High salinity pharmaceutical wastewater processing system

A pharmaceutical wastewater and treatment system technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the total amount of pollutants is difficult to reach the standard, the system is huge, and the operating cost is high, etc. problems, to achieve the effect of reducing the total amount of pollutants discharged, high treatment efficiency, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

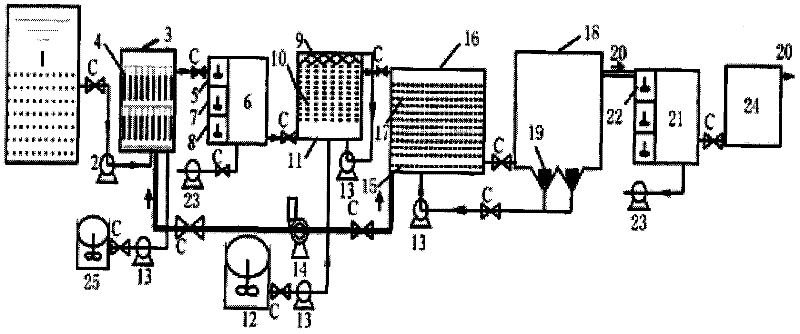

Image

Examples

Embodiment 1

[0036] High-salt pharmaceutical wastewater is fully homogenized and equalized in the aeration regulating tank 1, and the residence time is more than 3 days to ensure that the wastewater quality is stable and enters the follow-up system. In the regulating tank, the pH of the wastewater is adjusted to between 1 and 3. The pump 2 and the valve C control the flow into the catalytic micro-electrolysis reaction device 3, the catalytic micro-electrolysis reaction device 3 enters water from the bottom, and the upper part of the water exits. The device is equipped with a three-dimensional spatial structure of catalytic micro-electrolysis packing 4 to keep the filling rate of more than 30%. , under normal circumstances, the position is 1t filler / m3 space, and the total hydraulic retention time is 8-16h. The outlet water from the catalytic micro-electrolysis reaction device 3 is controlled by the valve C to enter the hydrogen peroxide catalytic oxidation tank 5, and the new ecological fer...

Embodiment 2

[0041] A pharmaceutical company mainly produces fermented products, including: maduramycin, ivermectin, dicrasul, and salinomycin veterinary drugs. The daily discharge of concentrated wastewater from the comprehensive process is about 650t. Using the present invention to treat high-salt pharmaceutical wastewater The system performs processing, and the processing process refers to embodiment 1.

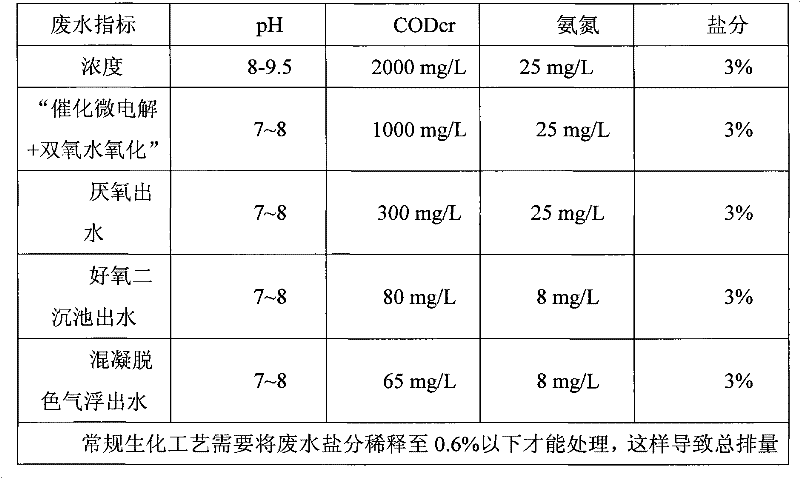

[0042] Table 1 The water quality concentration and removal rate of each section of a comprehensive pharmaceutical wastewater

[0043]

[0044]

[0045] After the raw water is fully homogenized in the adjustment tank, the pH value is adjusted to between 2 and 3, and it enters the iron-carbon micro-electrolysis tank, and the refractory organic matter in the wastewater is effectively decomposed by the reduction effect formed by the iron-carbon primary battery, and the residence time is 8h. , the effluent enters the hydrogen peroxide oxidation tank, and the dosage of hydrogen peroxid...

Embodiment 3

[0047] A pharmaceutical factory in Huzhou produces high viscosity hydroxypropyl methylcellulose (HPMC), hydroxyethyl hydroxypropyl methylcellulose (HEHPMC), and highly substituted hydroxypropyl cellulose (H-HPC), hydroxyethyl cellulose (HEC), ethyl cellulose (EC), polymethyl methacrylate (PMMA), etc., after expanding the production, the concentrated wastewater production capacity is 2000t / day, and the treatment system of the high-salt pharmaceutical wastewater of the present invention is used to process and treat Process with reference to embodiment 1.

[0048] Table 2 The water quality concentration and effluent water quality of a comprehensive pharmaceutical wastewater

[0049]

[0050] Conventional carboxymethyl cellulose ether pharmaceutical filler wastewater is often treated by dozens of times of dilution, often requiring a dilution water ratio of 1:5 to 1:10. At the moment when water resources are becoming increasingly tense, dilution treatment can no longer meet the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com