Process for preparing phosphoric acid from waste sulfuric acid as by-product of titanium oxide powder by wet method

A technology of by-production of titanium dioxide and wet-process phosphoric acid, which is applied in the direction of sulfur trioxide/sulfuric acid, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of restricting the production and development of sulfuric acid-process titanium dioxide, difficult to recycle and benefit, etc., to achieve The effect of environmental protection is huge, the effect of reducing production costs and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

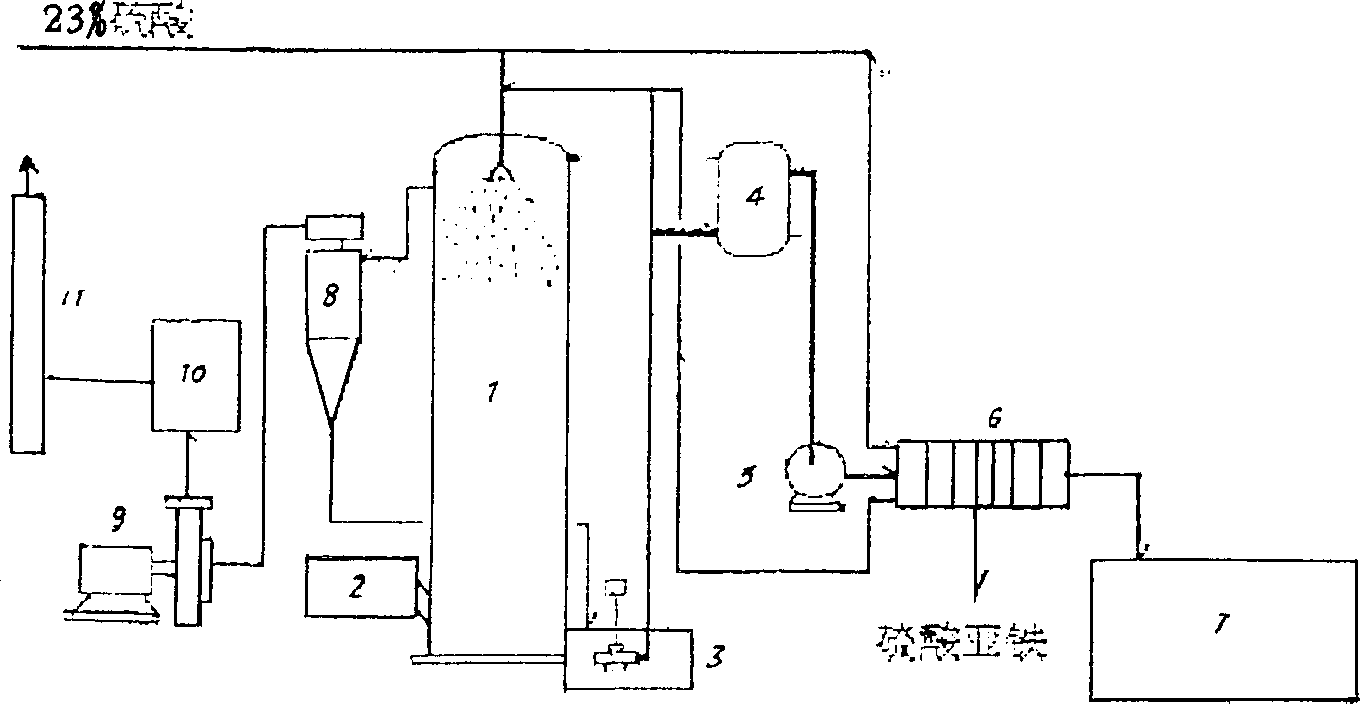

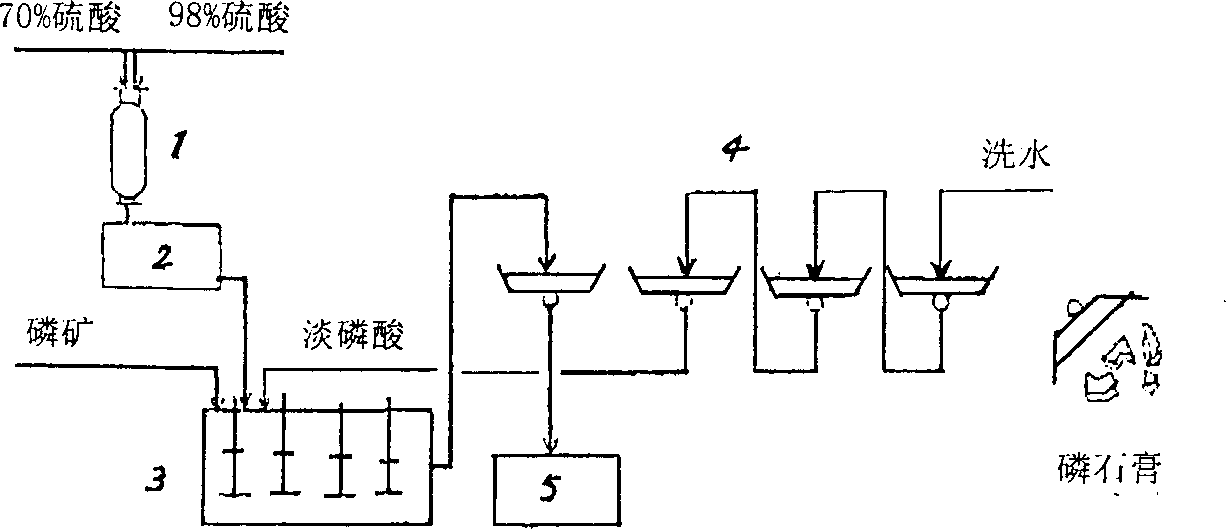

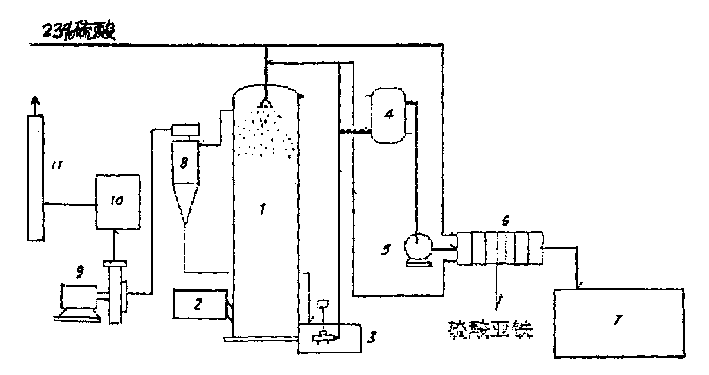

Method used

Image

Examples

Embodiment 1

[0040] With coal-fired high-temperature gas, the specification is Φ6×22m, and the volume is 600m 3 Feed dilute sulfuric acid 16.41t per hour in the spray concentration tower (its composition is: H 2 OSO 4 23.16%, FeSO 4 ·7H 2 O 17.6%; MnSO 4 1.1%; MgSO 4 1.3%; CaSO 4 ·H 2 O 1.2%; TiO 2 0.5%) carry out spray countercurrent contact heating and concentration, the temperature of hot air entering the tower is 600°C, the temperature of exiting the tower is 95°C, and the water evaporation rate per hour is 9.0t to obtain concentrated dilute 7.4t (it is composed of: H 2 OSO 4 51.3%, FeSO 4 ·7H 2 O 17.6%; MnSO 4 2.44%; MgSO 4 2.88%; CaSO 4 ·H 2 O 2.35%; TiO 2 1.11%).

Embodiment 2

[0042] Carry out spray concentration according to embodiment 1, the concentrated dilute sulfuric acid that comes out from the bottom of the concentration tower is cooled to 65 ℃, enters filter press and carries out solid-liquid separation, obtains 4.02t separation concentrated sulfuric acid per hour (it is composed of: H 2 OSO 4 70.7%, FeSO 4 ·7H 2 O 0.30%; MnSO 4 0.71%; Al 2 o 3 0.43%, TiO 2 0.06%), and 3.38t wet filter cake (liquid hold-up 35%).

Embodiment 3

[0044] Press the wet filter cake after the filter press separation of embodiment two, then use per hour 3.5t dilute sulfuric acid (its composition is: H 2 SO 4 23.16%; FeSO 4 ·7H 2 O 17.6%; MnSO 4 1.1%; MgSO 4 1.3%; CaSO 4 ·H 2 O 1.2%; TiO 2 0.5%) to wash dilute sulfuric acid 3.87t (its H 2 SO 4 Content: 37.13%), this acid is returned to Example 1 and merged with raw material dilute sulfuric acid for spray concentration; at the same time, 3.01t filter cake (liquid holding capacity 31%) is obtained per hour for sulfuric acid plant processing sulfuric acid or ferrous salt production treatment .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com