Process for producing aluminum-containing medium carbon steel through CaC2 deoxidization

A carbon steel and process technology, applied in the field of CaC2 deoxidation to produce aluminum-containing medium carbon steel and steelmaking process, can solve the problem of high aluminum consumption, and achieve the effect of reducing aluminum consumption, good quality of casting billet and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

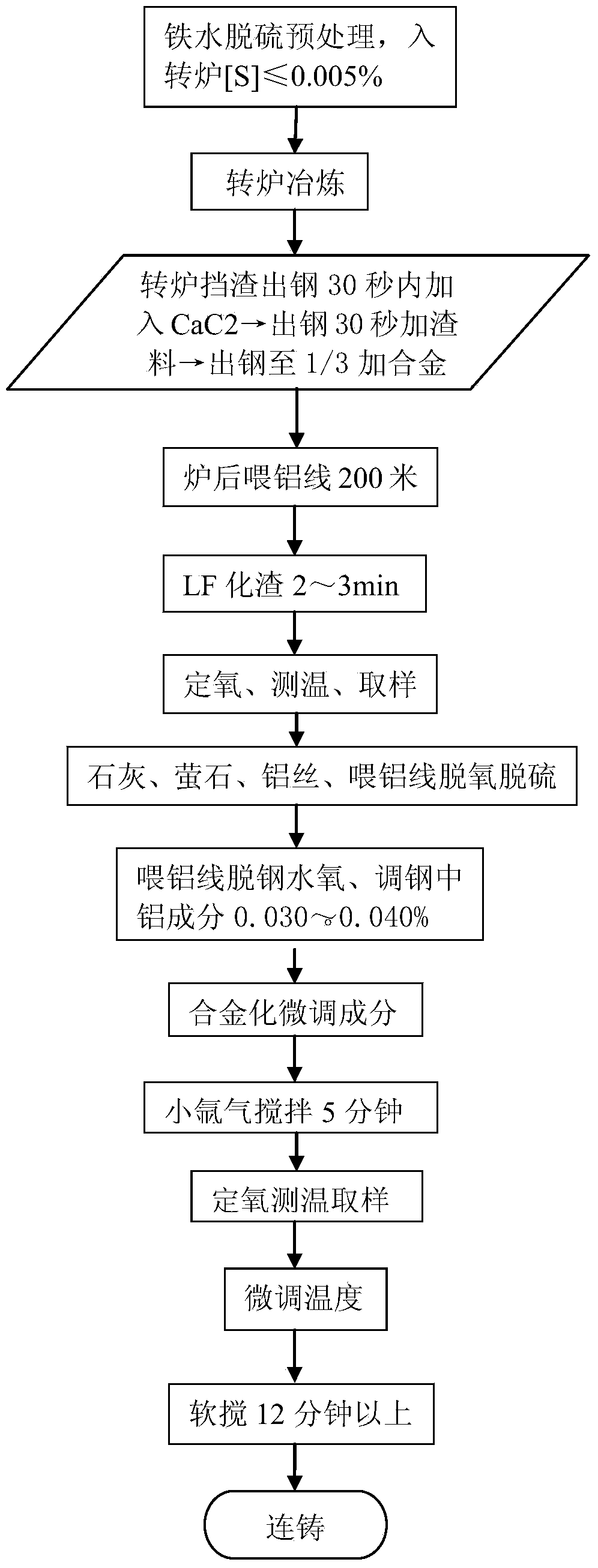

[0036] A kind of smelting process CaC 2 The control process of deoxidation to produce aluminum-containing medium carbon steel, the process is optimized through the deoxidation system and slagging system of converter tapping, adding an appropriate amount of CaC according to the oxygen value of the end point of converter tapping 2 , Feed 200 meters of aluminum wire after the furnace to adjust aluminum in molten steel, LF furnace CaC 2 , Aluminum wire deoxidation, slagging and desulfurization and fine-tuning the production process of aluminum in molten steel with LF furnace feeding aluminum wire. The aluminum content in molten steel is kept in the range of 0.030-0.040% to control the feeding amount of aluminum wire. Stir softly for more than 12 minutes after desulfurization and alloying.

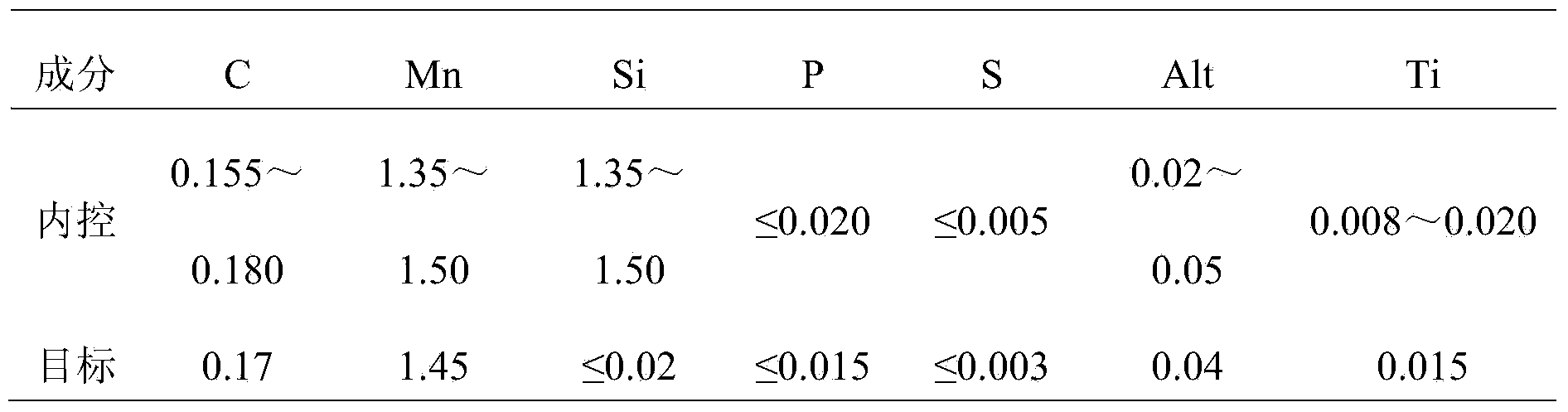

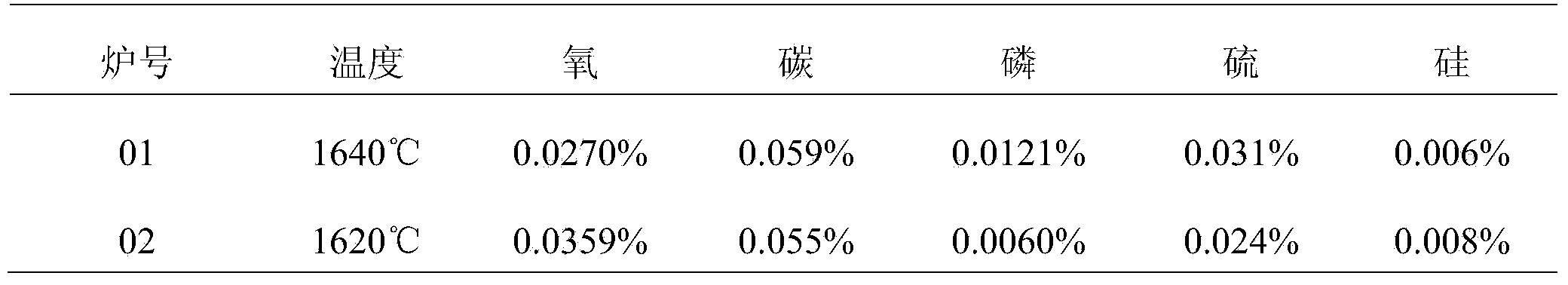

[0037] In this embodiment, S355J-1 steel grade is selected, and it is smelted in a 150-ton converter and a 150-ton ladle furnace. The chemical composition of its S355J-1 is shown in Table 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com