Cutting and edging equipment for high-end equipment manufacturing

An edge grinding equipment and equipment technology, applied in other manufacturing equipment/tools, manufacturing tools and other directions, can solve the problems of cumbersome fixing methods, inability to guarantee workpiece grinding efficiency, high cost, low labor intensity, reduced labor intensity, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

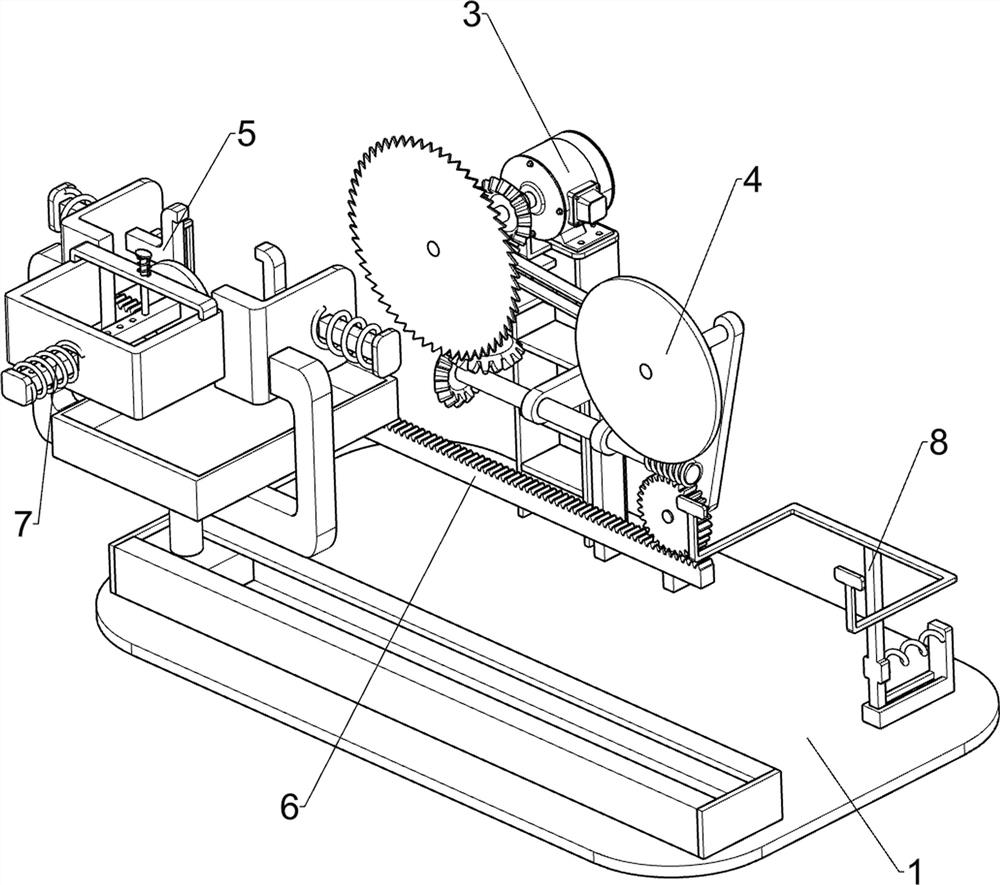

[0030] A cutting and edging equipment manufactured by high-end equipment, such as Figure 1 to Figure 4 As shown, it includes a base plate 1, a support frame 2, a cutting mechanism 3, a grinding mechanism 4 and a clamping mechanism 5. The top front side of the base plate 1 is connected with a support frame 2, and the top of the base plate 1 is equipped with a cutting mechanism 3. The cutting mechanism 3 A grinding mechanism 4 is connected with the support frame 2 , and the grinding mechanism 4 is connected to the cutting mechanism 3 in transmission, and a clamping mechanism 5 is installed on the rear side of the top of the bottom plate 1 .

[0031] The cutting mechanism 3 includes a base 31, a servo motor 32, a rotating shaft 33 and a two-way saw blade 34. The front side of the top of the base plate 1 is connected with a base 31. A servo motor 32 is installed on the base 31. The output shaft of the servo motor 32 is connected with a rotating shaft 33. , the rear end of the rot...

Embodiment 2

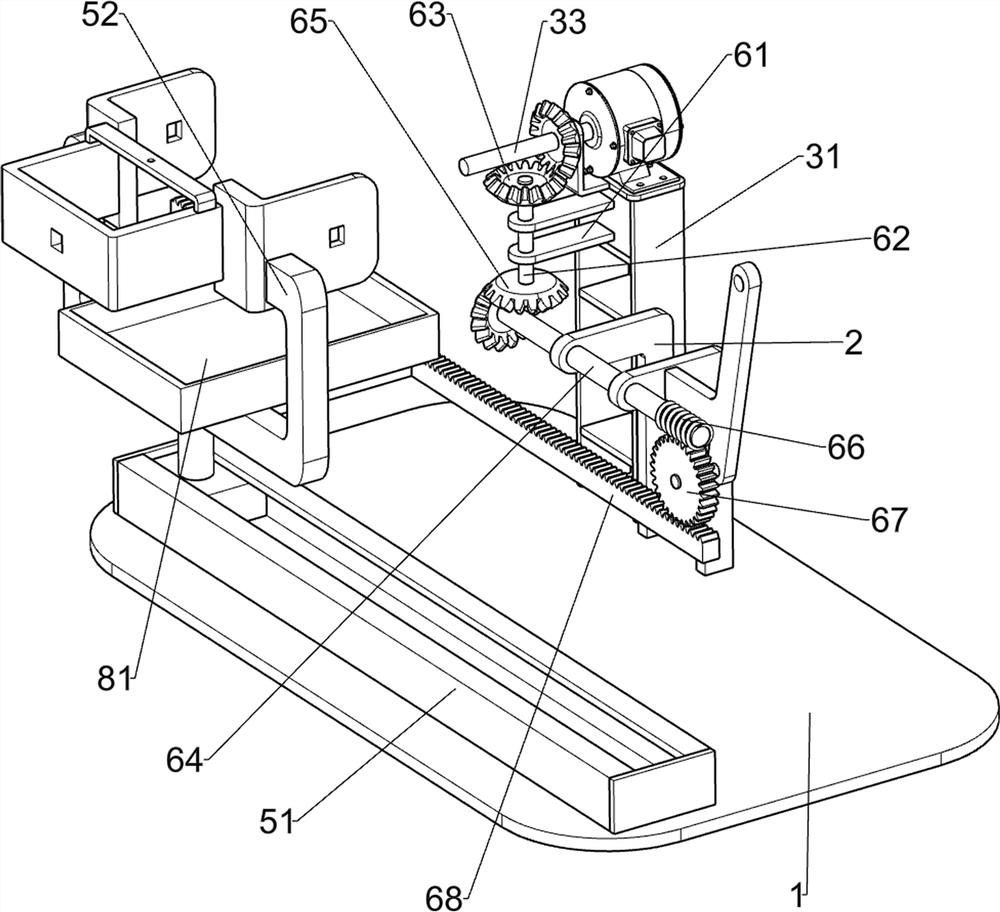

[0036] On the basis of Example 1, such as Figure 5As shown, a moving mechanism 6 is also included, and the moving mechanism 6 includes a fixed frame 61, a second connecting shaft 62, a first bevel gear set 63, a third connecting shaft 64, a second bevel gear set 65, a worm screw 66, and a worm wheel 67 With the rack frame 68, the rear side top of the base 31 is connected with a fixed mount 61, and the fixed mount 61 is connected with a second connecting shaft 62 in a rotational manner, and a first cone is installed between the top of the second connecting shaft 62 and the rotating shaft 33. Gear set 63, the middle part of support frame 2 is connected with the third connecting shaft 64 rotationally, the second bevel gear set 65 is connected between the right end of the third connecting shaft 64 and the bottom end of the second connecting shaft 62, the third connecting The left end of shaft 64 is equipped with worm screw 66, and the rear side bottom of support frame 2 is connec...

Embodiment 3

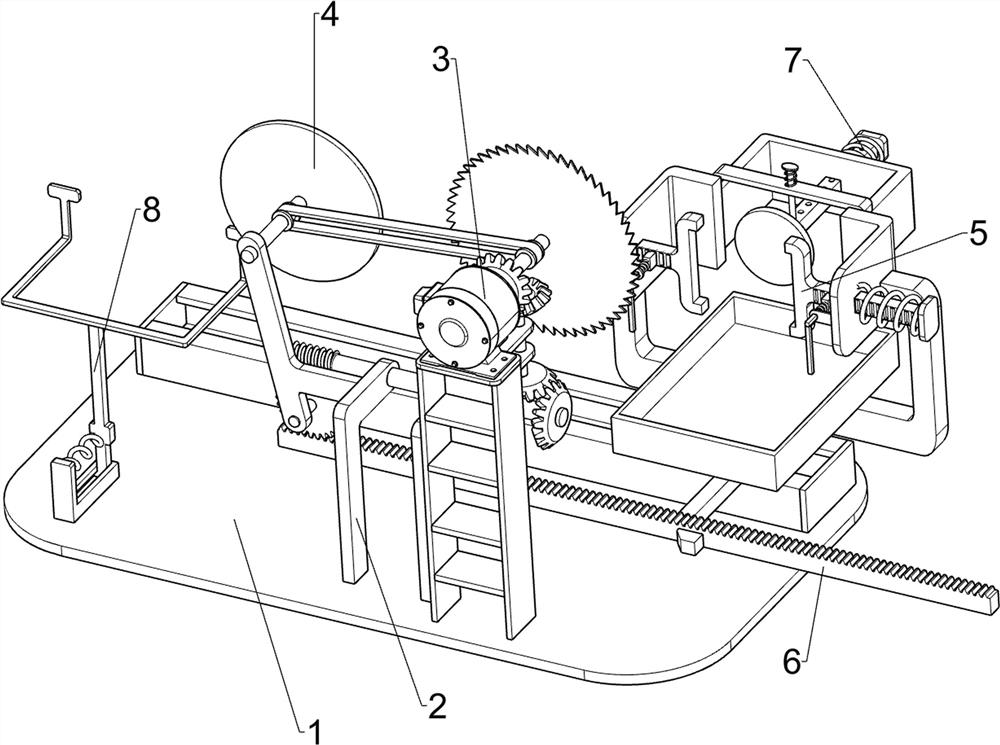

[0039] On the basis of Example 2, such as Figure 4 to Figure 7 As shown, feed mechanism 7 is also included, and feed mechanism 7 comprises hole guide rod 71, the 3rd spring 72, guide post 73 and the 4th spring 74, and the upper rear side of mounting frame 52 is slidably connected with belt The hole guide rod 71 is connected with the third spring 72 between the rear end of the hole guide rod 71 and the top rear side of the mounting frame 52, and the third spring 72 is sleeved on the outside of the hole guide rod 71, and the top of the mounting frame 52 A guide post 73 is slidably connected, and the guide post 73 is engaged with the guide rod 71 with a hole. A fourth spring 74 is connected between the top of the guide post 73 and the top of the installation frame 52 .

[0040] The workpiece can be positioned through the guide rod 71 with a hole to avoid moving backward on the mounting frame 52 when the workpiece is cut. When it is necessary to adjust the cutting position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com