A method for producing high-octane low-benzene gasoline

A high-octane, benzene gasoline technology, applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., can solve the problems of mismatch of excess benzene and high cost of ethylene recovery, achieve great economic and environmental benefits, suitable for The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

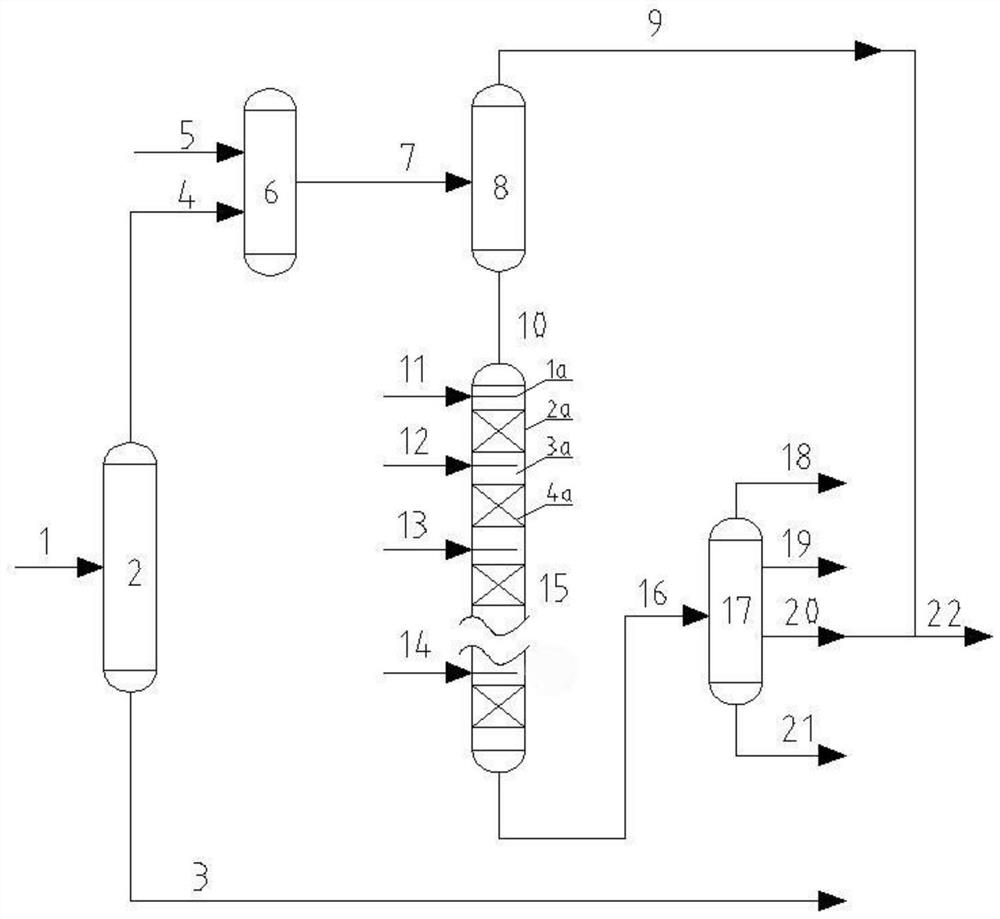

Method used

Image

Examples

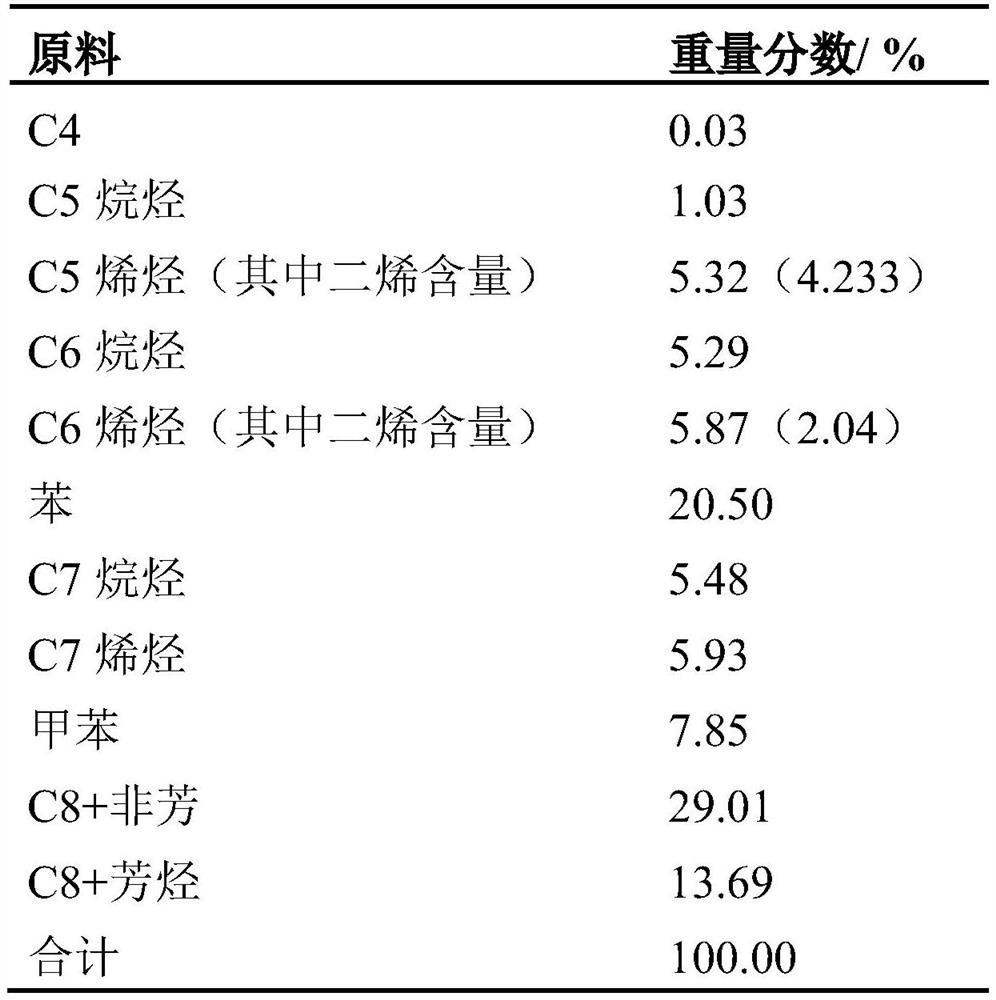

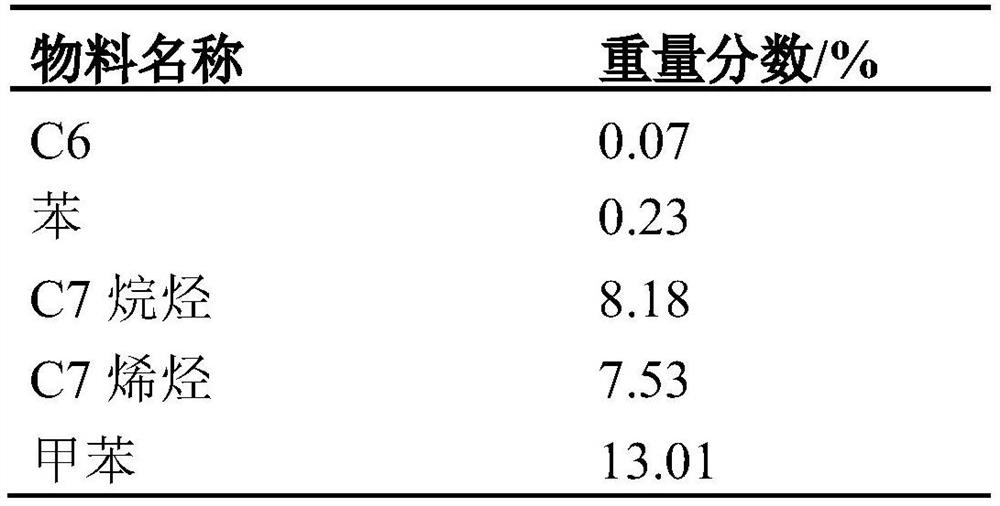

Embodiment 1

[0059] (1) Catalyst preparation

[0060] The hydrogenation catalyst carrier is made of aluminum hydroxide powder and silica sol with Al(OH) 3 / SiO 2 The dry basis ratio is 6:1, mixed evenly, extruded into a three-leaf strip shape, with an outer diameter of 1.4 mm, dried at 120 ° C for 4 hours, and roasted at 600 ° C for 3 hours to obtain a silicon oxide content of 18% (weight). Carrier; Weigh 200 grams of carrier, impregnate the carrier with 183 ml of aqueous solution containing 11.5 grams of ammonium paramolybdate, 20.6 grams of phosphoric acid, 19 grams of nickel nitrate, 36.8 grams of ammonium metatungstate, and 12.5 grams of phosphoric acid for 3 hours, and dry at 120°C Calcined at 480° C. for 4 hours for 4 hours to obtain a saturated hydrogenation catalyst for diolefins.

[0061]The catalyst used in the multi-stage adiabatic fixed-bed reactor is to obtain the hydrogen type ZSM-5 powder after the sodium type ZSM-5 powder is impregnated with ammonium nitrate, modified and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com