Intermittent feeding type coal briquette coarse crushing device for coal mine mining

A coal block and coarse crushing technology, which is applied in the direction of grain processing, etc., can solve the problems of poor coal crushing effect, reduced crushing effect, and incomplete coal crushing, so as to improve the crushing effect of kneading, sufficient crushing, and avoid excessive concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

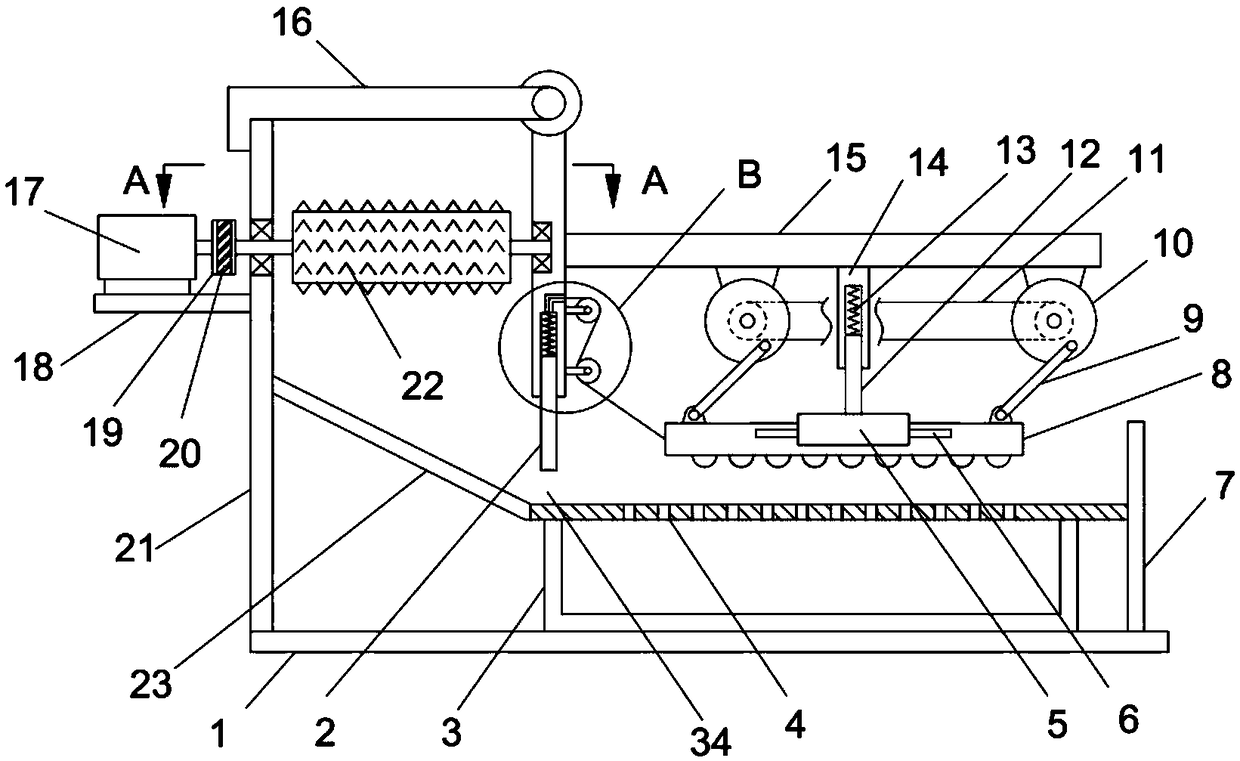

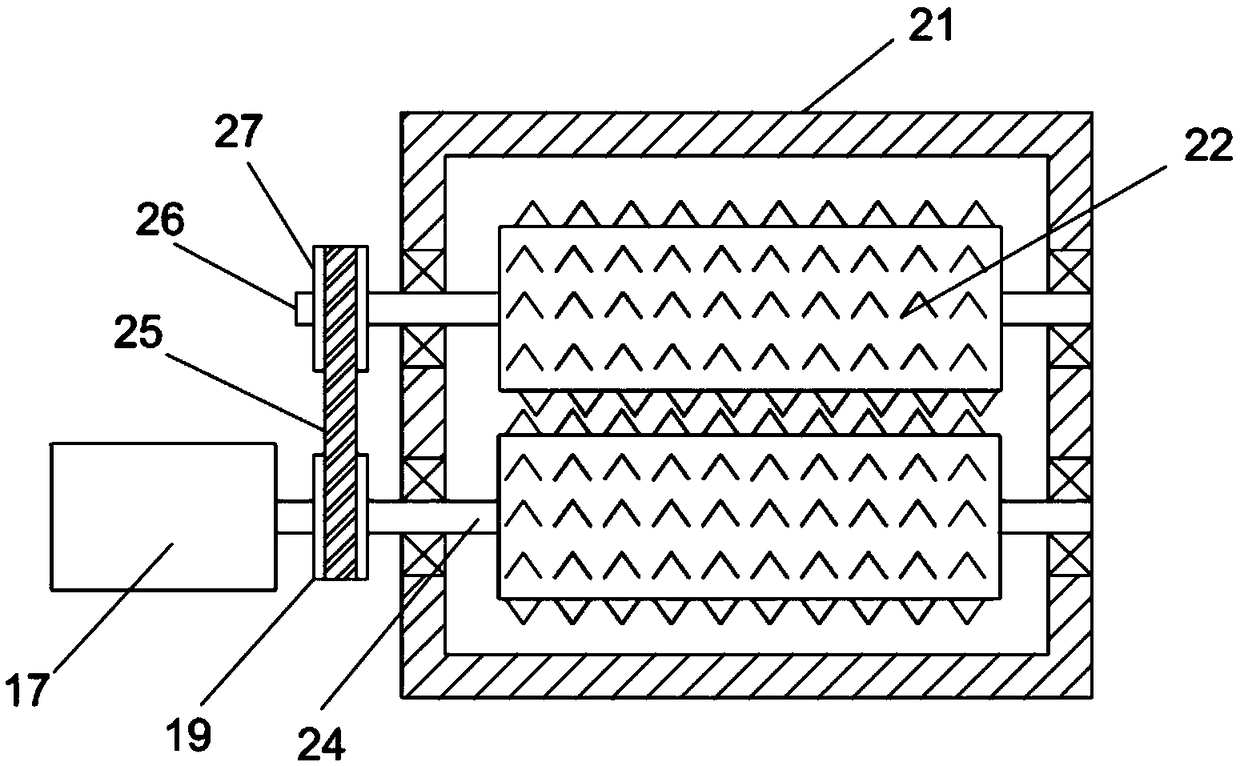

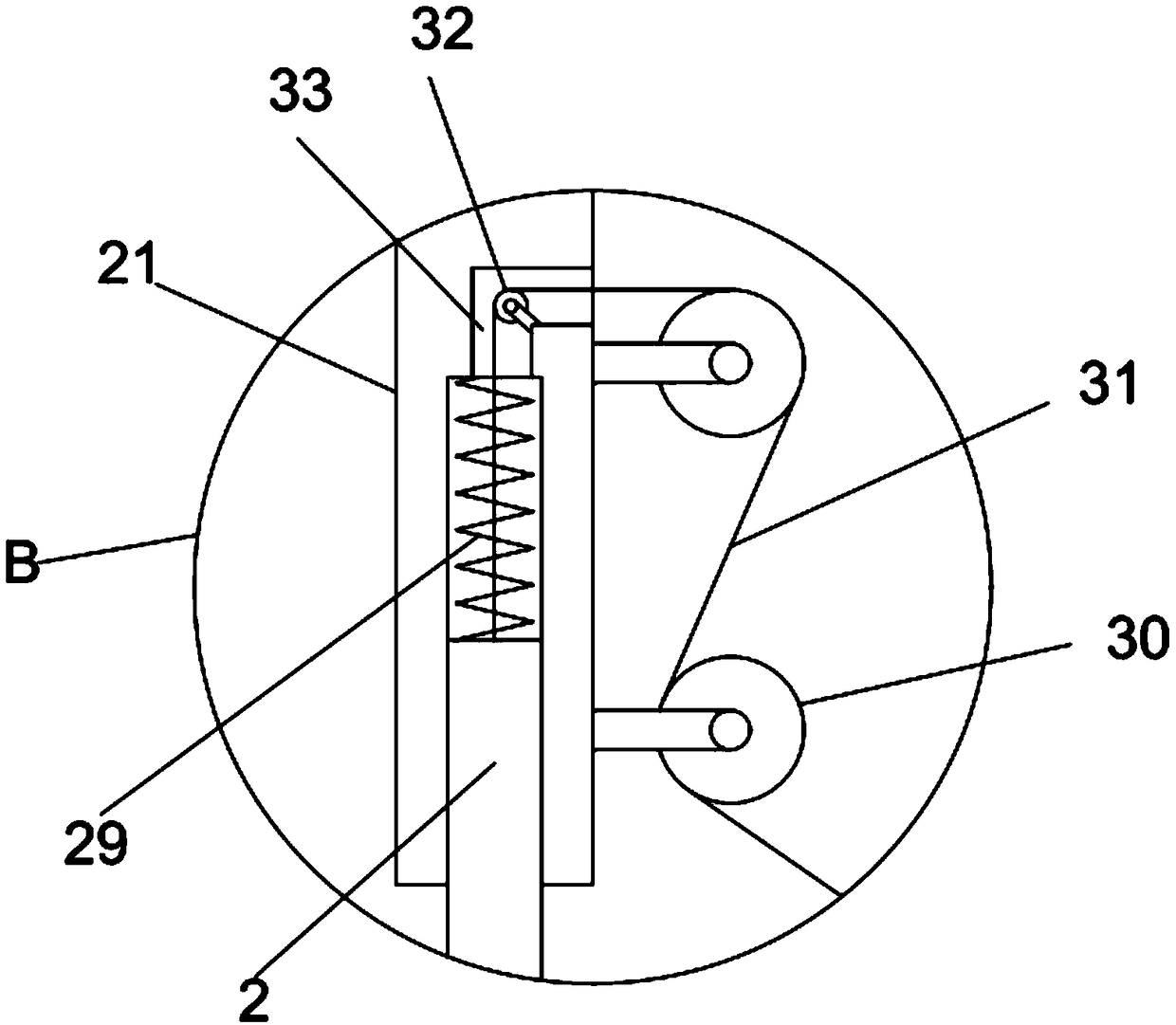

[0021] see Figure 1-4 , a kind of intermittent feed type coal mine exploitation adopts coarse coal crushing device, comprises bearing plate 1, is vertically fixedly installed on bearing plate 1 crushing box 21, and the top of crushing box 21 is rotatably provided with rotating cover plate 16, and described crushing The outer wall on the left side of the box 21 is fixed with a drive motor 17 through a bracket, the output shaft of the drive motor 17 is coaxially fixed with a drive shaft 24 extending to the inside of the crushing box 21, and a driven shaft 26 is provided in the crushing box 21 in a rotating and horizontal manner. The surfaces of the driven shaft 26 and the driving shaft 24 are both sleeved and fixedly installed with crushing rollers 22 arranged oppositely. The inside of the crushing box 21 is provided with a sloping guide plate 23, and a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com