Code spraying device

A technology of inkjet and nozzle, applied in the direction of marking conductors/cables, etc., can solve the problems of inconvenient movement of the inkjet printer, unstable cable movement, unreliable cable fixation, etc., to achieve simple structure, strong practicability, and avoid waste. and the effects of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

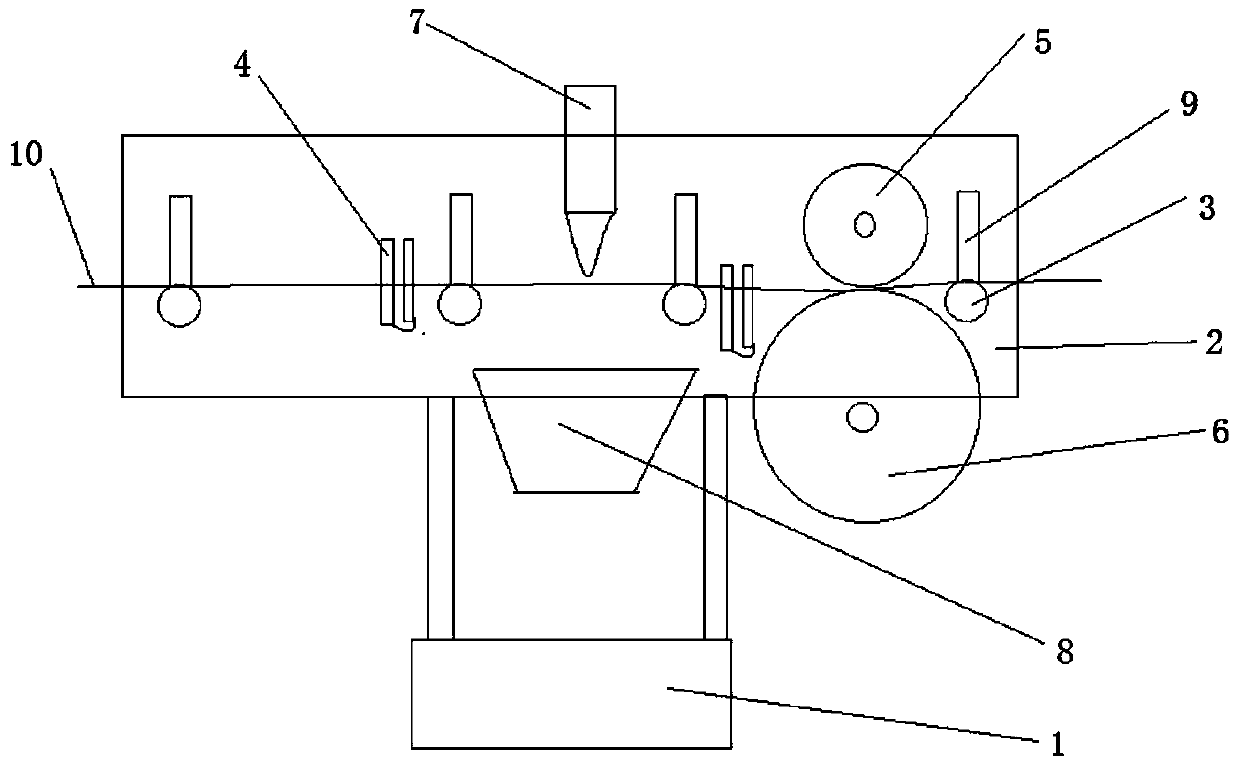

[0019] Such as figure 1 Shown, a kind of inkjet coding device comprises support frame 1, support plate 2, supporting wheel 3, guide column 4, first roller 5, second roller 6, nozzle 7 and collecting tank 8; Described support plate 2 is set On the support frame 1, the second roller 6 is arranged at one end of the support frame 1, the first roller 5 is arranged on the second roller 6, and the first roller 5 is arranged on the support plate 2; Wheel 3 is installed on the sliding track 9 of support plate 2, described guide column 4 is located on support plate 2, and described shower head 7 is arranged in the middle of support frame 1, and the following of shower head 7 is provided with collecting tank 8.

[0020] The number of the supporting rollers 3 is four, wherein two supporting rollers 3 are respectively arranged at both ends of the support plate 2, and the other two supporting rollers 2 are respectively arranged on both sides of the nozzle 7, and the supporting rollers 3 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com