Dry-type joint coal rock sampling device and sampling method thereof

A jointed coal rock and sampling device technology, which is applied in the direction of sampling devices, can solve the problems of high cost and low sampling success rate, and achieve the effect of enhancing stability, enhancing stability and accuracy, and increasing cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described:

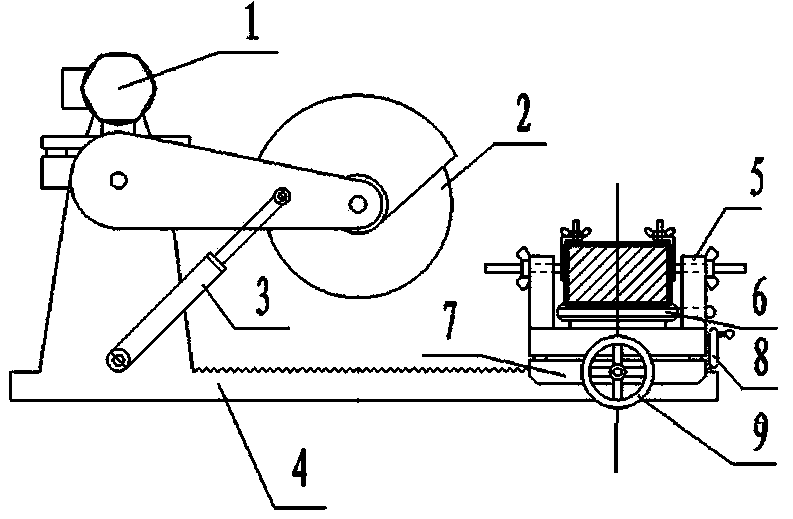

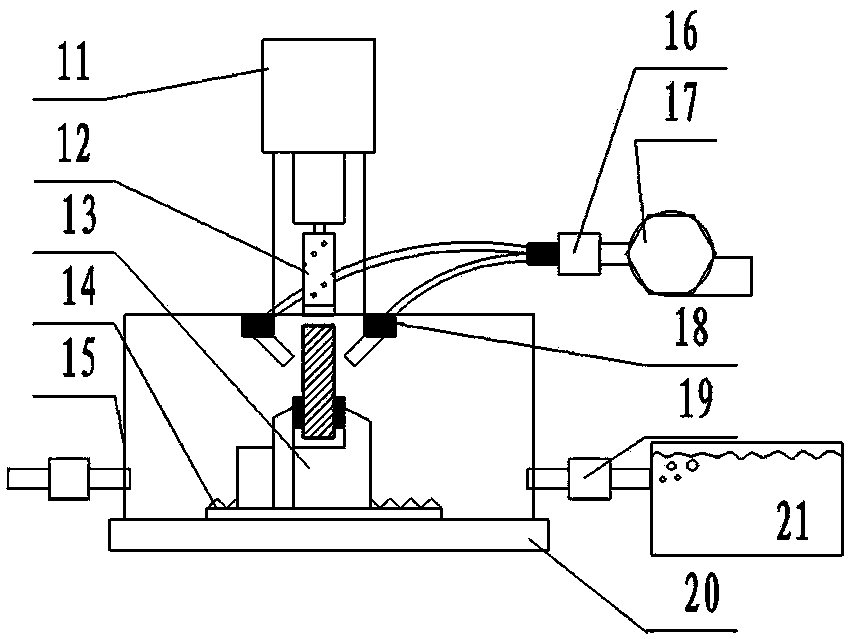

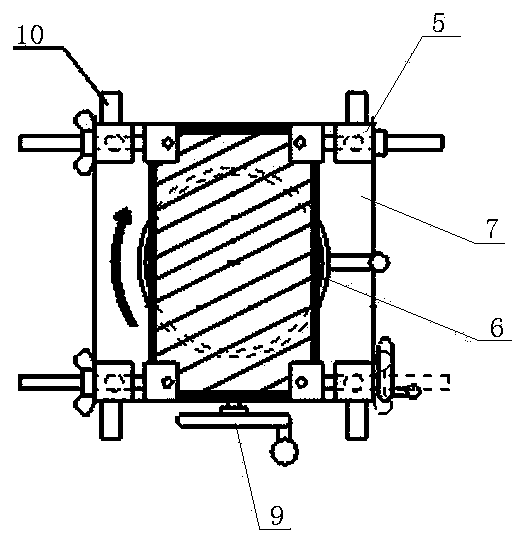

[0034] This jointed coal rock dry rock sampling device includes a cutting device and a sampling device, the cutting device has a cutting seat, see figure 1 , the cutting motor 1 is installed on the top of the cutting seat, the cutting motor 1 provides power, one end of the cutting wall is connected with the cutting seat, the other end of the cutting wall is installed with a saw blade 2, and a height adjustment device 3 is installed between the cutting seat and the saw blade 2, the height The adjustment device 3 is a hydraulic rod, the saw blade 2 can be switched, and the height of the saw blade 2 can be adjusted; the cutting seat also has a cutting track 4, and the slide rail base 7 is connected with the cutting track 4. The slide rail base 7 is a two-way slide rail, and the slide rail base 7 can be made by lathe slide crate; see image 3 , Figure 4 The slide rail base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com