Clean fuelization system and fuelization method for urban sludge

A technology of municipal sludge and municipal domestic sludge, which is applied in the clean fuel system of municipal sludge and the field of sludge fuelization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

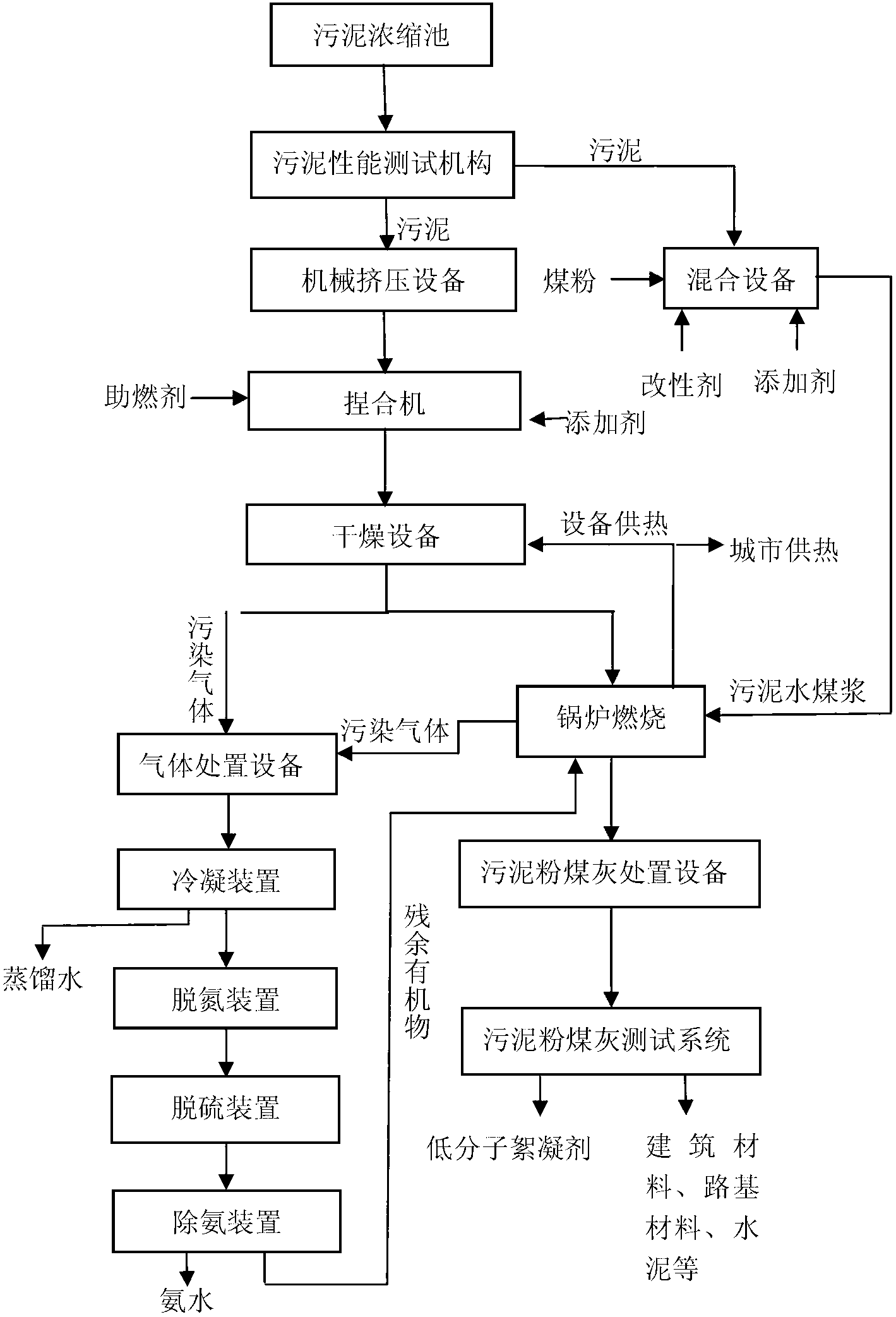

Method used

Image

Examples

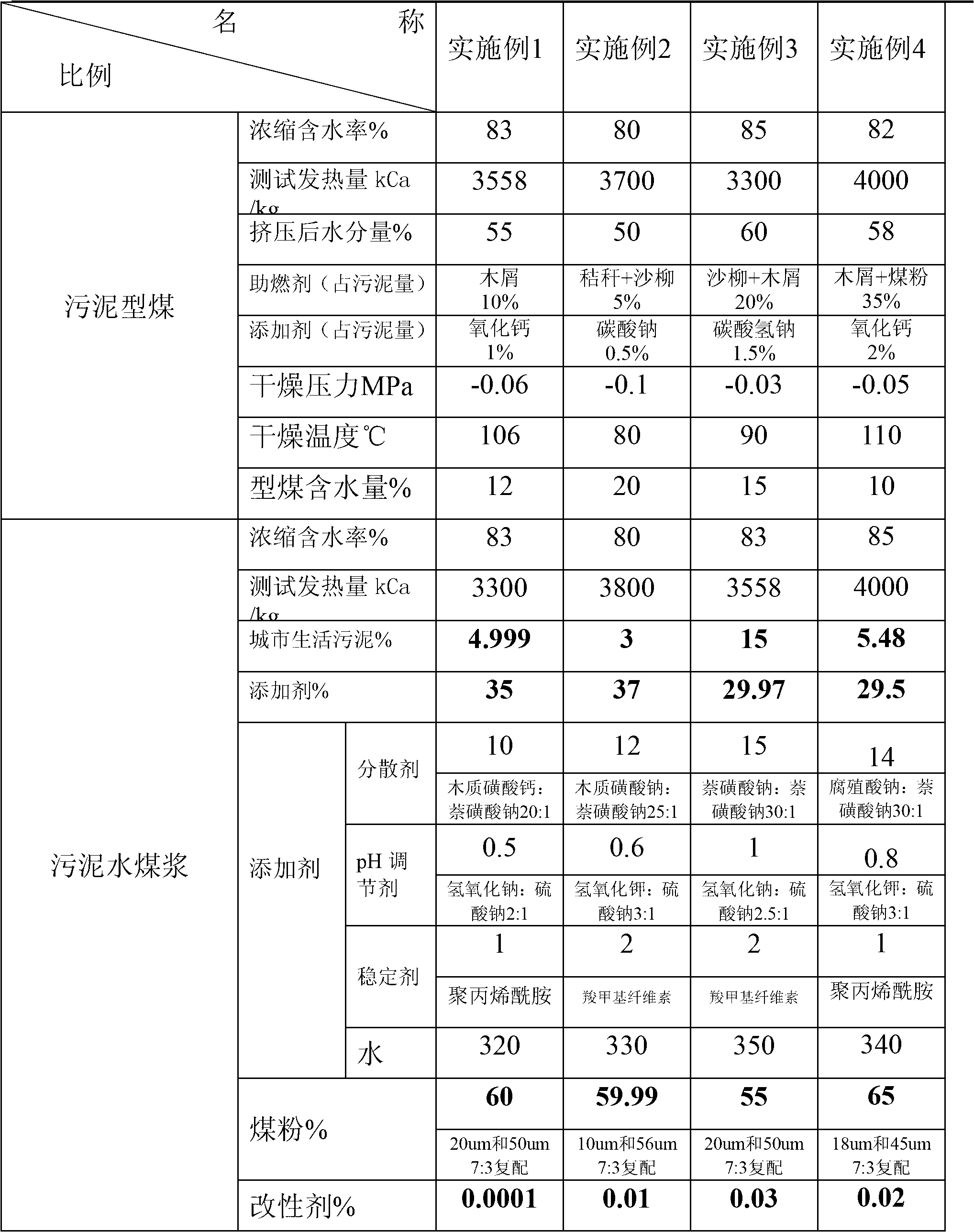

Embodiment 1

[0066] Preparation of sludge briquette (embodiment 1 in the table below)

[0067] 1) Concentrate the sludge produced by the urban sewage treatment plant so that the moisture content is about 83%, and the calorific value of the performance test is 3558kCa / kg;

[0068] 2) The sludge with a moisture content of 83% is mechanically extruded until the sludge moisture content is 50%;

[0069] 3) Crush the sawdust to a particle size of 3mm;

[0070] 4) Mix 100g of sludge with a moisture content of 50%, 10g of filler wood chips, and 1.25g of additive calcium oxide. After uniform mixing, it is prepared into a cylindrical shape by a kneader, and the sludge is dried at 106°C under a pressure of -0.06MPa. The moisture content of the briquettes is 20%, and the drying process adopts a closed circulation system;

[0071] 5) The gas in the drying process is dehydrated, denitrified, desulfurized and deammonized through the gas treatment system, and the distilled water and ammonia water in the...

Embodiment 3

[0076] 1) After the urban sewage treatment plant sludge is concentrated and treated with a water content of about 83%, the calorific value of the performance test is 3558kCa / kg;

[0077] 2) Modified with 15g of municipal domestic sludge and 0.03g of hydrogen peroxide, and left for 15-20min to obtain modified sludge;

[0078] 3) Prepare mixed pulverized coal with long-flame coal in northern Shaanxi with a particle size of 20um and 50um and a mass mixing ratio of 7:3, and add 55g of mixed pulverized coal to the modified sludge;

[0079] 4) According to the mass ratio of 15:1:2:350, add sodium lignosulfonate as a dispersant, a mixture of sodium hydroxide and sodium sulfate as a pH regulator, carboxymethylcellulose as a stabilizer, and water to form an additive mixed solution; in step 3) Add the additive mixed solution of 29.97g in;

[0080] 5) In the reactor, stir at a speed of 1000r / min for 20min to obtain sludge coal-water slurry;

[0081] 6) The gas burned by the sludge coal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com