Desulfurizer composition for removal of sulfides in MTBE

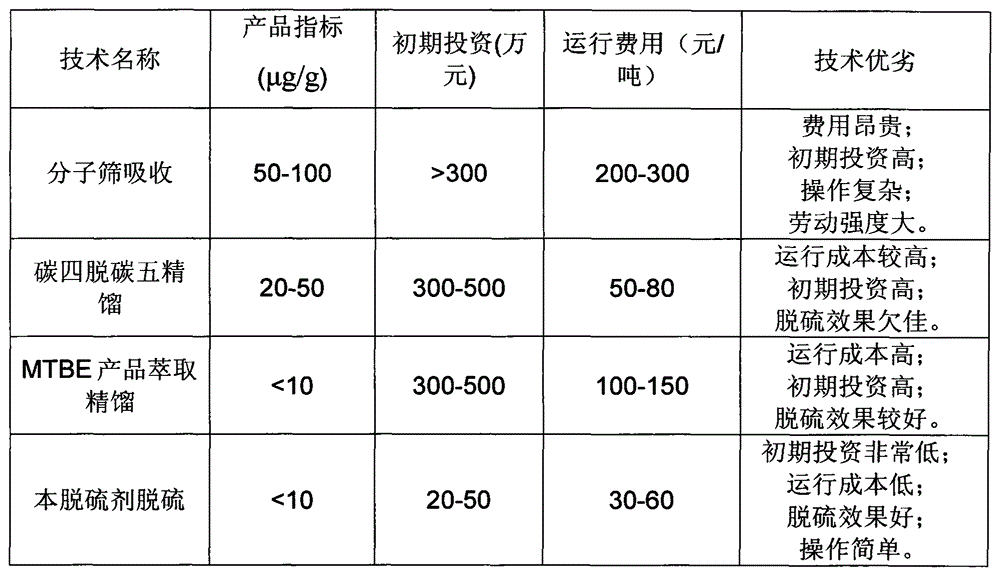

A desulfurizer and composition technology, applied in organic chemistry, ether separation/purification, ether preparation, etc., can solve the problems of high total sulfur in MTBE, high labor intensity, and difficult removal of neutral sulfur, so as to reduce consumption and Production cost, no secondary pollution discharge, guaranteed quality upgrade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

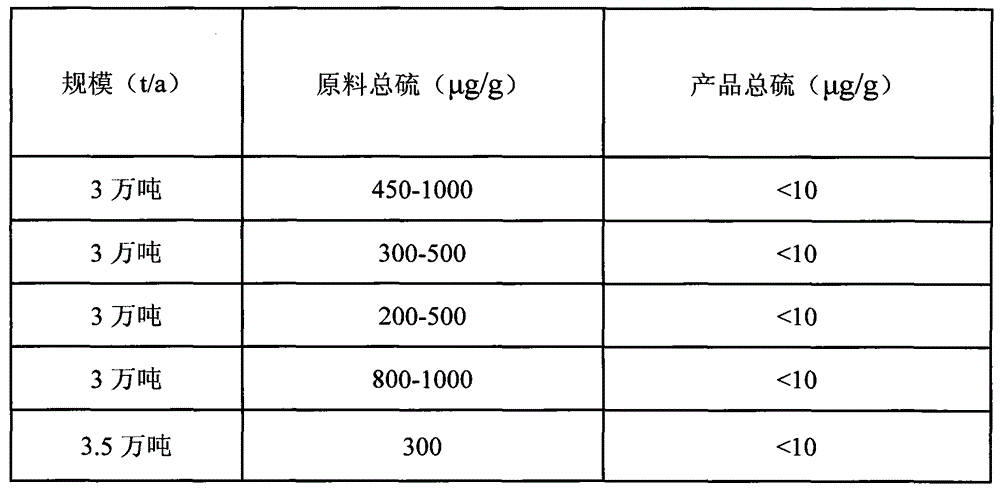

[0019] Take 100kg of mineral spirits and methyl tert-butyl ether (MTBE) containing 200μg / g of sulfur for desulfurization. The MTBE sulfur content of the desulfurized product is 8μg / g.

Embodiment 2

[0021] Take 99kg of mineral spirits and 1kg of anti-oxidation scorch inhibitor to prepare a solution to desulfurize methyl tert-butyl ether (MTBE) containing 300μg / g of sulfur, and analyze the MTBE sulfur content of the desulfurized product to be 5μg / g.

Embodiment 3

[0023] Take 82kg of gasoline, 10kg of N-methyldiethanolamine, 5kg of sulfolane, 1kg of anti-oxidant scorch inhibitor, defoamer, and surface active agent, and configure it as a solution. The methyl tert-butyl ether (MTBE) containing 300μg / g of sulfur ) Carry out desulfurization treatment, and analyze the sulfur content of MTBE after desulfurization is 4μg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com