Patents

Literature

56 results about "Gold processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold processing, preparation of the ore for use in various products. For thousands of years the word gold has connoted something of beauty or value.

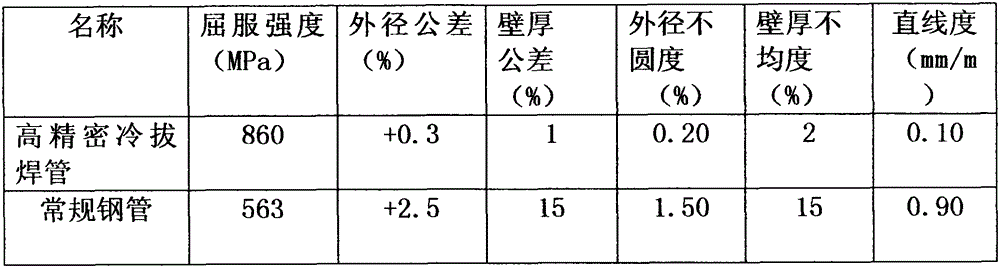

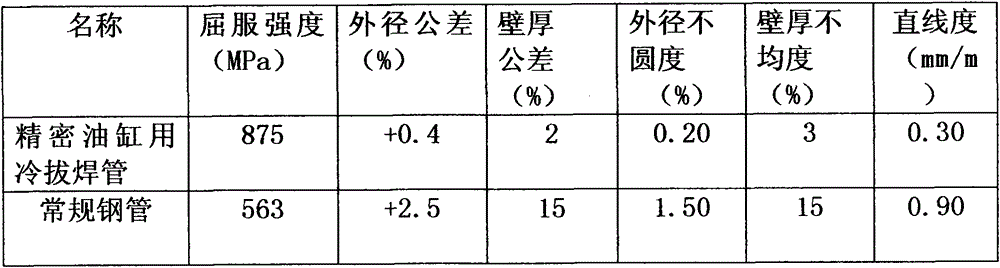

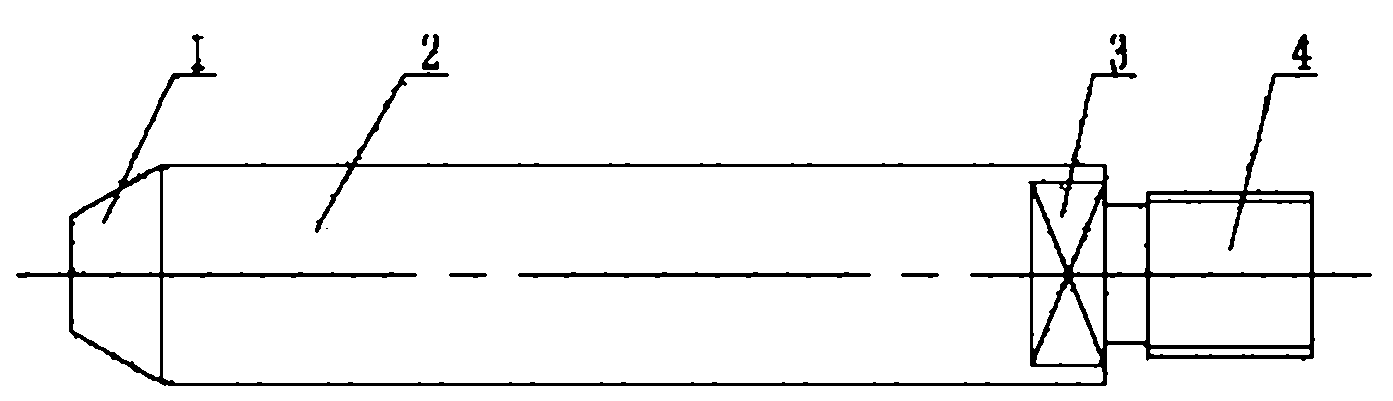

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

InactiveCN102527767AReduce processing difficultyImprove deburring speedEngineeringEddy-current testing

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

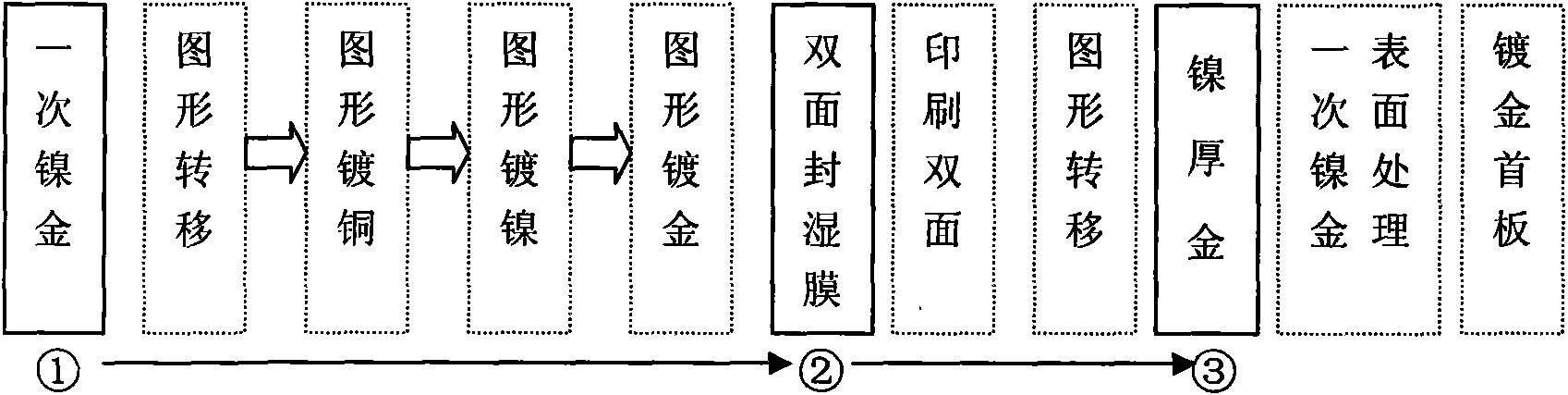

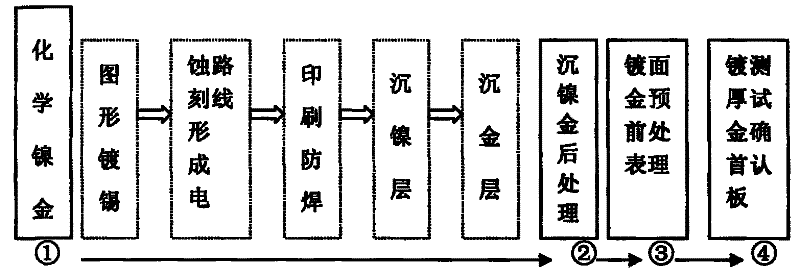

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427ANo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

Manufacturing method for high-precision cold-drawing welded pipe

The invention relates to a manufacturing method for high-precision cold-drawing welded pipe. The manufacturing method for the high-precision cold-drawing welded pipe includes steps of longitudinal shearing, roll-bending forming, high-frequency welding, weld joint treatment, sizing, online eddy current inspection, pre-straightening treatment, pipe cutting, stress relief annealing, pinching, acid dipping, phosphating, saponification treatment, cold drawing, induction furnace quenching treatment, tempering treatment in a box type furnace, straightening treatment, honing, magnetic leakage detection and pipe cutting measurement. The product obtained through the manufacturing method for the high-precision cold-drawing welded pipe is high in yield strength, high in tensile strength, precise in size, smooth in surface, fast in processing forming speed and high in yield, the manufacturing precision is obviously improved, the cold-drawn welded pipe is good in surface smoothness and low in roughness, the subsequent gold processing amount is reduced, the steel material use ratio is improved, the manufacturing cost is lowered, and the energy conservation and environment protection are boosted.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

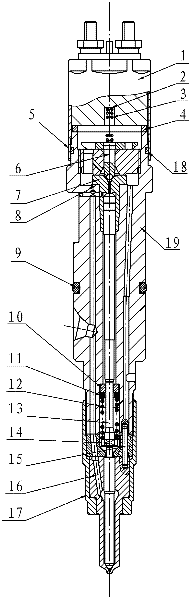

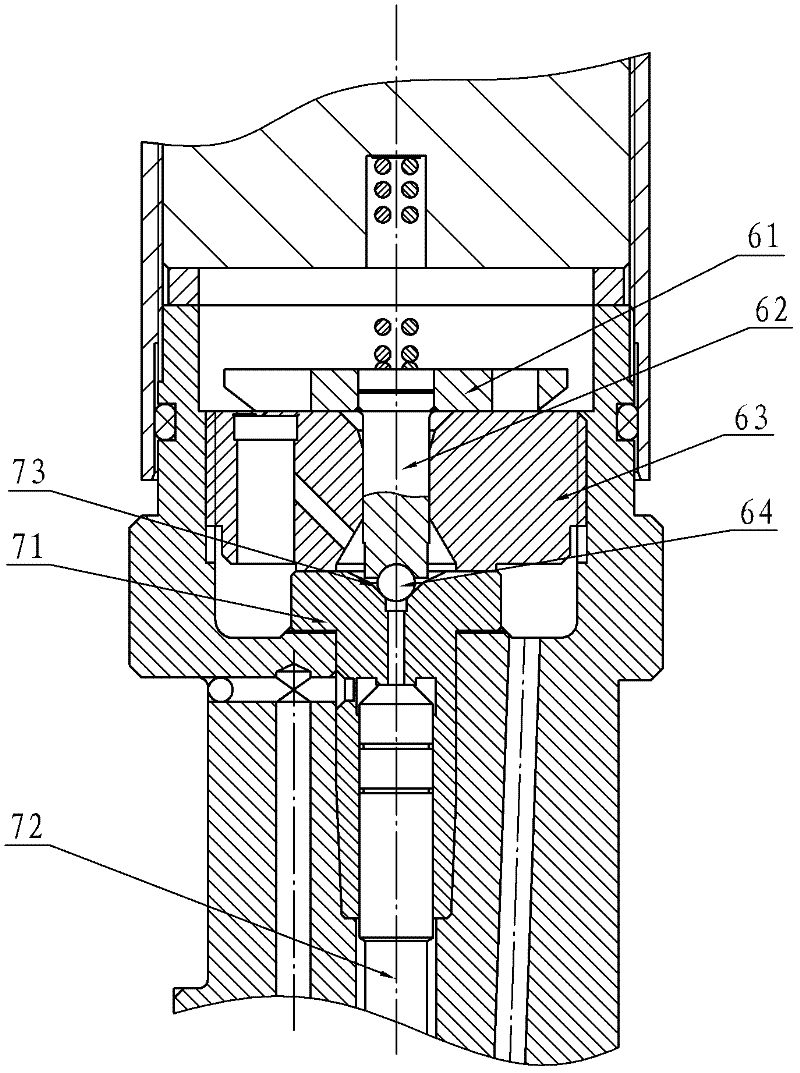

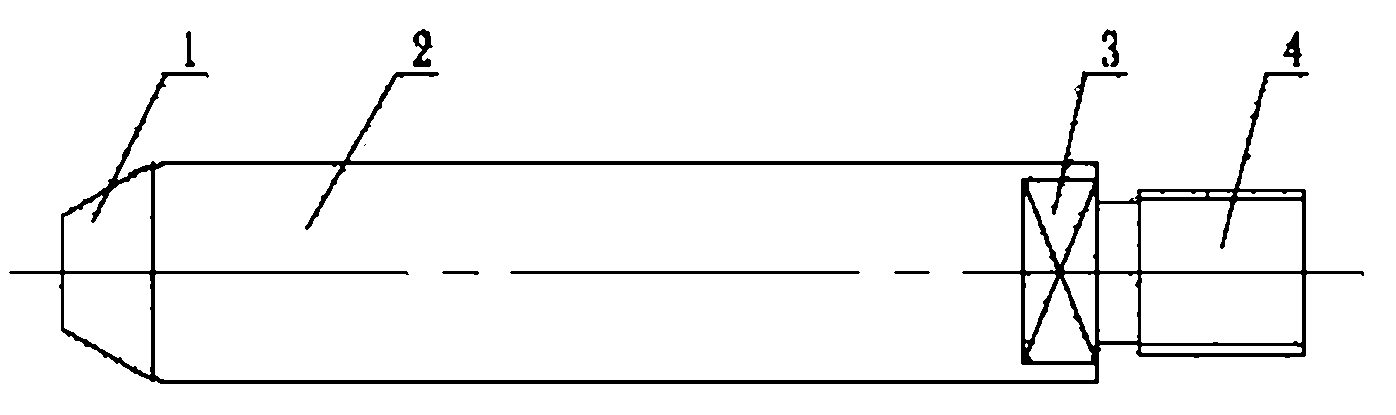

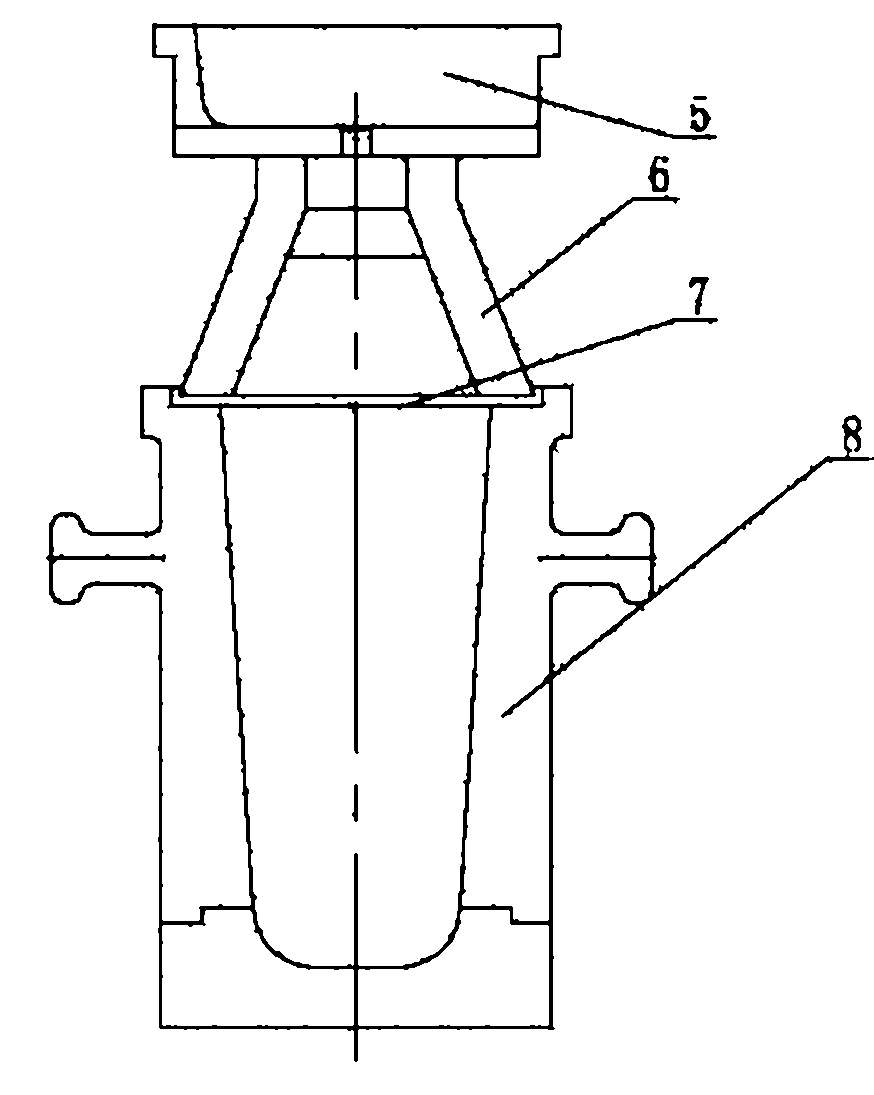

Plane opening and closing type diesel engine high-pressure common rail oil sprayer

ActiveCN102230435AMeet the high-frequency opening and closing sealing requirementsQuick releaseFuel injection apparatusMachines/enginesCommon railSurface roughness

The invention relates to a plane opening and closing type diesel engine high-pressure common rail oil sprayer. A seal ball in a control valve coupler is a plane seal ball; an annular seal plane, a throttling pit, a throttling hole and a rapid pressure relief structure are arranged on the upper end of a guide valve seat; the diameter of the seal plane of the plane seal ball is equivalent to the outer diameter of the annular seal plane; and the hardness, planeness and surface roughness of the seal plane and the annular seal plane reach the design requirement. Because a seal steel ball in the control valve coupler is changed into the plane seal ball with a seal plane, the seal form of the throttling taper hole on the upper end surface of the guide valve seat is changed into plane seal, and the rapid pressure relief structure is added, the invention ensures that high-frequency opening and closing seal performance is high and the machining process of a sealing element is greatly enhanced, can be finished through adopting the conventional gold processing and heat treatment, has high processing efficiency and stable and reliable seal performance and rapid pressure relief performance, and is an improvement of the traditional products of the Germany Bosch company.

Owner:常州博瑞油泵油嘴有限公司

Novel process for making piston ring

InactiveCN1632297AHigh surface hardnessReduce coefficient of frictionPiston ringsMachines/enginesPiston ringHigh energy laser beam

The new processing technology of piston ring involves the processing technology of piston ring. It includes the following process steps: casting→grinding→heat treatment→grinding→gold processing→laser strengthening treatment→heat setting→gold processing. Since the surface layer of the piston ring is processed by laser alloying or laser cladding, and is rapidly melted by a high-energy laser beam, the matrix at a certain depth on the outer surface of the piston ring is rapidly melted and then solidified to form a specific ceramic particle reinforced composite coating. The coating and the piston ring body are metallurgical structures, which will not fall off or peel off under the action of external force. The invention is easy for industrial production, has excellent anti-adhesive wear and anti-abrasive wear capabilities, and has good product technical stability.

Owner:江苏仪征威龙活塞环有限公司 +1

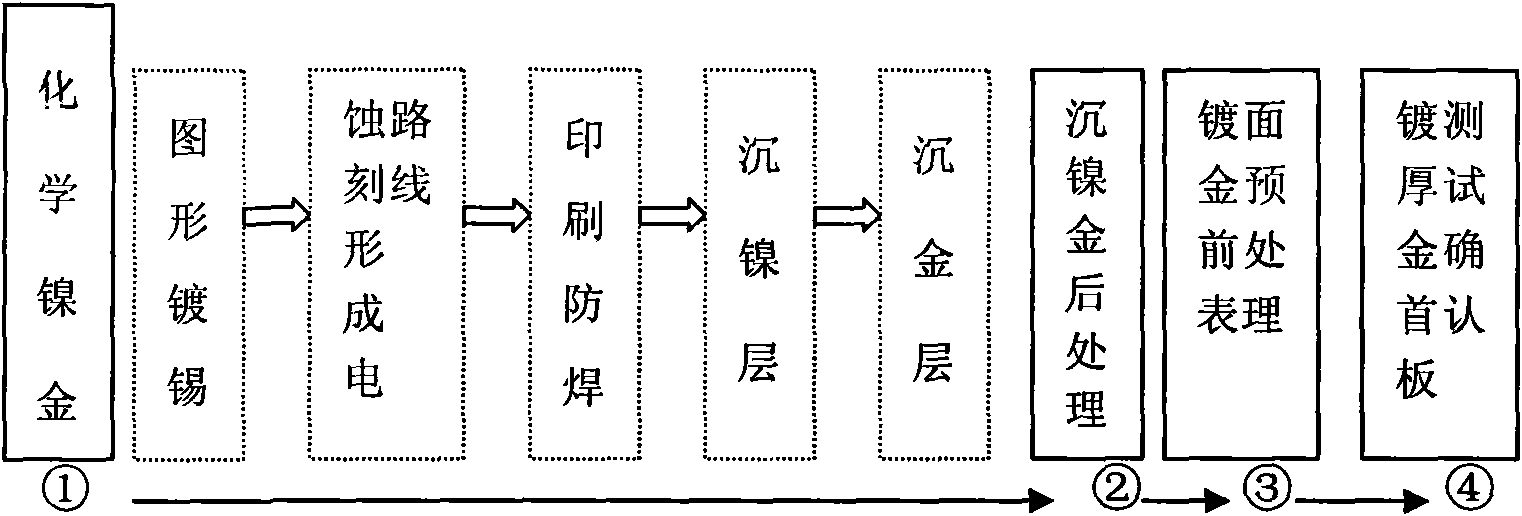

Method for preparing immersion gold printed circuit board

InactiveCN103763869AThe method is simple and controllableReduce stepsPrinted element electric connection formationPrinting inkEngineering

The invention discloses a method for preparing an immersion gold printed circuit board. The method includes the steps that an outer layer circuit diagram is provided and manufactured, and a PCB with plug holes and an aluminum sheet with guide holes are prepared, wherein the aluminum sheet is used for plugging printing ink into drill holes of the PCB through the aluminum sheet guide holes corresponding to the drill holes in the PCB; the printing ink is plugged into the drill holes of the PCB through the aluminum sheet; solder resisting is conducted on the PCB with the drill holes into which printing ink is plugged; exposure is conducted on the PCB, wherein in the exposure process, Favrini negative films are utilized to block light for the faces of the drill holes in which semi-plug holes need to be formed; the PCB on which exposure is conducted is developed, wherein in the developing process, printing ink of 20% to 80% of the depth of the drill holes is rinsed out through developing potions; immersion gold processing is conducted on the developed PCB. The method for preparing the semi-plug holes of the immersion gold board is easy to control, operation steps and production materials are reduced, production cost is greatly saved, and production efficiency can be rapidly improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

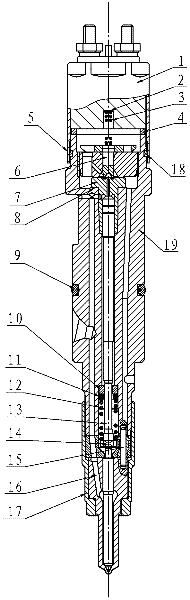

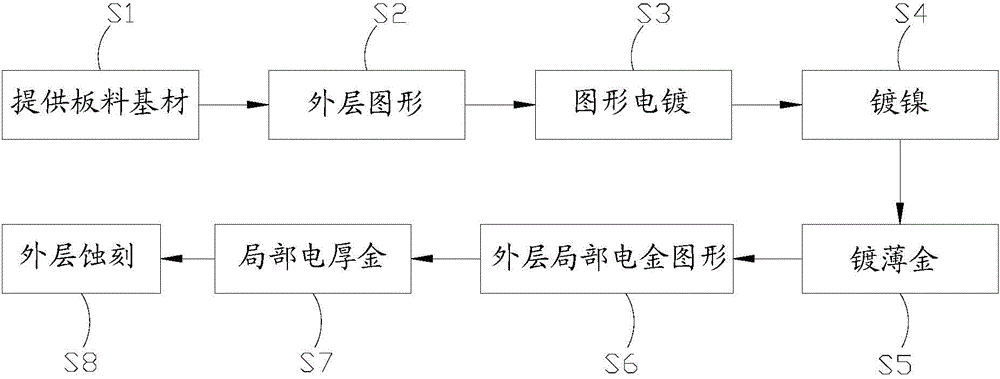

Printed circuit board and processing method thereof

InactiveCN104812171AEasy to remove filmShorten the processing cycleConductive pattern reinforcementCopper foilPattern processing

The invention is applied to the technical field of a printed circuit board, and provides a processing method of a printed circuit board and a printed circuit board formed by use of the processing method, for the purpose of solving the problems that since local electroplating thick gold processing is carried out after external-layer etching processing, a local electroplating thick gold position cannot be conductive and lead wires cannot be added to a part of the printed circuit board in the prior art. The processing method of the printed circuit board comprises the following step of providing a plate substrate, an external-layer pattern, pattern electroplating, nickel plating, thin gold plating, external-layer local electroplating gold pattern processing, the local electroplating thick gold processing and external-layer etching. According to the processing method, before the external-layer etching processing, the external-layer local electroplating gold pattern processing and the local electroplating thick gold processing are carried out, so that conductive lead wires are additionally arranged on an external-layer line pattern, the whole copper foil layer of the plate substrate can be conductive, the membrane removing operation is simple, the manufacturing efficiency is improved, and the processing period is shortened.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

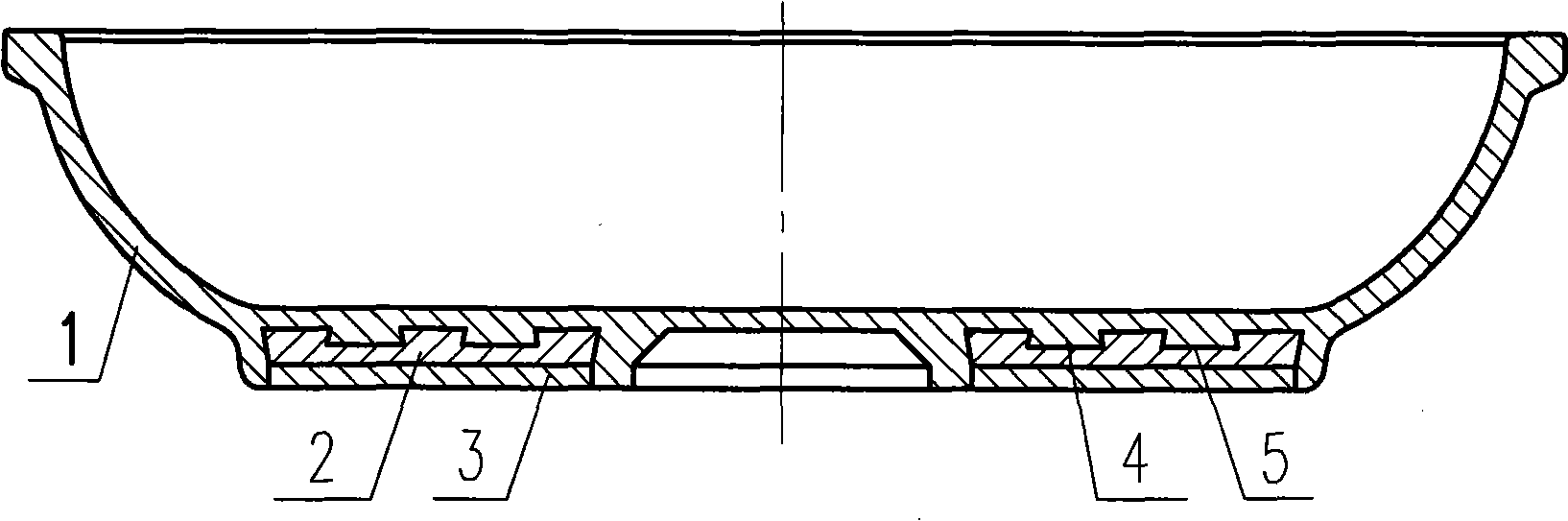

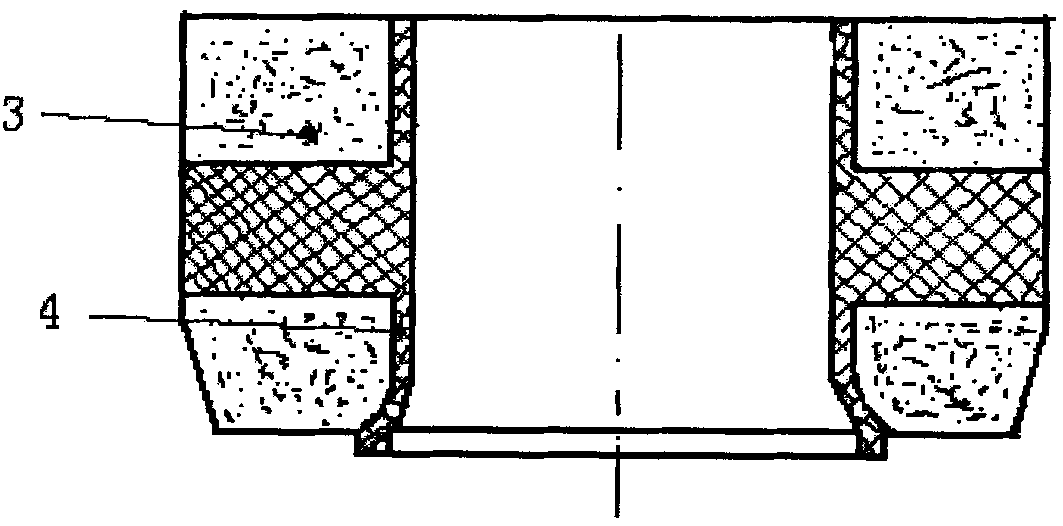

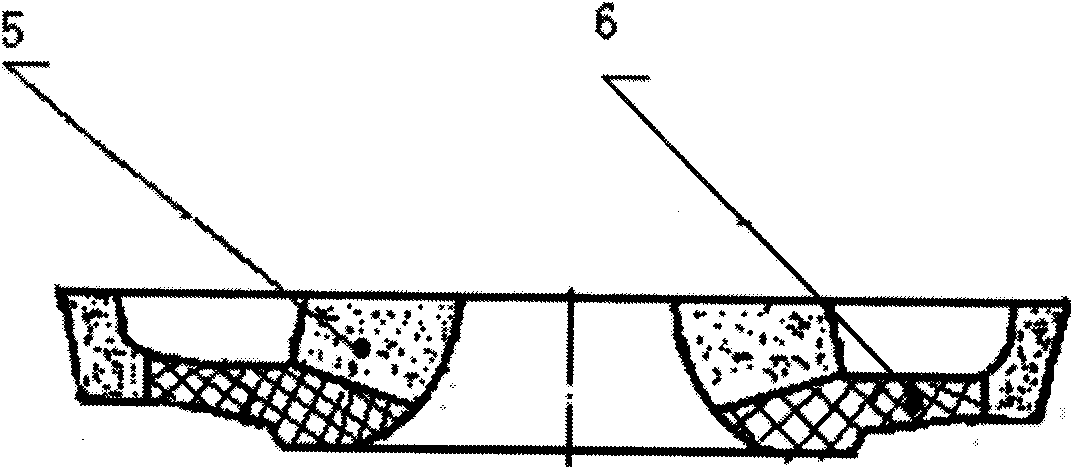

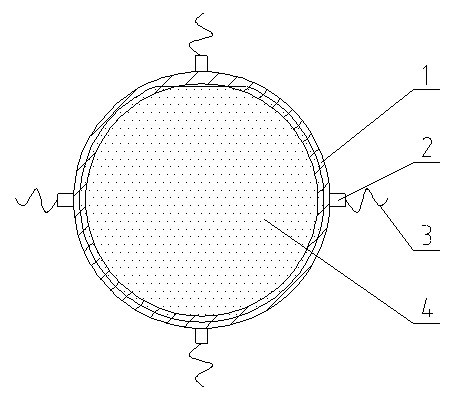

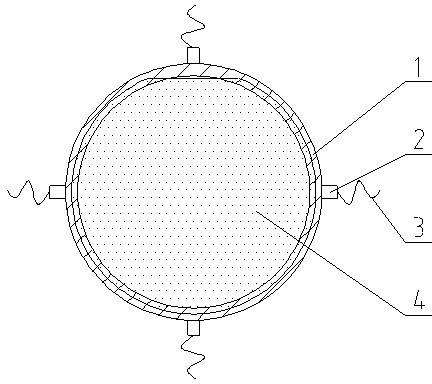

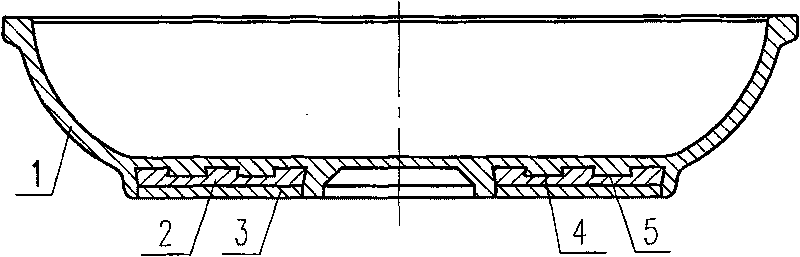

Stitching type compression casting composite bottom boiler and manufacture technique thereof

ActiveCN101357036AHigh thermal fatigue stabilitySimple structureCooking vesselsHeat resistanceDie casting

The invention relates to a fit-typed die-casting composite bottom pan, comprising an aluminium alloy pan body and a composite bottom sheet which is fit at the bottom of the pan body; the fit-typed die-casting composite bottom pan is characterized in that the pan is formed by the rolling and composing of a composite material sheet and a stainless steel sheet; the composite material sheet is provided with a plurality of circular concave troughs with internally inclined side wall; the bottom of the pan body is provided with a plurality of circular convex ribs which are embedded into the circular concave troughs; after being fit, the circular concave troughs and the circular convex ribs are rabbeted with each other; the composite material sheet is made of pure aluminium or aluminium alloy or material with the linear expansion coefficient approximate to the aluminium alloy. The invention also relates to a manufacture process used for the fit-typed die-casting composite bottom pan; the manufacture process of the invention is used for preparing the fit-typed die-casting composite bottom pan by the steps as follows: composite bottom sheet preparing, die casting of aluminium alloy pan body, flap edge removing of the pan body, gold processing, fitting, surface disposing, etc. The fit-typed die-casting composite bottom pan has the advantages of firm connection of the composite bottom sheet, high thermal efficiency, good heat-resistance fatigue performance, simple manufacture process, and the like, and is a cooker which is especially suitable for being used for induction cookers.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

Manufacturing method of cold drawn welded pipe for precision oil cylinder

The invention relates to a manufacturing method of a cold drawn welded pipe for a precision oil cylinder. The manufacturing method comprises the following steps: longitudinal shearing, rolling forming, high-frequency welding, tensioning, online eddy current inspection, stress relief annealing, normalizing air cooling treatment, pre-straightening treatment, pipe cutting, pinching, acid washing treatment, phosphating treatment, saponification treatment, cold drawing, induction furnace quenching treatment, tempering treatment in a box type furnace, straightening treatment, honing, magnetic leakage inspection and pipe cutting measurement. A product obtained by the method has the advantages of high yield strength, high tensile strength, precise size, smooth surface, high processing and forming speed, high yield, obviously improved manufacturing precision, good surface smoothness of the cold drawn welded pipe, low roughness, reduced subsequent gold processing, improved utilization rate of steel, reduced manufacturing cost and capability of promoting energy conservation and environmental protection.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

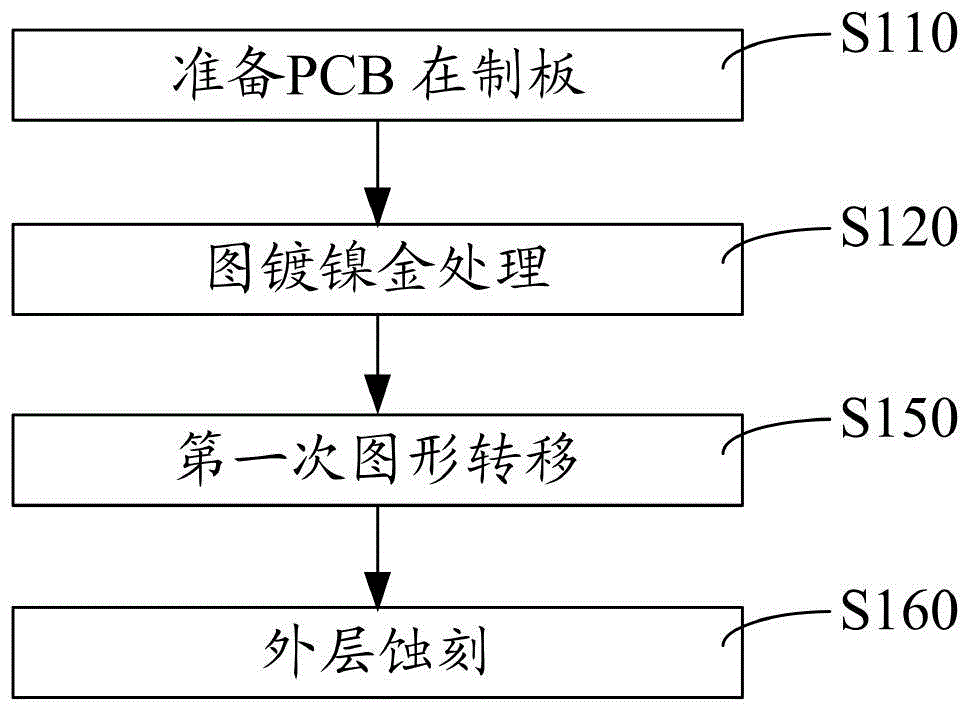

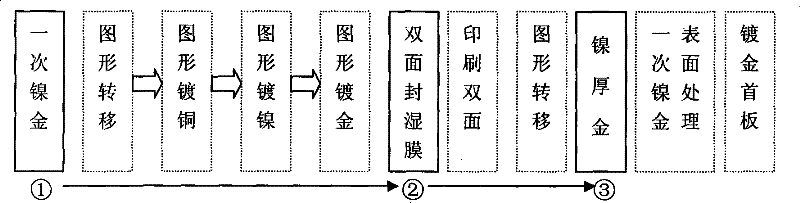

Printed circuit board and fabrication method thereof

ActiveCN105228359ANo defectSuspended Nickel SmallConductive material chemical/electrolytical removalConductive pattern reinforcementEtchingEngineering

The invention discloses a printed circuit board and a fabrication method thereof. The fabrication method of the printed circuit board includes following steps: preparing a PCB making plate; performing coating nickel-gold processing: electroplating a nickel layer and a gold layer in sequence in an area in need of electroplating nickel-gold patterns on the making plate of the PCB, and forming a nickel-gold cover head; performing the first pattern transfer: mounting a first external layer dry film on the making plate of the PCB after coating nickel-gold processing, and the outer edge width of the pattern area of the first external layer dry film being wider than the outer edge width of the nickel-gold cover head; and external layer etching: obtaining a whole line pattern via etching. The fabrication method of the printed circuit board is applicable to the whole line pattern, the suspension of nickel of a pad and the line can be prevented, or the nickel-suspension amount is small, and the problem of pad and line loss is improved. According to the printed circuit board, the suspension of nickel of the pad and the line can be prevented, or the nickel-suspension amount is small, pad and line loss is avoided, and the performance is stable and safe during usage.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

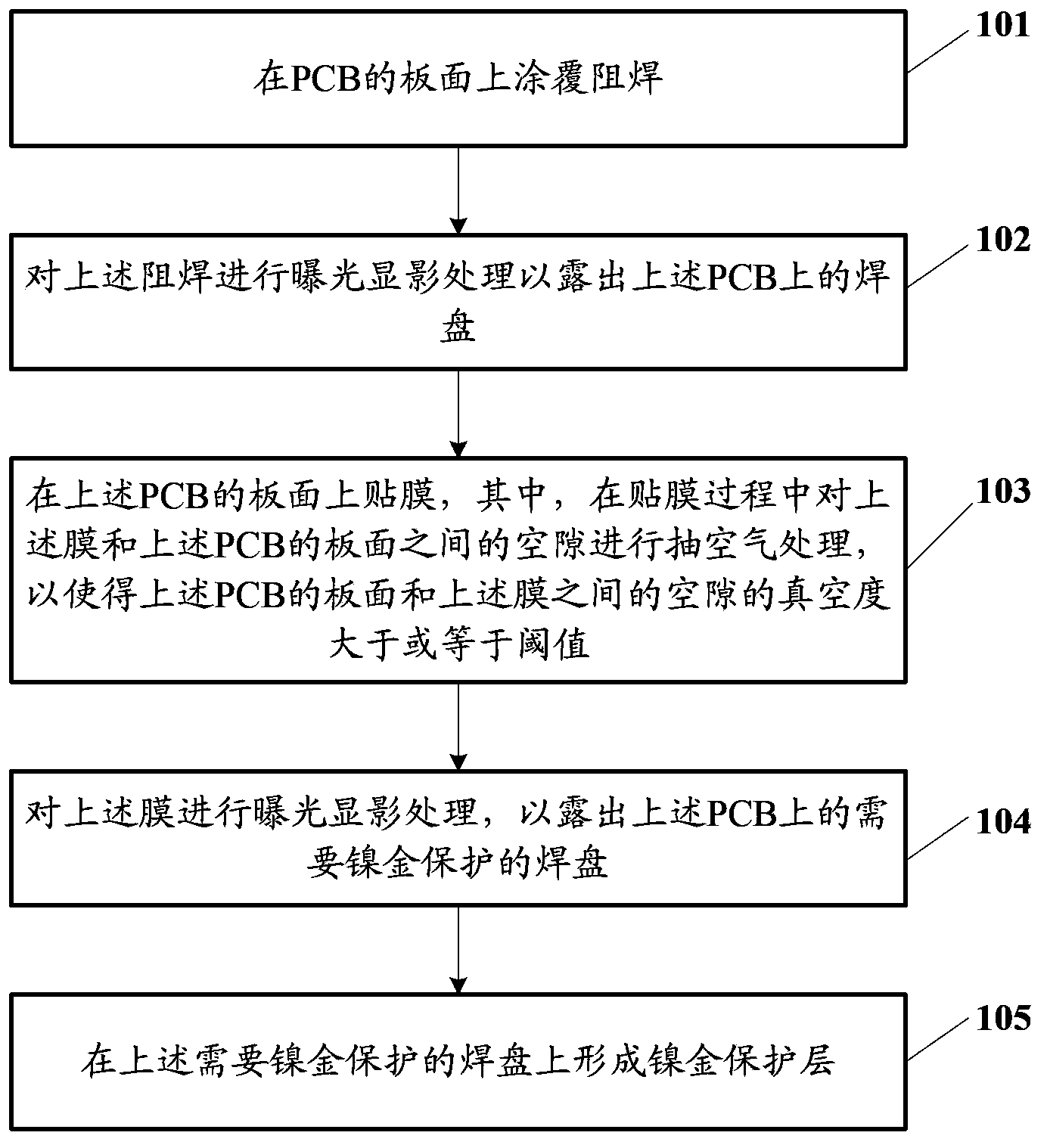

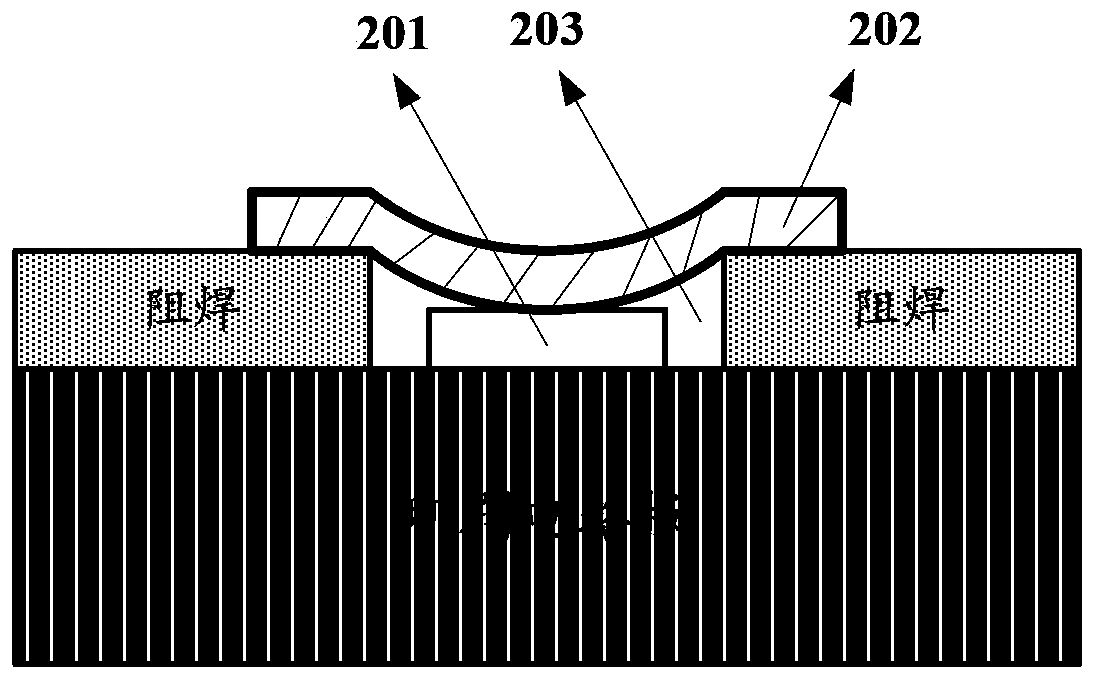

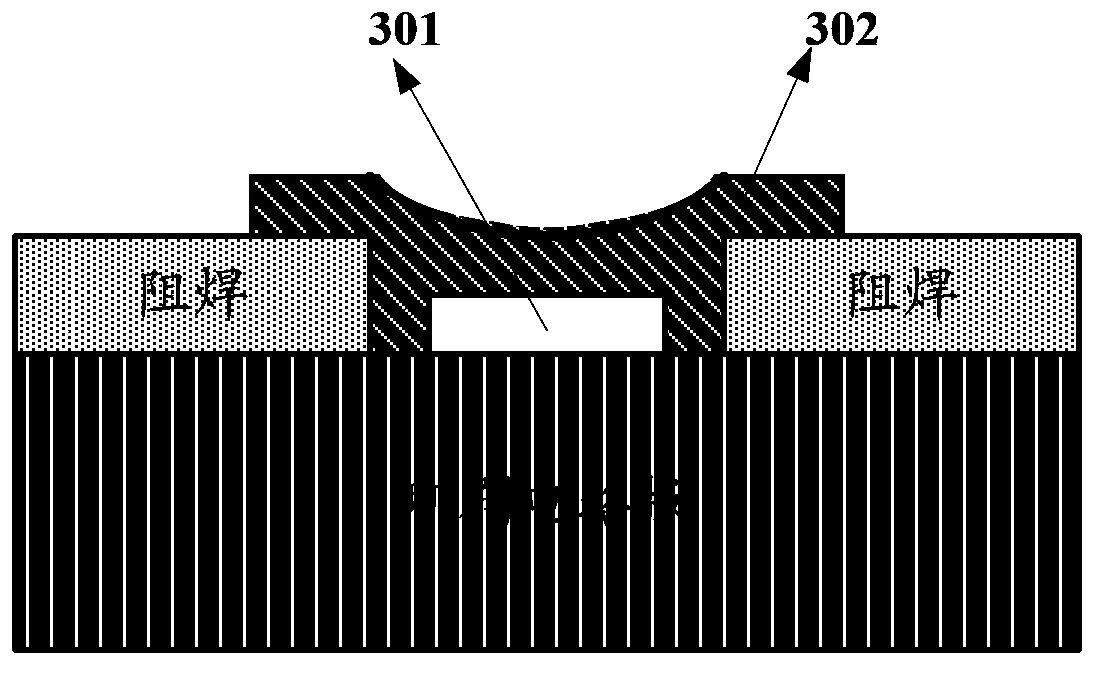

Nickel gold processing method for printed circuit board

InactiveCN103889160AReduce breakageImprove bindingConductive pattern reinforcementNon-metallic protective coating applicationProtection layerPrinted circuit board

The invention discloses a nickel gold processing method for a printed circuit board. The nickel gold processing method for the printed circuit board comprises steps that: a board surface of the printed circuit board is coated with resistance welding; exposure development treatment on the resistance welding is carried out to expose a welding disc on the printed circuit board; a film is pasted on the board surface of the printed circuit board, air extraction treatment on a gap between the film and the board surface of the printed circuit board is carried out in a film pasting process, so a vacuum degree of the gap between the film and the board surface of the printed circuit board is made to be greater than or equal to the threshold; exposure development treatment on the film is carried out to expose the welding disc needing nickel gold protection on the printed circuit board; a nickel gold protection layer is formed on the welding disc needing nickel gold protection. The nickel gold processing method facilitates to reduce break of a welding disc protection film and improves a product good rate.

Owner:SHENNAN CIRCUITS

Non-ceryl pattern material and manufacturing technology used for investment casting thereof

InactiveCN101879579AHigh strengthHigh hardnessFoundry moulding apparatusManufacturing technologyAluminum sulphate

The invention discloses a non-ceryl pattern material and a manufacturing technology used for investment casting thereof. The non-ceryl pattern material comprises the following components in percentage by weight: 48.2% of potassium aluminum sulphate, 32.2% of magnesium sulfate, 19.3% of aluminum sulfate and 0.3% of ferric oxide, wherein the manufacturing technology comprises the manufacturing process of non-ceryl investment and the manufacturing process of sand cores. The non-ceryl pattern material does not contain paraffin or stearic acid, replaces the ceryl pattern material for investment casting, has small deformation, is not easy to soften, has simple process, saves time and labor, reduces cost, and is particularly suitable for manufacturing large and medium-sized impeller precision castings with small production lot, which are delivered in a short time, have complicated inner chamber shape, are provided with blades and are inconvenient for gold processing.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Mandril for copper alloy pipe planetary rolling mill and manufacturing method thereof

ActiveCN101974717AImprove high temperature resistanceHigh strengthMandrelsMetal rolling arrangementsManganeseTemperature resistance

Owner:江苏隆达超合金股份有限公司

Surface treatment method for IC carrier board

InactiveCN109714903ASave spaceReduce manufacturing costPrinted circuit manufactureFinger surfaceCopper plating

The invention provides a surface treatment method for an IC carrier board. The method is characterized in that the method comprises the following specific steps: S1. performing pre-treatment on a substrate, namely a step including cutting materials and drilling holes; S2. performing electroless plating copper and copper plating by electroplating; S3. drying a film and performing acid etching; S4.performing AOI and anti-welding processing; S5. electroplating a bright nickel layer / hard gold layer on a gold finger surface; S6. electroplating a matte nickel layer and a soft gold layer on a bonding surface; and S7. performing post-treatment, namely a step including moulding, testing, performing FQC, performing FQA, and packaging. In the surface treatment method for the IC carrier board, the gold finger surface adopts electroplated nickel (Ni) / gold (Au), the bonding surface replaces an existing chemical nickel / palladium / gold process with an electroplating matte nickel + electroplating softgold process, thereby effectively improving a quality problem of instability of a connection position, and the quality of the IC carrier board is improved.

Owner:GUANGDONG KINGSHINE ELECTRONICS TECH CO LTD

Chip back side drape tin eutectic technology and loading method thereof

InactiveCN102593010AOvercome size limitationsAvoid torsional driftSemiconductor/solid-state device manufacturingTinningAlloy

The invention relates to a chip back side drape tin eutectic technology and a loading method thereof. The method comprises the following steps: step (1), carrying out backside silver or backside gold processing on a chip back side; step (2), carrying out tinning or tin alloy work on a backside silver surface or a backside gold surface of a chip which is subjected to the backside silver or backside gold processing in the step (1); step (3), cutting the chip whose backside silver surface or backside gold surface is subjected to the tinning or tin alloy work in the step (2); step (4), employing eutectic technology to install the chip which is cut in the step (3) to a basic island to complete loading. According to the chip back side drape tin eutectic technology and the loading method, there is no requirement to chip dimension, after the chip back side is coated with a layer of tin or tin alloy, since the thickness of the tin or tin alloy can be controlled, the thickness of the tin or tin alloy can effectively absorb different stresses between the chip and the basic island, and lamination and rupture problems of a traditional eutectic chip are solved.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

Reversing valve and manufacturing method thereof

ActiveCN108930816AReduce material consumptionSmall machining allowanceMultiple way valvesValve housingsProcessing costValve seat

The invention discloses a reversing valve and a manufacturing method thereof. The reversing valve comprises a valve body part and a sliding block part. The valve body part comprises a valve seat, a valve body and a connecting pipe. The reversing valve is characterized in that the valve seat comprises a valve seat body, the valve seat body is provided with flat plate segments which are connected mutually and used for matching with the sliding block part in a sliding mode and circular arc segments for connecting with the valve body, and the flat plate segments and the circular arc segments are enclosed to form a hollow cavity body. According to the reversing valve provided by the invention, the hollow cavity body is formed in the valve seat body, the overall amount of material using of the valve seat is effectively reduced, so that cost of materials is reduced; and the gold processing allowance of the hollow cavity body is less, a connecting pipe hole on the valve seat body is convenientto process, and the processing cost is reduced.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

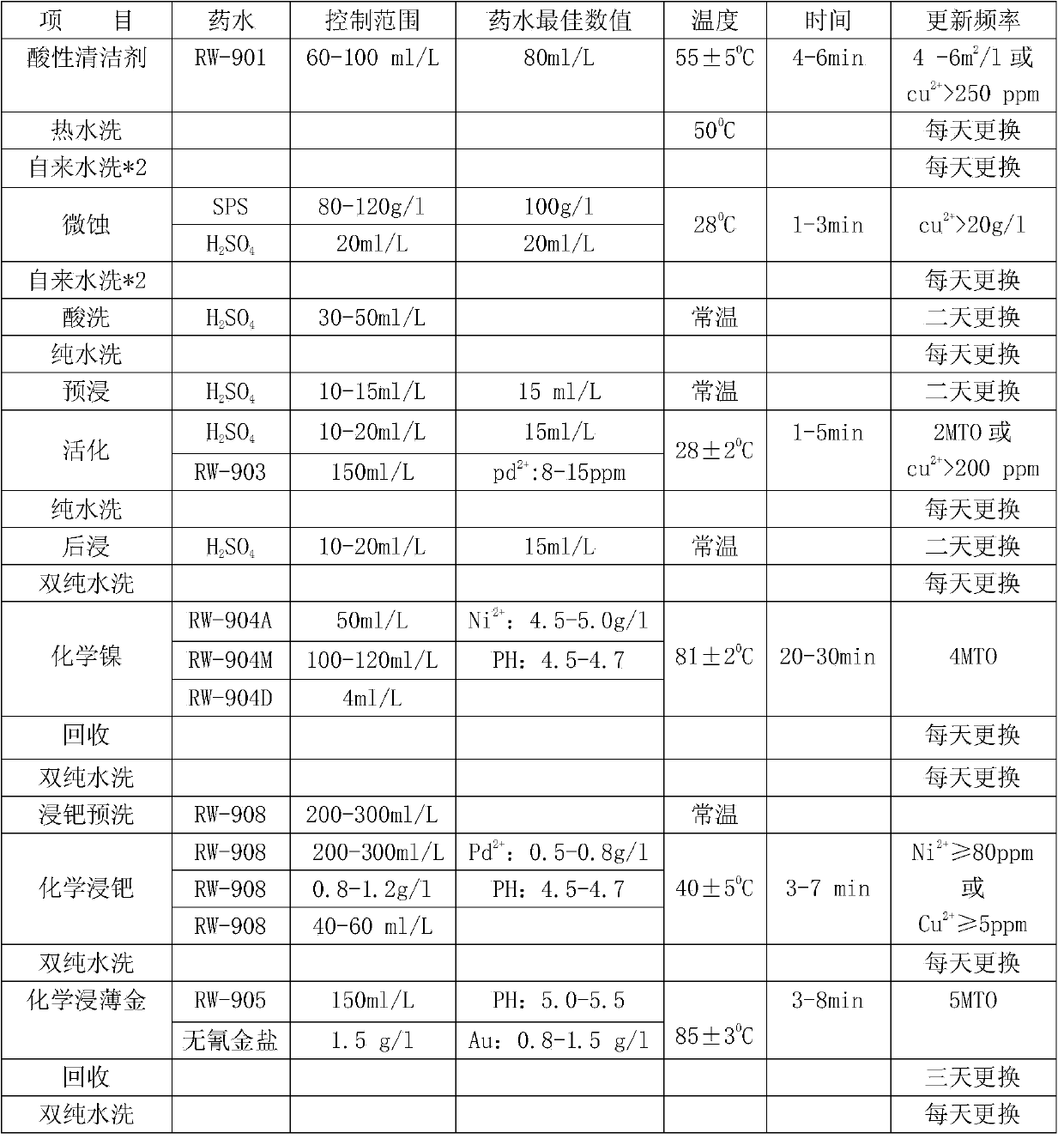

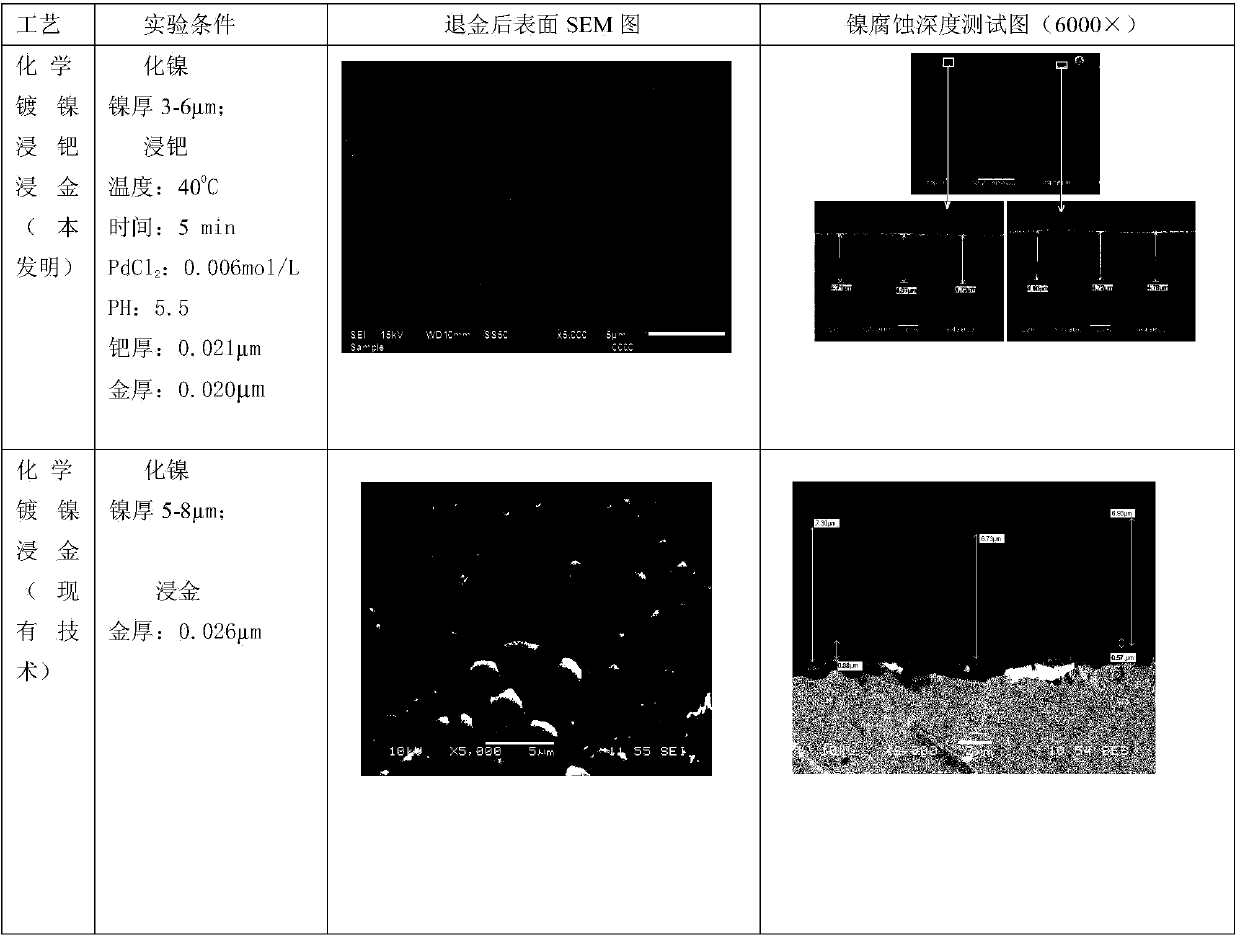

High-reliability type chemical palladium plating liquor and cyanide-free chemical nickel-palladium-gold processing method

ActiveCN103898490AImprove reliabilityLow costLiquid/solution decomposition chemical coatingSocial benefitsCyanide

The invention discloses high-reliability type chemical palladium plating liquor and a cyanide-free chemical nickel-palladium-gold processing method. The high-reliability type chemical palladium plating liquor mainly consists of the following components in concentration ratio: 0.20 mol / L-0.40mol / L of complexing agent, 0.004mol / L-0.010mol / L of palladium chloride, 20ppm-40ppm of additive, and the balance of water, wherein pH value of the plating liquor is 4.5-7.0. According to the cyanide-free chemical nickel-palladium-gold processing method, the palladium plating liquor is used for dipping palladium, wherein the palladium dipping temperature is 35 DEG C-45 DEG C and the palladium dipping time is 3-7 minutes. The high-reliability partner type chemical palladium plating liquor disclosed by the invention adopts a novel formula ratio, completes chemical palladium plating on workpieces such as a PCB (printed circuit board) in a substitute mode, so that gold-dipping thickness reaches 0.02 -0.03 mu m in a subsequent gold dipping process. The high-reliability type chemical palladium plating liquor has characteristics of low cost and high reliability, and pollution-free gold salt is used in the gold dipping process. The popularization and application of the high-reliability type chemical palladium plating liquor has very good economic benefits and social benefits.

Owner:珠海市钯金电子科技有限公司

Chemical nickel solution applied to wafer-level packaging chemical nickel-gold process

PendingCN109518172AImprove stabilityHigh activityLiquid/solution decomposition chemical coatingNickel saltCompound (substance)

The invention discloses a chemical nickel solution applied to a wafer-level packaging chemical nickel-gold process. Water is adopted as the dissolvent of the solution. The solution comprises, by concentration, 20-40g / L of nickel salt, 20-40g / L of a reducing agent, 20-50g / L of a complexing agent, 1-5mg / L of a stabilizing agent and 2-200mg / L of an impurity removing agent. The impurity removing agentcontains at least one pyridine type compound, and impurity metal ions can be chelated by the pyridine type compound in the impurity removing agent so as to reduce the influence of impurities in the solution on the performance of a plating solution. The pyridine type impurity removing agent is adopted by the chemical nickel solution to eliminate the influence of impurity heavy metal in the solution on the plating solution without any side effect brought to the plating solution by the pyridine type impurity removing agent. Therefore, even if the content of impurity ions in the plating solutionis very low or zero, the performance of the plating solution is not influenced by the added pyridine type compound.

Owner:DONGGUAN ZHIYUAN ELECTRONICS TECH

No-board-edge nickel-gold technology of circuit board

InactiveCN105072818AGuaranteed orientationReduce dosageConductive pattern reinforcementElectroless nickel immersion goldSolder mask

The invention discloses a no-board-edge nickel-gold technology of a circuit board. The no-board-edge nickel-gold technology of a circuit board comprises steps of performing cutting on a substrate of the circuit board, exposing an inner layer circuit, laminating, boring, precipitating copper and electroplating, adopting a positive technology to perform copper plating, tin plating, removing films, etching, removing tin, performing solder mask, and performing character back baking on the outer layer circuit. The steps before the chemical nickel-gold technology comprises steps of removing the technology edges on the circuit board, performing chemical nickel-gold processing on the circuit board, and testing and checking the electric performance and appearance of the finished board. The invention can save the nickel amount in the nickel gold technology so as to save the cost.

Owner:湖北建浩科技有限公司

Cold drawing welded tube manufacture process for high-accuracy hydraulic oil cylinder

The invention discloses a cold drawing welded tube manufacture process for a high-accuracy hydraulic oil cylinder, which sequentially comprises the following steps of longitudinal shearing, roll bending molding, high frequency welding, welding joint treatment, online eddy current testing, sizing cutting, normalization, pinching, surface treatment, cold drawing, annealing, straightening, defect detection and cutting for measurement. The method is quick in processing molding, high in production volume, free of damage on surfaces in cold drawing and high in manufacture accuracy. After cold drawing, bearing capacity of a welded tube is improved by about 60%, and the welded tube is high in tensile strength and good in elongation rate. Follow-up gold processing amount is reduced, utilization rate of steel materials is improved, and manufacture cost is reduced. The cold drawing welded tube can be directly applied to manufacture of high-accuracy hydraulic oil cylinders.

Owner:MARCEGAGLIA CHINA

Mandril for copper alloy pipe planetary rolling mill and manufacturing method thereof

ActiveCN101974717BImprove high temperature resistanceHigh strengthMandrelsMetal rolling arrangementsManganeseTitanium

The invention relates to a mandril for a copper alloy pipe planetary rolling mill, which comprises the following components of 35 to 40wt% of nickel, 19 to 21wt% of chromium, 9 to 12wt% of molybdenum, 0.8 to 1.8wt% of manganese, 1.2 to 1.5wt% of titanium, 0.1 to 0.5wt% of vanadium, 0.05 to 0.2wt% of aluminum and the balance ferrum. The mandril material of the invention is an alloy with the nickelas the main material and has the advantages of good high temperature resistance performance, high strength, good flexibility, no invalidation or chap when working at the temperature of 900 to 1000 DEG C for a long time, requirement satisfaction of the temperature of planetary rolling copper alloys, simple preparation technology, easy operation, in particular to the aspects of gold processing, andprocessing time and cost saving.

Owner:江苏隆达超合金股份有限公司

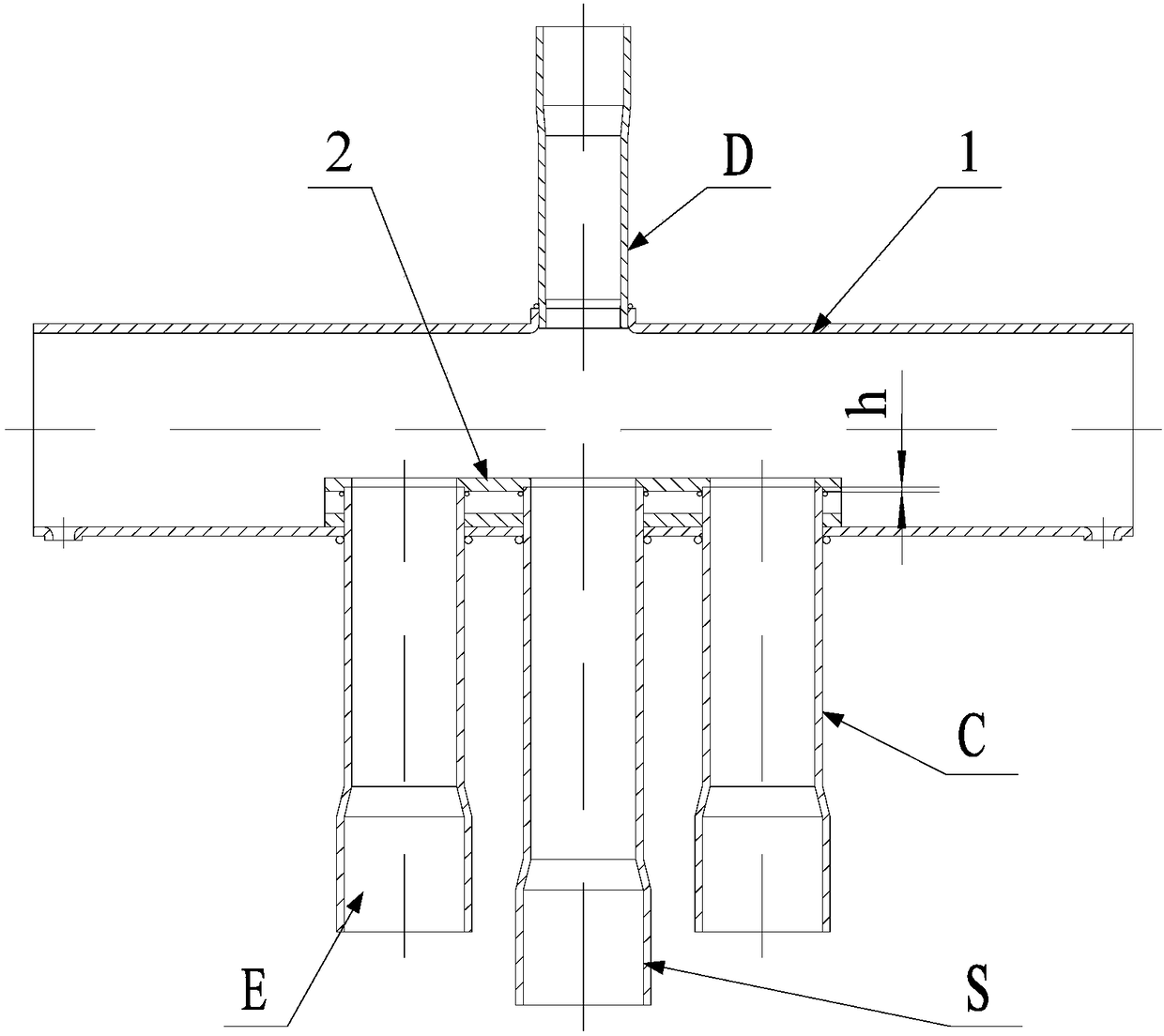

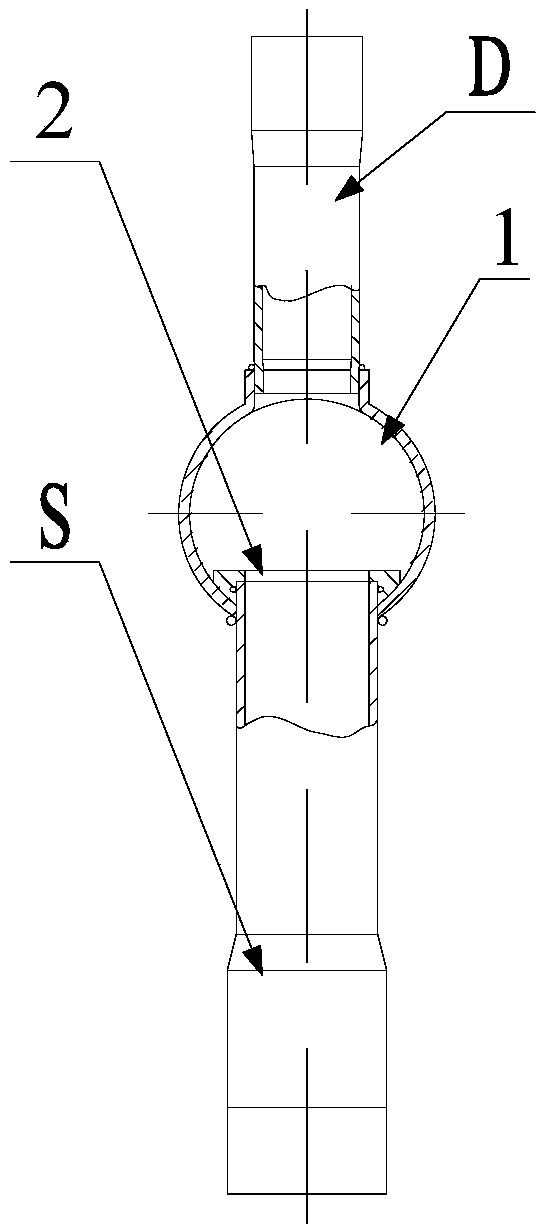

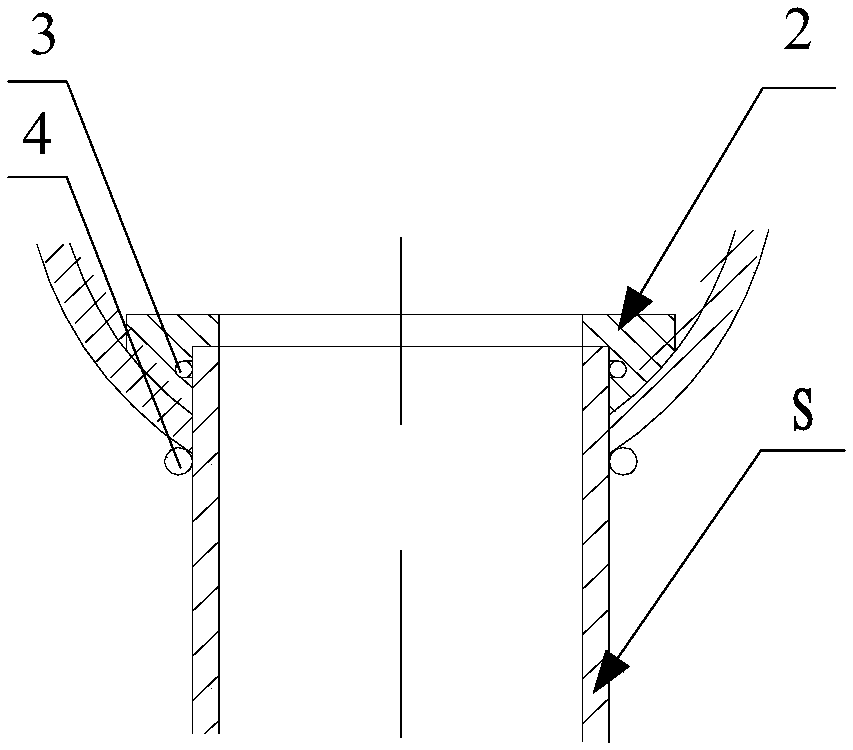

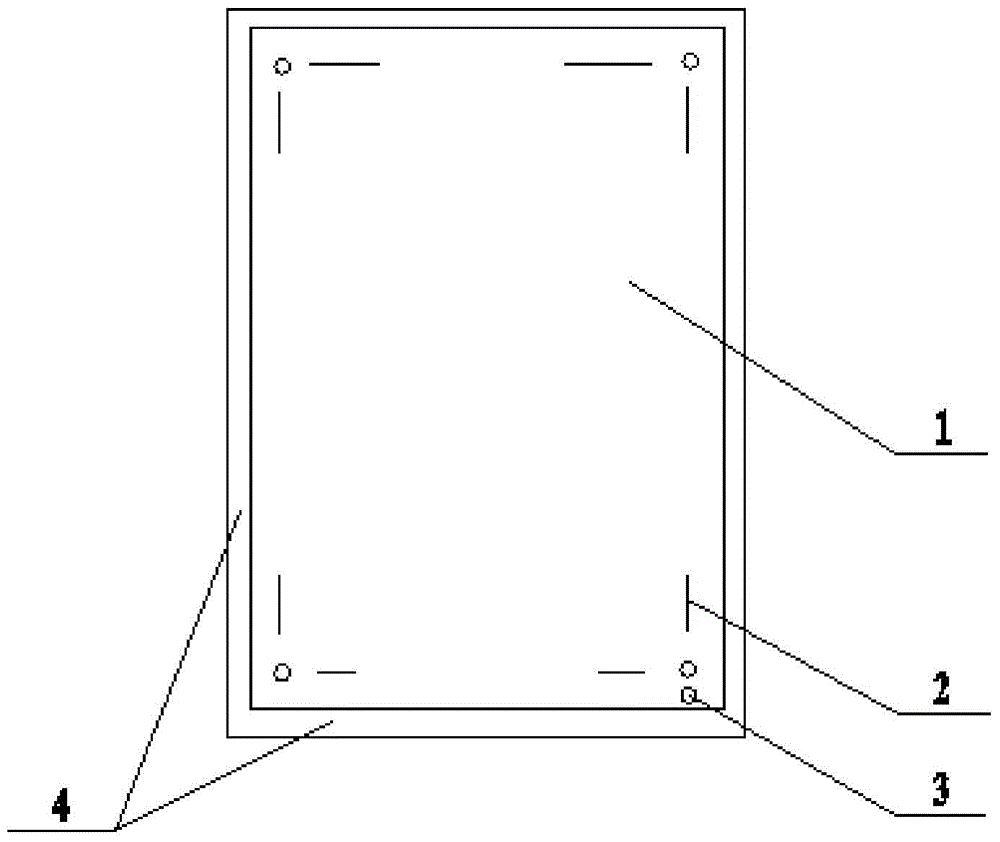

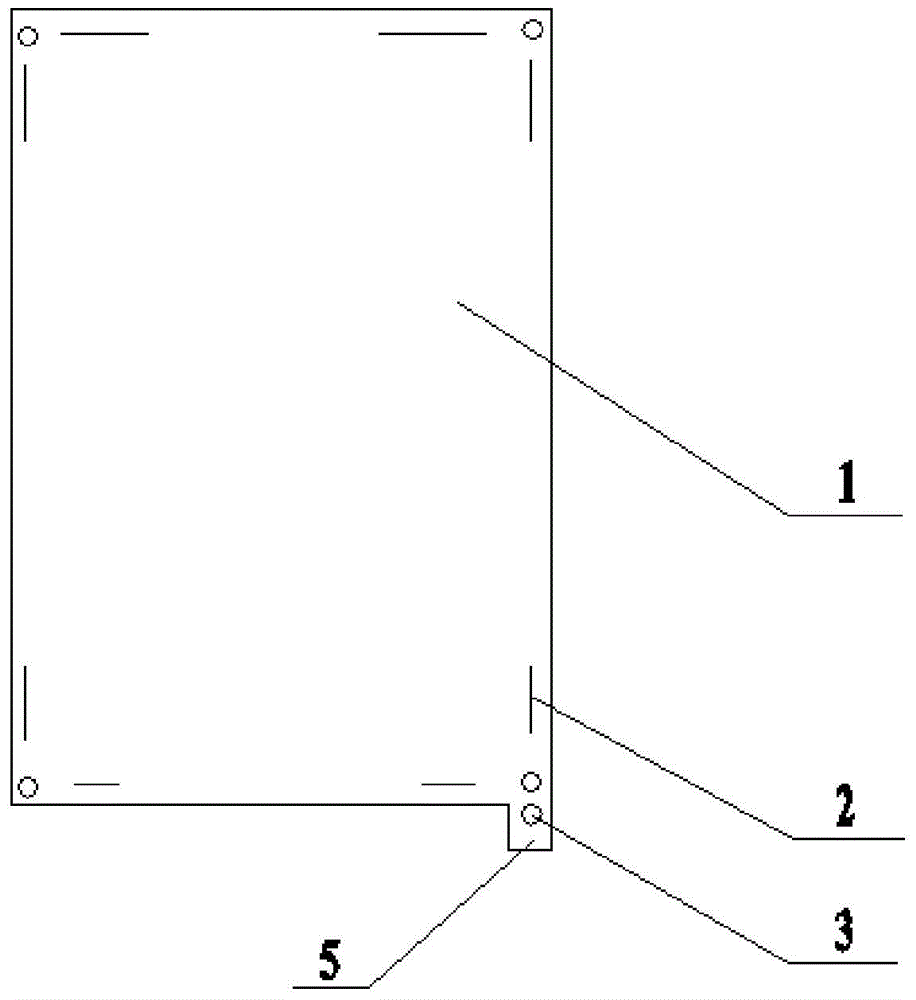

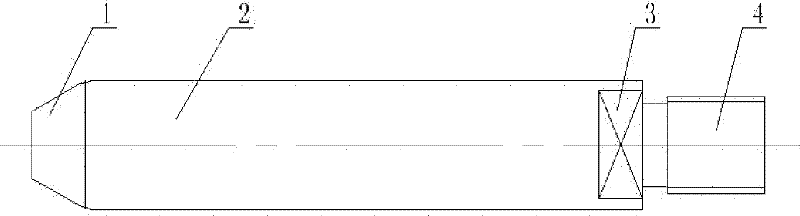

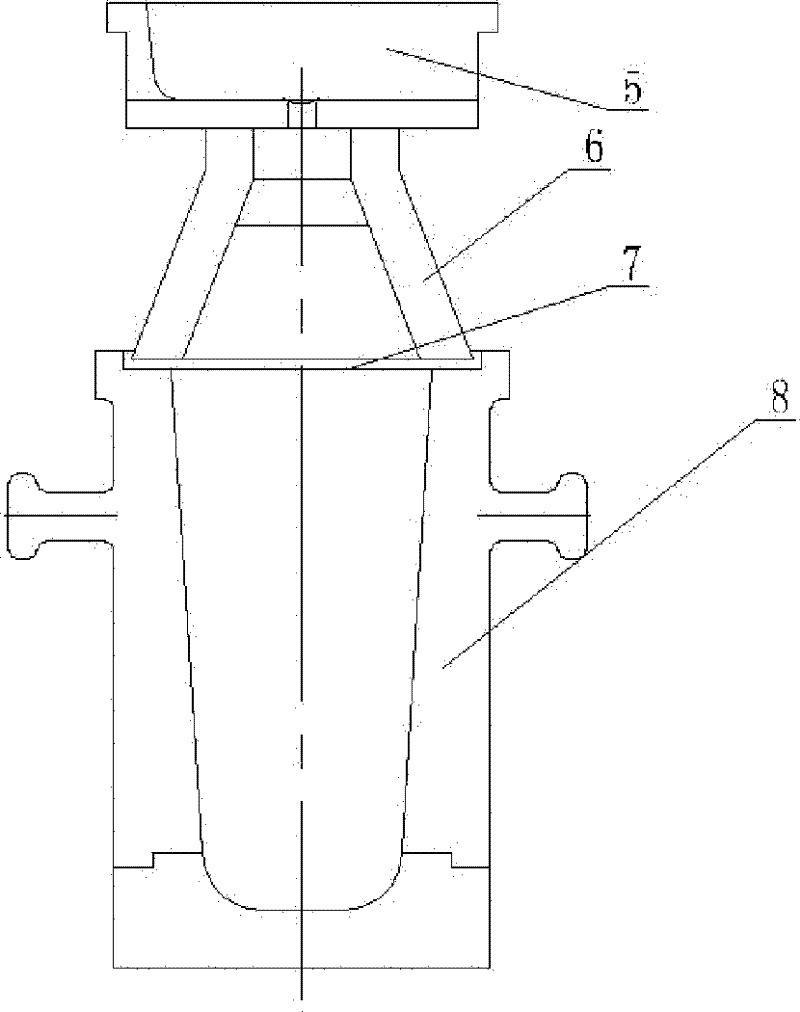

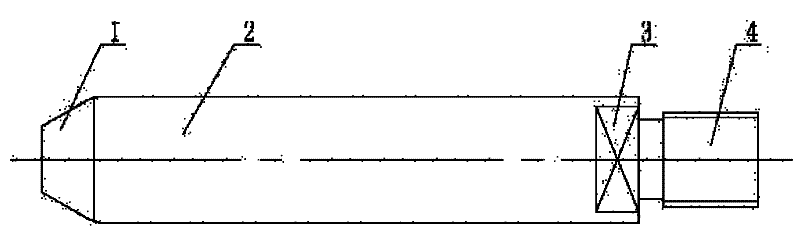

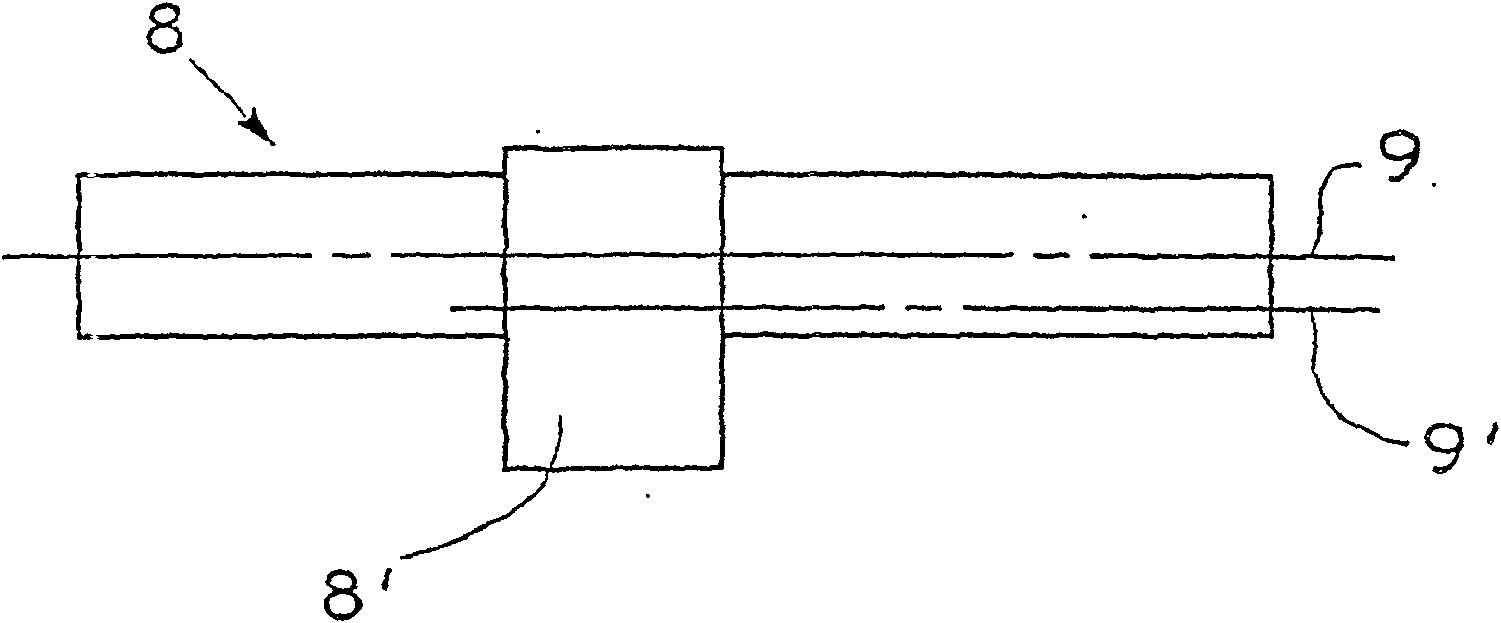

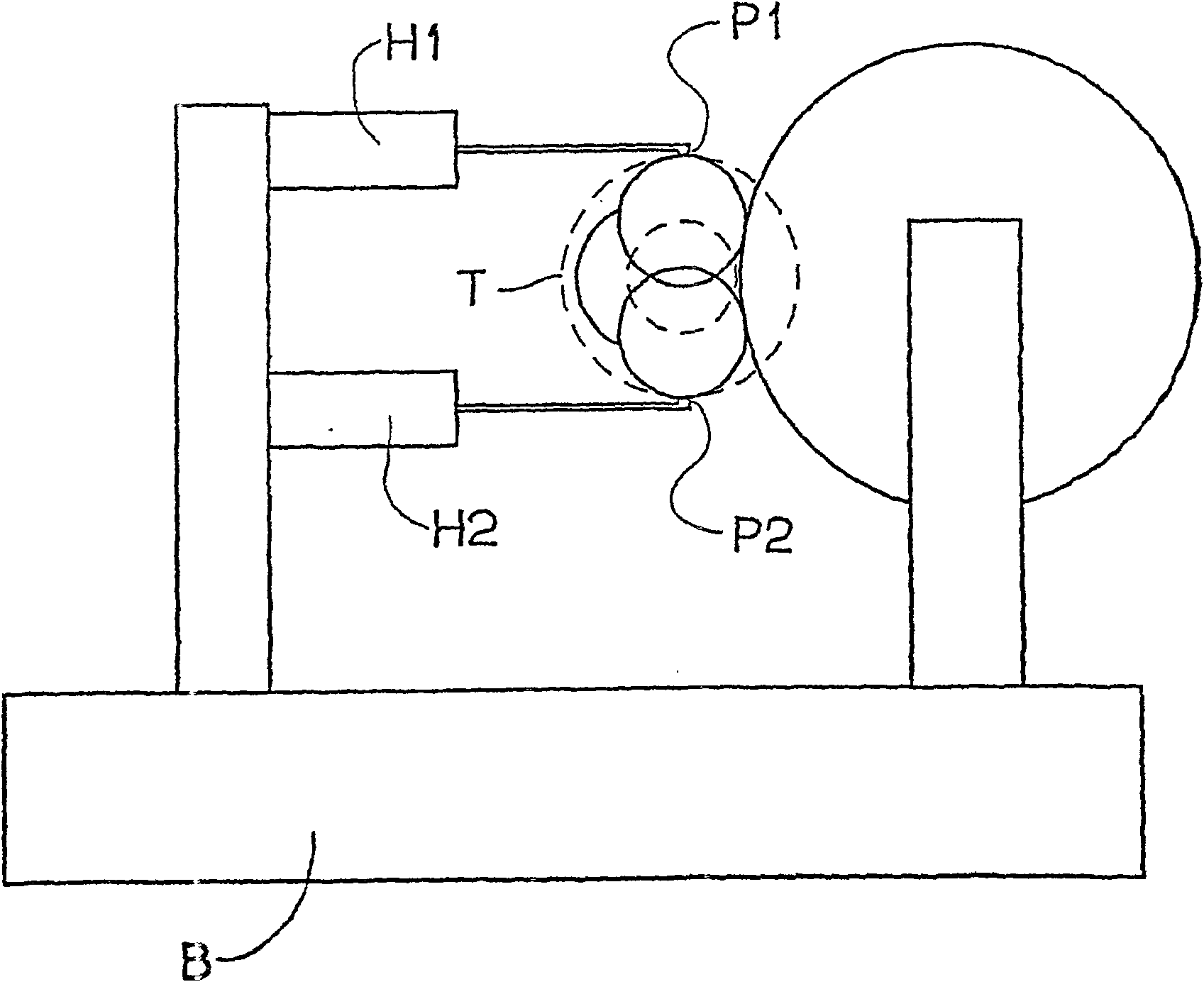

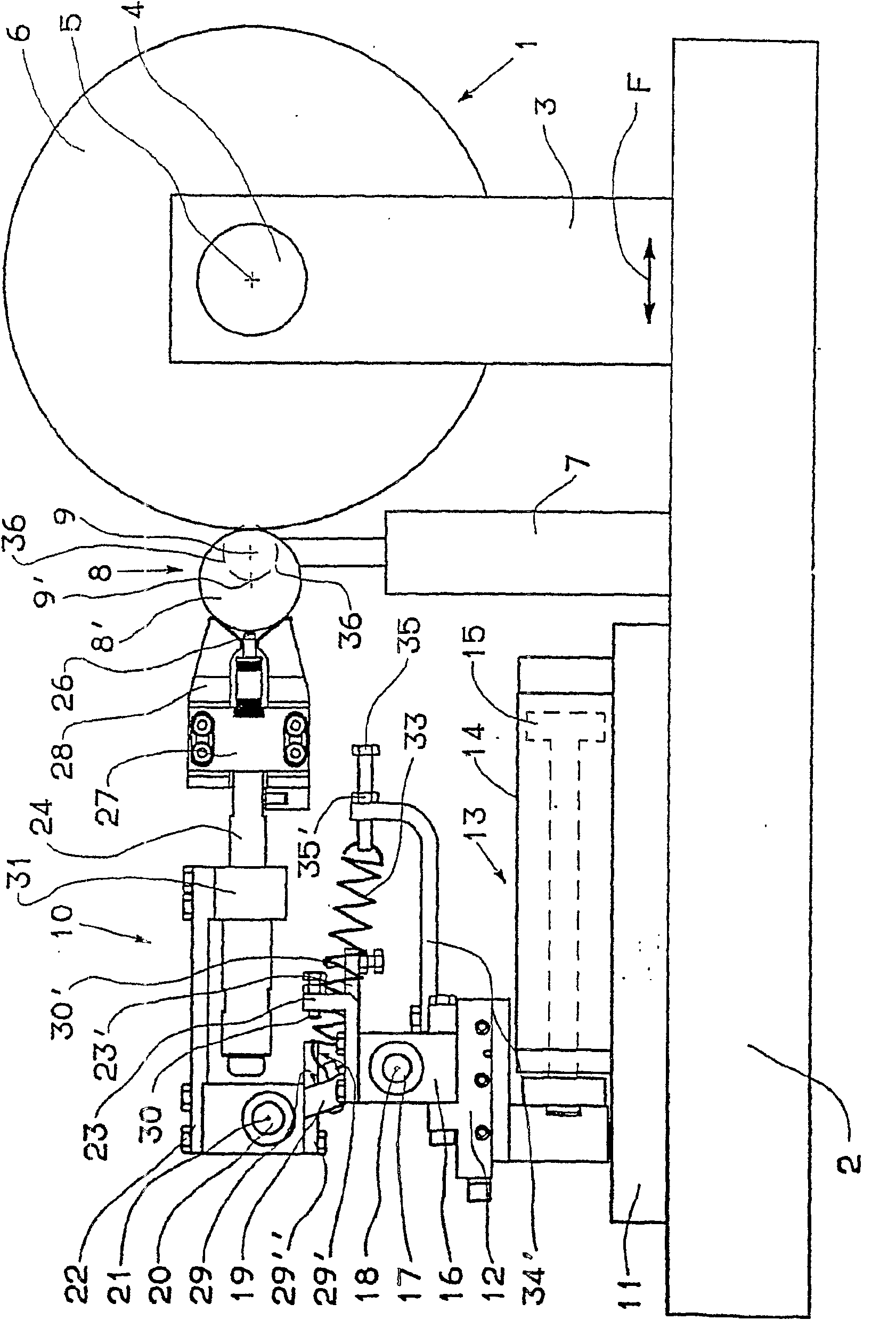

Device for detecting eccentric part diameter of machine element in course of gold processing on grinding machine

InactiveCN100588504CRevolution surface grinding machinesMechanical diameter measurementsMechanical componentsReference device

An apparatus (10) for checking the diameter of an eccentric pin (8') of a small-size shaft (8), for example a shaft for compressors, includes a support (16), a first arm (19) rotating with respect tothe support (16), a second arm (22) rotating with respect to the first, a Vee-shaped reference device (28) carried by the second arm, a measuring device (25,26,24,37,38) associated with the referencedevice, limiting devices (29,29',30,30') for limiting the rotations of the arms and thrust means (33) for keeping the reference device in contact with the pin in the course of the checking.A hydraulicactuator (13) displaces the apparatus (10) from a rest condition to a checking condition, in which the reference device (28) is in contact with the pin (8') to be checked, and vice versa.

Owner:诺丰股份公司

Processing technique for hard pure gold accessories

InactiveUS20100096272A1Reduce thicknessWeak coating capacityDuplicating/marking methodsActive material electrodesWaxHardness

A processing technique of electroforming for hard pure gold accessories, including carving waxwork, making silica molding, grafting wax, trimming wax, oiling, electroforming, wax removing and quality inspection, characterized in that LJJAS compounding agent was added to the electrolytic solution, the electroforming temperature is between 50 to 60 degrees, the electroforming speed is 0.05 g / h and pH value of electrolytic solution is between 7.0 to 7.5. Thus, even distribution, strong covering capacity, thin coating, short molding time, big size, lighy weight and high hardness can be achieved. This processing technique is particularly suitable to the gold processing industry.

Owner:SHANDONG ZHAOJIN WANZUJIN +1

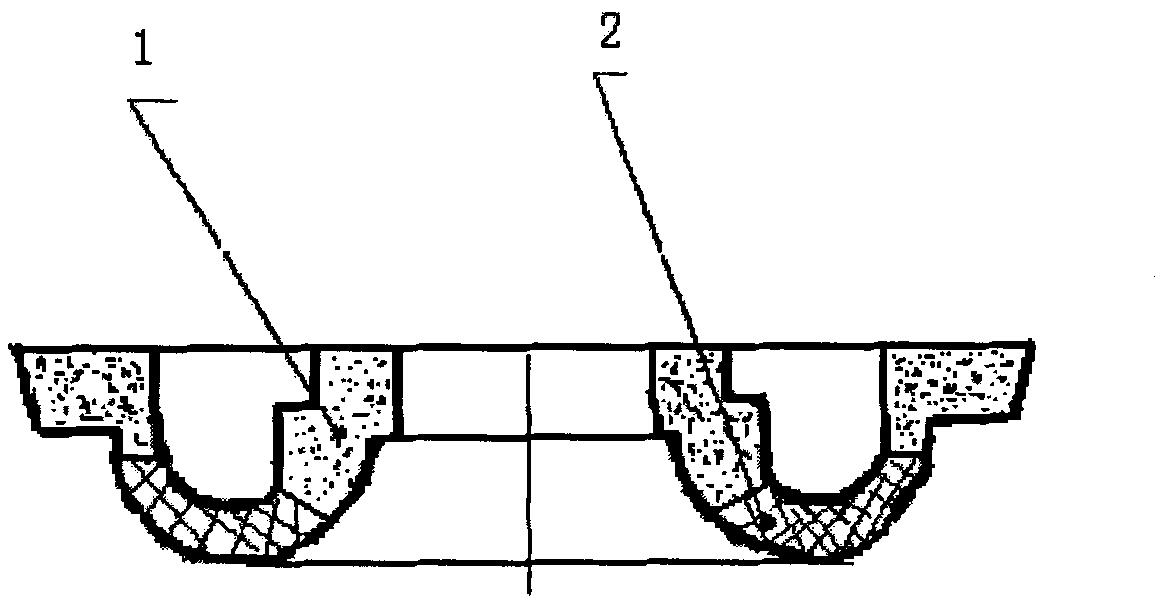

Stitching type compression casting composite bottom boiler and manufacture technique thereof

ActiveCN101357036BHigh thermal fatigue stabilitySimple structureCooking vesselsHeat resistanceDie casting

The invention relates to a fit-typed die-casting composite bottom pan, comprising an aluminium alloy pan body and a composite bottom sheet which is fit at the bottom of the pan body; the fit-typed die-casting composite bottom pan is characterized in that the pan is formed by the rolling and composing of a composite material sheet and a stainless steel sheet; the composite material sheet is provided with a plurality of circular concave troughs with internally inclined side wall; the bottom of the pan body is provided with a plurality of circular convex ribs which are embedded into the circularconcave troughs; after being fit, the circular concave troughs and the circular convex ribs are rabbeted with each other; the composite material sheet is made of pure aluminium or aluminium alloy or material with the linear expansion coefficient approximate to the aluminium alloy. The invention also relates to a manufacture process used for the fit-typed die-casting composite bottom pan; the manufacture process of the invention is used for preparing the fit-typed die-casting composite bottom pan by the steps as follows: composite bottom sheet preparing, die casting of aluminium alloy pan body,flap edge removing of the pan body, gold processing, fitting, surface disposing, etc. The fit-typed die-casting composite bottom pan has the advantages of firm connection of the composite bottom sheet, high thermal efficiency, good heat-resistance fatigue performance, simple manufacture process, and the like, and is a cooker which is especially suitable for being used for induction cookers.

Owner:ZHEJIANG CHUNZHOU ALUMINUM IND

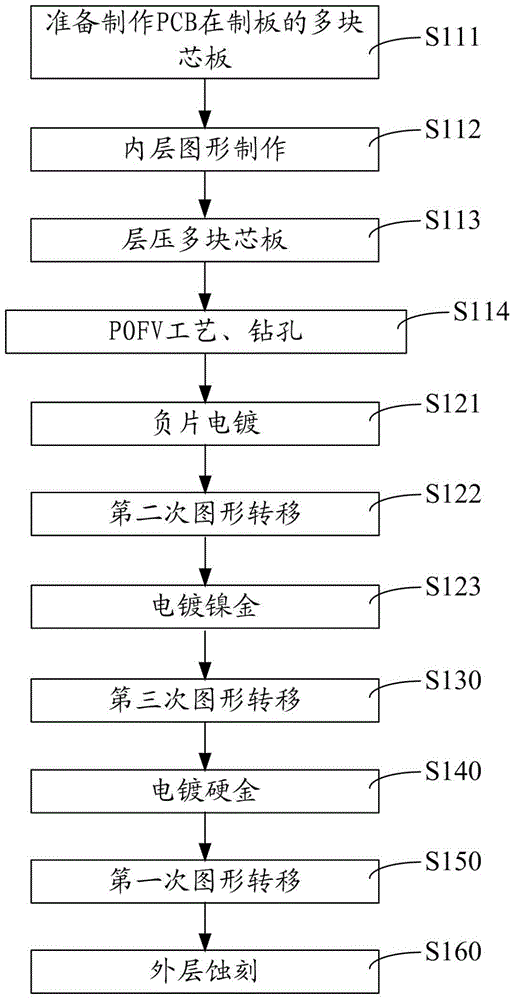

Method for manufacturing circuit board

InactiveCN107666781AFlat holePlug hole fullPrinted element electric connection formationEngineeringCopper

The invention discloses a method for manufacturing a circuit board. The method comprises the following steps: carrying out rough shape cutting on a PCB material; carrying out primary hole drilling; carrying out plated-through-hole processing; carrying out whole-board electroplating processing; carrying out first-time pattern transferring, carrying out copper thickening; carrying out resin hole plugging; carrying out resin grinding; carrying out film removing; carrying out second-time pattern transferring; carrying out flash gold processing; carrying out third-time pattern transferring; carrying out electric thick soft gold processing; carrying out secondary hole drilling; carrying out film removing; and carrying out outer-layer line etching. According to the invention, selective electroplating is carried out by two-times line transferring, so that the local copper thickness request is met. With the resin hole plugging and the third-time pattern transferring, requirements of plugged hole evenness and fullness from the client are met; and the line is bound with the PAD electric thick soft gold partially, so that application of the special function is realized.

Owner:深圳明阳电路科技股份有限公司

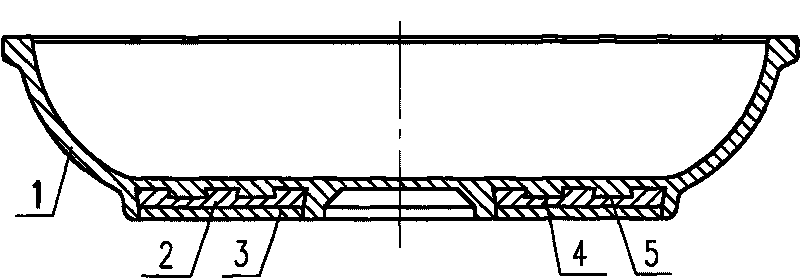

Method for plating thick gold layer in circuit board manufacturing process

InactiveCN101631427BNo pollutionImprove plating resistancePrinted circuit manufactureElectroless nickel immersion goldEtching

The invention discloses a method for plating a gold thick layer in a circuit board manufacturing process, which comprises the following steps of: A, firstly, subjecting a circuit board to pattern tin plating, circuit wire etching, solder-mask printing and chemical nickel and gold processing treatments of depositing a nickel layer and depositing a gold layer; B, carrying out the anti-oxidation post treatment of the circuit board subjected to the chemical nickel and gold processing treatments; C, covering a non-gold plated area of the circuit board; and D, after pre-treating the surface of the circuit board, plating the thick gold layer on a lead of the circuit board by a post drawing process. The invention provides a method for plating thick gold layer in the circuit board manufacturing process, which has advantages of pollution prevention, environment protection, gold salt conservation, good quality and easily controllable gold color.

Owner:深圳市九和咏精密电路有限公司

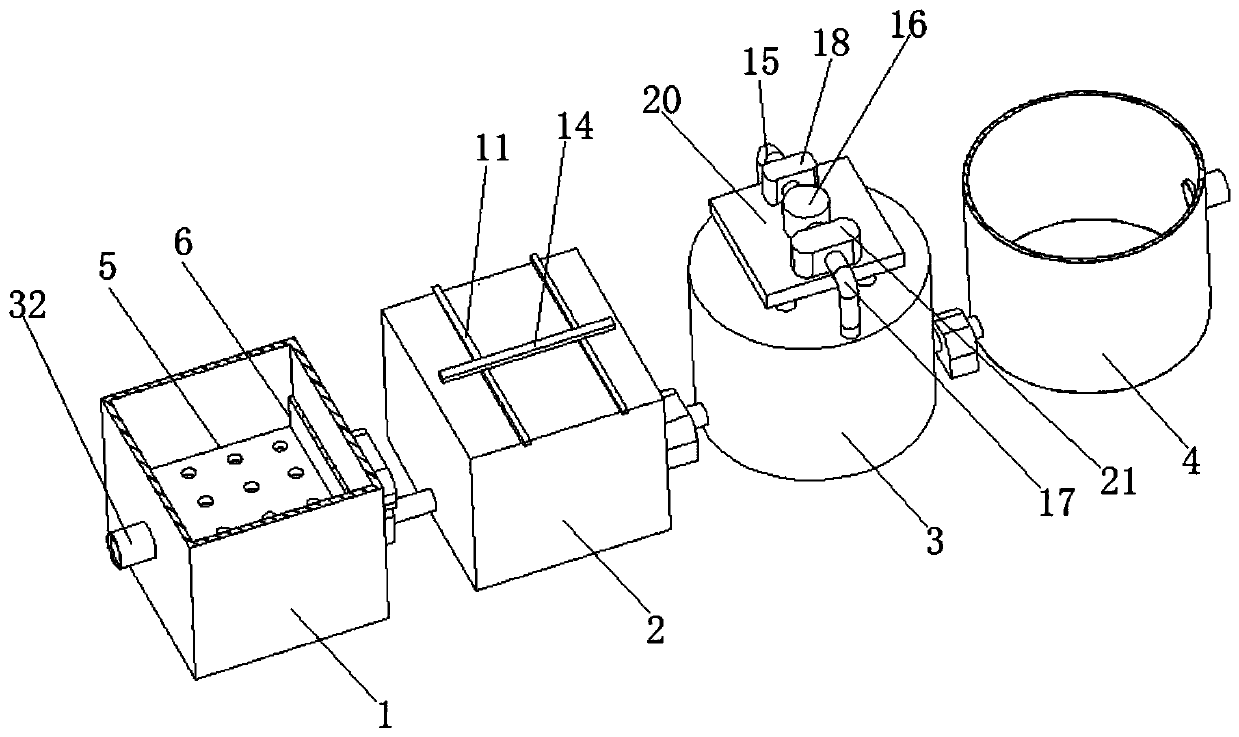

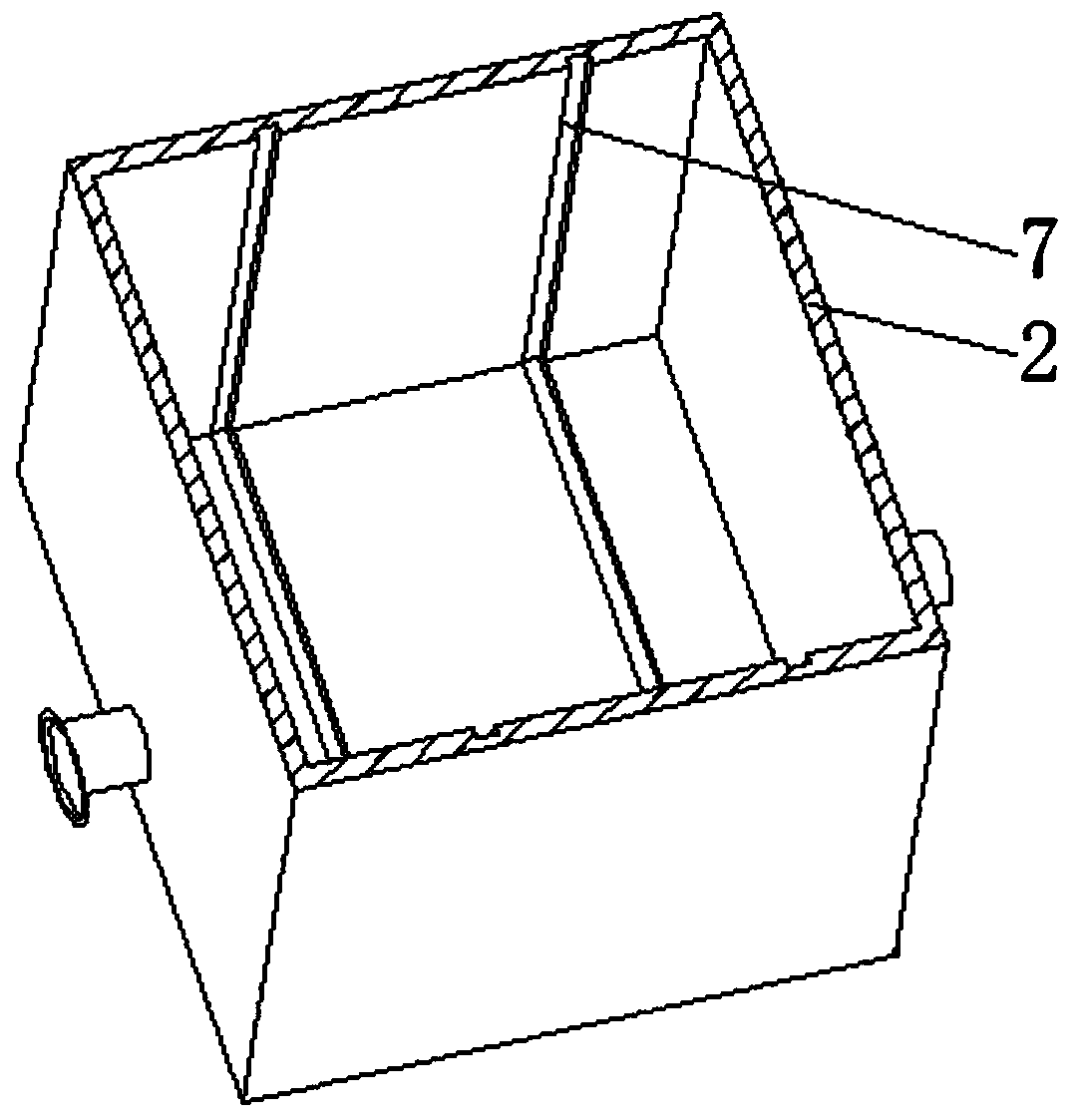

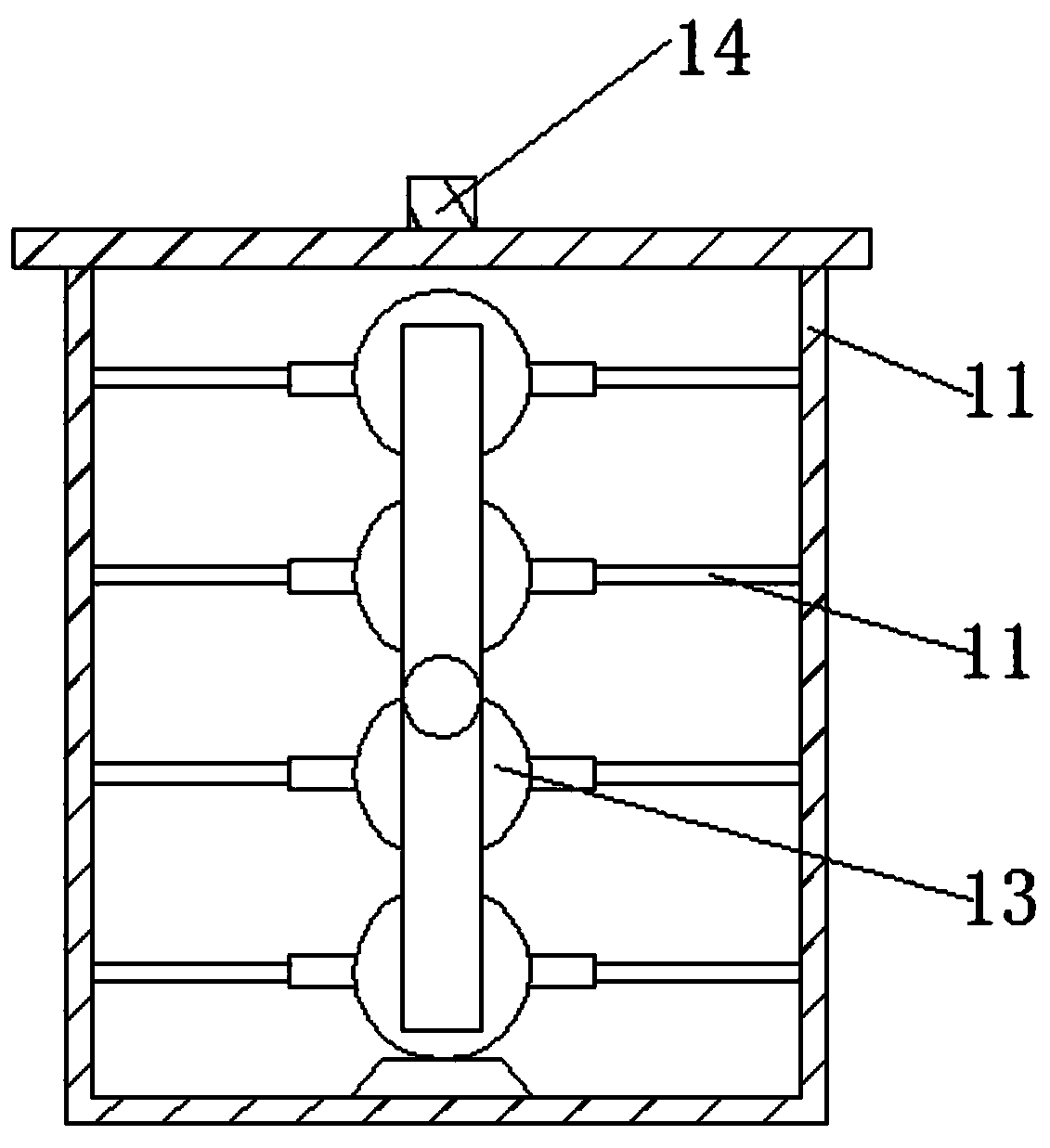

Gold processing sewage treatment device

PendingCN111499034ATimely replacementClean up in timeWater contaminantsTreatment involving filtrationReverse osmosisSewage treatment

The invention discloses a gold processing sewage treatment device. The device comprises a pretreatment tank, a reverse osmosis tank, a purification tank and a sedimentation tank; a filtering assemblyfor filtering large impurities is mounted in the pretreatment tank; a dirt removing assembly for preventing blockage is mounted above the filtering assembly; a plurality of mounting grooves are formedin the inner wall of the reverse osmosis tank; a detachable reverse osmosis assembly is mounted in each mounting groove; a chemical feeding assembly for preventing chemicals from being dissolved incompletely is mounted in the purification tank; a stirring assembly for assisting dissolution is mounted in the purification tank; according to the invention, the detachable reverse osmosis assembly isarranged, so the damaged filter element can be timely replaced; the air guide pipe and the chemical guide pipe are mounted in the vertical height direction of the purification tank, so that the chemical coverage area is effectively increased, the wastewater treatment quality is improved, the blockage of the filter assembly can be effectively prevented by arranging the dirt removing assembly, and the sewage treatment efficiency is greatly improved.

Owner:深圳市翠绿黄金精炼有限公司

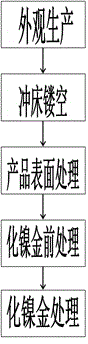

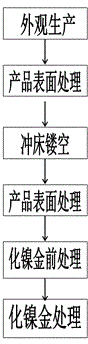

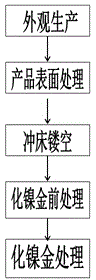

Nickel-gold plating circuit board production technology

The invention discloses a circuit board production technology, and especially relates to a nickel-gold plating circuit board production technology. The nickel-gold plating circuit board production technology is characterized in that step 1, an appearance of a circuit board can be produced; step 2, the hollowing-out of the circuit board can be carried out by the punching; step 3, the surface processing of the circuit board can be carried out after the stamping; step 4, the processing before the Electroless Nickel / Immersion Gold processing of the stamped circuit board can be carried out; and step 5, the Electroless Nickel / Immersion Gold processing can be carried out. The nickel-gold plating circuit board production technology is advantageous in that the common operation process adopted by convention circuit board production, and the stamping is preposed, and the two times of the circuit board surface processing can be combined, and then the loss of the opened liquid medicine can be reduced; compared to the prior art, the costs can be reduced by about 20%, and the success rate of one-time production can be increased by 15%, and therefore the production efficiency can be improved, the total production period can be reduced, and the economic benefit is obvious.

Owner:苏州市三生电子有限公司

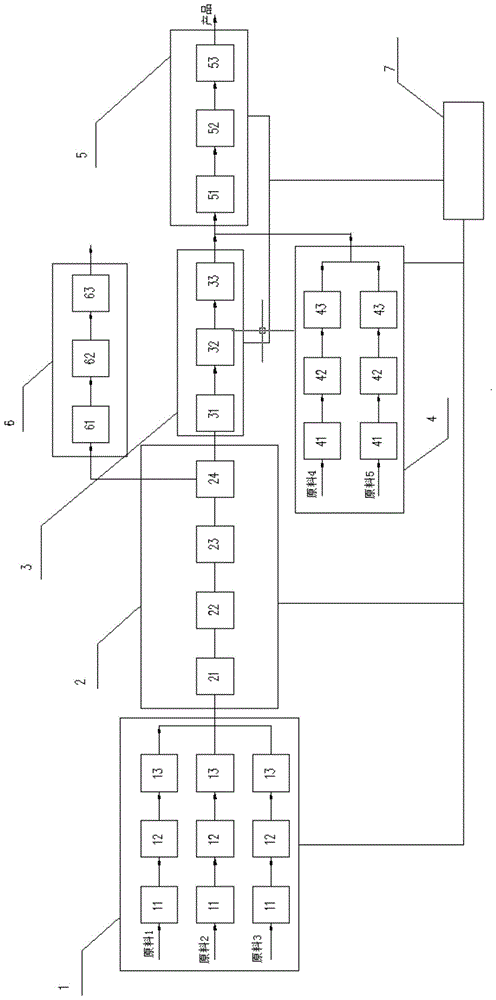

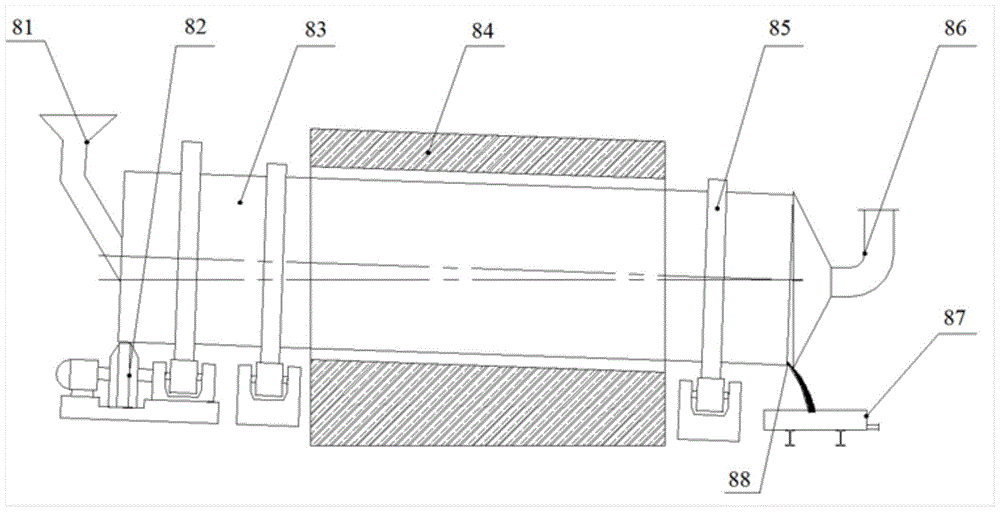

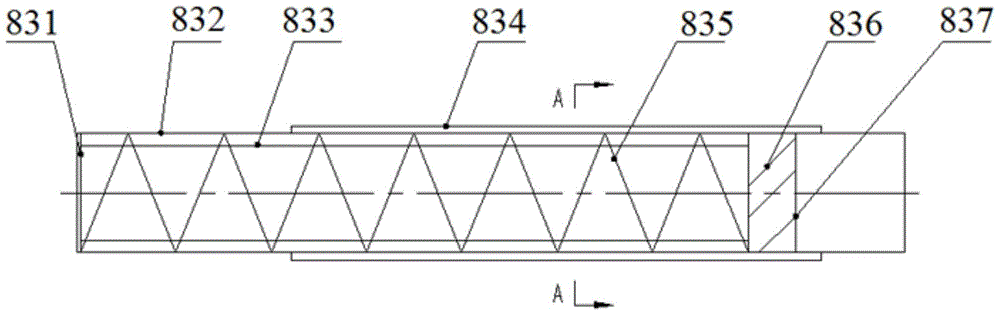

A kind of production system of environment-friendly gold ore beneficiation agent

The invention discloses a production system of an environmentally friendly gold ore dressing agent, which comprises a primary batching device, a mixing reaction device, a cooling and solidification device, a secondary batching device and a finished product packaging device connected in sequence, and the mixing reaction device is also connected with a tail gas treatment device. The automatic control system is respectively connected with the primary batching device, mixing reaction device, cooling and solidification device, secondary batching device, finished product packaging device and tail gas treatment device. The purpose of the present invention is to provide a production system of the environment-friendly gold ore dressing agent, which solves the problem that the existing production equipment cannot meet the continuous and efficient production of the environment-friendly gold ore dressing agent.

Owner:三门峡昊博化工工程有限公司

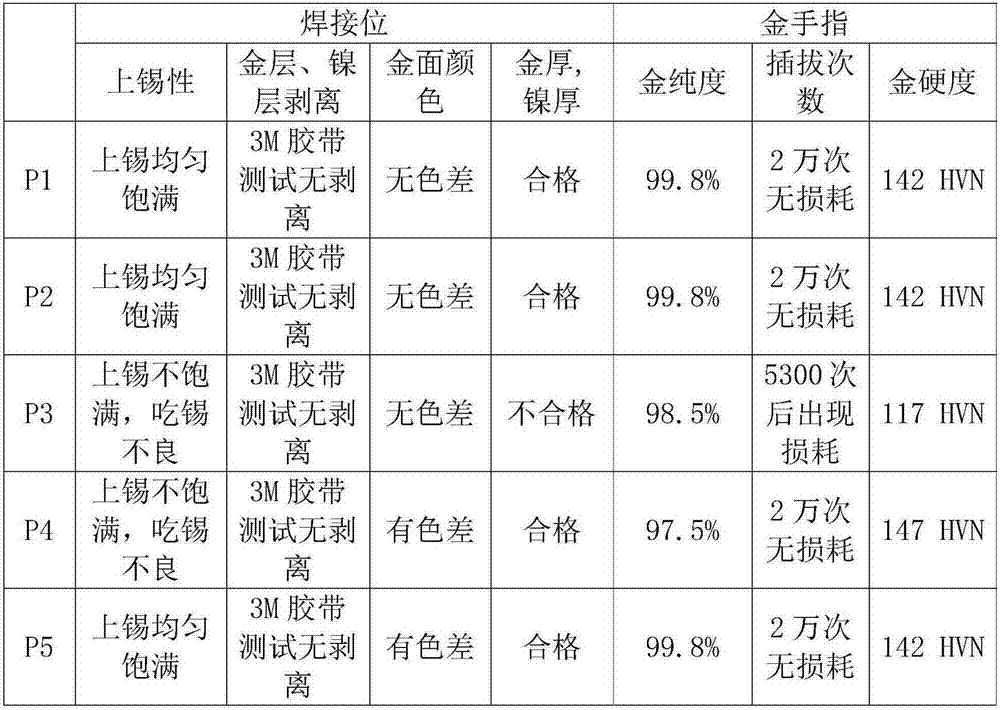

A kind of pcb surface treatment method

ActiveCN104284520BGuaranteed hardnessPrevent power-on goldNon-metallic protective coating applicationPrinted element electric connection formationHardnessGold layer

The invention relates to the technical field of circuit board production, in particular to a method for surface treatment of PCBs. Firstly, the nickel-gold treatment is carried out on the gold finger position and the welding position at the same time, and then the blue glue is pressed on the PCB, and then on the gold finger position. Electric thick gold treatment. The invention can reduce the process flow and save the process of pasting the dry film or coating the anti-static gold ink in the existing process, thereby avoiding the pollution of the gold surface by the dry film, unclean film removal, unclean development, and loss of anti-static gold ink The emergence of such phenomena and the problem of dumping money. By controlling the phosphorus content in the chemical water used in the nickel immersion gold treatment and controlling the electroplating solution in the electroplating gold treatment, the hardness of the gold finger can be guaranteed to be above 142 HVN, and it can be inserted more than 20,000 times without damage. By controlling the temperature of the blue glue, the blue glue can be closely attached to the immersion gold layer on the welding position, preventing the gold from being electro-plated on the immersion gold layer, and ensuring that the immersion gold layer is not polluted by the blue glue and maintaining good reliability. Solderability.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com