Wood board two-way grooving device for manual workshop

A workshop and wood board technology, which is applied to the field of two-way grooving devices for wood boards used in hand workshops, can solve the problems of uniformity, the position of grooving can not be guaranteed, and the speed of grooving is slow, so as to reduce the workload, improve the accuracy and standardize the position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

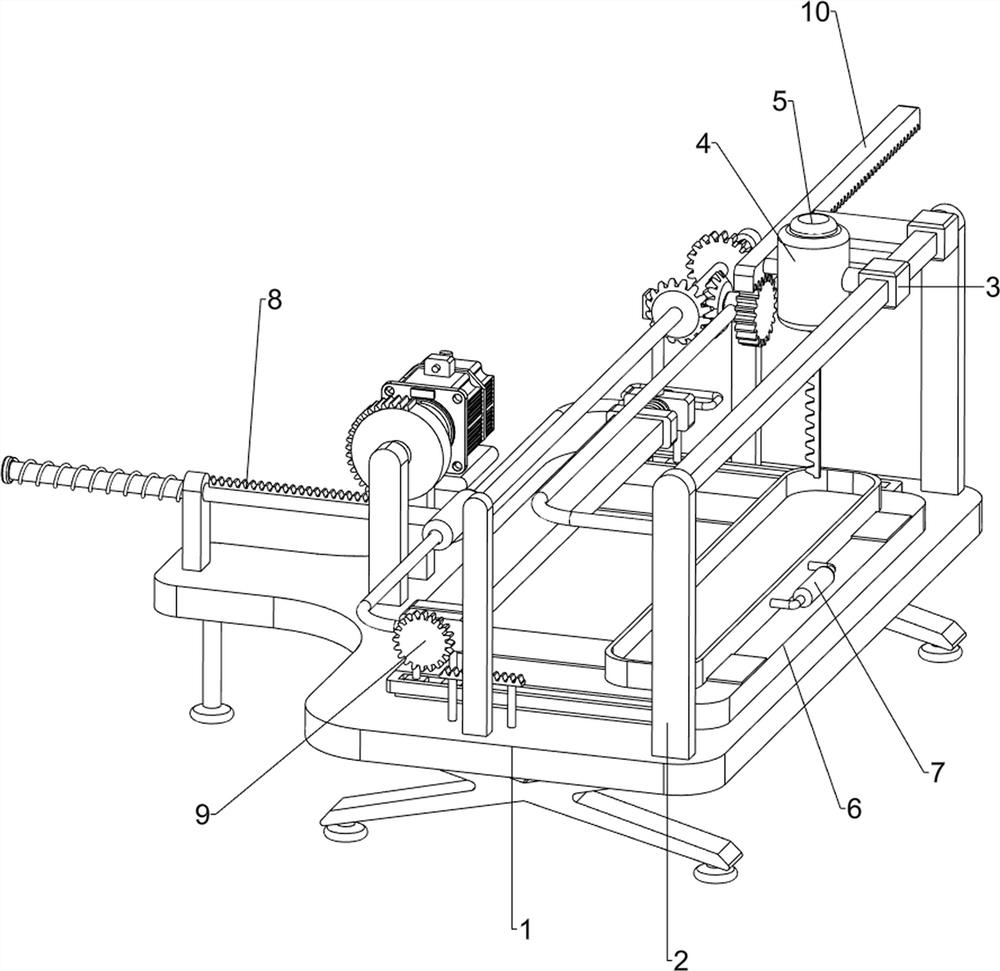

[0023] A two-way slotting device for wooden boards used in hand workshops, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it includes a base 1, a sliding rod frame 2, a first sliding sleeve 3, an installation frame 4, an electric saw 5, a slide rail block 6, a receiving frame 7, a reciprocating mechanism 8 and a rotating mechanism 9, and the right side of the base 1 A slide bar frame 2 is provided, and the slide bar frame 2 is slidably provided with a first sliding sleeve 3, and the left side of the first sliding sleeve 3 is provided with an installation frame 4, and an electric saw 5 is installed on the installation frame 4, and the middle of the base 1 is provided with a A slide rail block 6 is arranged, and the sliding rail block 6 is provided with a receiving frame 7, the left side of the base 1 is provided with a reciprocating mechanism 8, and the base 1 is provided with a rotating mechanism 9 in the middle.

[0024] First, people place the plank that ne...

Embodiment 2

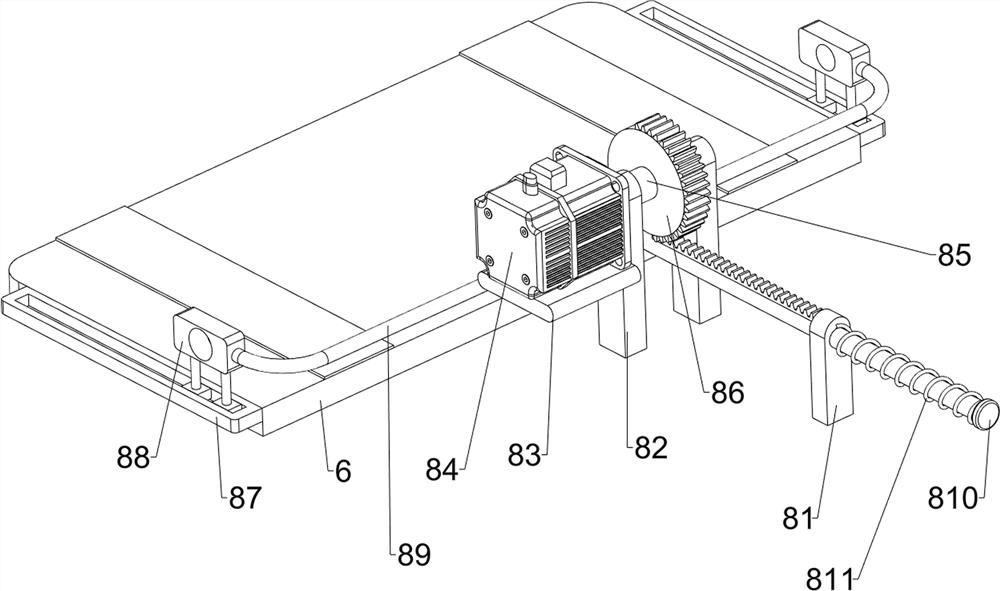

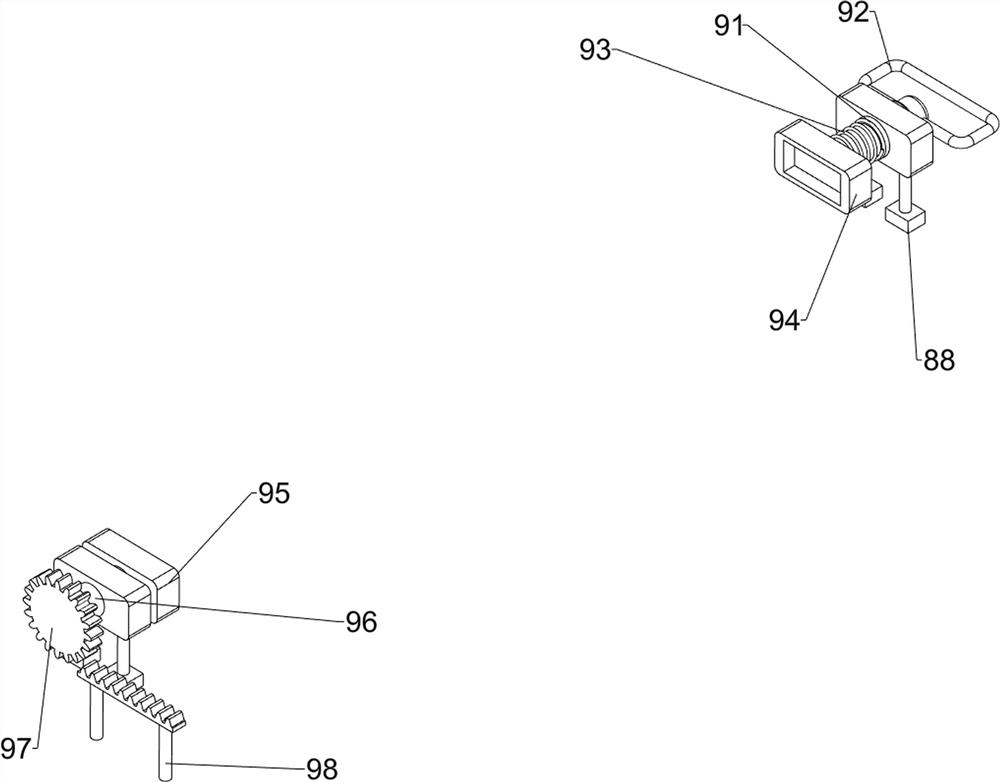

[0026] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the reciprocating mechanism 8 includes a sliding sleeve rod 81, a support frame 82, a mounting plate 83, a motor 84, a first rotating shaft 85, a half gear 86, a slide rail bar 87, a sliding block 88, a connecting rod 89, and a rack bar 810 With the first compression spring 811, the front and rear sides of the slide rail block 6 are all provided with a slide rail bar 87, and the slide rail bar 87 is provided with a sliding block 88, and a connecting rod 89 is provided between the two sliding block 88, and the base 1, the upper left side is provided with a support frame 82, the rear side of the support frame 82 is provided with a mounting plate 83, a motor 84 is installed on the mounting plate 83, the output shaft of the motor 84 is provided with a first rotating shaft 85, and the first rotating shaft 85 passes through the support Frame 82 is also connected in rotation with it. Th...

Embodiment 3

[0031] On the basis of Example 2, such as figure 1 and Figure 5 As shown, a moving mechanism 10 is also included, and the middle of the base 1 is provided with a moving mechanism 10. The moving mechanism 10 includes a second rack 101, a bracket 102, a rotating column 103, a second gear 104, a bevel gear set 105, a U-shaped Rod 106, the third gear 107, the third rack 108 and the second sliding sleeve 109, the base 1 is provided with brackets 102 symmetrically front and back in the middle, and the rotation type between the two brackets 102 is provided with a rotating column 103. The side is provided with a second gear 104 through a one-way clutch, and a second rack 101 is provided on the sliding block 88 on the rear side, and the second gear 104 is engaged with the second rack 101. Sliding sleeve 109, the left side of the second sliding sleeve 109 is provided with a third rack 108, the front of the third rack 108 is connected with the mounting frame 4, the left side of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com