Patents

Literature

575results about How to "Guaranteed cutting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cutting tool for improving coating structure, and preparation method thereof

ActiveCN103171178AHigh strengthImprove toughnessLayered productsWear resistanceChemical vapor deposition

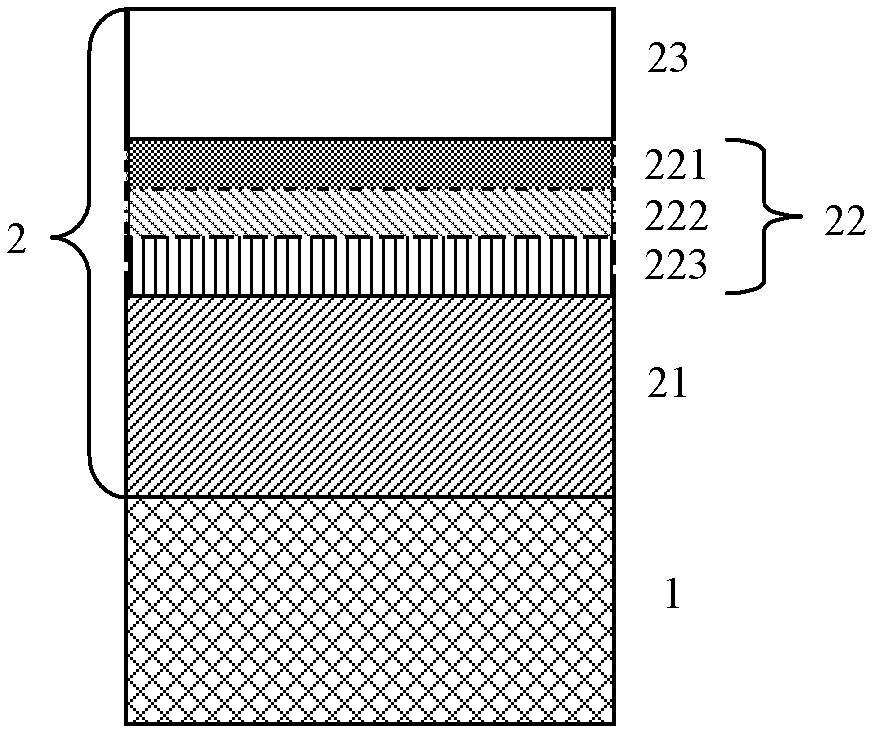

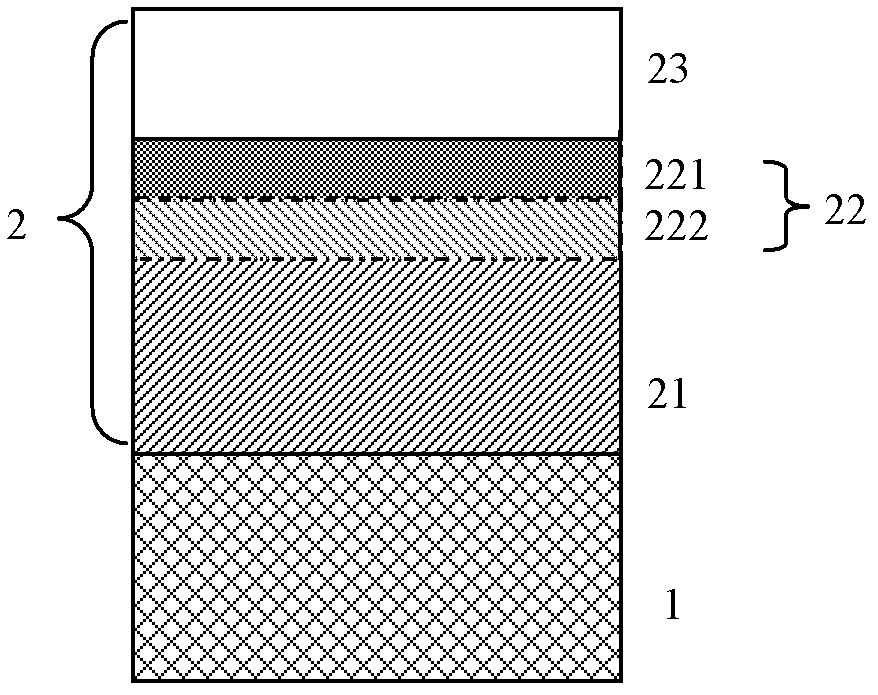

The invention discloses a cutting tool for improving a coating structure. The cutting tool comprises a base body and a coating arranged on the base body, wherein the coating comprises an inner layer A, a transition layer C and an outer layer B from inside to outside; the inner layer A mainly comprises compound material formed by transition elements and non-metallic elements; the outer layer B mainly comprises oxide and the like; the transition layer C comprises a transition layer C1, a transition layer C2 and a transition layer C3 from outside to inside; the transition layer C1 mainly consists of TiCx1Ny1Oz1; the transition layer C2 mainly consists of TiCx2Ny2Oz2; and the transition layer C3 mainly consists of TiAlCx3Ny3Oz3 or TiCx3Ny3Oz3. A preparation method of the cutting tool comprises the steps of: combining chemical vapor deposition (CVD) and high-temperature (HT)-CVD onto the base body, and coating in sequence by various coating technologies. The cutting tool has the advantages of being good in wear resistance, high in adhesive force, high in inhibition, etc.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Cutting tool for improving coating structure and preparation method thereof

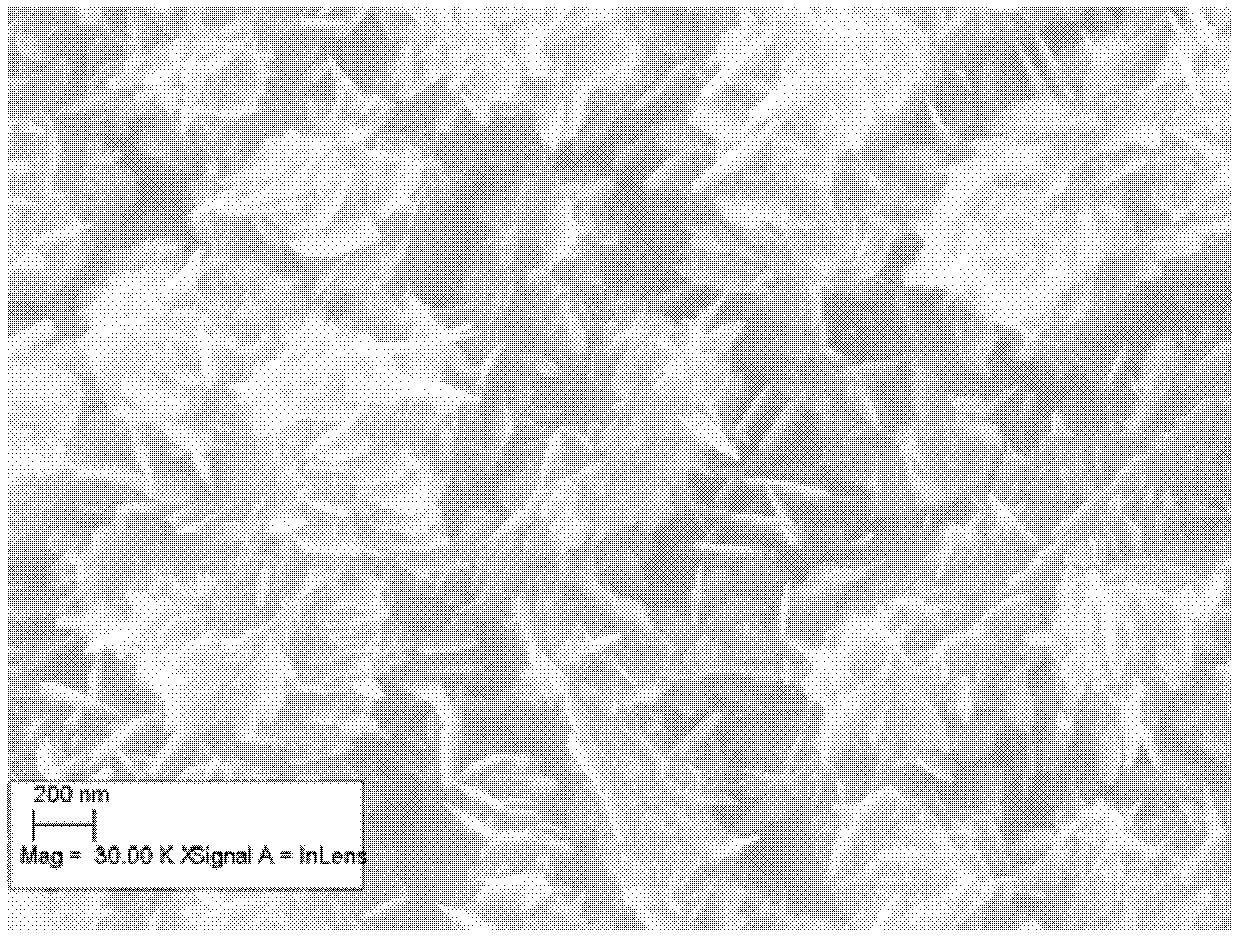

ActiveCN103173761AExcellent oxidation and crater wear resistanceImprove uniformityTurning toolsSuperimposed coating processSingle phaseCast iron

The invention discloses a cutting tool for improving a coating structure. The cutting tool comprises a matrix and a coating covering the matrix. The coating comprises an inner layer B, a transitional layer C and an outer layer D from inside to outside. The inner layer B consists of transitional elements and nonmetal compounds. The transitional layer C comprises a transitional layer C1 and / or a transitional layer C2. The transitional layer C1 and C2 are mainly formed by carbon oxynitride with titanium. The outer layer D has a single phase alpha-Al2O3 structure. The thickness d of the outer layer D is 0.5-4 mu m. The mean grain size S is greater than or equal to 0.2 mu m but less than or equal to 0.5 mu m. The preparation method comprises the following steps of: first, preparing the tool matrix; then, sequentially depositing the inner layer B, the transitional layer C2, the transitional layer C1 and the outer layer D in a same coating period; and then, performing surface treatment to manufacture the cutting tool. The cutting tool provided by the invention is high in hardness and good in wear resistance, and has excellent cutting performance in cutting materials such as steel, stainless steel and cast iron.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

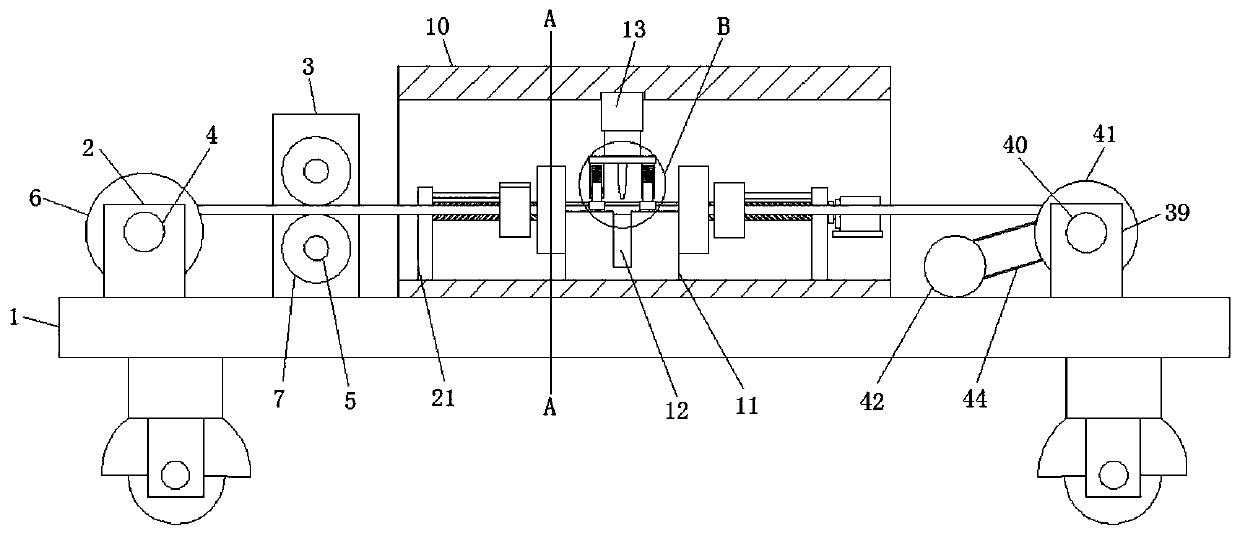

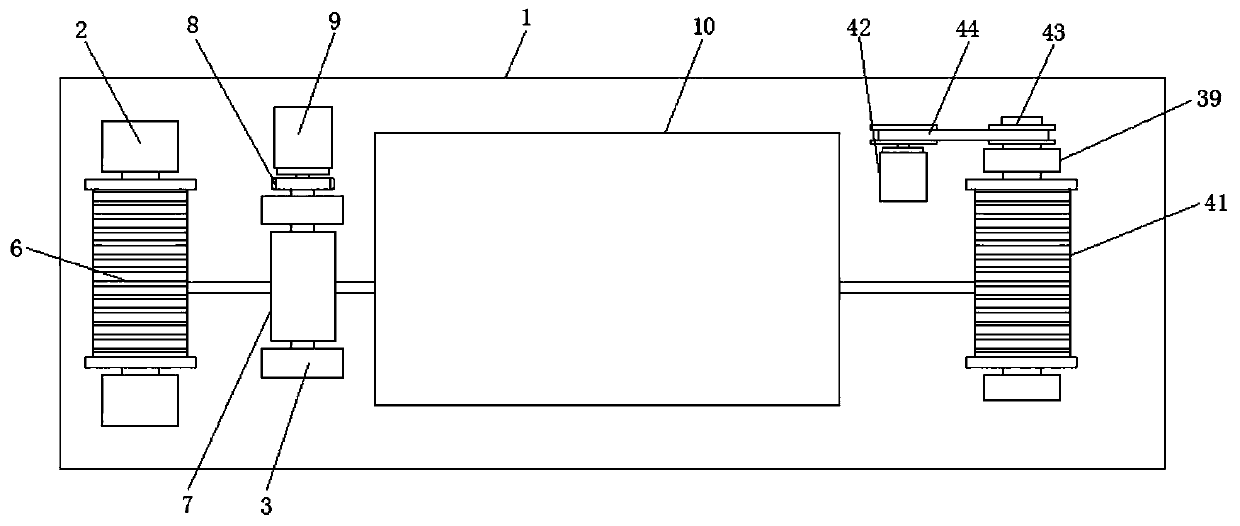

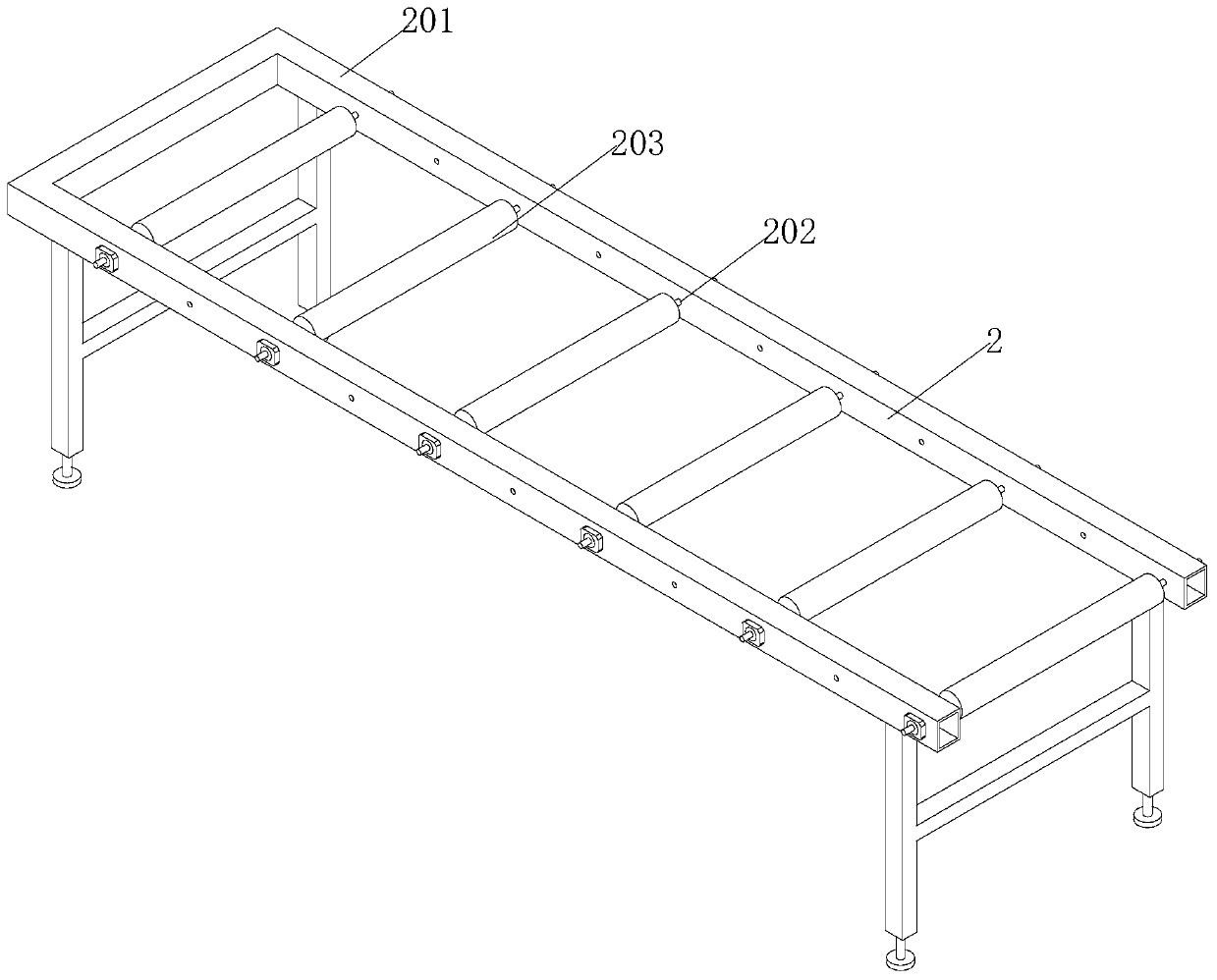

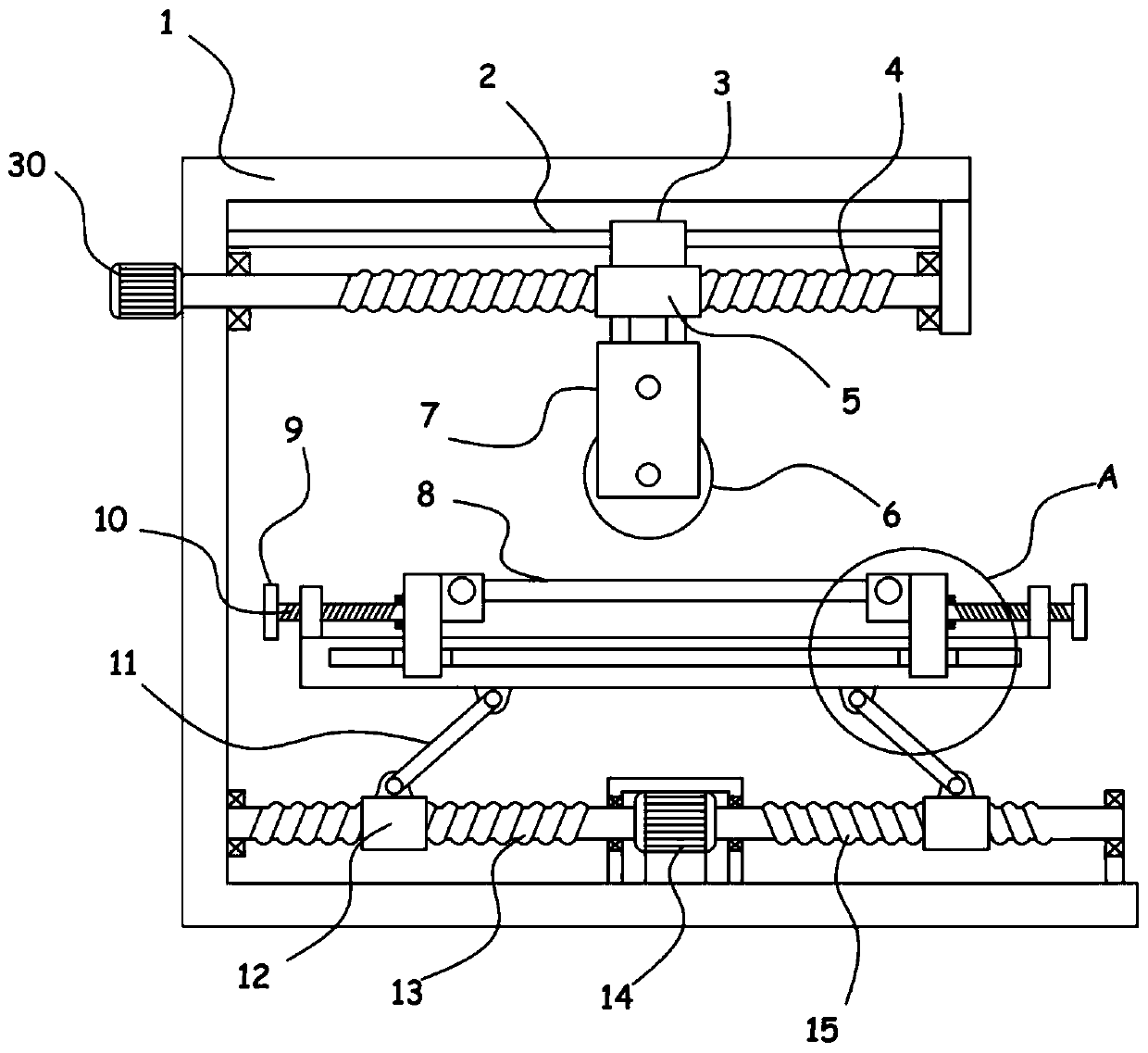

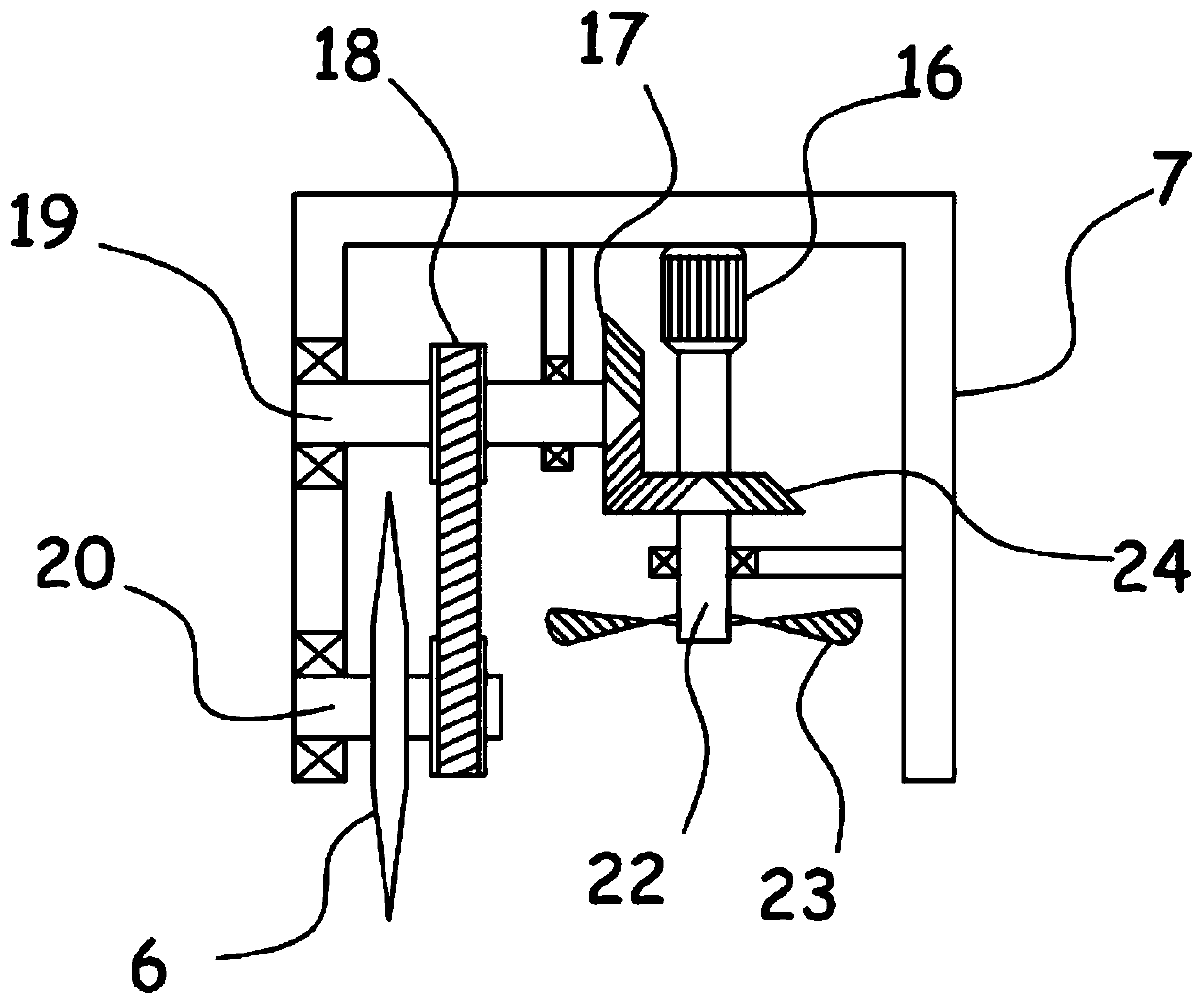

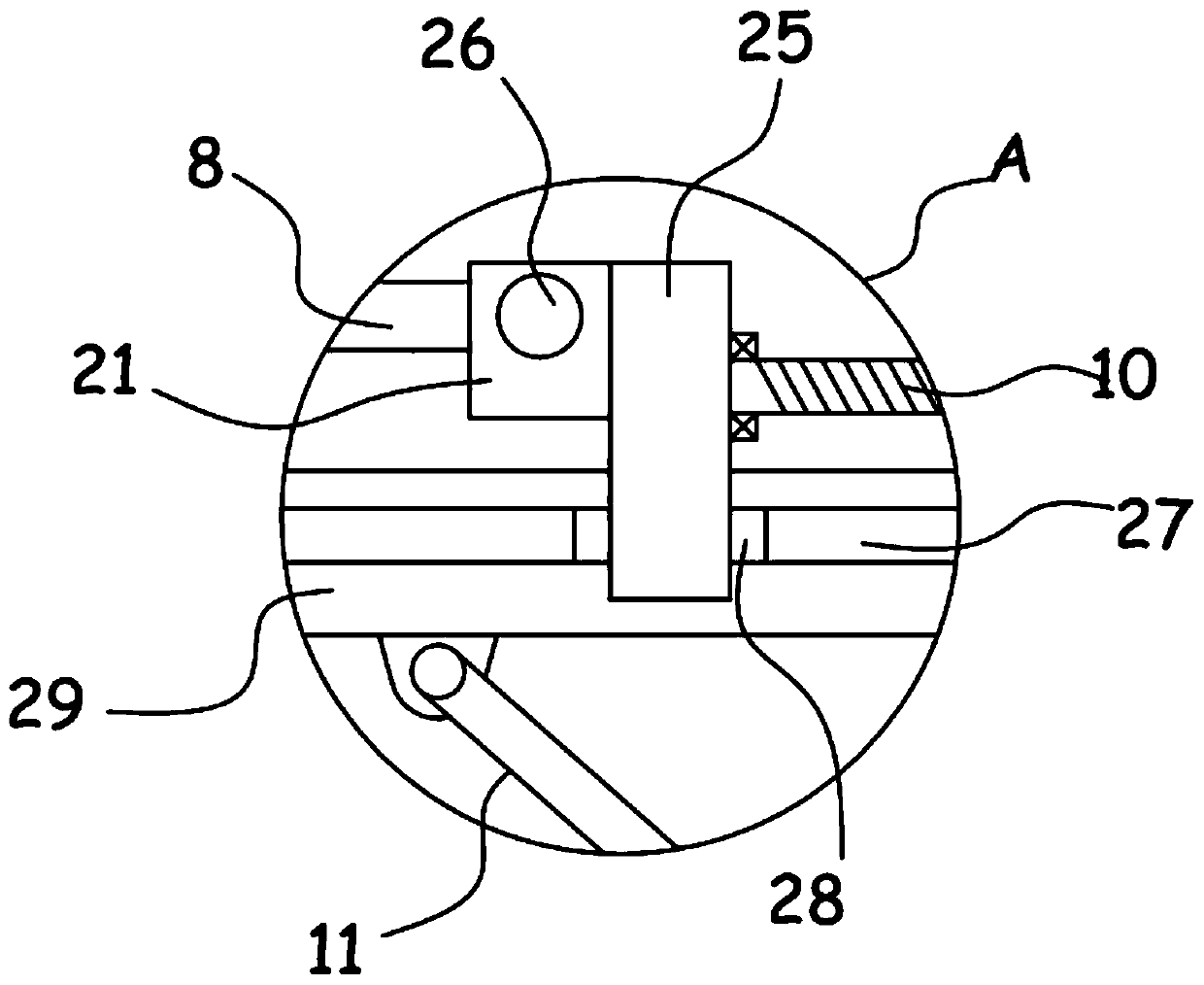

Cable laying and installation cutting and peeling equipment

InactiveCN110265933ALine optimizationConveying works wellApparatus for removing/armouring cablesApparatus for laying cablesBiochemical engineering

The invention discloses cable laying and installation cutting and peeling equipment, which comprises a work bench. The four corners of the lower end surface of the work bench are respectively and fixedly connected with a supporting leg through a screw; the lower end of each supporting leg is equipped with a universal wheel; one side of the upper end surface of the work bench is fixedly connected with support bases 1 and support bases 2 through screws; the support bases 2 are located at the side, close to the center of the work bench, of the support bases 1; the number of the support bases 1 and the number of the support bases 2 are two; a fixation shaft 1 is rotatably connected between the two support bases 1 through a rolling bearing and fixation shafts 2 are rotatably connected between the two support bases 2 through rolling bearings; the rod body outer walls of the fixation shaft 1 and the fixation shafts 2 are fixedly connected with a pay-off roller and a conveying roller through screws respectively; the two fixation shafts 2 are symmetrically arranged at the upper and lower ends of the support base 2; the back sides of the two fixation shafts 2 pass through the support bases 2 and are rotatably connected through a gear set; and the back end of the rear support base 2 is provided with a servo motor 1.

Owner:ANHUI TIANMING CABLE

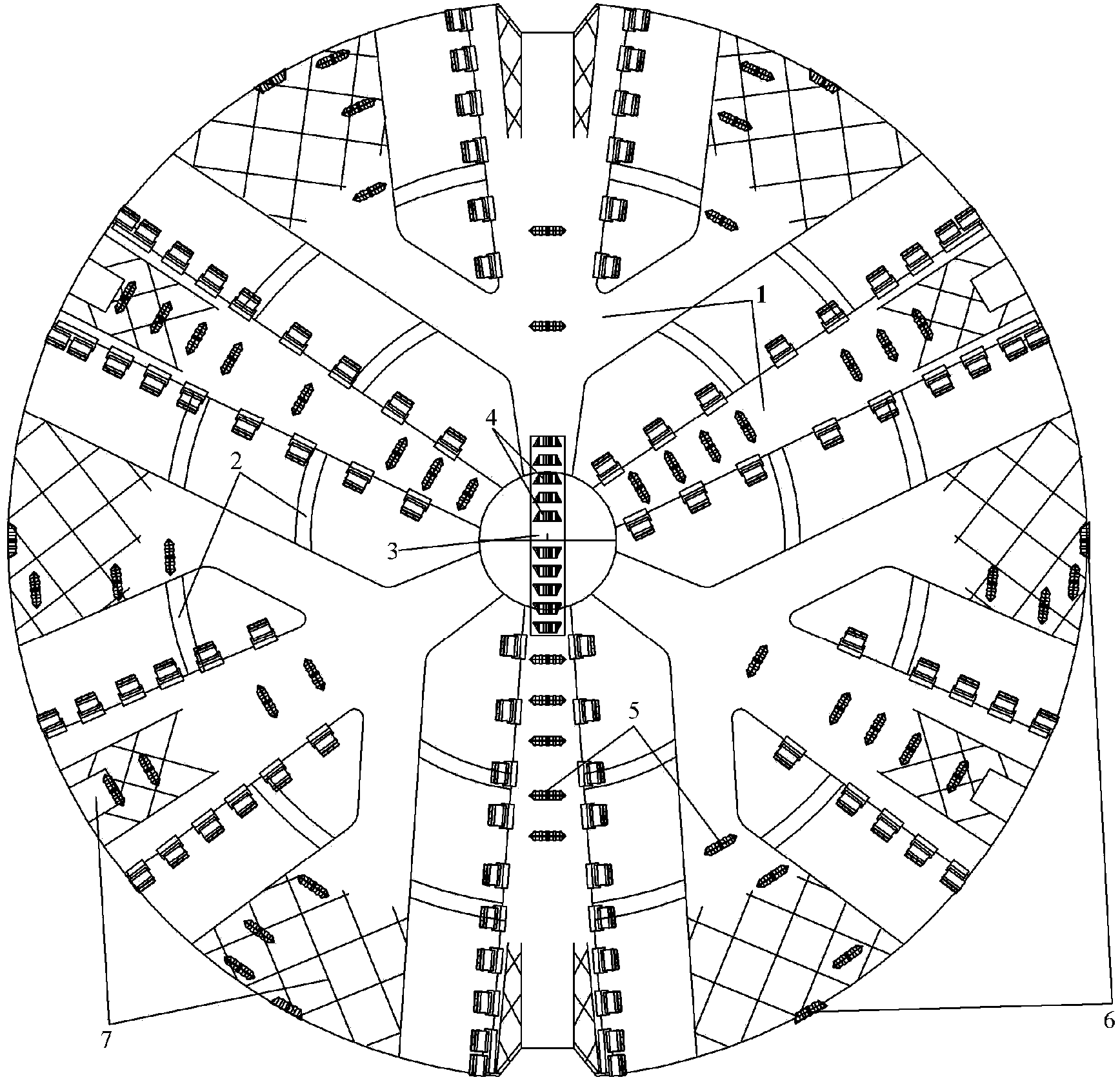

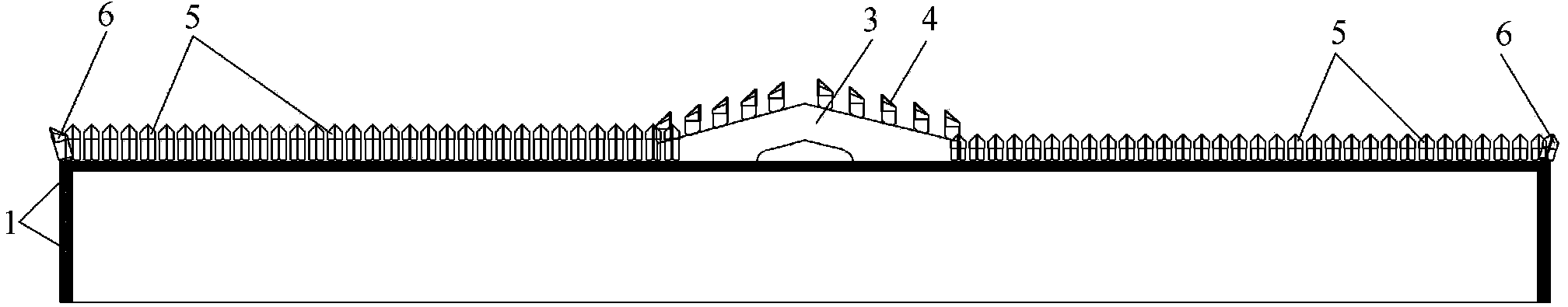

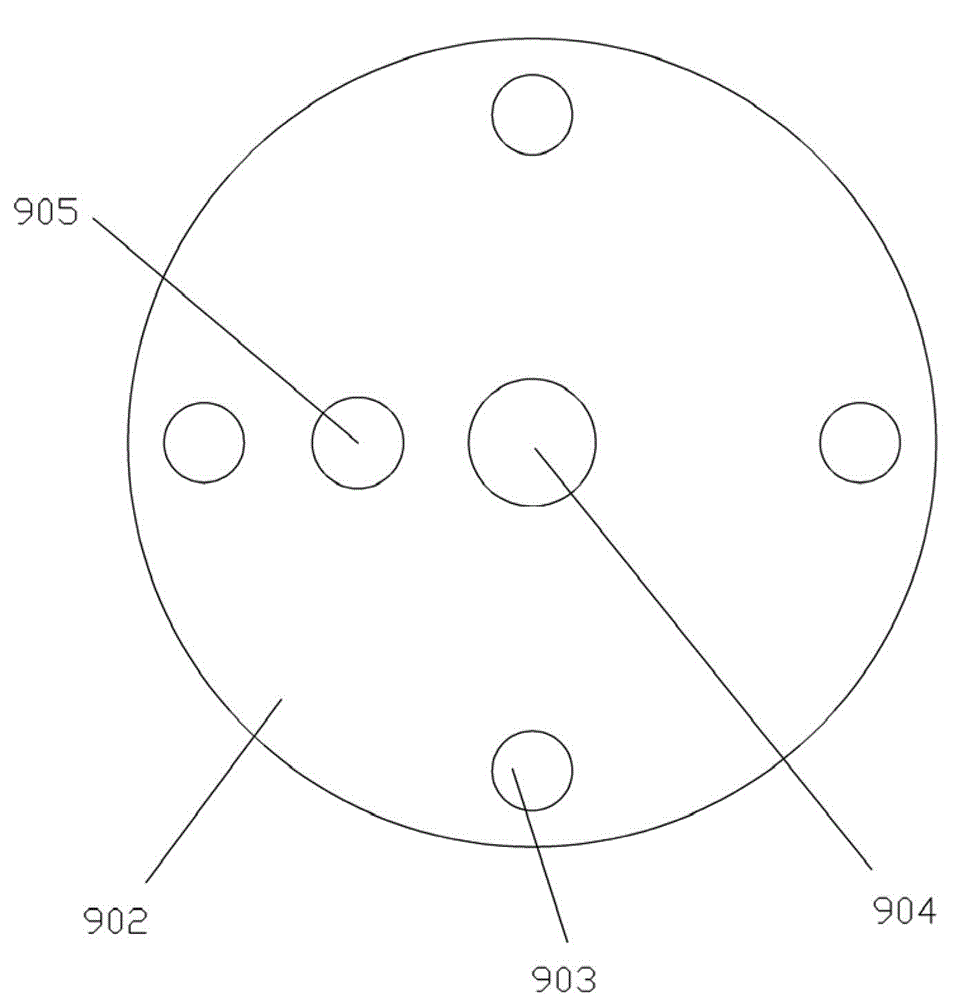

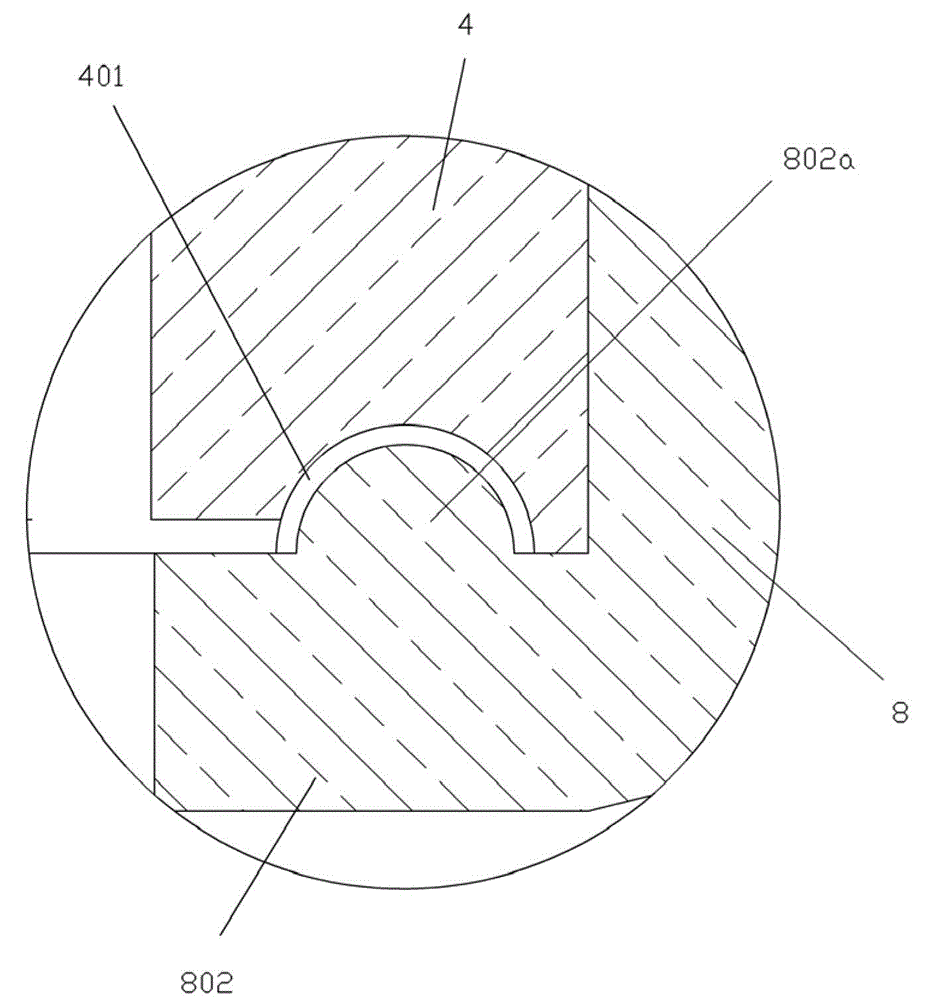

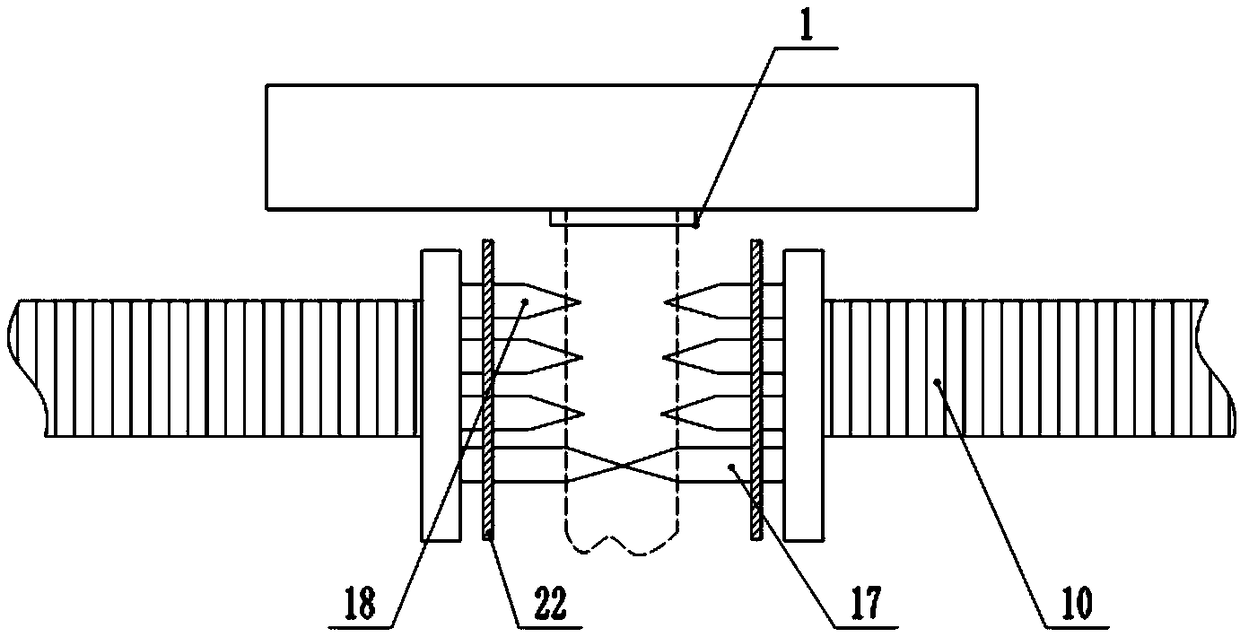

Cutterhead and cutter reinforcing method for directly cutting reinforced concrete pile foundations by shield

The invention belongs to the technical field of shield tunnel construction of city subways, in particular to a cutterhead and cutter reinforcing method for directly cutting reinforced concrete pile foundations by a shield. The method includes the steps of performing nondestructive inspection on a cutterhead, reinforcing rigidity of the cutterhead, modifying a center cutter, additionally arranging center pile cutters, front pile cutters and edge pile cutters, and reinforcing abrasive resistance of the cutterhead. By the method, rigidity and abrasive resistance of the cutterhead can be reinforced, pile cutting capability of a center-cutter region can be improved, and reserved cutting capability of the cutters can be enhanced, so that risks in directly cutting the reinforced concrete pile foundations by the shield are reduced and smooth pile cutting work is guaranteed.

Owner:BEIJING JIAOTONG UNIV

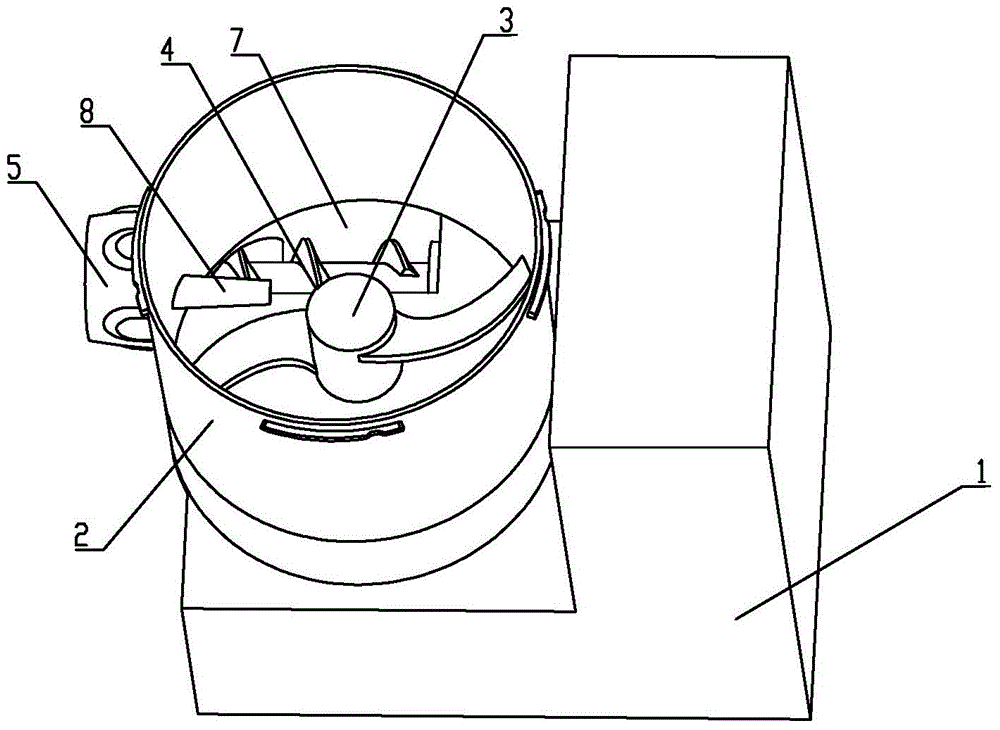

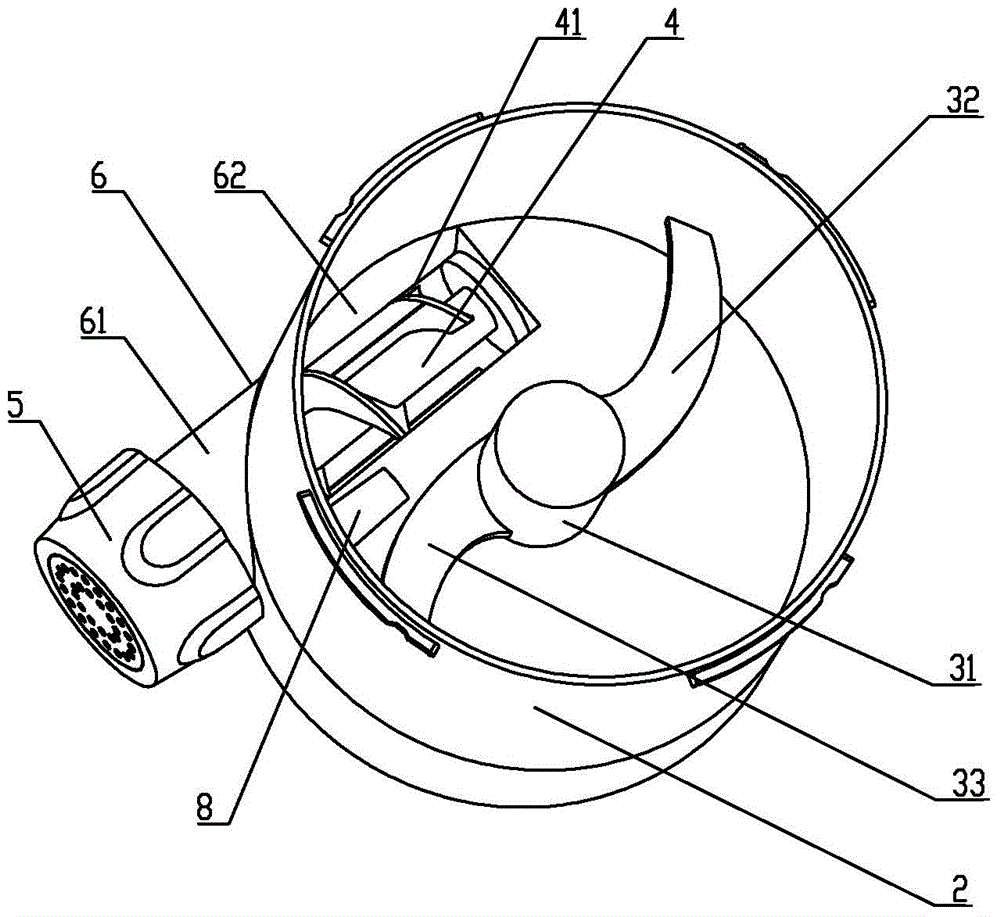

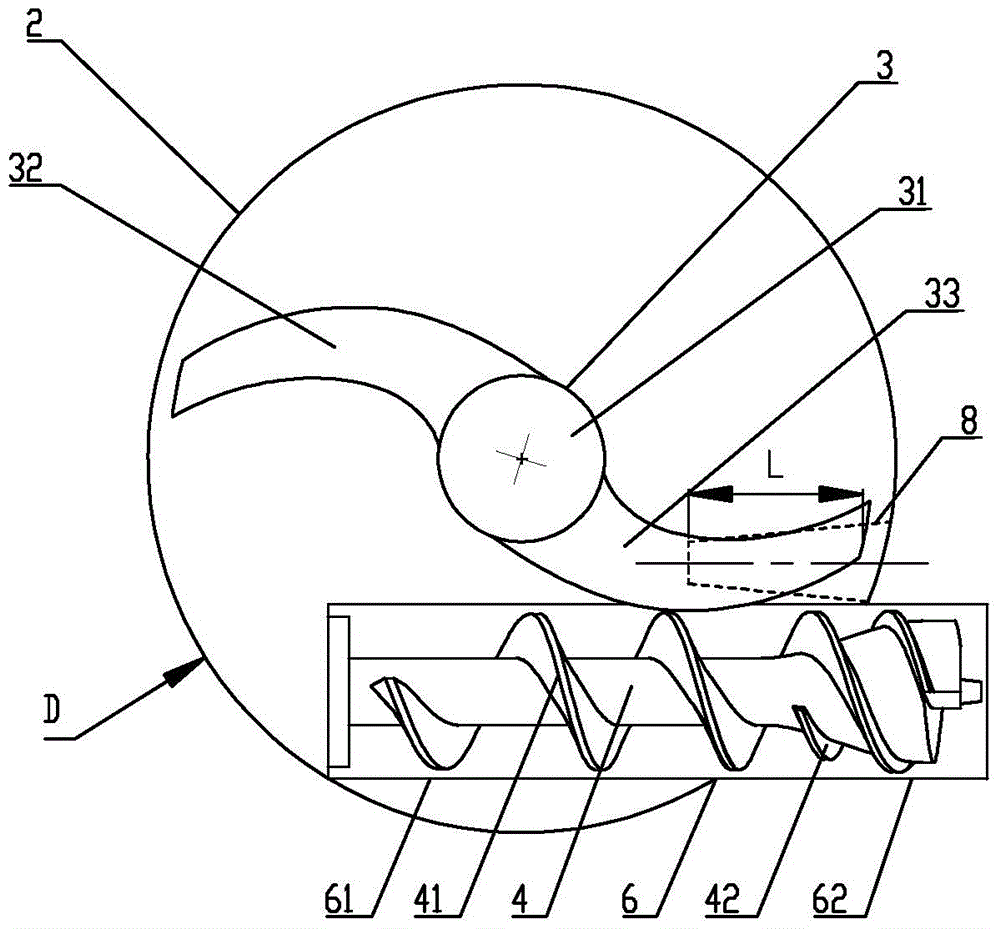

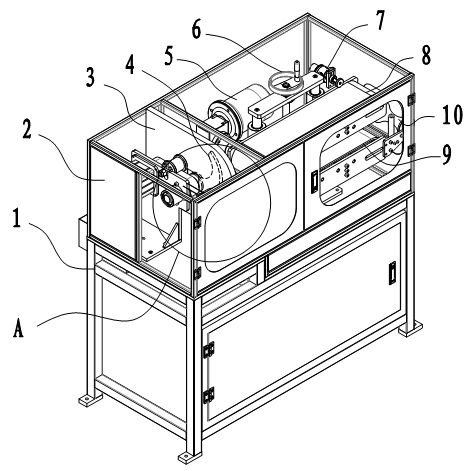

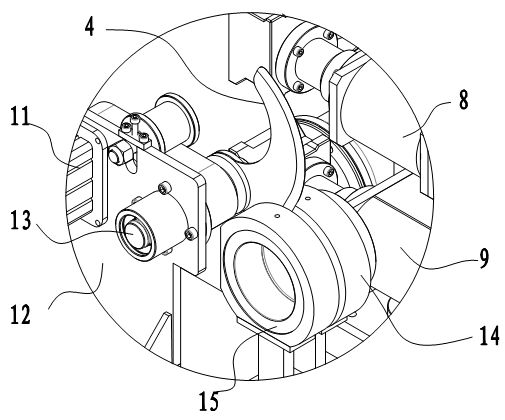

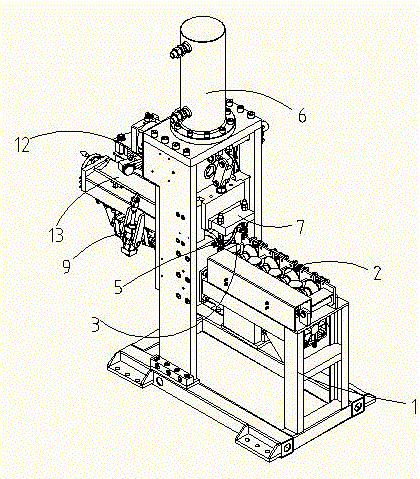

Domestic vertical type noodle maker

ActiveCN104542788AAccelerate the mixing speedImprove mixing efficiencyMixing/kneading with vertically-mounted toolsDough extruding machinesEngineeringExtrusion

The invention discloses a domestic vertical type noodle maker which comprises a base, a stirring cup, a stirring rod, a dough extrusion cylinder, a screw rod, a mold head and a control unit, wherein the base is provided with motors; the stirring cup is connected with the base; the stirring rod comprises a rod body as well as upper stirring teeth and lower stirring teeth which are arranged on the rod body; a dough inlet is formed in the communicating part of the stirring cup and the dough extrusion cylinder; a dough cutting rod is arranged on the inner wall of the stirring cup; the dough cutting rod is positioned between the upper stirring teeth and the lower stirring teeth; the stirring rod rotates to drive the upper stirring teeth and the lower stirring teeth to rotate and mix and stir flour with water to make dough; the dough cutting rod cooperates with the upper stirring teeth and the lower stirring teeth to cut off or tear and deform the dough into dough pieces which are smaller than the dough inlet; when the upper stirring teeth and / or the lower stirring teeth rotate to the dough cutting rod, the projects of the dough cutting rod and the upper stirring teeth and / or the lower stirring teeth in the horizontal direction are at least partially overlapped. By adopting the mode, the effects of no residue, high possibility of dough feeding and high processing efficiency can be achieved.

Owner:JOYOUNG CO LTD

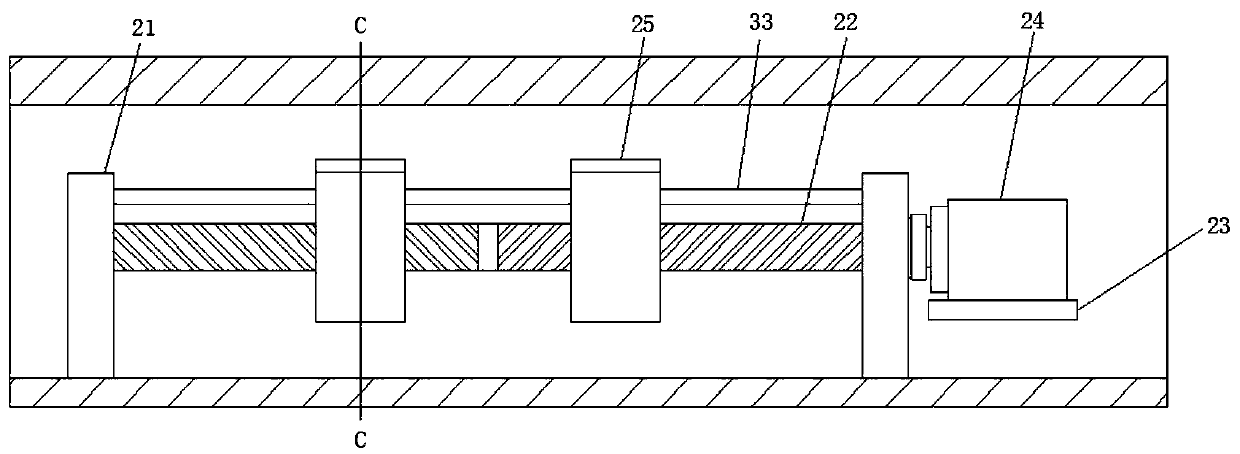

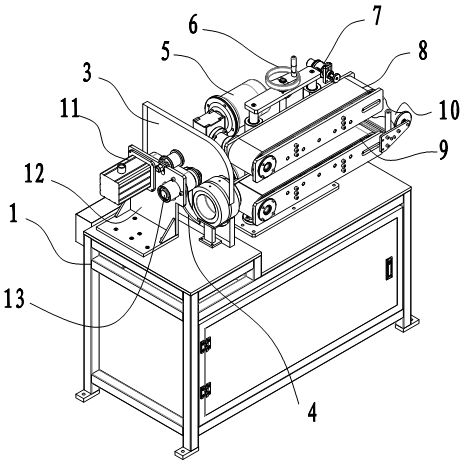

Servo rubber tube cutting machine

InactiveCN102528838AReduce distortionKeep height center constantMetal working apparatusEngineeringCutting force

The invention discloses a servo rubber tube cutting machine, which comprises a framework. A conveying belt is arranged on the framework, a bracket for carrying a rubber tube is disposed at the tail end of the conveying belt and consists of a front bracket and a rear bracket, a gap is reserved between the front bracket and the rear bracket, a flail knife which is controlled by a servo motor to realize rotational cutting is arranged at the gap, and is an arc-shaped structure, and an outer arc side of the flail knife is a knife edge side. The servo rubber tube cutting machine has the advantages that the arc-shaped flail knife is used for rotationally cutting, instantaneous cutting speed is fast, cutting force is dispersed in various directions, deformation of a cutting surface is low, and surface smoothness is good. In addition, the conveying belt is vertically symmetrically adjusted, the height center of the conveying belt keeps unchanged, and height alignment can be realized conveniently. Besides, a proximity switch is used for controlling, the flail knife is immersed in cooling liquid after cutting at a time, a good cutting effect is guaranteed, and knife surfaces with liquid cannot be easily adhered with rubber tube materials.

Owner:浙江百纳橡塑设备有限公司

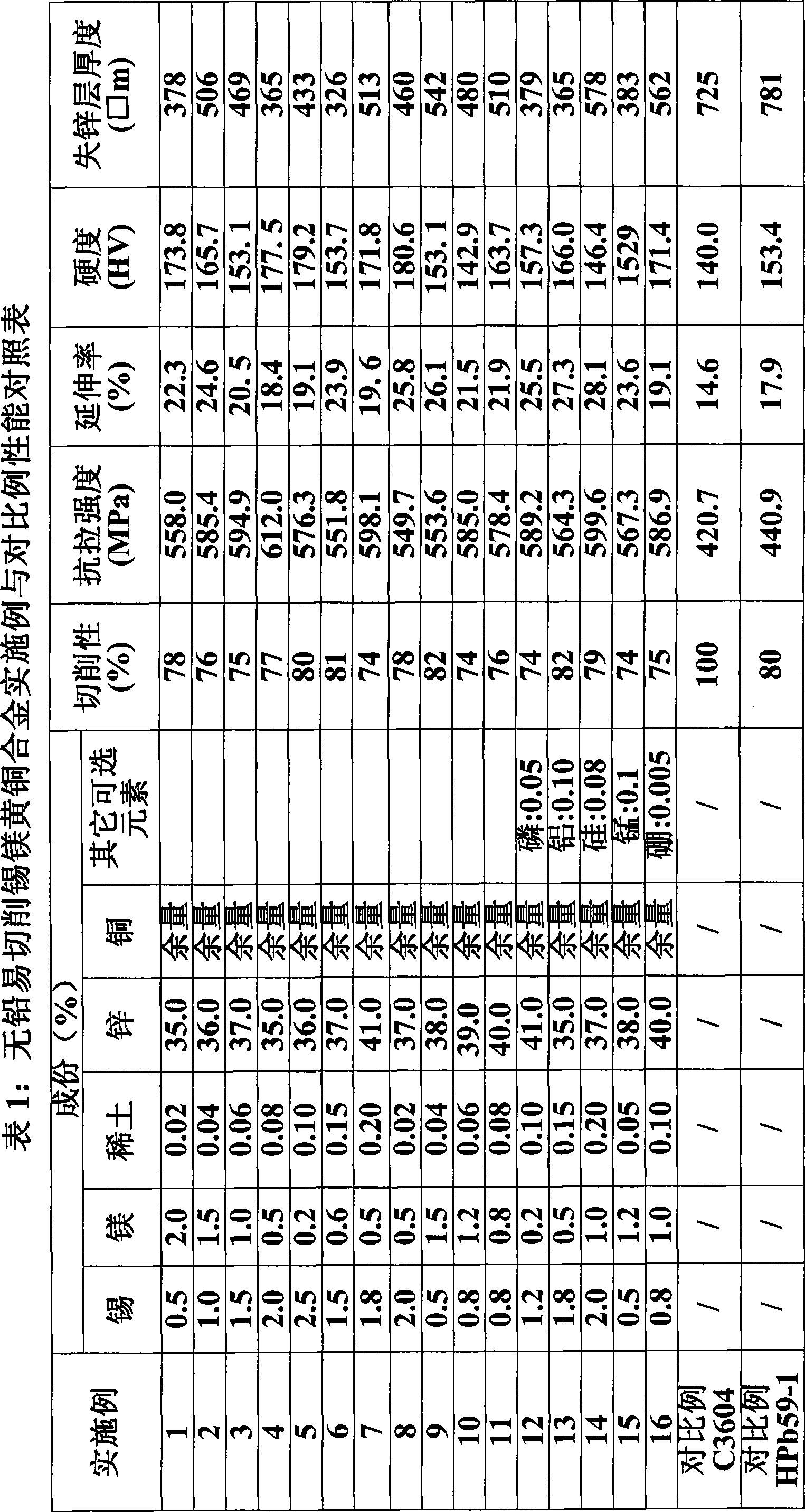

Leadless free-cutting tin-magnesium brass alloy

The invention relates to a leadless free cutting antimony magnesium brass alloy, belonging to the technical field of brass alloy material manufacture. The brass alloy comprises zinc, copper, tin, magnesium and rare earth; all the ingredients are as follows according to weight proportion: 35.0 to 41.0 percent of zinc, 0.5 to 2.5 percent of tin, 0.2 to 2.0 percent of magnesium, 0.02 to 0.2 percent of rare earth and the balance of copper and impurities with the amount of less than or equal to 0.05 percent and the total amount of the weight proportion of all the ingredients is 100 percent; any or more than one mixtures of silicon, phosphorus, aluminum, manganese, boron and iron can be added and the adding amount is not more than 1.0 percent of the total amount of the weight proportion of all the ingredients. The invention has scientific and reasonable compound formulation, utilizes the characteristic that the magnesium and the compound of magnesium and copper are uniformly and dispersively distributed in crystalline and crystal boundary so as to lead the obtained alloy product to have fine crystal grain, high strength as well as good plasticity, has good cutting performance, hot processing performance and excellent corrosion resistant performance and is particularly applicable to the fields of pipe fittings of water heating, bathroom and the like.

Owner:ZHEJIANG KEYU METAL MATERIALS +1

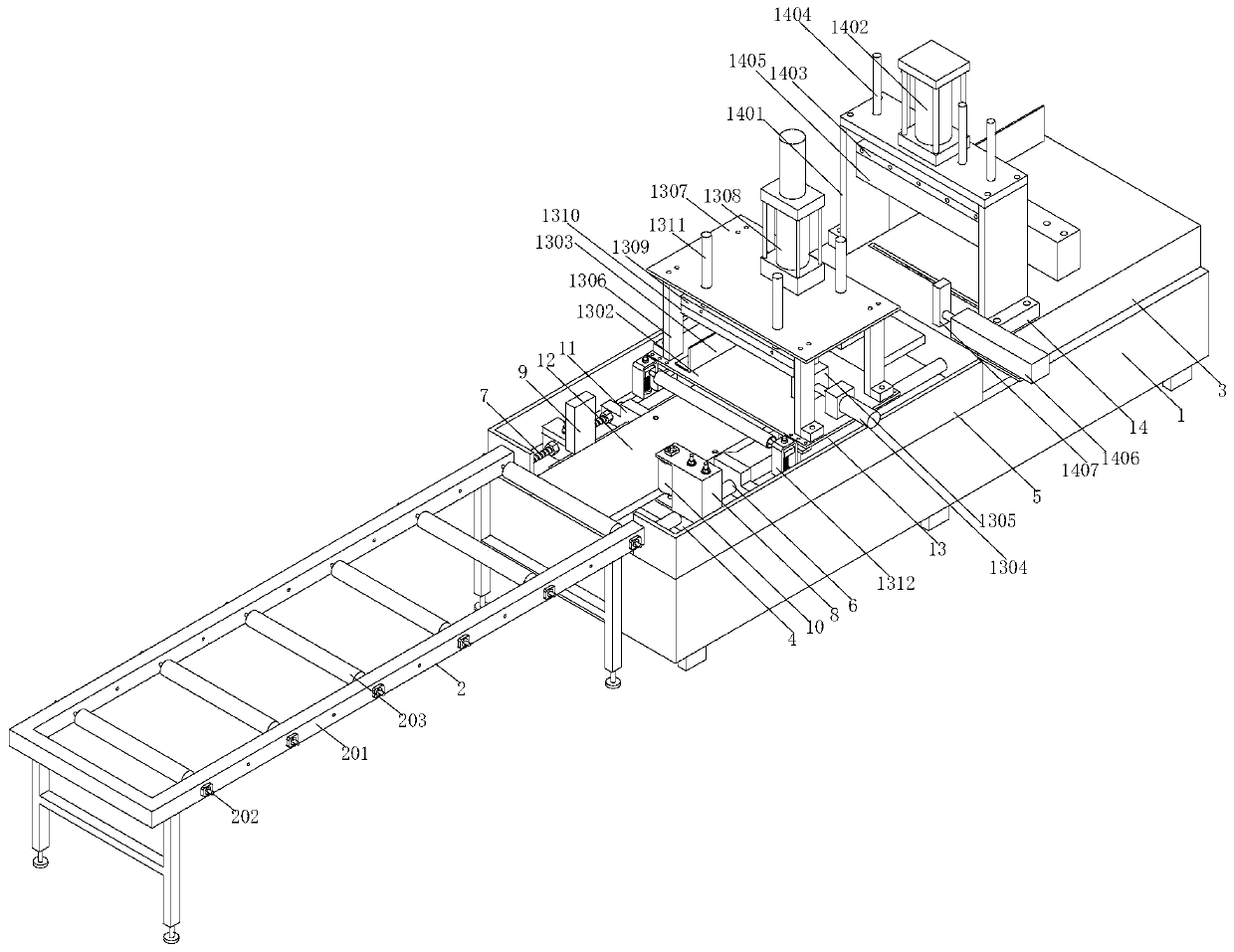

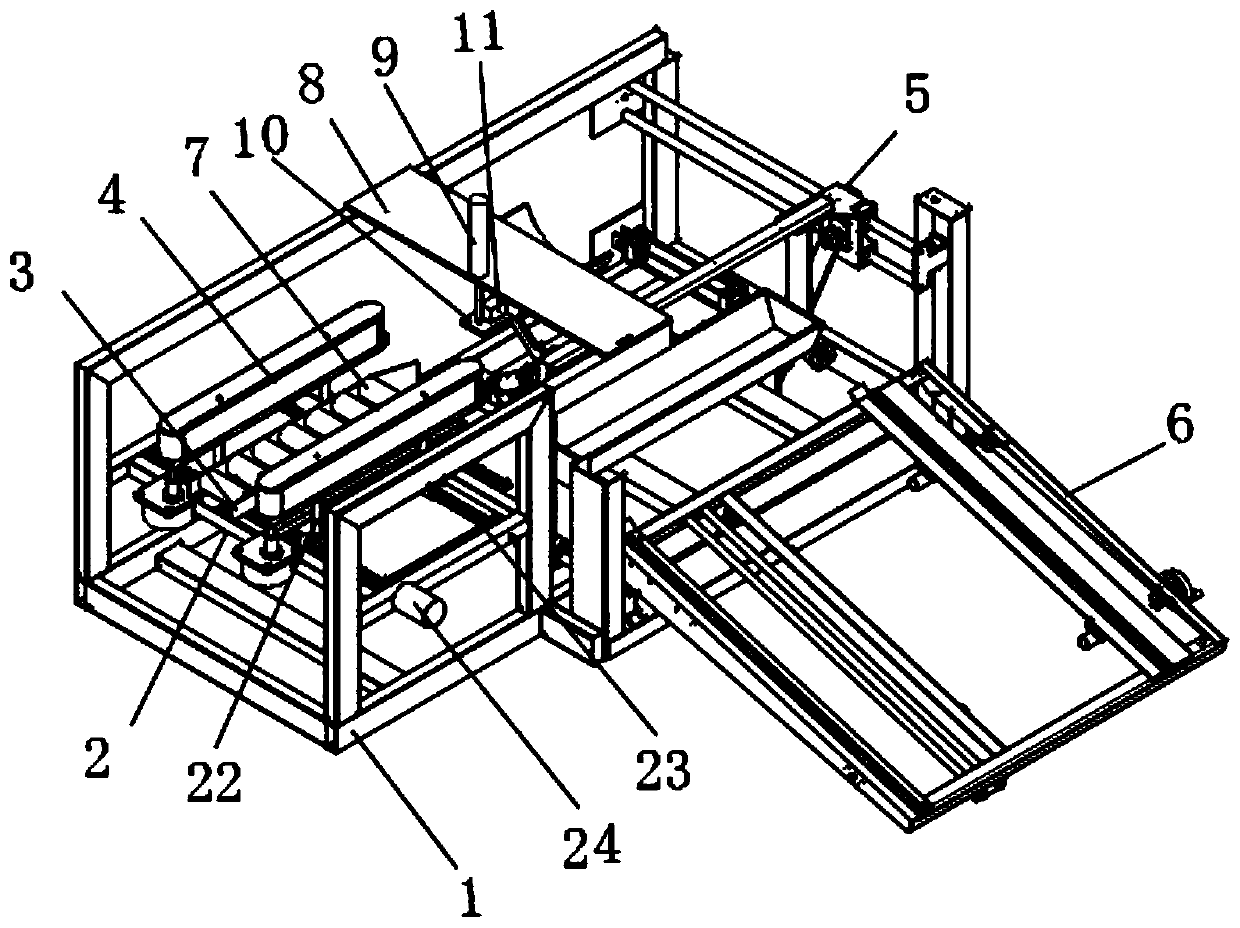

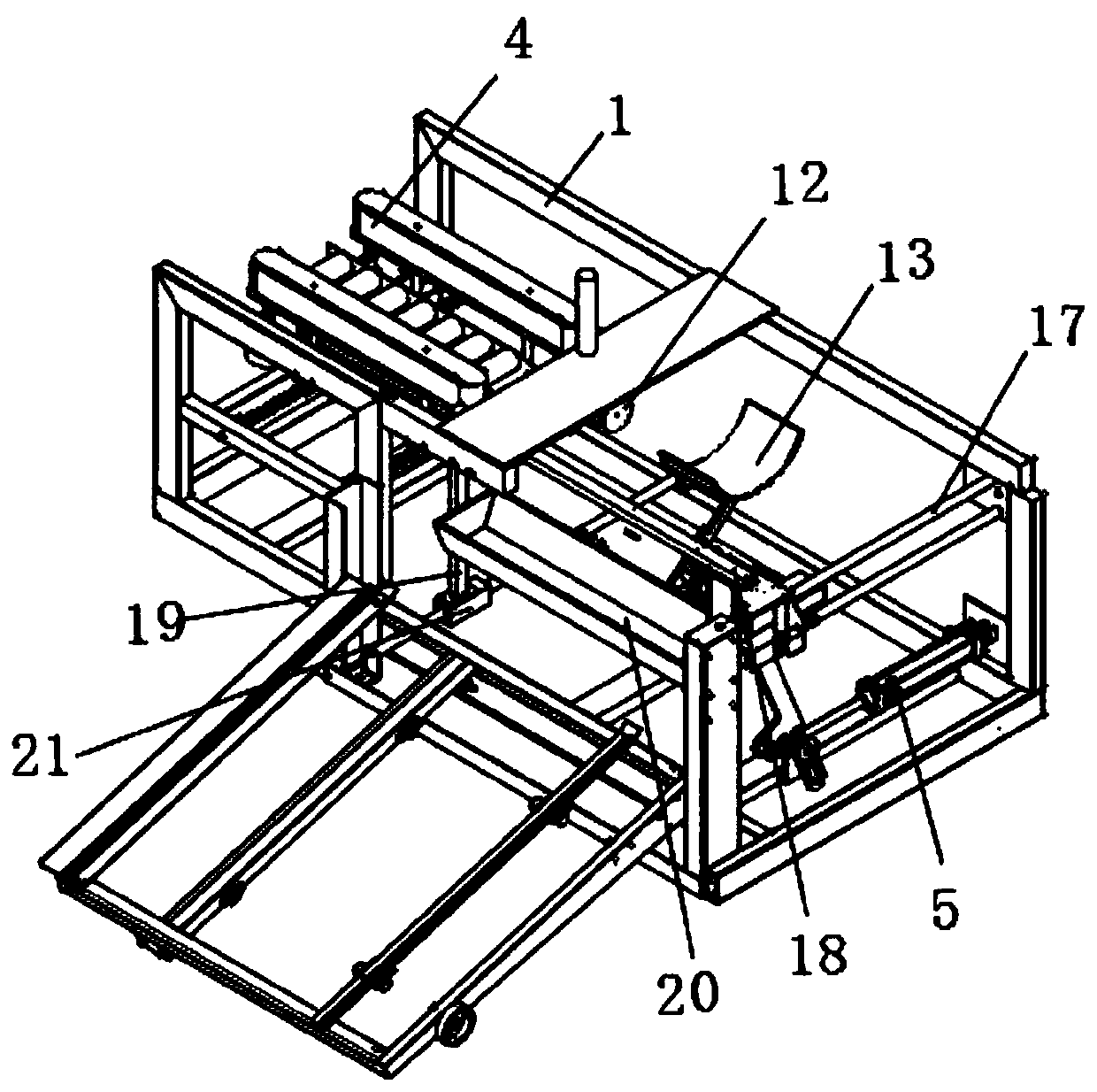

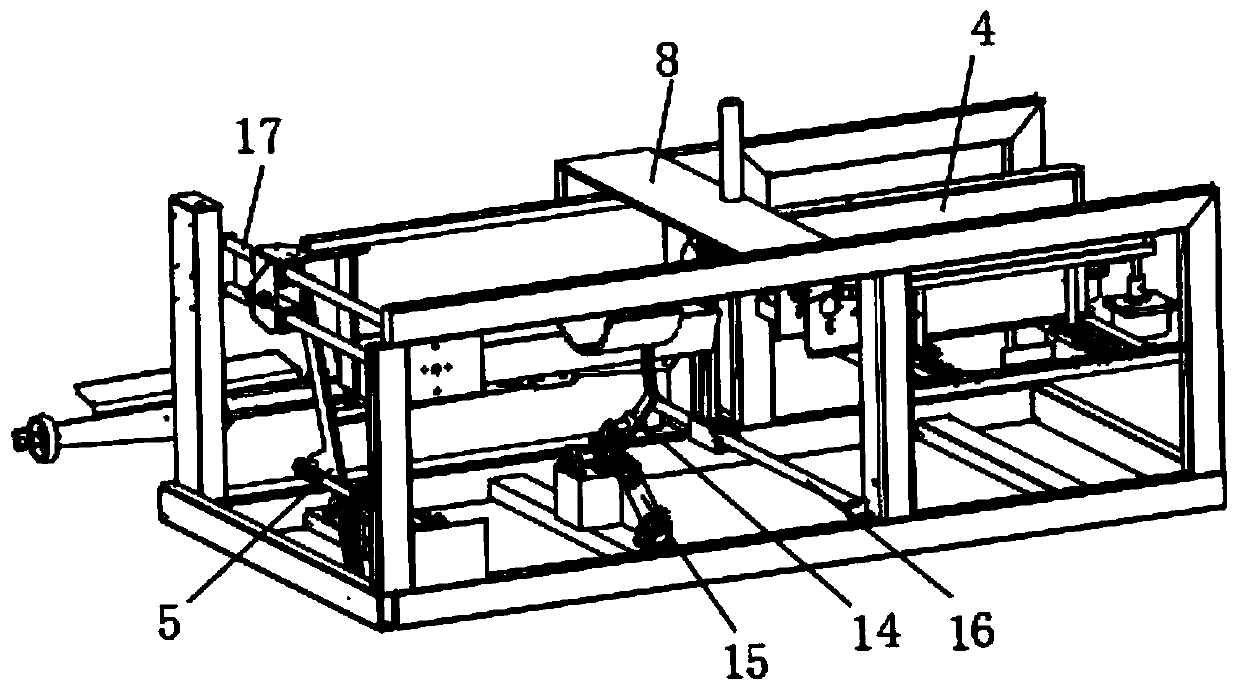

Aluminum alloy section cutting equipment

ActiveCN110315381ASimple and convenient cutting operationAdequate and effective fixationPositioning apparatusMetal working apparatusMaterials scienceAluminium alloy

The invention belongs to the technical field of aluminum alloy section processing equipment, and particularly relates to aluminum alloy section cutting equipment. The equipment comprises a rack and afeeding device used for conveying a aluminum alloy section, wherein a discharging plate, a mounting block and two L-shaped baffles are fixedly arranged at the top of the rack, the interior of the discharging plate communicates with the interior of the rack, and two sliding columns and two supporting rods are symmetrically arranged on the mounting block. According to the equipment, the cutting operation is simple and convenient, and the section is conveyed into the interior of the cutting equipment by the feeding device; through the design of a first material guiding roller and a second material guiding roller, the section can conveniently move in the equipment, and the phenomenon that moving is inconvenient due to the fact that friction is too large is avoided; cutting steps are simple andconvenient, so that the cutting working efficiency is improved; through matching of a limiting device and a reinforcing device, the section can be sufficiently and effectively fixed, so that the cutting precision of the section is improved; and meanwhile, through the design of a position structure of a cutting device is adopted,the safety of the equipment is improved.

Owner:南通金燃机械制造有限公司

Machining aluminum plate cutting device

InactiveCN111001872ACutting stabilityEnsure smooth cuttingShearing machinesMaintainance and safety accessoriesElectric machineryKnife blades

The invention discloses a machining aluminum plate cutting device and relates to the technical field of machining. The device comprises a supporting frame, wherein a motor II is fixed to the supporting frame, the motor II is in driving connection with a translation mechanism, the supporting frame is connected with a horizontally-arranged lifting frame through a lifting mechanism, and an adjustingmechanism used for longitudinally moving and adjusting an aluminum plate is arranged on a sliding frame. The device is advantaged in that two sliding frames are driven by the arranged locking mechanism to move in opposite directions, the sliding frame drives a bracket to move oppositely, transverse clamping and fixing of the aluminum plate are realized, the stability of the aluminum plate in the cutting process is ensured, the arranged lifting mechanism can drive the aluminum plate to move in the vertical direction, the complete cutting effect of a blade on the aluminum plate is guaranteed, the arranged translation mechanism can drive a hanging bracket to drive the cutting mechanism to move transversely and linearly, the stable cutting effect on the aluminum plate is achieved, the arrangedblowing mechanism can blow chippings while the aluminum plate is cut, and that the aluminum plate is stably cut and is not disturbed by the chippings is guaranteed.

Owner:武文家

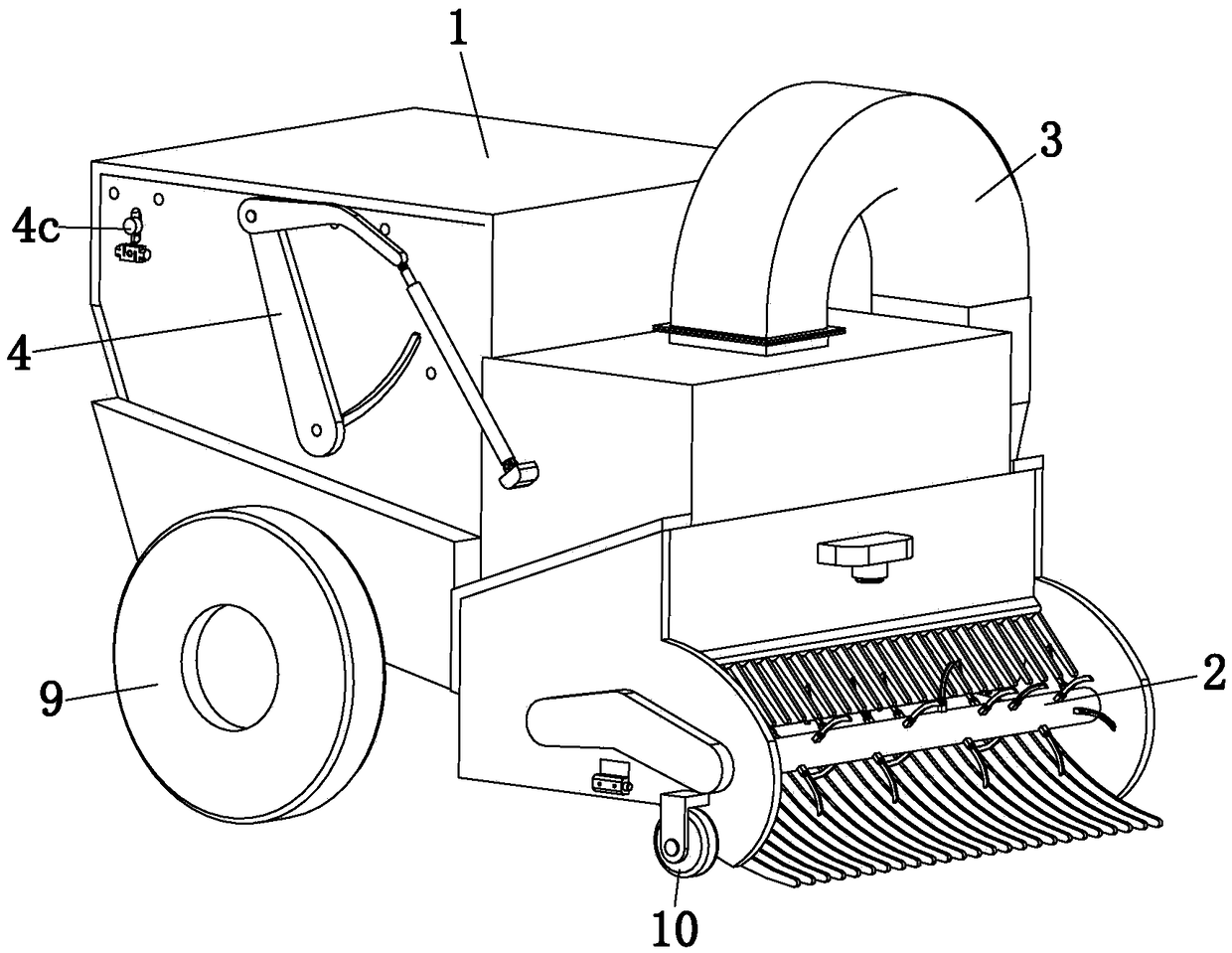

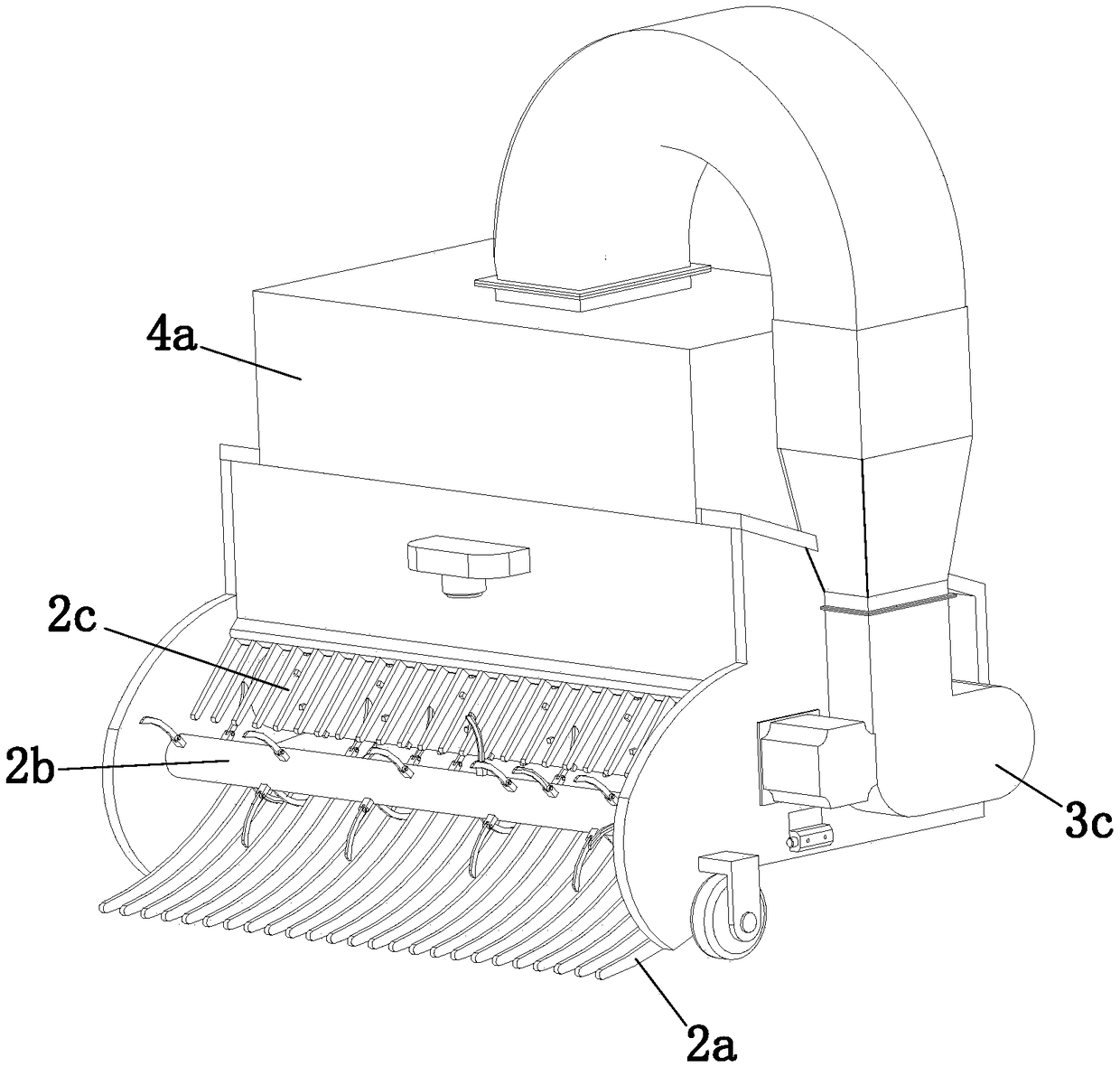

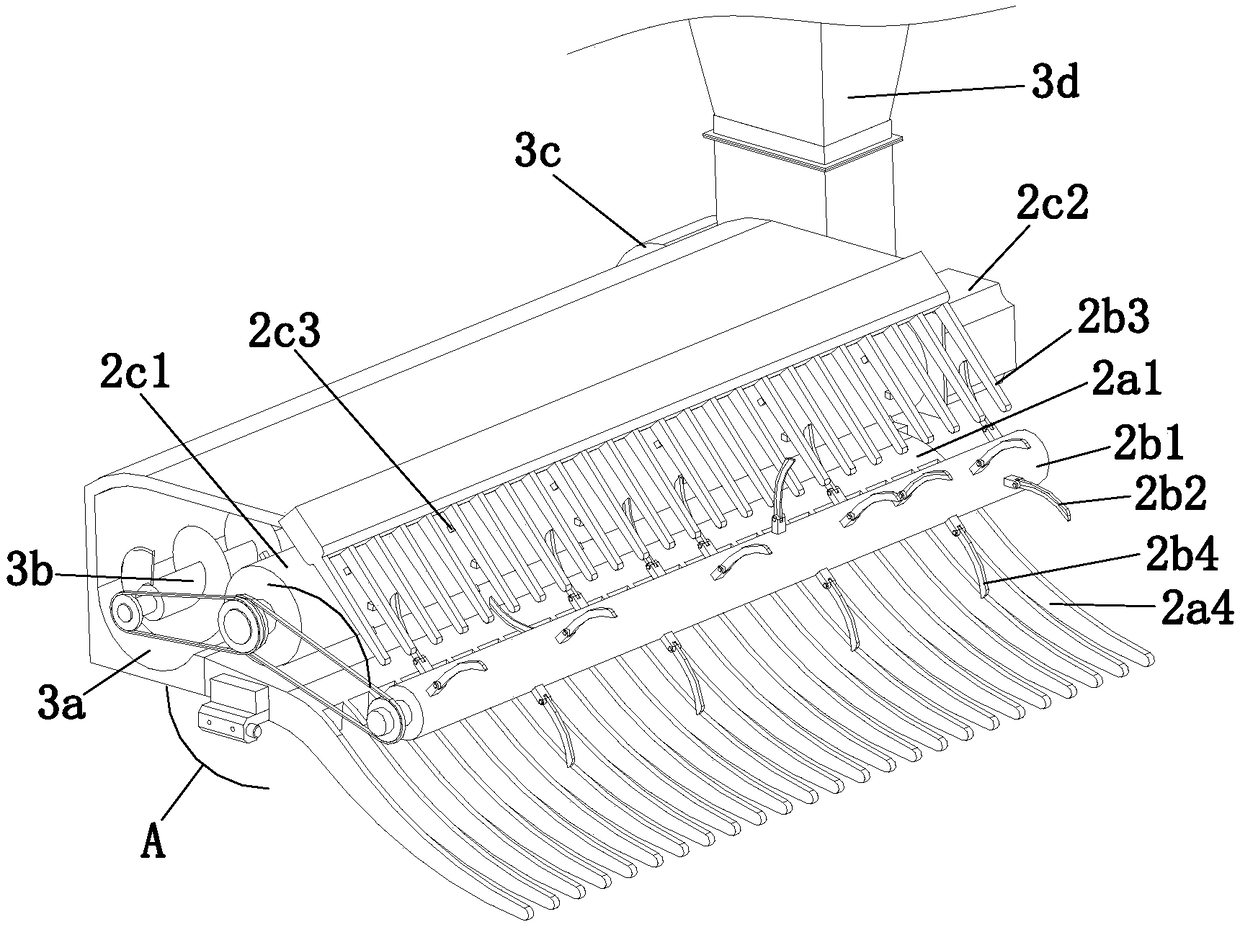

Straw baler capable of realizing automatic monitoring

PendingCN109275427APrevent stuck situationsStuck situation avoidanceBalingGratingAgricultural engineering

The invention discloses a straw baler capable of realizing automatic monitoring, and belongs to the technical field of agricultural machinery equipment. The straw baler comprises a frame, a collectingmechanism, a conveying mechanism, a bundling mechanism and a rope feeding mechanism, the collecting mechanism comprises a collecting assembly, a cutting assembly and a compacting assembly, the cutting assembly is located above the collecting assembly, the compacting assembly is located at the rear of the cutting assembly, the bundling mechanism comprises a material limiting assembly, a bundling assembly and a tension detecting assembly, the material limiting assembly is connected with the conveying mechanism, the bundling assembly is installed nearby the material limiting assembly, and the tension detecting assembly is fixedly connected the bundling assembly. According to the invention, a user can conveniently grasp the equipment working state in time by a camera, a tension sensor, a grating sensor and a pressure sensor, and the setting of the collecting mechanism and the conveying mechanism can effectively avoid occurrence of material jamming.

Owner:ANHUI SCI & TECH UNIV

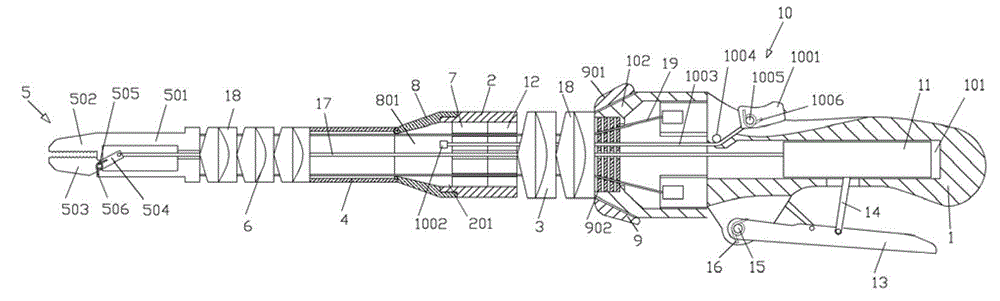

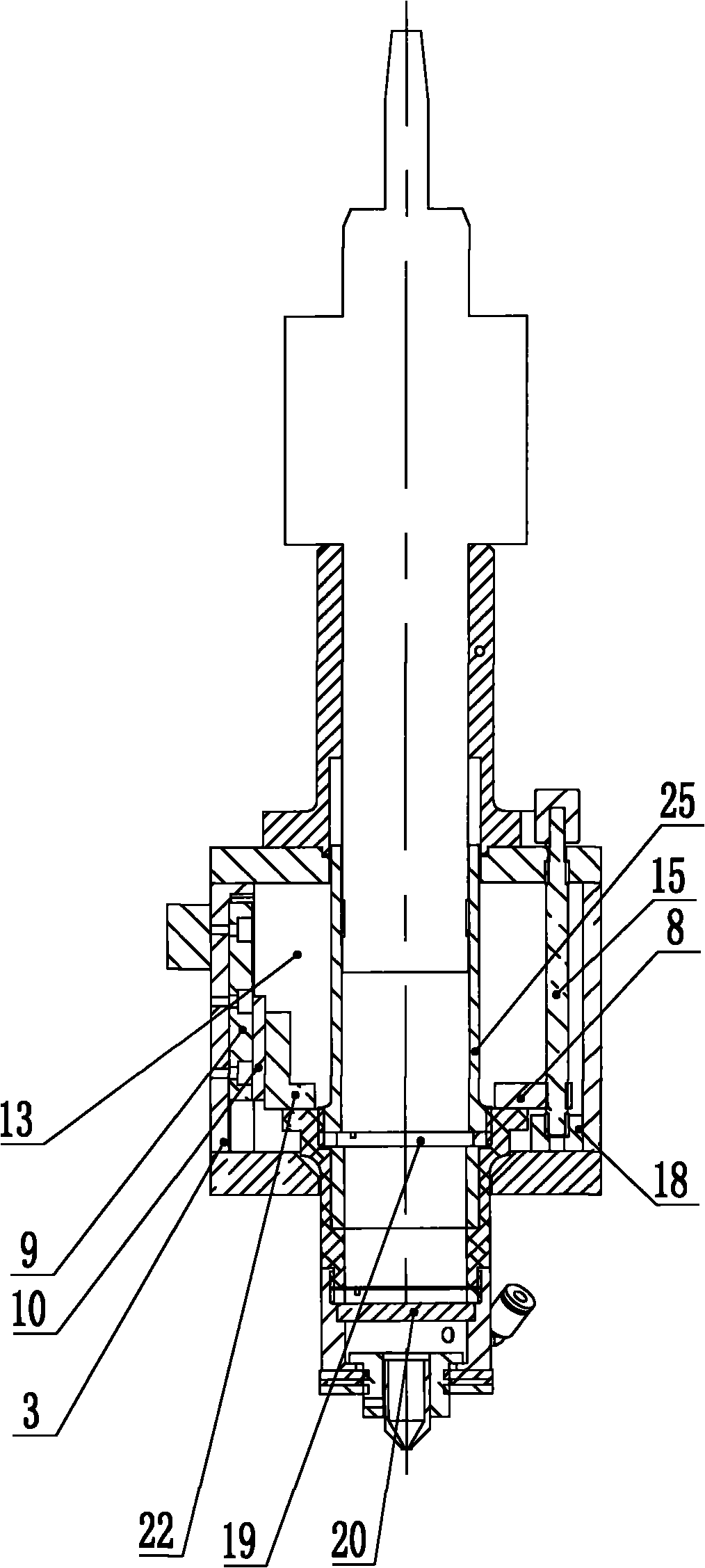

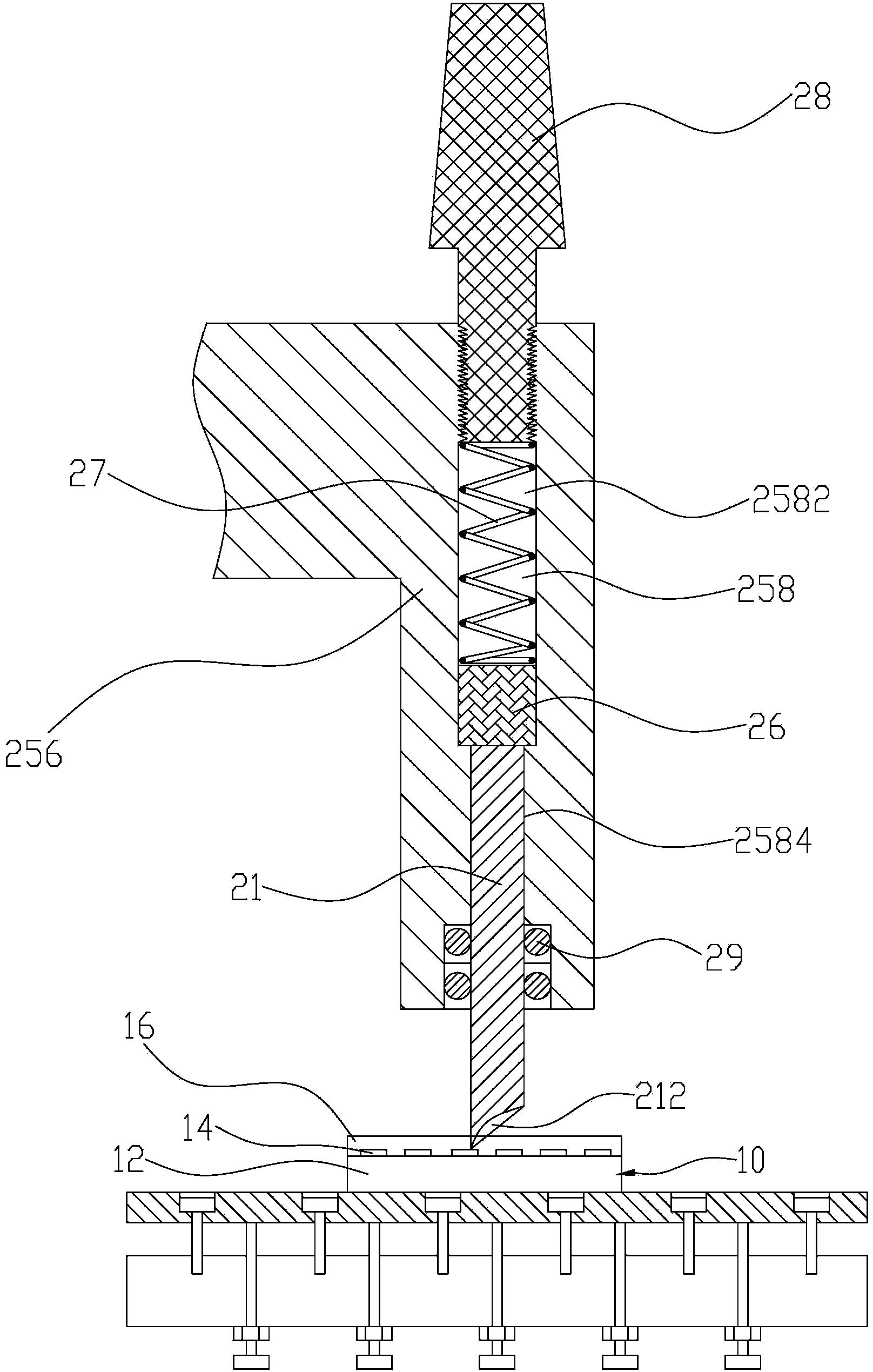

Ultrasonic scalpel

ActiveCN102715935AHigh output densityHave turning characteristicsIncision instrumentsTransducerEngineering

The invention discloses an ultrasonic scalpel. The ultrasonic scalpel comprises a handle, a middle rod, a rear bending connecting part, a rigid cutter bar, a cutter head and a front bending connecting part, wherein the rear bending connecting part is arranged between the handle and the middle rod; the rigid cutter bar is connected with the middle rod; the front bending connecting part is arranged between the rigid cutter bar and the cutter head; a front bending part and a rear bending part comprise a plurality of joint sheets and four transmission steel wires for connecting the plurality of joint sheets in series; the middle rod is provided with an accommodating cavity; a piezoelectric transducer is arranged in the accommodating cavity; a tail mass block is positioned at the rear end of the piezoelectric transducer; the middle rod is connected with the rigid cutter rod through an ultrasonic amplifier; and a locking device for maintaining the bending angle after the front bending connecting part and the rear bending connecting part are bent is arranged on the middle rod. According to the ultrasonic scalpel, the tail mass block is arranged on the rear part of the piezoelectric transducer, so the defect of ultrasonic energy attenuation caused by the bending parts is overcome and the cutting effect is guaranteed.

Owner:ZHEJIANG SHUYOU SURGICAL INSTR

Profile cutting machine capable of deburring

ActiveCN106078459AAvoid profile deformationPrecise positioningEdge grinding machinesGrinding drivesMechanical engineeringControl system

The invention provides a profile cutting machine capable of deburring. The profile cutting machine comprises a workbench, a sliding seat, a cutting device, a first conveying device, a hydraulic driving cylinder, a deburring device, a second conveying device, a clamping device and a motor, wherein the workbench is provided with the sliding seat which horizontally moves along a sliding rail under the drive of the hydraulic driving cylinder; the sliding seat is provided with the cutting device on which a grinding wheel is arranged; the grinding wheel rotates under the drive of the motor; the left side of the cutting device is provided with the deburring device on which a sliding table is arranged; a plurality of deburring mechanisms are mounted on the sliding table; a conveying platform is provided with the first conveying device and the second conveying device; the clamping device is matched with the first conveying device and the second conveying device; and a control system is connected with the hydraulic driving cylinder and the motor. The profile cutting machine is accurate in location and capable of avoiding the phenomenon such as deflection caused in a profile cutting process and deburring end surfaces of cut profiles.

Owner:浙江东方大港大河工程塑料有限公司

Cutting machine for cutting structural wall pipe

ActiveCN111037630ADrag minimizationAvoid consumptionMetal working apparatusElectric machineryKnife blades

The invention discloses a cutting machine for cutting a structural wall pipe. The cutting machine comprises a mounting frame, wherein two supporting cross rods are fixed on the mounting frame, two belt conveying assemblies are arranged on the supporting cross rod, the belt conveying assemblies are in threaded connection with threaded rods through connecting longitudinal rods, a top supporting plate is fixed to the top of the mounting frame, a lifting air cylinder is fixed to the top supporting plate, a first motor mounting plate is fixed to an end of an output rod of the lifting air cylinder,a cutting motor is fixed to the first motor mounting plate, and a cutting blade is fixed to an output shaft end of the cutting motor. The cutting machine is convenient to adjust, structural wall pipescan be conveniently cut and fixed, and thereby the structural wall pipes are prevented from moving in the cutting process, the cutting effect is guaranteed, resistance of the structural wall pipe during moving is minimized, the service life of the cutting machine is guaranteed, the structural wall pipe can be automatically conveyed and collected, labor intensity is reduced, and production efficiency is improved.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

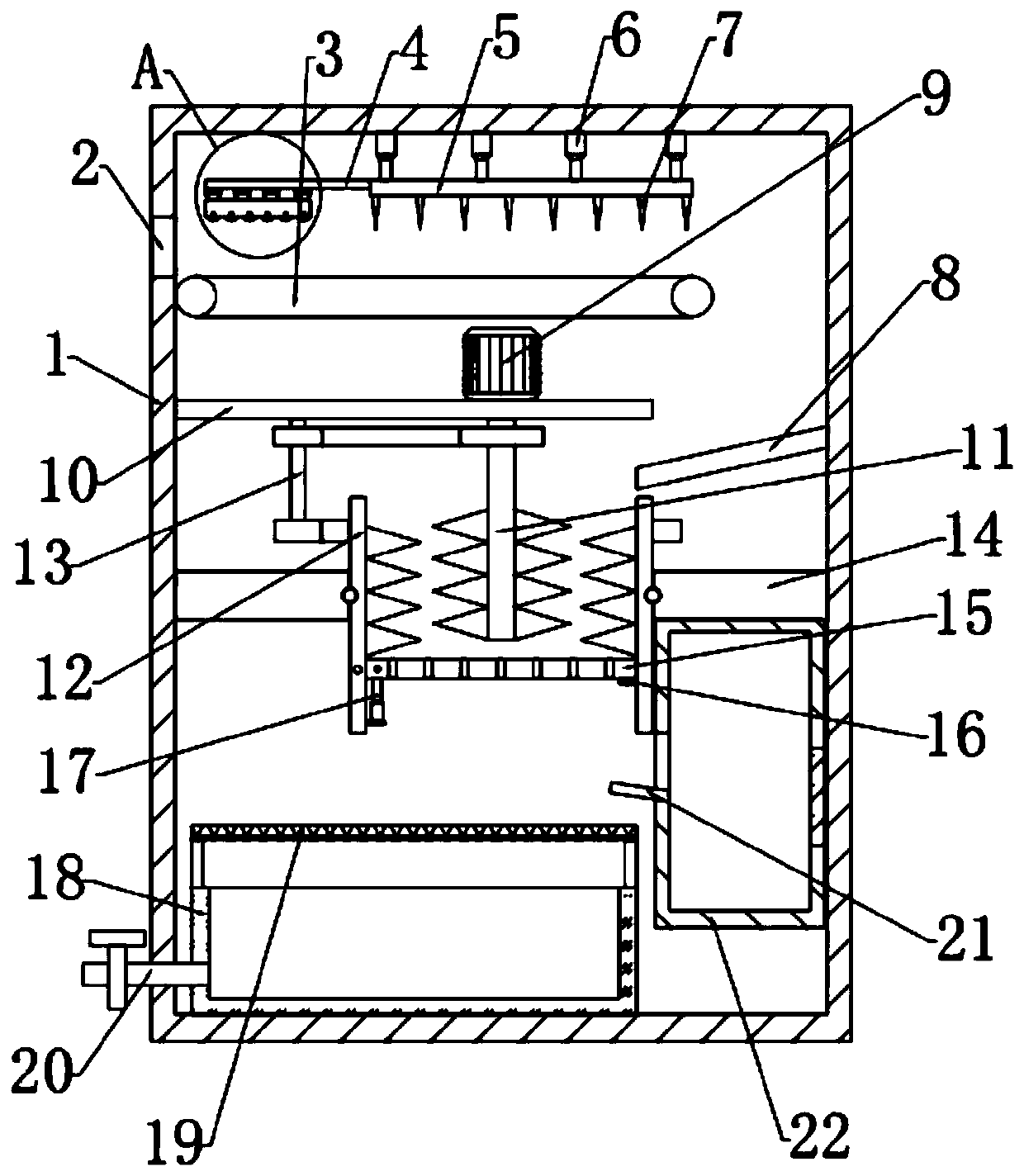

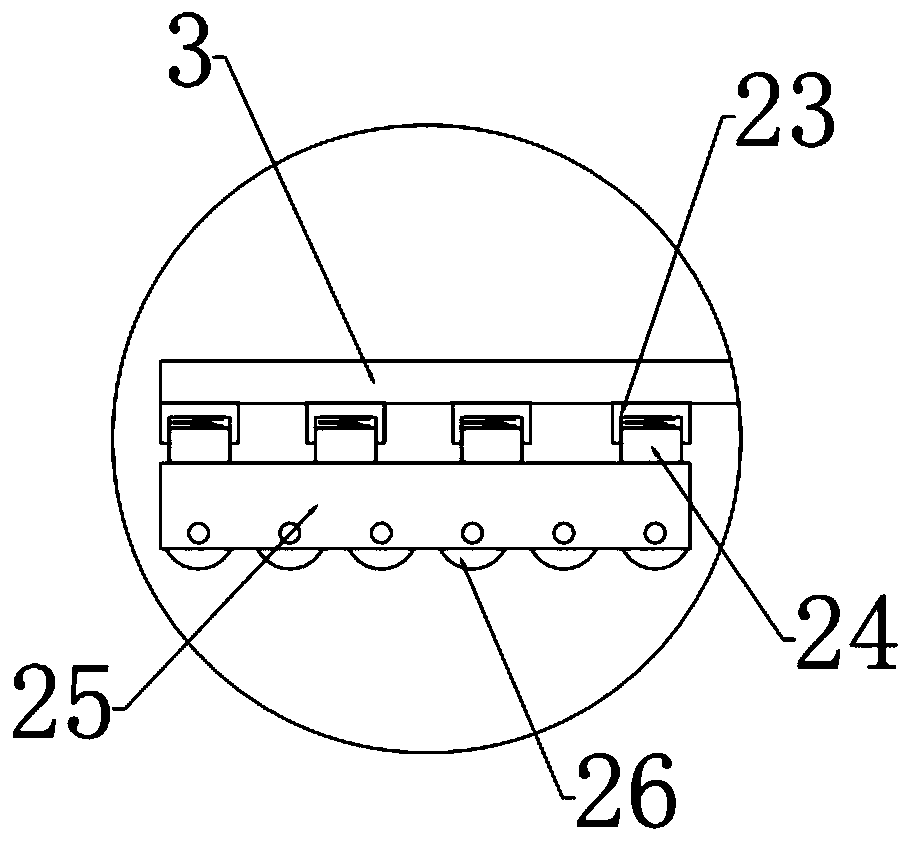

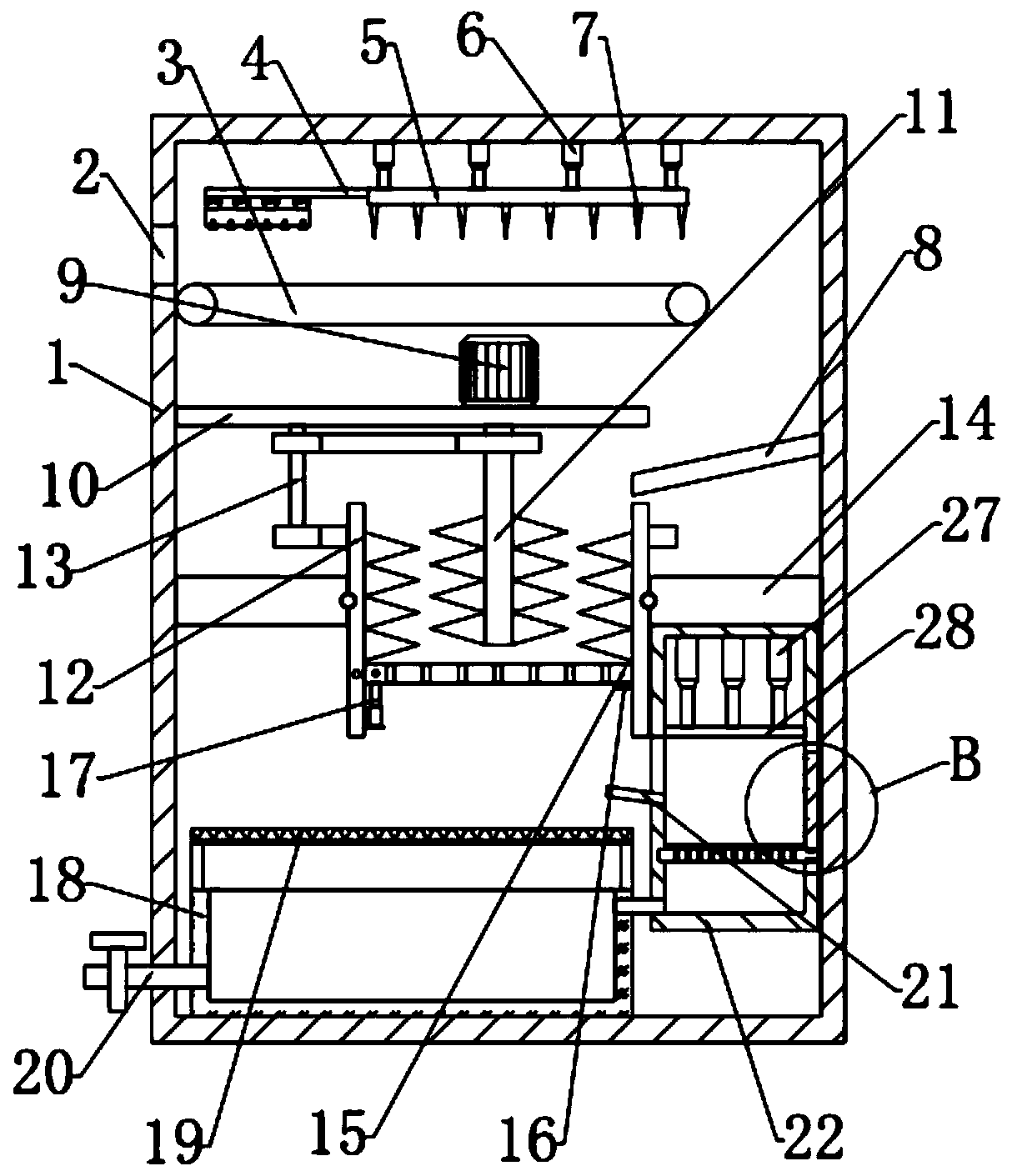

Wood cutting robot convenient to collect wood chips

InactiveCN107696163AEasy to collectImprove practicalityCircular sawsBark-zones/chip/dust/waste removalPistonAgricultural engineering

The invention discloses a wood cutting robot which is convenient for collecting sawdust, which comprises a box body and an installation cover. The middle part is connected with a second rotating shaft, the outer side of the second rotating shaft is connected with a transmission motor through a second transmission belt, one side of the connecting block is connected with a collecting plate through a pin shaft, and the top of the piston block is connected with a push rod , the top of the movable seat overlaps the bottom of the collecting plate, the bottom of the piston block is connected with a connecting spring, the bottom of the connecting spring is connected with a movable rod, the inner side of the mounting ring is inserted with a rotating shaft, the One side of the top of the rotating shaft is connected with a turntable. In the present invention, through the cooperative use of the jacking rod, the piston block, the movable rod and the turntable, the collecting plate drives the falling sawdust to slide into the collecting box when vibrating, so that the collecting of sawdust becomes more convenient.

Owner:吕龙鹰

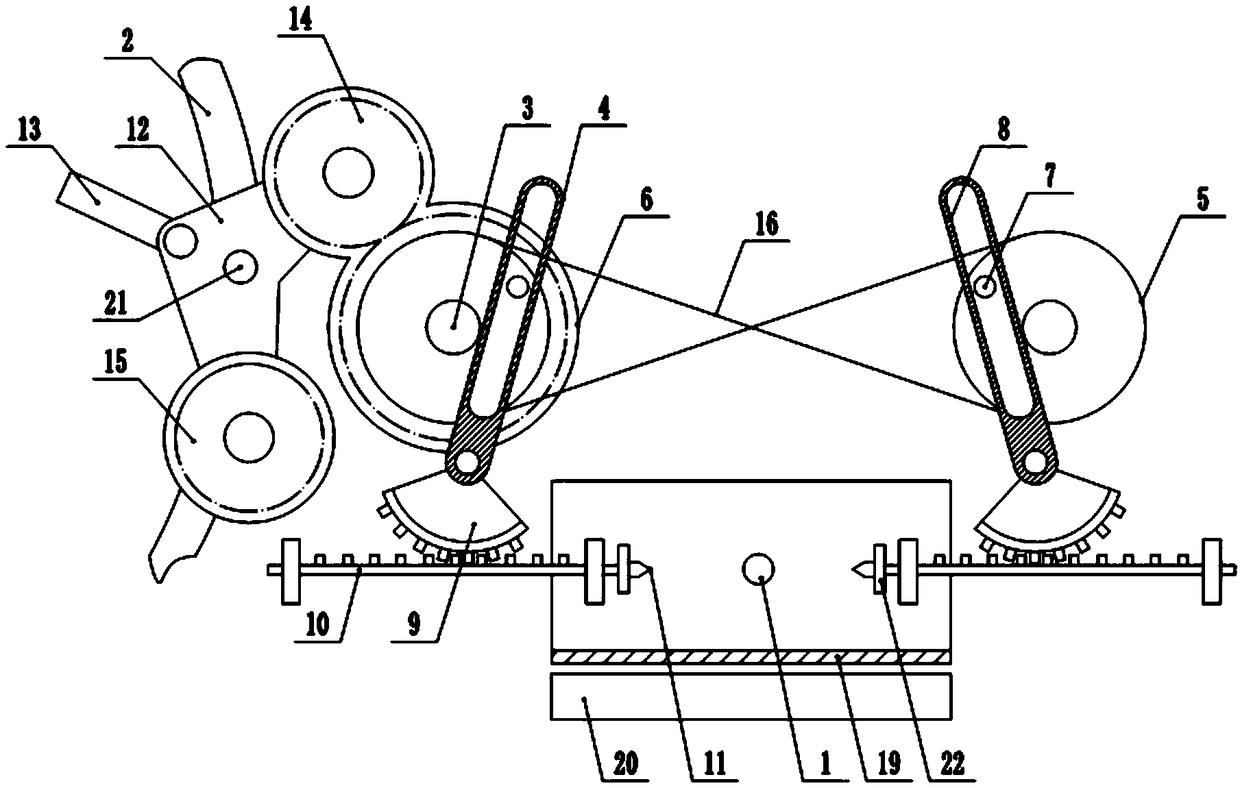

Cutting machine of fodder for giant salamanders

ActiveCN108789522AReduce swing frequencyIncrease the lengthFeeding-stuffMetal working apparatusGiant salamanderEngineering

The invention relates to a cutting machine of fodder for giant salamanders. The cutting machine comprises a machine frame, a first cutting mechanism and a driving mechanism. The machine frame is arranged close to an extrusion opening of a fodder hot-extrusion machine; the first cutting mechanism comprises a rotating shaft and a push rod, the rotating shaft is coaxially and fixedly connected with arotating disc, and the eccentric position of the rotating disc is fixedly connected with a supporting column; the lower portion of the push rod is rotatably connected to the machine frame, a slidinggroove is formed in the upper portion of the push rod in the length direction of the push rod, and the supporting column is slidably connected into the sliding groove; the bottom end of the push rod is fixedly connected with a sector gear, the sector gear is engaged with a rack, the rack is slidably connected to the machine frame, and cutting knife sets used for cutting the fodder are arranged atthe end of the rack; and the driving mechanism comprises a supporting plate rotatably connected to the machine frame, a swing rod is fixedly connected to the supporting plate, the two ends of the supporting plate are rotatably connected with a driving gear and a notched gear correspondingly, the rotating shaft is coaxially and fixedly connected with a rotating gear, and both the driving gear and the notched gear are engaged with the rotating gear intermittently. The cutting machine can cut the fodder in different lengths.

Owner:江苏拓诚农业发展有限公司

Composite plastic pipe fitting forming processing equipment and forming processing method

ActiveCN113427528AEnsure clamping limitEasy to handleMetal working apparatusPipe fittingStructural engineering

The invention relates to composite plastic pipe fitting forming machining equipment and a forming machining method, the composite plastic pipe fitting forming machining equipment comprises a bottom plate, a clamping device, a distance adjusting device, a cutting device and a driving device, wherein the clamping device is mounted at the upper end of the bottom plate, the distance adjusting device is arranged on the right side of the clamping device, and the distance adjusting device is fixedly connected with the bottom plate. The composite plastic pipe fitting forming machining equipment can solve the problems that when existing equipment is used for cutting a composite plastic pipe fitting, the composite plastic pipe fitting can only be clamped and limited from the uncut end, the composite plastic pipe fitting cannot be limited from the cut end, the composite plastic pipe fitting is prone to being bent under gravity when being about to be cut, the problems that the surface of a notch is uneven, the surface of the composite plastic pipe cannot be cleaned before cutting, stains on the surface of the composite plastic pipe easily affect cutting, the flatness of the notch cannot be kept during cutting, the condition that the notch is inclined easily occurs, and the cutting effect is poor are solved.

Owner:新沂市鼎丽塑胶制品有限公司

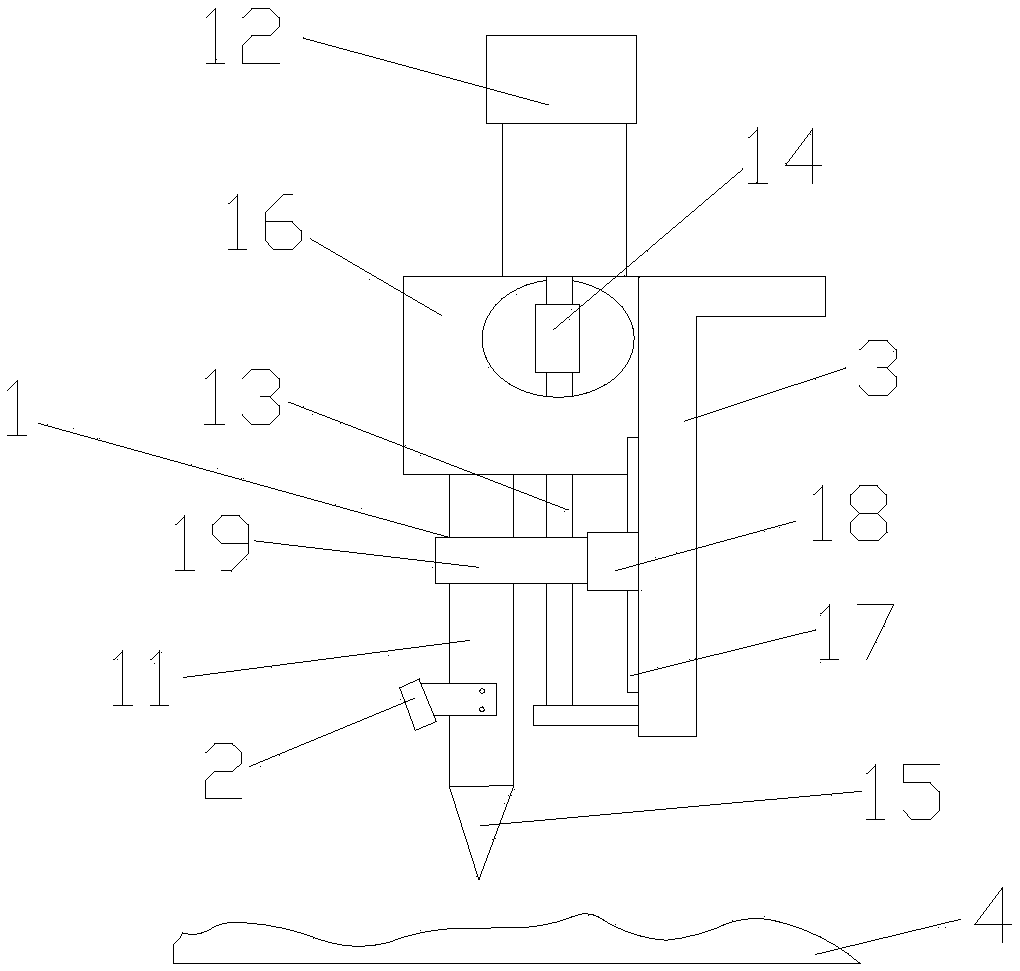

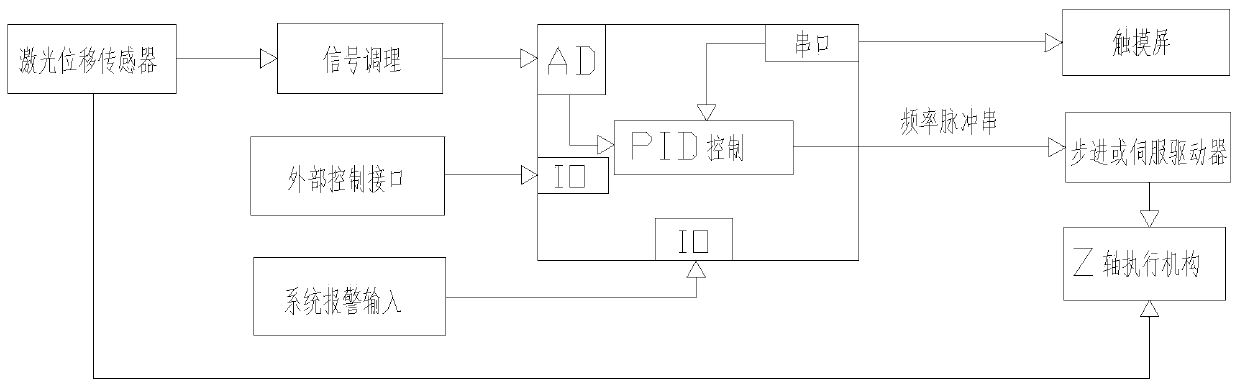

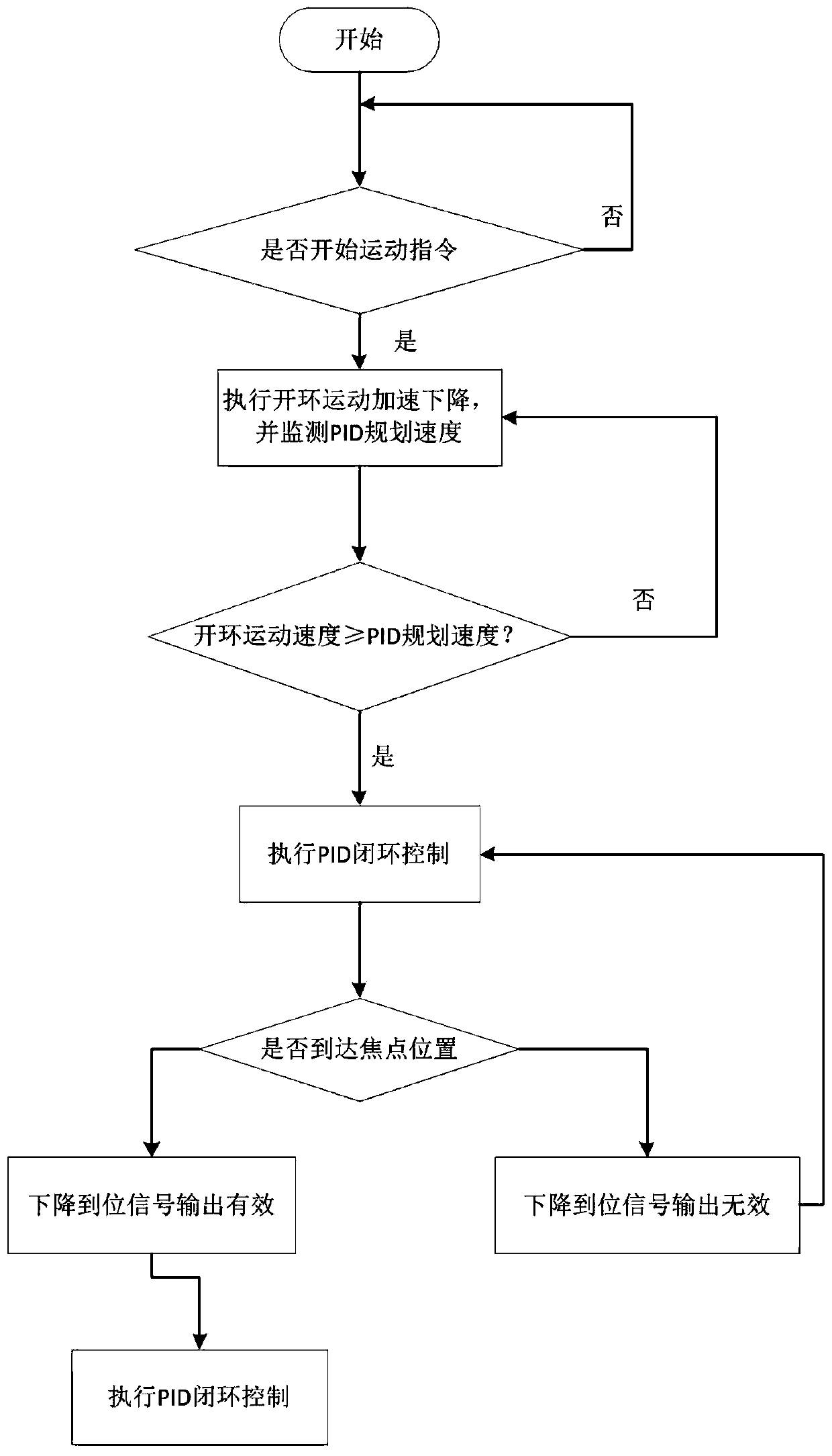

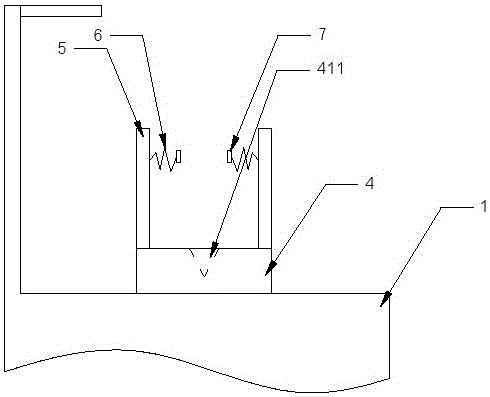

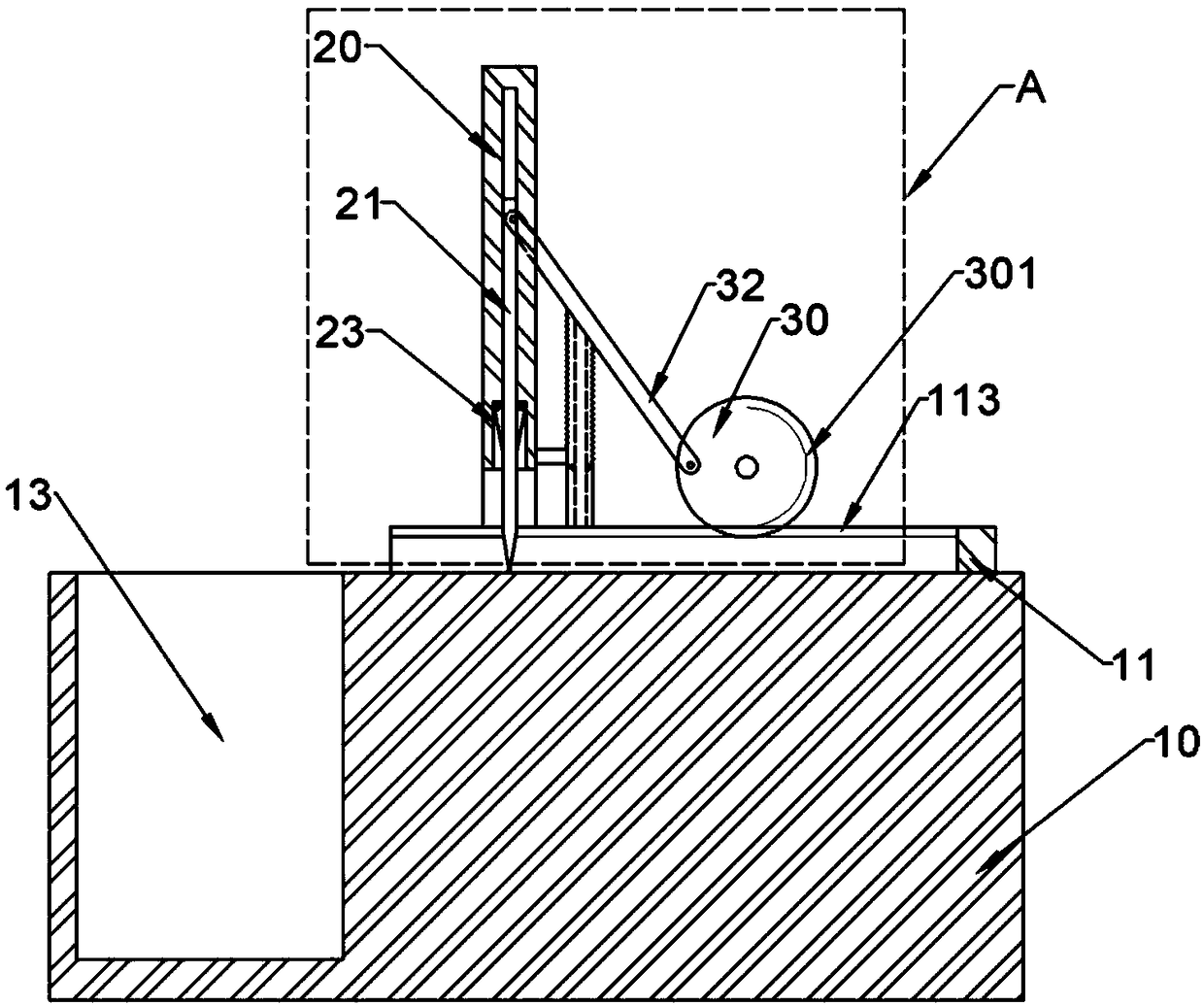

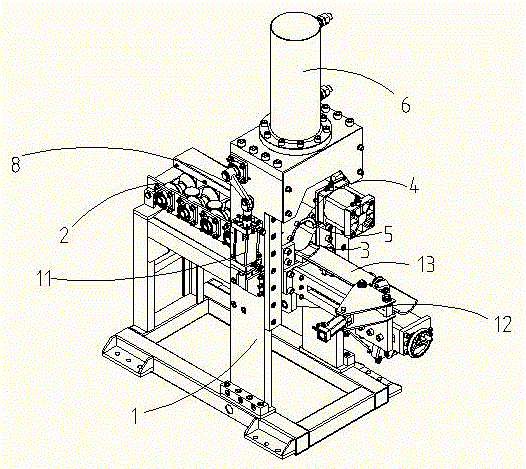

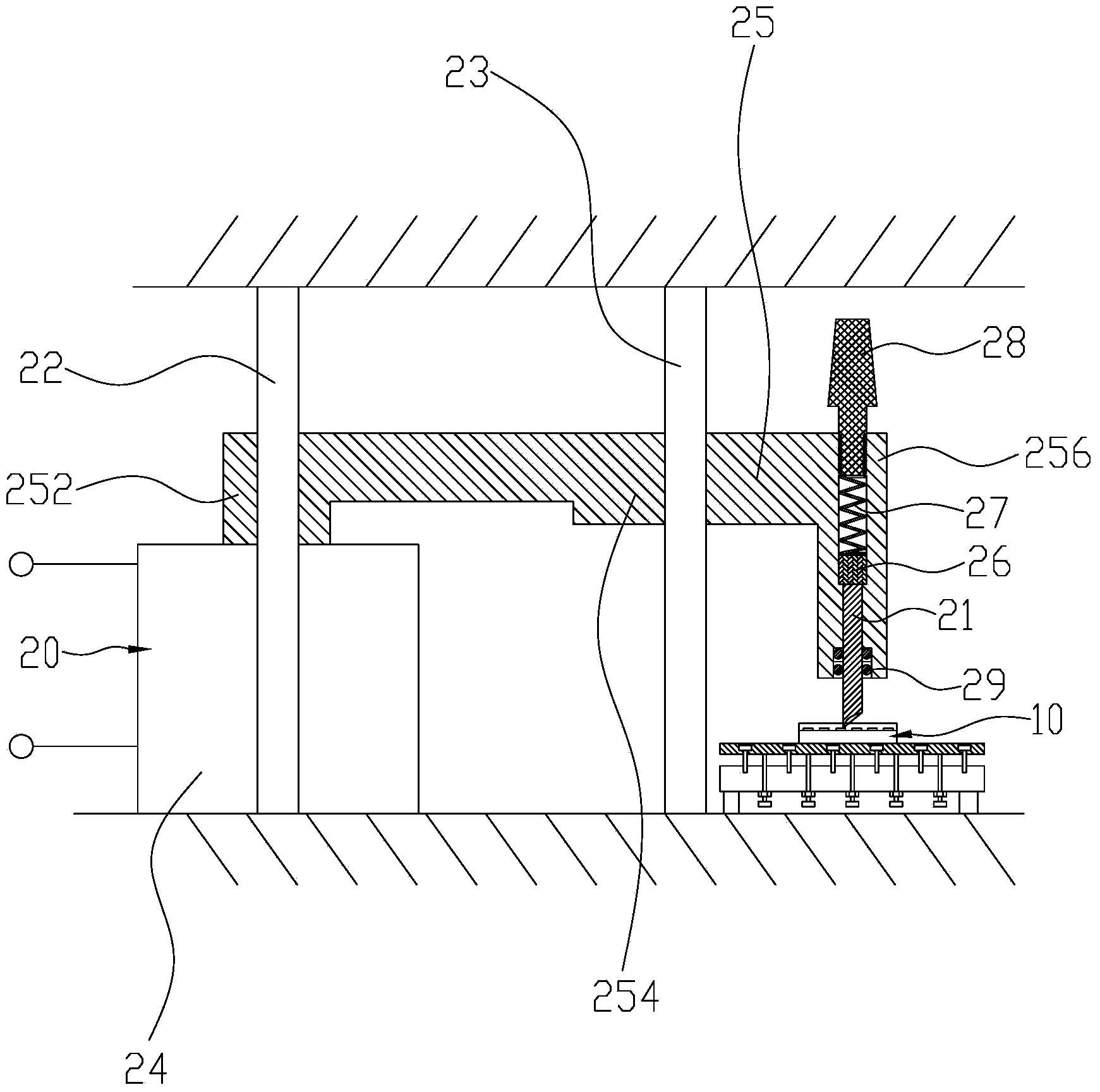

Automatic height adjusting device based on laser displacement sensor and control method thereof

PendingCN110202273ALong detection distanceHigh precisionLaser beam welding apparatusLaser cuttingWhole systems

The invention discloses an automatic height adjusting device based on a laser displacement sensor. The device comprises a Z-axis motor executing mechanism, a height adjusting controller and the laserdisplacement sensor. The automatic height-adjusting device is simple in structure. The laser displacement sensor examines the position of a workpiece and feeds back a distance signal, and the height adjusting controller then adjusts the height position of a laser cutting head according to a measurement feedback result. According to the device, the laser displacement sensor of Panasonic HG-C1100 model is adopted preferably, so that the detection precision is high. In addition, in the process of adjusting the height of the laser cutting head, the distances from positions of measuring spots of the laser displacement sensor to the cut workpiece are kept consistent, so that a purpose that a laser focusing point does not deviated from the cut workpiece. The invention also provides a control method of the automatic height adjusting device based on the laser displacement sensor. By collecting information of points in real time, the automatic height adjusting device carries out real-time control, so that the control precision is improved effectively and the operating efficiency of the whole system is improved.

Owner:深圳市睿达科技有限公司

Corrosion resistant plastic mould steel and manufacturing method thereof

InactiveCN108060368AImprove corrosion resistanceExpand the scope of applicationCorrosion resistantDuctility

The invention relates to the field of plastic steel, and specifically relates to a corrosion resistant plastic mould steel and a manufacturing method thereof. The plastic mould steel comprises following components in percentage by weight: 0.45 to 0.55% of C, 0.40 to 0.80% of Si, 0.80 to 1.60% of Mn, 0.10 to 0.25% of V, 0.007 to 0.015% of N, 0.005 to 0.050% of Al, not more than 0.035% of S, not more than 0.025% of P, 3.5 to 4.0% of Ni, 8.5 to 10.5% of Cr, 0.25 to 0.45% of Cu, and the balance being Fe and other impurities, which are introduced into the steel during the refining process, whereinCr+Ni=12-14.5%. The original strength, ductility, wear resistant performance, and cutting property of plastic mould steel are guaranteed, at the same time, the corrosion resistant performance of plastic mould steel is greatly improved; after polishing, the roughness is lower than that of products on the market; by controlling the using amounts of copper and molybdenum, the plastic mould steel canbe applied to different fields without influencing the performances of plastic mould steel, and the application range of plastic mould steel is enlarged.

Owner:莫祖勇

Multifunctional bamboo shoot cutting device

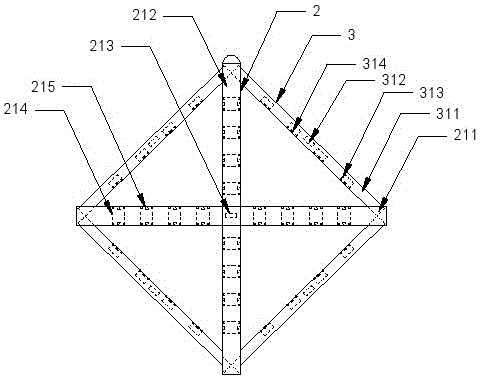

ActiveCN106313143AGuaranteed cutting effectImprove finishing effectFood shapingVegetable peelingCruciformBamboo shoot

The invention discloses a multifunctional bamboo shoot cutting mechanism. The multifunctional bamboo shoot cutting mechanism comprises a rack, a cutter and a clamp. The cutter comprises two same triangular blades which are arranged in a crossed manner to form a cross shape, and one ends of the two triangular blades face the same direction. Sliding grooves are formed in the two sides of the front face of each triangular blade and the two sides of the back face of each triangular blade, and a peeling blade is arranged between every two adjacent sliding grooves. A first cavity is formed in each triangular blade, the first cavities of the two triangular blades communicate, and each first cavity is internally provided with a first heating resistor connected with a power source. Each triangular blade is further provided with a plurality of through holes communicating with the corresponding first cavity, and each through hole is provided with a first fan blade connected with the power source. The clamp comprises a supporting base and supporting rods. The supporting base is provided with limiting grooves used for containing bamboo shoots. Each supporting rod is provided with a clamping arm. According to the scheme, the problems that time is consumed for bamboo shoot peeling, the hands are prone to getting hurt, and the bamboo shoot processing technology chain is long are mainly solved.

Owner:CHONGQING GUANGHENG FOOD DEV

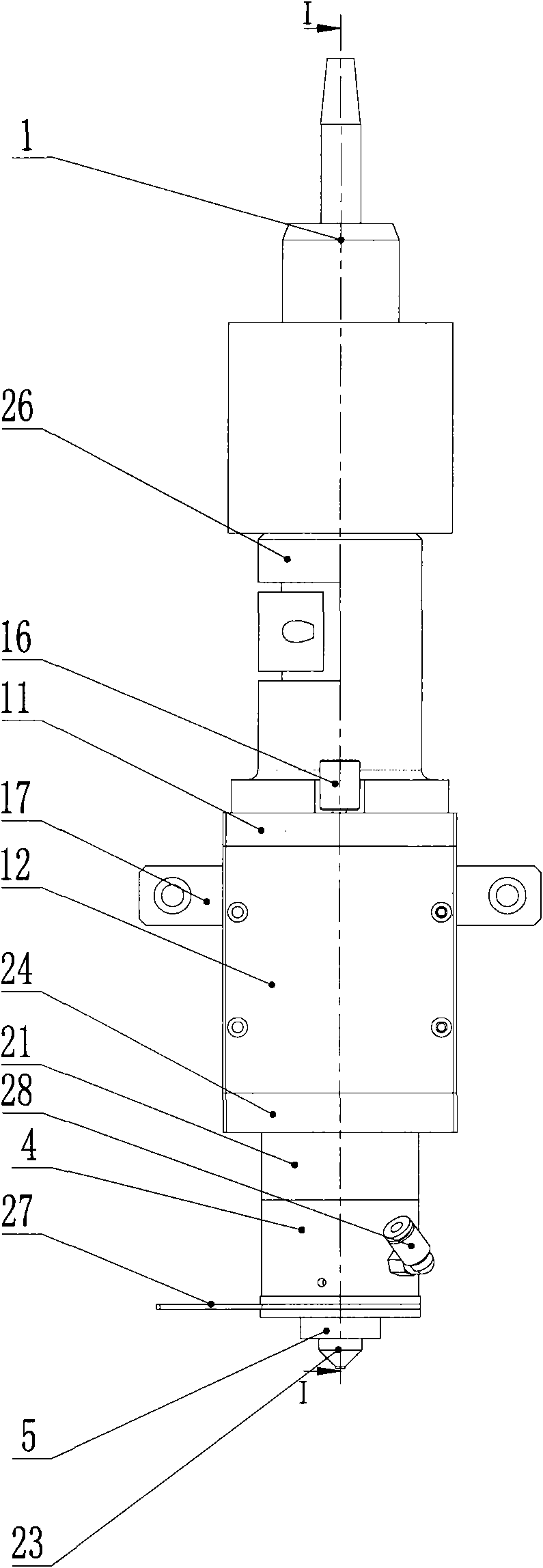

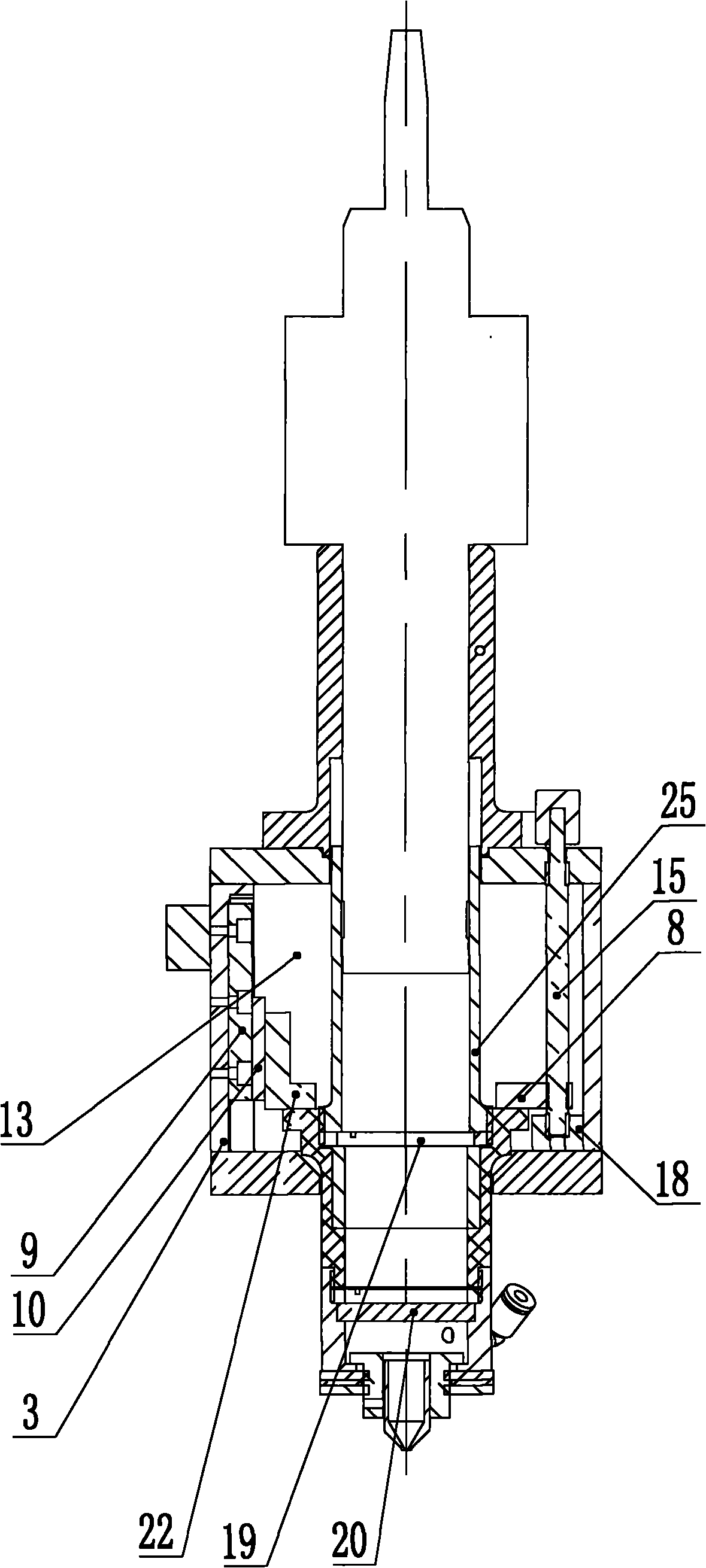

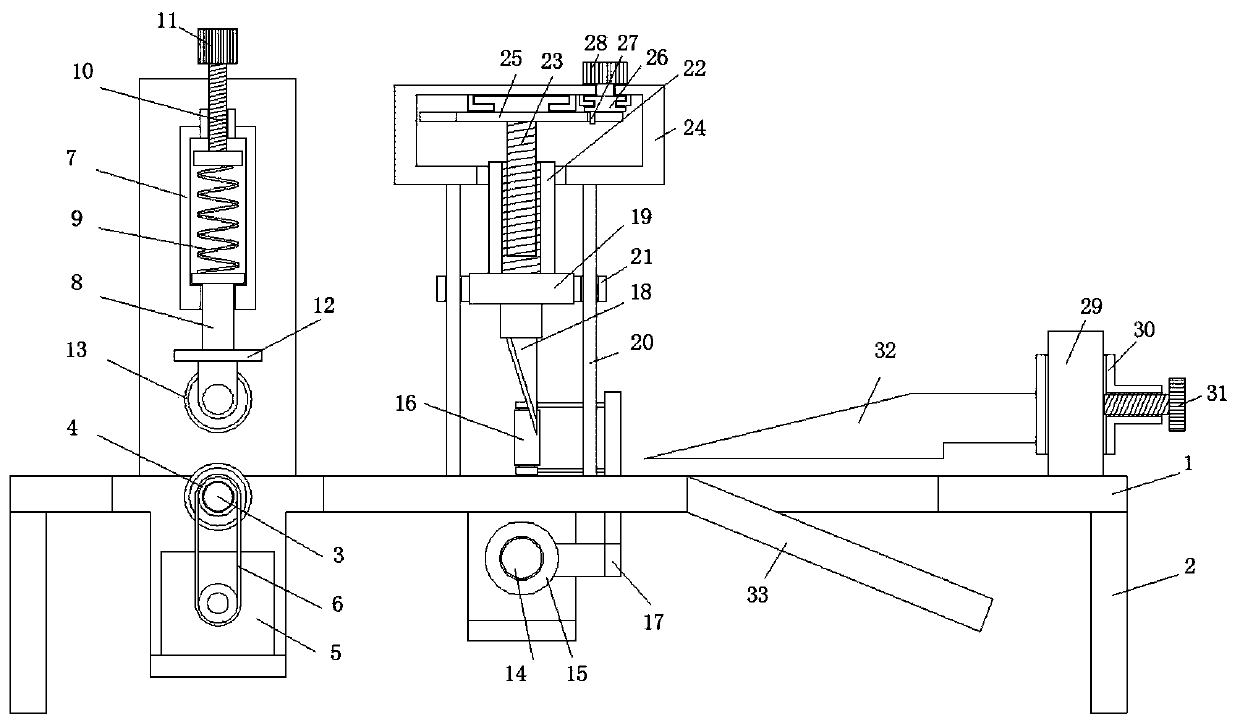

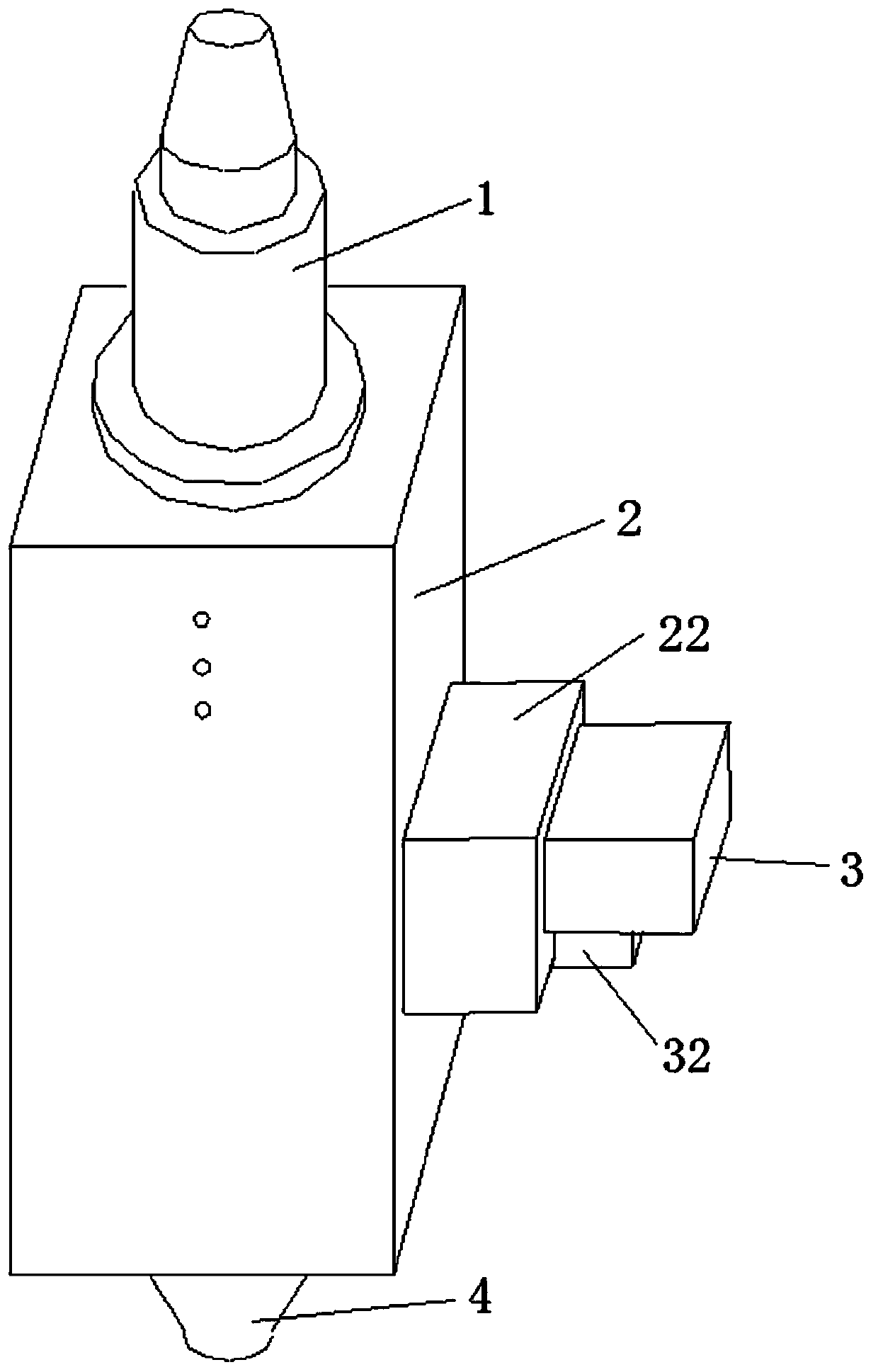

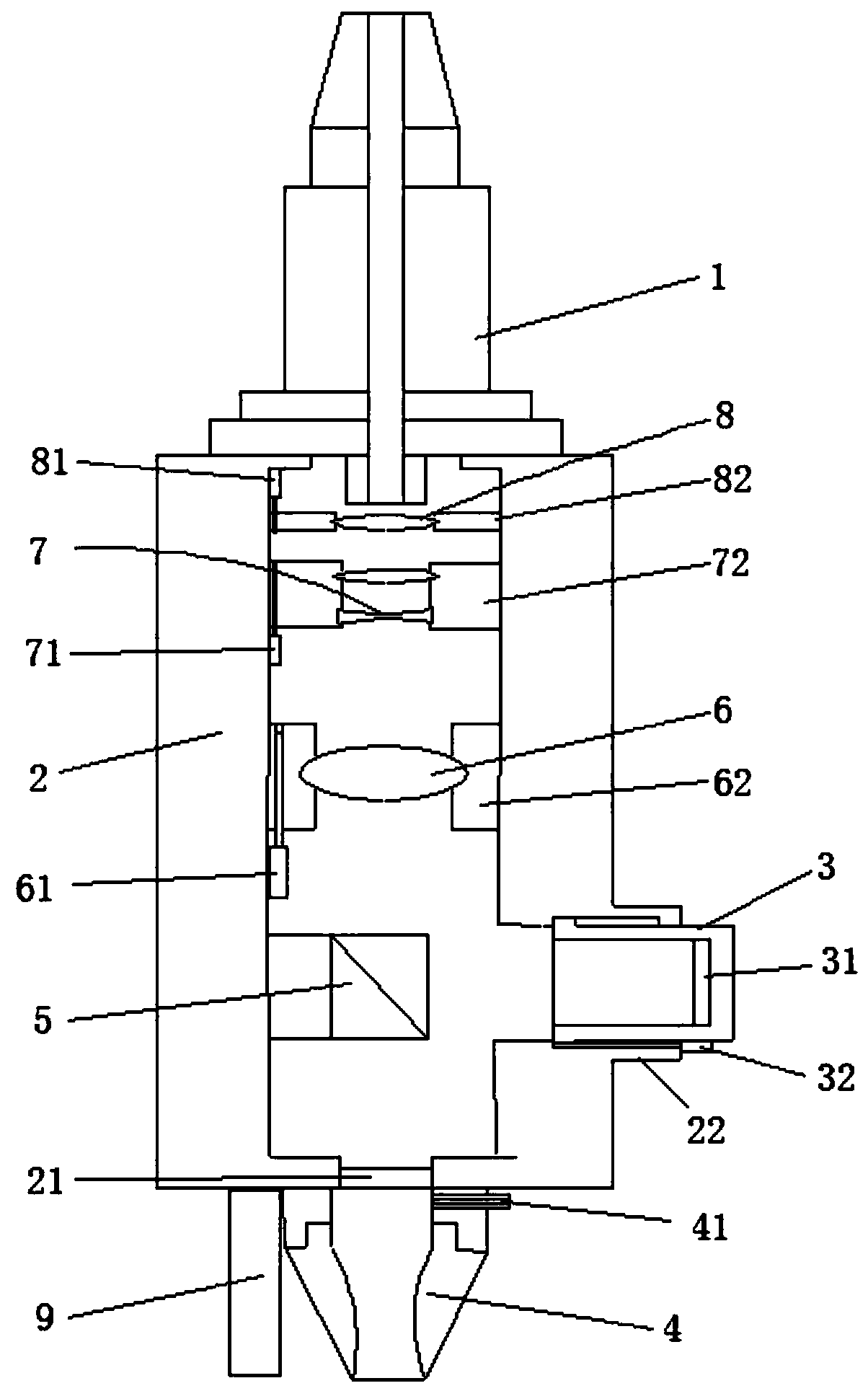

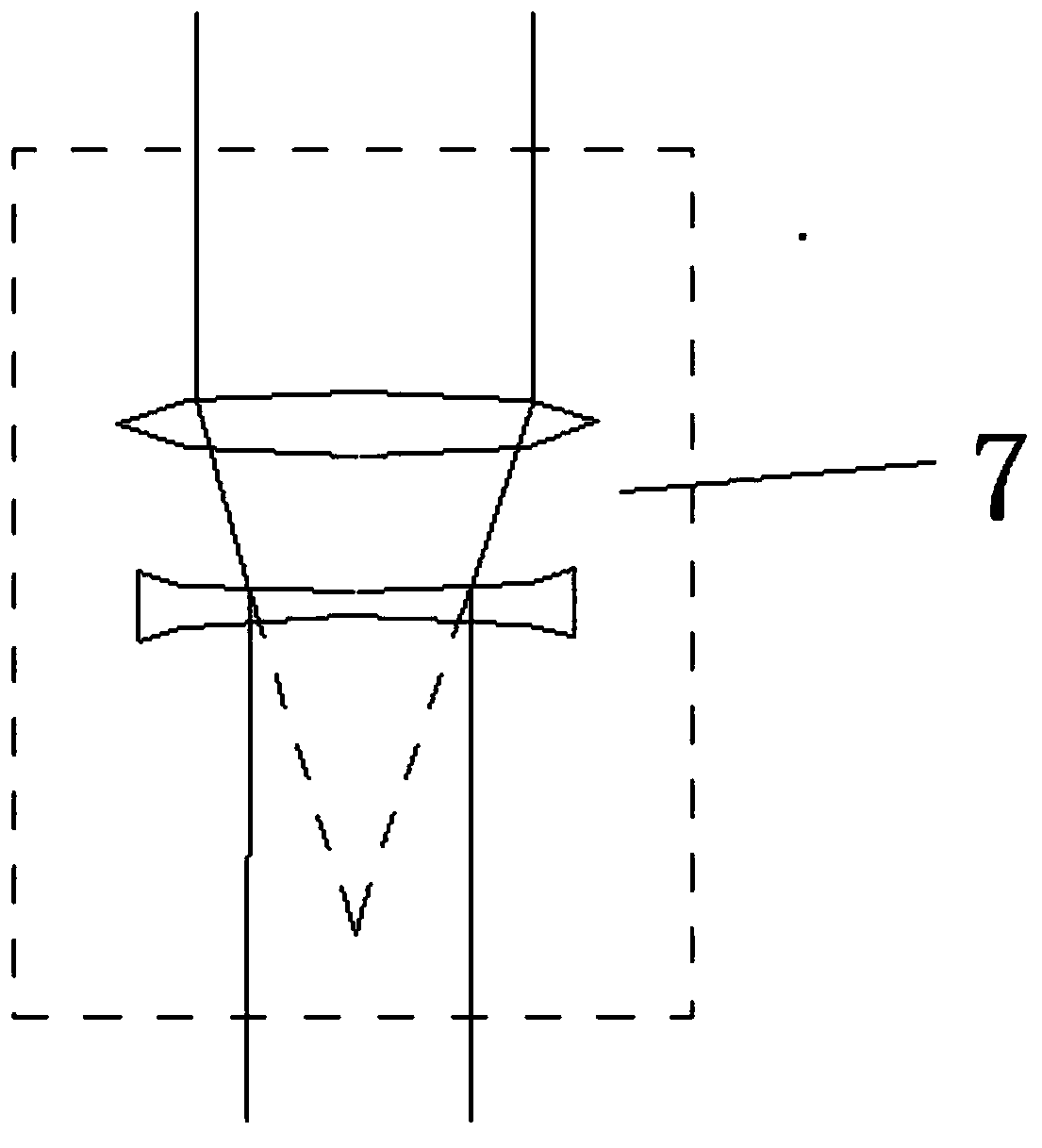

Laser cutting head

InactiveCN102148361AMeet production needsGuaranteed cutting effectCell electrodesLaser beam welding apparatusLaser cuttingCopper foil

The invention discloses a laser cutting head for cutting a pole piece of a power lithium ion battery. The head comprises a mounting housing, a focusing lens seat, a cutting nozzle, a focal length fine adjustment device and a laser input head, wherein the interior of the mounting housing is a cavity; a focusing lens is assembled in the focusing lens seat; the upper part of the cutting nozzle is connected with the focusing lens seat; the focal length fine adjustment device is fixed in the mounting housing, and the focusing lens seat is connected and fixed with the focal length fine adjustment device; the laser input head is connected and fixed with the mounting housing through a mounting seat of the laser input head; and a light path is formed in the laser input head, the mounting housing, the focusing lens seat and the cutting nozzle. The laser cutting head can be used for replacing a traditional mechanical cutting head for cutting copper foils, aluminum foils and coating regions thereof with a high reflection characteristic, and meet the production need of cutting the pole piece of the power lithium ion battery.

Owner:VANSUN SOFTWARE TECH

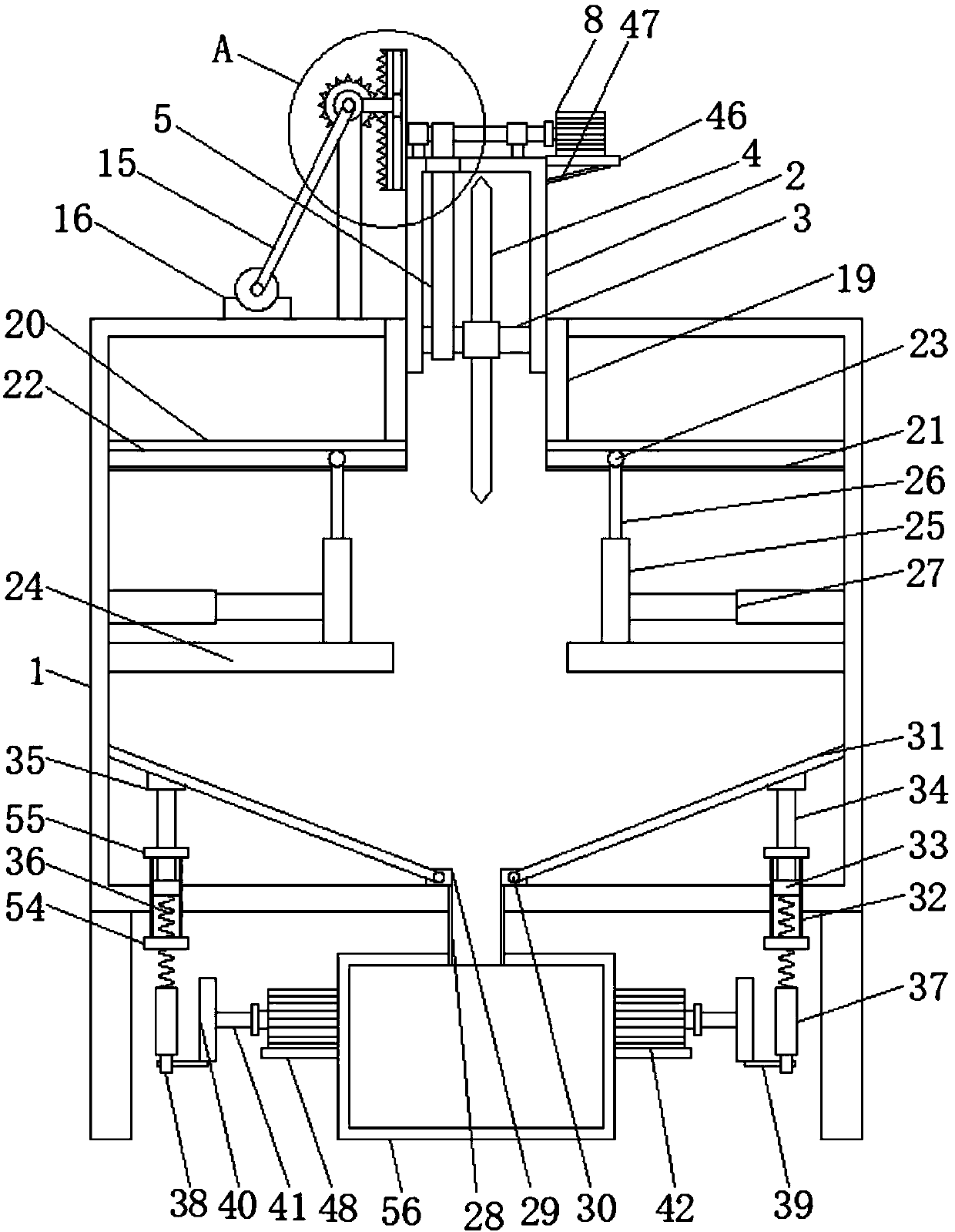

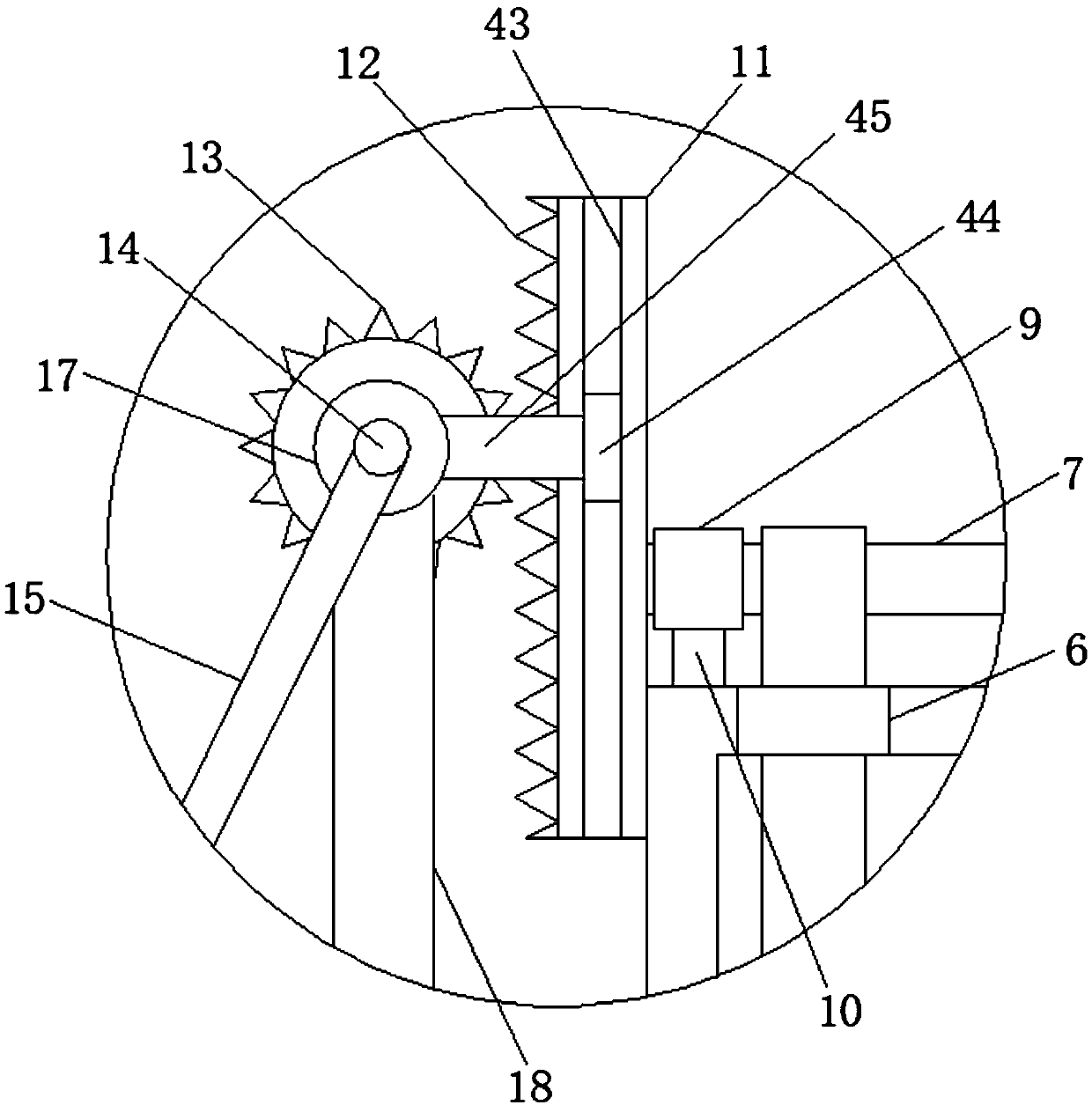

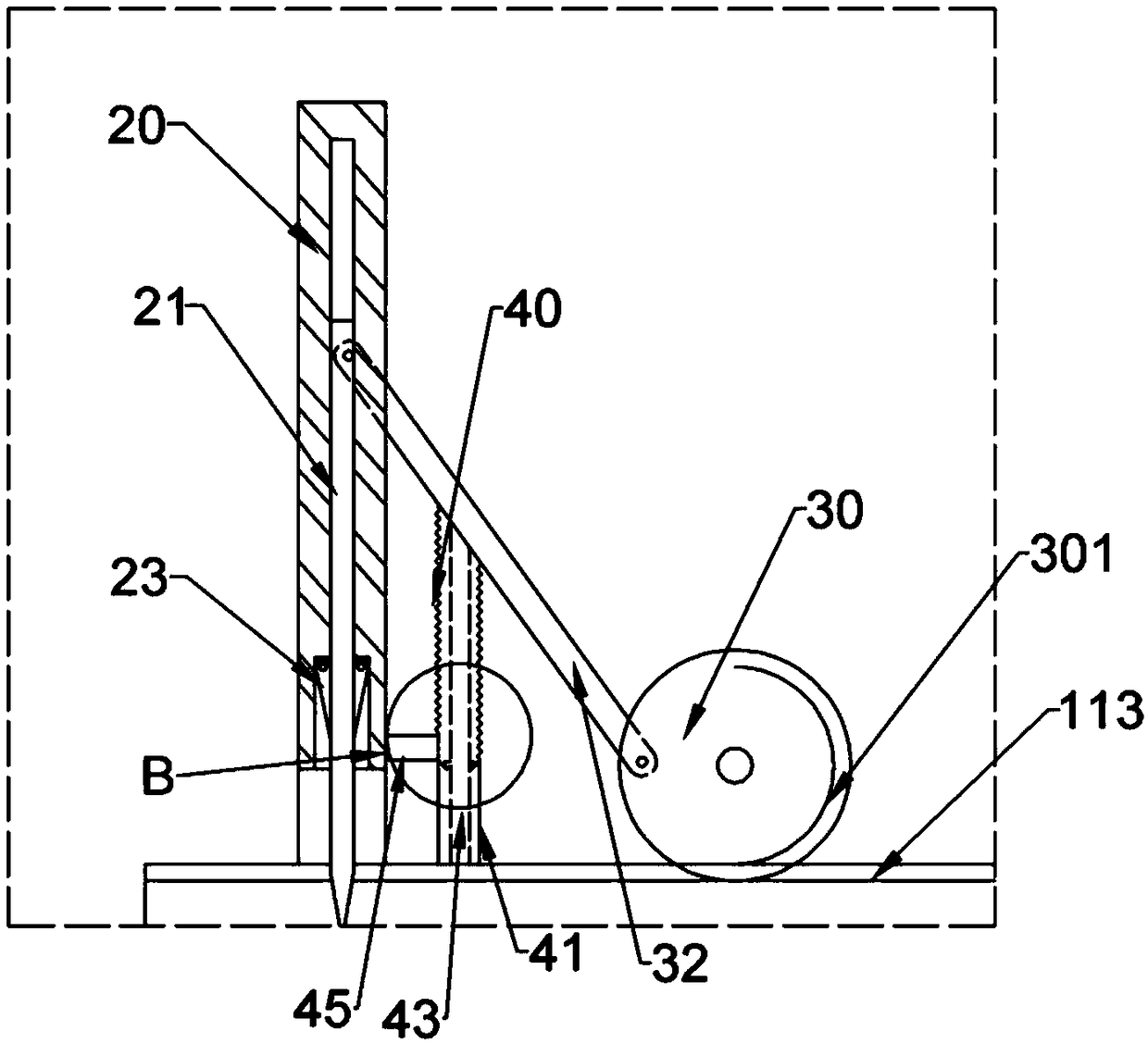

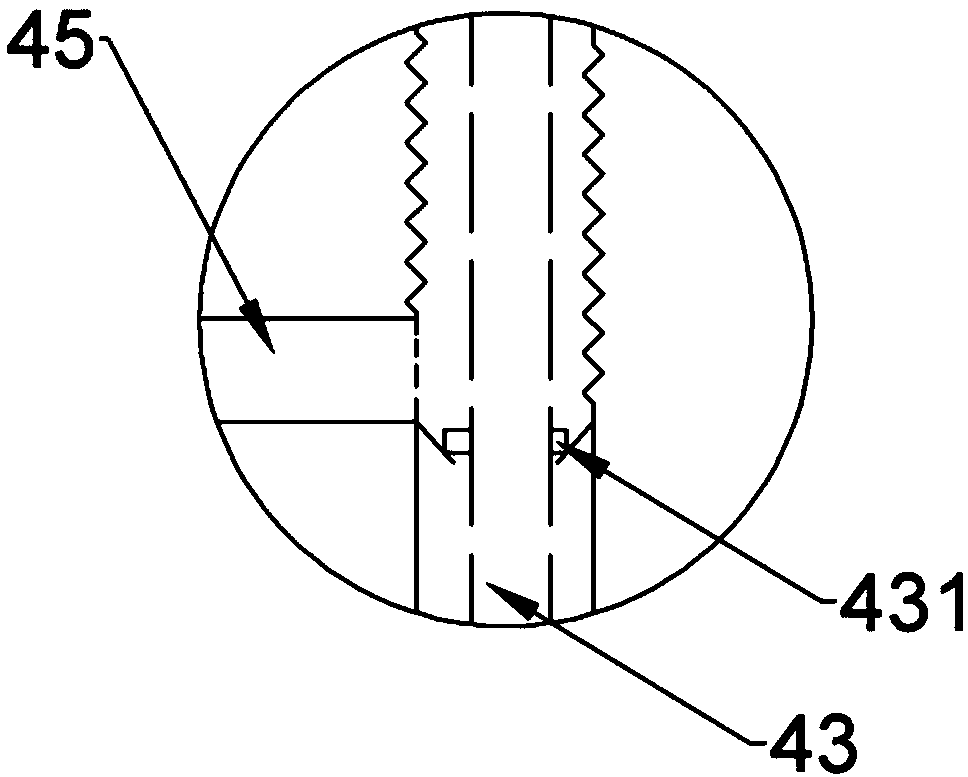

Cutting device for waste cable recycling

ActiveCN110600207AGuaranteed cutting effectImprove applicabilityBasic electric elementsElectronic waste recyclingMechanical engineeringEngineering

The invention discloses a cutting device for waste cable recycling. The cutting device comprises a workbench, wherein support legs are arranged at four corners of the bottom of the workbench, a cabledriving mechanism is arranged at a top side of the workbench and comprises a bottom roller and a top roller, a first groove is formed in the workbench, a horizontal shaft is fixedly connected betweeninner walls of the first groove, the bottom roller rotatably sleeves an outer side of the horizontal shaft, a sliding cylinder is erected at a top side of the workbench and is arranged above a vertical part of the first groove, a sliding rod is connected to the sliding cylinder in a sliding way, a bottom end of the sliding rod extends to a bottom side of the sliding cylinder and is fixedly connected with a connection plate, the top roller is rotatably connected to a bottom side of the connection plate, a threaded hole is formed in a top end of the sliding cylinder, the top end of the sliding cylinder is in threaded connection with a threaded push rod, and a pressurization spring is arranged between the threaded push rod and the top end of the sliding rod. By the cutting device, the cuttingeffect is ensured, the cutting device is high in applicability, labor is saved, the production efficiency is improved, and the application demand of people in production life is satisfied.

Owner:安徽飞马电缆有限公司

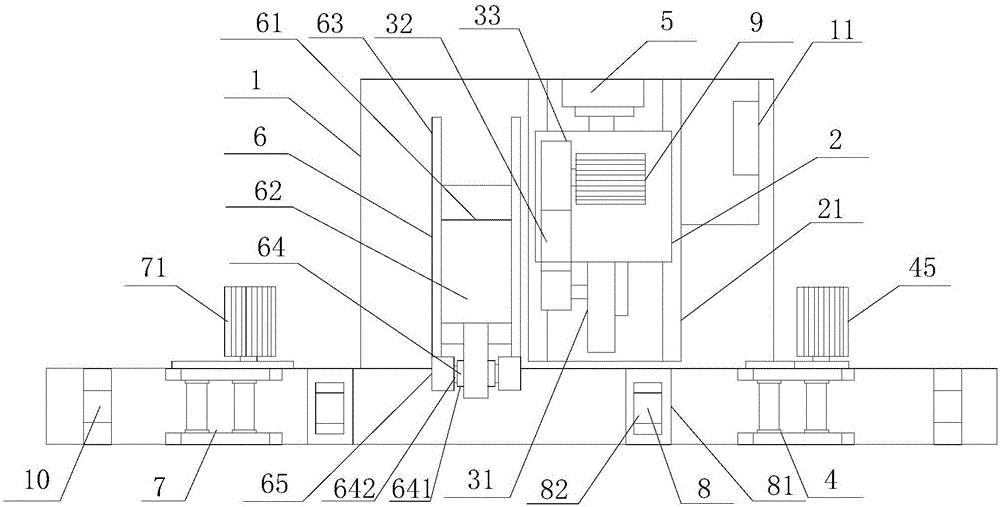

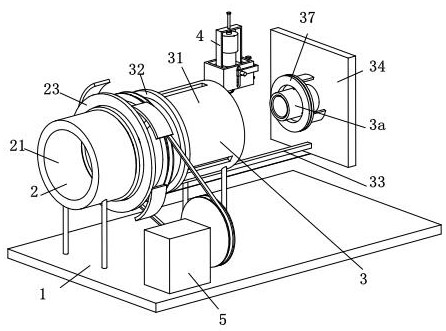

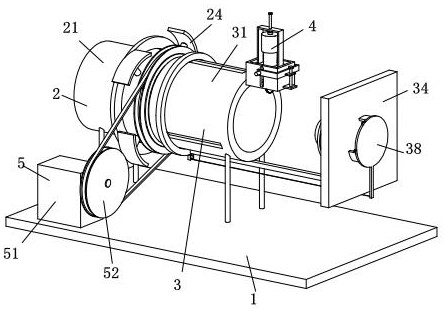

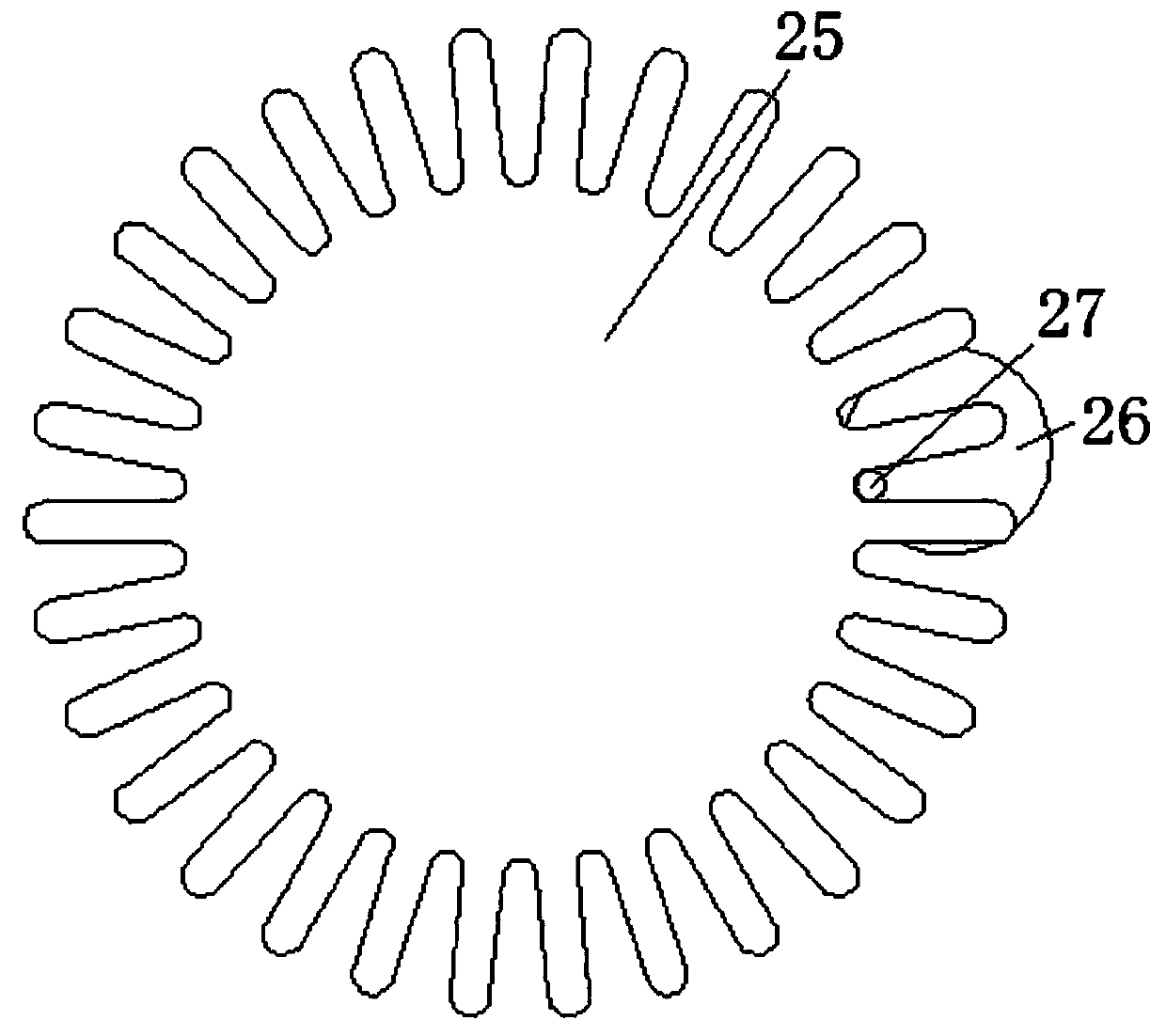

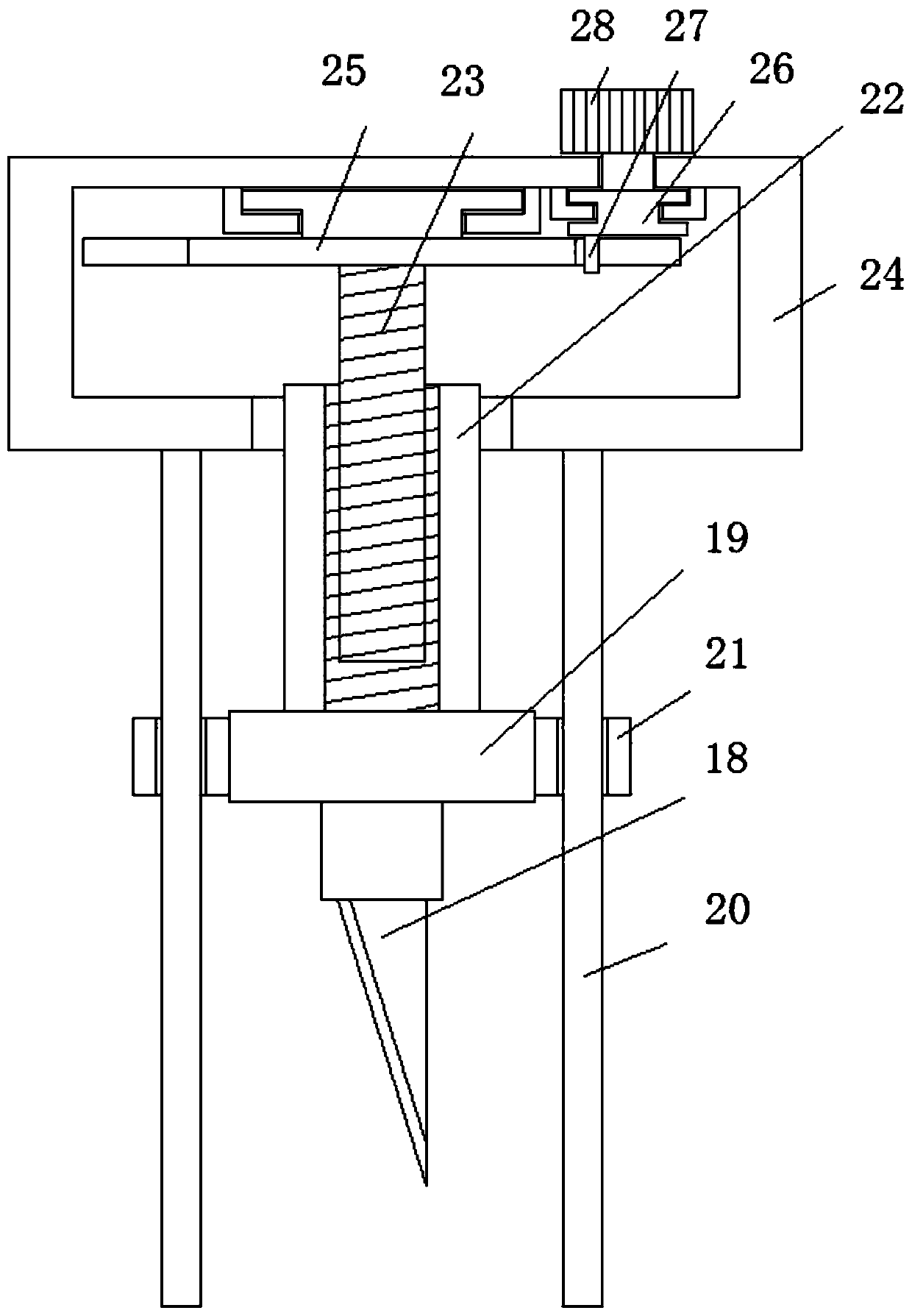

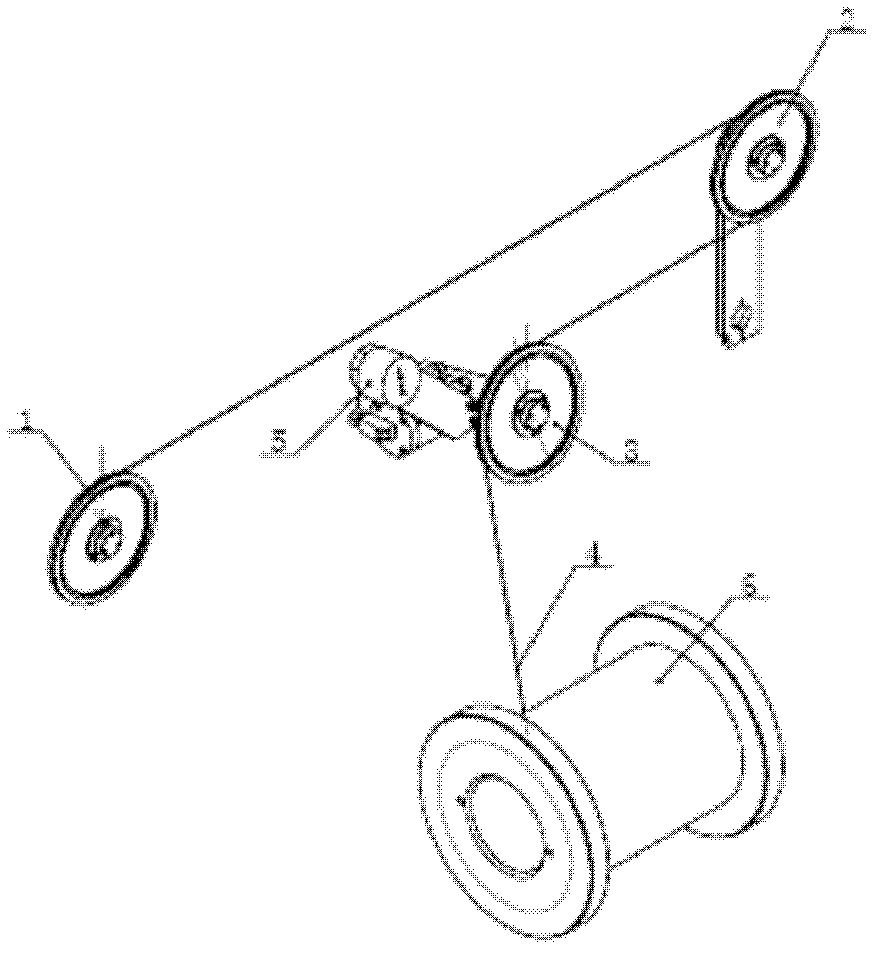

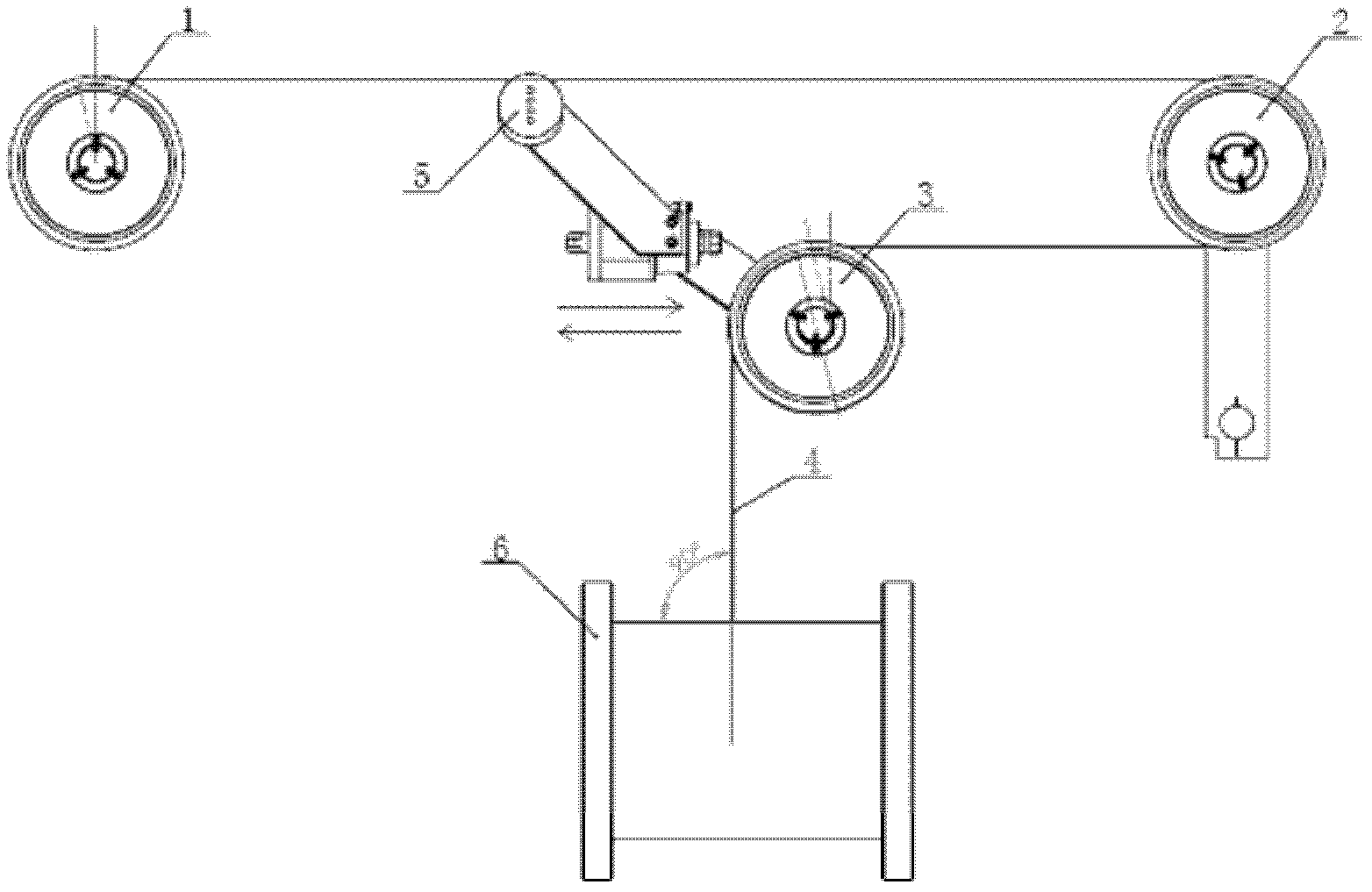

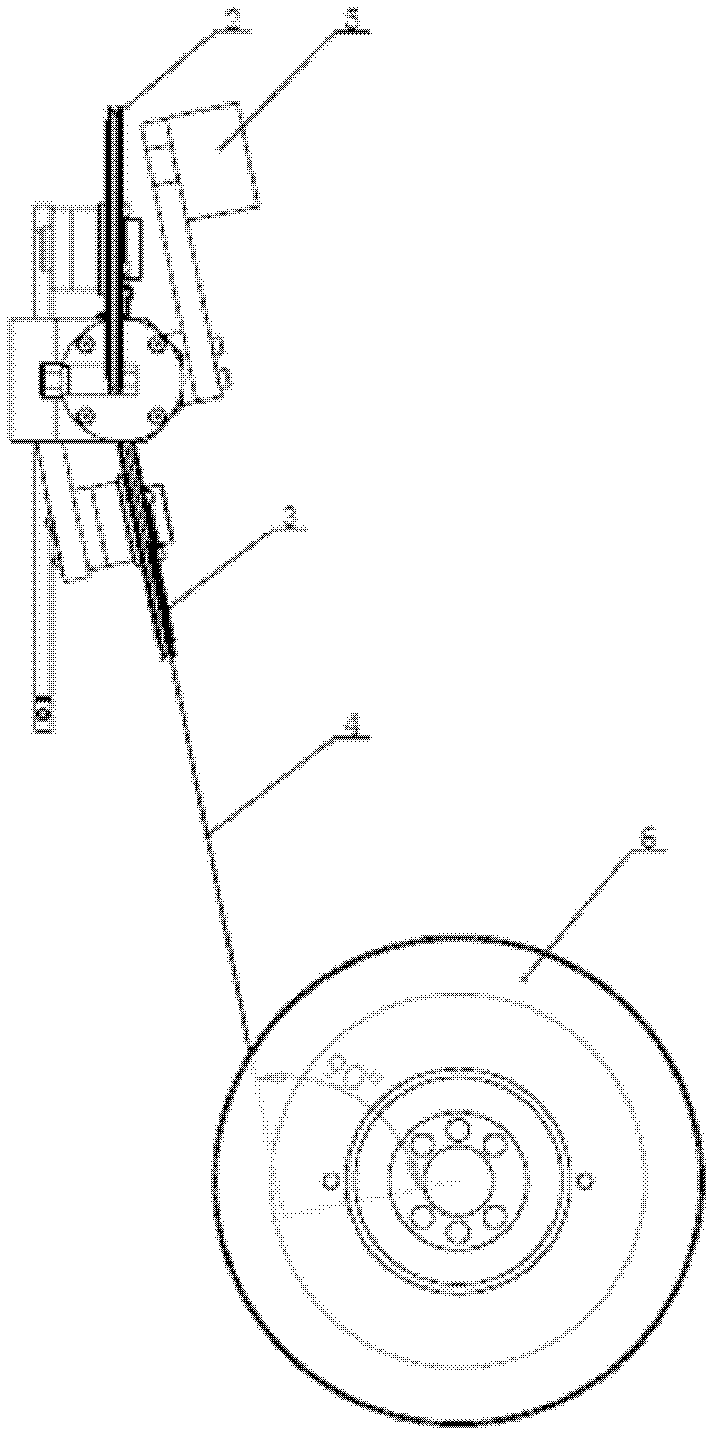

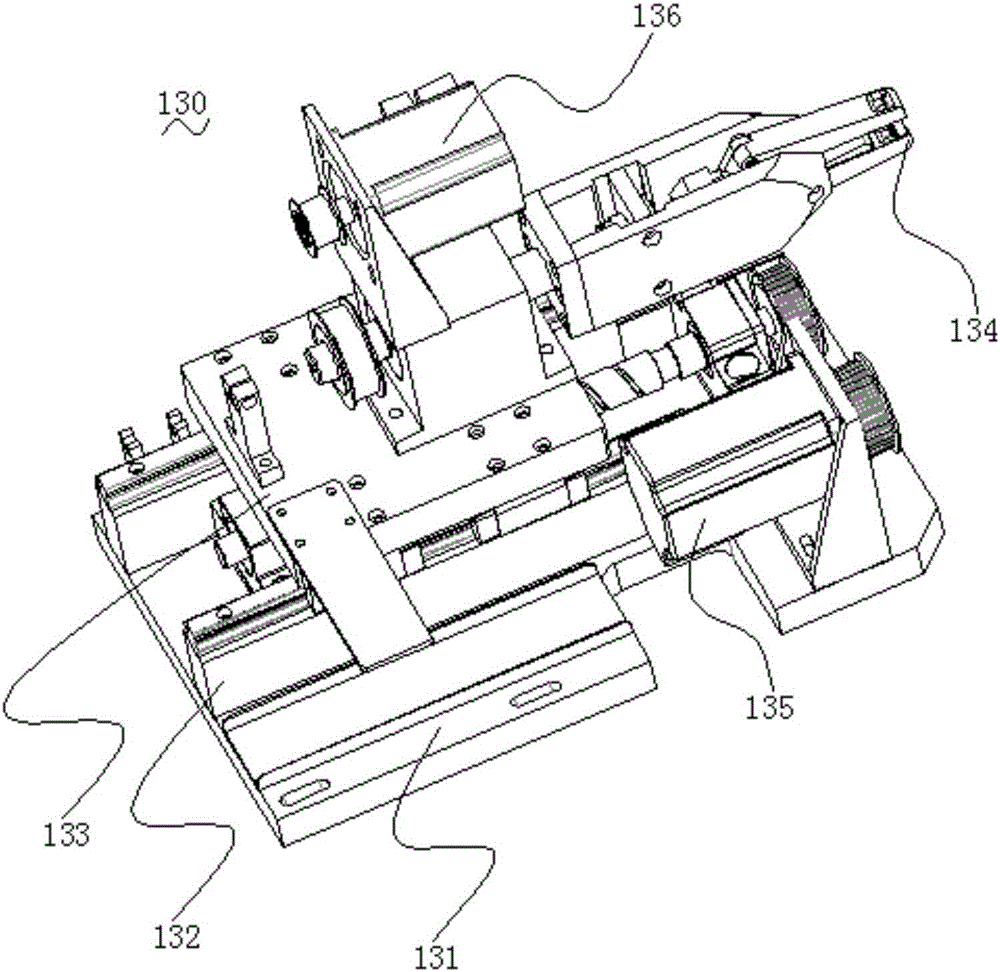

Automatic wire arrangement and balance device of multi-wire cutting machine

InactiveCN102615730AGuaranteed uniformityImprove qualityWorking accessoriesFine working devicesWire cuttingEngineering

The invention relates to an automatic wire arrangement and balance device of a multi-wire cutting machine. The automatic wire arrangement and balance device is characterized by comprising a conducting wire pulley, a tension control pulley, a swinging conducting wire pulley and a wire coil used for coiling a cutting steel wire; the cutting steel wire is wound on the wire coil sequentially by the conducting wire pulley, the tension control pulley and the swinging conducting wire pulley; and the cutting steel wire is wound on the wire coil in the tangential direction of the peripheral surface of the wire coil. The swinging conducting wire pulley is provided with a balance hammer. The automatic wire arrangement and balance device of the multi-wire cutting machine has the beneficial effects that wires can be arranged automatically, the tension can be balanced automatically, the steel wire can be guaranteed to keep the tangential and vertical winding direction when wound on the wire coil, the uniformity of the arranged wires and the force bearing constancy are guaranteed, the probability of wire breaking is reduced, the phenomenon of fretsaw on a product is eliminated, the cutting effect is guaranteed, and the quality of the cut product is also greatly improved.

Owner:无锡市协清机械制造有限公司

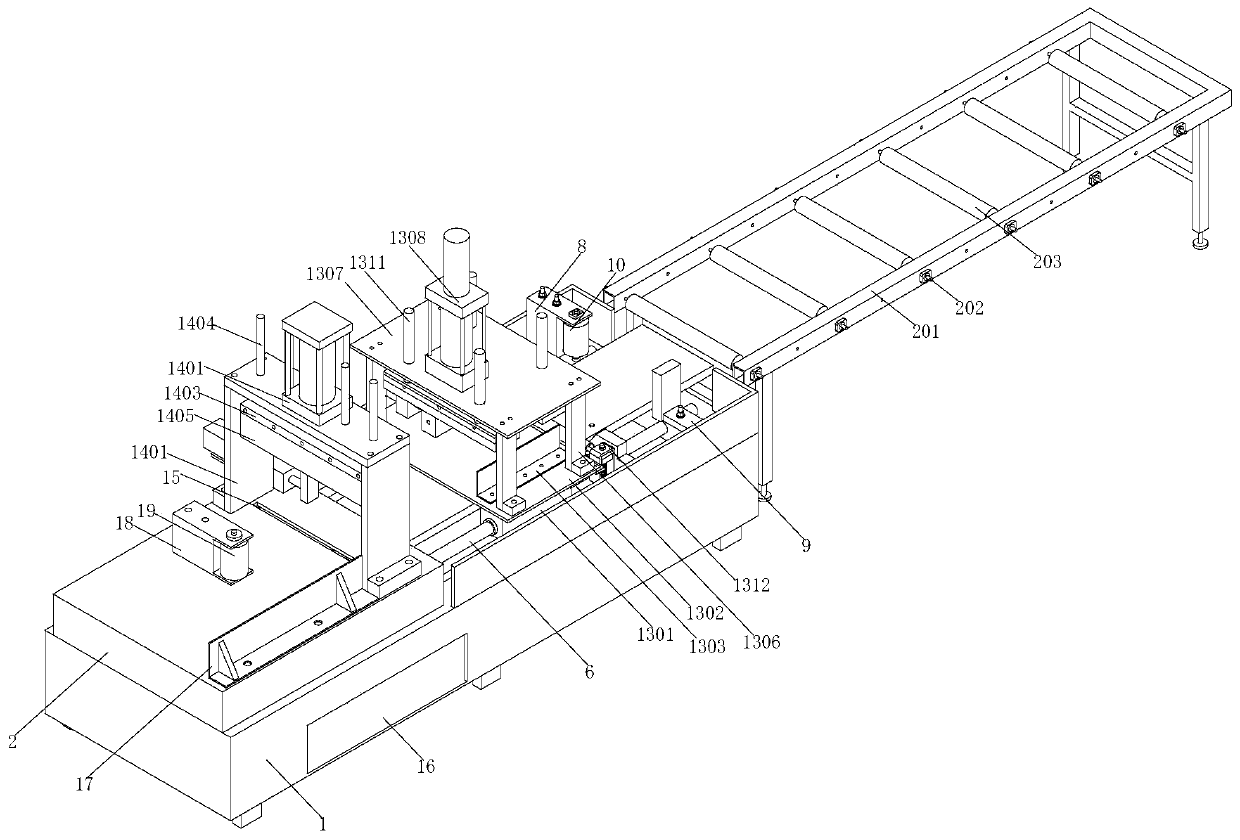

Processing device for cured ribs

ActiveCN108789532AGuaranteed cutting effectReduce laborMetal working apparatusMeat processing devicesEngineeringHinge joint

The invention relates to the field of processing devices of pickled foods. In order to solve the problem that in the existing rib processing process, because mince sticks to a cutter during cutting, cuts in ribs are irregular or ribs cannot be cut off, the invention provides a processing device for cured ribs. The processing device for cured ribs comprises a cutting table and a cutting knife and further comprises a mounting rack which is used for the mounting of the cutting knife, wherein a first mounting end of the mounting rack is connected to the cutting table; a second mounting end of themounting rack is connected to the cutting knife; a vertical mounting groove is formed in the second mounting end; the cutting knife is positioned in the mounting groove and can do reciprocating motionalong the mounting groove; after the cutting knife moves downward, a knife edge part at the lower end of the cutting knife can extend out of the mounting groove; a clamping plate is arranged at the lower end of the mounting groove; a connecting end of the clamping plate is hinged at the lower end of the mounting groove; a returning part is arranged at the hinged joint between the connecting end and the mounting groove; a free end of the clamping plate faces towards the knife edge part; and in the movement process of the cutting knife, the clamping plate abuts against the surfaces of the cutting knife.

Owner:湛江市坡头区恒泽肉食制品有限公司

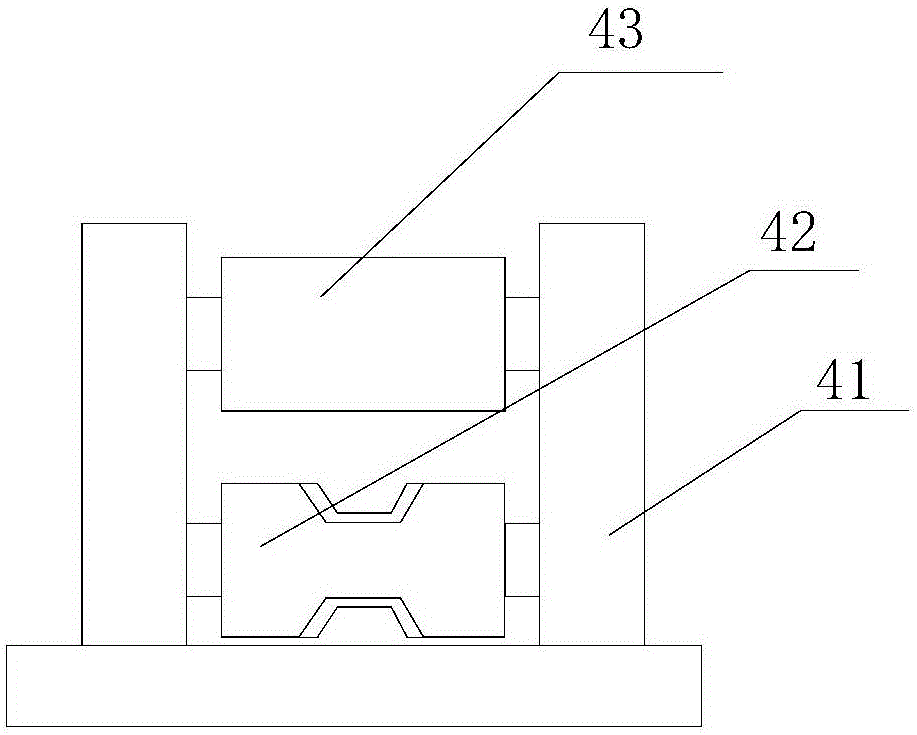

Single-face automatic feeding four-column cutting machine

The invention discloses a single-face automatic feeding four-column cutting machine. The single-face automatic feeding four-column cutting machine comprises a workbench, a lifting rod and a container.Fixing supports are arranged on the two sides of a cutting mechanism, and fixing buckles are arranged below the cutting mechanism. A motor is arranged on the inner surface of the base, and a carryingtable is arranged on one side of the base. Rotation rods are arranged on the outer surface of the container, and mechanical arms are arranged at one ends of the rotation rods. Sharpening blocks are arranged in the cutting mechanism. According to the single-face automatic feeding four-column cutting machine, the fixing buckles, the carrying table, the mechanical arms and the sharpening blocks arearranged, to-be-cut materials on the workbench can be fixed, it is guaranteed that the materials are flatly placed on the workbench, cutting is convenient, the cut materials can be received, automaticfeeding can be conducted, and the work efficiency is improved; and a cutting blade can be ground, the sharpness of the cutting blade is guaranteed, the cutting effect is ensured, the single-face automatic feeding four-column cutting machine is applicable to different work conditions, and better using prospects are brought.

Owner:江苏华驰机械有限公司

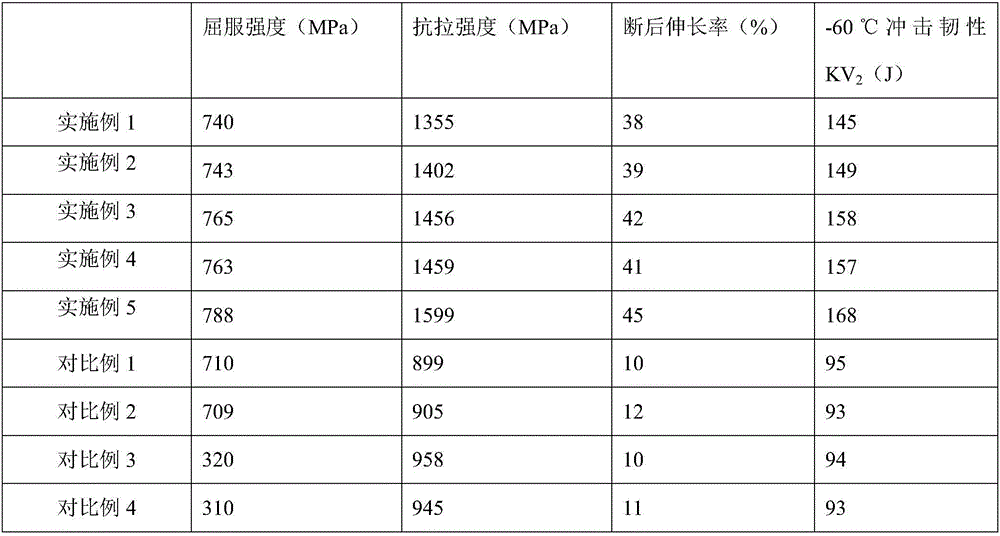

Steel plate for marine ocean energy source equipment and preparation technique thereof

The invention discloses a steel plate for marine ocean energy source equipment and a preparation technique thereof. The steel plate is composed of the following chemical components in percentage by mass: 0.21-0.33% of carbon, 0.55-0.85% of silicon, 0.15-0.22% of aluminum, 0.001-0.002% of boron, 1.00-1.45% of chromium, 0.55-0.75% of manganese, 0.009-0.013% of phosphorus, 0.002-0.005% of sulfur, 2.5-3.5% of molybdenum, 0.05-0.1% of niobium, 0.08-0.15% of vanadium and the balance of iron and inevitable impurities. The steel plate for ocean energy source equipment is composed of the carbon, silicon, aluminum, boron, chromium, manganese, phosphorus, sulfur, molybdenum, niobium, vanadium and iron according to specific proportioning, is especially suitable for long-term use in the ocean environment, effectively avoids cracking, and has favorable toughness and corrosion resistance.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

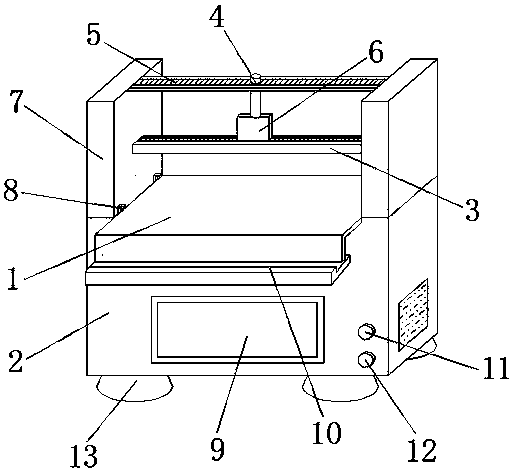

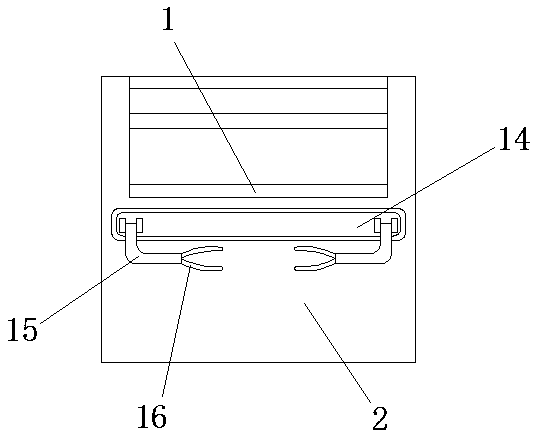

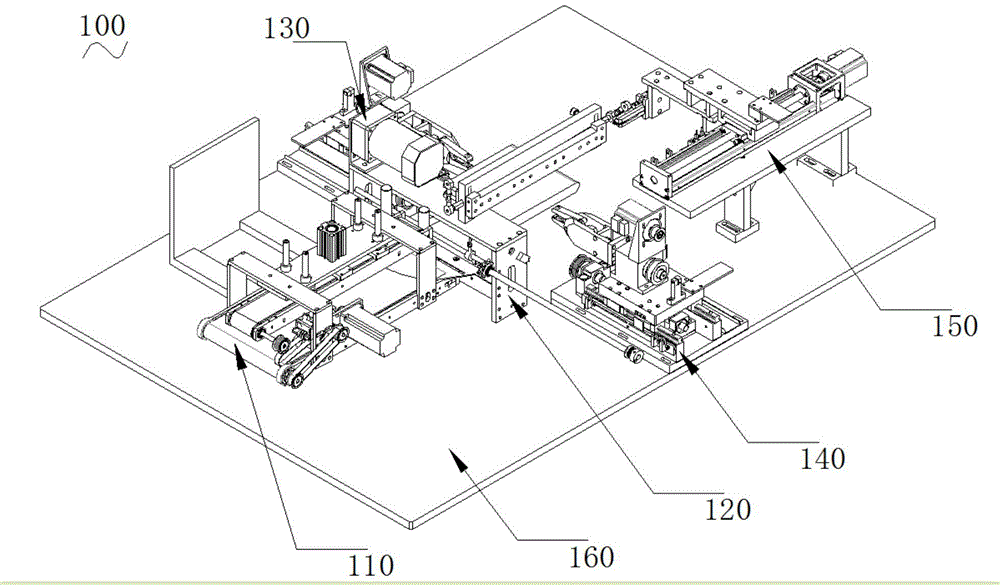

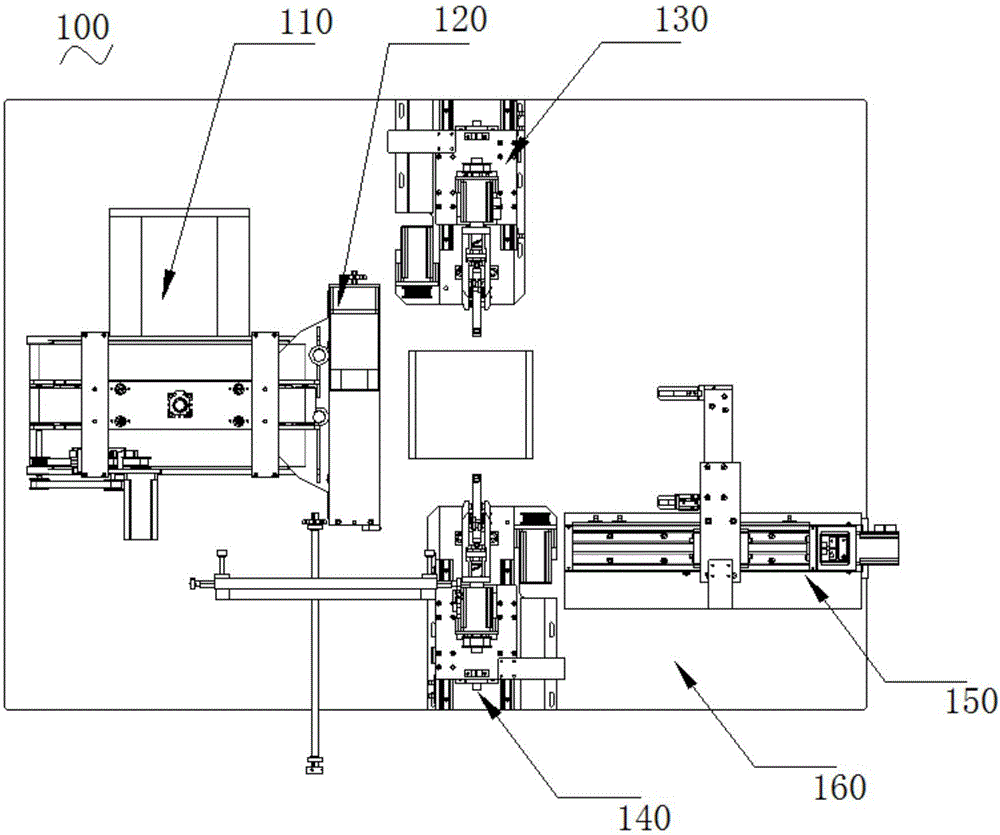

Winding device for battery cell winding lamination machine

ActiveCN105742720AEven by forceLamination effect is goodFinal product manufactureSecondary cellsEngineeringPole piece

The invention relates to the technical field of battery pole piece processing equipment, in particular to a winding device for a battery cell winding lamination machine. The winding device for the battery cell winding lamination machine comprises a sheet loading assembly, a sheet cutting assembly, a first winding assembly, a second winding assembly and a battery cell unloading assembly, wherein the sheet loading assembly is used for loading a diaphragm sheet; an anode piece and a cathode piece are pasted on two sides of the diaphragm sheet respectively; the sheet cutting assembly is used for cutting a diaphragm of the sheet; the first winding assembly and the second winding assembly are used for clamping the sheet and driving the sheet to rotate to wind the sheet into a battery cell; the battery cell unloading assembly is used for unloading the battery cell; the first winding assembly and the second winding assembly are symmetrically arranged at two sides of a connection line for the sheet loading assembly and the sheet cutting assembly; the first winding assembly and the second winding assembly are located at the rear part of the sheet cutting assembly; and the battery cell unloading assembly is located at the rear parts of the first winding assembly and the second winding assembly. The winding device for the battery cell winding lamination machine is simple in structure, high in work efficiency, stable to run and good in lamination effect.

Owner:GUANGDONG YI XINFENG INTELLIGENT EQUIP CO LTD

Agricultural sugarcane juicer

InactiveCN110771908AGuaranteed cutting effectEasy to crushJuice extractionAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural juicing equipment, in particular to an agricultural sugarcane juicer. The agricultural sugarcane juicer comprises a casing, wherein a conveyor belt is arranged on the inner side of the casing; a feeding hole is formed in the left side of the conveyor belt; a cutting mechanism is arranged on the upper side of the conveyor belt; a guide plate is arranged on the lower side of the right end of the conveyor belt; a supporting plate is arranged on the lower side of the guide plate; a crushing and juicing mechanism is arranged in the supporting plate in a bearing connection manner; a liquid storage tank is arranged on the lower side of the smashing and juicing mechanism; a residue box is arranged on the right side of the liquid storagebox; and a squeezing mechanism is arranged in the residue box. According to the agricultural sugarcane juicer, the cutting mechanism is arranged, and sugarcane can be cut into a plurality of small sections and is conveniently crushed, by arranging the crushing and juicing mechanism, automatic separation of sugarcane juice and bagasse can be achieved, meanwhile, the sugarcane crushing effect of thedevice can be enhanced through opposite rotation between a crushing barrel and a first rotating rod, and by arranging a second filtering plate and a pressing plate, residual sugarcane juice in residues can be extruded out, so that the sugarcane is fully utilized.

Owner:长沙市天珍科技有限公司

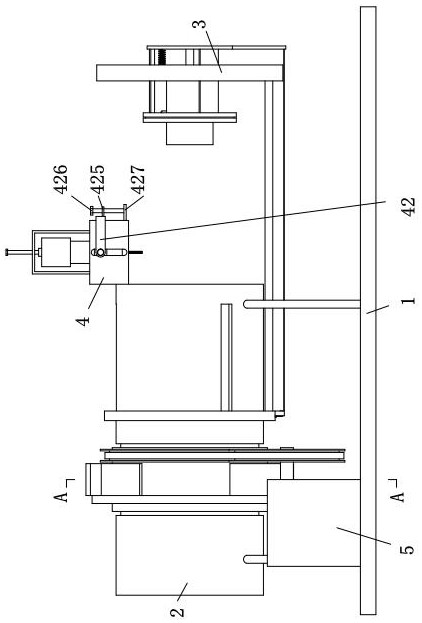

Focusing device and focusing method of laser cutting machine

ActiveCN111168230AAccurately determineHigh precisionLaser beam welding apparatusBeam splitterLight sensing

The invention provides a focusing device of a laser cutting machine. The focusing device comprises an optical fiber joint, a shell, a sleeve, a sliding barrel, a light sensing mechanism, a linear motor, a protective mirror, a nozzle, a distance measuring mechanism, a beam splitter prism and a lens set. The optical fiber joint is arranged at one end of the shell. The sleeve is arranged on the sidewall of the shell and is provided with the sliding barrel in a sliding manner. The linear motor drives the sliding barrel to move. The light sensing mechanism is arranged in the sliding barrel. The beam splitter prism and the lens set are arranged in the shell. The protective mirror and the nozzle are arranged at the other end of the shell. According to the focusing device of the laser cutting machine, through multiple times of quantitative moving of the sliding barrel, the focal position is measured precisely, the focal position and the preset focal position are compared to form feedback, andtherefore focusing is achieved more precisely; and after precise focusing, the distance measuring mechanism is used for cooperating with a controller to adjust the laser cutting machine, it is guaranteed that the focal point is located on the surface of a workpiece, and the workpiece cutting effect is guaranteed.

Owner:JINAN BODOR LASER CO LTD

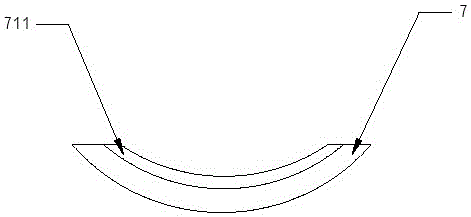

Aluminum rod shearing machine

The invention discloses an aluminum rod shearing machine. The aluminum rod shearing machine comprises a rack, an aluminum rod conveying frame and an aluminum rod output frame, wherein the rack is fixedly provided with a fixed tool apron and a sliding frame; the sliding frame is provided with a movable tool apron; each of the fixed tool apron and the movable tool apron is provided with a pair of scissors; the sliding frame is driven by an oil cylinder to slide; an aluminum rod positioning seat is arranged at the output end of the aluminum rod conveying frame; the aluminum rod positioning seat is driven by a driving mechanism to do reciprocated up-down sliding relative to the rack; the aluminum rod output frame comprises an aluminum rod overturning frame with a circular-arc-shaped section; the aluminum rod overturning frame is rotatably connected with the rack and is driven by a first air cylinder to rotate; each pair of scissors is semi-annular; the aluminum rod positioning seat, the fixed tool apron and the movable tool apron are provided with arc-shaped surfaces adapted to the outer circumference of an aluminum rod; the aluminum rod is sheared through setting the semi-annular scissors and are orderly sheared, and cutting openings are flat; the aluminum rod is simultaneously positioned in upper and lower directions through the aluminum rod positioning seat and the aluminum rod overturning frame in a shearing process, so that the shearing effect is guaranteed.

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

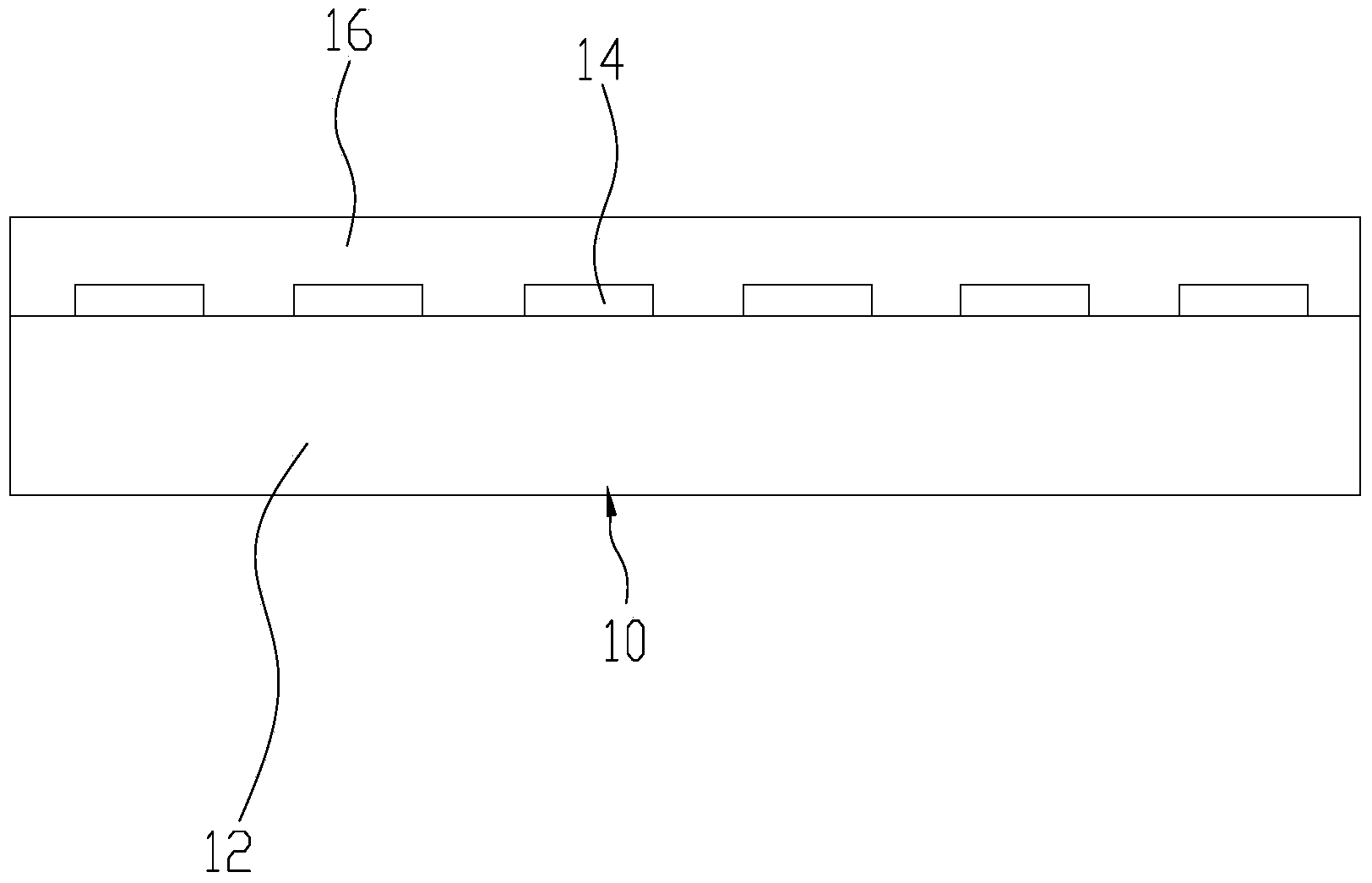

Tool component for cutting touch screen protection film

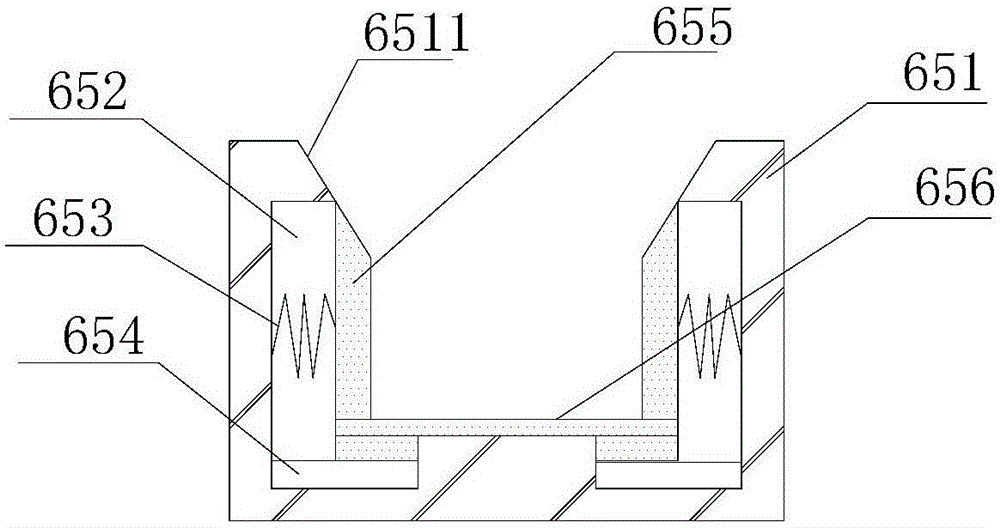

ActiveCN103538108AControl pressureGuaranteed cutting effectMetal working apparatusTectorial membranePower flow

The invention discloses a tool component for cutting a touch screen protection film. The tool component comprises a cutter, a first guide column, a second guide column, an electromagnet, a tool apron, a magnetic block, an elastic ejector and a knob. The first guide column and the second guide column are parallelly arranged at intervals, the tool apron comprises a first guide portion, a second guide portion and a mounting portion, the first guide portion and the second guide portion penetrate the first guide column and the second guide column respectively, the mounting portion is provided with a through hole, the cutter, the magnetic block, the elastic ejector and the knob are arranged in the through hole, the magnetic block attracts the cutter so that a cutting edge of the cutter downwardly extends out of the through hole, the elastic ejector is elastically ejected between the magnetic block and the knob, the knob is connected with the mounting portion in a threaded manner, the electromagnet generates magnetic force in electrification and attracts the tool apron to move downwards, and the cutting edge of the cutter is pressed on the touch screen protection film. The pressure of the cutter is controlled by adjusting current and can be accurately controlled, and cutting effects are ensured.

Owner:FUJIAN FEIYANG OPTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com