Laser cutting head

A laser cutting head and laser technology, applied in laser welding equipment, electrical components, circuits, etc., can solve problems such as unsatisfactory cutting effect, burrs, and inability to cut pole pieces accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

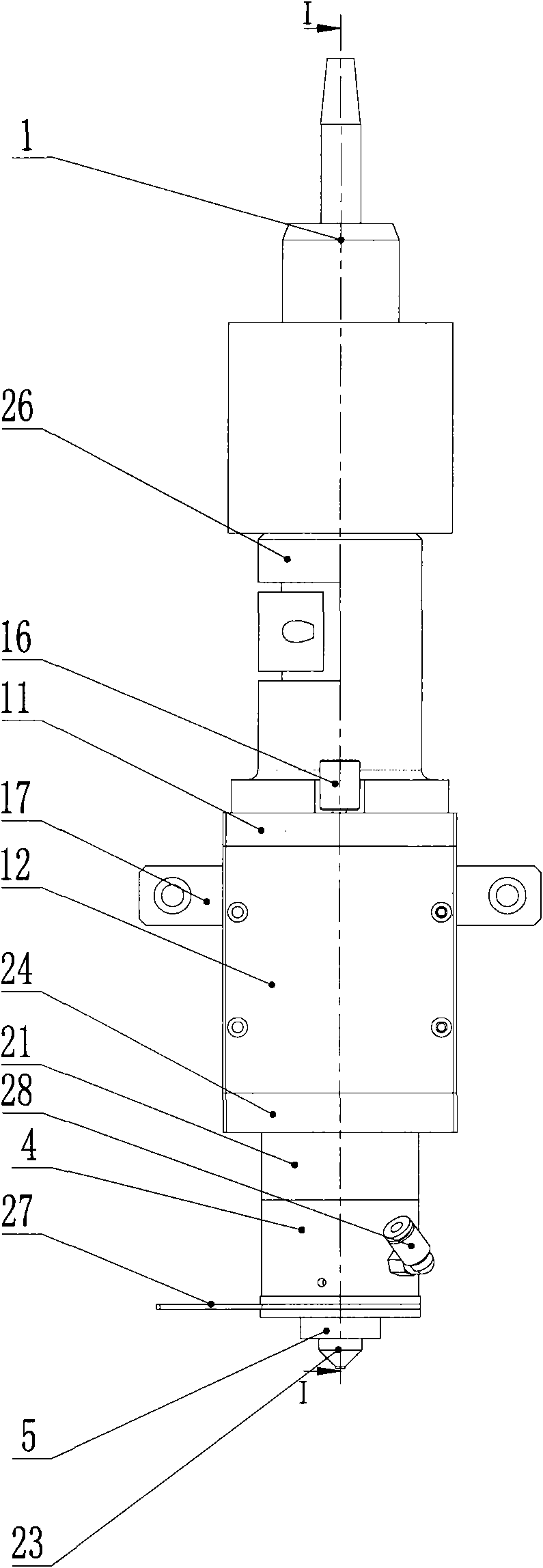

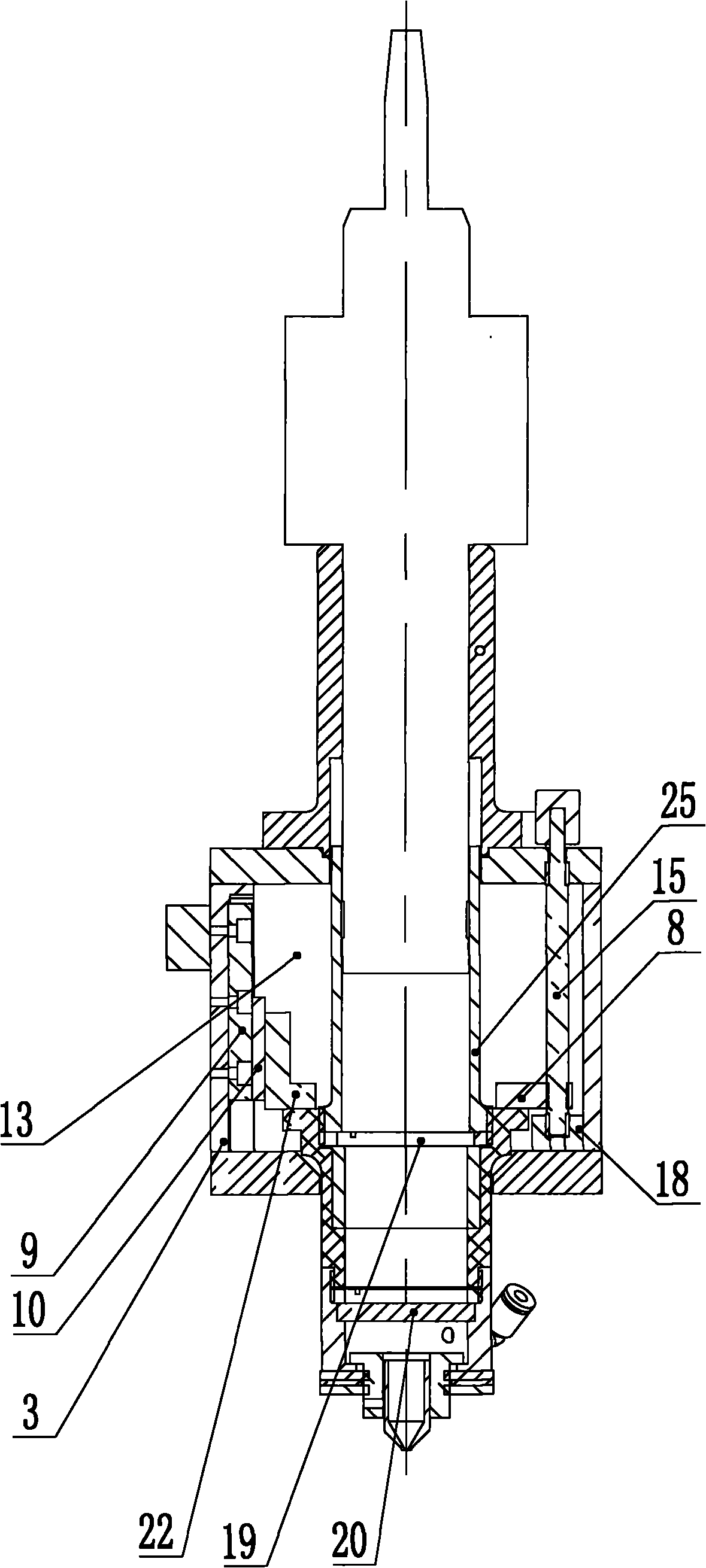

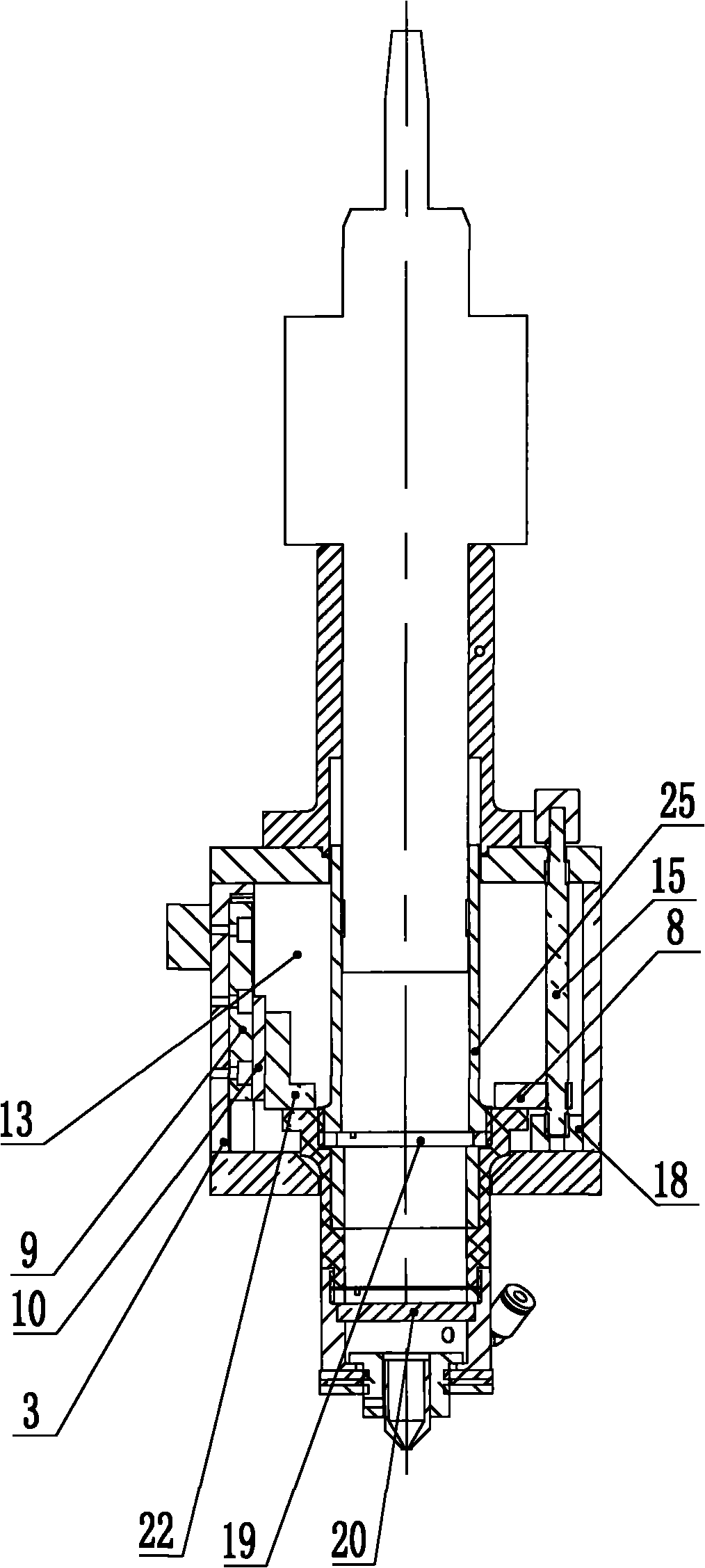

[0031] Such as figure 1 and figure 2 A laser cutting head is shown, which is used to cut the plates of power lithium-ion batteries. The upper cover plate 11, the lower cover plate 24, the front cover plate 12, the rear cover plate 3 and the left and right side plates 13 form an installation housing. The interior of the installation housing is a cavity. The upper cover plate 11 and the lower cover plate 24 are provided with through holes as light passages. The laser input head installation base 26 is installed on the upper end of the installation housing, and is fixed at the through hole on the upper cover plate 11 . The laser input head 1 is installed on the mounting base 26 to introduce the laser into the cutting head.

[0032] The bottom of the installation housing is equipped with a focusing mirror seat 21 . The inside of the focusing mirror base 21 is hollow, and a focusing lens 19 is installed therein. A protective sleeve 25 is also provided above the focusing lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com