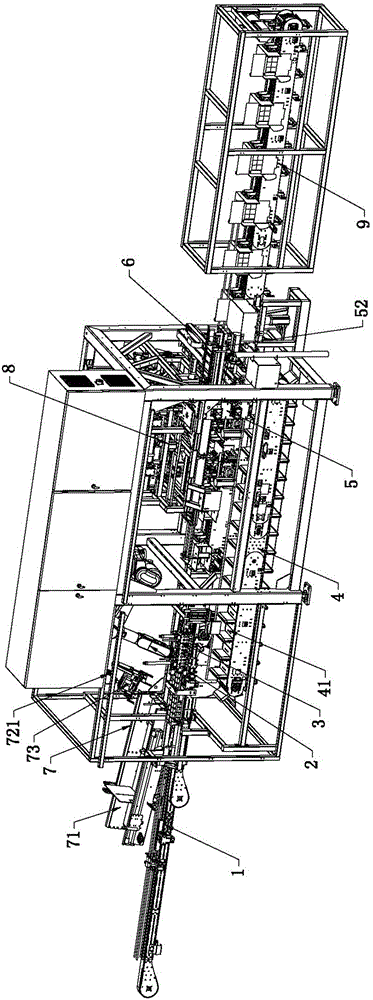

Automatic encasement system for Lilezuan milk bag gift boxes

An automatic packing and gift box technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problems of low efficiency, artificiality, and inability to use room temperature sour milk packaging for automatic packing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

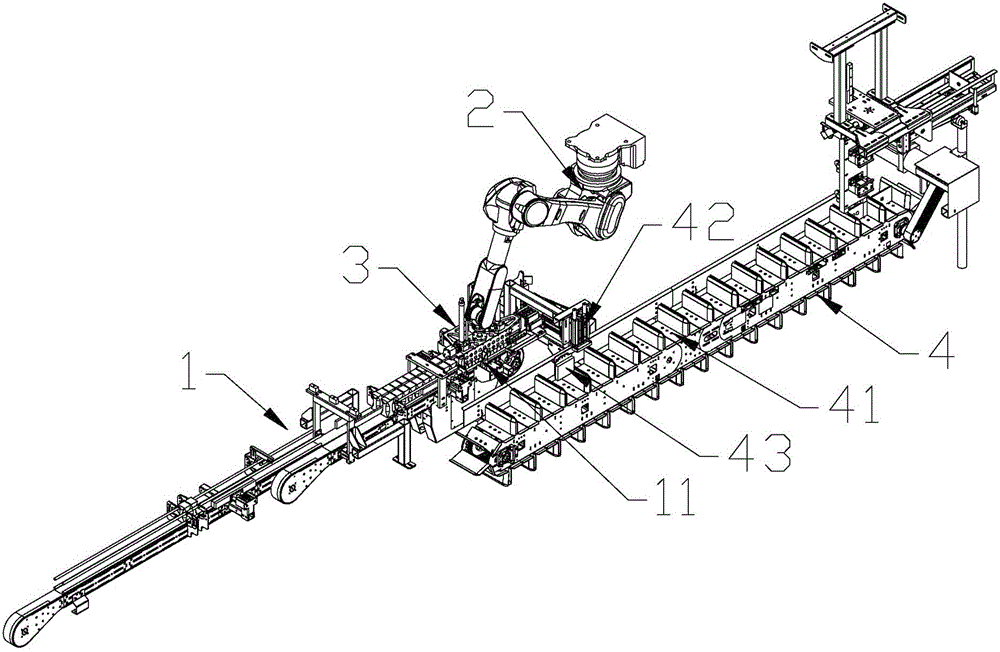

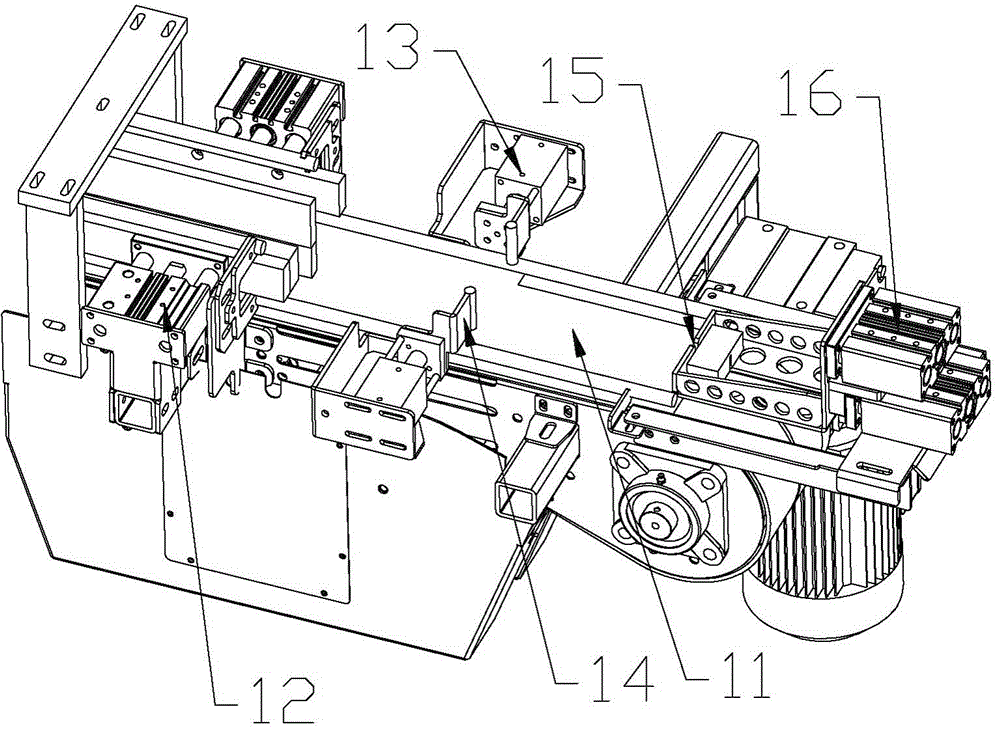

[0060] Such as Figure 1-20 Shown: an automatic boxing system for Tetra Pak milk pack gift boxes, including a milk pack integrated conveying line 1, a milk pack robot 2 and a milk pack unit conveying line 4 are provided beside the milk pack integrated conveying line 1, The upright milk bag is integrated at the tail end of the milk bag integration conveyor line 1 and then grabbed by the milk bag tool fixture 3 at the lower end of the manipulator of the milk bag robot 2. The milk bag robot 2’s manipulator drives the milk bag tool fixture 3 to turn over so that After the milk bag is horizontal, it is pushed into the corresponding milk bag unit compartment 41 on the milk bag unit conveying line 4; Insert the small partition into the middle gap of the milk bag unit when it is down, and the milk bag unit inserted into the small partition is transported by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com