Patents

Literature

111results about How to "Move at a constant speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

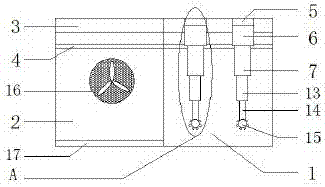

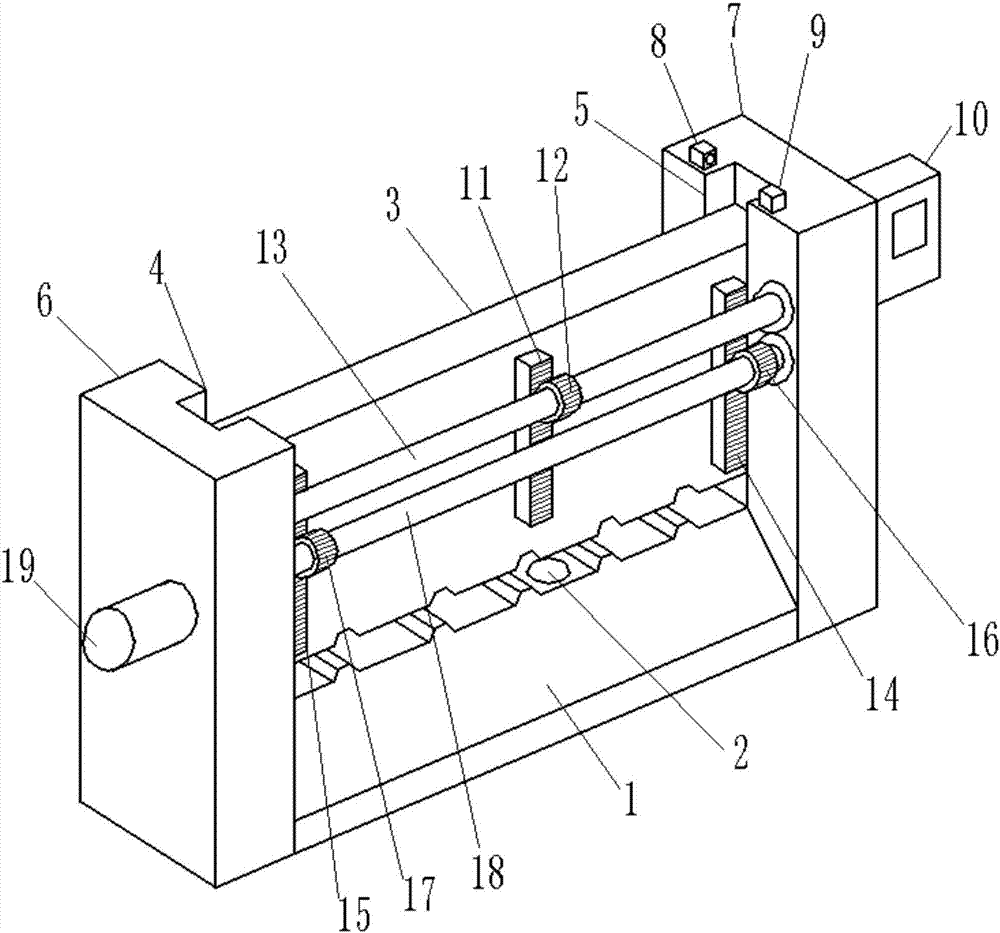

Apparatus and method for measuring small rocket engine thrust force vector in vacuum

InactiveCN101435728AGuaranteed movement accuracyGuaranteed Reset AccuracyEngine testingApparatus for force/torque/work measurementRotary stageMeasurement device

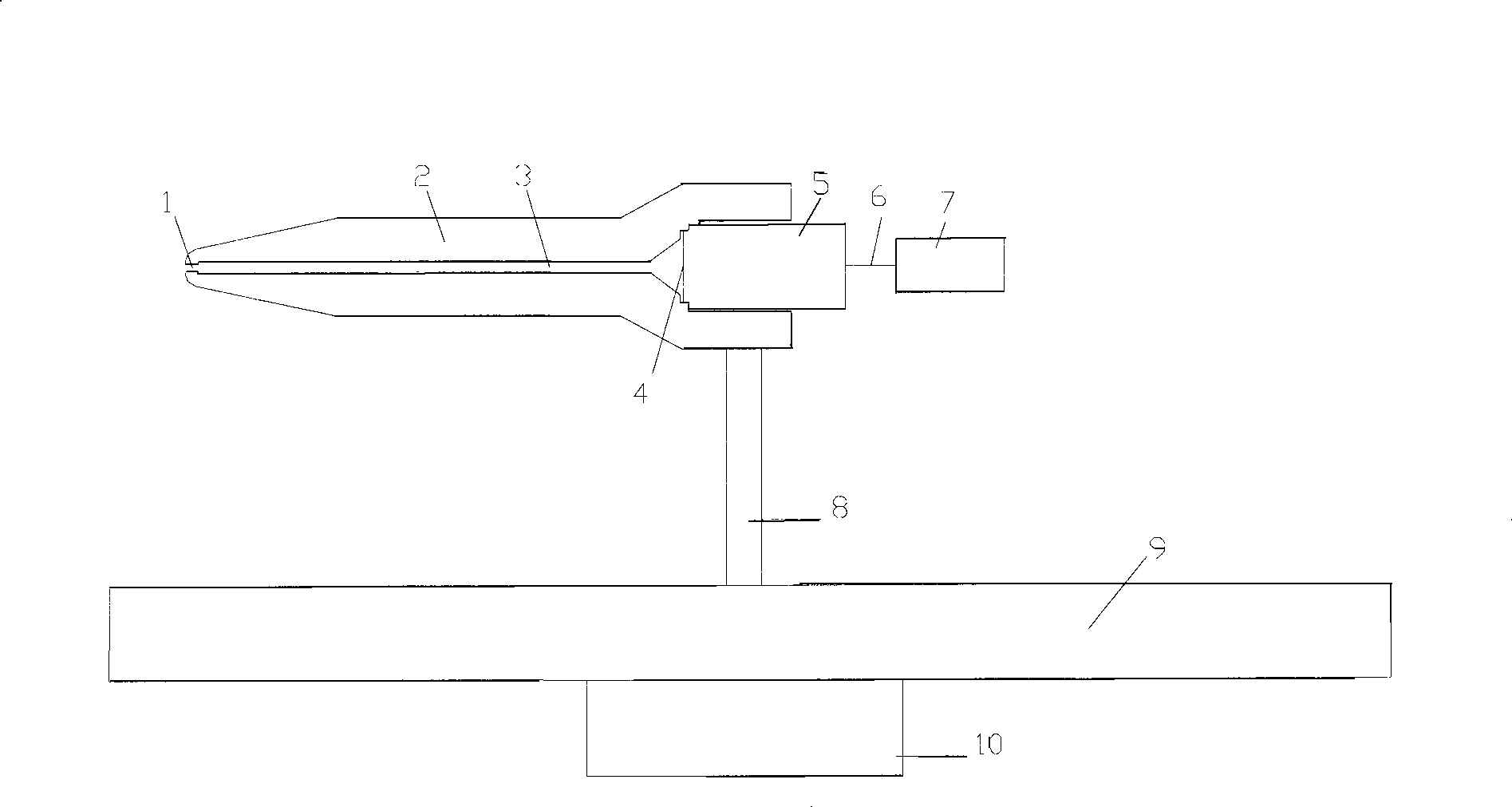

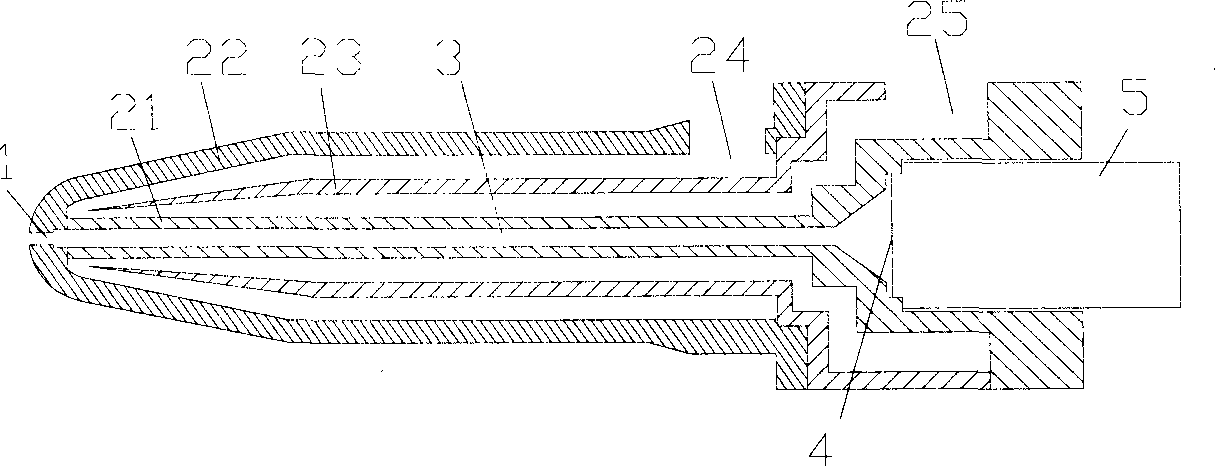

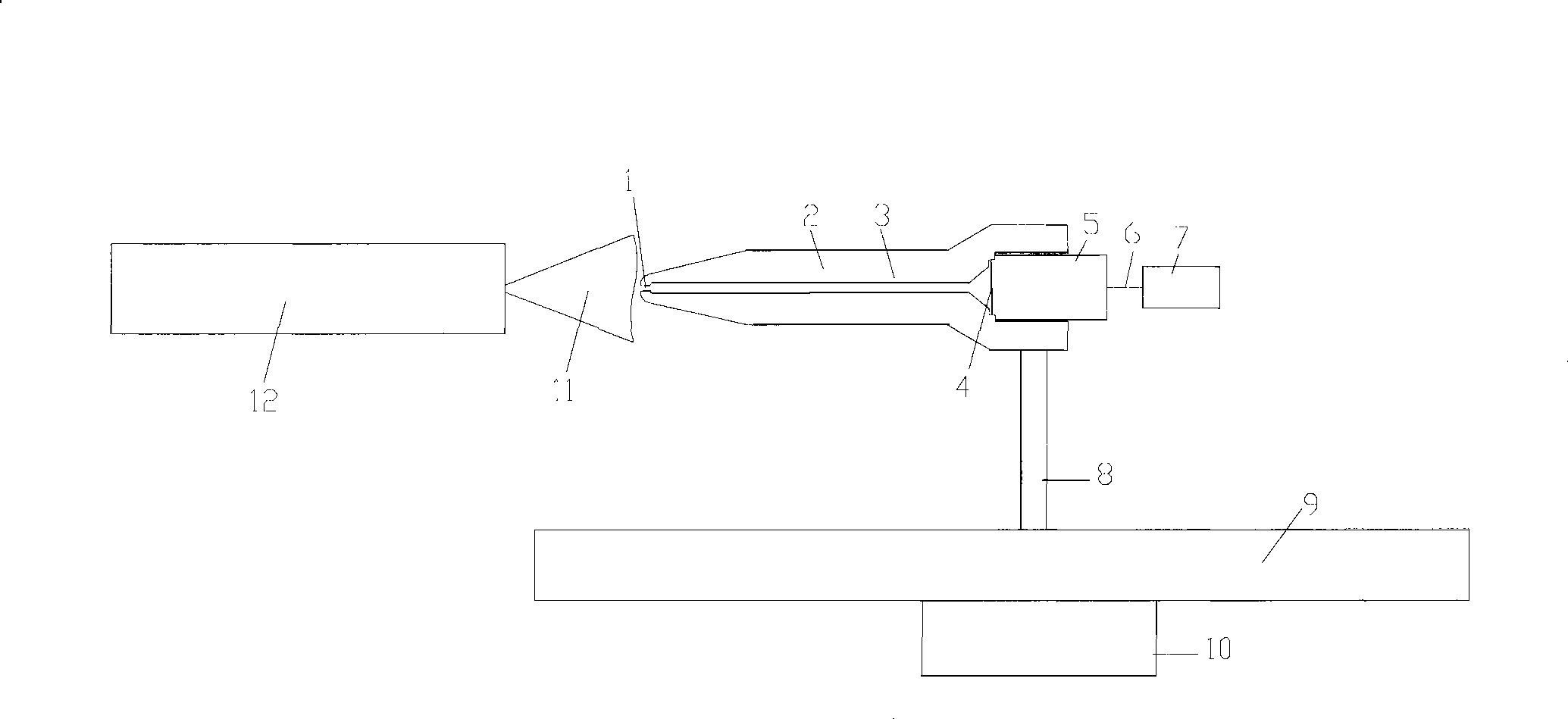

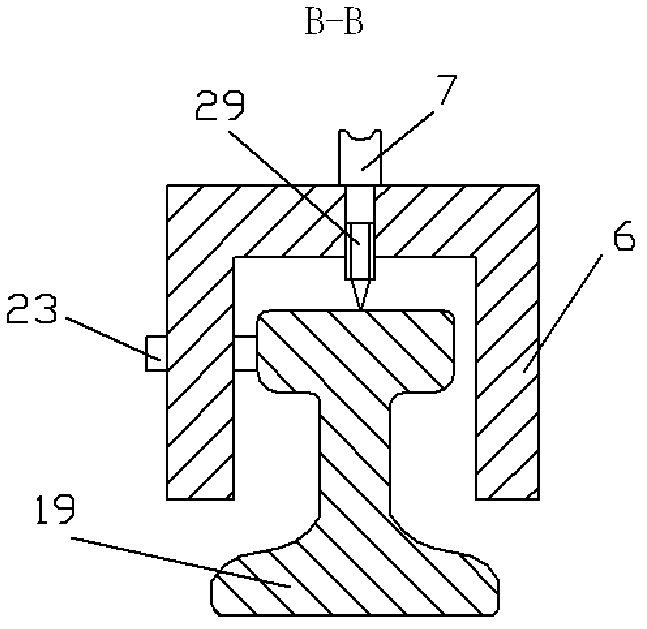

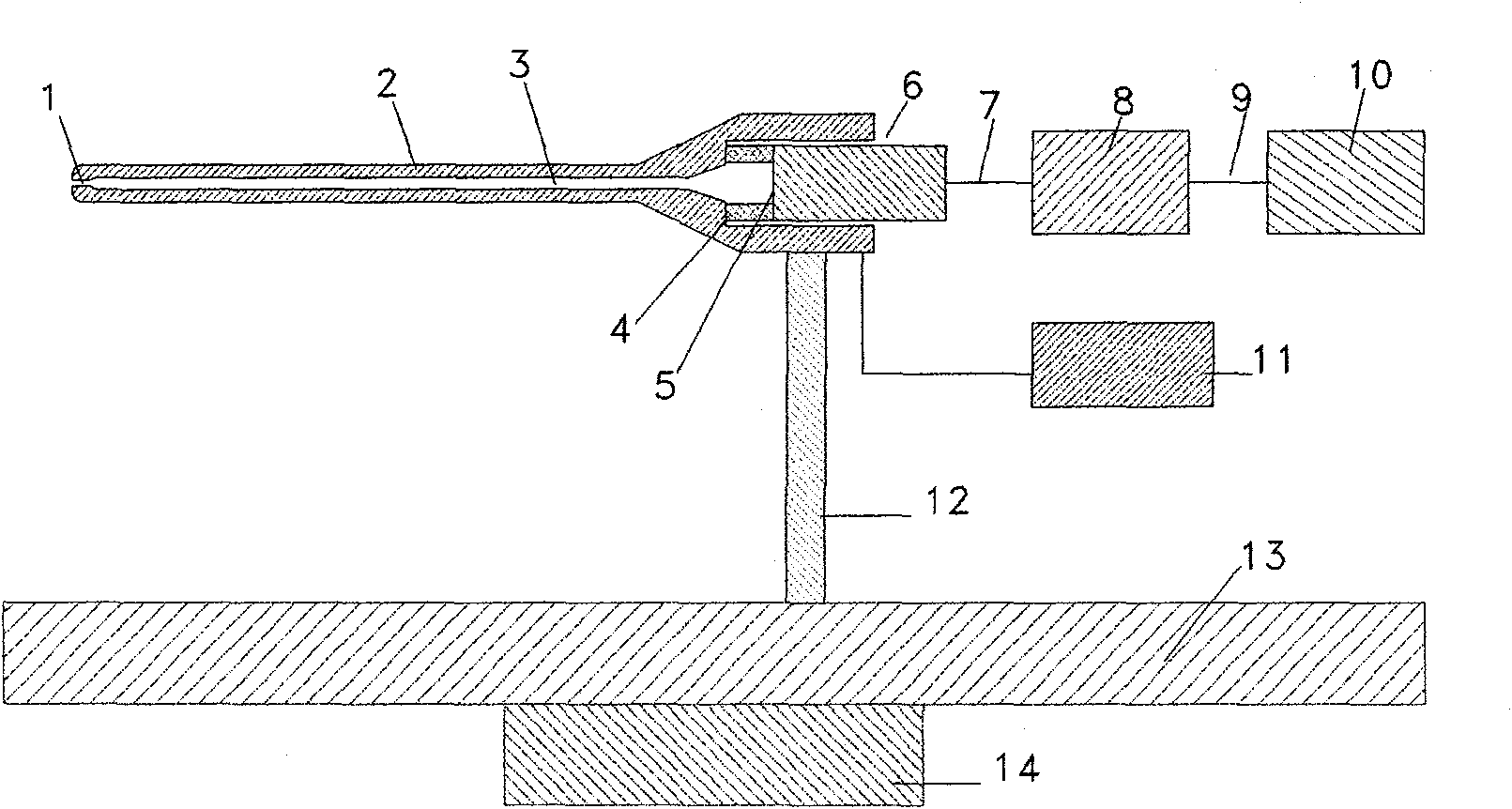

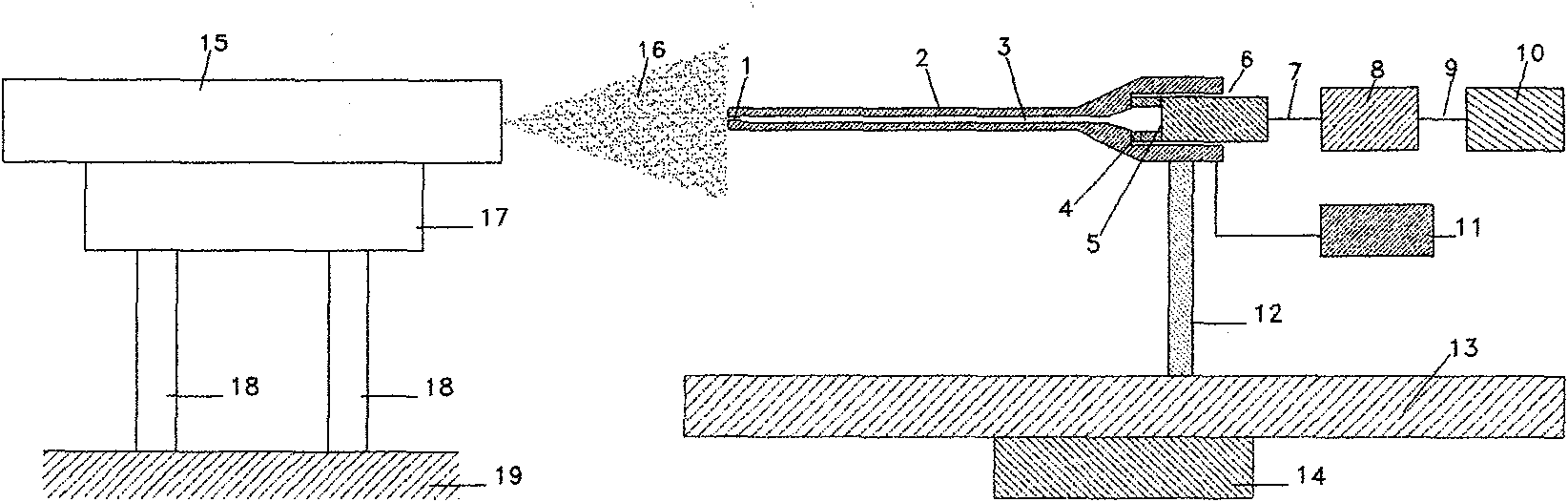

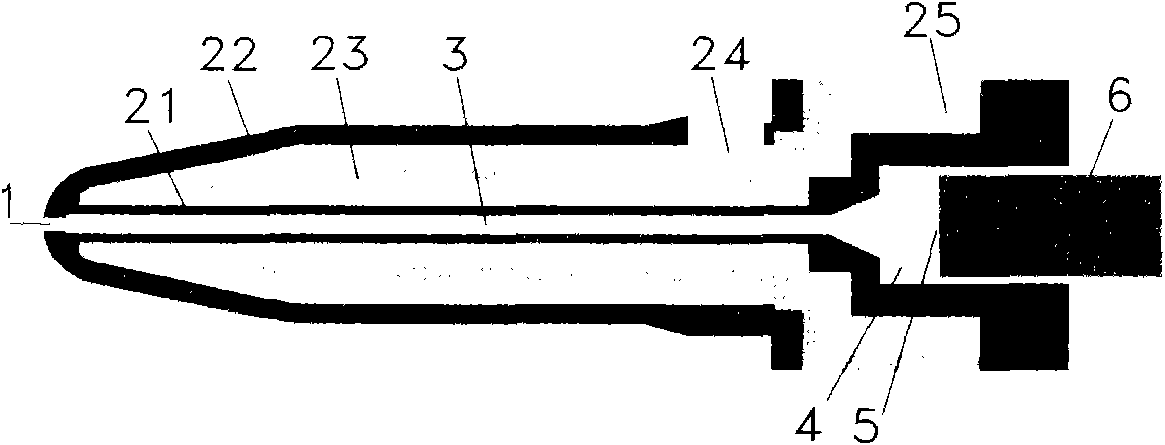

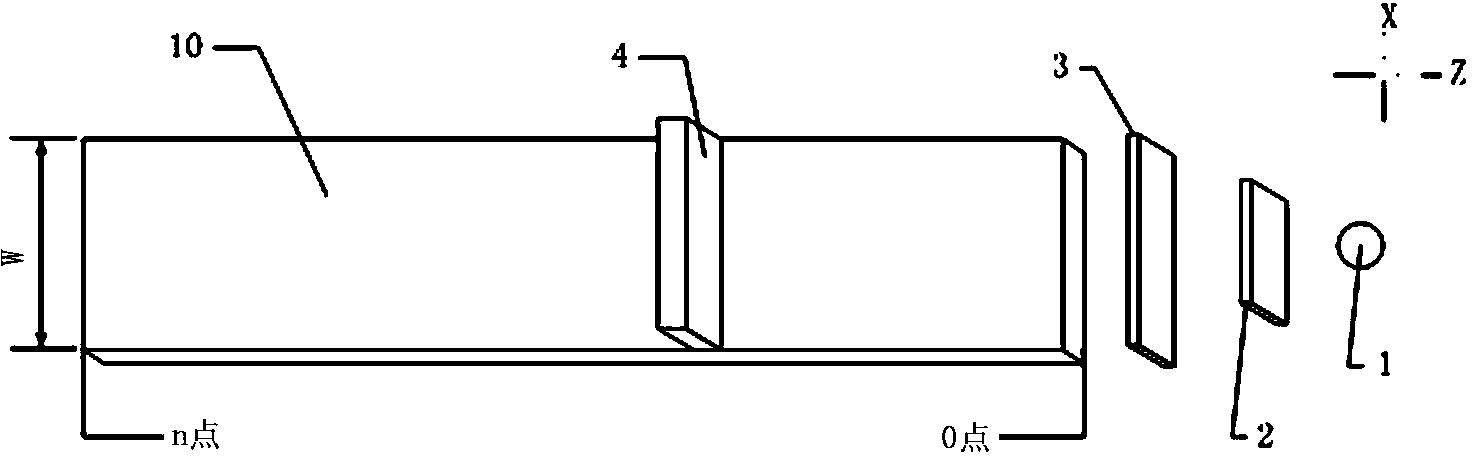

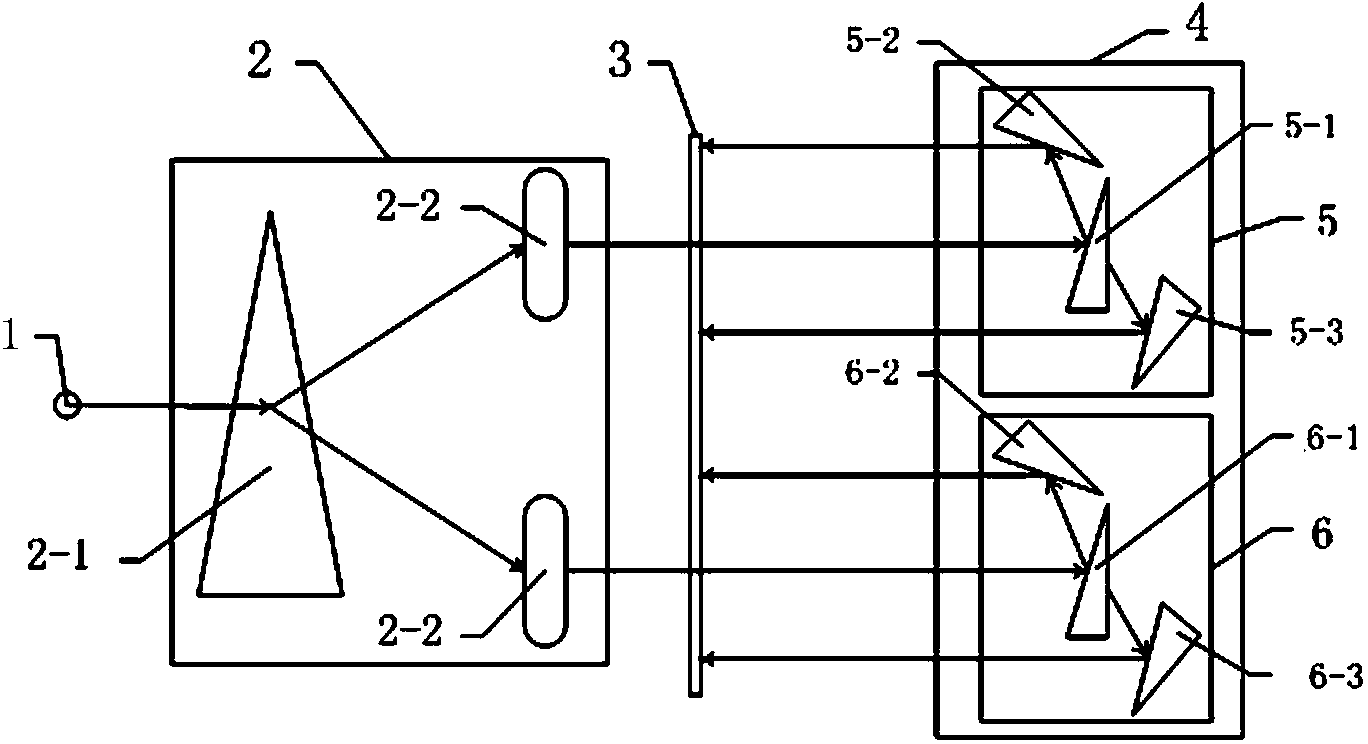

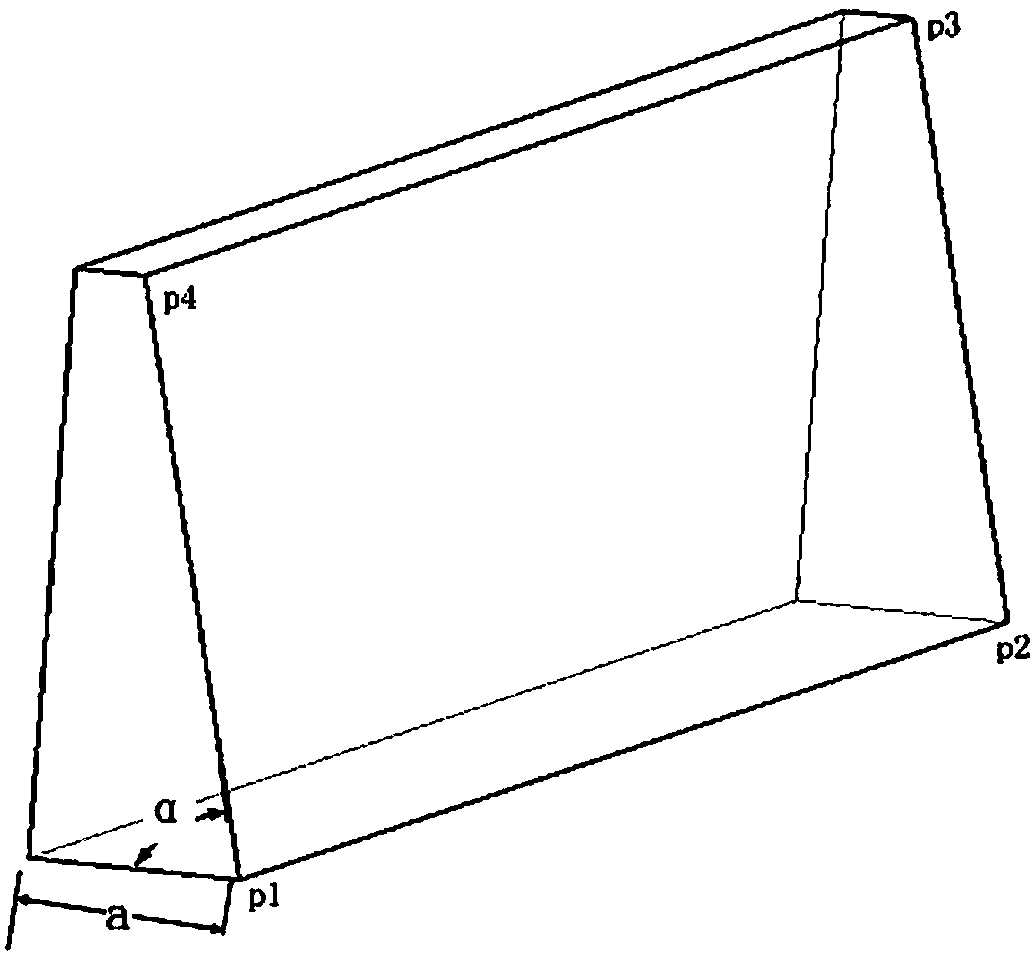

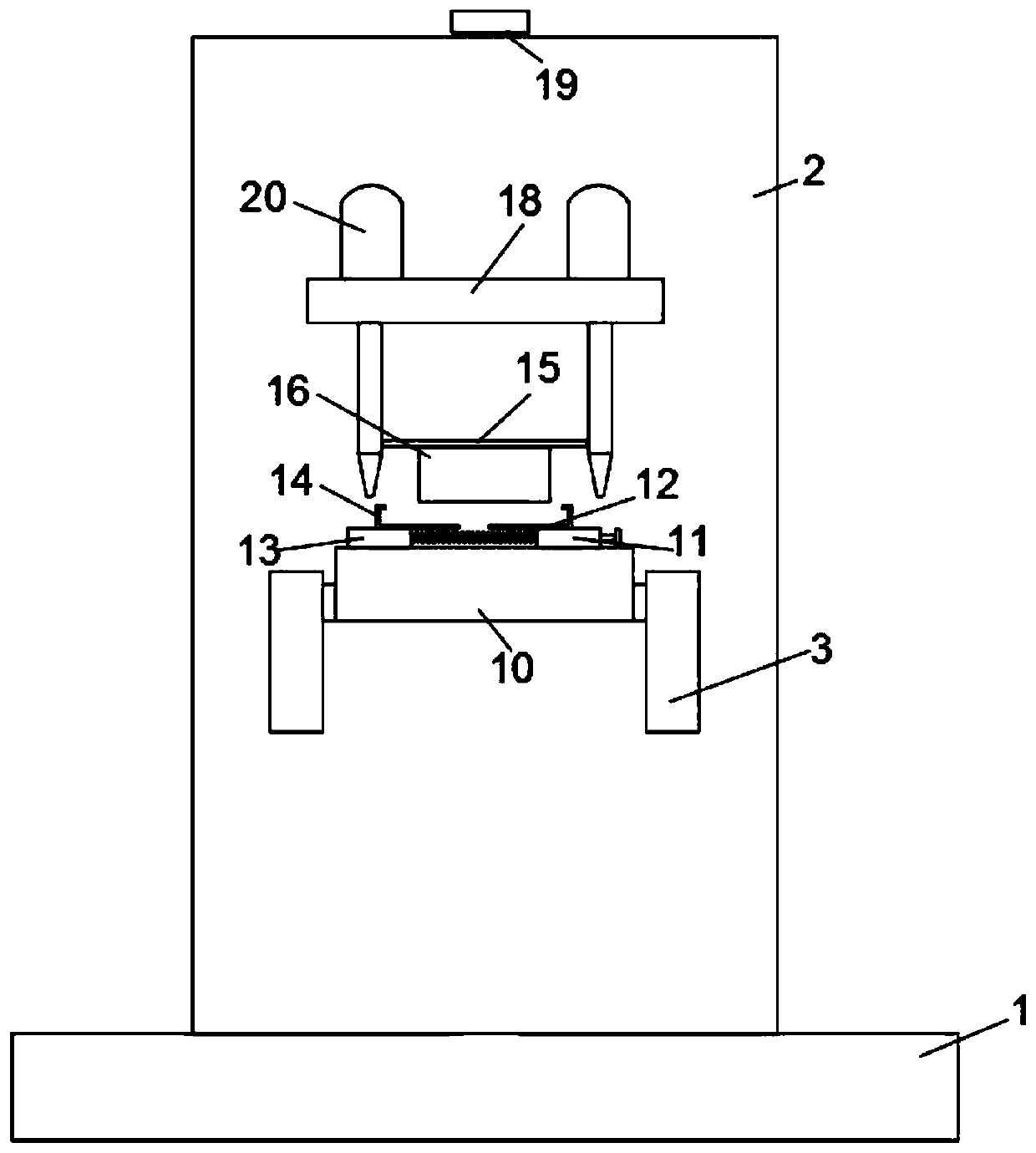

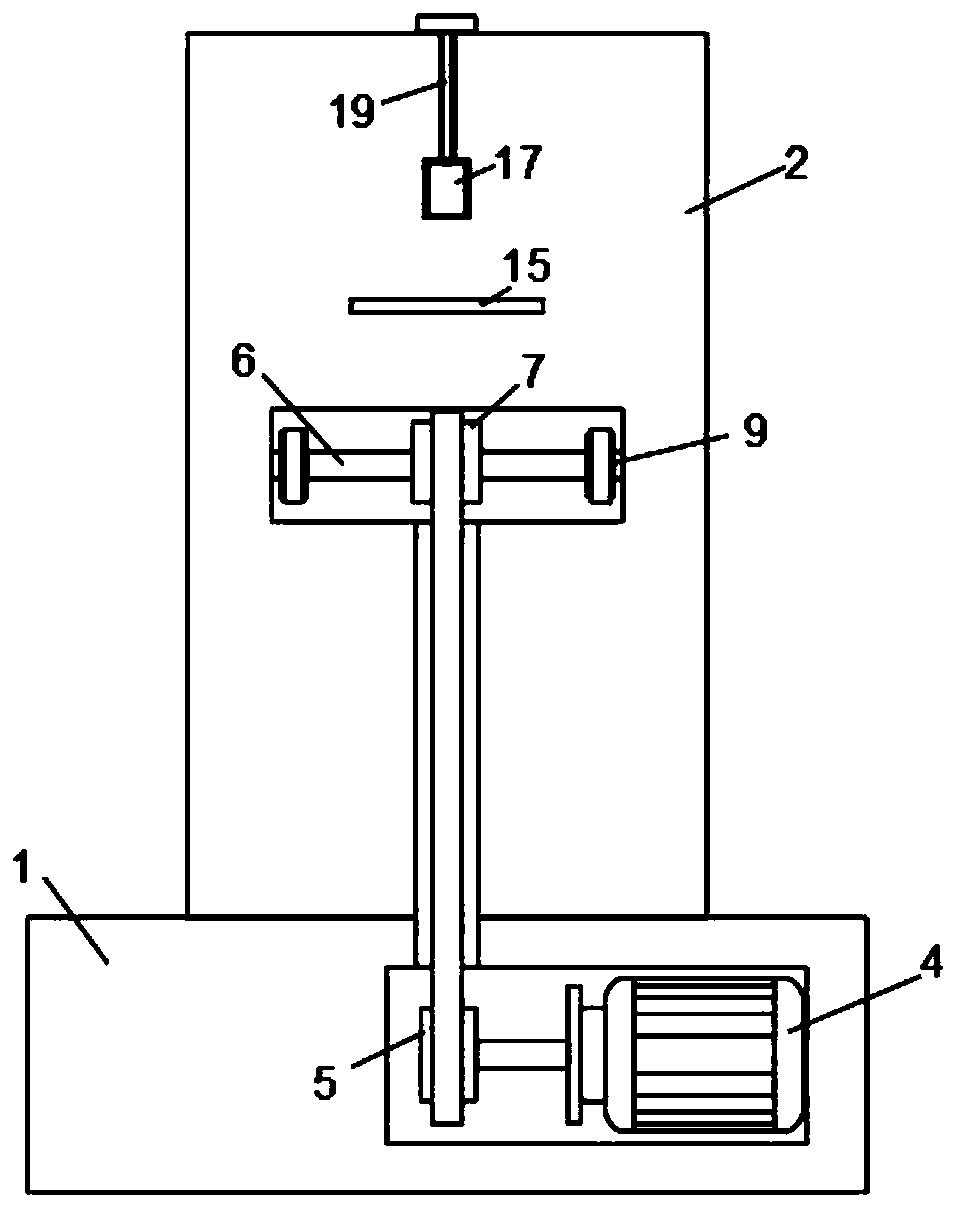

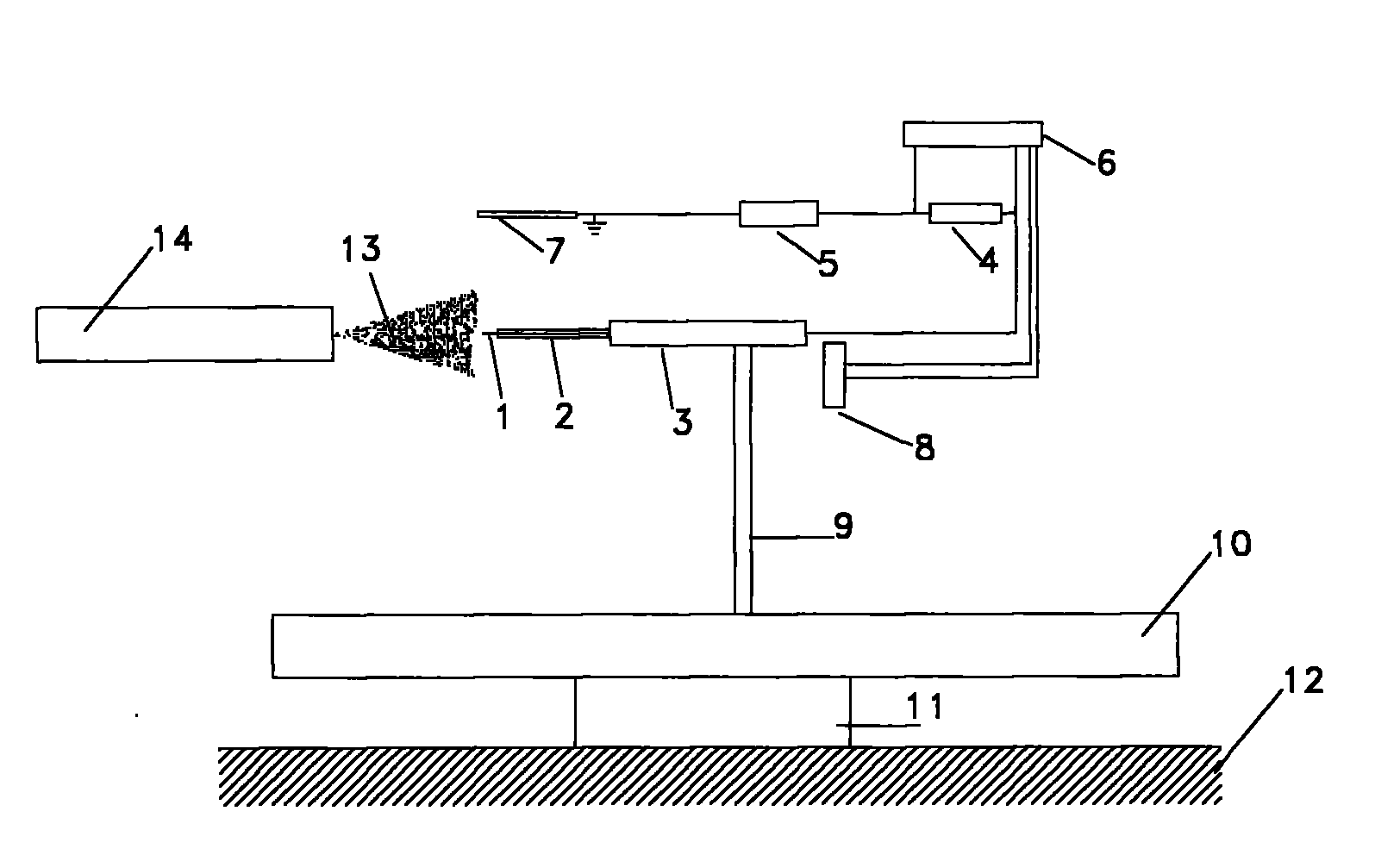

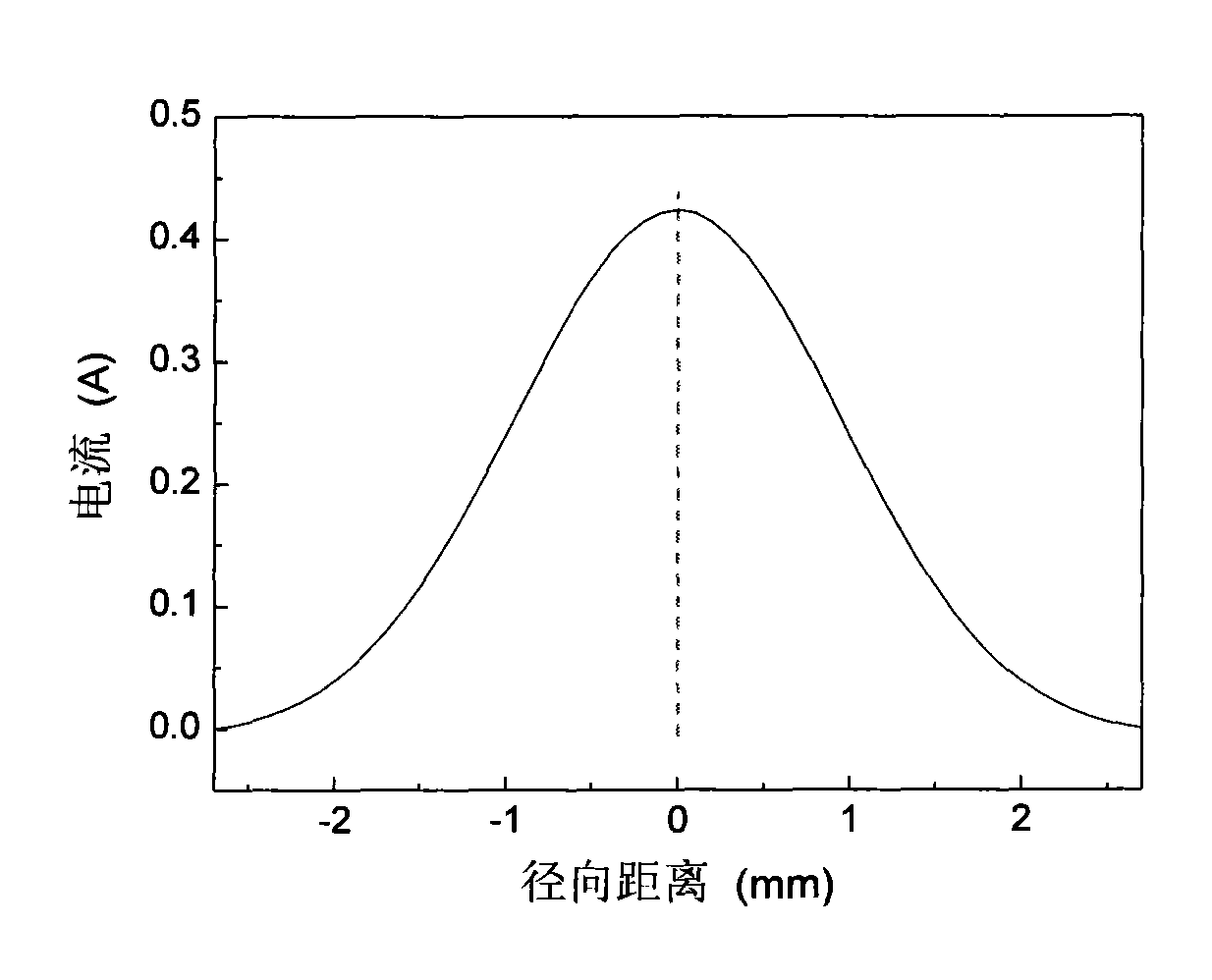

The invention relates to a measuring device and a method for detecting thrust vector of a tiny rocket motor used in vacuum. The device for detecting the thrust vector mainly comprises a pressure probe, a movable platform, a rotating table and a data acquisition system. The method comprises the following steps: fixing the pressure probe to the movable platform first, and then adjusting the position of the pressure probe simultaneously, so as to make an axis of the pressure probe parallel to an axis of the tiny rocket motor. When the movable platform moves at constant speed along the direction perpendicular to the axis of the tiny rocket motor, a sensor positioned in the pressure probe senses local dynamic pressure signals in jet current generated by the tiny rocket motor in real time, and the acquisition system acquires and transmits the signals to a data processing and displaying system. Through analyzing symmetry of the dynamic pressure relative to the axis of the tiny rocket motor, the method studies deflection conditions of actual thrust vector and design objective.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

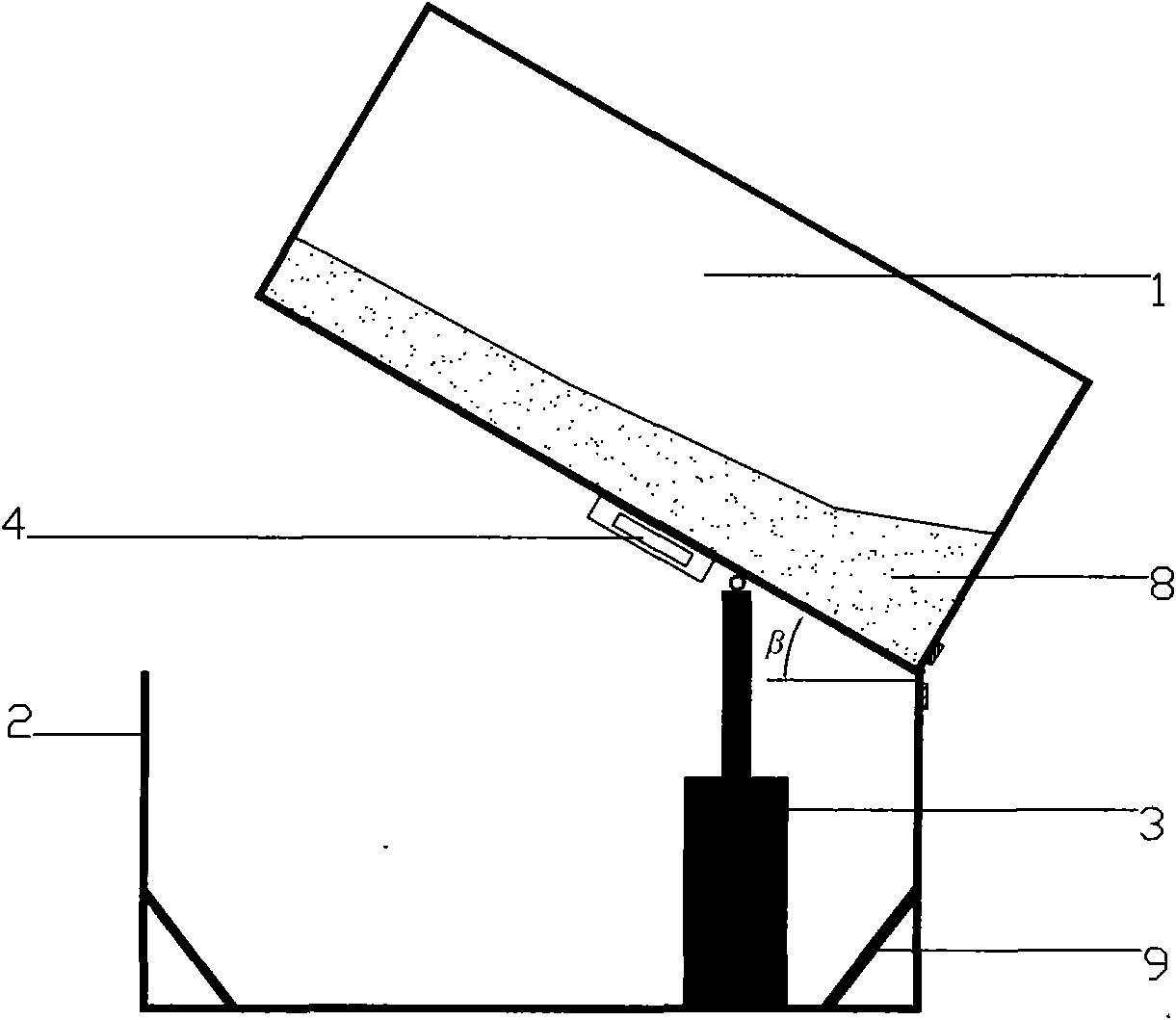

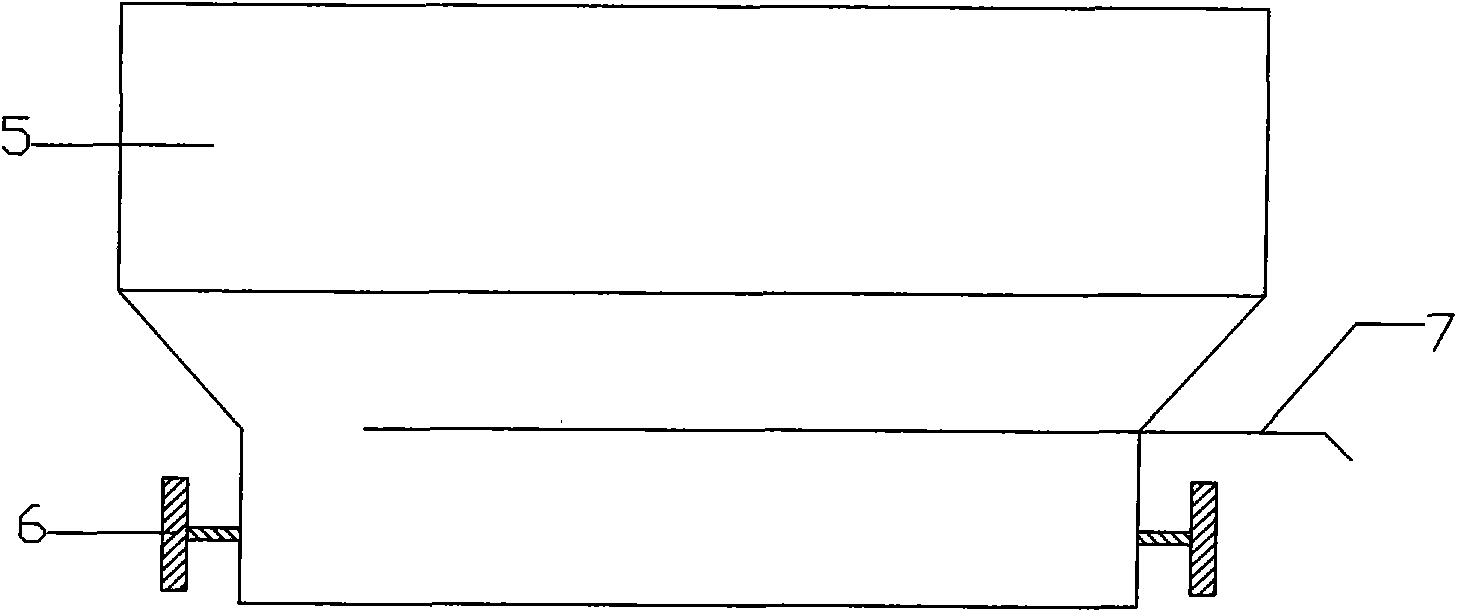

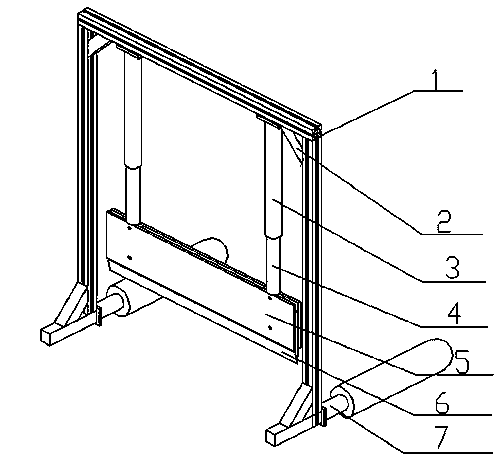

Landslide simulation experimental device

InactiveCN101839714AFulfil requirementsSatisfy the requirement of approximately the same porosityAngle measurementOptical rangefindersGoniometerSingle degree of freedom

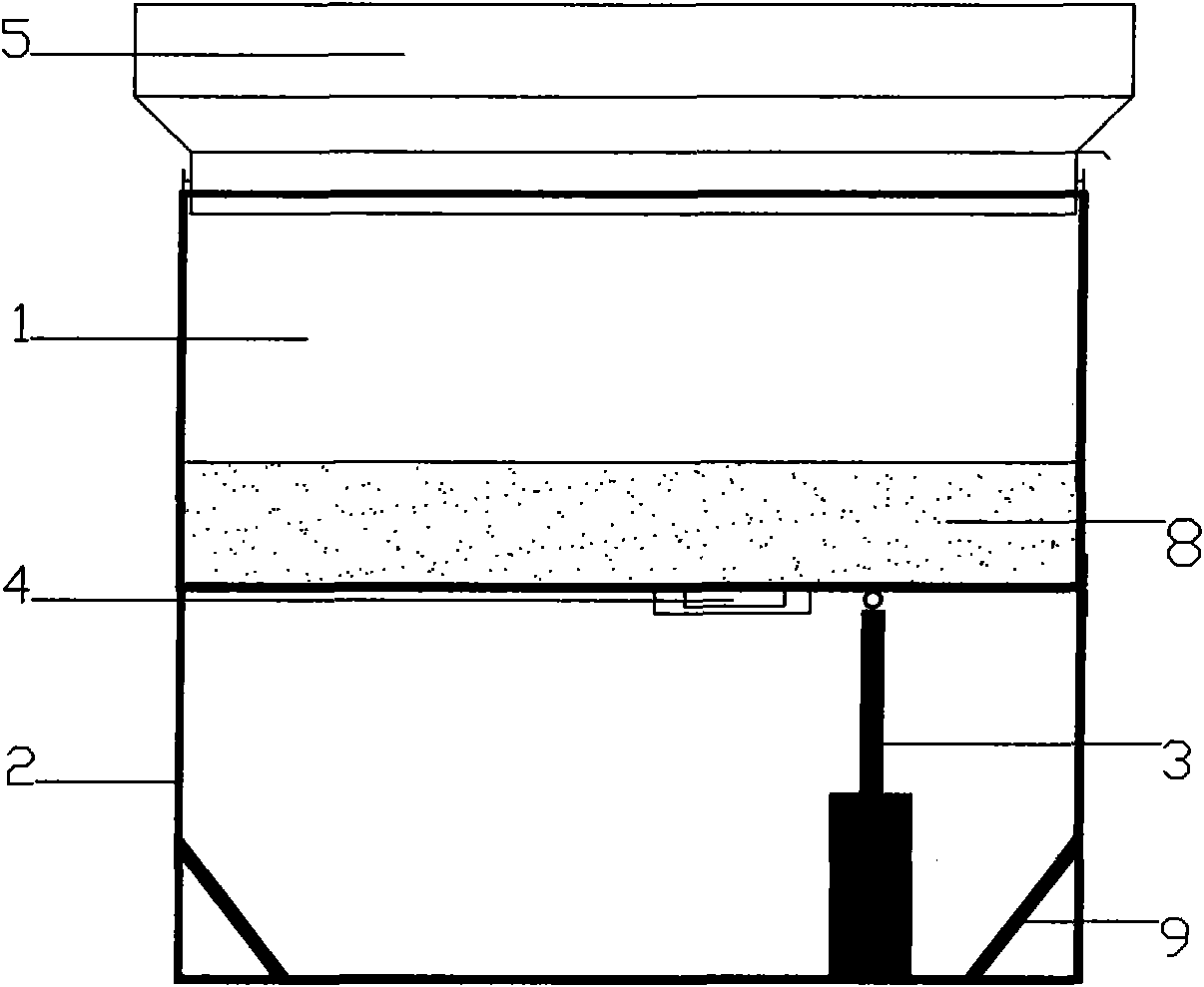

The invention provides a landslide simulation experimental device which comprises an open experimental box, a horizontal bracket, an experimental box drive device and an automatic goniometer, wherein a positive panel of the experimental box is made of transparent materials, a back panel is parallel to the positive panel and is arranged between two side panels in a mode of moving along the direction vertical to the positive panel, a back panel fixing device is arranged on each side panel, the experimental box is arranged on the horizontal bracket, the bottom surface of the experimental box is articulated to the horizontal bracket with a single degree of freedom along the direction vertical to the positive panel, the experimental box is provided with the automatic goniometer, a video camera and a multi-negativemachine are erected in the front of the experimental box, and the experimental device can regulate the width of the experimental box based on side slope moulds with different widths, can also automatically measure a slope angle and record the whole process of an experimental process through the video camera and the camera, thereby being convenient for experimental personnel to observe and search.

Owner:CHONGQING UNIV

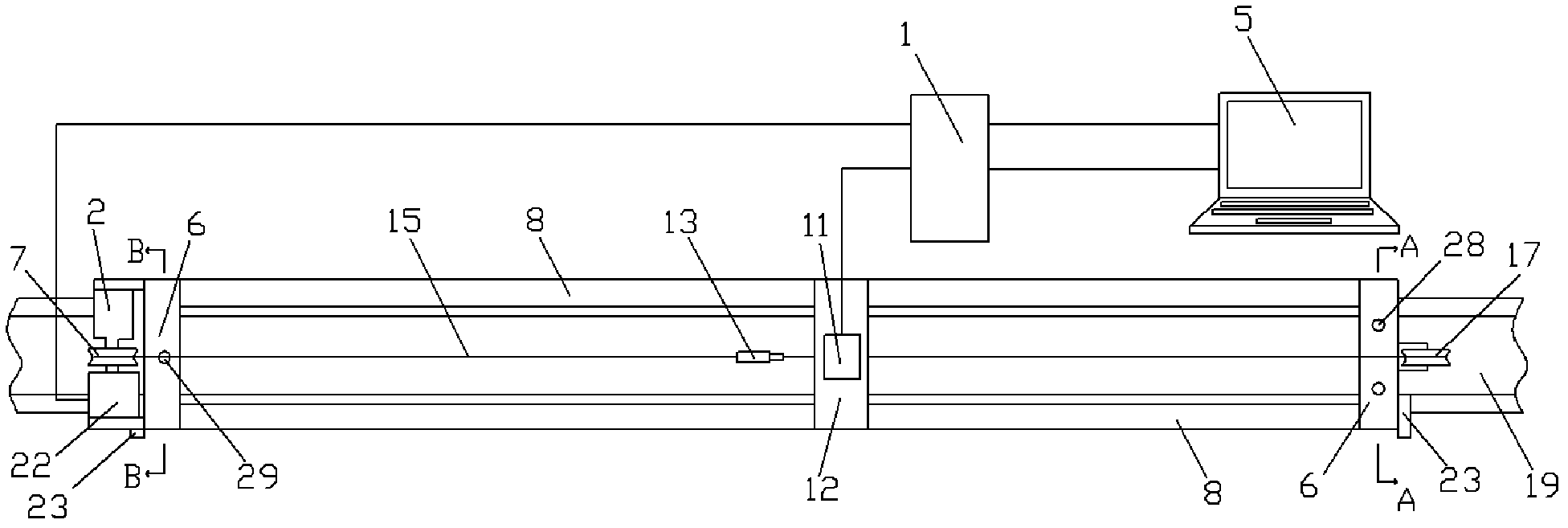

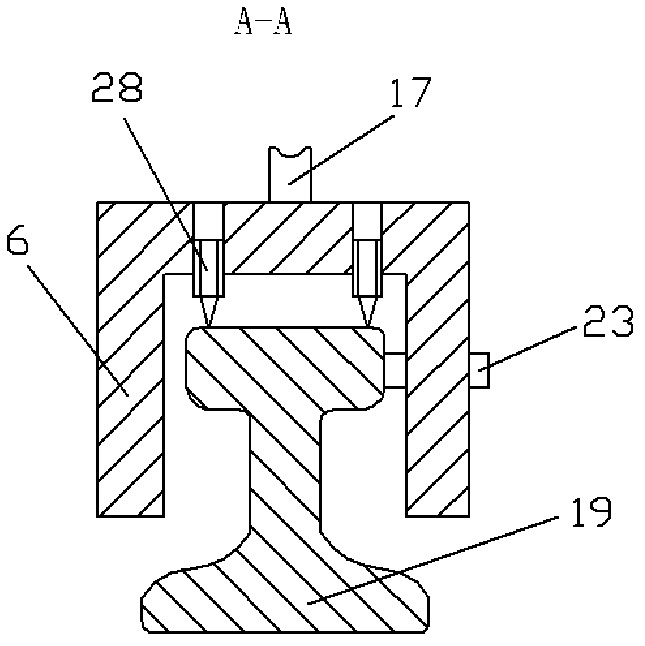

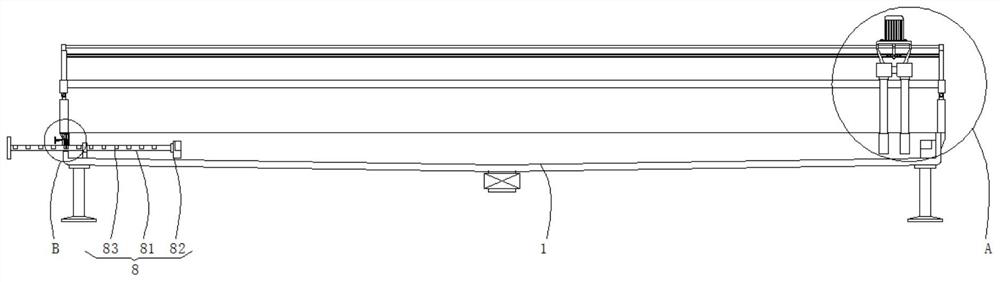

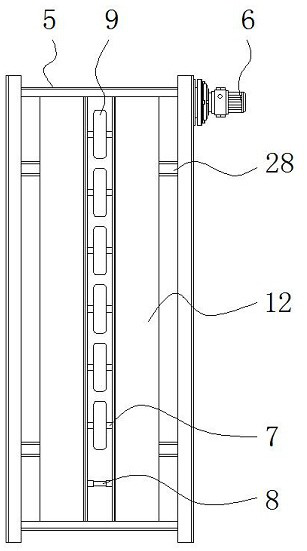

Steel rail corrugation laser measuring device

The invention relates to a steel rail corrugation laser measuring device. The steel rail corrugation laser measuring device has a structure that: both ends of the device are provided with a bracket which can be arranged on a steel rail respectively; both sides of the top of each bracket are fixedly provided with guide rails; a sliding block is sleeved on the guide rails; the laser head of a laser displacement sensor is fixed to the sliding block; the serial port and the universal serial bus (USB) interface of the laser displacement sensor are connected with the serial port and the USB interface of a computer respectively; the bracket on one end is fixedly provided with a motor; the shaft of the motor is connected with a fixed pulley 1; the bracket on the other end is provided with a fixed pulley 2; one end of a steel wire is connected with the sliding block, and the other end of the steel wire rounds the fixed pulley 1 and the fixed pulley 2 and then is connected with the sliding block; the shaft end of the motor is connected with an incremental photoelectric encoder; and the signal output end of the incremental photoelectric encoder is connected with the control signal input end of the laser displacement sensor. The measuring device can conveniently measure the condition of corrugation on the surface of the steel rail in the site and has the advantages of high automation degree, convenience for operation, high measurement accuracy and high reproducibility of test data.

Owner:SOUTHWEST JIAOTONG UNIV

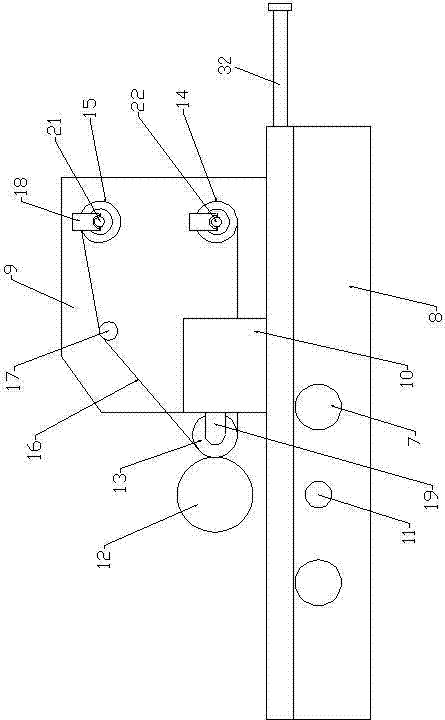

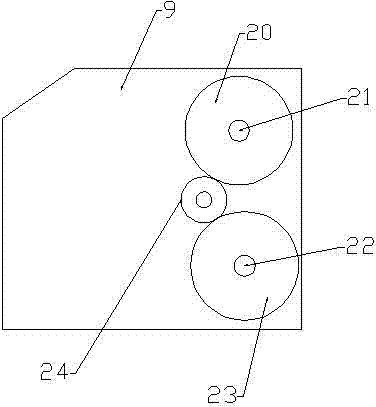

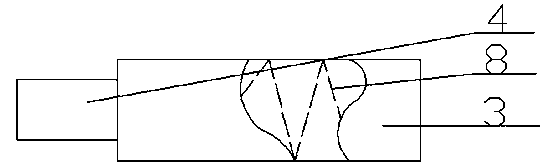

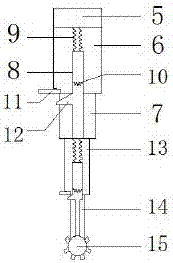

Method and device for measuring pneumatic thrust indirectly

InactiveCN101806261AEasy to operateDoes not affect incoming flowRocket engine plantsMeasurement deviceJet flow

The invention discloses a method and a device for measuring pneumatic thrust indirectly, and the pneumatic thrust measuring device mainly comprises a dynamic pressure probe, a probe supporting part, a movable platform, a data acquisition system and a data processing and analysis system. The method is as follows: the dynamic pressure probe is fixed on the movable platform by the probe supporting part, and the dynamic pressure probe is regulated to enable the axis of the dynamic pressure probe and that of a rocket engine to be parallel and to be at the same height. When the movable platform moves at a uniform speed along the direction perpendicular to the axis of the engine to enable the dynamic pressure probe to sweep over a hypersonic jet flow which is ejected from an engine nozzle, a differential pressure transducer which is arranged at the back end of the dynamic pressure probe responds to the dynamic pressure signals of the hypersonic jet flow in real time, the data acquisition system acquires the dynamic pressure and the distribution signals in real time, and the data processing and analysis system obtains the pneumatic thrust by carrying out surface integral processing on the measured radial distribution signals of the dynamic pressure.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

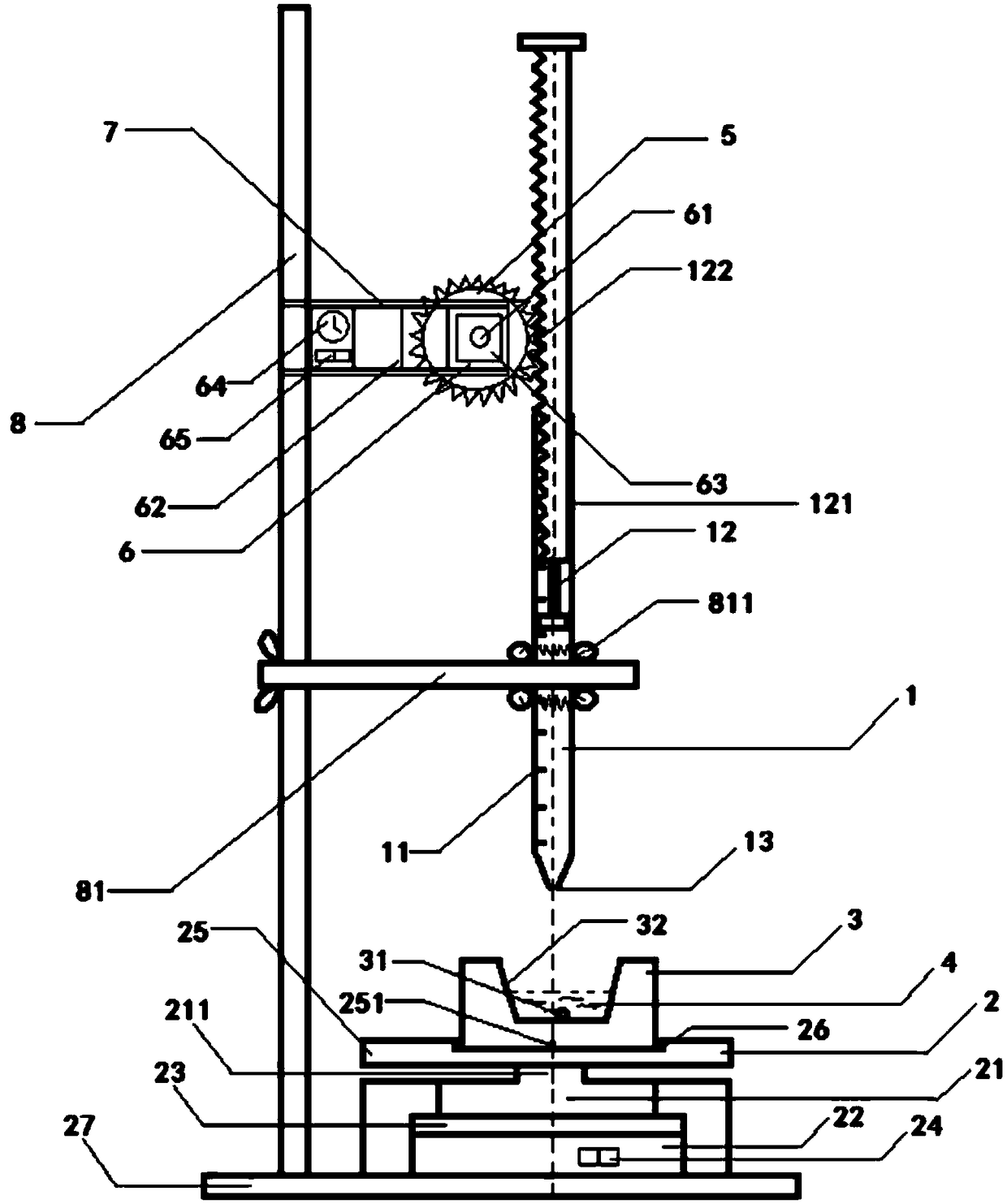

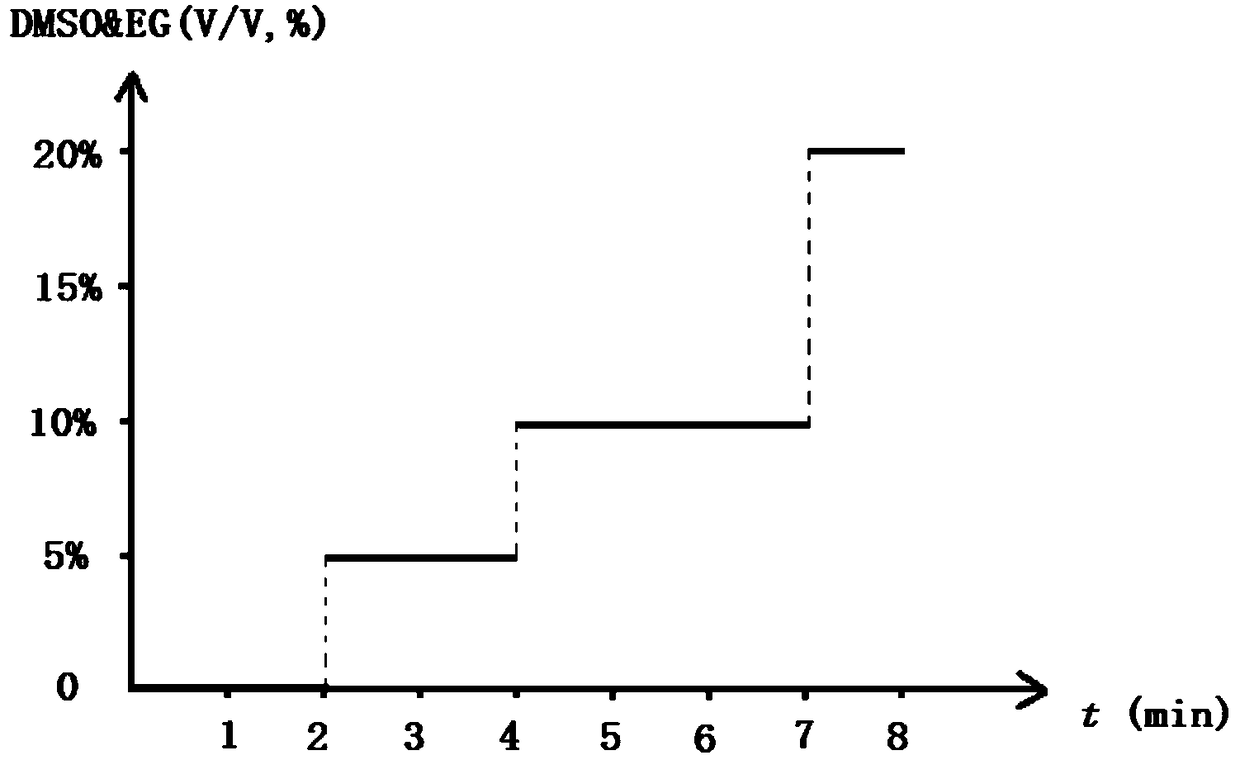

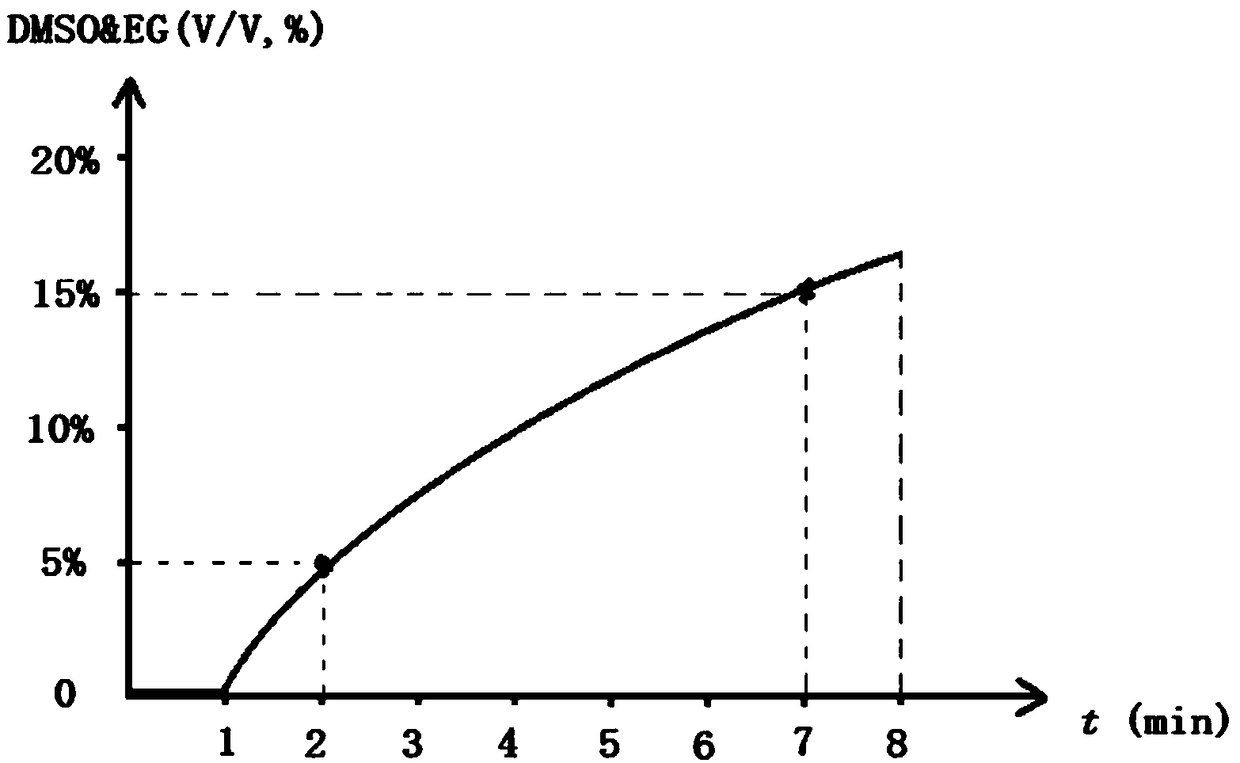

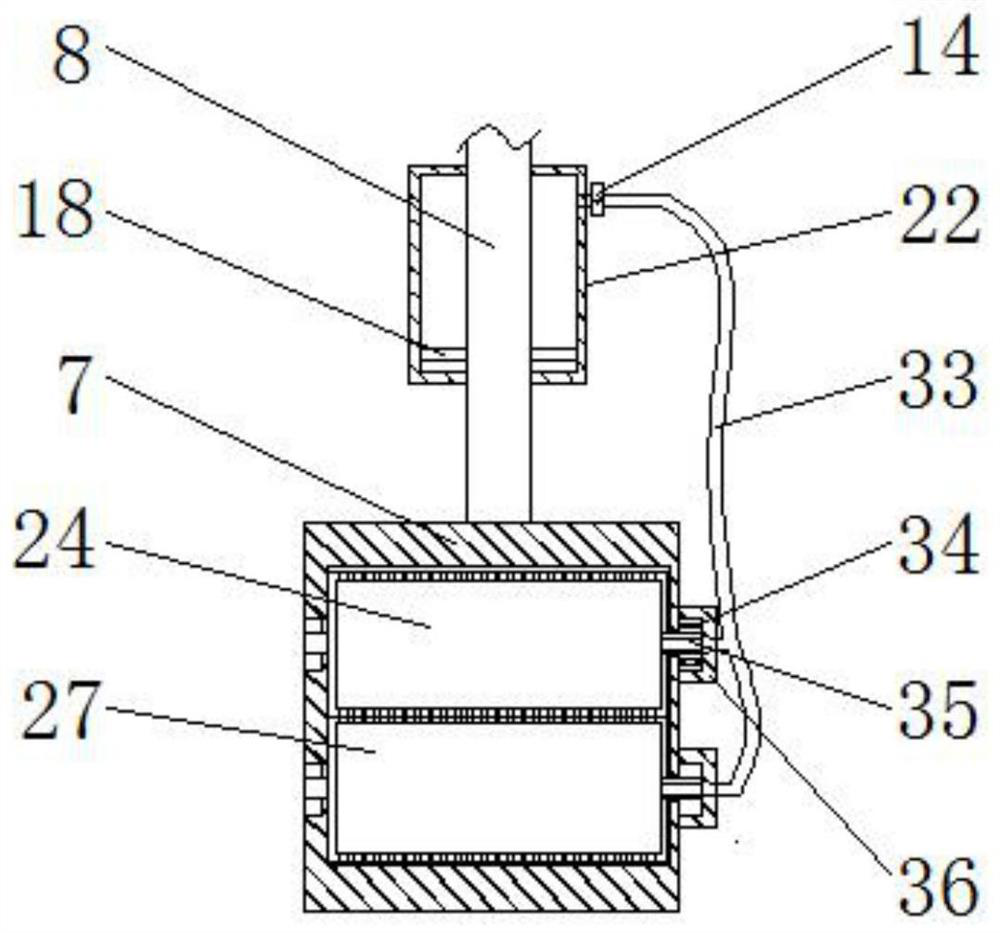

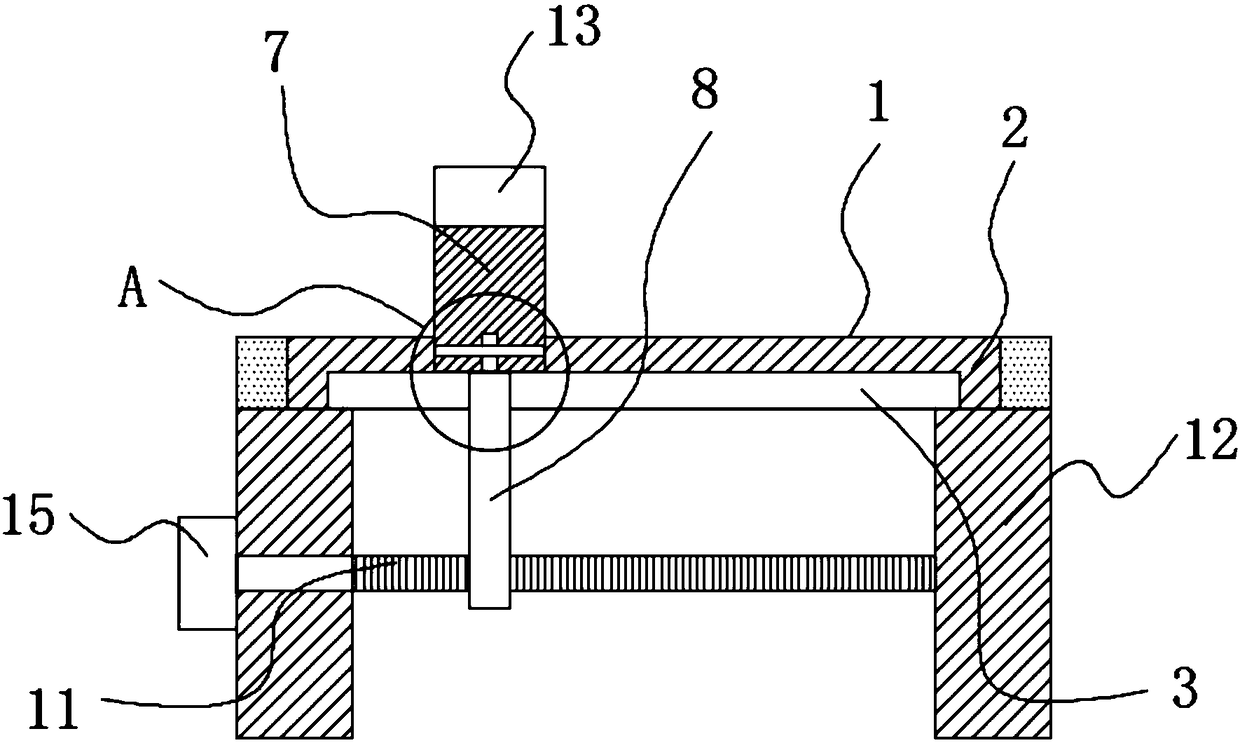

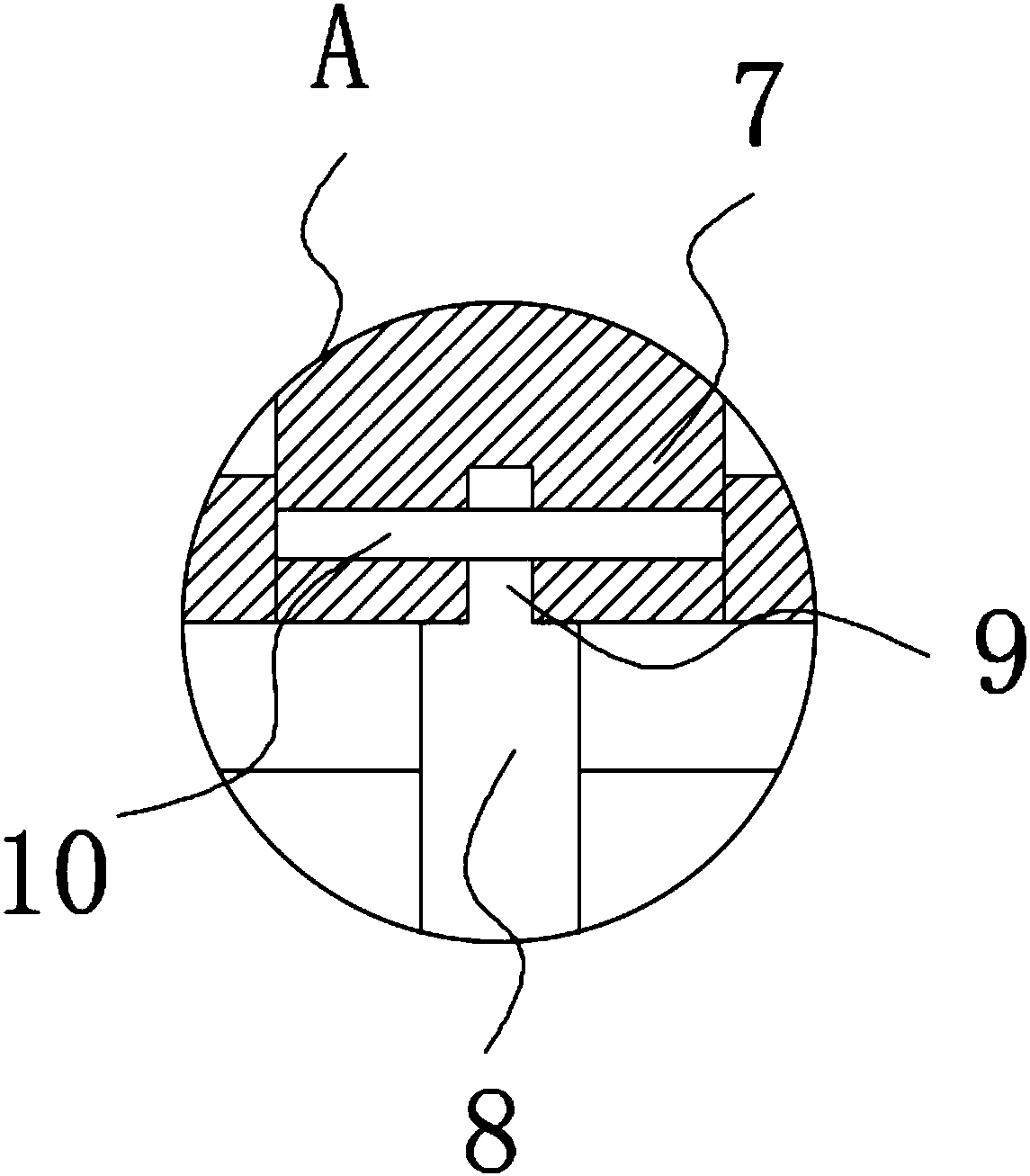

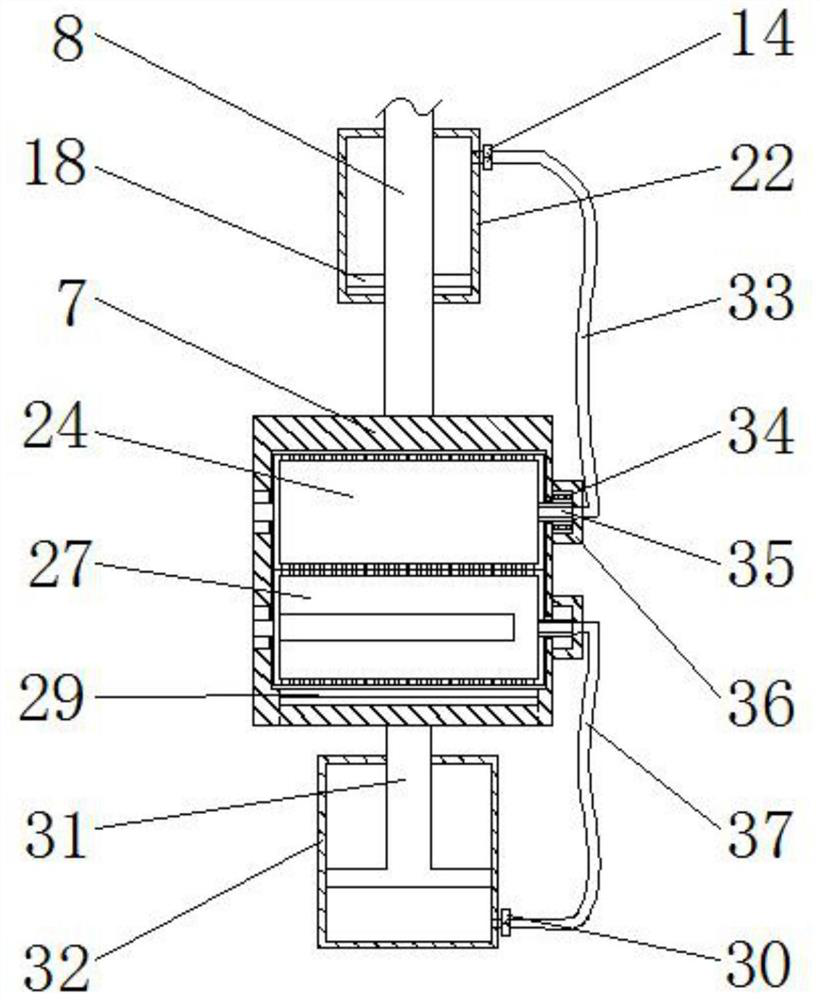

Human oocyte and embryo vitrification freezing and thawing device and application method thereof

ActiveCN109497040AReduce the effects of stressful stimuliReduce work intensityDead animal preservationEmbryonic cellsVitrificationEngineering

The invention provides a human oocyte and embryo vitrification freezing and thawing device and an application method thereof. The lower surface of a rotary vibration tray is fixedly connected with anoutput shaft of a first motor; a liquid outlet pipe penetrates through a through hole in a sliding manner and is fixed on an extending clamp through a clamping assembly; a liquid outlet is formed at the bottom end of the liquid outlet pipe; the liquid outlet is located above an opening of the open groove; the top end of the liquid outlet pipe is internally connected with a driving part which can move vertically along the liquid outlet pipe and is used for sucking or injecting the liquid. According to the human oocyte and embryo vitrification freezing and thawing device provided by the invention, oocytes / embryos are located in an environment with continuous gradient changes of concentration of a freezing solution or a thawing solution in a process of vitrification freezing and thawing in vitro due to a common effect of the liquid outlet pipe and the rotary vibration tray, and operation of repeatedly sucking, blowing, transferring, stirring the embryos and the like of experimenters is avoided; influences of an in vitro environment and man-made operation on irritable stimulation of the embryos are effectively reduced; long-term development of the embryos and the safety of descendantsare facilitated; meanwhile, the working strength of the experimenters is also alleviated.

Owner:ZHEJIANG UNIV

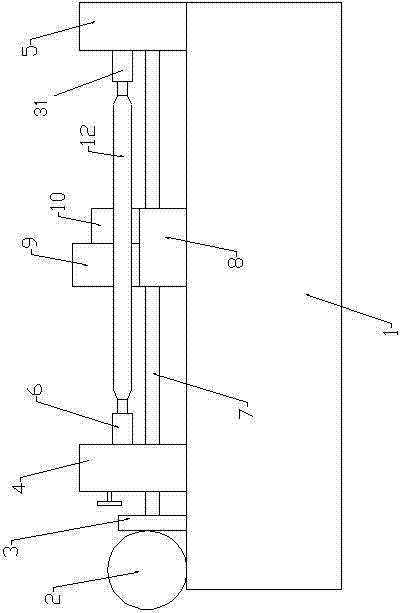

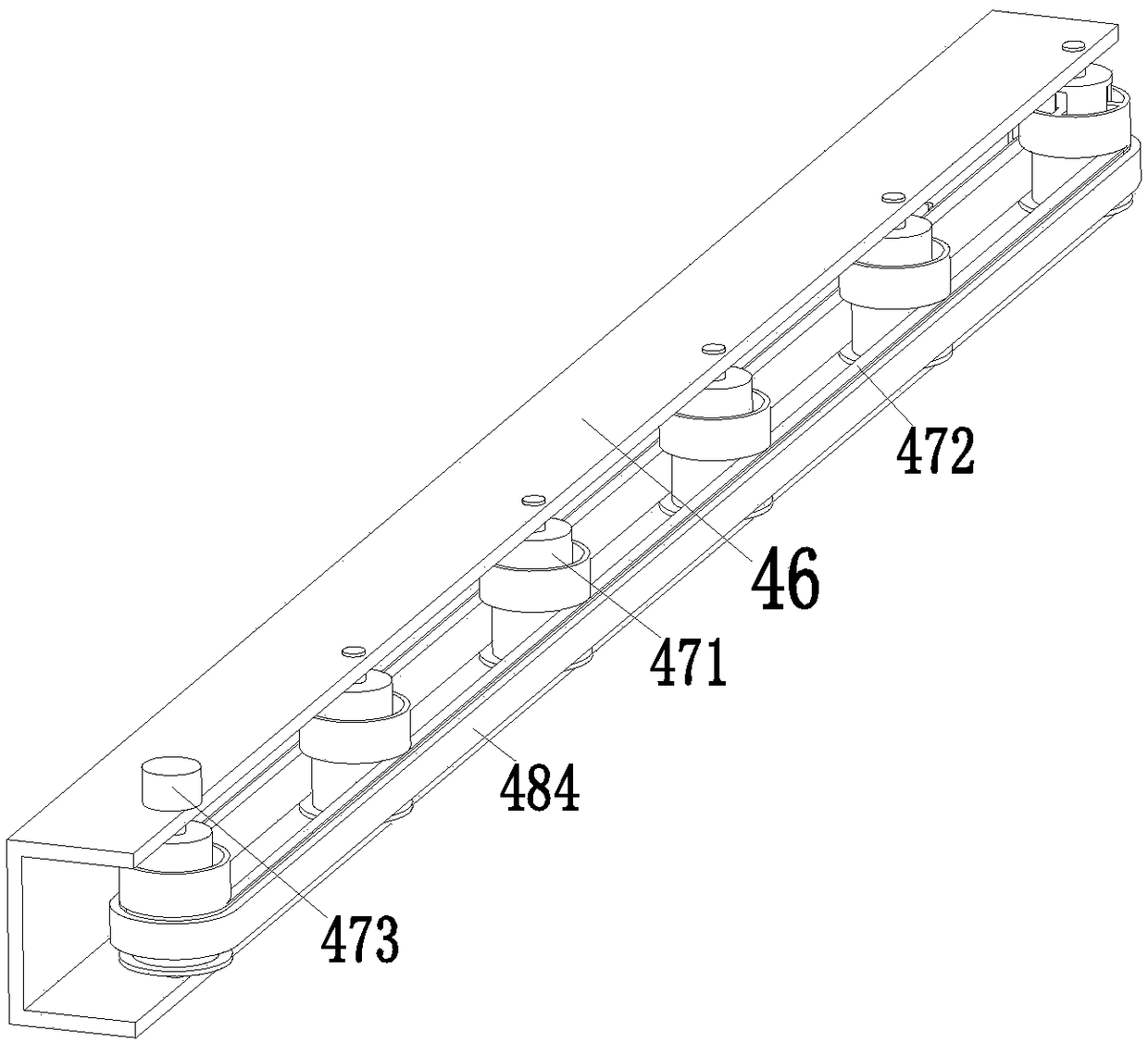

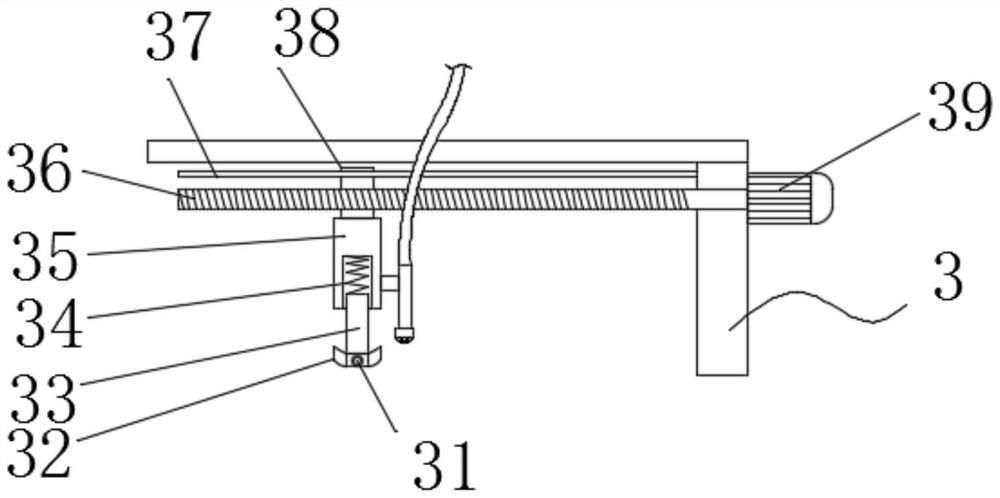

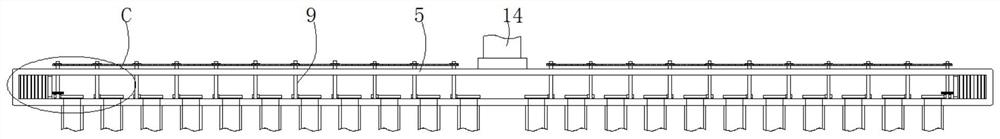

Strip-shaped polishing machine

The invention relates to a strip-shaped polishing machine. A polishing machine base is arranged on the outer portion of a guiding rod and the outer portion of a stroke pushing screw rod in a sleeved mode. A polishing transmission shell body and a polishing output shell body are arranged above the polishing machine base. A polishing strip driven shaft and a polishing strip driving shaft with a motor are arranged on the polishing transmission shell body. A polishing wheel is arranged on the polishing output shell body. A first polishing strip rolling shaft is arranged on the polishing strip driving shaft. A second polishing strip rolling shaft is arranged on the polishing strip driven shaft. The polishing wheel, the first polishing strip rolling shaft and the second polishing strip rolling shaft are connected with polishing abrasive belts. The axis of the polishing wheel and the axis of a rolling shaft rotating driving shaft are parallel. Polishing quality is guaranteed, constant-speed taking up of the polishing abrasive belts during operation is achieved, the polishing performance of the contacting face of a rolling shaft is great, polishing accuracy is greatly improved, polishing speed and efficiency are improved, secondary using of the rolling shaft can be guaranteed each time polishing is carried out, expenditure is saved for an enterprise, benefit is brought, energy is saved, and environment is protected.

Owner:HENAN XUYUAN STAINLESS STEEL

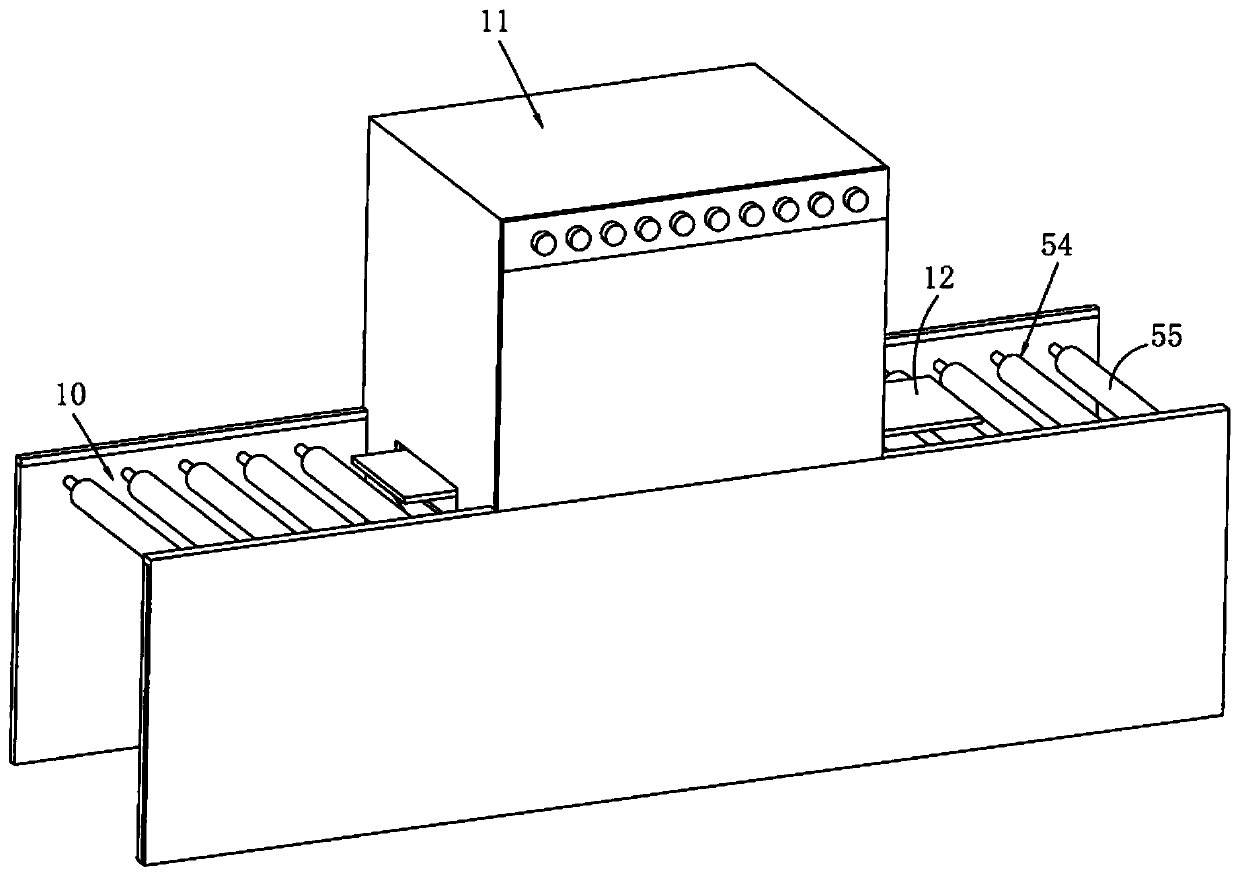

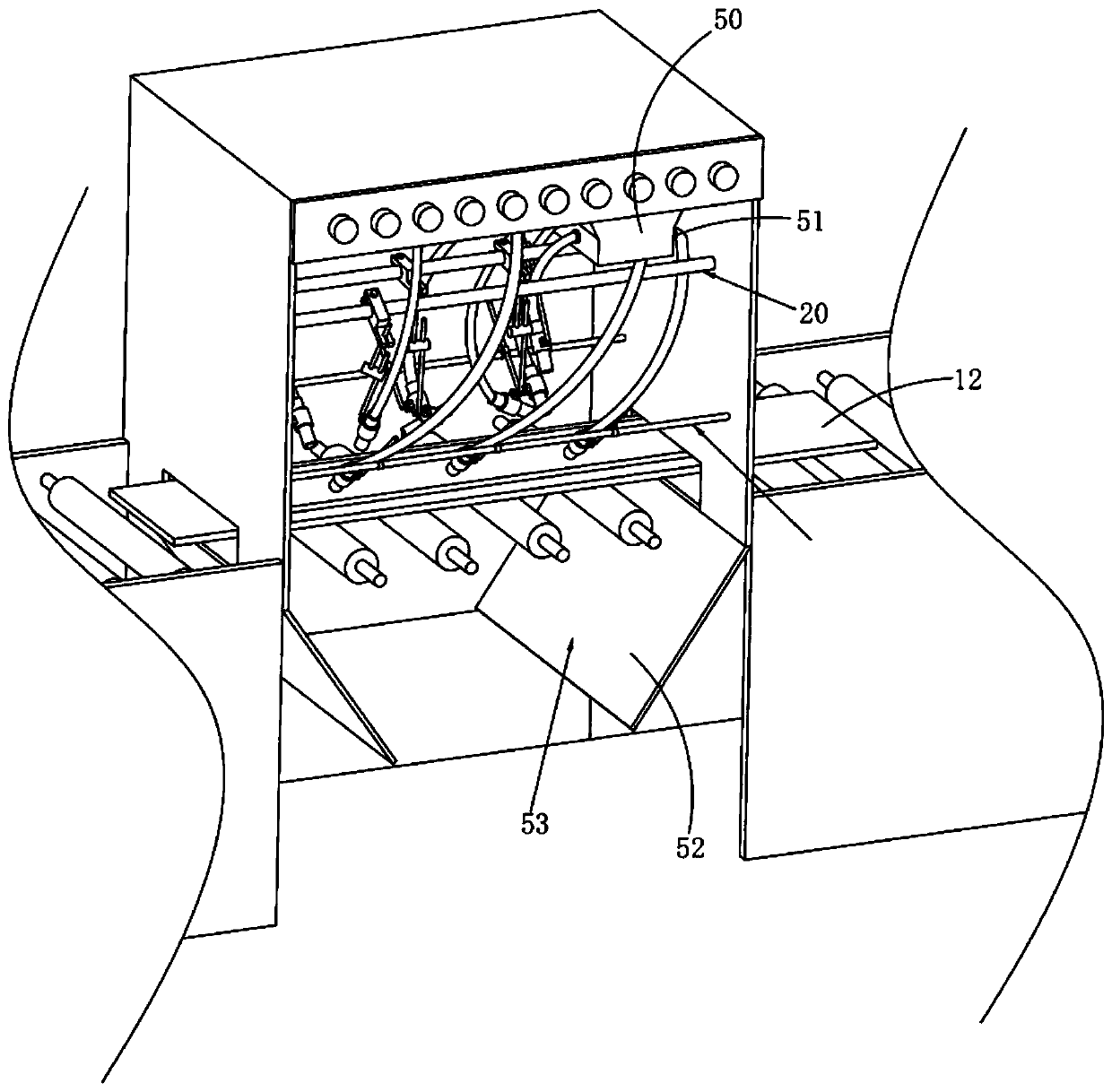

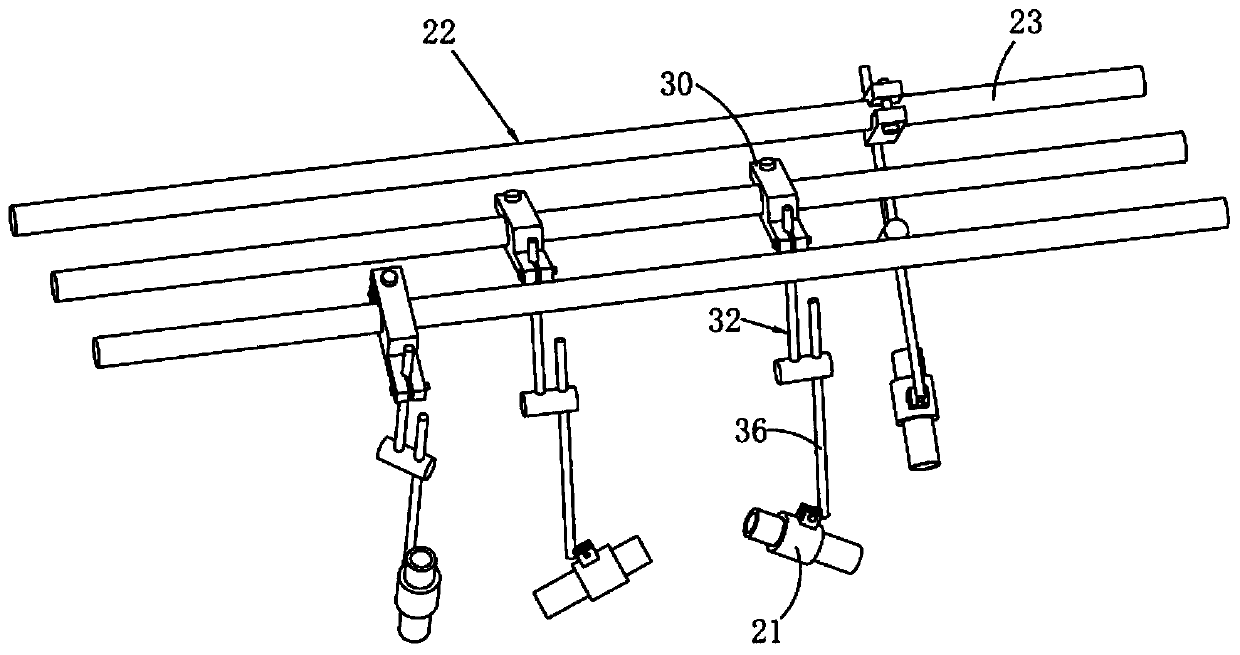

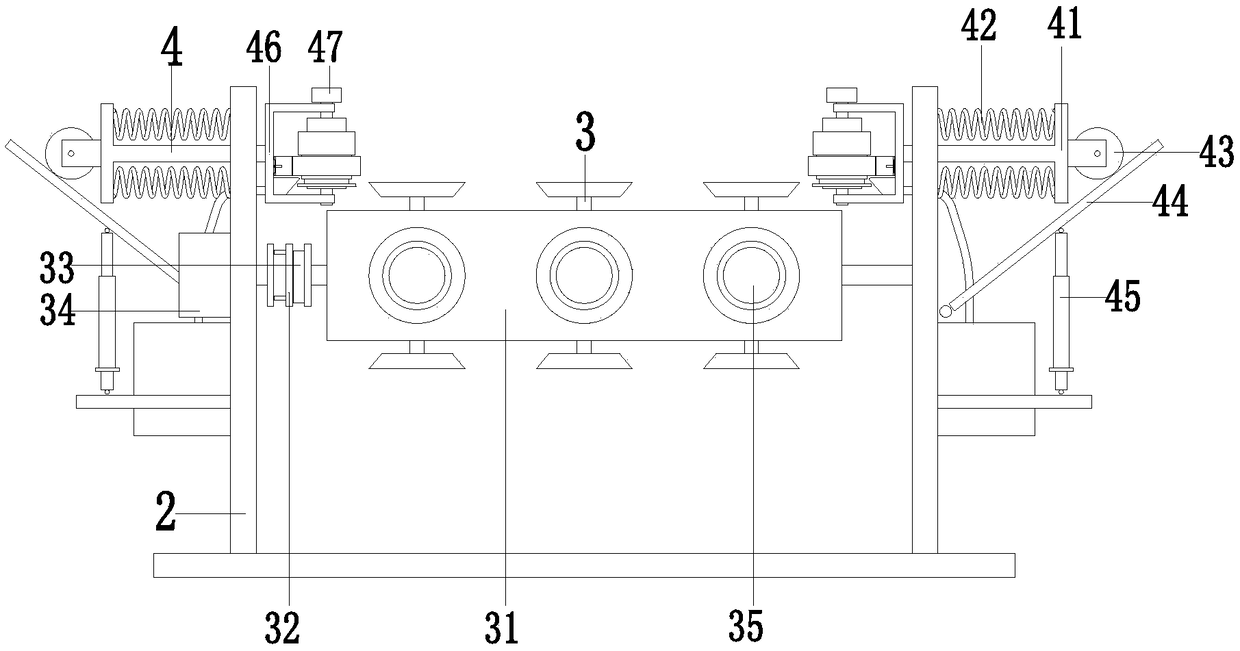

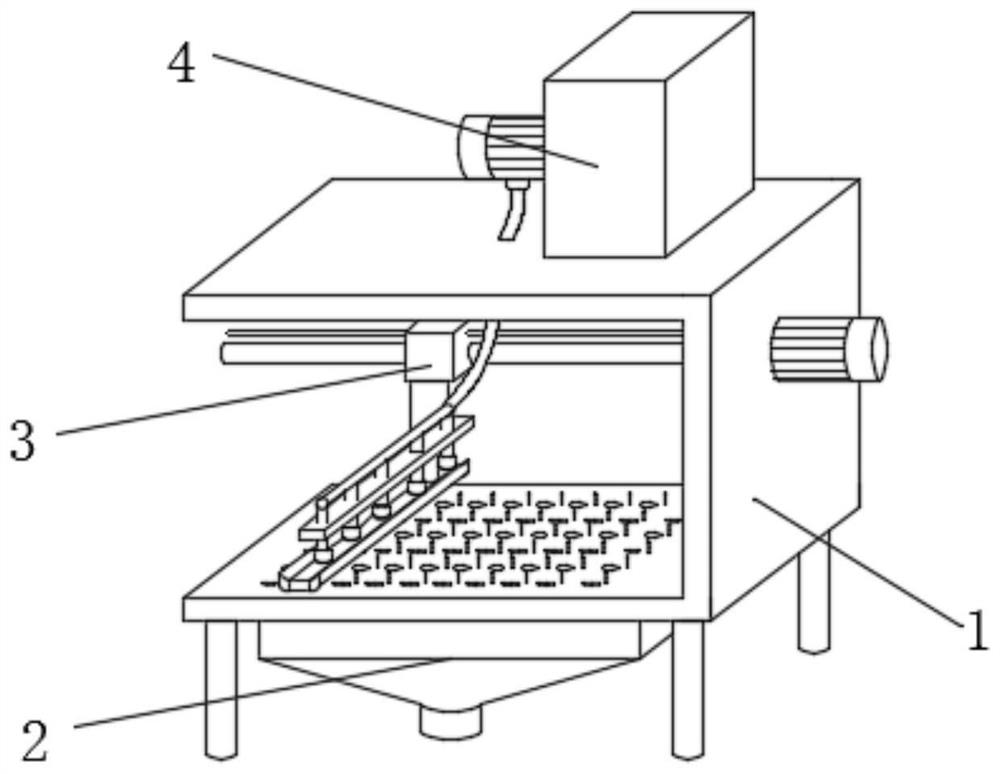

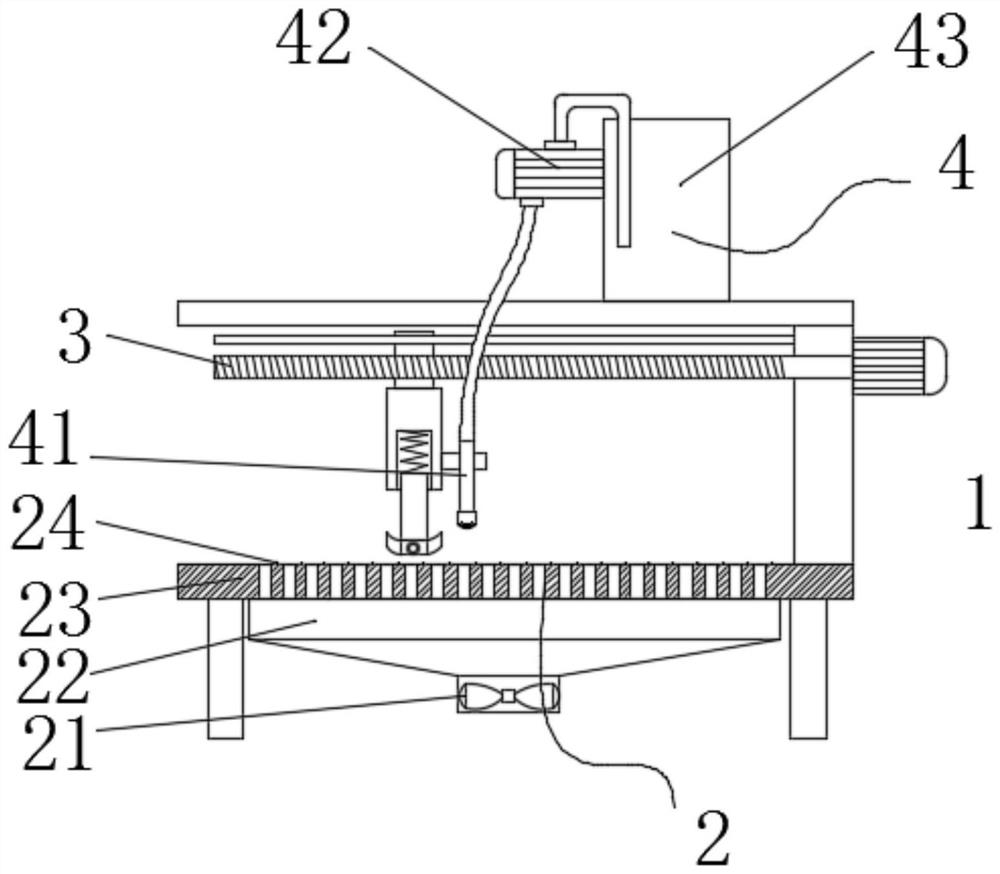

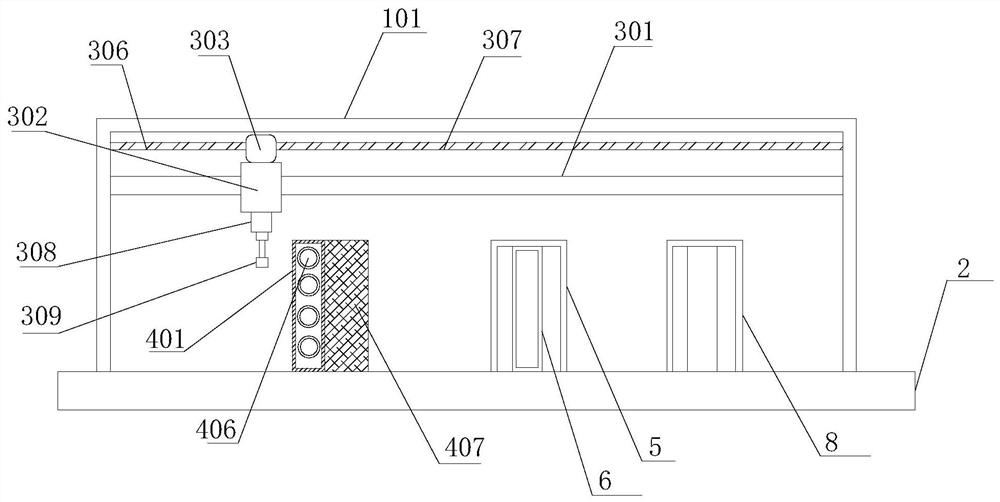

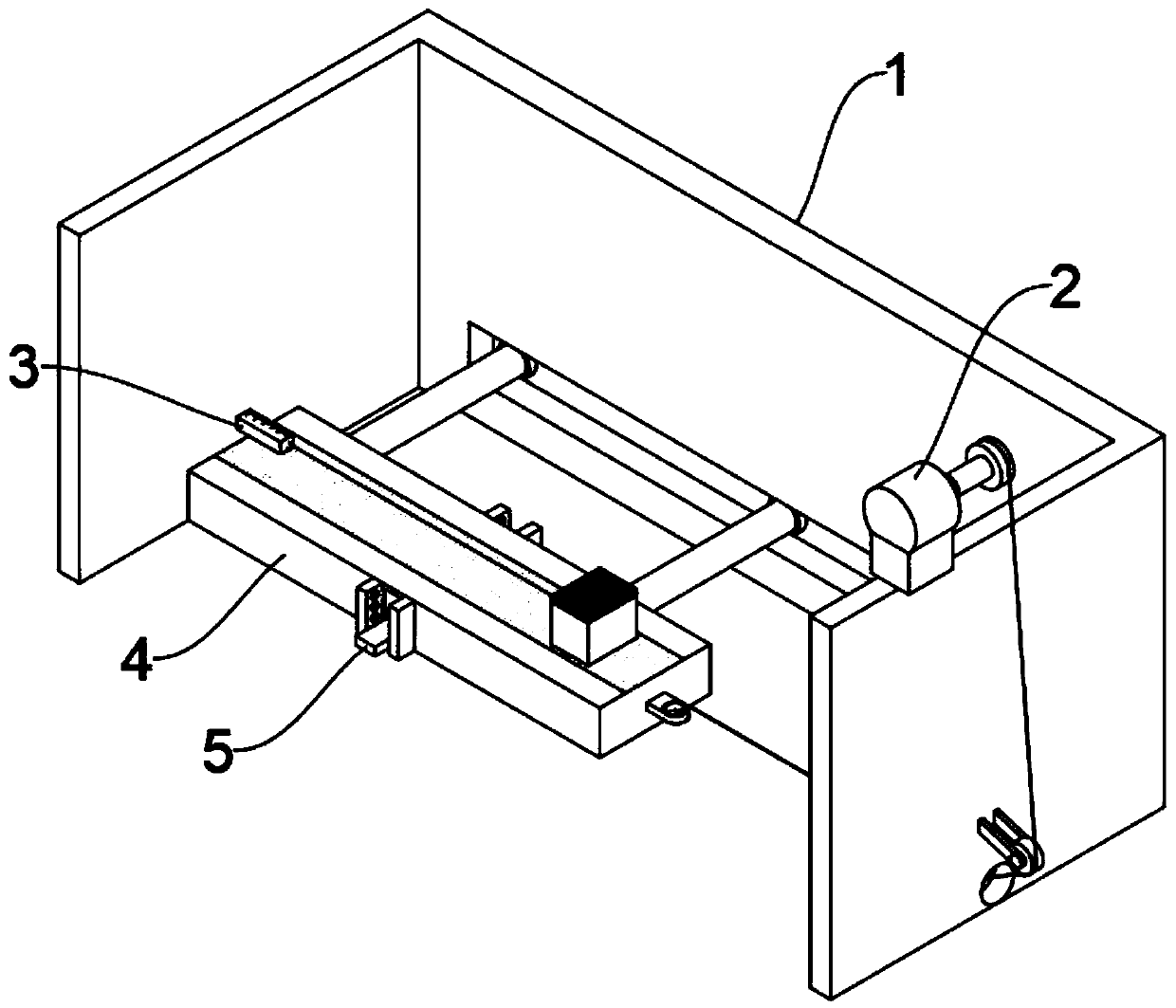

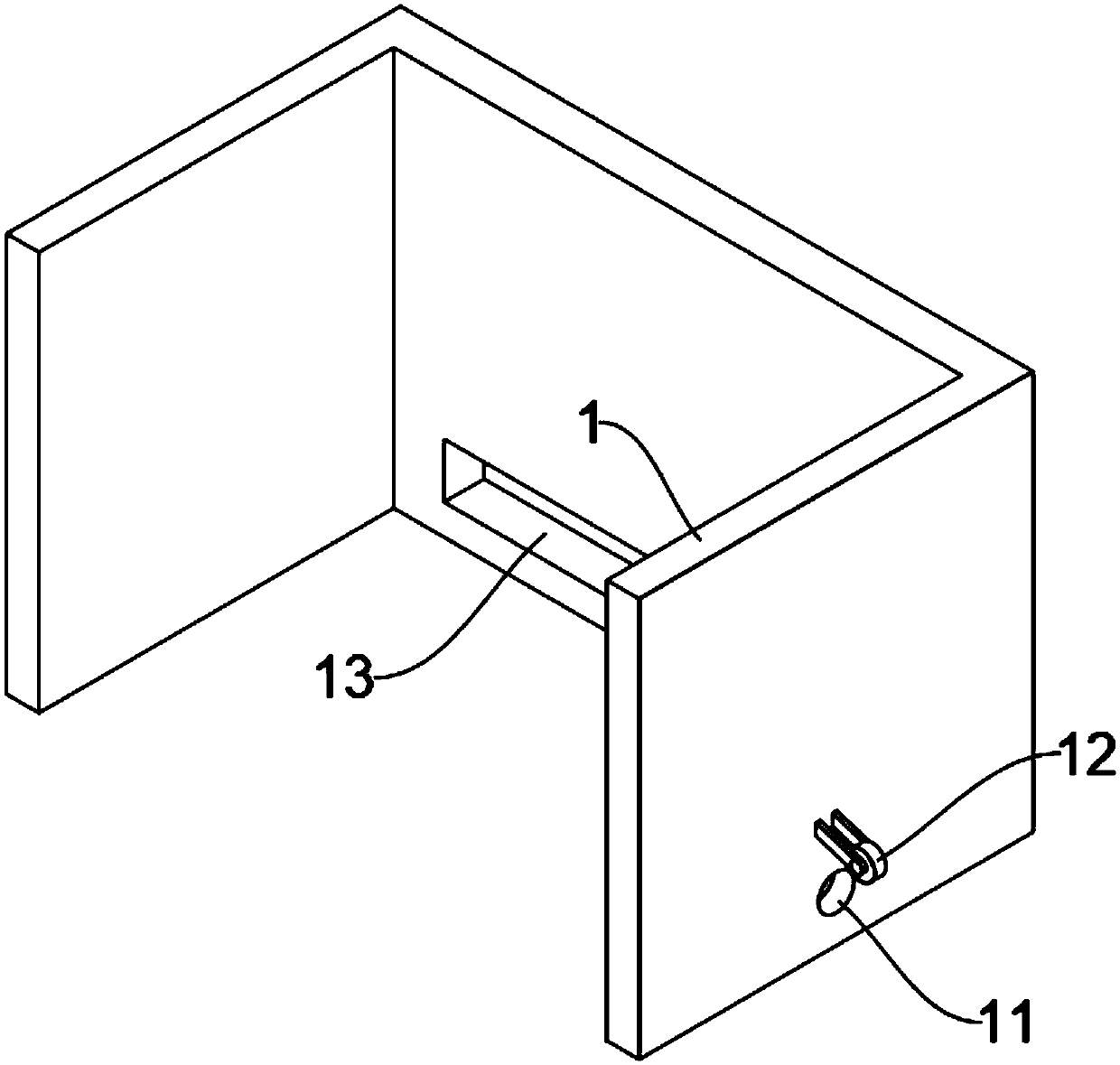

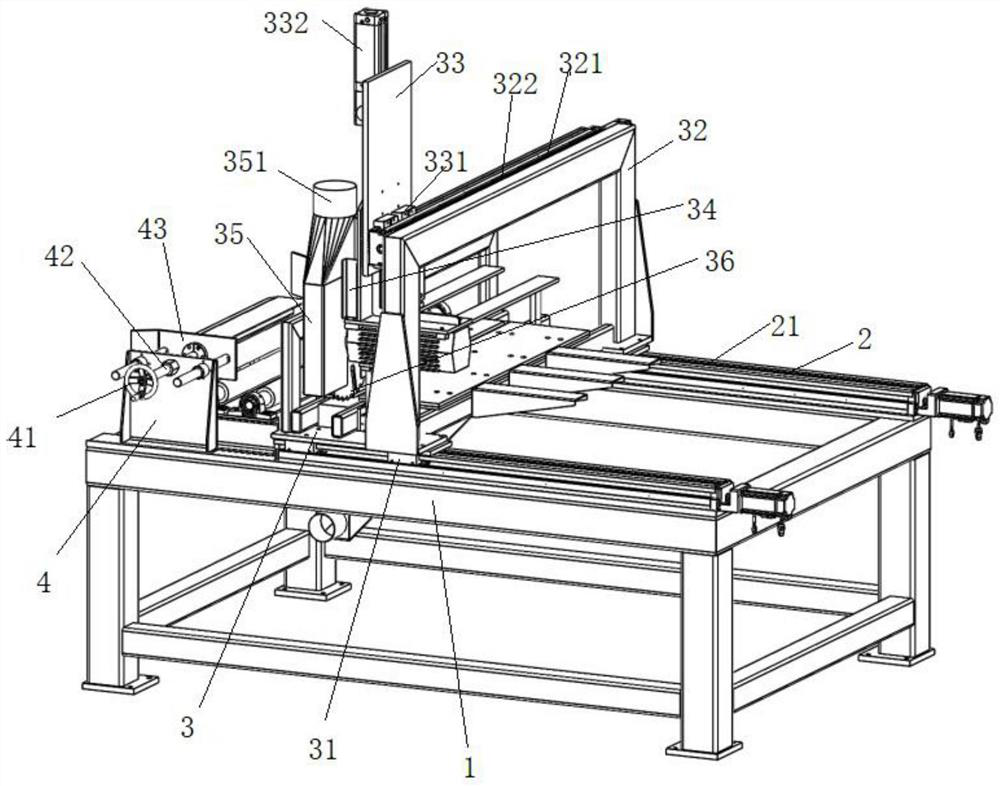

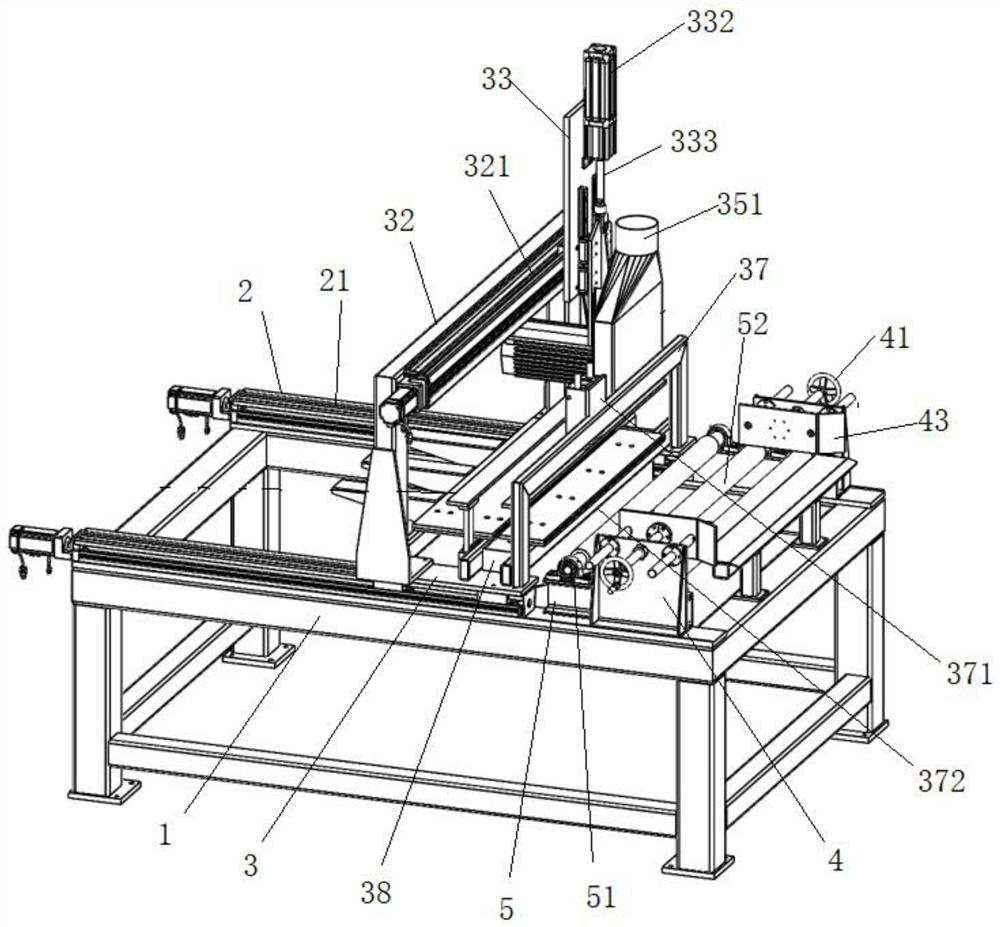

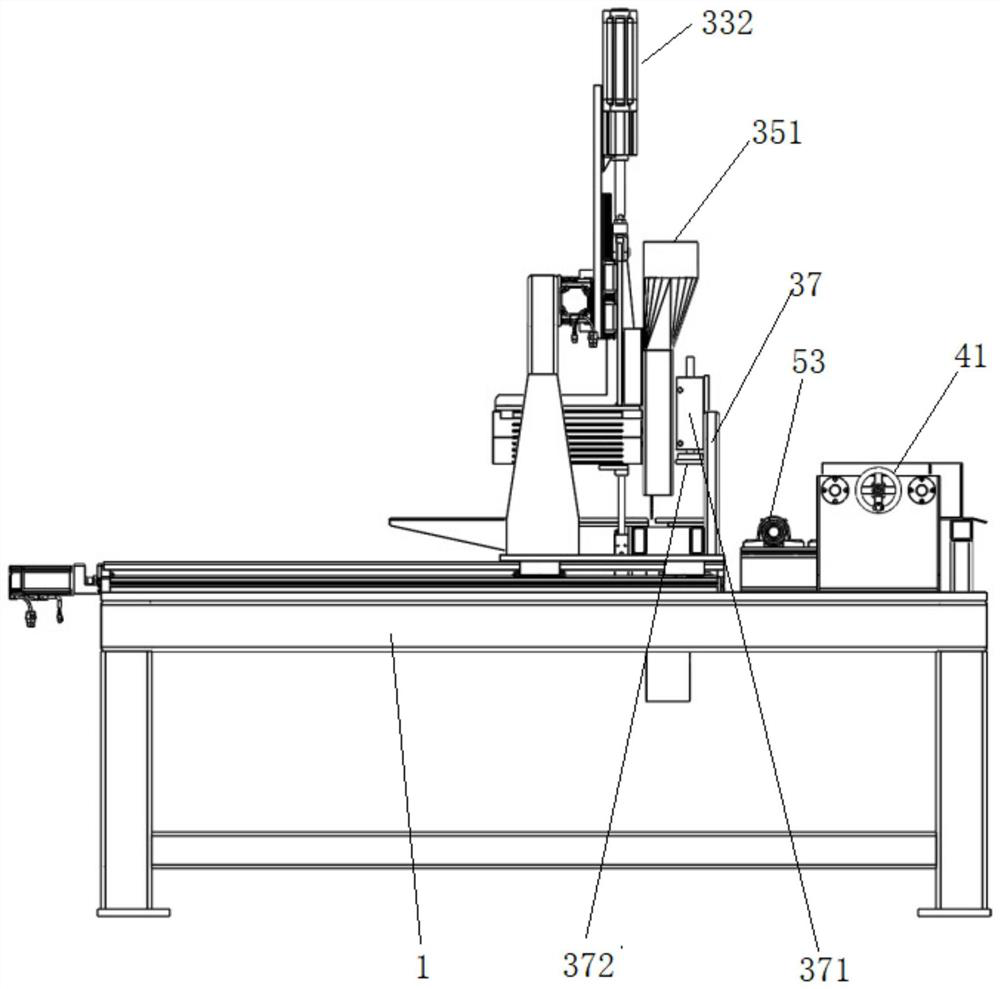

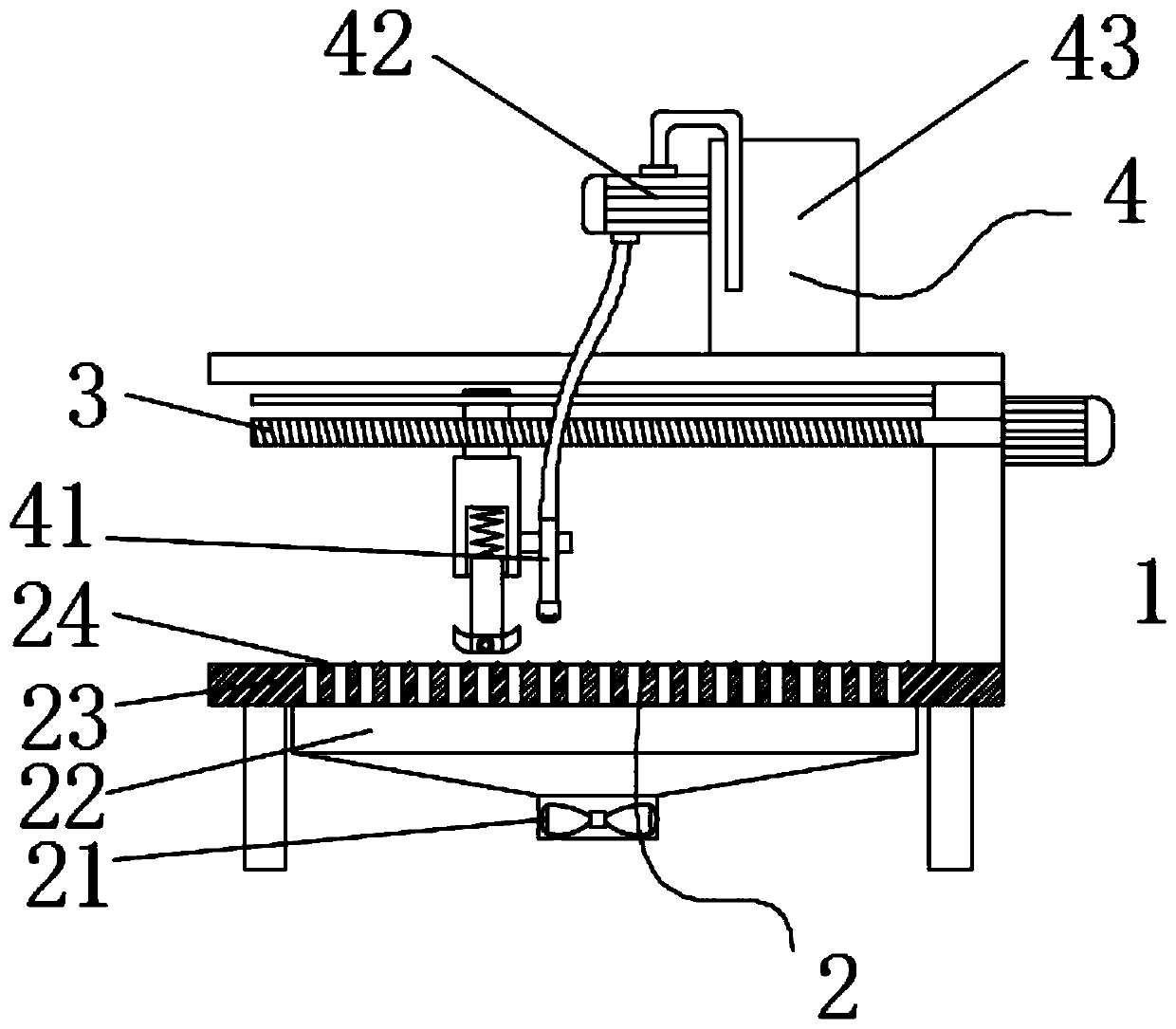

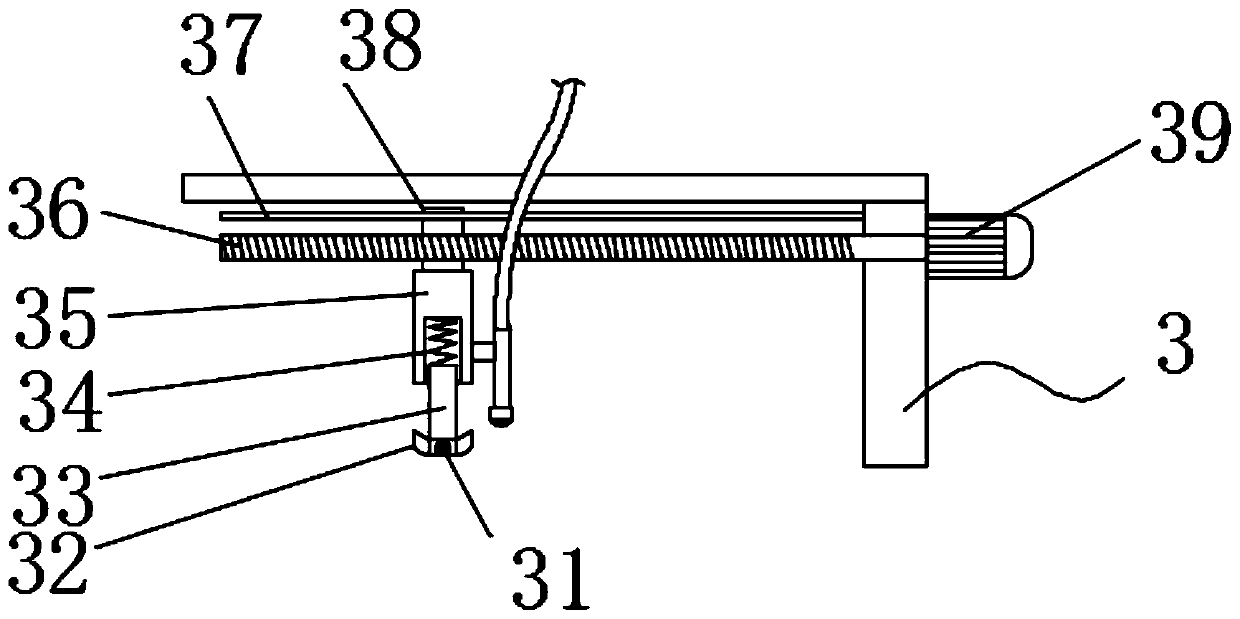

Automatic sand blasting device and method for planar target material

PendingCN111451942AImprove blasting efficiencyEliminate job hazardsAbrasive machine appurtenancesAbrasive blasting machinesGeotechnical engineeringStructural engineering

The invention discloses an automatic sand blasting device and method for a planar target material. The sand blasting device comprises a middle sand blasting unit and a side sand blasting unit, whereinthe side sand blasting unit is provided with a side sand blasting gun; a muzzle of the side sand blasting gun faces the side part of the target material; the middle sand blasting unit is provided with a middle sand blasting gun; a muzzle of the middle sand blasting gun faces the plate surface of the target material; at least the middle sand blasting gun is a swinging spray gun; and the swinging direction of the middle sand blasting gun is perpendicular to the moving advancing direction of a conveying device. The invention discloses the automatic sand blasting method for the planar target material. According to the automatic sand blasting device and the automatic sand blasting method, the sand blasting efficiency can be effectively improved, and the sand blasting yield is increased.

Owner:东莞市欧莱溅射靶材有限公司 +1

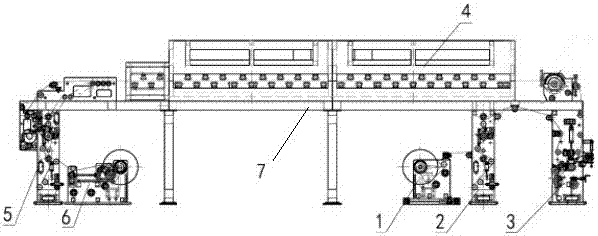

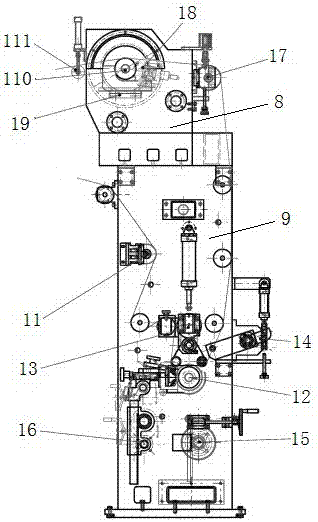

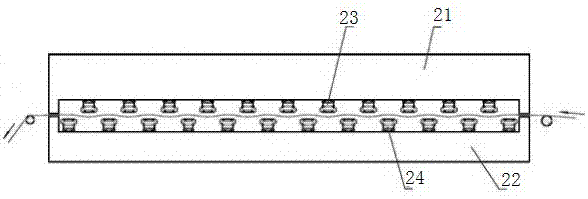

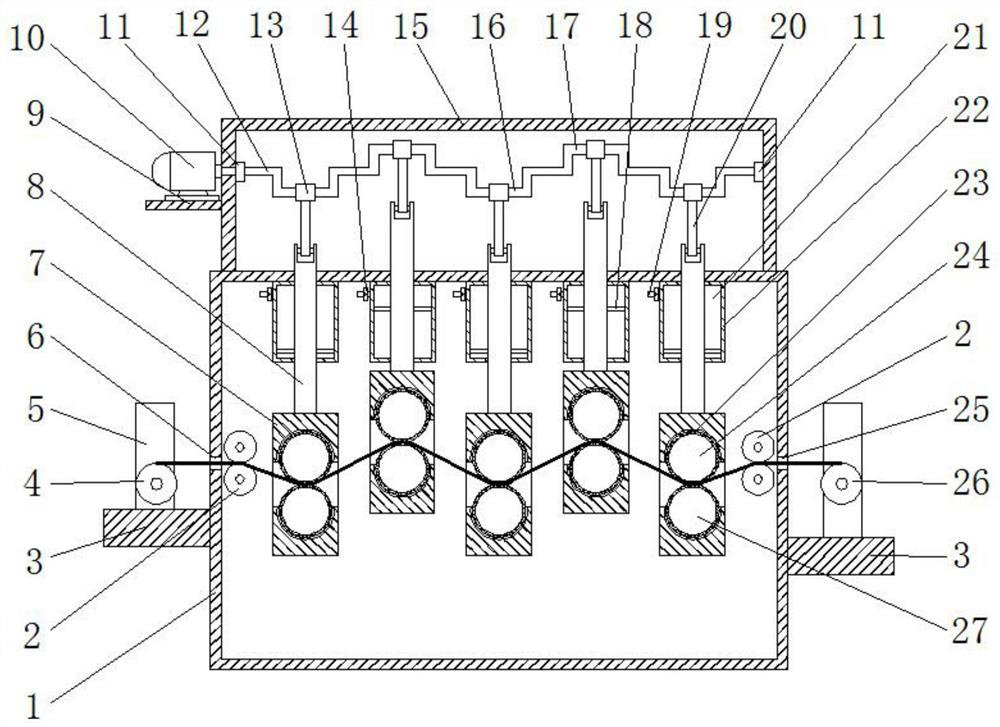

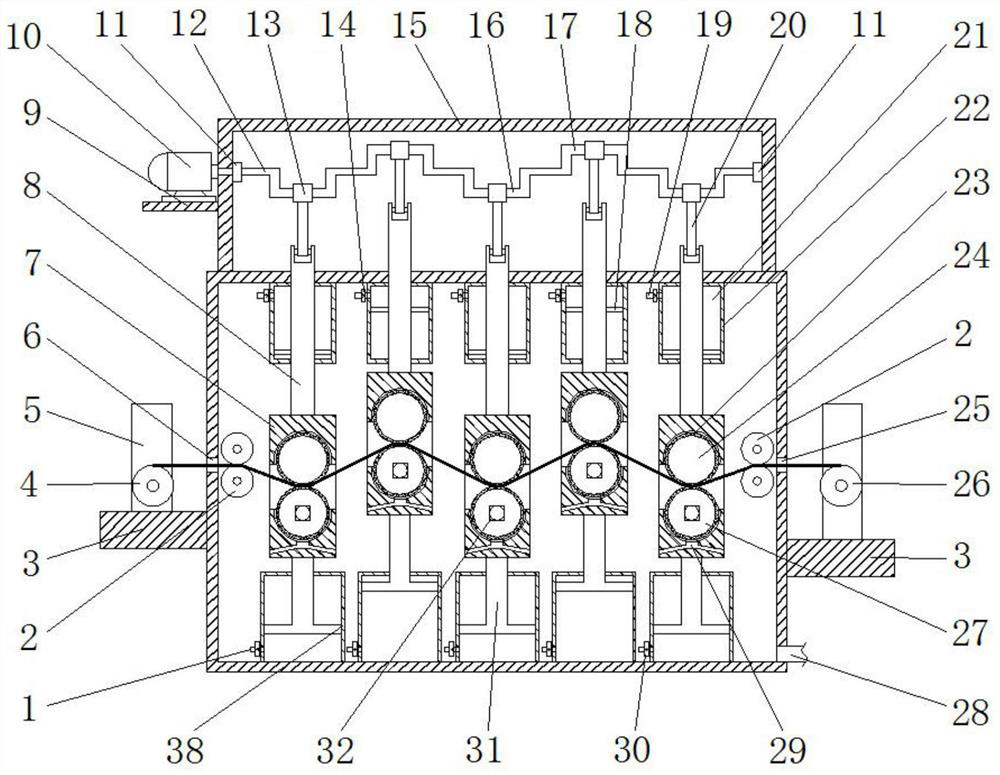

Aluminum foil double-face fast coating device and method

InactiveCN107159524ASave spaceFast coatingPretreated surfacesCoatingsEngineeringStructural engineering

The invention provides an aluminum foil double-face fast coating device. The aluminum foil double-face fast coating device comprises a first frame, an unwinding mechanism, a feeding drawing mechanism, a coating mechanism, a drying oven, a discharging drawing mechanism and a winding mechanism, wherein the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism are arranged on the first frame. The coating mechanism is a double-face ladder type coating mechanism which comprises a front side coating mechanism body and a back side coating mechanism body. The drying oven is a suspension drying oven. Aluminum foil sequentially passes through the unwinding mechanism, the feeding drawing mechanism, the coating mechanism, the drying oven, the discharging drawing mechanism and the winding mechanism, and then double-face coating is completed. An aluminum foil double-face fast coating method sequentially comprises the steps of unwinding, front side coating, back side coating, double-face drying and winding. According to the aluminum foil double-face fast coating device and method, through the ladder type one-time front side and back side coating and one-time double-face drying technologies, the material conveying path is greatly shortened, fast coating is achieved, the coating speed can reach 150m / min, in addition, the double faces are dried at a time after being coated, the space of the drying oven is saved, the manufacturing cost is reduced, meanwhile, energy is saved by about 160KW / h, and the aluminum foil double-face fast coating device and method are suitable for gravure coating and reverse kiss coating.

Owner:XIAN XINDA MACHINERY

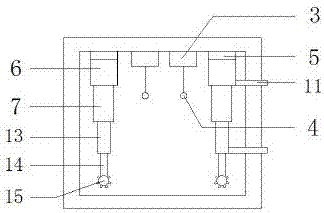

Automatic silk screen printing machine

InactiveCN103358666AMove at a constant speedGuaranteed uptimeScreen printersScreen printingEngineering

The invention discloses an automatic silk screen printing machine comprising a movable support, a connection rod and a scraper, wherein the movable support is of a gantry structure vertical to the surface of a workbench, an inclined strip is arranged above the movable support, a vertically mounted cylinder plug magnetic air cylinder is arranged below the movable support, the connection rod is a length-adjustable connection mechanism and is arranged vertical to the movable support, the pressure of the connection rod to the surface of the workbench is adjustable, and a clamping plate is arranged below the connection rod and is connected with the scraper. The automatic silk screen printing machine disclosed by the invention can be greatly suitable for printing surfaces with various heights and has adjustable force.

Owner:WUJIANG YUEYANG TEXTILE

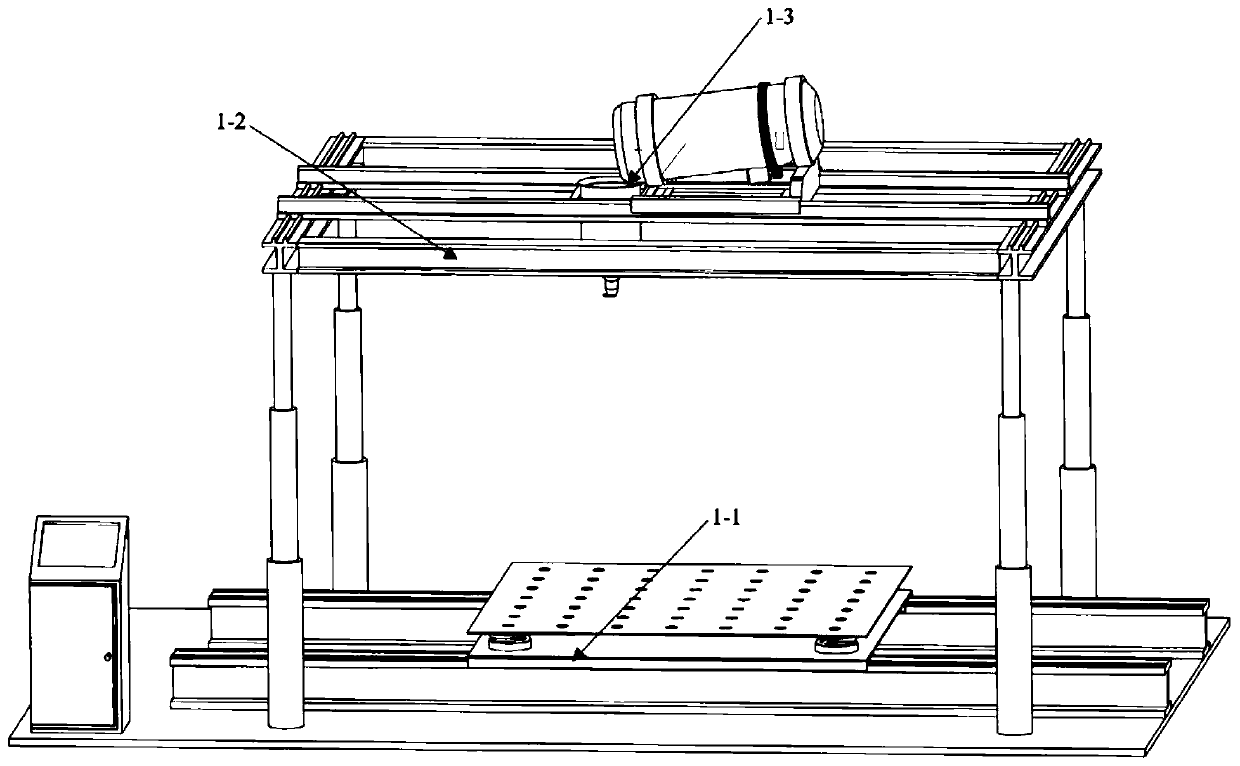

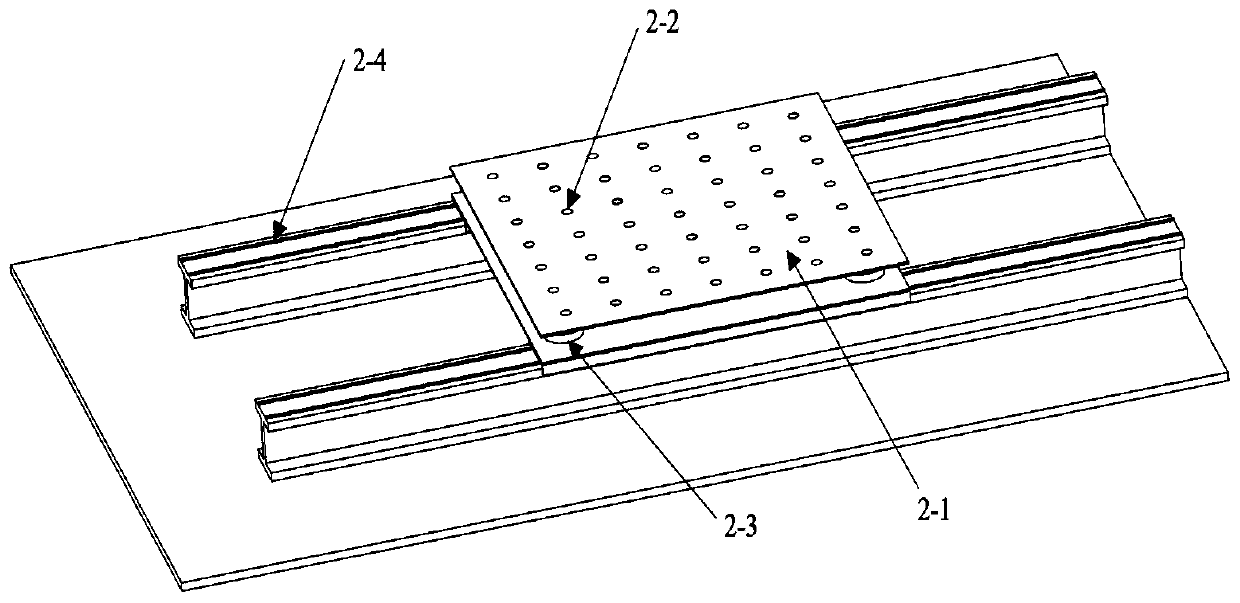

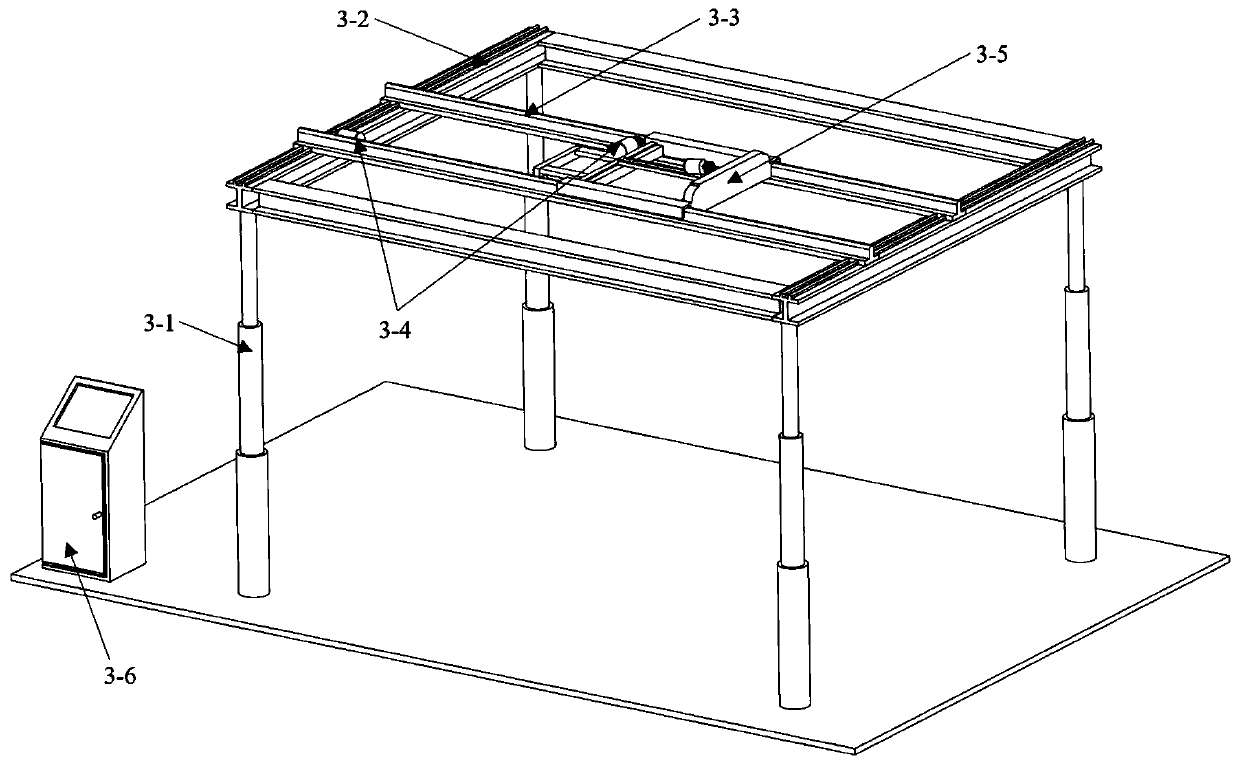

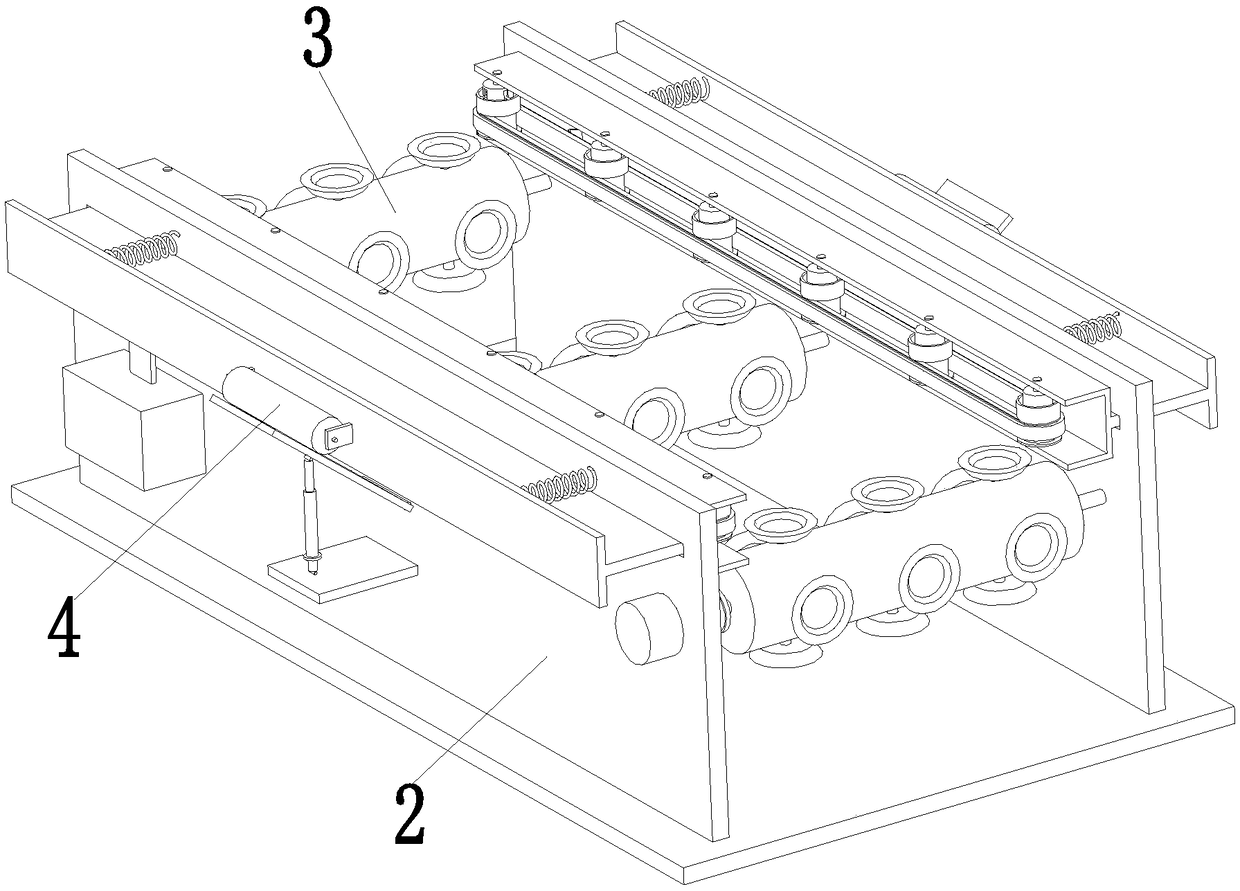

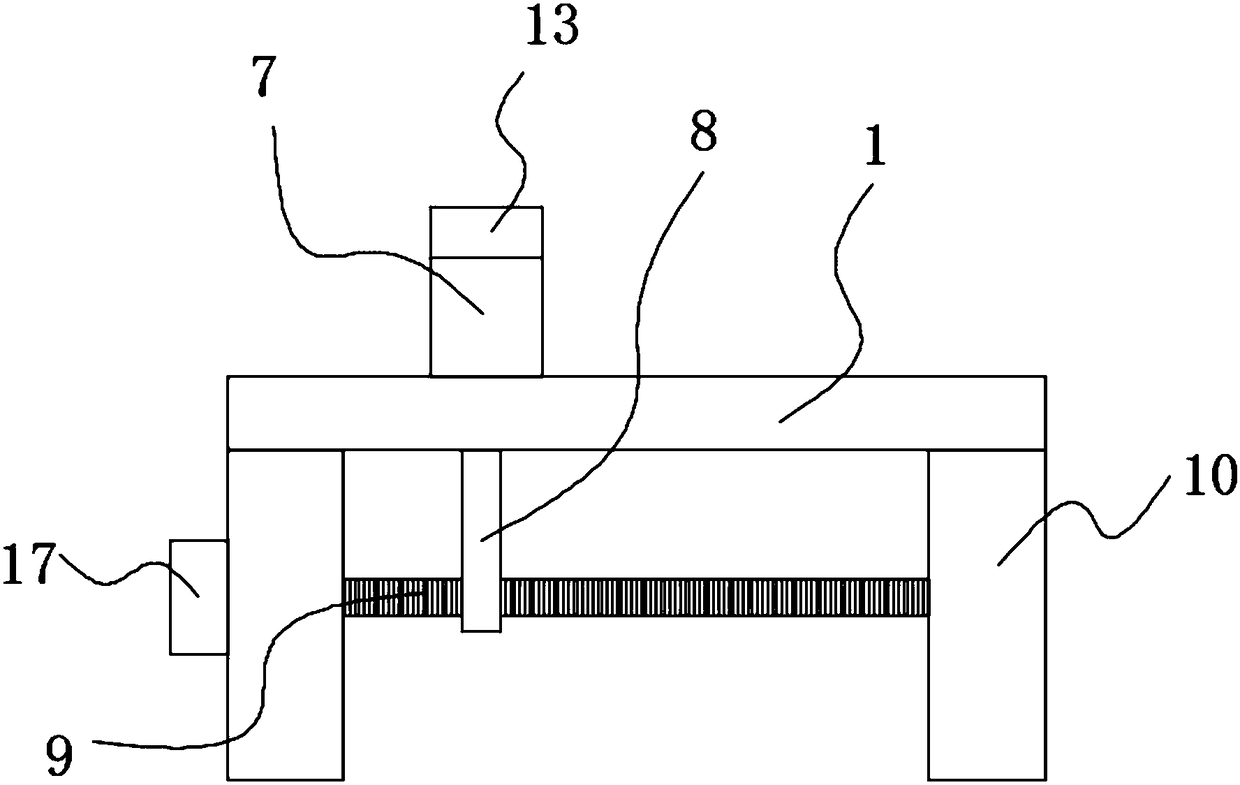

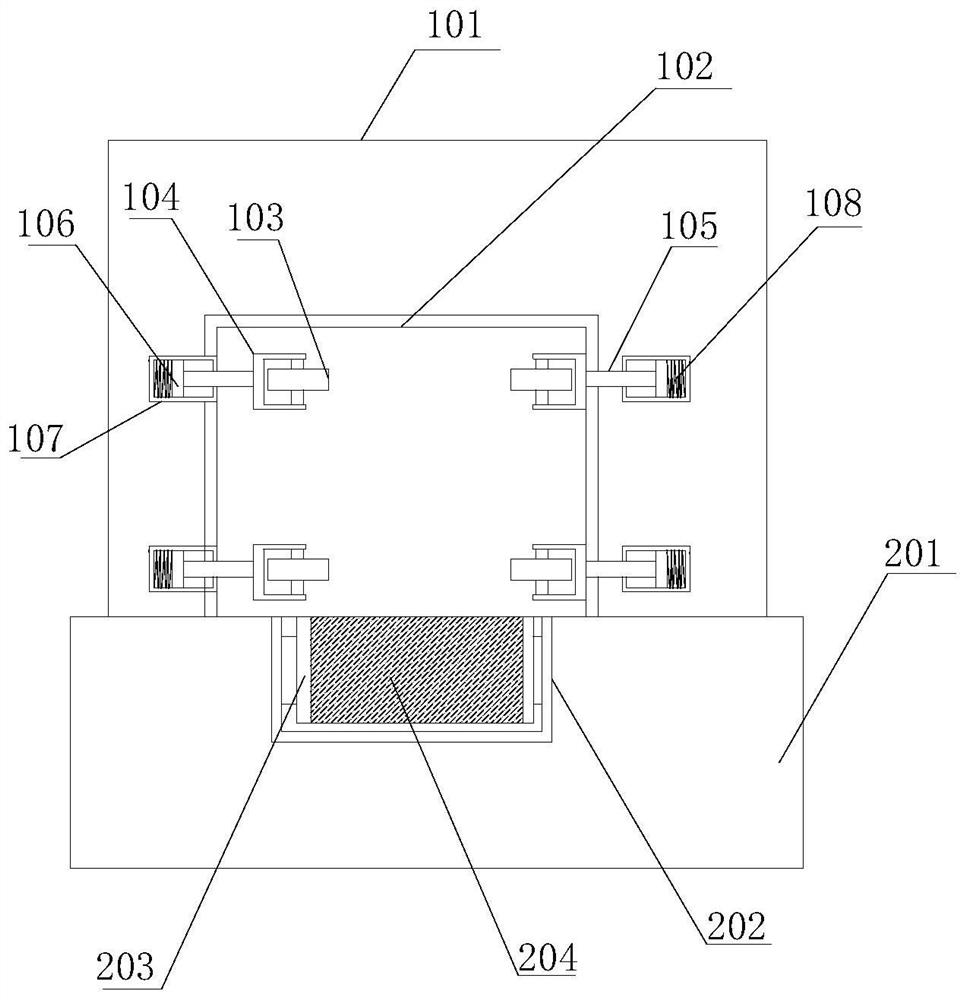

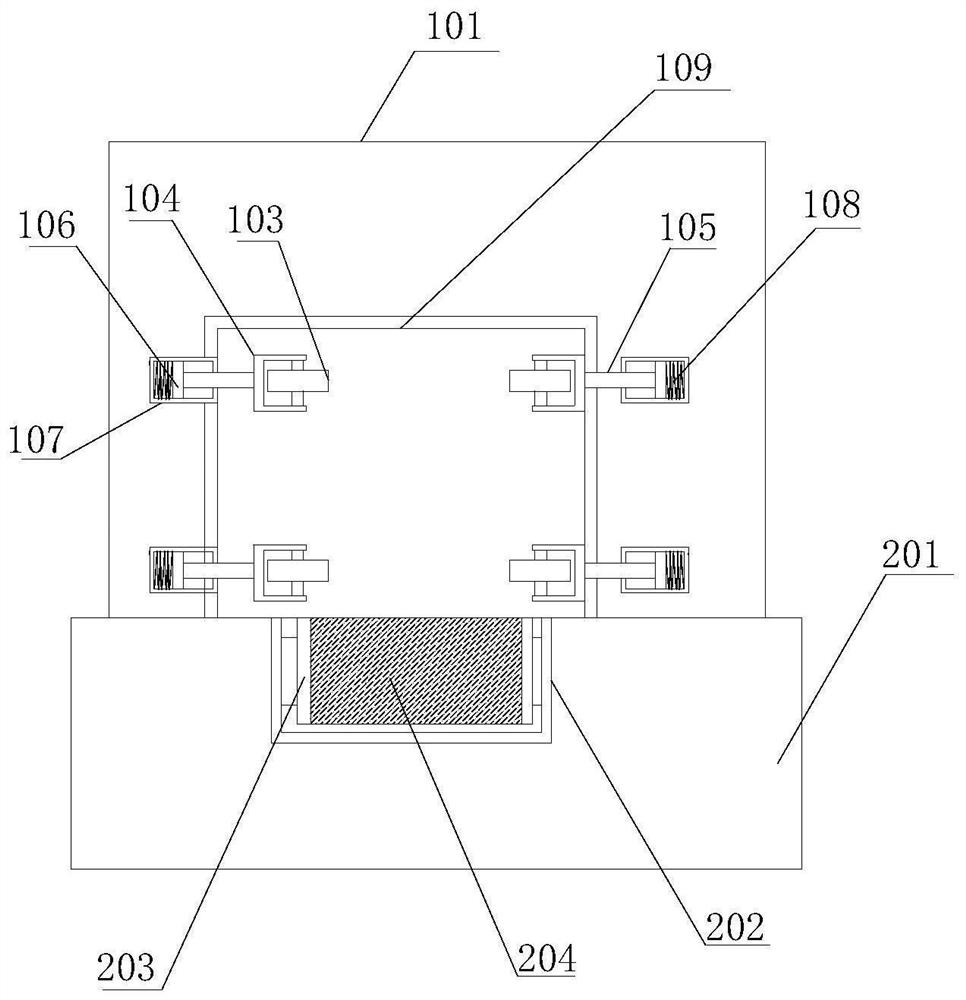

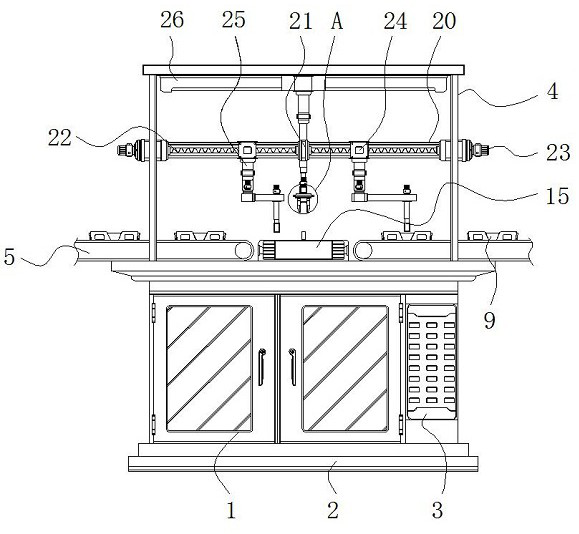

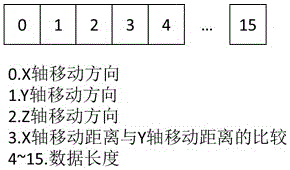

Concrete preparing, mobile filling and vibrating integration device and method

ActiveCN110370458AFully automatedImprove experimental efficiencyDischarging apparatusFeeding arrangmentsEngineeringThree dimensional motion

The invention provides a concrete preparing, mobile filling and vibrating integration device and method. The integration device comprises a base and a control desk. Sliding rails are arranged on the base. A vibration table capable of moving along the sliding rails is arranged on the sliding rails. A three-dimensional motion working platform is arranged on the base and can drive a machine base to move on the base. A stirrer is arranged on the machine base. A filling machine is arranged at a discharge port of the stirrer. An outlet of the filling machine faces the vibration table. The control desk is used for controlling the vibration table and the three-dimensional motion working platform to move so as to control the filling position, the filling height and / or vibration parameters.

Owner:SHANDONG UNIV +1

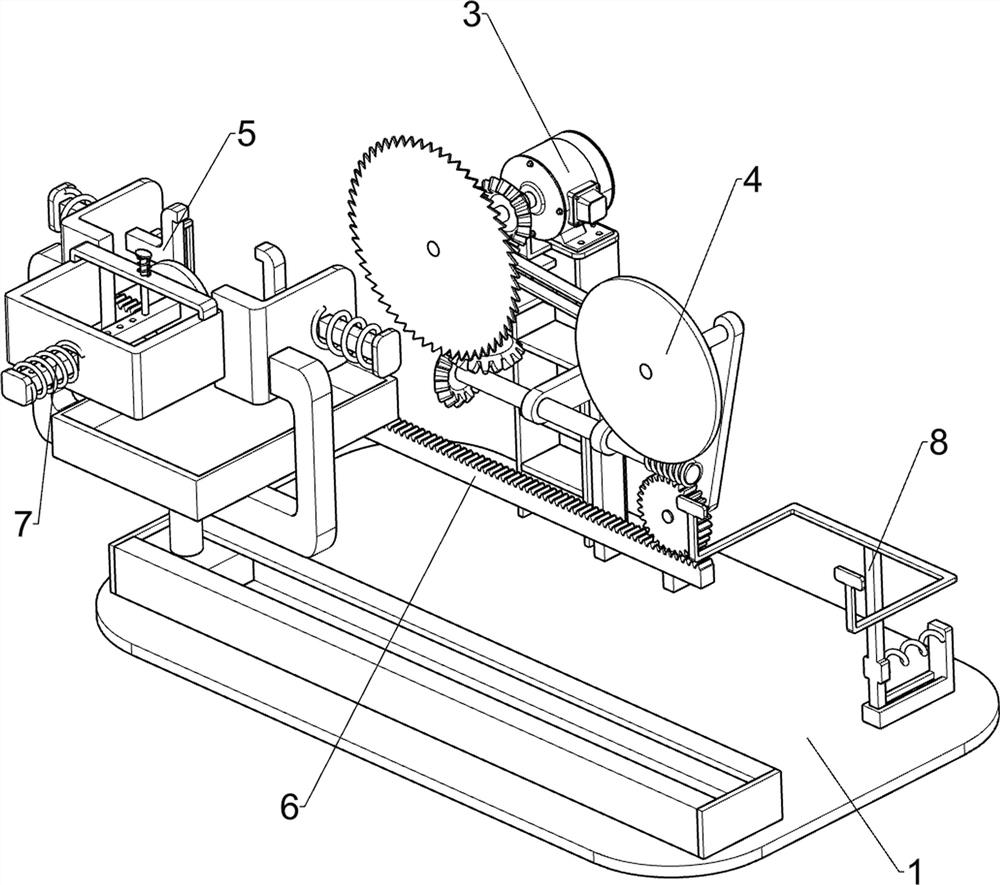

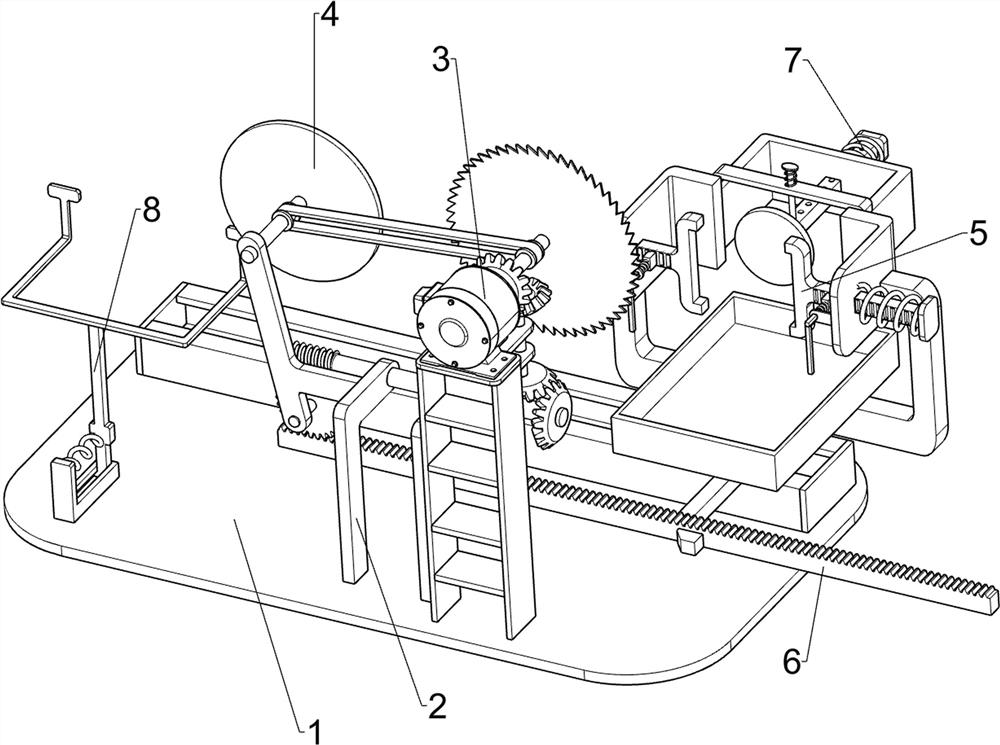

Cutting and edging equipment for high-end equipment manufacturing

ActiveCN113059352AEasy to operateReduce labor intensityOther manufacturing equipments/toolsGrindingManufacturing engineering

The invention relates to cutting and edging equipment, in particular to cutting and edging equipment for high-end equipment manufacturing. According to the cutting and edge grinding equipment for high-end equipment manufacturing, the fixing mode of a workpiece is simple, the workpiece grinding efficiency can be improved, and the workpiece can be cut. In order to solve the technical problem, the invention provides the cutting and edging equipment for high-end equipment manufacturing. The cutting and edging equipment comprises a bottom plate, a cutting mechanism, a grinding mechanism and a clamping mechanism, wherein the top of the bottom plate is connected with a supporting frame; the cutting mechanism is mounted at one side of the top of the bottom plate; the grinding mechanism is connected between the cutting mechanism and the supporting frame; and the clamping mechanism is mounted at the other side of the top of the bottom plate. According to the cutting and edging equipment, by means of the cutting mechanism, the grinding mechanism and the clamping mechanism, the workpiece can be integrally cut and ground, the mounting frame only needs to be manually pushed to move, operation is easy, and the labor intensity is low.

Owner:东营华洋金属制品有限公司

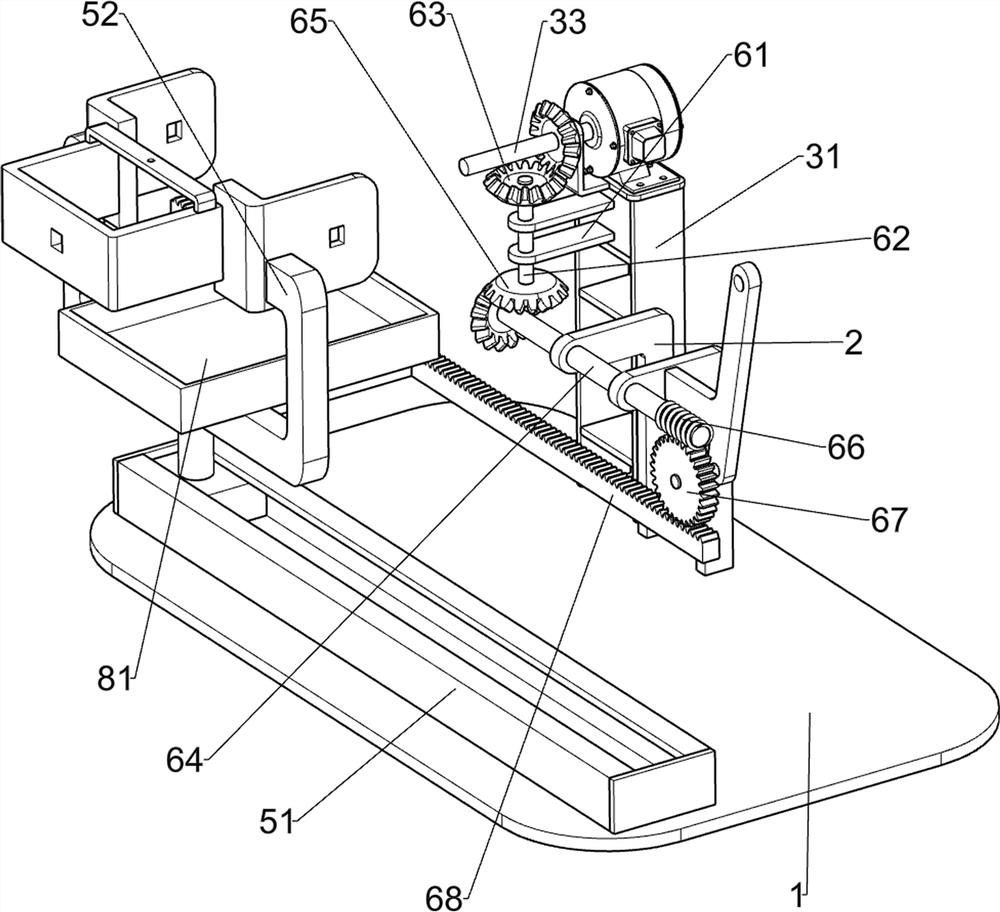

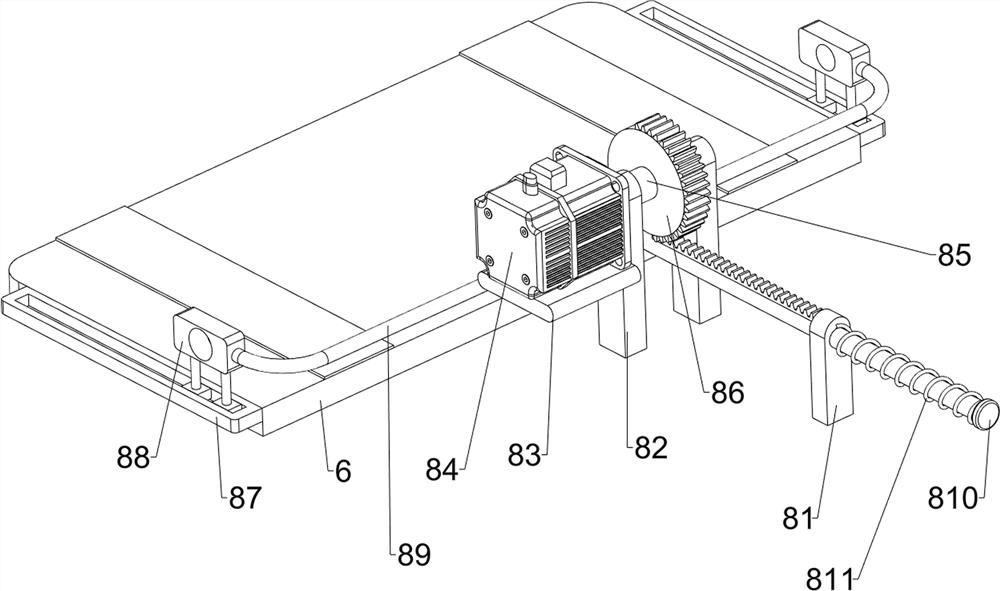

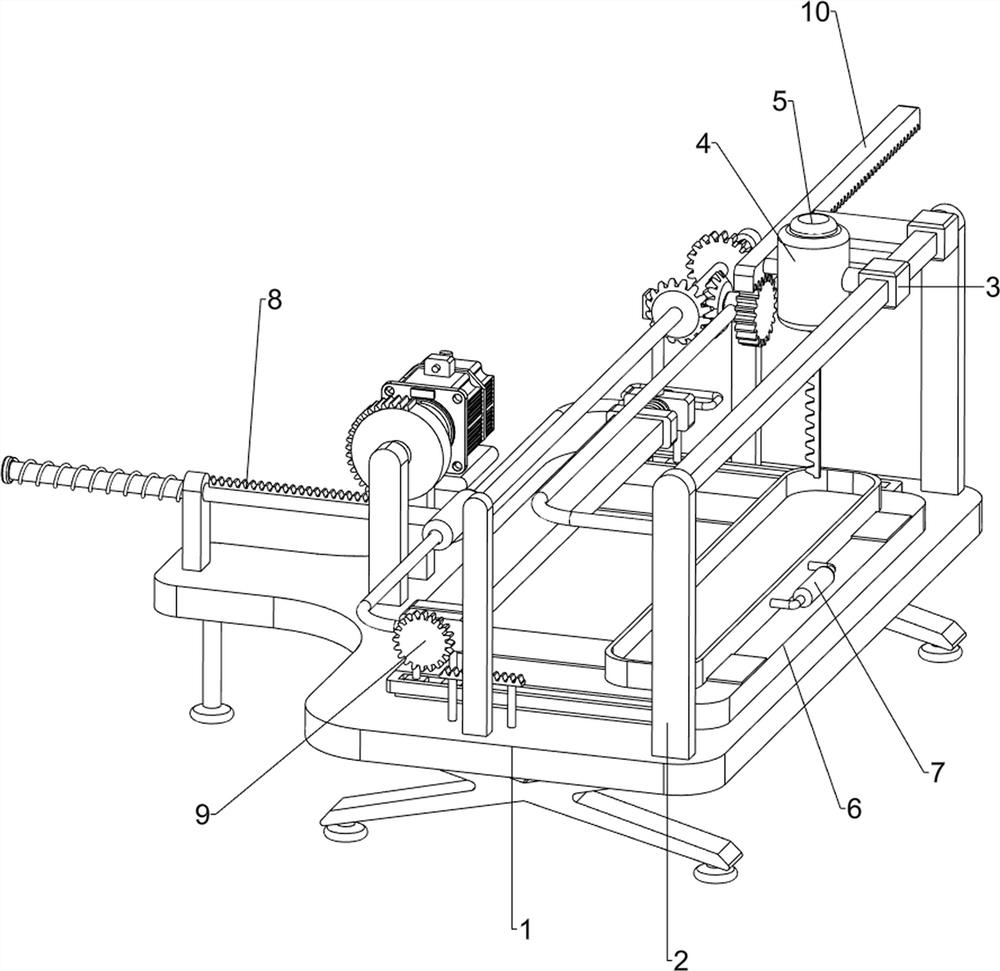

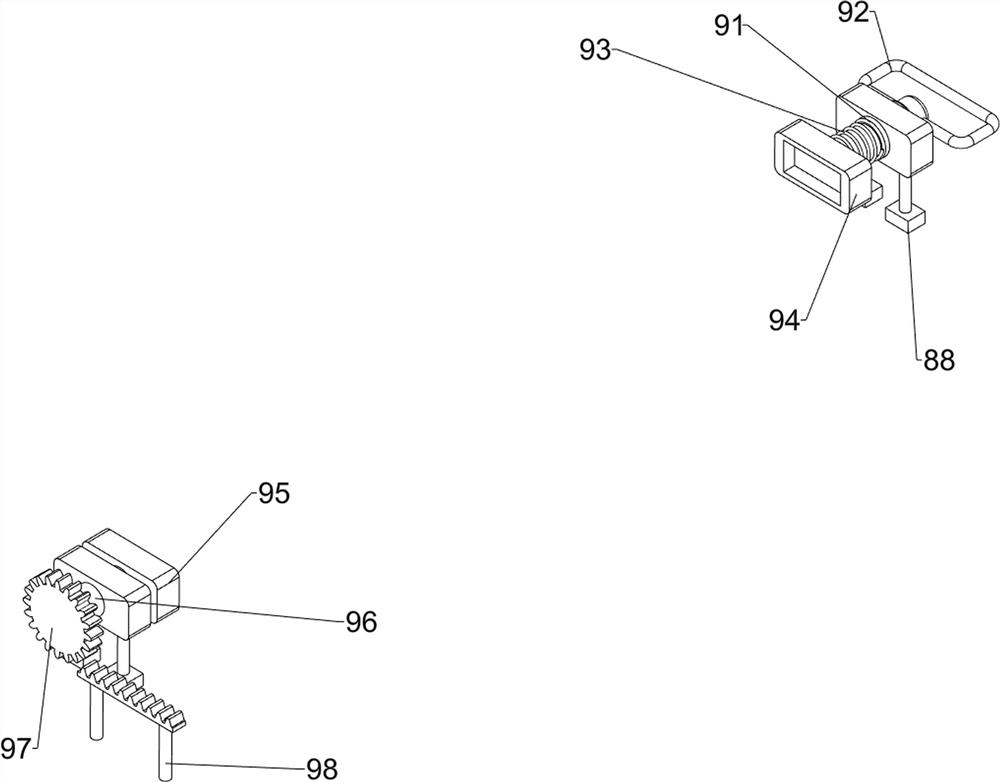

Wood board two-way grooving device for manual workshop

ActiveCN111975894AMove at a constant speedReduced risk of fratricideWood mortising machinesWood slotting machinesMechanical engineeringWood plank

The invention relates to a grooving device, in particular to a wood board two-way grooving device for a manual workshop. The wood board two-way grooving device for the manual workshop can automatically carry out two-way grooving on wood blocks and meanwhile improve the grooving precision. The wood board two-way grooving device for the manual workshop comprises a base, a sliding rod frame, a firstsliding sleeve, a mounting frame, an electric saw, a sliding rail block, a collecting frame, a reciprocating mechanism and a rotating mechanism. The sliding rod frame is arranged on the base. The first sliding sleeve is slidingly arranged on the sliding rod frame. The mounting frame is arranged on the first sliding sleeve. The electric saw is mounted on the mounting frame. The sliding rail block is arranged in the middle of the base. The collecting frame is slidingly arranged on the sliding rail block. The reciprocating mechanism is arranged on one side of the base. The rotating mechanism is arranged in the middle of the base. Through the design of the reciprocating mechanism, wood boards can be automatically moved at a uniform speed, under the cooperation of the electric saw, the wood boards are moved through a machine replacing labor, and grooves formed in the wood boards can be more uniform.

Owner:临沂临港国有资产运营集团有限公司

Single-surface galvanized steel plate surface protection process

ActiveCN108914030AEasy to moveUniform movementHot-dipping/immersion processesPolyurea/polyurethane coatingsSheet steelDust particles

The invention relates to a single-surface galvanized steel plate surface protection process. The single-surface galvanized steel plate surface protection process comprises the following specific steps: (1) steel is received and inspected; (2) dust particles on the surfaces of steel plates are cleaned through pretreatment to guarantee the surface cleanness of the steel plates; and the lower end surfaces and two sides of the steel plates are fixed through a fixing device 1; (3) degreasing treatment: a dipping method is used in degreasing; the temperature is controlled within 50-60 DEG C; and removed grease is prevented from attaching on the surfaces of the steel plates again; (4) hot galvanization is performed; and (5) drying is performed. The single-surface galvanized steel plate surface protection process solves the problems of need of manual movement of the steel plates, need of manual protection of galvanized end surfaces of the steel plates, nonuniform moving speed of the steel plates caused by manual control, incapability of guaranteeing the coating uniformity of acid-resistance substances, imprecise manual protection of the steel plates and incapability of guaranteeing no influence on the galvanized end surfaces of the steel plates by the acid-resistance substances due to wrong operation of the galvanized end surfaces of the steel plates.

Owner:山东亚洪新材料科技有限公司

Efficient fishing net cleaning machine

InactiveCN107051947AMove at a constant speedRealize all-round cleaningDrying gas arrangementsCleaning using liquidsWater storage tankEngineering

The invention relates to cleaning of fishing nets, in particular to a high-efficiency fishing net cleaning machine, which includes a cleaning room and a drying room. The top of the cleaning room is provided with a traction device and a water storage tank. The traction device is connected with a cross bar through a connecting rod, and a first The telescopic rod, the second telescopic rod, the third telescopic rod and the fourth telescopic rod, the first telescopic rod and the second telescopic rod are connected by a telescopic bracket, and one end of the telescopic bracket is connected to the top of the first telescopic rod through a first spring , the other end of the telescopic bracket is connected to the bottom of the second telescopic rod, the telescopic bracket is provided with a second spring and a clip, the side wall of the cleaning room is provided with a button that cooperates with the clip, the bottom of the fourth telescopic rod is provided with a porous nozzle, and the drying chamber An electric fan is provided on the side wall, and an electric heater is provided at the bottom of the drying chamber; the technical solution provided by the invention can effectively overcome the defects of limited cleaning number and long drying time in the existing fishing net cleaning machine.

Owner:WEIHAI HAOYUNTONG NETAB TECH

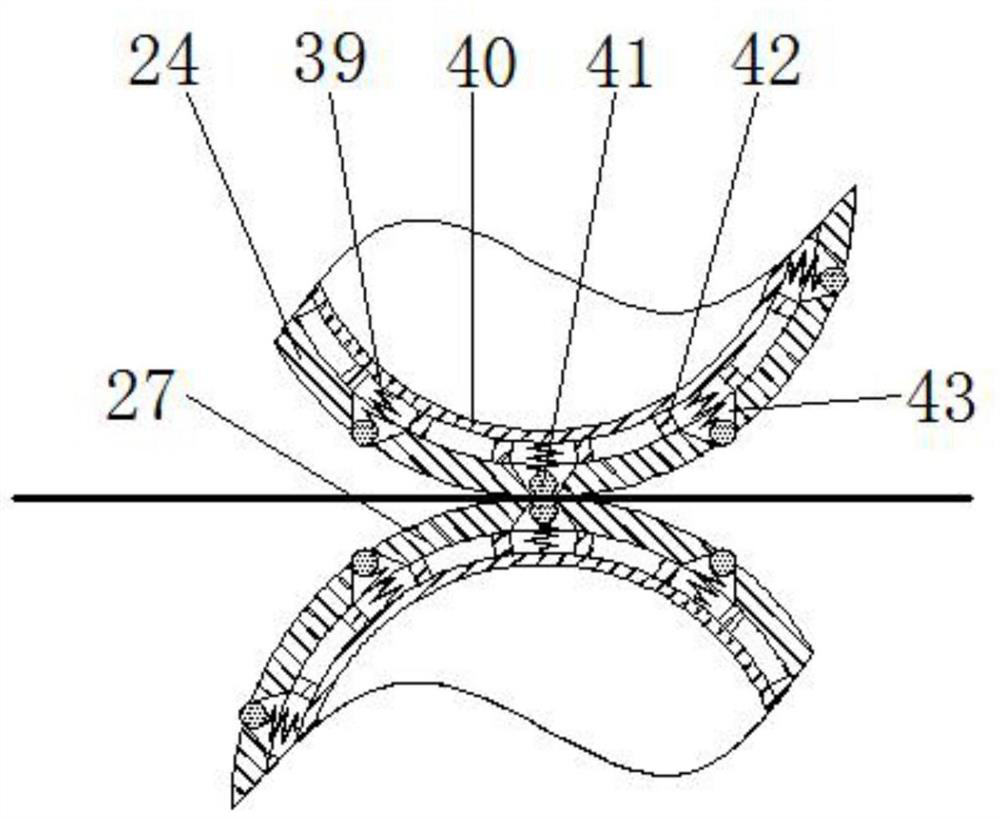

High-efficiency dyed cloth drying device

ActiveCN112050596AMove at a constant speedGuaranteed uniformityDrying gas arrangementsDrying machines with progressive movementsExhaust pipeCotton material

The invention discloses a high-efficiency dyed cloth drying device, and belongs to the field of drying equipment. The high-efficiency dyed cloth drying device comprises a box body internally providedwith an electric heating element, two or more lifting frame bodies are arranged in the box body at equal intervals, the tops of the lifting frame bodies are connected with lifting rods, and the upperends of the lifting rods are connected with a lifting driving mechanism; an upper roller and a lower roller used for clamping a cloth are arranged in each lifting frame body, through holes are evenlyspread over the side faces of the upper rollers and the lower rollers, the upper rollers communicate with a first air cylinder arranged at the top in the box body through a first exhaust pipe, the opening diameter of each through hole is gradually reduced from the inner side end to the outer side end of the through hole, and a blocking assembly used for blocking an outer port of each through holeis arranged in the through hole; and the blocking assemblies each comprise a blocking ball with the diameter between the diameter of an inner port and the diameter of the outer port of the corresponding blocked through hole, and a spring connected to the plugging ball. The high-efficiency dyed cloth drying device is high in drying treatment efficiency, good in uniformity, and capable of thoroughlydrying the cloth and treating water vapor generated in the drying process in time, only needs one power driving mechanism, is convenient to control and can save energy.

Owner:泉州台商投资区飞翔机械设计服务中心

Numerical control machine tool guide rail molded surface rapid detection device and method

ActiveCN104132627AMove at a constant speedImprove test accuracyUsing optical meansNumerical controlLaser transmitter

The invention relates to a numerical control machine tool guide rail molded surface rapid detection device. According to the numerical control machine tool guide rail molded surface rapid detection device, no strict rules for placement positions of a laser transmitter and a laser receiver exist, and a test result only depends on relative position relations between received lasers on the laser receiver and the initial test deviation of a test end guide rail. When a test is performed, the laser transmitter is well fixed, data are collected at equal intervals by moving an optical lens set, an auxiliary traction device can also be added, the optical lens set is moved at a constant speed, real-time high-density test data collection is achieved, and test precision is improved. The numerical control machine tool guide rail molded surface rapid detection device has the advantages of being accurate, reliable, rapid and the like, and can complete detection work of a plurality of test indexes at a time, and time and manpower are saved. Compared with the prior art, the numerical control machine tool guide rail molded surface rapid detection device has obvious accuracy and innovativeness.

Owner:通用技术集团沈阳机床有限责任公司

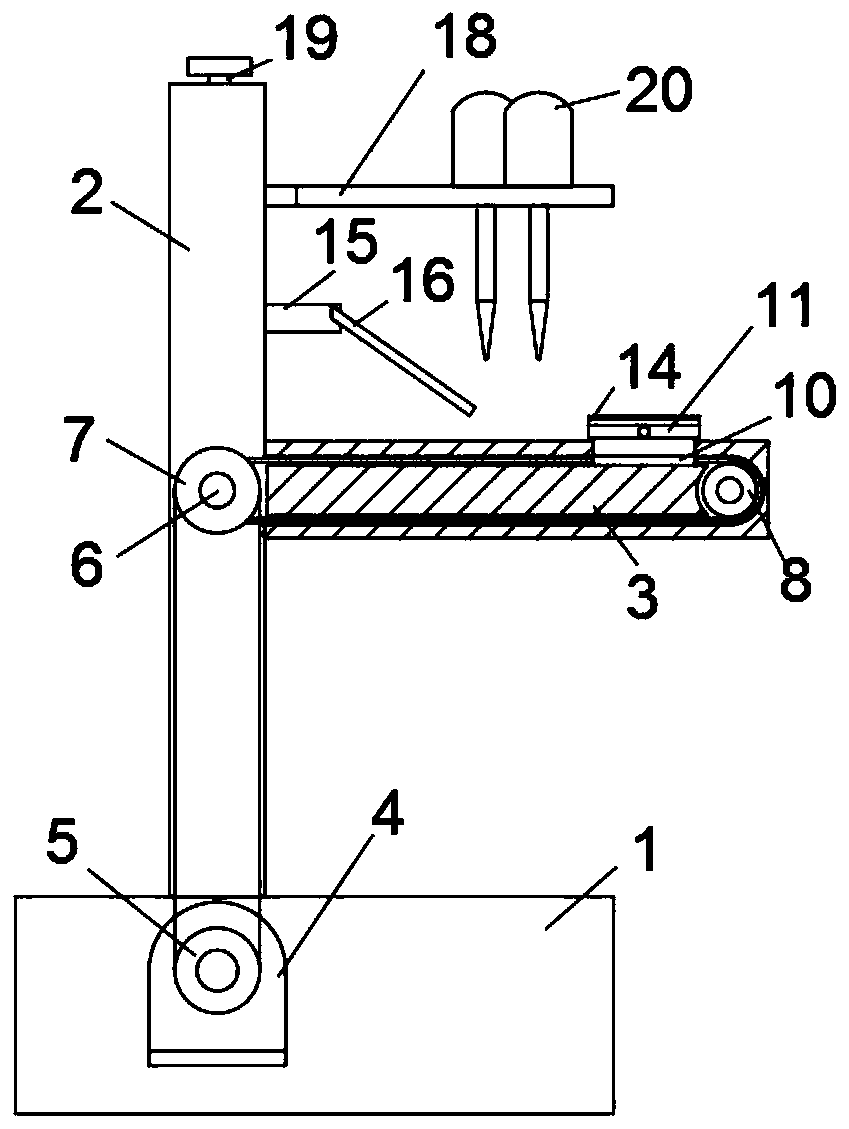

Dyeing device for manufacturing blood smear

PendingCN110987574AEasy to processIncrease processing efficiencyPreparing sample for investigationElectric machineryBlood smear

The invention discloses a dyeing device for manufacturing a blood smear. The dyeing device comprises a base. A supporting plate is fixedly connected to the base. A processing device is arranged on thesupporting plate; two oppositely-arranged horizontal plates are fixedly connected to the side wall of the supporting plate, and clamping devices are arranged on the horizontal plates. A cavity is formed in the base, a motor is arranged in the cavity, the output end of the motor is connected with a first transmission chain wheel, and the first transmission chain wheel is connected with a transmission mechanism in an engaged mode. According to the invention, a control column is rotated; under the action of L-shaped clamping blocks on a fixed block and a movable block, a glass slide is stably clamped; the working plate is moved under the action of the motor, the first transmission chain wheel, a rotating shaft and a second transmission chain wheel, the glass slide is moved at a constant speed, a push piece is manufactured; the blood smear is manufactured under the assistance of mechanical equipment, so that machining is facilitated, the machining efficiency is improved, and the success rate of the blood smear is increased.

Owner:保山中医药高等专科学校

An integrated garment automatic production system for sweaters

ActiveCN110777521BEasy to moveMove at a constant speedIroning machinesHeating/cooling textile fabricsIndustrial engineeringElectric heating

Owner:苏州贺轩时装有限公司

Dyeing device for flax textile processing

InactiveCN108589097AMove at a constant speedEasy to moveLiquid/gas/vapor removalTextile treatment by spraying/projectingEngineeringFriction force

The invention discloses a dyeing device for flax textile processing, and relates to the technical field of flax textile dyeing devices. The dyeing device comprises a workbench, sliding channels are formed in the two ends of the workbench, a sliding groove is formed in the middle of each sliding channel, and moving grooves are formed in the two ends of each sliding channels, and supporting rods arearranged in the middles of the moving grooves. The surfaces of the supporting rods are movably connected with roll wheels, supporting plates are movably connected in the sliding channels, a movable rod is arranged at one end of each supporting plate, a clamping column is fixedly connected with one end of each movable rod, and the other end of each movable rod is movably connected with a lead screw. According to the dyeing device for flax textile processing, the movable rods can drive a top plate to move through rotation of the lead screws, and therefore spray heads evenly dye flax textile cloth; the roll wheels are arranged in the moving grooves, the friction force of the supporting plates on the sliding channels can be reduced, the supporting plates smoothly move, the work efficiency ofdyeing is improved, and the phenomena of uneven dyeing and dyeing omissions are reduced.

Owner:浙江载信亚麻科技有限公司

Textile cloth printing, dyeing and drying device

ActiveCN112050598AMove at a constant speedSpray to the goodDrying gas arrangementsDrying machines with progressive movementsProcess engineeringMechanical engineering

The invention discloses a textile fabric printing, dyeing and drying device, and belongs to the field of drying equipment. The textile fabric printing, dyeing and drying device comprises a box body internally provided with an electric heating element, two or more lifting frame bodies are arranged in the box body at equal intervals, the tops of the lifting frame bodies are connected with lifting rods, and the upper ends of the lifting rods are connected with a lifting driving mechanism; an air blowing roller and an air suction roller which are used for clamping a cloth are arranged in each lifting frame body, and through holes are evenly spread over the side faces of the air blowing rollers and the air suction rollers; and the air blowing rollers communicate with a first air cylinder arranged at the top in the box body through a first exhaust pipe, the air suction rollers communicate with a second air cylinder arranged at the bottom in the box body through a second air inlet pipe, condensers are arranged in the air suction rollers, the lower ends of the lifting frame bodies are provided with liquid discharging channels communicating with the two sides of the lifting frame bodies, and the bottom of one side of the box body is connected with a liquid discharging pipe. The textile fabric printing, dyeing and drying device is high in drying efficiency, can be thoroughly dry the cloth, can treat water vapor generated in the drying process in time and thus can avoid the adverse effects on the drying efficiency of the cloth, and the environment in the box body is maintained advantageously.

Owner:泉州台商投资区飞翔机械设计服务中心

Bamboo weaving handicraft mildew-proof treatment method and device

InactiveCN112676081AMove at a constant speedSpray evenlyWood treatment detailsReed/straw treatmentComposite materialCeramic materials

The invention discloses a bamboo weaving handicraft mildew-proof treatment method and device, and relates to the technical field of bamboo weaving handicrafts. The treatment method is characterized by comprising the following steps that S1, polishing treatment is carried out, and specifically, bamboo filaments and thin bamboo strips of a bamboo weaving product are ground and polished for later use; and S2, cooking treatment is conducted, wherein the bamboo filaments and the thin bamboo strips treated in the step S1 are put into a pot containing cooking liquor, heating is conducted, the temperature of the cooking liquor is kept at 60-65 DEG C, the bamboo filaments and the thin bamboo strips are taken out after cooking treatment is conducted for 25-30 min, and the bamboo filaments and the thin bamboo strips are naturally cooled to the room temperature for standby application. According to the bamboo weaving handicraft mildew-proof treatment method and device, a driving assembly is arranged to cooperate with a paint spraying connecting pipe and a drying connecting pipe, and a spray head can be driven to move at a constant speed, so that the spray head can uniformly spray the thin bamboo strips, the thin bamboo strips are located in the center of the spray head, it can be guaranteed that paint liquid can be sprayed to each surface, and the spraying quality is improved; and meanwhile, the drying connecting pipe is used in a cooperative mode to blow-dry the thin bamboo strips simultaneously, so that the drying speed is increased.

Owner:赤水市牵手竹艺发展有限公司

Piano cover painting device

InactiveCN112317186AAvoid bruisesExtended service lifeCleaning using toolsSpray boothsRubber materialPiano

The invention relates to the technical field of piano component processing equipment, and discloses a piano cover painting device. The piano cover painting device comprises a box body assembly, a bottom plate assembly, a traction device and a dust removal device, and the bottom of the box body assembly is fixedly connected with the bottom plate assembly. In the box body assembly, a plate inlet anda plate outlet are formed in the left end and the right end of a box body correspondingly, meanwhile, mounting grooves are formed in the front sides and the rear sides of the plate inlet and the plate outlet, first springs and limiting plates are placed in the mounting grooves, the sides, away from second springs, of the limiting plates are connected with connecting rods, the ends, away from thelimiting plates, of the connecting rods are connected with mounting supports, and meanwhile, guide wheels made of the rubber material are arranged in the middles of the mounting supports, so that whena piano cover plate is put into the box body and discharged out of the box body, the piano cover plate can be buffered while being guided, and the piano cover plate is prevented from being collided and damaged.

Owner:德清浦赛尔钢琴有限公司

Production machining equipment of color steel tiles

ActiveCN107138573AMove at a constant speedReduce axial forceMetal working apparatusLaser transmitterDrive wheel

The invention discloses production machining equipment of color steel tiles. The equipment comprises a base, a pressure sensor, a movable pressing plate, a left chute, a right chute, a left support, a right support, a laser transmitter, a laser receiver, a control module, a driven rack, a driven wheel, a driven rotating shaft, a right driving rack, a left driving rack, a right driving wheel, a left driving wheel, a driving shaft and a motor. The equipment is novel in structure and scientific in design; the driven rack is mounted in the middle of the front end surface of the movable pressing plate and is meshed with the driven wheel to realize constant-speed motion of the movable pressing plate; moreover, the gravity of the sliding pressing plate is borne, so that axial force of the motor is reduced, the service life of the equipment is greatly prolonged, and manual intervention in a whole machining process is not needed, the automation degree is high, the machining efficiency is improved, the pressure sensor is increased, controlled machining pressure is realized, and the quality and consistence of the machining are improved; due to the arrangement of the laser transmitter and the laser receiver, the using security performance of the equipment are further improved.

Owner:颍上县双盛金属制品股份有限公司

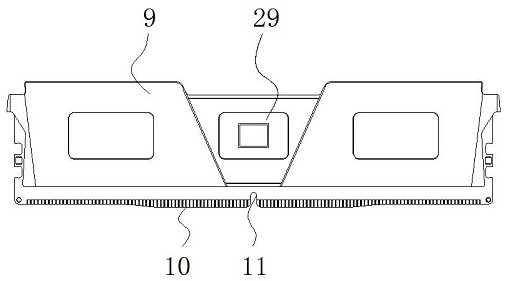

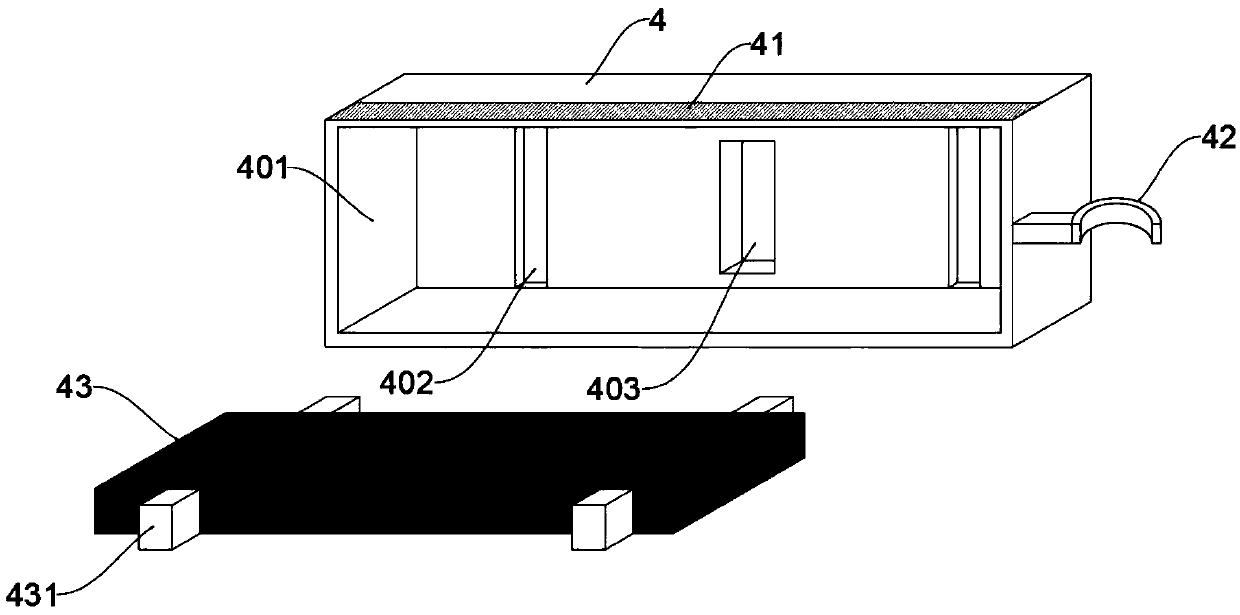

Contact chip detection device with sorting structure for computer memory bank processing

InactiveCN113333322AEnsure safetyAvoid interferenceCleaning using gasesSortingMemory bankTransmission belt

The invention discloses a contact chip detection device with a sorting structure for computer memory bank processing, and relates to the technical field. The contact chip detection device comprises a bottom cabinet and a driving assembly, the bottom of the bottom cabinet is fixedly provided with a base, the right side of the bottom cabinet is provided with a console, the top of the bottom cabinet is connected with a detection cabinet, and the two ends of the detection cabinet are provided with first transmission belts. A driving motor is arranged on one side of each first transmission belt, the surfaces of the first transmission belts are connected with sleepers, and grooves are formed in the surfaces of the sleepers. According to the contact chip detection device with the sorting structure for computer memory bank processing, limiting plates are arranged on the two sides of a memory bank, and the limiting plates are fixed to the first transmission belts through supporting rods, so that stability of the limiting plates is guaranteed. Detection probes on the surfaces of the limiting plates are matched, and the detection probes and the memory bank are distributed in parallel, so that when the memory bank is conveyed, the appearance of a contact chip on the surface of the memory bank and the contamination condition of pollutants can be detected, and the practicability of the device is improved.

Owner:深圳聚和文化有限公司

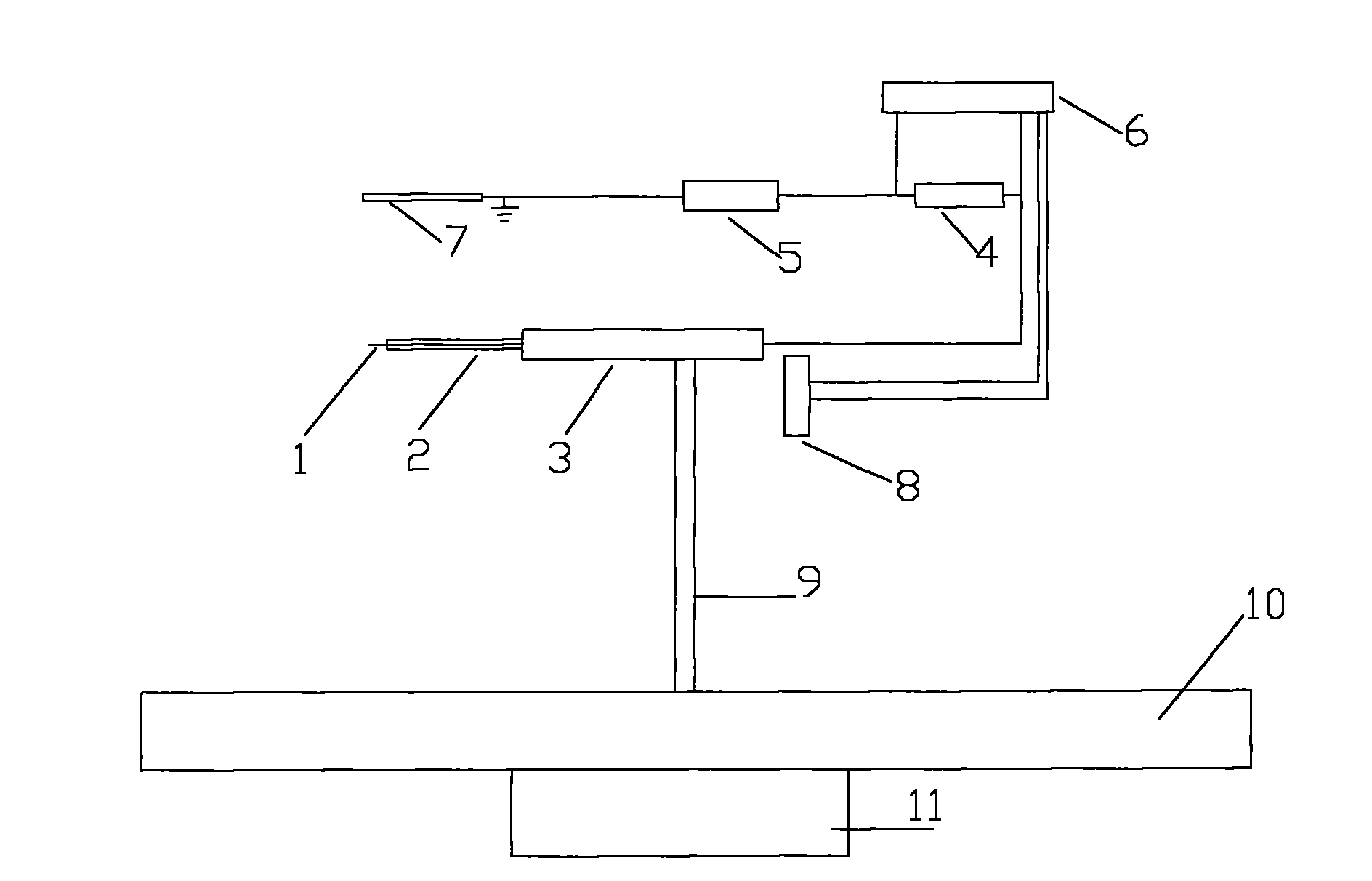

Friction exploring experimental equipment

InactiveCN109615986AMove at a constant speedAvoid the situation where the experiment is disturbed by human factorsEducational modelsApparatus for force/torque/work measurementDynamometerEngineering

The invention relates to the technical field of experimental equipment, in particular to friction exploring experimental equipment. The friction exploring experimental equipment comprises an outer cover, wherein a rotating motor is arranged at the top end of the side wall of the outer cover; a spring dynamometer is adhered to the inner wall of the left side of the outer cover; a supporting plate is arranged inside the outer cover. Through the rotating motor and the supporting plate which are mounted on the experimental equipment, the effect of relative uniform movement of an experimental slideblock is achieved and occurrence of the situation that an experiment is interfered by human factors due to conventional manual pulling of the slide block is avoided; through a lifting mechanism and the supporting plate which are mounted inside the experimental equipment, the effect of conveniently adjusting the contact surface pressure is achieved and occurrence of the situation that the contactsurface pressure can be changed only by constantly changing the slide block in the conventional experimental equipment is avoided; in a way of fixing the spring dynamometer on the experimental equipment for pulling the supporting plate, the effect of reading the reading of the spring dynamometer conveniently is achieved and occurrence of the situation of an reading error due to movement of the spring dynamometer in the conventional technology is avoided.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

Measuring device and method of thrust vector of detection space plasma thruster

InactiveCN101614606BNovel measuring methodEasy to operateUsing electrical meansApparatus for force/torque/work measurementElectrical resistance and conductanceData acquisition

The invention relates to a measuring device and a method of the thrust vector of a detection space plasma thruster. The measuring device of the thrust vector mainly comprises an electrostatic probe, an electrostatic probe regulating mechanism, a locating piece and a data acquisition and processing system. The method comprises the following steps: first fixing the electrostatic probe on a movable platform, simultaneously regulating the position of the electrostatic probe, installing the locating piece on the position which the probe can contact when the axis of the probe coincides with that ofthe plasma thruster, collecting the electrons jetted on the local position by the thruster in real time by the electrostatic probe on which positive bias voltage is applied when the movable platform moves at a constant speed along the direction vertical to the axis of the thruster, thus collecting the voltage signals at both ends of sample resistance in real time by the data acquisition and processing system when current flows through a probe circuit, and educing deflection of the actual thrust vector from the design objective by comparing the differences between the time corresponding to thevertex of the voltage signals at both ends of the sample resistance and the sudden change time of the voltage signals at both ends of the locating piece according to the moving speed of a translationstage and the distance from the electrostatic probe to the exit of the thruster.

Owner:INST OF MECHANICS CHINESE ACAD OF SCI

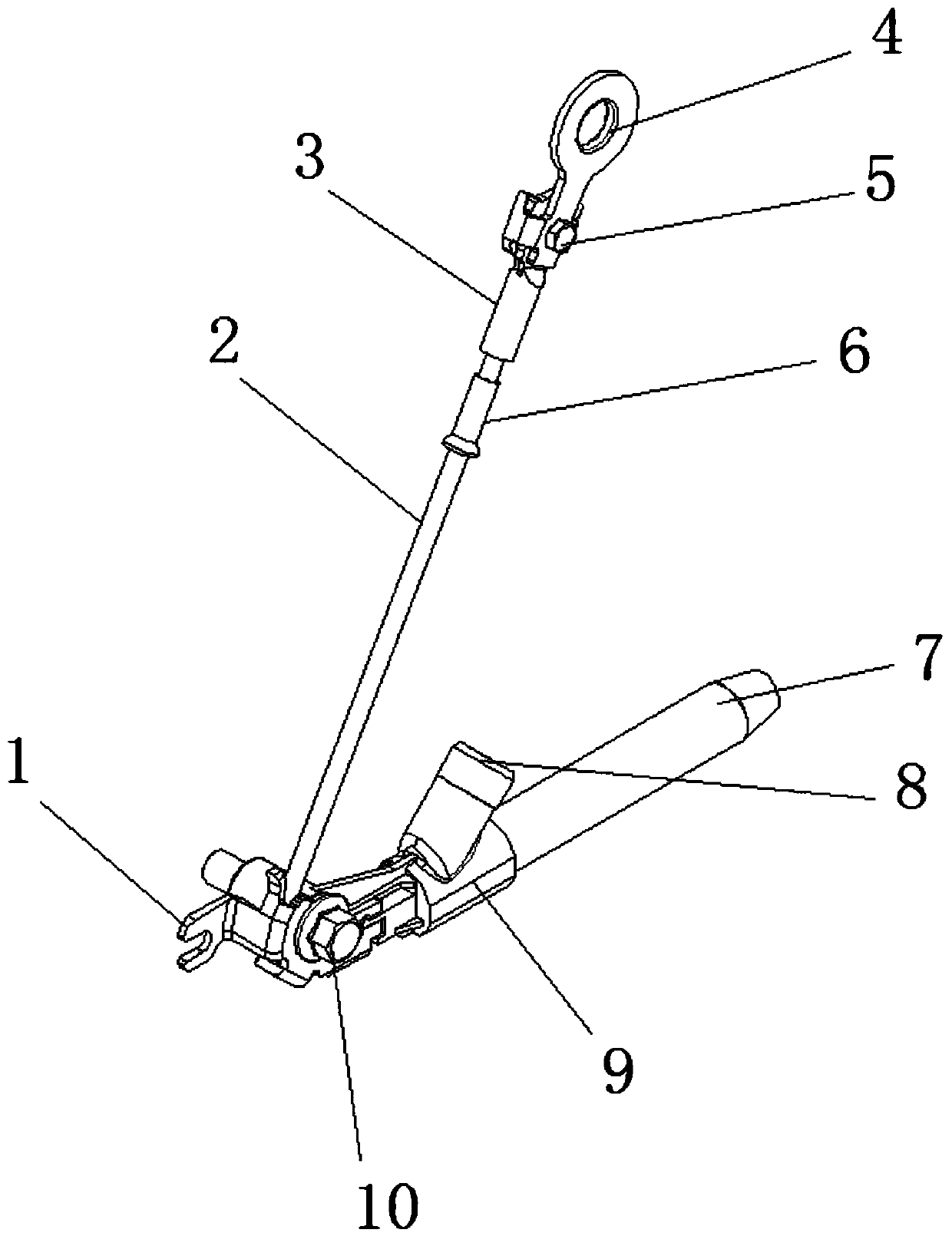

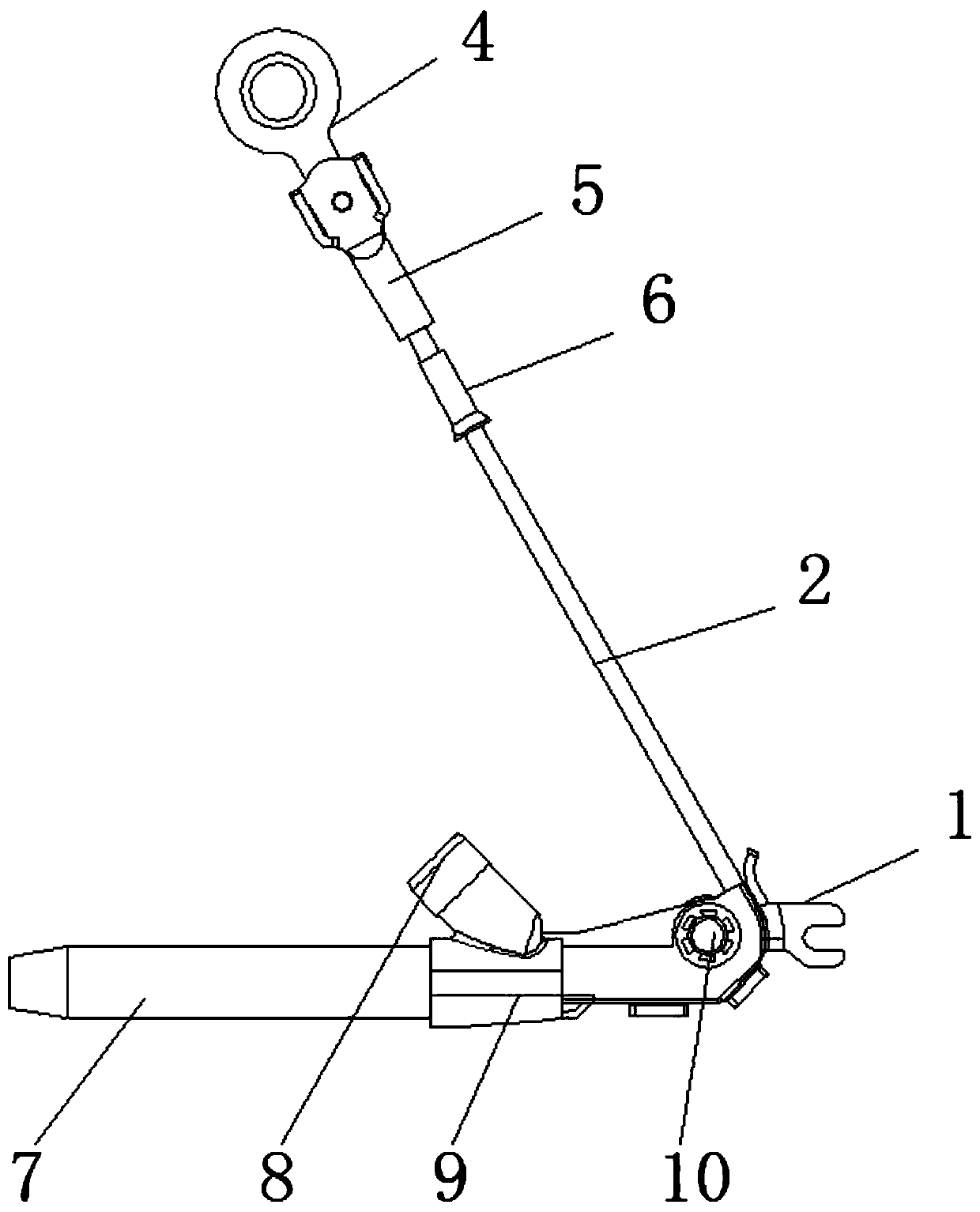

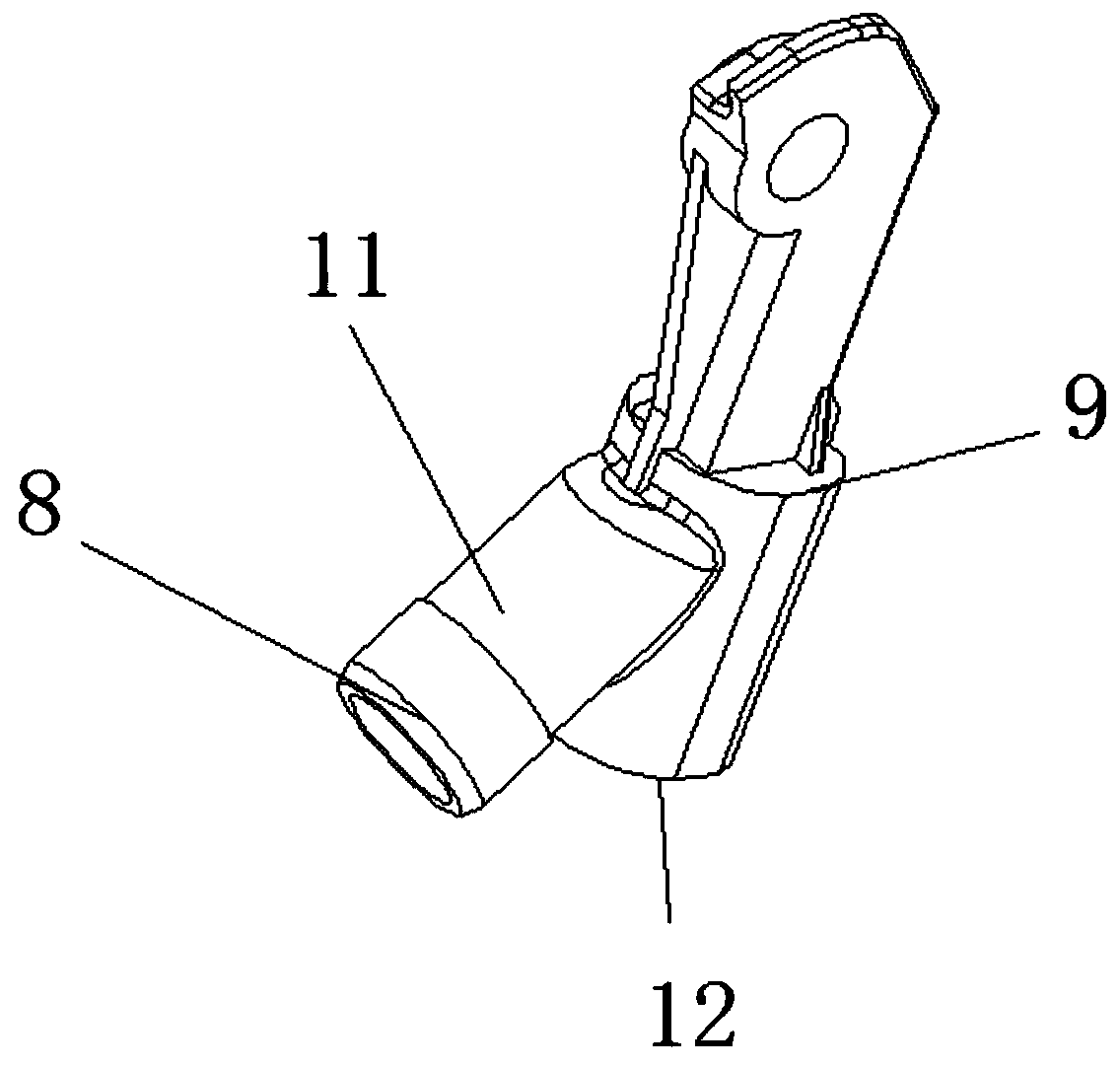

End piece pretightening assembly for automobile seat belt

PendingCN109849840AEasy maintenanceEasy to realize disassembly and installationBelt retractorsSeat beltEngineering

The invention discloses an end piece pretightening assembly for an automobile seat belt. The end piece pretightening assembly for the automobile seat belt includes a cylinder, a pretightening seat anda check piston. A first adaptor port and a second adaptor port are respectively arranged on the pretightening seat, a gas generator is fixed in the first adaptor port, the cylinder is fixed on the second adaptor port, the inner end of the second adaptor port is staggered and fixed with a spoiler, a steel rope sleeve transversely penetrates through the spoiler, a cover plate is fixed to one end ofthe pretightening seat through a second locking bolt, a steel rope sequentially passes through the steel rope sleeve and the cover plate, an end piece connecting member is welded to the other end ofthe wire rope, and the end piece connecting member is fixed with a head end piece through a first locking bolt. By arranging internal threads on the inner side wall of the second adaptor port and external threads cooperating with the internal threads on the outer side wall of one end of the cylinder, the cylinder and the pretensioning seat are spirally connected, the disassembly and installation of the two are facilitated, the maintenance is facilitated, and the use is convenient.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Transverse cutting device for PET foamed plate and using method thereof

PendingCN112589864AMove at a constant speedImprove the efficiency of cross-cutting workMetal working apparatusStructural engineeringMechanical engineering

The invention discloses a transverse cutting device for a PET foamed plate and a using method thereof. The transverse cutting device comprises a rack, and a first sliding mechanism, a second sliding mechanism, an auxiliary compressing mechanism, a pull-out protection mechanism, an anti-deviation mechanism and a pushing mechanism which are mounted on the rack; a slidable base is arranged on the rack; a mounting frame is mounted on one side of the base; a fixed frame is mounted on the side, away from the mounting frame, of the base; a slidable mounting plate is arranged on the mounting frame; and the mounting plate is connected with a saw blade through a connecting block. According to the transverse cutting device for the PET foamed plate, the plate can be transversely cut while being conveyed and moved by the pushing mechanism without shutting down the pushing mechanism to stop cutting and then starting up the pushing mechanism, and uninterrupted working is achieved, so that the plate transverse cutting work efficiency is improved; and all the mechanisms are matched for use, so that not only can the transverse cutting work efficiency be improved, but also the precision of the cut plate can be guaranteed, and errors are reduced.

Owner:镇江越升智能装备制造有限公司

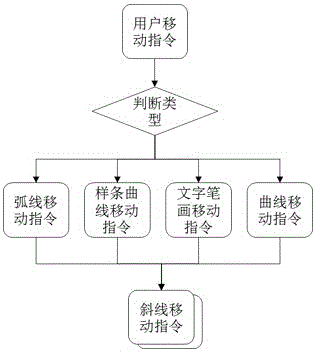

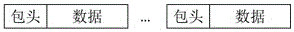

Triaxiality uniform speed moving method driven by single-chip microcomputer

The invention relates to a triaxiality uniform speed moving method driven by a single-chip microcomputer. The method is used for a triaxiality sliding platform and is characterized by comprising the following steps: (1) converting plane moving instructions on an X axis and a Y axis by a user into broken line moving instructions; (2) combining the broken line moving instructions and a moving instruction on a Z axis, merging and combining instructions, and converting the merged instructions into step-by-step moving instructions on the X axis, the Y axis and the Z axis; (3) encoding the step-by-step moving instructions on the X axis, the Y axis and the Z axis, and saving the encoded moving instructions in a memory; and (4) reading the step-by-step moving instructions on the X axis, the Y axis and the Z axis in the memory, and driving triaxiality to move. The method has the advantages of converting the triaxiality moving instructions by the user into the step-by-step moving instructions in advance, and saving the step-by-step moving instructions in the memory, wherein a moving platform does not perform complex floating operation during operation, so that the effect of moving at a uniform speed is achieved. When the method is used, a CPU with a lower frequency can be adopted, so that the cost of products can be effectively reduced.

Owner:北京美科华仪科技有限公司

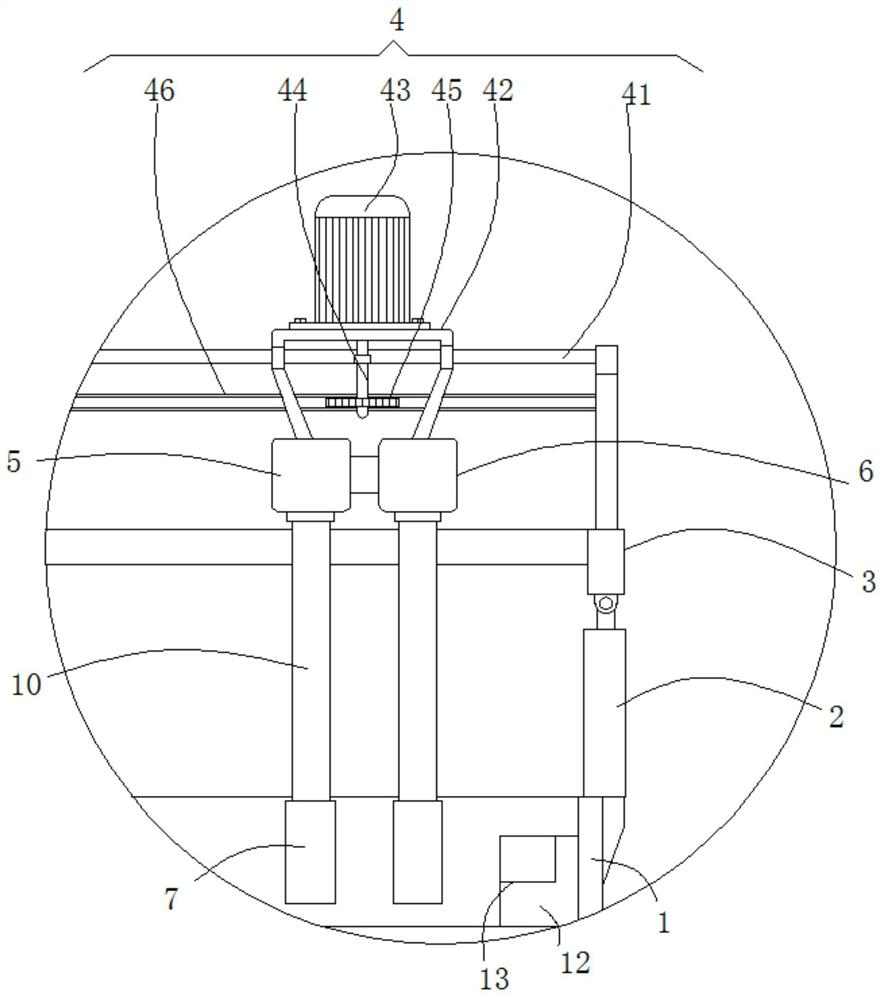

Automatic sweater production system of integrated garment

ActiveCN110777521AEasy to moveMove at a constant speedIroning machinesHeating/cooling textile fabricsMechanical engineeringIndustrial engineering

The invention discloses an automatic sweater production system of an integrated garment. The system relates to the field of sweater production equipment, and comprises an ironing frame, an air suctioncooling structure, a movable ironing structure and a wetting structure, wherein the ironing frame is mounted on the top side of the air suction cooling structure; the movable ironing structure is mounted on the bottom side of the ironing frame; and the wetting structure is arranged on the top side of the ironing frame. Through the operation of a servo motor, a screw rod can drive a movable blockto slide to realize uniform movement of an electric heating block; with the cooperation of an extrusion spring, sweaters can be pressed with the same strength, ironing speed and ironing quality, and thus the finishing quality of sweaters is ensured, automatic ironing finishing can be realized, automatic production is realized, and the production efficiency is improved; and after ironing, an induced draft fan operates to realize air circulation on the top side of a ventilation mesh plate, so that the sweaters can be rapidly cooled, and the fact that the ironed sweaters maintain a good shape isguaranteed.

Owner:苏州贺轩时装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com