Patents

Literature

42results about How to "Accurate coding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

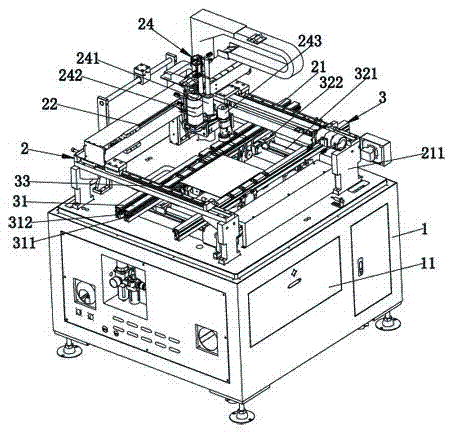

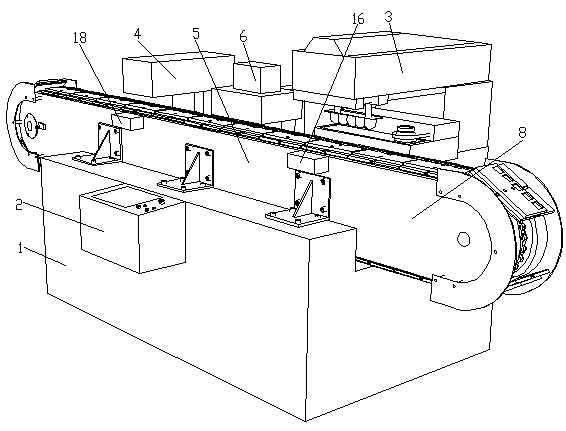

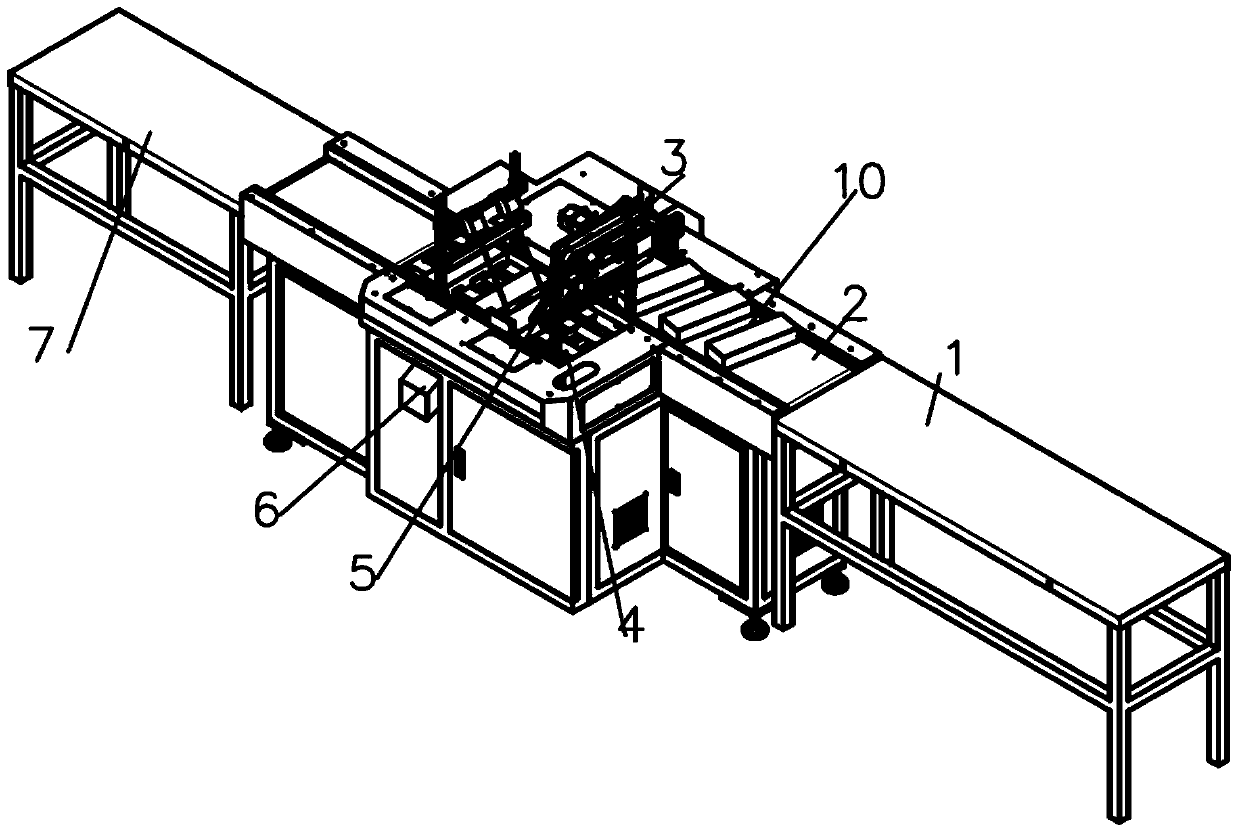

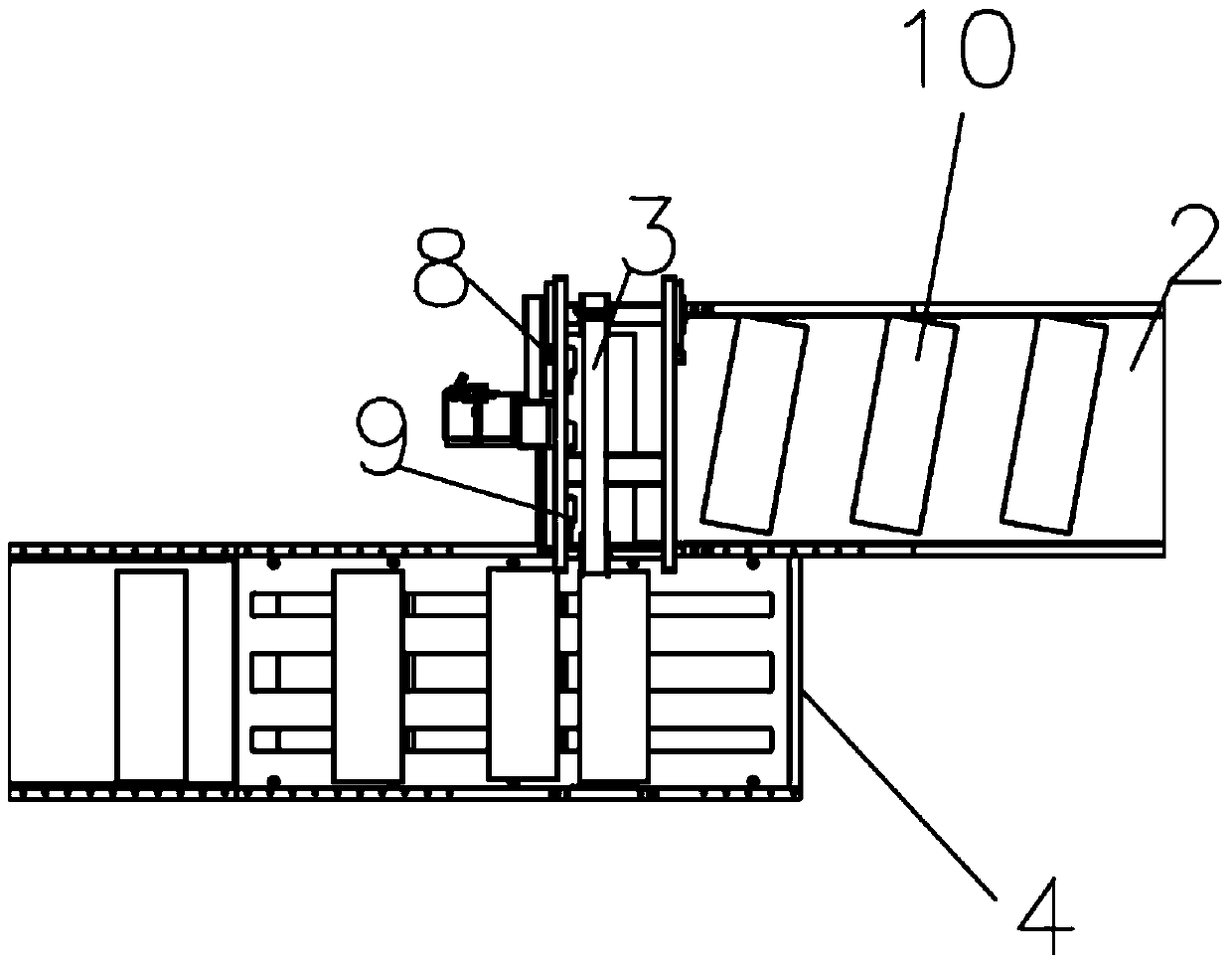

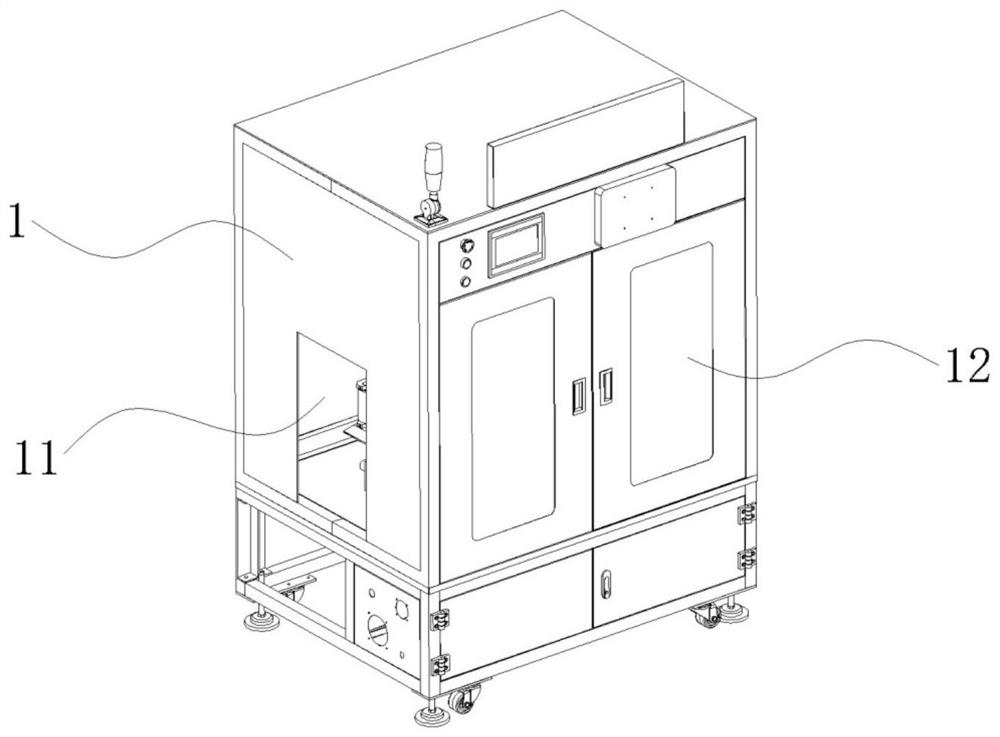

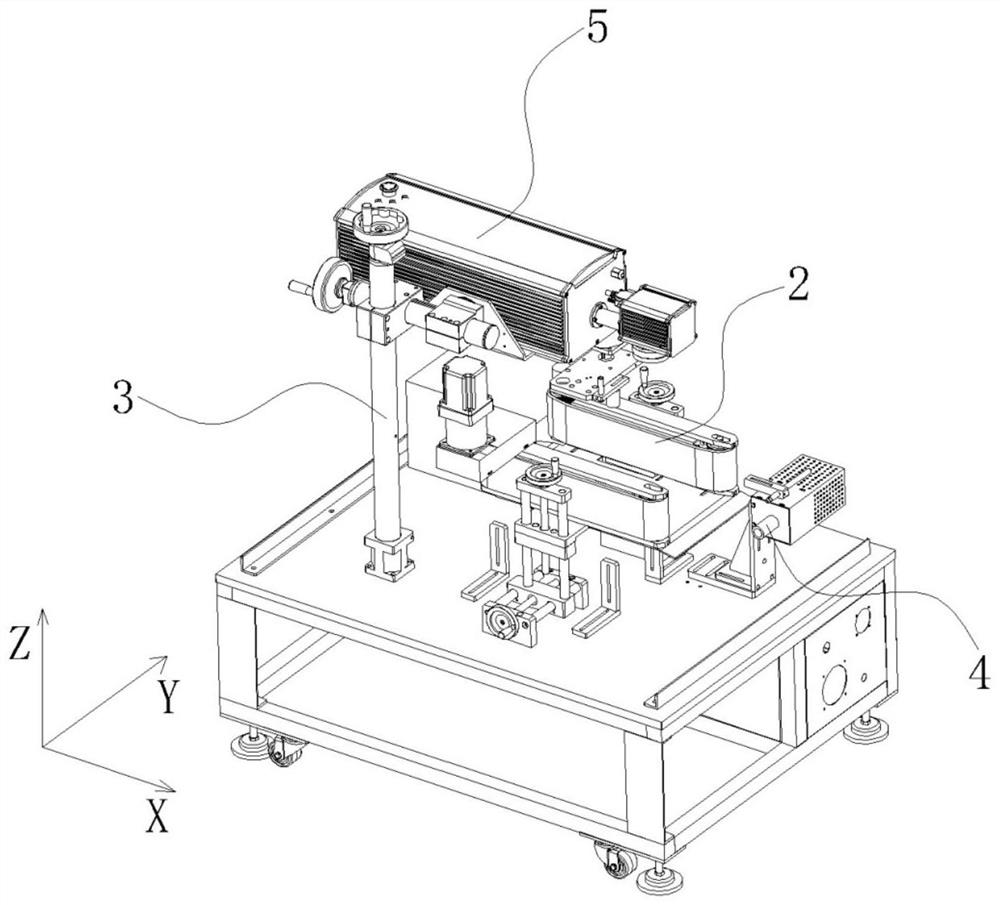

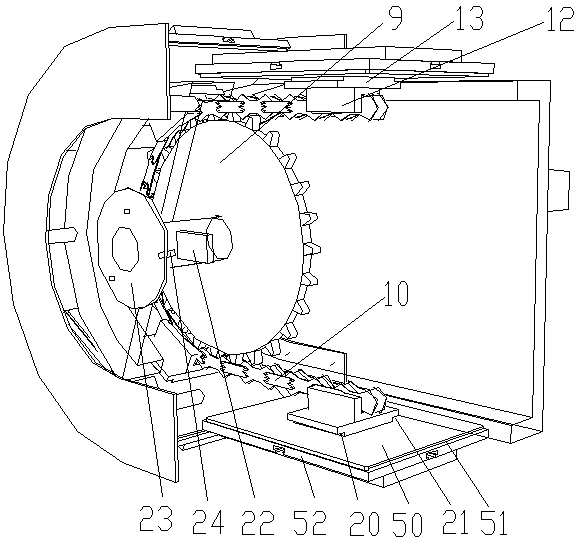

Continuous type pad printing and coding device

ActiveCN106364152APad printing stabilityPad printing precisionRotary pressesPrinting press partsPad printingEngineering

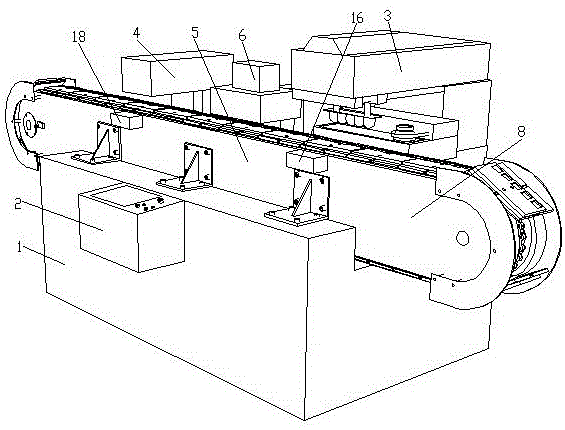

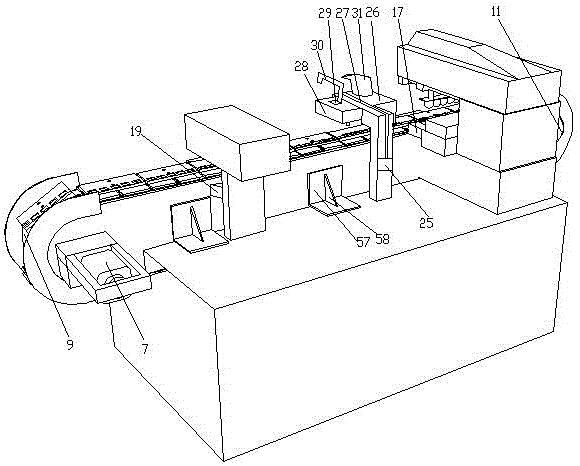

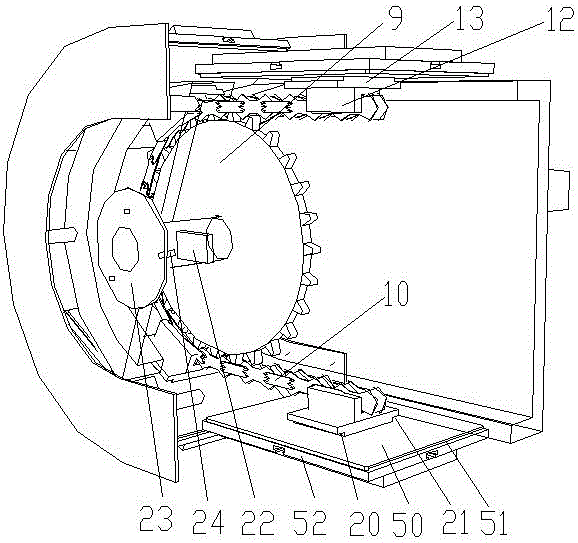

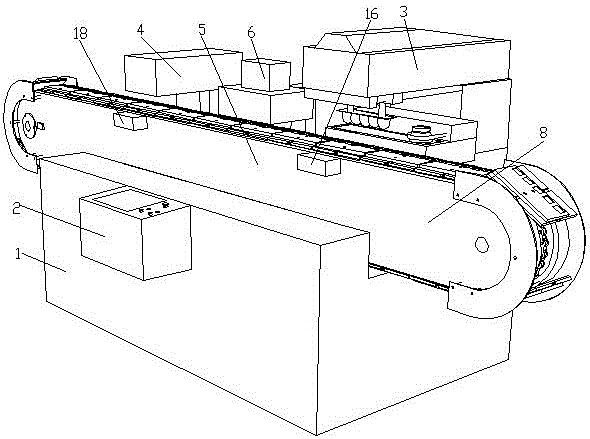

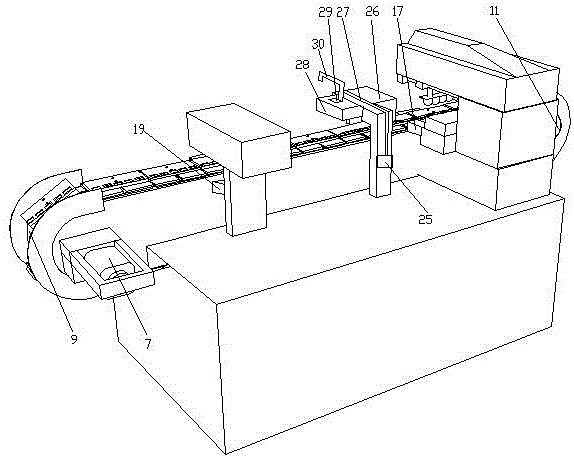

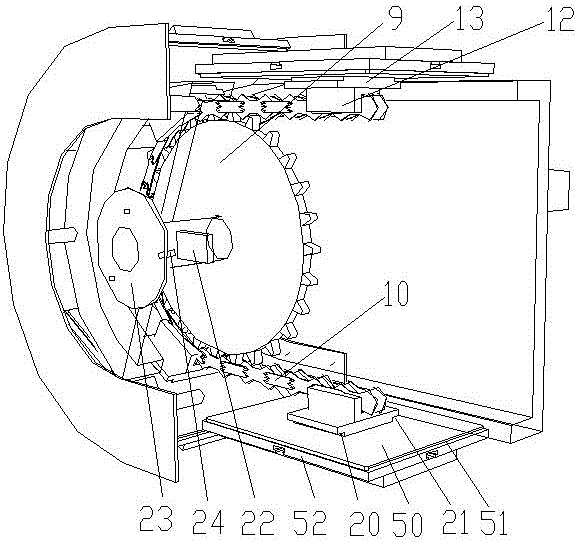

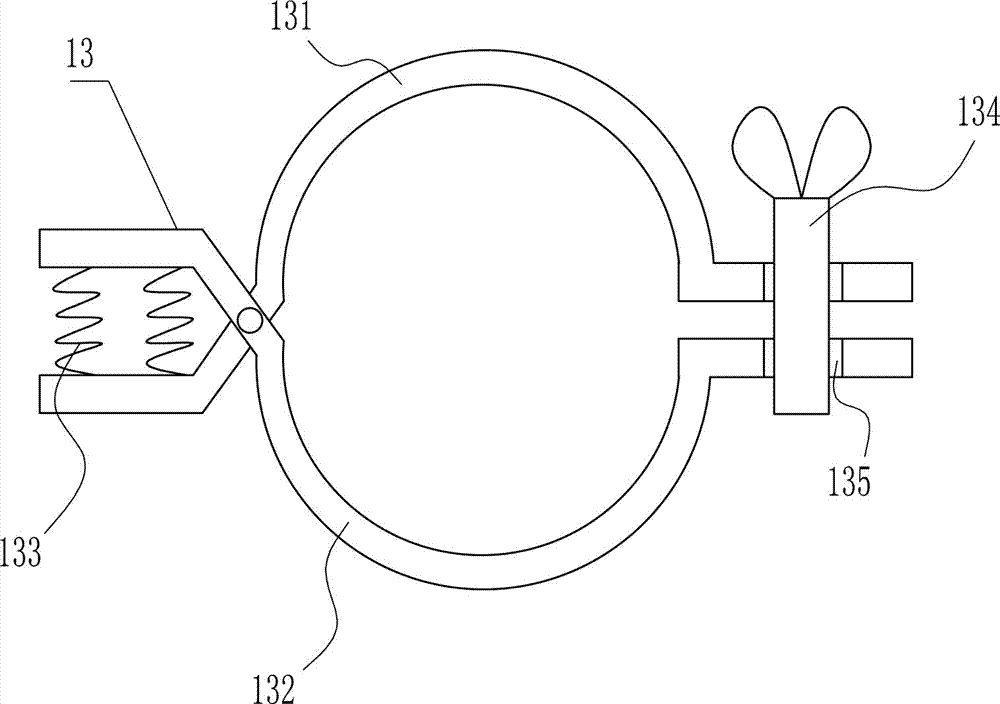

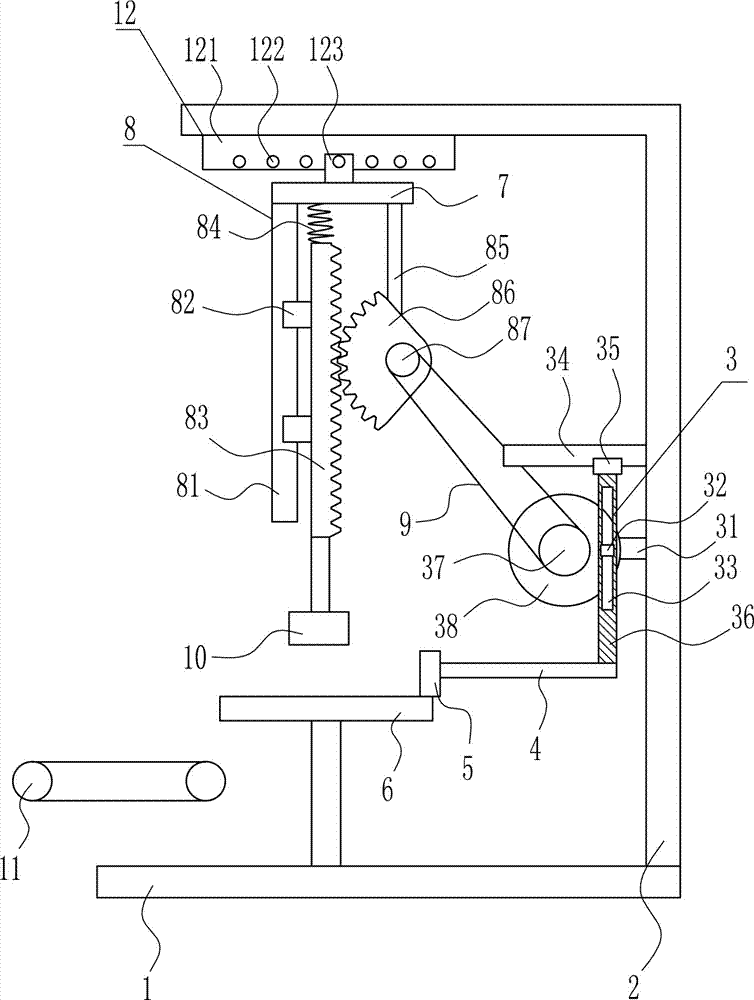

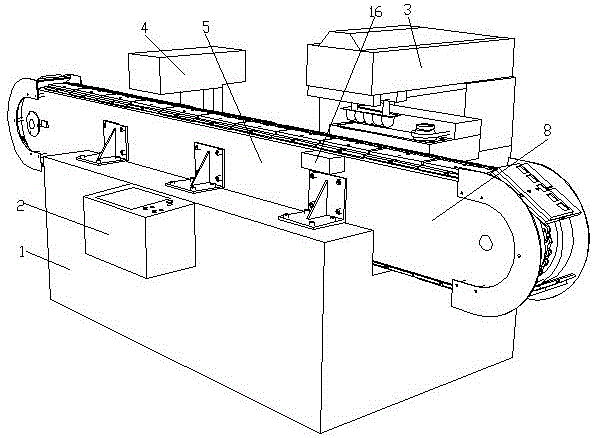

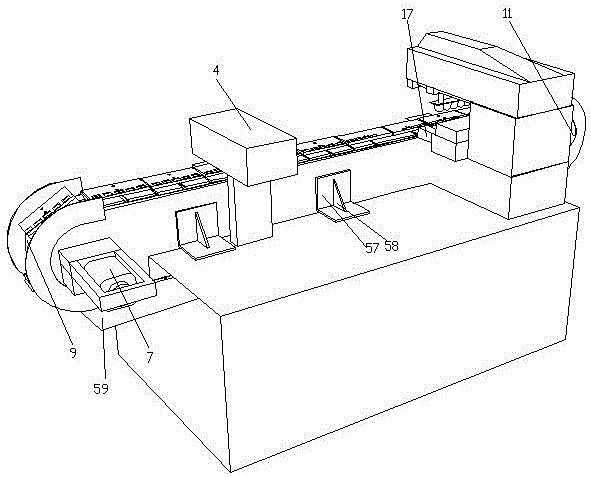

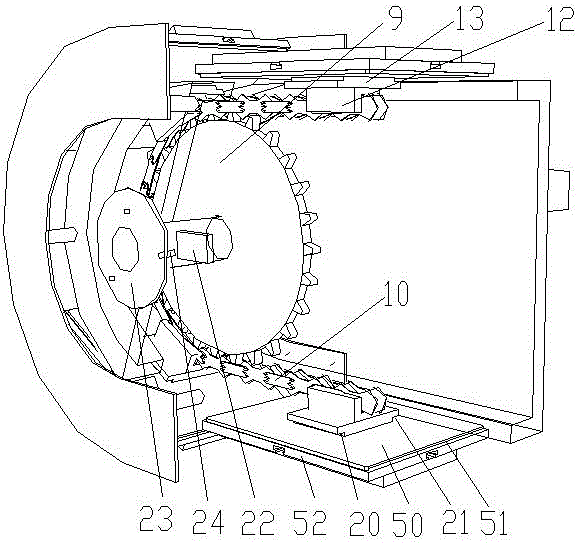

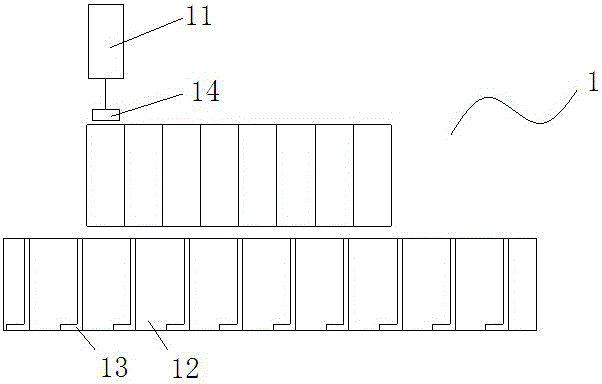

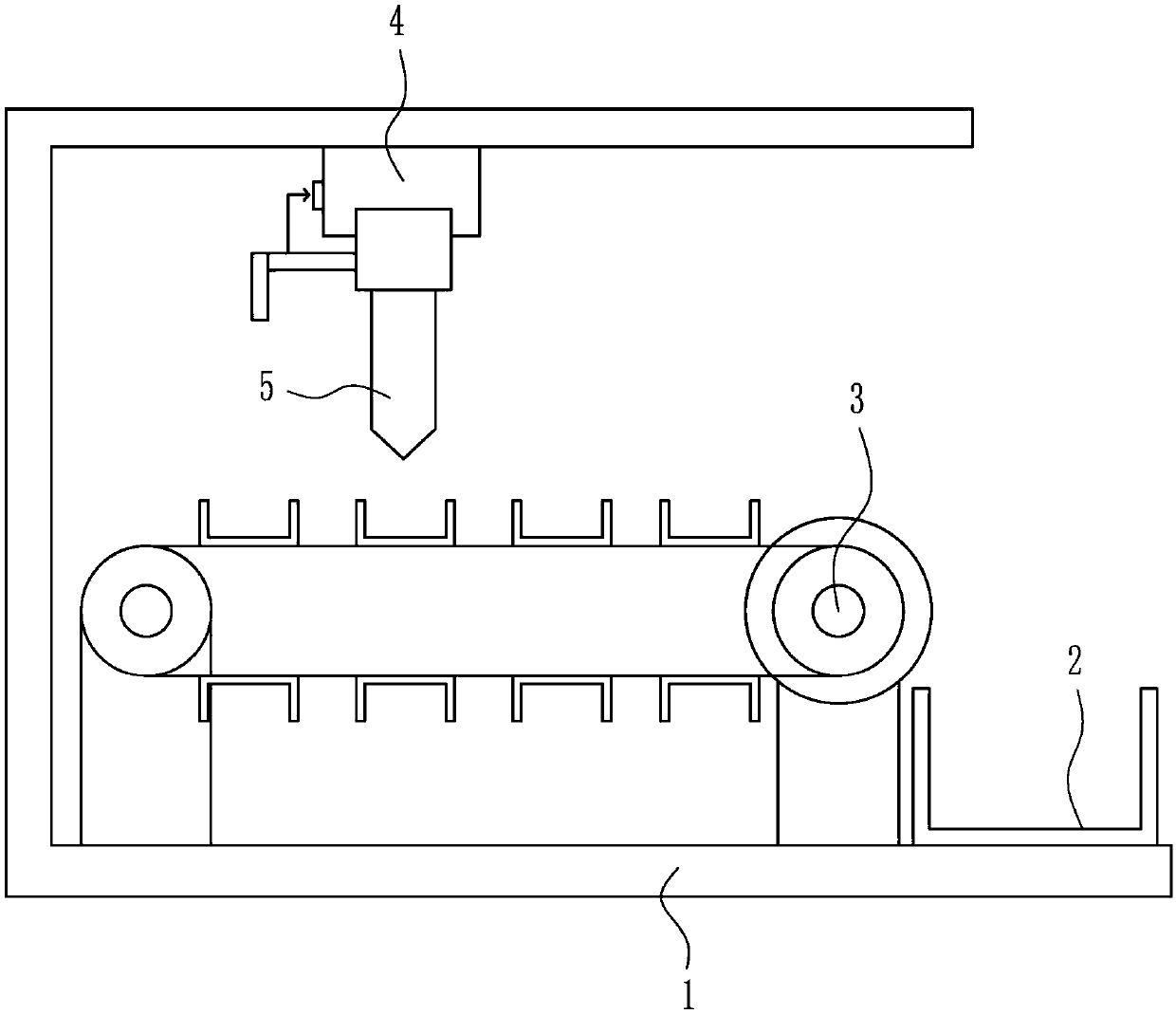

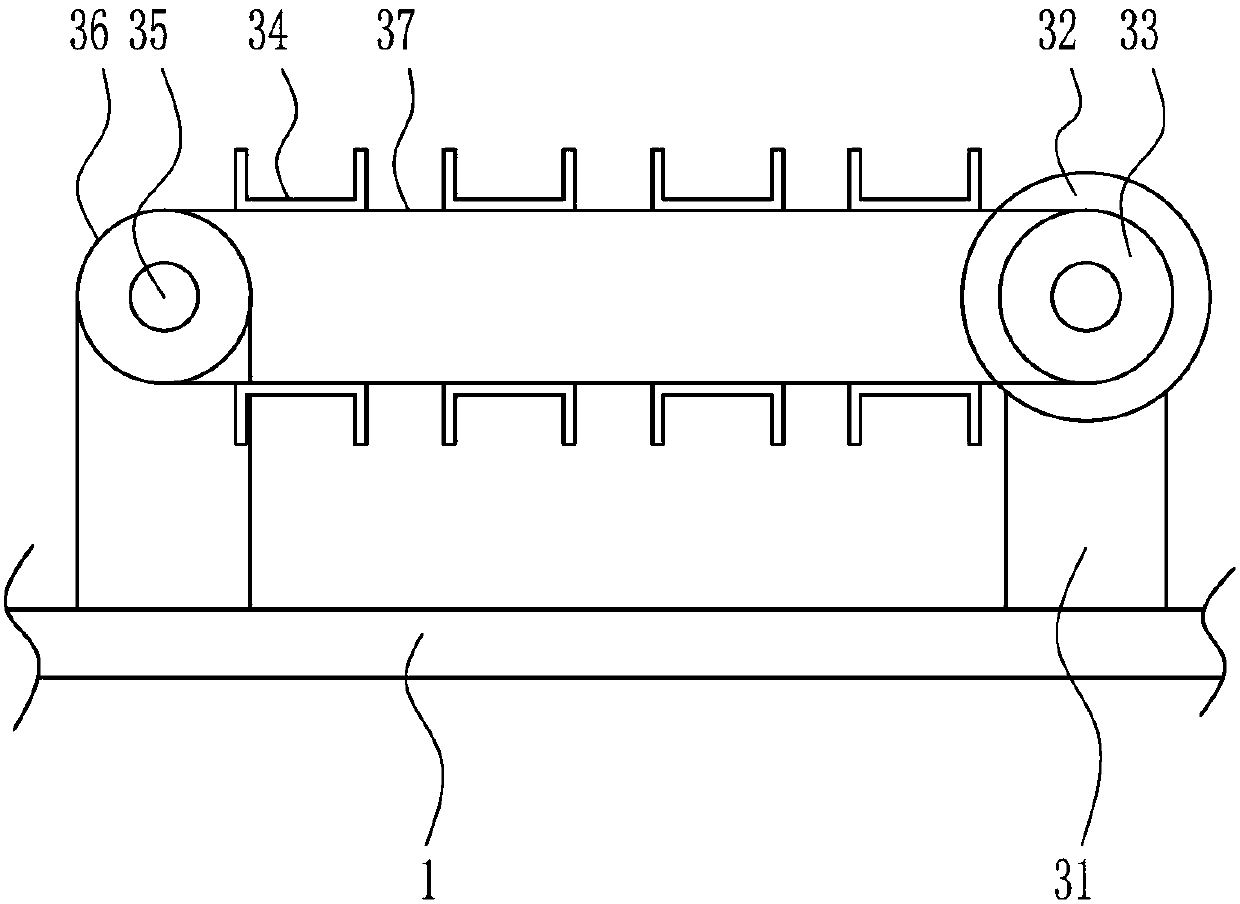

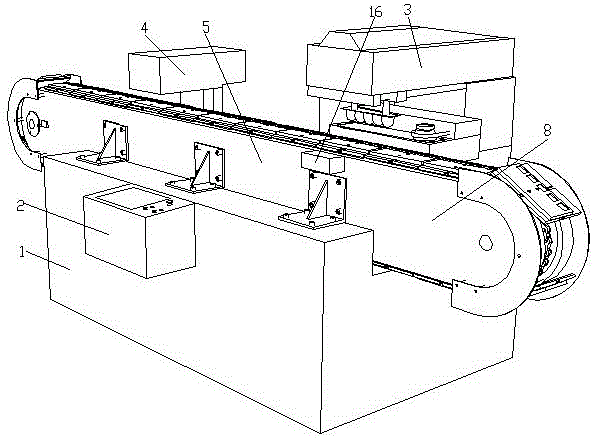

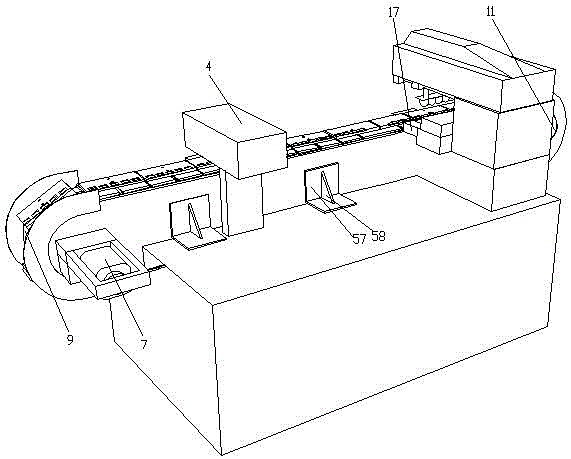

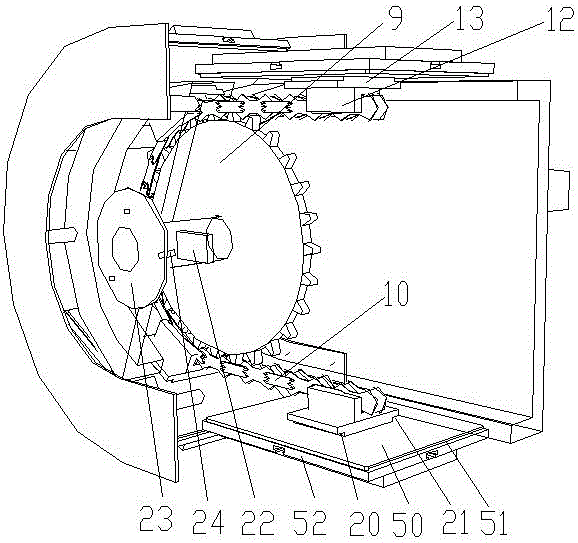

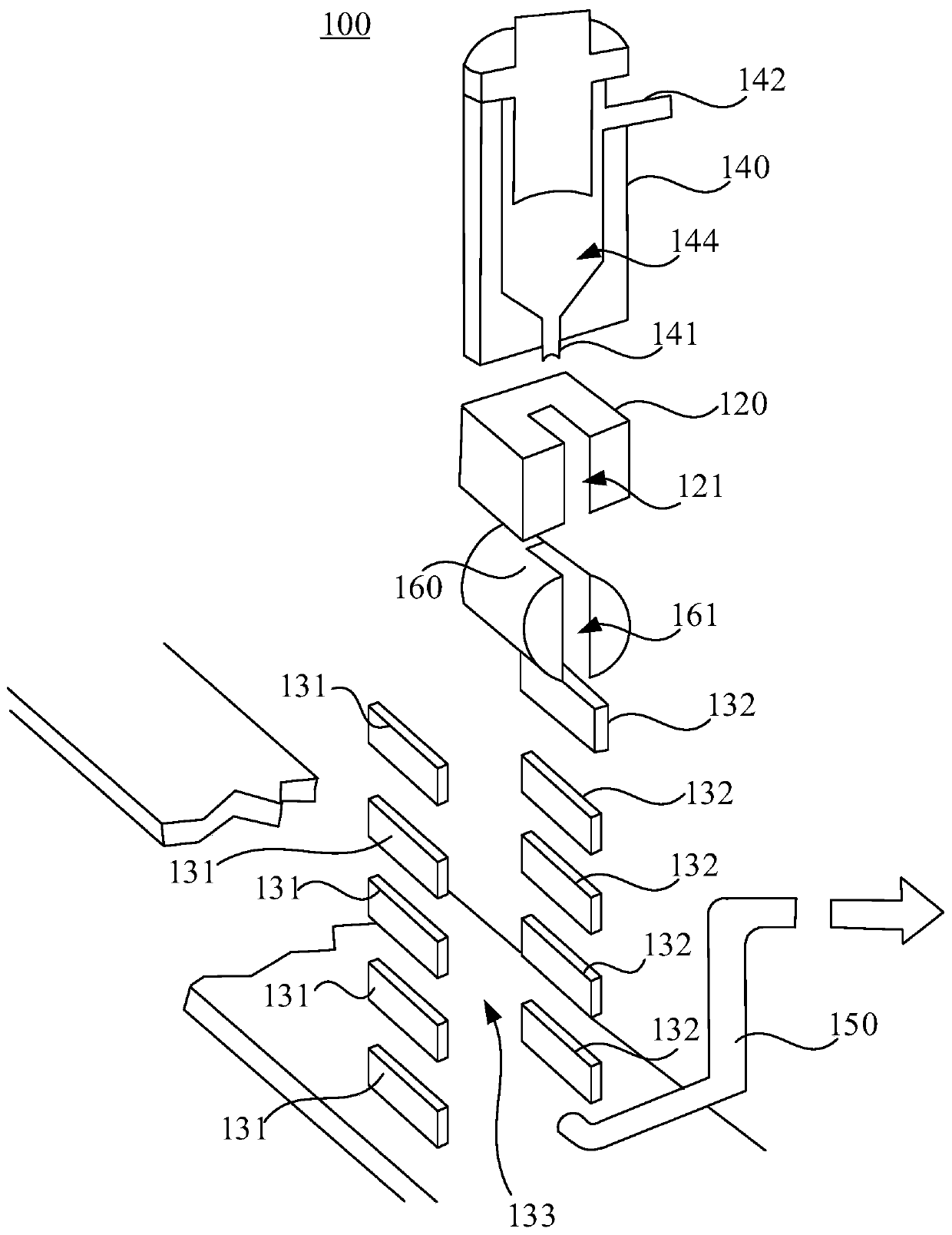

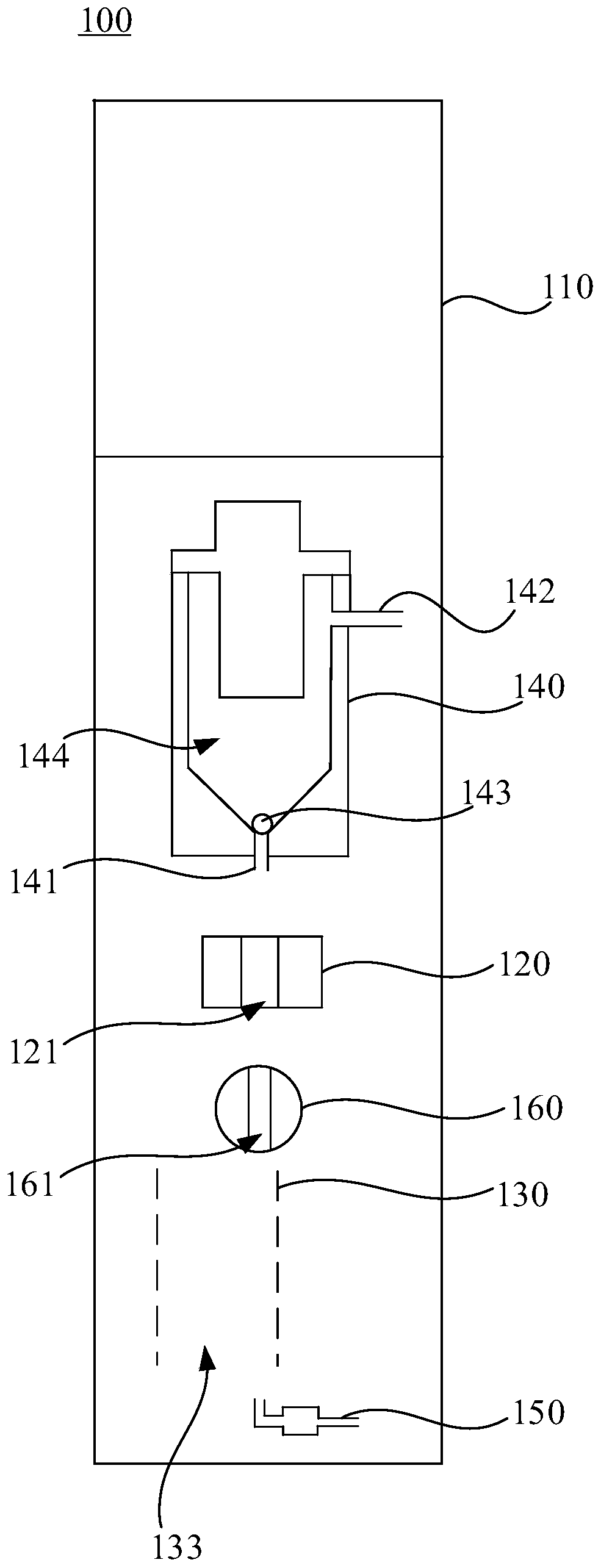

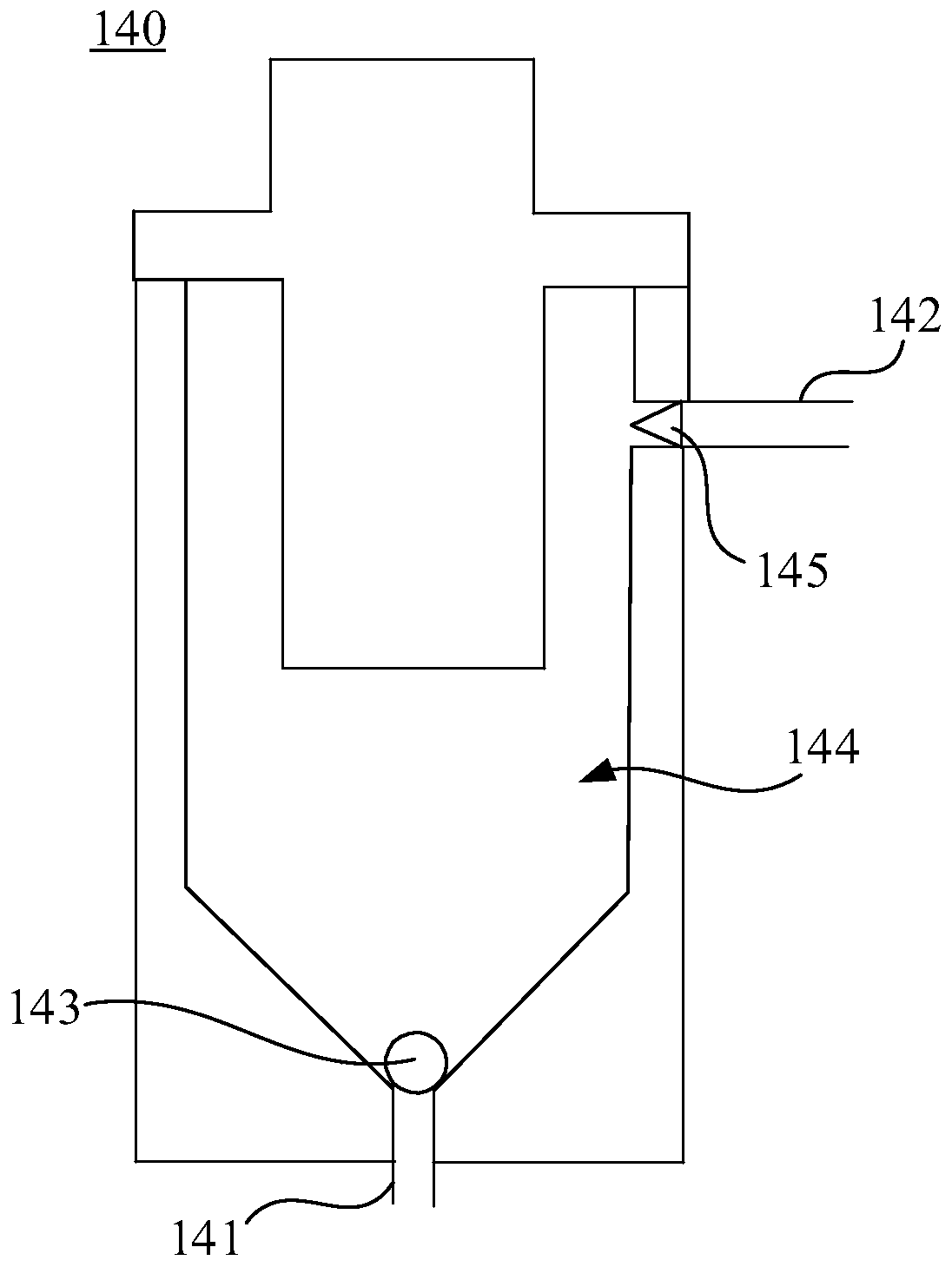

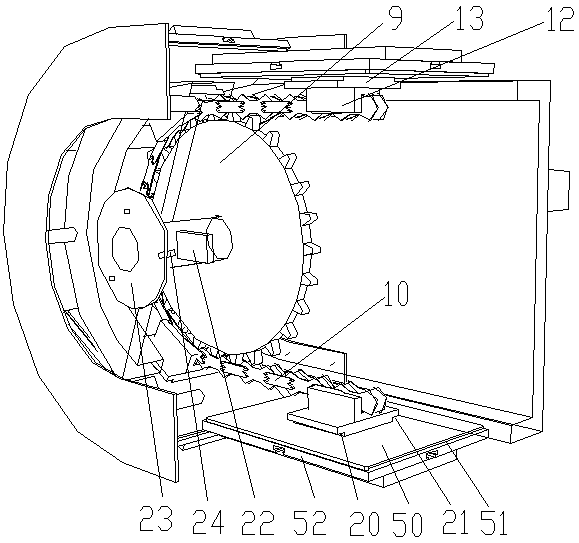

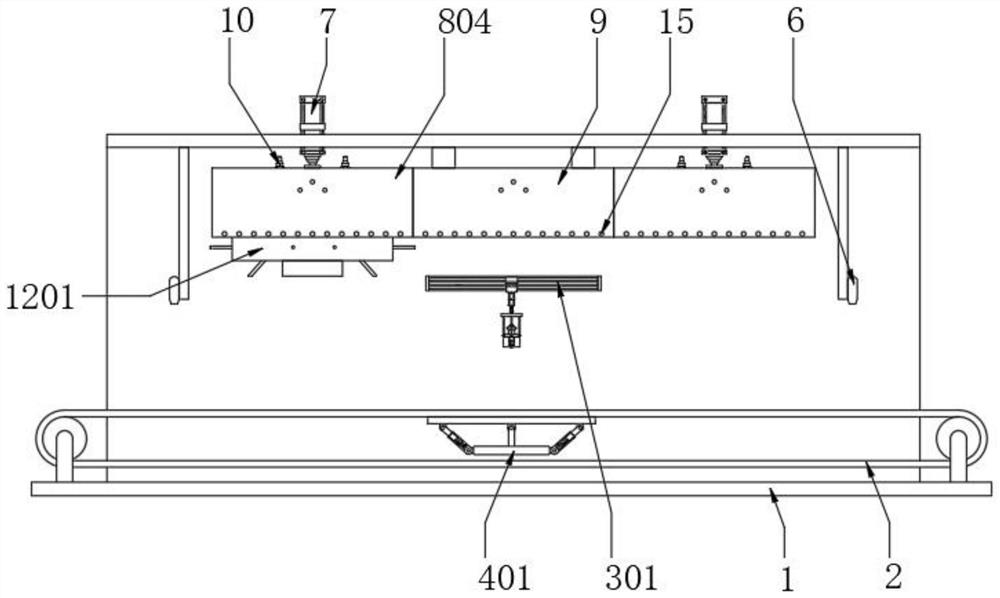

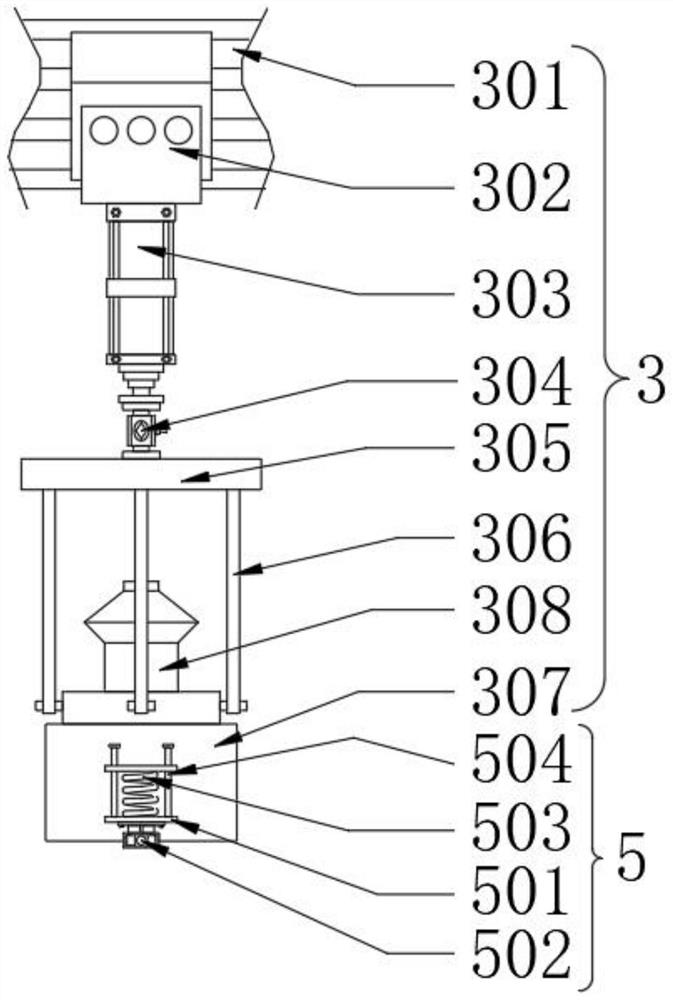

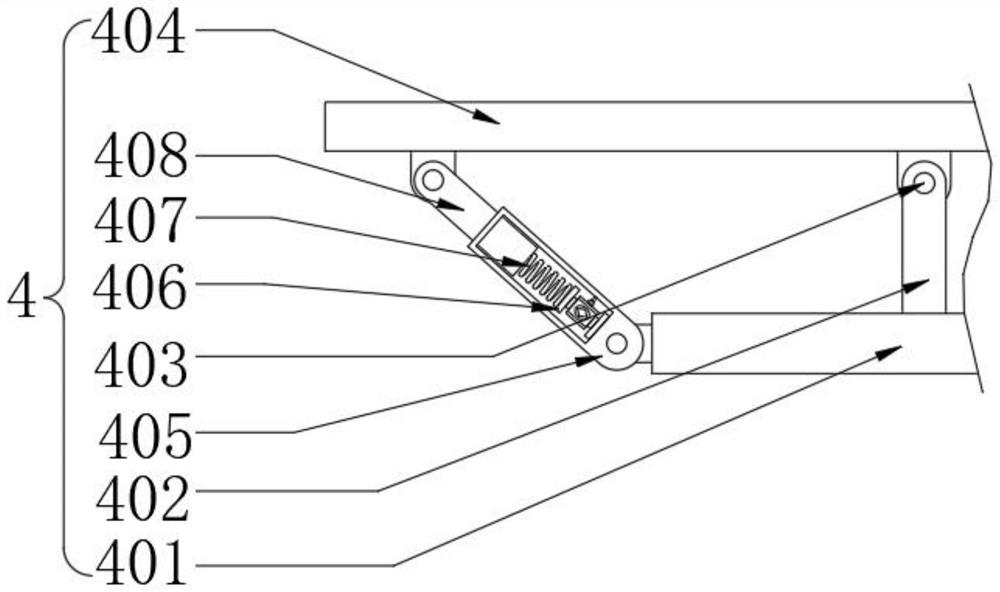

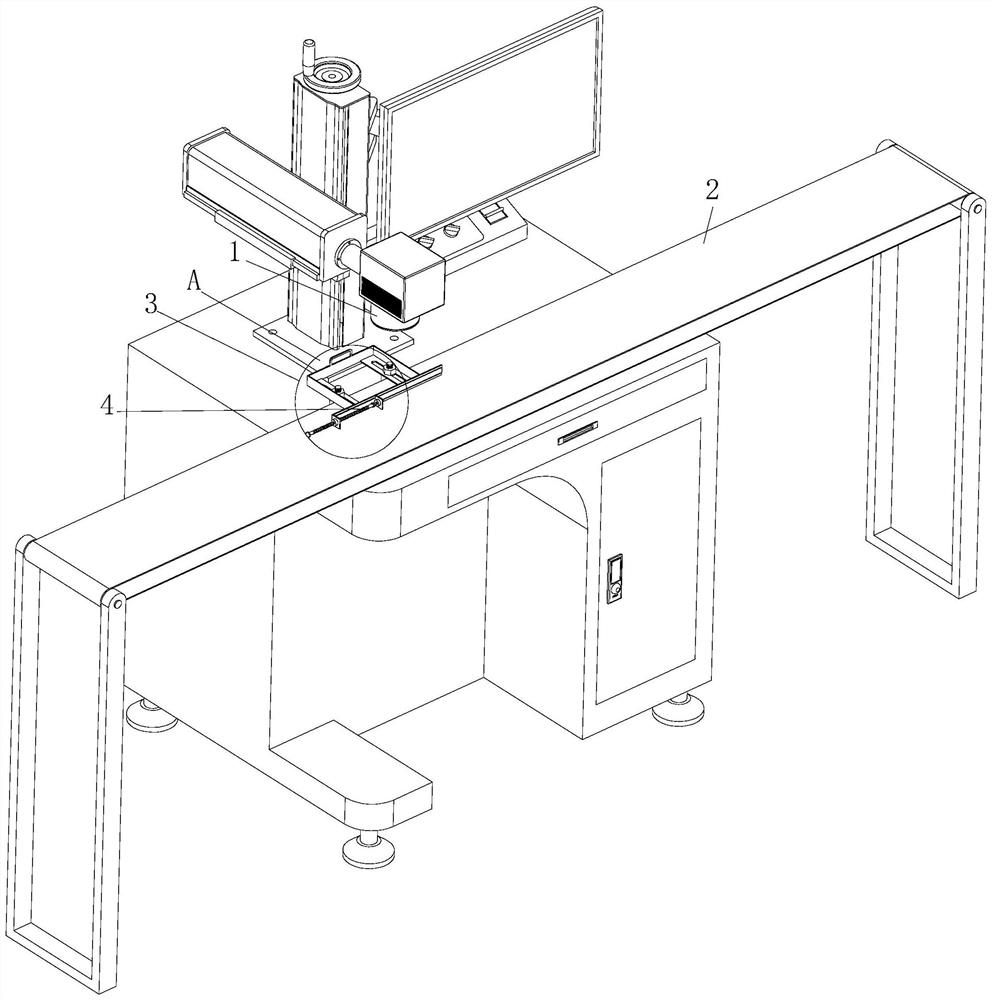

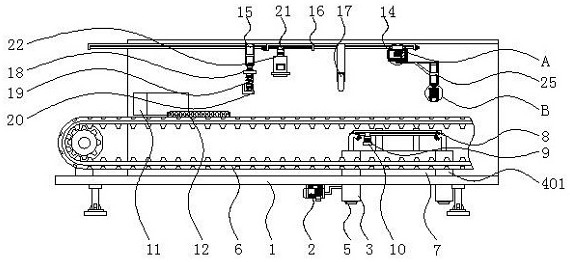

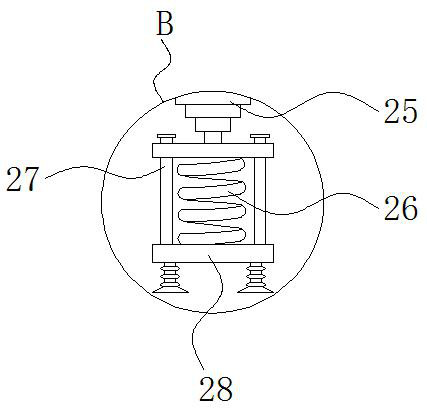

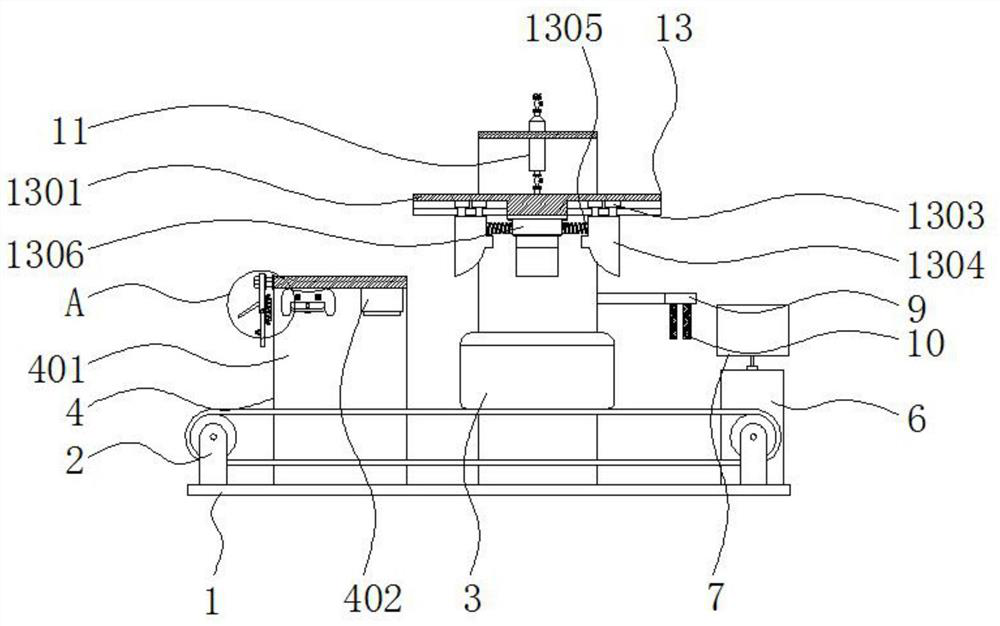

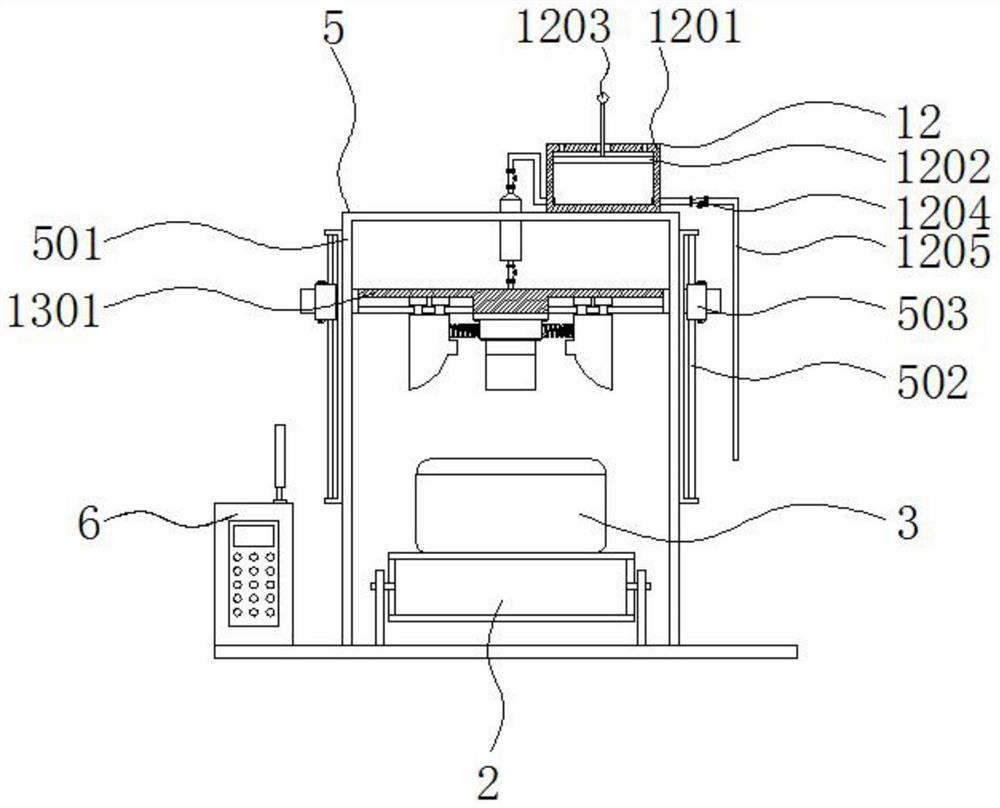

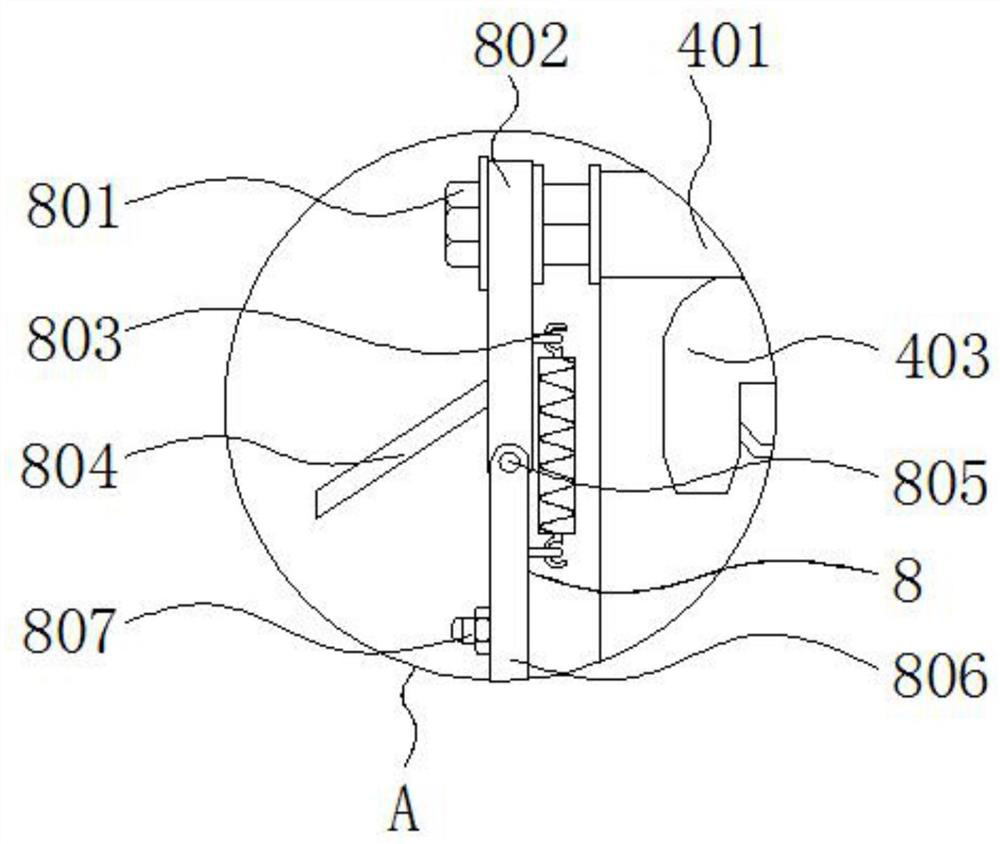

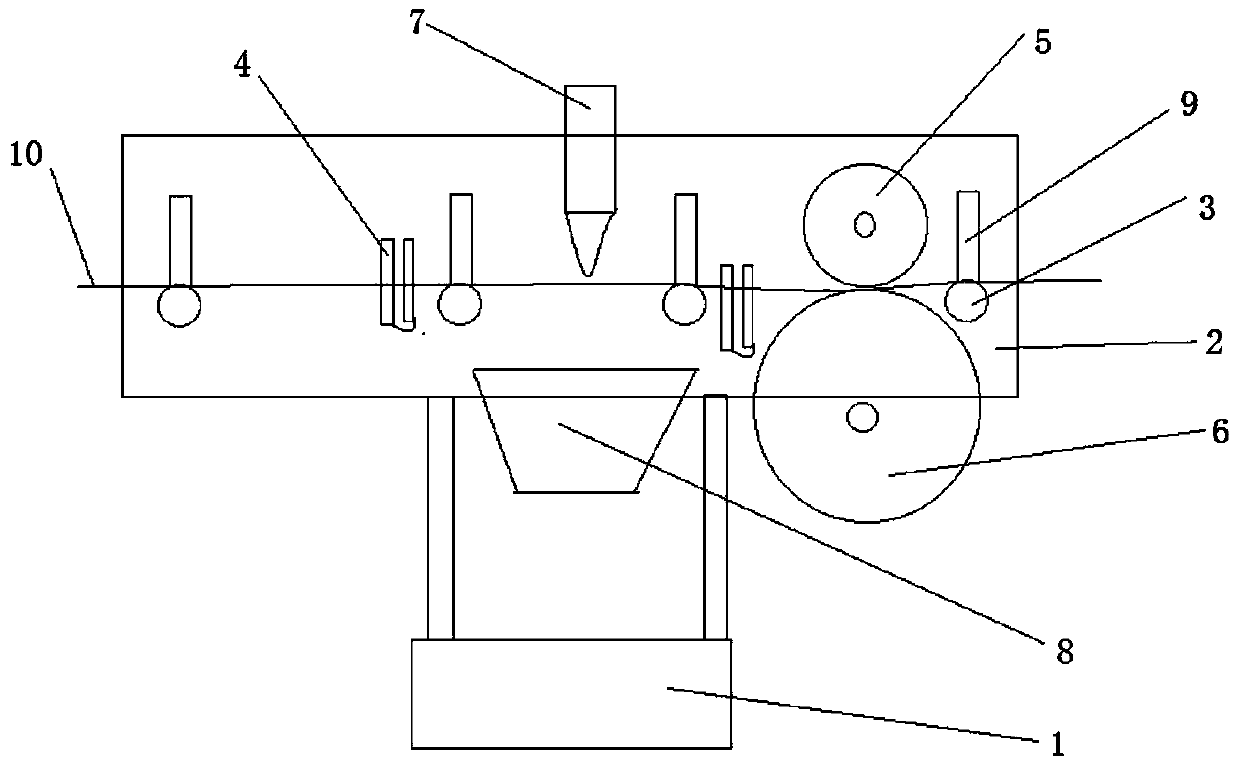

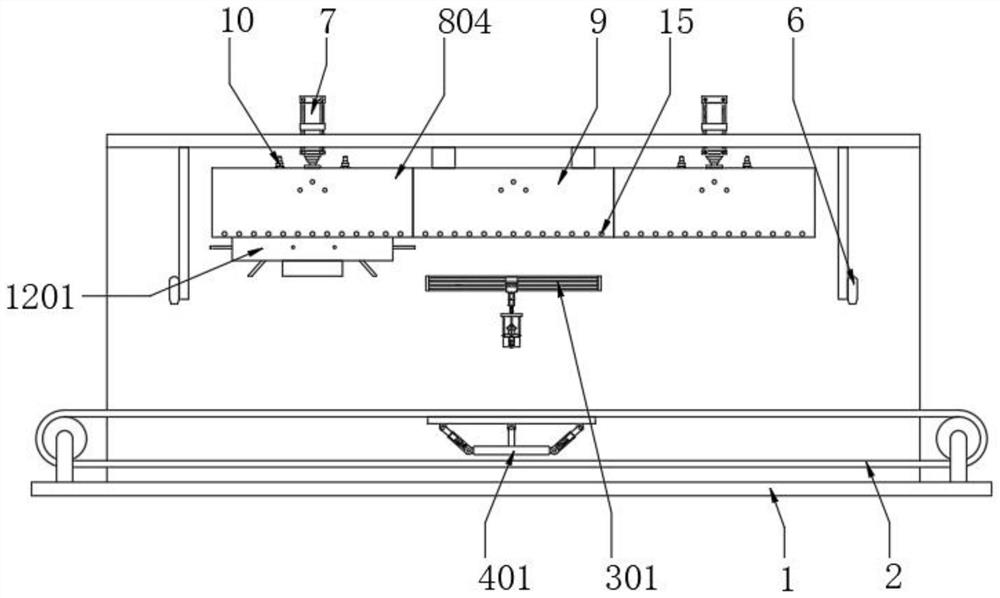

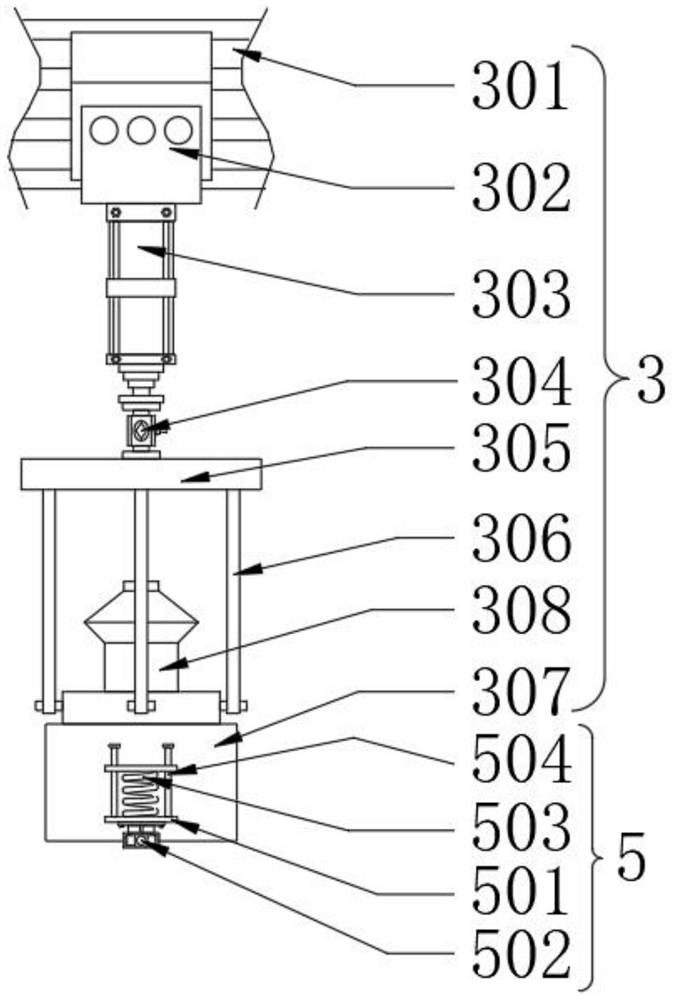

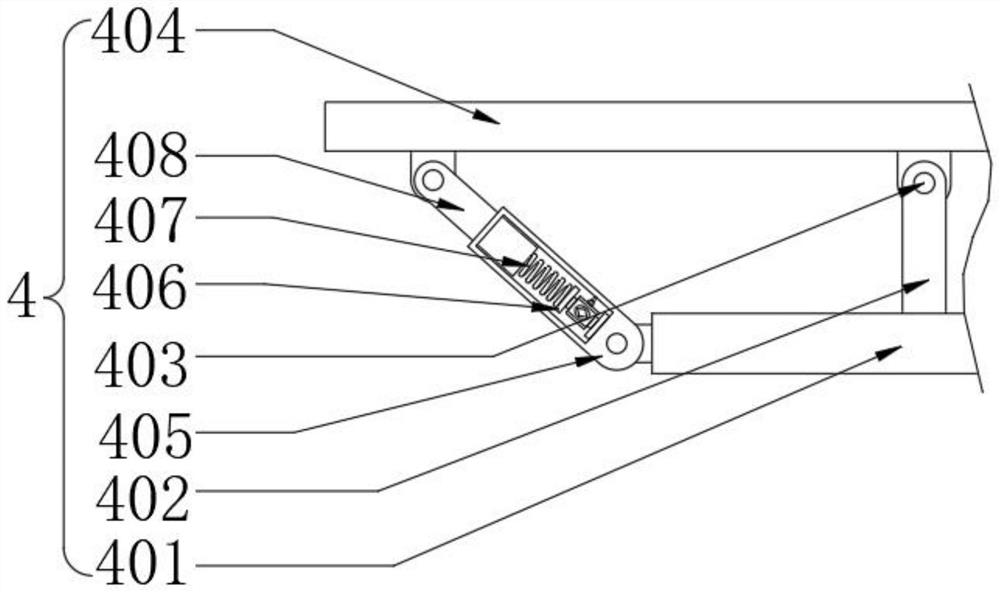

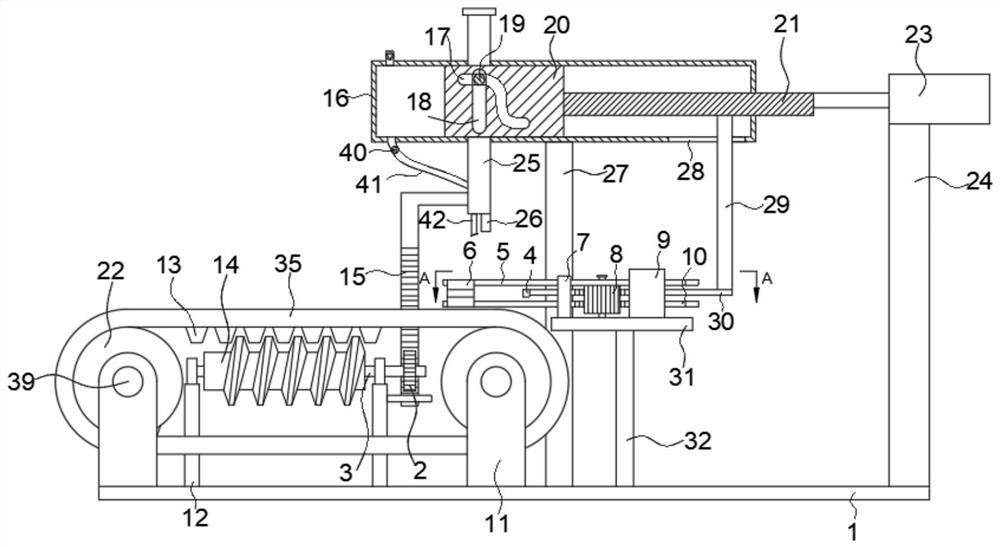

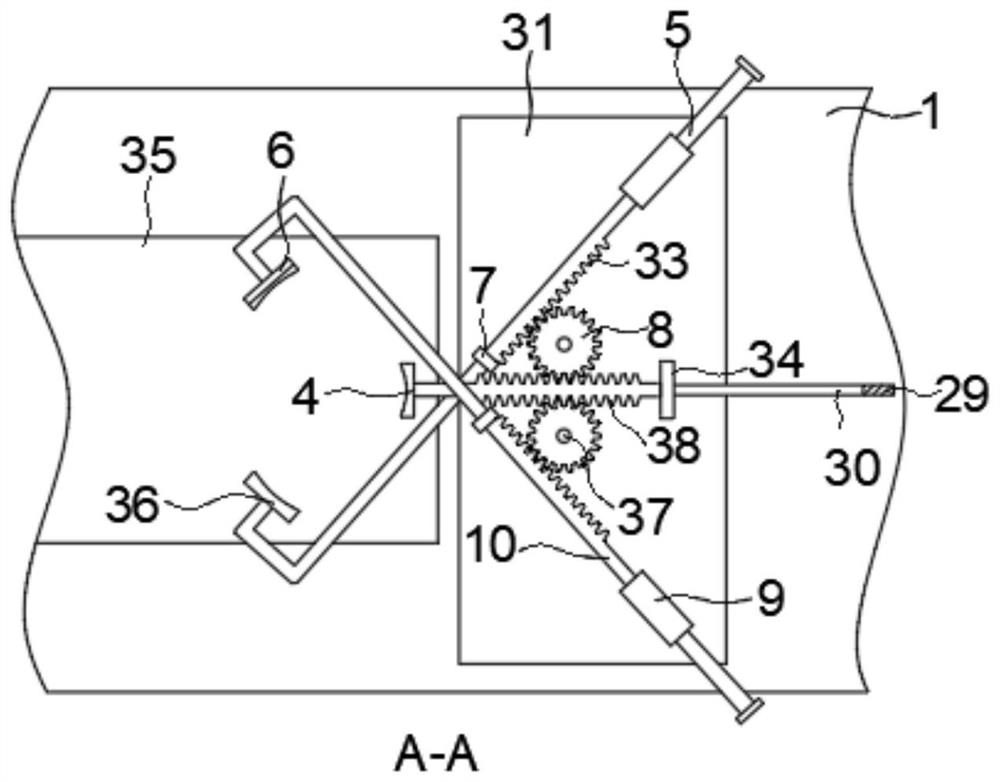

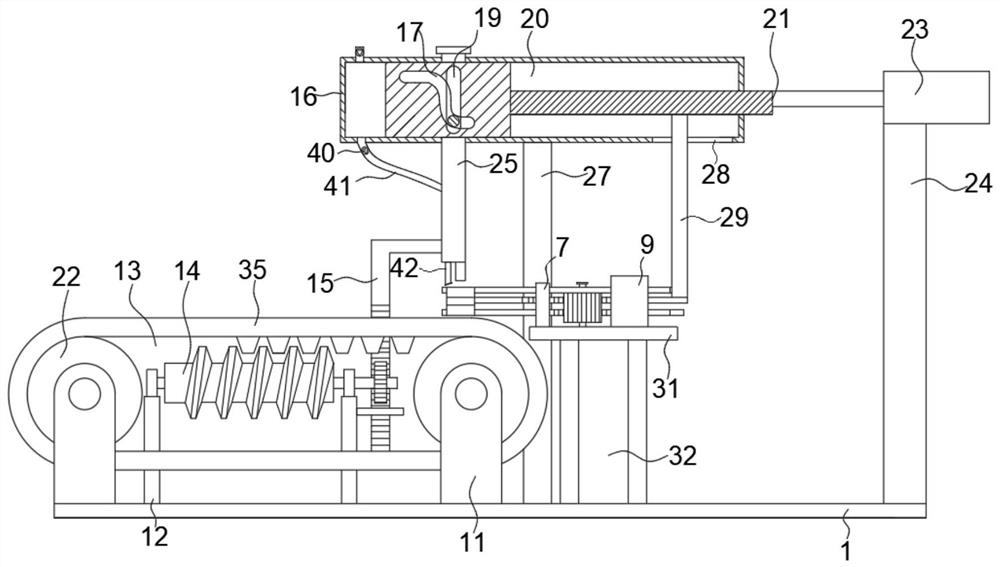

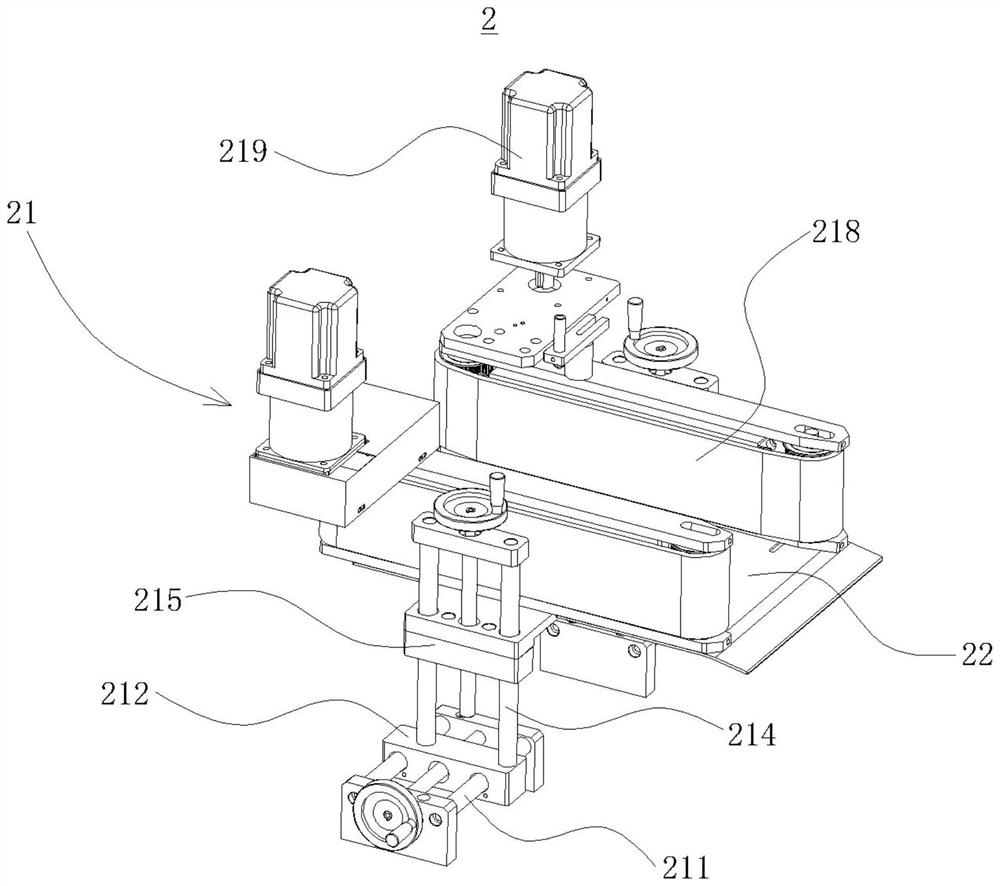

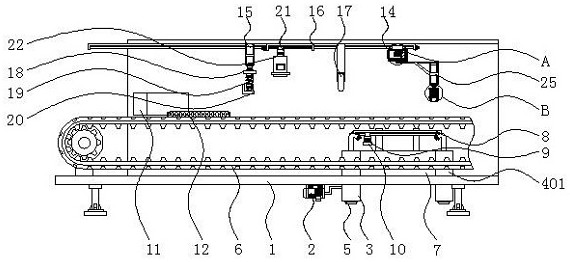

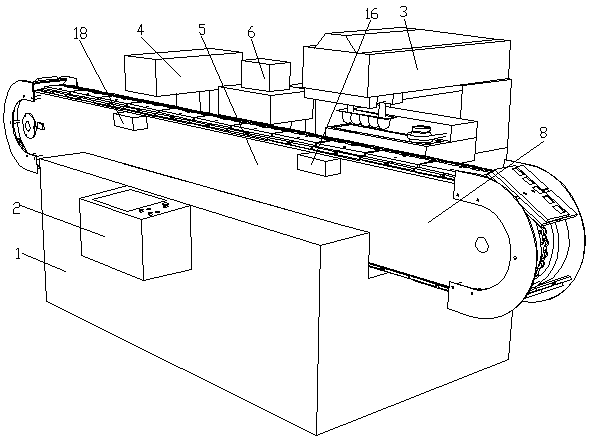

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

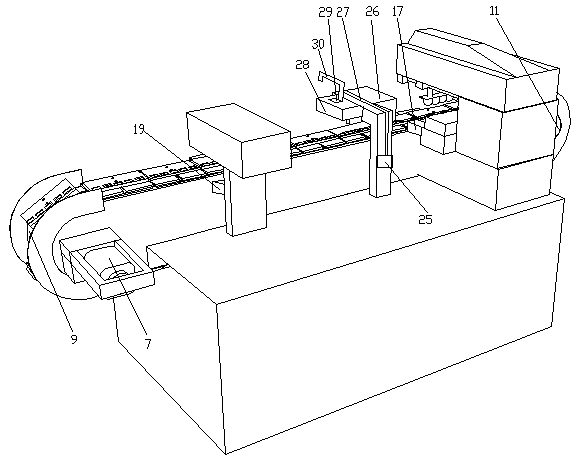

Continuous transfer-printing coding method

ActiveCN106379042AClear outlineSqueegee steps increaseRotary pressesPrinting press partsContinuous operationLaser

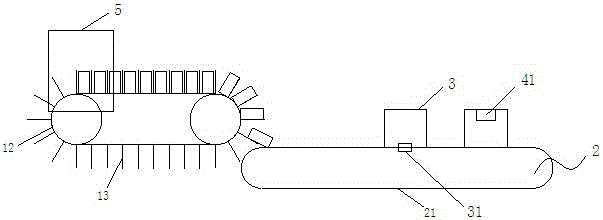

The invention discloses a continuous transfer-printing coding method. The continuous transfer-printing coding method comprises the following steps: step (a) inking an etching plate by using a sealed oil cup of a transfer-printing coding device; step (b) forwards pushing a rubber head of a transfer printing machine to the upper portion of the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and downwards pressing the rubber head to make the rubber head be stained with ink with patterns; step (c) backwards pushing the rubber head to a transfer printing work position, and then driving the rubber head to be pressed downwards so that the rubber head is capable of printing the ink with patterns on a to-be-printed object inside a mold groove; step (d) moving the transfer-printed object to a drying work position for drying by using a conveying component; step (e) moving the transfer-printed and dried object to a coding work position and coding the transfer-printed and dried object by using a laser coding machine. The continuous transfer-printing coding method disclosed by the invention is capable of realizing continuous operation on large-batch to-be-printed objects and improving the production efficiency; the patterns are clearer after the printed objects are dried at the drying work position; a coded product is high in exquisite degree and is fadeless after being used for a long time.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

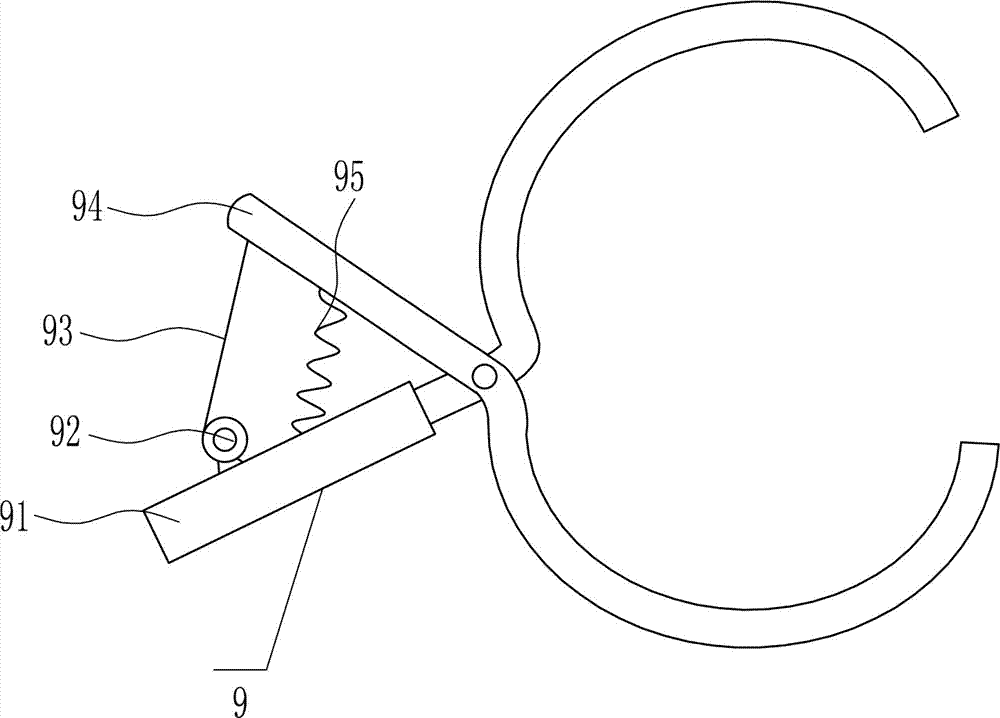

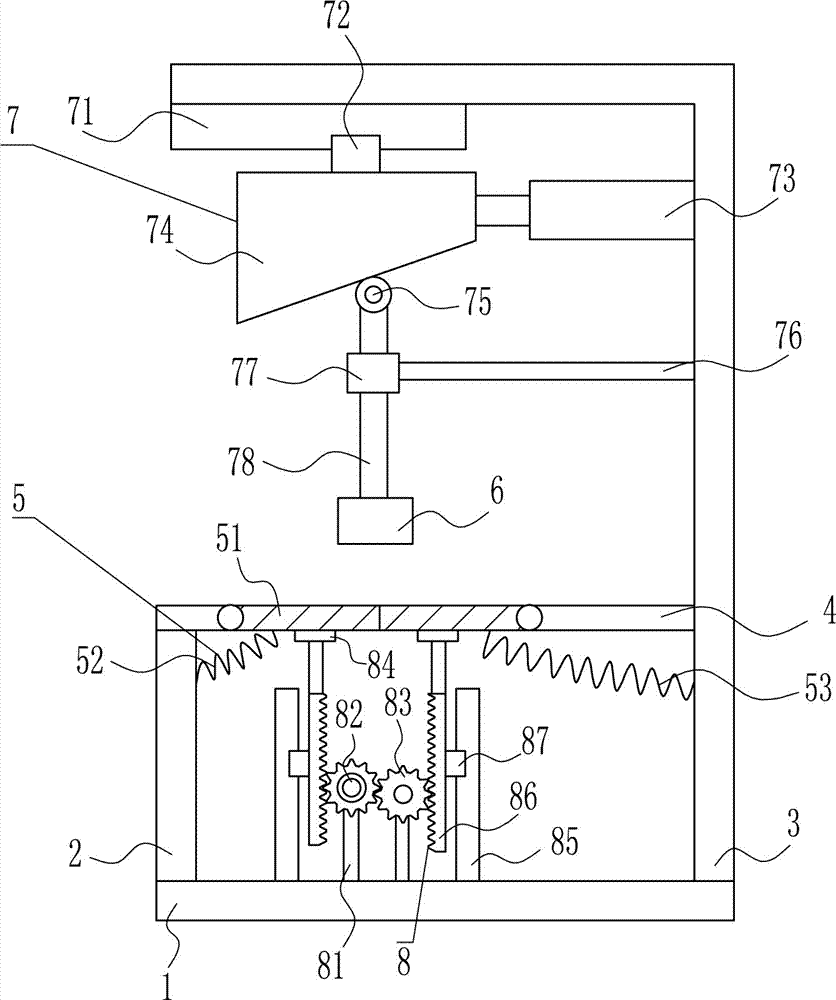

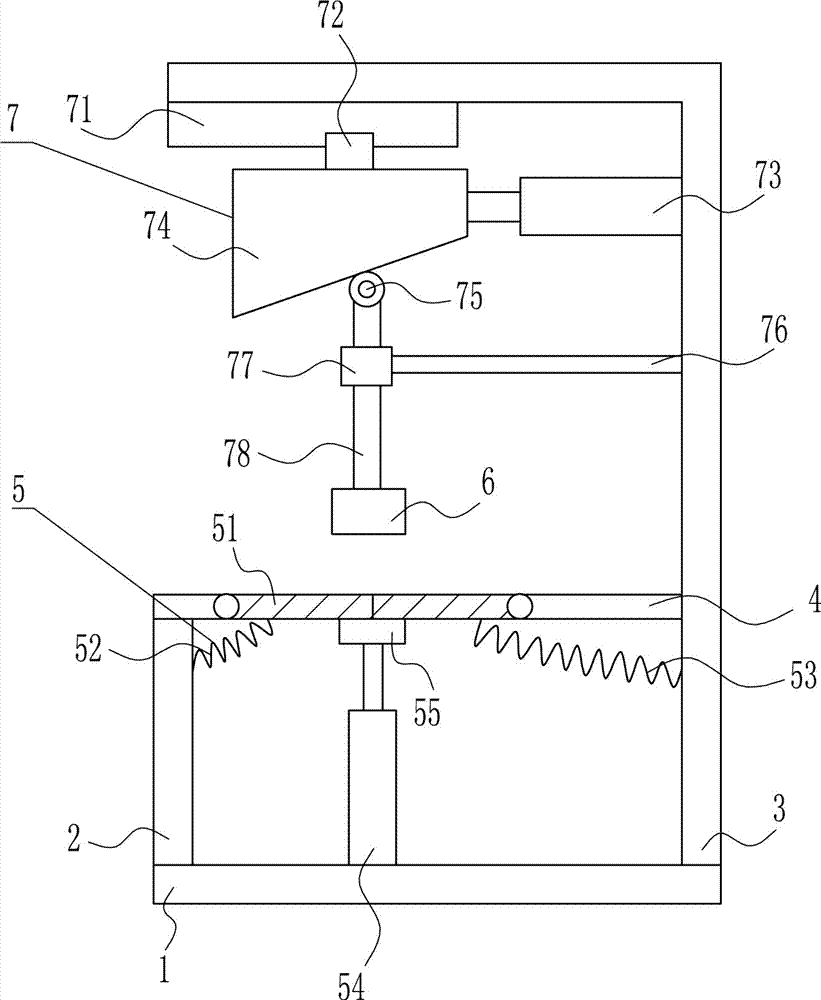

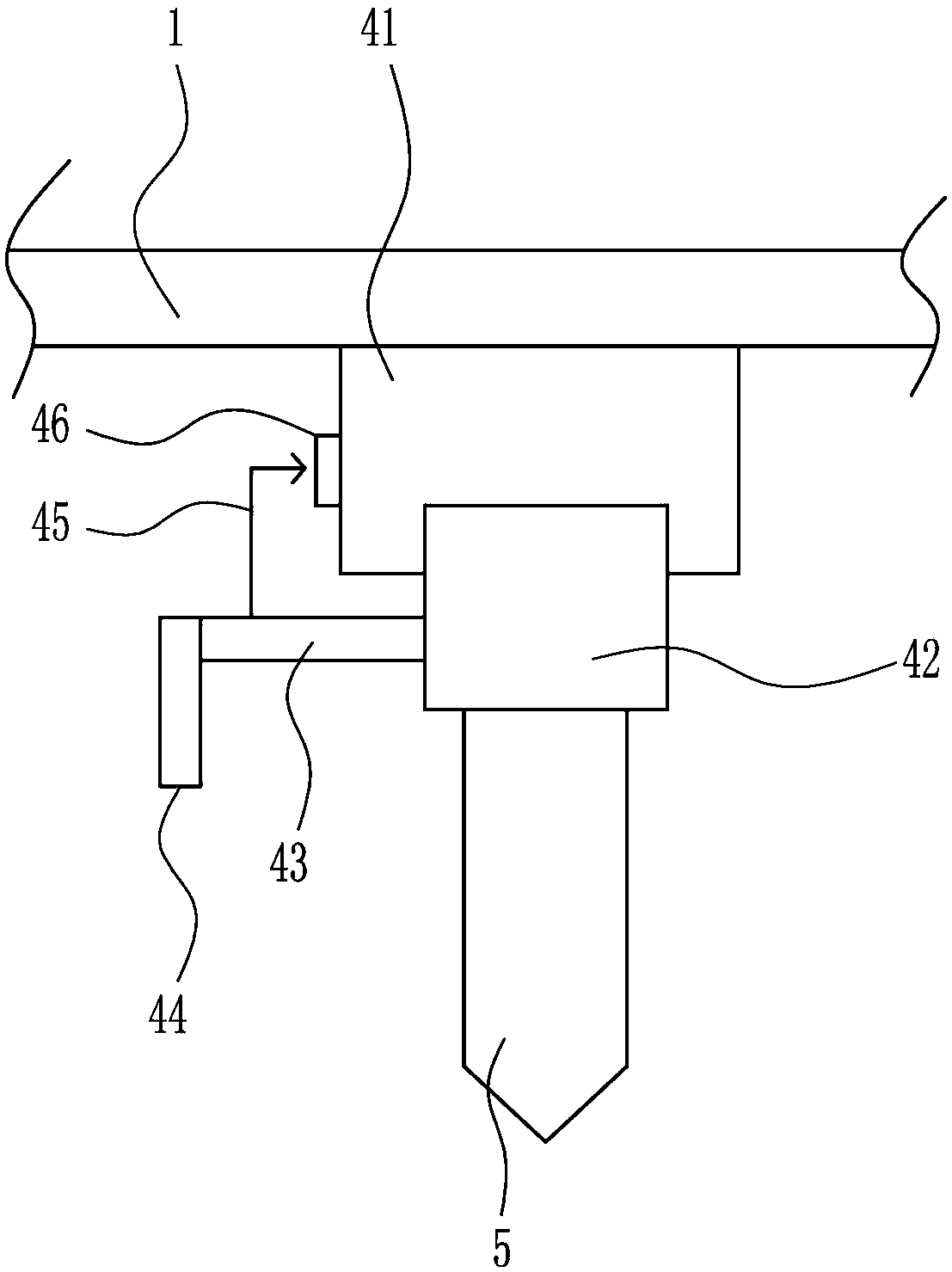

Rapid shoe size printing device for leather shoe production

InactiveCN106974370AImprove coding efficiencyAccurate codingShoemaking devicesSoftware engineeringConveyor belt

The invention relates to a coding device, in particular to a fast coding device for leather shoe production. The technical problem to be solved by the present invention is to provide a quick coding device for leather shoe production with high coding efficiency, accurate coding and convenient adjustment. In order to solve the above-mentioned technical problems, the present invention provides such a quick coding device for leather shoes production, which includes a bottom plate, a right bracket, a push device, a fixed rod, a push plate, a placing platform, a fixed plate, etc.; Conveyor belt, there is a placing table on the top of the bottom plate, a right bracket on the right side of the top of the bottom plate, a pushing device on the left side of the right bracket, a fixing rod on the bottom of the pushing device, a push plate connected to the left end of the fixing rod, and a push plate on the bottom of the push plate. Taiwan contacts. The invention achieves the effects of high coding efficiency, accurate coding, and convenient adjustment. The coding and pushing are performed at the same time, the coding efficiency is high, and coding at different positions can be adjusted according to the model of leather shoes.

Owner:郑世珍

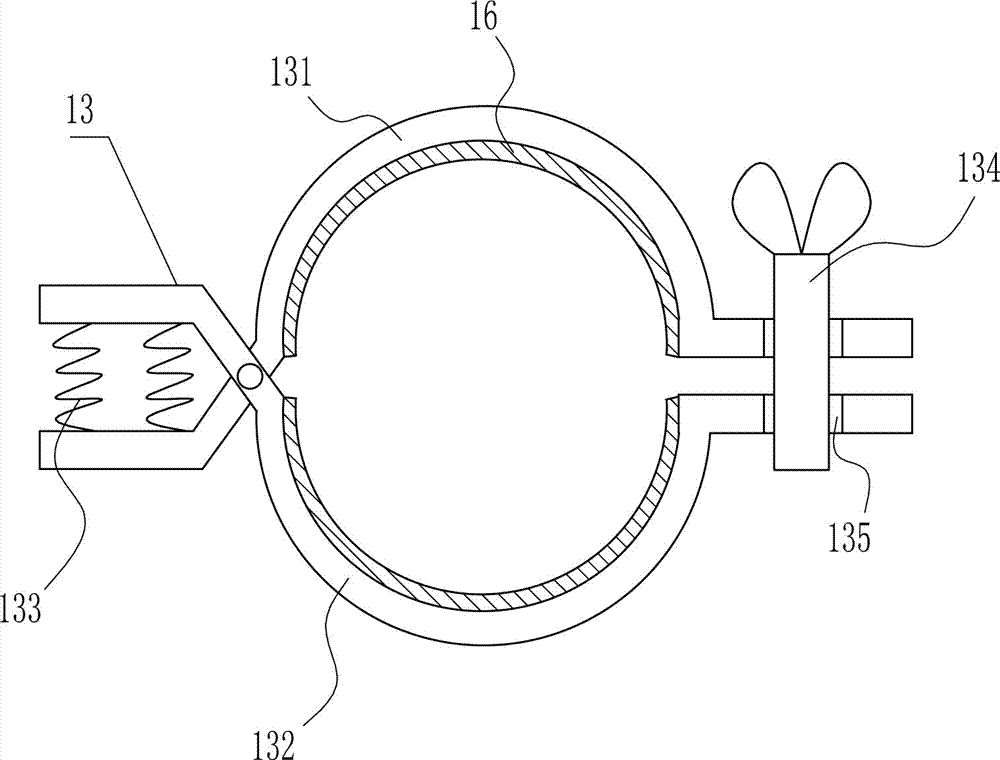

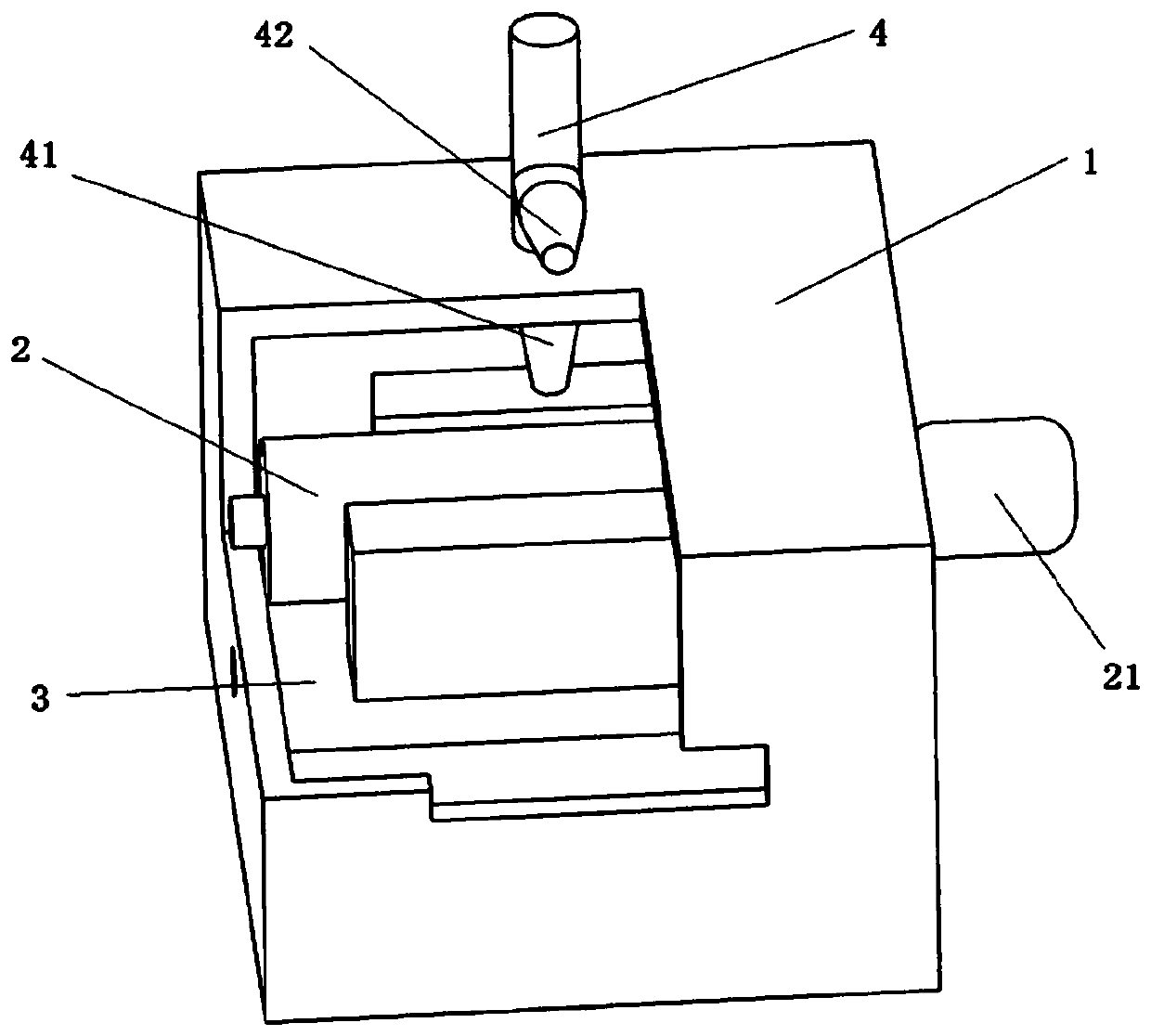

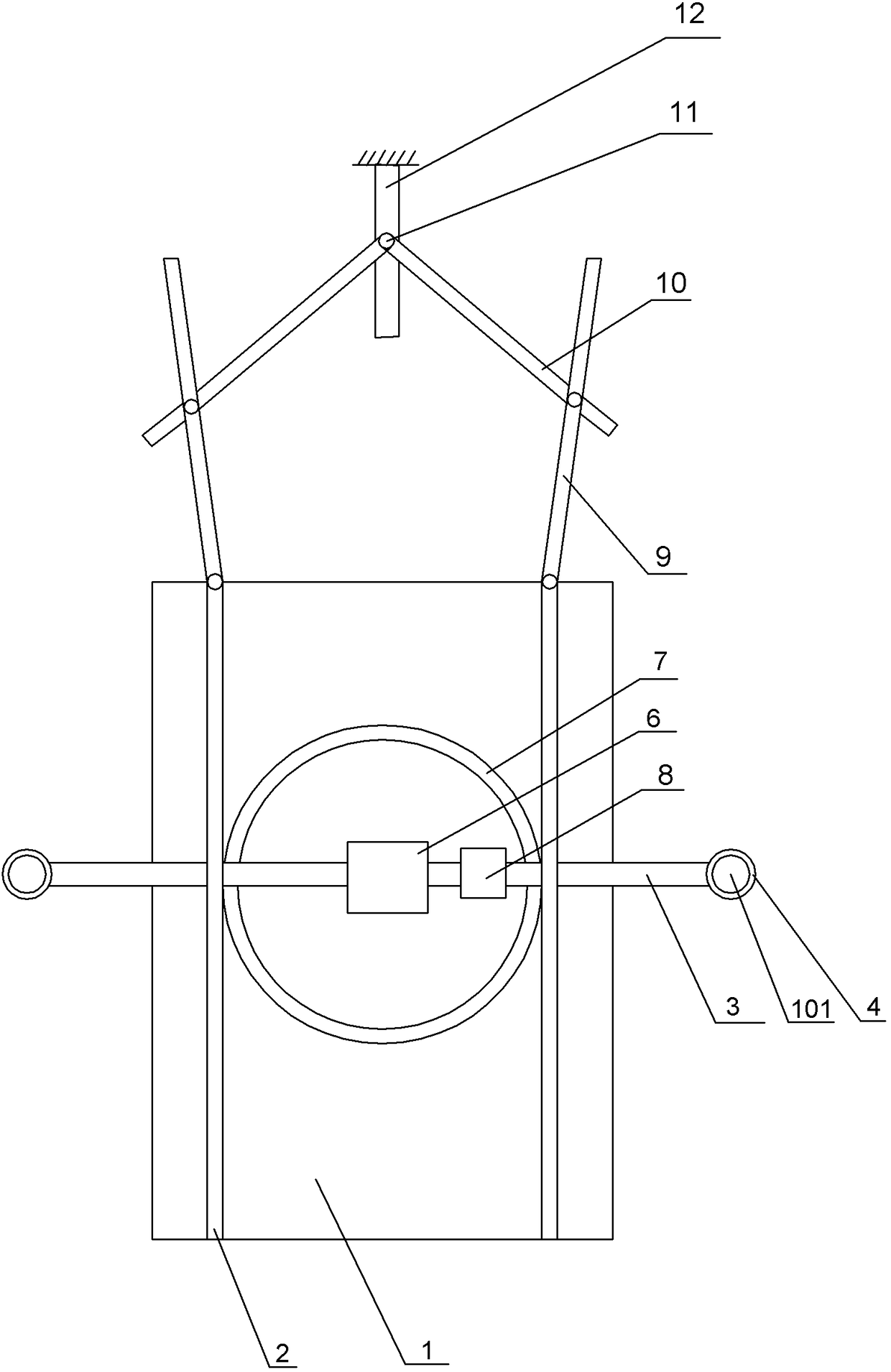

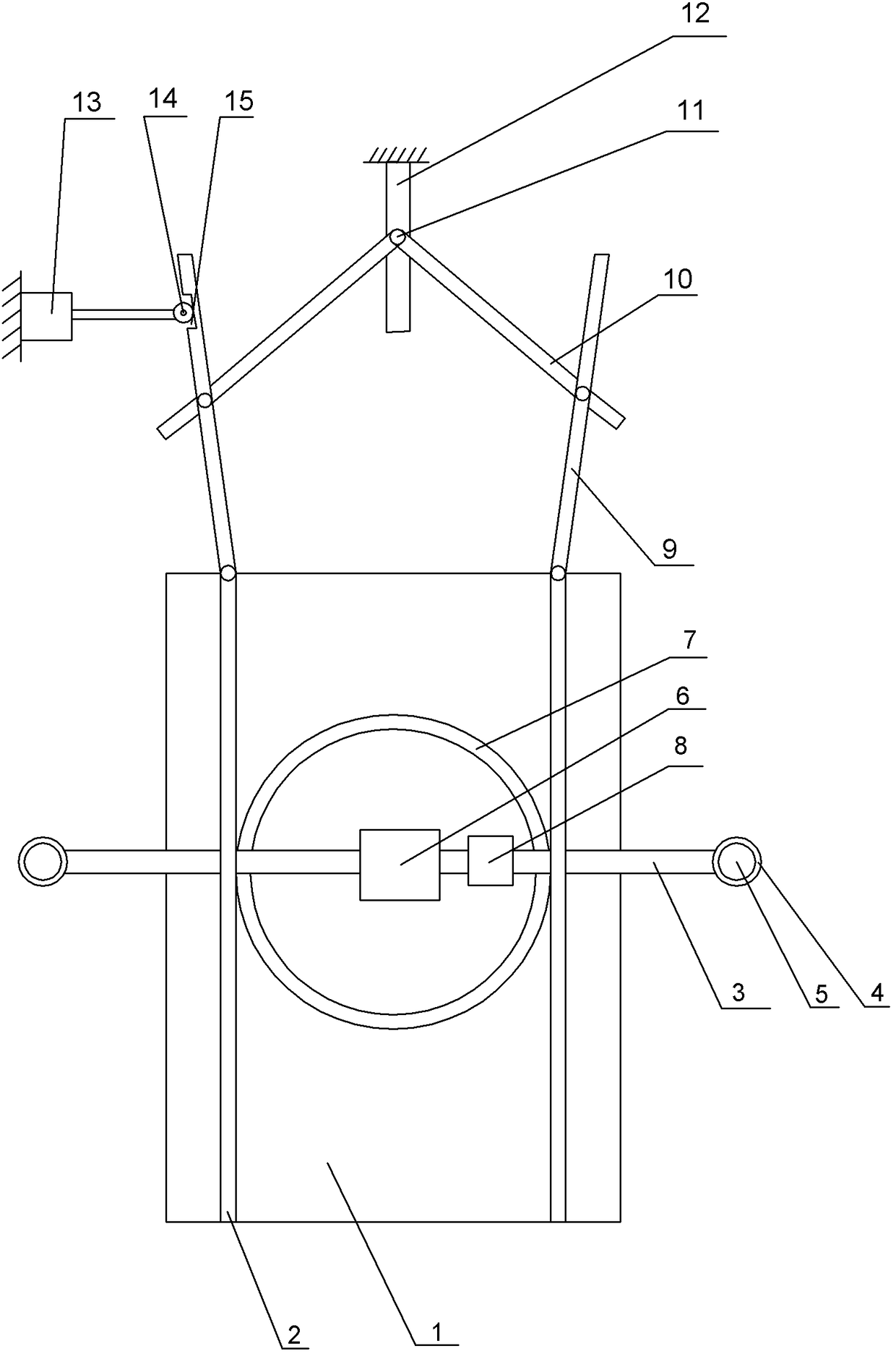

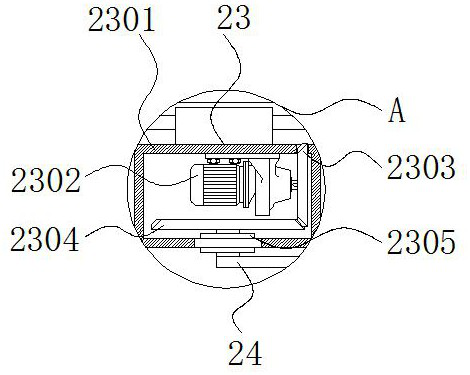

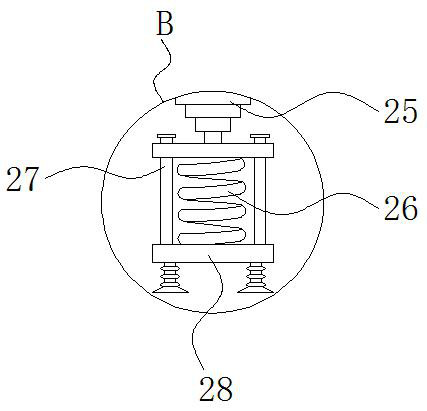

Transfer printing and coding equipment

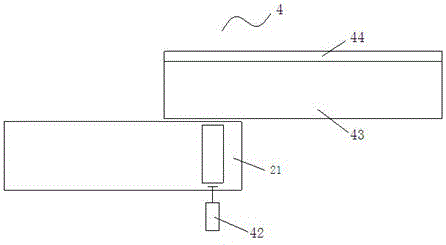

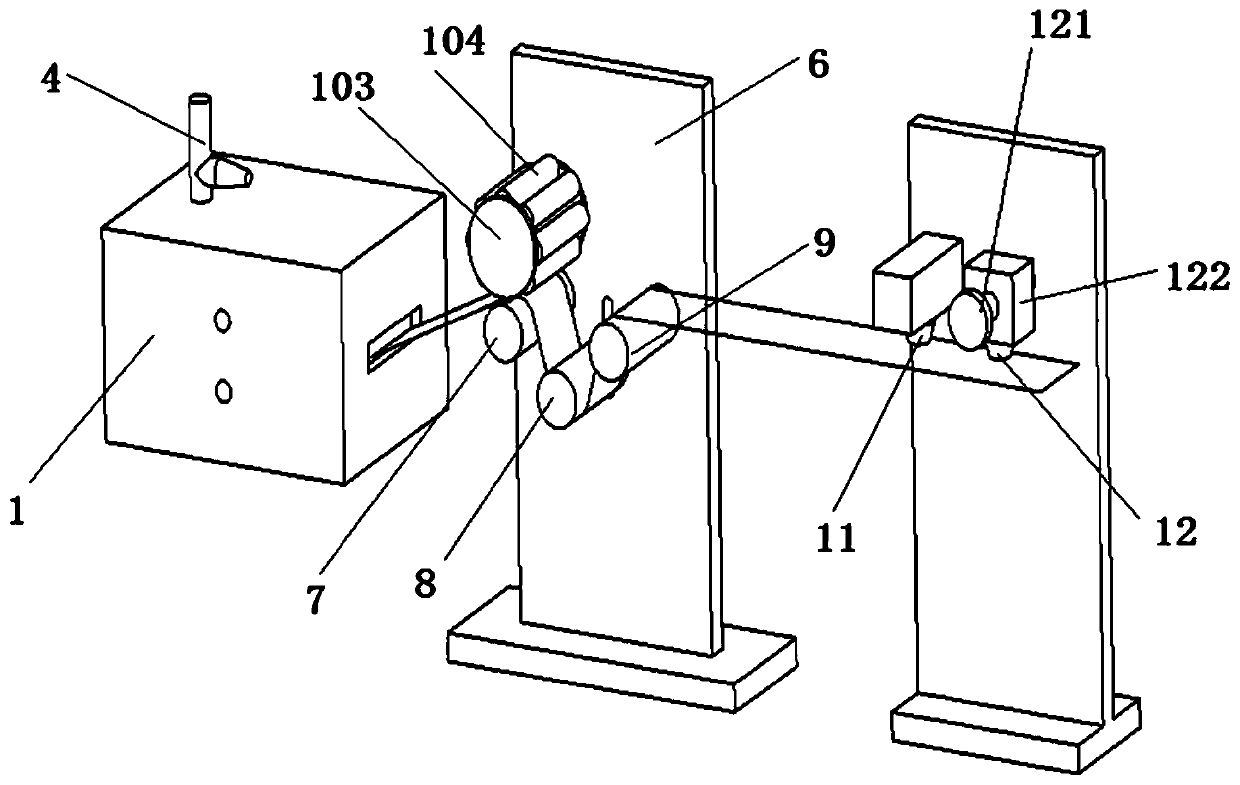

ActiveCN106364151AEasy to clamp and positionGood pauseRotary pressesPrinting press partsElectricityFinesse

The invention discloses transfer printing and coding equipment which comprises a workbench, a PLC and a transfer printer, and further comprises a laser coding machine and a conveying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. Multiple fixing bases are fixed to the chain and connected with positioning blocks. A bracket is connected to the positioning blocks and provided with die grooves. The side wall of the transmission case is provided with a transfer printing positioning part. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disc. Three sensing columns are distributed on the wheel disc. The infrared sensor, the transfer printer and the laser coding machine are electrically connected with the PLC. By means of organic combination of transfer printing and coding, continuous transfer printing and coding operation of large batches of printed products is achieved, the production efficiency is greatly improved, transfer printing and coding are clearer, and the finesses degree is higher.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Device, system and method for realizing precise code tagging of top covers of zip-top cans

InactiveCN109014586AAccurate codingGuaranteed setting positionTypewritersLaser beam welding apparatusProduction lineEngineering

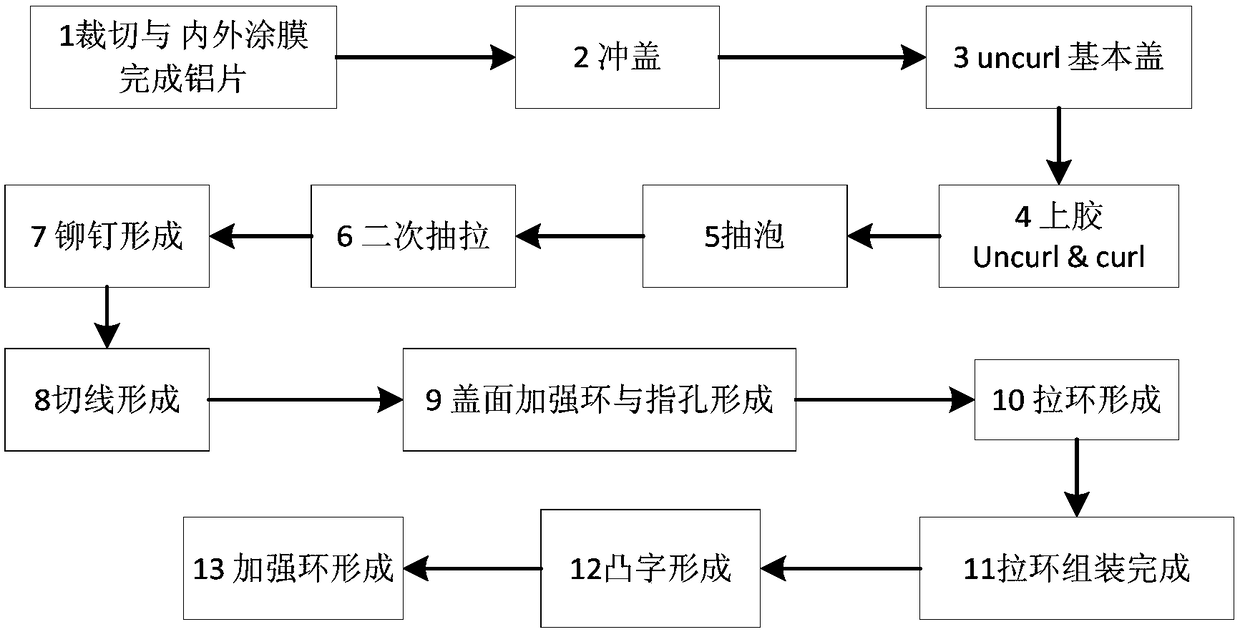

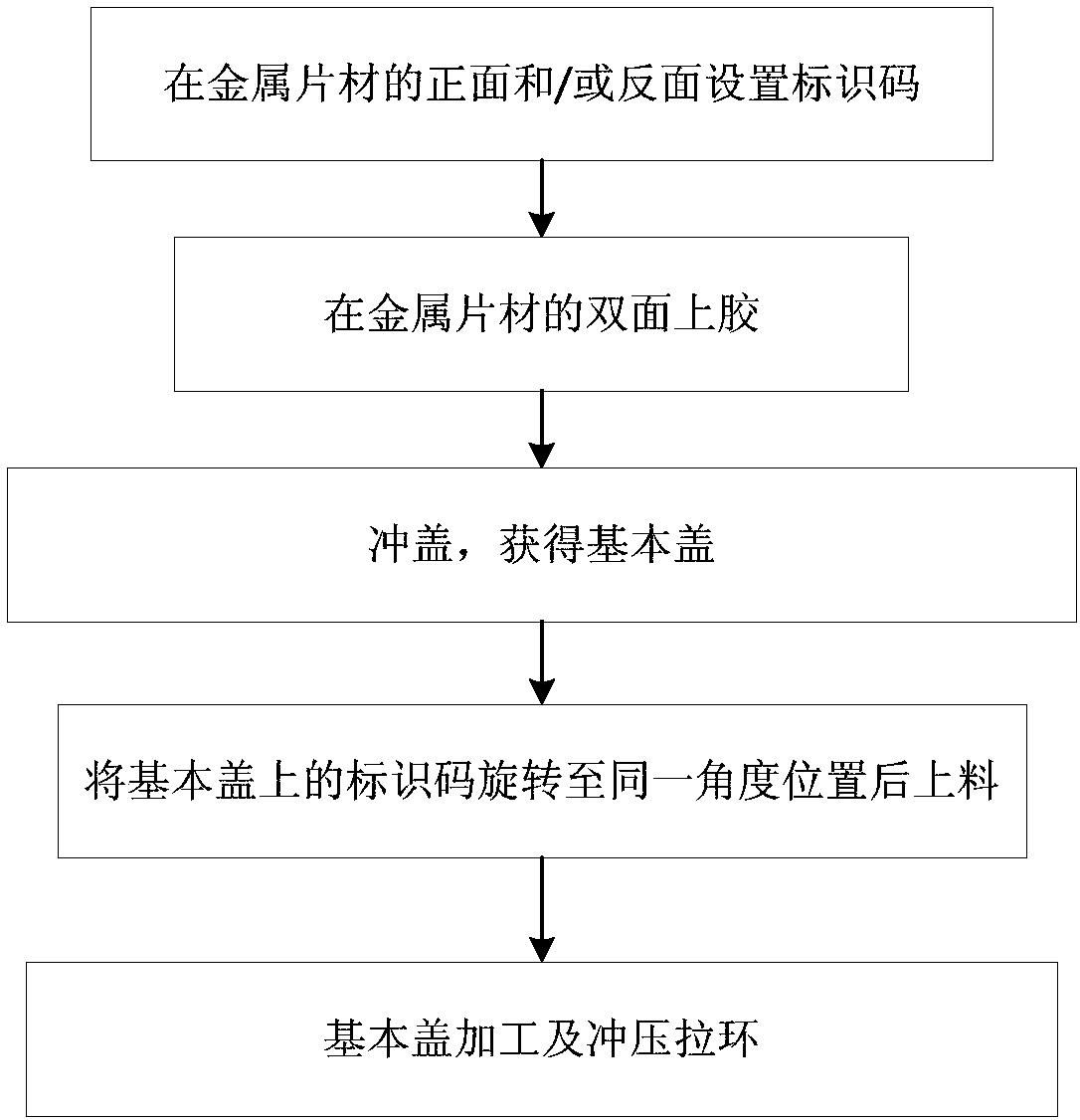

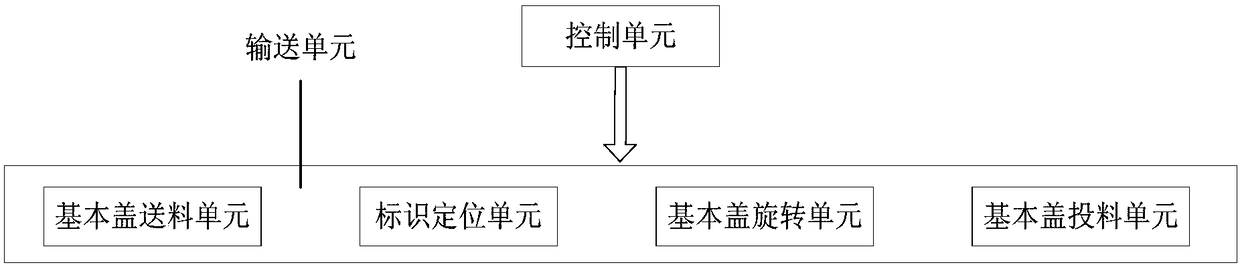

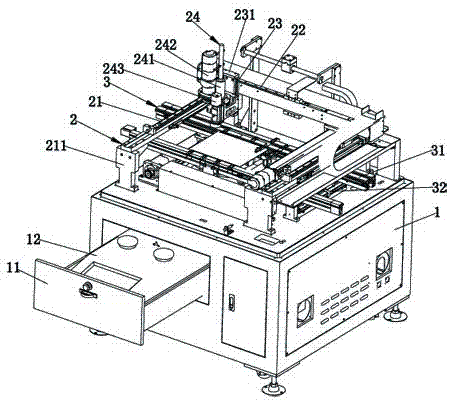

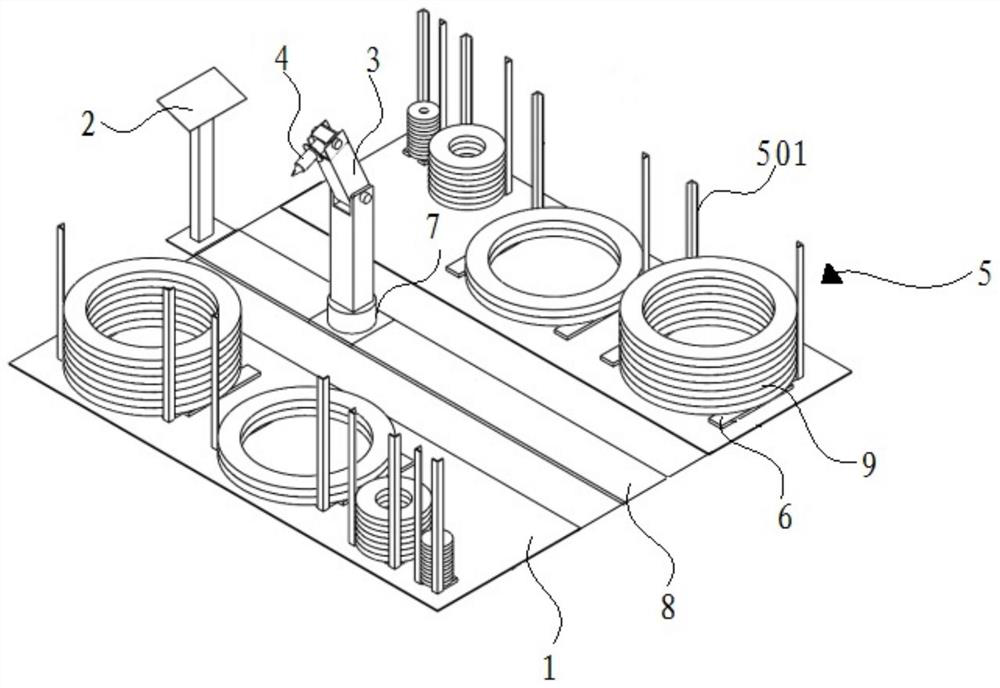

The invention provides a device, system and method for realizing precise code tagging of top covers of zip-top cans. Code tagging is conducted on a large metal sheet, the initial forms of basic coversentering a zip-top can top cover processing device are adjusted, thus all the basic covers are rotated to the same angle and then fed, the set positions, on the basic covers entering a production line, of identification codes are ensured, thus after processing, the identification code are located at the same position of finished zip-top can top cover products, and precise code tagging of the topcovers of the zip-top cans is achieved. The same angle means that after all the basic covers are rotated, the identification codes are located at the same position on the basic covers relative to a conveying unit. According to the code tagging method, the identification codes in all the basic covers are rotated to the same position in the feeding process, thus it can be ensured that the identification codes in the basic covers conveyed into the zip-top can top cover processing device are located at the same position, accordingly the positions of the identification codes in the finished zip-topcan top cover products can be ensured, and precise code tagging of the top covers of the zip-top cans is achieved.

Owner:SIGMATRIX TECH CO LTD

Full-automatic ink-jet printer

Owner:KELI ELECTRONICS EQUIP

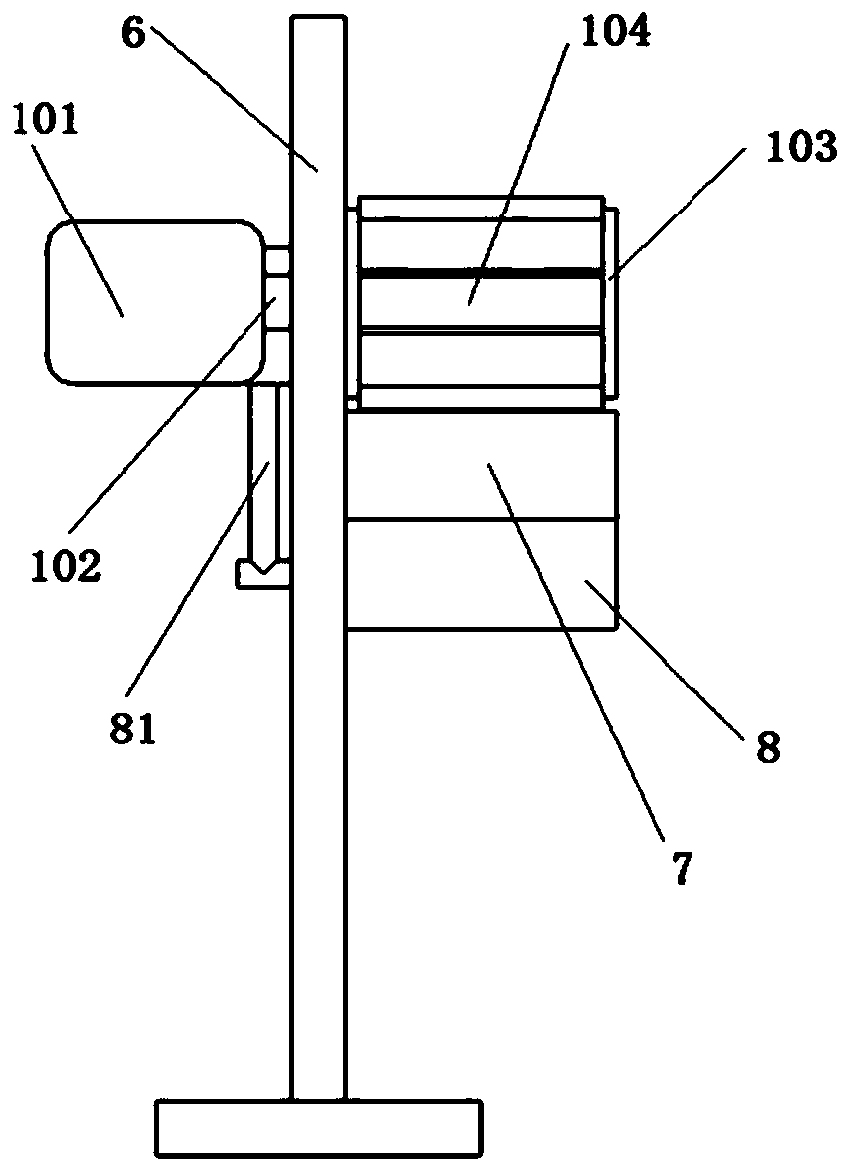

Shoe sole coding device for leather shoe production

InactiveCN106923450AImprove coding efficiencyAccurate codingShoemaking devicesEngineeringMobile device

The invention relates to a shoe sole coding device and in particular relates to a shoe sole coding device for leather shoe production. The invention aims to provide the shoe sole coding device for leather shoe production high in coding efficiency, precise to code and convenient to adjust. In order to solve the technical problem, the invention provides the shoe sole coding device for leather shoe production. The shoe sole coding device for leather shoe production comprises a bottom plate and the like, wherein a left bracket is arranged on the left side of the top of the bottom plate, a right bracket is arranged on the right side of the top of the bottom plate, a transverse plate is arranged between the left bracket and the right bracket, a fixing device is arranged between the transverse plate and the bottom plate, a mobile device is arranged on the top of the right bracket, and a coding model is connected to the bottom of the mobile device. The device provided by the invention achieves the effects of being high in coding efficiency, precise to code and convenient to adjust, the coding model can be replaced and adjusted, and the device is simple to operate.

Owner:张传波

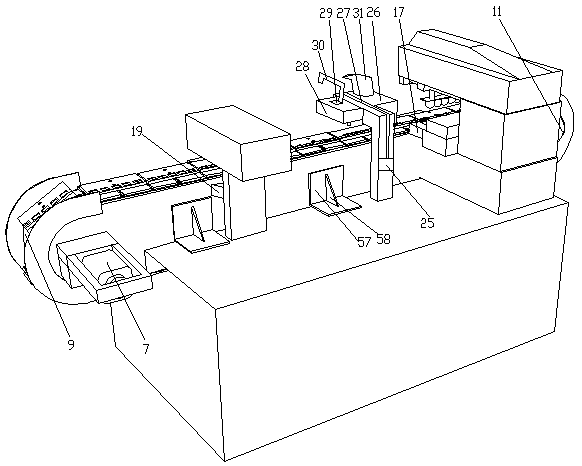

Box-packed chemical transmission, separation, coding and sorting system

InactiveCN106005626AAvoid sticking to each otherAvoid empty pushConveyorsControl devices for conveyorsLaser scanningCompound (substance)

The invention relates to a box-packed chemical transmission, separation, coding and sorting system. The system comprises a transmission device, a separation device, a coding device and a sorting device which are arranged in sequence, wherein the transmission device is arranged on one side of the outlet of a packing device, and comprises a transmission cylinder and a conveyor belt; the transmission cylinder is mounted at the other side of the outlet of the packing device; the conveyor belt is mounted on conveyor rollers; partition plates are mounted on the conveyor belt at equal intervals; the separation device comprises a sinking separation conveyor belt; the coding device is arranged on the separation conveyor belt; a photoelectric detection switch is arranged on the coding device; the sorting device is arranged at the output end of the separation conveyor belt, and comprises a laser scanning light, an elimination cylinder and an elimination conveyor belt; the laser scanning light is arranged right above the separation conveyor belt; the elimination cylinder is arranged on one side of the separation conveyor belt; and the elimination conveyor belt is arranged on the other side of the separation conveyor belt. According to the system provided by the invention, the moving posture of a box-packed chemical, the identification of chemical specification, and precise laser coding can be guaranteed.

Owner:JIANGSU JIAHUA ADVANCED MATERIALS TECH

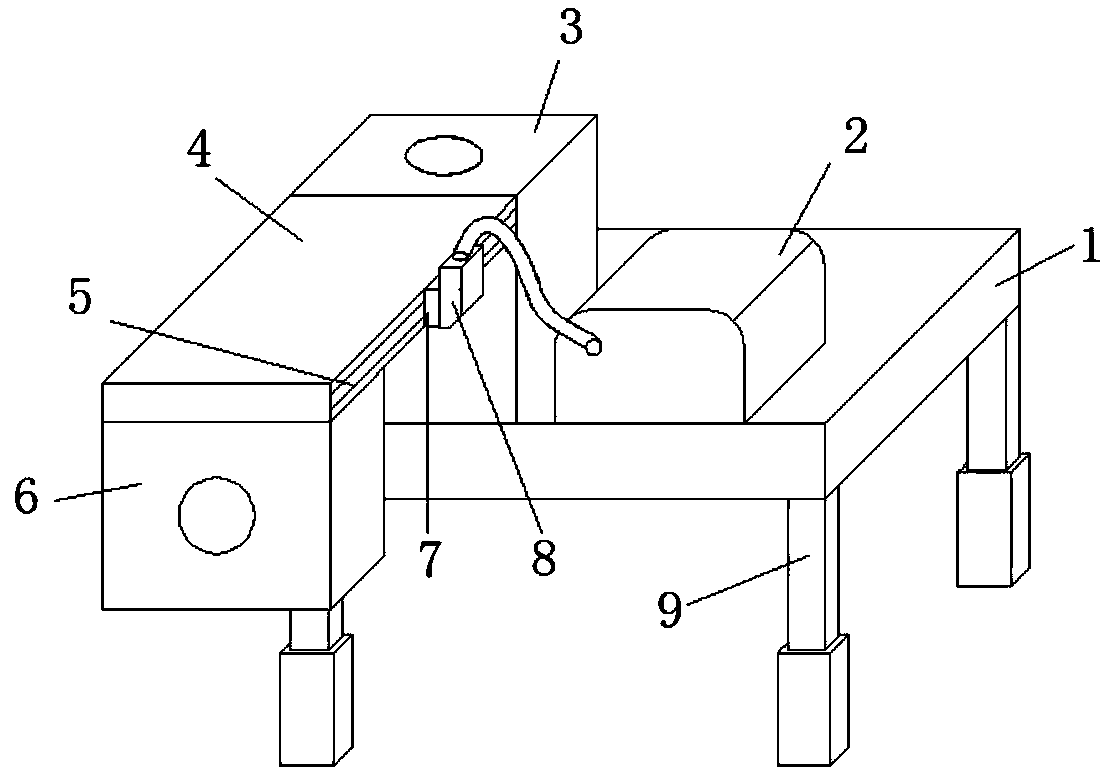

Code spraying device for entrance guard card surface processing

InactiveCN107672312AAccurate codingImprove air drying effectOther printing apparatusTelescopic cylinderRapid access

The invention relates to a coding device, in particular to a coding device for processing the surface of an access control card. The technical problem to be solved by the present invention is to provide a code spraying device for surface processing of access control cards with fast code spraying. In order to solve the above technical problems, the present invention provides such a coding device for surface processing of access control cards, including a mounting frame, etc.; There is a transmission device, an adjustment device is installed on the left side of the top of the installation frame, and an inkjet printer is installed at the bottom of the adjustment device. The invention can quickly and accurately know the forward and backward movement distance of the inkjet printer through the pointer and the scale, so that the inkjet can be more accurate, and the wind direction can be adjusted by controlling the expansion and contraction of the cylinder to improve the air-drying effect.

Owner:刘斌

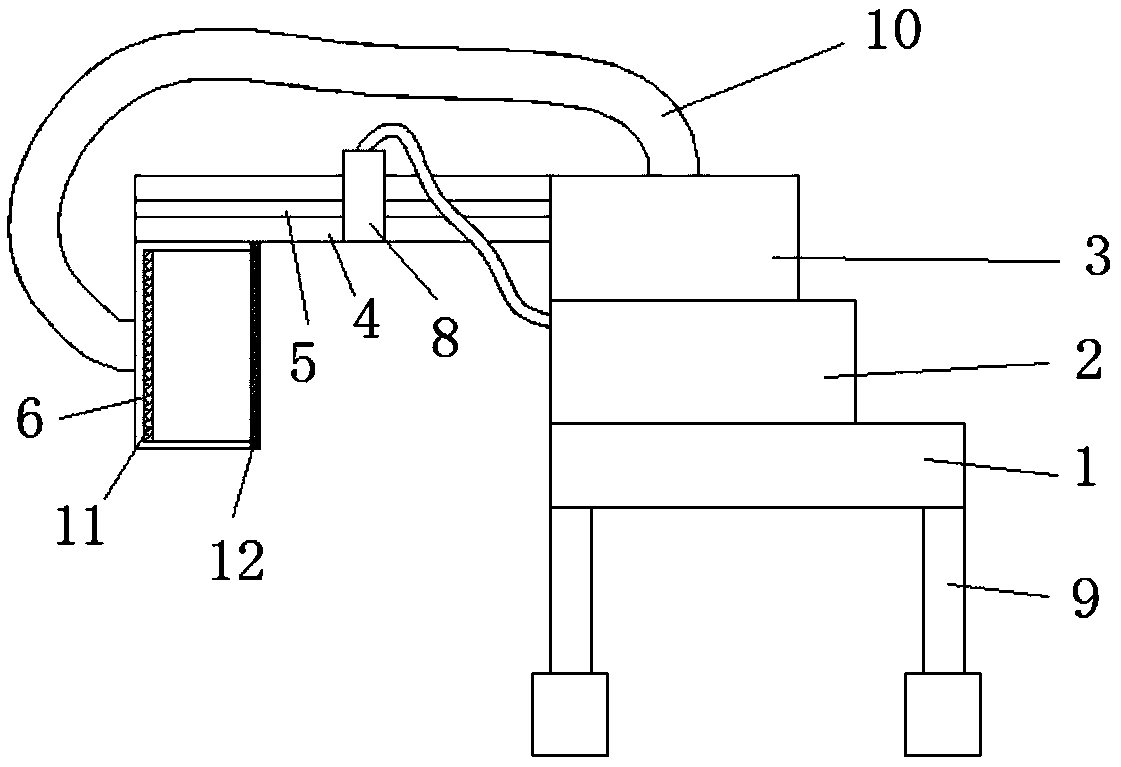

Electronic product production code spraying device with dust removal function

InactiveCN108790426AEasy to replaceEasy to adjustTypewritersOther printing apparatusWorking environmentEngineering

The invention discloses an electronic product production code spraying device with a dust removal function. The code spraying device comprises a workbench; hydraulic supporting rods are welded to thefour corners of the outer wall of the bottom of the workbench; a blower box is welded to one side of the outer wall of the top of the workbench, and one side of the blower box is provided with a firstthrough hole; a blower box cover is connected to the inner wall of the side surface of the blower box through a hinge, and the middle of the blower box cover is provided with a second through hole; an air feeding pipe is inserted and connected to the inner wall of the second through hole; a blower is connected to the inner wall of the bottom of the blower box through screws, and the outer wall ofan air outlet of the blower is sleeved with an air blowing pipe; and the outer wall of the air blowing pipe is inserted and connected to the inner wall of the first through hole. The code spraying device can adapt to assembly line conveying platforms with different heights, the working environment can be conveniently changed, dust on the surfaces of electronic products can be removed, ink can adhere to the electronic products better, codes can be accurately sprayed onto the assigned positions of the electronic products, and thus, code spraying is normalized.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Transfer-printing coding method

ActiveCN106394049ARealize continuous operationIncrease productivityDuplicating/marking methodsContinuous operationLaser

The invention discloses a transfer-printing coding method. The transfer-printing coding method comprises the following steps: (a) an ink feeding step, namely feeding ink to an etching plate by using a sealed type oil cup of a transfer-printing coding device; (b) an ink staining step, namely forwards pushing a rubber head of a transfer printer to a position above the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and pressing the rubber head downwards to be stained with the ink having patterns; (c) a transfer printing step, namely backwards pushing the rubber head to a position above a supporting plate of a conveying component, and then driving the rubber head to be pressed downwards, wherein the rubber is capable of printing the ink having patterns on a to-be-printed object in a mold groove; (d) a coding step, moving the transfer-printed object to a position below a laser coding machine, and performing laser coding by using the laser coding machine. According to the transfer-printing coding method disclosed by the invention, the laser coding machine is capable of coding the last transfer-printed object during transfer printing of a to-be-printed object of the next period, so continuous operation on large-batch to-be-printed objects can be realized, the production efficiency is greatly improved, and a coded product is high in fineness.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Spray head, ink-jet printer and ink-jet printing method

PendingCN110757954AExtended service lifeUnlimited printing speedPrintingEngineeringMechanical engineering

The invention relates to a spray head, an ink-jet printer and an ink-jet printing method. The spray head comprises a charging panel and a plurality of groups of deflection plates, wherein the chargingvoltage of the charging panel is a fixed value, and a first ink line channel for ink droplets to pass through is formed in the charging panel; each group of deflection plates comprises a positive plate and a negative plate, the positive plate and the negative plate are arranged oppositely, and a gap is formed between the positive plate and the negative plate and used for forming a second ink linechannel for the ink droplets to pass through; the second ink line channels of the multiple groups of deflection plates are communicated; the deflection plates are arranged adjacent to the charging panel; and the second ink line channels and the first ink line channel are communicated to form a movement channel for the ink droplets. The charging voltage of the charging panel is a fixed value, so that the electric charge quantity of all the single ink droplets passing through the charging panel is the same, in the ink-jet printing process, the charging panel can be always in a power-on state, the ink droplets are charged uninterruptedly, in the abovementioned way, the jet printing speed of the ink-jet printer can be not limited, and the service life of the charging panel can be prolonged.

Owner:广州市贝云科技有限公司

Code spraying system and method for glued surface printing label

The invention provides a code spraying system and method for a glued surface printing label. The system comprises a solidifying unit, a leveling unit and a detecting and code spraying unit; the solidifying unit is used for improving the bonding strength of the glued surface printing label and preventing the label from being unglued; the leveling unit is arranged on the outlet side of the solidifying unit and is used for preventing edges of the glued surface printing label from being folded; and the detecting and code spraying unit is arranged on the outlet side of the leveling unit and is usedfor performing identification and sequence code spraying on the glued surface printing label. By the aid of the code spraying system and method for the glued surface printing label, the sequence codespraying accuracy of the glued surface printing label can be improved, and the phenomena of code spraying errors can be avoided.

Owner:天津英友标贴科技有限公司

A continuous pad printing coding equipment

ActiveCN106364152BPad printing stabilityPad printing precisionRotary pressesPrinting press partsElectricityPad printing

The invention discloses a continuous type pad printing and coding device. The continuous type pad printing and coding device comprises a workbench, a PLC controller and a pad printing machine. The continuous type pad printing and coding device further comprises a laser coding machine, a conveying component and a drying component. The conveying component comprises a motor, a transmission case, a main chain wheel, a chain and an auxiliary chain wheel. The chain is fixedly provided with multiple fixing seats. Locating blocks are connected to the fixing seats. Brackets are connected to the locating blocks, and the brackets are provided with mold grooves. The side wall of the transmission case is provided with a pad printing locating piece and a coding locating piece. Each locating block is provided with a left groove and a right groove. One end of the transmission case is provided with an infrared sensor. A motor shaft of the motor is sleeved with a wheel disk. Three sensing columns are distributed on the wheel disk. The infrared sensor, the pad printing machine and the laser coding machine are electrically connected with the PLC controller. The continuous type pad printing and coding device conducts continuous pad printing and coding operations on printed objects on a large scale and greatly improves the production efficiency; and pad printing and coding are clearer, the precision is high, the manufactured products are free from fading after being used for a long time and high in recognition capacity.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

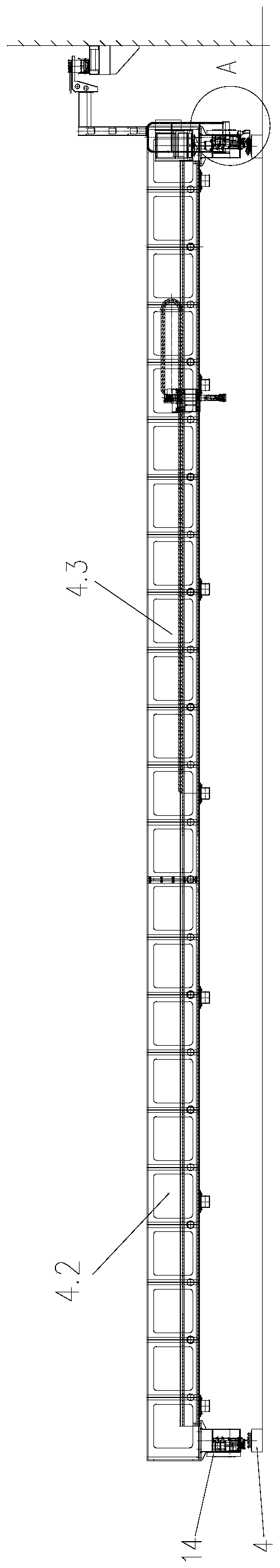

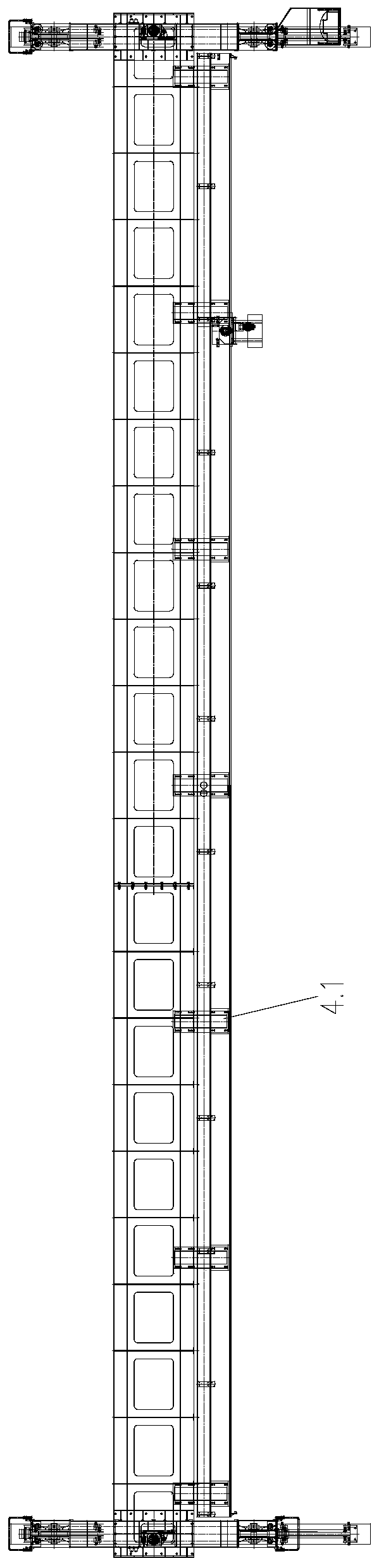

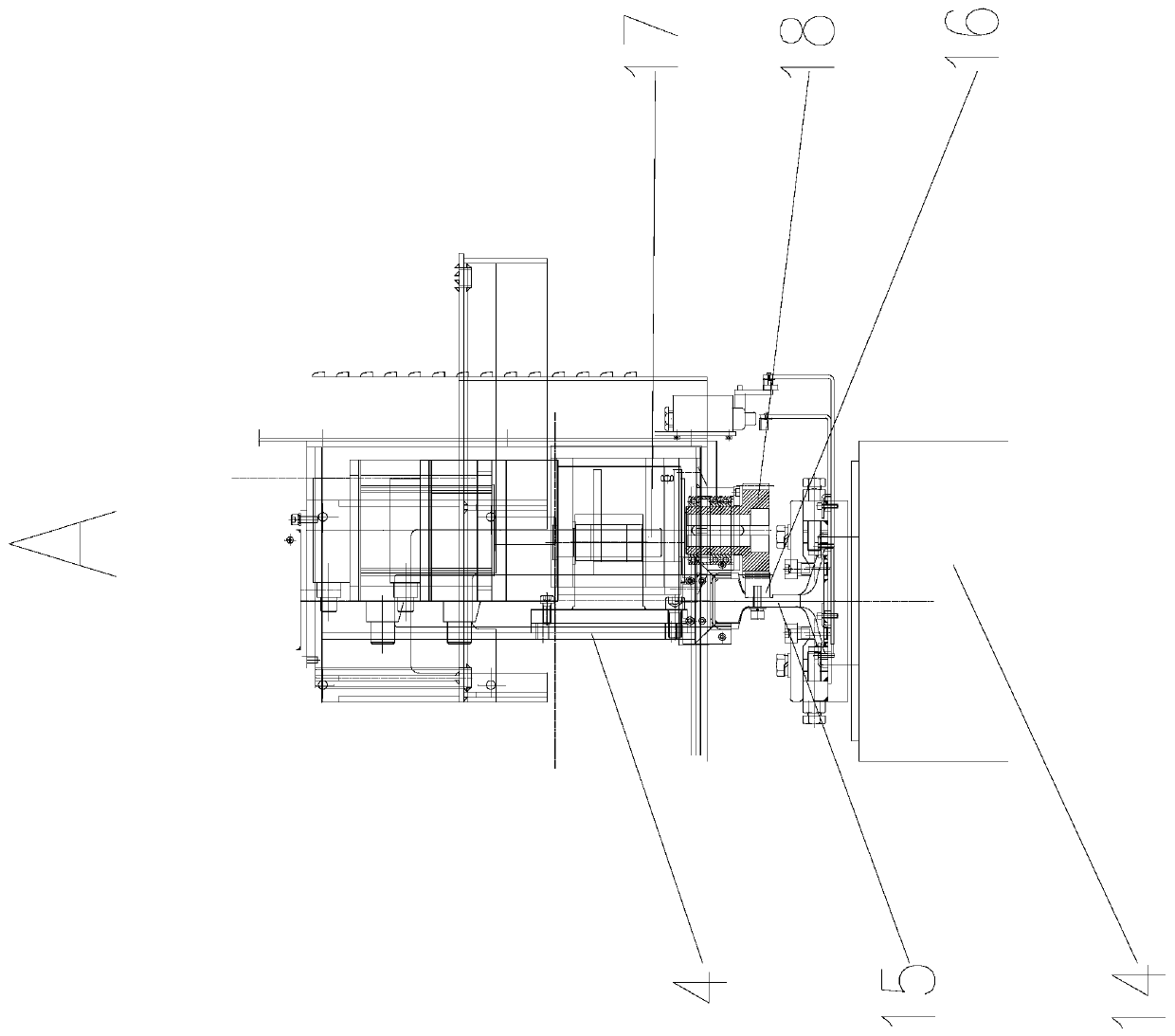

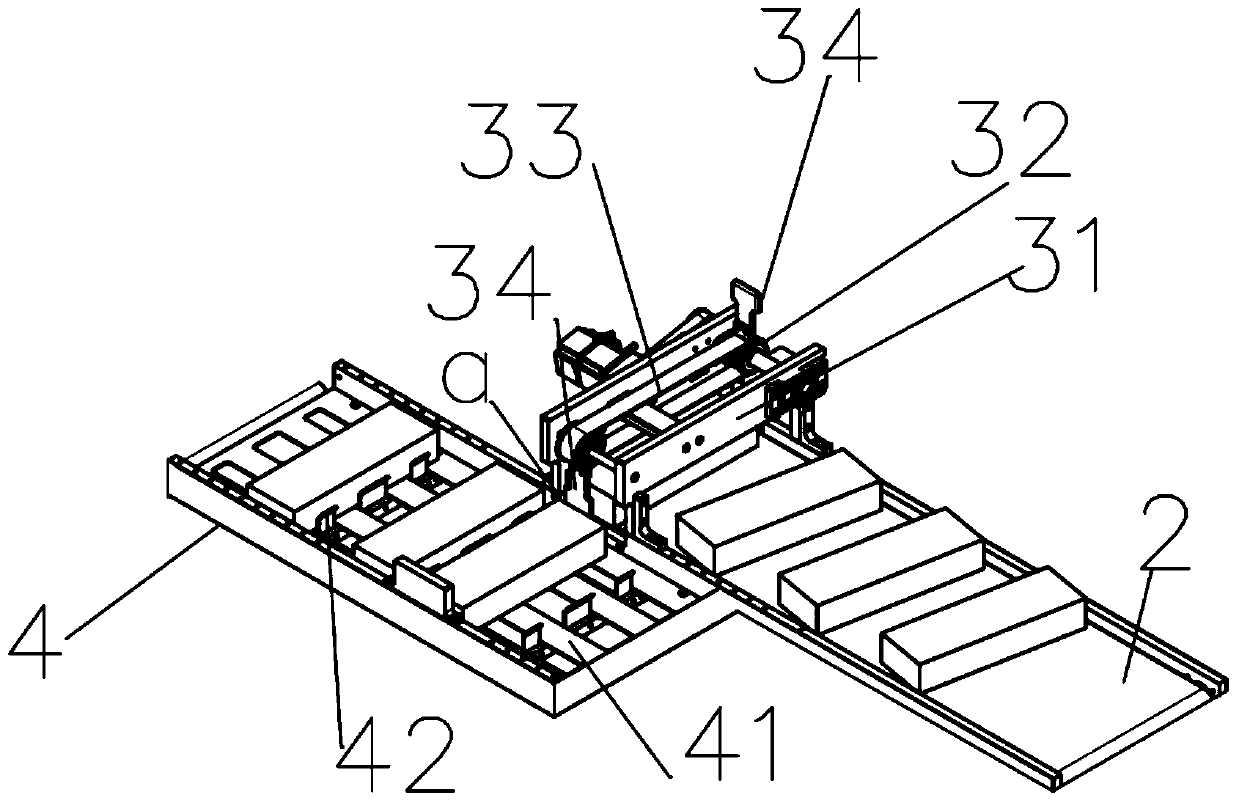

Large-span code spraying machine

The invention relates to a large-span code spraying machine. The large-span code spraying machine comprises a base, the base is horizontally provided with a moving guide rail, one side of the moving guide rail is provided with a moving toothed bar, the moving guide rail is movably connected with a supporting rack, the bottom of the supporting rack is vertically provided with a moving motor, an output shaft of the moving motor is provided with a moving gear, the moving gear is engaged with the moving toothed bar, the upper end of the supporting rack is provided with horizontal beams, one sidesof the bottoms of the horizontal beams are provided with adjusting brackets, the upper portions of the adjusting brackets are provided with front beams, one sides of the front beams are provided witha linear guide rail, one side of the linear guide rail is provided with a horizontal toothed bar, the linear guide rail is slidably provided with a driving slide carriage, the driving slide carriage is provided with a horizontal moving motor, the output end of the horizontal moving motor is provided with a horizontal moving gear, and the horizontal moving gear is engaged with the horizontal toothed bar. The large-span code spraying machine is simple in structure and small in space occupation, split type processing is adopted, the processing difficulty can be reduced, the production cost is saved, and large-area accurate code spraying can be realized through toothed bar transmission and motor control.

Owner:WUXI HUALIAN SCI & TECH GROUP

Intelligent manufacturing laser ink-jet printer capable of identifying ink-jet position

ActiveCN113787260AUse many timesAvoid offsetLaser beam welding apparatusForce sensorSmart manufacturing

The invention relates to an intelligent manufacturing laser ink-jet printer capable of identifying an ink-jet position. The intelligent manufacturing laser ink-jet printer comprises a shell and a connecting assembly, a belt conveyor is arranged on the lower wall of the interior of the shell, the supporting assembly comprises a second plate, a supporting rod, a connecting pin, a third plate, outer sleeves, a second pressure sensor, a first spring and a telescopic rod, the supporting rod is arranged at the upper end of the second plate, the connecting pin is connected to the upper end of the supporting rod, the third plate is connected to the outer part of the connecting pin, and the outer sleeves are movably connected to the left side and the right side of the second plate. The intelligent manufacturing laser ink-jet printer has the beneficial effects that the code spraying position can be positioned in advance through the intelligent manufacturing laser ink-jet printer, then accurate code spraying is achieved in an accurate butt joint mode, products can be positioned through the intelligent manufacturing laser ink-jet printer, deviation of the code spraying position caused by deviation of the product position is prevented, and the intelligent manufacturing laser ink-jet printer can convey an auxiliary device, so that the auxiliary device can be used for multiple times.

Owner:深圳市海纳激光科技有限公司

Dried tofu packaging inkjet printer

ActiveCN107458089BAvoid contactCoding is clear and accurateTypewritersOther printing apparatusEngineeringDry bean

The invention belongs to the technical field of food packaging, and particularly discloses an ink-jet printer for outer packages of dried bean curd. The ink-jet printer comprises a horizontal rod and a vertical shift driving mechanism, comprises an air blowing device, and further comprises a material guiding mechanism, wherein the horizontal rod and the vertical displacement driving mechanism are connected to a machine frame in a sliding mode; an air outlet of the air blowing device is located above a conveying belt; a vertical rod used for opening the air outlet is fixedly arranged on the horizontal rod; the material guiding mechanism comprises two side plates arranged on the two sides of the conveying belt; the side plates are hinged to the machine frame; a side plate linkage device is arranged between the two side plates and comprises a sliding groove, a sliding block and two connecting rods; the sliding groove is fixed to the machine frame; one ends of the connecting rods are hinged to the two side plates correspondingly, and the other ends of the connecting rods are hinged to the sliding block; and the sliding block is arranged in the sliding groove in a sliding mode. When the ink-jet printer is used for spraying codes on the outer packages of the dried bean curd, static electricity on the outer packages of the dried bean curd can be effectively removed, and therefore the outer packages of the dried bean curd can be prevented from being shifted on the conveying belt, code spraying is accurate and normative, and the outer packages of the dried bean curd can not be stuck.

Owner:CHONGQING HAOJIE FOOD

A kind of cigarette sorting system and method

ActiveCN107021337BAvoid market disputesAccurate codingControl devices for conveyorsCarton flowBarcode

The invention relates to the technical field of tobacco carton sorting, in particular to a tobacco carton sorting system and method. The tobacco carton sorting system comprises a first conveying line, a transverse conveying mechanism, a second conveying line, a barcode recognition system and a laser coding machine; the second conveying line is arranged on one side of the first conveying line in parallel, and the first conveying line is connected with the second conveying line; the transverse conveying mechanism is arranged at the tail end of the first conveying line and located at the connecting position of the first conveying line and the second conveying line; and the second conveying line and the barcode recognition system are located on the laser coding machine, and the second conveying line is connected with the barcode recognition system. By means of the tobacco carton sorting system and method, the problems that coding is inclined, the coding effect is poor, coding has errors, and code leakage exists are solved, market disputes caused by the fact that mistakenly-sorted tobacco cartons flow into markets are avoided, it is guaranteed that commodity codes of the tobacco cartons correspond to the tobacco cartons in a one-to-one manner, tracing and querying are facilitated, and anti-fake verification is prevented.

Owner:HANS LASER TECH IND GRP CO LTD

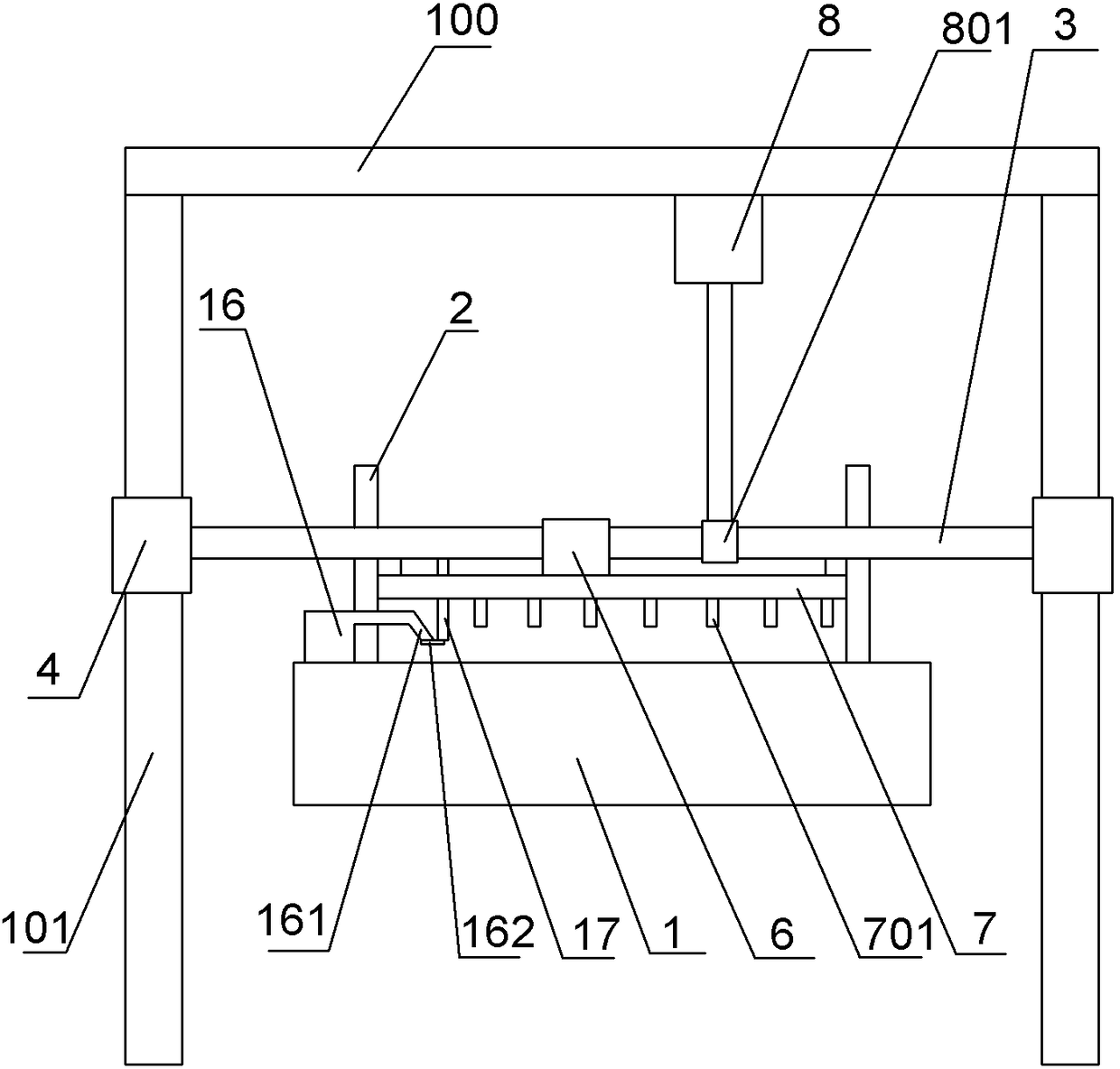

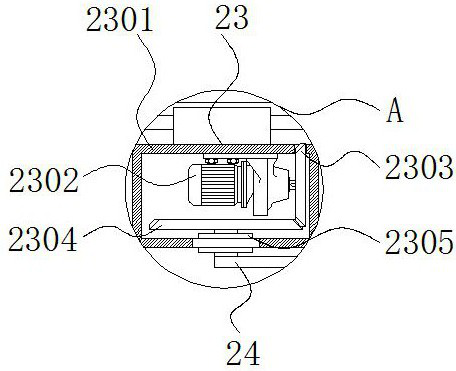

Novel cloth inspection machine station

ActiveCN105220441ACompact structureEasy to useMarking textilesInspecting textilesMechanical engineeringViewfinder

A novel cloth inspection machine station comprises the components of a body, a cloth inspection lamp box which is arranged on the body, and transmission rollers which are arranged on the body and at two ends of the cloth inspection lamp. Each transmission roller comprises an inner roller part and an outer roller part which is arranged outside the inner roller part. The outer roller part is provided with an open space and a cloth surface pressing mechanism which is arranged in the open space. The novel cloth inspection machine station further comprises a top cover arranged on the body and an observing device arranged on the top cover. The observing device comprises the components of an observing magnifier which is arranged above the cloth inspection table and is parallel with the surface of the cloth inspection table, an illuminating mechanism which is arranged on the observing magnifier, and an electronic viewfinder mechanism which is arranged above the magnifier. The body is also provided with a marking mechanism which is used for cooperating with the electronic viewfinder mechanism. The novel cloth inspection machine has advantages of compact structure, convenient use, high accuracy in cloth marking and cloth inspection, high rolling effect and high integral inspection effect.

Owner:FUJIAN HANGGANG TEXTILE TECH CO LTD

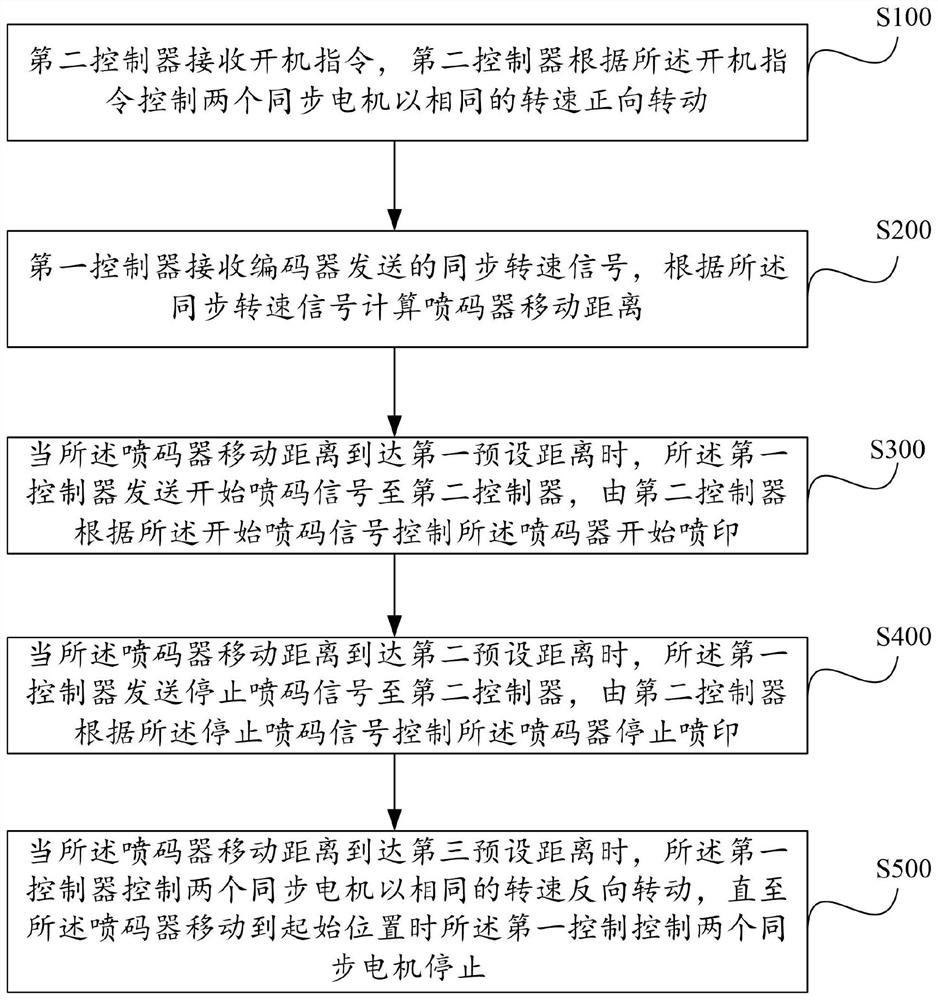

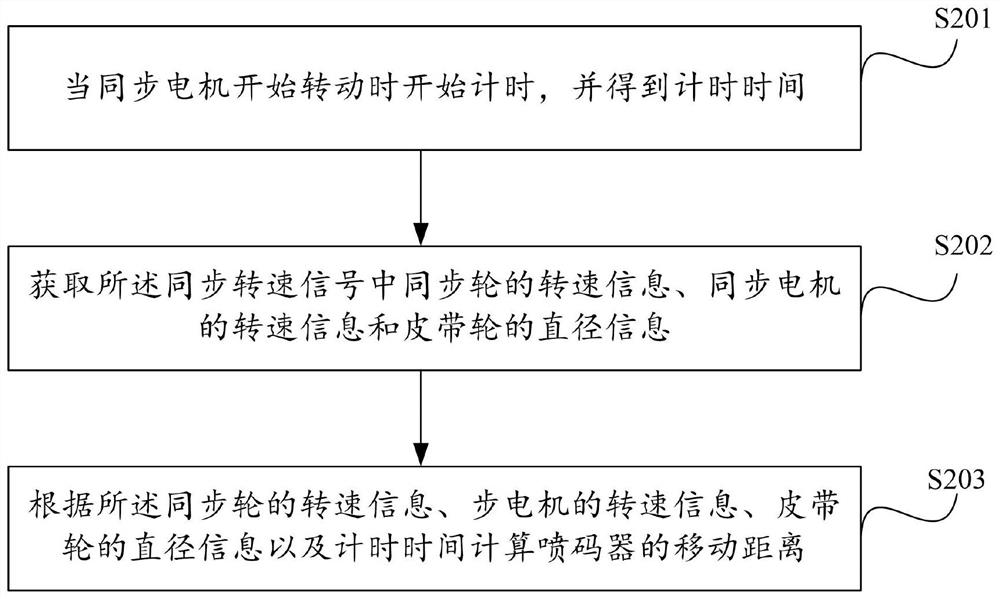

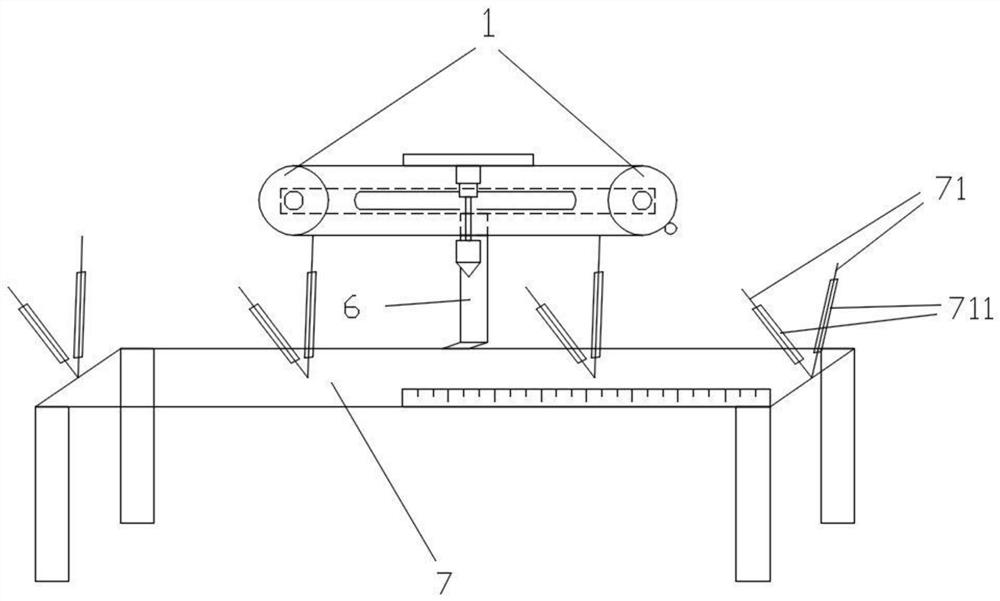

A printing control method for a printing system

ActiveCN110254058BConsistent movement speedAvoid inaccurate codingTypewritersOther printing apparatusSynchronous motorControl engineering

The present invention is applicable to the technical field of pipe material spray printing, and provides a spray printing control method of a spray printing system, comprising: the second controller controls two synchronous motors to rotate forward at the same speed according to the start-up command, and the belt drives the spray printing The encoder moves forward along the guide rail; the first controller calculates the moving distance of the inkjet printer according to the synchronous speed signal; when the moving distance of the inkjet printer reaches the first preset distance, the second controller starts The coding signal controls the inkjet printer to start printing; when the moving distance of the inkjet printer reaches the second preset distance, the second controller controls the inkjet printer to stop printing according to the stop coding signal ; When the moving distance of the inkjet printer reaches the third preset distance, the second controller controls the synchronous motor to rotate in reverse according to the signal, so that accurate inkjet can be realized, and the inkjet is highly controllable.

Owner:DENG QUAN PLASTIC TECH HUNAN CO LTD

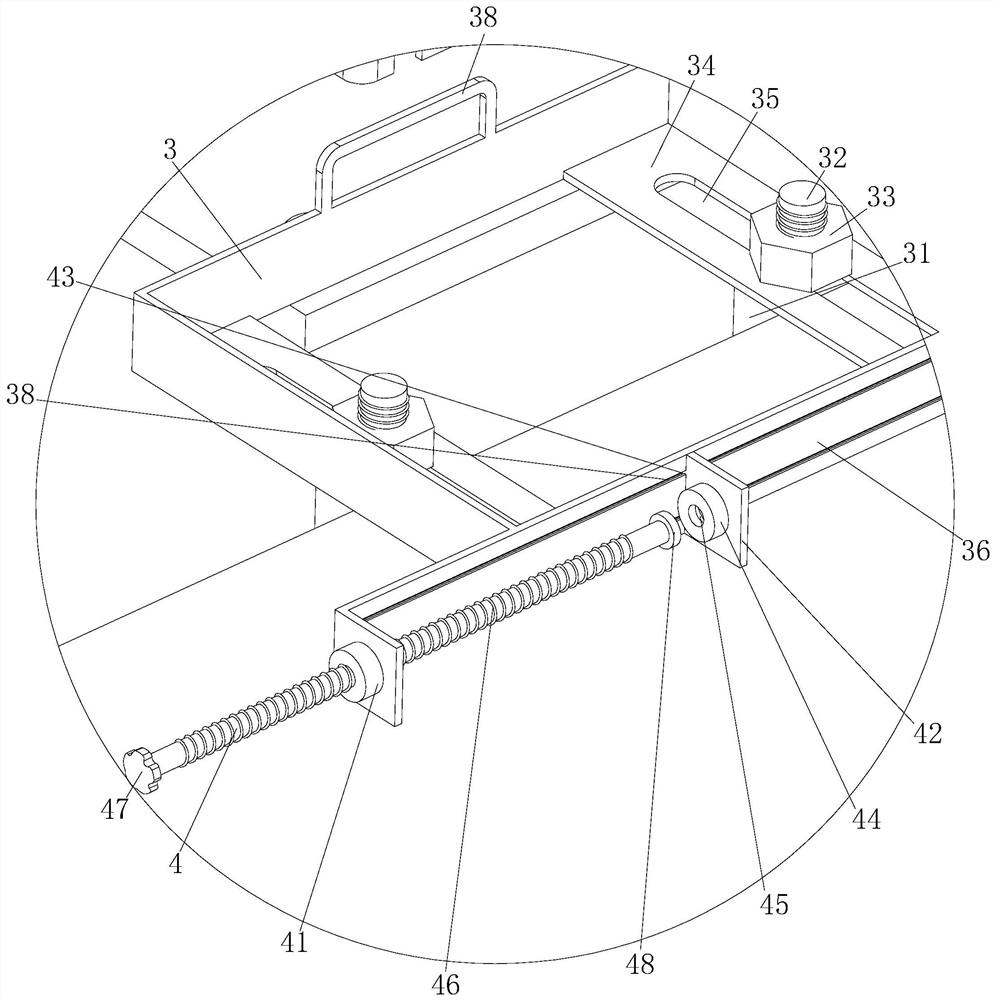

Positioning code printing equipment

PendingCN113733760AAccurate codingImprove work efficiencyTypewritersOther printing apparatusControl engineeringMechanical equipment

The invention relates to positioning code printing equipment, and belongs to the field of mechanical equipment. The positioning code printing equipment comprises a marking machine and a conveying belt, and is structurally characterized by further comprising a positioning mechanism and an adjusting mechanism; the conveying belt is arranged below the marking machine; the positioning mechanism is installed on a rack of the marking machine and matched with the conveying belt; the adjusting mechanism is installed on the positioning mechanism; the positioning mechanism comprises a positioning seat, a positioning support and a positioning side plate; the adjusting mechanism comprises an adjusting seat, an adjusting plate and an adjusting screw rod; the positioning seat is installed on the rack of the marking machine; the positioning support is installed on the positioning seat; the positioning side plate is arranged on the positioning support; the adjusting seat and the adjusting plate are both installed on the positioning side plate; the adjusting screw rod is installed on the adjusting seat; and one end of the adjusting screw rod is connected with the adjusting plate.

Owner:TONGLU YUXIN AUTOMOBILE PARTS

A cooling processing device with protective performance for tablet computer memory

ActiveCN112297656BAvoid corrosion damageInkjet code can notTypewritersOther printing apparatusEngineeringThreaded rod

The invention relates to a cooling processing device with protective performance for a tablet computer memory, comprising a bottom plate and a third electric guide rail, a condenser, a first air blowing box and a heating and drying mechanism are installed on the lower end of the bottom plate, the inside of the bottom plate The upper surface is sequentially installed with a belt conveyor and a placement table from front to back, the lower end of the first electric guide rail is installed with a second electric guide rail, and the upper end of the belt conveyor is respectively provided with a tablet computer storage body from the middle to the front and rear sides and a limiting plate, and one side of the limiting plate is connected with a threaded rod, and the third electric guide rail is located in the middle of the inner lower end of the bottom plate. The beneficial effects of the present invention are: the tablet computer memory is used with a cooling processing device with protective performance, The clamping suction cup is buffered by the spring to prevent the clamping suction cup from applying too much pressure to the storage when the clamping suction cup clamps the memory, causing the pins of the memory to be bent and damaged under pressure, thereby causing unnecessary damage.

Owner:DONGGUAN UNIV OF TECH

A uv ultraviolet laser inkjet printer for intelligent manufacturing

ActiveCN113352001BEasy to addAvoid spraying by mistakeLaser beam welding apparatusUltraviolet laser lightMechanical engineering

The invention relates to a UV ultraviolet laser inkjet printer for intelligent manufacturing, which includes a base and a drying detection assembly. The upper end of the base is sequentially provided with a drying detection assembly, a supporting lifting assembly and an operating table from left to right. The drying detection assembly It includes a fixed frame, an ultraviolet laser curing device and a scanner, and the upper wall and the lower side of the fixed frame are sequentially installed with an ultraviolet laser curing device and a scanner from right to left, and a counting mechanism is installed on the left side of the drying detection component. The beneficial effects of the present invention are: the UV ultraviolet laser inkjet printer for intelligent manufacturing can count the products, and then scan the code to determine whether the code is accurate, and at the same time, the equipment can adjust the distance between the inkjet printer and the product, and Position the product so that the inkjet can be sprayed at the same position of the product every time, the equipment can quantitatively adjust the ink to the inkjet, and the equipment can also visually see the remaining ink of the equipment, which is convenient for the equipment to add ink .

Owner:深圳市海纳激光科技有限公司

Code spraying device

The invention discloses a code spraying device and belongs to the technical field of cable machining. The code spraying device comprises a supporting frame, a supporting plate, supporting wheels, guide pillars, a first rolling wheel, a second rolling wheel, a spray head and a collection tank. The supporting plate is arranged on the supporting frame. The second rolling wheel is arranged at one end of the supporting frame. The first rolling wheel is arranged above the second rolling wheel and arranged on the supporting plate. The supporting wheels are mounted on a sliding track of the supporting plate. The guide pillars are arranged on the supporting plate. The spray head is arranged in the middle of the supporting frame. The collection tank is arranged below the spray head. The code spraying device is simple in structure, capable of effectively locating a cable subjected to code spraying and preventing unclearness, skewing, missing and the like of sprayed codes, and high in practicality, thereby having wide market development prospects.

Owner:METALLURGICA BRESCIANA MAANSHAN SPECIAL CABLES

A laser inkjet printer that can identify the location of the inkjet code for intelligent manufacturing

The invention relates to a laser inkjet printer capable of identifying the coding position for intelligent manufacturing, comprising a casing and a connecting assembly, the inner lower wall of the casing is provided with a belt conveyor, and the supporting assembly includes a second plate and a supporting rod , a connecting pin, a third plate, an overcoat, a second pressure sensor, a first spring, and a telescopic rod, and the upper end of the second plate is provided with a support rod, and the upper end of the support rod is connected with a connecting pin, and the connecting pin The outside is connected with a third plate, and the left and right sides of the second plate are movably connected with jackets. The beneficial effects of the present invention are: the intelligent manufacturing uses a laser inkjet printer that can identify the coding position, and the coding position can be positioned in advance through the device, and then the precise coding can be realized through precise docking. Positioning, to prevent positioning from shifting the coding position due to the deviation of the product position, the equipment can transport the auxiliary device, so that the auxiliary device can be used multiple times.

Owner:深圳市海纳激光科技有限公司

Ink-jet printer for computer part manufacturing

InactiveCN113334931AKeep coding heightCalibration inkjet OKTypewritersPower drive mechanismsMechanical engineeringInkjet printing

The invention discloses an ink-jet printer for computer part manufacturing. The ink-jet printer comprises a bottom plate, the top of the bottom plate is fixedly connected with a first supporting seat, a third supporting seat and a second supporting seat in sequence from right to left, the top of the second supporting seat is fixedly connected with a mounting box, grooves are formed in the upper surface and the lower surface of the mounting box, a first transmission rod is vertically and slidably connected in the grooves, an inkjet printing head is mounted at the bottom of the first transmission rod, a transmission mechanism enabling the inkjet printing head to move up and down is arranged on the inner wall of the mounting box, a driving mechanism used for driving the transmission mechanism is arranged at the top of the first supporting seat, a calibration mechanism is arranged at the top of the third supporting seat, a material returning mechanism is arranged below the position, at the top of the bottom plate, of the inkjet printing head, and a cleaning mechanism used for cleaning the inkjet printing position is arranged at the bottom of the first transmission rod. According to the ink-jet printer, through cooperation of the above structures, the inkjet printing area of a part can be calibrated and fixed while automatic inkjet printing is achieved, and the inkjet printing procedure is more accurate.

Owner:苏辉

A flange coding device and method

ActiveCN112297653BRealize automatic codingIncrease productivityDuplicating/marking methodsTypewritersControl engineeringElectrical connection

The invention relates to the technical field of ship construction and production, and discloses a flange coding device and method. The coding device comprises: a platform, a plurality of storage racks, and a robot, and a controller is arranged on the platform; The material racks are installed on the platform for storing flanges; the robot is slidably installed on the platform, and the robot is provided with a coder, and the robot and the coder are respectively connected with the controller Electrical connection, the controller controls the robot to slide to the corresponding storage rack, and then controls the coder to code the flange placed on the storage rack. The invention abandons the traditional manual flange coding method, realizes fully automatic flange coding, greatly improves the production efficiency, and also ensures the quality of the flange coding.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Code printing platform

PendingCN114801508AInhibit sheddingAccurate codingTypewritersPower drive mechanismsProduction lineEngineering

The invention relates to the technical field of code printing equipment, and discloses a code printing platform which comprises a code printing box, a code printing machine, a clamping mechanism, an adjusting mechanism and a lifting mechanism, the code printing machine, the clamping mechanism, the adjusting mechanism and the lifting mechanism are arranged in the code printing box, safety doors allowing a production line conveying belt to penetrate through are formed in the two opposite side faces of the code printing box, and the clamping mechanism comprises a clamping piece and a cargo carrying plate. The lifting mechanism comprises a lifting pulley and is used for jacking a production line conveying belt, the adjusting mechanism comprises a plurality of guide rails and a plurality of movable blocks and is used for adjusting the position of the coding machine, and the coding machine is used for completing coding. Compared with the prior art, the coding platform can complete coding quickly and accurately, the influence of vibration of a production line on coding is avoided, coding errors are reduced, the coding box separates a coding machine and part of the production line from operators, direct contact between the operators and the coding machine during coding is avoided, and hidden industrial injury risks are eliminated.

Owner:广东铭钰科技股份有限公司

Cooling processing device with protection performance for tablet personal computer memory

ActiveCN112297656AAvoid corrosion damageInkjet code can notTypewritersOther printing apparatusEngineeringPersonal computer

The invention relates to a cooling processing device with protection performance for a tablet personal computer memory. The cooling processing device comprises a bottom plate and a third electric guide rail, a condenser, a first air blowing box and a heating drying mechanism are installed at the lower end of the bottom plate, and a belt conveyor and a placing table are sequentially installed on the upper surface of the interior of the bottom plate from front to back. A second electric guide rail is installed at the lower end of a first electric guide rail, a tablet personal computer memory body and a limiting plate are arranged at the upper end of the belt conveyor from the middle to the front side and the rear side correspondingly, a threaded rod is connected to one side of the limiting plate, and the third electric guide rail is located in the middle of the lower end in the bottom plate. The cooling processing device has the beneficial effects that according to the cooling processingdevice with the protection performance for the tablet personal computer memory, clamping suction cups are buffered through springs, so that the situation that when the clamping suction cups clamp thememory, the pressurizing pressure of the clamping suction cups on the memory is too large, pins of the memory are bent and damaged, and unnecessary damage is caused is prevented.

Owner:DONGGUAN UNIV OF TECH

A continuous pad printing coding method

ActiveCN106379042BClear outlineSqueegee steps increaseRotary pressesPrinting press partsPad printingEngineering

The invention discloses a continuous transfer-printing coding method. The continuous transfer-printing coding method comprises the following steps: step (a) inking an etching plate by using a sealed oil cup of a transfer-printing coding device; step (b) forwards pushing a rubber head of a transfer printing machine to the upper portion of the etching plate, subsequently driving the rubber head to move down to have contact with the etching plate, and downwards pressing the rubber head to make the rubber head be stained with ink with patterns; step (c) backwards pushing the rubber head to a transfer printing work position, and then driving the rubber head to be pressed downwards so that the rubber head is capable of printing the ink with patterns on a to-be-printed object inside a mold groove; step (d) moving the transfer-printed object to a drying work position for drying by using a conveying component; step (e) moving the transfer-printed and dried object to a coding work position and coding the transfer-printed and dried object by using a laser coding machine. The continuous transfer-printing coding method disclosed by the invention is capable of realizing continuous operation on large-batch to-be-printed objects and improving the production efficiency; the patterns are clearer after the printed objects are dried at the drying work position; a coded product is high in exquisite degree and is fadeless after being used for a long time.

Owner:CHENGDU OJA AIRCRAFT CABIN EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com