Ultralow sulfur steel quick smelting method

A smelting method, ultra-low sulfur steel technology, applied in the field of metallurgy, can solve the problems of strict sulfur content requirements, smelting desulfurization process can not fully meet the needs of large-scale production, to meet production needs, ensure the pace of smelting production, and converter steel tapping The effect of deoxygenation stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

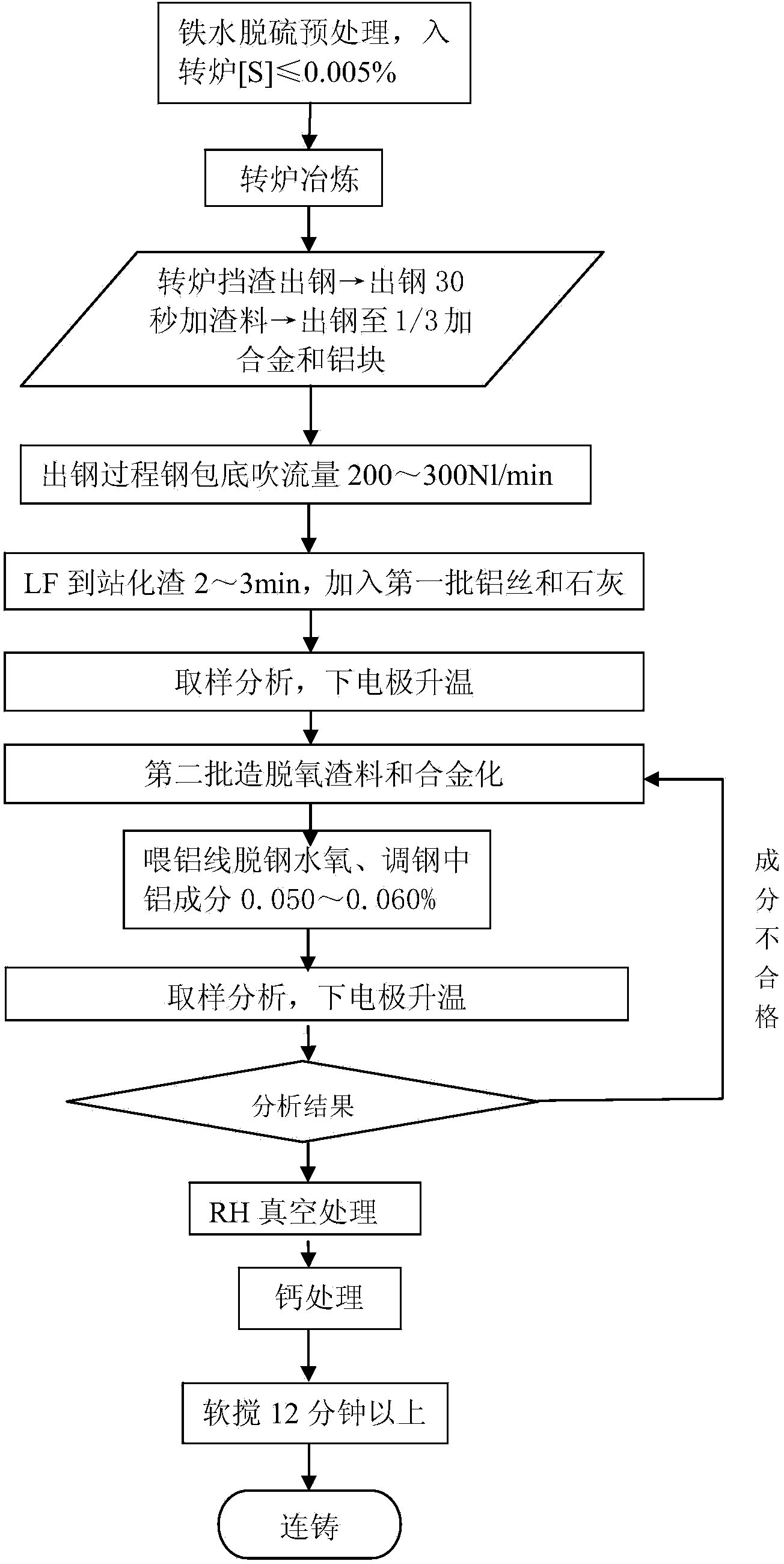

Method used

Image

Examples

Embodiment 1

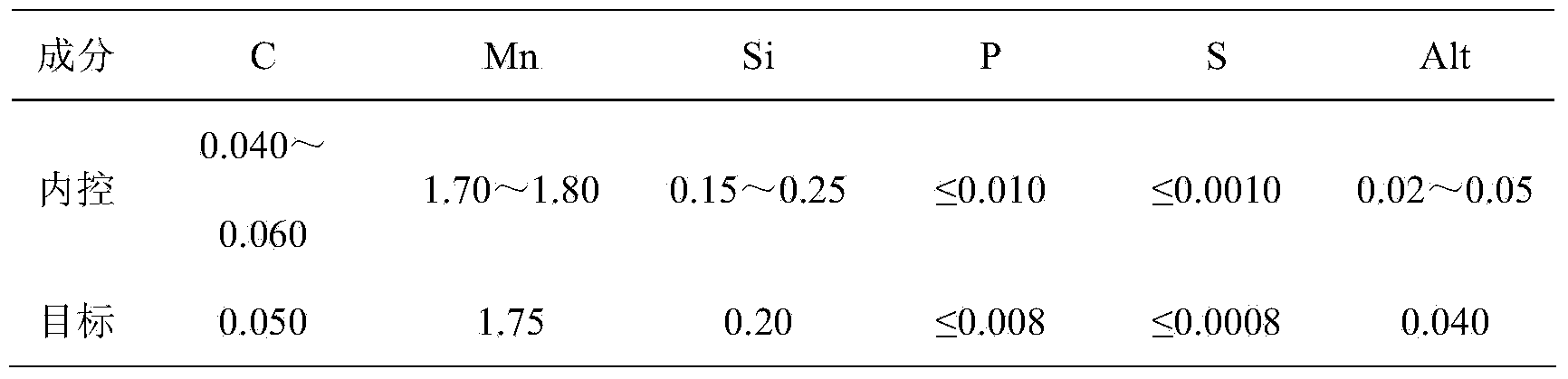

[0035] In this embodiment, the X80 pipeline steel grade is selected, and a 150-ton converter and a 150-ton ladle furnace are used for smelting according to the above-mentioned method. The chemical composition of its X80 pipeline steel is shown in Table 1.

[0036] Table 1X80 main chemical composition (%)

[0037]

[0038] The whole smelting process is controlled as follows:

[0039] (1) Converter blowing. The composition and temperature control at the end of blowing are shown in Table 2.

[0040] Table 2 Converter end point composition (%)

[0041]

[0042] (2) Deoxidation and slagging alloying after converter furnace. The order of adding auxiliary materials in the tapping process: start tapping→lime, refining slag→aluminum block, silicomanganese, manganese metal. See Table 3 for the addition amount and composition control after furnace.

[0043]Table 3 Composition after furnace

[0044]

[0045] (3) Refining deoxidation, slagging desulfurization, and removal of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com