Patents

Literature

31results about How to "Convenient coding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

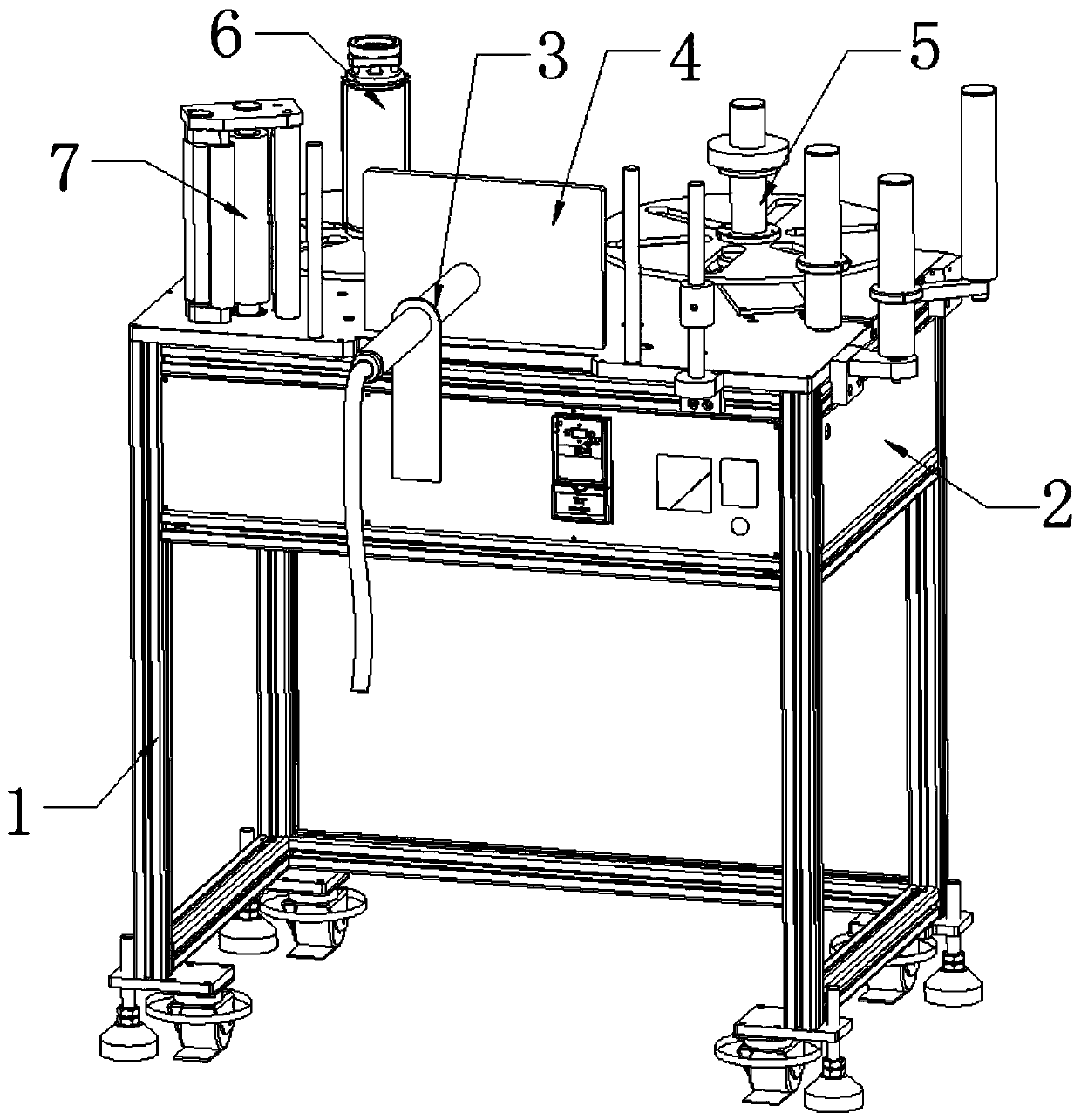

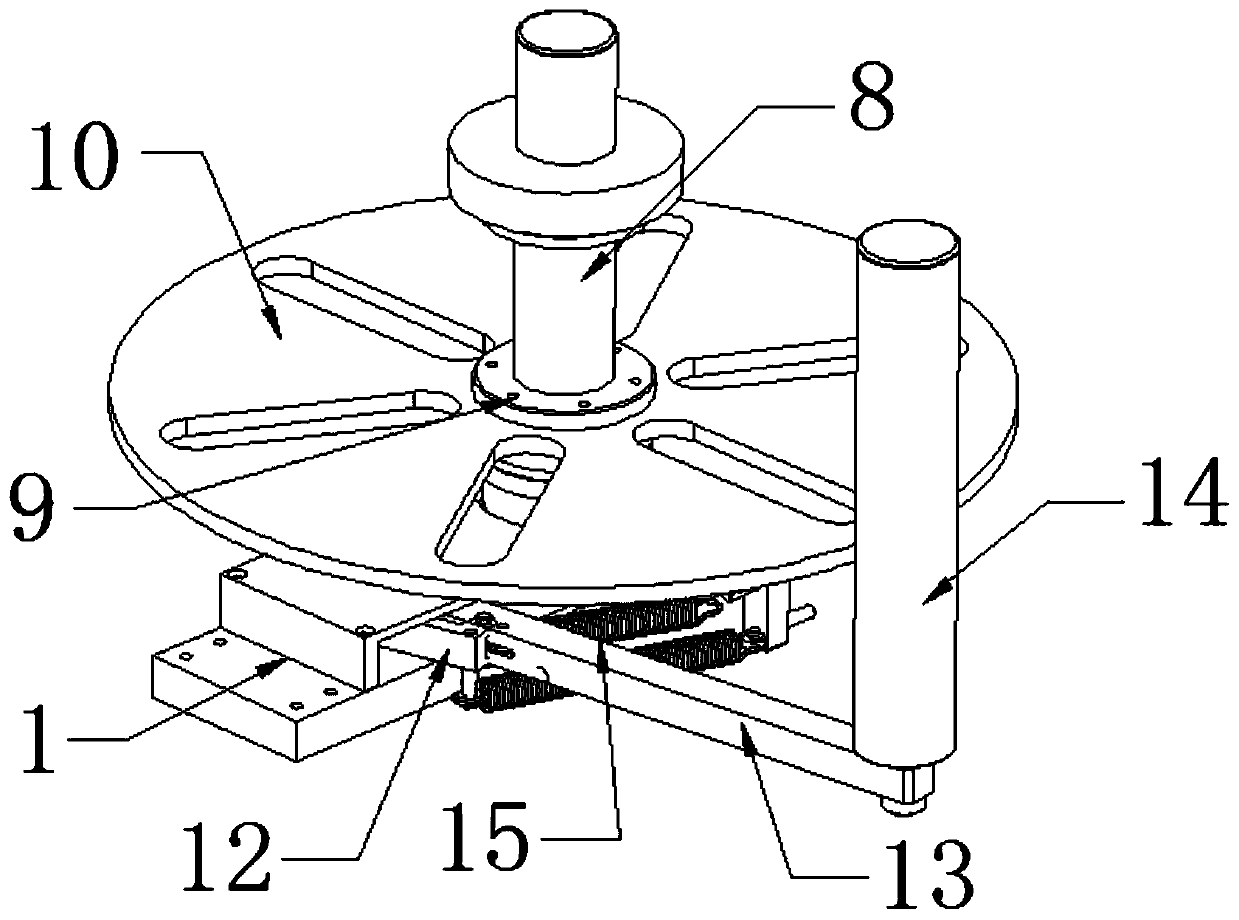

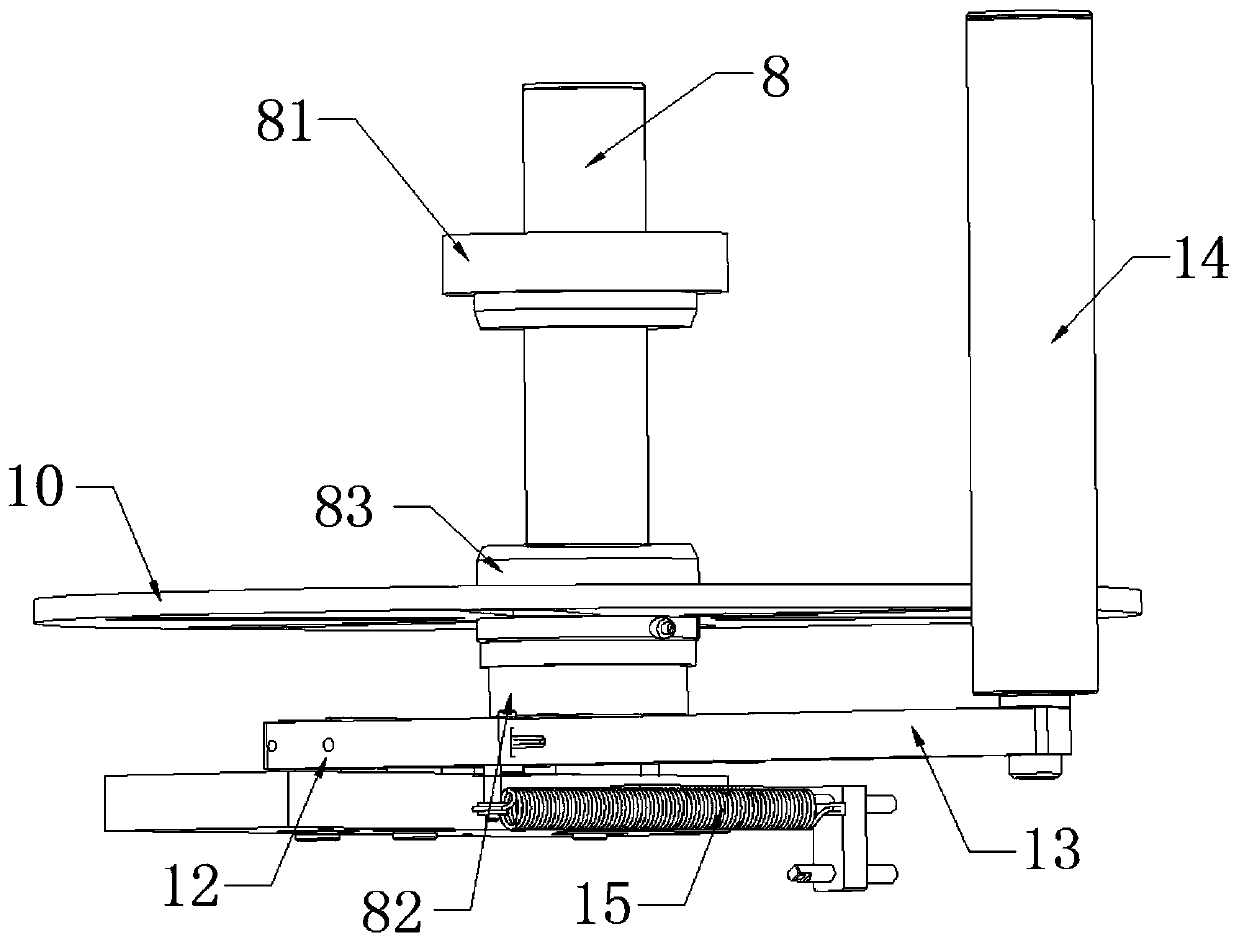

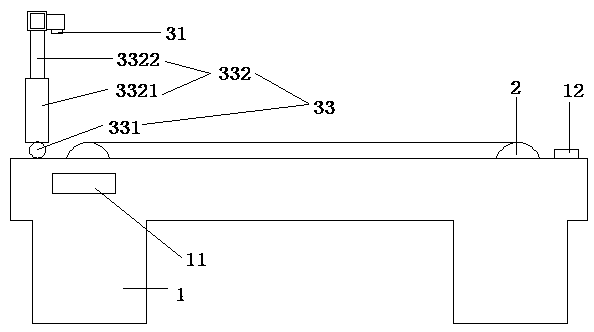

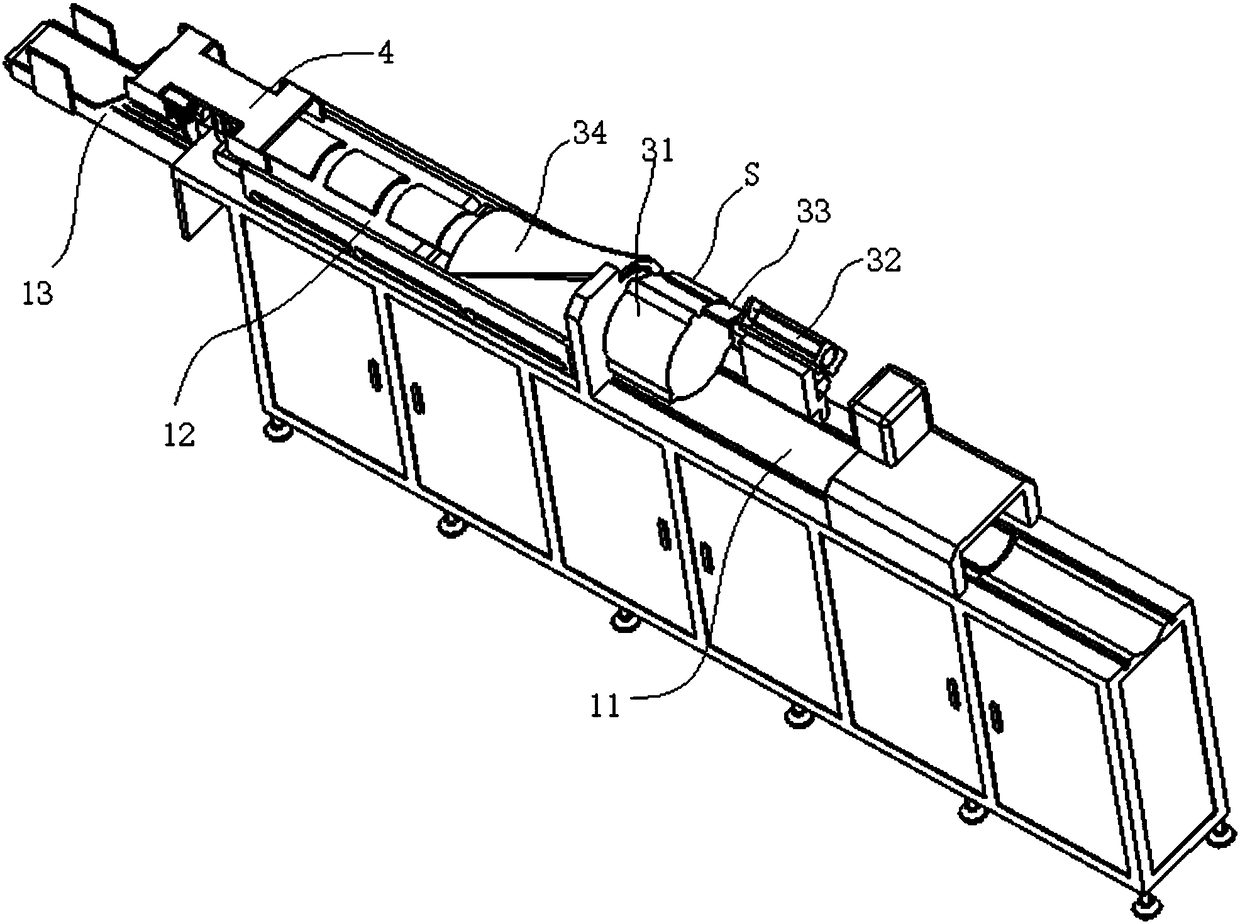

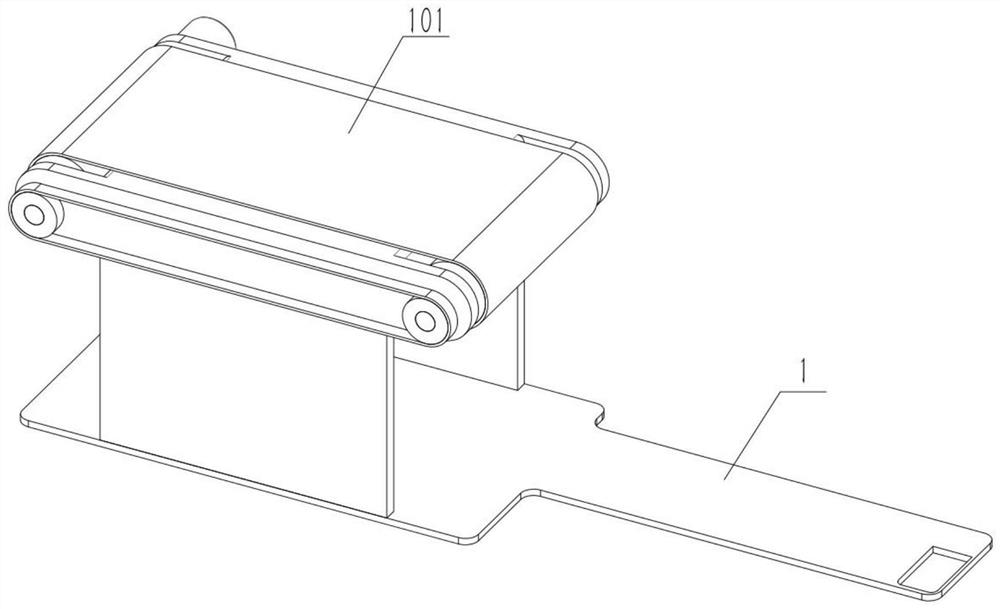

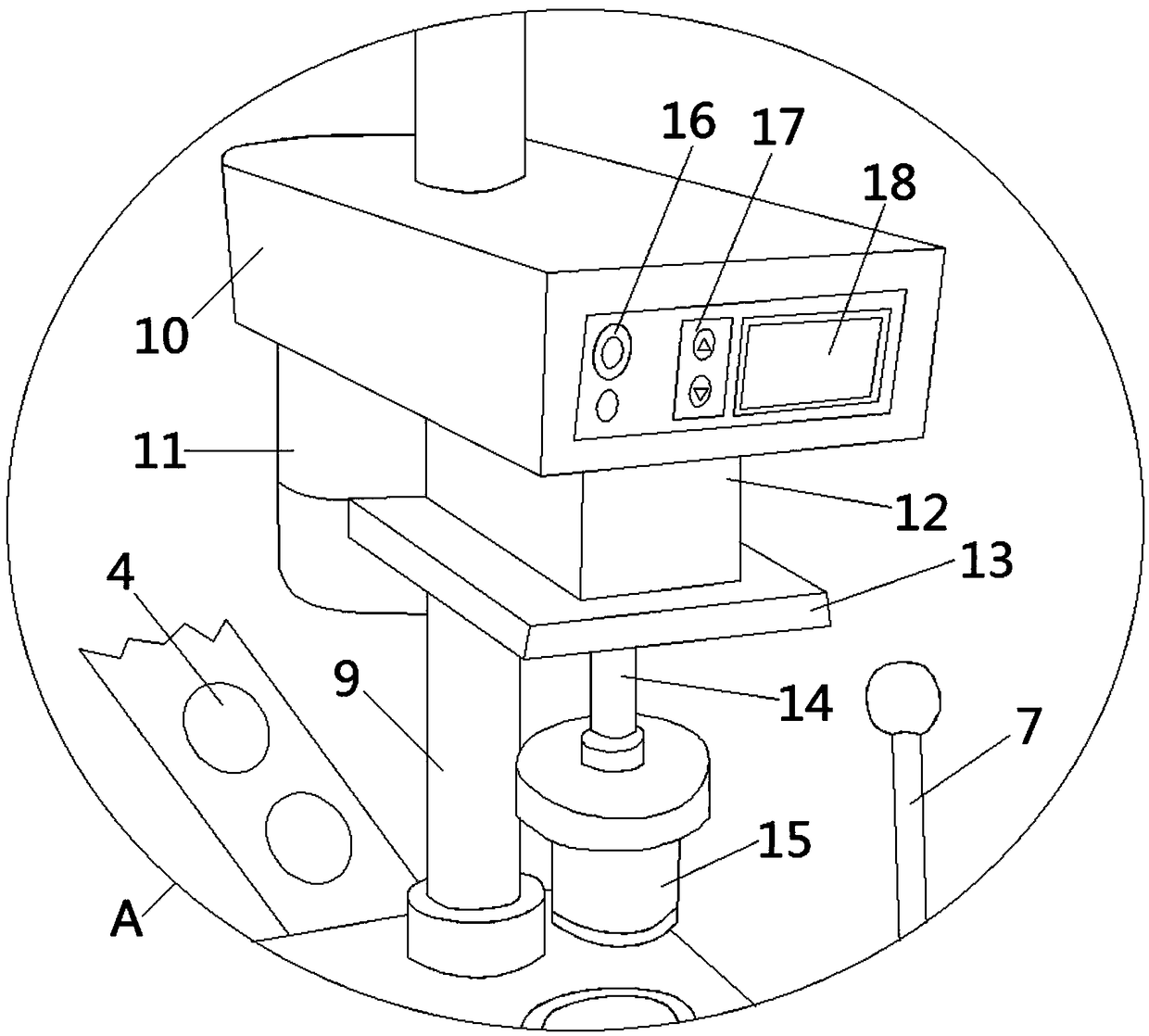

Label rewinding machine running at uniform speed

ActiveCN110844661AConvenient codingUniform linear velocityFunction indicatorsTypewritersElectric machineryDrive motor

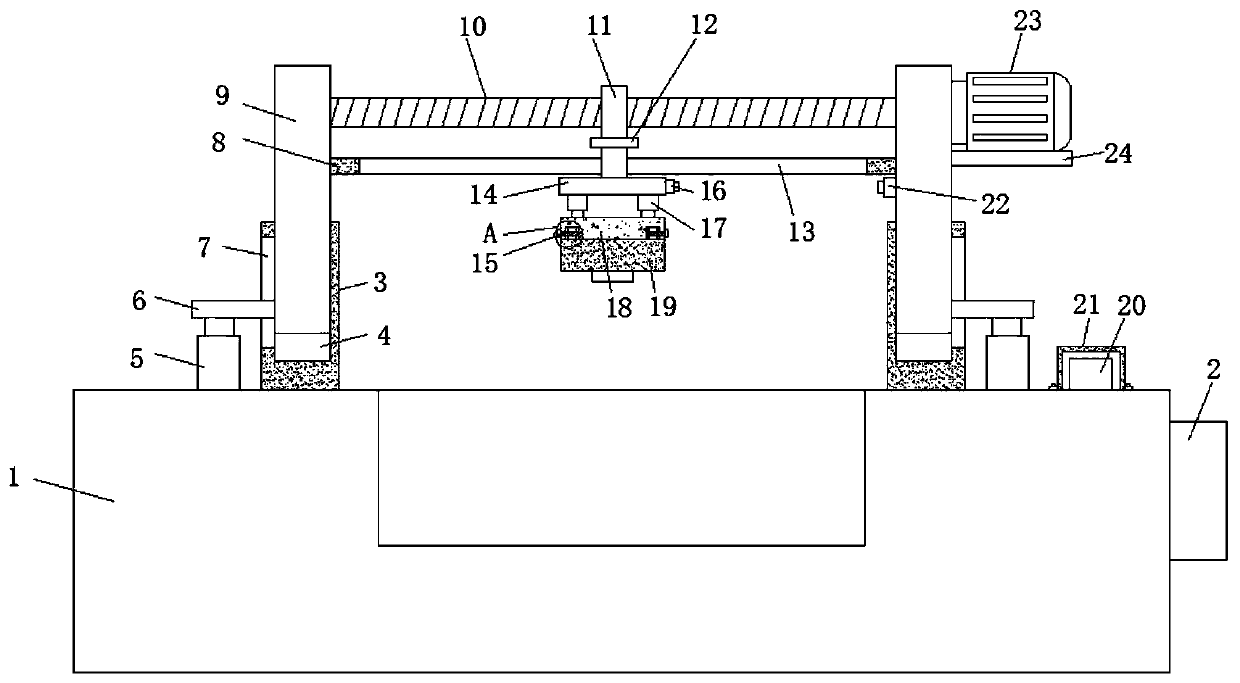

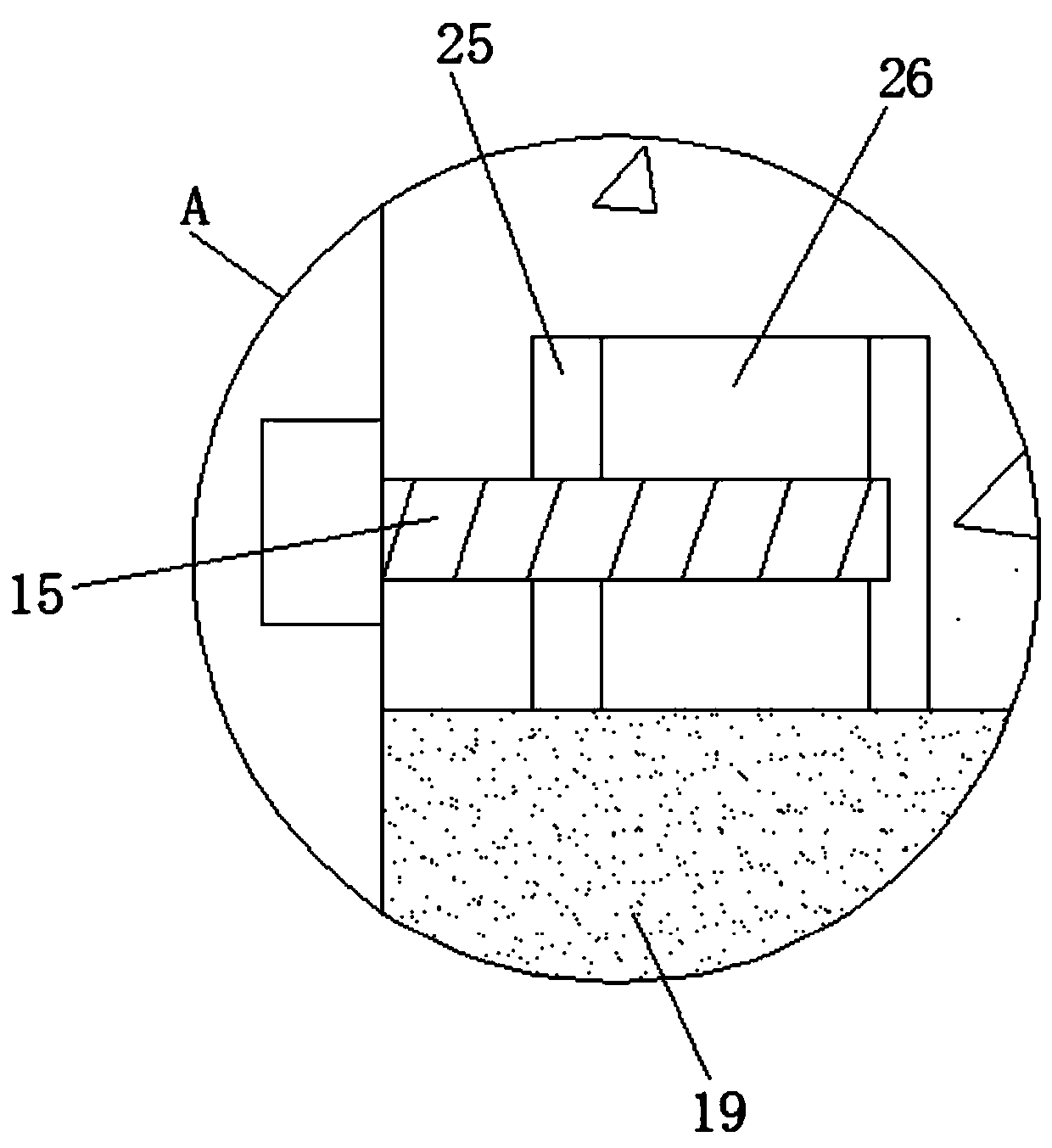

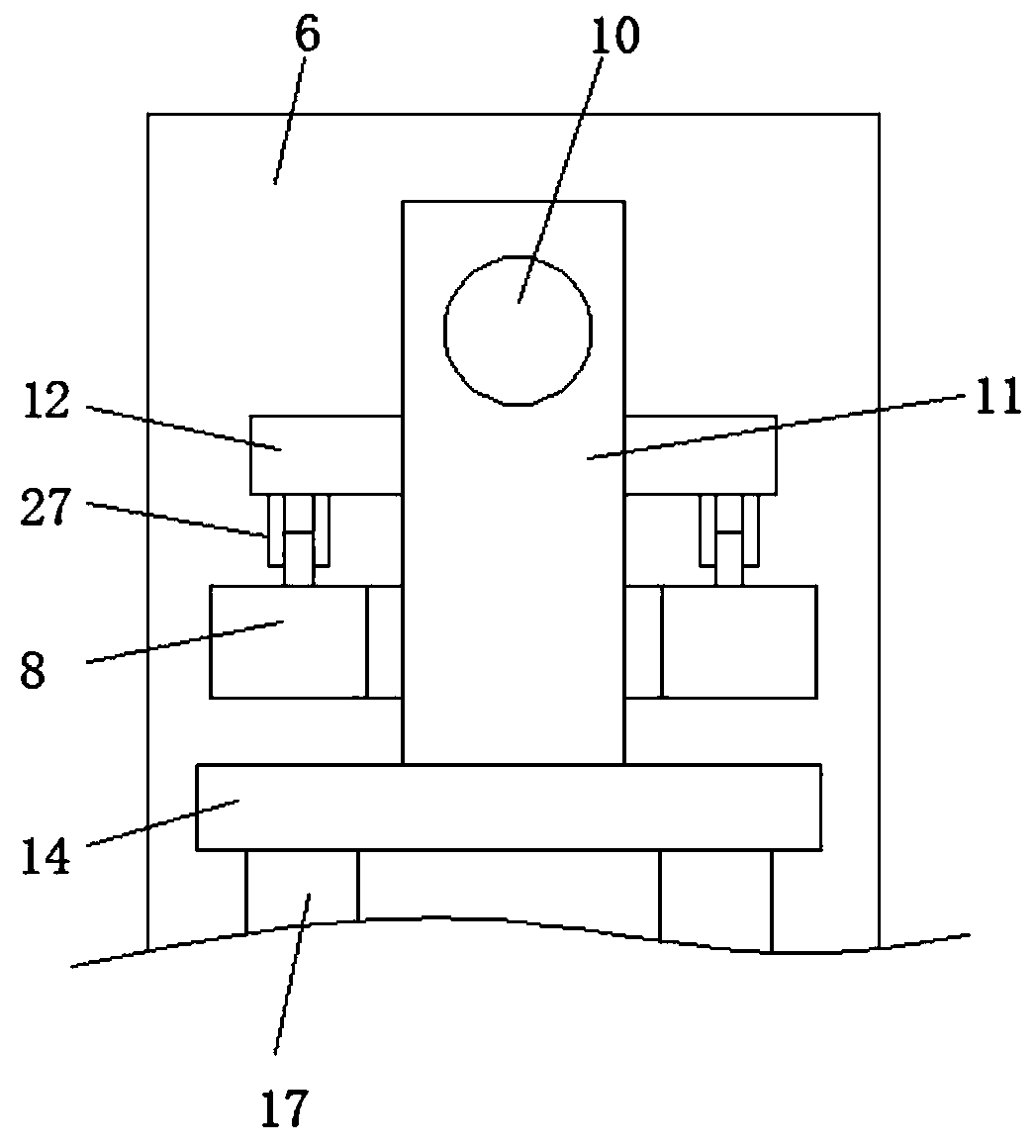

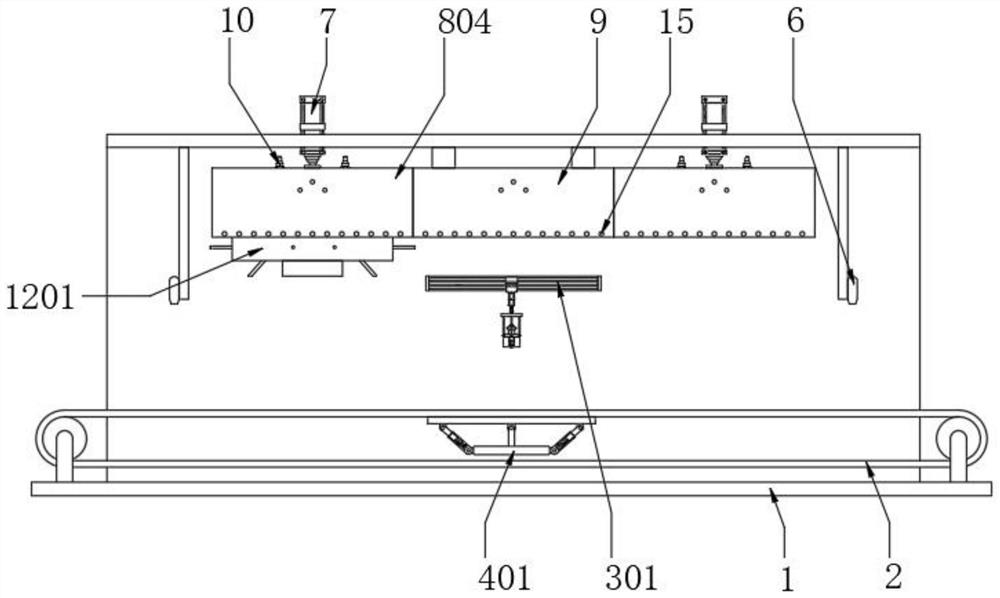

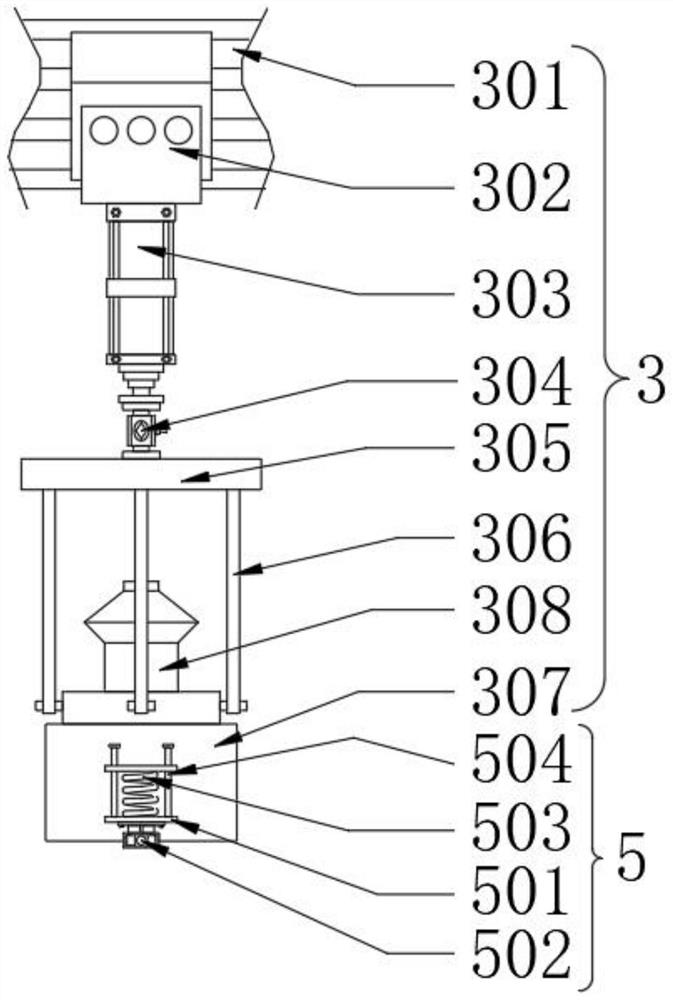

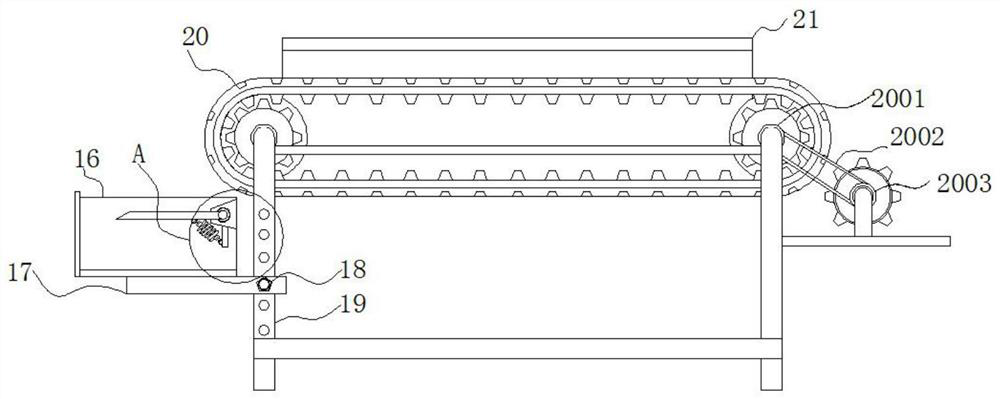

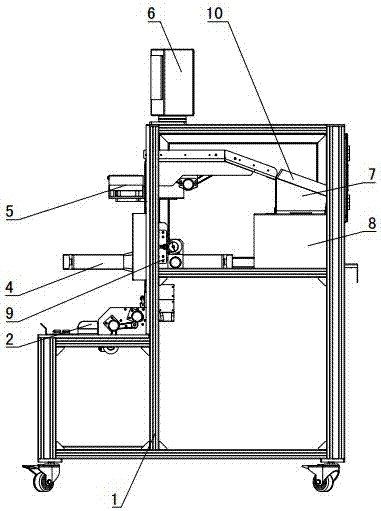

The invention relates to the technical field of label equipment, and discloses a label rewinding machine running at a uniform speed. The machine comprises a rack with the top surface and four sides ofthe top end made of stainless steel panels, wherein an electric box is fixedly installed in an inner cavity on one side of the top end of the rack; a code spraying gun is fixedly installed in the middle of the stainless steel panel on the front surface of the rack by a fixing block; and a code spraying baffle is installed at the code spraying end of the code spraying gun. A motor pulley drives adriving rubber roller big pulley during moving, a driving rubber roller small pulley drives a driving plate pulley, and the driving rubber roller big pulley and the driving rubber roller small pulleyare connected together, so that secondary transmission of the driving motor to the driving plate pulley can be achieved; when the linear speed of the label on the driving plate roller exceeds the linear speed of a driving rubber roller assembly, the driving plate pulley slips, and thus, the linear speed of the driving rubber roller assembly is uniform, the running linear speed of the label is uniform, and code spraying for the label at the designated position is facilitated.

Owner:广州恒拓包装科技有限公司

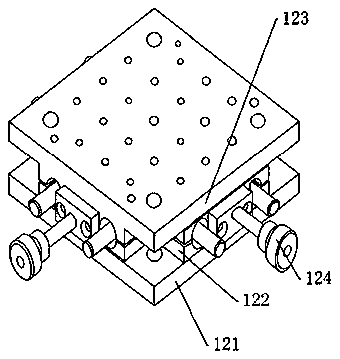

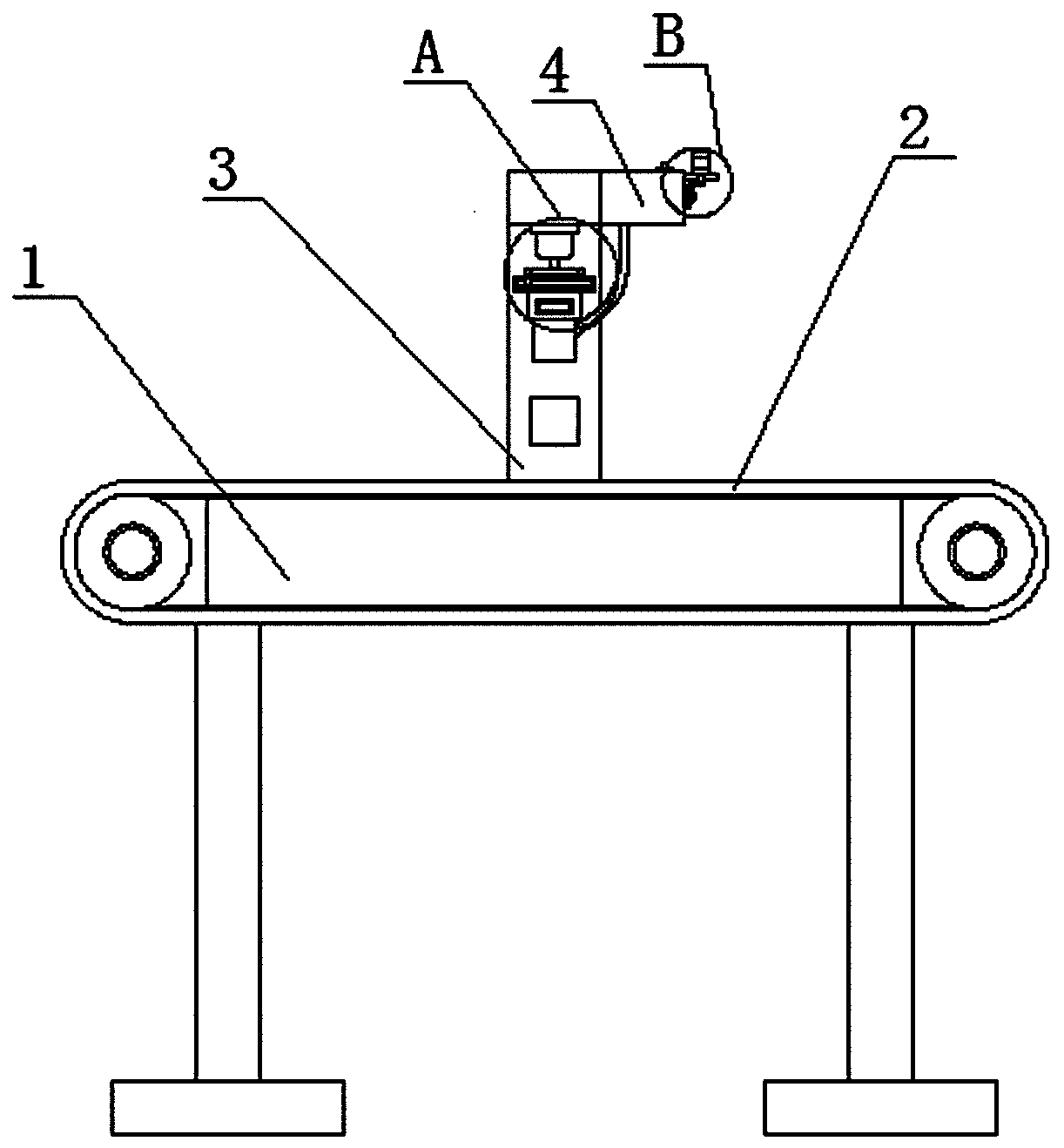

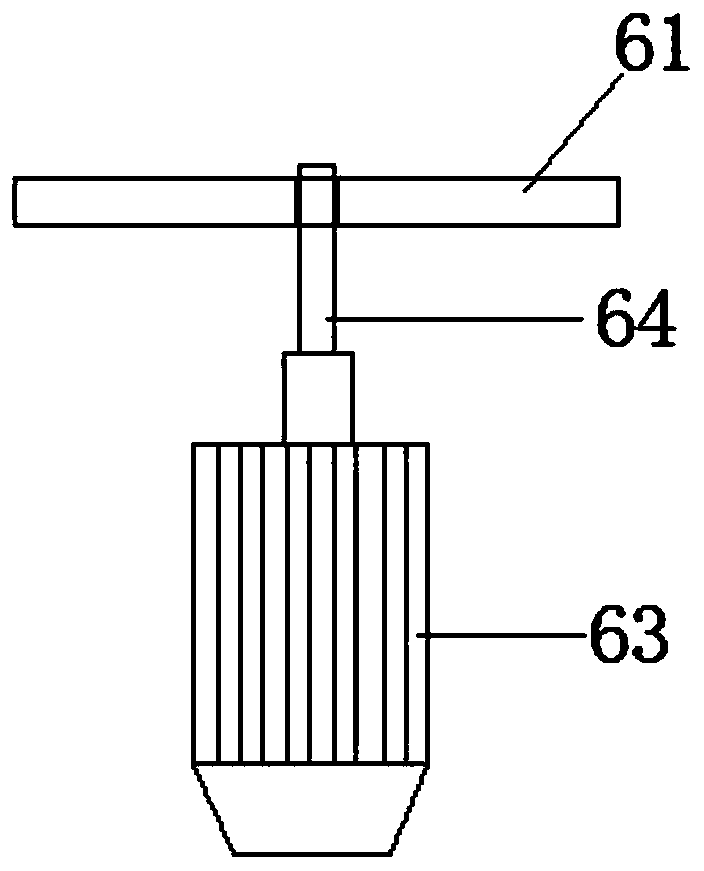

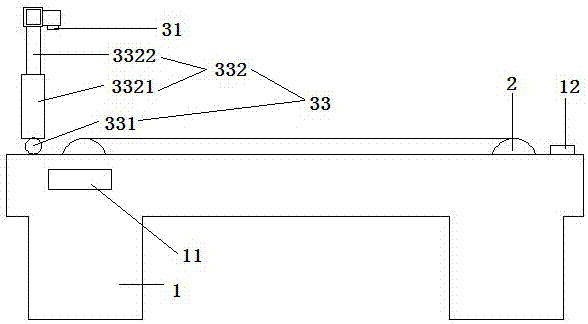

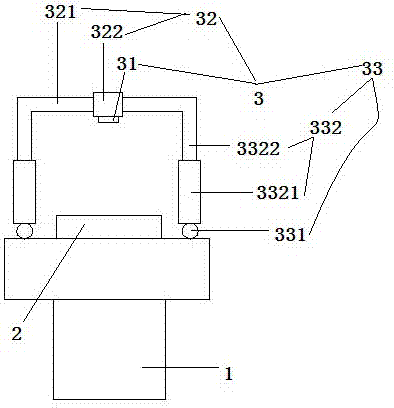

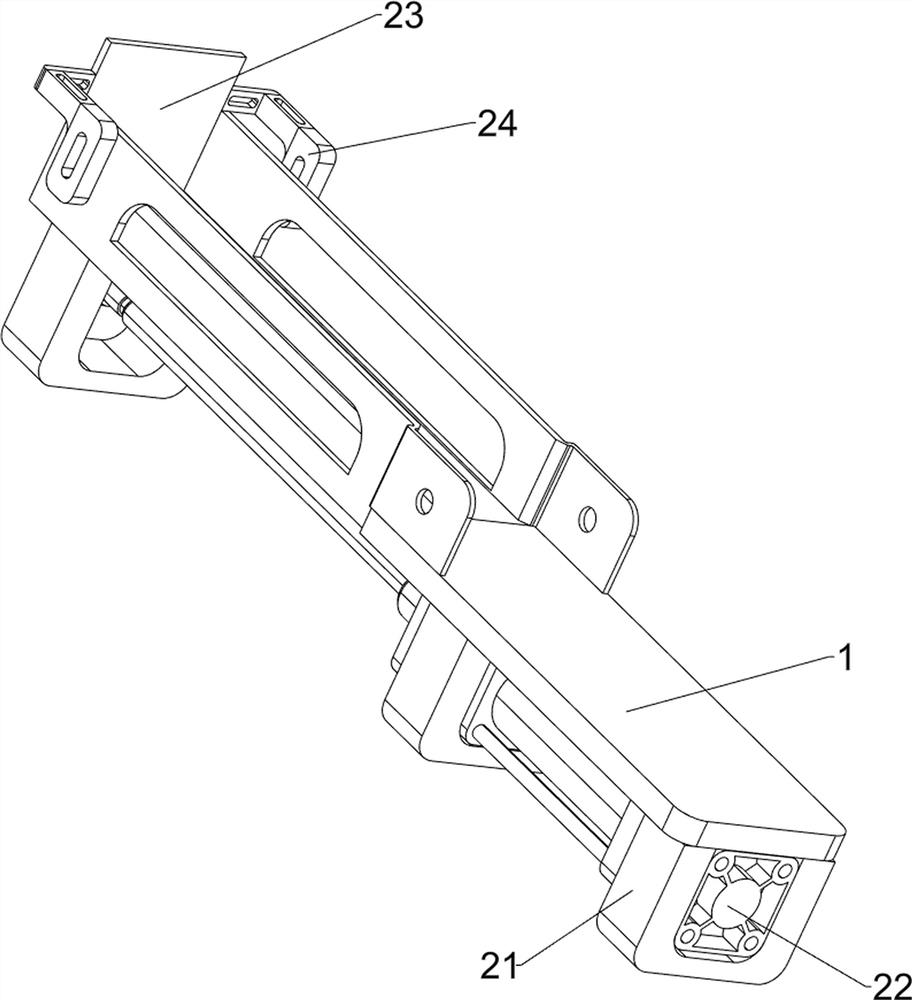

High-precision position-adjustable code spraying device

InactiveCN109624522AConvenient codingMeet the coding needsTypewritersOther printing apparatusEngineeringMechanical engineering

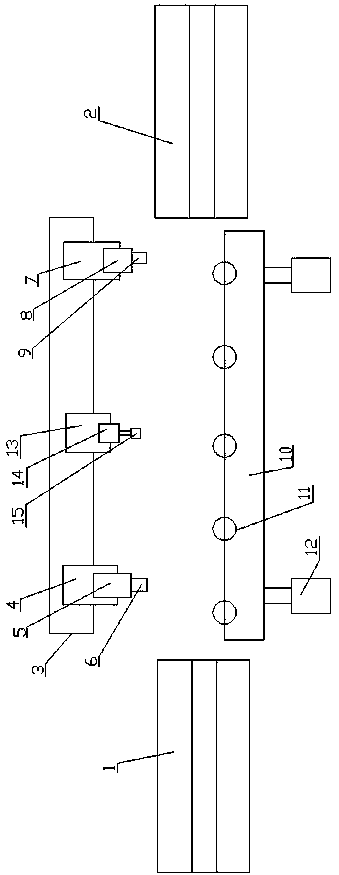

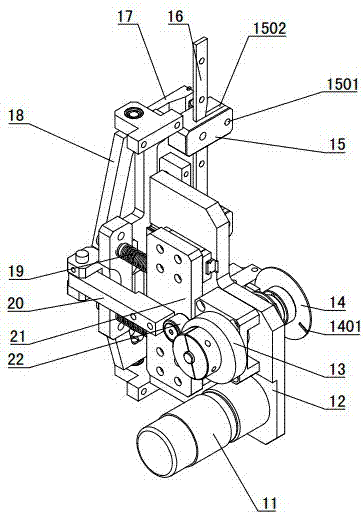

The invention discloses a high-precision position-adjustable code spraying device, solves the problem of capability of adjusting the position of a nozzle to meet different optical fiber code sprayingdemands, and relates to the field of code spraying for optical fibers, cables or linear products. The device comprises a support frame, a code spraying machine nozzle arranged on the support frame, and a first conveying wheel set arranged on the support frame and used for conveying optical fibers under the code spraying machine nozzle; the support frame is provided with a second conveying wheel set for conveying the optical fibers, conveyed out from the lower side of the code spraying machine nozzle, to a winding roller; a movable plate is connected under the support frame; a base plate is arranged under the movable plate; and the base plate is provided with a driving piece for shifting the movable plate in the length direction of the base plate.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD

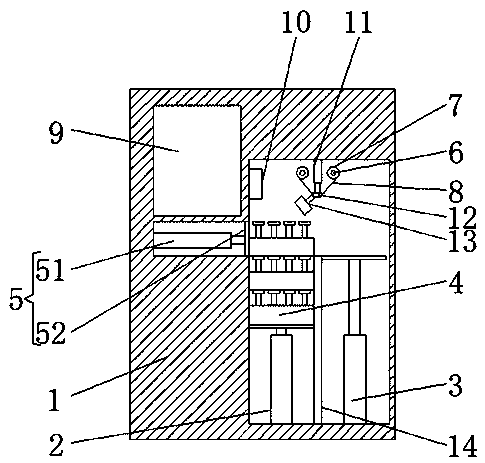

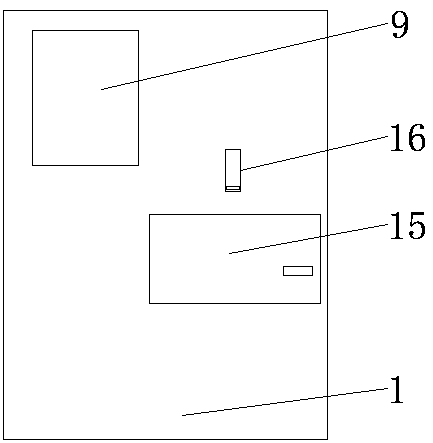

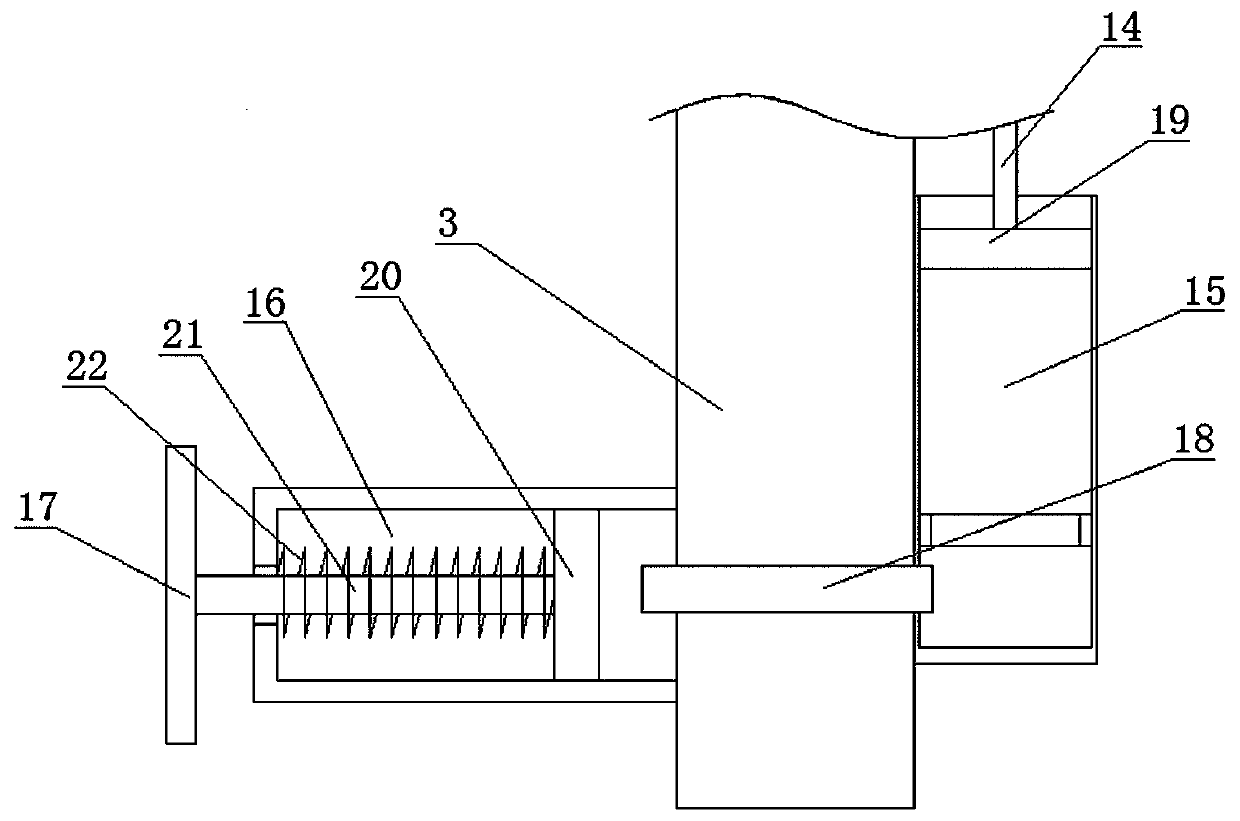

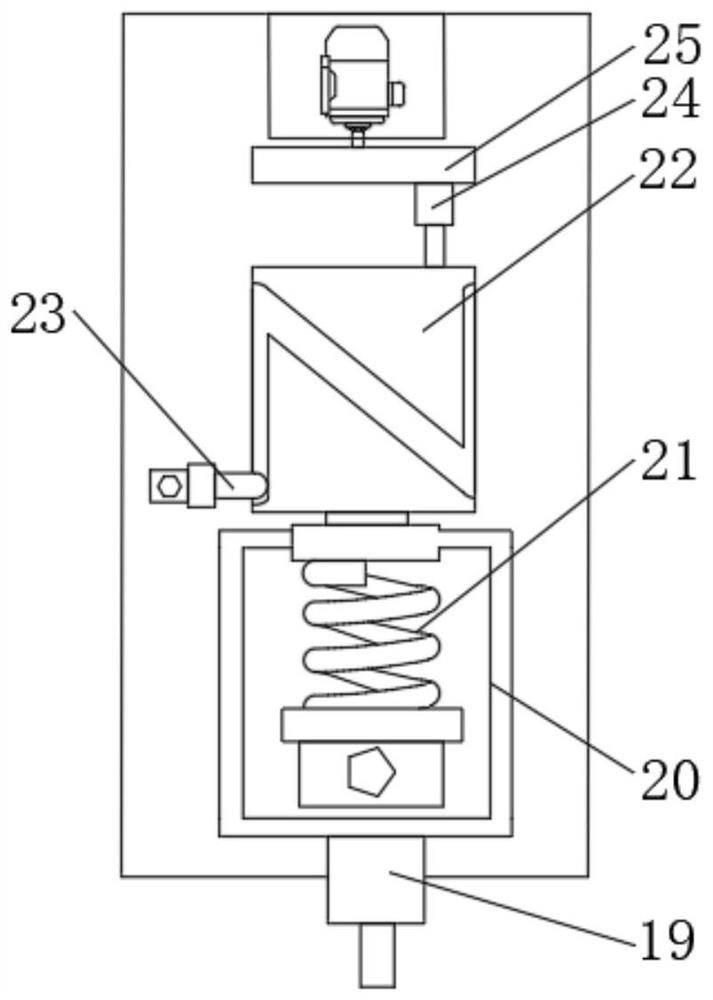

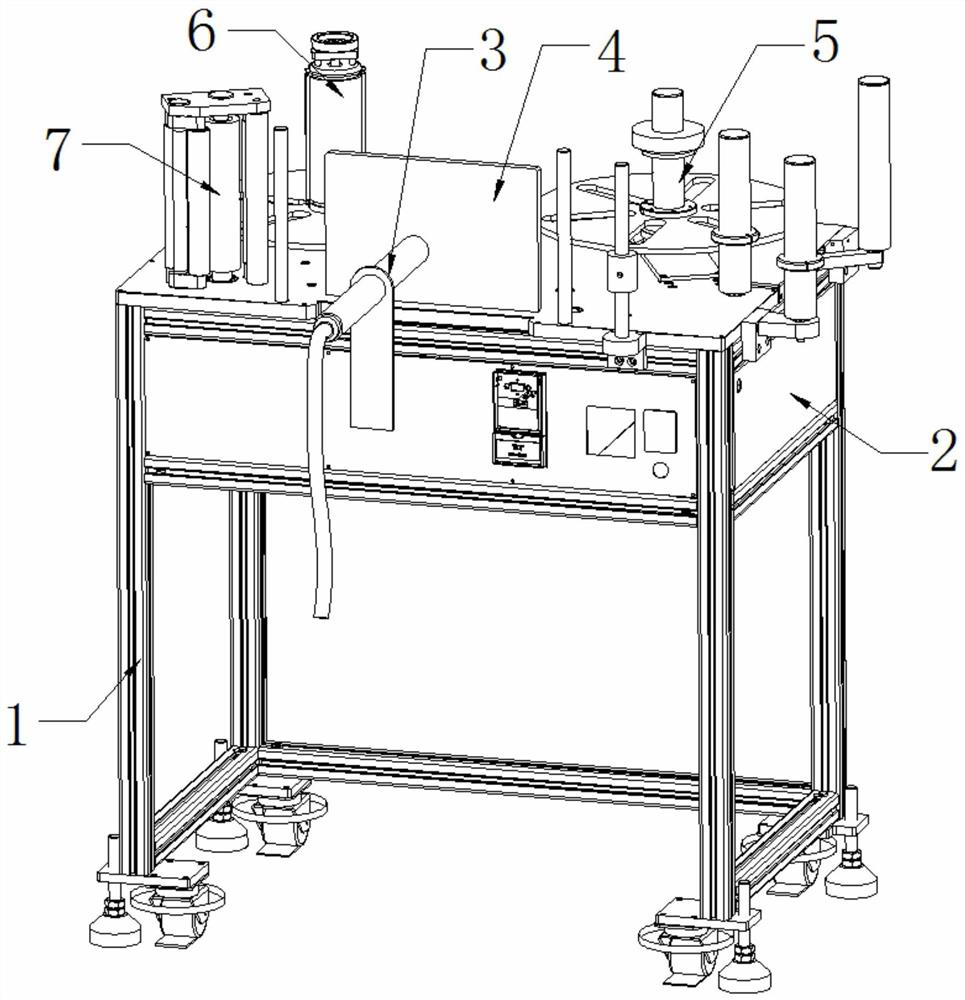

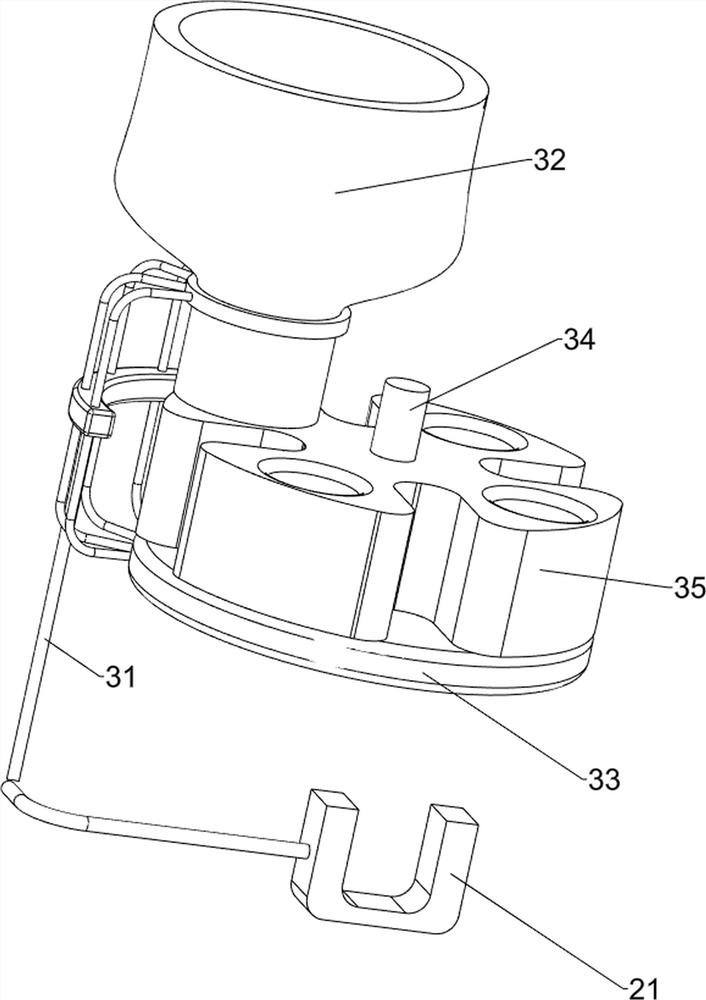

Full-self-service nasal swab sampler and use method thereof

PendingCN111317513AEasy accessEasy to markSurgeryVaccination/ovulation diagnosticsElectric machineryEngineering

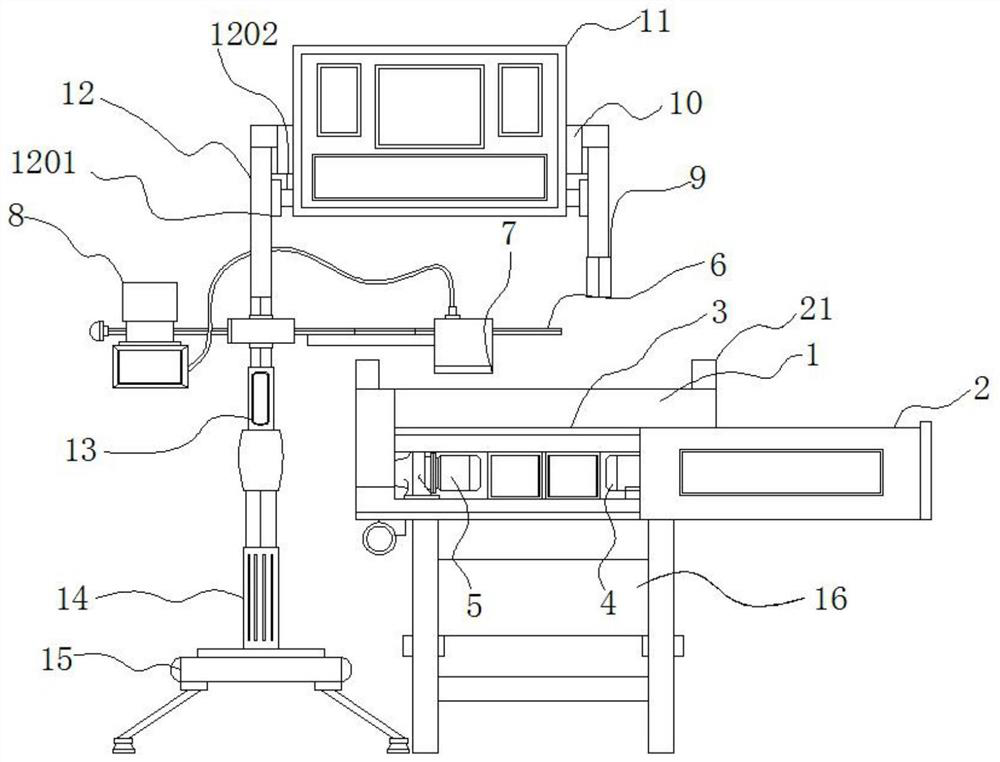

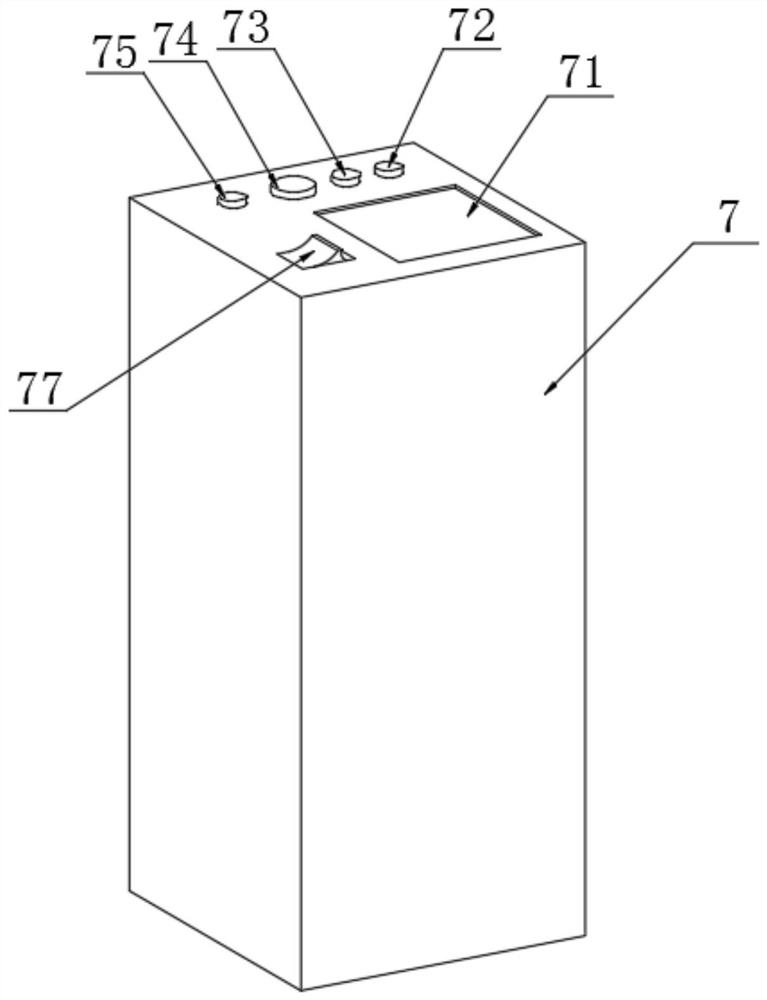

The invention discloses a full-self-service nasal swab sampler and a use method thereof. The full-self-service nasal swab sampler comprises a cabinet, wherein a first electric telescopic rod is fixedly connected to the left side of the bottom of an inner cavity of the cabinet; a placement plate is fixedly connected to the top of the first electric telescopic rod; a nasal swab storage mechanism isarranged at the top of the placement plate; a feeding mechanism is fixedly connected to the left side of the inner cavity of the cabinet; and a driving motor is fixedly connected to the back of the inner cavity of the cabinet. By designing a touch display screen, the use method of the nasal swab sampler can be displayed on the touch display screen, and the working efficiency is improved; by meansof cooperation of the first electric telescopic rod, the placement plate, the feeding mechanism and a sampling door, a tester can conveniently take the nasal swab sampler, and the operation is convenient; and by means of cooperation of the driving motor, a rotating wheel and code paper, each nasal swab sampler can be conveniently marked, later searching is facilitated, and therefore the effect ofhigh working efficiency is achieved, the problem that an existing device is low in working efficiency is solved, and medical workers can be prevented from being infected.

Owner:THE SEVENTH AFFILIATED HOSPITAL SUN YAT SEN UNIV SHENZHEN

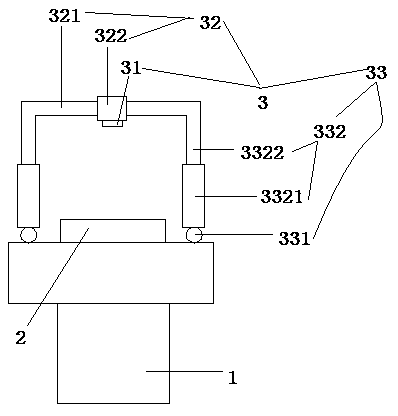

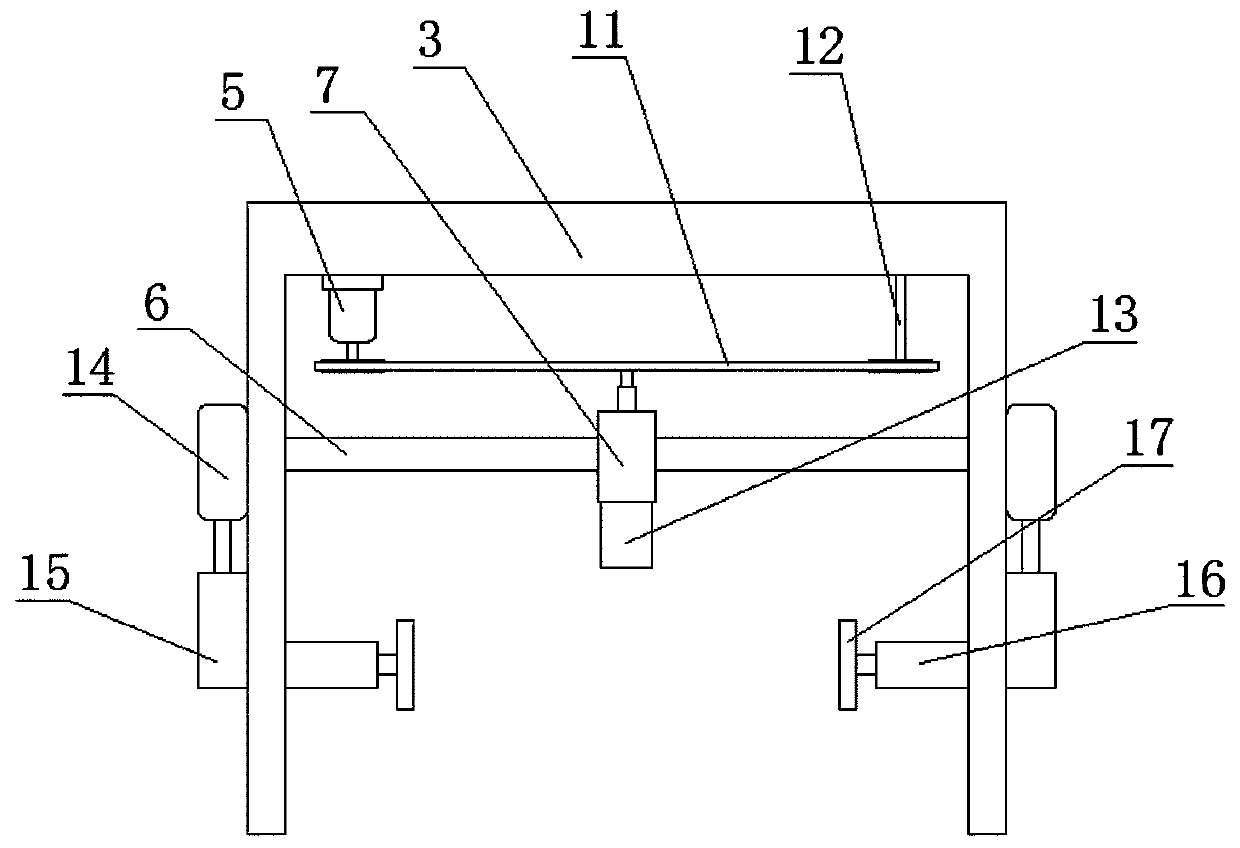

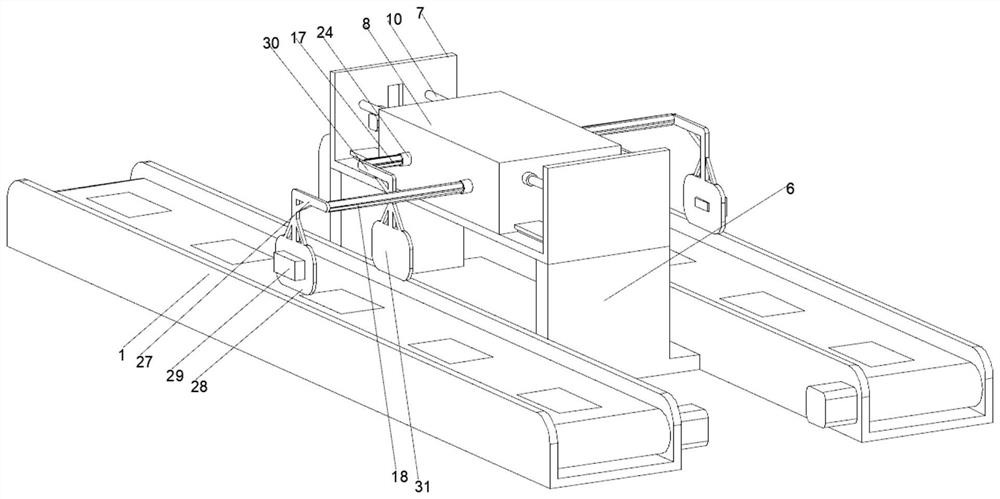

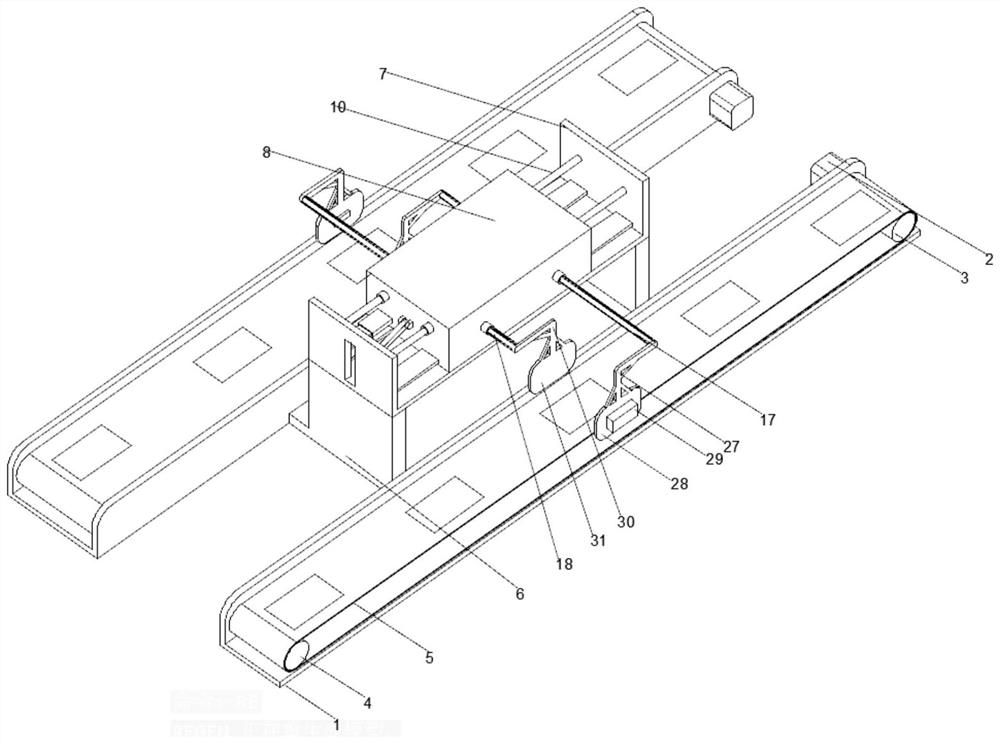

Energy-saving efficient code spraying printing machine

InactiveCN105500923ASimple structureImprove printing effectTypewritersOther printing apparatusSprayerEngineering

The invention discloses an energy-saving efficient code spraying printing machine. The code spraying printing machine comprises a rack, a conveying mechanism arranged on the rack and used for conveying materials, and a code spraying mechanism arranged on the rack and used for code spraying. The code spraying mechanism comprises a code spraying printing machine sprayer, an adjusting mechanism for fixing the code spraying mechanism sprayer and adjusting the position of the code spraying mechanism sprayer, and a supporting frame arranged on the rack and used for fixing or moving the adjusting mechanism. The supporting frame comprises moving idler wheels used for moving the whole code spraying mechanism to advance or retreat, and a lifting support arranged on the moving idler wheels and used for lifting the adjusting mechanism. The adjusting mechanism comprises a transverse support connected with the lifting support and used for moving the code spraying mechanism sprayer to move transversely, and a sliding support, wherein the sliding support is arranged on the transverse support, can slide on the transverse support and is used for being connected with the code spraying mechanism sprayer. The machine is simple in structure, and convenient to operate and maintain, waste of work hours is avoided, products are neat and uniform in code spraying after codes are sprayed, the derating rate is reduced, and the production cost is reduced.

Owner:蒙托壁(杭州)智能科技有限公司

Automatic code spraying guide device

InactiveCN105365414AGood stabilityExtended service lifeTypewritersPower drive mechanismsEngineeringMechanical engineering

The invention provides an automatic code spraying guide device and belongs to the technical field of code spraying equipment. The automatic code spraying guide device comprises a linear sliding unit, a servo motor and a lead screw. A sliding block is slidably arranged on guide rails. A supporting plate is horizontally fixed to the sliding block. A spraying head installation base is fixed to the supporting plate. Fixing nuts are welded to one side of the spraying head installation base. Swing bolts are in threaded connection with the fixing nuts. Connecting plates are located at the two ends of the linear sliding unit. Limiting screws are further arranged on the connecting plates and located at the outer sides of fastening screws. Lead screw supports are installed on the connecting plates. The lead screw is rotatably arranged on the lead screw supports. The lead screw is in threaded connection with a lead screw nut. One end of the lead screw is coaxially connected with the servo motor. By the adoption of the automatic code spraying guide device, different types of spraying heads can be guided, code spraying can be conducted on a large-size and excessively-heavy product conveniently, code spraying is even, and the effect is good.

Owner:ZHEJIANG HUASHUN METAL MATERIAL CO LTD

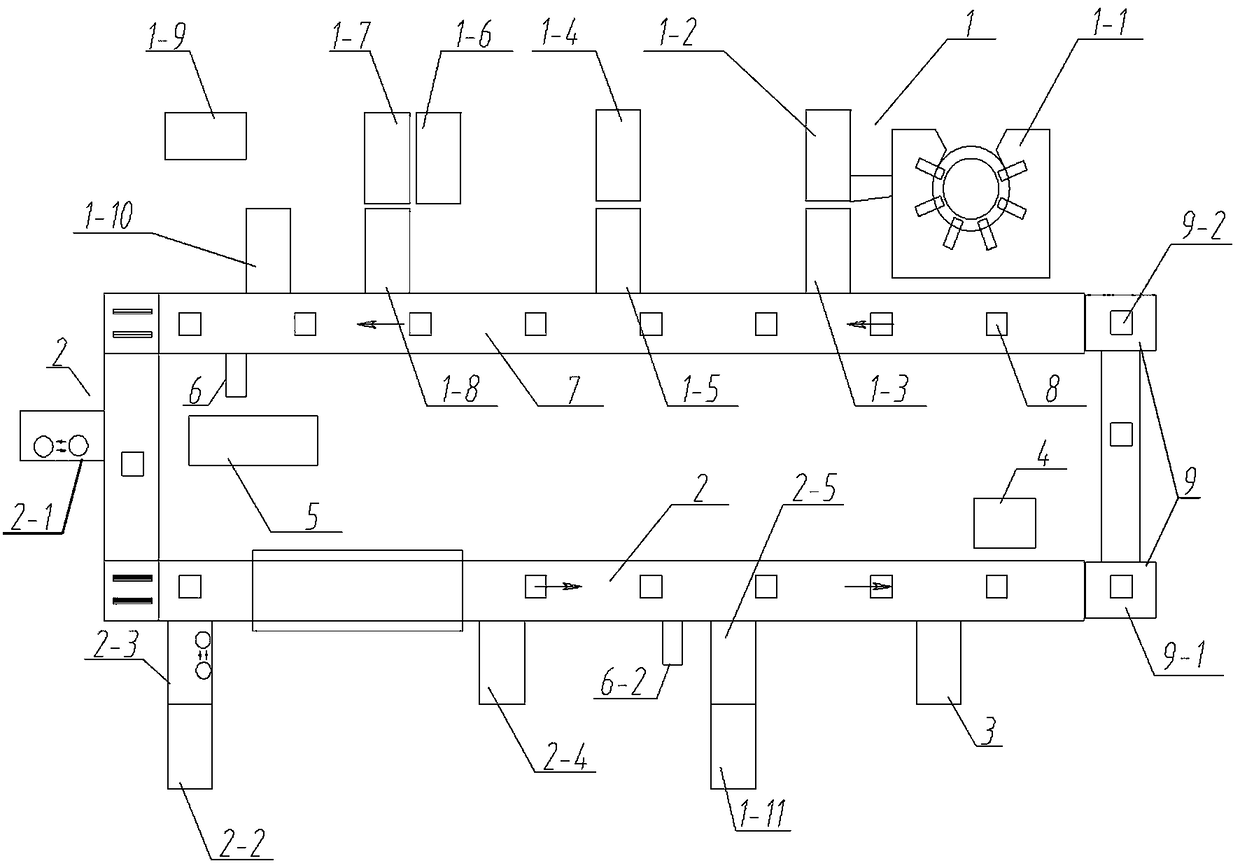

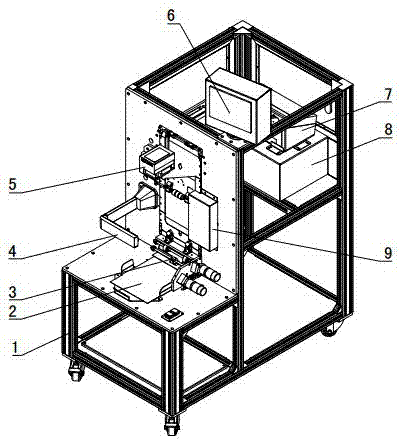

Production line of gas mask assembly

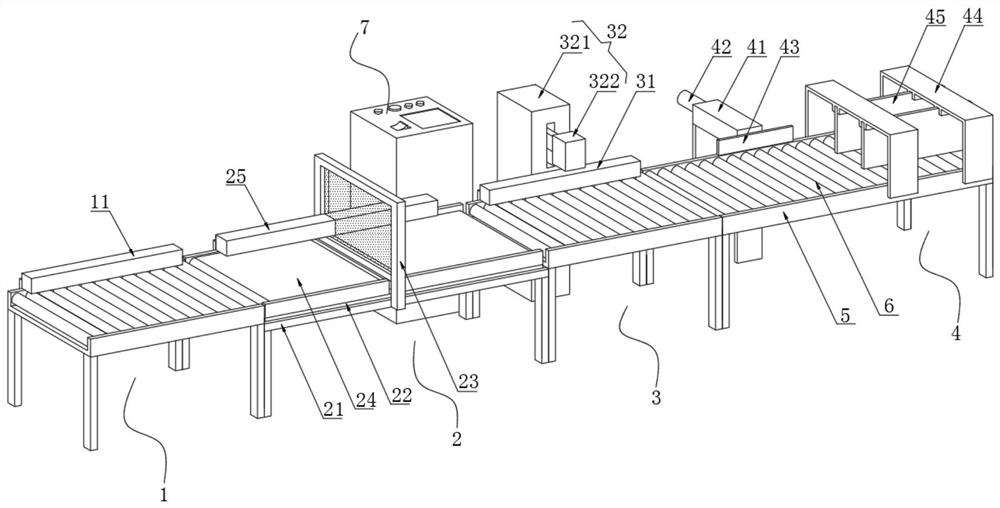

PendingCN108312590AAutomate assemblyAutomatic feedingDomestic articlesTotal factory controlProduction lineElectric machinery

A production line of a gas mask assembly comprises a main control cabinet, an assembling station, a detecting station, an inspection station, an industrial personal computer, an ink-jet printer, a conveying line body, a tray, a charging station, a packing station, a compressed air pipeline, a connecting cable, a servo motor, a cylinder and a manual button. The production line is characterized in that the charging station is provided and is connected to the assembling station through a material conveying device; the assembling station is connected to the inspection station, and the inspection station is connected to the packing station through the material conveying device. The production line integrates the gas mask charging, automatic assembling, detecting and packing functions.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

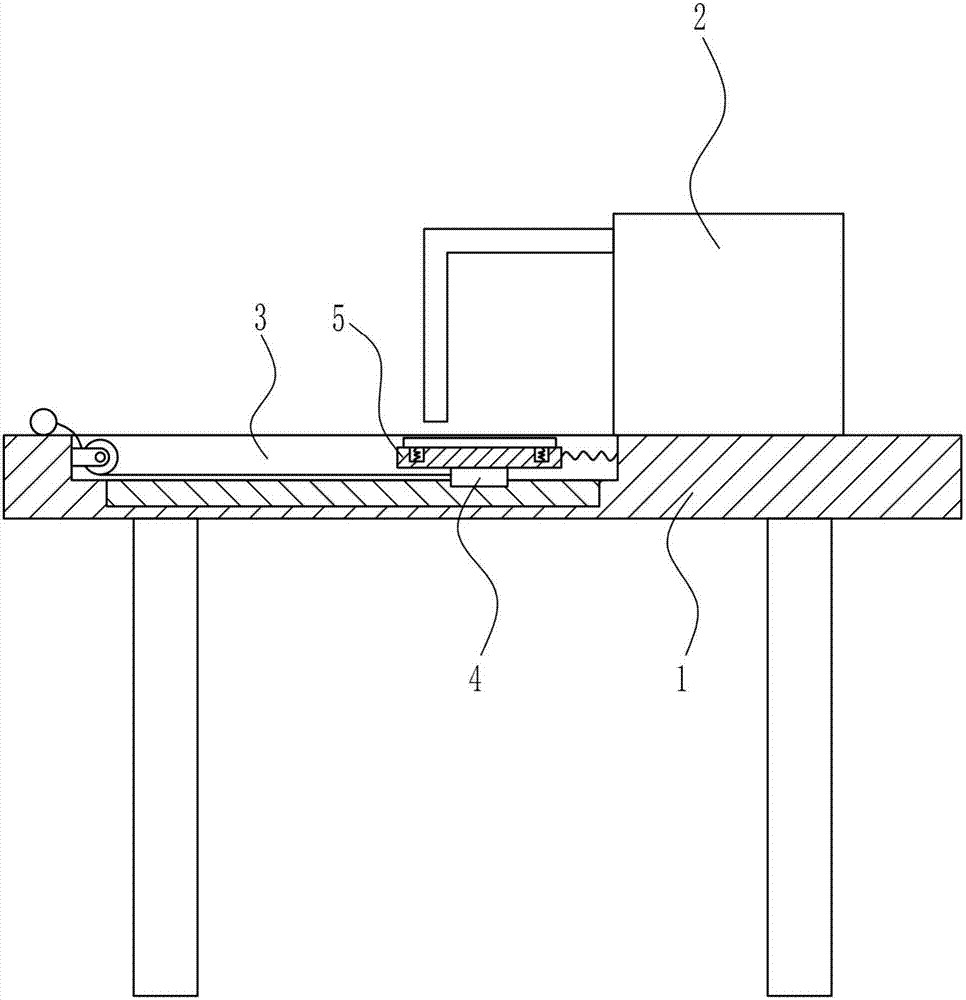

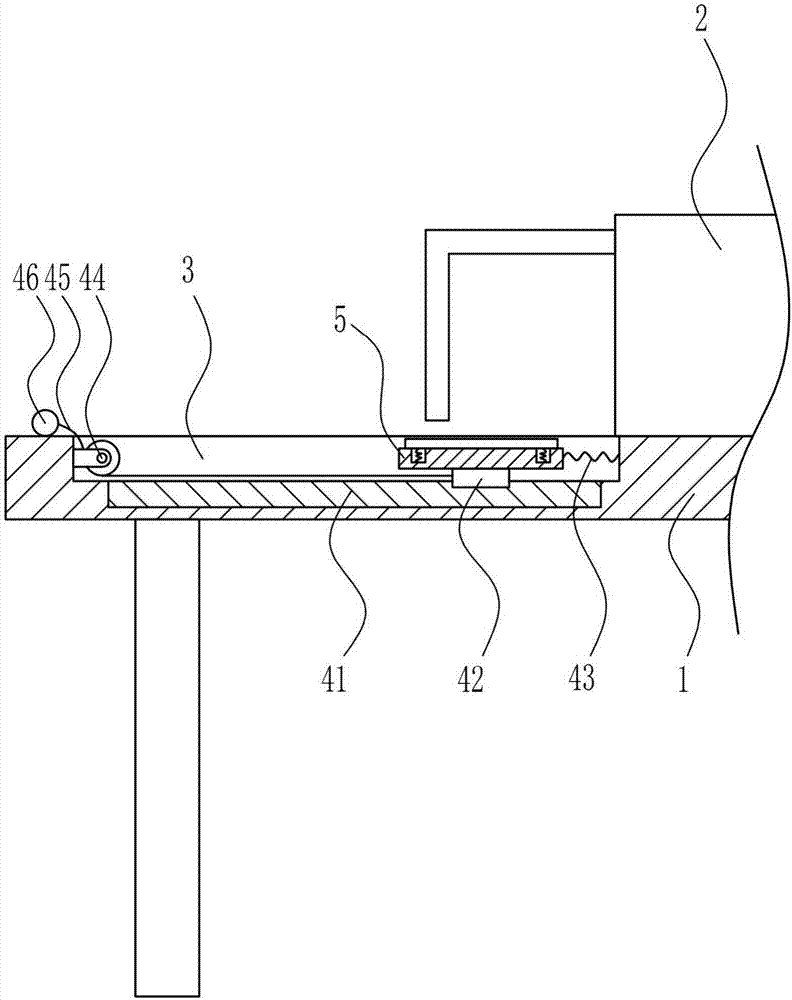

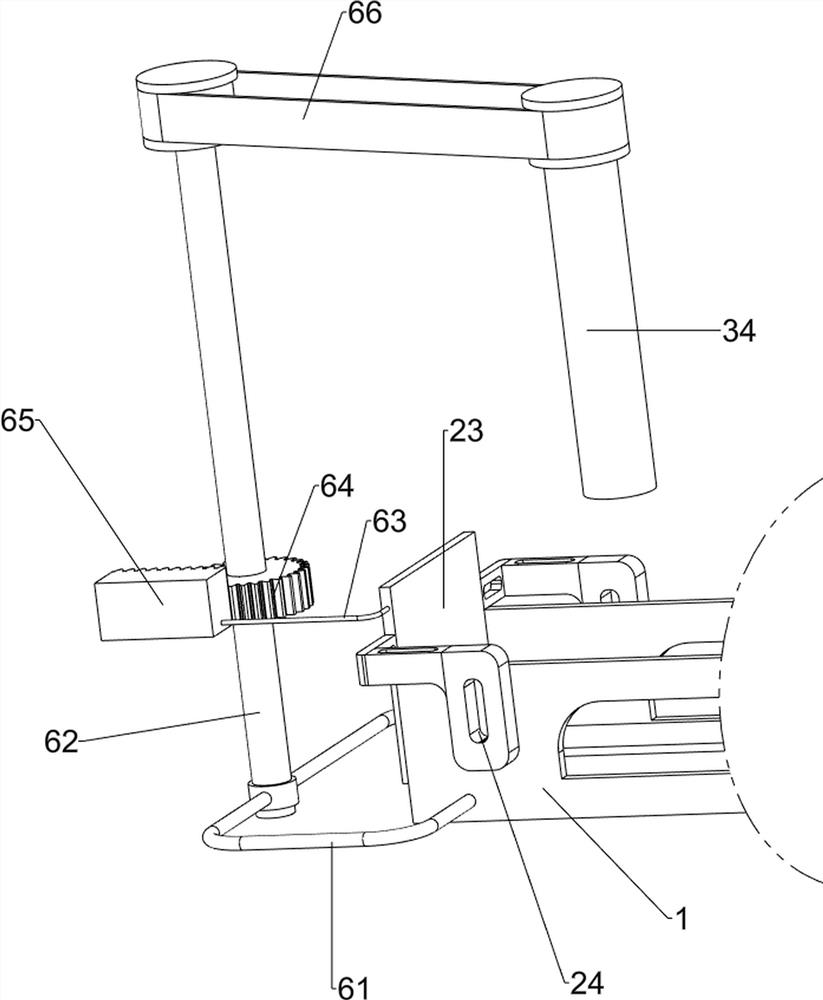

Moving code spraying device for food packaging machine

InactiveCN111038796APrecise movement controlConvenient codingPackagingStructural engineeringFood packaging

The invention relates to the technical field of food packaging, in particular to a moving code spraying device for a food packaging machine. Specific to the problems that in the prior art, the heightof a moving code spraying device cannot be adjusted conveniently, and demounting and mounting of a code spraying machine are not convenient, the following scheme is now put forwards. According to thefollowing scheme, the moving code spraying device comprises a base and a code spraying machine, two supporting plates and two first electric telescopic rods are fixed to the top of the base, containing grooves are formed in the tops of the two supporting plates, lifting plates are arranged in the two containing grooves, and the tops of the two lifting plates extend to the outer portions of the containing grooves. Connecting grooves are formed in the sides, away from each other, of the two supporting plates, and connecting plates are fixed to one sides of the two lifting plates. The moving codespraying device is reasonable in structure, ingenious in design and easy to operate, the height of the code spraying machine can be adjusted conveniently, and therefore the moving code spraying device can adapt to code spraying of objects with different heights; and in addition, the code spraying machine can be demounted and mounted conveniently, and therefore the purpose of conveniently overhauling the code spraying machine is achieved.

Owner:安徽采林间食品有限公司

Intelligent manufacturing laser ink-jet printer capable of identifying ink-jet position

ActiveCN113787260AUse many timesAvoid offsetLaser beam welding apparatusForce sensorSmart manufacturing

The invention relates to an intelligent manufacturing laser ink-jet printer capable of identifying an ink-jet position. The intelligent manufacturing laser ink-jet printer comprises a shell and a connecting assembly, a belt conveyor is arranged on the lower wall of the interior of the shell, the supporting assembly comprises a second plate, a supporting rod, a connecting pin, a third plate, outer sleeves, a second pressure sensor, a first spring and a telescopic rod, the supporting rod is arranged at the upper end of the second plate, the connecting pin is connected to the upper end of the supporting rod, the third plate is connected to the outer part of the connecting pin, and the outer sleeves are movably connected to the left side and the right side of the second plate. The intelligent manufacturing laser ink-jet printer has the beneficial effects that the code spraying position can be positioned in advance through the intelligent manufacturing laser ink-jet printer, then accurate code spraying is achieved in an accurate butt joint mode, products can be positioned through the intelligent manufacturing laser ink-jet printer, deviation of the code spraying position caused by deviation of the product position is prevented, and the intelligent manufacturing laser ink-jet printer can convey an auxiliary device, so that the auxiliary device can be used for multiple times.

Owner:深圳市海纳激光科技有限公司

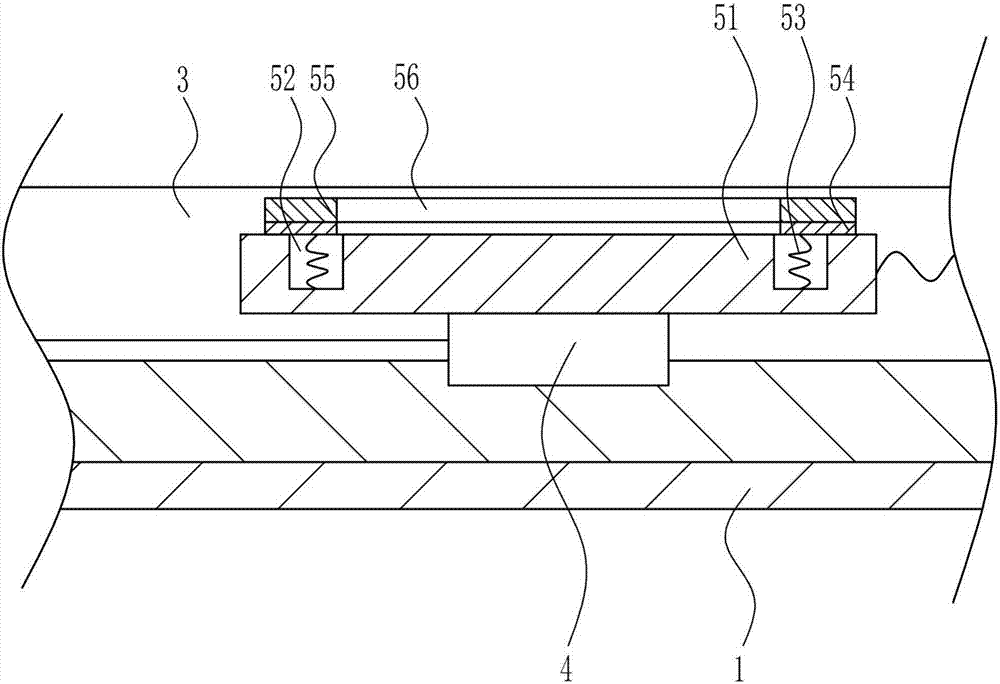

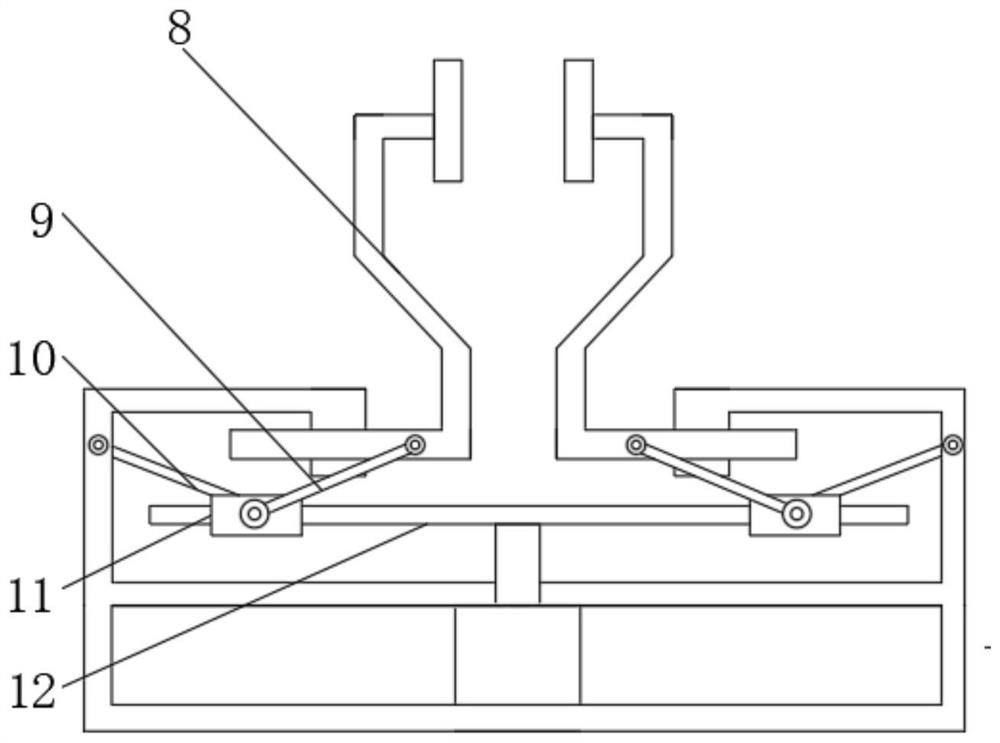

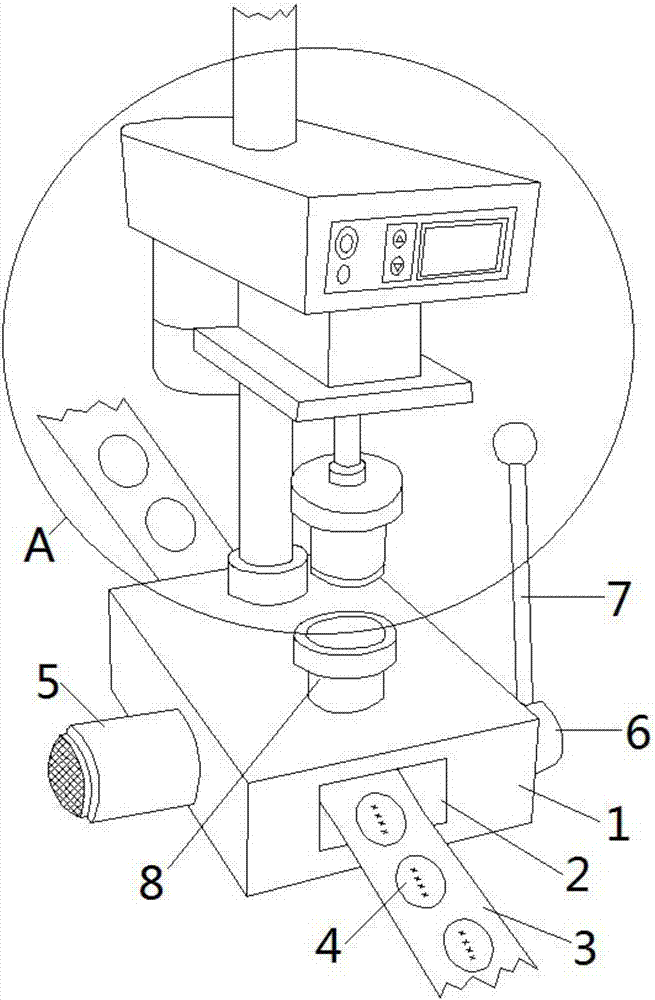

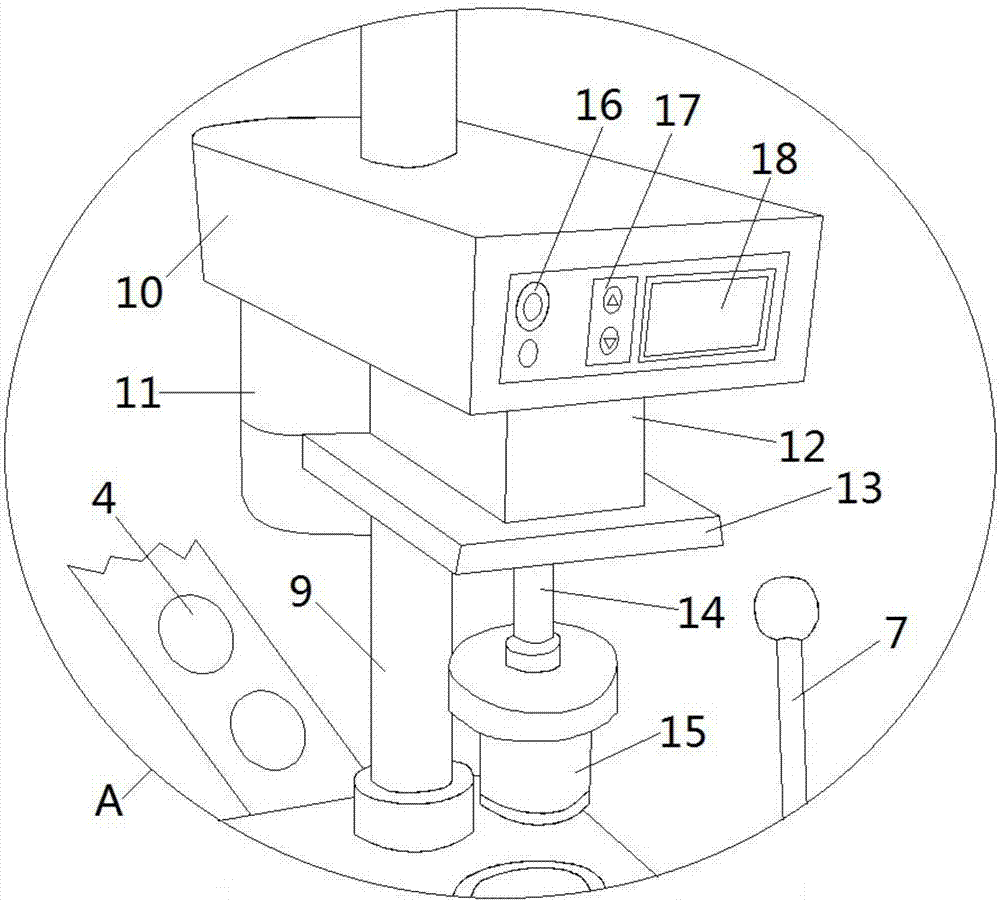

Code spraying equipment for entrance guard card manufacturing

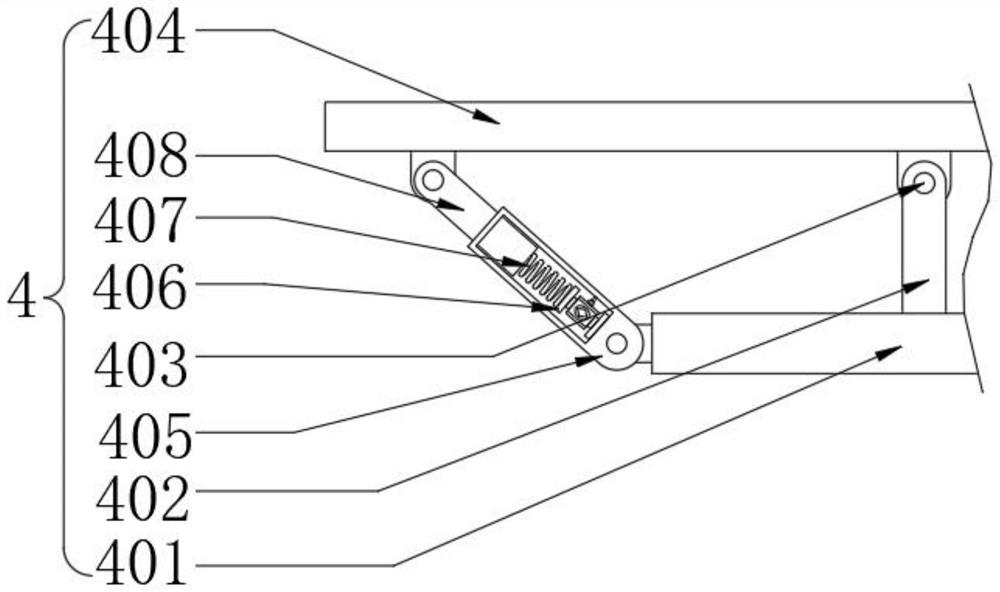

InactiveCN107297963AConvenient codingAvoid failureTypewritersOther printing apparatusComputer hardware

The invention relates to a code spraying device, in particular to a code spraying device for making access control cards. The technical problem to be solved by the present invention is to provide a coding equipment for making access control cards which can spray codes comprehensively and can spray codes on access control cards of various sizes. In order to solve the above-mentioned technical problems, the present invention provides such a coding device for making access control cards, which includes a table body, etc.; The bottom of the first groove is provided with a left and right moving device, and the top of the left and right moving device is provided with a fixing device, and the fixing device is below the inkjet printer. The invention is convenient for the coder to spray the code on the access control card in an all-round way, preventing the failure of the access control card caused by insufficient code spraying, the access control card can be effectively protected by the sponge, and the equipment can be used for access control cards of different sizes by adjusting the position of the connecting rod Coding is carried out to achieve the effect of improving the stability of the equipment.

Owner:陈云蕾

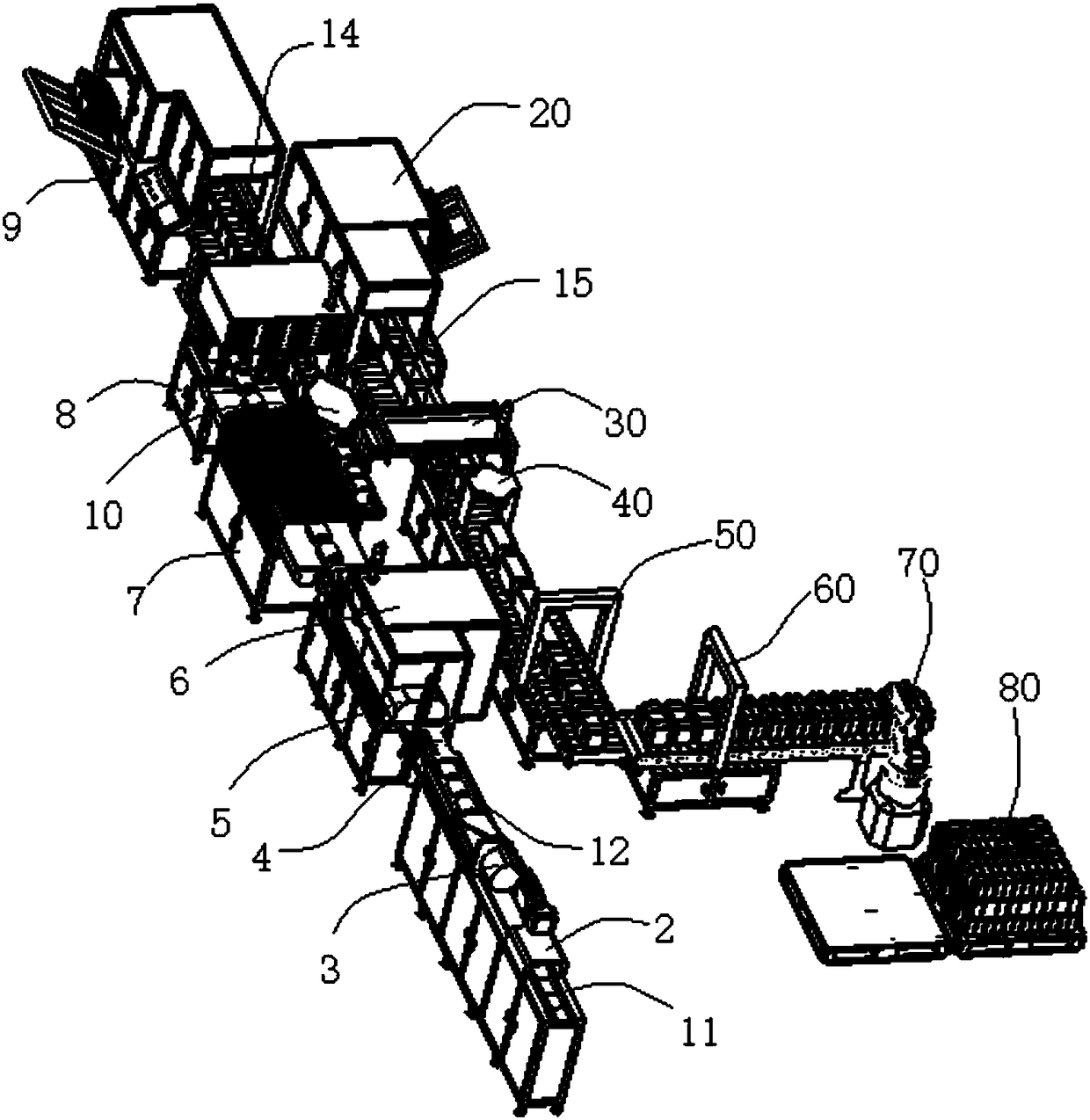

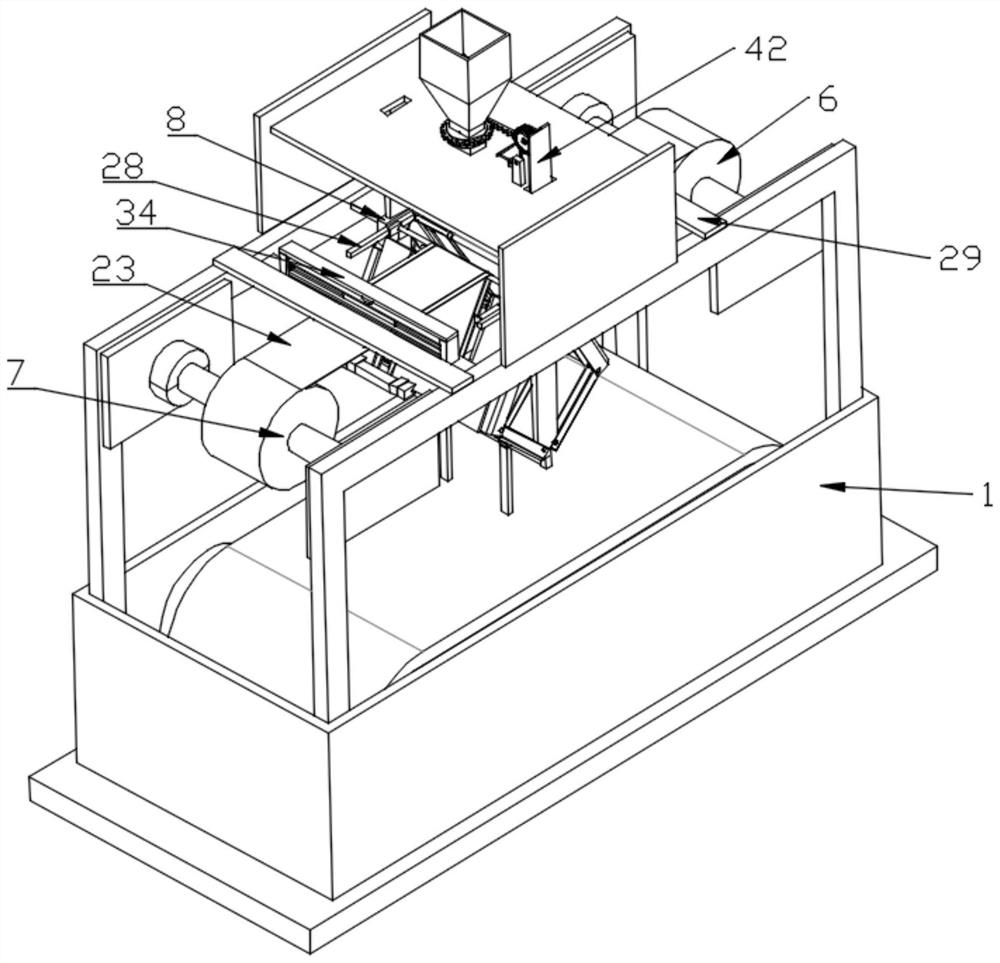

Drum-type automobile brake pad automatic packaging system and method

PendingCN108609241ANeatly stackedEasy to carry outWrapper twisting/gatheringPackaging protectionCartonBrake pad

The invention provides a drum-type automobile brake pad automatic packaging system and method. According to the drum-type automobile brake pad automatic packaging system and method, a turning mechanism, a second horizontal conveyer belt and a code spraying mechanism are arranged, turning is carried out on a cleaned brake pad without dust so that codes can be conveniently sprayed on the brake pad,and the brake pads with the sprayed codes are turned till an inner face is downward so that the brake pads can be conveniently stacked up into a pile; a mechanical gripper, a lifting platform, an aircylinder and a rotary platform are arranged, the brake pads can be quickly stacked up neatly by a stacking mechanism, and follow-up procedures of film sealing and encasement can be conveniently carried out; and piles of brake pads are automatically encased in a small carton, small cartons are encased in a large carton, and storage and transportation are convenient to carry out. The drum-type automobile brake pad automatic packaging system is low in cost, stable and reliable, and convenient for large-scale promotion for application.

Owner:襄阳凌浩科技有限公司

Ink-jet printer for lithium battery processing and method thereof

InactiveCN110525058AAchieve clampingPrevent precipitationRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention discloses an ink-jet printer for lithium battery processing and a method thereof. The ink-jet printer is provided; existing code spraying is mostly carried out manually or via mechanicaloperation, however, the structure cannot be adjusted and only suits the lithium battery of only one size; in order to solve the problems that an existing ink-jet printer is only suitable for lithiumbatteries of one size and is large in use limitation, the proposed ink-jet printer comprises a workbench and a conveying motor, the workbench is in transmission connection with a conveying belt, the conveying motor is in transmission connection with the conveying belt, a U-shaped frame is fixedly installed on the workbench, and an ink-jet printer head is connected to the U-shaped frame in a sliding mode. According to the invention, the lithium battery can be conveyed to the lower part of the ink-jet printer head by respectively starting the conveying motor; and then a driving motor is startedto drive the ink-jet printer head to move, so that code spraying can be conveniently carried out on any part of the lithium battery, namely code spraying can be carried out on the lithium battery, andmanual code spraying can be replaced, the efficiency can be improved, code spraying can be carried out on any position, and the ink-jet printer is very convenient to use.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

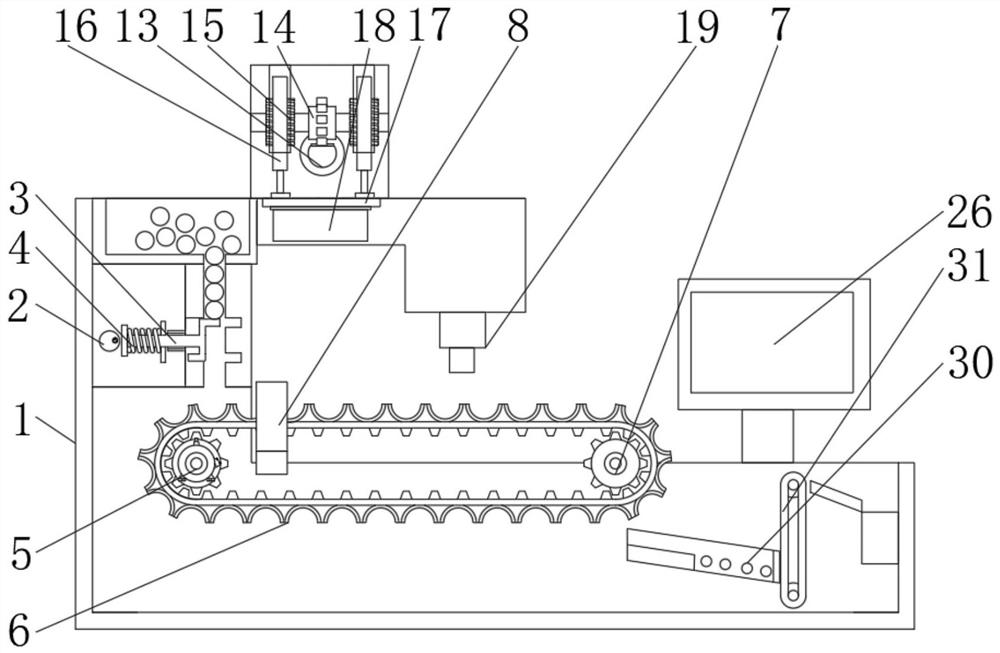

Code spraying device with guiding and limiting functions for ternary lithium battery processing

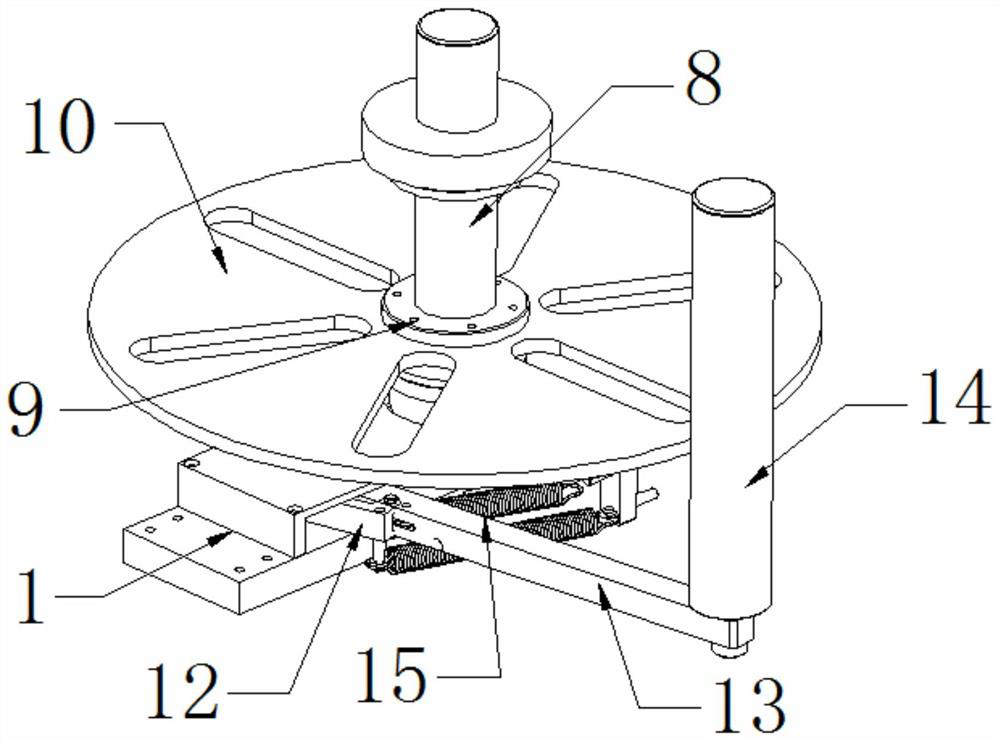

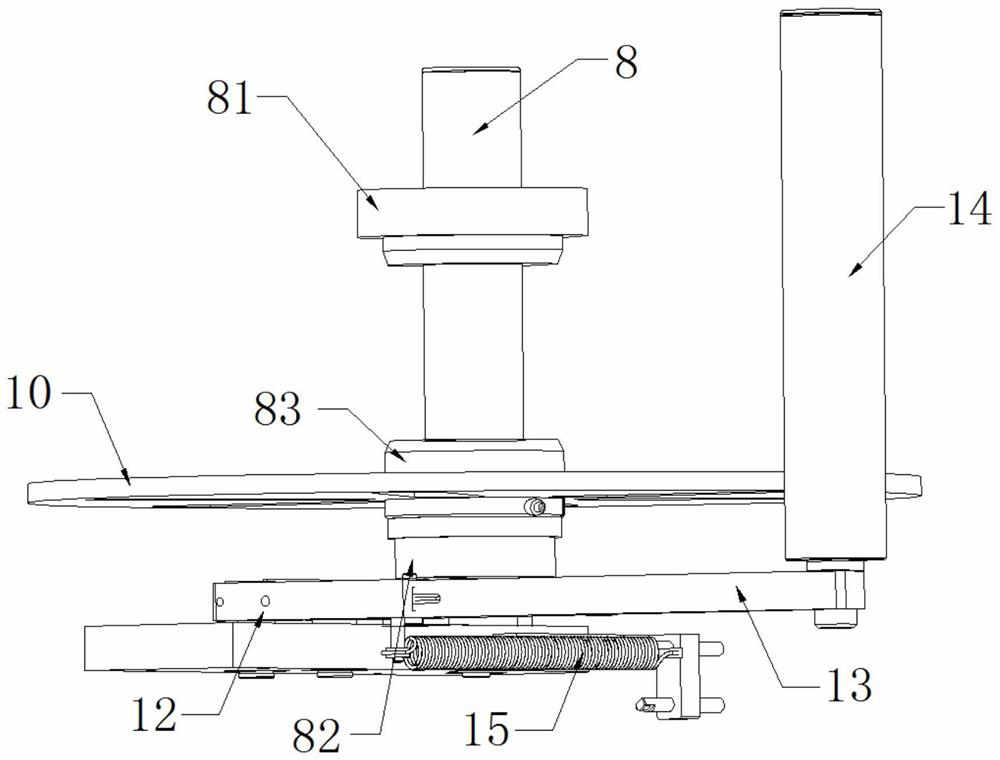

InactiveCN112549793AWith guide limit functionEasy to adjust the angleTypewritersPower drive mechanismsMechanical engineeringLithium battery

The invention discloses a code spraying device with guiding and limiting functions for ternary lithium battery processing, and belongs to the field of code spraying devices. The invention discloses acode spraying device with guiding and limiting functions for ternary lithium battery processing. The code spraying device with the guiding and limiting functions for ternary lithium battery processingcomprises a device body, a limiting block and a display screen, a rotary disc is arranged in the device body, an isolation block is arranged on the side of the rotary disc, a first spring is arrangedon the periphery of the isolation block, a first rotary shaft is arranged below the first spring, the edge side of the first rotating shaft is connected with a conveying belt, the edge side of the conveying belt is connected with a second rotating shaft, the limiting block is arranged on the edge side of the conveying belt, the edge side of the limiting block is connected with a first connectingrod, the edge side of the first connecting rod is provided with a second connecting rod, and the end of the second connecting rod is connected with a sliding block. The code spraying device is provided with the conveying belt, lithium battery transferring is facilitated, automatic lithium battery code spraying is facilitated, and lithium batteries are continuously processed according to the steps.

Owner:深圳市华宇新能源科技有限公司

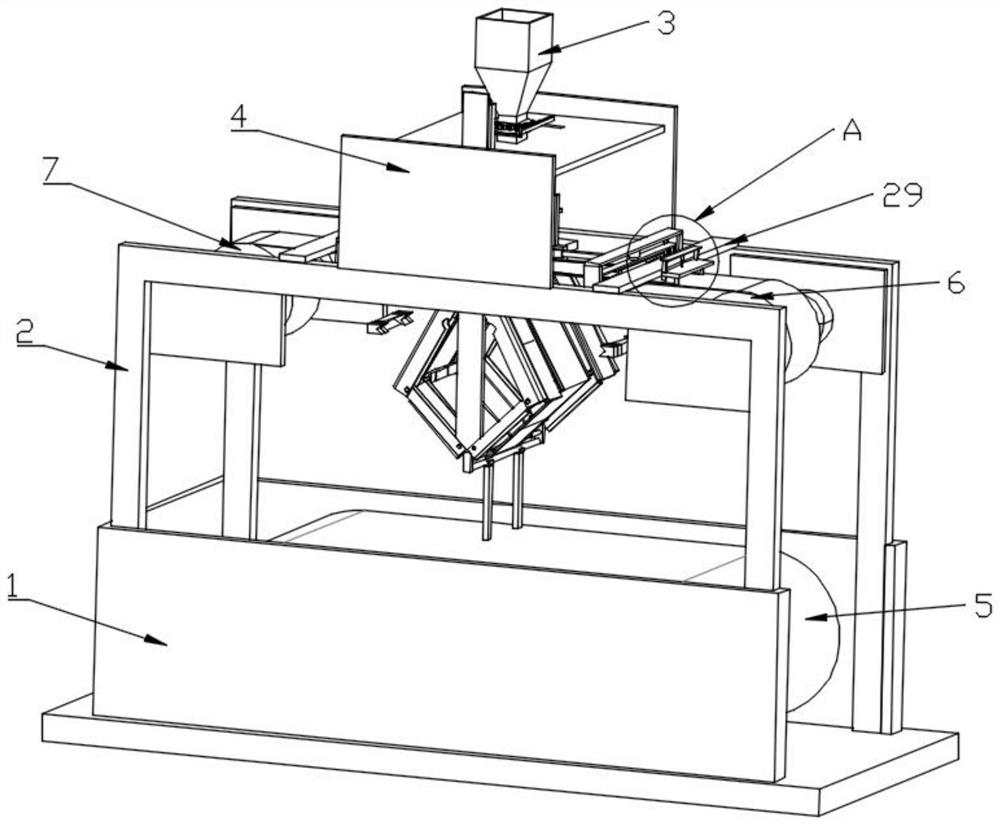

Vacuum packaging equipment based on folding forming of bottom film container and novel packaging box

ActiveCN114671056AConvenient codingStrong appreciationWrapping material feeding apparatusWrapper twisting/gatheringIndustrial engineeringSupport plane

The vacuum packaging equipment comprises a base and a supporting frame fixedly installed on the base, the end, close to the top, of the supporting frame is provided with a discharging roller, the other end, close to the top, of the supporting frame is provided with a discharging roller, and a film body belt is connected between the discharging roller and a collecting roller. A folding mechanism used for container packaging forming is installed in the middle of the supporting frame, one end of the film body belt is fixedly connected to the outer wall of the discharging roller, and the other end of the film body belt penetrates through the folding mechanism, extends to the outer wall of the collecting roller and is fixedly connected with the collecting roller. Through the structure and principle design of the folding mechanism, a packaging box with a bottom folding and top sealing structure can be automatically formed, adverse effects such as wrinkles and local thinning of the formed container wall are effectively avoided, the surface printing and code spraying process is facilitated, and meanwhile the high ornamental degree is achieved.

Owner:长沙弘晨包装有限公司

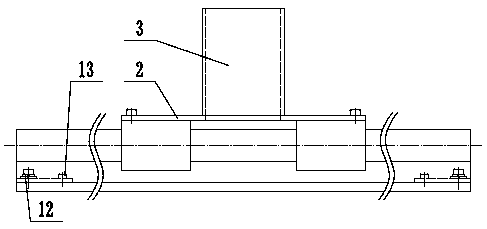

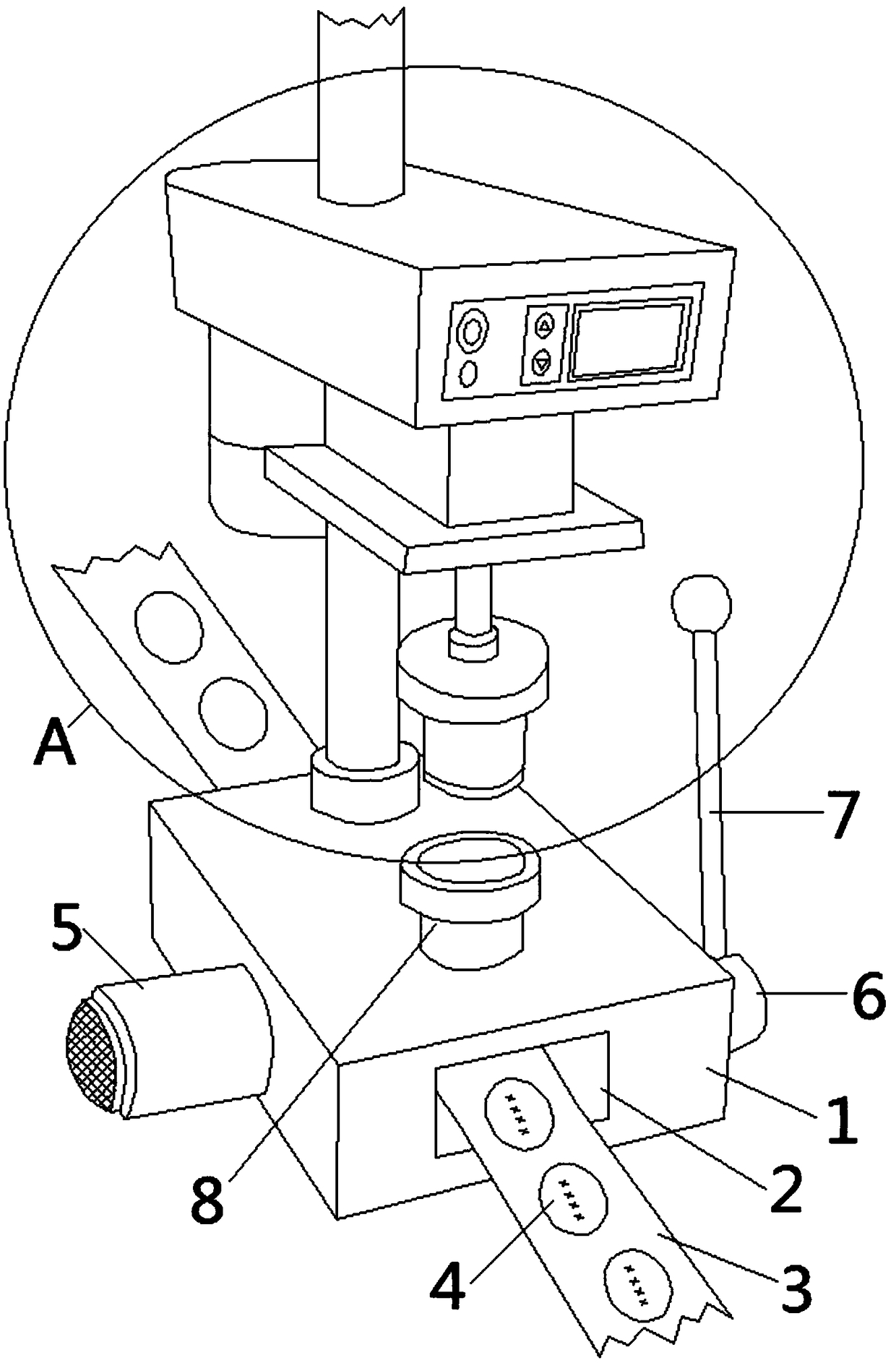

Belt type bottle cap code spraying device

InactiveCN107336528AReduce lossEasy and stable placementConveyorsTypewritersTransmission beltTransmission loss

The invention discloses a belt type bottle cap code spraying device and relates to the field of cap conveying and machining devices. According to the belt type bottle cap code spraying device, a belt channel longitudinally penetrates through the middle of a front side panel and the rear side panel of a base plate, a transmission belt passes through the belt channel, a transmission motor is arranged on the side face of the base plate, a connecting shaft structure of the transmission motor is connected with the transmission belt in the belt channel in a transmission contact mode, a control shaft lever is located on the other side of the base plate, a connecting shaft structure of the inner side of the control shaft lever is connected with the transmission belt in the belt channel in a transmission contact mode, a hand control lever is perpendicularly connected with the control shaft lever, and a code spraying well is formed in an upper side panel of the base plate and perpendicularly communicates with the belt channel. The base plate is provided with the belt channel, and the transmission belt is provided with a bottle cap fixing groove structure, so that stable placing and accurate positioning of bottle caps on the transmission belt are facilitated, the transport volume is decreased, and the belt transmission loss is decreased.

Owner:绍兴兴宽五金塑料有限公司

A biopharmaceutical filling system

The invention relates to the field of filling, in particular to a biomedicine filling system. It includes a belt transport device, a guide plate, a guide plate, a sliding plate, a directional bottle outlet and a baffle plate, and the part for storing vials composed of a storage box cooperates with the transport part of the belt transport device to output stacked vials in a single layer; includes The guide part formed by the guide plate turns the single-layer transported vials into single-layer and single-row transported vials, ensuring that the bottle mouths are in a straight line; the sliding block is used to unify the orientation of the bottle mouths; the pick belt mechanism is used to facilitate spraying on the bottom of the bottles At the same time, the vials after coding will be transported to the next station in the same direction.

Owner:扬州凯芬机械有限公司

A laser inkjet printer that can identify the location of the inkjet code for intelligent manufacturing

The invention relates to a laser inkjet printer capable of identifying the coding position for intelligent manufacturing, comprising a casing and a connecting assembly, the inner lower wall of the casing is provided with a belt conveyor, and the supporting assembly includes a second plate and a supporting rod , a connecting pin, a third plate, an overcoat, a second pressure sensor, a first spring, and a telescopic rod, and the upper end of the second plate is provided with a support rod, and the upper end of the support rod is connected with a connecting pin, and the connecting pin The outside is connected with a third plate, and the left and right sides of the second plate are movably connected with jackets. The beneficial effects of the present invention are: the intelligent manufacturing uses a laser inkjet printer that can identify the coding position, and the coding position can be positioned in advance through the device, and then the precise coding can be realized through precise docking. Positioning, to prevent positioning from shifting the coding position due to the deviation of the product position, the equipment can transport the auxiliary device, so that the auxiliary device can be used multiple times.

Owner:深圳市海纳激光科技有限公司

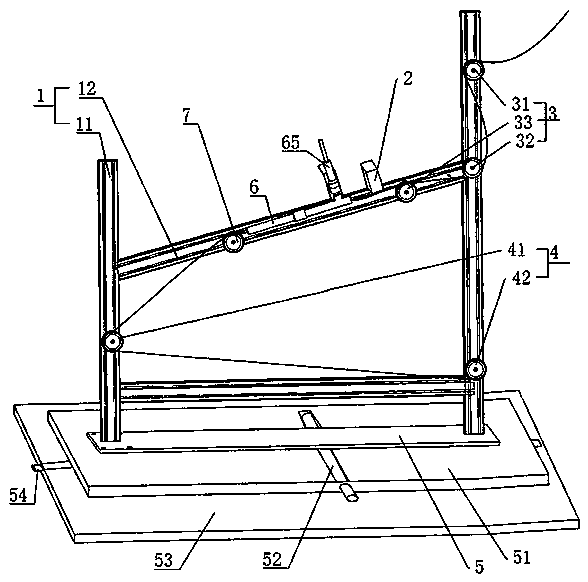

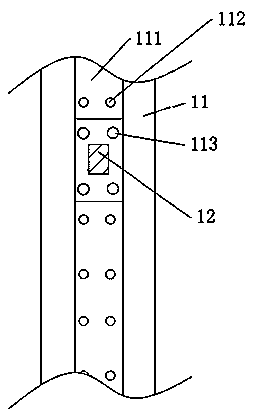

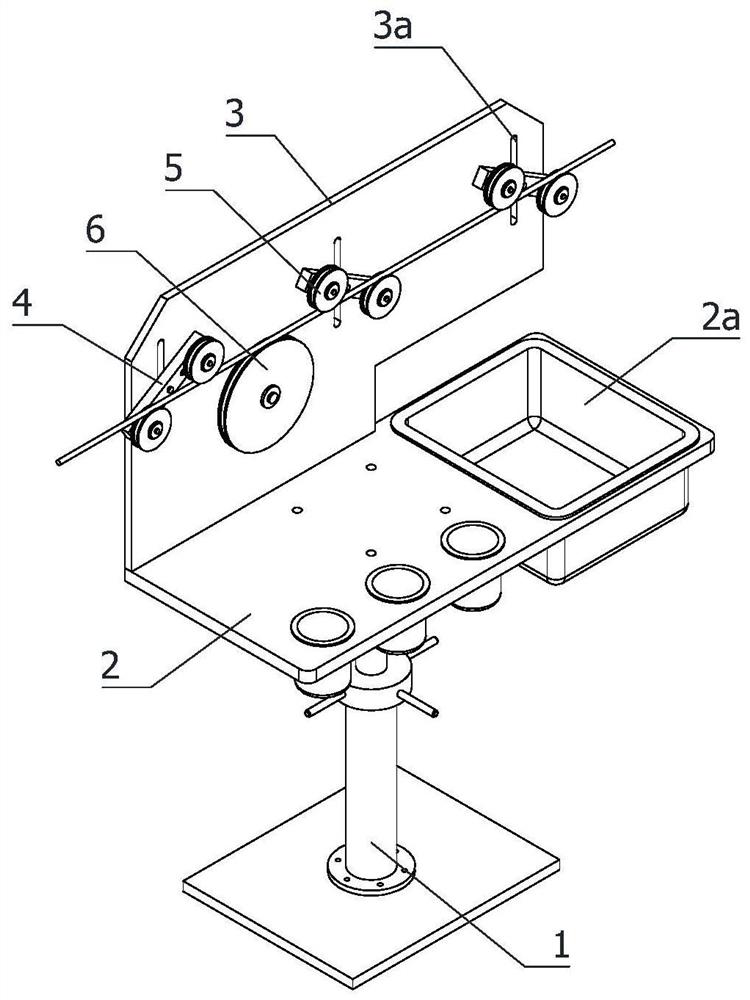

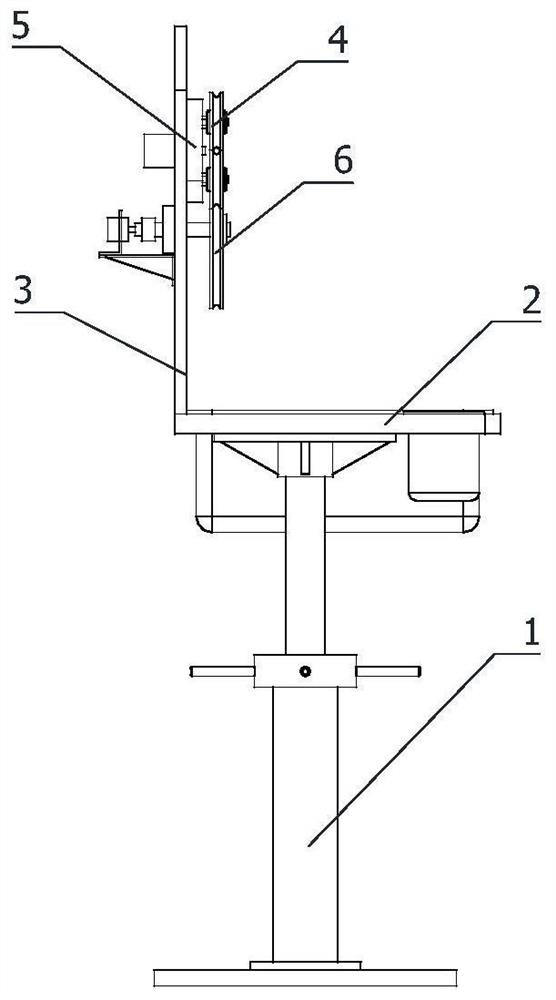

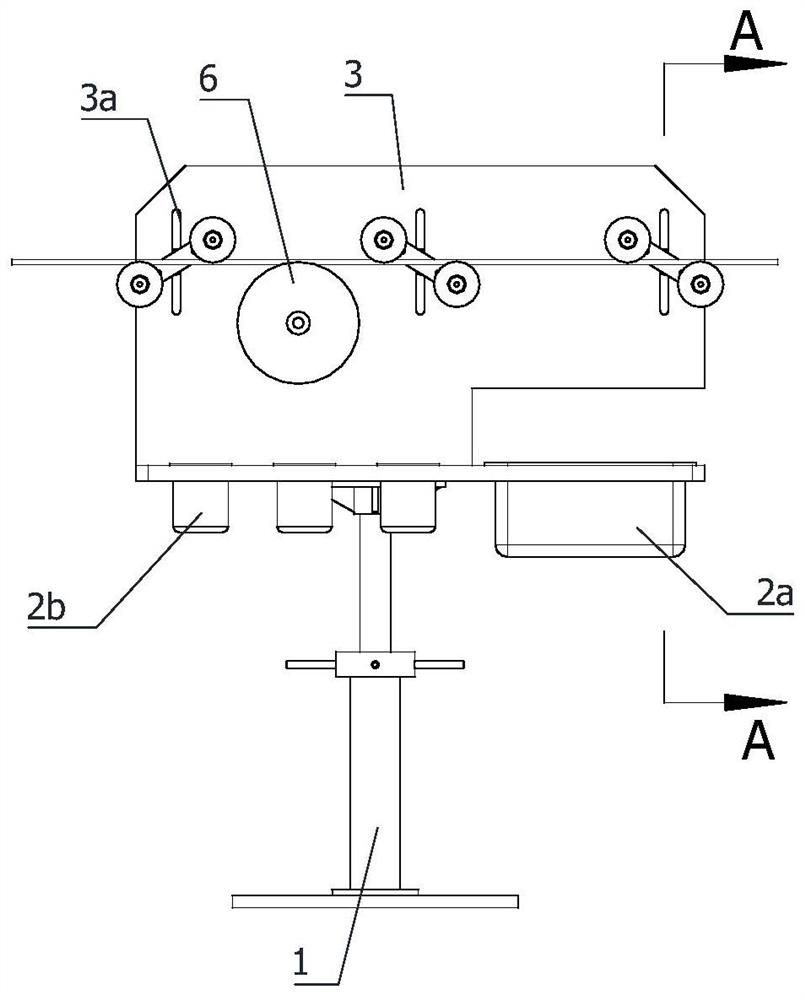

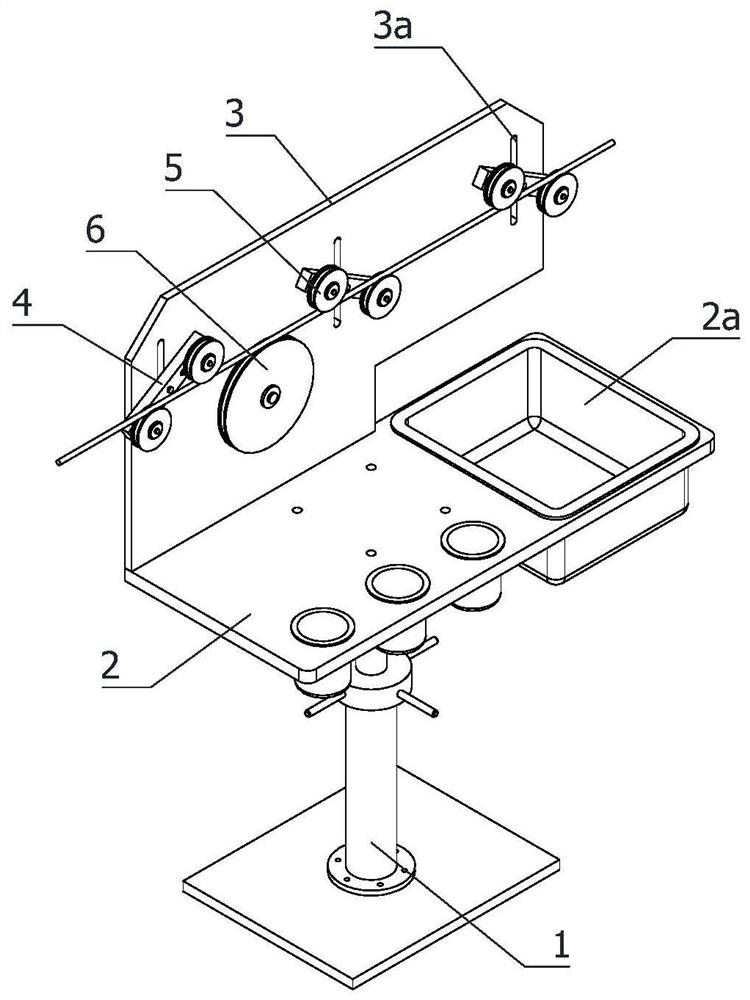

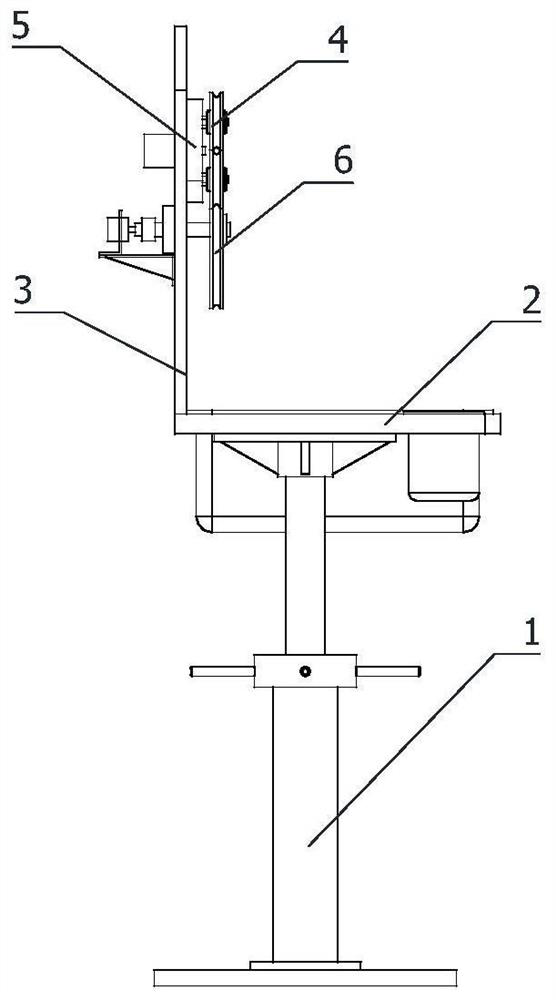

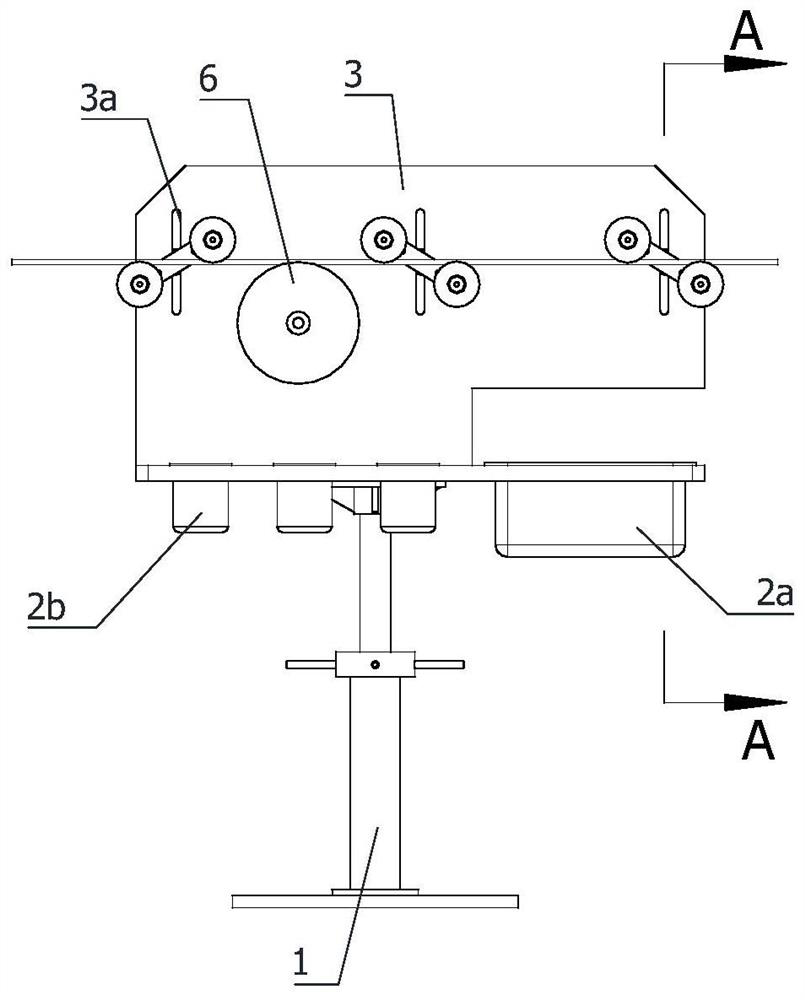

A cable inkjet printing frame

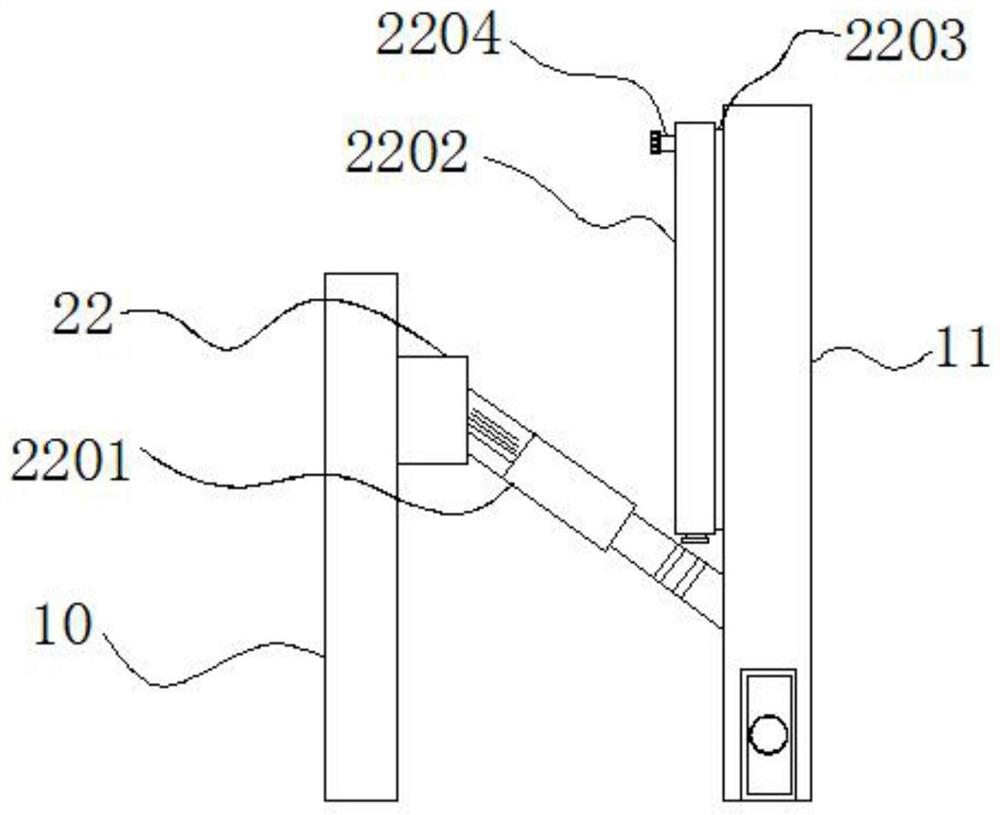

ActiveCN112172358BConvenient codingEasy level adjustmentTypewritersOther printing apparatusWorking environmentEngineering

The present invention relates to the technical field of cable code spraying, in particular to a cable code spraying and printing frame, which includes: a liftable and adjustable installation base; There is a stainless steel box located at the bottom of the working end of the inkjet printer and used to collect inkjet; the installation vertical plate is vertically arranged on the top of one side of the operation table, and there are at least three vertically distributed vertical vertical plates on the installation vertical plate at equal intervals. A waist-shaped groove; the guide wheel installation assembly, the installation part and the top surface of the console are fixedly arranged on the first waist-shaped groove, and the installation part of the guide wheel installation assembly can adjust the height along the vertical direction on the first waist-shaped groove; For the wheel set, the working wheels rotate coaxially and horizontally at both ends of the installation part of the guide wheel installation assembly; the photoelectric detection guide wheel assembly, which rotates coaxially with the working wheel of the guide wheel set, is installed on the installation vertical plate and is electrically connected to the controller. The printing frame can improve the impedance and echo performance of the product, and it is beautiful and elegant, and the working environment is clean and tidy.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

A label rewinder running at a constant speed

ActiveCN110844661BConvenient codingUniform linear velocityFunction indicatorsTypewritersElectric machineSS - Stainless steel

The invention relates to the technical field of labeling equipment, and discloses a label rewinding machine running at a constant speed, which includes a frame made of stainless steel panels on the top surface and four sides of the top end, and the inner cavity on the top side of the frame is fixedly installed with Electric box, the middle part of the stainless steel panel on the front of the frame is fixed with a coding gun through a fixed block, and the coding end of the coding gun is provided with a coding baffle. In the present invention, the motor pulley drives the large pulley of the driving rubber roller, and the small pulley of the driving rubber roller drives the driving pulley. Since the large pulley of the driving rubber roller and the small pulley of the driving rubber roller are connected together, It can realize the secondary transmission from the driving motor to the driving pulley. When the linear speed of the label on the driving pulley exceeds the linear speed of the driving rubber roller assembly, the driving driving pulley will slip, thus ensuring the safety of the driving rubber roller assembly. The line speed is uniform, so that the running line speed of the label is uniform, so that the label can be sprayed at the specified position.

Owner:广州恒拓包装科技有限公司

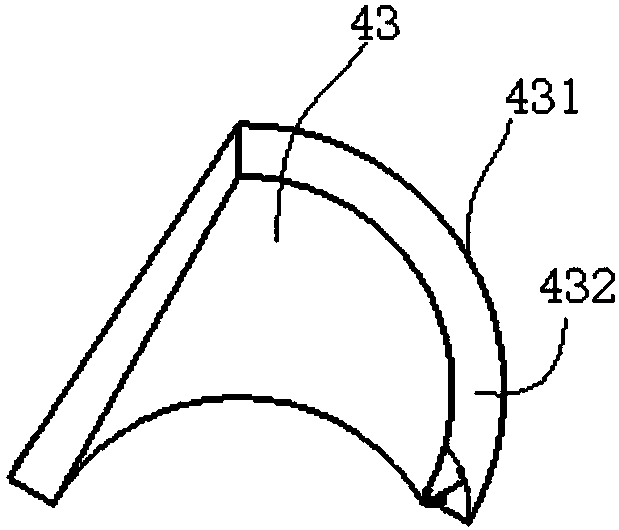

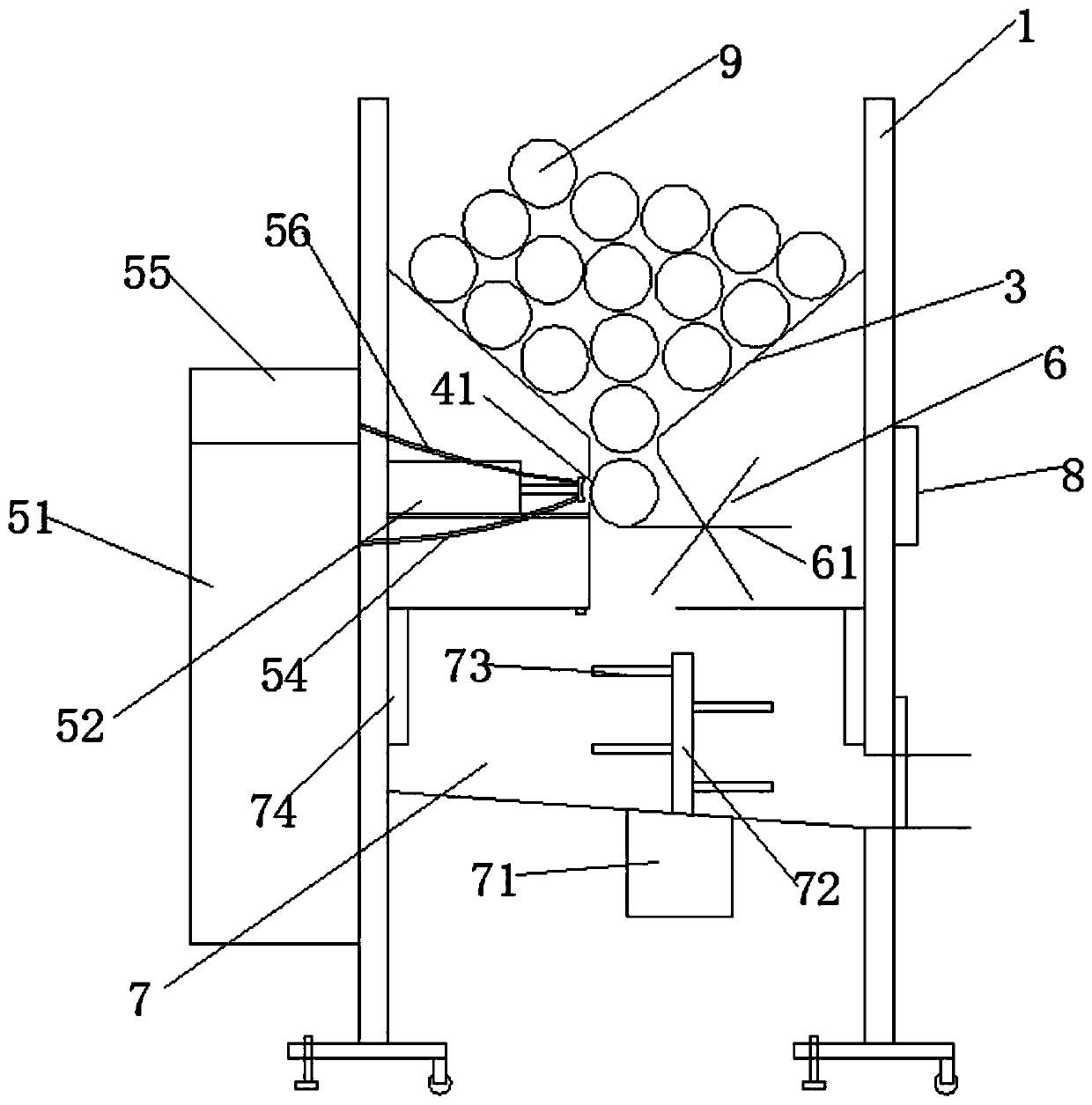

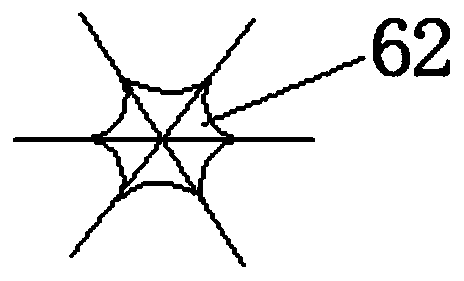

Sphere code spraying and counting device

ActiveCN110126483AImprove slipEasy to sprayTypewritersOther printing apparatusDisplay deviceMechanical engineering

The invention discloses a sphere code spraying and counting device. The device comprises a box, a support device, a bin, a slide way, a spraying device, a sphere limiting device, a drying chamber, a control displayer and spheres; the bin is arranged at the middle upper end in the box; the slide way is arranged in the bottom end center of the bin; the spraying device is arranged on one side of theslide way; the sphere limiting device is arranged on the other side of the slide way; the drying chamber is arranged at the middle lower end of the box; support devices are arranged at front, back, left and right corners of the bottom end of the box; and the control displayer is arranged on the side surface of the box, is electrically connected with the device, and controls the device to operate.The device is reasonable in design, convenient to use, various in function, high in working efficiency and convenient to popularize.

Owner:朱立飞

Cable code spraying and printing frame

ActiveCN112172358AConvenient codingEasy level adjustmentTypewritersOther printing apparatusWorking environmentStructural engineering

The invention relates to the technical field of cable code spraying, in particular to a cable code spraying and printing frame. The cable code spraying and printing frame comprises a liftable adjusting mounting base; an operation table horizontally arranged at the top end of a liftable adjusting mounting base working part, wherein a stainless steel box which is located at the bottom of the ink-jetprinter working end and used for collecting jet ink is arranged on the operation table; a mounting vertical plate vertically arranged at the top end of one side of the operation table, wherein at least three first kidney-shaped grooves in the vertical direction are evenly distributed in the mounting vertical plate at equal intervals; a guide wheel mounting assembly, wherein a mounting part and the top surface of the operation table are obliquely and fixedly arranged on the first kidney-shaped grooves, and the height of the mounting part of the guide wheel mounting assembly can be adjusted onthe first kidney-shaped grooves in the vertical direction; a guide wheel set, wherein working wheels are coaxially and horizontally rotationally arranged at the two ends of the mounting part of the guide wheel mounting assembly; and a photoelectric detection guide wheel assembly, wherein the photoelectric detection guide wheel assembly and the guide wheel set working wheels are coaxially and rotationally arranged on the mounting vertical plate and electrically connected with the controller. The printing frame can improve the impedance and echo performance of products, the appearance is attractive and elegant, and the working environment is clean and tidy.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

An energy-saving and high-efficiency inkjet printer

InactiveCN105500923BSimple structureImprove printing effectTypewritersOther printing apparatusEngineeringIdler-wheel

Owner:蒙托壁(杭州)智能科技有限公司

Code spraying device for biscuit packaging box

PendingCN114454615AConvenient codingImprove coding accuracyTypewritersClassical mechanicsStructural engineering

The code spraying device for the biscuit packaging box comprises bases, a support is fixedly connected between the two bases, a fixing base is fixedly installed on the upper side of the support, a protective shell is slidably connected to the upper side of the fixing base, and limiting rods are fixedly installed in the bases; first sliding sleeves are fixedly mounted on the left side wall and the right side wall of the shell correspondingly, the first sliding sleeves are slidably connected with the limiting rods, a fixing shaft is rotationally connected to the bottom of the protection shell, a connecting piece is fixedly mounted on the top of the fixing shaft, a supporting rod is fixedly mounted on the outer side of the fixing shaft, and a guide block is fixedly mounted on the lower side of the supporting rod; and a connecting frame is fixedly mounted on one side of the fixed seat. The first baffle and the second baffle are fixedly installed at the two ends of the first sliding rod and the two ends of the second sliding rod correspondingly, and the first baffle and the second baffle are opposite, so that the code spraying device can adapt to code spraying operation of two assembly lines at the same time, and the production efficiency is further improved.

Owner:陈展

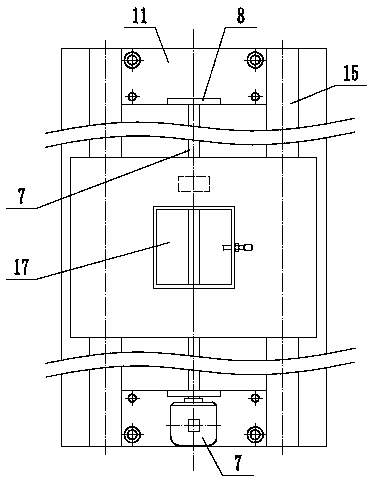

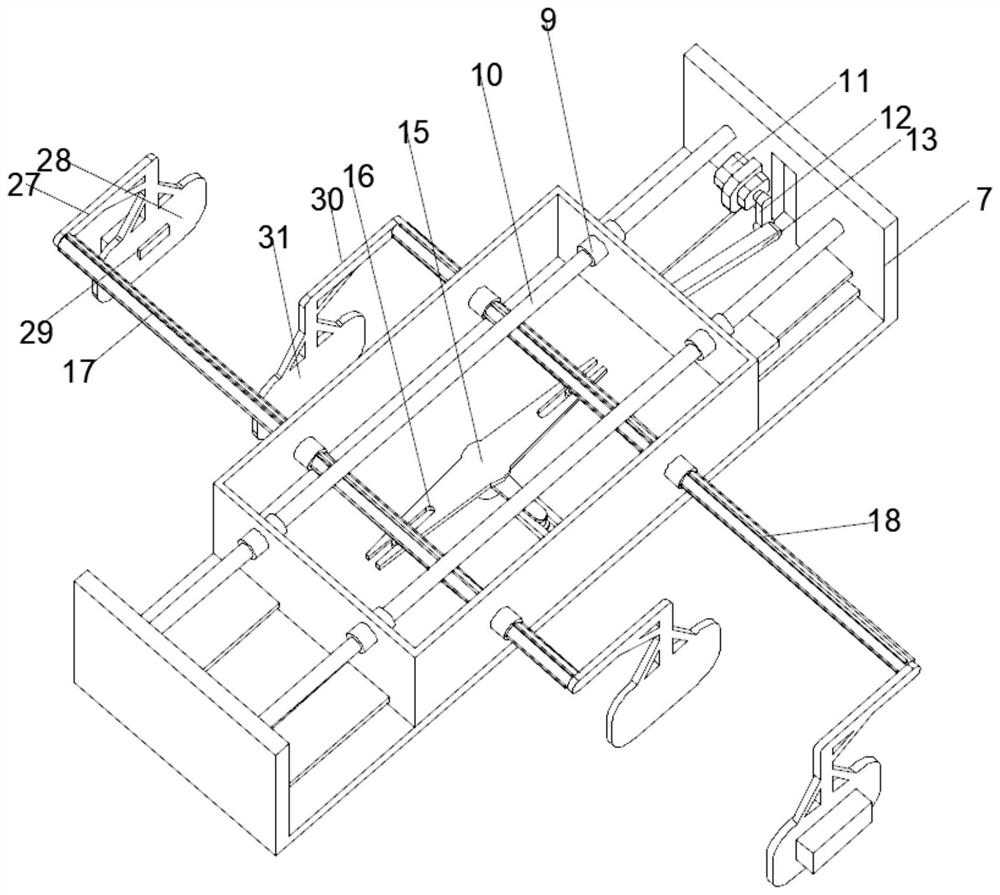

Display module turnover mechanism

InactiveCN106932930AAvoid damageEasy to print on the backNon-linear opticsEngineeringMechanical engineering

Owner:KUSN JINGXUN ELECTRONICS TECH

Code-spraying device for electric wire

InactiveCN109461544AConvenient codingCoding is efficient and fastTypewritersConductor/cable markingEngineeringElectric wire

An object of the present invention is to provide a code-spraying device for an electric wire. Code spraying and drying are performed on the electric wire transported between a feed transport path anda discharge transport path by setting a spray gun and a blower to push forward. Both the spray gun and the blower can be slid on a slide rail and can be pushed forward. A backward-pushing cylinder isdisposed to bring a guide wheel into contact with the electric wire to tension the electric wire transported between the feed transport path and the discharge transport path, so that it is convenientto spray code, and a slidable forward-pushing camera is disposed for monitoring, which can efficiently and quickly perform code spraying on the electric wire and is applicable in production.

Owner:WUHU SHUNCHENG ELECTRONICS

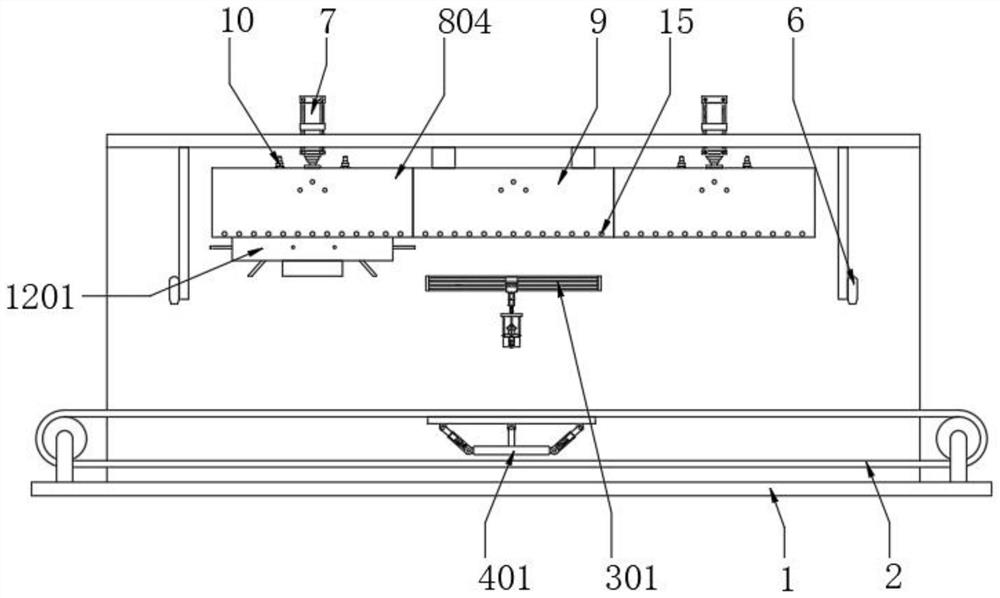

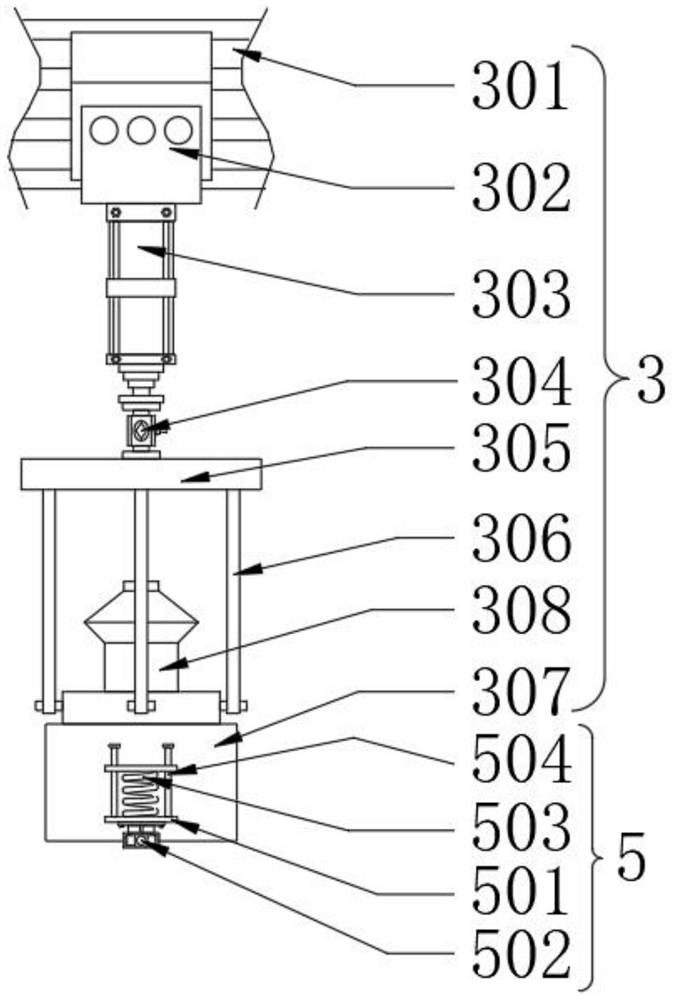

A coding device for a flexible printed circuit board

ActiveCN112265383BEasy to adjustImprove comfortTypewritersPrinted circuit manufactureElectric machineryControl theory

The invention discloses a coding device for a flexible printed circuit board, which relates to the technical field of coding machines, and includes a working platform and a base. Both ends of the working platform are provided with protective side plates. The front end is equipped with a second motor, and one end inside the second motor is provided with a transmission device. In the present invention, through the setting of the guide device, the limit fixing block, the limit sleeve groove, the rotating shaft, the hanging ring, the fixing spring and the connection riser, when the printed circuit board falls from the surface of the conveying device, the limit can be used. The interaction between the fixed block, the limit sleeve groove and the rotating shaft adjusts the angle of the guide device, and when the printed circuit board is dropped, the force exerted on the guide device will exert a certain force on the fixed spring stretched at the bottom, thereby printing The circuit board can use the function of the guiding device to perform force unloading treatment and then fall to the inside of the storage frame, effectively reducing the damage to the printed circuit board due to gravity during transportation.

Owner:益阳维胜科技有限公司

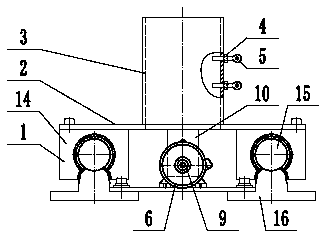

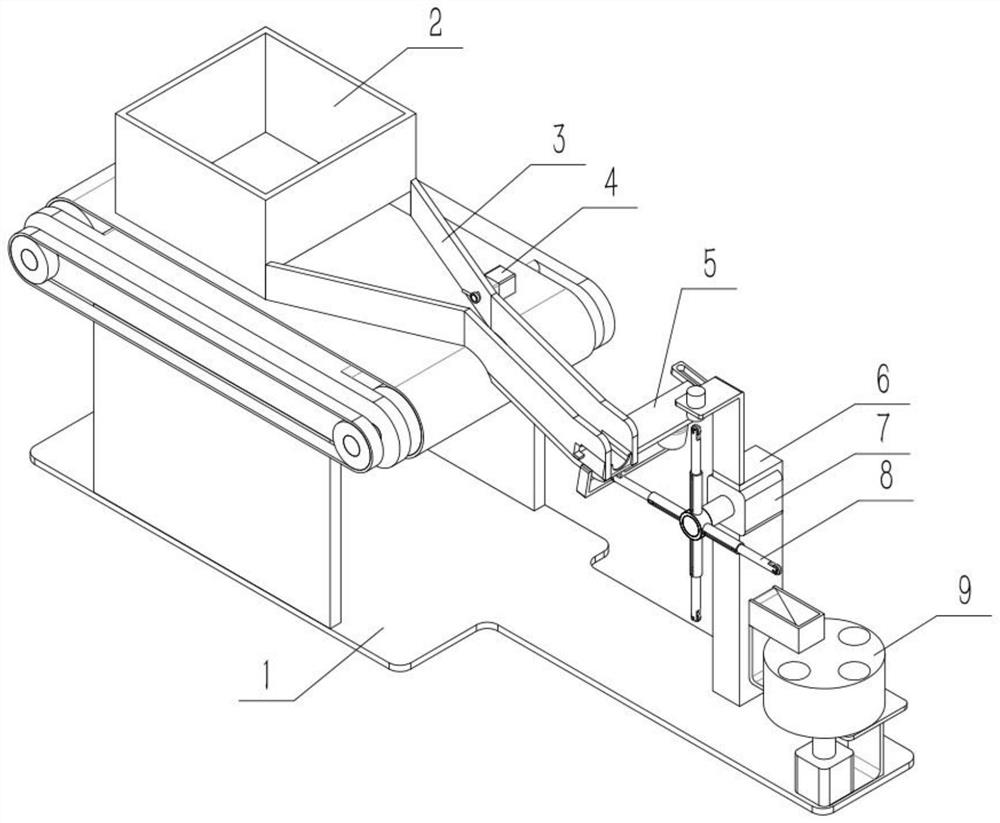

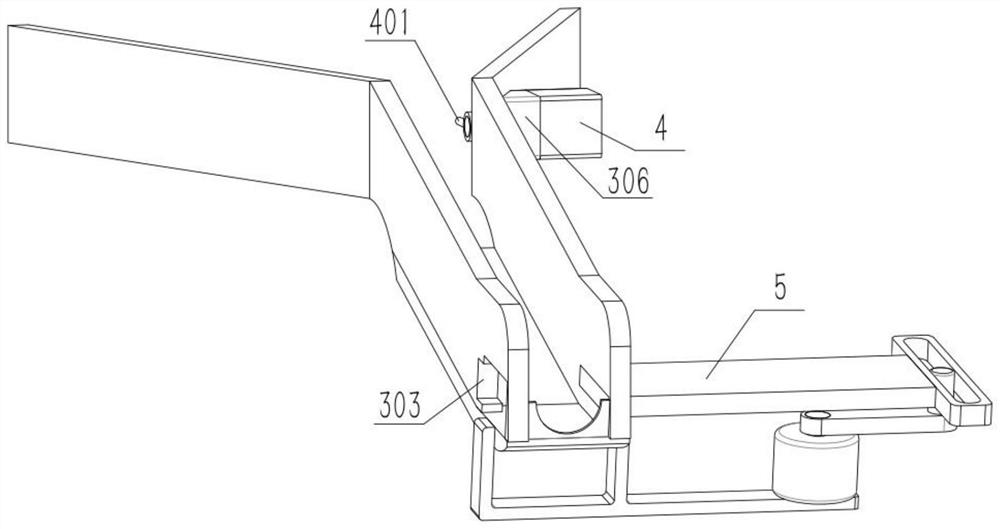

Medical medicine packaging bottle code spraying equipment

The invention relates to packaging bottle code spraying equipment, in particular to medical medicine packaging bottle code spraying equipment. According to the medical medicine packaging bottle code spraying equipment, medicine packaging bottles which are subjected to code spraying can be clamped, so that the medicine packaging bottles cannot move freely. The medical medicine packaging bottle code spraying equipment comprises a bottom plate, a pushing mechanism, a discharging mechanism and a code spraying mechanism; the bottom plate is placed on the ground, and the pushing mechanism is arranged between the upper side and the lower side of the bottom plate; the discharging mechanism is arranged between the pushing mechanism and the bottom plate; the code spraying mechanism is arranged on the lateral portion of the bottom plate. According to the medical medicine packaging bottle code spraying device, the pushing mechanism and the discharging mechanism are matched with the code spraying mechanism, so that a material pushing plate pushes the medicine packaging bottles discharged by a rotating disc with holes, and a code spraying assembly sprays codes on the medicine packaging bottles, so that manpower consumed by people for spraying the codes on the medicine packaging bottles is less, and the effect that people can conveniently spray the codes on the medicine packaging bottles is achieved.

Owner:高嘉浓

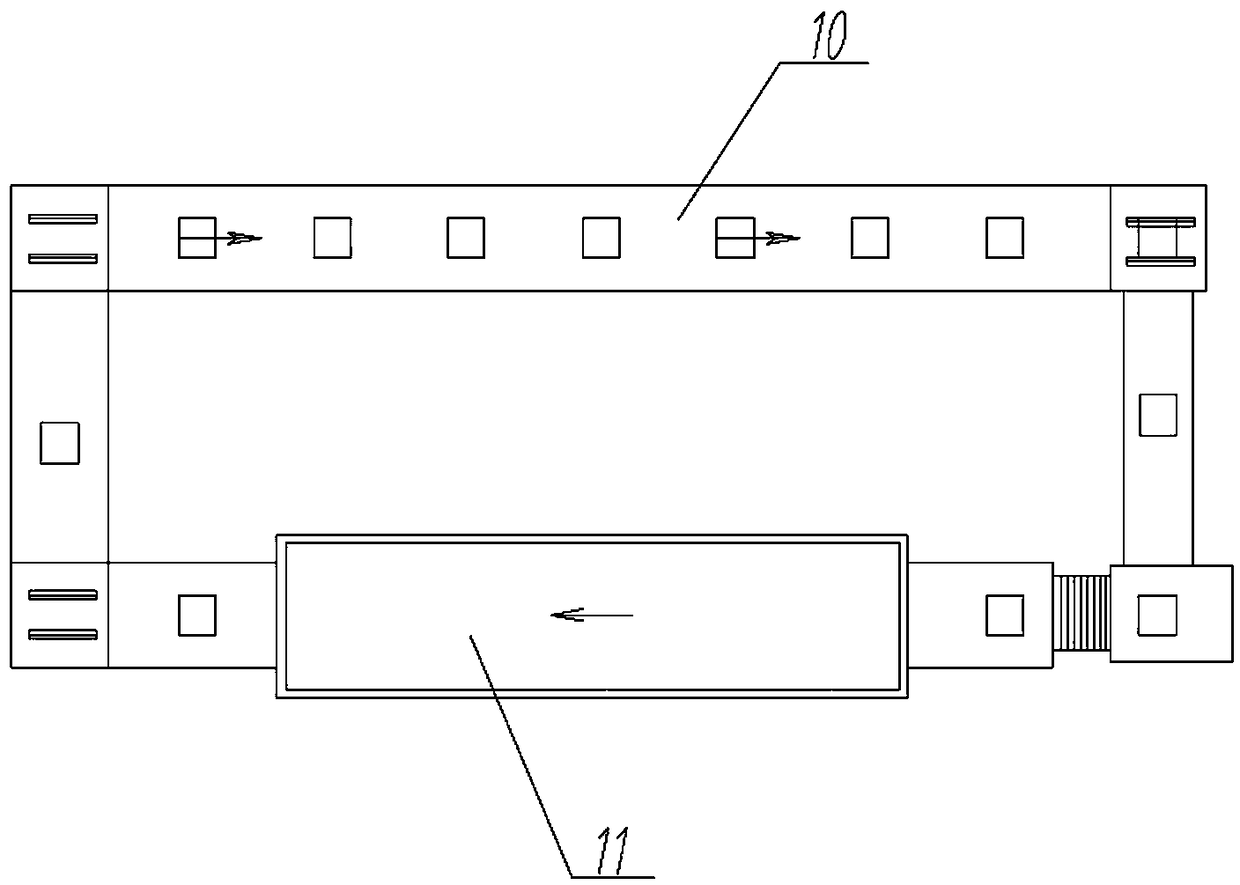

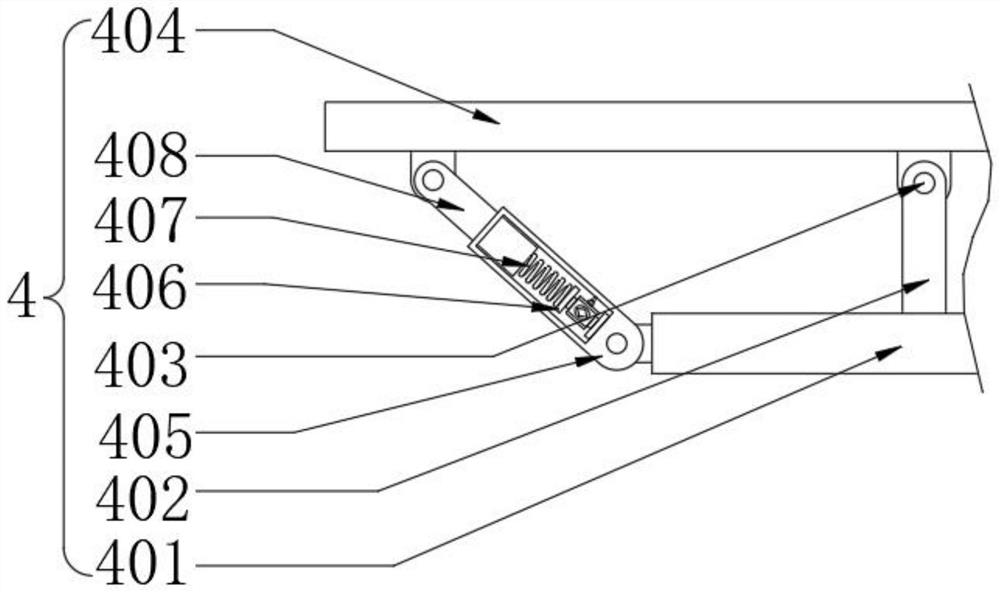

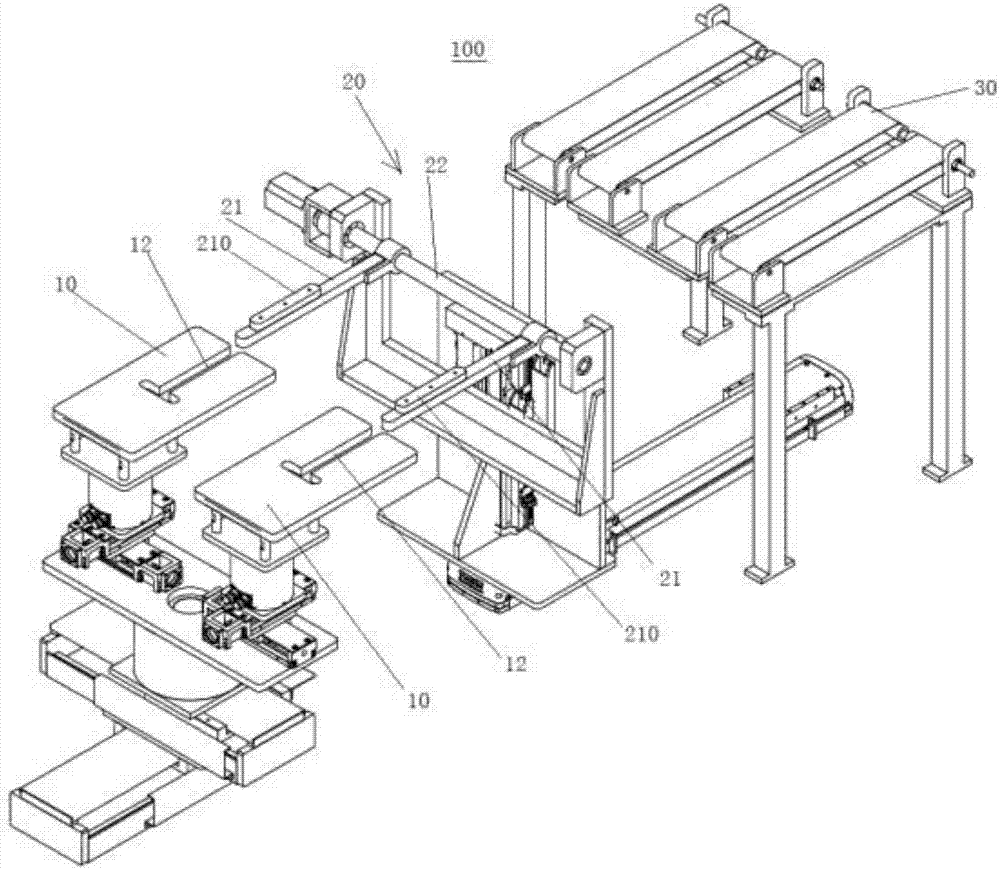

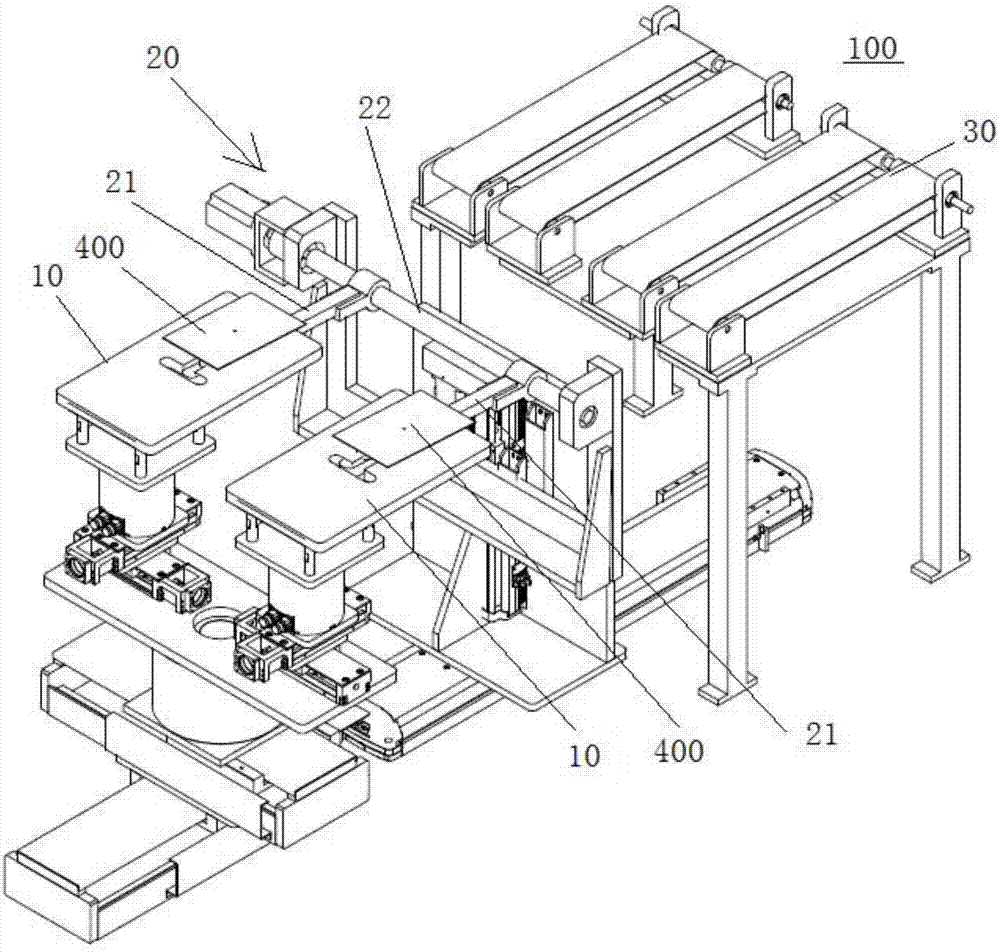

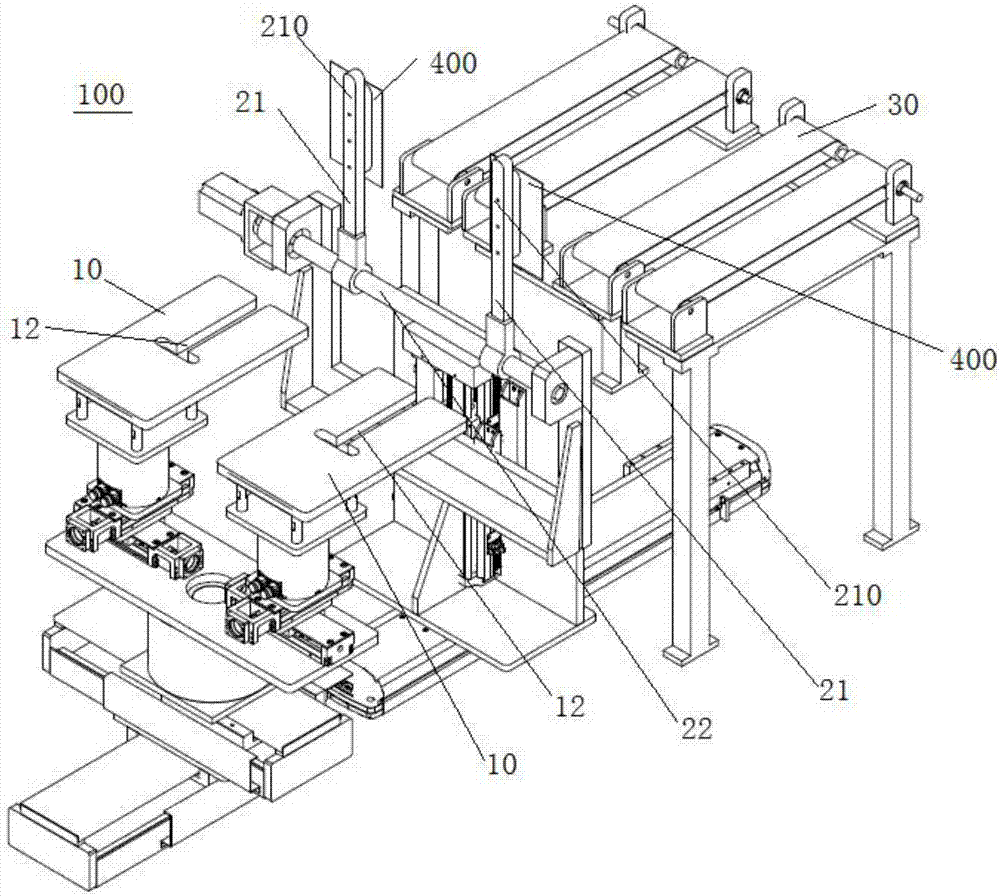

A file processing device

ActiveCN106335293BHigh degree of automationImprove work efficiencyTypewritersLaser scanningOperating system

A file processing apparatus belongs to the technical field of office equipment. The file processing apparatus comprises a scanning unit for scanning files, a conveying mechanism (10) for transferring the files to the scanning unit, a character detecting mechanism (4) for detecting the characters on the files during the conveyance of the files by the conveying mechanism (10), and a code printing unit for spraying page numbers on pages of the files with texts. The conveying mechanism of the file processing apparatus conveys files, and the character detecting mechanism is capable of detecting pages of files with characters, so that the code printing unit can conveniently sprays page numbers on the pages with characters. The scanning unit scans the files conveyed by the conveying mechanism, so that the entire process of file scanning and code spraying is completed automatically. The automation degree is high, the work efficiency is greatly improved, and the error rate is reduced. The labor cost is also greatly reduced, and the work efficiency is improved.

Owner:SHANDONG CAIJU ELECTRONICS TECH CO LTD

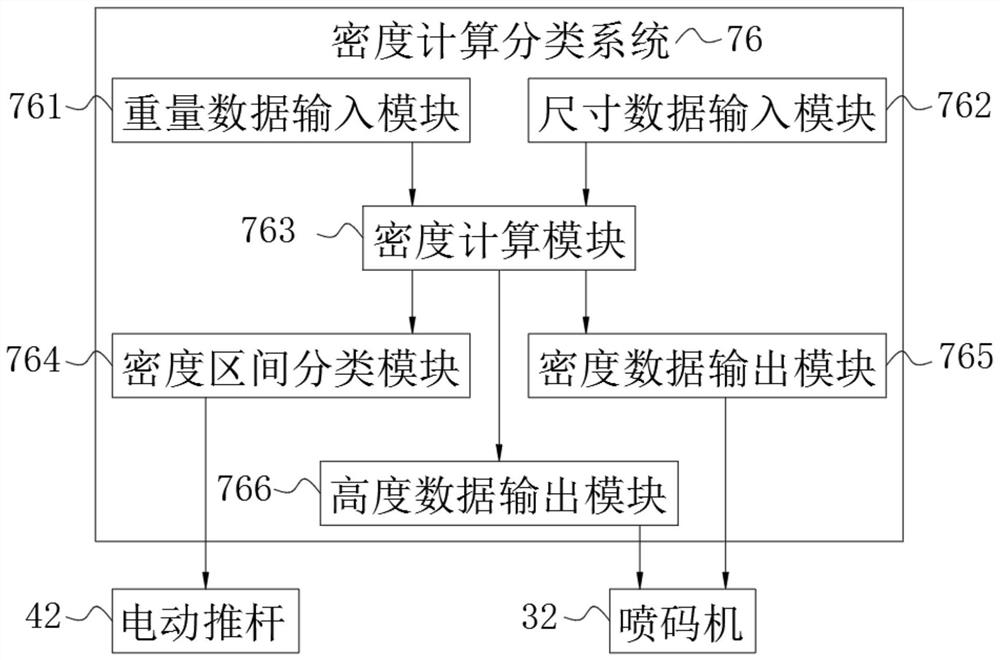

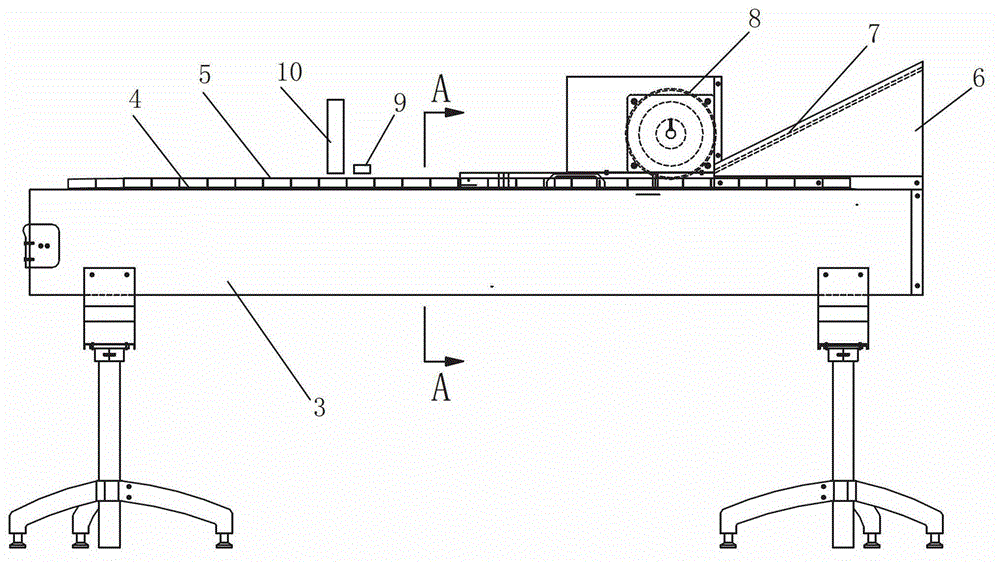

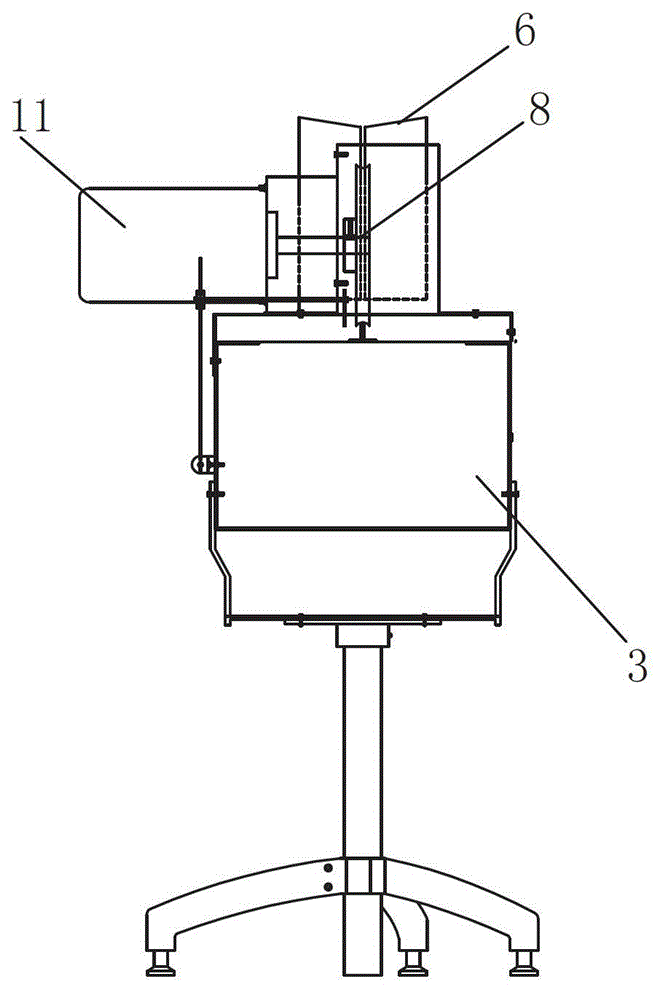

Fully-automatic density code-spurting and sorting machine

InactiveCN111957599AMachine measurement is simple and convenientImprove accuracy and efficiencyTypewritersSortingEngineeringElectrical and Electronics engineering

The invention discloses a fully-automatic density code-spurting and sorting machine. The fully-automatic density code-spurting and sorting machine comprises a feeding mechanism, a weighing mechanism,a code-spurting mechanism and a sorting mechanism which are connected in parallel, wherein the weighing mechanism comprises a first underframe, a weighing device is fixedly connected with the top of the first underframe, a light curtain measuring device is fixedly connected between the middles of the front side and the rear side of the first underframe and located above the weighing device, and conveying belt mechanisms are fixedly connected to the top of the weighing device and located on the left side and the right side of the light curtain measuring device. The invention relates to the technical field of automatic equipment. According to the fully-automatic density code-spurting and sorting machine, the weighing mechanism is arranged and matched with the light curtain measuring device,weight and volume of battens can be measured simultaneously, and then by means of simple calculation, density of the battens can be obtained; and besides, comprehensive size measurement on the battenspassing at a constant speed can be directly performed by the light curtain measuring device, the machine measurement is simple and convenient, tedious manual measurement by workers is omitted, and efficiency and precision are higher.

Owner:科锐奇新能源材料科技(江苏)有限公司

Anti-counterfeiting code spraying device for cigarette turnover box lock

ActiveCN103802488BConvenient codingReduce labor intensityTypewritersEngineeringMechanical engineering

The invention provides a cigarette container snap close security code spraying device. According to the cigarette container snap close security code spraying device, an annular conveyer belt is provided with an annular snap close fixing belt, the annular snap close fixing belt is provided with a loop of annular snap close fixing grooves, during use, snap closes are disposed on the annular snap close fixing belt, snap close pins are enabled to correspond to positions of the annular snap close fixing grooves, when the snap closes move below a pressure wheel along the annular conveyer belt, the snap close pins can be automatically pressed by the pressure wheel into the annular snap close fixing grooves to fix the snap closes, end caps of the snap closes are horizontally pressed on the annular snap close fixing belt, and thereby code spraying for the end caps of the snap closes is conveniently carried out by a spraying machine. The cigarette container snap close security code spraying device can realize automatic code spraying of the snap closes, so labor intensity of a worker can be effectively reduced, and work efficiency is improved.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

A belt type bottle cap spraying device

InactiveCN107336528BReduce lossEasy and stable placementConveyorsTypewritersTransmission beltEngineering

Owner:绍兴兴宽五金塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com