Long-span rotor system and gas turbine generator set

A gas turbine, long-span technology, applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of unstable operation of the rotor system, complex thrust bearing structure, size limitation, etc., to achieve good heat dissipation, low cost, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

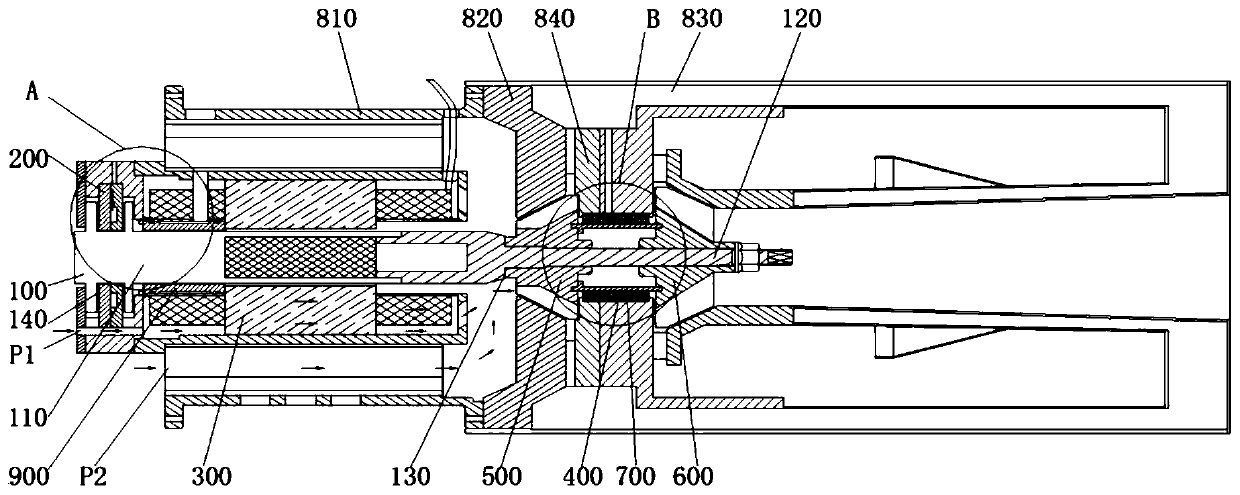

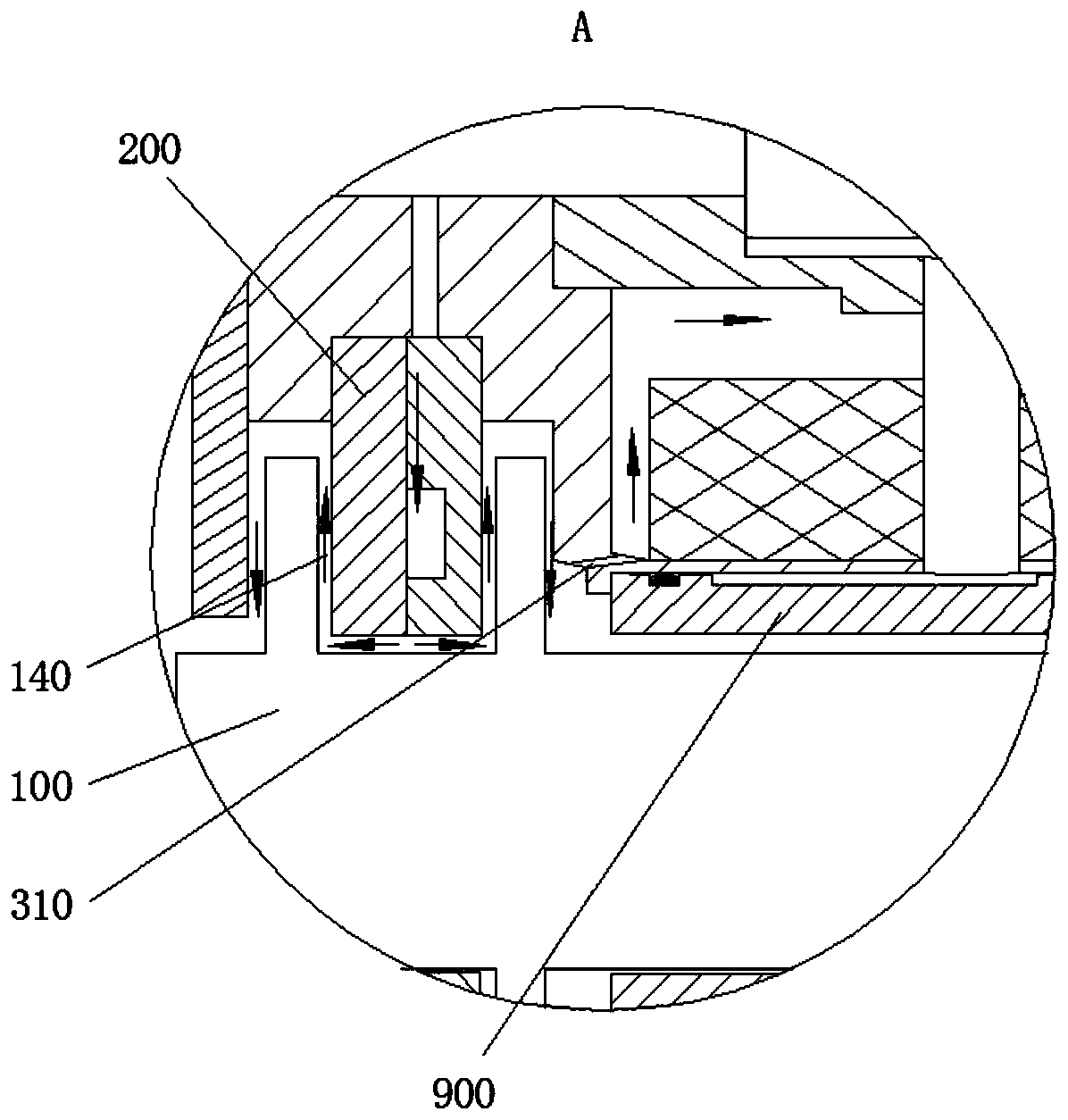

[0042] Such as figure 1 As shown, it includes a rotating shaft 100, and the rotating shaft 100 includes an integrally formed first shaft segment 110 and a second shaft segment 120, the diameter of the first shaft segment 110 is larger than the diameter of the second shaft segment 120, the first shaft segment 110 and the second shaft segment A stepped surface 130 is formed at the transition of the shaft section 120;

[0043] Among them, the thrust bearing 200, the first radial bearing 900, and the motor 300 are sequentially arranged on the first shaft section 110, and the compressor 500, the second radial bearing 400 and the turbine 600 are sequentially arranged on the second shaft section 120. One end of the machine 500 is in contact with the stepped surface 130 .

[0044] In the rotor system of the present invention, the rotating shaft 100 is supported by the bearings at both ends (the first radial bearing 900 and the second radial bearing 400 ), so that the force is uniform...

Embodiment 2

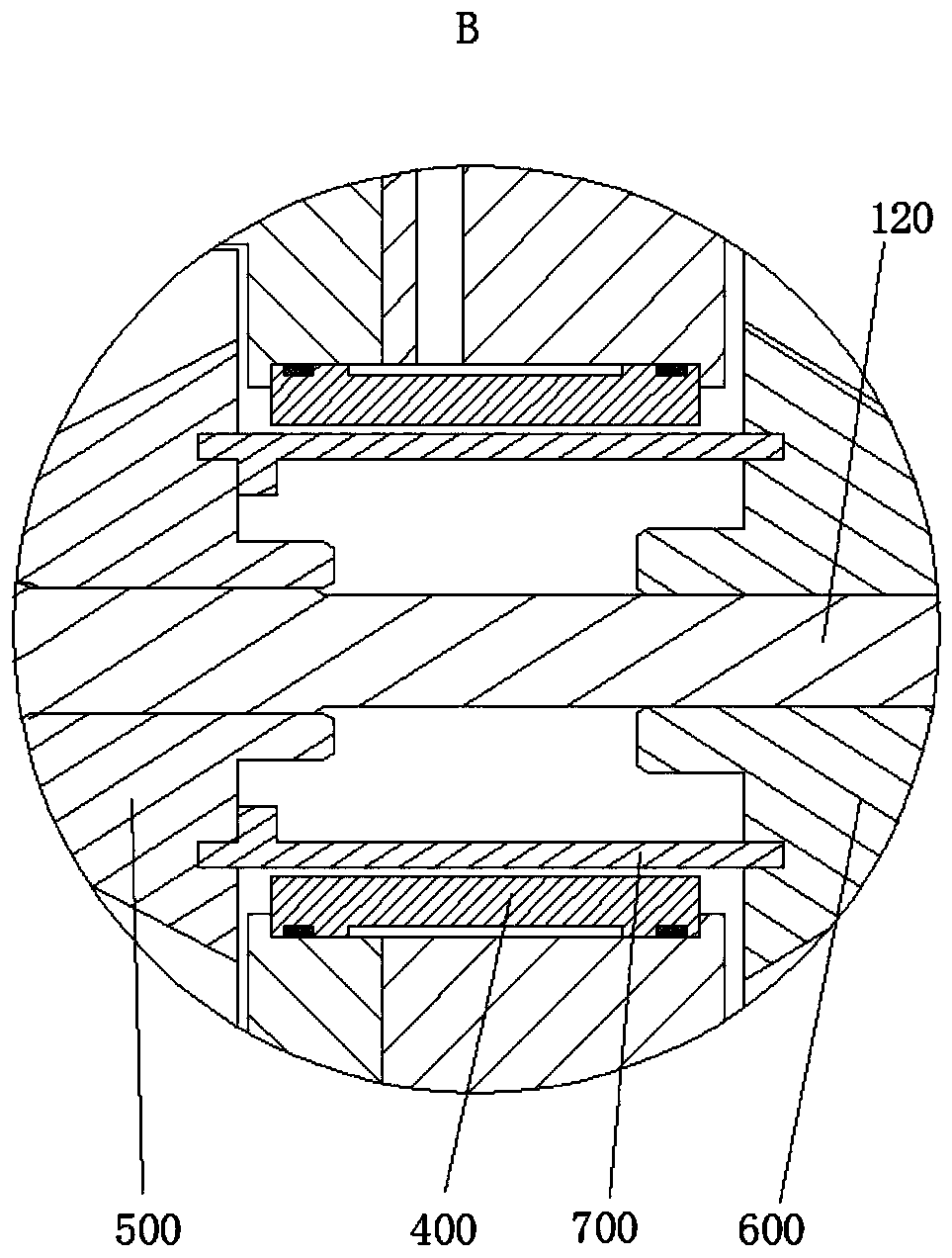

[0060] The first radial bearing 900 and the thrust bearing 200 in the first embodiment can also be set as an integrated bearing, and the thrust plate is set as one. The one-piece bearing is an integrated air bearing, which not only has the function of radial support, but also has the function of axial support.

[0061] Such as Figure 4 , 5 As shown, the integrated bearing in this embodiment includes: a first bearing body, a thrust plate, and a second bearing body; the thrust plate is fixedly connected or integrally formed with the rotating shaft 100; both the first bearing body and the second bearing body are sleeved on the rotating shaft And located on both sides of the thrust plate; the first bearing body has a radial bearing part and a thrust bearing part integrally formed, the radial bearing part and the rotating shaft 100 have a predetermined radial clearance in the radial direction, the thrust bearing part and the thrust plate on the shaft The second bearing body and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com