Intelligent manufacturing laser ink-jet printer capable of identifying ink-jet position

A technology of intelligent manufacturing and inkjet printers, which is applied in the field of laser inkjet printers, can solve problems such as the wrong location of equipment inkjet inkjet, and achieve the effect of convenient inkjet inkjet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

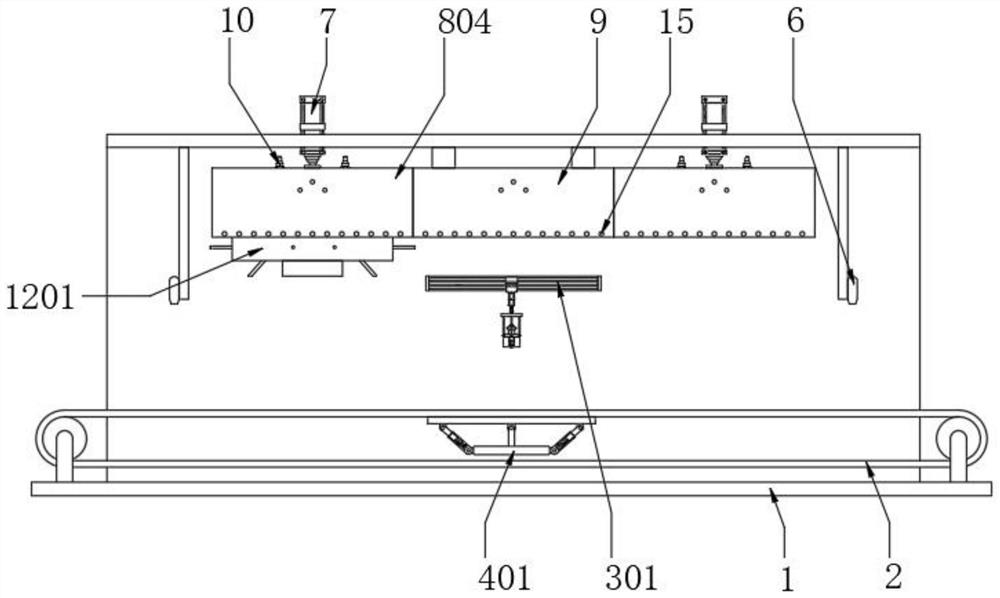

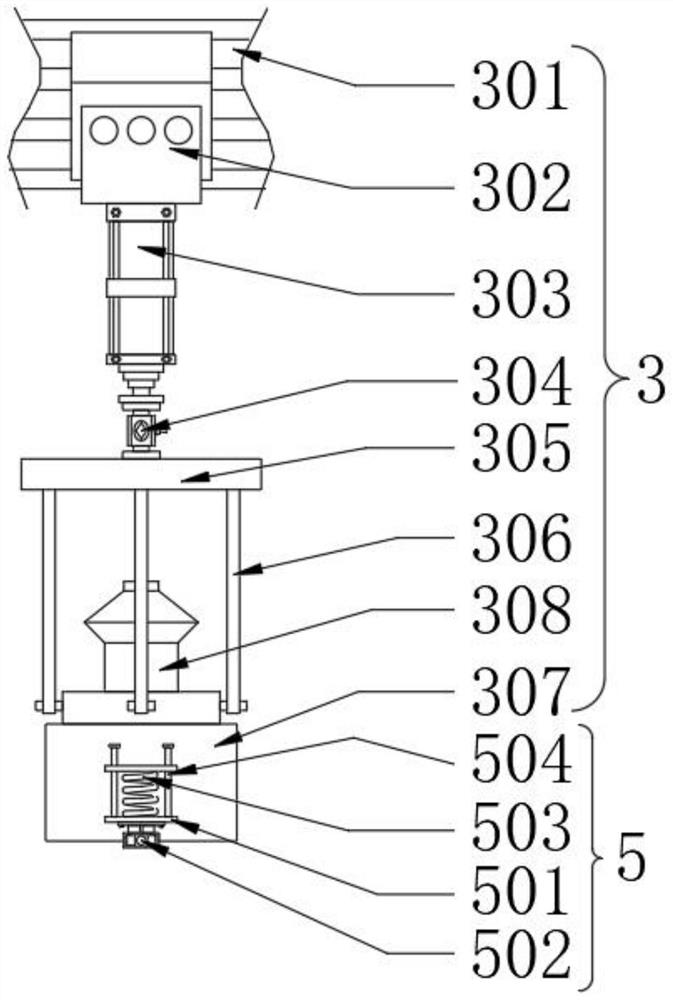

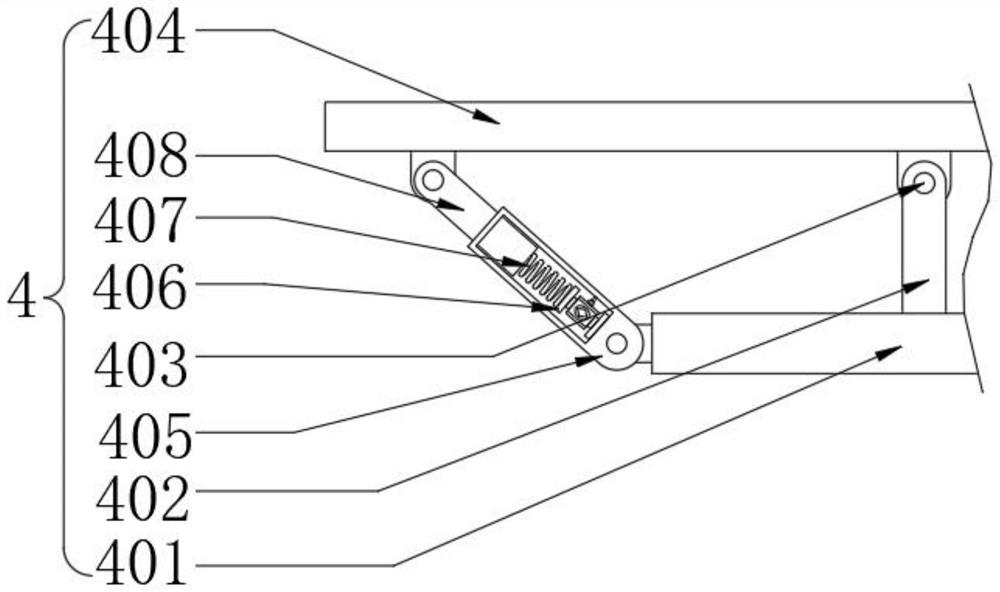

[0031] like Figure 1 to Figure 8As shown, the present invention provides a technical solution: a laser inkjet printer for intelligent manufacturing that can identify the coding position, including a casing 1 and a connecting assembly 5, the inner lower wall of the casing 1 is provided with a belt conveyor 2, and the casing The inner front and rear walls of 1 are sequentially provided with a docking assembly 3 and a support assembly 4 from top to bottom, and the support assembly 4 includes a second plate 401, a support rod 402, a connecting pin 403, a third plate 404, an outer casing 405, a second Pressure sensor 406, first spring 407 and telescopic rod 408, and the upper end of second plate 401 is provided with support rod 402, and the upper end of support rod 402 is connected with connecting pin 403, and the outside of connecting pin 403 is connected with the 3rd plate 404, the left and right sides of the second plate 401 are movably connected with a jacket 405, and the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com