Chip back side drape tin eutectic technology and loading method thereof

A chip and tin coating technology, which is applied to the tin coating eutectic process on the back of the chip and the field of chip loading, can solve the problems of chip rotation or twisting, chip size requirements, scrapping and other problems, so as to improve the quality of chip loading and reliable packaging. The effect of sexual enhancement and avoidance of delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A kind of tin eutectic process and chip loading method of the present invention, it comprises the following process steps:

[0029] Step 1. Use the existing mature technology to process the back of the chip with silver or gold;

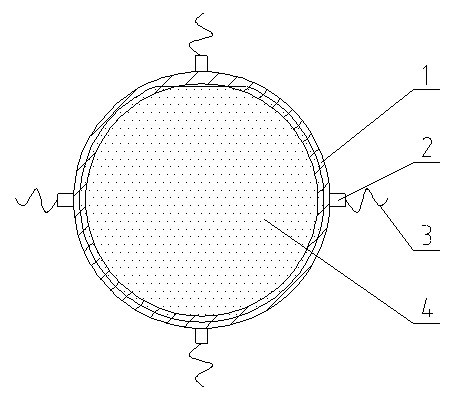

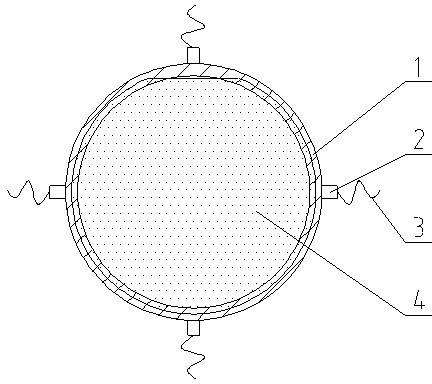

[0030] Step 2. Place the chip with back silver or back gold treatment on the tooling fixture (such as figure 1 As shown), the jig and the chip are electroplated with tin or tin alloy. At this time, the back silver or back gold of the chip will be plated with a layer of tin or tin alloy, and the thickness and speed of the coating can be controlled;

[0031] The tooling fixture includes a fixture body 1, the fixture body 1 is annular, and a plurality of electroplating pins 2 are evenly distributed on the outer edge of the annular fixture body 1. During electroplating, the electroplating pins 2 is connected with wires, and the chip 4 is placed on the fixture body 1 with the front facing up.

[0032] The back silver or gold back surface of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com