Patents

Literature

304results about How to "Solve the way out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

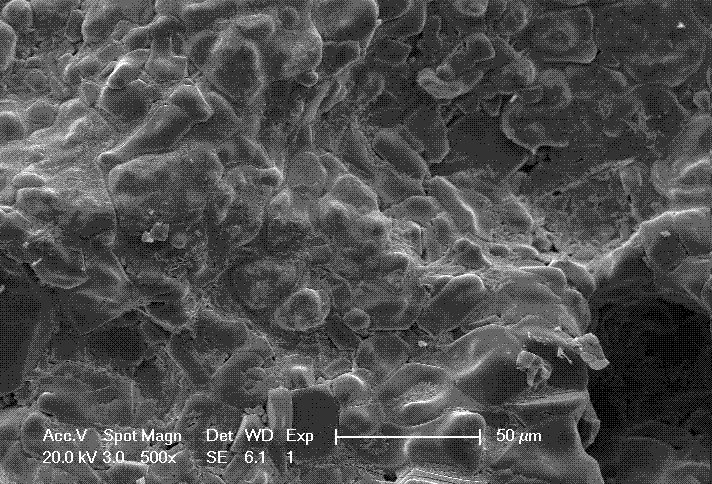

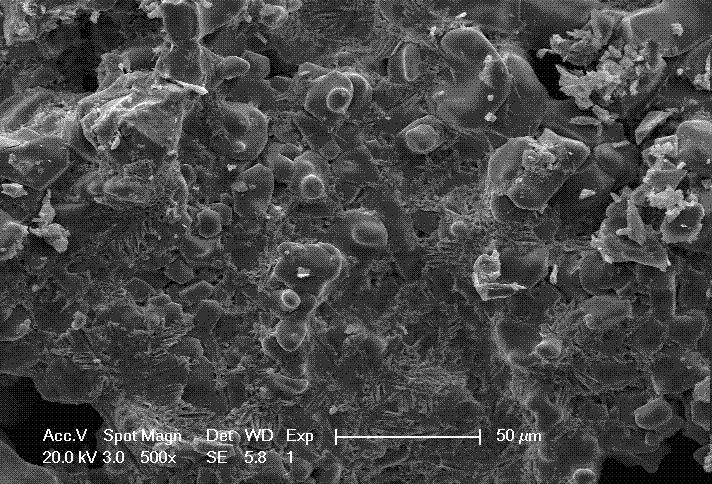

Sludge-based activated carbon and preparation method thereof

The invention relates to a sludge-based activated carbon and a preparation method thereof. In the invention, according to composition of sludge, a certain amount of biomass material (such as corn straw, wheat straw, peanut shell and the like) is appropriately added, mixing to be uniform is carried out, and carbon content of agricultural waste such as crop straw, peanut shell and the like is relatively higher, thus adsorption capacity of the activated carbon is improved (can be improved) when the crop straw and the peanut shell are added into sludge. Activating agent with certain concentration (such as ZnCl2, KOH, KCO3 and the like) is added into the sludge which is mixed to be uniform, impregnating and activating treatment is carried out, and then high temperature activation is carried out, thus the sludge-based activated carbon can be obtained. The sludge-based activated carbon provided by the invention has the advantages of simple process, low cost, and high specific surface area; meanwhile, a way is provided for recycling sludge and treating the agricultural waste, and hazard-free treatment, reduction and reutilization on waste treatment are realized.

Owner:BEIJING UNIV OF TECH

Spherical porous light haydite for treating waste water and its production method

InactiveCN1380137AHigh economic valueSolve the way outOther chemical processesSustainable biological treatmentPorosityEnvironmental resistance

The present invention relates to a kind of spherical porous loight-ceramsite produced by using industrial waste slag, steel-smelting rod mud and flyash as main raw material, using clay as binding agent, adding proper quantity of pore-forming agent and adopting high-temp., sintering process. Said invention also provides its production method, and said product can be specially used as filtration material for water treatment. Its product quality is as follows: specific surface area is 4-10 sq.m / g, average pore size is 50-250 micrometers, apparent density is 1.40-1.80 g / cu.cm and its voidage is 30-40%.

Owner:HUAQI ENVIRONMENT PROTECTION SCI & TECH

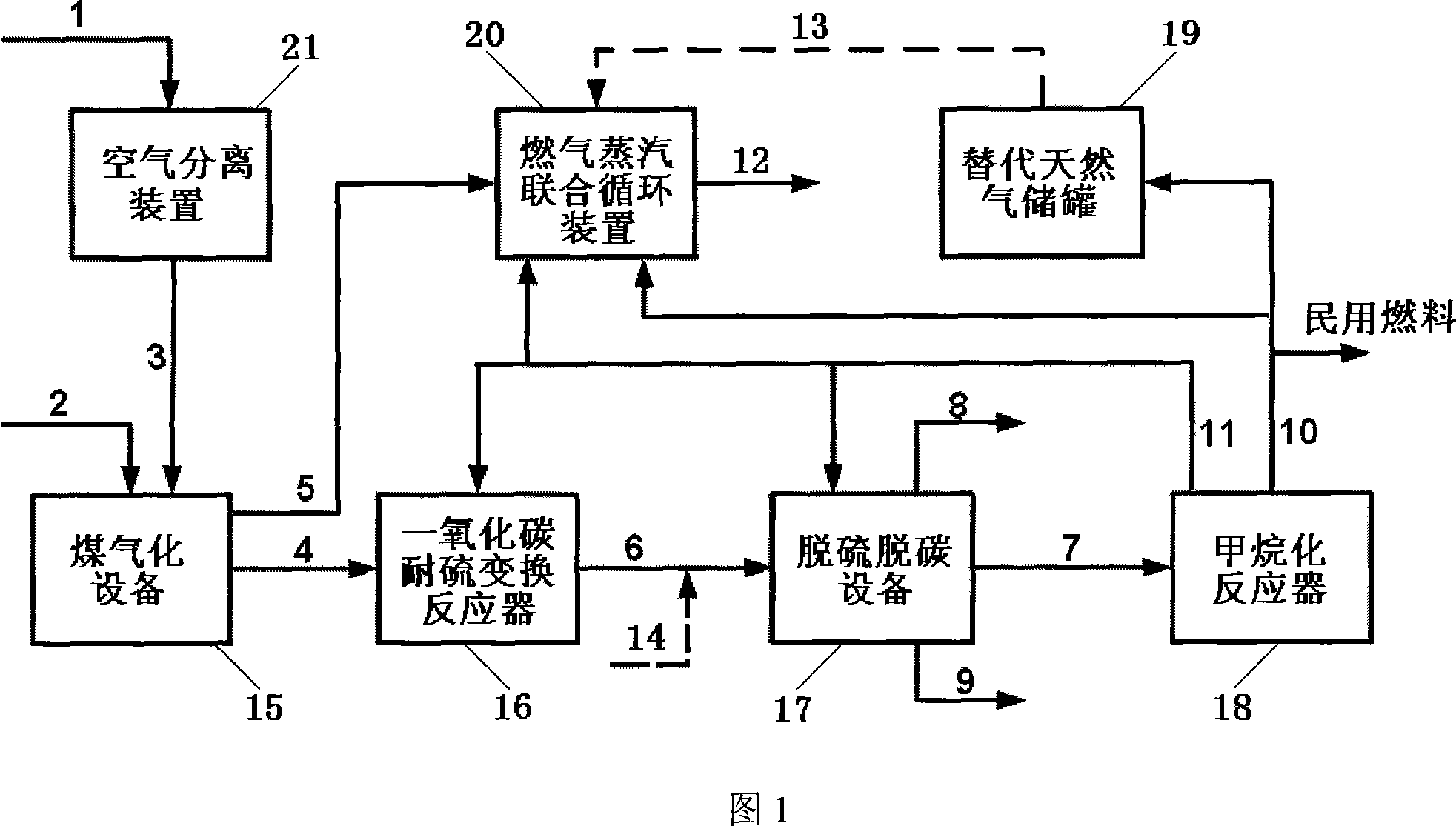

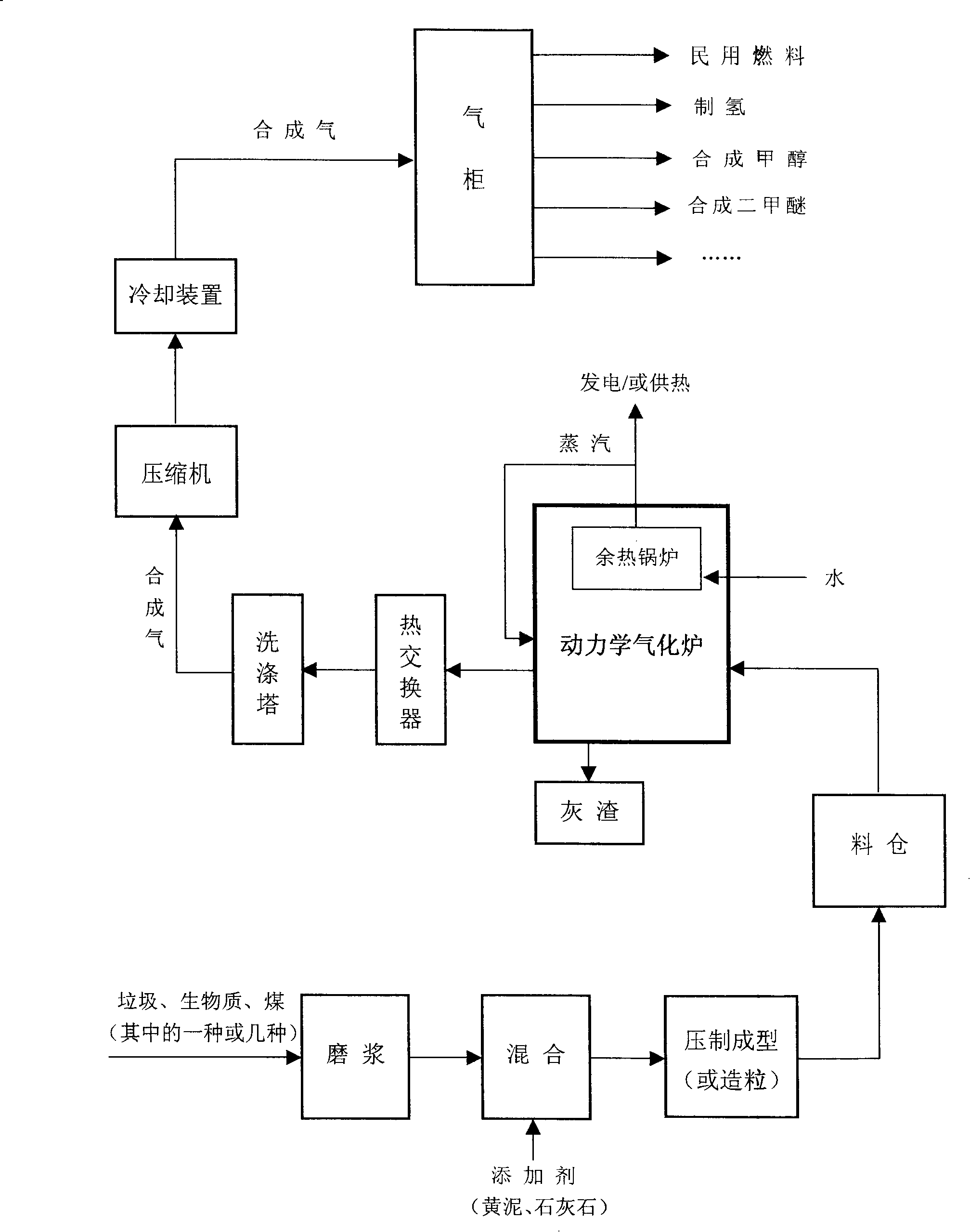

Combined system and process for producing electric-substituted natural gas based on coal gasification and methanation

ActiveCN101074397AEfficient and clean utilizationEfficient use ofCombustible gas chemical modificationCombustible gas purificationMethanationSlurry

An electric-substituting natural gas combined system and process based on coal gasification and methanation are disclosed. The process is carried out by delivering oxygen, powdered coal or water-gas slurry into gasified apparatus, recovering for crude gasified gas by wet heat, delivering into sulfur-resisting carbon monoxide carbon reactor, adjusting hydrogen-carbon ratio, entering into desulfurizing decarbonizer, recovering elementary sulfur while enriching carbon dioxide, delivering synthetic gas into methane reactor to generate substituted natural gas as domestic gas partially, entering into gas and steam combined circulator partially, and entering into substituted natural gas storage tank partially. It integrates coal gasified, methanation and gas steam combined circulation together, it's efficient and clean, has better utilizing rate, no CO2 discharge and need for changing gas turbine or load.

Owner:TSINGHUA UNIV

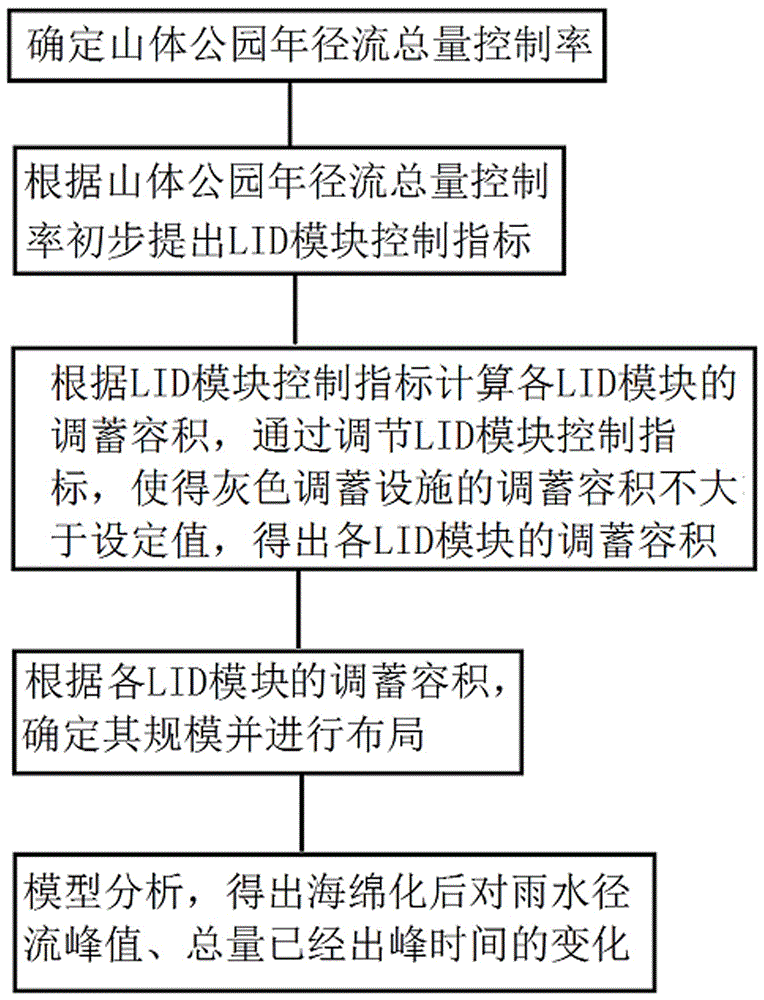

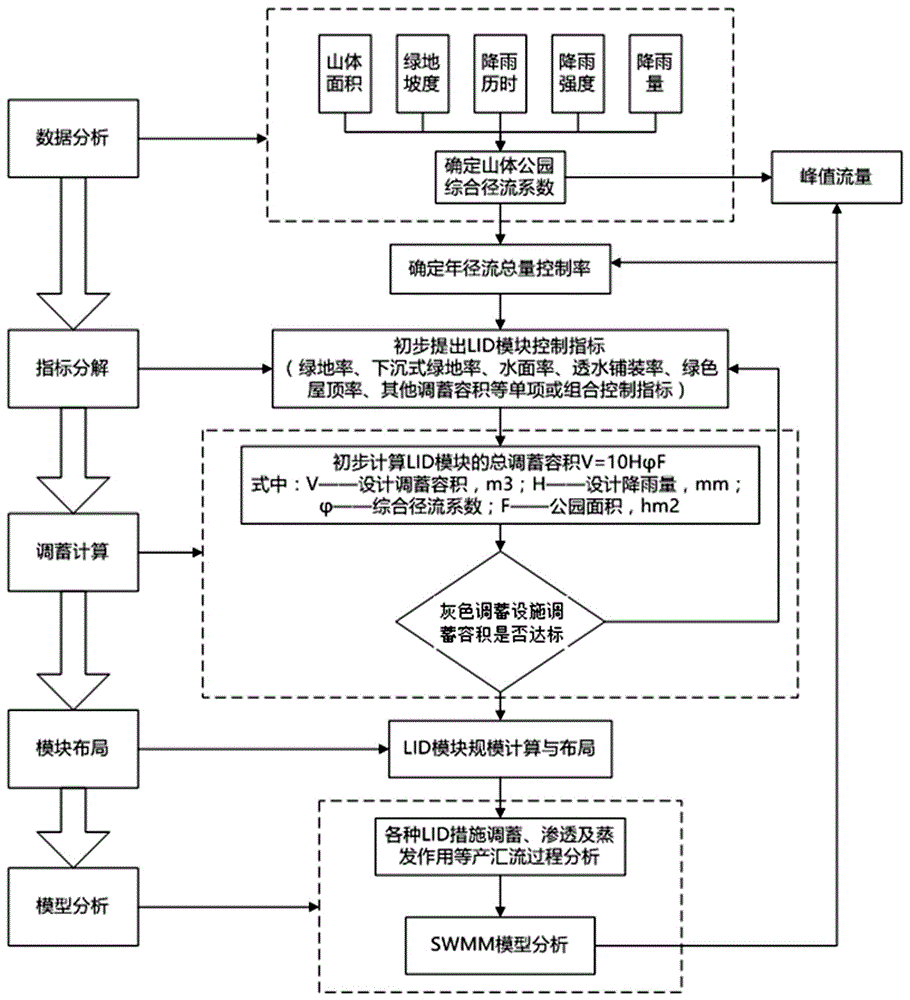

Regulation and storage design and model verification method for mountain parks built on the basis of sponge city concept

ActiveCN106570267ARealize natural accumulationImprove permeabilityClimate change adaptationDesign optimisation/simulationModelling analysisComputer science

The invention relates to a regulation and storage design and model verification method for mountain parks built on the basis of sponge city concept. The method comprises following steps: A. determining the annual runoff volume control rate of a mountain park; B. initially bringing up LID module control indexes according to the annual runoff volume control rate of a mountain park; C. calculating the regulation and storage volume of each LID module according to the LID module control indexes, adjusting the LID module control indexes so that the regulation and storage volume of gray regulation and storage devices is no more than a preset value and obtaining the regulation and storage volume of the LID module; D. module layout; E. model analysis. The method puts the idea of sponge city into practice comprehensively; the construction of mountain parks and the building of sponge city are integrated; the design method of constructing sponge parks is further fulfilled so as to realize natural accumulation, penetration and purification of rainwater by the mountain parks.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

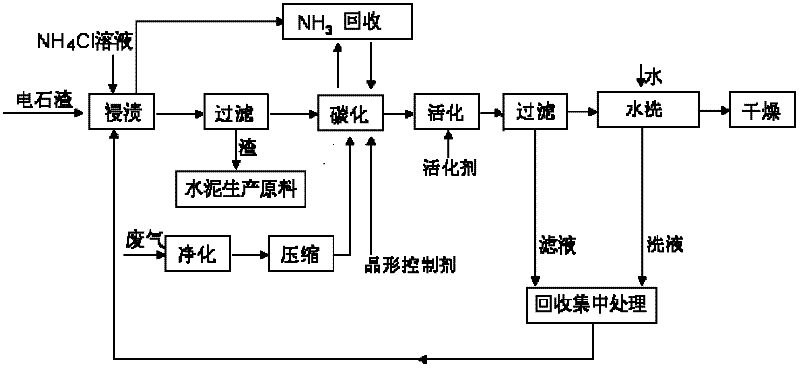

Method for synthesizing ultrafine calcium carbonate by utilizing carbide slag

ActiveCN102602973AImprove conversion rateUniform particle size distributionCalcium/strontium/barium carbonatesSolid waste disposalWater contentCis-Butenedioic Acid

The invention relates to a method for synthesizing ultrafine calcium carbonate by utilizing carbide slag. The method comprises the following steps of: (1) dissolving carbide slag: uniformly mixing carbide slag with water in a ratio of (1:6)-(1:20) to ensure that the carbide slag is fully dissolved into a turbid liquid, wherein the water content of the carbide slag is 20-45%; (2) carrying out impregnation reaction: adding ammonium chloride into the turbid liquid of the carbide slag for uniformly mixing, wherein the mass ratio of carbide slag to ammonium chloride is (1:0.7)-(1:2.5), after the impregnation reaction is finished, filtering and removing the slag to obtain a clear calcium chloride solution; and (3) carrying out carbonization reaction: adding a crystal form control agent into a calcium chloride solution for fully dissolving, introducing CO2 into the solution to carry out carbonization reaction till the pH (potential of Hydrogen) value of the reaction solution is less than or equal to 7 to obtain ultrafine calcium carbonate slurry, wherein the crystal form control agent is one or more than two mixtures of sulfate, chloride, citrate, sodium dodecyl benzene sulfonate, pyrophosphate, oleic acid, ammonium citrate, N-methyl pyrrolidone and maleic acid.

Owner:SINOMA INT ENG +1

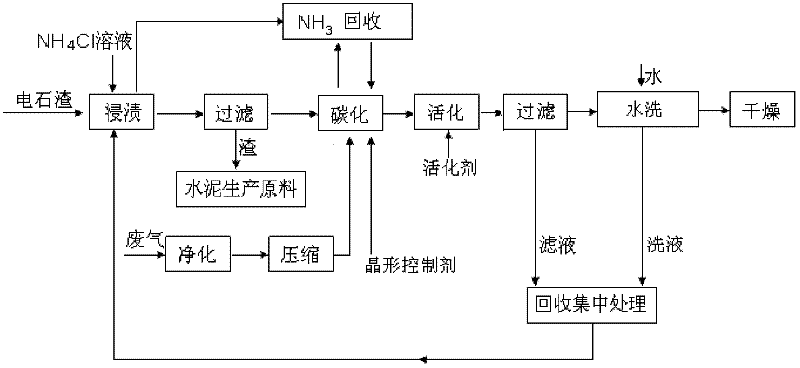

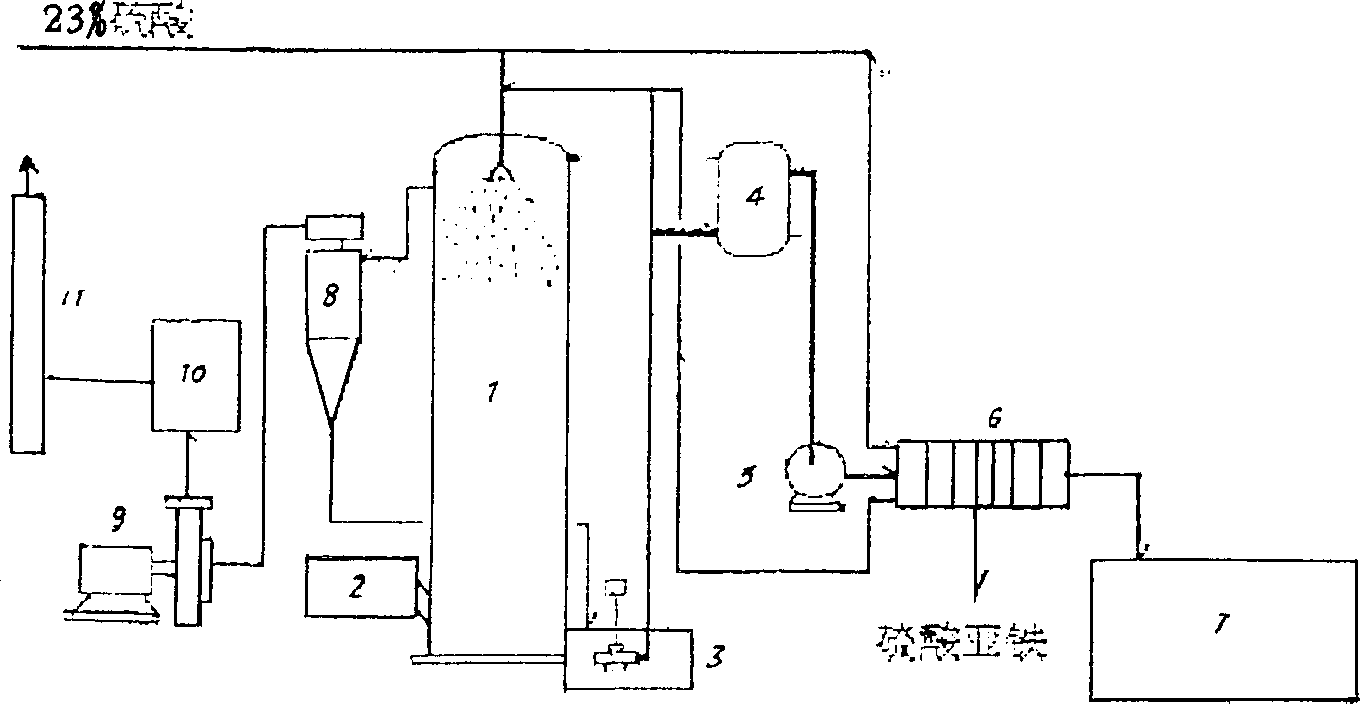

Process for preparing fine algae cultivation coupling biological diesel oil refining

The invention relates to the fields of microalgae culturing project, biodiesel refining and environment protection, in particular to a production method for refining the biodiesel through microalgae culturing and coupling. In the method, carbon dioxide industrial waste water and eutrophicated surface water or industrial waste water is used as main material to extensively culture the microalgae containing oil, and microalgae oil is used as the material to refine the biodiesel and simultaneously realize the drainage reducing of carbon dioxide, the control of polluted water and the cleaning production of biodiesel. The method is characterized in that the waste gas of carbon dioxide and the eutrophicated water are firstly used to culture and collect the microalgae; and then extraction, pre-processing and interchange esterification reaction of microalgae is carried out. In the invention, the two processing of culturing the microalgae and refining the biodiesel are coupled together; the ''three wastes'' and waste heat generated during the reefing process of the biodiesel and the unsalable outgrowth of crude glycerine are used as the materials and the heat source for culturing the microalgae; therefore, not only the production cost is reduced, but also the discharge of the ''three wastes'' is eliminated.

Owner:王彤

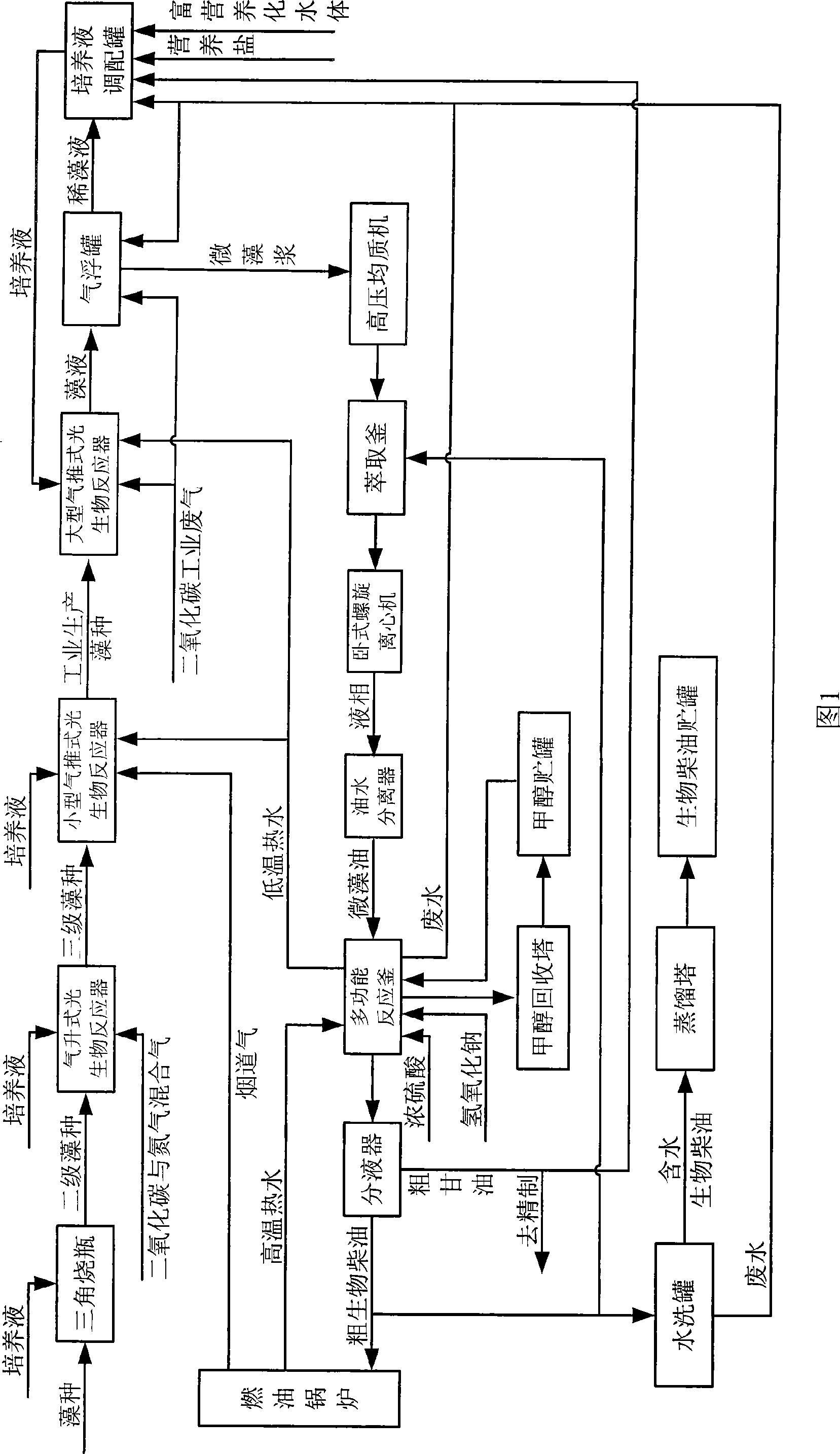

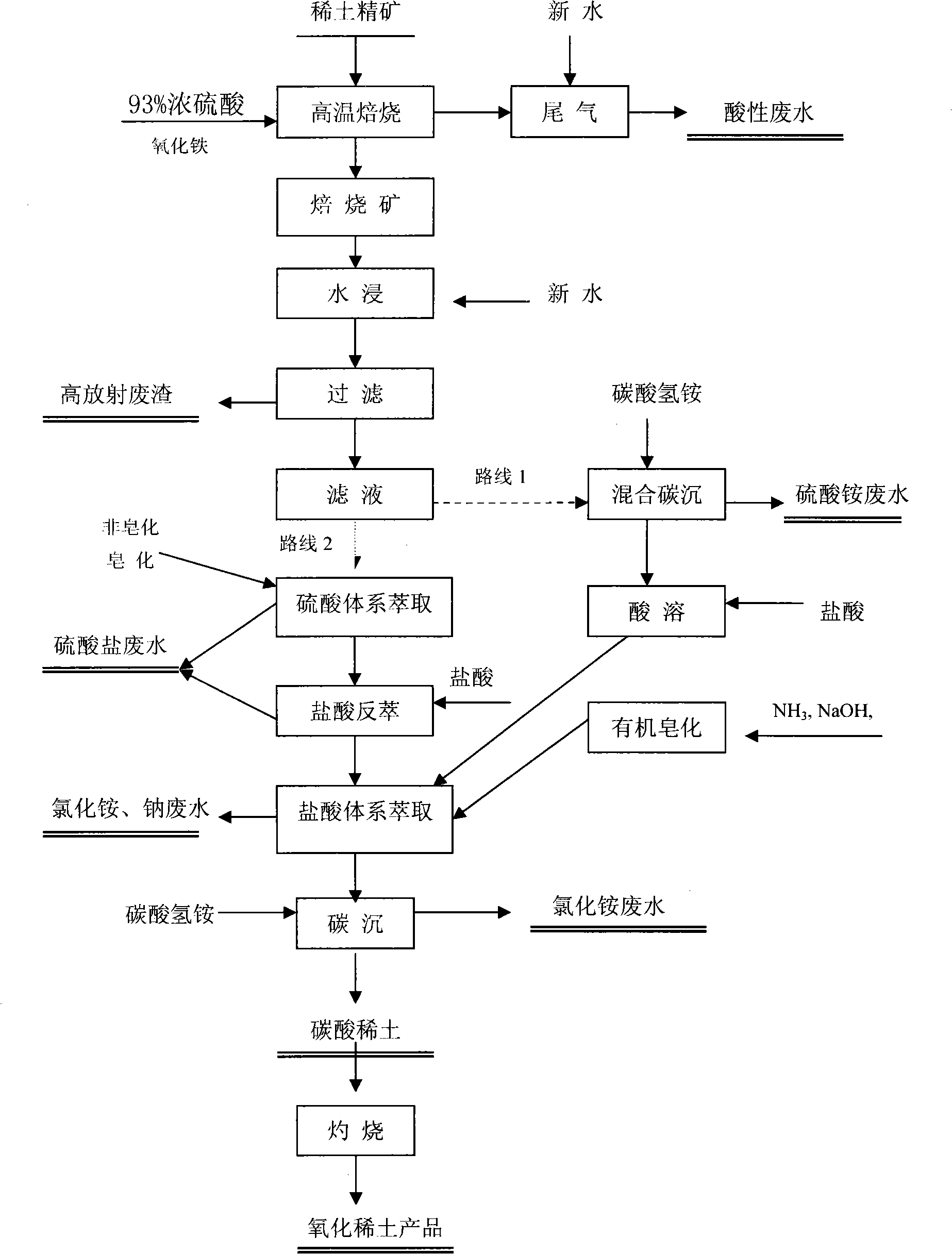

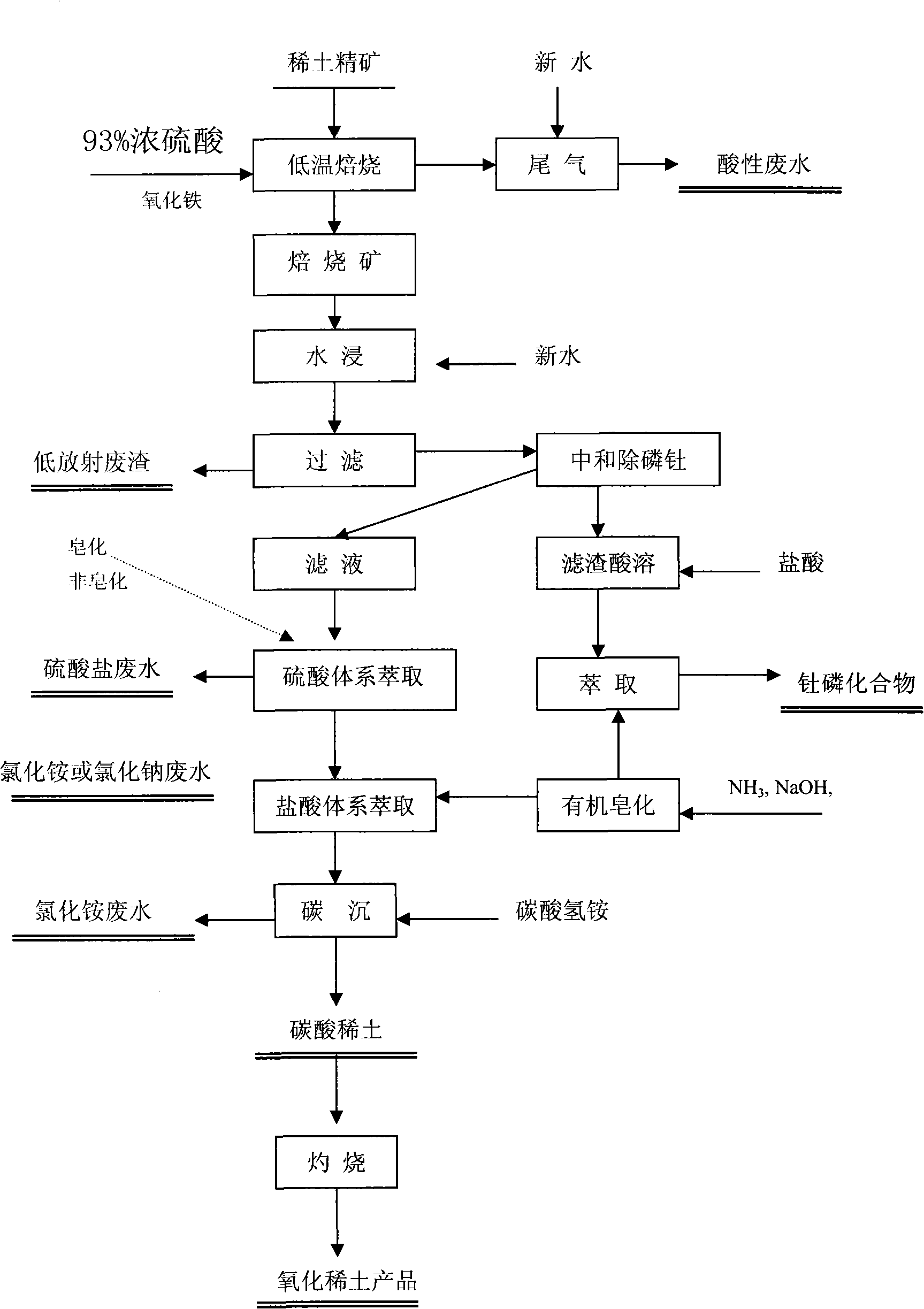

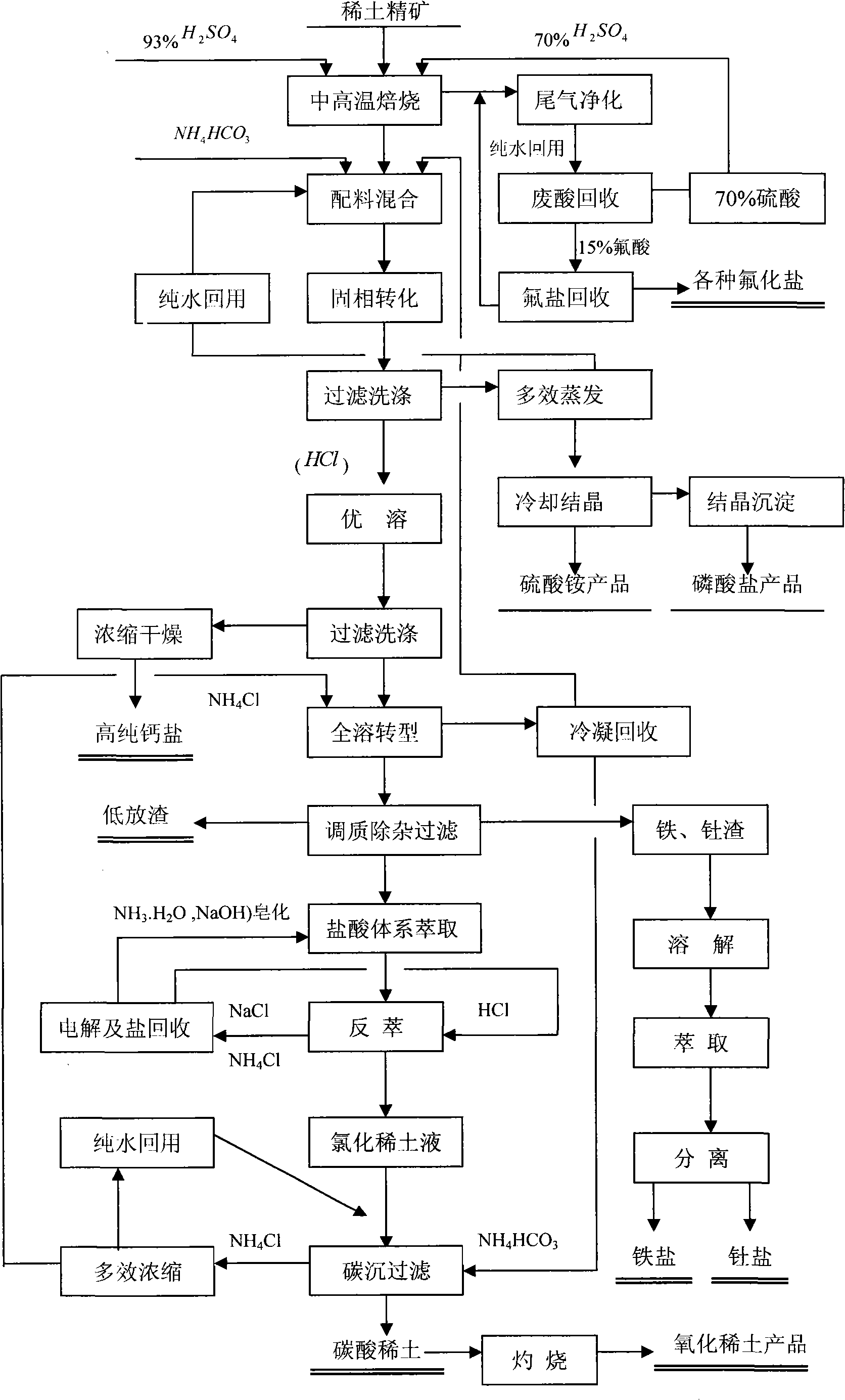

Process for rare-earth smelting resource reclamation and cyclic production

InactiveCN101880782AAchieve governanceAchieve recyclingProcess efficiency improvementIndustrial waste waterSmelting process

The invention relates to a process for rare-earth smelting resource reclamation and cyclic production. The process has the main characteristic of comprehensively and systematically solving the problems of environmental protection and industrial promotion of the whole rare-earth industrial chain by adopting innovative integrated technical means. The process mainly comprises administration and comprehensive utilization of waste gas, waste water and waste slag, revolution of a rare-earth smelting process, and reclamation and repeated utilization of various important resources such as sulfur, fluorine, ammonium, thorium, phosphorus, calcium and the like so as to achieve smokeless and harmless treatment of the waste gas, full utilization of the resources and zero discharge of industrial waste water and fulfill the final goal of cyclic production. The process radically solves the maximum environment-friendly bottleneck problem in a sustainable development process of the Baotou rare-earth industry from resource advantage to industrial advantage, in particular the historical key environment-friendly technical problem, reduces energy consumption of a large amount of resources and pollutiondischarge, greatly reduces the production cost, upgrades the rare-earth industry, and extends the larger industrial chain at the same time.

Owner:马克印 +1

Method for preparing active carbon from municipal sludge by two-step thermal decomposition

The invention provides a method for preparing active carbon from municipal sludge by two-step thermal decomposition, belonging to the technical field of active carbon. The method comprises the following steps of: thermally decomposing and carbonizing dried municipal sludge for 30-90 minutes at 400-550 DEG C, and then adding an activator in an amount of 2-4mol / l into the carbonized sample, impregnating and activating, and then thermally decomposing and activating at high temperature of 450-600 DEG C to obtain the sludge-activated carbon. According to the method provided by the invention, the sludge is carbonized and activated by the two-step thermal decomposition and then the carbonized sludge is activated by the activator, so that the demand of the activator is greatly decreased and a way of recycling the sludge is provided to realize harmless, reduction and reclamation of the waste treatment.

Owner:BEIJING UNIV OF TECH

Sludge fuel stick and its prepn

InactiveCN1810940ALow costSolve the way outSludge treatment by de-watering/drying/thickeningBiofuelsCombustionPlant stalk

The present invention is one kind of sludge fuel stick and its preparation process, and belongs to the field of solid waste treating technology. The sludge fuel stick is prepared with dewatered sludge 50-70 wt%, combustion improver 20-50 wt%, adhesive 3-5 wt% and desulfurizing agent 5-10 wt%. The preparation process includes mixing the said materials in a stirrer, pelletizing in a pelletizer, forming and stoving. The present invention can treating sludge as well as plant stalk, furnace slag, coal slag, flyash and other solid waste and utilize heat in sludge.

Owner:TSINGHUA UNIV

Energy-saving consumption-reducing technique for preparing haydite by co-disposing polluted soil and desilting sediment

ActiveCN102173850APromote healthy developmentLow running costCeramicwareExpanded clay aggregateWater content

The invention relates to an energy-saving consumption-reducing environment-friendly method for preparing haydite by co-disposing municipal massive solid wastes, which comprises the following steps: directly mixing polluted soil and polluted desilting sediment (without energy-consuming drying), adding a conditioner, granulating, and firing at 900-1200 DEG C for 15-40 minutes. The test indicates that the prepared haydite product has the following properties: the bulk density is 500-900 kg / m<3>, the cylindrical compressive strength is 5.0-10.0 Mpa, and the water absorptivity is 4.8-9.2%; and the leaching toxicities of typical heavy metals are as follows: Cu<0.26 mg / L, As<0.03 mg / L, Cd<0.0002 mg / L, and Hg<0.0001 mg / L. The method provided by the invention fully utilizes the water-content complementarity of the polluted soil and sewage reservoir sediment as well as the characteristic of mutual catalytic degradation of heavy metal pollutants and organic pollutants, implements energy saving and consumption reduction in the technical field of traditional techniques for preparing haydite from solid wastes, lowers the cost and secondary pollution in solid waste disposal industry, enhances the properties of the solid waste haydite, and widens the application field of the solid waste haydite.

Owner:TIANJIN YIMING ENVIRONMENTAL TECH CO LTD

Productive technology for extrating diet fiber from sea-tangle

InactiveCN1413513AImprove physical functionImprove use valueFood preservationFood preparationChlorideSoluble dietary fiber

A process for extracting edible fibres from kelp includes such steps as washing, drying and pulverizing raw kelp, enzymolyzing, treating with hydrochloric acid, extracting by sodium carbonate, filter, neutralizing the filtrate, adding calcium chloride to obtain gel, treating the dregs with sodium hydroxide and hdyrochloric acid, mixing the said gel with the treated dregs, bleaching with sodium hypochlorite, activating, dewatering, baking and pulverizing.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Sludge-based desulfurizer and preparation method thereof

InactiveCN101837231ASolve the way outIncrease capacityDispersed particle separationActivated sludgeSlag

The invention discloses a sludge-based desulfurizer and a preparation method thereof. A sludge agent consists of 60 to 80 percent of active ingredient, 12 to 20 percent of binder and 8 to 20 percent of pore expanding agent. The preparation method comprises the following steps of: preparing activated sludge particles from sludge particles and an active agent in a mass ratio; performing thermal treatment on the activated sludge particles, cooling the activated sludge particles subjected to thermal treatment in nitrogen and treating the cooled activated sludge particles to obtain sludge active carbon; mixing the sludge active carbon, blast furnace iron slag, red mud, quicklime and copper ash to obtain the active ingredient; and mixing the active ingredient, the binder and the pore expanding agent, grinding the mixture, adding deionized water into the ground mixture, performing extrusion molding on the mixture, drying the molded mixture and baking the dried mixture to obtain the sludge-based desulfurizer. The sludge-based desulfurizer of the invention has the advantages of high degree of purification, high sulfur dioxide adsorption capacity, simple preparation and low cost.

Owner:龙澳(天津)生物医药技术有限公司

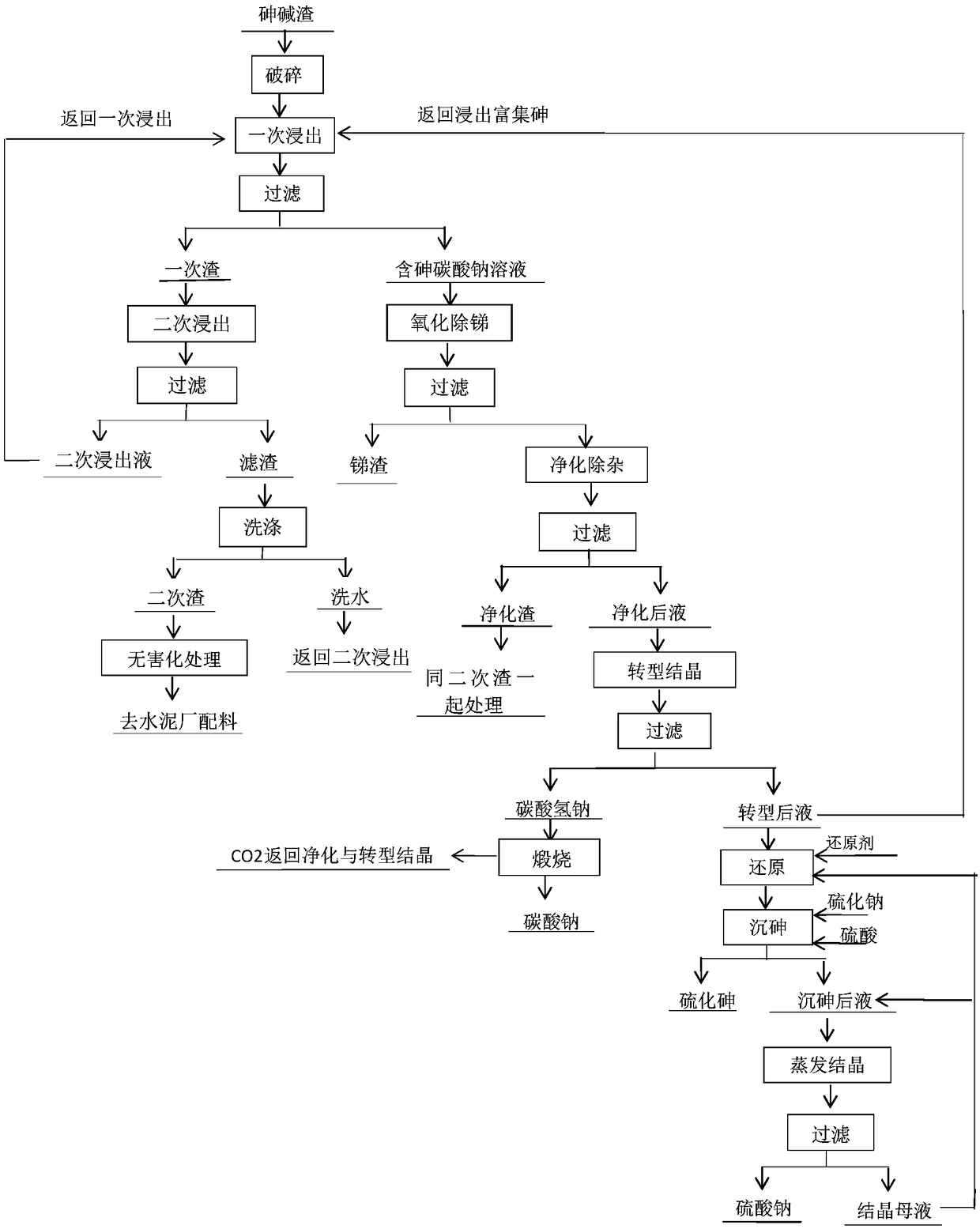

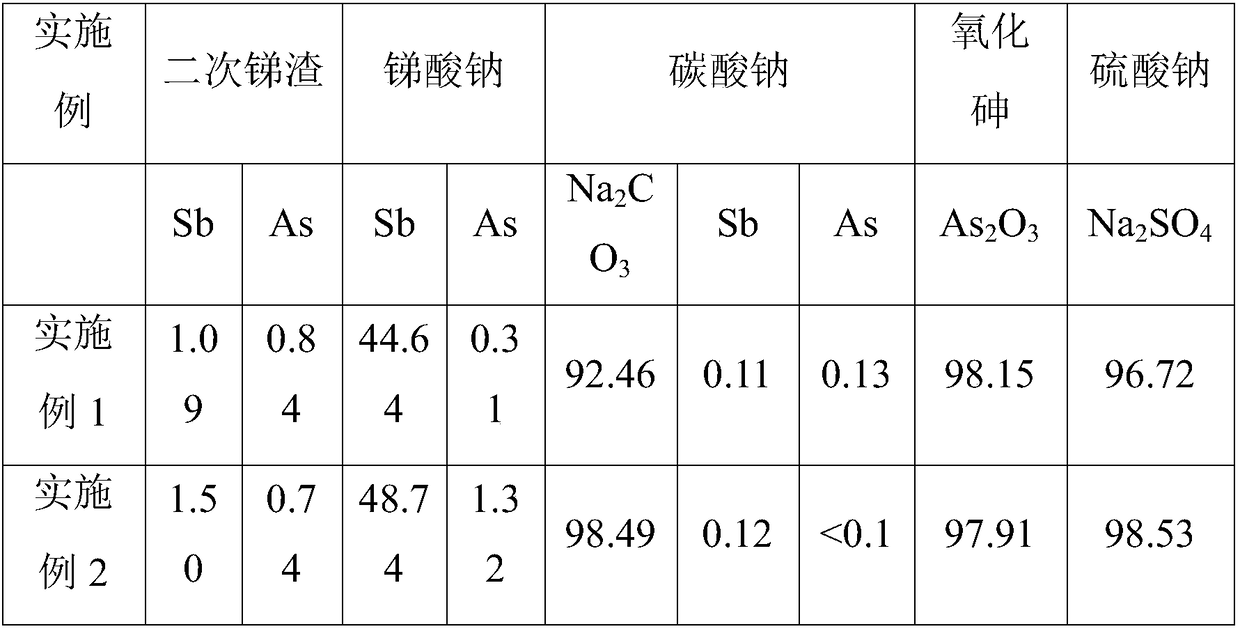

Wet-method recycling and harmless treatment process for antimony smelting arsenic alkali residue

PendingCN108441642ARealize green and clean cycle productionHigh recovery rateSolid waste disposalAlkali metal sulfite/sulfate purificationWastewaterImpurity

The invention belongs to the field of antimony smelting arsenic alkali residue treatment and particularly discloses a wet-method recycling and harmless treatment process for antimony smelting arsenicalkali residue. The process adopts a whole-wet-method treatment process and mainly comprises the eight working procedures of breaking, dissolving for leaching, oxidation for antimony outlet, purification for impurity removing, transition for crystallizing, reduction for arsenic sinking, evaporative crystallization and secondary residue harmless treatment. Recycling and harmless treatment of the arsenic alkali residue, zero emission of waste residue and waste water and up-to-standard discharge of exhaust gas are thoroughly achieved, the long-term plagued arsenic alkali residue environmental pollution problem in the antimony smelting industry in China is thoroughly solved, and the environmental risk caused by stacking the arsenic alkali residue is eliminated; and meanwhile, separation, enrichment and effective recovering of valuable elements are achieved.

Owner:CHENZHOU YANGTAO CHEM

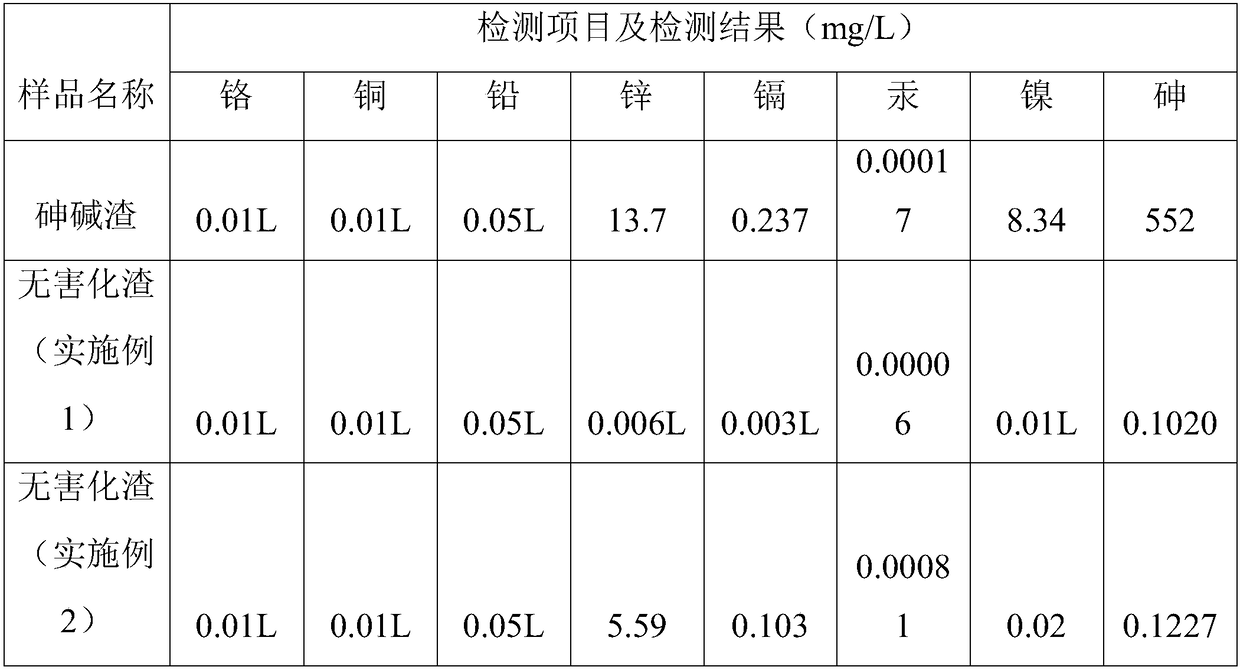

Method for producing propene using silicoaluminophosphate molecular sieve catalytic cracking

ActiveCN1762931ALow purity requirementLow aromatic contentMolecular sieve catalystsBulk chemical productionMolecular sieveHydrocarbon mixtures

The present invention relates to propylene producing catalytically cracking process, and is especially propylene producing process with catalytically cracking aluminum silicophosphate. In fixed bed or fluidized bed reactor and at the conditions of temperature 350-550 deg.c, pressure 0.1-0.3 MPa and space velocity 0.1-300 / hr, dry gas, C4 component and other material are cracked in catalyst containing aluminum silicophosphate molecular sieve SAPO-34. The output hydrocarbon mixture is separated to obtain destination product propylene before the other components are returned to the reactor for circular use. The process of the present invention has low reaction temperature, pressure near normal pressure, simple technological process and high propylene selectivity. The present invention can utilizes dry gas and C4 component effectively.

Owner:TSINGHUA UNIV

Refining process for lepidolite in tantalum-niobium ore waste rocks

ActiveCN105251606ASolve the way outHigh Lithium Oxide ContentHigh gradient magnetic separatorsFlotationNiobiumIron removal

The invention relates to a refining process for lepidolite in tantalum-niobium ore waste rocks. A combined method with magnetic separation, high gradient magnetic separation, dense medium separation and flotation is adopted. The flotation adopts the process of rough flotation, dual fine flotations and sweeping. The process for refining the lepidolite from the granite-type tantalum-niobium ore waste rocks is provided. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, dense medium separation and flotation, so that lepidolite concentrates are obtained. By means of the method, the lepidolite concentrates are separated from the tantalum-niobium ore waste rocks. The lepidolite concentrates contain at least 4.5% of Li2O, at least 8.0% of K2O and Na2O and at most 0.10% of TiO2 and Fe2O3, the recovery rate of the lepidolite concentrates is larger than 80%, the qualities of the lepidolite concentrates meet the requirement of national standards, and the recovery rate of the lepidolite concentrates exceeds the industry level.

Owner:江西金辉再生资源股份有限公司

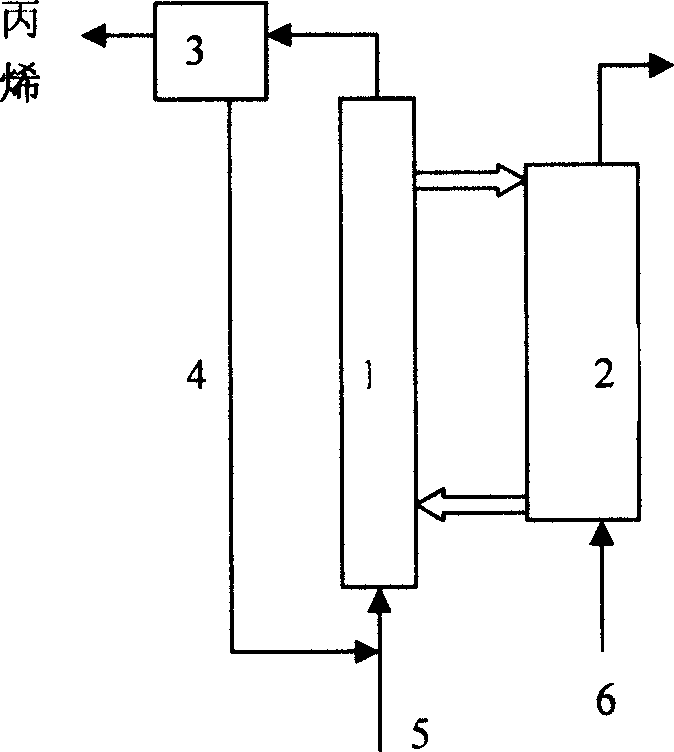

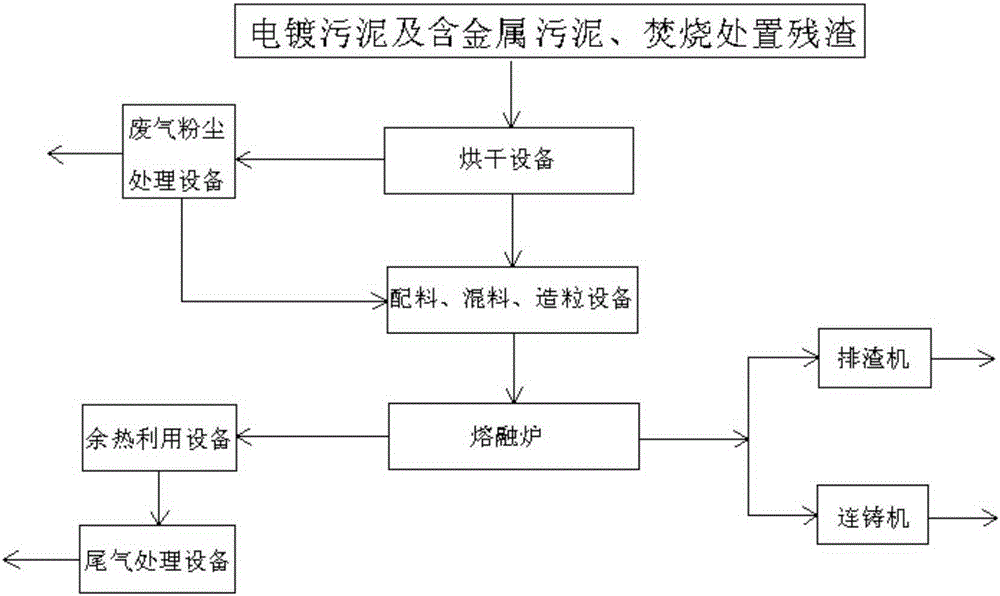

Method for treating specific pollutants through high-temperature melting technology

InactiveCN105344698AReduce operating costsResourcefulSolid waste disposalTransportation and packagingSludgeSlag

The invention provides a method for treating specific pollutants through a high-temperature melting technology. The specific pollutants comprise electroplating sludge, sludge containing metal and / or incineration disposal residues. The method comprises the steps that pretreatment is carried out, wherein the specific pollutants are pretreated, the water content of the specific pollutants is reduced to be 10 wt% or lower, and dry specific pollutant materials are obtained; burdening, blending and granulating are carried out, wherein regulating components are added as needed, mixed and granulated, and a granulated mixture is obtained; melting is carried out, wherein the granulated mixture is melted at the melting temperature ranging from 1,200 DEG C to 1,800 DEG C; and products are obtained, wherein the melted metal is settled on the lower layer and is discharged to obtain a metal alloy, and slag and a small part of metal float above the melted metal and are discharged to obtain glassy-state slag. After the specific pollutants are treated through the method, harmless and pollution-free resource materials can be obtained, and the method can be used for resource recycling, and is good in economic benefit and beneficial to commercial popularization.

Owner:SHANGHAI LVCHENG ENVIRONMENTAL PROTECTION TECH

Treatment method for solidifying sludge of sewage plant in city

This invention relates to a method for solidification treatment of sludge discharged from urban sewage treatment plant. The method utilizes solidification and stabilization techniques to treat sludge discharged from urban sewage treatment plant, and improve its landfill physicochemical properties, thus can solve the problems related to sludge landfill. The method adopts cement as the solidification agent, and one or more of lime, aluminum salt, aluminum oxide and cinder as the coagulant aid. The method comprises: adding 3-8% solidification agent and 1-8% coagulant aid into sludge, mechanically stirring uniformly, spreading onto a landfill site, covering with a waterproof film, dry-maintaining for 3-15 days, and performing following landfill. The method has such advantages as low cost, easy operation and good effect. The treated sludge has such advantages as high compressive strength, high soaking resistance and low leaching toxicity.

Owner:GUOZHONG AIHUA TIANJIN MUNICIPAL ENCIRONMENT ENG

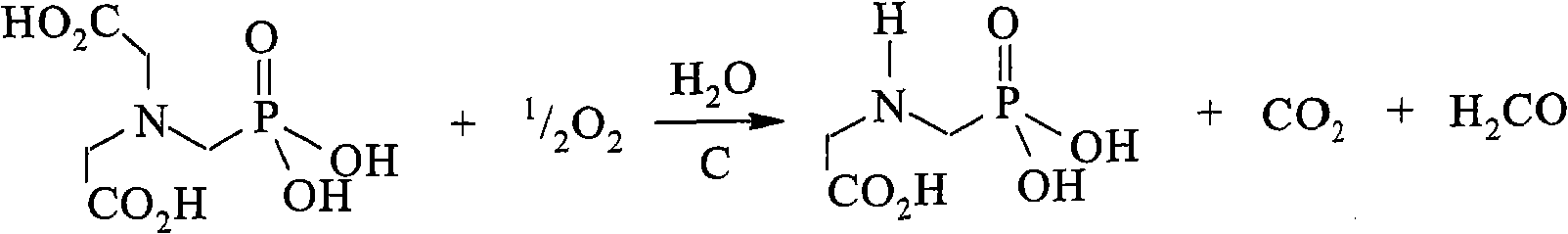

Comprehensive treatment method for glyphosate mother liquid

The invention relates to a comprehensive treatment method for mother liquid synthesized by oxidizing glyphosate by N-(Phosphonomethyl) iminodiacetic acid with an IDA (Iminodiacetic Acid) method. The mother liquid is treated by a condensed system to obtain condensed liquid and thin liquid, wherein the condensed liquid subjected to formaldehyde removal is used for preparing a gyphosate solution with high content or carrying out oxidation treatment, the treated thin liquid can be used for gyphosate production or biochemical treatment. The comprehensive treatment method not only recovers gyphosate, but also reduces the pollution to the environment.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Biological solidification and stabilization method of bottom mud in riverways and lakes

InactiveCN102092916ASolve the way outReduce curing costsSludge treatment by de-watering/drying/thickeningBiological sludge treatmentAmylaseActive agent

The invention relates to improvement of a biological solidification and stabilization method of dredge bottom mud. The biological solidification and stabilization method is characterized by comprising the following steps: primarily dehydrating clay particles which have less possibility of being dehydrated, and mixing and stirring the dehydrated clay particles with dry soil to form mixed soil; and spraying a compound biological enzyme liquid at least consisting of reductase, amylase, cellulase, esterase, lipase, ligninase, prolease, urease, xylanase and a detergent surface active agent to be mixed with the mixed soil, then compacting and solidifying. The biological solidification and stabilization method has the advantages of short process flow and simplicity; by utilizing the method, the volume of the bottom mud to be solidified and stabilized is greatly reduced, the volume of the bottom mud to be solidified after classification and dehydration is 10%-15% of that of the bottom mud to be conventionally solidified, the processing flow is reduced compared with the existing biological enzyme solidification, the solidification cost is reduced, the solidification strength is high, the solidification filling shear strength can reach the Mpa grade, thus the method can be used for road construction, parking lots, slope solidification, reservoir surface solidification, refuse landfill bottom solidification and seepage prevention and public road building. By using the method, the outlet problem of the dredge bottom mud is effectively solved, and a novel decrement and solidification process for the bottom mud in the lakes is created.

Owner:GUANGZHOU ZHUSHUI ENVIRONMENT TECH

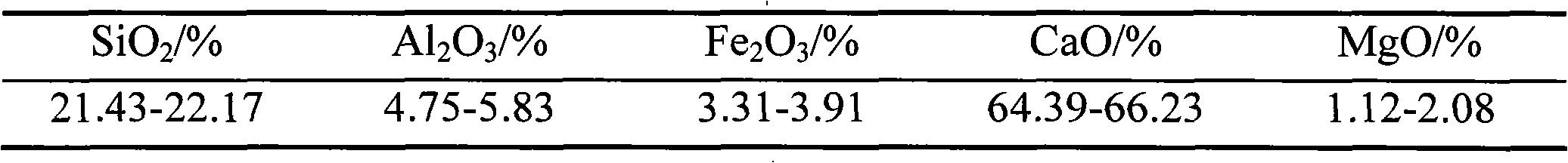

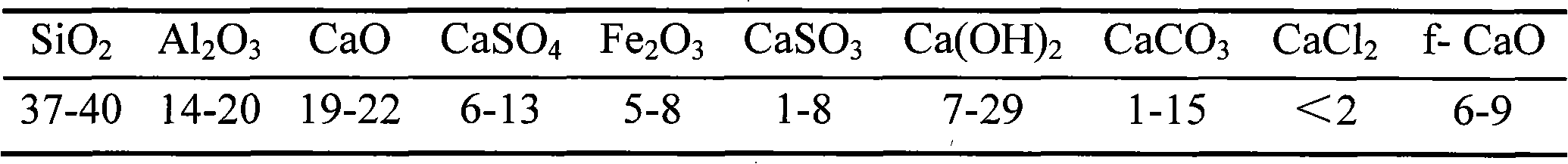

Method for adjusting and controlling feeding mode of lime-dried municipal sludge cooperatively treated with cement kiln

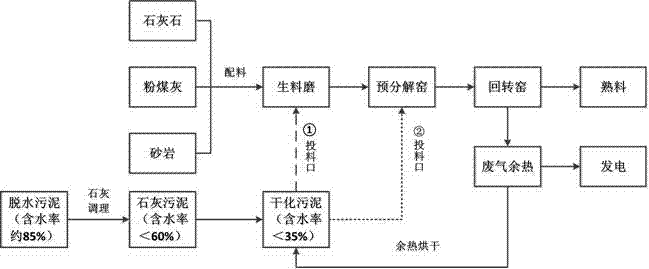

The invention relates to a method for adjusting and controlling a feeding mode of lime-dried municipal sludge cooperatively treated with a cement kiln. The method comprises the following steps: producing cement clinker by virtue of an existing novel dry-process cement clinker production line; recycling lime-stabilized sludge; specifically, conditioning the sludge with the water content being more than 80% by using lime, drying by virtue of residual heat of flue gas until the water content of the sludge is less than 35%, directly feeding the dried sludge to a vertical mill or a predecomposition kiln to serve as substitute raw material and fuel for cement raw materials, homogenizing, and firing in a rotary kiln to obtain the cement clinker, wherein the additive amount of the lime-dried sludge is 1wt%-21wt% of the cement raw materials; feeding from a proper feeding hole according to the components of the lime sludge, and effectively adjusting and controlling the cement raw materials to keep the cement production line stable and ensure good clinker quality. According to the method, the efficiency of cooperatively treating the lime-dried sludge with the cement kiln is improved, the sludge treatment capacity is high, the secondary pollution is alleviated, the consumption of calcium carbonate in the cement raw materials can be reduced, microelements in the sludge take the effect of a mineralizing agent, and the clinker can be conveniently fired. The method can provide a reference for study on cooperative treatment of solid wastes and the like during industrial production by the cement kiln.

Owner:TONGJI UNIV

Straw gypsum lightweight plate and preparation method thereof

InactiveCN101733832AStrong enoughReduce weightConstruction materialDischarging arrangementCelluloseIsolation effect

The invention discloses a straw gypsum lightweight plate, which comprises the following materials in part by weight: 90 to 100 parts of calcined gypsum, 20 to 40 parts of pulverized straw, 0.2 to 0.4 part of redispersible powder, 0.5 to 0.7 part of gypsum retarder, 0.2 to 0.4 part of polyvinyl alcohol (PVA) powder, 5 to 15 parts of white cement and 0.1 to 0.2 part of defoaming agent. The invention also discloses a method for preparing the straw gypsum lightweight plate, which comprises the following steps: firstly, pulverizing and putting straw in a reaction kettle for pretreatment; secondly, performing enzymolysis on the straw by adopting cellulose and centrifugalizing the straw to remove moisture: and thirdly, uniformly mixing in a stirring machine in a proportion of the raw material and water, paving mixture in a paving machine into a plate blank, performing fastening and cold compression on the plate blank to form the plate, and performing subsequent treatment to obtain the straw gypsum lightweight plate. The straw gypsum lightweight plate prepared by the method has the advantages of light weight, fireproofing, waterproofing, good sound isolation effect and good durability, is particularly suitable for an inner wall partition, a non-bearing wall and other building parts, and has good market prospect.

Owner:BEIJING UNIV OF TECH

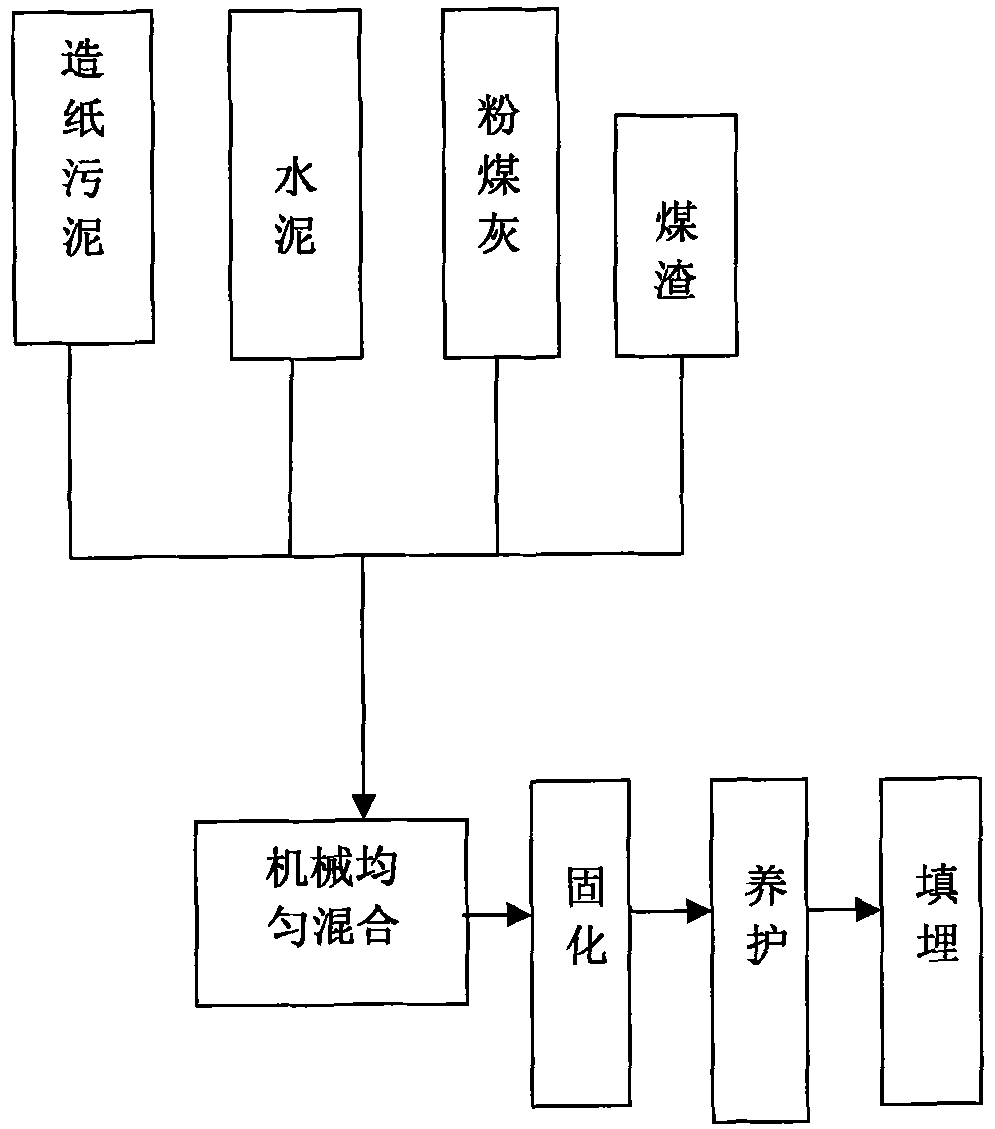

Solidification/stabilization treatment method for papermaking sludge

InactiveCN101885575AHarm reductionReduce cement consumptionSludge treatment by de-watering/drying/thickeningCinderWater content

The invention discloses a solidification / stabilization treatment method for papermaking sludge. The method comprises the following steps of: adding a solidifying agent into the papermaking sludge with water content of 70 to 80 percent according to a weight ratio of the sludge to the solidifying agent of 100:14-24, stirring the mixture to react for 10 to 15 minutes and uniformly mixing the mixture to form solidified block precursors; and laying solidified block precursors which are uniformly stirred in a sludge landfill site according to a thickness of 5 to 100cm, covering a water-proof membrane on the solidified blocks and curing the solidified blocks for 2 to 10 days by using a dry curing method to form sludge solidified blocks, wherein the compressive strength of the sludge solidified block is 160 to 320kPa, the COD concentration in solidified block leaching solution is 110 to 200mg / L, and the water content of the solidified block is 30 to 40 percent; and the solidifying agent comprises the following components in percentage by weight: 40 to 50 percent of aluminate cement, 15 to 25 percent of fly ash and 30 to 40 percent of cinder; toxic heavy metal ions are wrapped after the sludge solidification, so that the pollution of the sludge is reduced; the solidified sludge does not have foul smell of the original sludge and reduces the harm to an operator during the operation; and the method has the advantages of readily available raw material, low cost, stable effect and simple operation procedure.

Owner:GUANGDONG UNIV OF TECH

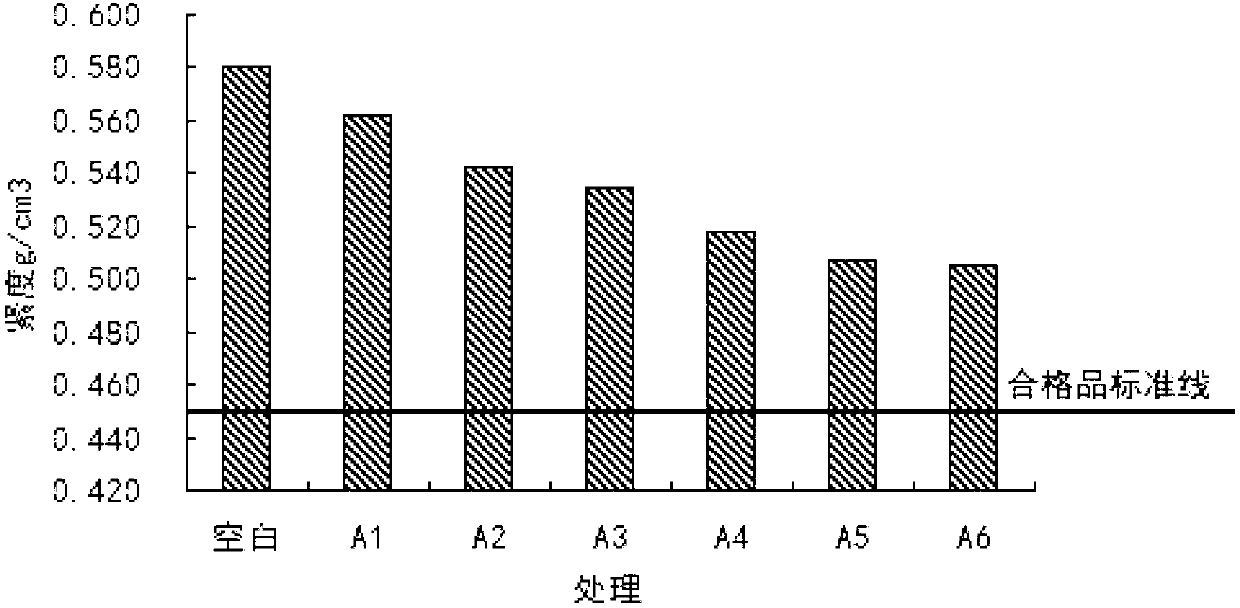

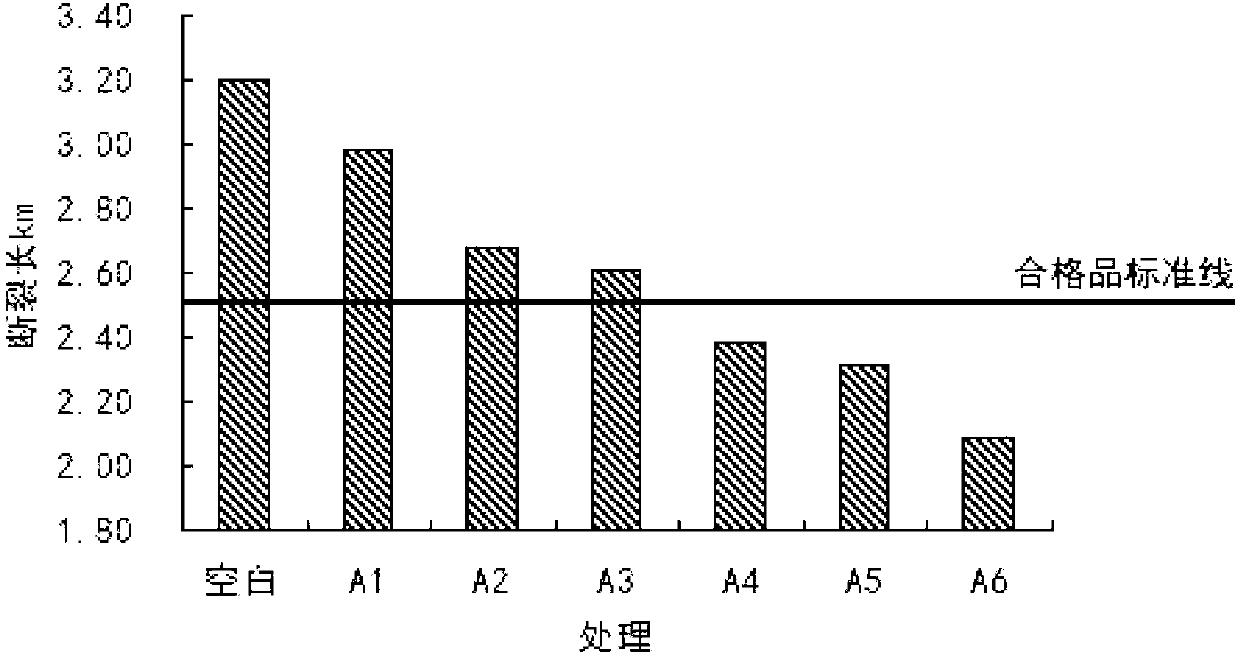

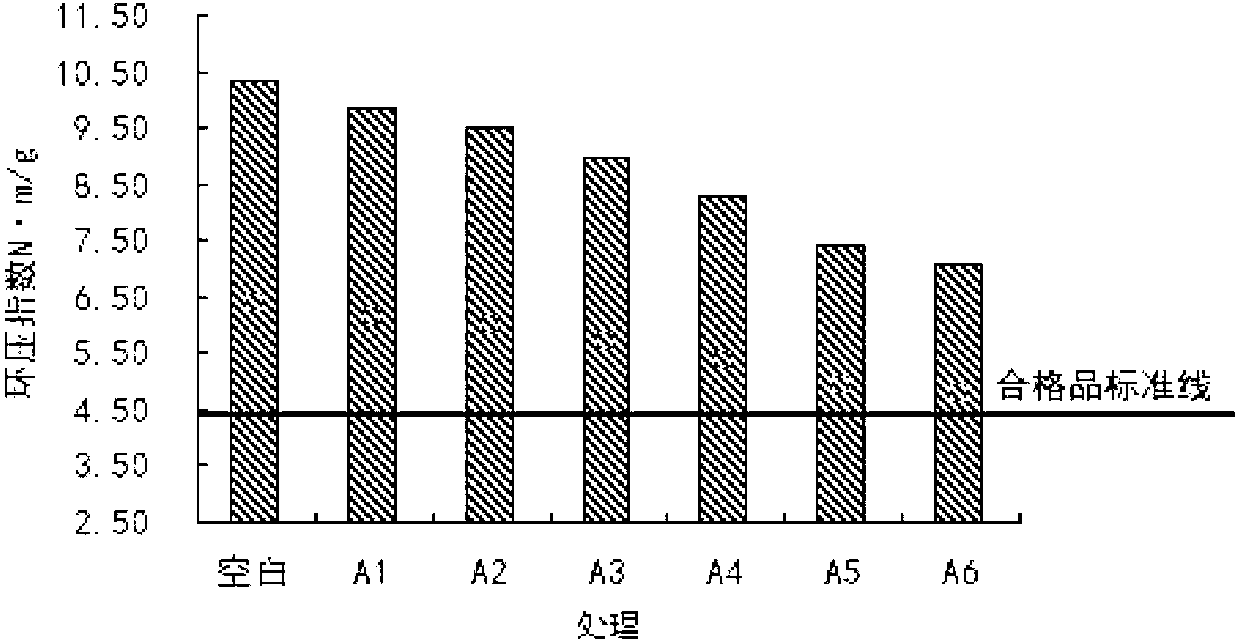

Method for blending corrugating base paper by utilizing secondary fiber after anaerobic digestion of paper mill sludge

ActiveCN103103866ASimple processEasy to operateSecondary cellulose fibresPaper-making machinesFiberResource utilization

The invention discloses a method for blending corrugating base paper by utilizing secondary fiber after anaerobic digestion of paper mill sludge, belonging to the fields of recyclable material and environmental protection. The method comprises the following steps of: by using the secondary fiber obtained after anaerobic digestion of paper mill sludge, waste paper pulp and softwood pulp as raw materials, separating and brooming the fiber through defibering and beating treatment, then dewatering, mixing, and then adding a reinforcing agent and a sizing agent to defiber; and adding paper pulp after defibering in a sheet machine so as to form uniform pages, and then pressing and drying to form corrugating base paper. The method is simple in process and high in operability, and the secondary fiber after anaerobic digestion of paper mill sludge is utilized for mixing with the waste paper pulp for papermaking, so that the energy of papermaking enterprises is saved, simultaneously efficient resource utilization of remaining secondary fiber after anaerobic digestion of paper mill sludge is realized, a new raw material source is created for papermaking factories, the cleaner production level of papermaking enterprises is improved, the resource utilization ratio of paper mill sludge is realized to the maximum, and the method has important engineering application value.

Owner:SOUTH CHINA AGRI UNIV

Soil conditioner and application method thereof

InactiveCN103820124AImprove fertilityPrevent proliferationOther chemical processesContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a soil conditioner. The soil conditioner comprises the following components calculated by dry weight, in percentage by weight: 80%-85% of sludge and 15%-20% of flyash. The soil conditioner is environmental-friendly and suitable for soil remediation in desolated mountains and mine areas, can effectively prevent harmful gases released by the sludge from dispersing into the atmosphere, and at the same time has the effects that the soil fertility is prominently improved and the site condition for a plant is improved as well. The soil conditioner provided by the invention is easy and practicable, enables waste to be profitable, and can quicken soil remediation and land reclamation.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Method for producing aldehyde-free soft board made of wheat straw

InactiveCN1861348ASimple processNo environmental pollutionDrying solid materials with heatCane mechanical workingAldehydeEngineering

A soft wheat straw board without aldehyde is prepared through breaking by 10-15 mm, drying, fine breaking by 3-8 mm, sorting, mixing with glue, mechanical spreading, pre-pressing, hot pressing, intermittent pressing, cutting for removing edges, and cooling.

Owner:江苏大盛板业有限公司

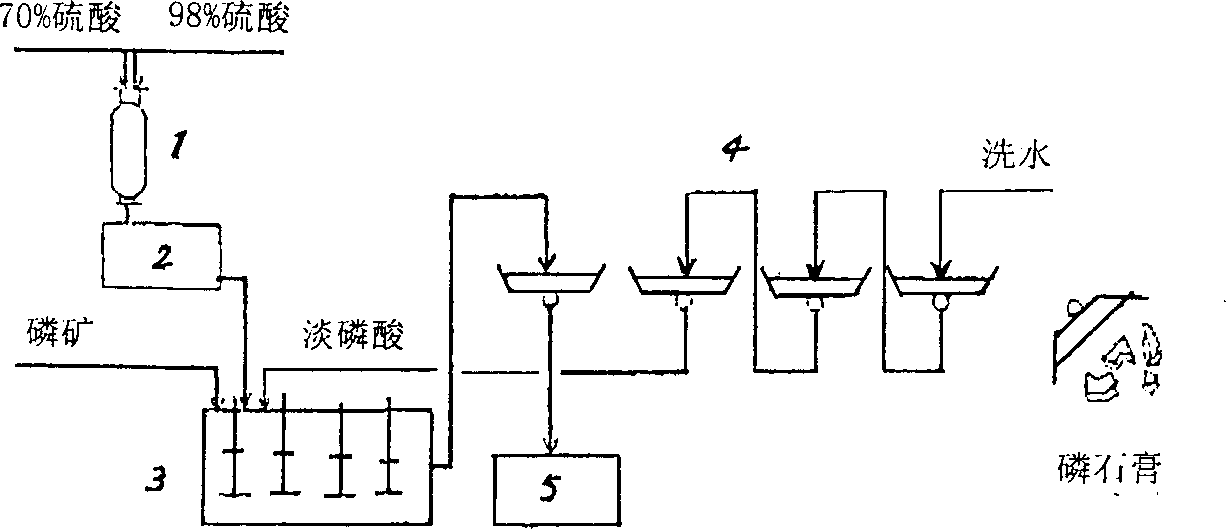

Process for preparing phosphoric acid from waste sulfuric acid as by-product of titanium oxide powder by wet method

InactiveCN1376635AGuarantee product qualityReduce manufacturing costSulfur-trioxide/sulfuric-acidPhosphorus compoundsEvaporationPhosphoric acid

A process for preparing phosphoric acid from the waste sulfuric acid as by-product in preparing titanium oxide powder features the counter-current contact of said diluted sulfuric with high-temp gas for instantaneous evaporation and concentration. The compound impurities contained in the diluted sulfuric acid is deposited with the raising up of temp and acid concentration. Its advantages are low cost and protection environment.

Owner:SICHUAN LOMON CORP

Urban waters mud local dewatered process

InactiveCN1792900ASolve the way outAvoid Migratory Secondary PollutionSludge treatment by de-watering/drying/thickeningTerrainHigh intensity

A method for in-situ dewatering of the silt in water system of urban area includes such steps as preparing the tubular bag whose size and shape are determined by the local terrain, digging the silt from the bottom of lake or river and conveying it in said tubular bags, and laying aside for filtering the water under the action of the pressure from bag wall and the dead weight while solidifying the solid for 3-5 weeks.

Owner:HOHAI UNIV

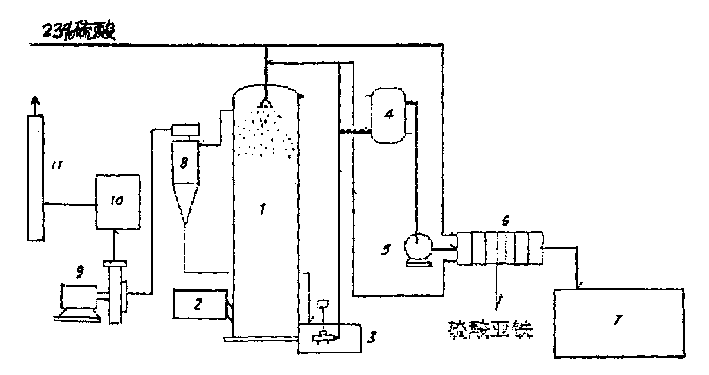

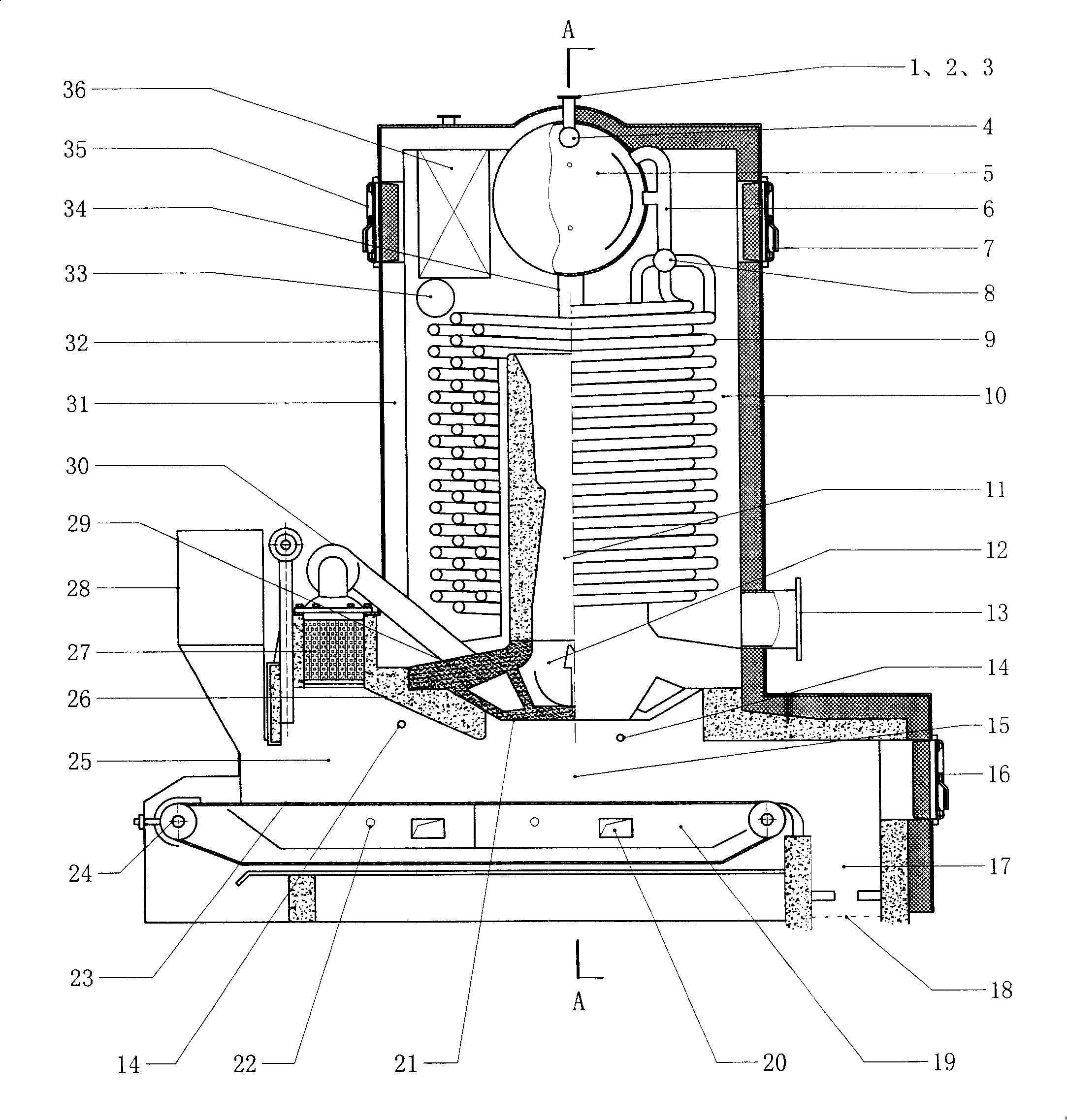

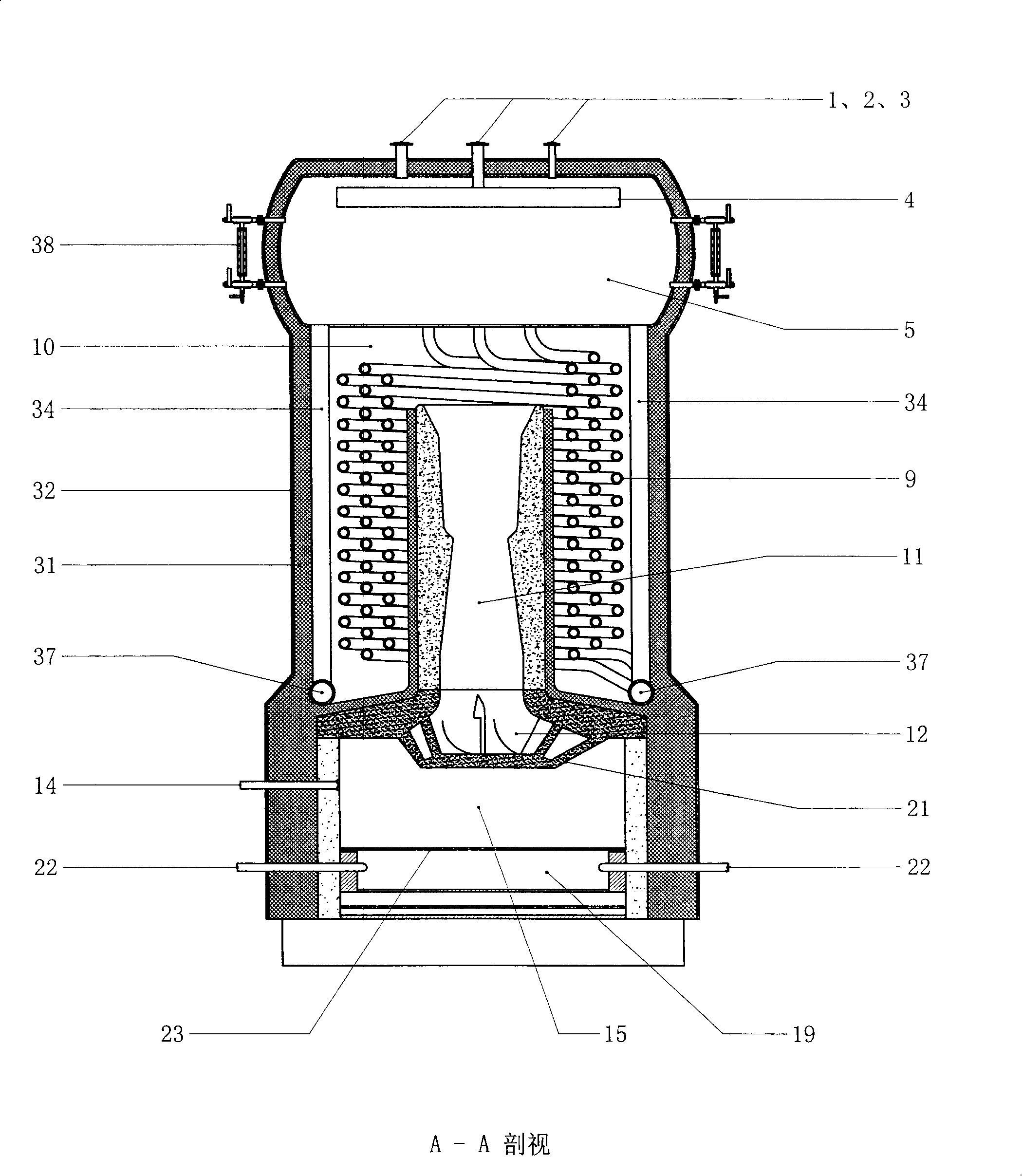

Dynamics gasification furnace and exhaust heat boiler composed by the same

InactiveCN101191059AReduce tensionSolve the way outEnergy inputWater heatersCoal briquetteClean energy

The invention discloses a dynamic gasification furnace and a waste heat boiler formed by the dynamic gasification furnace and relates to gasification equipment using solid fuel to produce synthesis gas. The invention has wide raw material suitability, and the raw materials comprise original msw, biomass, bio-coal briquette, coal-based briquettes, raw coal and loose coal. Through applying the invention, garbage and biomass gasification equipment with low investment, simple operation and easy popularization can be designed, can be operated as conventional boilers and can realize continuous raw material input, continuous deslagging and continuous synthesis gas output. The invention contributes to the active utilization of renewable energy, solves the problem of the treatment of domestic garbage and agricultural and agricultural and forest residues, ensures that the domestic garbage and agricultural and forest residues are transformed into clean energy, on one hand, the problem of environmental protection is solved, on the other hand, the situation of energy crisis is alleviated, creates conditions for promoting the overall coordinated and sustainable development of the economic society, and creates good development chance for rural areas which provide biological resources.

Owner:周开根

Waste oil-based environment-friendly mold separating agent and preparation method thereof

ActiveCN103409219ASolve the way outReduce the possibility of reflux tableDischarging arrangementLubricant compositionSeparating agentMineral oil

The invention discloses a waste oil-based environment-friendly mold separating agent and a preparation method thereof. The technical scheme provided by the invention adopts key points that the waste oil-based environment-friendly mold separating agent is mainly prepared from the following raw materials by weight percent: 20 to 40 percent of waste oil, 5 to 10 percent of emulsifier, 1 to 5 percent of wetting agent, 0.1 to 2 percent of sliding component and the balance of water. The invention further discloses the preparation method of the waste oil-based environment-friendly mold separating agent and the using method thereof. The waste oil-based environment-friendly mold separating agent provided by the invention is high in temperature resistance, has a good demolding effect, has strong rust preventing performance and is high in water scouring resisting performance, and the preparation method takes waste oil as raw material, gets rid of the dependence of a traditional mold separating agent on mineral oil, not only achieves waste comprehensive utilization, but also lowers the cost, and reduces environment pollutions and harm to human bodies.

Owner:ZHEJIANG NORMAL UNIVERSITY

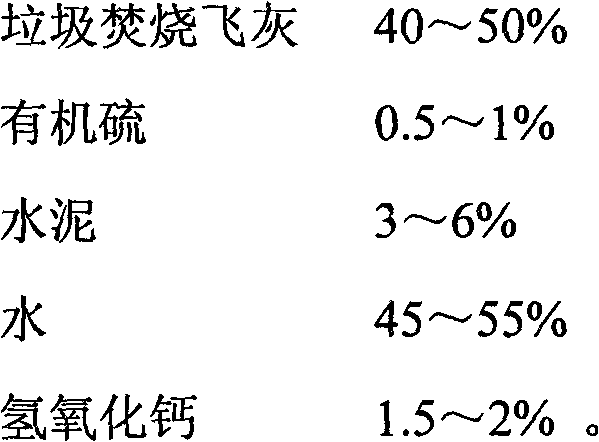

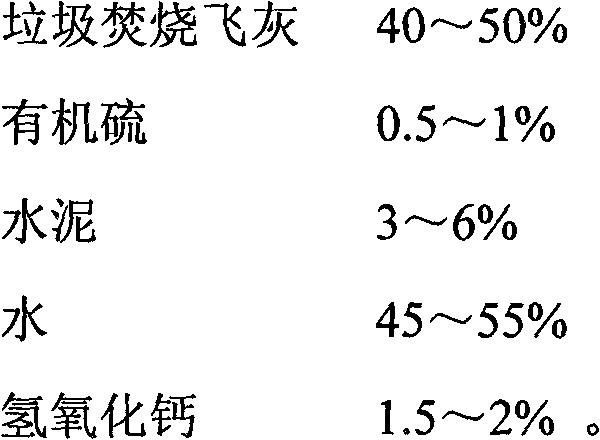

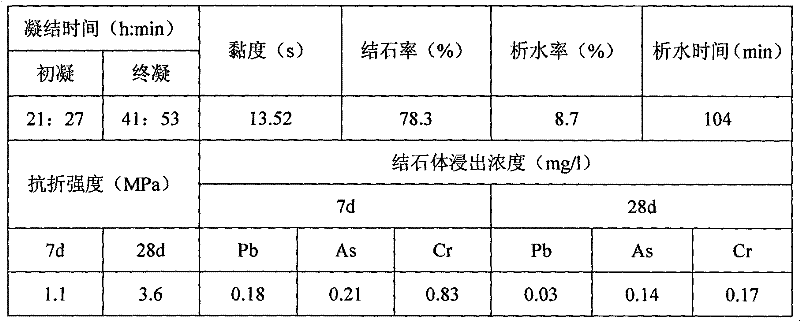

Grouting material for impervious curtain of refuse landfill and preparation method of grouting material

The invention relates to a grouting material for an impervious curtain of a refuse landfill and a preparation method of the grouting material. The grouting material comprises the following components in percentage by mass: 40 to 50 percent of MSWI (Municipal Solid Waste Incineration) fly ash, 0.5 to 1 percent of organic sulfur, 3 to 6 percent of cement, 45 to 55 percent of water, and 1.5 to 2 percent of calcium hydroxide. The method for preparing the grouting material comprises the following steps of: (1) weighing raw materials; (2) mixing the MSWI fly ash, the water and the organic sulfur, and uniformly stirring for 5 to 10 minutes; and (3) interfusing the cement and the calcium hydroxide, and uniformly stirring for 3 to 5 minutes. According to the grouting material, the problems of material selection difficulty, high cost, poor fluidity, low stability and poor impermeability of a conventional grouting material can be solved. The preparation method has the advantages of short processroute, simple operation, time saving and the like.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com