Production technical process of zinc-steel guardrails

A production process and production process technology, applied in the field of production process of zinc steel guardrail, can solve the problems of coating peeling, powder falling, acid and alkali resistance, corrosion resistance and oxidation resistance, low self-cleaning performance of ultraviolet surface, etc. Achieve the effect of improving acid resistance and high impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

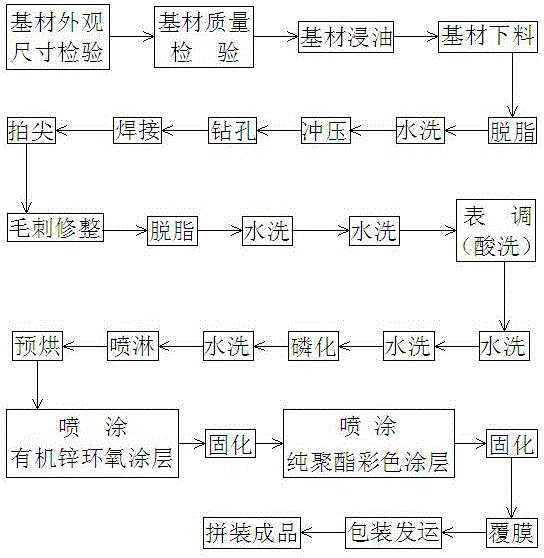

[0040] Such as figure 1 Shown: the present invention discloses a production process of zinc steel guardrail, and its production process is:

[0041] (1) Inspection of the appearance and size of the base material, the appearance of the base material has no obvious rust, and the error of the base material thickness is ±0.2mm;

[0042](2) Substrate quality inspection, including: galvanized layer uniformity inspection, galvanized layer thickness inspection and galvanized layer adhesion inspection, among which the galvanized layer uniformity inspection refers to the use of copper sulfate solution for 4 dips in accordance with GB2694. The red spot of metal copper adhesion is qualified; the thickness inspection of galvanized layer refers to taking a sample section and weighing it by antimony chloride dezincificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com