Patents

Literature

113results about How to "Good desulfurization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

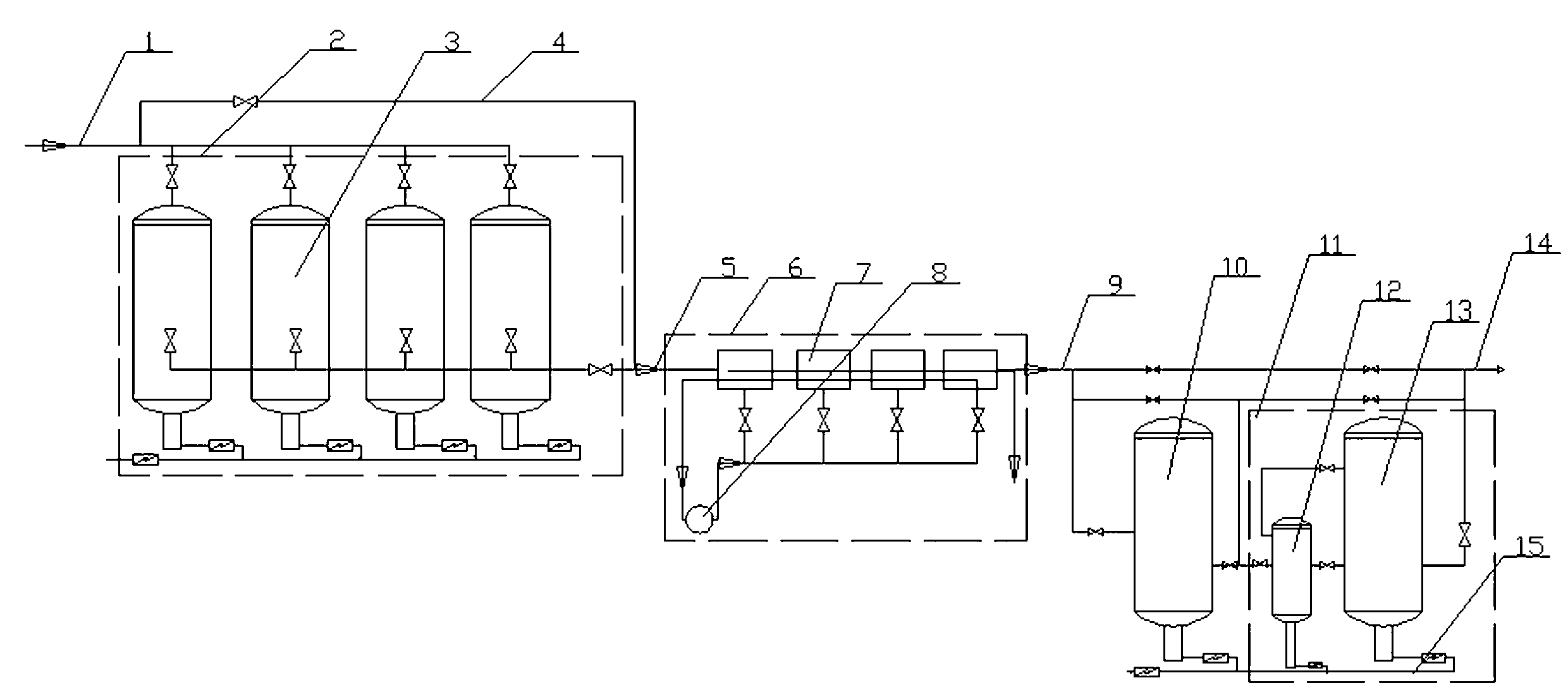

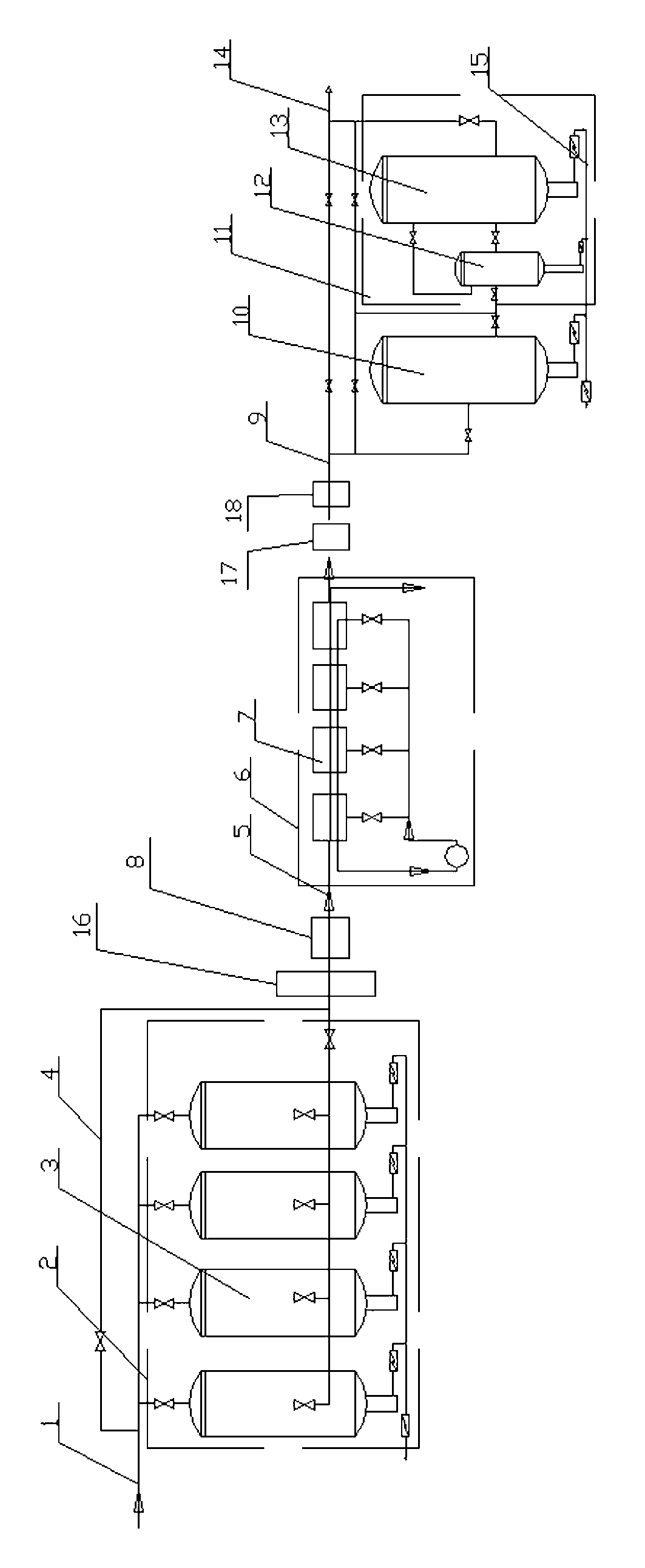

Gas turbine generating coke oven gas comprehensive purification system and purification method thereof

InactiveCN102994171AGood desulfurization effectGood purification effectCombustible gas purificationCoke oven gasProcess engineering

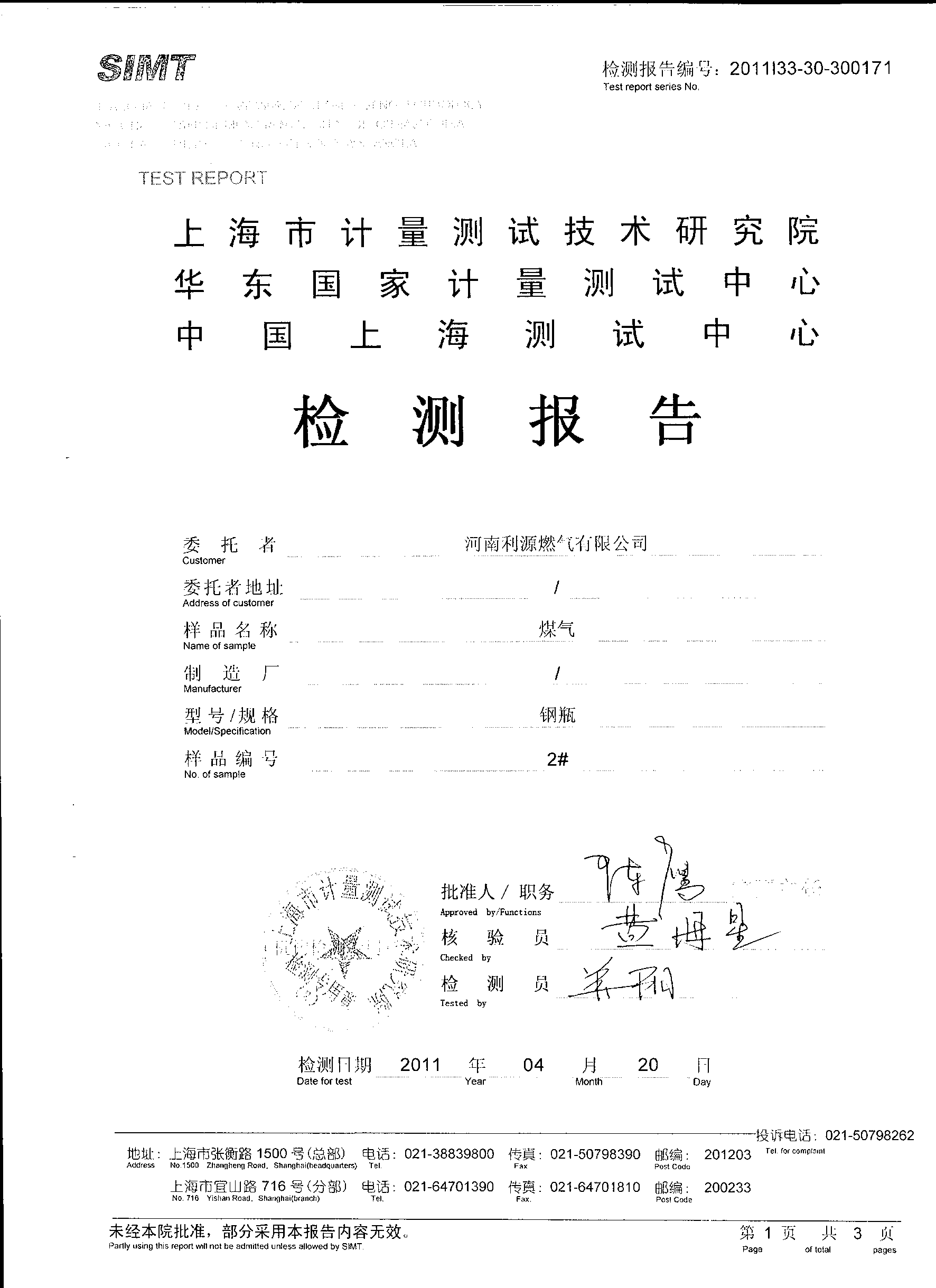

The invention relates to a gas turbine generating coke oven gas comprehensive purification system and a purification method thereof. The gas turbine generating coke oven gas comprehensive purification system is characterized in that coke oven gas in a gas pipe enters into a gas turbine by virtue of a desulphurization system, a compressor filtering system and a coal oven gas filtering system sequentially, wherein the desulphurization system is formed by connecting four dry desulphurizing towers on the gas pipe in parallel, and the compressor filtering system is formed by connecting four compressor filters on a first gas pipe from the desulphurization system in series; and the purification method utilizing the coke oven gas comprehensive purification system comprises the following steps of: a, desulphurizing coal oven gas; b, filtering and compressing the coal oven gas obtained by the step a; c, carrying out isobaric warming on the coal oven gas obtained by the step b; d, carrying out primary filtering on the coal oven gas obtained by the step c; and e, carrying out fine filtering on the coal oven gas obtained by the step d, so that the coal oven gas meeting the requirement of a gas turbine is obtained. According to the gas turbine generating coke oven gas comprehensive purification system provided by the invention, on the basis of crude benzene purification treatment, four dry desulphurization towers are additionally arranged, a desulphurization effect is good, the compressor filtering system and the coal oven gas filtering system are optimized, and quality of the coal oven gas is improved.

Owner:HENAN LIYUAN CHAR GROUP

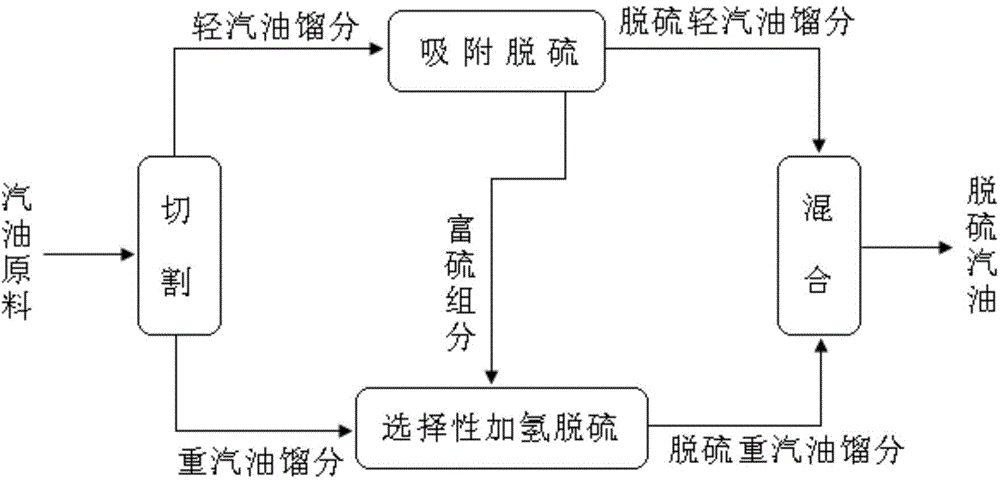

Gasoline desulfurization method

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

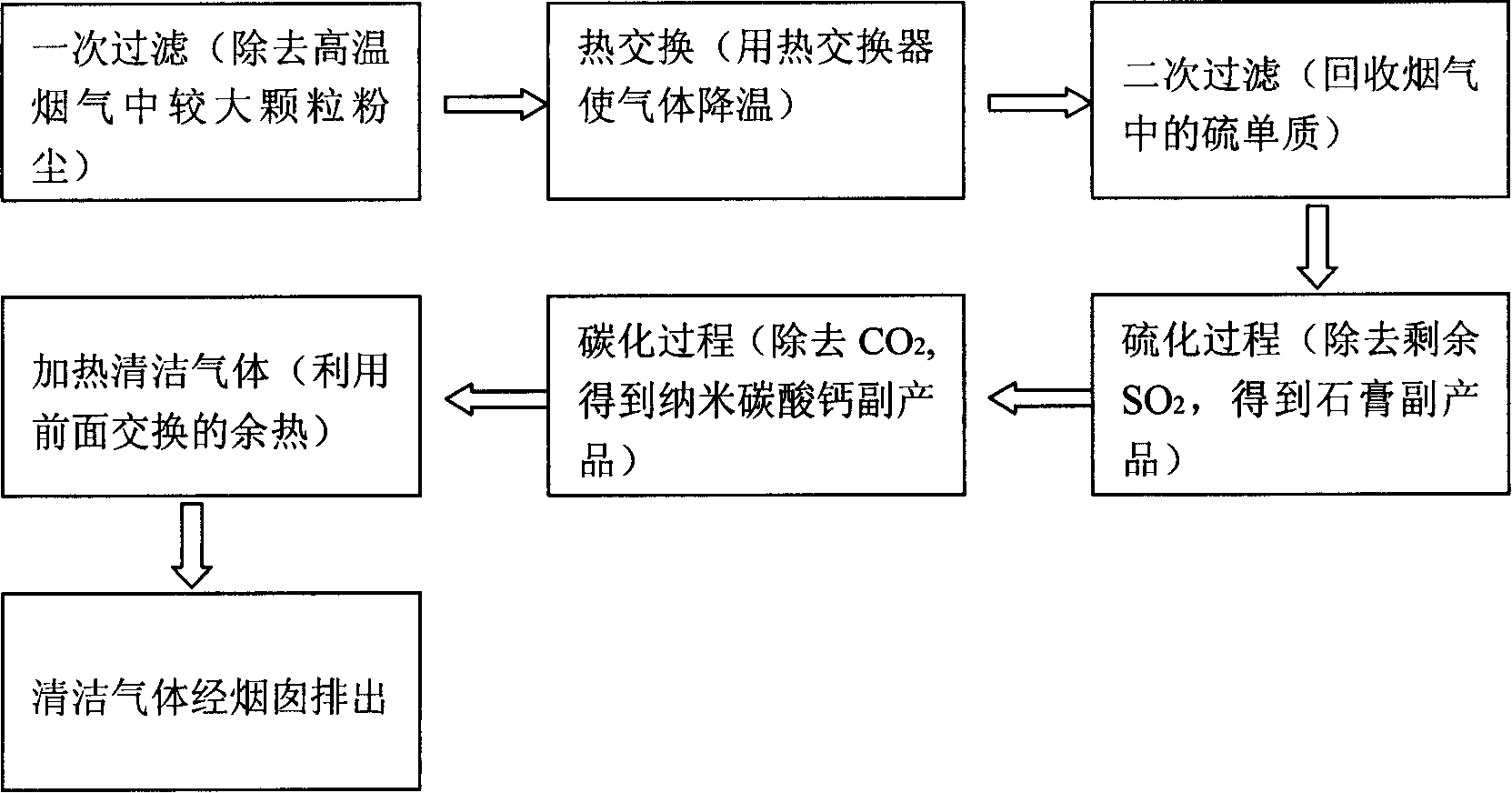

A processing method and apparatus of coal-firing gas

InactiveCN101157005AImprove heat exchange efficiencyGood desulfurization effectCombination devicesLighting and heating apparatusChemistryDust particles

The invention relates to a processing method for coal flue gas. Smoke dust particles and sulfur are removed from the coal flue gas through dry filtration, and sulfur dioxide is removed through a wet process, wherein, the dry filtration process comprises the steps that the coal flue gas passes through ceramic filtering materials; the process for removing the sulfur dioxide with a wet method has the steps that the sulfur dioxide is removed through the reaction of the coal flue gas after being processed with a dry method and calcium carbonate serosity. The invention has evident desulfation effect, and a formed accessory substance has very high added value; the invention can rationally use the residual heat of the high temperature coal flue gas; the invention realizes the removing of an element S and the recovery of the high purity, simultaneously performs the decarbonization process, and avoids the environmental pollution; the equipment adopted by the invention is easy to be assembled and disassembled, cleaned, and maintained; the invention resolves the contradiction between the operating costs and the operating effects of the desulfation and the decarbonization, and has huge economic interest and huge application foreground.

Owner:ZHENGZHOU UNIV

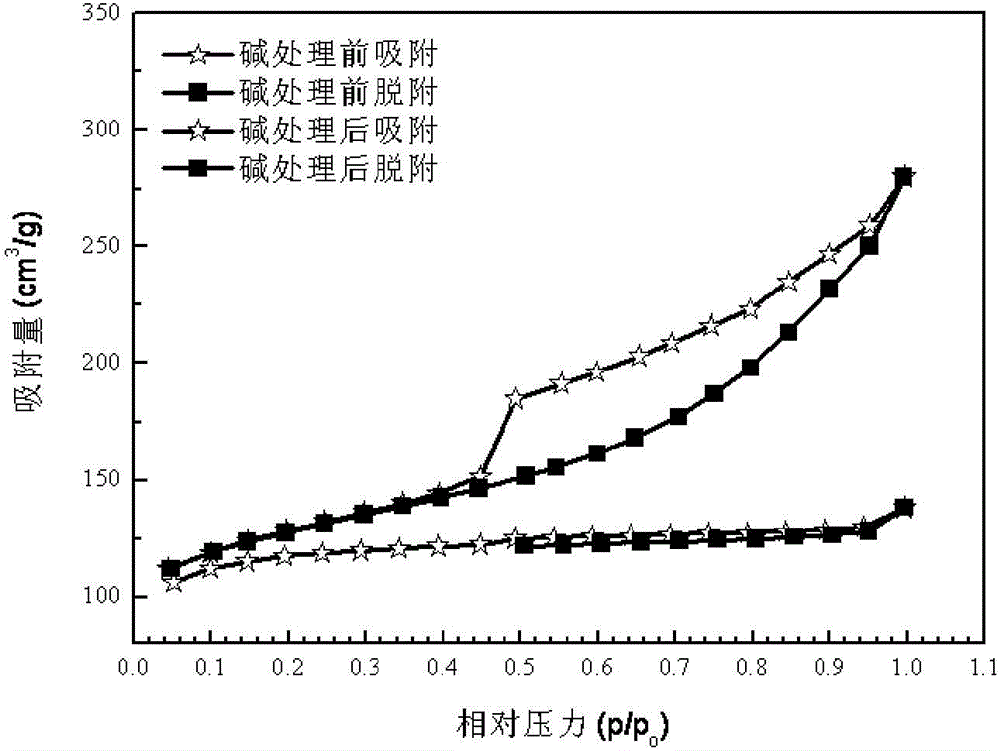

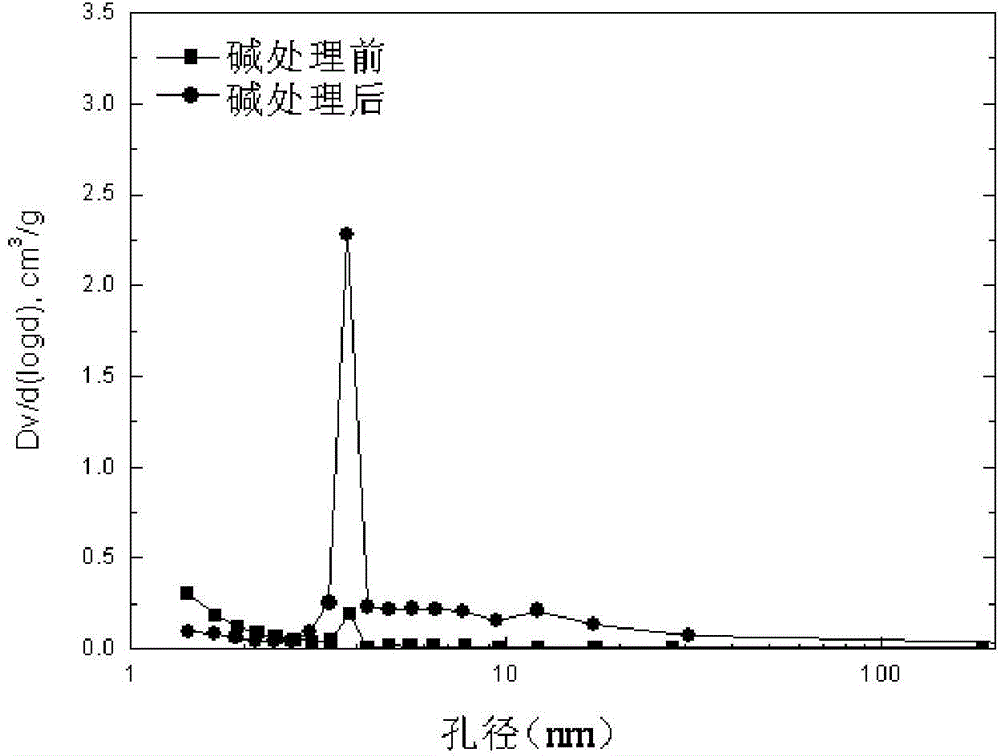

Adsorbent used for desulfurating gasoline, preparation method thereof and method for desulfurating gasoline by the same

ActiveCN101804329AGood dispersionEffective adsorption and removalOther chemical processesHydrocarbon oils refiningSorbentCyclodextrin

The invention discloses an adsorbent used for desulfurating gasoline, a preparation method thereof and a method for desulfurating gasoline by the same, which belongs to the technical field of fuel oil processing. The adsorbent is cyclodextrin modified by the copper element; the gasoline desulfurating method comprises the following steps: enabling the adsorbent and the fuel oil containing sulphur to contact and utilizing an adsorption method to realize desulfuration. The adsorption operation can be carried out at normal pressure and temperature; the operation cost is low and the adsorption effect is good.

Owner:NANJING UNIV OF TECH

Pre-molten low-melting point composite calcium aluminate desulfurizer and its prepn.

The invention discloses a kind of premelt-type, low-melting point, calcium aluminate complex desulfurizing agent and its preparation method, which is prepared according to the below components and proportion (weight): aluminum alum earth (calculated according to the Al2O3 content) 30-60%, and calcium oxide 40-70%. In advance perform passivating treatment on calcium oxide, then mix all the components according to the required proportion, then smelt them in the electric stove or the reflecting stove, then cool them, and by crashing, prepare the particle-shape or powder-shape desulfurizing agent. By the premelting treatment, the melting point of desulfurizing agent lowers to 1250-1400 centigrade, which obviously raises its desulfurizing rate in the molten iron molten steel and shortens the reactive time and production cycle.

Owner:盛富春

Desulfurization agent

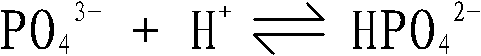

InactiveCN103084050AImprove desulfurization efficiencyImprove solubilityDispersed particle separationSolubilityCalcium biphosphate

The invention discloses a desulfurization agent, which comprises organic calcium carboxylates and calcium phosphate, and concretely comprises the following components, by mass, 15-20% of calcium formate, 10-16% of EDTA calcium disodium, 10-16% of calcium lactate, 0-10% of calcium phytate, 25-30% of calcium citrate, 0-10% of calcium gluconate, 10-20% of calcium oxalate, and 1-10% of calcium phosphate. According to the desulfurization agent, combination of the organic calcium carboxylates and the calcium phosphate is adopted, solubility in the solution is high, calcium ions can be ionized quickly, a desulfurization reaction speed is rapid, and desulfurization efficiency is high.

Owner:SNTO TECH GRP

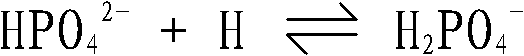

RH refining desulphurization process of non-oriented electrical steel

InactiveCN102010934AGood desulfurization effectMeet the requirements of deep desulfurizationAlkalinityElectrical steel

The invention discloses an RH refining desulphurization process of non-oriented electrical steel, belonging to the technical field of steel making. The process comprises the following steps: setting the lift gas flowrate to 1200 NL / min after the entering of the RH, and enhancing the lift gas flowrate to 1600 NL / min 3 minutes later; blowing oxygen to perform the forced decarburization when the vacuum degree is reduced to 2.0 mba, and when the oxygen blowing is finished and the vacuum degree is lower than 2.0 mba, performing the natural decarburization for 20 minutes; adding the aluminum for deoxidation when the vacuum decarburization is finished; and performing the silicon alloying by using the low carbon ferrosilicon, and adding the desulfurizing agent into the vacuum chamber in two timesthrough the RH alloy bin. The circulation time of the test furnace batch is from 10 minutes to 15 minutes. The process provided by the invention has the advantages that the RH device needs no reconstruction, and the operation is simple. The average RH desulphurization degree is 36.7%, and the desulphurization effect is better. The contents of the FeO and the MnO of the ladle slag have significantinfluence on the desulphurization effect, and the enhancing of the alkalinity of the ladle slag can increase the RH desulphurization efficiency as well as reduce the corrosion of the RH device.

Owner:KUNMING UNIV OF SCI & TECH

Medium temperature iron-manganese desulfurizing agent and preparation method thereof

InactiveCN102039086AGood desulfurization effectHigh breakthrough sulfur capacityDispersed particle separationManganese oxideBrown iron oxide

The invention relates to an iron-manganese desulfurizing agent. The desulfurizing agent consists of 10 to 85 weight percent of iron oxide, 10 to 85 weight percent of manganese oxide and 5 to 20 weight percent of inorganic adhesive. The invention further discloses a preparation method for the iron-manganese desulfurizing agent. The iron-manganese desulfurizing agent is prepared by extruding and molding with a dry method and roasting at a specific temperature. The iron-manganese desulfurizing agent prepared by using the preparation method has optimal desulfurizing effect and high penetrating sulfur capacity. The test shows that the penetrating sulfur capacity of the desulfurizing agent can reach 25.1 percent. Moreover, the desulfurizing agent has high mechanical strength, can be widely applied in a chemical refining and desulfurizing process, and can be prevented from being broken to cause loss and affect the desulfurizing effect; and the test shows that the mechanical strength of the iron-manganese desulfurizing agent can reach 100N / cm.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

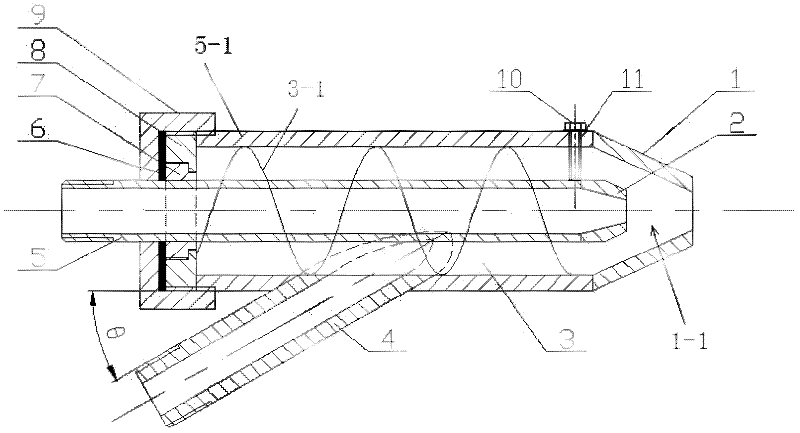

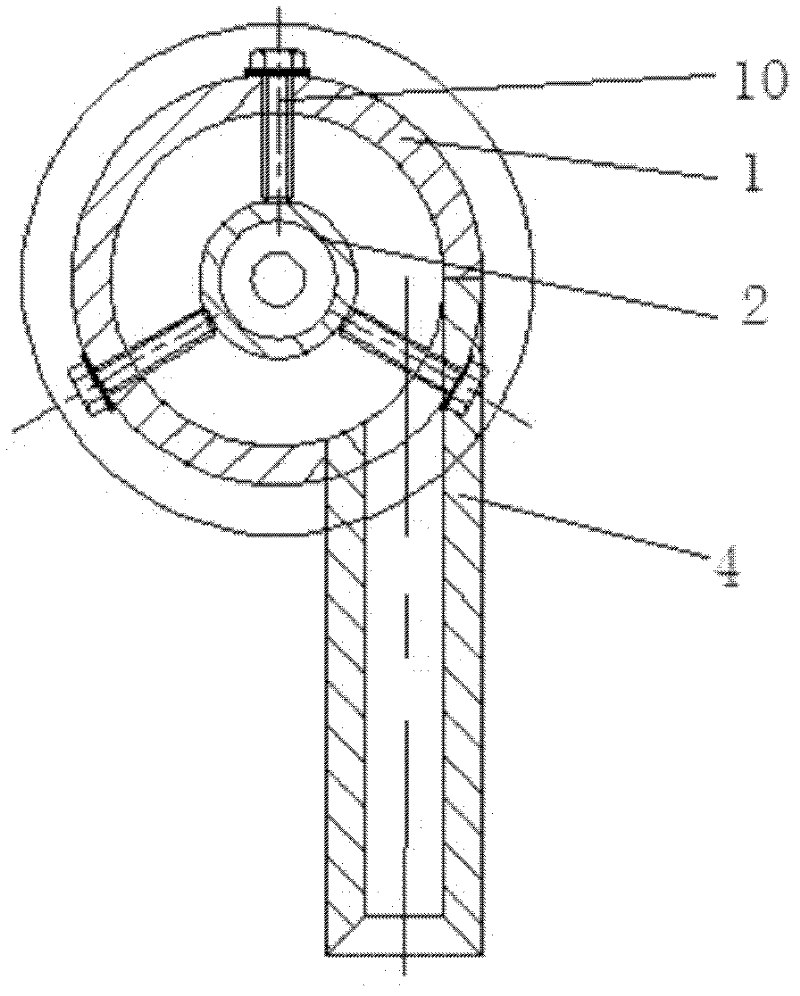

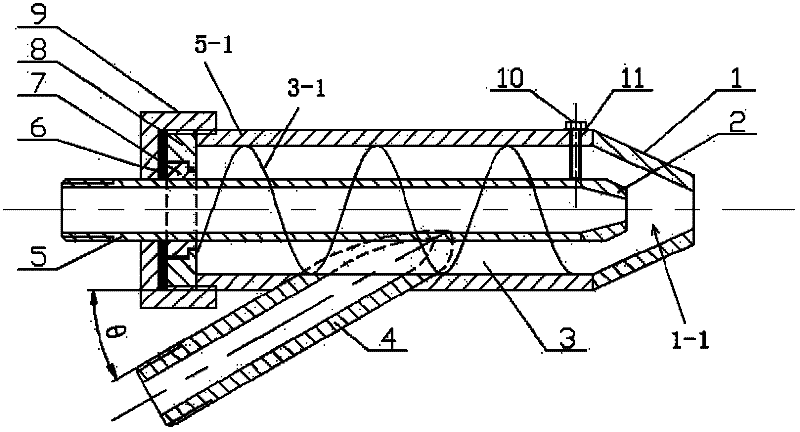

Liquid-coated gas desulfurizing/atomizing nozzle

InactiveCN102389703AImprove efficient atomizationGood desulfurization effectDispersed particle separationLiquid spraying apparatusEngineeringSlurry

The invention discloses a liquid-coated gas desulfurizing / atomizing nozzle which comprises an internal tapered slurry nozzle and an internal tapered gas nozzle, wherein the gas nozzle is arranged in the slurry nozzle, a gap is formed between the outer wall of the gas nozzle and the inner wall of the slurry nozzle, the outer wall of the slurry nozzle is provided with a slurry inlet pipe, and the internal circumferential surface of the slurry nozzle is a thread surface. Pressure gas subjected to pressurization is fed into the gas nozzle with an internal tapered end, further compressed, jetted out from the gas nozzle, and then converged with slurry in a tapered jet chamber of the slurry nozzle so as to form 'liquid-coated gas'; and under the action of high speed and pressure difference, the 'liquid-coated gas' is broken, and liquid drops are separated and broken and finally jetted out by the slurry nozzle, so that the slurry is efficiently atomized, thereby achieving an optimal flue gas desulfurization effect. The slurry inlet pipe is communicated with the gas nozzle in an obliquely-tangential direction, and the installation angle is consistent with the spiral angle of a thread structure, thereby further facilitating the formation of a natural spiral rotational flow when the slurry is fed into a slurry cavity, and facilitating the formation of the 'liquid-coated gas'.

Owner:SOUTH CHINA UNIV OF TECH

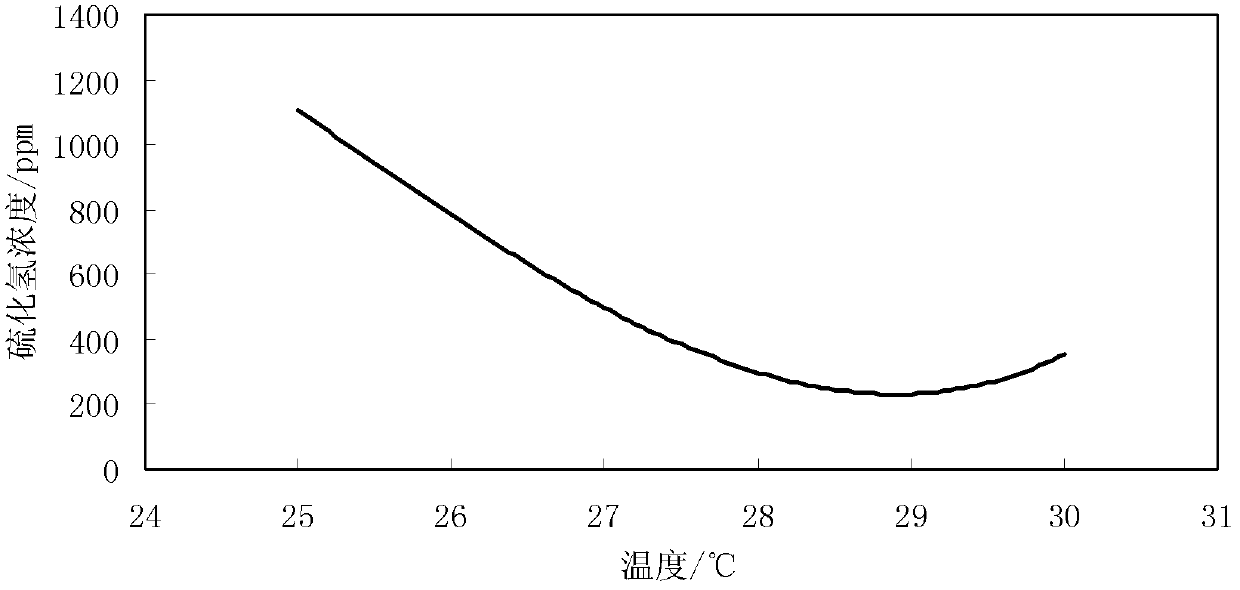

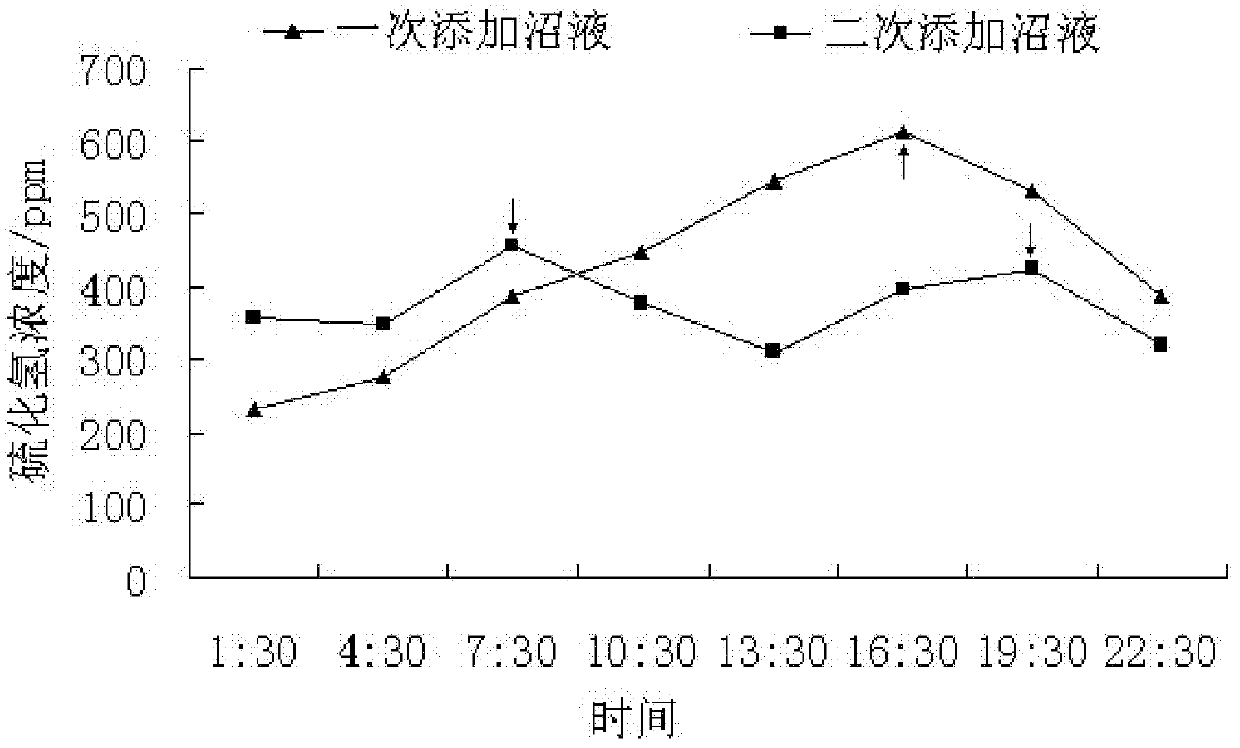

Methane biodesulfurization method

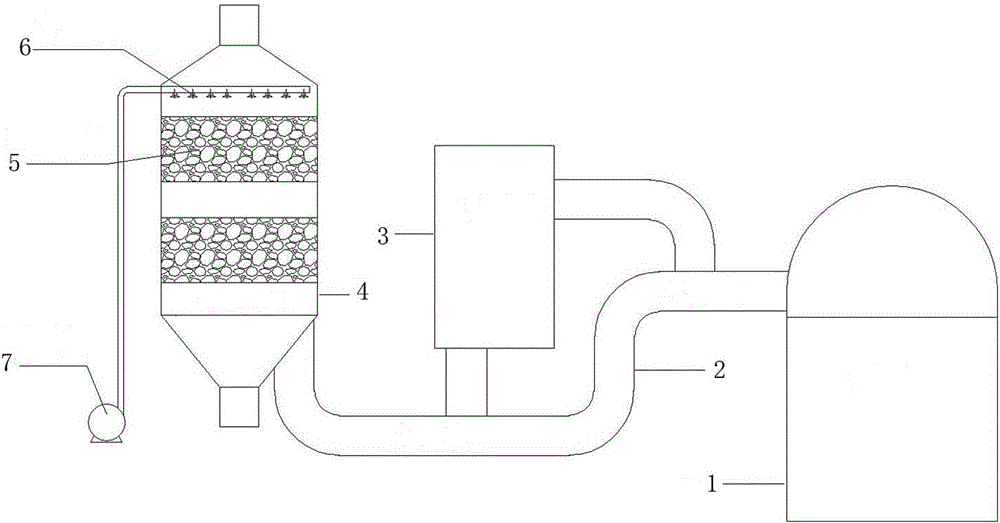

ActiveCN102604701AGood desulfurization effectReduce the impactGaseous fuelsWaste based fuelBiological oxidationTower

The invention belongs to the technical field of methane desulfurization, and particularly relates to a methane biodesulfurization method. The methane biodesulfurization method comprises the following steps that: a circulating liquid containing desulfurizing bacteria is sprayed down by a spraying head at the top part of a desulfurization tower, methane is blown into a gas inlet pipe from the lower part of the desulfurization tower, and is fully contacted with the circulating liquid in the middle filler, the desulfurizing bacteria contained in the circulating liquid oxidizes and removes hydrogen sulfide in the methane by the action of biological oxidation, wherein 2.0-2.5L methane liquid is added into each cubic meter of circulating liquid every day. The methane biodesulfurization method has the characteristics that the control is convenient, the operation is simple, and the desulfurization efficiency is high.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

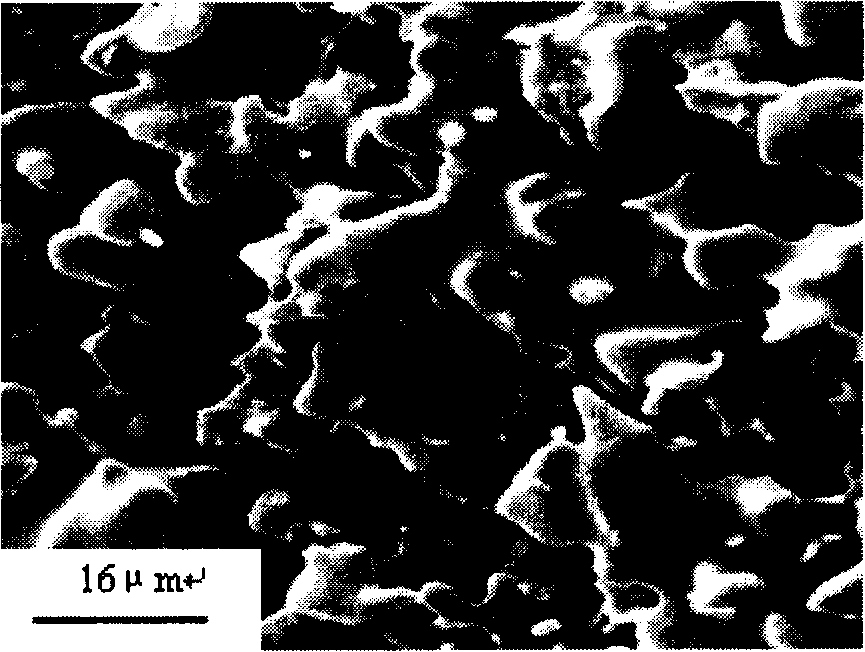

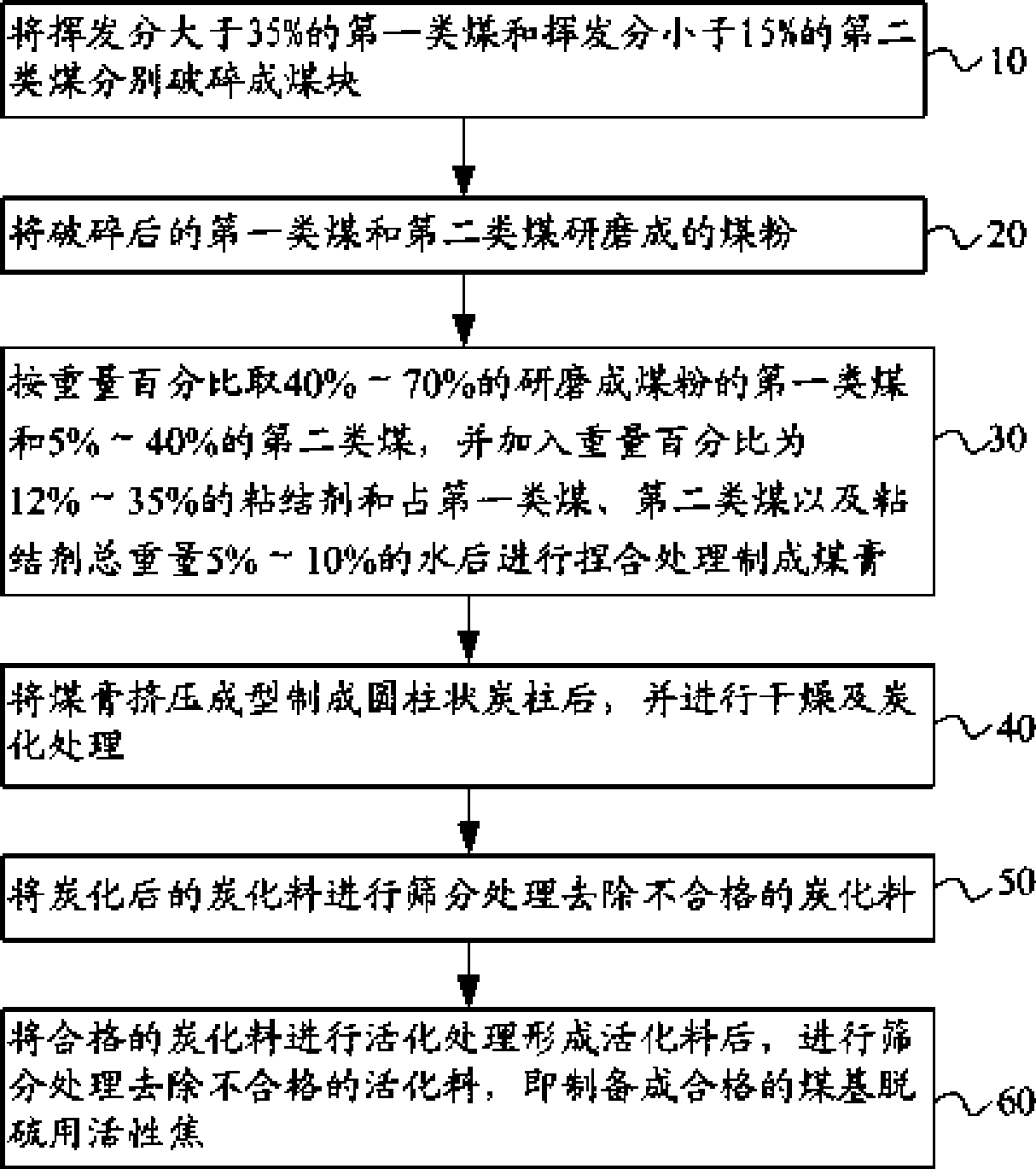

Coal-based activated coke for desulfuration and preparation method thereof

ActiveCN101485972AHigh activation yieldHigh specific gravityOther chemical processesCoal briquetteCoal

The invention relates to a method for preparing active coke for coal based desulfurization. The method comprises the following steps: crushing the first-class coal and the second-class coal into coal briquettes respectively; grinding the coal briquettes into pulverized coal; picking up the coal which is ground into the pulverized coal, adding a binder and water, and subjecting the mixture to kneading treatment to obtain coal paste; after forming the coal paste by extrusion to obtain a cylindrical charcoal column, drying and charring the charcoal column; screening the charring material which is charred to remove the unqualified charring material; and activating the qualified charring material to form an activated material, namely preparing the qualified active coke for coal based desulfurization. In the method, the first-class coal with low added-value and the second-class coal with high added-value are used to prepare macro-aggregate active coke products particularly for fume desulfurizatio with the advantages of low production cost, desirable quality, obvious desulfurizatio effect and strong market competitive power.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

ActiveCN101767830AHigh sulfur capacityGood desulfurization effectIron oxides/hydroxidesIron oxideHydroxide

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

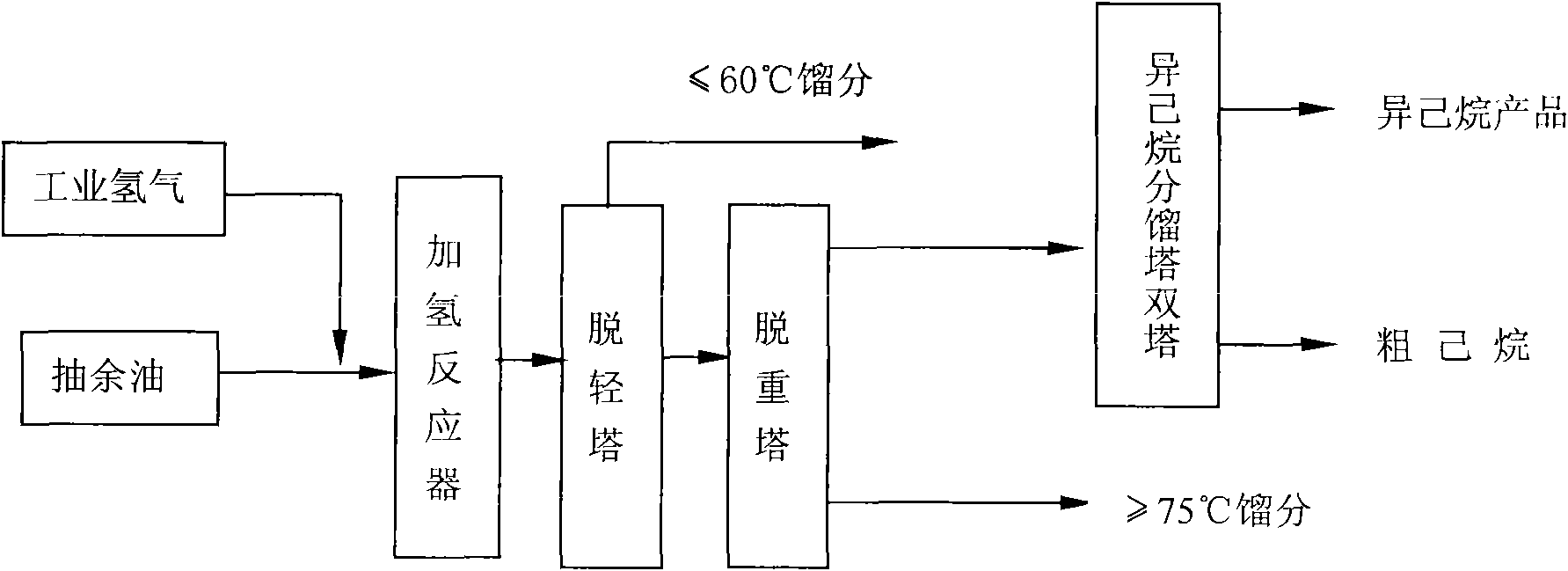

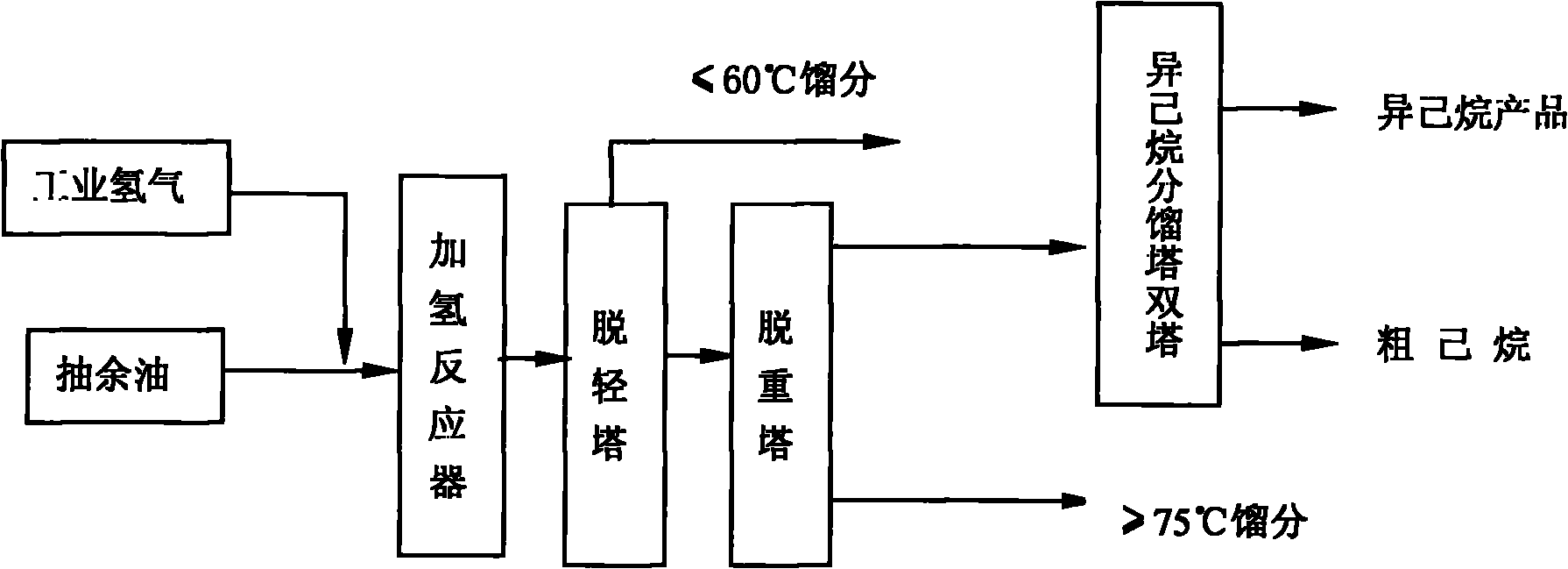

Method for preparing narrow fraction nontoxic high-purity isohexane

InactiveCN101875594AMild operating conditionsGood desulfurization effectHydrocarbon by hydrogenationDistillation purification/separationIsohexanesNickel

The invention relates to a method for preparing narrow fraction nontoxic high-purity isohexane, which is characterized in that: active metal nickel is used as a benzene catalytic hydrogenation catalyst; catalytic reforming raffinate oil, which has a distilling range of less than or equal to 140 DEG C, aromatic hydrocarbon content of less than or equal to 1.3 percent and sulfur content of less than or equal to 1ppm, and industrial hydrogen are pumped into a hydrogenation reactor to undergo all-component catalytic hydrogenation under conditions of a hydrogen to oil ratio of 5.5-7.5:100, a liquid benzene space velocity of 0.01 to 1 hour, a temperature of 160 to 175 DEG C, a pressure of 0.3 to 1.5MPa and in the presence of the catalyst for dearomatization and desulfuration; the product of the dearomatization and desulfuration is introduced to a dehydrogenation tower, the temperature of the tower is controlled to be 63 to 102 DEG C and light components with a distilling range less than or equal to 60 DEG C are removed; the residual fraction obtained after dehydrogenation is introduced into a heavy component removing tower, and the heavy components of which the distilling range is more than or equal to 75 DEG C are removed; and the fraction (of which the distilling range is 60 to 75 DEG C) left after the removal of the heavy components is introduced into an isohexane tower for fine fractionation, and a fraction obtained at 60 to 64.5 DEG C is the required product. The preparation method has the advantages of relatively mild catalyst operation conditions, obvious dearomatization and desulfuration effects, simple and practical process, stable and reliable product quality and high economic efficiency.

Owner:CHINA NAT OFFSHORE OIL CORP +1

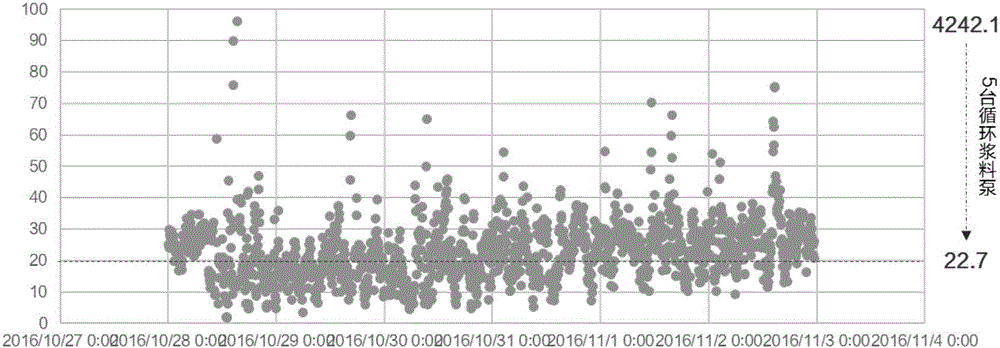

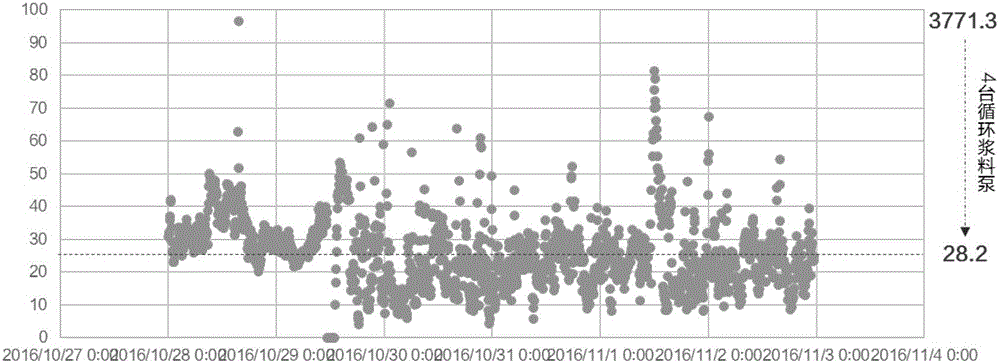

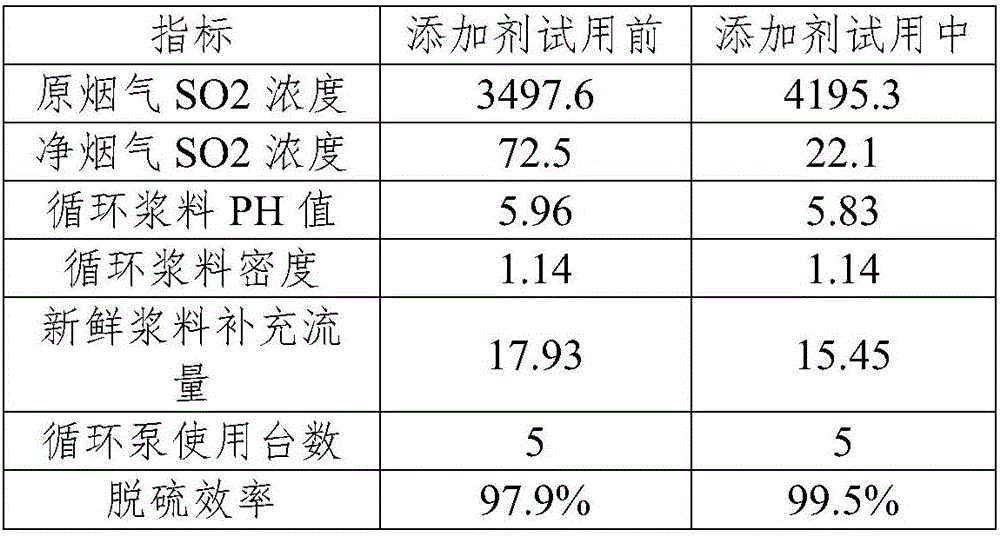

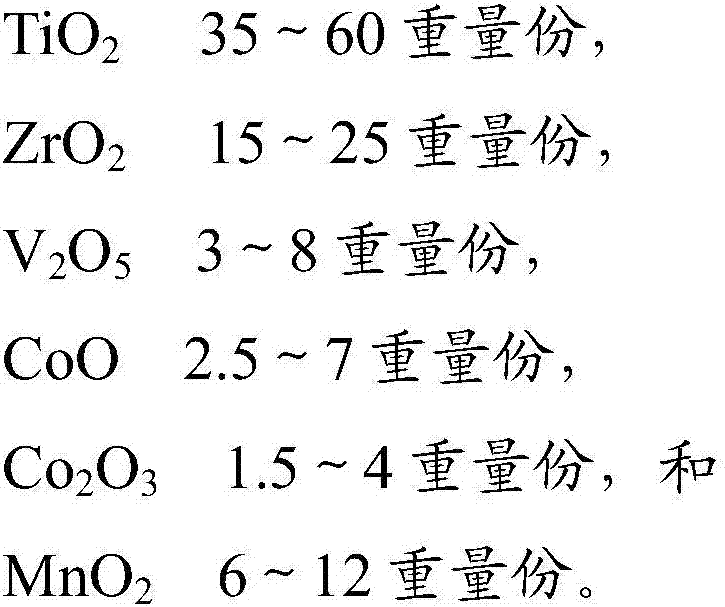

Compound additive for limestone-gypsum wet-process flue gas desulfurization

InactiveCN106731637AHigh activityIncrease dissolution rateGas treatmentDispersed particle separationFood additiveFoaming agent

The invention relates to a compound additive for limestone-gypsum wet-process flue gas desulfurization. The compound additive is prepared from the following components in percentage by mass: 25 percent to 50 percent of a limestone dissolving promoter, 20 percent to 60 percent of a pH (Potential of Hydrogen) buffering agent, 5 percent to 15 percent of a surfactant, 3 percent to 10 percent of an oxidization catalyst, 2 percent to 5 percent of a de-foaming agent and 2 percent to 10 percent of a correlated auxiliary agent. The compound additive provided by the invention combines the dual advantages of an inorganic additive and an organic additive of rapid effect, less use amount, long lasting time, less consumption and the like in a limestone-gypsum wet-process flue gas desulfurization system of a thermal power plant; the formula is simple and components have a low price and are easy to obtain; on the basis of not doing any engineering reconstruction, the absorption efficiency of SO2 can be greatly improved, the quality of gypsum can also be improved and the scaling and blocking of the system are reduced.

Owner:鄂尔多斯市瀚博科技有限公司

A kind of precipitating agent used for refining desulfurization of wet-process phosphoric acid and its application method

Owner:武汉睿远昌科技有限公司

Deep desulfurization method for diesel by coupling of oxidation and extraction

InactiveCN101717659AHigh catalytic activityHigh yieldCatalyst activation/preparationTreatment with plural serial refining stagesTungstateCatalytic oxidation

The invention relates to a deep desulfurization method for diesel by coupling of oxidation and extraction, that is a catalyzed oxidation desulfurization method for diesel in petroleum refining technologies. The method comprises the following steps of crushing and fine grinding a zirconium hydroxide carrier, dipping into impregnation liquid formed by aqueous ammonium meta-tungstate solution, placing the impregnation liquid in an ultrasonic generator to carry out ultrasonic facilitating impregnation, boiling off water after the impregnation is finished, drying and baking at high temperature to obtain a WO3 / ZrO2 super solid acidic catalyst; adding aqueous hydrogen peroxide solution, extraction solvent and the WO3 / ZrO2 super solid acidic catalyst in diesel containing sulfur, carrying out catalyzed oxidation desulfurization reaction under the action of power ultrasonics, cooling to the room temperature after the reaction is finished, separating and recycling the solid catalyst, standing and layering, wherein the upper layer is desulfurized diesel and the lower layer can be reused after regeneration. The invention has simple process, mild condition, high desulfurization degree and gasoline recovery, low cost and no pollution to environment and can obtain ultra-low sulfur clean diesel products.

Owner:YANGZHOU UNIV

Technique for procuring desulfurization type water-solubility instant coal powder

InactiveCN101144042AQuality improvementHigh slurry concentrationLiquid carbonaceous fuelsLump/pulverulent fuel preparationSolubilityFluidized bed

The present invention relates to the liquid coalite slurry dry processing technology, in particular to a desulphurization type dry liquid coalite slurry production process. The process includes the steps that: firstly, rough coal is broken up to below 30 mm through a jaw crusher or a roll crusher, the water content is controlled below 7 percent, and the coal is chosen by a dry coal cleaning way through an air dense medium fluidized bed; secondly, the full or the part of addition agent, desulfurization agent, desulfurization additive is added into the deashing float coal after the dry coal cleaning, and combined through two to eight swing type powder machines or bowl type powder machines, and powder is prepared through a parallel or series combination grade, the qualified powdered coal is collected through the air separation with a pipeline, the partial or full addition agent mixture is added again, namely, the dustless desulfurization type water soluble quick dissolving powdered coal.The appearance of the product can be non-dust emission powdery, or granulated, or massive. The present invention provides a high grade liquid coalite slurry dry formed slurry process which has high quality, desulfurization, and low cost, the liquid coalite slurry is convenient to be transported, when being used, the water content or the other industrial organic waste water is only required to be added into according to the proportion, the slurry is formed through agitating.

Owner:张绍龙

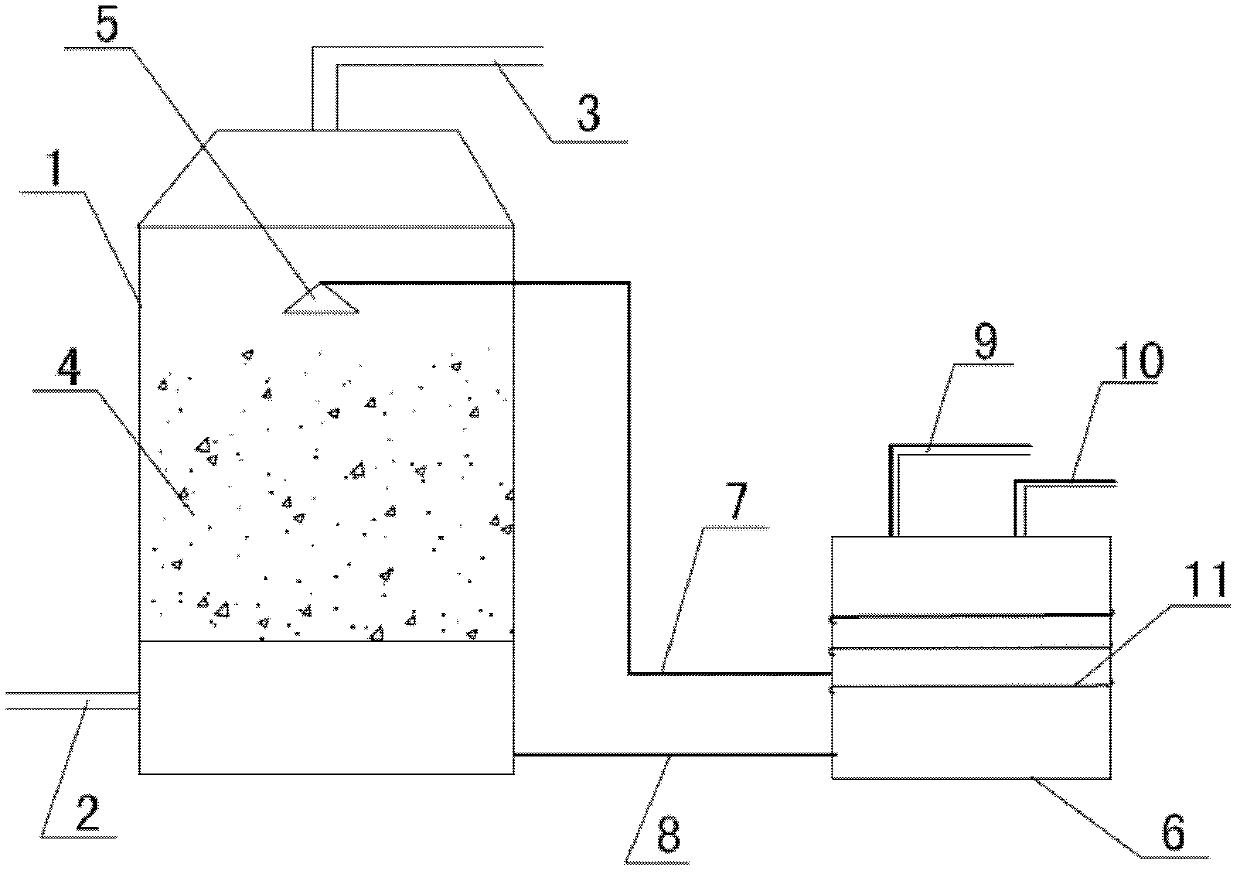

High-efficiency method for flue gas desulfurization

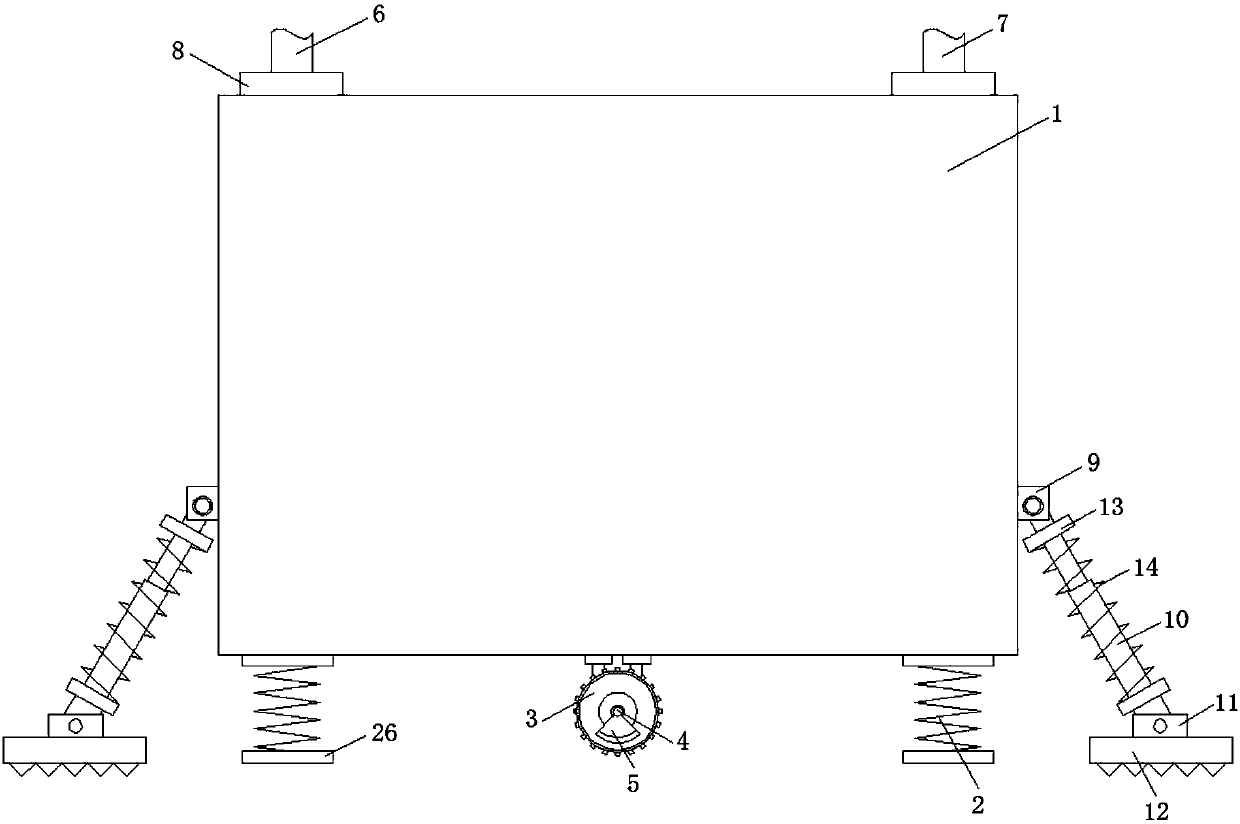

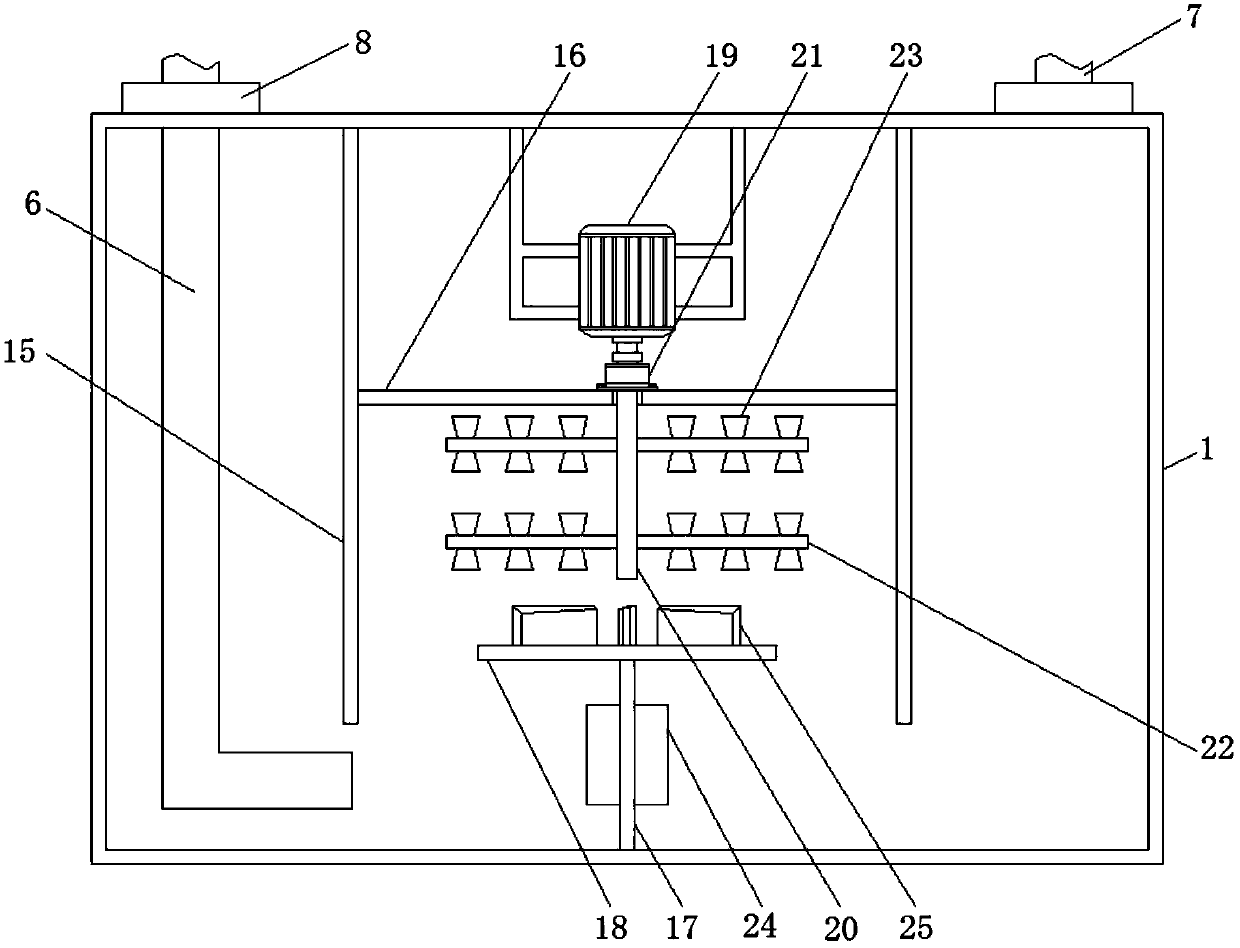

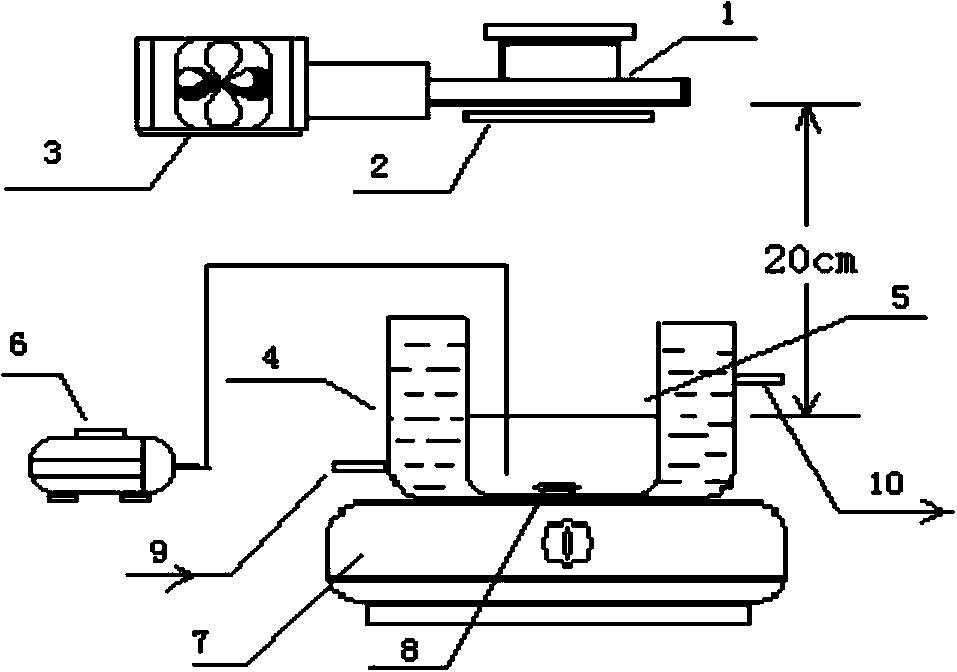

InactiveCN108043196ASimple structureGood desulfurization effectGas treatmentShaking/oscillating/vibrating mixersStability coefficientEngineering

The invention discloses a high-efficiency method for flue gas desulfurization. A vibration motor (3), a driving rotating shaft (4), an eccentric block (5), supporting springs (2) and supporting base plates (26) are used in mutual cooperation, the vibration motor (3) drives the driving rotating shaft (4) and the eccentric block (5) to rotate, and a desulfurization box (1) is driven by the eccentricblock (5) to vibrate on the supporting springs (2), so that a desulfurization solution inside the desulfurization box (1) can vibrate during the vibration of the desulfurization box (1), the combination of the desulfurization solution and sulfur-containing gas is more complete, the desulfurization efficiency is greatly improved, the stability coefficient of the desulfurization box is effectivelyimproved, an effective guarantee is provided for normal operation of desulfurization, and the desulfurization effect can be better. The structure is simple, the amount of the sulfur-containing smoke discharged into the atmosphere is effectively reduced, and pollution and damage caused by the sulfur-containing smoke to the atmospheric environment are effectively reduced.

Owner:卞汉琦

Desulphurization method of cracked C5 fraction

ActiveCN105112093AGood desulfurization effectLow processing costTreatment with plural serial refining stagesChemistryBenzene

The invention relates to a desulphurization method of cracked C5 fraction. The desulphurization method of cracked C5 fraction comprises the following steps: firstly adding a desulfurizer into a cracked C5 fraction raw material, and carrying out a reaction at a certain pressure and a certain temperature for a while; separating a cracked C5 fraction which is free of sulfur from the top of a tower by a filtering and a distillation method; after reaction, obtaining a sulfur compound in a column bottom; the desulfurizer comprises the following components: 3-8% of triethanolamine, 3-8% of acetonitrile, 3-8% of toluene, 3-8% of acetone, 8-12% of benzene, 25-35% of saturated ammoniacal liquor, 8-12% of butyronityile, 8-12% of cyclohexane, 10-20% of aniline, and 3-8% of diethyltoluenediamine. According to the method, a proper amount of desulfurizer is added into the cracked C5 fraction raw material, and the purpose for desulphurization of cracked C5 fraction is realized by the methods of filtering and distillation. The method provided by the invention has a good desulphurization effect, by-products are not introduced into the desulphurized product, and the composition of the cracked C5 fraction is not changed; the desulfurizer has little toxicity and is not volatile and inflammable.

Owner:濮阳市联众兴业化工有限公司

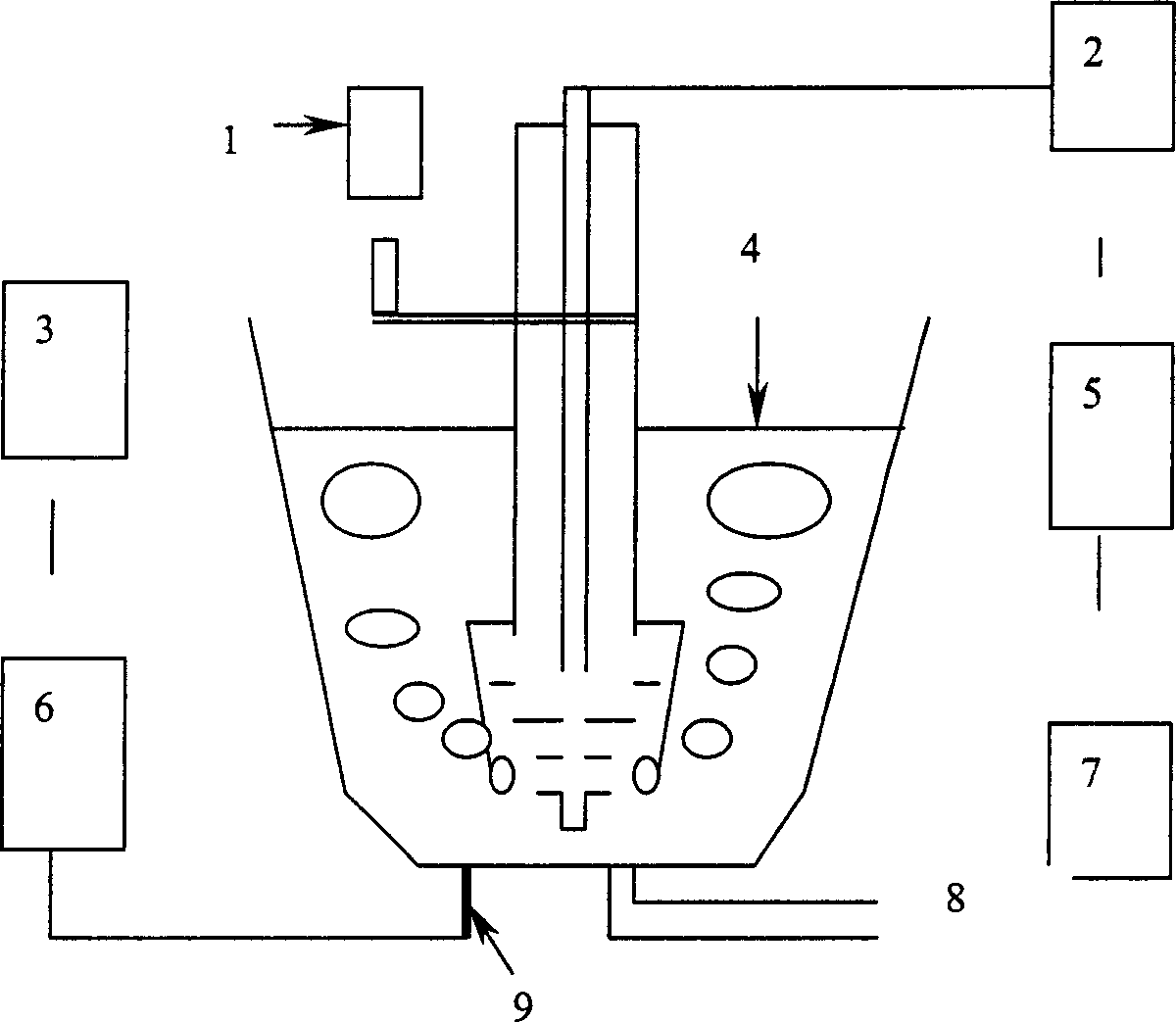

Composite desulfurization blender of double-blade molten iron

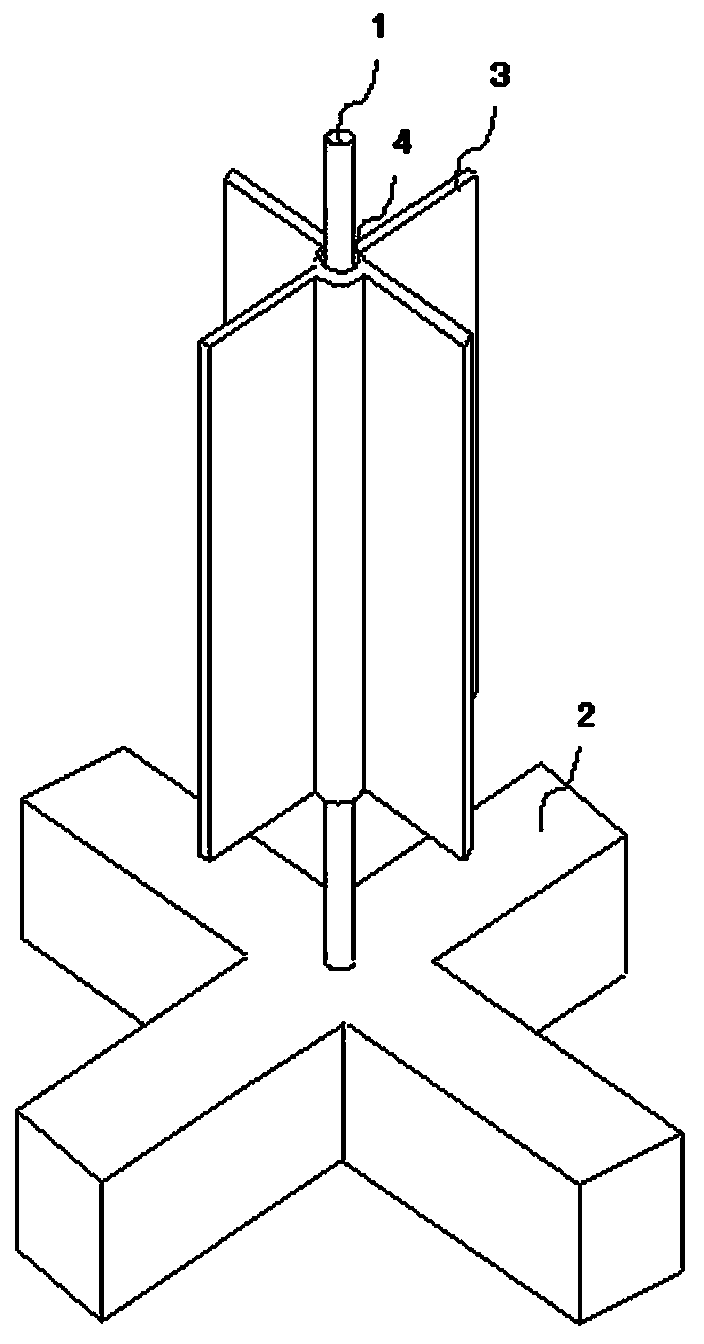

InactiveCN103642986AImprove stirring efficiencyGood desulfurization effectEddy current effectMaterials science

The invention belongs to the field of metallurgical desulfurization equipment, and particularly relates to a composite desulfurization blender of double-blade molten iron. The composite desulfurization blender comprises a center stirring shaft (1), a bottom stirring blade (2) and an upper stirring blade (3), wherein the bottom stirring blade (2) is fixedly connected with the lower end part of the center stirring shaft (1); a center sleeve (4) of the upper stirring blade (3) is sleeved with the center stirring shaft (1) in a sliding manner; the bottom stirring blade (2) adopts a four-blade structure; and the upper stirring blade (3) adopts a four-blade structure. By adopting the composite desulfurization blender, a composite eddy current effect is formed in a stirring region under the composite motion action of the upper stirring blade and the bottom stirring blade by adopting the bottom stirring blade and the upper blade structure of the upper stirring blade, so that the stirring efficiency of the blender is higher, and the desulfurization effect is more ideal.

Owner:LIAONING ZHONGBANG HI TECH DEV

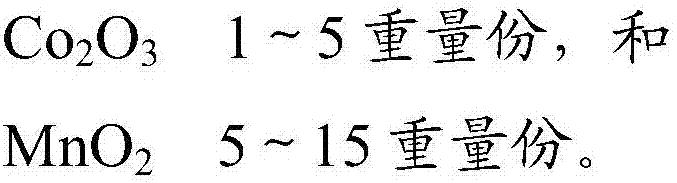

Filler for smoke desulfurization and denitrification and preparation method thereof

ActiveCN106422746AIncrease costLarge initial investmentGas treatmentDispersed particle separationAdhesivePhosphoric acid

The invention belongs to the technical field of smoke control, and particularly relates to filler for smoke desulfurization and denitrification and a preparation method thereof. The filler is prepared from, by weight, 4-6 parts of magnesium oxide, 5-8 parts of magnesium chloride, 0.1-0.5 part of phosphoric acid, 0.2-1 part of glass fiber, 0.5-1 part of adhesive and 0.5-1 part of foaming agent. The filler block can be directly placed in a container for smoke to pass through (desulfurization tower or denitrification tower) in smoke desulfurization and denitrification; a water spraying pipe is arranged at the upper portion of the container, and water is used for collecting and adsorbing crystal substances produced on the surface of the filler in the reaction process. The filler block is low in cost, can effectively remove nitrogen compounds and sulfur compounds in smoke and can not cause secondary pollution.

Owner:LIAONING BEIHUAN PURIFICATION TECH

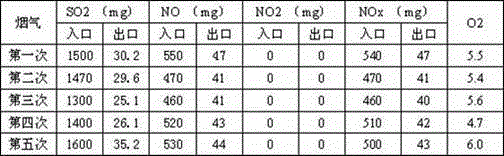

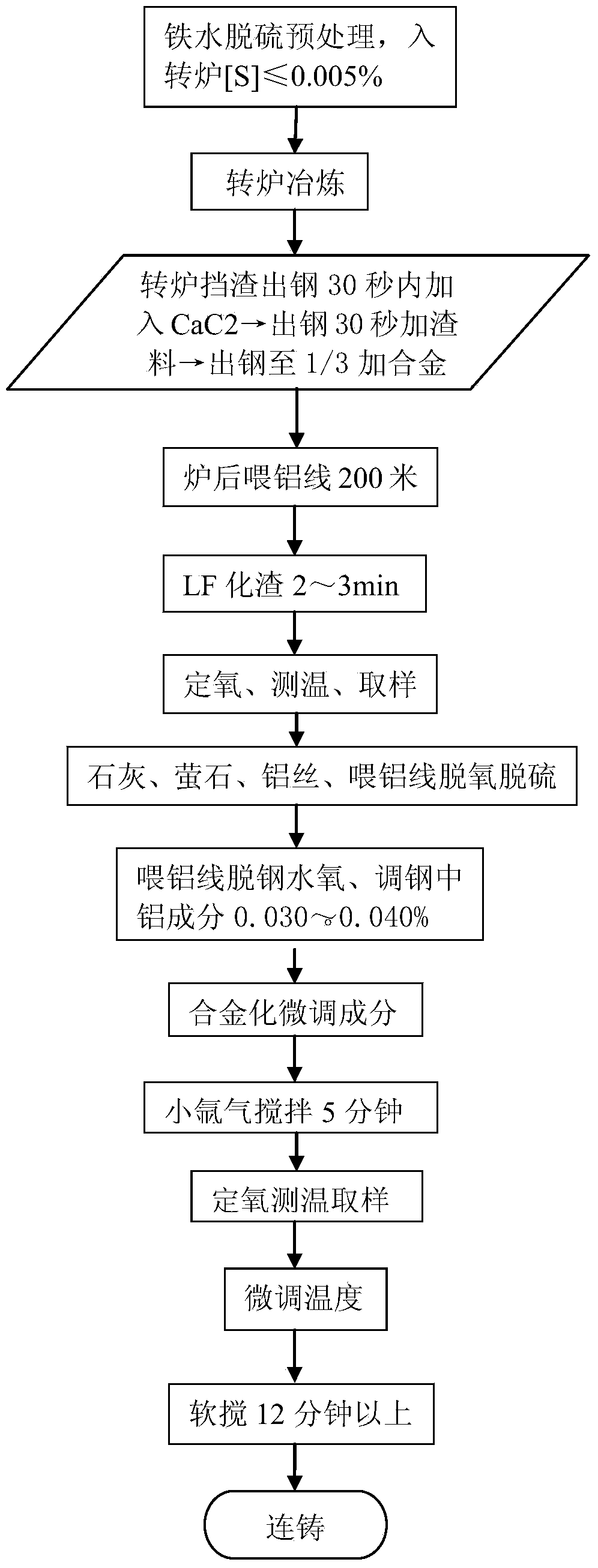

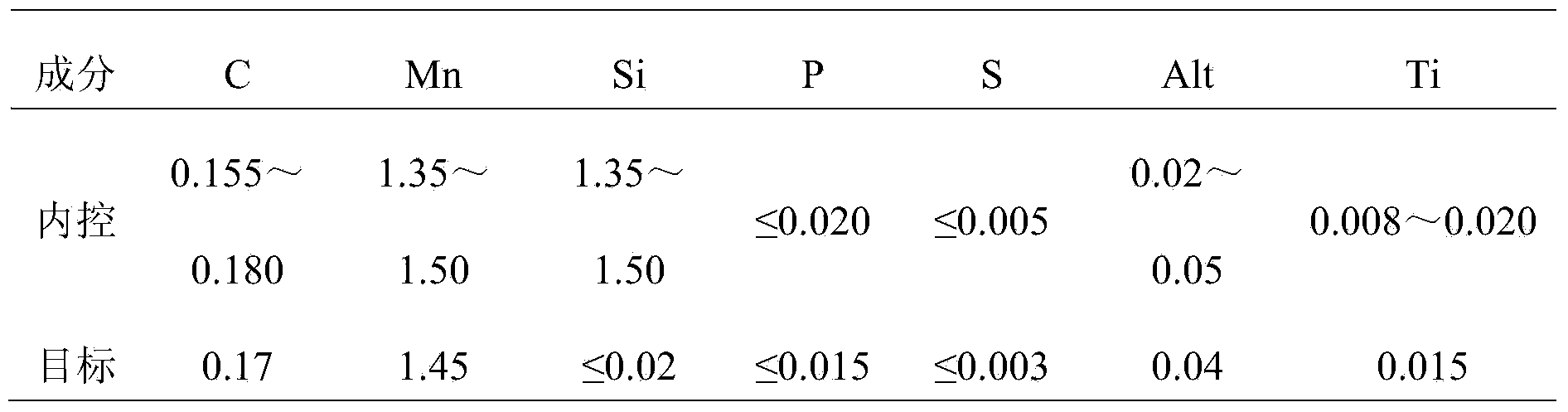

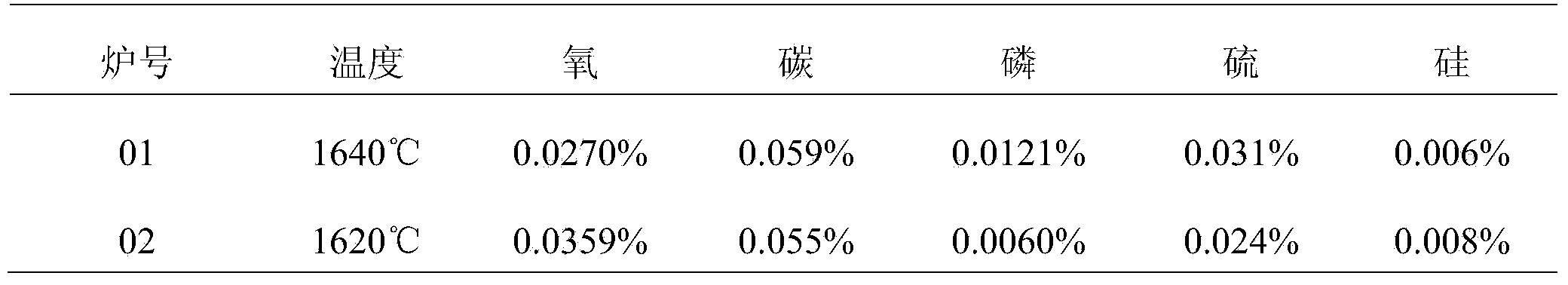

Process for producing aluminum-containing medium carbon steel through CaC2 deoxidization

InactiveCN104263873AObvious slag desulfurization effectGood desulfurization effectManufacturing convertersSteelmakingSmelting process

The invention discloses a control method for producing aluminum-containing medium carbon steel through CaC2 deoxidization in the steelmaking process. According to production process, in the smelting process, a deoxidization mode of combining CaC2 diffusion deoxidization and aluminum wire deoxidization is adopted, a converter tapping deoxidization principle in a converter smelting process and a slagging principle in a refining furnace smelting process are optimized, aluminum in the molten steel is regulated by feeding aluminum wires on the furnace rear of the converter, a small amount of aluminum wires is added into CaC2 in the LF converter for deoxidizing and slagging, and the aluminum in the molten steel is finely adjusted y matching with aluminum wire feeding in the LF furnace. According to the process, the converter tapping deoxidization is stable, the slagging and desulfurizing effects of the LF furnace are obvious, the cast slab quality is high, and the effect of reducing the aluminum consumption in tons of steel in the produced aluminum-containing medium carbon steel by 0.80kg is achieved. The aluminum yield is high, namely the content of average arrival aluminum in the LF furnace is 0.029 percent, and the aluminum yield is 59.5 percent. The deoxidization cost is low, namely the aluminum consumption in tons of steel is reduced by 0.8kg, the cost of CaC2 is reduced, and the deoxidization cost is reduced by 12 yuan per ton. The refining slag conditions are improved, namely the average sulfur content in the final molten steel of a refining furnace is 0.0026 percent, the desulfurization efficiency is 92.6 percent, and the cast slab quality is improved.

Owner:SHANGLUO UNIV

Alloy cored wire for deeply desulfurization of steel bucket finery and its preparation method

The invention discloses a core-spun yarn and preparing method of steel drum finer deep desulfuration, which comprises the following parts: blending 3-12 wt percent passivation magnesium residual Fe powder or adjusted CaO-CaF2 premelting ground-slag agent or adjusted CaO-BaO-CaF2 premelting ground-slag agent; covering through 0.20-0.30 mm thickness thin steel to produce Mg-Fe core-spun yarn, or Mg-CaO-CaF2 core-spun yarn or Mg-CaO-BaO-CaF2 core-spun yarn. The invention reduces the cost, which possesses excellent desulfuration effect to control steel liquid ingredient.

Owner:WUHAN UNIV OF SCI & TECH

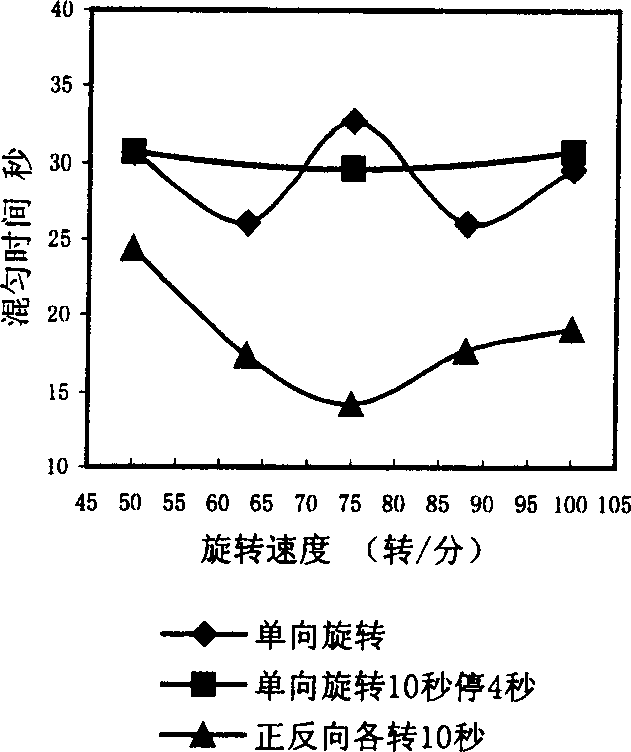

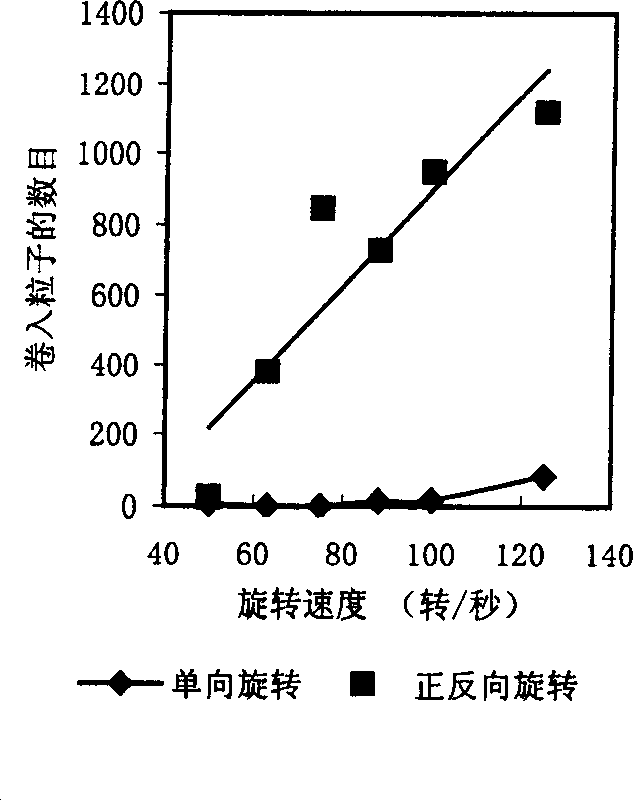

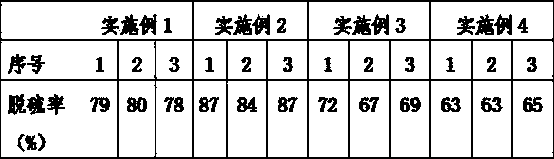

Composite desulfuration method for molten iron

InactiveCN1831155AGood desulfurization effectImprove desulfurization efficiencySulfur contentNitrogen gas

The invention relates to molten iron desulfurization technology. It adopts rotating airbrush tool and pulse type whisking system that the spraying head has blender, while adding the desulfurizer, the blender whisking the molten iron. The whisking method could be negative or positive two-way whisking, or rotate-stop-rotate pulse rotating whisking. Another kind of desulfurizer could be added into molten iron and spraying little nitrogen gas into molten iron. The invention has good desulfurization effect, and the sulfur content could be less than 0.001% after being treated. And it has little temperature drop, less than 1 degree centigrade / min. The consumption of desulfurizer is low, about 0.2-0.5kg / t molten iron. It has good integrated economic effect.

Owner:CENT IRON & STEEL RES INST

Dry desulfurization method for cement production

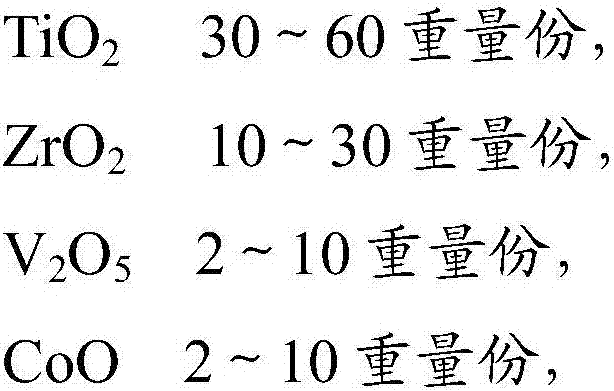

InactiveCN104353349AGood desulfurization effectThe desulfurization method is simple and easyDispersed particle separationRare earthKiln

The invention belongs to the field of cement production, and particularly relates to a desulfurization method implemented by using a rare earth-containing dry desulfurization agent. The desulfurization method comprises the following specific steps: in the cement producing process, crushing cement raw material into a blocky material with the particle size being smaller than 25mm, mixing the blocky material with a dry desulfurization agent which contains rare earths, vanadium pentoxide and quick lime, calcining in a kiln, and synchronously desulfurizing by the dry desulfurization agent in the calcining process. Compared with the conventional dry desulfurization and semidry desulfurization, the dry desulfurization method provided by the invention has the advantages of higher desulfurization efficiency and easiness in operation; compared with the wet desulfurization with complicated working procedures, the dry desulfurization method provided by the invention has the advantages of saving of more equipment transformation and labor cost, and easier popularization and implementation; in the dry desulfurization method, a cement producing way, a cement producing method and cement producing equipment are not required to be changed, and only the dry desulfurization agent is proportionally added in a raw material calcining link, so that the dry desulfurization method is simple and convenient and easy to operate.

Owner:冯艳萍

Calcium-calcium aluminate core-spun yarn for steel smelting

The invention relates to a cored wire which is used for external final melting of a liquid steel furnace and which contains calcium metal. The invention is characterized in that a certain amount of powder made by using calcium silicate is contained in a cored wire, wherein, calcium metaaluminate 12CaO7Al2O3 powder is optimal. The external final melting through the cored wire can obviously enhance the utilization rate of the calcium metal, reduce the temperature reduction of the liquid steel, and achieve satisfactory metallurgy effect.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

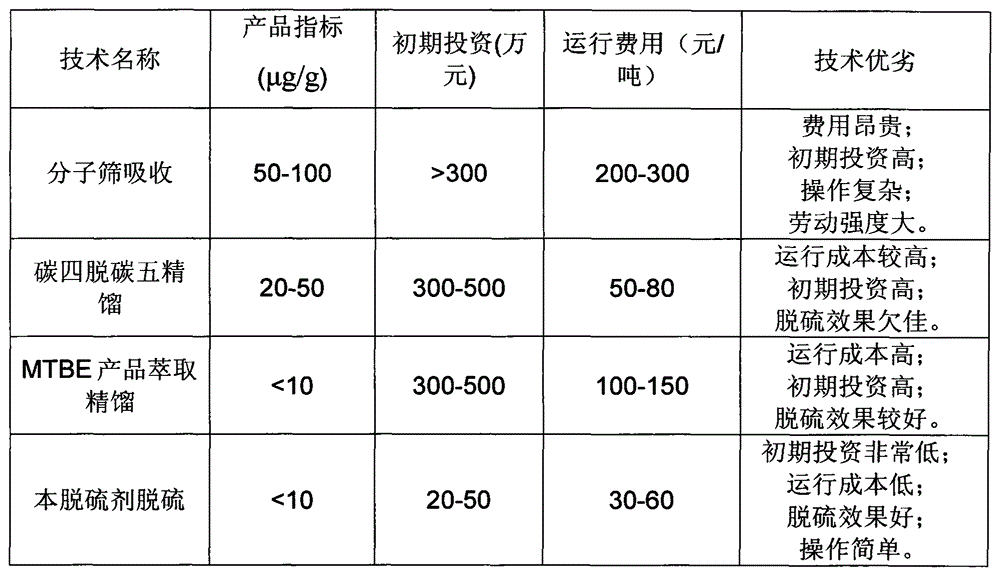

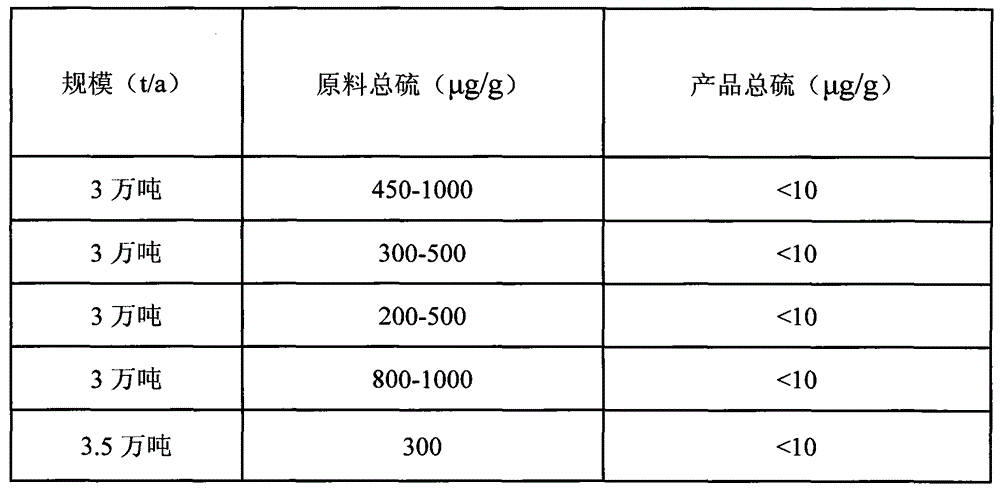

Desulfurizer composition for removal of sulfides in MTBE

InactiveCN105837408AFlexible adjustment of the amount addedGuaranteed quality upgradeEther separation/purificationLiquid wasteDistillation

The invention relates to a desulfurizer composition for removal of sulfides in MTBE. The desulfurizer composition is composed of the following components by weight percentage: 60-100% of a main absorbent, and 0-10% of a conditioning agent, wherein the main absorbent is a petroleum product with a distillation range of 140-250DEG C. The desulfurizer composition provided by the invention can remove thioether, disulfide, thiophenic sulfur and other sulfides in MTBE, ensures that the total sulfur of MTBE decreases from hundreds or even thousands of microgram / g to less than microgram / g, the desulfurization effect is obvious, so that as a blending component of gasoline, the desulfurizer composition ensures the quality upgrading of gasoline, and reduces the influence of sulfur-containing tail gas on the environment. In addition, the desulfurizer adding amount can be flexibly adjusted according to the sulfur content of different products so as to reduce the energy consumption and production cost. Also, the sulfur-rich desulfurizer waste liquid can be recycled, causes no secondary pollution emission, and is energy saving and environment-friendly.

Owner:NINGBO ZHANGFU ENERGY TECH CO LTD

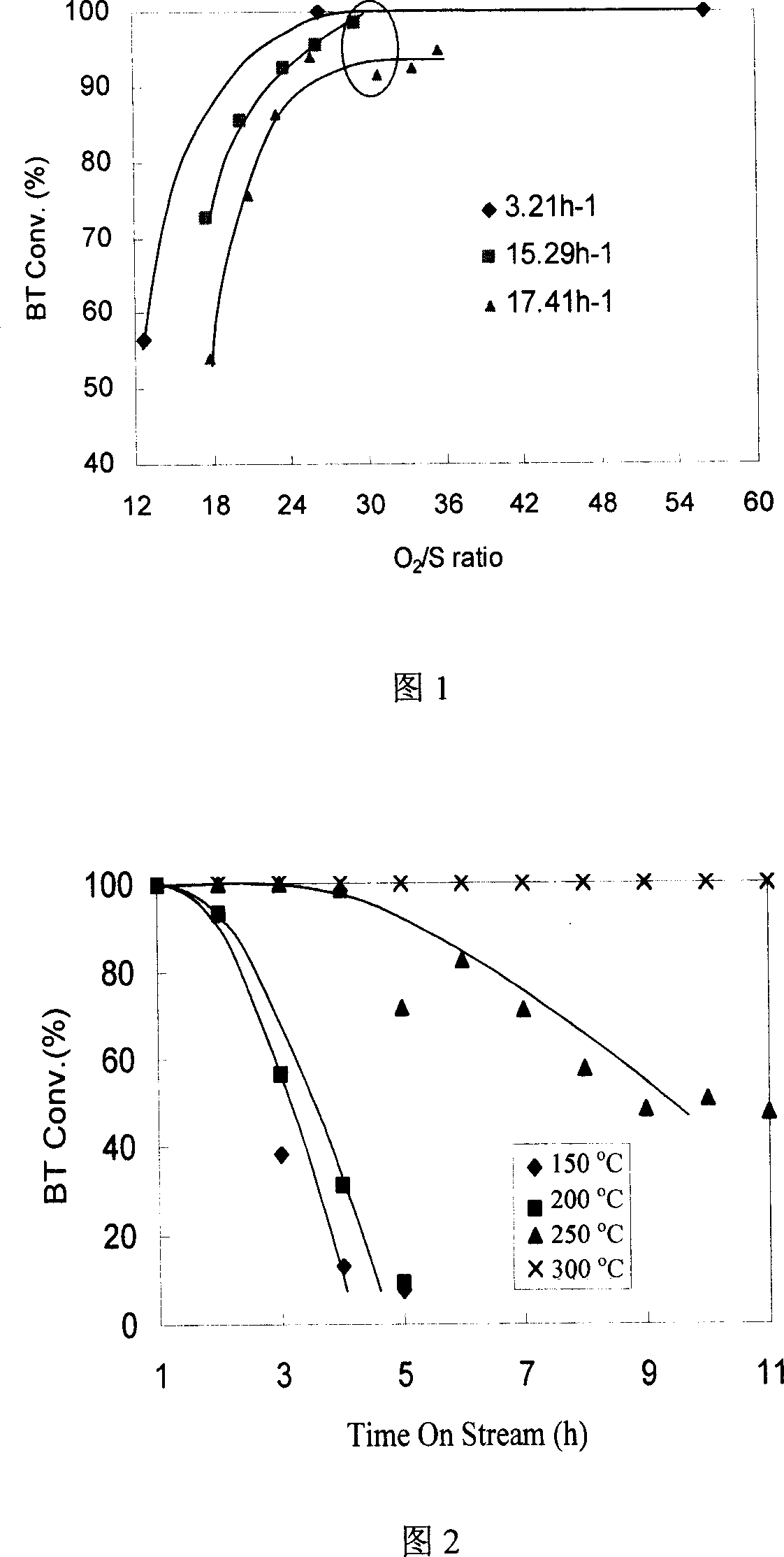

Method for removing sulfur-containing compound from carbon fuel by catalytic oxidation

InactiveCN101007963AHigh desulfurization rateLow costRefining with oxygen compoundsChemical industryHydrodesulfurization

The invention relates to a catalytic oxidation method for removing sulfur-containing compound from hydrocarbon fuel, belonging to petroleum chemical industry field. The method takes air as oxidant, continuously oxidates the sulfur compound in hydrocarbon fuel in catalytic reactor at 150- 350 Deg. C and normal pressure into sulfoxide Sox, and the percentage of desulfurization reaches above 90%. The invention is characterized in that the post treatment for extraction of desulfurized hydrocarbon fuel is not complicated, and the process can be carried out continuously, it takes air as oxidant, which reduces cost, and it overcomes problems of high cost of hydrodesulphurization, loe efficiency of adsorption desulphurization, wastewater treatment and separation.

Owner:EAST CHINA NORMAL UNIV

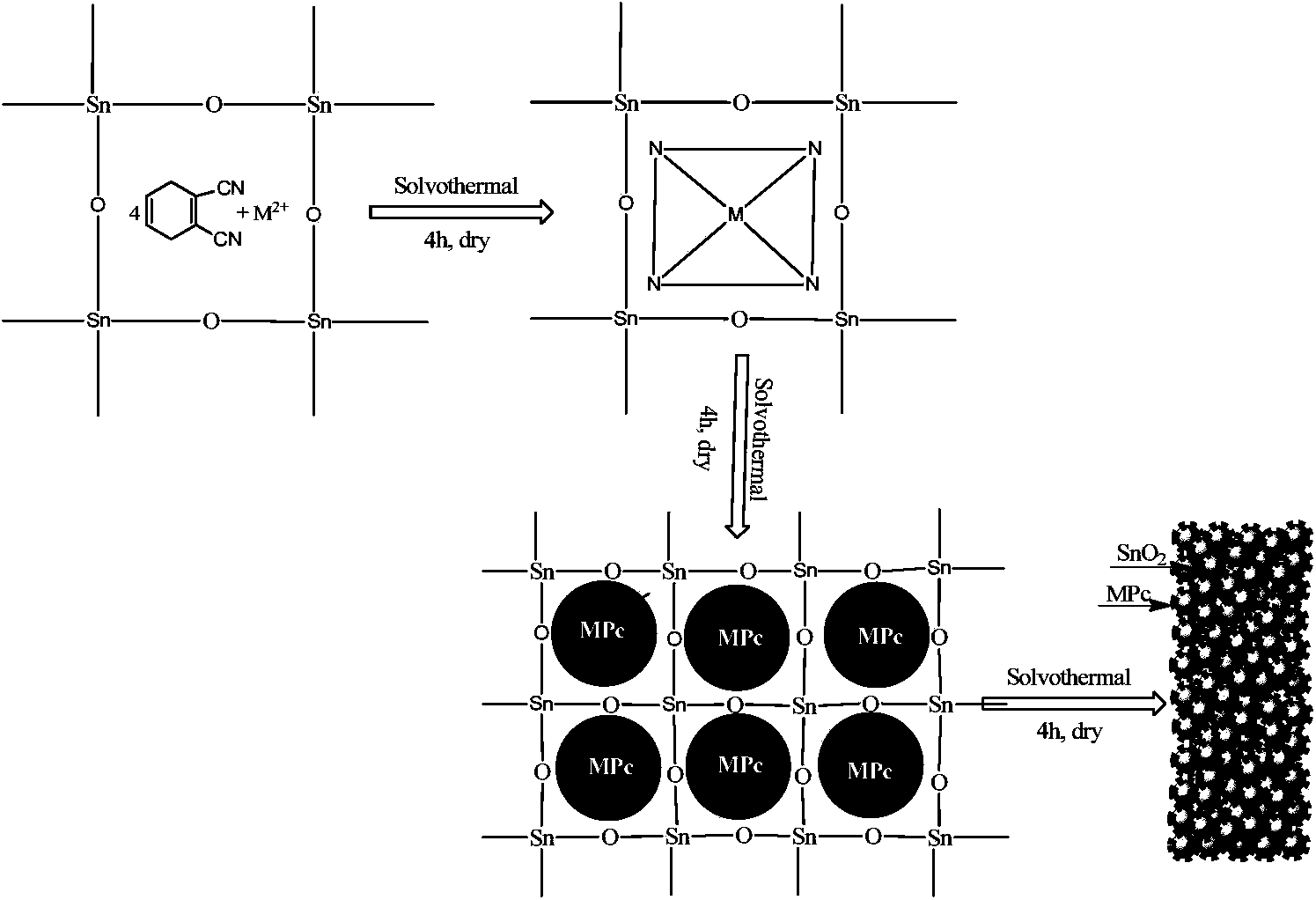

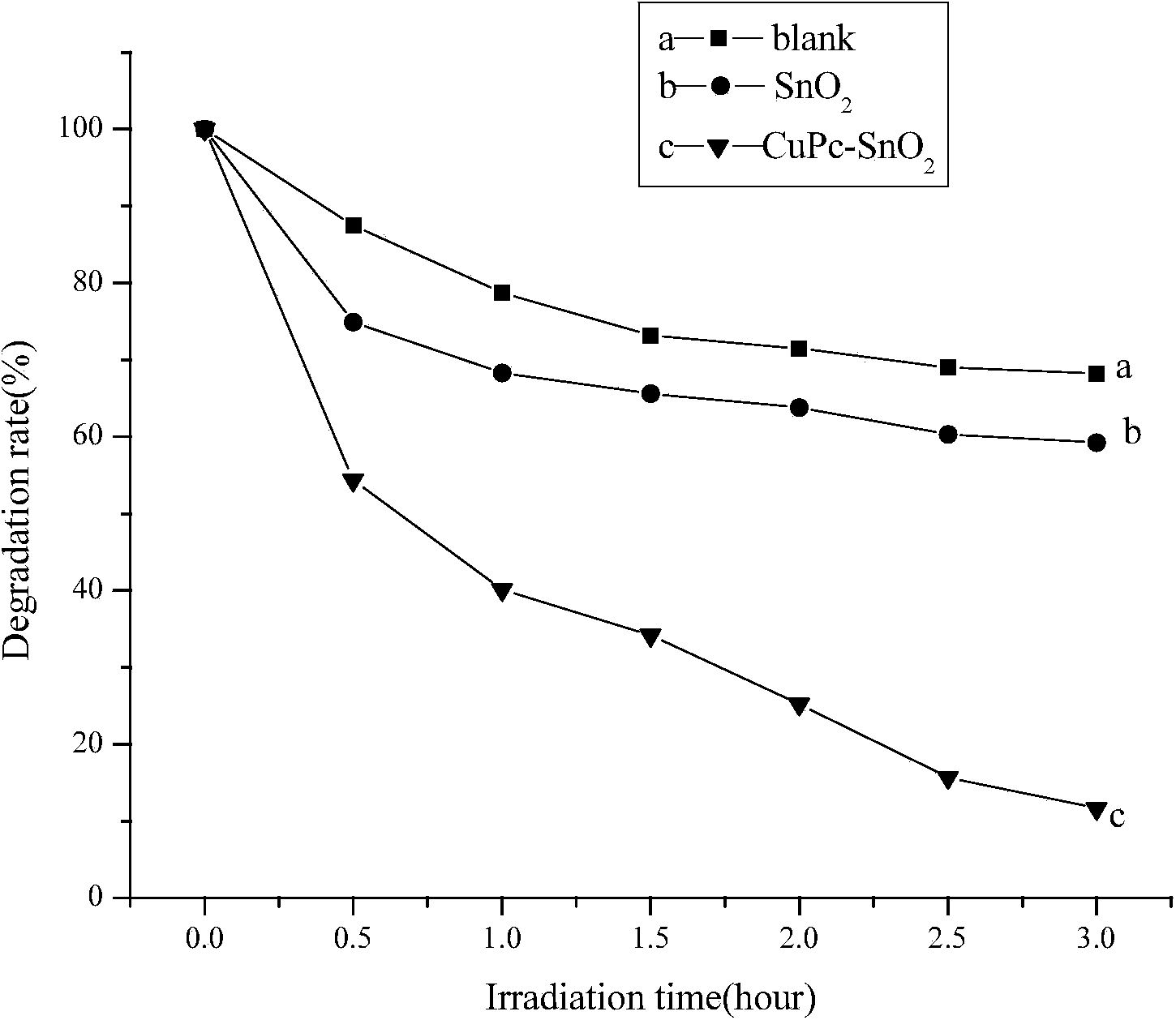

Metal phthalocyanine sensitized tin dioxide photocatalyst and preparation method thereof

InactiveCN103846106AGood desulfurization effectPracticalOrganic-compounds/hydrides/coordination-complexes catalystsRefining with oxygen compoundsTin dioxidePhthalocyanine

The invention discloses a metal phthalocyanine sensitized tin dioxide photocatalyst and a preparation method of the photocatalyst. The desulfurization catalyst contains MPc / SnO2 powder, wherein Pc represents phthalocyanine, and M is one or a combination of more of metal ions such as Mn<2+>, Fe<2+>, Co<2+>, Ni<2+>, Cu<2+> and Zn<2+>. After the dye-sensitized semiconductor photocatalytic desulfurizer is used for desulfuration for 3h, the removal rate of thiophene reaches up to 89% and is increased by 50% compared with that of a semiconductor which is not sensitized.

Owner:NORTHWEST UNIV(CN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com