Dynamics gasification furnace and exhaust heat boiler composed by the same

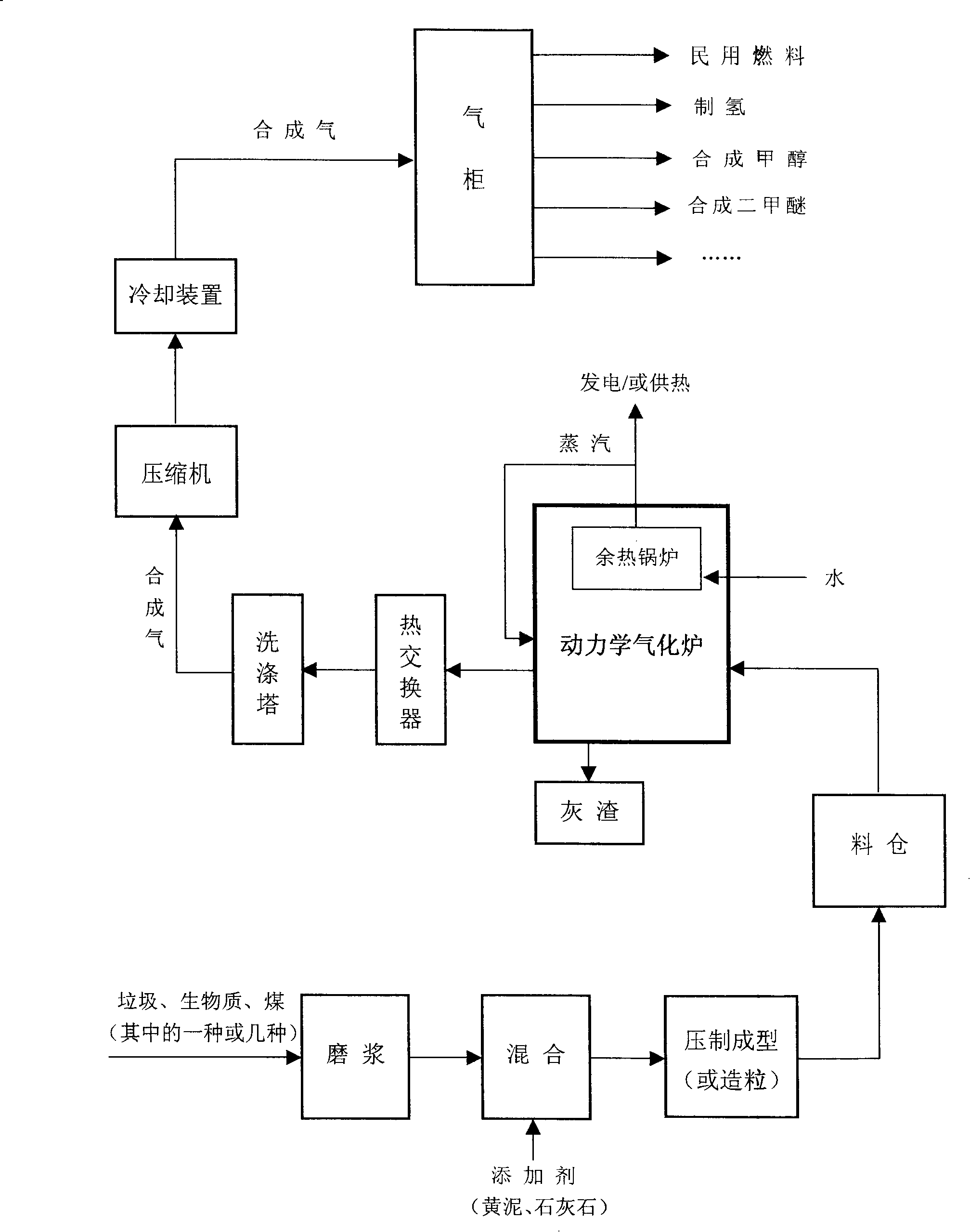

A waste heat boiler and kinetic technology, applied in coke ovens, water heaters, fluid heaters, etc., can solve problems such as cases and reports without commercial applications, and achieve the effect of alleviating energy shortage and solving environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

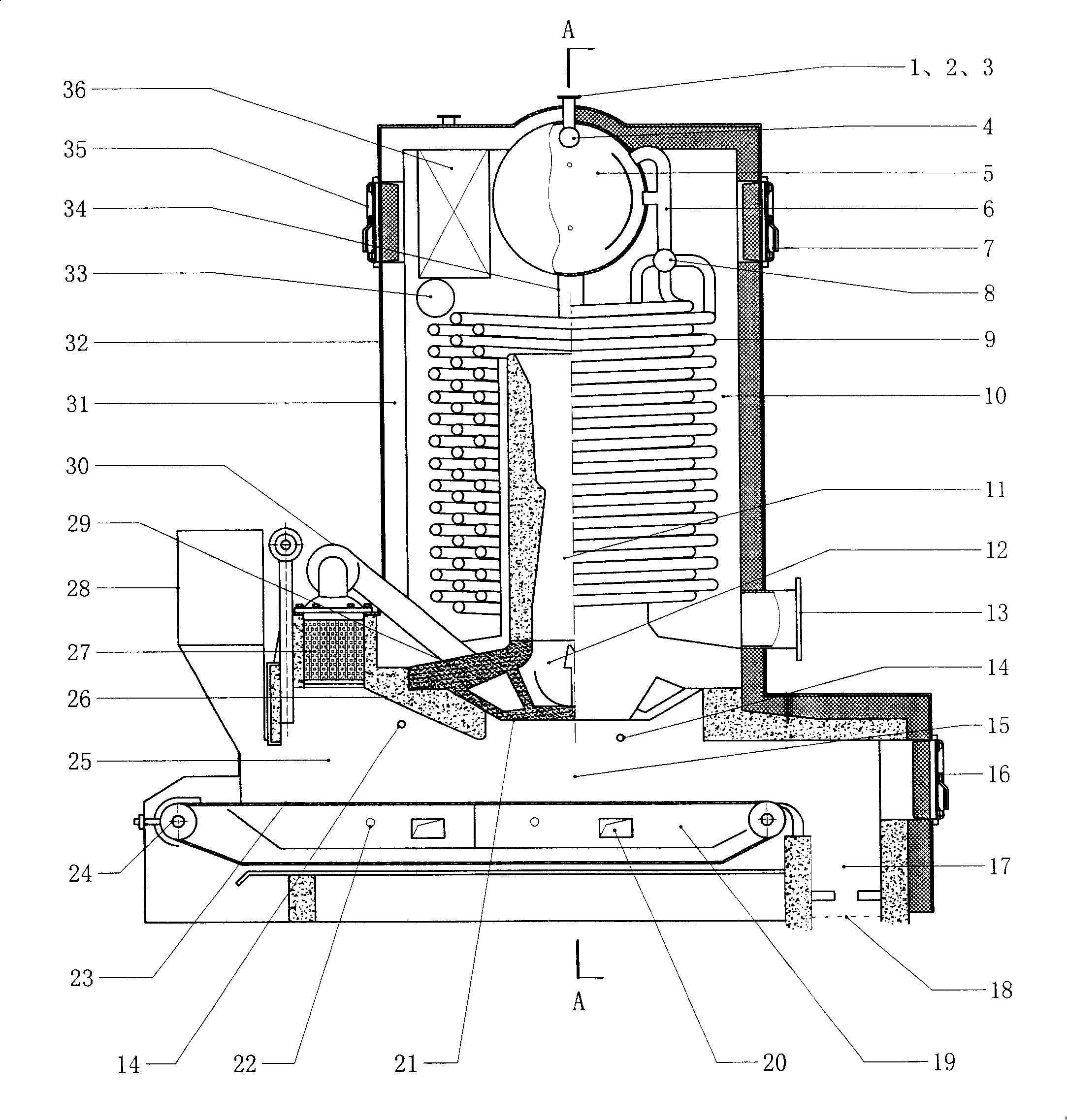

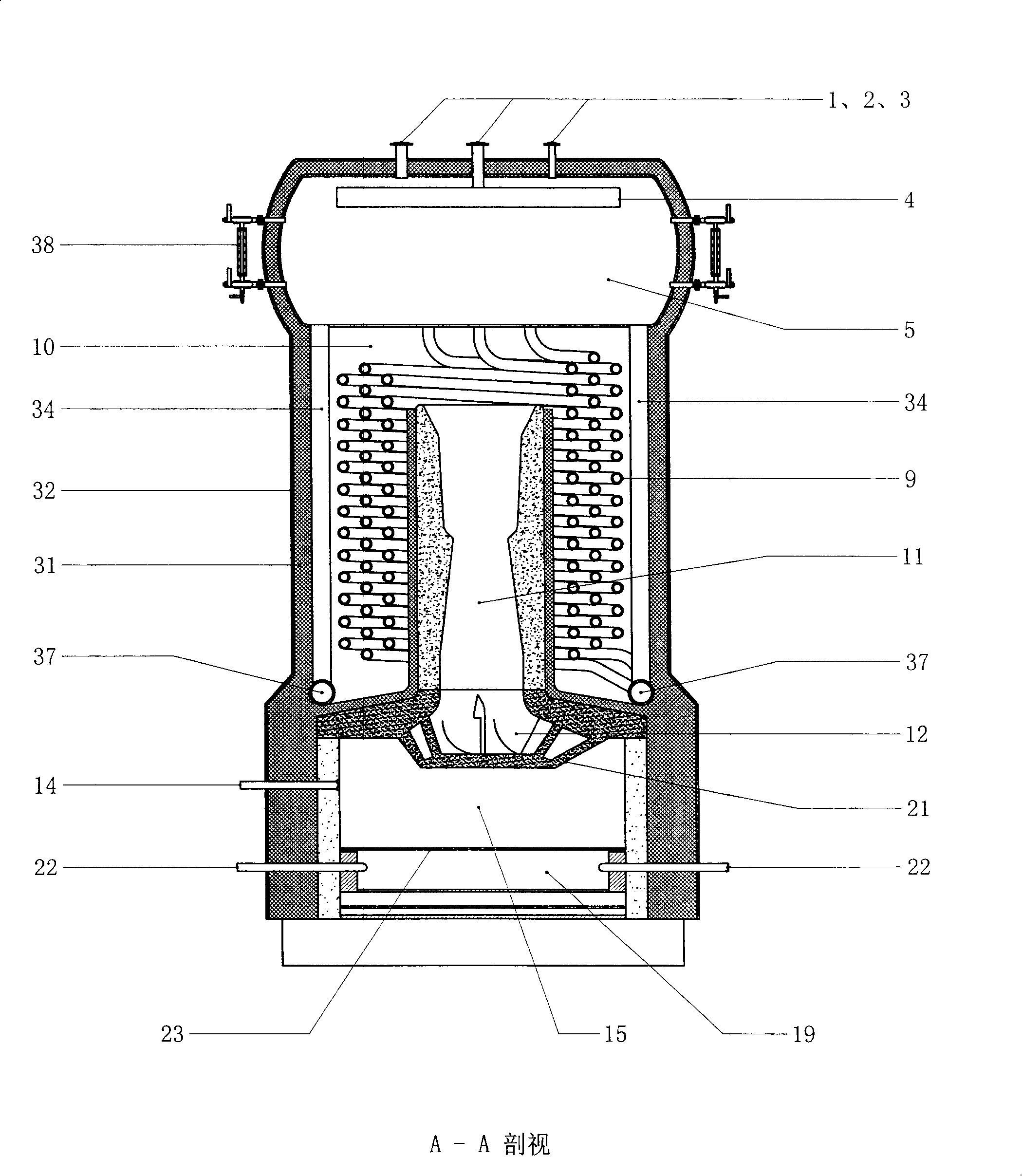

[0019] figure 2The illustrated embodiment is one of the gasifiers of the present invention, the equipment mainly consists of a drum (5), a heat receiver (9), a heat exchange chamber (10), a dynamic heat-gathering air duct (11), a dry distillation Pyrolysis zone (25), embers zone (15), fire grate (23), air distribution chamber (19), damper (20), steam nozzle (22), slag cooling chamber (17), induced air fan (30), feed bin (28), thermal insulation enclosure body (31), housing (32) form. Among them: the entrance of the dynamic heat-gathering air duct (11) has a swirl chamber (12) and a swirler (21); the dry distillation pyrolysis zone (25) communicates with the burnout zone (15) to form a combustion gasification furnace There are dechlorination / desulfurization agent (27) and reflective drying (26) above the dry distillation pyrolysis zone (25); the top of the burnout zone (15) is a cyclone (21), a cyclone chamber (12), and the cyclone The top of the flow chamber (12) is the dyn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com