High-precision position-adjustable code spraying device

A high-precision, coding technology, used in printing devices, printing, typewriters, etc., can solve problems such as affecting the coding effect and different coding positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

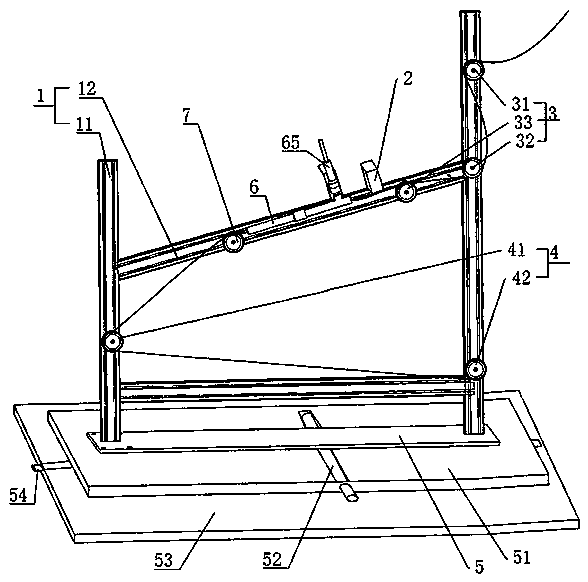

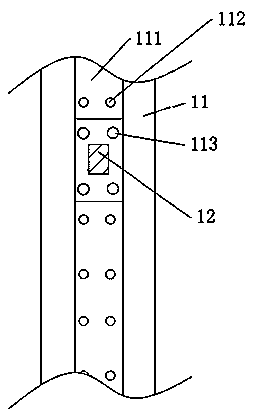

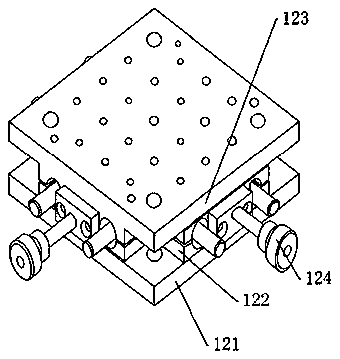

[0036] A high-precision position-adjustable inkjet device, such as figure 1 , including a support frame 1, an inkjet printer head 2 set on the support frame 1, a first transmission wheel set 3 arranged on the support frame 1 and transmitting the optical fiber to the bottom of the inkjet printer head 2, and the inkjet printer can be FT300 model, at this time, fix the nozzle 2 of the inkjet printer on the support frame 1; 2 is fixed on the connecting rod 12, and the support frame 1 is provided with a second transmission wheel set 4 that transmits the optical fiber transmitted from the bottom of the inkjet printer nozzle 2 to the winding roller.

[0037] Such as figure 1 , the first transmission wheel set 3 includes the first transmission wheel 31 and the second transmission wheel 32 arranged on the pole 11 and the third transmission wheel 33 arranged on the connecting rod 12, the third transmission wheel 33 is arranged near the inkjet The position of the nozzle 2 of the inkjet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com