Patents

Literature

962 results about "Coal briquette" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

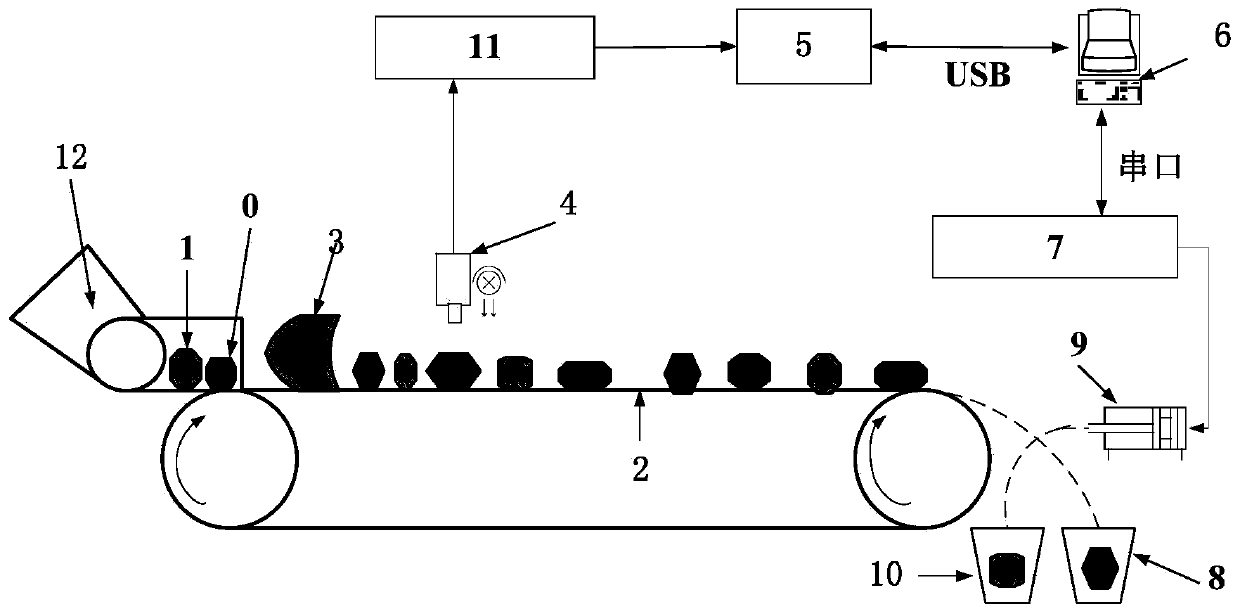

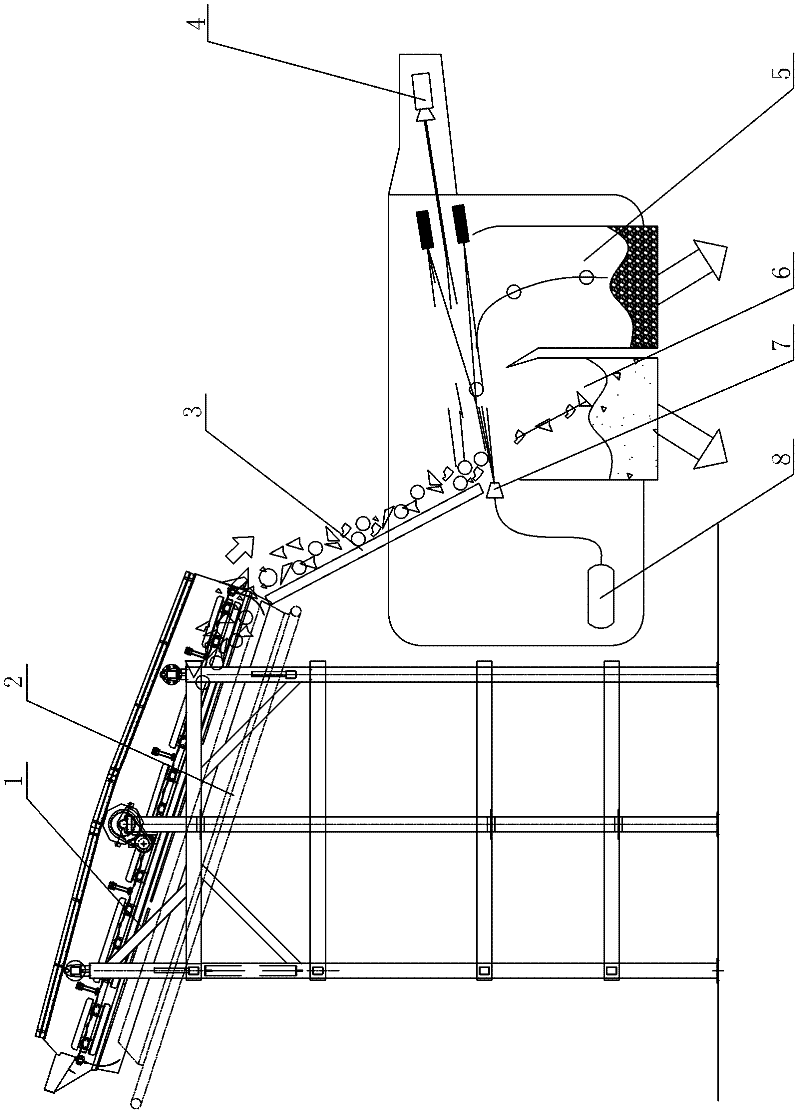

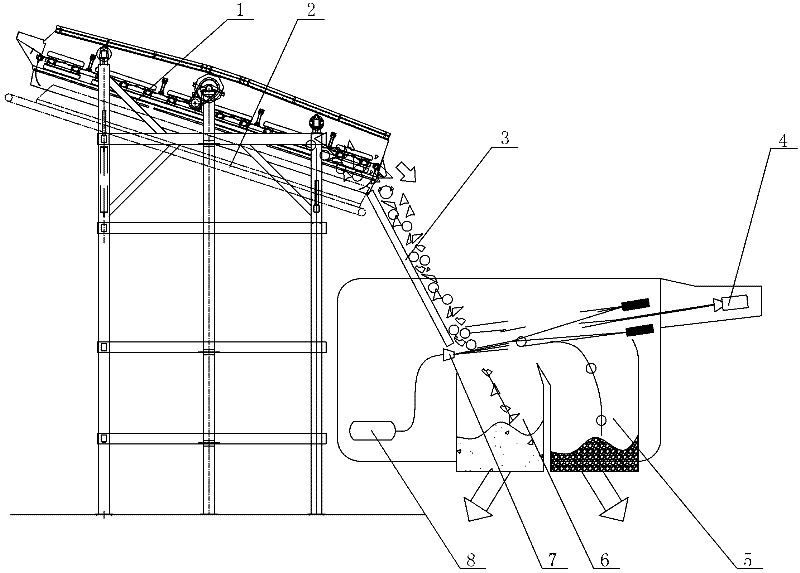

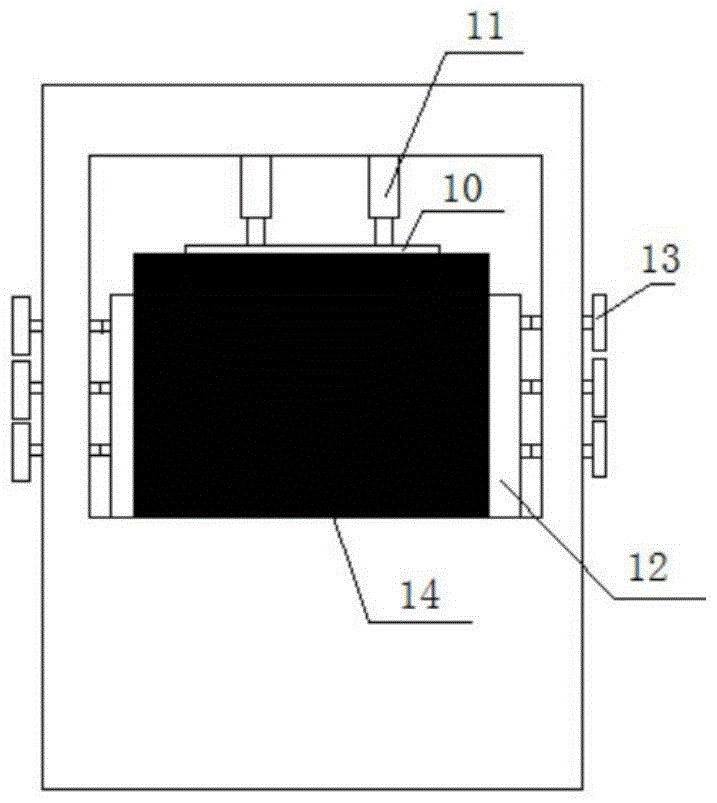

Separation device for coal and waste rocks and separation method thereof

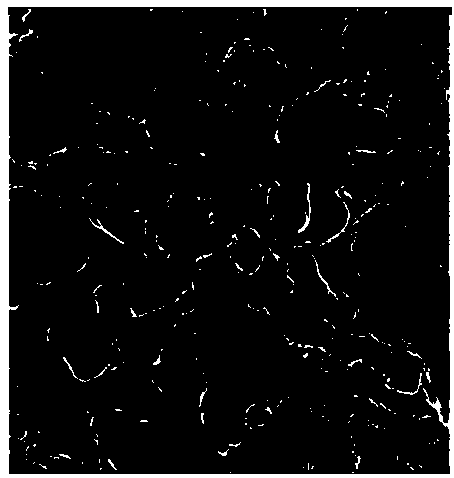

InactiveCN103473568AReduce pollutionHigh sorting accuracyCharacter and pattern recognitionSortingCoal briquetteFeature extraction

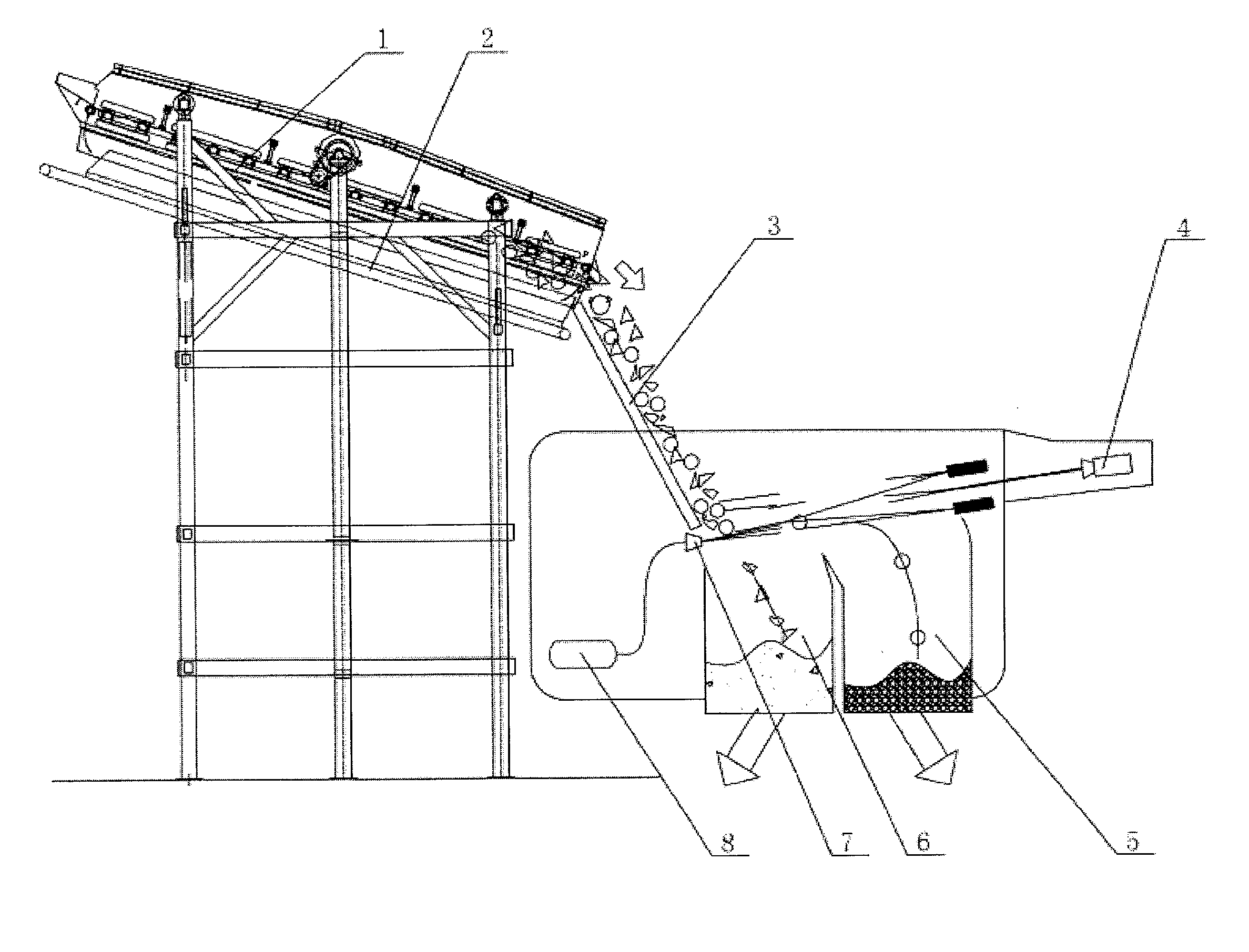

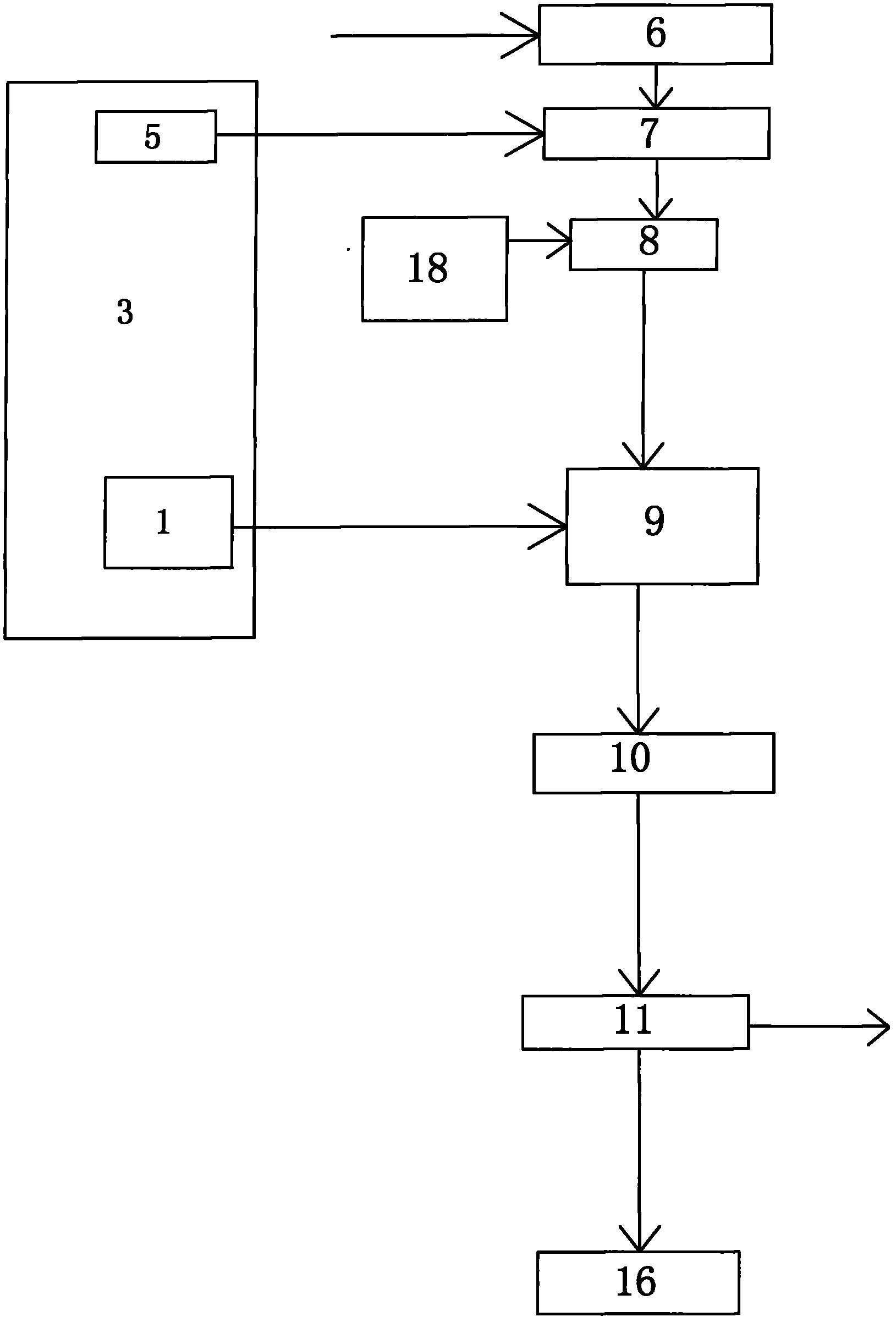

The invention provides a separation device for coal and waste rocks. The separation device comprises a vibrating coal feeder, a conveying belt, a queuing device, an image sensor, an image collector, a microprocessor, an upper computer, a separation controller, a high-pressure spray gun, a coal briquette channel and a waste rock channel. Information of the image sensor is processed in real time through the microprocessor and then sent to the upper computer, image information preprocessing, feature extraction, soft measurement model establishing and separation signal outputting are carried out, separation signals are sent to the separation controller, raw coal naturally falls into the coal briquette channel, and the waste rocks fall into the waste rock channel through the high-pressure spray gun. The invention further provides a separation method. The separation device and the separation method have the advantages that the defects of a low recognition rate, heavy environmental pollution and the like existing in an existing coal and waste rock separation method are effectively overcome, the recognition rate of the separation method is high, the environmental pollution can be effectively lightened, the separation device is small in size, easy to install and maintain and low in cost, separation precision and the automation degree of the raw coal are greatly improved, and manual waste rock picking is replaced.

Owner:SHANDONG UNIV OF SCI & TECH

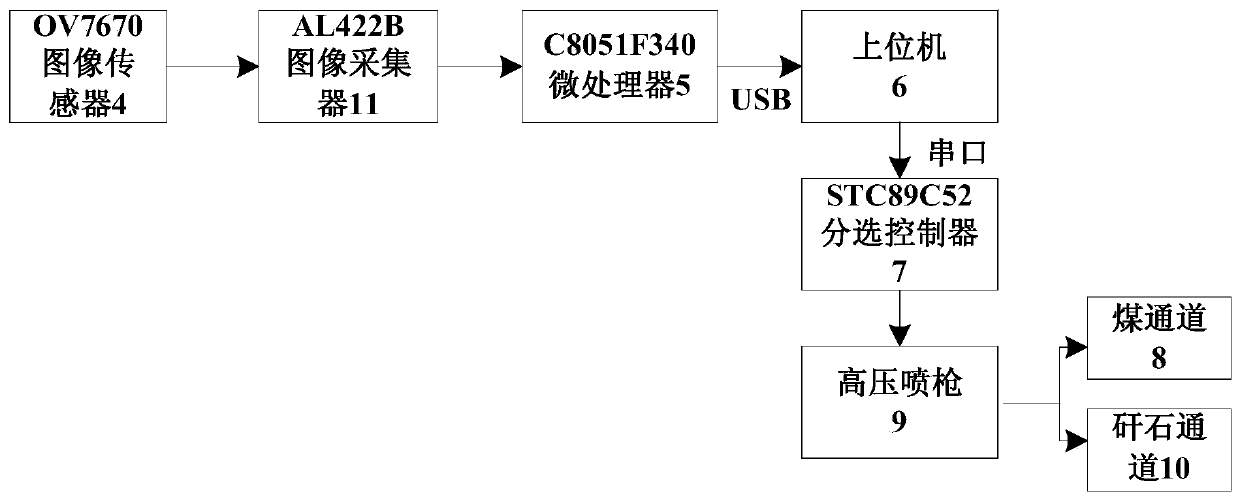

Preparation method of high strength-hyper reactivity iron containing coke

InactiveCN103468287AReduce the temperatureEmission reductionBlast furnace detailsSpecial form destructive distillationCoal briquettePtru catalyst

The invention relates to a preparation method of high strength-hyper reactivity iron containing coke. The preparation method comprises the steps of screening twice to obtain a proper coal sample, drying the coal sample together with iron ore powder which is less than 74 microns in granularity and is taken as a catalyst, and uniformly mixing to obtain a mixed material, adding water which is 9-11% of the mass of the mixed material in a coking reaction tank, and smashing and sealing to obtain a coal cake, wherein the iron ore powder is 0-15% of the mass of the mixed material and stacking density of the mixed material in the coking reaction tank is 950-1150kg / m<3>, rapidly placing the coking reaction tank in the center of a hearth when heating a coke oven to 800 DEG C, increasing temperature of the oven to 1000-1100 DEG C and preserving the heat for 6-8 hours, taking coke out of the reaction tank, and cooling to obtain the high strength-hyper reactivity iron containing coke. The iron containing coke which is close to conventional coke in strength is prepared under a condition that a binding agent is not added, thus reducing addition quantity of strongly adhesive coal in coking coal; the preparation method is low in slag generation in a blast furnace iron-making process in comparison with high-calcium coal coke, and enhances loss reaction of the coke.

Owner:CHONGQING UNIV

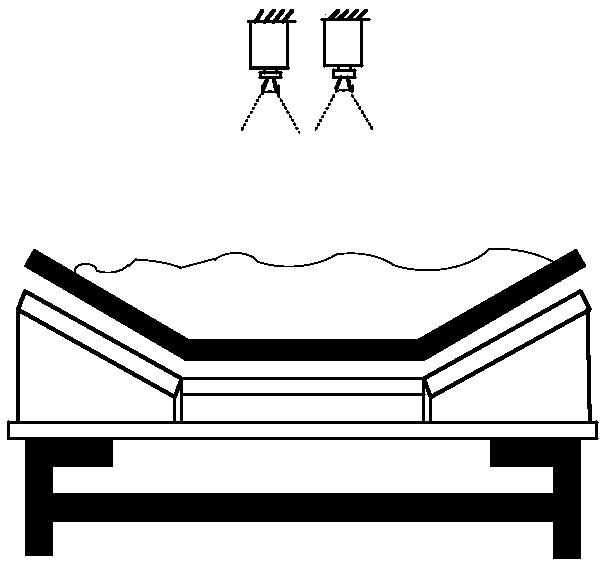

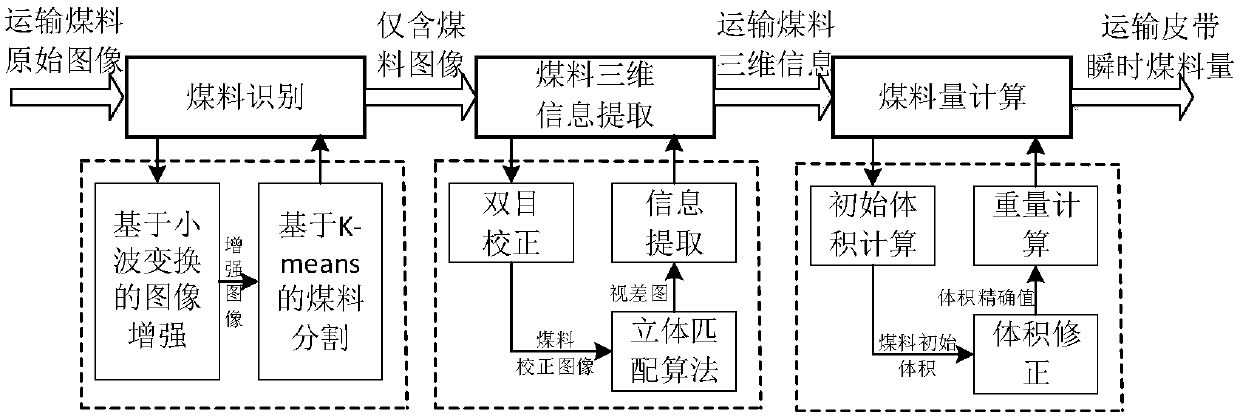

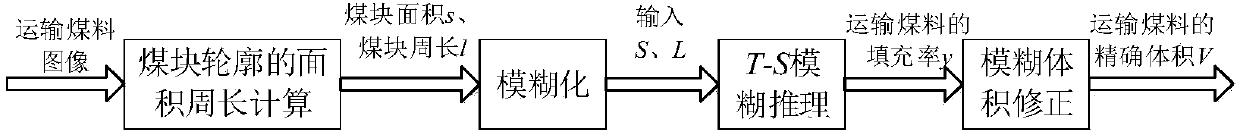

Mining belt conveyor coal amount detection method based on binocular stereo vision depth perception

ActiveCN107424143AImprove calculation accuracySatisfactory measurement errorImage enhancementImage analysisCoal briquetteBinocular stereo

A mining belt conveyor coal amount detection method based on binocular vision depth perception is provided. A speed sensor is installed on a belt conveyor to collect speed signals of a conveying belt in real time and transmit the signals to a host computer. Two parallelly placed cameras are installed above the conveying belt to collect conveyed coal material images in real time and transmit the images to the host computer for image analysis and processing. The specific steps are as follows: a multi-resolution wavelet transform algorithm is used to enhance the conveyed coal material images, and a K-means clustering algorithm is combined to segment the images only with the coal material; a binocular vision method is used to acquire three-dimensional point cloud information of the coal material; and a Delaunay algorithm is used to calculate an initial volume of the conveyed coal material, a T-S fuzzy logical reasoning method is combined to correct the volume of the conveyed coal material, and a coal amount formula is applied to achieve detection of the amount of the coal material. The method of the invention can measure the amount of the currently conveyed coal material in real time according to the characteristics of the coal briquette on the surface of the conveyed coal material, has few errors and high effectiveness, has a practical value and is convenient for popularization.

Owner:CHINA UNIV OF MINING & TECH

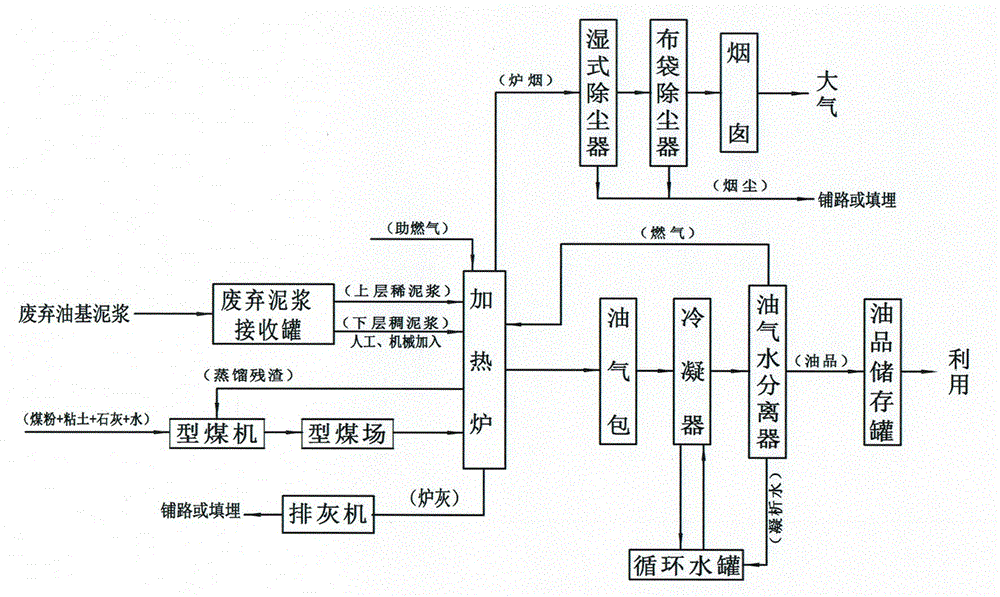

Process and system for dry coal separation by coal gangue removal

InactiveUS20140291213A1High separation precisionImprove efficiencySievingGas current separationCoal briquetteControl system

The process for coal separation includes two steps of size grading and oversize raw coal separating. A size range is obtained through size grading, then the obtained raw coal is separated by a sensor system, and coal briquettes with high impurity contents are blown into an impurity chamber through high-speed compressed air, thus improving the separating accuracy and efficiency. The system for coal separation includes a dry screening machine, an oversize raw coal conveying chute, a sensor system, a control system, nozzles and a flow division chamber. The tail end of the dry screening machine is connected with the charge end of the chute; the sensor system and the discharge end of the chute are correspondingly arranged; the flow division chamber is arranged below the chute; and the nozzles operated and controlled by the control system are arranged between the discharge end of the chute and the flow division chamber.

Owner:SHANDONG BO RUN IND TECH

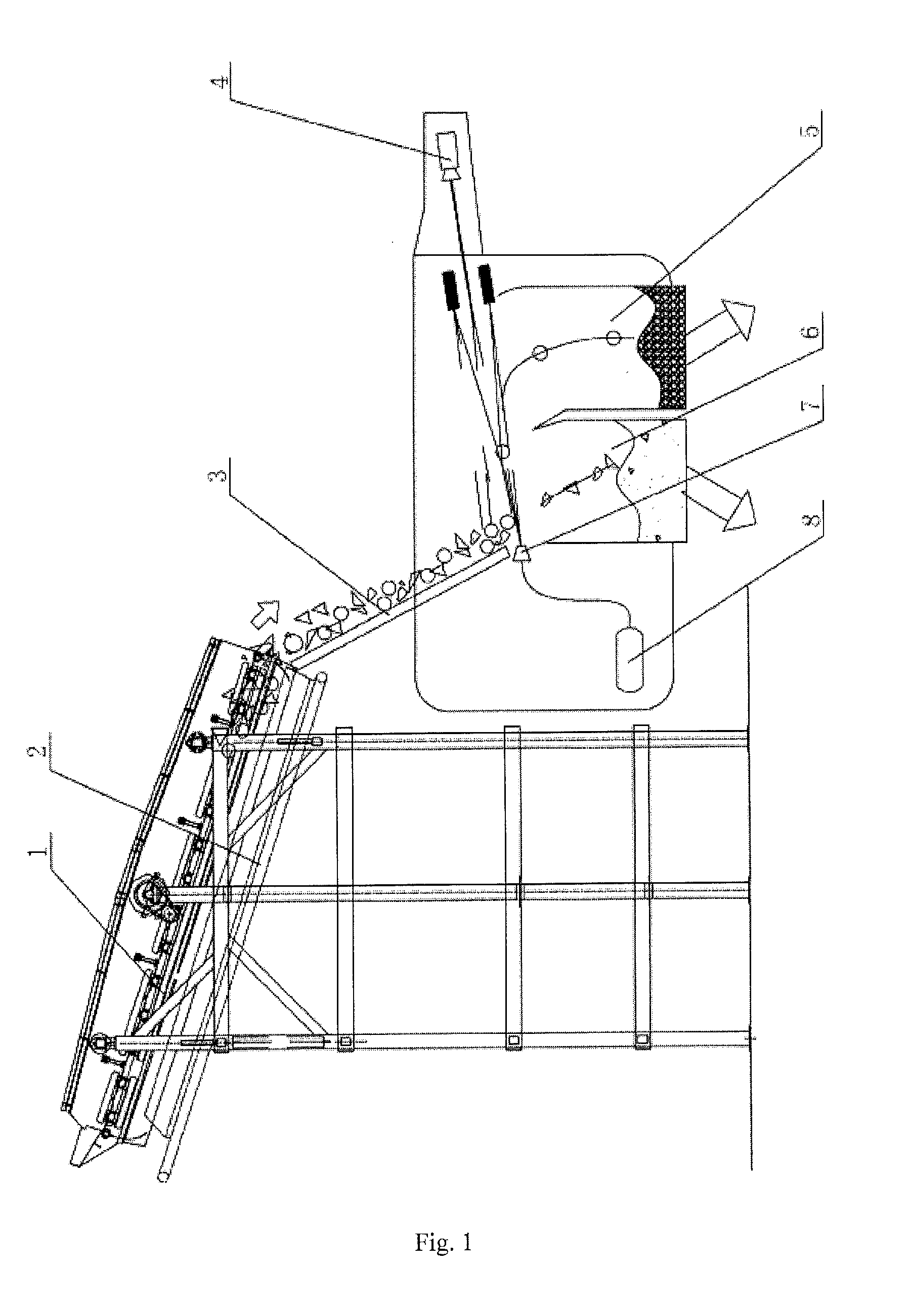

Resource utilization method of oil and gas field well drilling abandoned oil-base mud

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

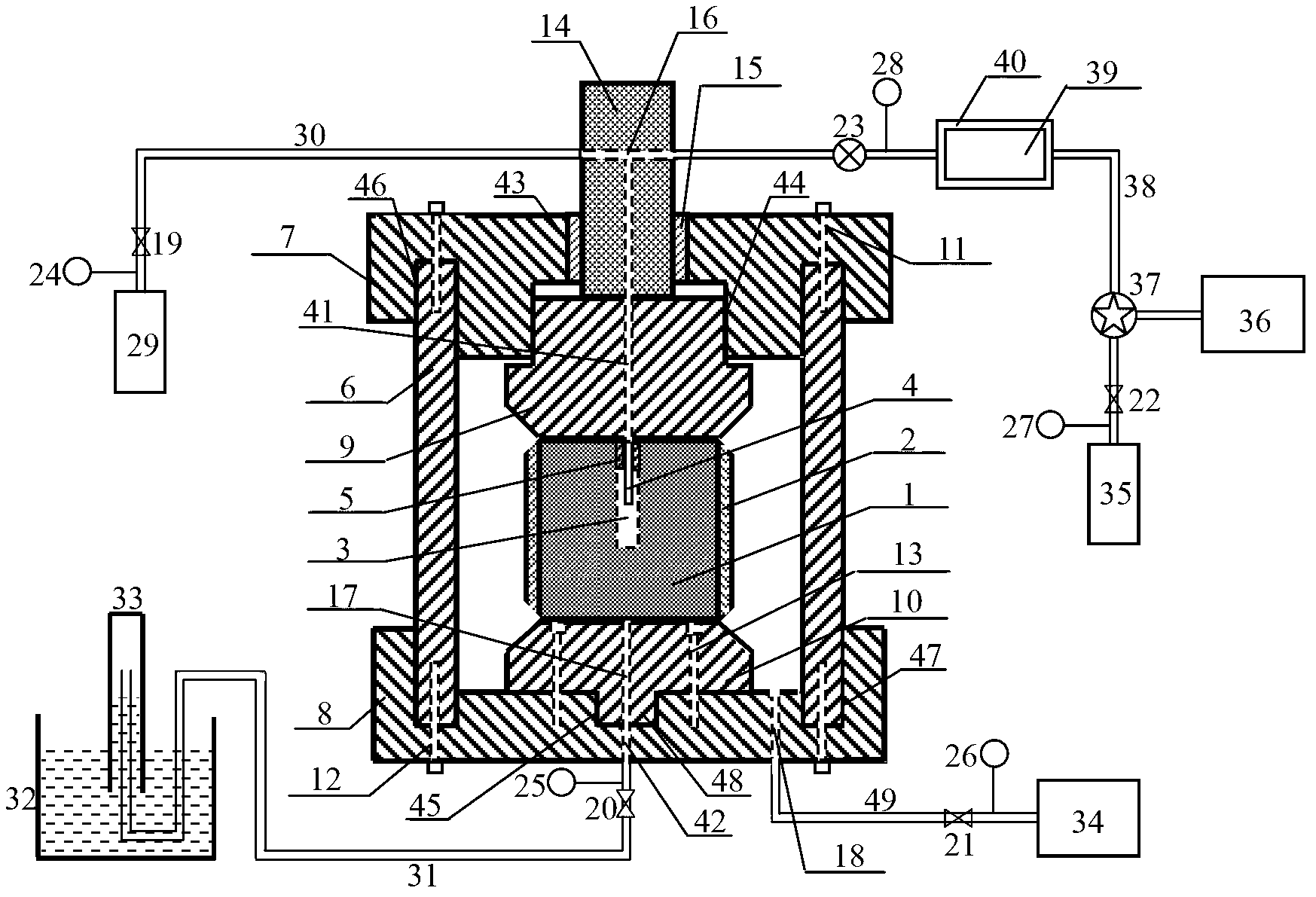

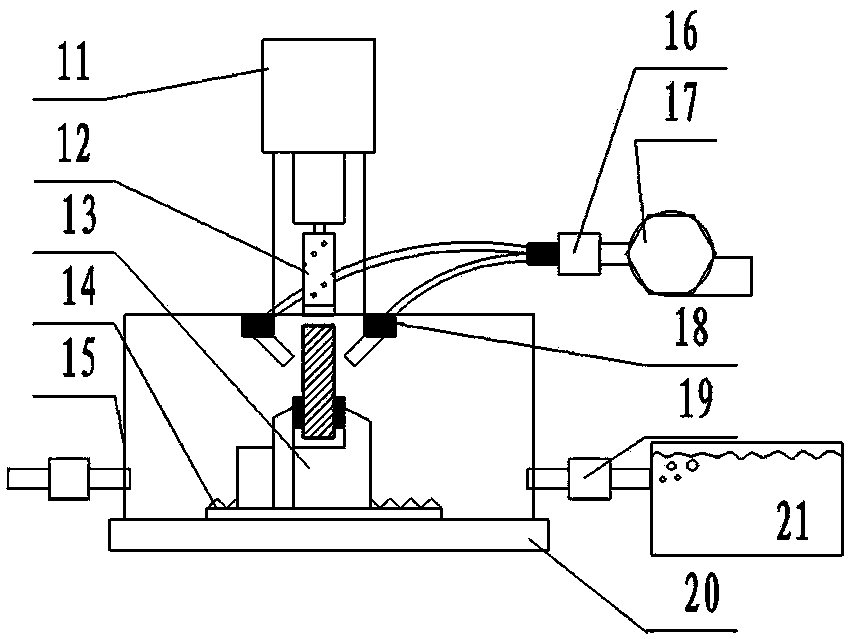

Low-permeability coal high-pressure gas cycle pulse fracturing anti-reflection experimental method

InactiveCN103234891AMonitor disseminationMonitor the laws of disseminationPermeability/surface area analysisCoal briquetteExperimental methods

Owner:LIAONING TECHNICAL UNIVERSITY

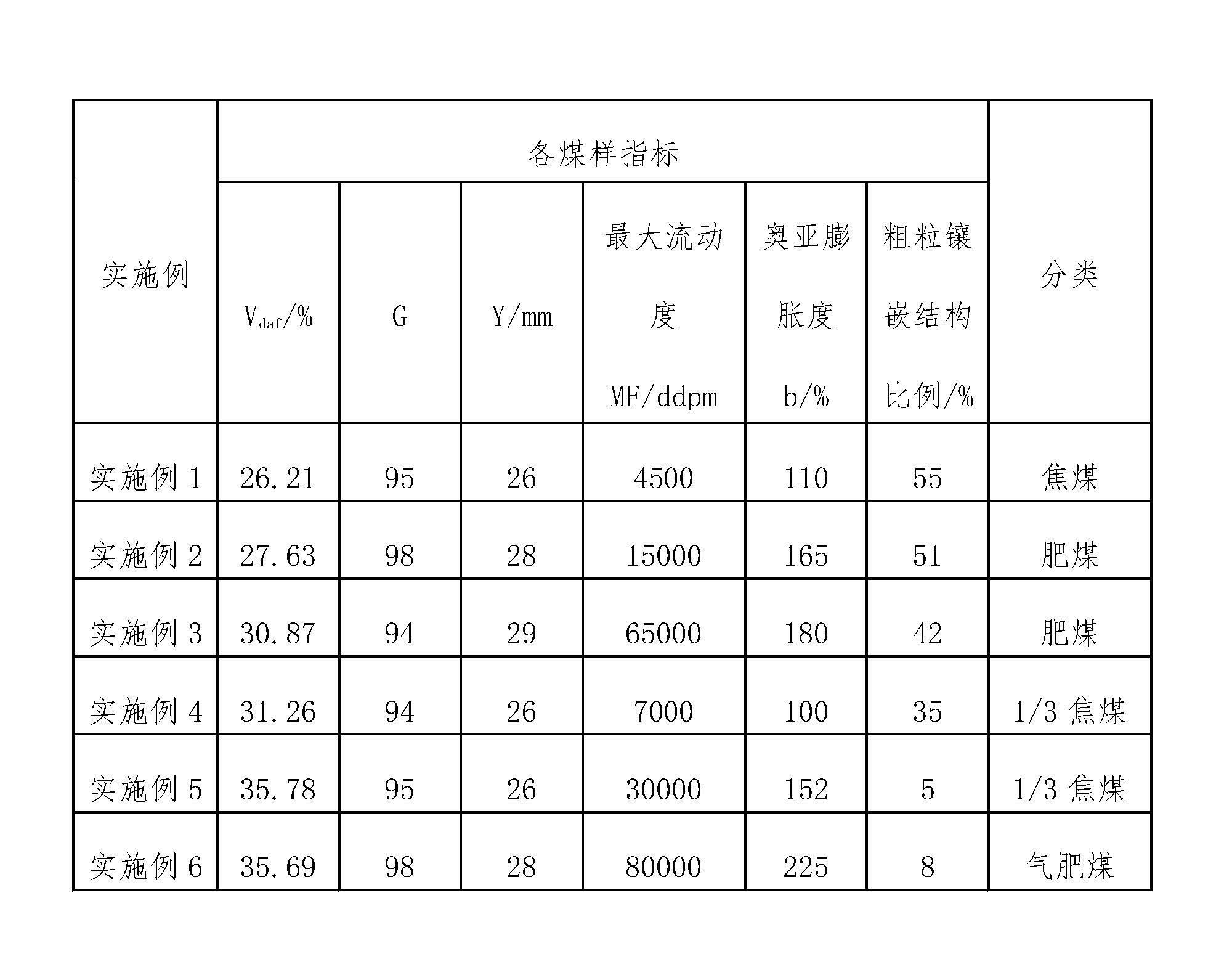

Russian fat coal participant coking and coal blending method

The invention discloses a Russian fat coal participant coking and coal blending method, which comprises a step of mixing and blending various single coking coals. The single coking coals in percentage by weight comprise 0-6 percent of gas coal, 8-12 percent of Russian fat coal, 15-18 percent of 1 / 3 coking coal of G being more than 85, 12-15 percent of 1 / 3 coking coal of G being less than 85, 15-20 percent of coal of G being more than 85, 20 percent of coal of G being less than 85 and 15-20 percent of lean coal. Under the process condition without stage crushing, coal briquette process or tamping coking, the method of the invention reasonably and efficiently utilizes the Russian fat coal, the coke quality is not deteriorated, and the coal blending cost can be reduced.

Owner:武汉钢铁有限公司

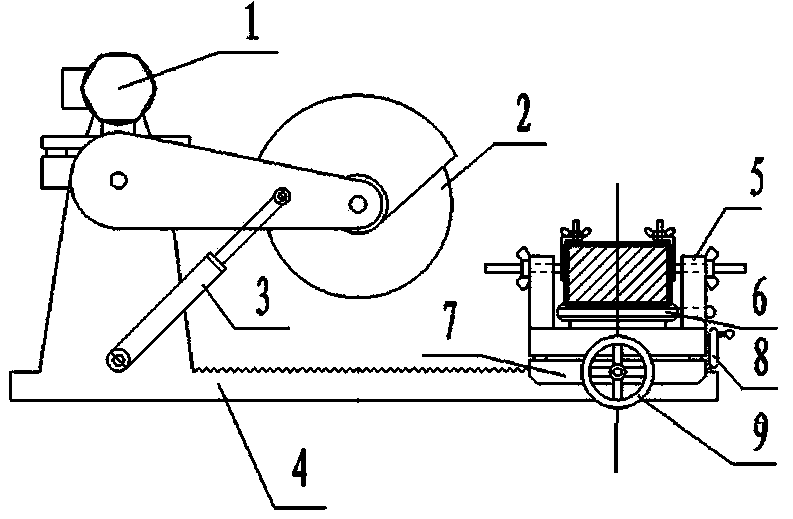

Dry-type joint coal rock sampling device and sampling method thereof

InactiveCN103837368AImprove stabilityAvoid crackingWithdrawing sample devicesCoal briquetteInstability

The invention relates to a dry-type joint coal rock sampling device and a sampling method thereof. The dry-type joint coal rock sampling device comprises a cutting device and a sampling device, wherein the cutting device is provided with a cutting base, one end of a cutting wall is connected with the cutting base, a saw blade is mounted on the other end of the cutting wall, and a height regulating device is mounted between the cutting base and the saw blade; the cutting base further comprises a cutting track; a sliding rail base is connected with the cutting track, the sliding rail base is a two-way sliding rail and capable of moving along the cutting track or in a direction perpendicular to the cutting track, and a base translation control handwheel is mounted on the sliding rail base; a turnplate is mounted at the center of the sliding rail base and is provided with a handwheel, and rock samples are arranged on the turnplate; the sampling device comprises a sampling base, a clamping device, a diamond sampling drill bit, an openable transparent cover, a refrigerating device, an air blowing device and an exhaust fan. The dry-type joint coal rock sampling device is capable of either effectively avoiding coal briquette falling and coal rock cracking due to instability in the coal rock cutting process or accurately controlling the cutting thickness of the coal rock, and therefore, the purpose of accurate cutting is achieved.

Owner:嘉兴骏博精密机械有限公司

Process and system for sorting coal by discharging coal gangue through dry method

ActiveCN102416386ACompact structureSmall footprintSievingGas current separationCoal briquetteControl system

Owner:BIRTLEY TIANJIN IND EQUIP

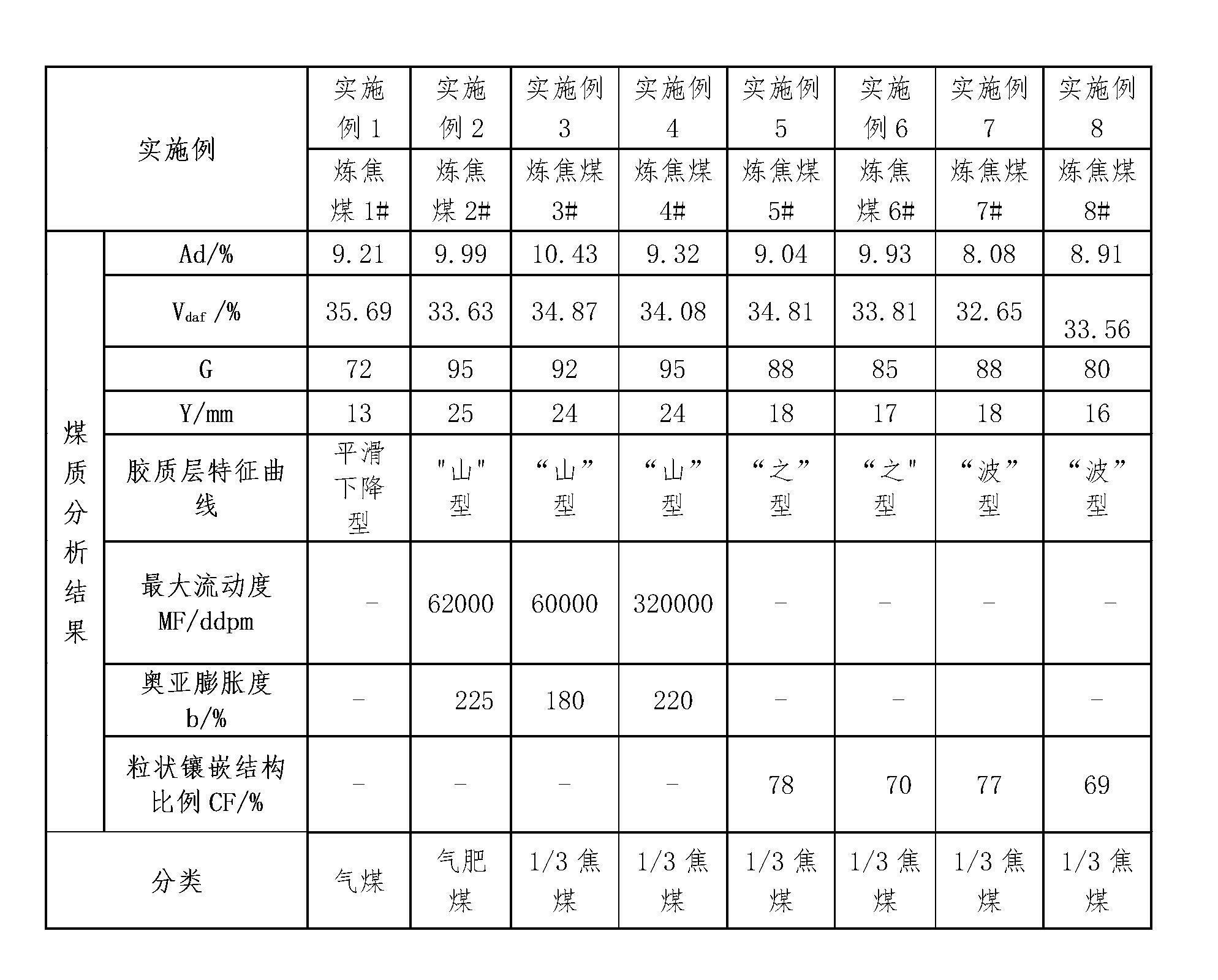

Method for sorting coking coal with 32-37% volatile component and coking blending method

The invention discloses a method for sorting coking coal with 32-37% volatile component and a coking blending method. A dried ash-less volatile component Vdaf of the coking coal is greater than or equal to 32.0-37.0%, a caking index G value is 65, and a maximum thickness Y value of a gelatinous layer is smaller than or equal to 25.0mm. According to the method, the coking coal is respectively divided into gas coal, 1 / 3 coking coal and gas-fat coal according to three indexes including a gelatinous layer characteristic curve, a maximum fluidity and an Arnu-Audibert's dilatometer, so that the coking blending method for the coking coal is determined. According to the method which is used for blending and coking, the quality of the coke is stably improved, the fluctuation range of CSR (China standard rubber) is reduced remarkably, and the coke ratio of a blast furnace is reduced under a condition that coal moisture control and coal briquette technologies and a pre-grinding process are not adopted. And the CSR of coke smelted by 6m above coke ovens is 63%.

Owner:武汉钢铁有限公司

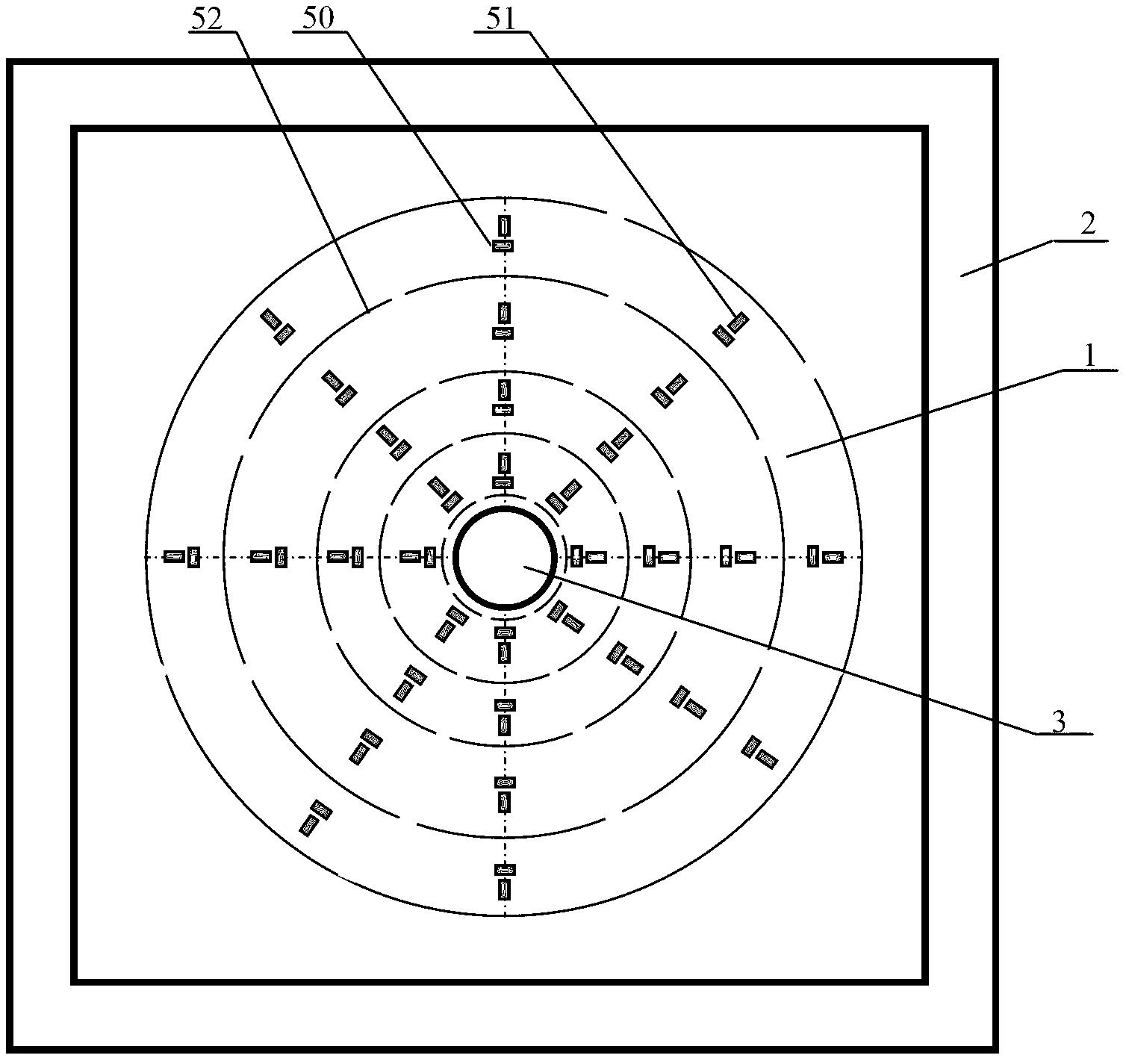

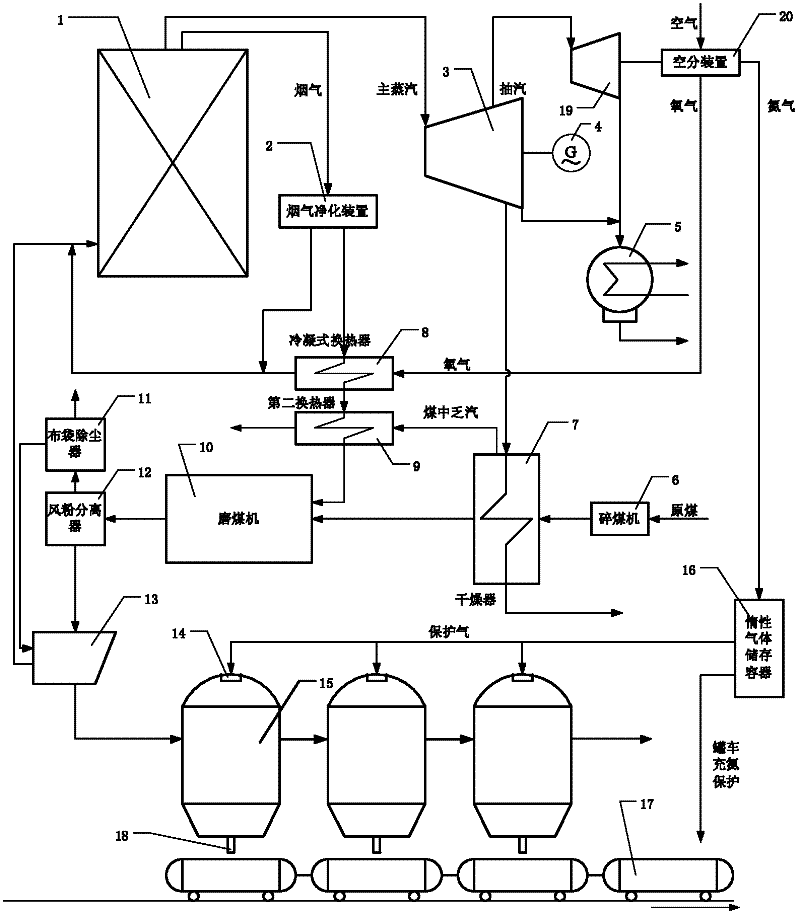

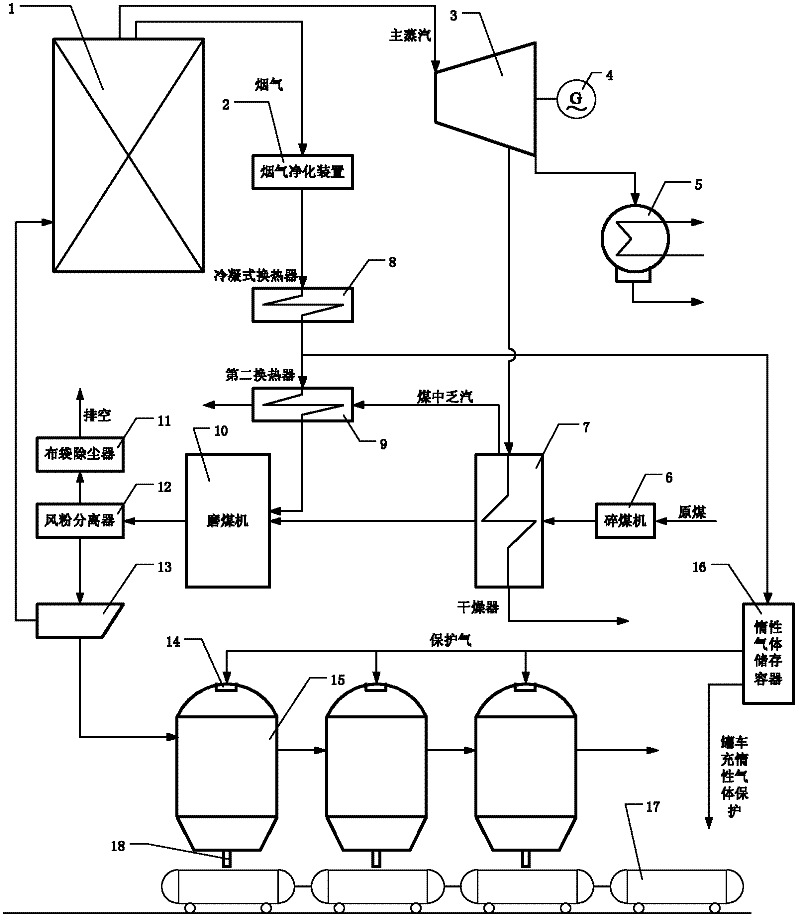

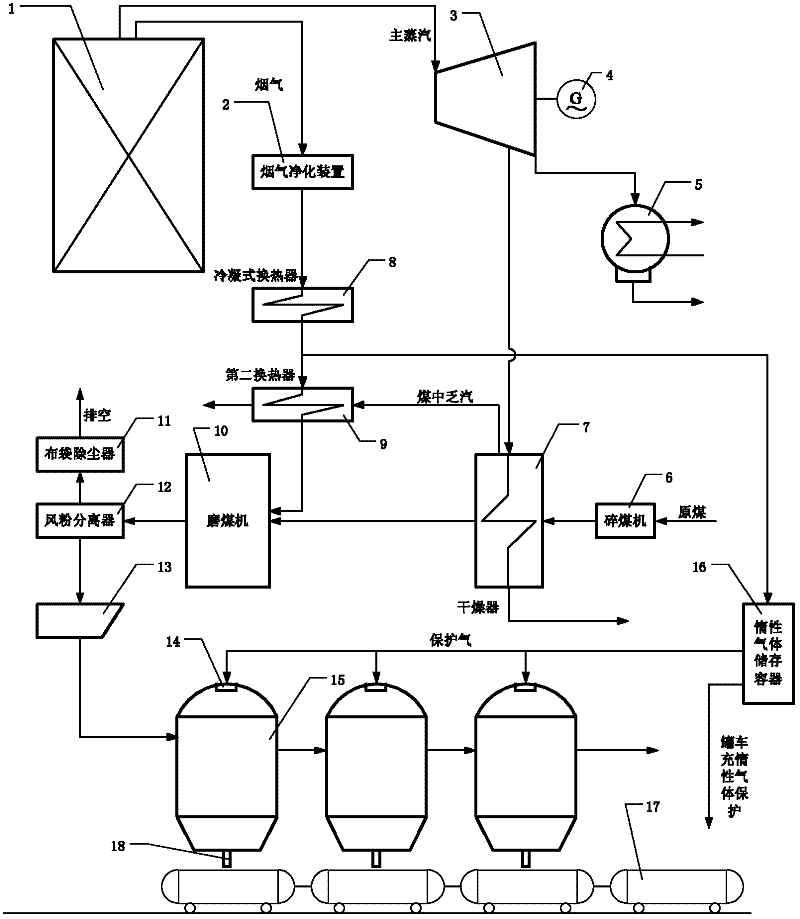

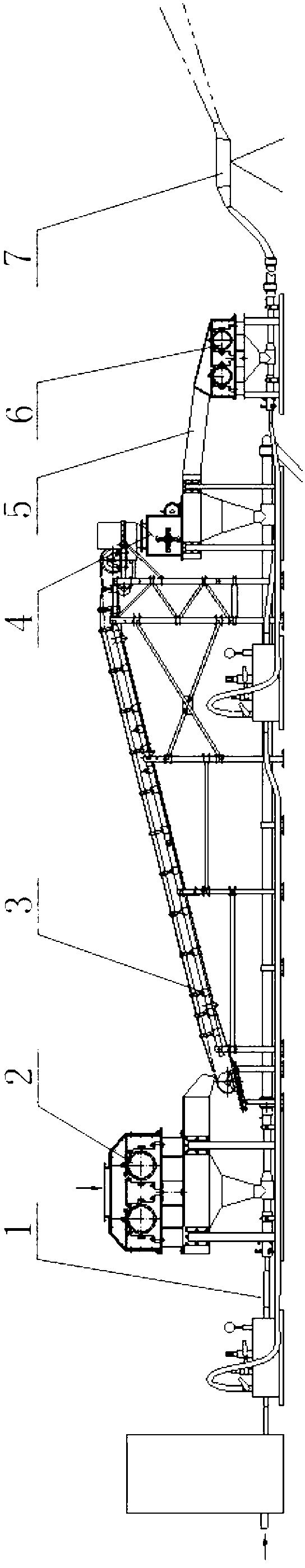

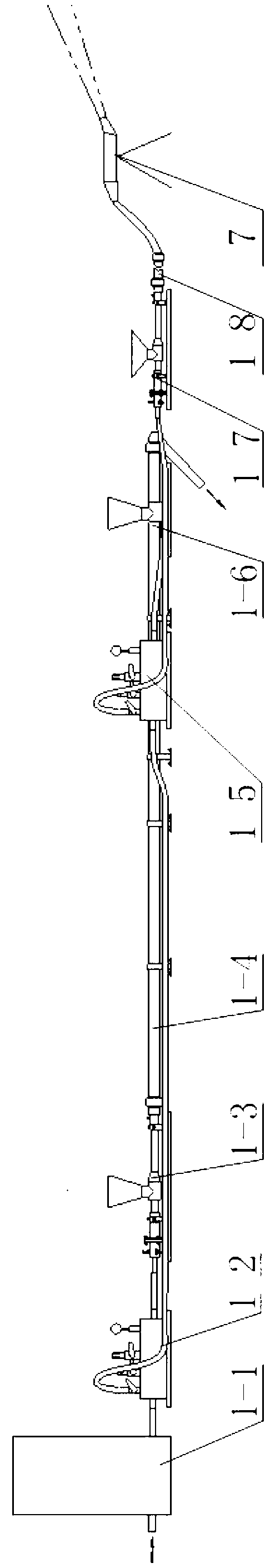

Large-scale centralized preparation system for pulverized coal and distribution method

InactiveCN102410552AGuaranteed feasibilityEnsure safetyLump/pulverulent fuel preparationCoal briquetteDistribution method

The invention discloses a large-scale centralized preparation system for pulverized coal and a distribution method. In the invention, raw coal is dried in a drying system by virtue of heat energy from a power generation enterprise in a raw coal producing area; dried coal briquettes are input into a grinding system so as to be processed into qualified pulverized coal; then the qualified pulverized coal is conveyed to coal-based power enterprises and other pulverized coal users for use by means of conveying equipment; and the whole pulverized coal processing and transportation process is in an inert environment so as to ensure the safe operation of the whole system. The large-scale centralized preparation system and the distribution method are mainly applied to large-scale centralized pulverized coal manufacturing factories in mining areas, wherein the factories provide the pulverized coal for the coal-based power enterprises and other pulverized coal users by a mode of conveying the qualified pulverized coal.

Owner:XI AN JIAOTONG UNIV

Preparation of biomass coal briquette by using common water hyacinths and anthracite fine coal

InactiveCN101250454ALow volatileLow combustion gasification activitySolid fuelsWaste based fuelCoal briquetteLow activity

The invention provides a method for utilizing common water hyacinths and anthracite fine coal to prepare bio-coal briquette, the method for producing bio-coal briquette comprises the following steps: evenly mixing anthracite fine coal, biomass and binder, and pressing to mold with a wet method. The invention is a new approach for developing anthracite fine coal and water hyacinth biomass energy, which utilizes common water hyacinths to be biomass source, the new approach changes wastes into valuables, which makes full use of own advantages of coals and common water hyacinths, and mutually learns from other's strong points to offset weakness, and the new approach utilizes high activities of common water hyacinths, overcomes the shortcomings of low energy density, improves gasification reactivity of low-activity anthracite fine coal, bio-coal briquette which is prepared has the advantages of low production cost, high activity, excellent intensity and the like, which has double functions of saving coal and replacing coal with biomass, and has great significance to protect environment and save energy.

Owner:FUZHOU UNIV

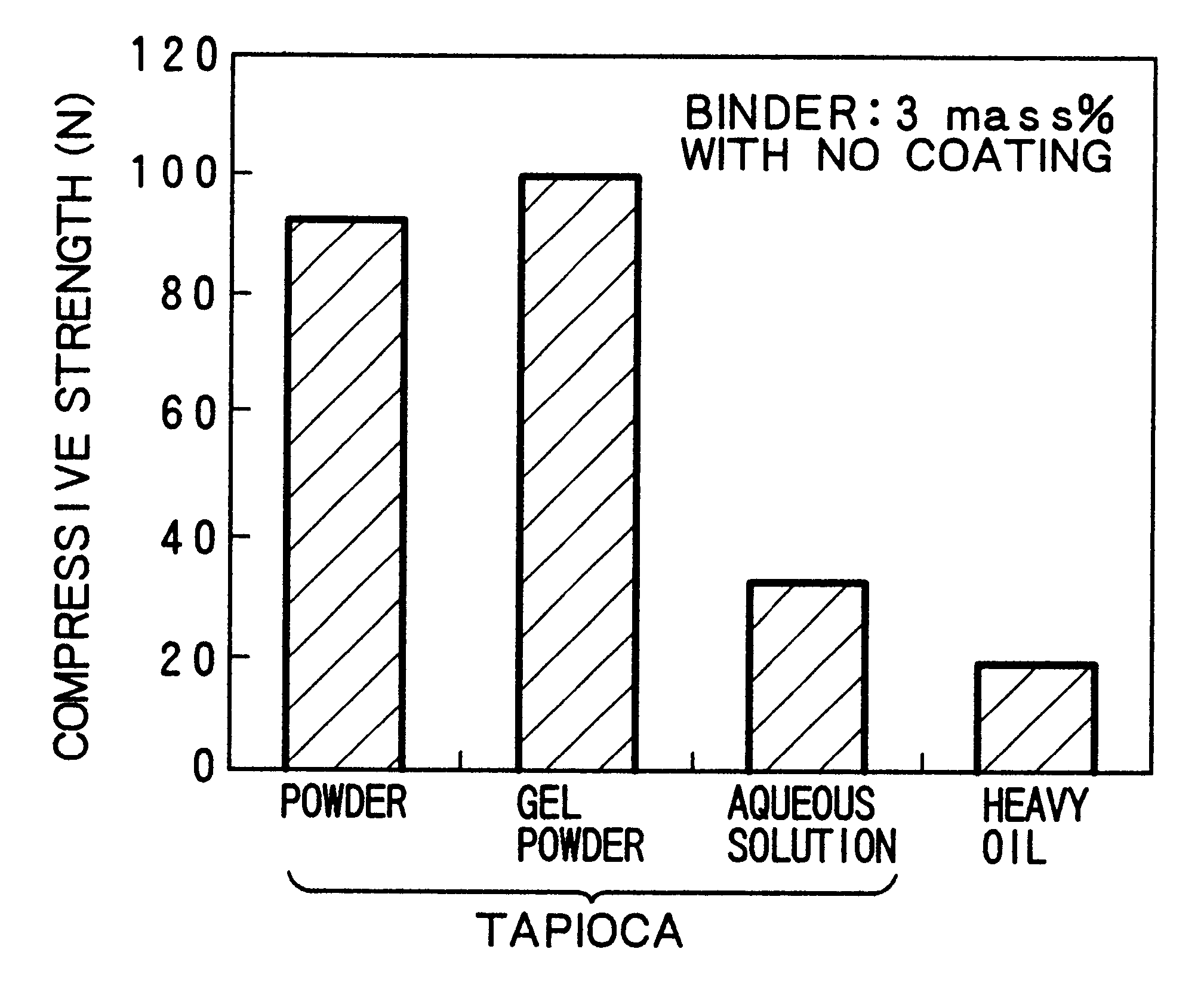

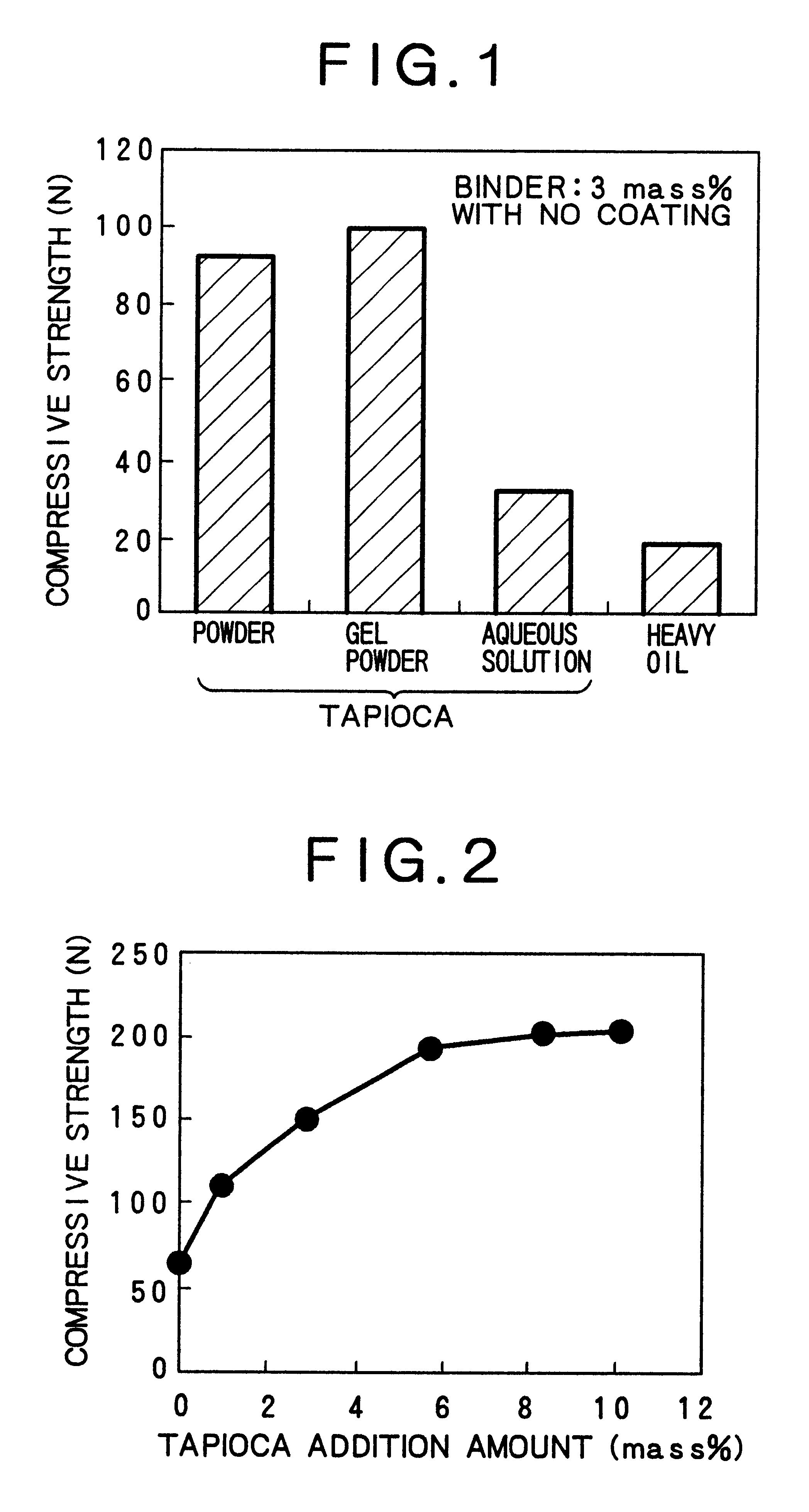

Coal briquette and production thereof

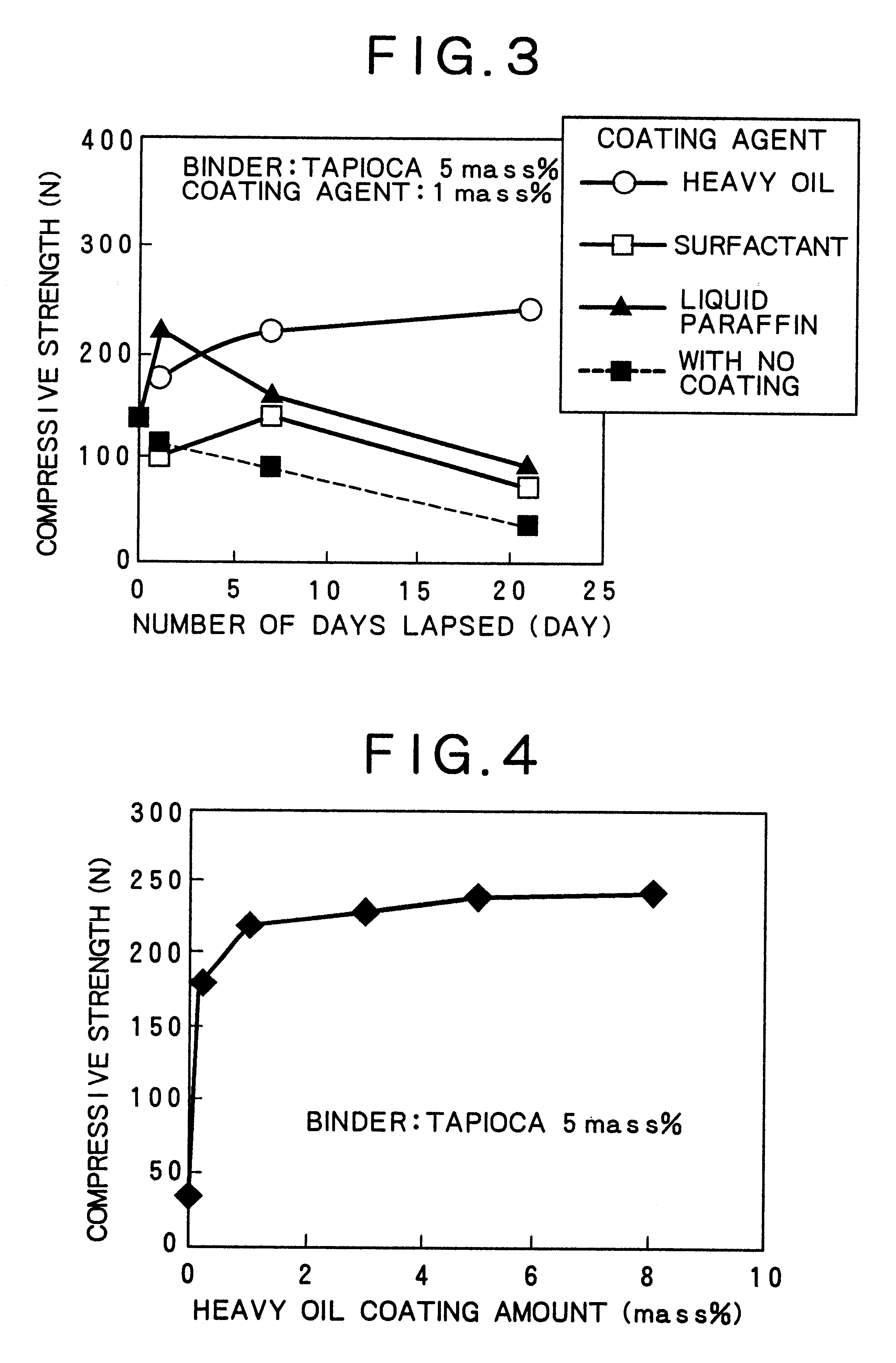

A method of producing coal briquette at a low energy cost by saving heating step or drying step for fine coal, which comprises adding and mixing from 1 to 10 mass parts of powdery starch to a coal having 15 mass % or more of water content and comprising 50 mass % or more of particles with grain size of 5 mm or less to form 100 mass parts of a mixture, and coating the surface of the briquette product with 0.1 to 5 mass parts of a heavy oil component simultaneously with or after pressure briquetting the mixture by a double roll briquetting machine in which concaves are formed on the roll surface, as well as coal briquette which is inexpensive and has high strength and high waterproof.

Owner:KOBE STEEL LTD

Clean fuelization system and fuelization method for urban sludge

ActiveCN103013613AEfficient use ofNo pollution in the processBiofuelsSolid fuelsCoal briquetteCoal water

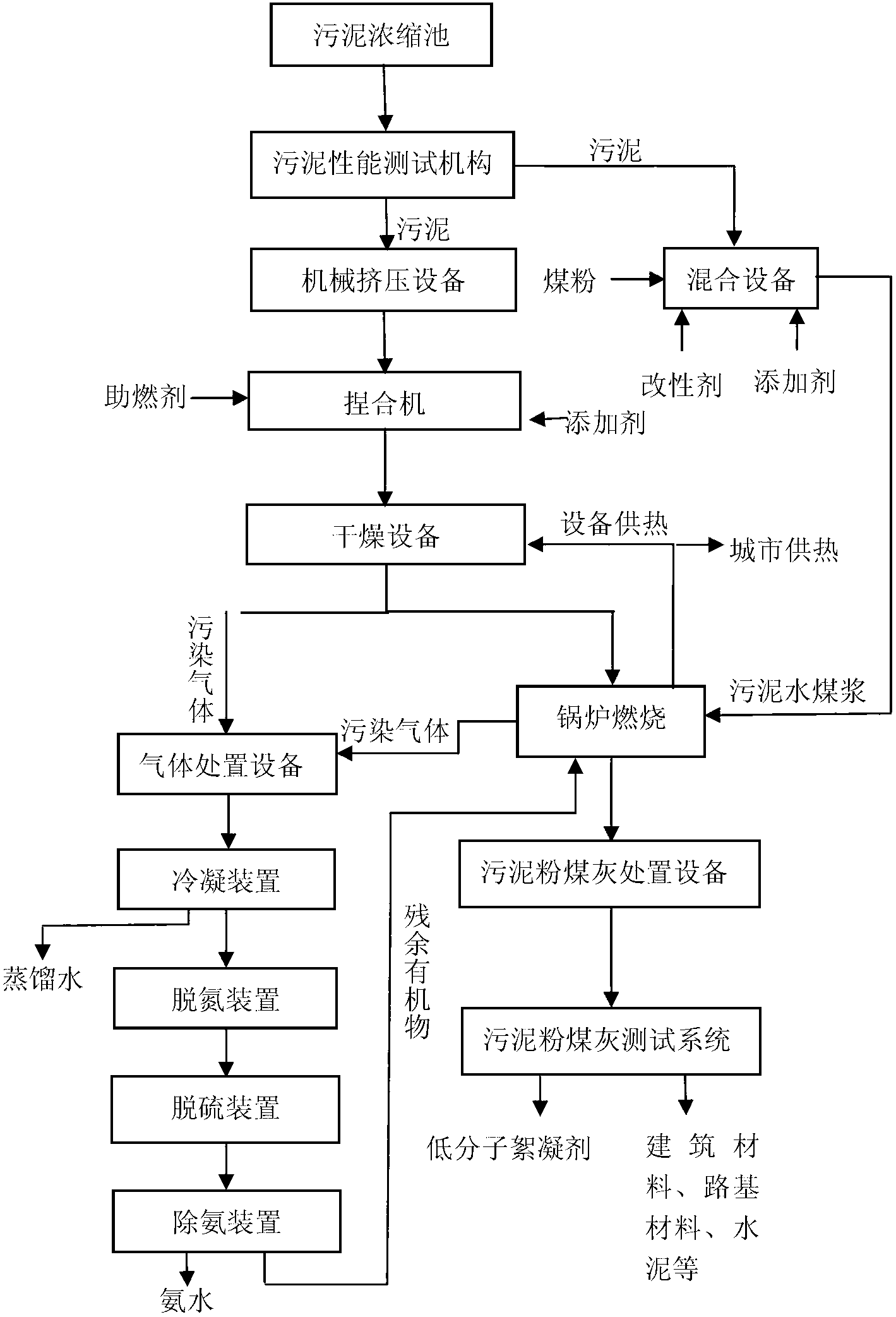

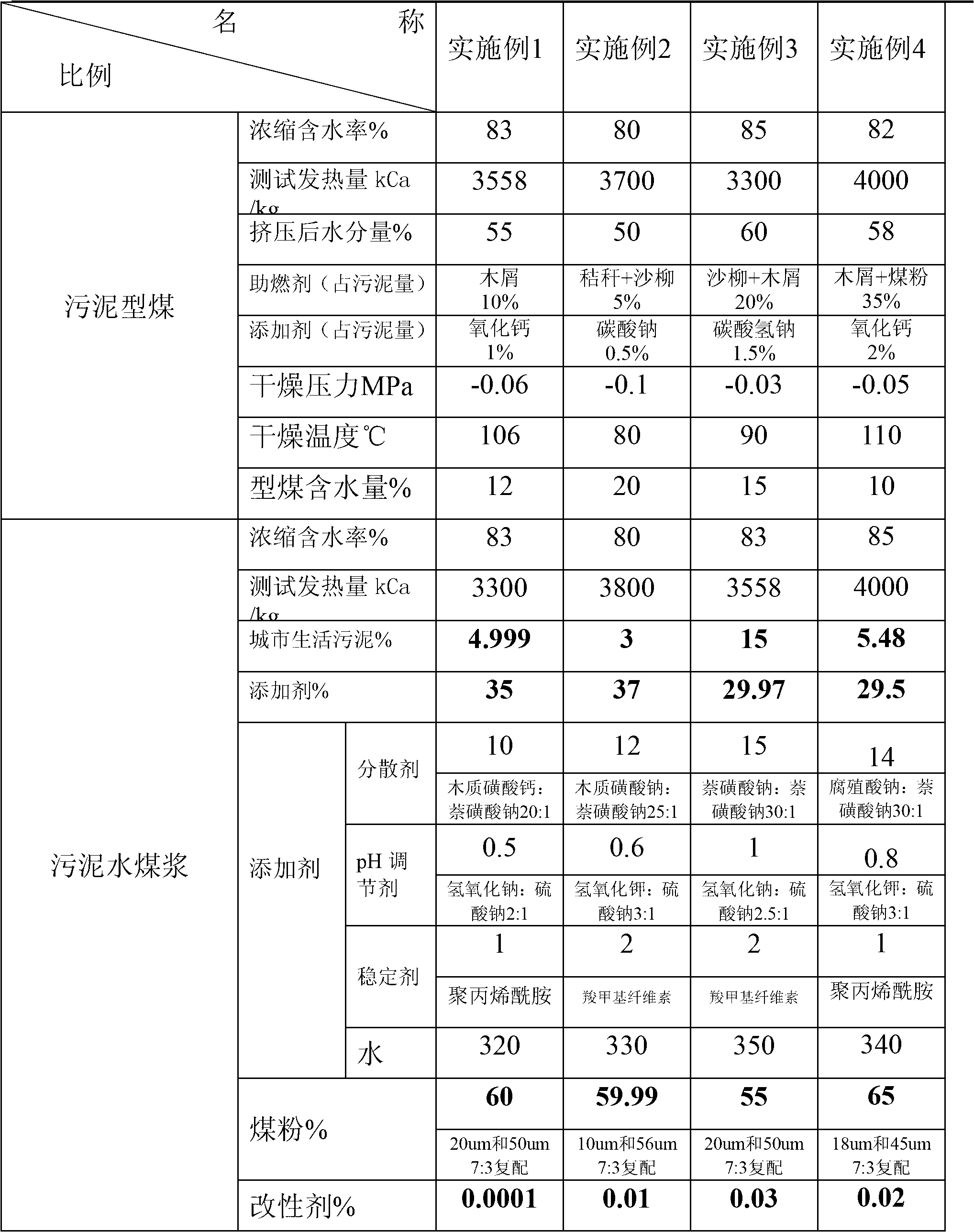

The invention discloses a clean fuelization system and a fuelization method for urban sludge. The system comprises a thickening tank and a sludge testing mechanism, wherein the sludge testing mechanism is connected with a mechanical extruding and drying mechanism or a mixing reactor; the mechanical extruding and drying mechanism is connected with a burning boiler and gas treatment equipment respectively; the mixing reactor is connected with the burning boiler; the burning boiler is connected with the gas treatment equipment, an urban heating system and sludge coal ash treatment equipment respectively; the sludge coal ash treatment equipment is connected with a sludge coal ash testing system; the gas treatment equipment is connected with a condensing device; the condensing device is connected with a denitrification device, a desulfuration device and an ammonia removal device in sequence; and the ammonia removal device is connected with an ammonia water storage tank and the burning boiler respectively. The method comprises the steps of conducting sludge thickening treatment, performance testing, extruding or mixing to obtain a sludge coal briquette or sludge coal water slurry, using the sludge coal ash burnt in the burning boiler to prepare a low molecule flocculating agent or for building materials, and recycling treated gas. According to the system and the method, sludge fuelization is adopted to realize greenness and environmental protection.

Owner:XIAN UNIV OF SCI & TECH

Preparation method of machine-made wood charcoal

The invention discloses a preparation method of machine-made wood charcoal, belonging to the technical field of wood charcoal processing. The preparation process comprises the following steps: raw material selection: selecting corn cobs, sawdust, plant straws, pinecones, nutshells, medicine dregs and an adhesive as main raw materials; raw material treatment: mixing the raw materials, and drying the raw materials at 150-200 DEG C for 3-4 hours; sending the raw materials into an extruding machine, and extruding into coal briquettes in various shapes; and putting the coal briquettes into a kiln, firing for about 2-3 days, taking out, and cooling to obtain the high-temperature machine-made wood charcoal. The traditional Chinese medicine dregs are used as the raw material to produce the machine-made wood charcoal, thereby implementing comprehensive recycling on the traditional Chinese medicine dregs, and reducing the pollution of the traditional Chinese medicine dregs on the environment. The adhesive is a natural adhesive, does not generate harmful substances after being combusted, does not pollute the environment or jeopardize human health, and is very environment-friendly. The detection proves that various indexes of the wood charcoal produced by the method satisfy related national standards.

Owner:SHANDONG LIANXING ENERGY GRP CO LTD

Biomass moulded coal and preparation method thereof

The invention provides a biomass moulded coal and a preparation method thereof, relates to a fuel coal, and solves the problems of coal slurry such as poor quality, insufficient burning, lower heat and high cost while the coal slurry is adopted in most of the existing moulded coal. The biomass moulded coal is prepared from the following raw materials by weight percent: 65-75% of the coal slurry, 23-33% of straw carbonized powder, 0.5-1% of adhesive and 1-2% of water. The preparation method comprises the following steps: carbonizing straw by a straw carbonized oven to obtain straw carbonized powder, mixing and stirring evenly the straw carbonized powder with the coal slurry, the adhesive and the water by weight percent, and putting the mixture into a coal briquetting machine to obtain the biomass moulded coal. In the invention, biomass is added into the coal slurry, so that waste plants improve the moulded coal quality. The invention has the advantages of sufficient burning, high heat improved by 7.6-15% compared with the existing coal slurry-type coal, less energy consumption and low cost.

Owner:吴长明

Coal blending and coking method with participation of 1/3 coking coal having volatile of 28-32%

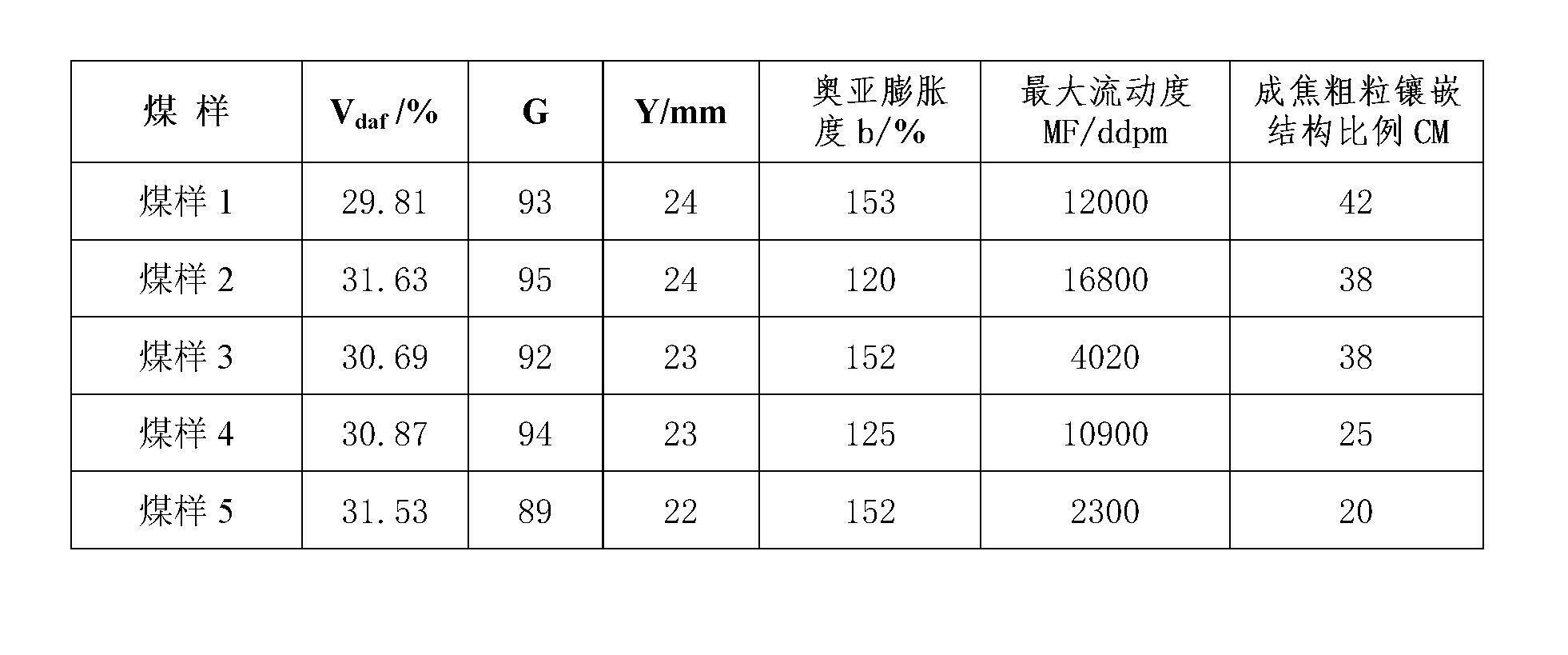

The invention discloses a coal blending and coking method with participation of 1 / 3 coking coal having the volatile of 28-32%. The caking index G value of the 1 / 3 coking coal is larger than or equal to 85, and the maximum thickness Y value of a plastic layer is larger than or equal to 20.0mm. The method includes the steps: firstly, detecting gieseler fluidity of single types of coal to obtain themaximum fluidity MF and rubber expansion b of the coal; and secondly, determining a coal blending scheme according to the detection results obtained at the step one, using the coal as fat coal for coal blending when the maximum fluidity MF is equal to or larger than 10000ddpm while the rubber expansion b is equal to or larger than 150%, and using the coal as 1 / 3 coking coal for coal blending whenthe maximum fluidity MF is smaller than 10000ddpm while the rubber expansion b is smaller than 150%. The 1 / 3 coking coal with the volatile of 28-32% is reasonably differentiated according to indexes of the maximum fluidity MF and rubber expansion b and then subjected to coal blending and coking, so that coal resources can be effectively utilized. Coke quality is stably improved without adoption of coal humidifying, coal briquette technique and pre-crushing process, and CSR (coke strength after reaction) of cokes coked in coke ovens higher than 6m is larger than 63%.

Owner:武汉钢铁有限公司

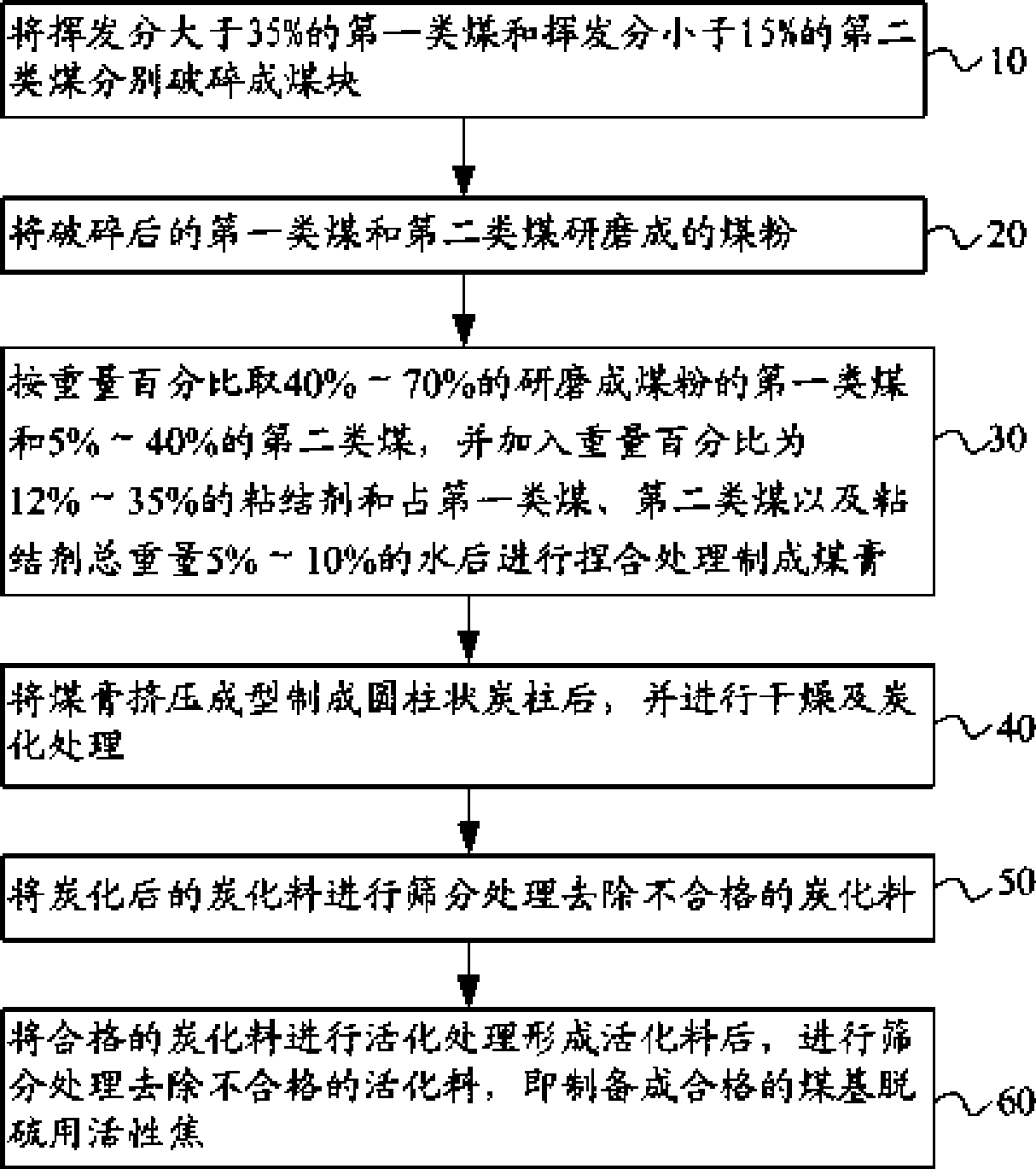

Coal-based activated coke for desulfuration and preparation method thereof

ActiveCN101485972AHigh activation yieldHigh specific gravityOther chemical processesCoal briquetteCoal

The invention relates to a method for preparing active coke for coal based desulfurization. The method comprises the following steps: crushing the first-class coal and the second-class coal into coal briquettes respectively; grinding the coal briquettes into pulverized coal; picking up the coal which is ground into the pulverized coal, adding a binder and water, and subjecting the mixture to kneading treatment to obtain coal paste; after forming the coal paste by extrusion to obtain a cylindrical charcoal column, drying and charring the charcoal column; screening the charring material which is charred to remove the unqualified charring material; and activating the qualified charring material to form an activated material, namely preparing the qualified active coke for coal based desulfurization. In the method, the first-class coal with low added-value and the second-class coal with high added-value are used to prepare macro-aggregate active coke products particularly for fume desulfurizatio with the advantages of low production cost, desirable quality, obvious desulfurizatio effect and strong market competitive power.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

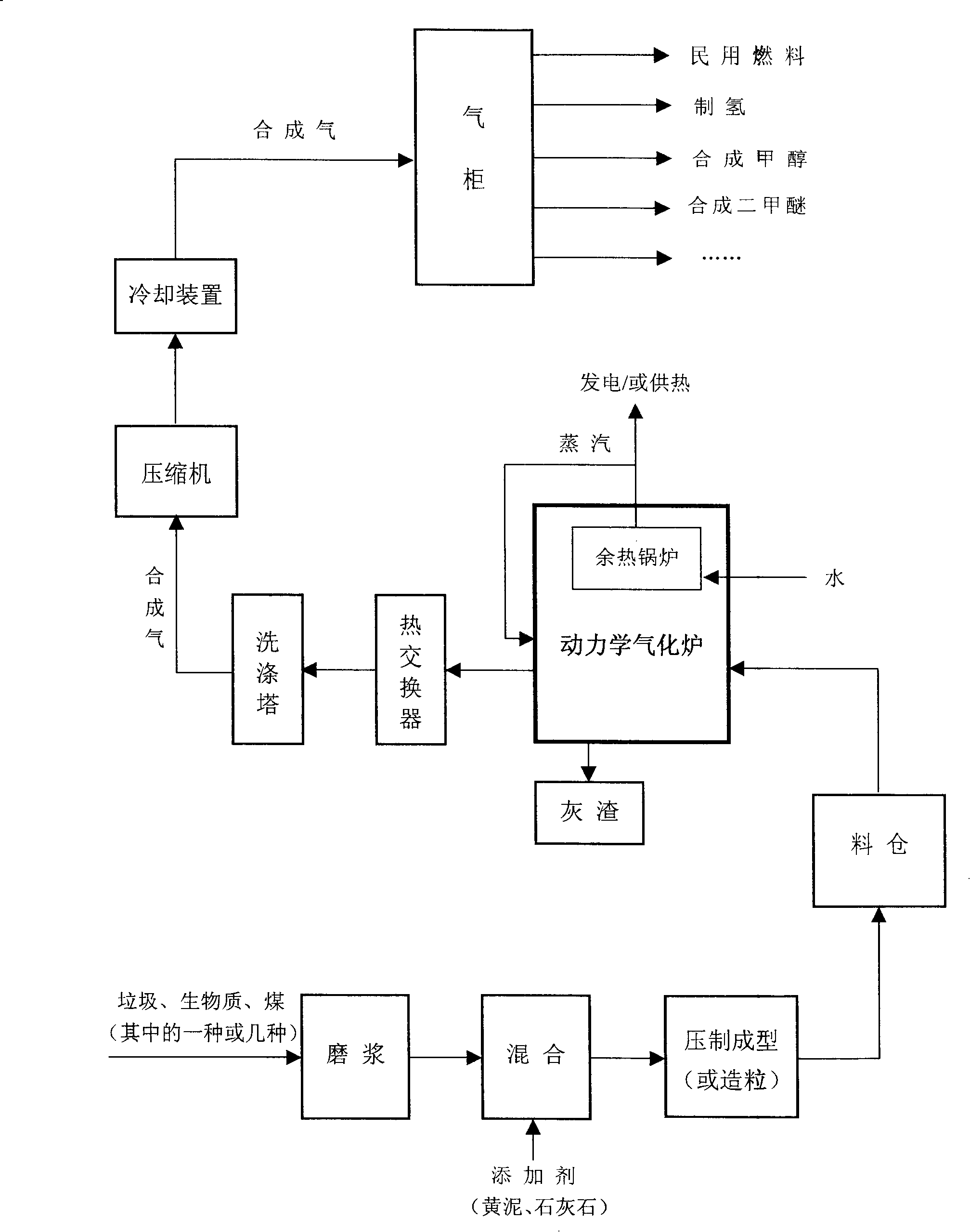

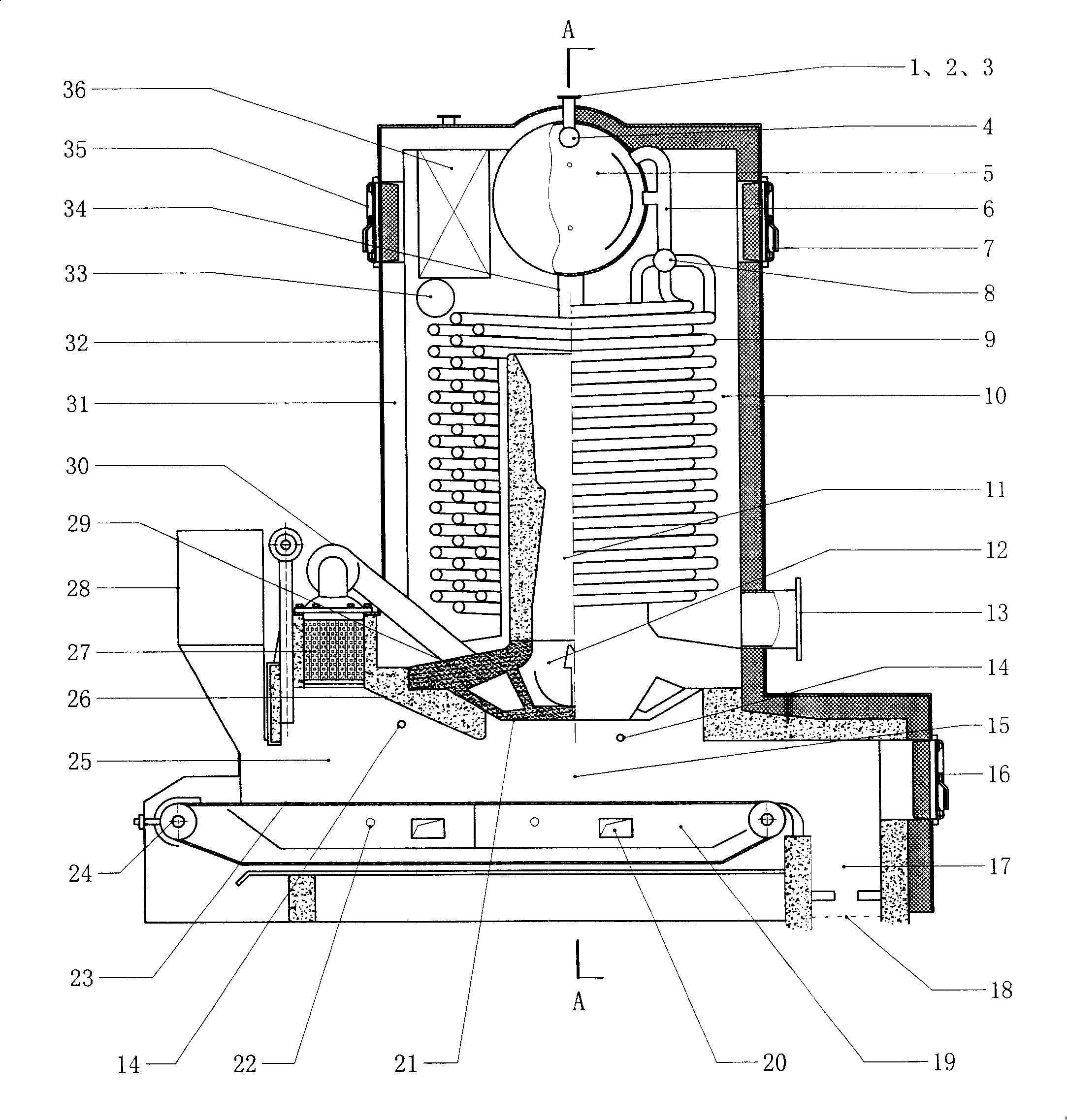

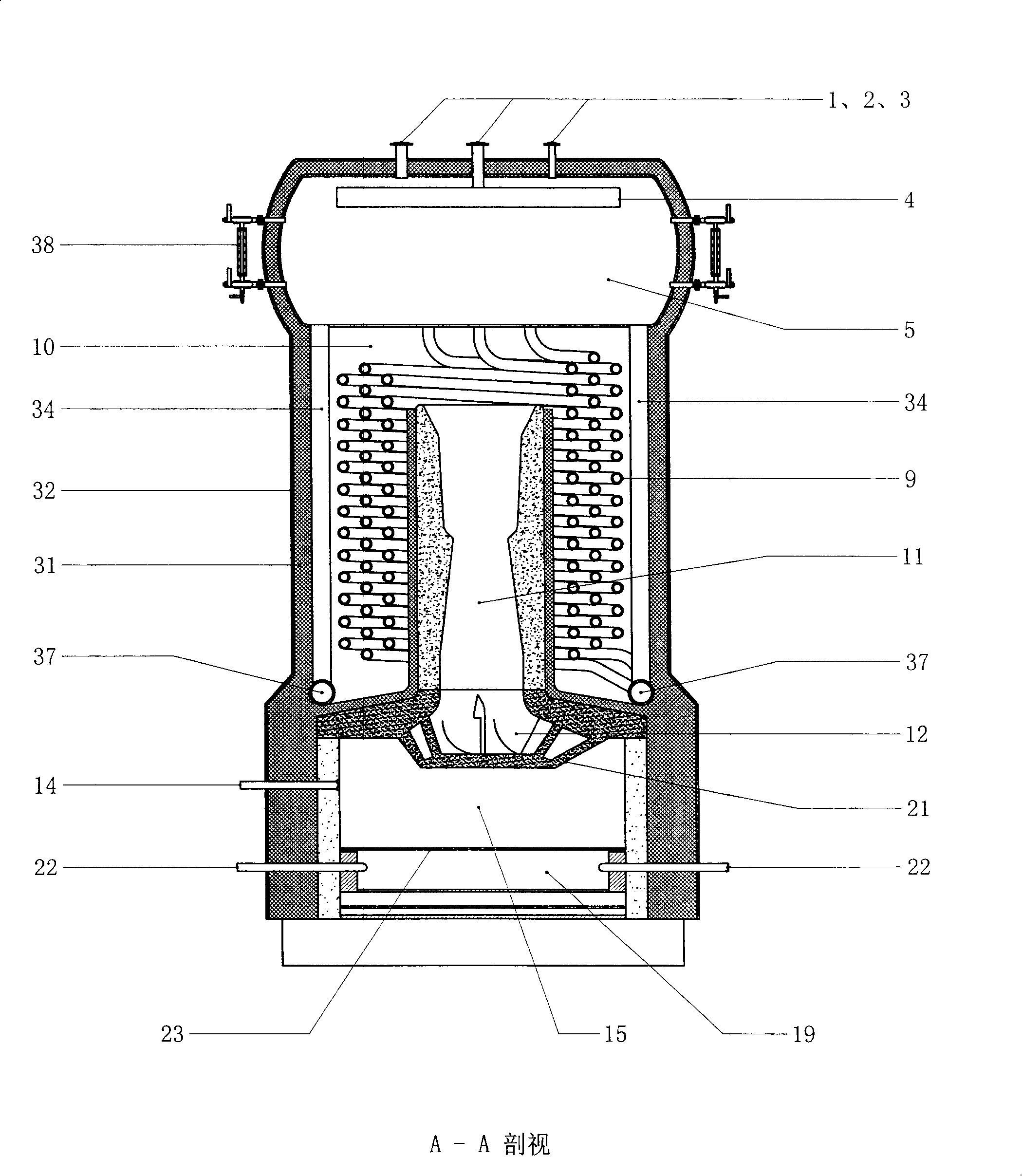

Dynamics gasification furnace and exhaust heat boiler composed by the same

InactiveCN101191059AReduce tensionSolve the way outEnergy inputWater heatersCoal briquetteClean energy

The invention discloses a dynamic gasification furnace and a waste heat boiler formed by the dynamic gasification furnace and relates to gasification equipment using solid fuel to produce synthesis gas. The invention has wide raw material suitability, and the raw materials comprise original msw, biomass, bio-coal briquette, coal-based briquettes, raw coal and loose coal. Through applying the invention, garbage and biomass gasification equipment with low investment, simple operation and easy popularization can be designed, can be operated as conventional boilers and can realize continuous raw material input, continuous deslagging and continuous synthesis gas output. The invention contributes to the active utilization of renewable energy, solves the problem of the treatment of domestic garbage and agricultural and agricultural and forest residues, ensures that the domestic garbage and agricultural and forest residues are transformed into clean energy, on one hand, the problem of environmental protection is solved, on the other hand, the situation of energy crisis is alleviated, creates conditions for promoting the overall coordinated and sustainable development of the economic society, and creates good development chance for rural areas which provide biological resources.

Owner:周开根

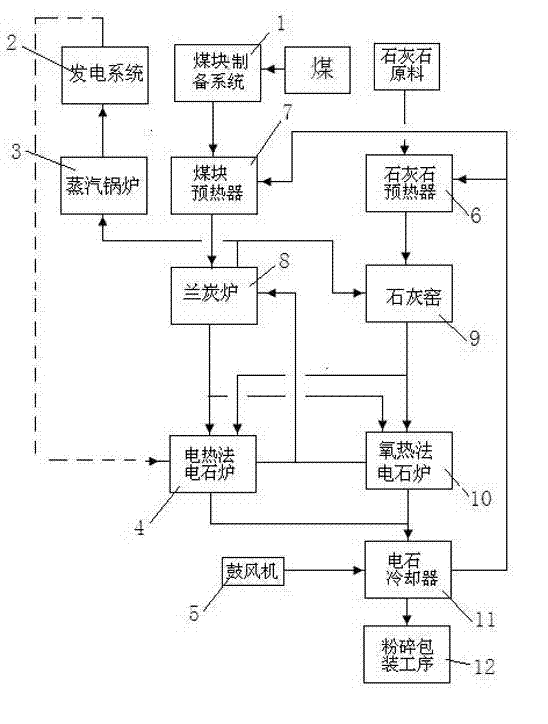

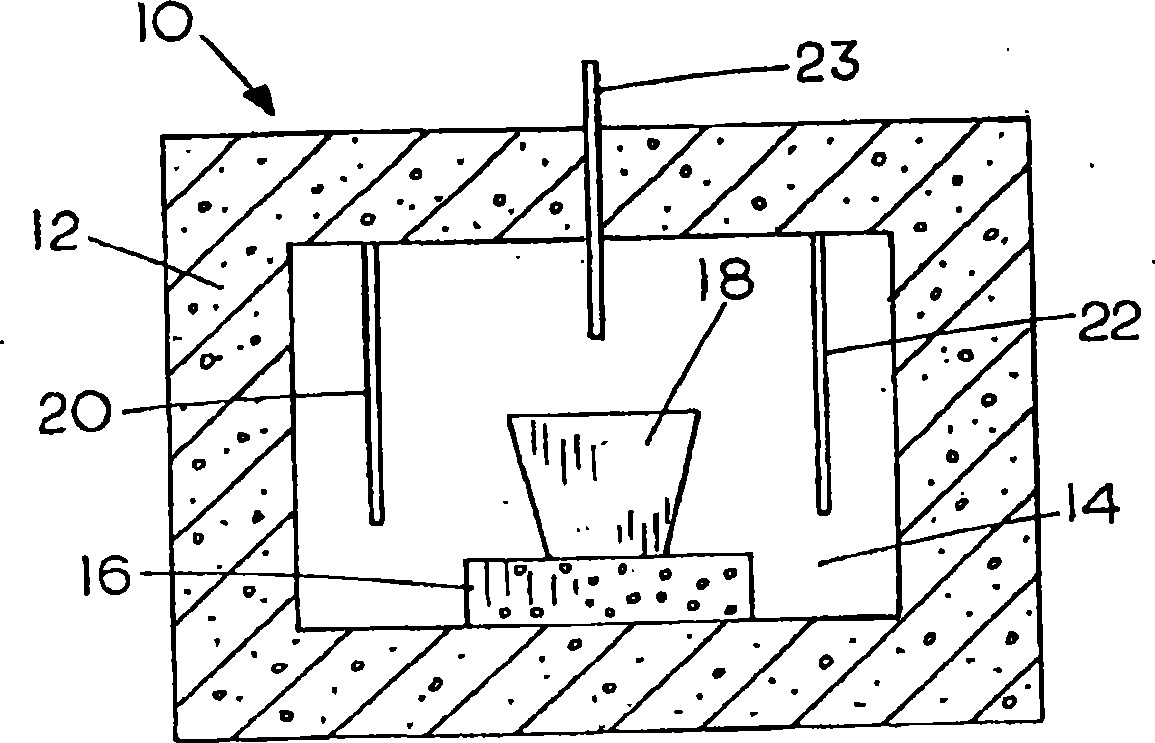

Production device for coproduction of calcium carbide by electrothermal method and oxygen thermal method

The invention relates to a production device for coproduction of calcium carbide by an electrothermal method and an oxygen thermal method. The production device comprises an oxygen thermal method calcium carbide furnace, an electrothermal method calcium carbide furnace, a semi-coke furnace, a lime kiln and a power generation system. A coal briquette preparation system is connected to the semi-coke furnace through a coal briquette preheater, and the semi-coke furnace is connected to the electrothermal method calcium carbide furnace and the oxygen thermal method calcium carbide furnace. A limestone supply device is connected to the lime kiln through a limestone preheater, and the lime kiln is connected to the electrothermal method calcium carbide furnace and the oxygen thermal method calcium carbide furnace. Calcium carbide furnace gas outlets of the calcium carbide furnaces are connected to a fuel inlet of the semi-coke furnace, a semi-coke tail gas outlet of the semi-coke furnace is connected to the fuel inlet of the lime kiln and the fuel inlet of a steam boiler, and a waste heat boiler is connected to a steam turbine. A power generator set is connected to the wiring end of the electrothermal method calcium carbide furnace through a power transmission device. The production device provided by the invention fully utilizes byproducts and waste heat of the calcium carbide furnaces and the semi-coke furnace, reduces the energy consumption and the calcium carbide production cost and improves the comprehensive economic benefits of an enterprise by combining the oxygen thermal method calcium carbide furnace and the electrothermal method calcium carbide furnace with the semi-coke furnace, the lime kiln and the power generation system.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

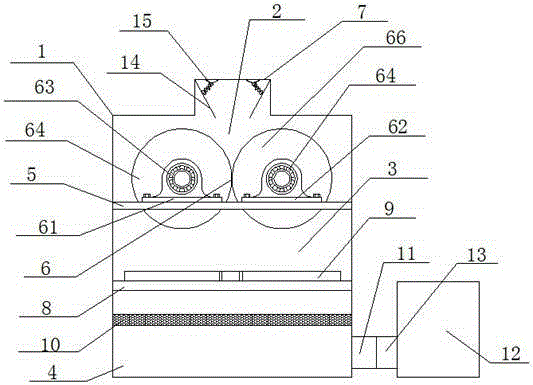

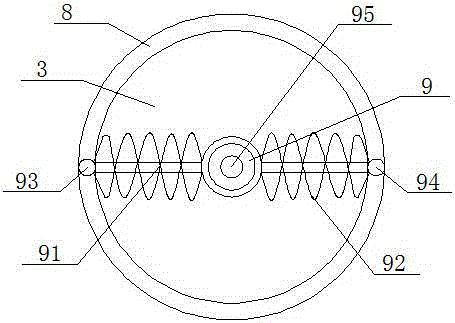

Coal briquette crashing device used for boiler

The invention discloses a coal briquette crashing device used for a boiler. The coal briquette crashing device comprises a shell, the shell comprises an upper cavity, a middle cavity and a lower cavity, the three cavities are a first-stage crashing chamber, a second-stage crashing chamber and a coal briquette storing chamber in sequence, a support is horizontally arranged inside the first-stage crashing chamber, and an extrusion roll mechanism is installed on the support. A feeding port is formed in the portion, over the extrusion roll mechanism, of the shell, a circle of roller path is arranged on the internal surface of the second-stage crashing chamber, a rotating crashing device assembly is installed on the roller path, a vibration metal screening plate is arranged at the connecting position of the second-stage crashing chamber and the coal briquette storing chamber, and a discharging connecting opening is formed in one side of the coal briquette storing chamber and connected with a feeding connecting opening of the boiler. The coal briquette crashing device and the boiler are of an integrated structure, the defect that in the prior art, coal is carried back and forth is completely overcome, working intensity is relieved, cost investment is small, working efficiency is high, the mode of two times of crashing is adopted, coal at edges can be crashed, the crashing effect is good, and the heat efficiency when the coal is combusted in the boiler is improved.

Owner:TAICANG YINGDA BOILER EQUIP

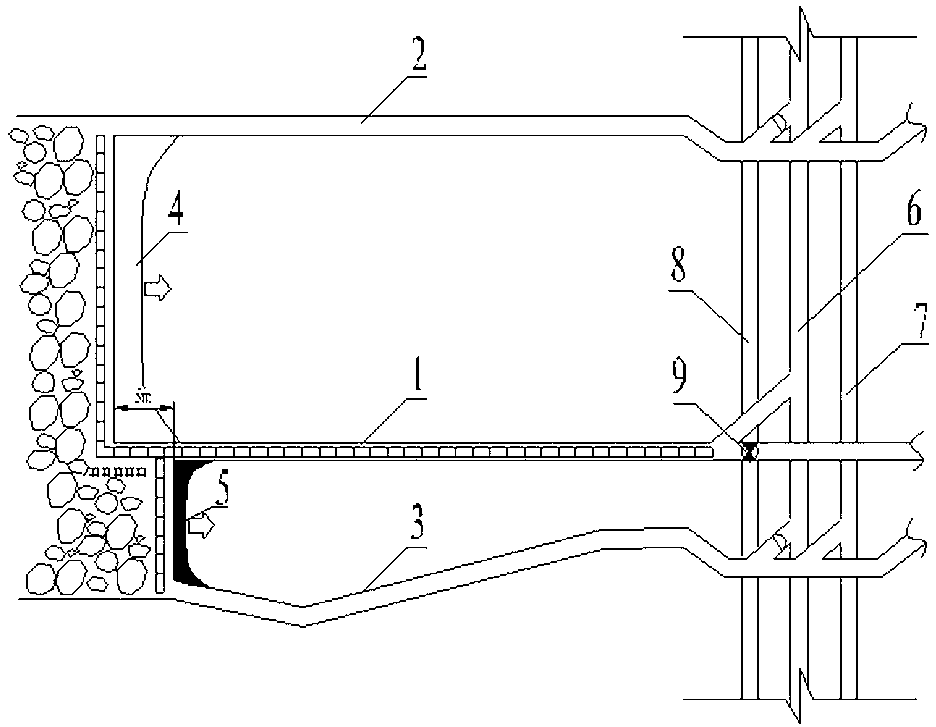

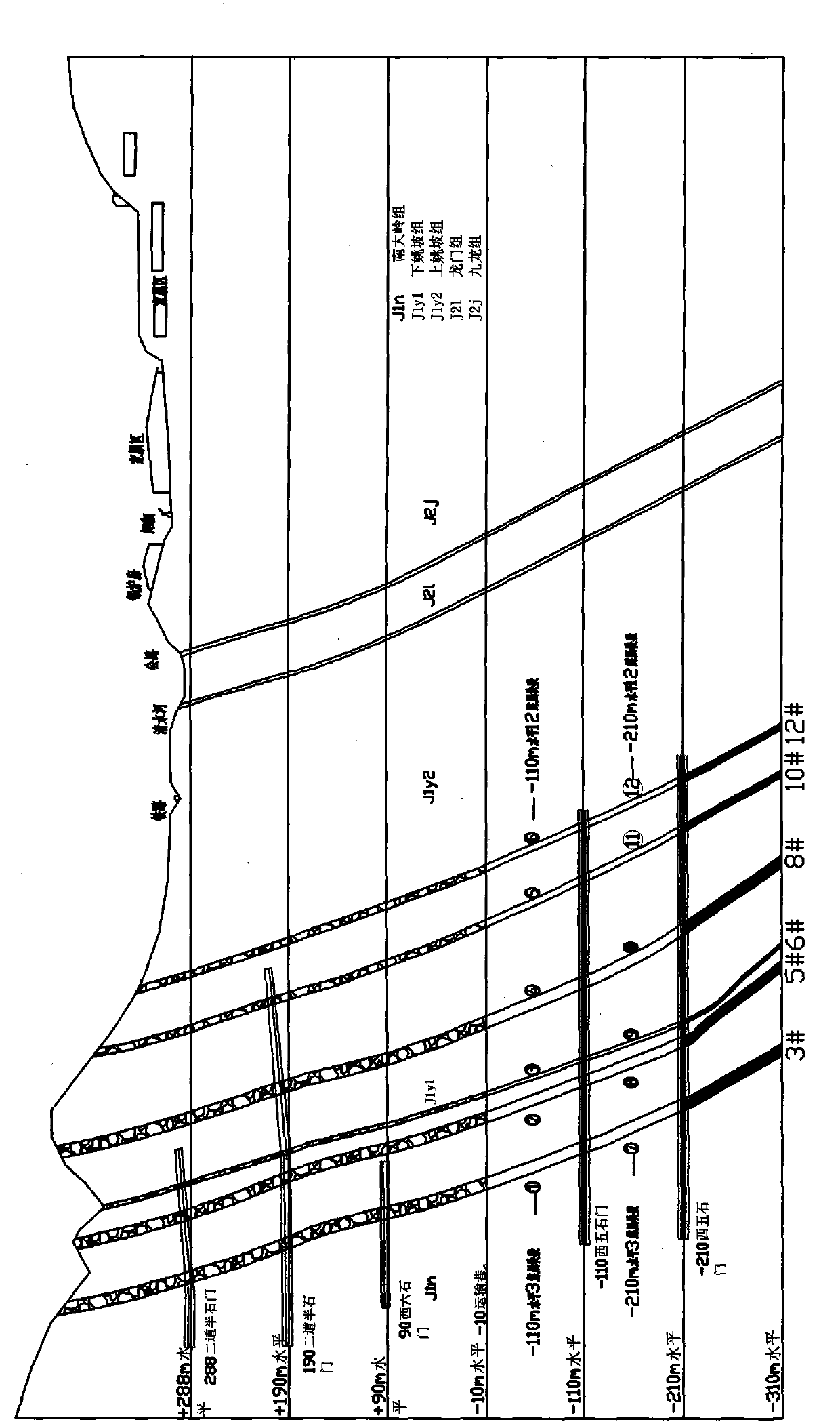

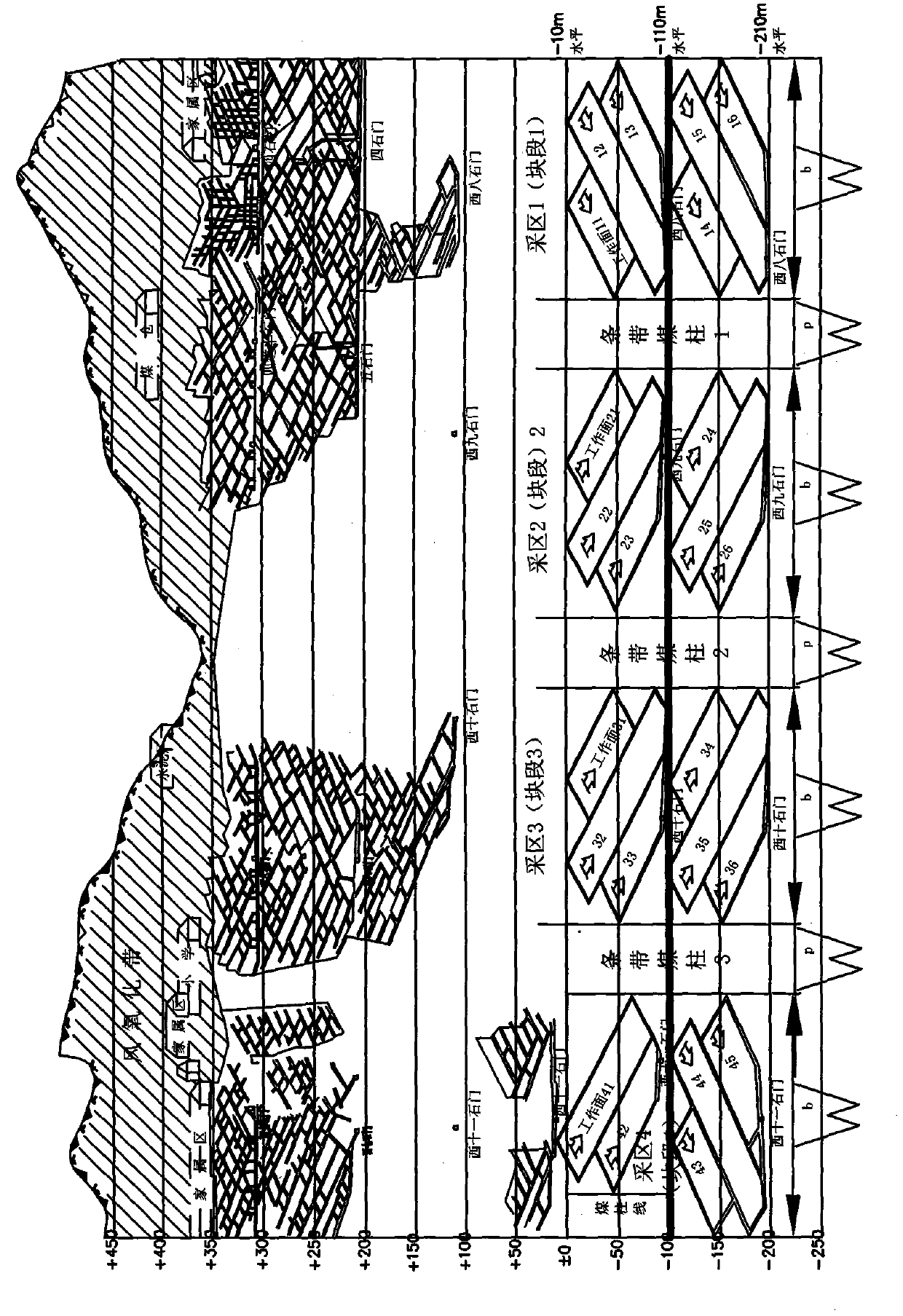

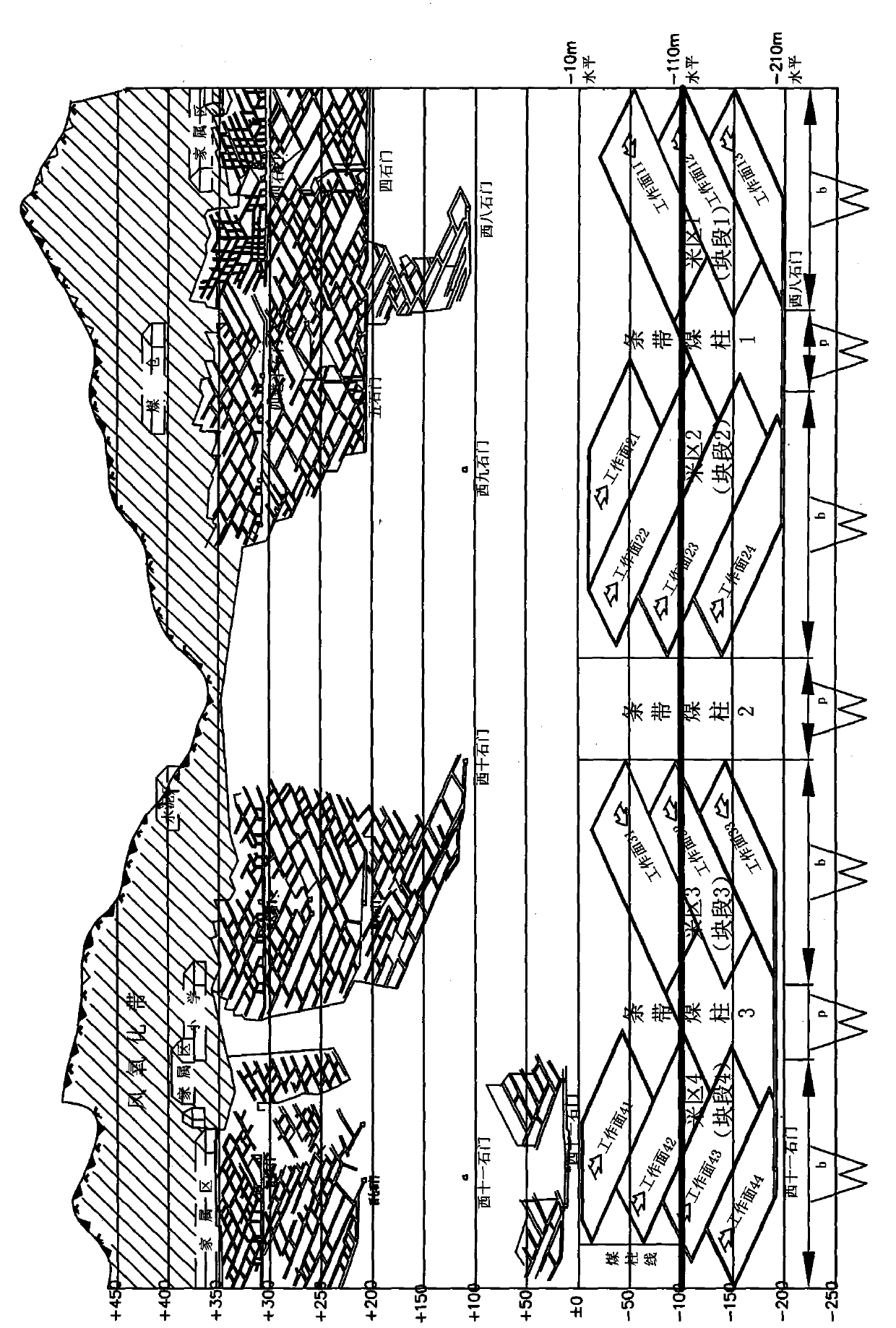

Comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions

InactiveCN103104260AImprove mining efficiencyHigh recovery rateUnderground miningSurface miningCoal briquetteLength variation

The invention provides a comprehensive-conventional mechanical mining double-unit face coal mining method under complicated geological conditions. Directed at mining of coal resources in irregular sections under complicated geological conditions, the method includes: arranging an equal length comprehensive mechanical mining face on the upper part of a coal briquette in a section, arranging an unequal length conventional mechanical mining face on the lower part of the coal briquette according to the remaining coal briquette shape in the section, making use of three section drifts to prepare two stope faces so as to form a double unit mining form between the equal length comprehensive mechanical mining face and the unequal length conventional mechanical mining face, advancing the two faces in a coordinated way, and always keeping the conventional mechanical mining face ahead of the comprehensive mechanical mining face by 5m, and when the length of the conventional mechanical mining face varies, increasing or decreasing the number of single hydraulic props and articulated roof beams in the conventional mechanical mining face or properly adjusting the prop space based on required support density so as to adapt to the face length variation. The method provided in the invention achieves arrangement of the equal length comprehensive mechanical mining face during irregular coal briquette mining under complicated geological conditions, simultaneously recovers coal resources to the utmost, and improves the mechanization level of coal mining under complicated geological conditions.

Owner:HUNAN UNIV OF SCI & TECH

Coking coal quality classification method and coal blending and coking method with participation of coking coal

ActiveCN102690669ASteady improvement in qualityEfficient use ofCoke ovensCoal briquetteProcess engineering

The invention discloses a coking coal quality classification method and a coal blending and coking method with participation of coking coal. The dry ash-free volatile of the coking coal is higher than 10.0-37.0%, the caking index G value is larger than 85, and the maximum thickness Y value of a plastic layer is larger than 25.0mm. Indexes of dry ash-free volatile, maximum fluidity and rubber expansion are obtained by detecting dry ash-free volatile, gieseler fluidity and rubber expansion of coking coal, and the coking coal is classified into primary coking coal, fat coal, 1 / 3 coking coal and air fat coal according to different ranges of the indexes so as to determine the coal blending and coking method with participation of the coking coal. Coking coal is classified according to the method and then used for coal blending and coking, coke quality is stably improved without adoption of coal humidifying, coal briquette technique and pre-crushing process, and CSR (coke strength after reaction) of cokes coked in coke ovens higher than 6m is larger than 63%.

Owner:武汉钢铁有限公司

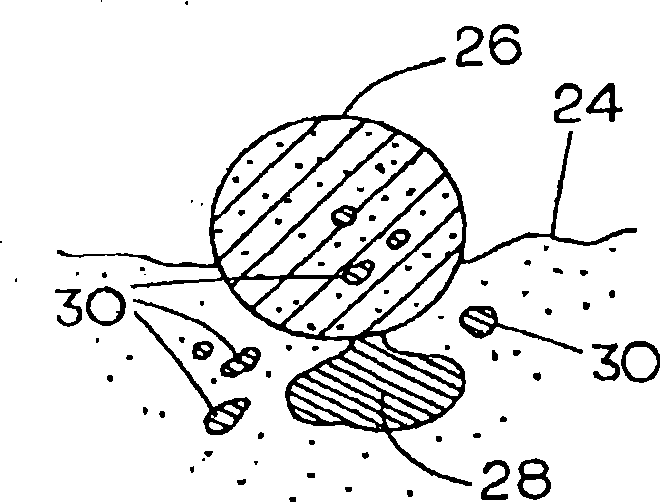

Production of iron using environmentally-benign renewable or recycled reducing agent

To produce metallic iron from iron ore, a composition comprising a mass of material formed from a mixture of iron ore particles and particles of a reductant that is either a biomass material in particulate form or a plastic resinous material in particulate form is used. The reductant can also be a mixture of biomass material and resin in any proportions. The mass of material comprises at least one body having a shape adapted for smelting such as pellets, briquettes, pieces or lumps. The pellets have sufficient cohesion to maintain the shape into which they have been formed. The invention also provides a new method for smelting iron from its ore which comprises subdividing the ore into particles of a selected size, mixing the subdivided ore particles with particles of a biomass material or particles of a plastic resinous material or with mixtures thereof, forming a mass of the mixture into at least one body with a shape that is suited for smelting in a furnace and placing the body in a furnace and exposing it to sufficient heat to bring the iron therein to smelting temperature within the furnace to thereby produce metallic iron directly from the ore.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

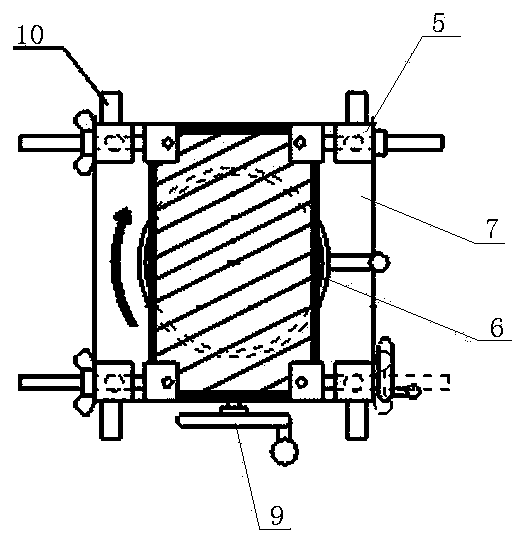

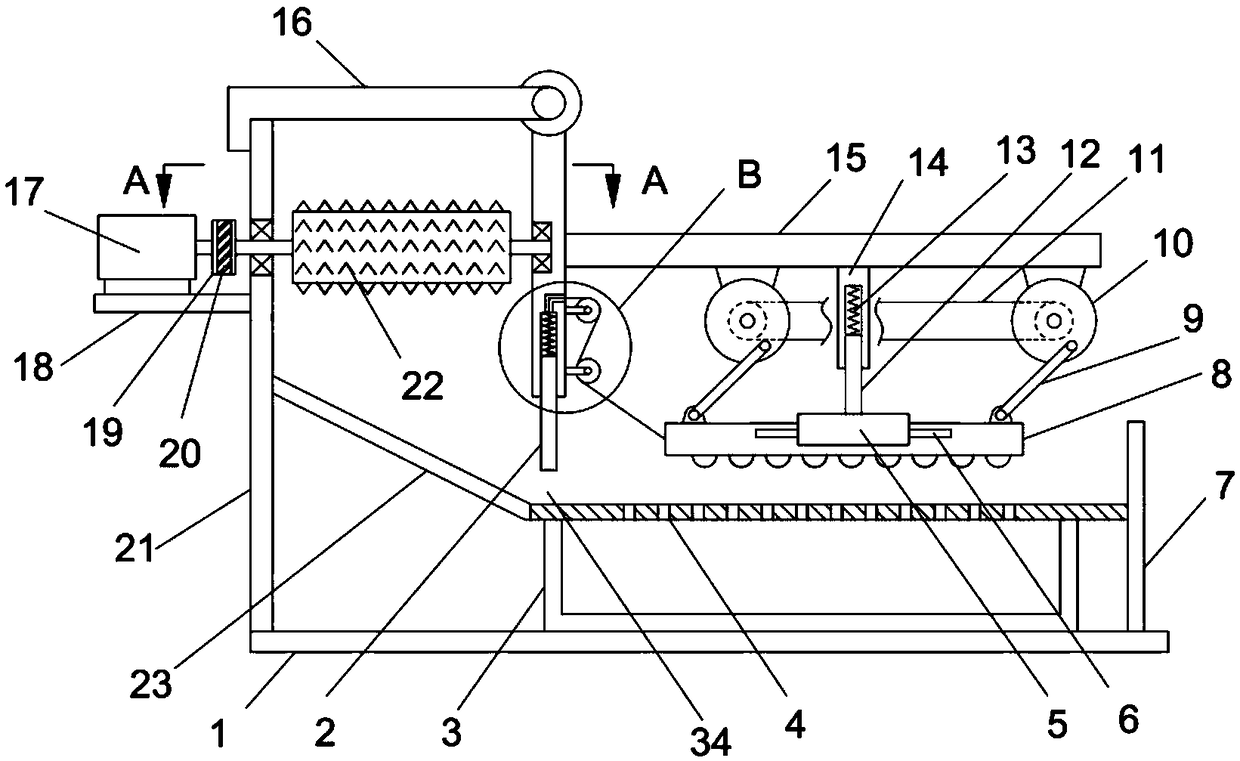

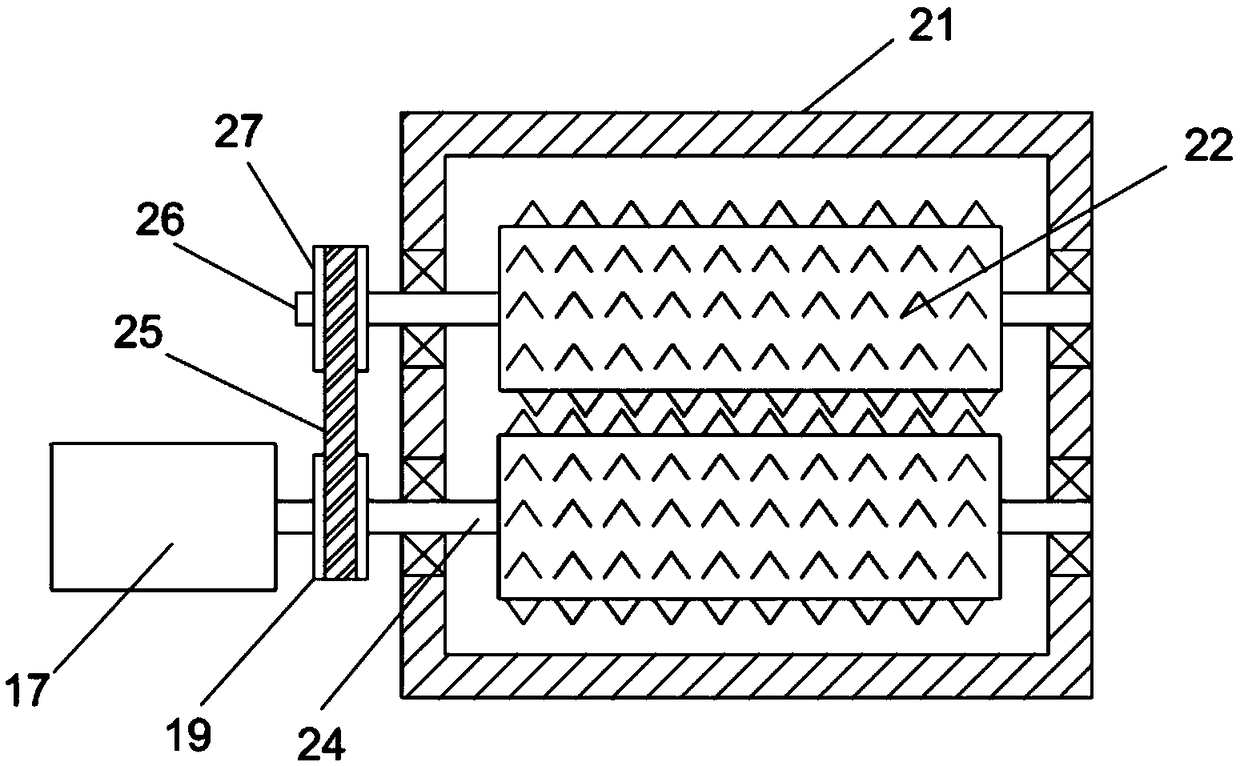

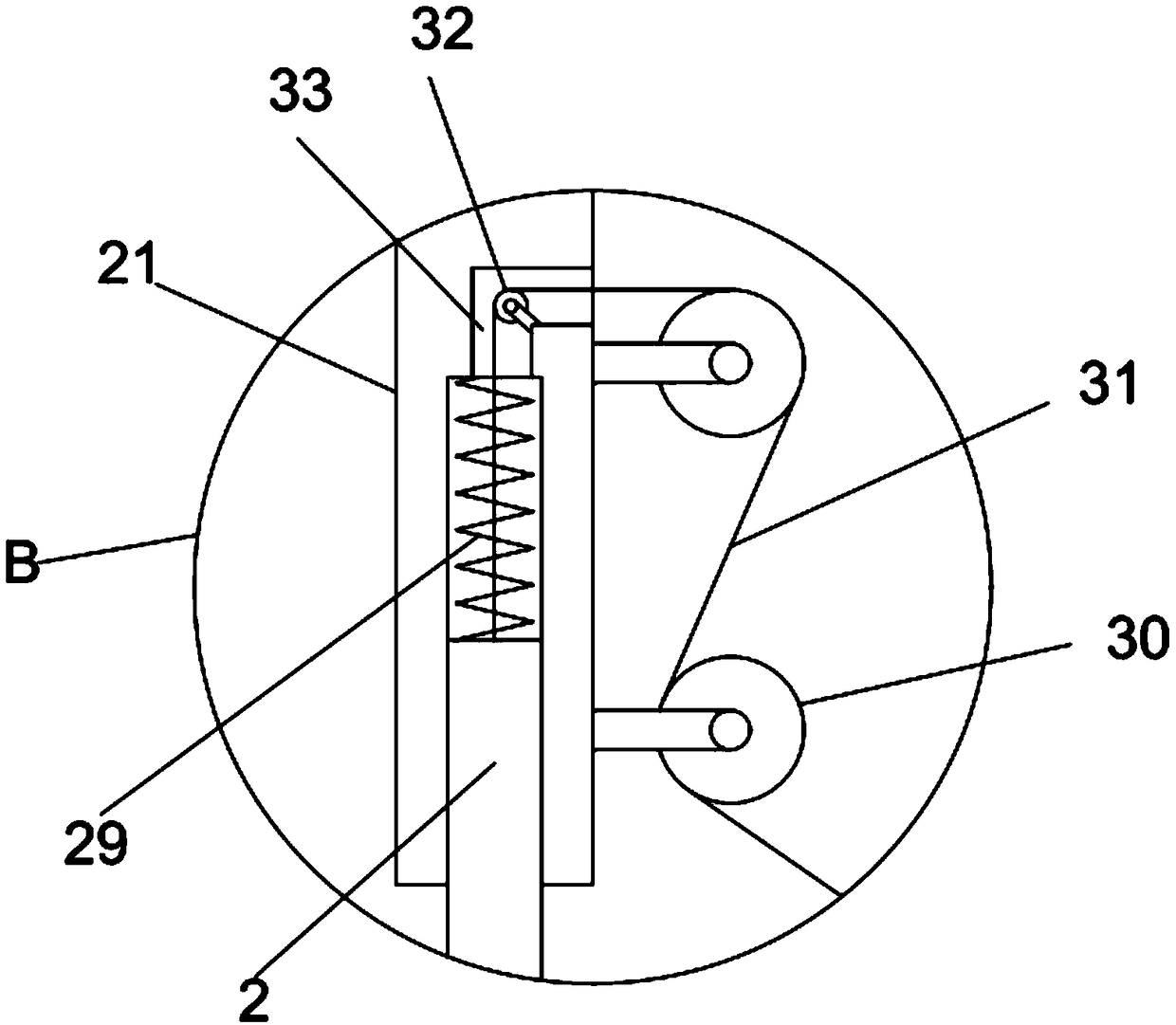

Intermittent feeding type coal briquette coarse crushing device for coal mine mining

InactiveCN108714473ARealize extrusion crushingFully brokenGrain treatmentsCoal briquetteReciprocating motion

The invention discloses an intermittent feeding type coal briquette coarse crushing device for coal mine mining. The intermittent feeding type coal briquette coarse crushing device comprises a bearingplate. A crushing box is fixedly installed on the bearing plate vertically. A rotating cover plate is arranged on the top of the crushing box in a rotating manner. A drive motor is fixedly installedon the outer wall of the left side of the crushing box through a support. The left end of a pulling rope penetrates the interior of a resetting spring and is fixed to the upper end of a sliding baffle. A guide sliding groove is horizontally formed in the side wall of a crushing pressing plate. A clamping block embedded in the guide sliding groove in a sliding manner is fixedly installed on the inner side wall of the sliding support. According to the intermittent feeding type coal briquette coarse crushing device, by means of rotating of a crushing roller, the extruding and crushing effect on coal briquettes is achieved, by means of vertical reciprocating motion of the sliding baffle, the coal briquettes on a material guide oblique plate enter a screening plate intermittently, the coal briquettes falling on the screening plate are extruded and rubbed repeatedly through the crushing pressing disc, excessive centralizing of the coal briquettes is avoided, the rubbing and crushing effectsof the crushing pressing disc are improved greatly, the coal briquettes are crushed more fully, the screening plate has a screening function, and it is ensured that the coal briquettes on the screening plate are refined fully.

Owner:SHANDONG INST OF BUSINESS & TECH

Coal briquette using coke tar slag and dust ash as raw materials as well as method for making same

InactiveCN101255368AReduce manufacturing costSolving problems plaguing coking plantsSolid fuelsWaste based fuelCoal briquetteSlag

Disclosed are a briquette produced from raw materials of tar residue and precipitator dust, and method for making the same, wherein the proportion of raw materials by weight is tar residue 20%-40%; precipitator 80%-60%. The mentioned materials are agitated by double-shaft spiral agitator after mixed according to weight percentage, then are extrusion molded by forming machine, and it can be used as coking coal. The invention reuses waste produced in production process of coke-oven plant in the same enterprises. The invention realizes that wastes is not discharged out of the plant, thoroughly solves problems that bothers coke-oven plant for years, changes waste into valuables, cuts production cost, and enhances economic benefit.

Owner:太原钢城企业集团化工有限公司

Harmonious mining method for block-type dip stripes in deep spanned mining areas of steep inclined seam

InactiveCN103628876AReduce uniformityReduce distortionUnderground miningSurface miningCoal briquetteMining engineering

Aiming at the problems that a lower steep inclined deep part of a building (structure) is large in coal briquetting range and a traditional dip stripe method is low in recovery ratio and production efficiency, the invention discloses a harmonious mining method for block-type dip stripes in deep spanned mining areas of a steep inclined seam. By centering on a protective coal pillar of a building (structure) group, the steep inclined seam with a dip angle of over 45 degrees is divided into multiple block-type mining areas according to the mining level along the trending direction of the seam, and mining blocks and stripe coal pillars are arranged. According to an insufficient mining subsidence principle and the stability requirements of the coal pillar, the width of the block-type mining areas and the width of the dip stripe coal pillars are determined, and multiple bow pseudo-inclined working faces are arranged in the mining areas. The top-to-bottom jointed mining of multiple working faces with aligned cut holes is performed in each mining area, and skip-mining-area intermittent layout and cross-mining-area coordinated mining are adopted between the mining areas. According to the invention, the subsidence influence of each stage of coal pillar mining can be balanced, and the deformation of surface movement can be controlled, so that the recovery rate of the protective coal pillar is improved, and the production efficiency is improved, therefore, the method has good adaptation for the dip angle of the seam.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

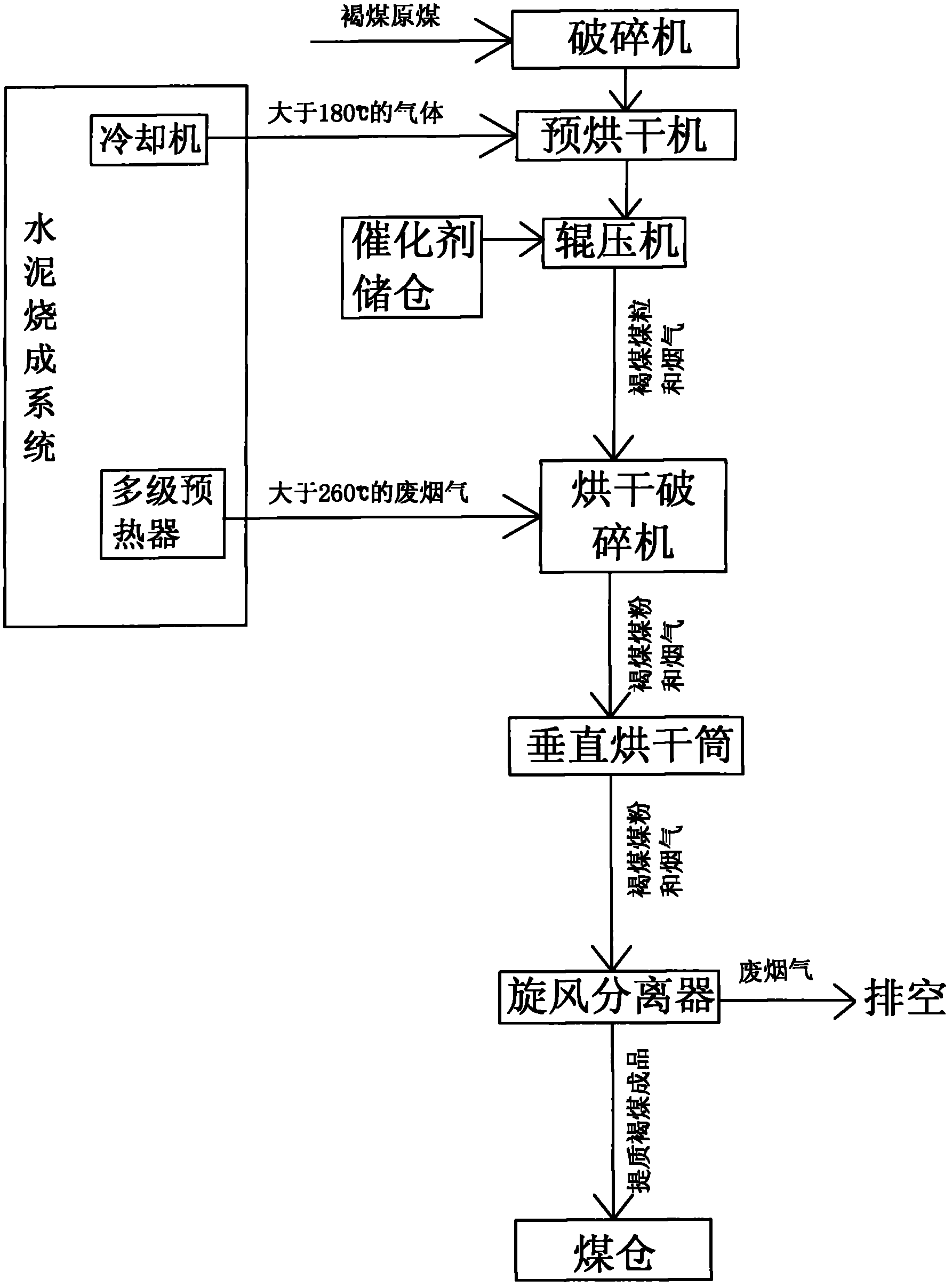

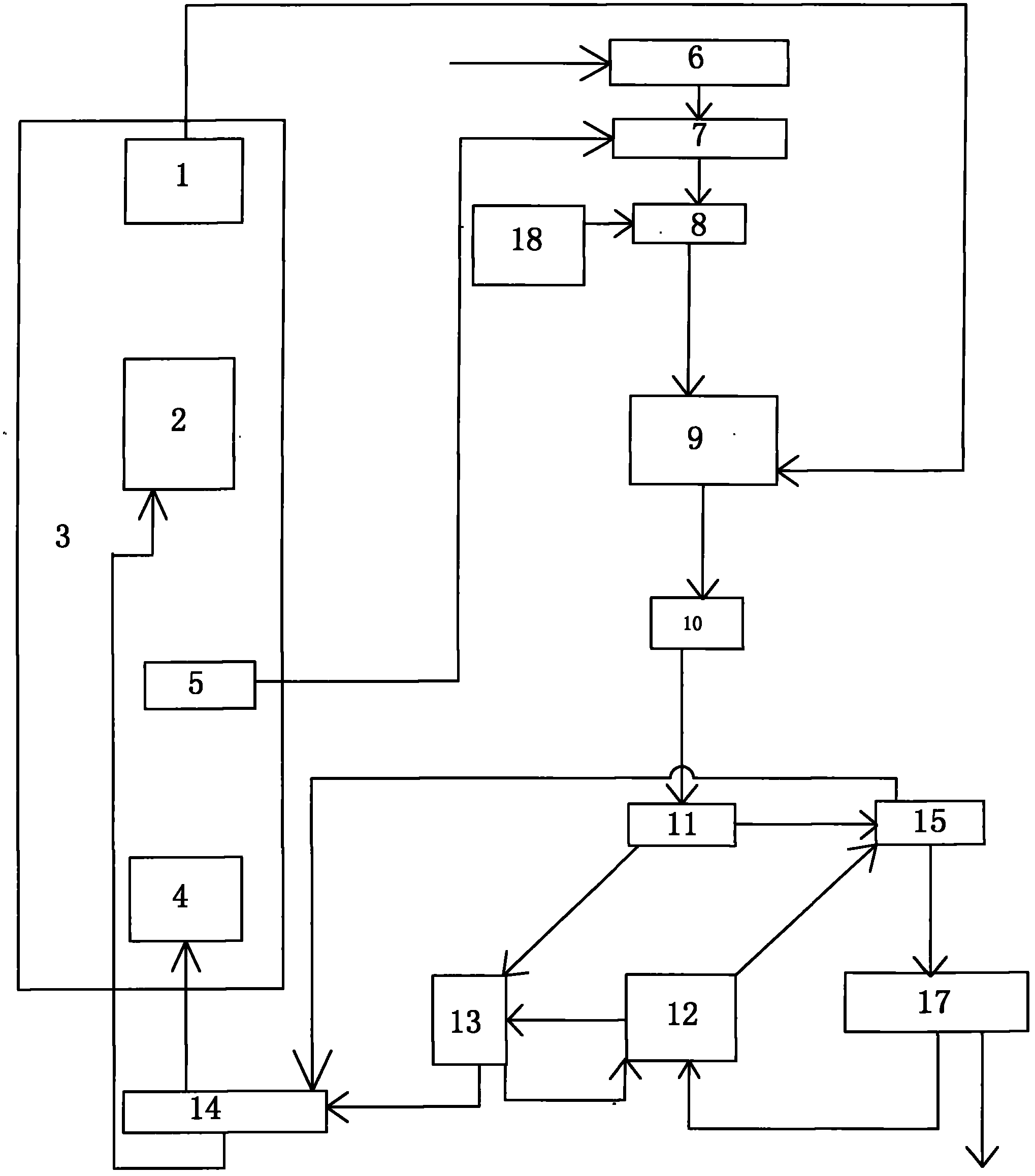

Integral purified integration system and process of lignite in cement production through catalytic mild pyrolysis

InactiveCN102061211AIncrease water vapor contentReduce dust contentSolid fuelsClinker productionCoal briquetteProduction line

The invention discloses an integral purified integration system and process of lignite in cement production through catalytic mild pyrolysis. The system comprises a cement firing system, a crusher, a pre-drying machine, a roll squeezer, a catalyst storage bin, a drying crusher, a vertical drying cylinder and a cyclone separator. The process sequentially comprises the following steps of: (1) initially crushing raw coal of the lignite into coal briquettes; (2) pre-drying the coal briquettes and rolling to crush the coal briquettes to form coal particles; (3) crushing the coal particles to be coal powder through the drying crusher; (4) carrying out heat exchanging, drying and purification on the fine coal powder through the vertical drying cylinder; and (5) separating the purified lignite from the gas through the cyclone separator to obtain a purified lignite finished product. The invention has the advantages that the afterheat in the cement production is fully utilized so as to save energy, reduce consumption and decrease the emission of carbon dioxide; and by utilizing the original process equipment, in the cement production, an additional device is not needed, therefore, the investment is less and the profit is great, and 10,000,000 Yuan on 2500T / d cement production line can be saved every year.

Owner:INNER MONGOLIA UNIV OF TECH

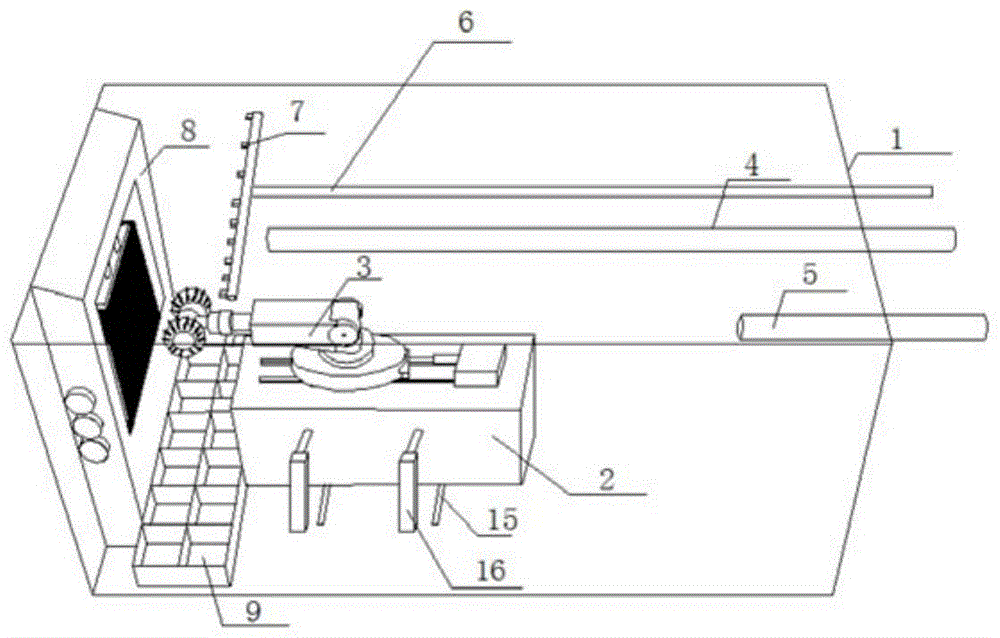

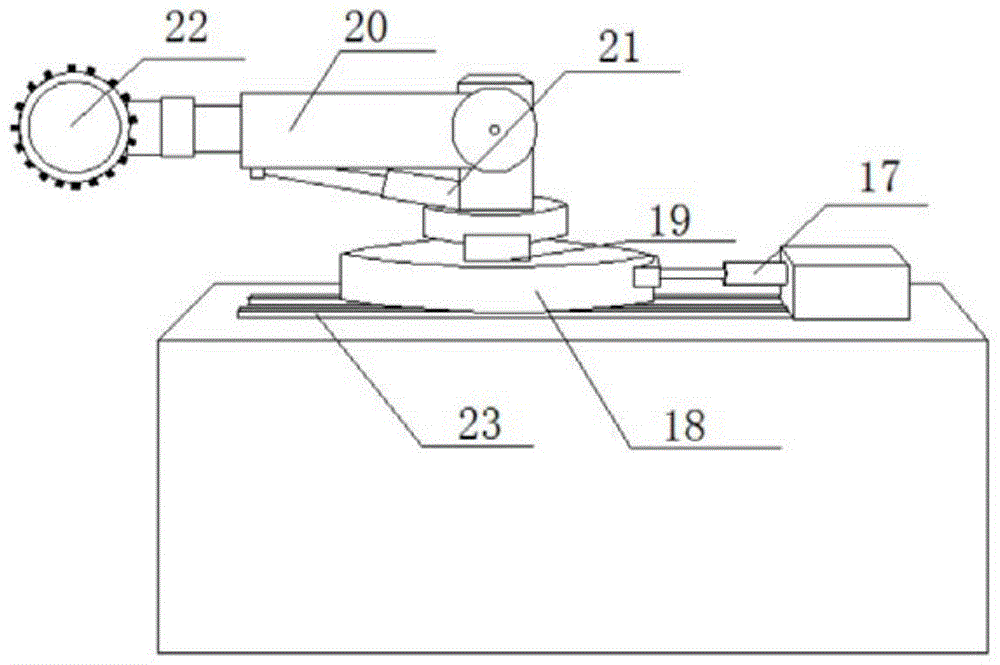

Dust production simulation experiment device for heading machine cutting head and experiment method thereof

ActiveCN105699061AAdjustable and controllable speedRealize detectionMachine part testingCoal briquetteOrganic glass

The invention discloses a dust production simulation experiment device for a heading machine cutting head and an experiment method thereof. The device comprises: an organic glass cover, a heading machine simulation device mounting platform, a heading machine simulation device, a compressed air airduct, a ventilation air duct, a pushing rod, and a measuring meter; According to the method, combination of outer computer control and manual regulation is adopted; through adjusting parameters such as stress of coal briquettes or rocks to be cut, cutting angles, cutting positions, and rotation speed during cutting operation, and air-flowing field of the organic glass cover, the real condition of dust production by the heading machine cutting head in the process of coal mining is simulated. The device is simple in structure, reasonable in layout, and is easy to adjust; the dust production condition of the heading machine cutting head with different cutting angles, at different rotation speed, and under different coal bed conditions can be simulated; the method also has functions of timing record and synchronous data processing.

Owner:SHANDONG UNIV OF SCI & TECH

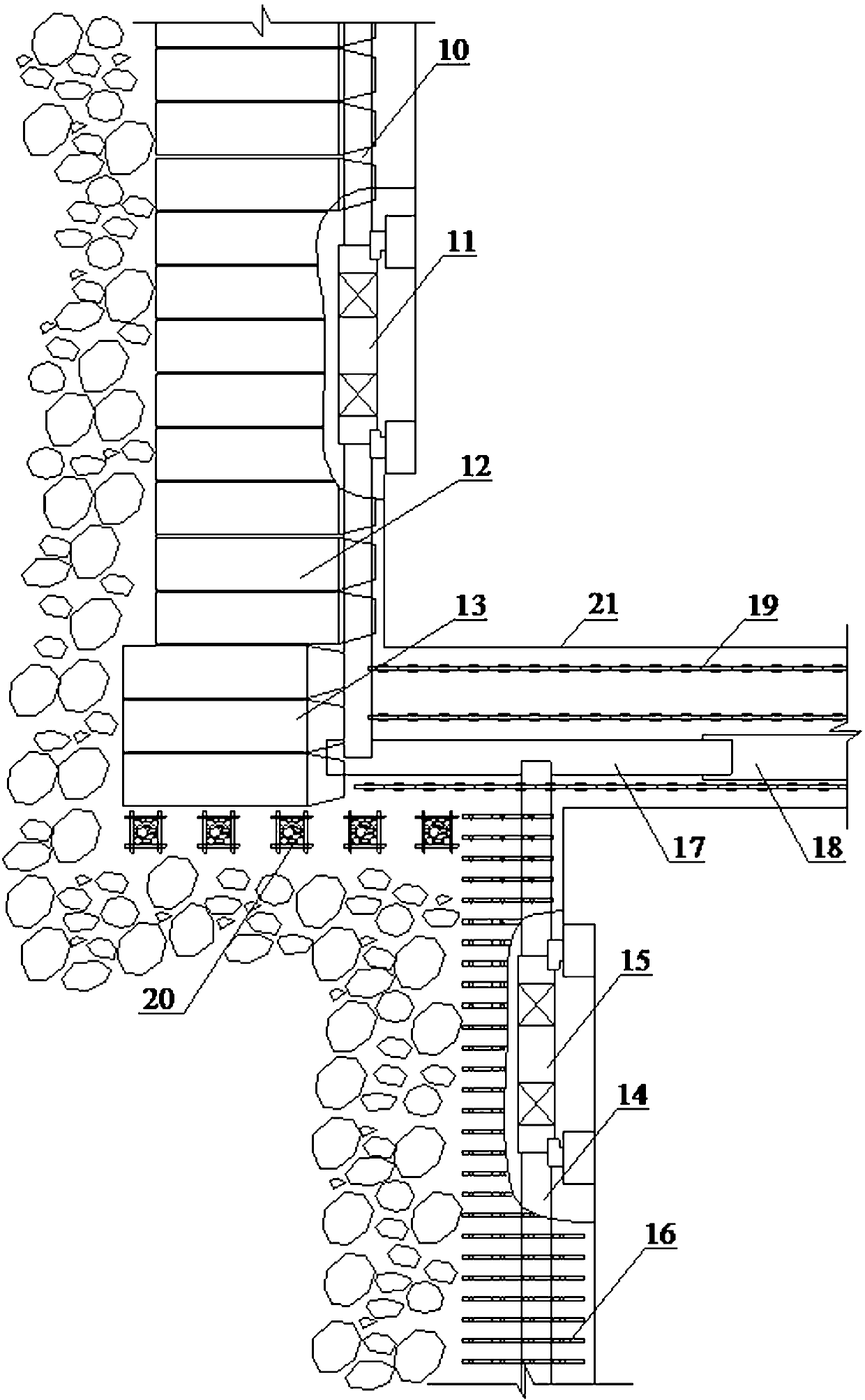

Method and equipment for separating, conveying and filling underground coal and gangues

InactiveCN103133031APrevent collapseAvoid problems such as gangue pile accumulationSolid separationMaterial fill-upCoal briquetteProcess engineering

The invention discloses a method and equipment for separating, conveying and filling underground coal and gangues. The method includes crushing and separating the coal and the gangues directly in an underground environment twice by a roll crushing separator and a hammer crushing separator; directly feeding separated coal briquettes into an underground coal bunker by a pneumatic conveying and filling system; crushing separated gangues into gangue fragments by a roll crusher; and conveying the crushed gangues to a mined-out region to fill the mined-out region. The method and the equipment have the advantages that the problem in the aspect of transportation for underground coal and underground gangues is solved, underground space is saved, large quantities of raw materials are provided for filling the underground mined-out region, problems of surface subsidence, accumulation of a gangue dump and the like are solved, and requirements on environment-friendly coal mining and environment-friendly production are met; and the method is smart in conception, the structure is reasonable, the equipment is simple, the occupied underground space is small, particularly, an underground transportation structure is changed owing to the pneumatic conveying and filling system, the underground space utilization rate is increased, coal and gangue separating equipment is good in separation effect, and the method and the equipment are wide in applicability and high in novelty in the field.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com