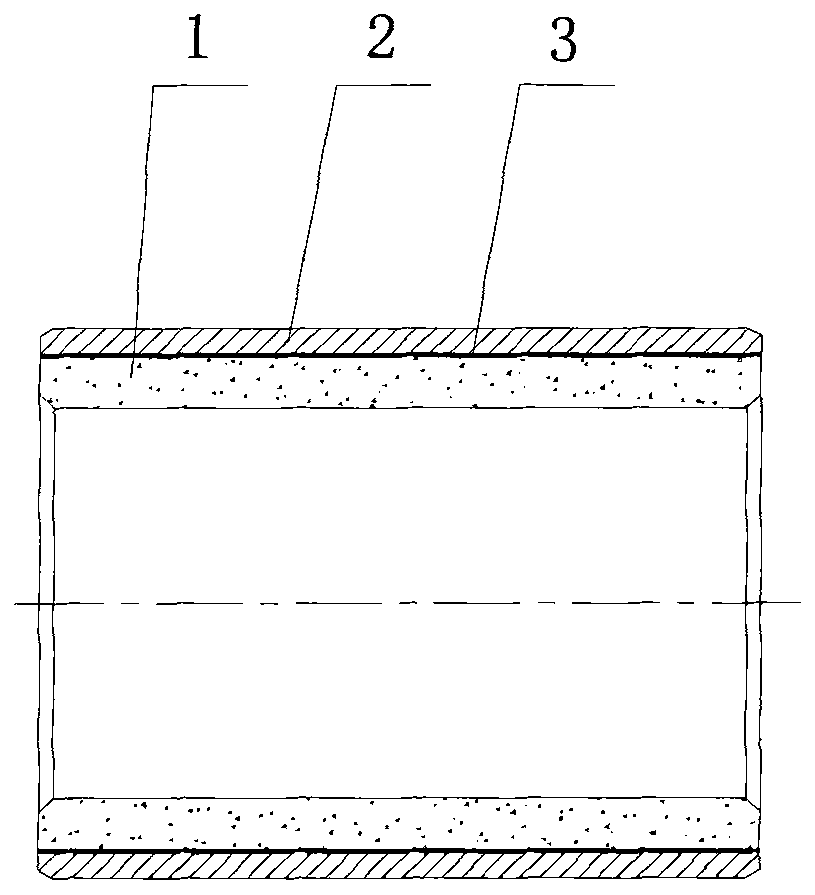

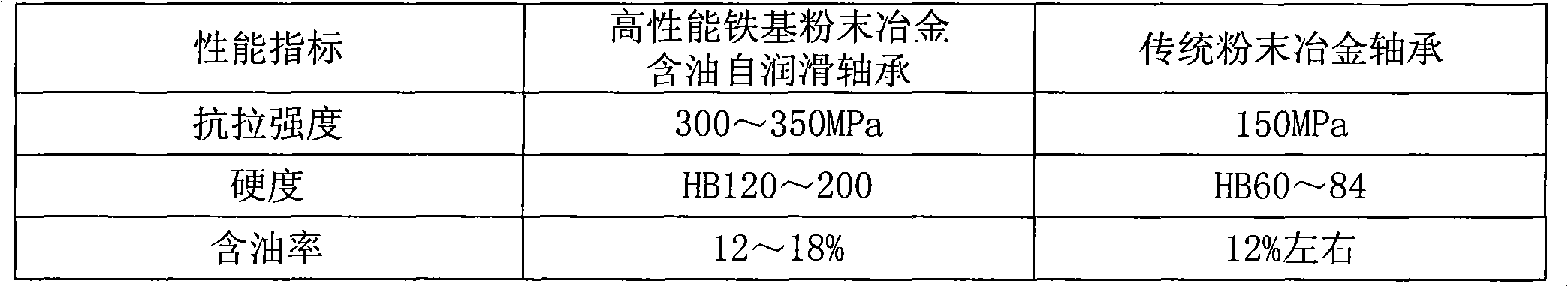

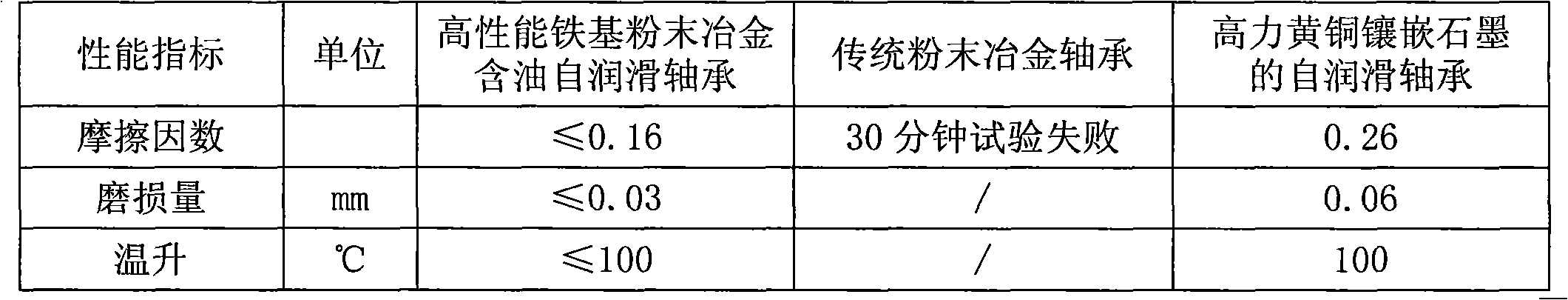

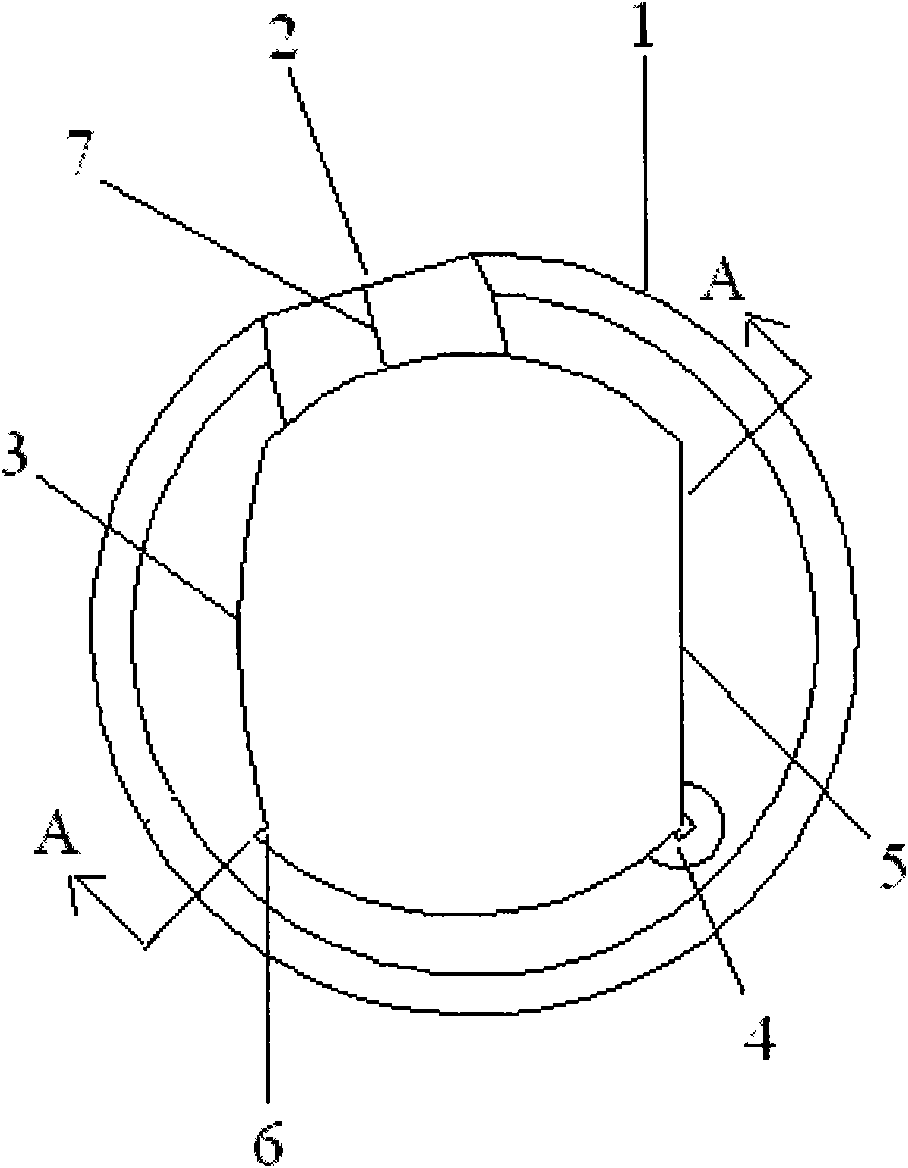

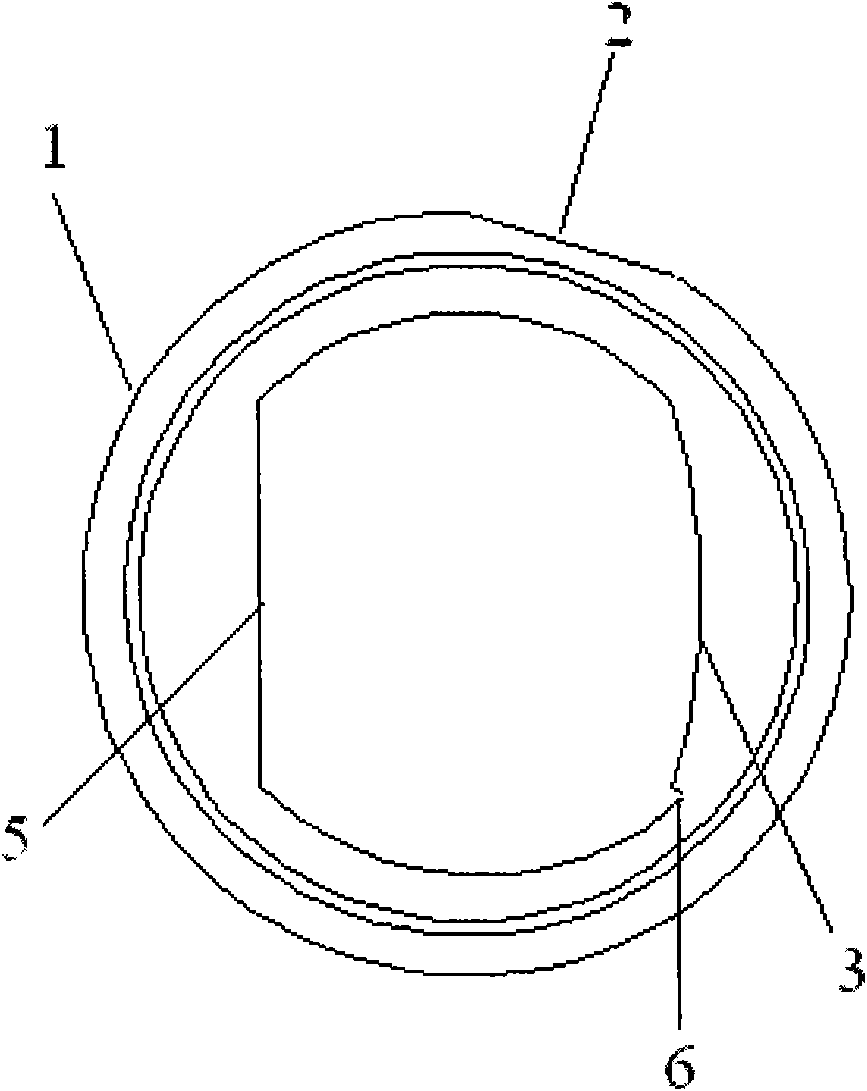

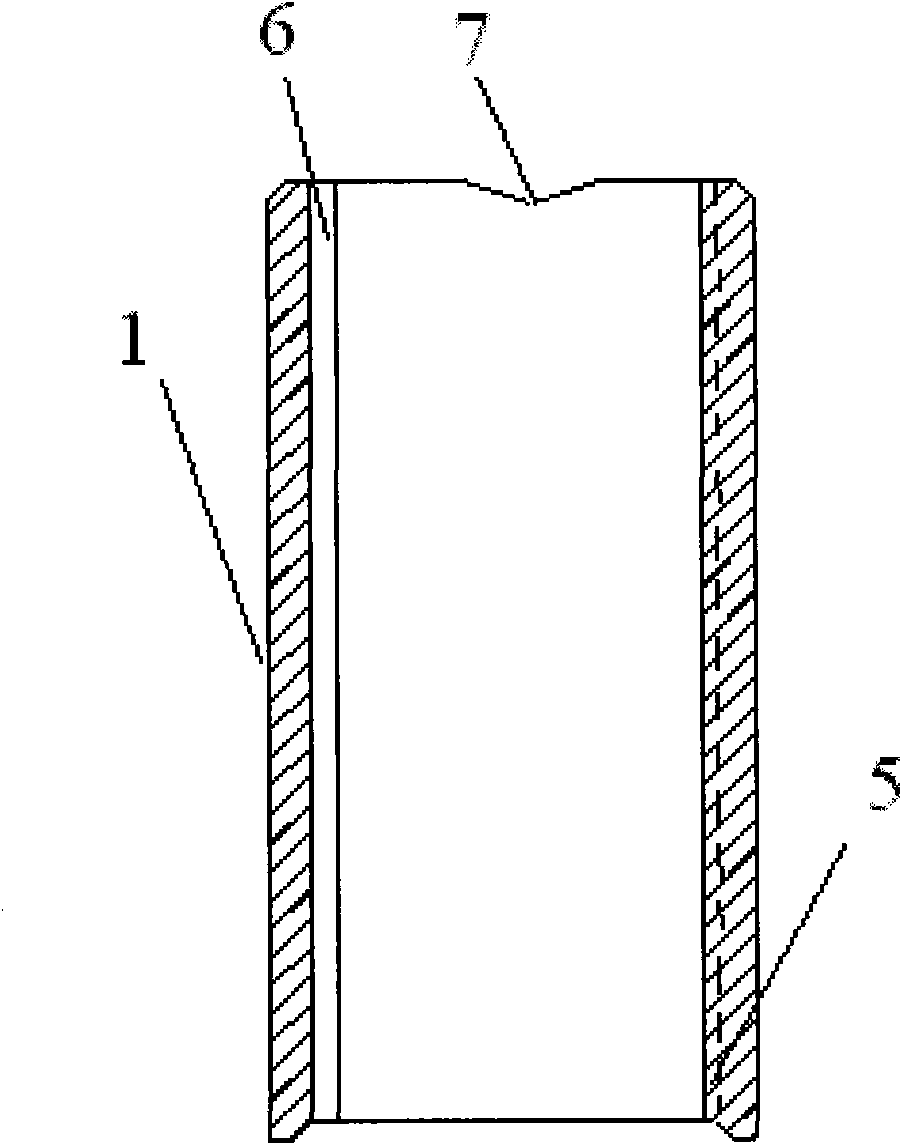

High-performance iron-based powder metallurgy oil-containing self-lubricating bearing and production process thereof

The invention discloses a high-performance iron-based powder metallurgy oil-containing self-lubricating bearing and a production process thereof, aiming to provide a bearing which is suitable for rotating, swinging and linear reciprocating motion under the conditions of high bearing and low speed and is also suitable for places which can not be reached through traditional lubrication or are forbidden to use. The high-performance iron-based powder metallurgy oil-containing self-lubricating bearing is in a shaft sleeve shape and is characterized by comprising the following raw materials in percentage by weight: 18-22 percent of copper powder, 1-4.8 percent of aluminum powder, 0.6-1 percent of graphite, 1-5 percent of hard particle, 1-5 percent of zinc stearate and the balance of iron powder. The high-performance iron-based powder metallurgy oil-containing self-lubricating bearing sequentially comprises the following making process routes according to the raw material composition: mixing the raw materials, pressing into shaft sleeve-shaped blank, vacuum sintering, carburizing, quenching, turning to be in a required geometric size, and carrying out vacuum oil immersion to make a finished product. The high-performance iron-based powder metallurgy oil-containing self-lubricating bearing is superior to a traditional powder metallurgy bearing and a self-lubricating bearing with high force brass embedding graphite in aspects of both the mechanical property and the friction and wear property and also has obvious advantages on the manufacture cost of the product.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

Powder metallurgy compressor unloading shaft sleeve and method for preparing same

InactiveCN101576072AImprove yieldReduce frictionPositive displacement pump componentsPositive-displacement liquid enginesHardnessLife testing

The invention discloses a powder metallurgy compressor unloading shaft sleeve and a method for preparing the same. The shaft sleeve comprises a shaft sleeve body provided with a shaft center hole, the outer side surface of the shaft sleeve body is provided with a tangent plane, and the inner side surface of the shaft sleeve body is an arc protrusion curved surface. The preparation method comprises the following steps: evenly mixing Cu powder, Fe powder, C powder and Mo powder and forming in a forming machine; controlling the temperature to between 850 and 940 DEG C, and performing presintering; performing shaping, controlling the temperature to between 1,050 and 1,200 DEG C, and performing sintering again; orderly performing thermal treatment and deep cooling treatment; and orderly performing vacuum oil immersion and centrifugal separation to prepare the powder metallurgy compressor unloading shaft sleeve. The internal diameter of the shaft sleeve has a shape of the arc protrusion curved surface, the average hardness (HRC) of the shaft sleeve is more than or equal to 38, the minimum hardness (HRC) of the shaft sleeve is more than or equal to 35, and the retained austenite structure of the shaft sleeve is less than 15 percent. The preparation method has the advantages of less steps and simple operation; and products meet life testing requirements through durability tests.

Owner:扬州保来得科技实业有限公司

Oil immersion type water proof diving pump

PendingCN101338761AReduce temperature riseIncrease powerPump componentsCooling/ventillation arrangementWater sourceStator coil

The present invention relates to an oil-immersed waterproof submerged pump. A rotor and a stator coil wound with waterproof wires are arranged in the housing cavity of a submerged motor; insulating oil is used as the cooling medium of the housing cavity; a rear bearing and a bearing cover are mounted on the rear end of a motor shaft; a lead-out wire tube, which can lead out a lead-out wire, is mounted on a base; a housing, the base and a front cover close the housing cavity; a front bearing and a mechanical seal, which are fastened in the central hole of the front cover, are mounted in the middle part of the motor shaft; water fills up a sealing chamber; a submerged pump vane wheel is mounted on the front end of the motor shaft; a pump seat is mounted on the front end of the sealing chamber; a pump cover is mounted on the front end of the pump seat; the pump cover is provided with a water inlet; a filtering net is mounted on the front end of the pump cover; a water outlet is arranged on a submerged pump body. The oil-immersed waterproof submerged pump has the advantages that: the temperature raise of the motor is reduced, and the power of the motor is increased; the service life of the motor is increased; the service life of a bearing is prolonged; water source is prevented from being polluted; the oil-immersed waterproof submerged pump can be used in dirty water.

Owner:TIANJIN GANQUAN GROUP

Hardware plate oil immersion device with automatic moving and feeding structure

InactiveCN107716210ANo need for manual applicationHigh degree of automationLiquid surface applicatorsCoatingsRotational axisElectric machine

The invention discloses a hardware plate oil immersion device with an automatic moving and feeding structure. The device comprises a rack. A vertical supporting plate is fixedly arranged on the top face of one side of a top plate of the rack, a main supporting column is fixedly arranged on the other side of the top plate of the rack, an upper main plate is fixedly arranged at the top end of the main supporting column, a feeding rotating motor is fixedly arranged on the bottom face of the right side of the upper main plate, an output shaft of the feeding rotating motor penetrates through the upper main plate and is fixedly provided with a feeding driving gear, a rotating shaft is hinged to the left side of the upper main plate, a feeding transmission gear is fixedly arranged in the middle of the rotating shaft, the feeding transmission gear is meshed with the feeding driving gear, a feeding plate is fixedly arranged at the top end of the rotating shaft, and a stretchable cylinder is fixedly arranged on the top face of the left end of the feeding plate. A plate to be machined can be automatically moved to a permanent magnet and attached to the permanent magnet, the grabbed plate to be machined can be automatically rotated, an oil drum can be lifted, and the plate to be machined is immersed into the oil drum, so that no artificial smearing is needed, and the device is high in automatic degree, good in effect and high in efficiency.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

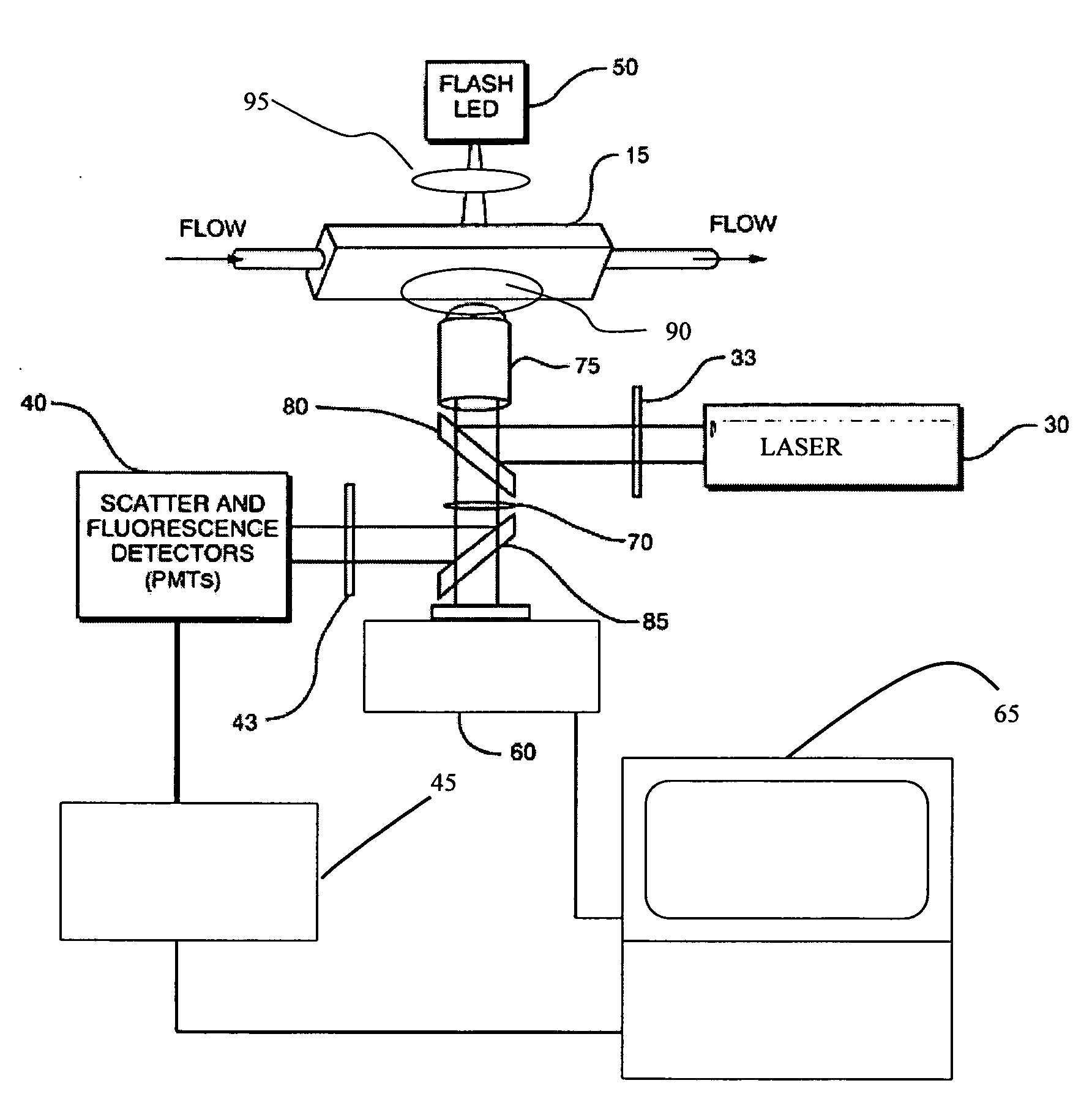

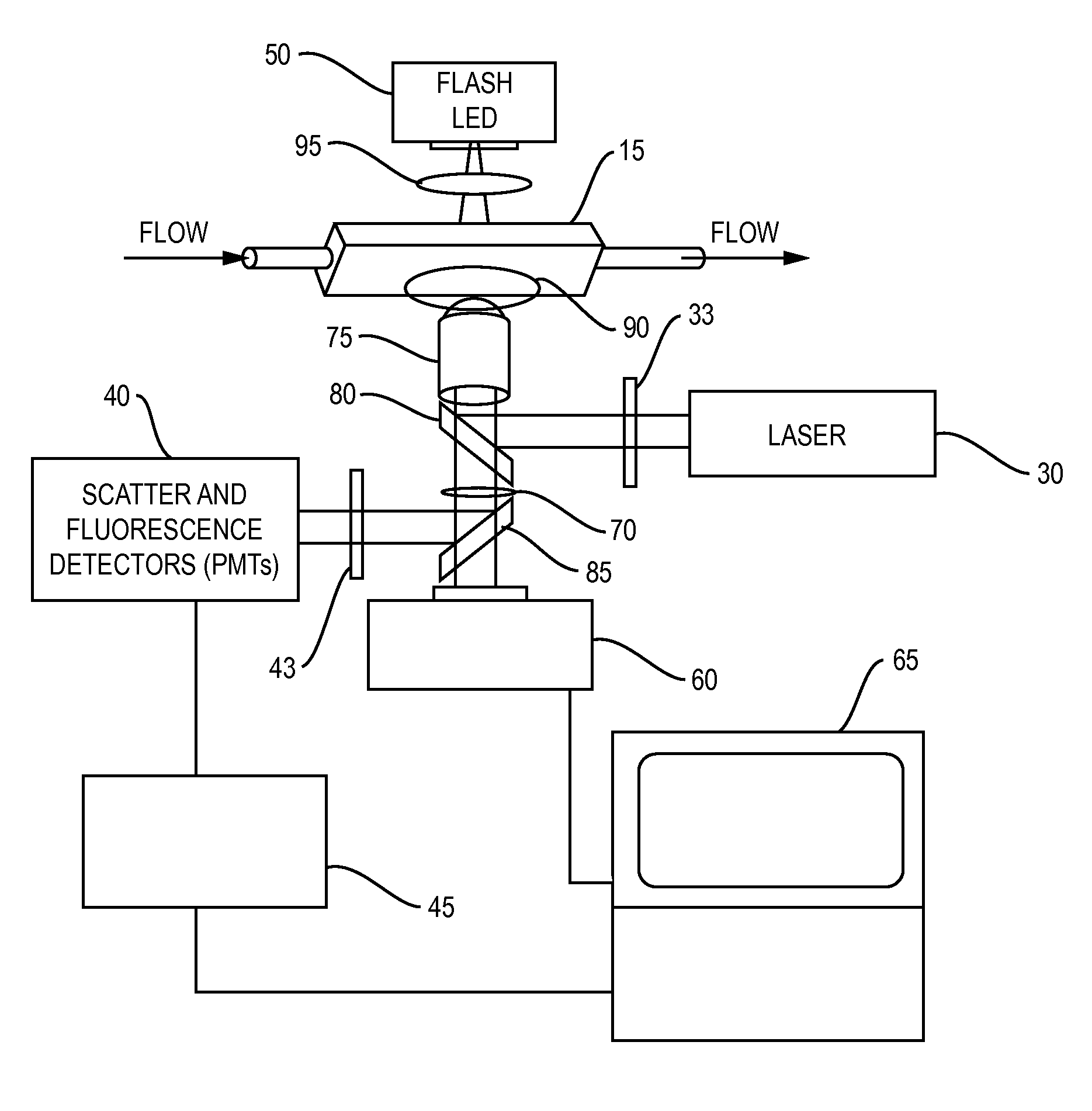

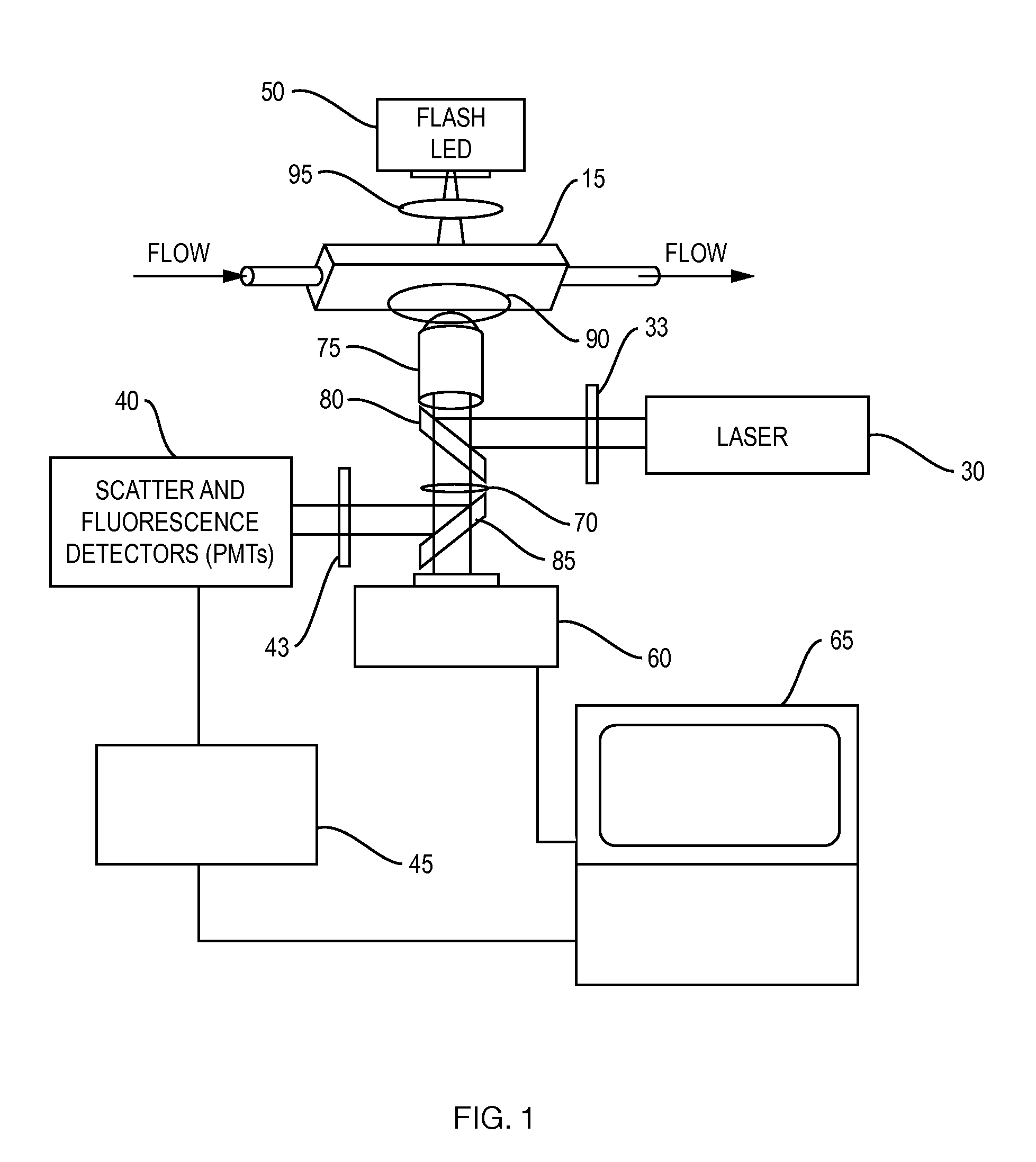

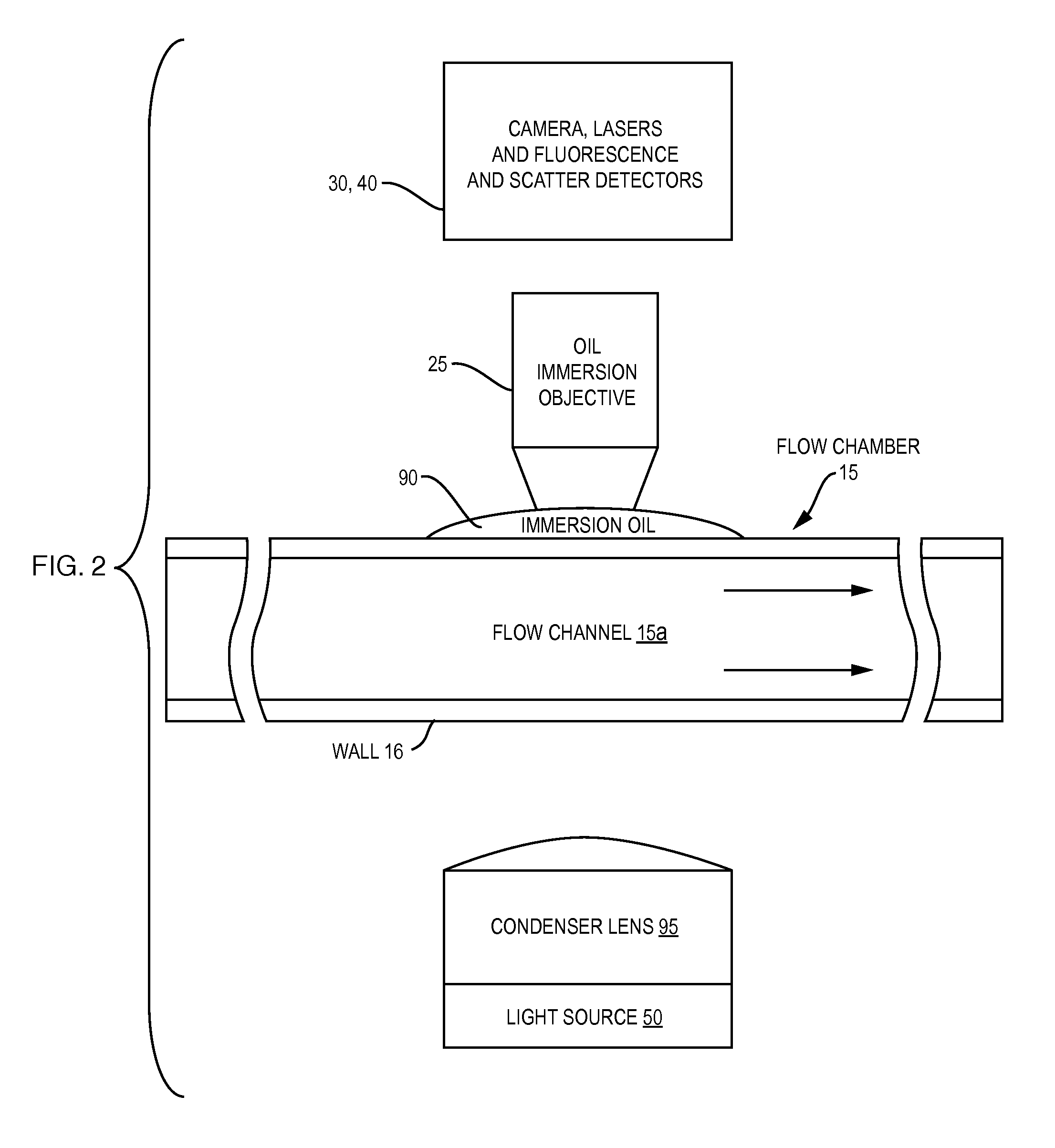

Oil-immersion enhanced imaging flow cytometer

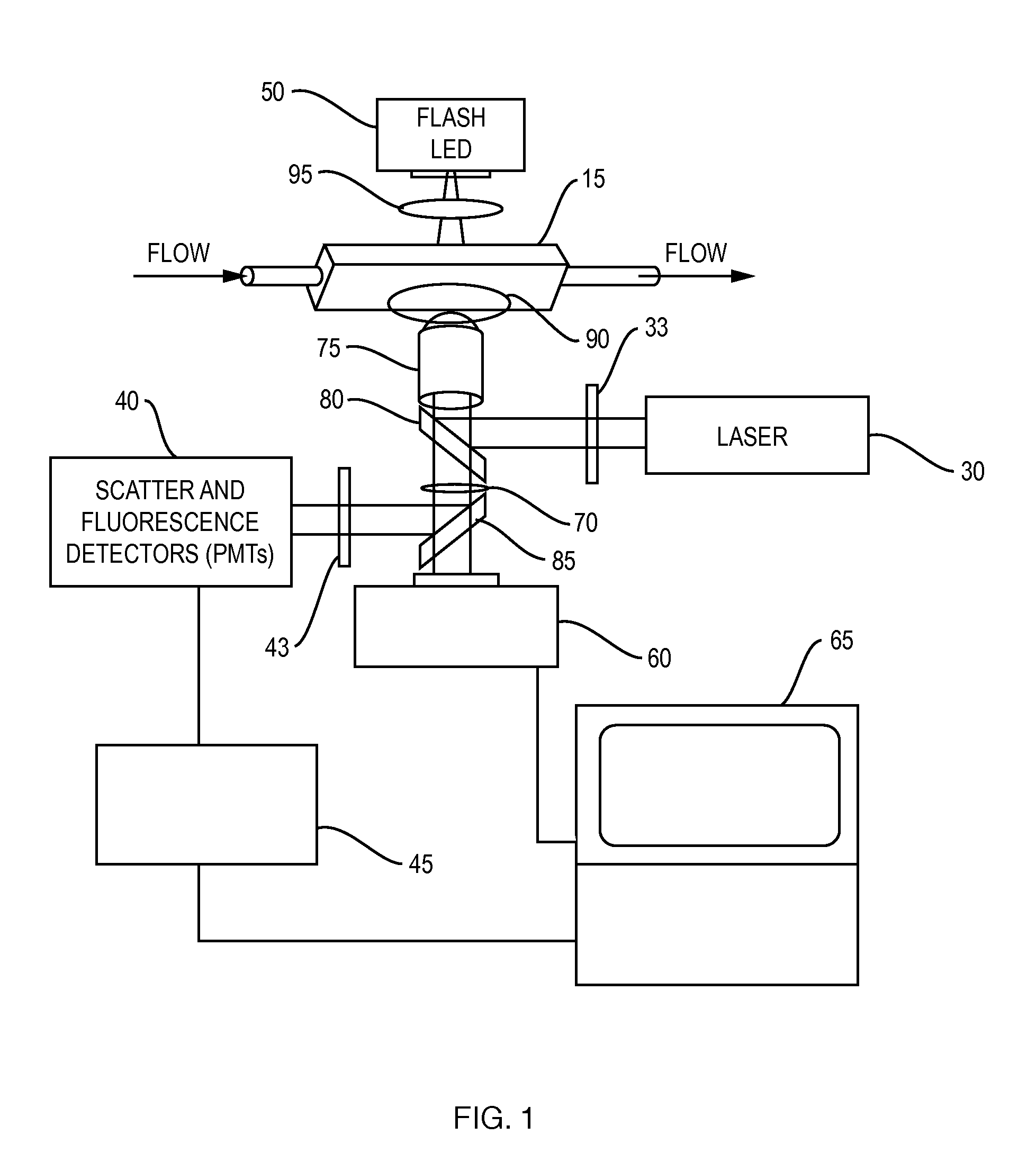

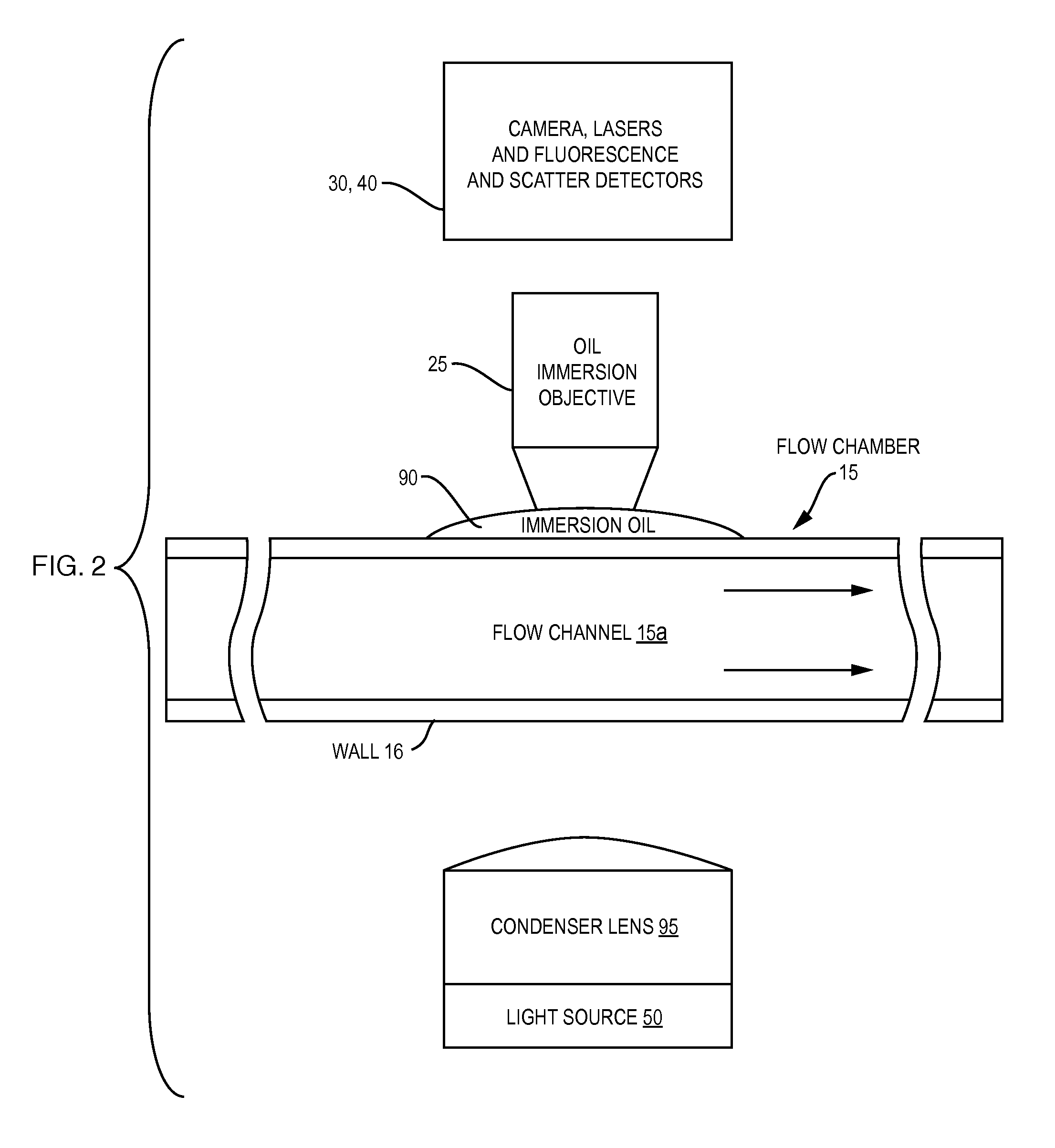

ActiveUS20090273774A1High resolutionImprove analytical abilityRadiation pyrometryNanoparticle analysisFluorescenceHigh numerical aperture

A flow chamber, imaging objective, condenser and imaging light source as part of an optical system includes an oil-immersion objective and high numerical aperture condenser matched to a rectangular flow chamber. The oil-immersion objective and flow chamber include a high index of refraction immersion oil so as to enhance the optical resolution and optical coupling therethrough. The imaging light source generates light which passes through the condenser, the flow chamber and then the objective before being focused onto an imaging camera. Fluorescence excitation passes through the objective to the flow chamber where the oil immersion configuration enhances the focus and collection of the light back through the objective.

Owner:YOKOGAWA FLUID IMAGING TECH INC

Technique for processing engine valve spring

InactiveCN101642867AHigh thermal relaxation resistanceReasonable process designThermal forceEngineering

The invention relates to the field of spring processing technique, in particular to a technique for processing an engine valve spring. The technique includes inspection of raw materials, self inspection of cold forming flaw detection length, 25 to 60 minutes of annealing under the temperature from 250 to 480 DEG C and cross section grinding; the mode of automatic working of the grinding head of apower drive grinding wheel is used for internal and external chamfering grinding, the secondary shot peening technology with the gradual upgrade from thickness to thinness is adopted, 100 percent of demagnetization is carried out, and the thermal forced compression technology is carried out at the temperature from 100 to 300 DEG C under the pressure from 2 to 20 Mpa; loading selection is carried out according to the requirements of different loading sections; and FUCHS rust-preventative oil immersion is carried out, and finally finished products are packed and then are stored.

Owner:QIANJIANG SPRING HANGZHOU CO LTD

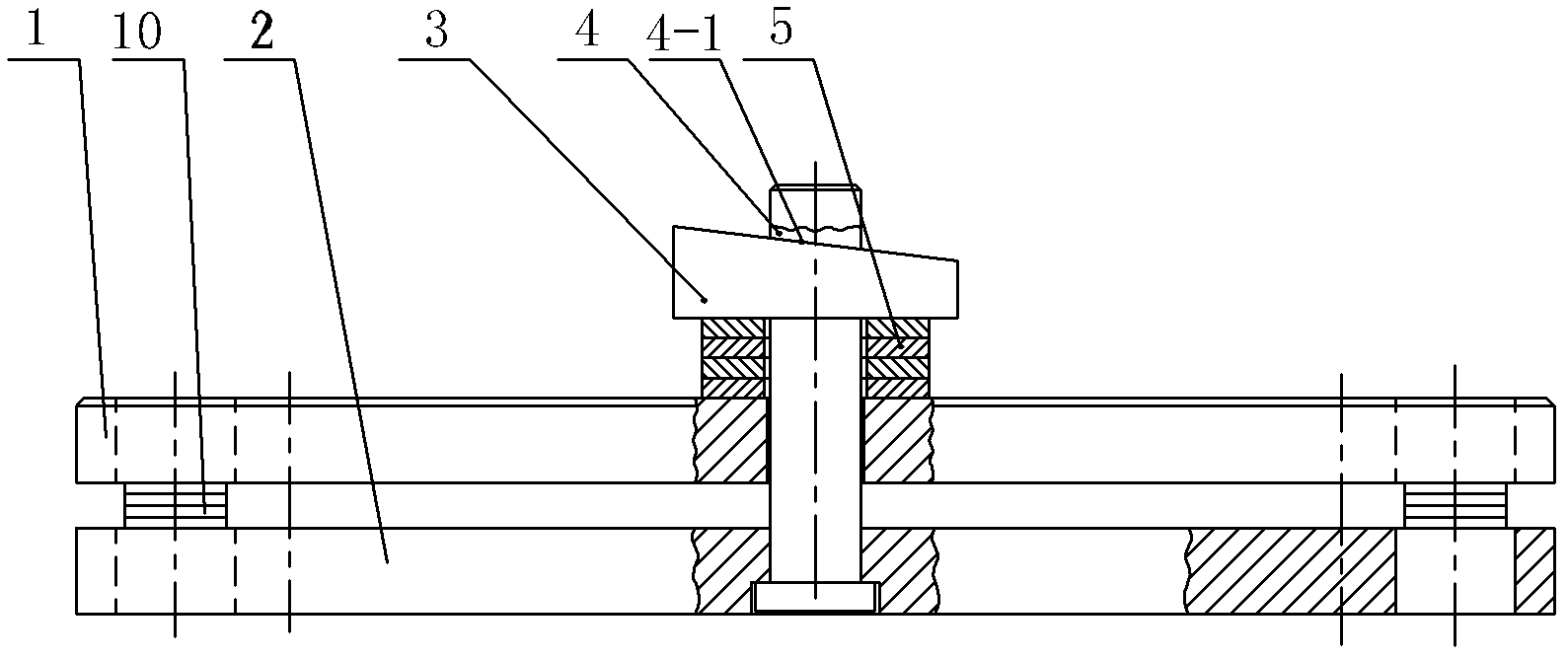

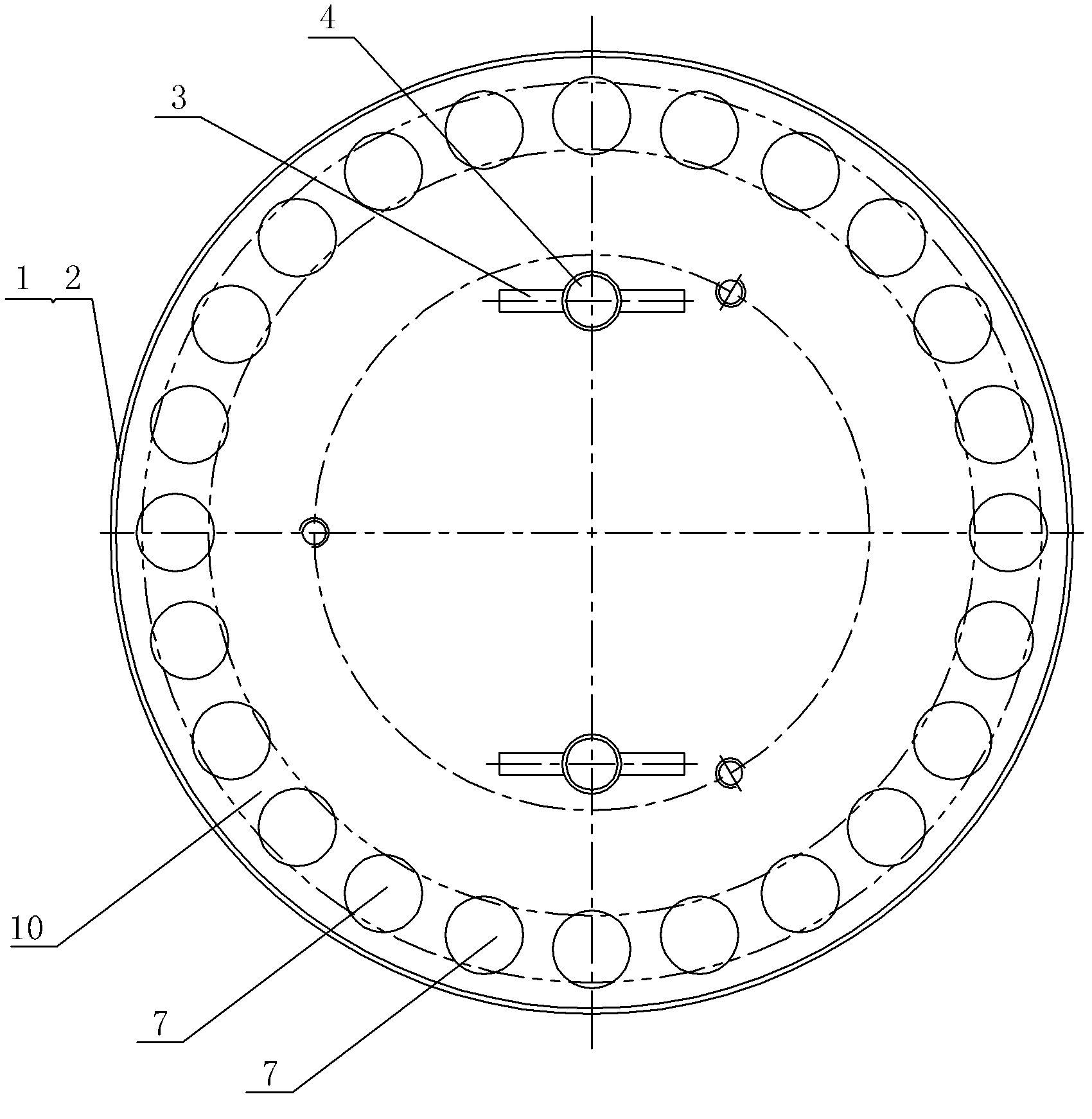

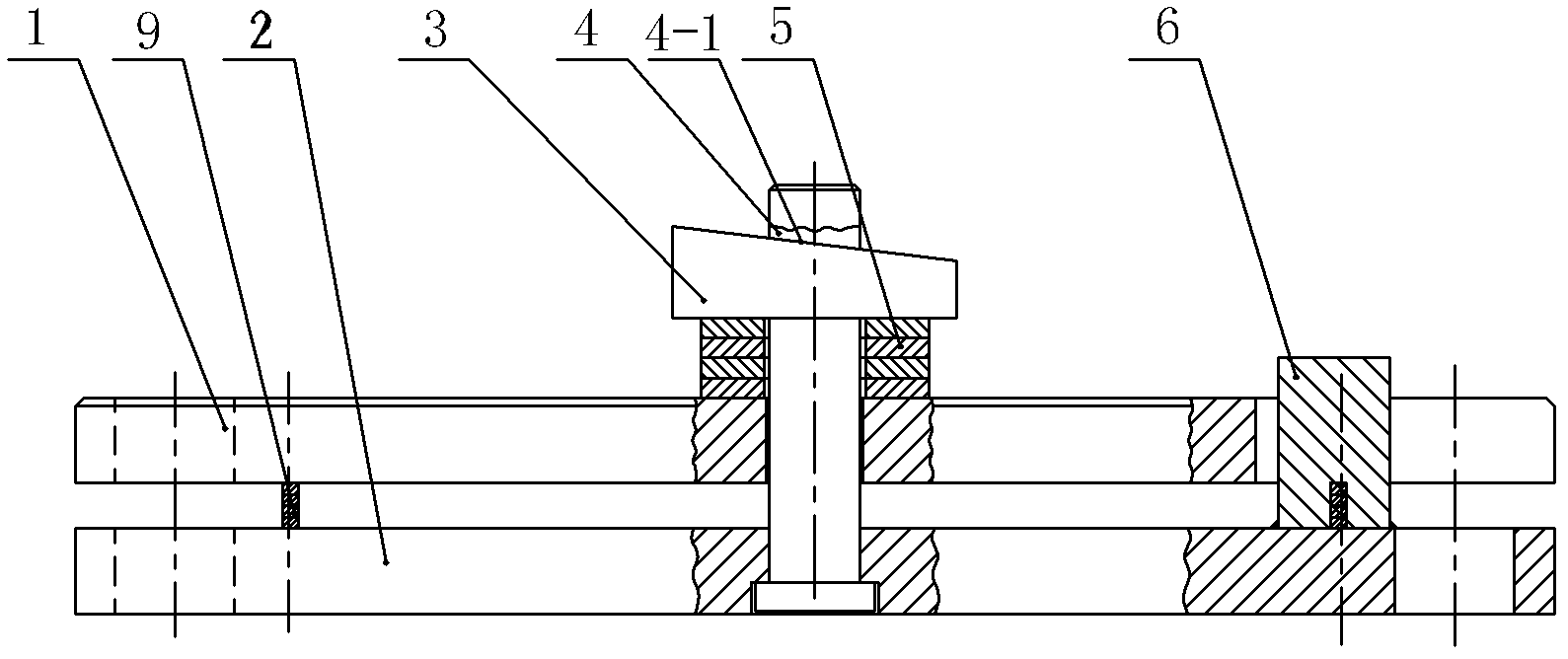

Heat shaping fixture and heat shaping method in quenching process of metal material seal ring

ActiveCN102321796AQuality assuranceEasy to operateFurnace typesHeat treatment furnacesMetallic materialsWaste product

The invention discloses a heat shaping fixture and a heat shaping method in the quenching process of a metal material seal ring, and relates to a heat shaping fixture and a heat shaping method in the quenching process of a seal ring. The invention solves the problems that the integral hardness of a seal ring cannot be improved, the opening size cannot be ensured and waste products are easily produced in the conventional quenching technology. The device comprises that: an upper cover plate and a bottom plate are vertically aligned; a wedge block is nailed in an inclined hole of each shaft; the shaft is sleeved with number adjustable gaskets; the metal material seal ring is arranged between the upper cover plate and the bottom plate; an oil immersion hole on the upper cover plate corresponds to the upper end face of the metal material seal ring; and an oil immersion hole of a lower cover plate corresponds to the lower end face of the metal material seal ring. The method comprises the following steps of: clamping the seal ring in the heat shaping fixture; putting the seal ring and the heat shaping fixture into a heat treatment furnace, and completing quenching and tempering procedures of the heat treatment, which meet the hardness requirement; and detaching the heat shaping fixture and taking the seal ring out. The invention is used for heat shaping in the quenching process of the metal material seal ring.

Owner:HARBIN TURBINE

Deodorizing and sterilizing device for low-temperature plasma garbage station

InactiveCN103285718AImprove adsorption capacityEasy to replaceDispersed particle separationGaseous substancesActivated carbon filtrationPolyvinyl chloride

The invention discloses whole equipment for deodorizing and sterilizing a garbage station. The equipment is composed of a PVC(polyvinyl chloride) air collecting pipeline, a nanometer titanium dioxide catalytic reaction cavity, a low-temperature plasma reaction device, an ozone catalytic activated carbon filtration layer, a fan, an air outlet and a stainless steel outer shell, wherein the low-temperature plasma reaction device utilizes 8-16 pipe-shaped medium blocking low-temperature plasma generating pipes as a main body; the pipe-shaped low-temperature plasma generating pipes are placed in a nanometer titanium dioxide catalytic reaction cavity body, the top of the reaction cavity body is connected with the ozone catalytic activated carbon filtration layer, and the bottom of the reaction cavity is connected with an oil immersion type step-up transformer and is connected with an integrated control circuit; the ozone catalytic activated carbon filtration layer is arranged on the plasma reaction device, and the air after purifying is output through the rotation of the fan. The whole device equipment provided by the invention has the advantages of simple structure, convenience in use, obvious deodorizing sterilizing effect, low energy consumption and the like.

Owner:BEIJING LANGCLEAN ENVIRONMENT

Macromolecular PTC composite material with crystalline polymer as matrix

InactiveCN103554588AImprove conductivityPTC performance improvementTemperature controlPolymer science

The invention discloses a macromolecular PTC composite material with a crystalline polymer as the matrix. The PTC composite material comprises, by volume: (a) 40-70% of a thermoplastic polymer, i.e. a crystalline polymer substrate; (b) 30-60% of conductive filler: and (c) 1-5% of additives. The composite material provided by the invention has excellent electrical conductivity and PTC performance, and national standard tests prove that the tensile properties, bending properties and oil immersion aging performance and the like all do not show a downward trend. An automatic temperature control type heating cable prepared from the composite material provided by the invention is especially suitable for antifreezing thermal insulation and temperature limited heating of chemical and petroleum pipelines, valves, monitoring and inspection instruments and for fluid flow promotion.

Owner:ANHUI PRINTING MECHANICAL & ELECTRICAL

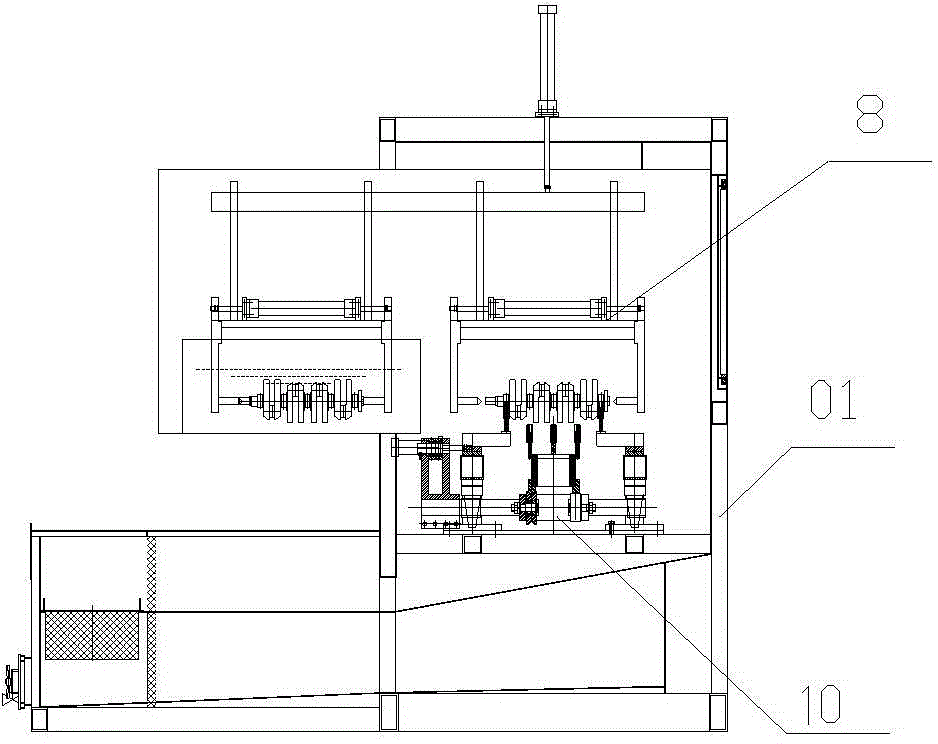

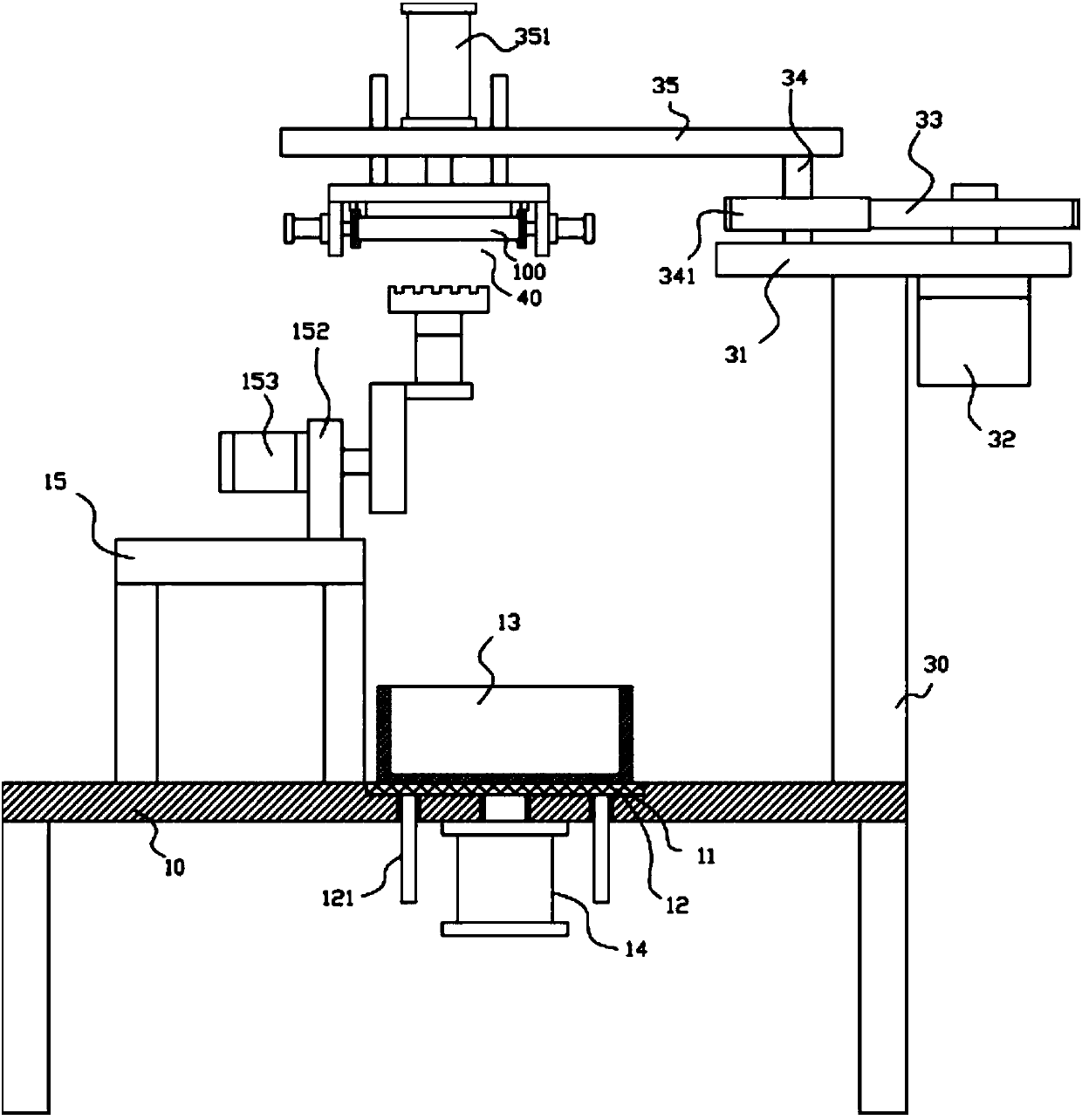

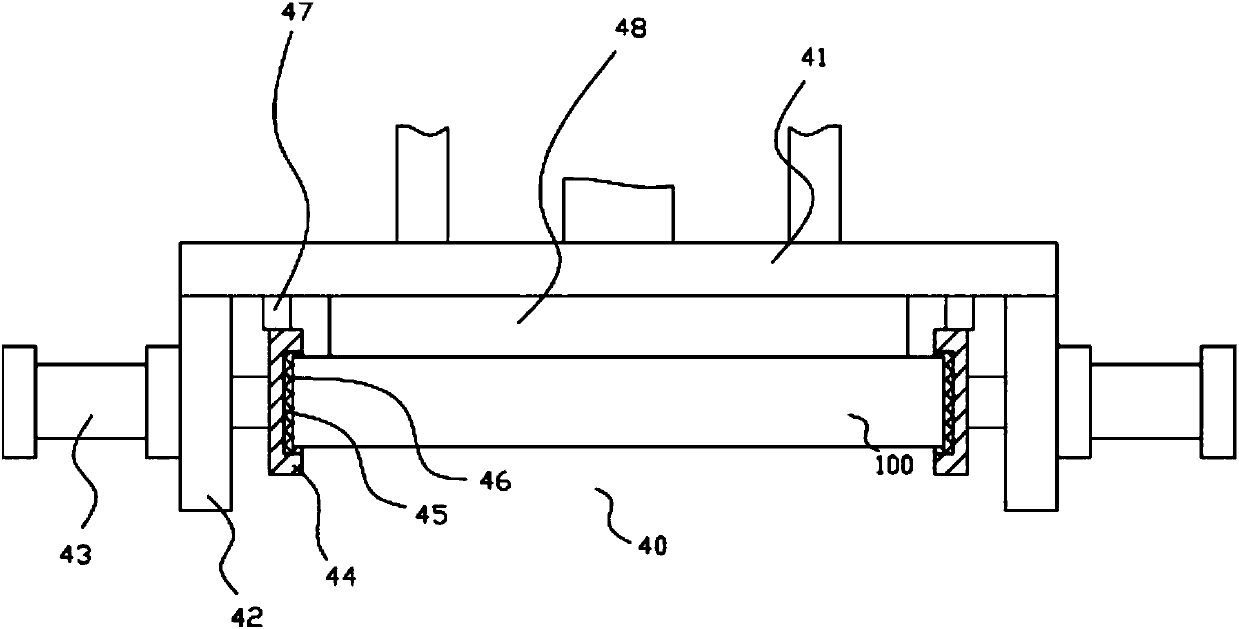

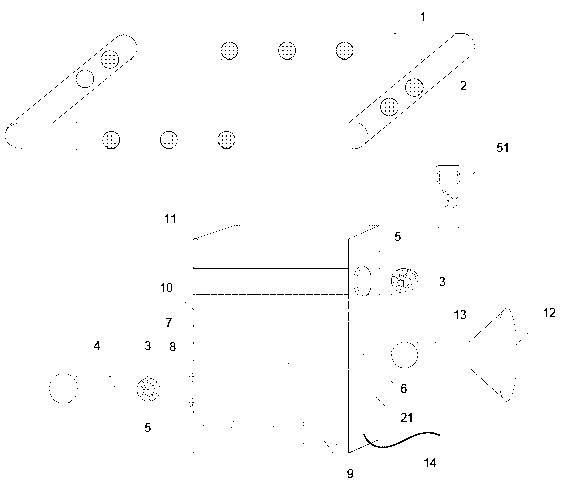

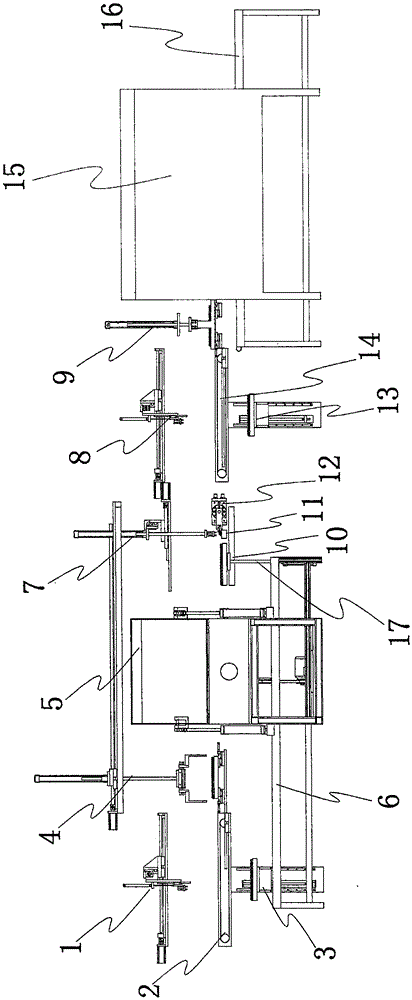

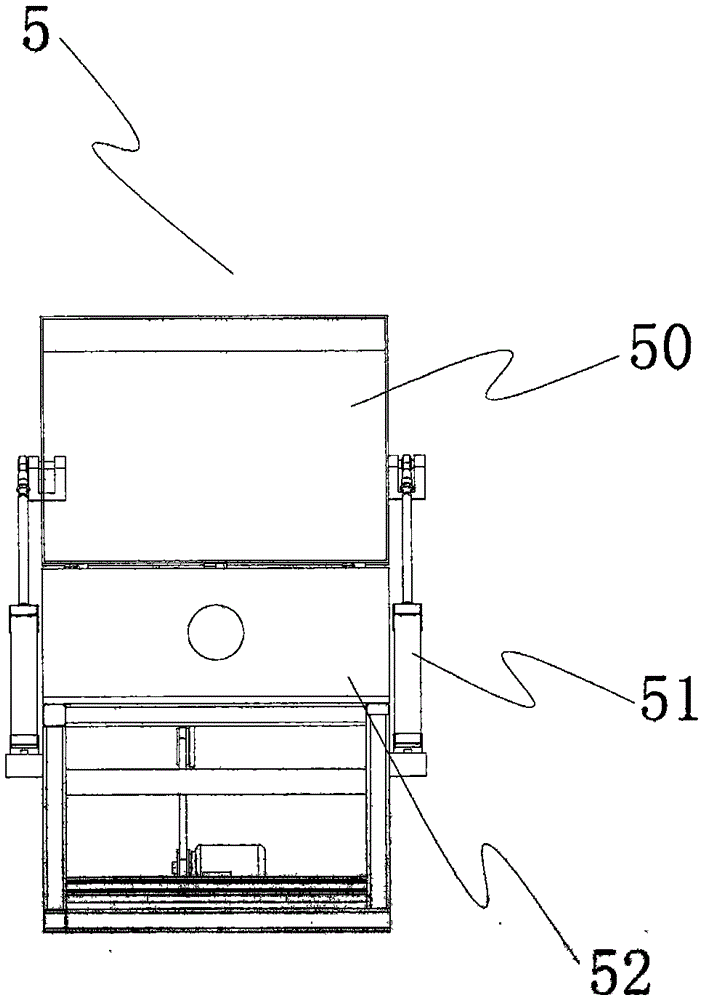

Automatic oil immersion method and apparatus for transformer

ActiveCN105469972AAutomatic immersion oil realizationAvoid participationPretreated surfacesInductances/transformers/magnets manufactureTransformerBatch operation

The invention discloses an automatic oil immersion method and apparatus for a transformer. The automatic oil immersion apparatus comprises a first material-taking mechanical arm, a second material-taking mechanical arm, a third material-taking mechanical arm, a fourth material-taking mechanical arm, a fifth material-taking mechanical arm, a first conveying unit, a second conveying unit, a third conveying unit, an oil immersion machine, a turning mechanical arm, a tunnel type oven and the like. The automatic oil immersion apparatus arranges the transformer and carries jigs through the first material-taking mechanical arm, the second material-taking mechanical arm, the third material-taking mechanical arm, the fourth material-taking mechanical arm and the fifth material-taking mechanical arm; the join of the jigs in each station is realized through the first conveying unit and the second conveying unit; an automatic oil immersion process for the transformer is realized through the oil immersion machine; and the process for baking the transformer is realized through a fifth conveying unit finally; the automatic batch operation, such as automatic oil immersion, automatic baking and the like, for the transformer can be implemented through the automatic oil immersion apparatus; and meanwhile, a manual operation is avoided, so that workers can be prevented from being hurt by chemicals in the oil immersion machine.

Owner:SUIZHOU RUISHUO ELECTRONIC CO LTD

Oil-immersion enhanced imaging flow cytometer

ActiveUS7796256B2Easy to collectEnhance excitationRadiation pyrometryNanoparticle analysisHigh numerical apertureFluorescence

A flow chamber, imaging objective, condenser and imaging light source as part of an optical system includes an oil-immersion objective and high numerical aperture condenser matched to a rectangular flow chamber. The oil-immersion objective and flow chamber include a high index of refraction immersion oil so as to enhance the optical resolution and optical coupling therethrough. The imaging light source generates light which passes through the condenser, the flow chamber and then the objective before being focused onto an imaging camera. Fluorescence excitation passes through the objective to the flow chamber where the oil immersion configuration enhances the focus and collection of the light back through the objective.

Owner:YOKOGAWA FLUID IMAGING TECH INC

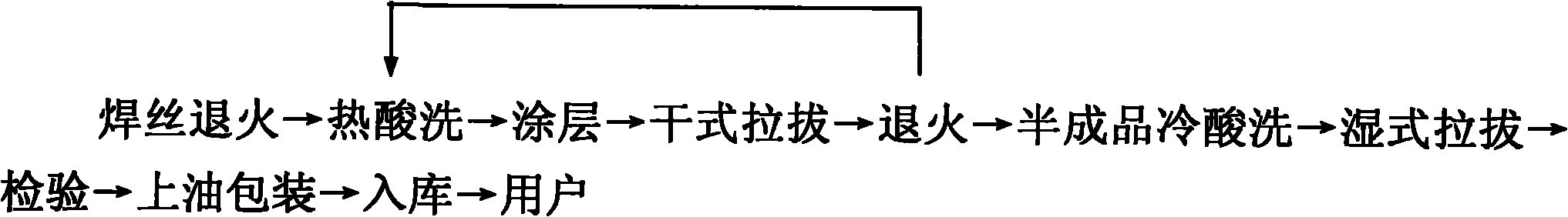

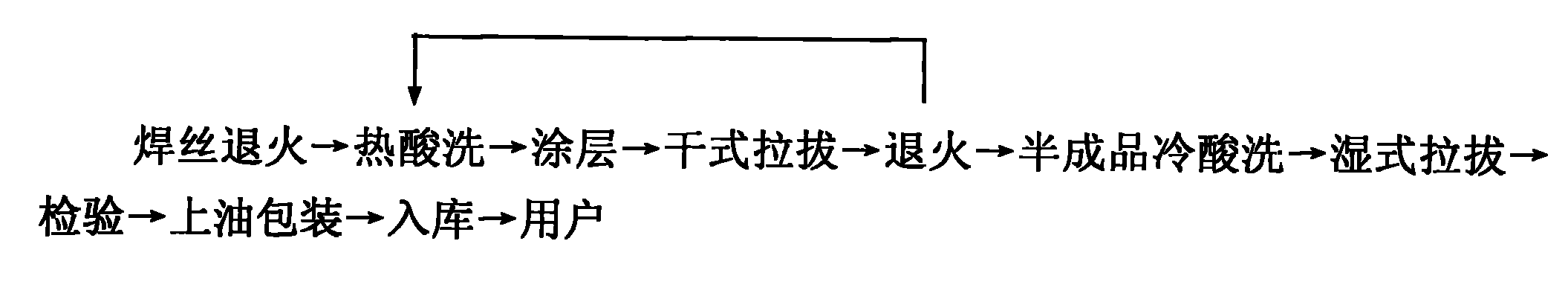

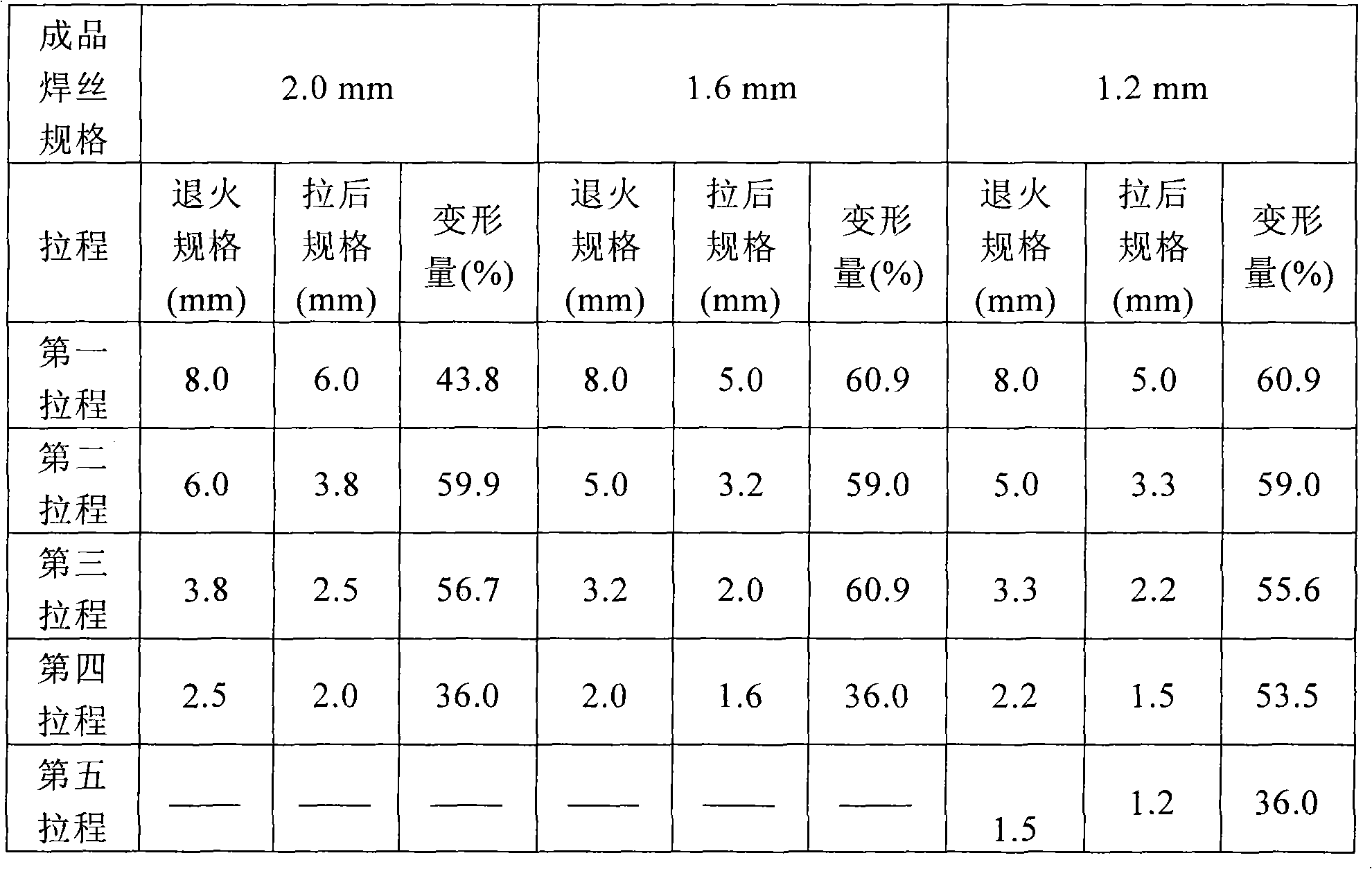

Antirust method for cold drawing production of high-strength alloy welding wire

InactiveCN102166693AVolatileKeep it brightWelding/cutting media/materialsSoldering mediaVacuum packWork in process

The invention discloses an antirust method for cold drawing production of a high-strength alloy welding wire, which comprises the following steps of: a) annealing the welding wire; b) thermally pickling; c) coating; d) performing dry drawing; e) performing cold pickling process and oil immersion operation on a semi-finished welding wire; and f) performing wet drawing on a finished welding wire. The processing method mainly solves the problem of low antirust performance in the cold drawing production process of the high-strength alloy welding wire, a bright welding wire is produced by a novel method for annealing and cooling segmentally, performing cold acid pickling, oiling and performing wet drawing, the original protective atmosphere annealing and vacuum packaging production mode is replaced, and the problem that the high-strength alloy welding wire is easy to rust is solved. The product meets the requirement on technical conditions of the high-strength bright alloy welding wire, and the specification of the product is that the high-strength bright alloy welding wire has the size phi of 1.2 to 2.0mm.

Owner:宝钢特钢有限公司

Metal surface salt bath nitrocarburizing method

ActiveCN102899604AReduce contentImprove regenerative abilitySolid state diffusion coatingCyanideNitrogen

The invention discloses a metal surface salt bath nitrocarburizing method which comprises the following steps: (1) workpiece cleaning; (2) workpiece clamping; (3) workpiece preheating; (4) nitrocarburizing: transferring the workpieces preheated by the step (3) into a salt bath furnace, immersing the workpieces in the salt bath, and keeping the workpieces in the 535-585 DEG C salt bath for 30-180 minutes to complete nitrocarburizing, wherein when starting from the treatment of the first batch of workpieces to be nitrocarburized, taking salt samples from the salt bath furnace every 12-24 hours, determining the concentrations of cyanides and cyanates in the salt bath, and adding sulfur-containing compounds for lowering the cyanide content and regenerated salt into the salt bath furnace when the mass percent of the cyanides in the salt bath exceeds 3 wt%; and after completing the nitrocarburizing, cooling the workpieces, cleaning, drying, and carrying out oil immersion. According to the metal surface salt bath nitrocarburizing method disclosed by the invention, the sulfur-containing compounds are added into the salt bath composition in the nitrocarburizing process to lower the content of cyanides and enhance the regeneration capacity of the regenerated salt.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

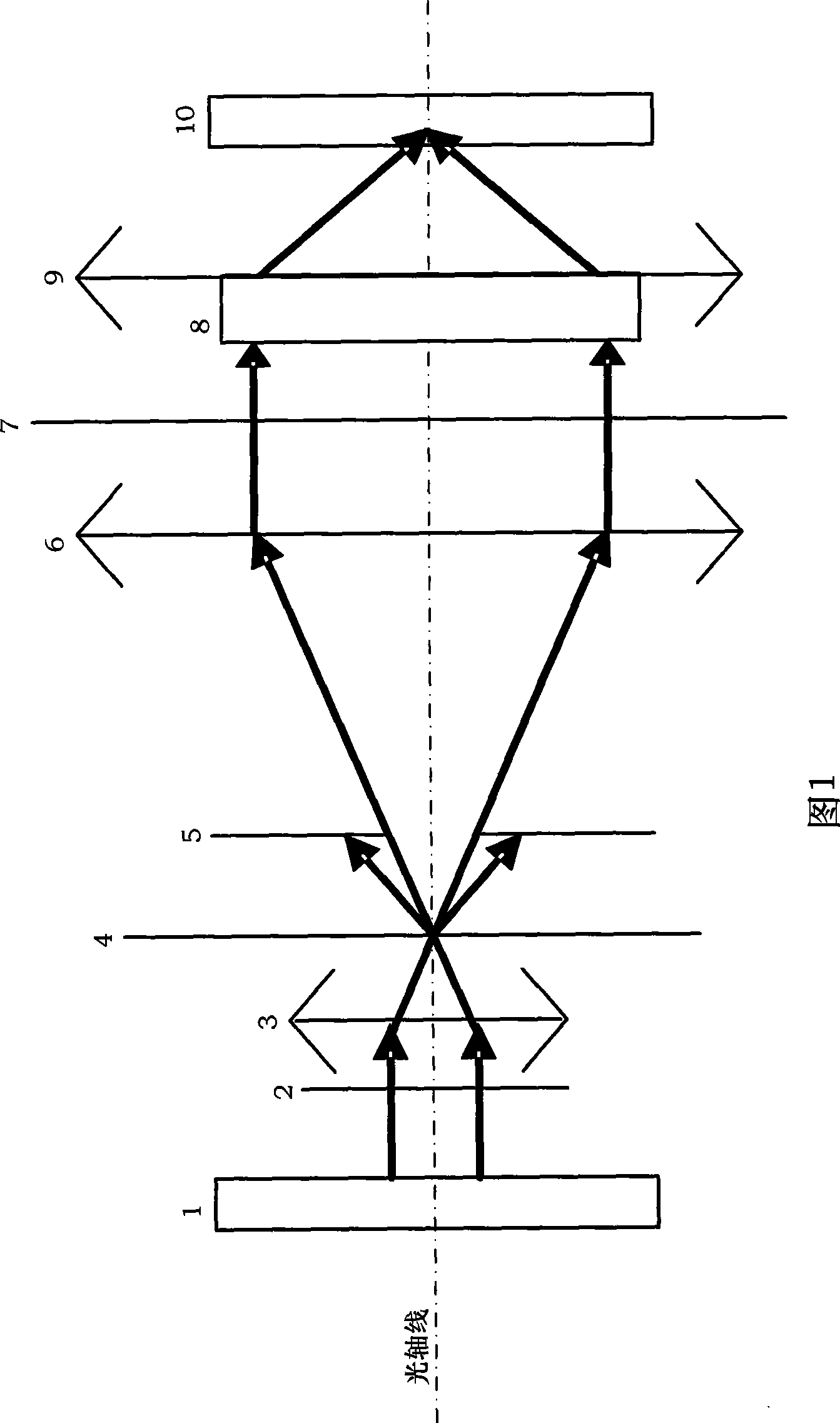

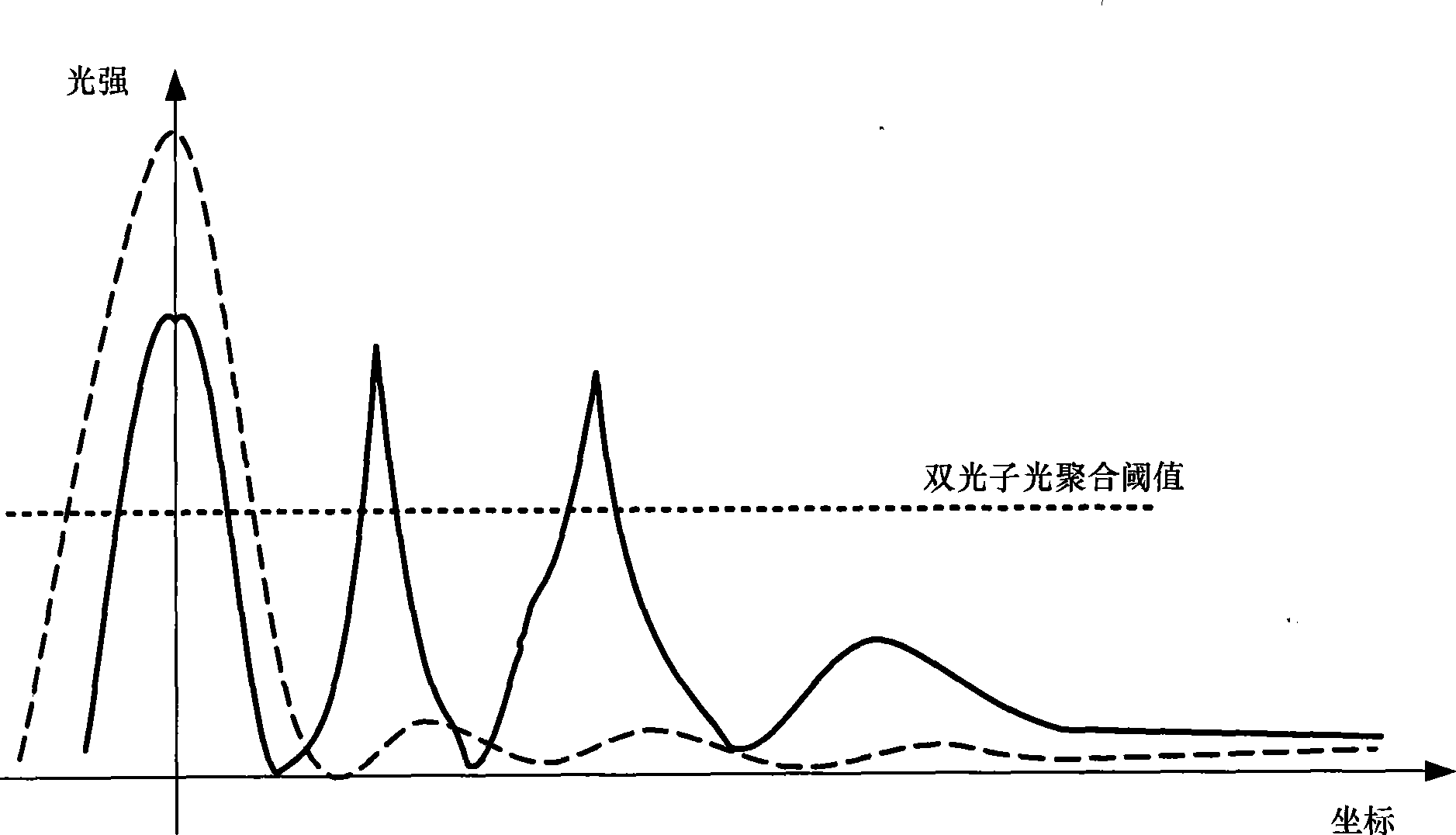

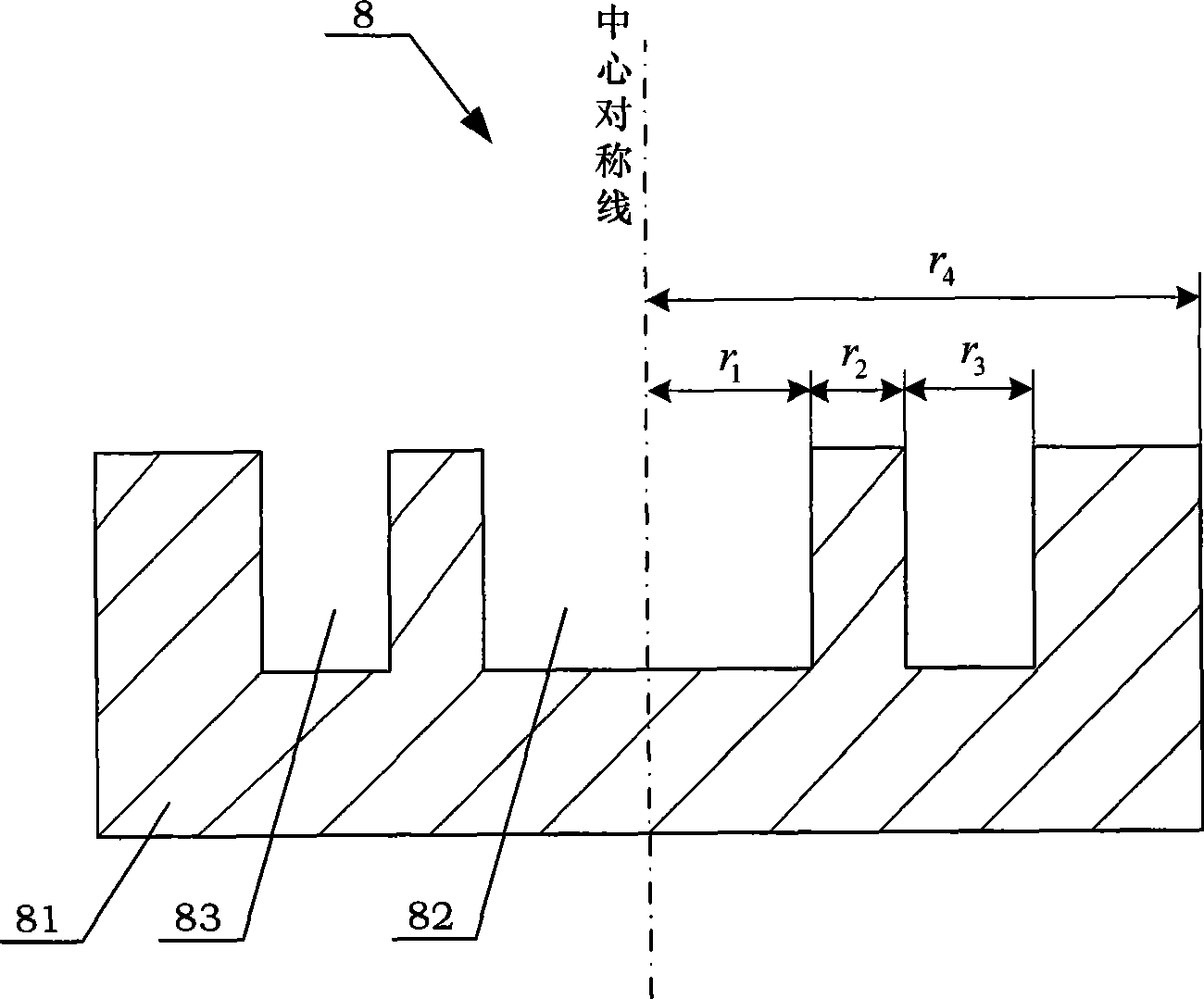

Light path structure suitable for femtosecond laser two-photon mirco-nano processing system

InactiveCN101458451AHas the effect of filtering clutterLight intensity sharpeningPhotomechanical apparatusNon-linear opticsMicro nanoProcess systems

The invention discloses a light path structure suitable for a femto-second laser two-photon micro-nano processing system. The light path structure consists of a femto-second two-photon laser, a light gradient attenuator, a filtering convex lens, a pinhole filter, an intercepting diaphragm, a collimating lens, an aperture diaphragm, a super resolution diffractometer and an oil immersion objective. The light gradient attenuator, the filtering convex lens, the pinhole filter, the intercepting diaphragm, the collimating lens, the aperture diaphragm, the super resolution diffractometer and the oil immersion objective are arranged between the femto-second two-photon laser and photosensitive resin in sequence by using an optical axes as the center. The super resolution diffractometer is arranged on the oil immersion objective. The light path structure changes power distribution of femto-second laser in a focus local area by the super resolution diffractometer, so that the light intensity of a side lobe is larger than a two-photon converged power threshold value, thus achieving multi-point processing in two-photon micro-nano processing.

Owner:BEIHANG UNIV

Side sealing plate for thin-belt continuous casting and manufacturing method

The invention relates to a side sealing plate for a thin-belt continuous casting system. The side sealing plate is characterized by comprising the components in percentage by weight: 10-50% of boron nitride, 5-35% of zirconium boride, 5-25% of zirconium oxide, 1-15% of boron powder, 1-10% of graphite and 0.1-5% of carbon fiber. As the fabricate particles are firstly adopted in the side sealing plate, then the techniques such as high-temperature sintering and oil immersion and the like are adopted in the common sizing flame-resistant material technique, the porosity and the density of a product are obviously improved, and boron carbide (extremely hard substance) is formed in high-temperature sintering, so that the strength is further improved.

Owner:上海柯瑞冶金炉料有限公司

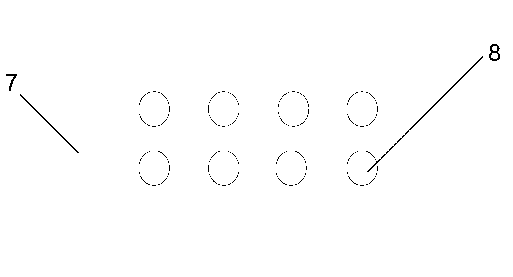

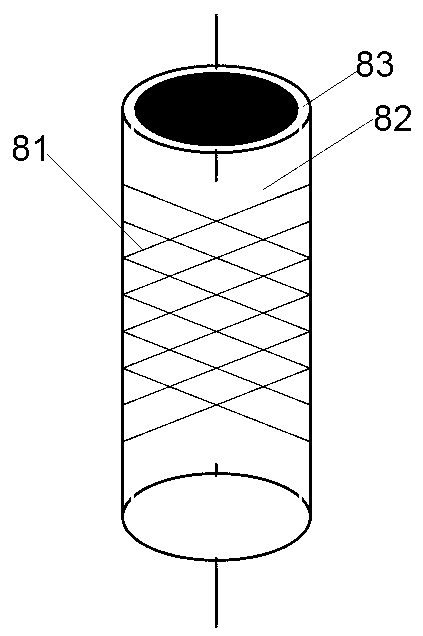

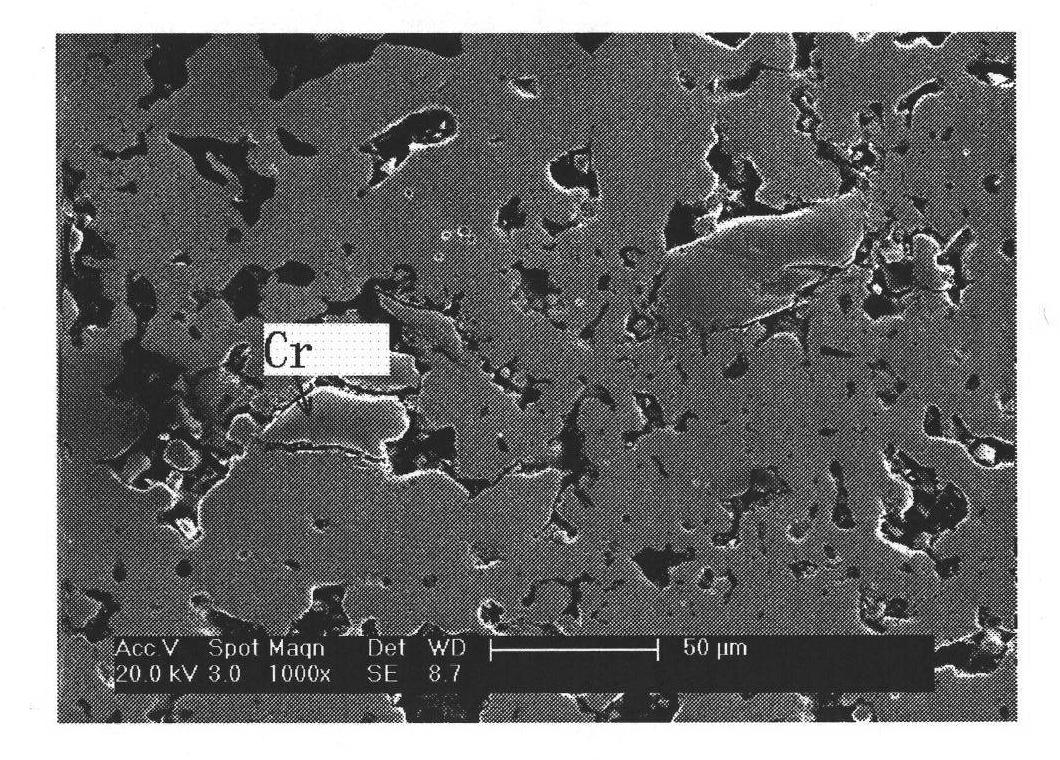

Oil impregnated bearing of powder metallurgy with ultra-long service life and manufacturing method thereof

The invention discloses an oil impregnated bearing of powder metallurgy with an ultra-long service life and a manufacturing method thereof. The bearing comprises the components by weight percent: 7% to 11% of Sn, 0.2% to 1.0% of P, 2% to 6% of Cr, 2% to 6% of MoS2, the balance of Cu and unavoidable impurities. The bearing is prepared by the following method of treating the powder of the components by mixing, low-temperature diffusion, pressing formation, sintering, shaping and oil immersion into the bearing according to a certain proportion. In the bearing, MoS2 powder is added to be used as a solid lubricant, and phosphorus is used as a hardening agent for a Cu-Sn base body, which ensures that Cu-Sn alloy is distributed at a low-temperature state to be more easily combined and the alloy is distributed more evenly by the treatment of mixing and low-temperature diffusion; meanwhile, the phosphorus is beneficial to grain refinement of the alloy; the surface of a sintering body has spongy fine through holes with the porosity communication rate reaching more than 95%; the friction of the inner diameter surface of the bearing is reduced during operation; the sliding noise is low; Cr is added to enhance the strength of the base body; therefore, the wearing resistance is enhanced in the operation of the bearing and the service life can exceed 30,000 hours.

Owner:JIANGSU YINGQIU GRP CO LTD

Sequence continuous casted AL2O3-SiO2-C metal composite sliding plate

The invention discloses a sequence continuous casted AL2O3-SiO2-C metal composite sliding plate, and helps to solve problems that steel ladle is recycled rapidly, the sliding plate is used continuously and sequence continuous casting is employed. Characteristics of the metal composite sliding plate are that: aluminum compounds such as tabular corundum, top alumina, metallic silicon and metallic aluminium powder are taken as main materials, asphalt and silicon carbide are added, and phenolic resins is taken as a binder; the ingredients are prepared, mixed, shaped under high pressure, roasted at a temperature of 1300 to 1500 DEG C in reductive atmosphere, and subjected to oil immersion and carbonization treatment; a working surface is polished; the sliding plate is hooped with steel bands; and mineral wool boards and tinplate are adhered to a non-working surface. The sliding plate possesses high flatness, erosion wear resistance, physical wear strength and thermal shock resistance, and does not adhere to steel or lag, and is suitable for alloying and pure steel smelting.

Owner:YANGQUAN DONGFENG REFRACTORY MATERIAL CO LTD

Optical microscope and method for removing cedar oil on glass slide

InactiveCN101658848AEffective dissolutionEffective wipingFlexible article cleaningMicroscopesCamera lensAcetic acid

The invention discloses a method for cleaning away cedar oil after an optical microscope uses an oil immersion lens. In the method, components including organic solvents such as absolute ethanol, ethyl acetate and propylene glycol are used; the absolute ethanol, the ethyl acetate and the propylene glycol are uniformly mixed at normal temperature in a ratio of 1:1:1; and the mixed liquid is drippedon to lens cleaning paper which is then used to clean the objective lens or a glass slide of the microscope to completely dissolve the cedar oil to clean the cedar oil. The solution is volatile and can avoid residues after use.

Owner:阎树昕

Preparing method of recombined bamboo sectional bar

ActiveCN105171888AImprove work efficiencyAvoid duplicationWood treatment detailsFlat articlesOil immersionCorrosion

The invention discloses a preparing method of a recombined bamboo sectional bar. The preparing method comprises the steps such as sizing treatment, drying, cold pressing, oil immersion processing and automatic oil sucking. The preparing method has the beneficial effects that the work efficiency is high, the equipment input is less, and the processing effect is even. The prepared recombined bamboo sectional bar is good in mechanical performance, size stability, corrosion resistance and mould resistance.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

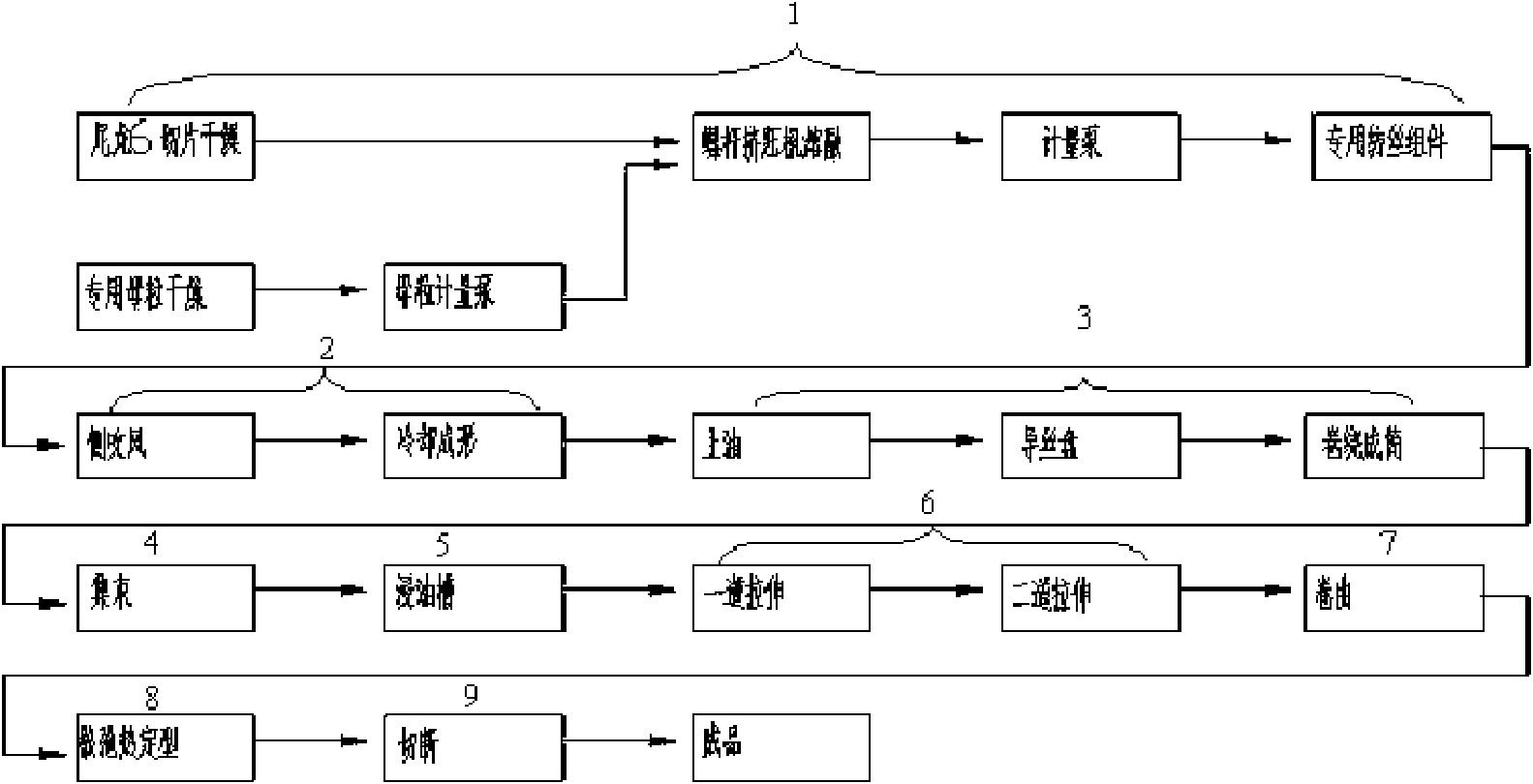

Ultra-fine denier nylon stable fiber production method

ActiveCN101671856ASimple processLow costFilament manufactureSevering to form staple fibresPulp and paper industryUltra fine

The invention relates to an ultra-fine denier nylon stable fiber production method which solves technical problems that a conventional spinning device can produce ultra-fine denier nylon, the spun ultra-fine nylon has stable performance and is easily dyed, and the production cost is substantially reduced. The production method comprises the following steps: (1) spinning, on a double-screw melt-spinning device, master batches are added and mixed with nylon slices to lead that the content of the master batches is 1-10%, the melt mixture fusant is extruded into a spinning pack by a screw, filtered by sea sand and squeezed out by a spinneret orifice to form silk flock, wherein the diameter of the spinneret orifice is 0.15-0.35mm and the length-diameter is 2-4; the pressure of the screw is 80-100kg / cm<2>; sea sand is 60 meshes, 80 meshes or 100 meshes; and a filter screen is 250 meshes or 400 meshes; (2) cooling; (3) oiling and winding; (4) bundling; (5) oil immersion; (6) drawing; (7) curling; (8) loosing and heat shaping; (9) cutting, obtaining the product.

Owner:南通久润网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com