Patents

Literature

48results about How to "Play a screening role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

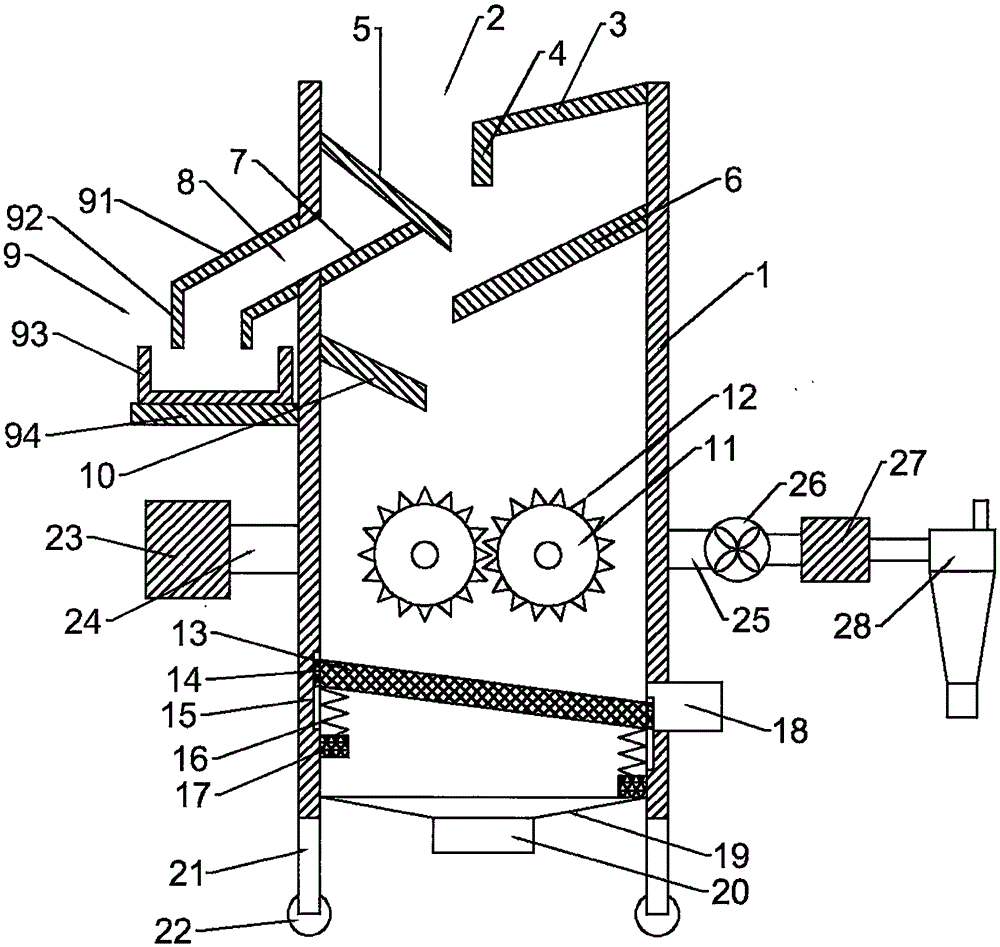

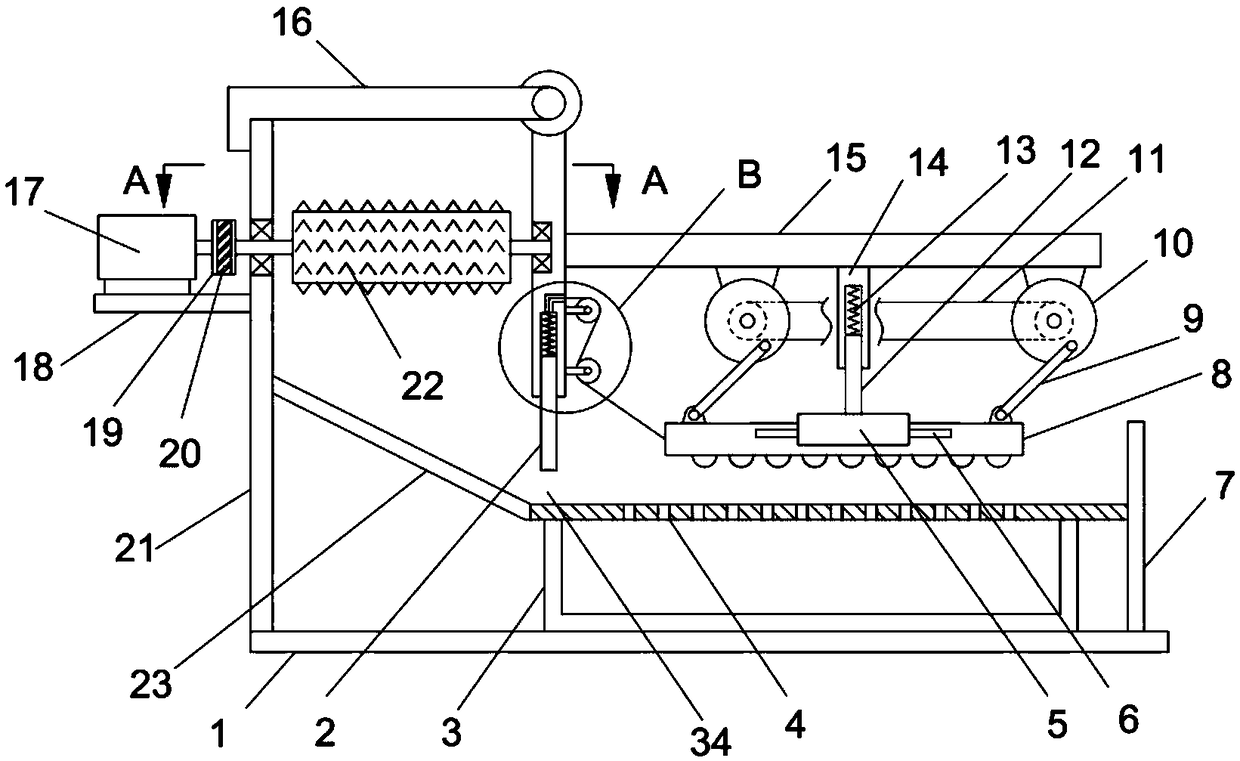

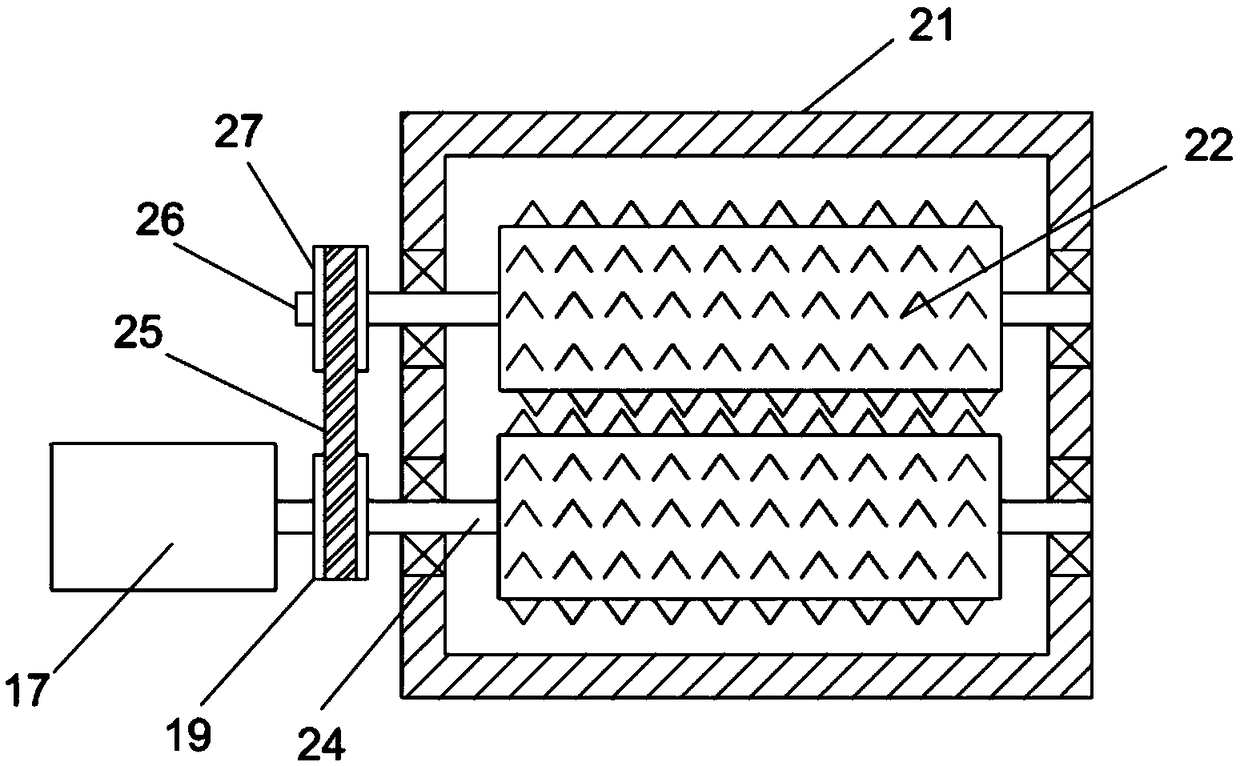

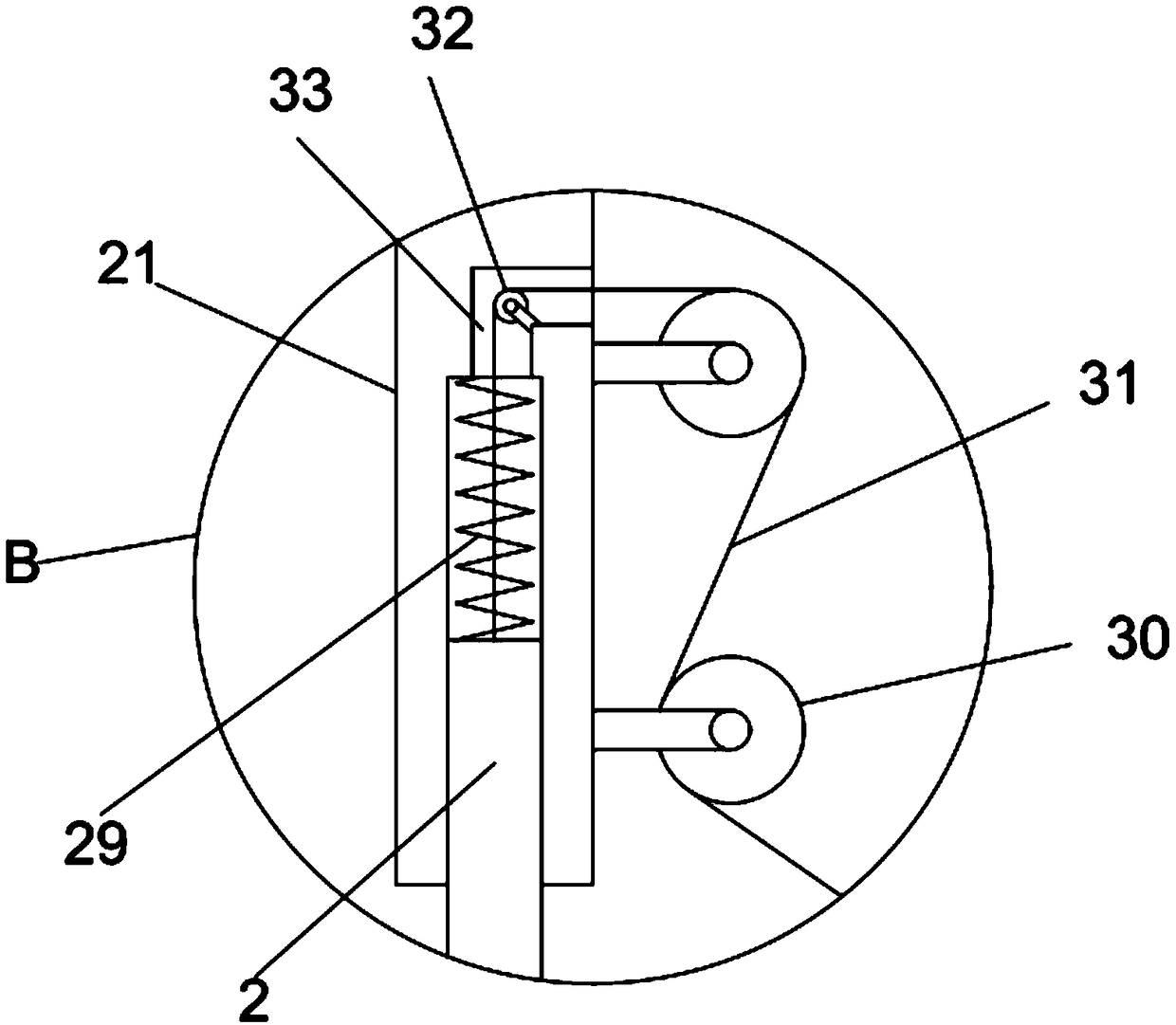

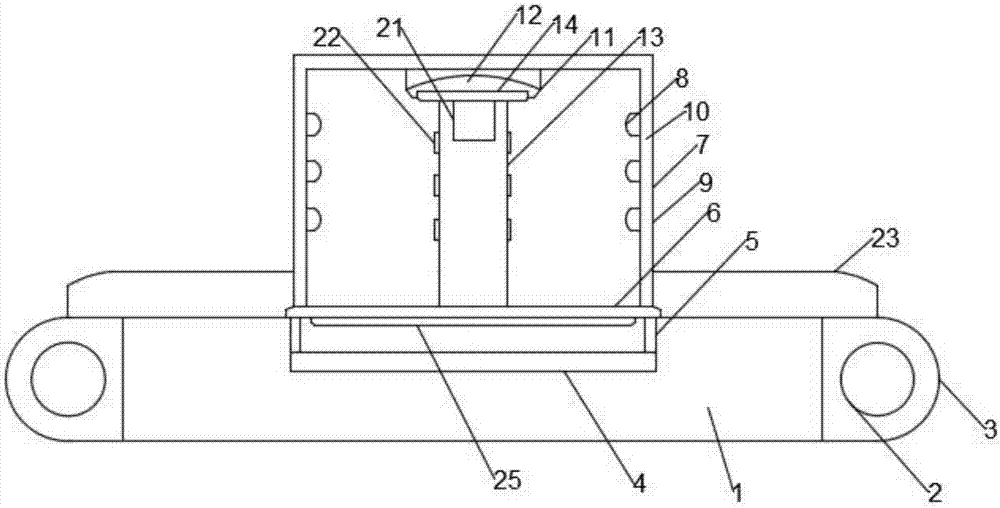

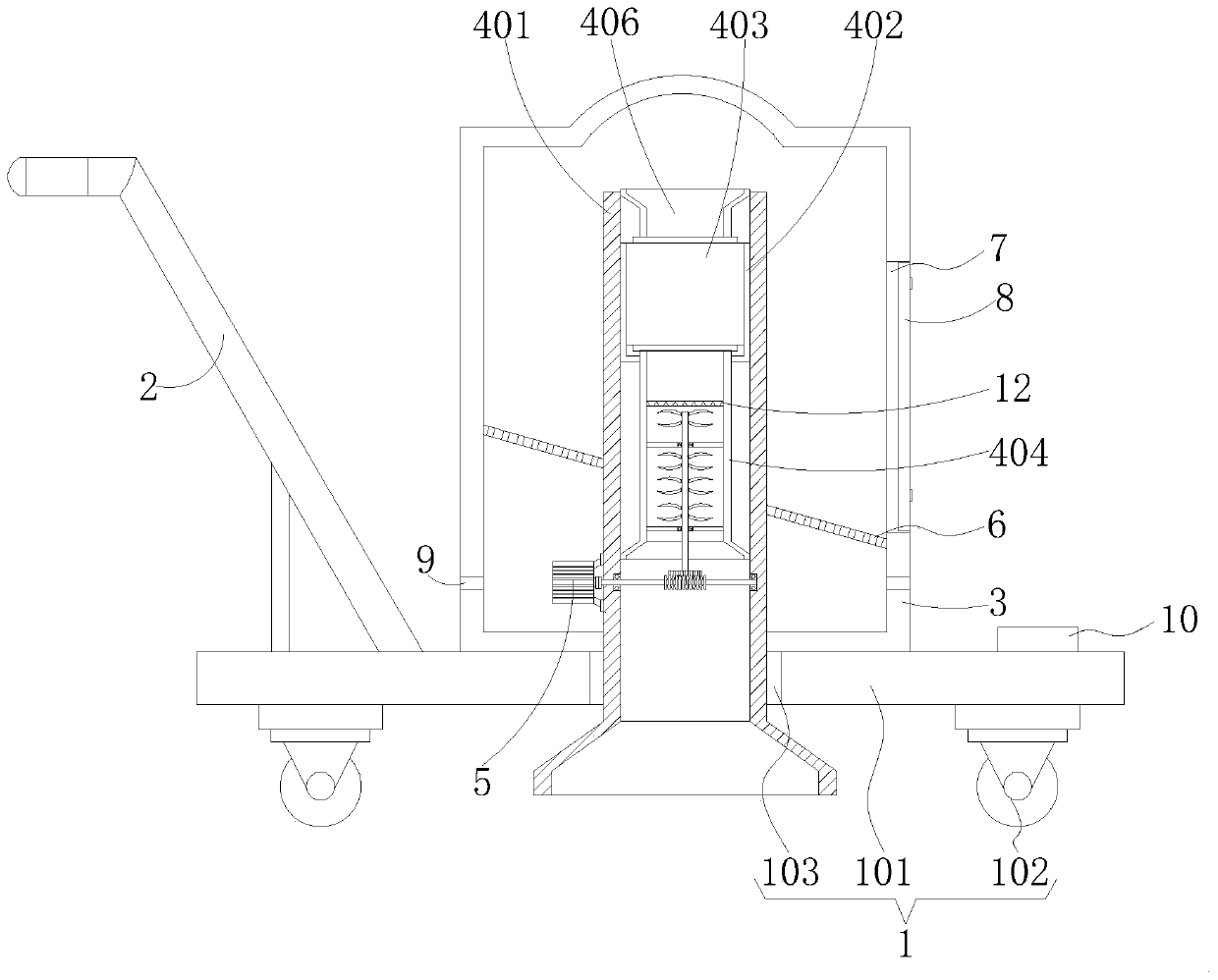

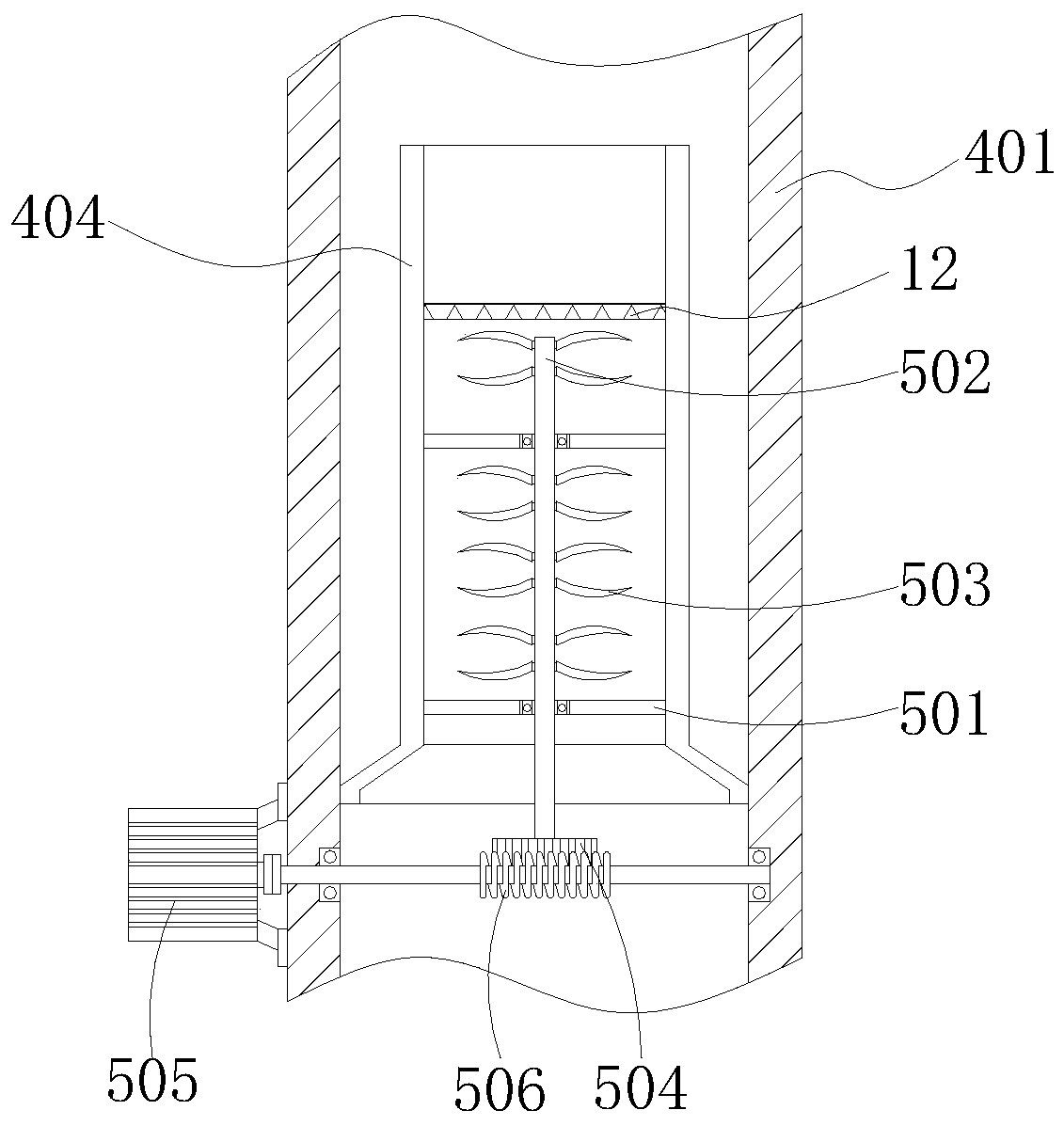

Plastic particle smashing, screening and drying device

InactiveCN105665069ASimple structureEasy to useGranular material dryingDrying gas arrangementsEngineeringAir blower

The invention discloses a crushing, screening and drying device for plastic particles, which comprises a machine body, a feed inlet is arranged at the upper end of the machine body, a through hole is opened on the left surface of the machine body, and a recovery device fixed on the outer wall of the machine body is arranged under the through hole; the machine body There is also a material guide plate inside. Two crushing rollers are installed under the lowest end of the material guide plate. There is an inclined filter plate under the crushing roller. Sliders are welded at both ends of the filter plate. The chute matched with the block, springs are connected to both ends of the filter plate, outriggers are provided at the lower end of the body, and rollers are installed at the bottom of the legs; a hot air blower is installed on the left side of the body, and the right end of the hot air blower passes through the air The pipe is connected with the body, the right side of the body is connected with the exhaust fan through the air outlet pipe, and the right end of the exhaust fan is connected with the drying device through the pipeline. The invention has the advantages of simple structure, convenient use, improved crushing efficiency, energy saving, environmental protection and convenient movement.

Owner:杨露萍

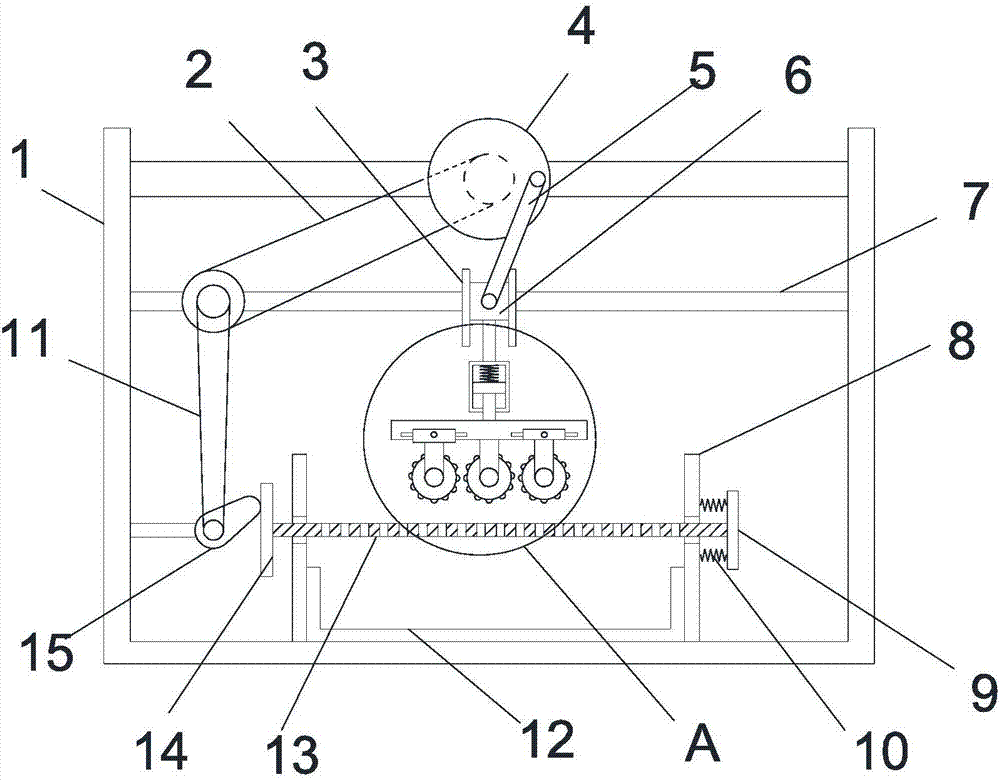

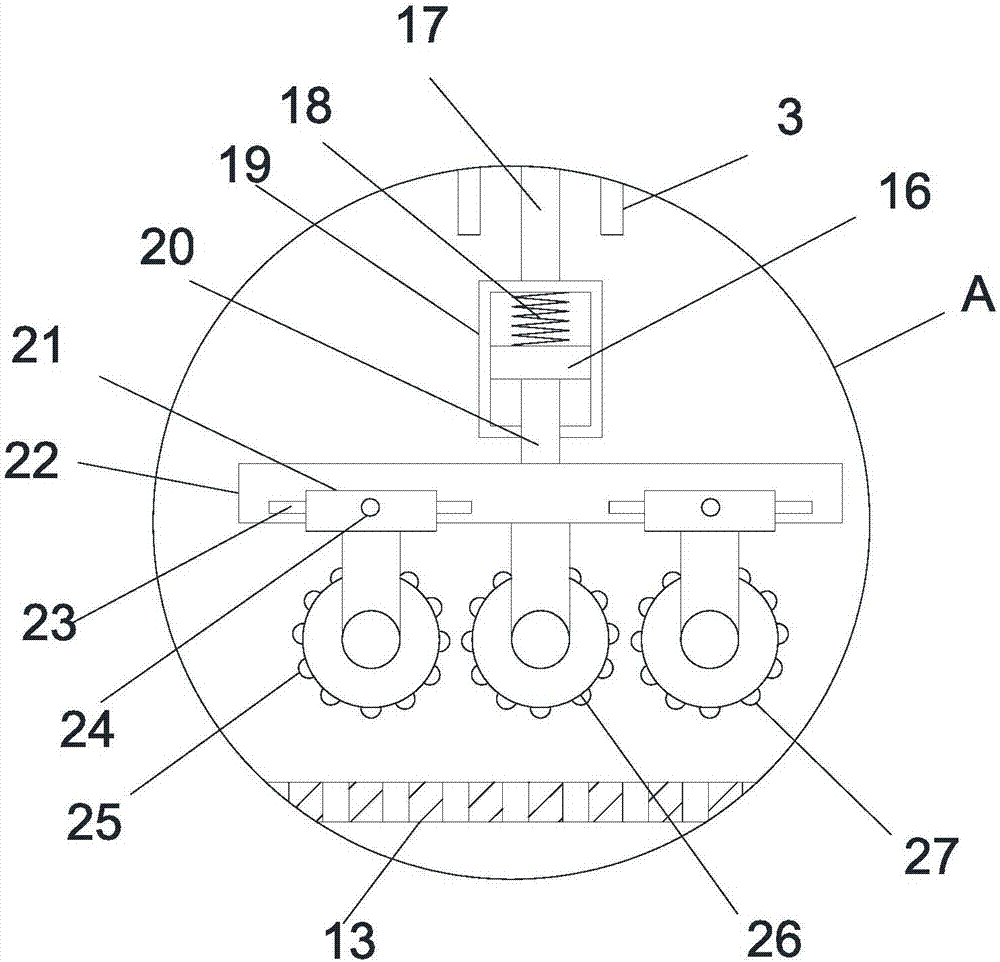

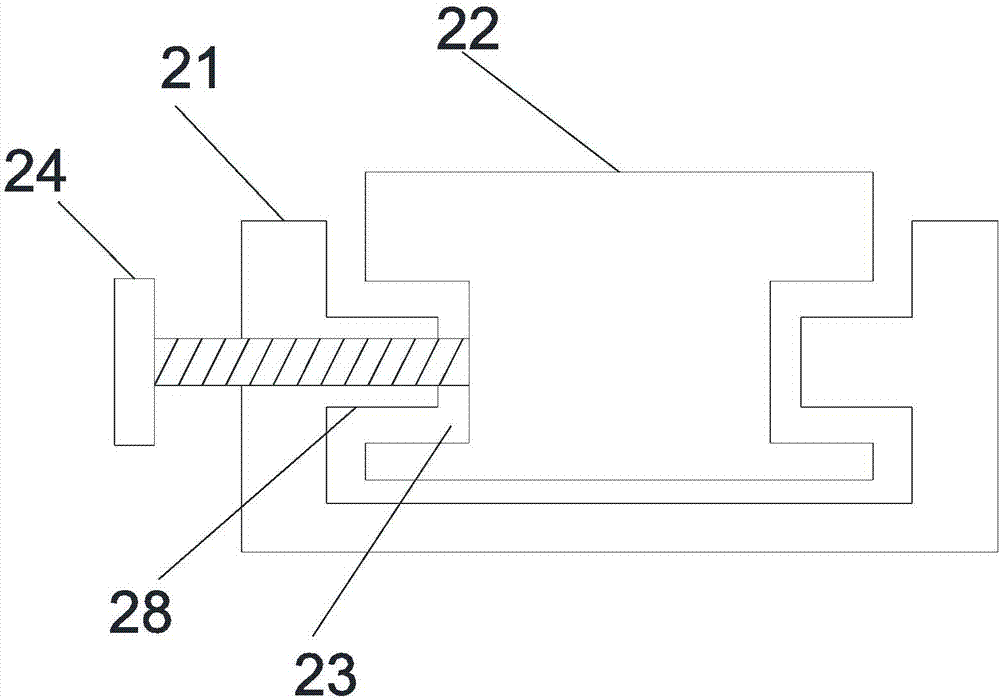

Rapid peanut deshelling device with screening function

InactiveCN107874279AImprove the efficiency of breaking upSpread evenlySievingScreeningEngineeringCam

The invention discloses a rapid peanut deshelling device with a screening function. The rapid peanut deshelling device comprises a frame, wherein a horizontal plate is fixedly mounted horizontally inside the frame; a deshelling tank is fixedly mounted at the bottom inside the frame; a collecting tank is arranged at the bottom inside the deshelling tank; a metal screening plate is arranged inside the frame in a horizontal sliding and penetration manner; a limiting push plate is fixedly mounted vertically art the left end of the metal screening plate; a rotating wheel is rotationally arranged onthe frame; a deshelling rotating roller I is vertically rotationally arranged on the lower surface of a sliding rack; a cam which is propped against the limiting push plate is rotationally arranged inside the frame; and a first belt pulley mechanism in transmission connection with the rotating wheel is arranged on the horizontal plate. Peanuts are subjected to deshelling operation through downward extrusion of the deshelling rotating roller I and a deshelling rotating roller II, the deshelling rotating roller I and the deshelling rotating roller II are moved relative to the metal screening plate, then the peanuts are subjected to rolling extrusion and deshelling of the deshelling rotating roller I and the deshelling rotating roller II, the peanut deshelling efficiency is greatly improved,and the peanuts can be deshelled relatively sufficiently and completely.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Intermittent feeding type coal briquette coarse crushing device for coal mine mining

InactiveCN108714473ARealize extrusion crushingFully brokenGrain treatmentsCoal briquetteReciprocating motion

The invention discloses an intermittent feeding type coal briquette coarse crushing device for coal mine mining. The intermittent feeding type coal briquette coarse crushing device comprises a bearingplate. A crushing box is fixedly installed on the bearing plate vertically. A rotating cover plate is arranged on the top of the crushing box in a rotating manner. A drive motor is fixedly installedon the outer wall of the left side of the crushing box through a support. The left end of a pulling rope penetrates the interior of a resetting spring and is fixed to the upper end of a sliding baffle. A guide sliding groove is horizontally formed in the side wall of a crushing pressing plate. A clamping block embedded in the guide sliding groove in a sliding manner is fixedly installed on the inner side wall of the sliding support. According to the intermittent feeding type coal briquette coarse crushing device, by means of rotating of a crushing roller, the extruding and crushing effect on coal briquettes is achieved, by means of vertical reciprocating motion of the sliding baffle, the coal briquettes on a material guide oblique plate enter a screening plate intermittently, the coal briquettes falling on the screening plate are extruded and rubbed repeatedly through the crushing pressing disc, excessive centralizing of the coal briquettes is avoided, the rubbing and crushing effectsof the crushing pressing disc are improved greatly, the coal briquettes are crushed more fully, the screening plate has a screening function, and it is ensured that the coal briquettes on the screening plate are refined fully.

Owner:SHANDONG INST OF BUSINESS & TECH

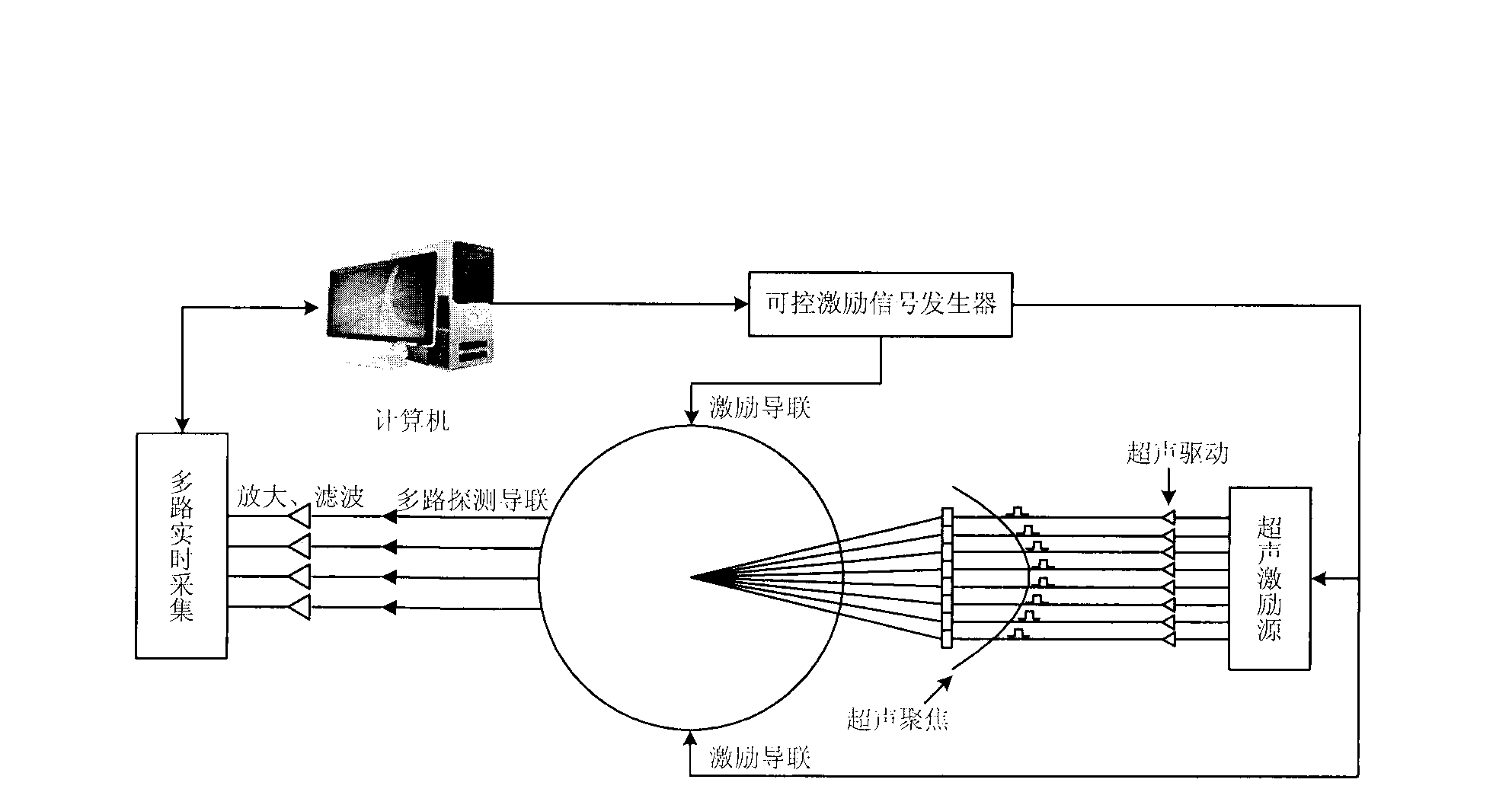

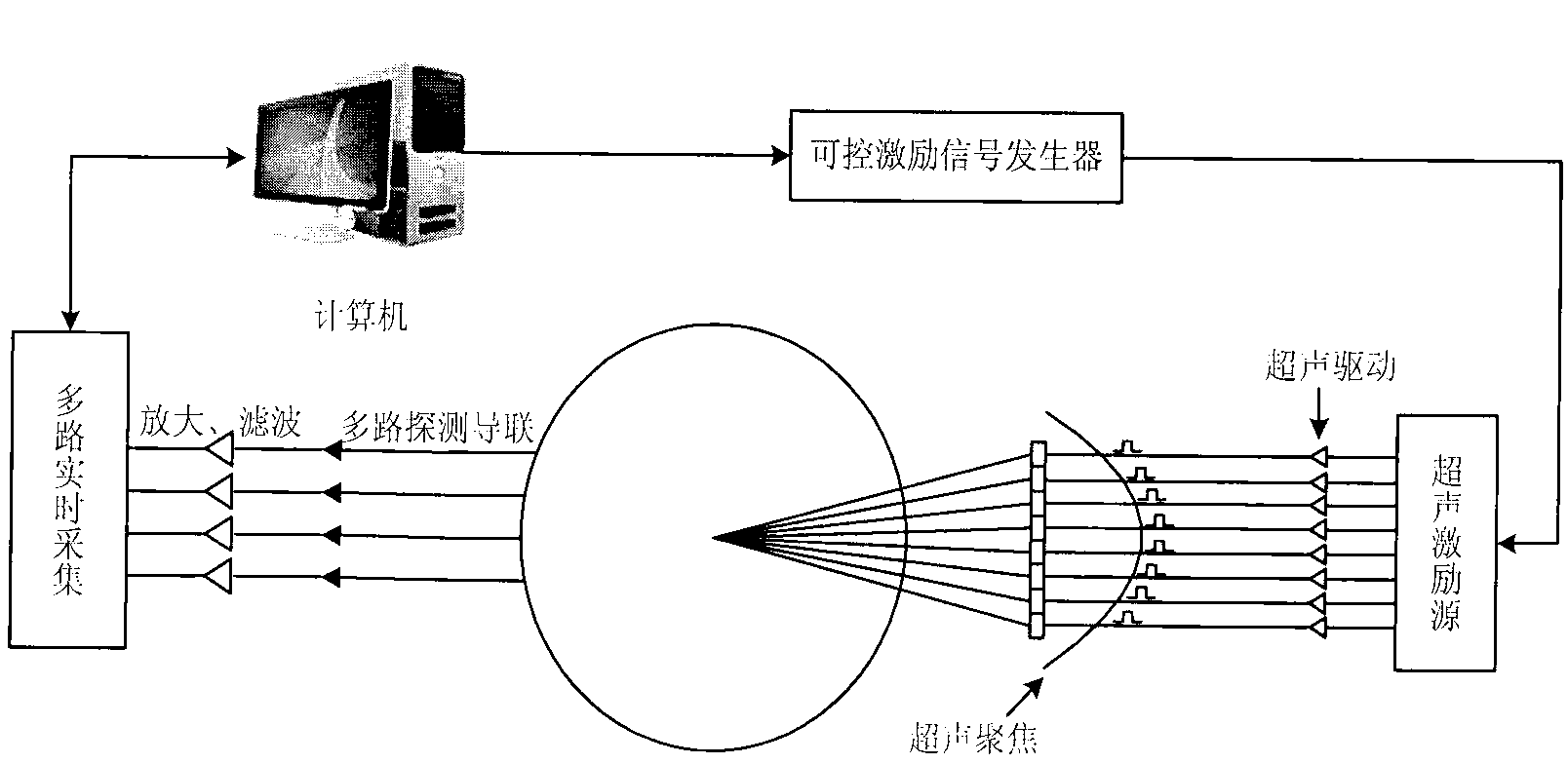

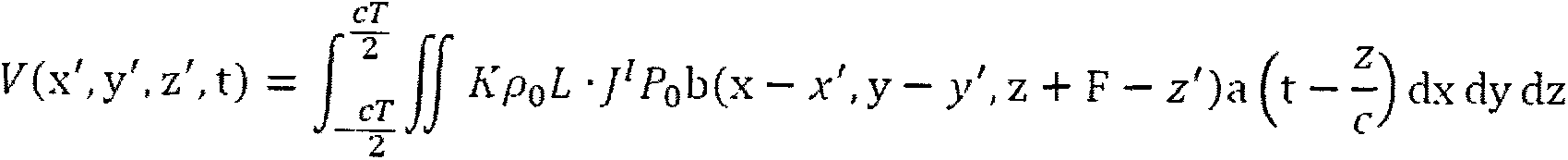

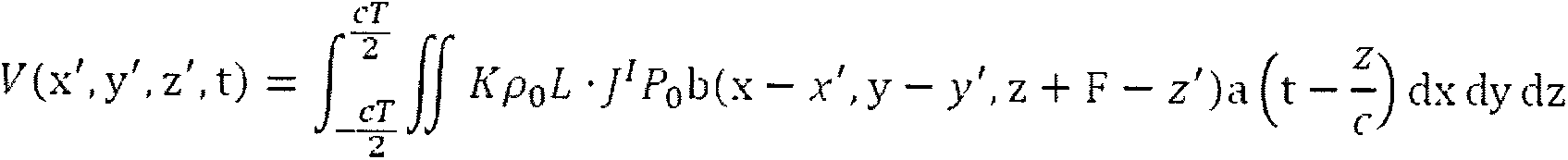

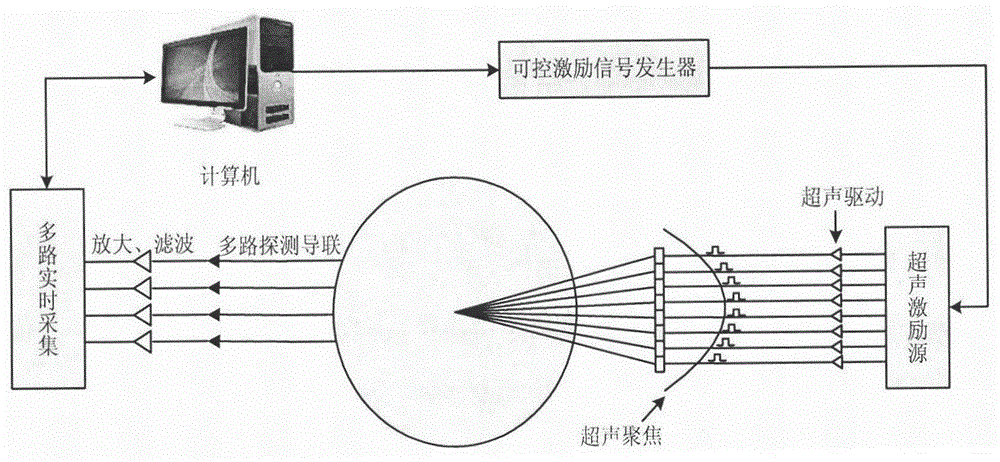

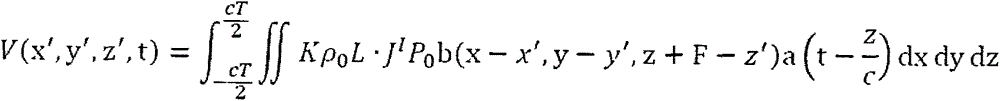

Electrical impedance imaging method of ultrasonic-synergy biological tissue

InactiveCN103156604APromote reconstructionHigh precisionOrgan movement/changes detectionDiagnostic recording/measuringSonificationSynergy

The invention discloses an electrical impedance imaging method of an ultrasonic-synergy biological tissue. The electrical impedance imaging method comprises that a plurality of electric excitation leads and detection guide leads are arranged on the surface of the biological tissue, and an ultrasonic excitation source is adopted to generate ultrasonic waves and the ultrasonic waves are focused in the biological tissue through ultrasonic drive; the ultrasonic waves focused in the biological tissue are located in a continuous mode, and integral or partial scanning to the biological tissue is finished; signals are collected, the ultrasonic waves are focused at a certain spatial position, and a high-frequency signal corresponding to electrical impedance of the spatial position is generated, the signals are collected through the multi-channel detection leads, amplified, filtered, and then output; after focusing and scanning of the ultrasonic waves are finished, a voltage signal after being collected is guided in a computer, and a signal is obtained according to the collected integral scanning and partial scanning to the biological tissue, and electrical impedance distribution of the biological tissue is calculated and rebuilt. Through the electrical impedance imaging method of the ultrasonic-synergy biological tissue, a high-precision and high-resolution electrical impedance image can be obtained.

Owner:CHINA JILIANG UNIV

Imaging method of biological tissue electric current density based on acoustoelectric effect

InactiveCN103156605AHigh precisionHigh resolutionOrgan movement/changes detectionDiagnostic recording/measuringDensity basedMedical diagnosis

The invention discloses an imaging method of the biological tissue electric current density based on the acoustoelectric effect. The imaging method of the biological tissue electric current density based on the acoustoelectric effect comprises the following steps: (1) adopting an ultrasound excitation source to generate ultrasonic wave, driving and focusing the ultrasonic wave at the inner portion of biological tissue by the ultrasound; (2) continuously positioning the ultrasonic wave which is focused at the inner portion of the biological tissue, and finishing scanning of the whole or the local of the biological tissue; (3) collecting signals, focusing and positioning in a certain spatial position by the ultrasonic wave, generating a high frequency electrical signal which corresponds to the electric current density in the spatial position, and obtaining a set of signals of the whole or the local of the biological tissue; and (4) calculating and rebuilding the electric current density at the inner portion of the biological tissue according to the signals obtained after the scanning of the whole or the local of the biological tissue. The imaging method of the biological tissue electric current density based on the acoustoelectric effect is dynamic imaging, can intuitively reflect internal activities in the biological tissue, can obtain an electric current density image which is high in precision and resolution, and can facilitate medical diagnosis.

Owner:CHINA JILIANG UNIV

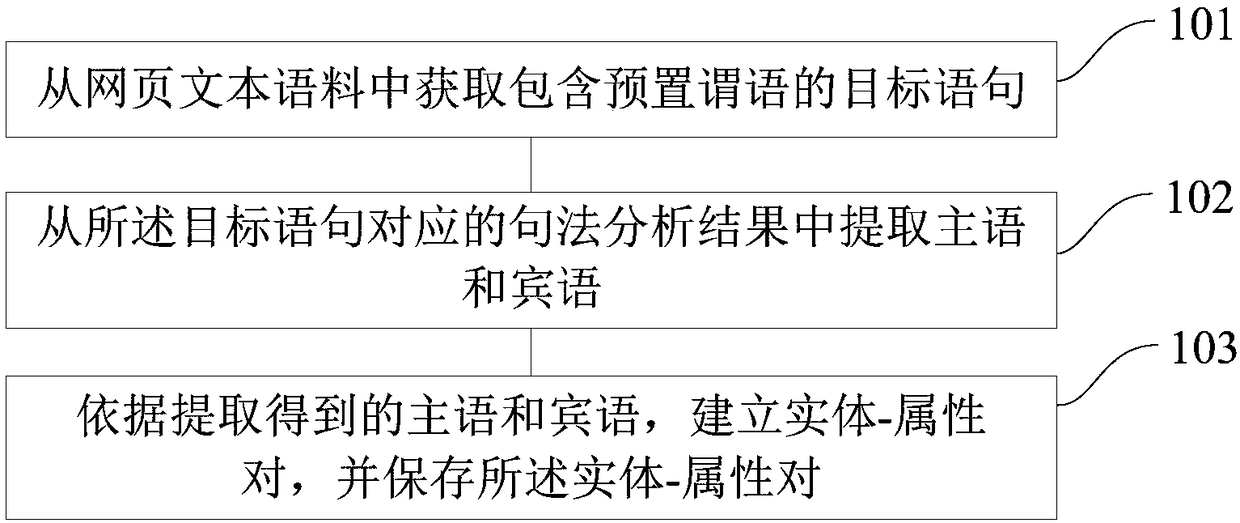

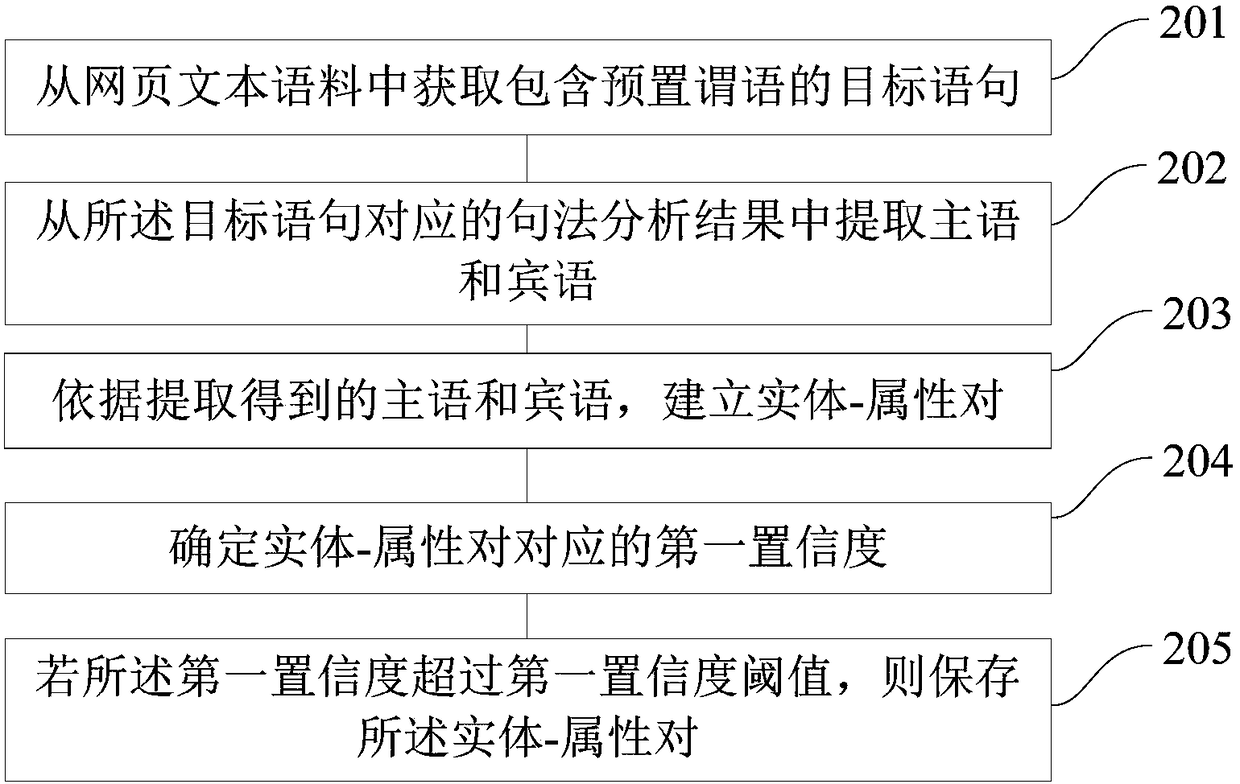

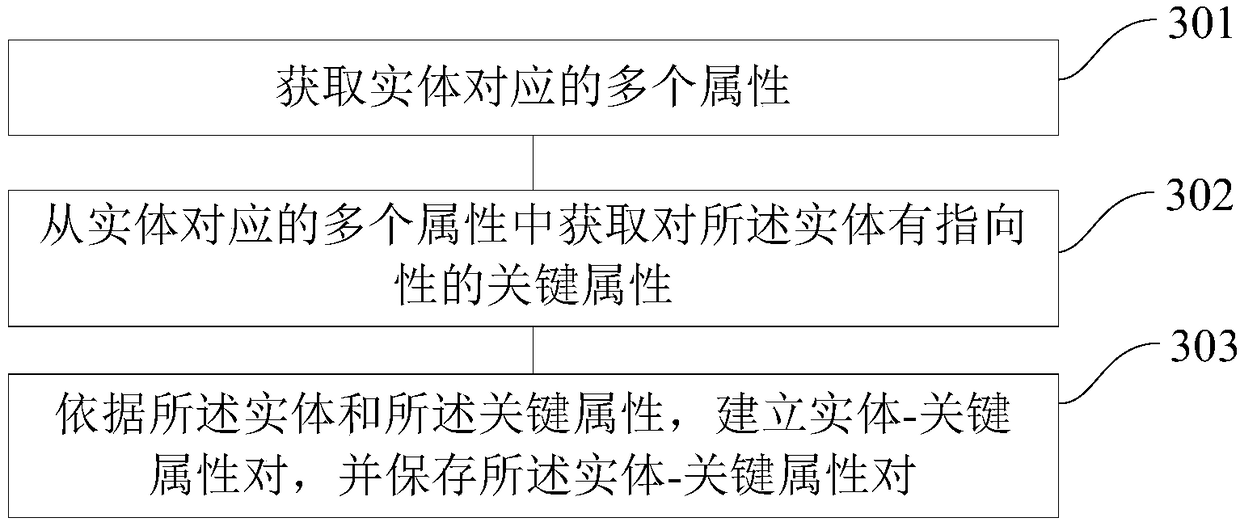

Information mining method and apparatus, and apparatus used for information mining

ActiveCN108345625AImprove timelinessReduce computational complexitySpecial data processing applicationsText corpusSyntax

Embodiments of the invention provide an information mining method and apparatus, and an apparatus used for information mining. The method specifically comprises the steps of obtaining a target statement comprising a preset predicate from a webpage text corpus; extracting a subject and an object from a syntactic analysis result corresponding to the target statement; and according to the extracted subject and object, establishing an entity-attribute pair, and storing the entity-attribute pair. New entities or newest attributes of entities can be timely mined from a webpage text with higher timeliness, so that the timeliness of entity information can be improved.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

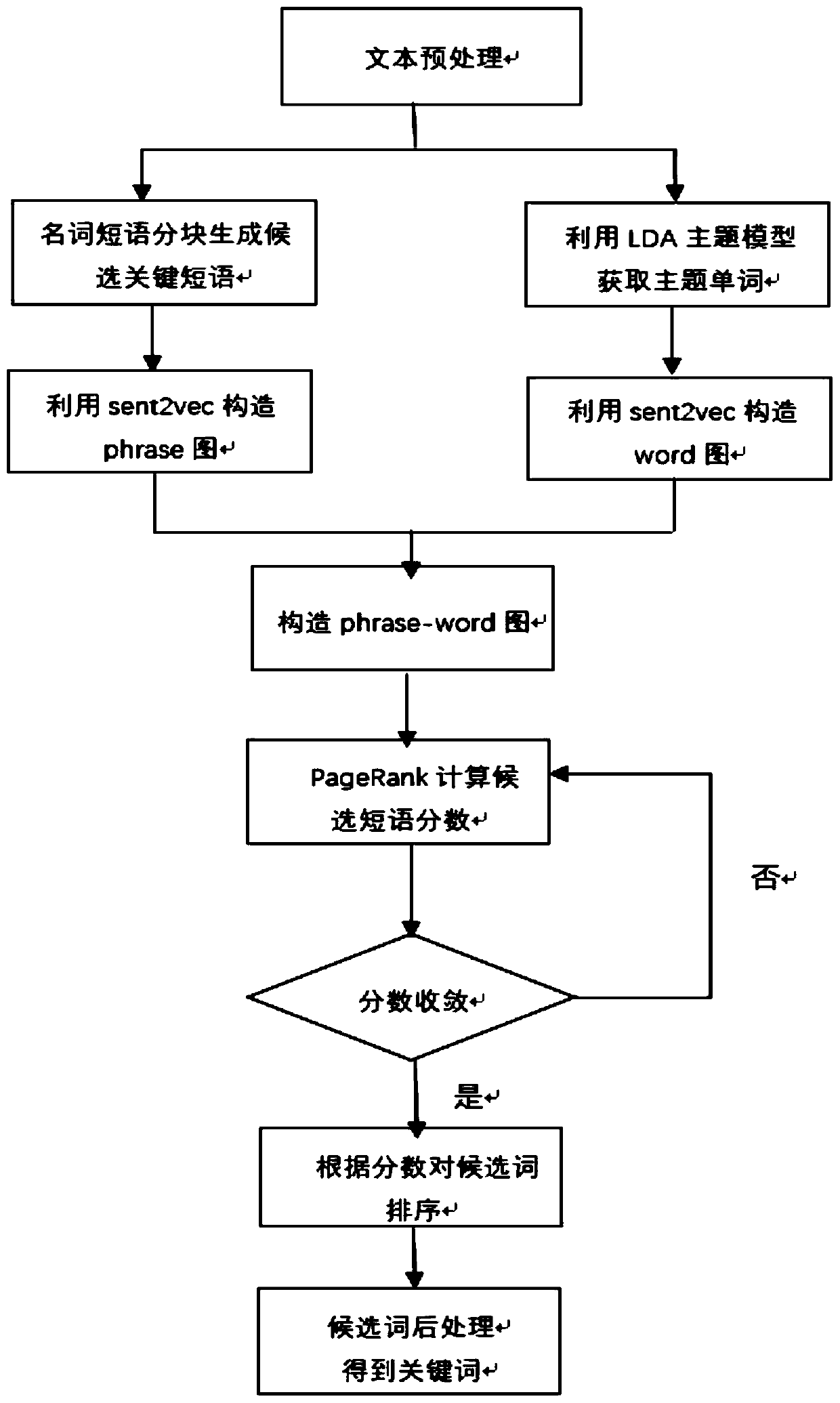

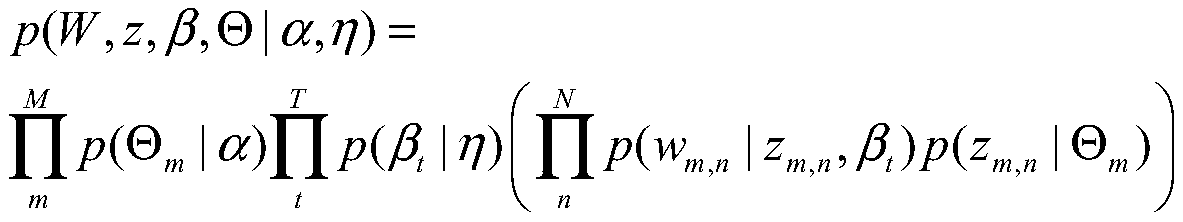

Unsupervised keyword extraction method

PendingCN110472005ARich semantic informationImprove the effectText database queryingSpecial data processing applicationsKeyword extractionTopic model

The invention provides an unsupervised keyword extraction method, and the method comprises the steps: obtaining a part of topic words with higher topic correlation degree through an LDA topic model, and building a phrase-word graph through employing topic words and candidate phrases as nodes; screening and promoting candidate phrases with higher topic association degree by utilizing the topic words, so that the influence of noise candidate phrases on a result is indirectly inhibited. On the other hand, aiming at the condition that short text candidate phrases are insufficient, the theme wordsare used as supplements of semantic information, so that the semantic information of the algorithm graph structure is richer. For the situation that candidate phrases of a long text are too large andare mingled with too much noise, the topic words play a certain role in screening. Keyword extraction is not sensitive to the length of an article any more, and the effect is further improved.

Owner:SUN YAT SEN UNIV +1

Strain capable of degrading waste feathers, screening method and application thereof

ActiveCN108795814AImprove screening efficiencySimple and efficient operationBacteriaMicroorganism based processesBiomassScreen method

The invention relates to a strain capable of degrading waste feathers and belongs to the technical field of microorganisms. The strain is Bacillus cereus FDB-18B, deposited in the China Center for Type Culture Collection on June 13, 2018 with the deposit number of CCTCC NO. 2018365. The strain is obtained from the soil of a tea garden after air drying, and can efficiently degrade the waste feathers to obtain amino acids and polypeptides that can be used as feed additives or for farmland irrigation to achieve comprehensive utilization of biomass resources. At the same time, the pollution of poultry breeding to the environment can be reduced. In addition, the strain can produce amylase, and can simultaneously achieve comprehensive treatment of wastewater generated from processing of the waste feathers and starch-containing food. Due to high degradation capability and short fermentation cycle, the strain keeps the protein, polypeptide and amino acid components to the greatest extent, andthe nutritional value and the utilization rate of the feed additives can be improved.

Owner:XINYANG NORMAL UNIVERSITY

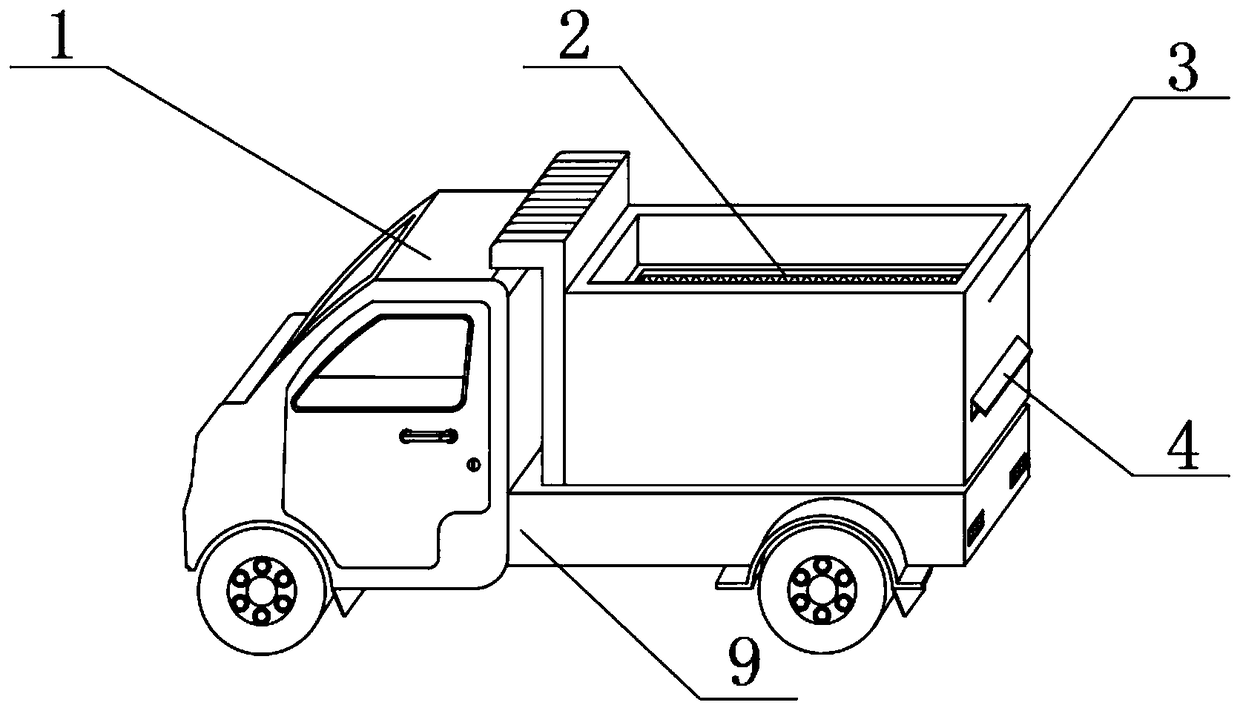

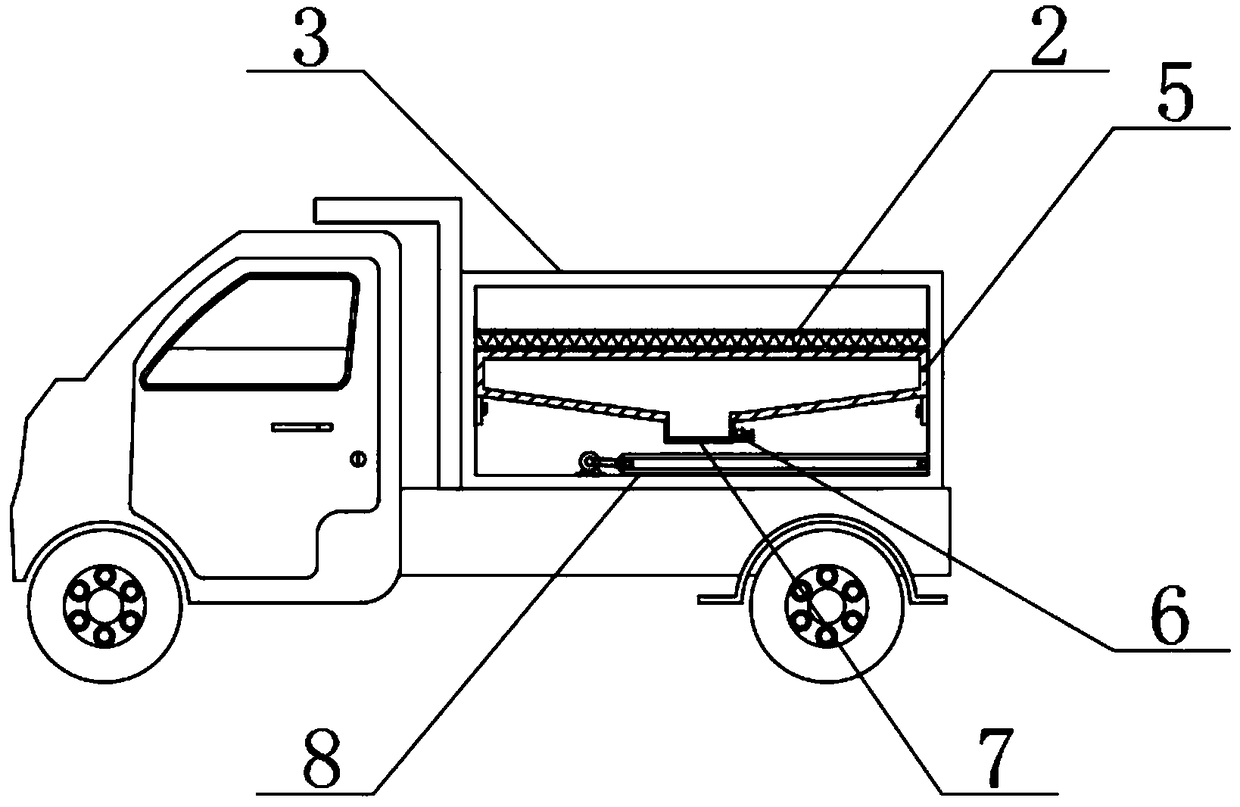

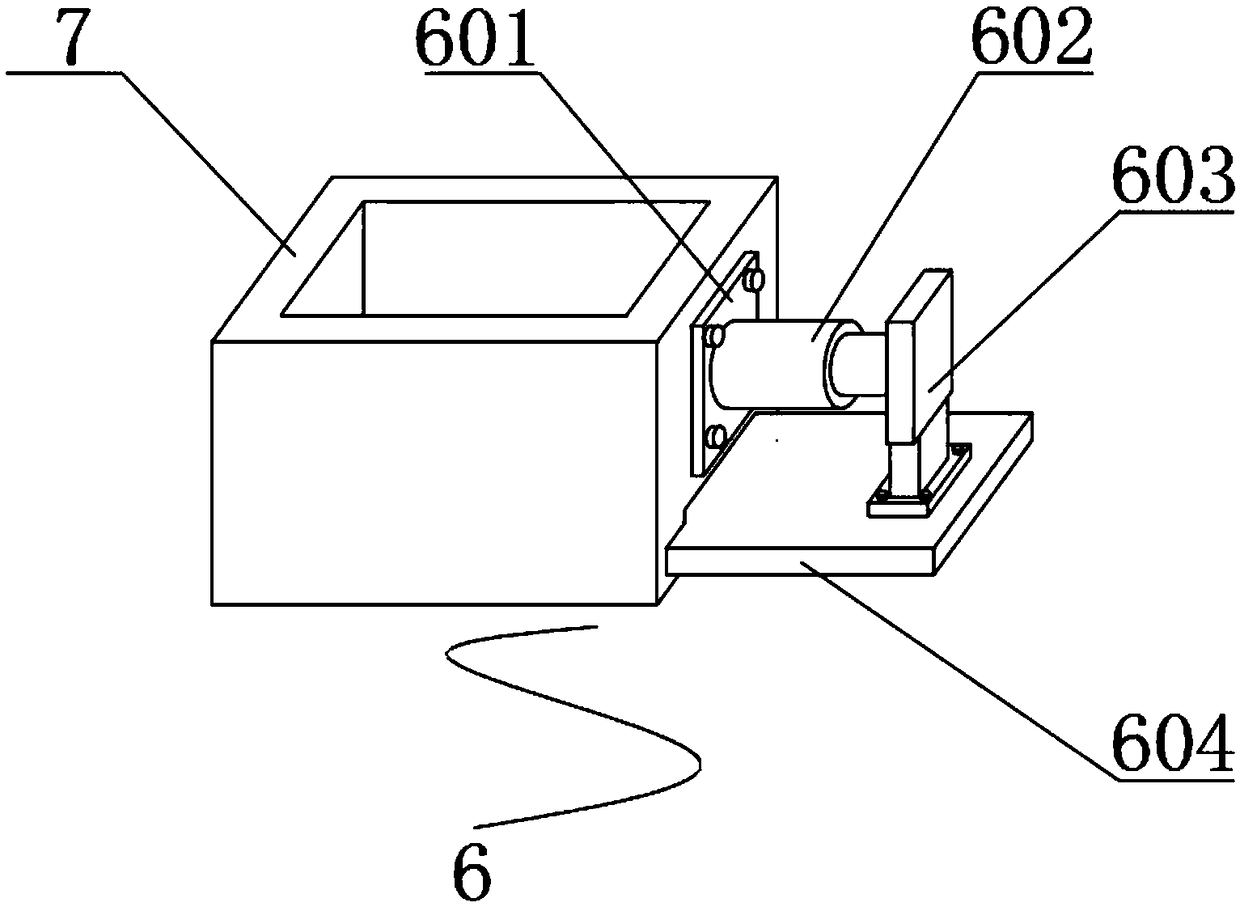

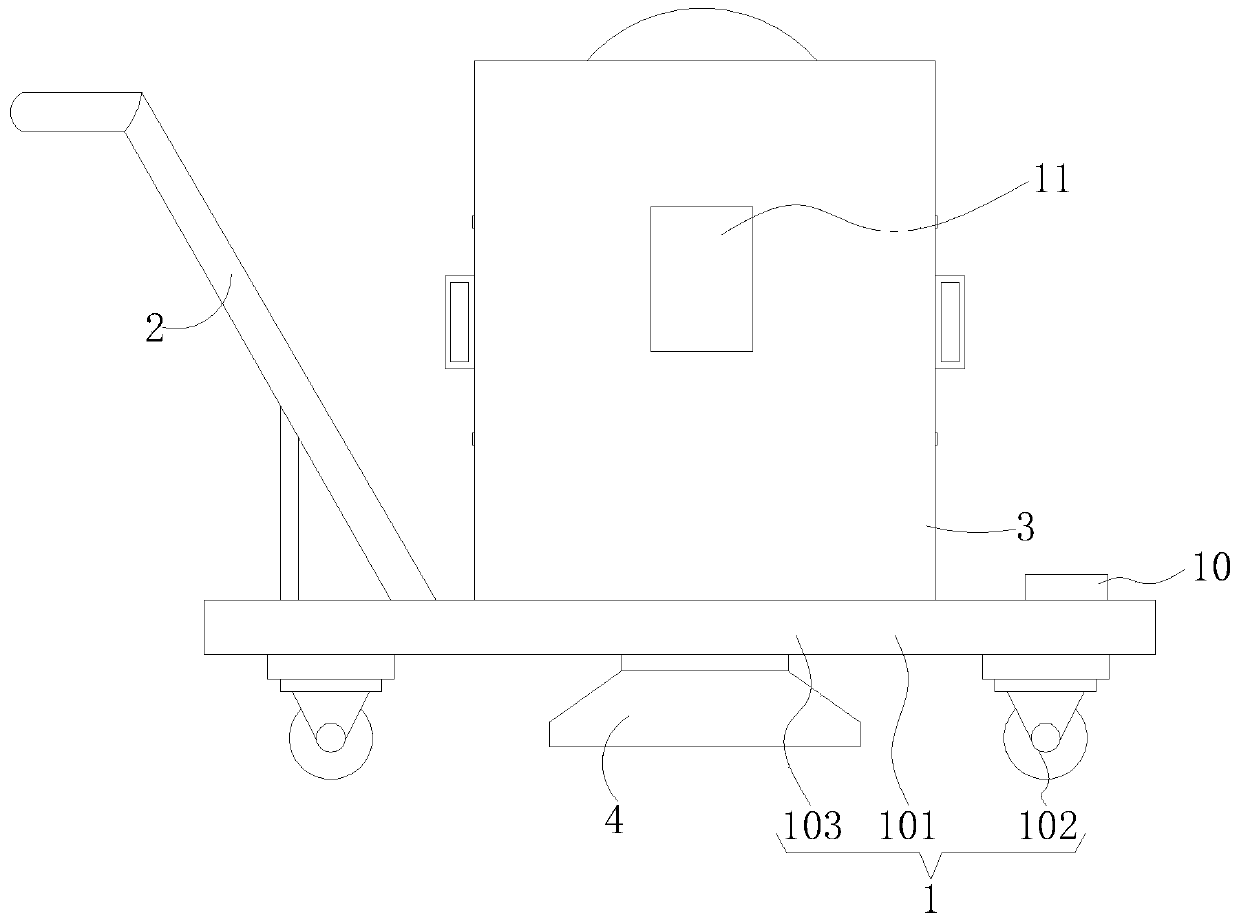

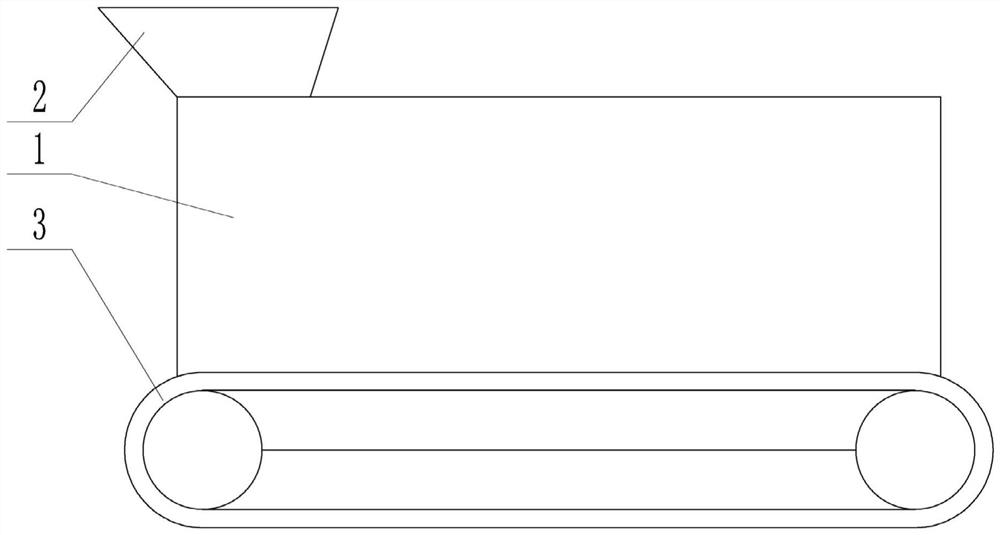

A transport device for ore and rock crushing

The invention discloses a transport device for ore and rock crushing. The device includes a front, one side of the vehicle head is provided with a vehicle frame, the upper surface of the vehicle frameis provided with a cargo compartment, the inner side of the cargo compartment is fixedly provided with a screen, and the inside of the cargo compartment is fixedly provided with an aggregate box at the lower position of the screen, the inner bottom end of the cargo compartment is installed with a conveying mechanism at the center line position, and one side of the cargo compartment is provided with a material outlet at the end position of the conveying mechanism. The advantage of that invention are ingenious in design, simple in structure, easy to use, the screen set is arranged to serve as ascreening function, by ensuring the uniformity of the size of the ore and rock, the ore and rock can be screened in the transportation process, the screening time is saved, the energy efficiency consumption is reduced, the work efficiency is improved, and a transmission mechanism is provided, so that the operation of the transmission belt can be driven by the operation of the motor, the crushed ore and rock can be transported, the labor intensity is reduced, and the work efficiency is improved.

Owner:GUIZHOU UNIV

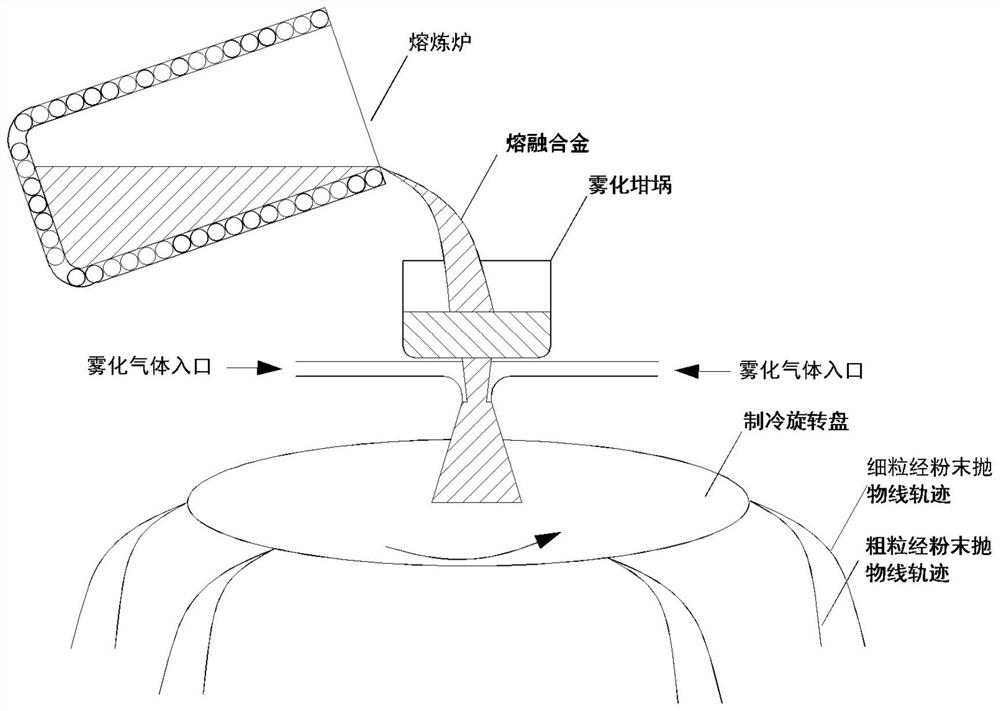

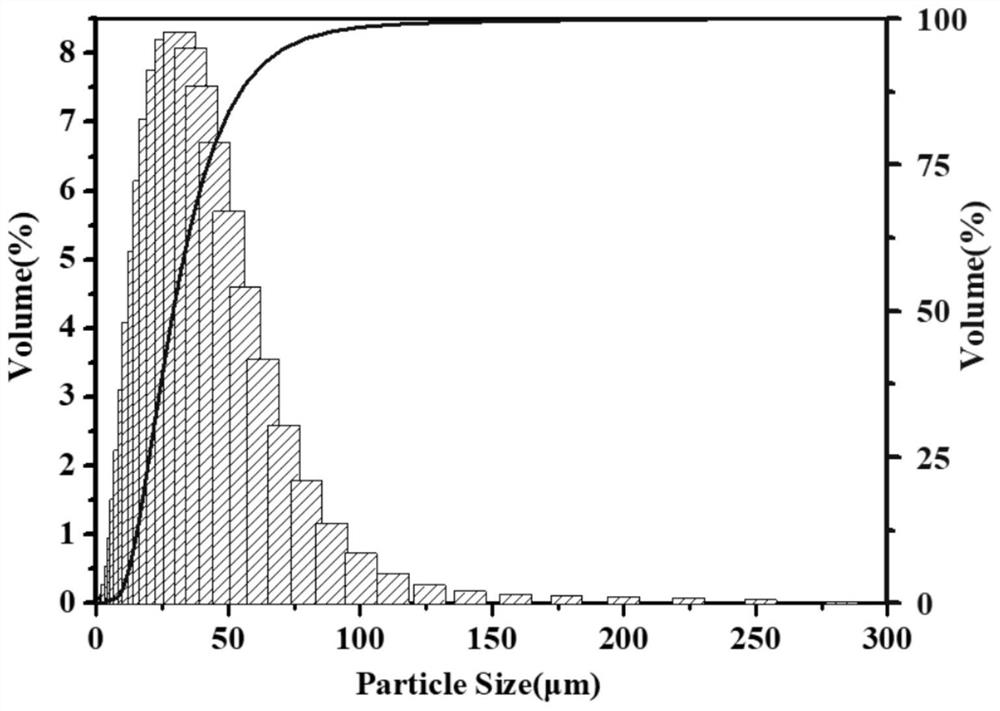

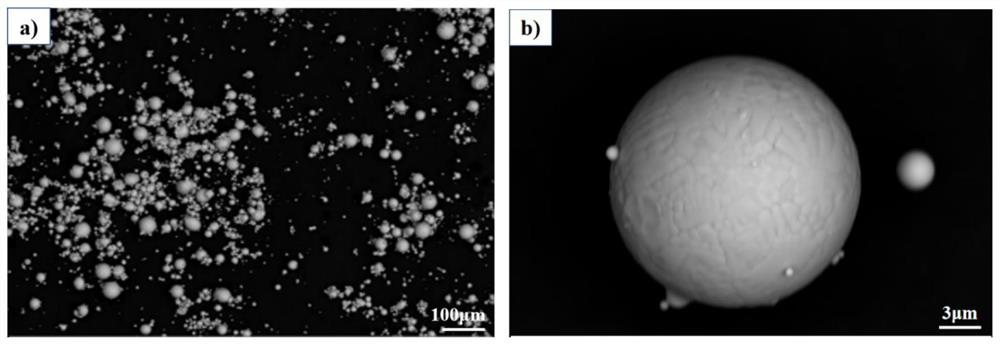

Nickel-based high-temperature alloy powder suitable for powder metallurgy and preparation method thereof

InactiveCN113186431ALow oxygenReduce nitrogen contentTransportation and packagingMetal-working apparatusAlloyToughness

The invention provides nickel-based high-temperature alloy powder suitable for powder metallurgy and a preparation method thereof. The nickel-based high-temperature alloy powder comprises the following components in percentage by mass: 8.5%-16% of Cr, 14%-20% of Co, 3%-6% of Mo, 0%-2.5% of Ta, 1%-4% of Ti, 2.5%-5% of Al, 0%-6% of W, 0%-3% of Nb, 0.1%-0.5% of Hf, 0.003%-0.03% of B, 0.01%-0.05% of C and the balance of Ni and impurities. According to the technical scheme, the nickel-based high-temperature alloy powder has the comprehensive performance of high strength, high hardness and high toughness. The alloy powder prepared through the preparation method is uniform in chemical component, free of generation of brittle harmful phases, low in oxygen content, low in nitrogen content, low in sulfur content, high in sphericity degree, low in hollow powder rate, low in inclusions, small in particle size and low in production cost.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

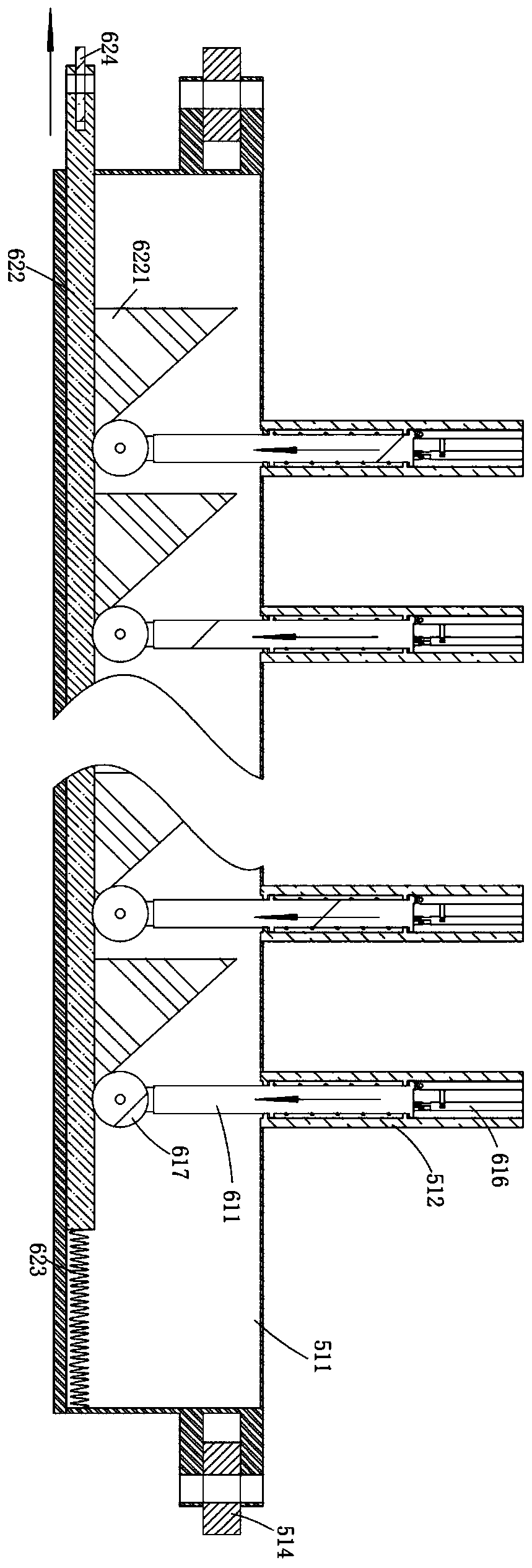

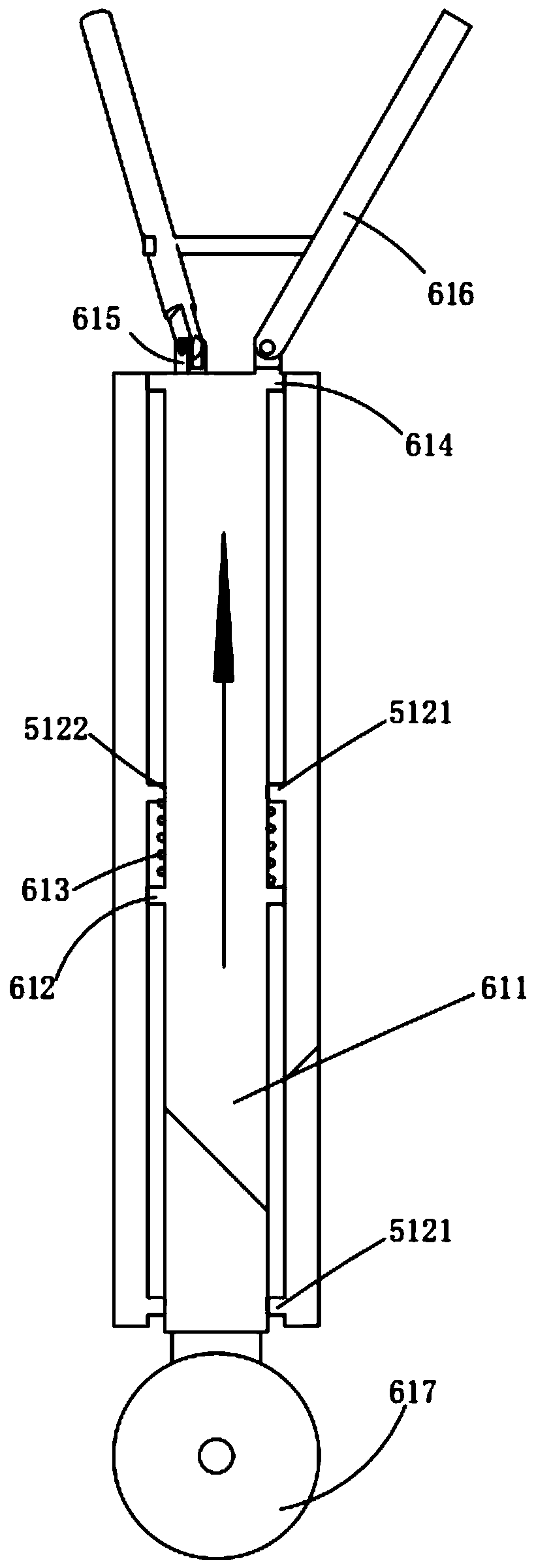

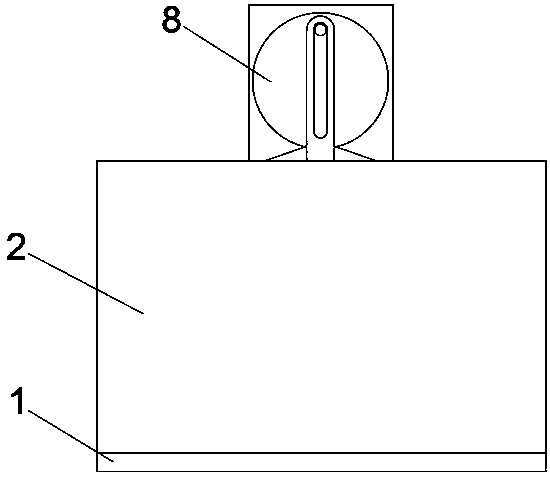

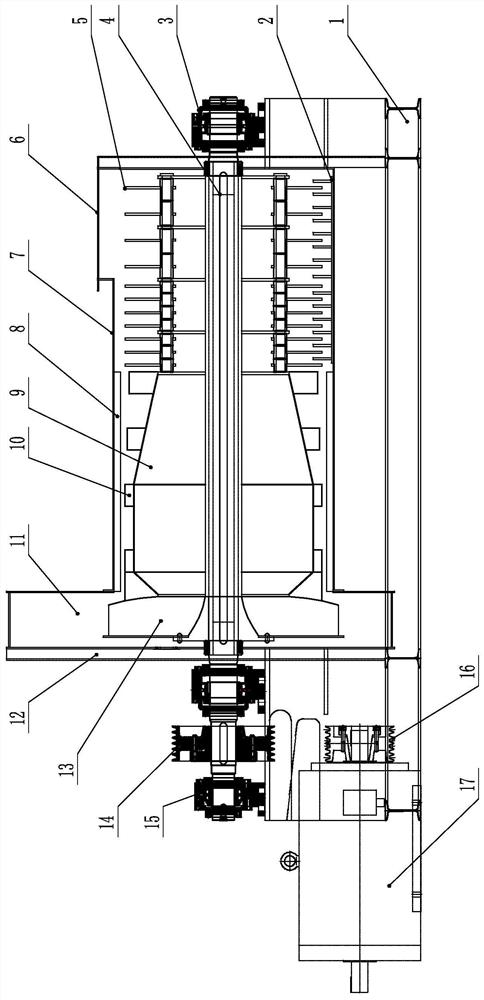

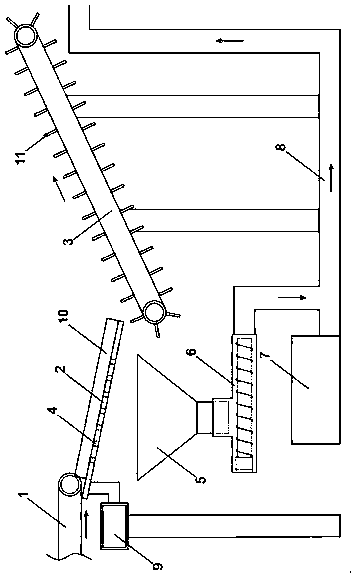

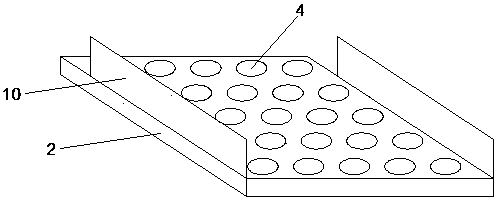

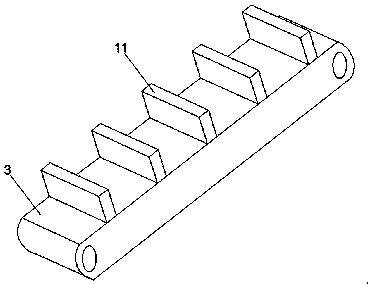

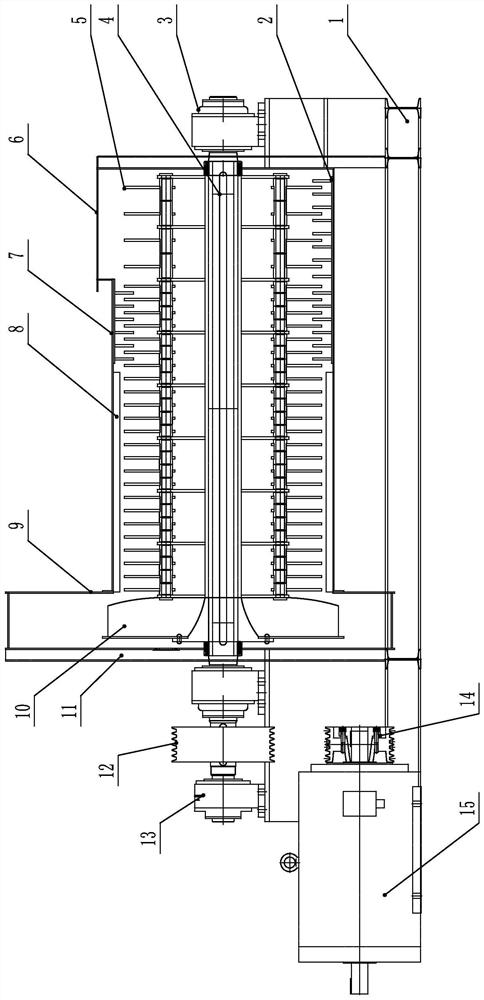

Automatic grain conveying and drying device for agriculture

InactiveCN107543407ARealize automatic transportationEasy to dryDrying gas arrangementsDrying solid materialsCircular discElectrical resistance and conductance

The invention discloses an automatic grain conveying and drying device for agriculture. The automatic grain conveying and drying device comprises a conveying table internally of a hollow structure. Driving shafts are connected to the two ends inside the conveying table correspondingly and drive a conveying plate on the surface of the conveying table to rotate; the surface of the conveying plate isof a net-shaped structure, and the sizes of meshes are smaller than that of grains; an opening is formed in the upper surface of the conveying table; the two sides of the conveying table are both connected with connecting frames; the outer ends of the connecting frames are connected with connecting rods; the top ends of the connecting rods are connected with a fixing frame; the fixing frame is sleeved with a drying cylinder; a plurality of heating resistors are arranged on the inner layer of the drying cylinder; a fixed seat is mounted at the top end inside the drying cylinder; a groove is formed in the bottom face of the fixed seat; a rotating shaft is mounted inside the groove; the bottom end of the rotating shaft is connected with a disc; stirring blades are evenly connected to the outer circle of the disc; and a centrifugal fan is mounted inside the rotating shaft. The grains can be rapidly dried while being automatically conveyed, mildewing of the grains is avoided, and agricultural products are effectively protected.

Owner:安徽诺鑫自动化设备有限公司

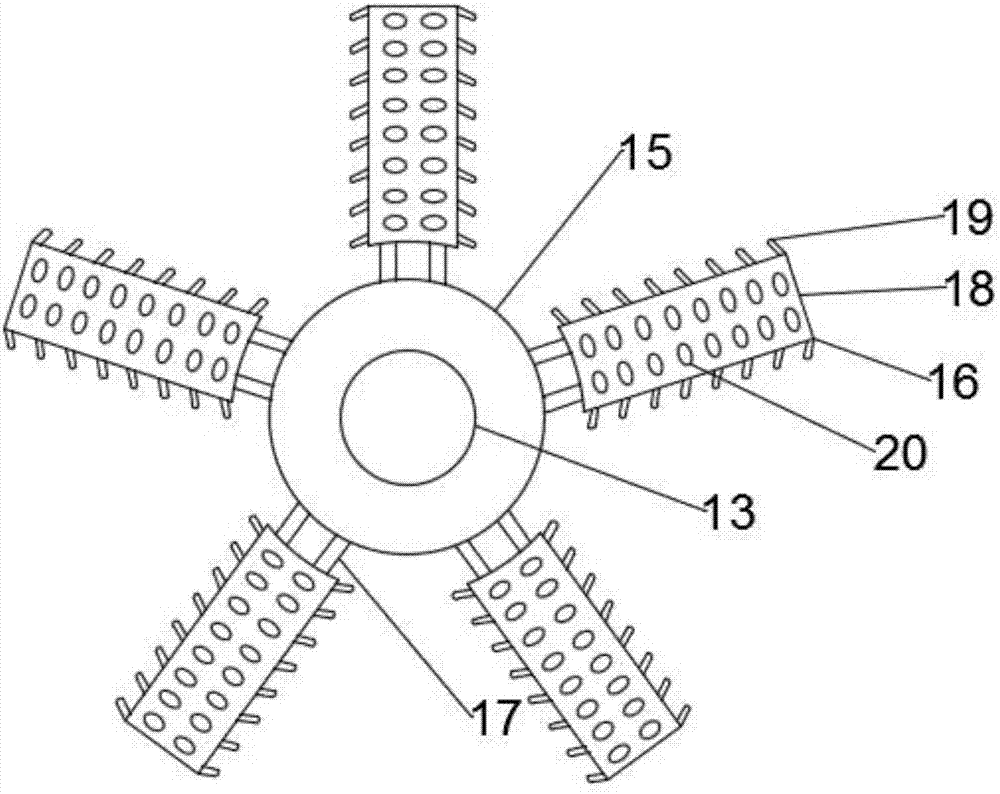

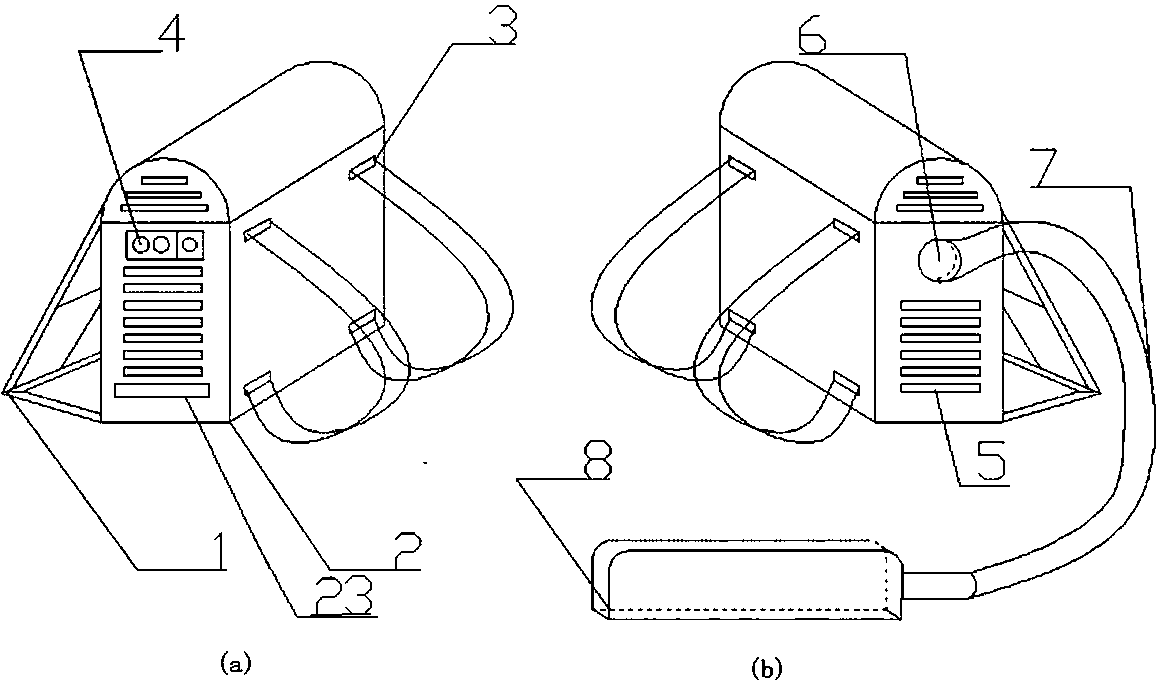

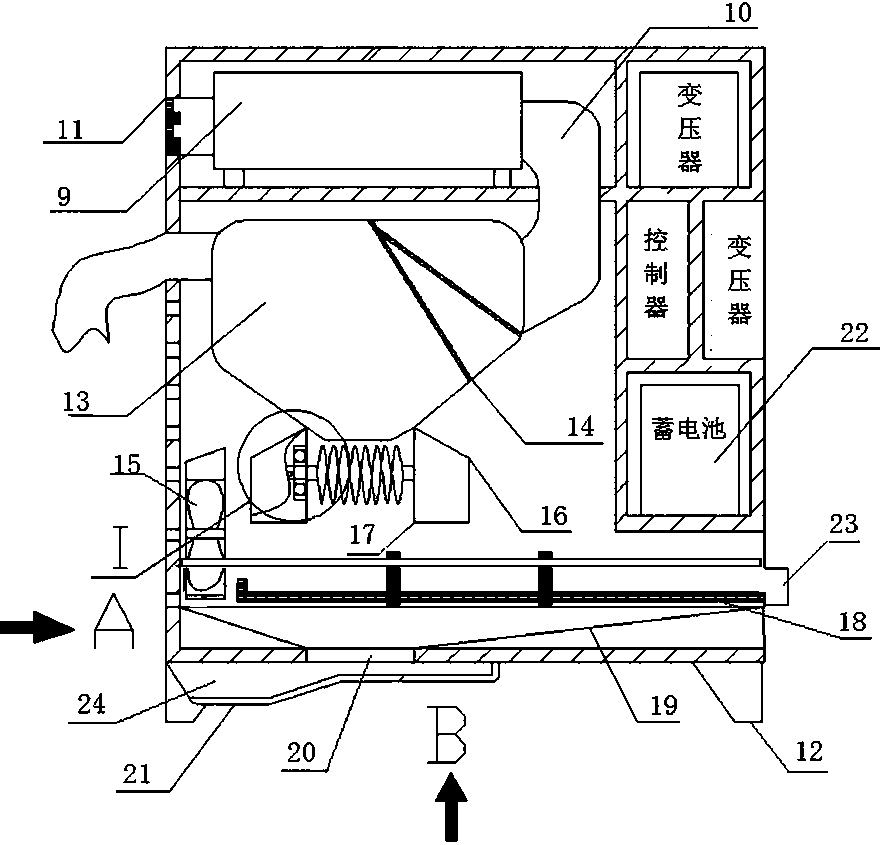

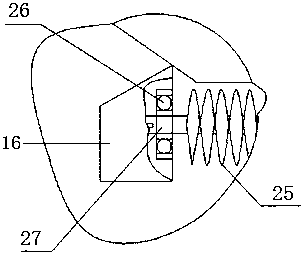

Tea leaf picking machine based on photovoltaic generation

InactiveCN107912140AImprove picking efficiencyEasy to separateSievingScreeningElectricityEngineering

The invention discloses a tea leaf picking machine based on photovoltaic generation. The tea leaf picking machine based on photovoltaic generation comprises a box body as well as a photovoltaic paneland a picking device which are arranged outside the box body, wherein a leaf storage bin, an air bellow, a spiral separator, a leaf gathering device, an inertia screening device, a storage battery anda controller are arranged inside the box body, the picking device is connected with the leaf storage bin in the box body by virtue of a rubber hose, the leaf storage bin is connected with the air bellow by virtue of an air hose, the spiral separator is arranged below the leaf storage bin, the inertia screening device is arranged below the spiral separator, the leaf gathering device is arranged below the inertia screening device, a discharging hole is formed in the bottom of the box body, the leaf gathering device is communicated with the discharging hole, the photovoltaic panel is electrically connected with the storage battery, the storage battery is electrically connected with the controller, and the controller is respectively electrically connected with the air bellows, a first motor and a second motor. The tea leaf picking machine based on the photovoltaic generation has the advantages that picking efficiency is high, tea leaves can be screened and also can be automatically collected, and a photovoltaic technology is adopted and solar power generation is utilized, so that energy is saved.

Owner:JINLING INST OF TECH

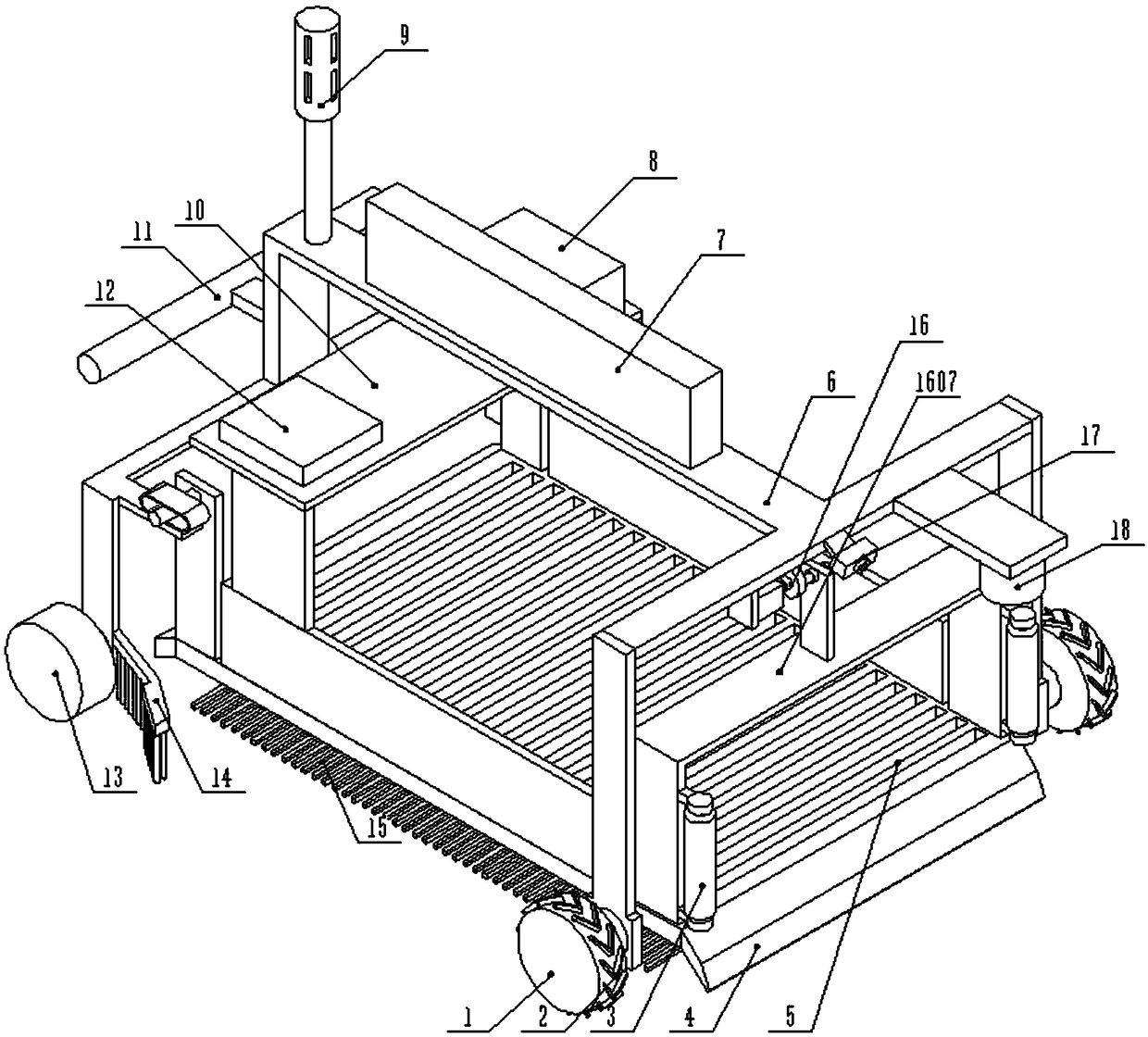

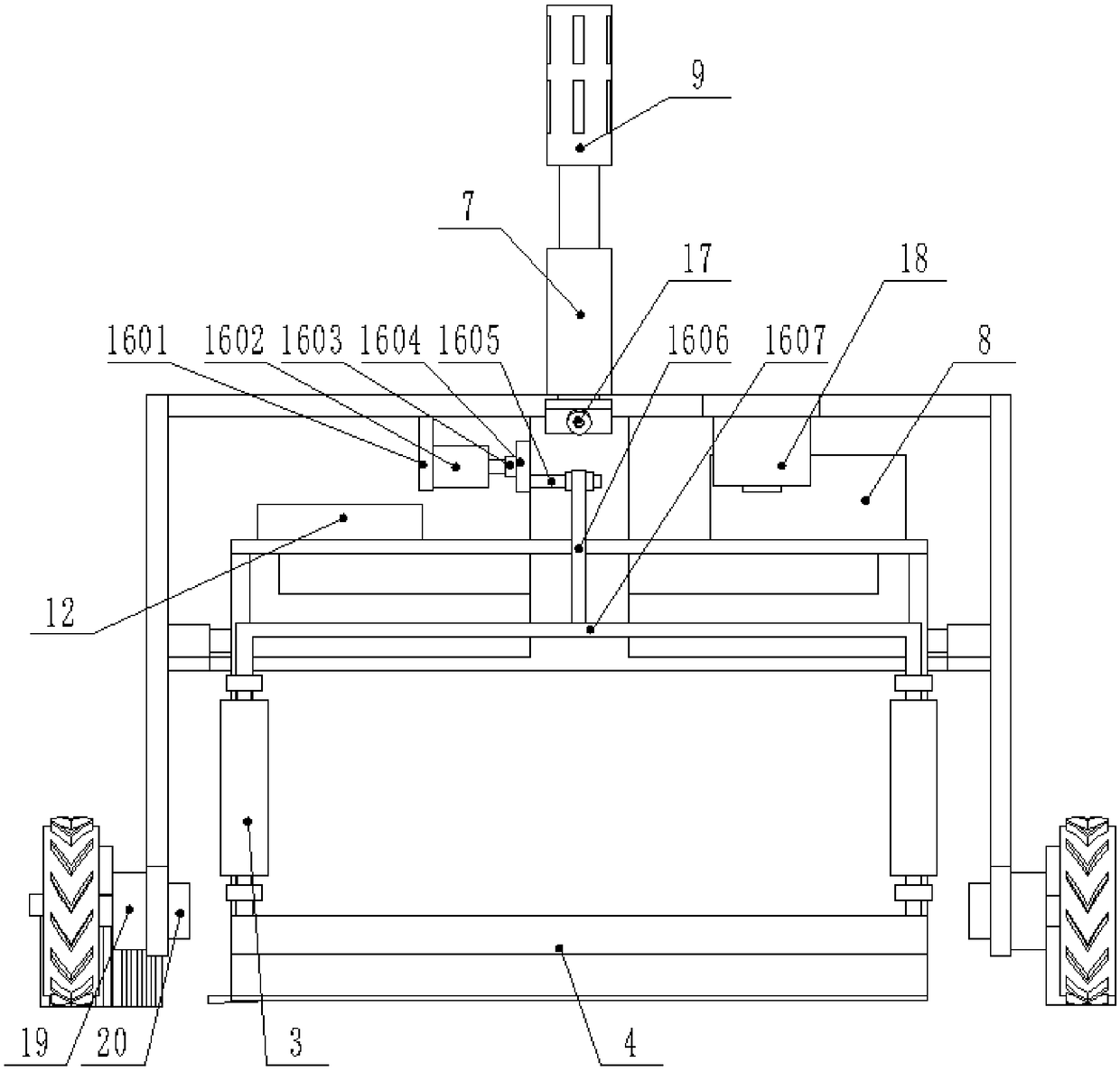

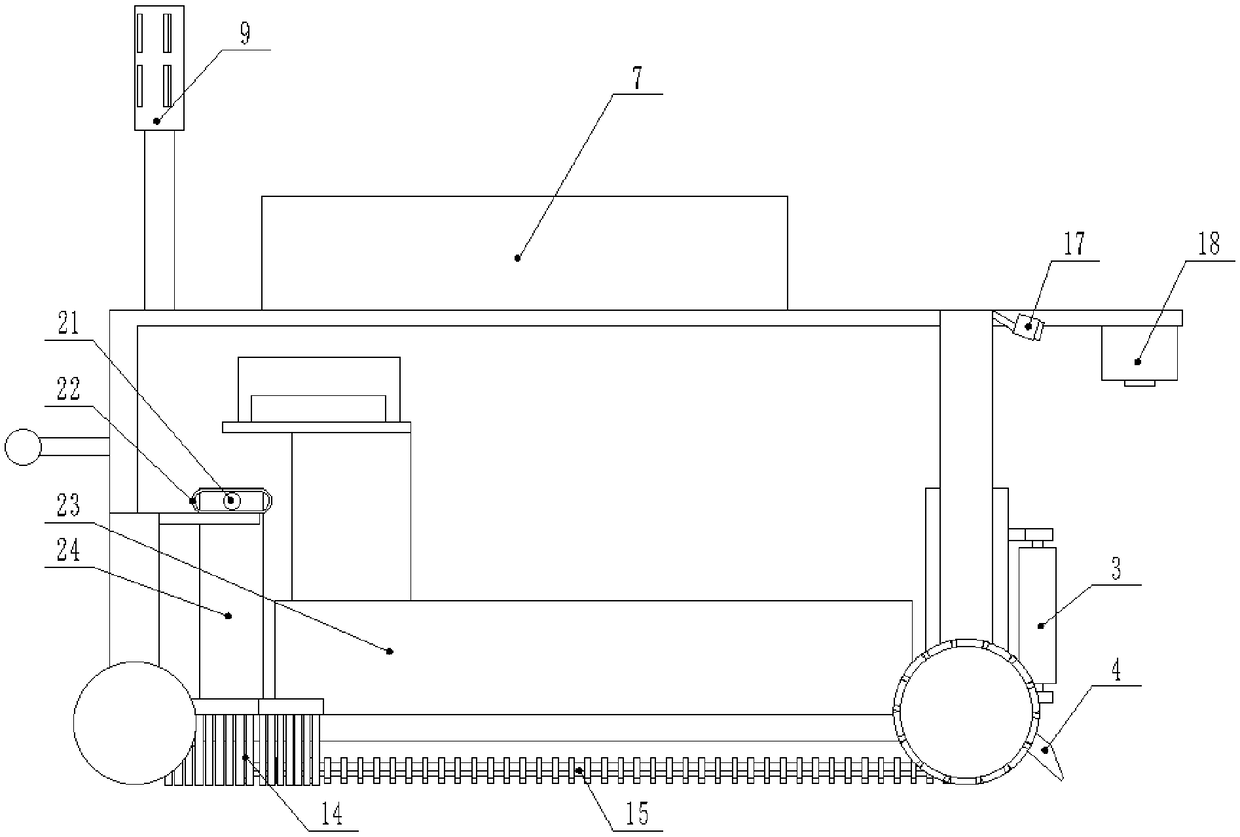

Vibration type unmanned potato harvester

ActiveCN109479488AHigh degree of intelligenceReduce manual involvementAlarmsDiggersEngineeringDrive wheel

The invention discloses a vibration type unmanned potato harvester. The potato harvester comprises driving wheels, tread patterns, separation rotating cylinders, a vibration pushing plate, a first vibration screening plate, a support frame, a balance weight block, a battery pack, an alarm apparatus, a placing plate, a handle, a controller, driven wheels, guide baffles, a second vibration screeningplate, a vibration device, a first camera, a second camera, second motors, encoders, a support shaft, a displacement limiting ring, a side baffle and a support plate; the second motors are provided with the encoders, the driving wheels are provided with the tread patterns, the separation rotating cylinder is installed at the front end of the vibration pushing plate, and the first vibration screening plate is installed at the bottom of the vibration pushing plate. Potatoes in soil are driven to move to the first vibration screening plate through the vibration of the vibration pushing plate driven by the vibration device, the potatoes larger in size can roll out from the rear end, and the potatoes smaller in size can roll from the second vibration screening plate to the side face so that not only can the soil be separated from the potatoes, but also the effect of screening the potatoes different in size can be achieved.

Owner:SHANGHAI MARITIME UNIVERSITY

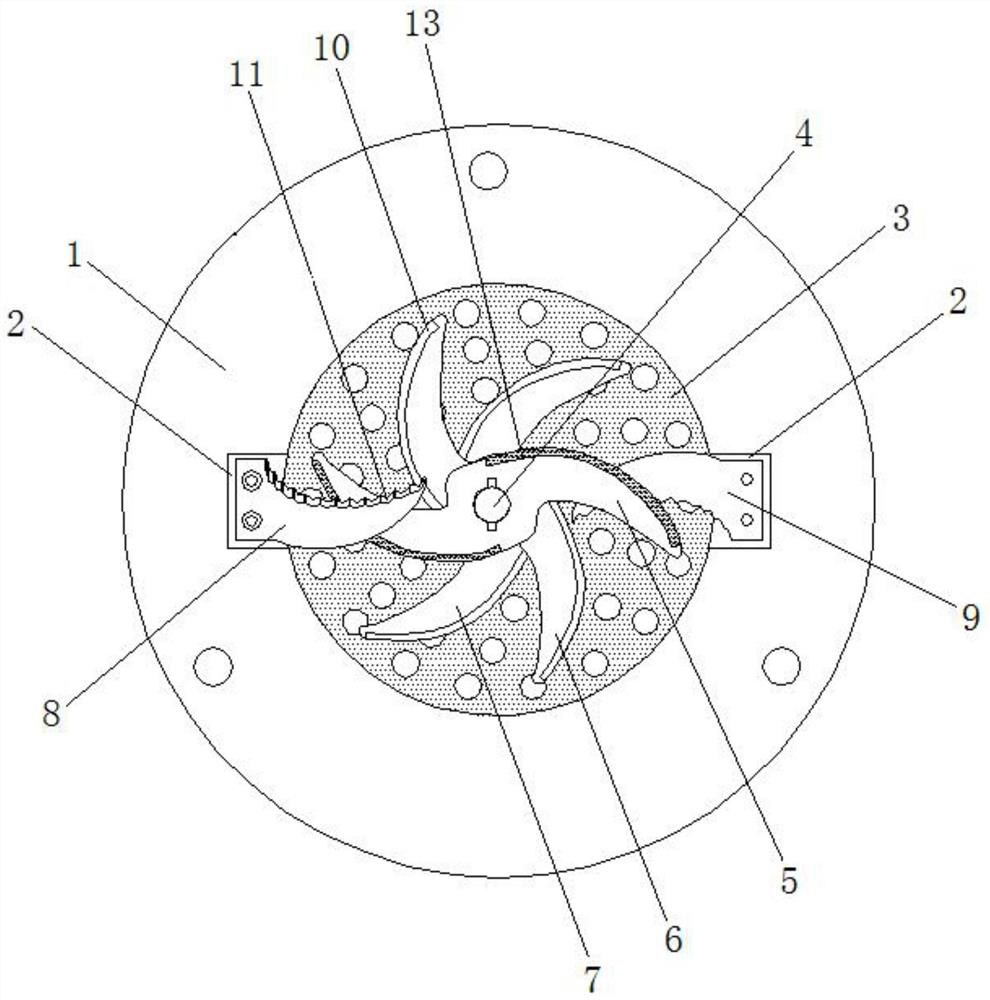

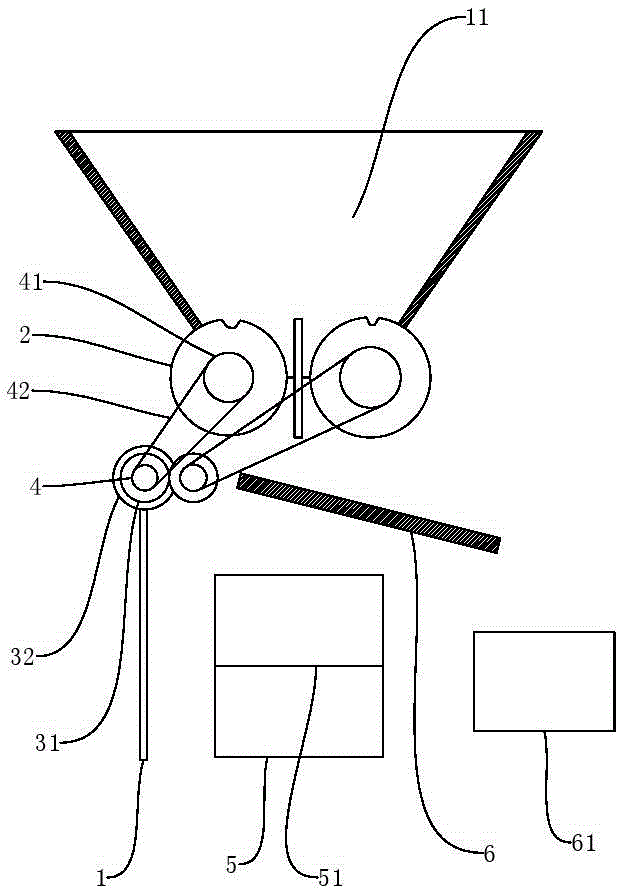

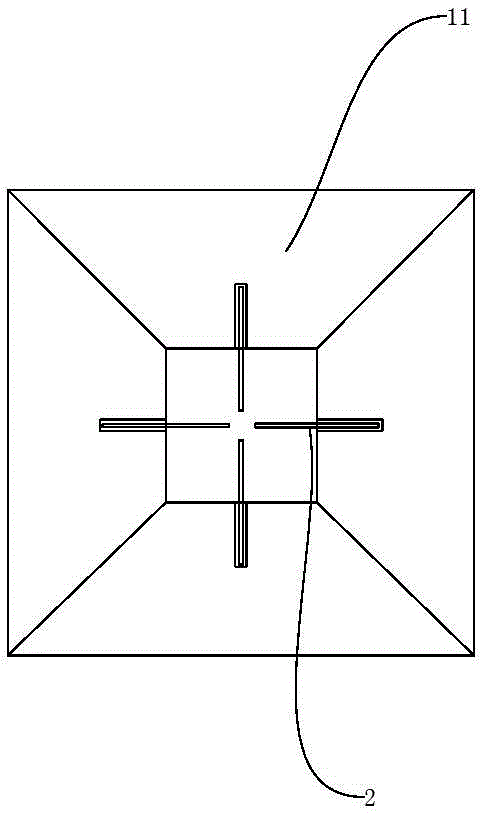

Pulping assembly of pulping pump

PendingCN111608917AExtended service lifeExtended maintenance cycleSpecific fluid pumpsPump componentsEngineeringKnife blades

The invention discloses a pulping assembly of a pulping pump. The pulping assembly is composed of a cavity shell, a power extension shaft, a pulping sieve plate, three S-shaped blades and two arc-shaped tool sets, the cavity shell is provided with a basin cavity, the pulping sieve plate is transversely embedded in the basin cavity, and the power extension shaft is installed on the central axis ofthe basin cavity and penetrates through a shaft hole in the pulping sieve plate; the three S-shaped blades are all installed on the power extension shaft, one S-shaped blade is attached to the pulpingsieve plate on the lower portion, and the other two S-shaped blades are installed on the upper portion in a stacked mode; and the two arc-shaped tool sets are oppositely installed on the two sides ofthe basin cavity and face the center of the basin cavity, one arc-shaped tool set is attached to the top face of the uppermost S-shaped blade, and the other arc-shaped tool set is attached to the bottom surface of the S-shaped blade in the middle. The pulping assembly provides a 3G pulping mode of three solid cutting and three dynamic cutting, achieves step-by-step crushing of materials from coarse crushing to fine crushing and then to refined crushing, and enables the pulping pump to have extremely high crushing efficiency and an extremely good crushing effect.

Owner:赤壁圆源环保设备科技有限公司

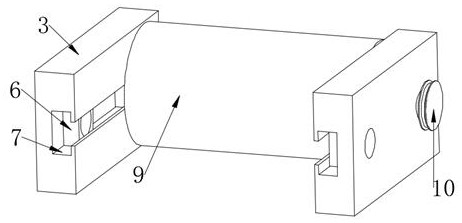

Axial rubbing machine

The invention discloses an axial rubbing machine, and relates to the field of crushers. The problems that a shell of an existing rubbing machine is small in rubbing acting area, low in crushing efficiency, poor in material crushing effect, and high in power consumption, and the material crushing effect is not easy to control are solved. When entering the rubbing machine, materials can continuously move towards a discharging port, blockage is avoided, the materials are rubbed in the moving process, rubbing is more uniform, the number of rubbing blocks at the discharging end of a rubbing rotor is increased, the rubbing effect is improved, meanwhile, the screening effect is achieved, the materials with the too large size can be continuously rubbed, due to the fact that discharging is smoother and more uniform under the action of negative pressure of blades of a discharging fan, power consumption is correspondingly reduced, production cost is reduced, the smashing effect is improved, and therefore the crushing efficiency is improved. The invention belongs to the field of crushers.

Owner:HEGANG TIANFENG AGRI MACHINERY MFG

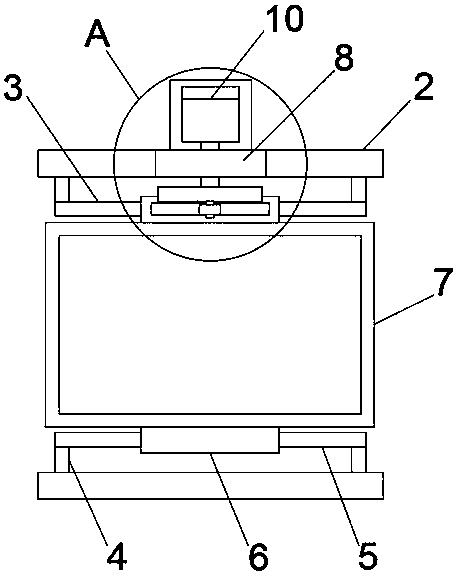

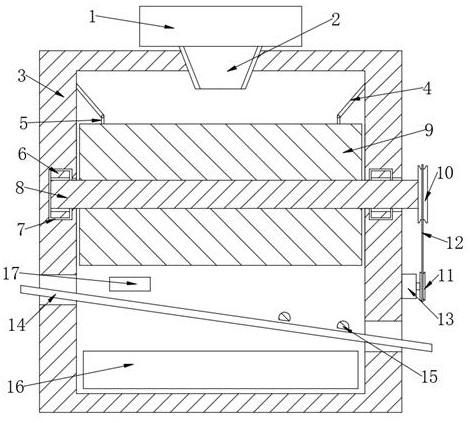

Prefabricated part full-automatic pouring device capable of raking materials

ActiveCN110640865AQuality improvementImprove pouring efficiencyFeeding arrangmentsStructural engineeringMechanical engineering

The invention provides a prefabricated part full-automatic pouring device capable of raking materials, The prefabricated part full-automatic pouring device comprises a pouring table, a pouring formwork, a travelling crane, a discharging device, a material rubbing device and a material raking device, wherein the discharging device is fixed on the travelling crane, and comprises a material storing box and a rotating roller rotationally mounted on the material storing box, the material rubbing device comprises a material rubbing piece and control pieces, the plurality of material rubbing pieces are arranged on the rotating roller in a circumferential arraying mode, two control pieces are arranged at the two ends of the length direction of the rotating roller, two control pieces are fixed on the material storing box, the material raking device comprises a switching piece and a material raking piece, and the switching piece is connected with the control pieces and controls the material raking piece to extend out of the material rubbing piece. According to the prefabricated part full-automatic pouring device, the material raking piece is controlled to extend out through the switching piece, meanwhile, the material raking piece moves back and forth along with the material rubbing piece, concrete accumulated on the pouring formwork is dispersed in a raking mode, meanwhile, the concretein the pouring formwork is subjected to vibrating and cement surface scabbling treatment, and the technical problem that manual vibration and scabbling are needed which causes pouring efficiency is low when pouring equipment is used for pouring in the prior art is solved.

Owner:ZHEJIANG FAEN INTEGRATED HOUSING CO LTD

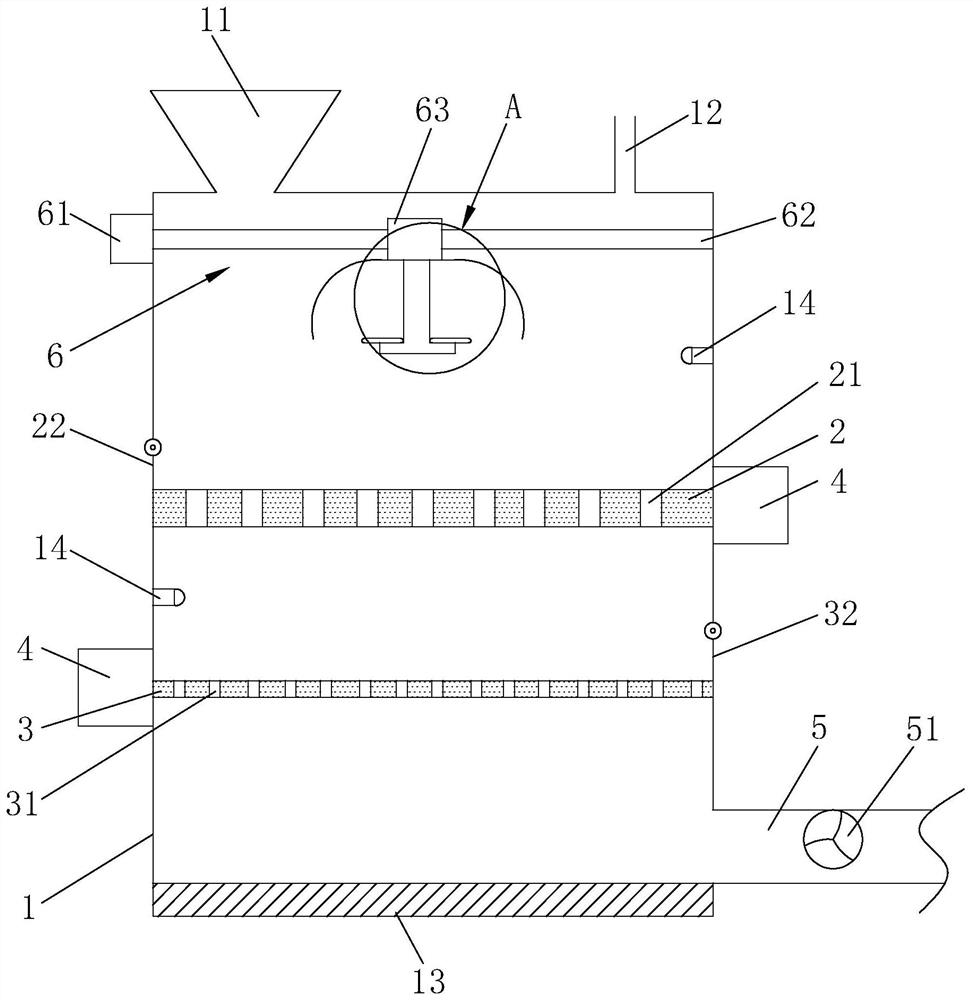

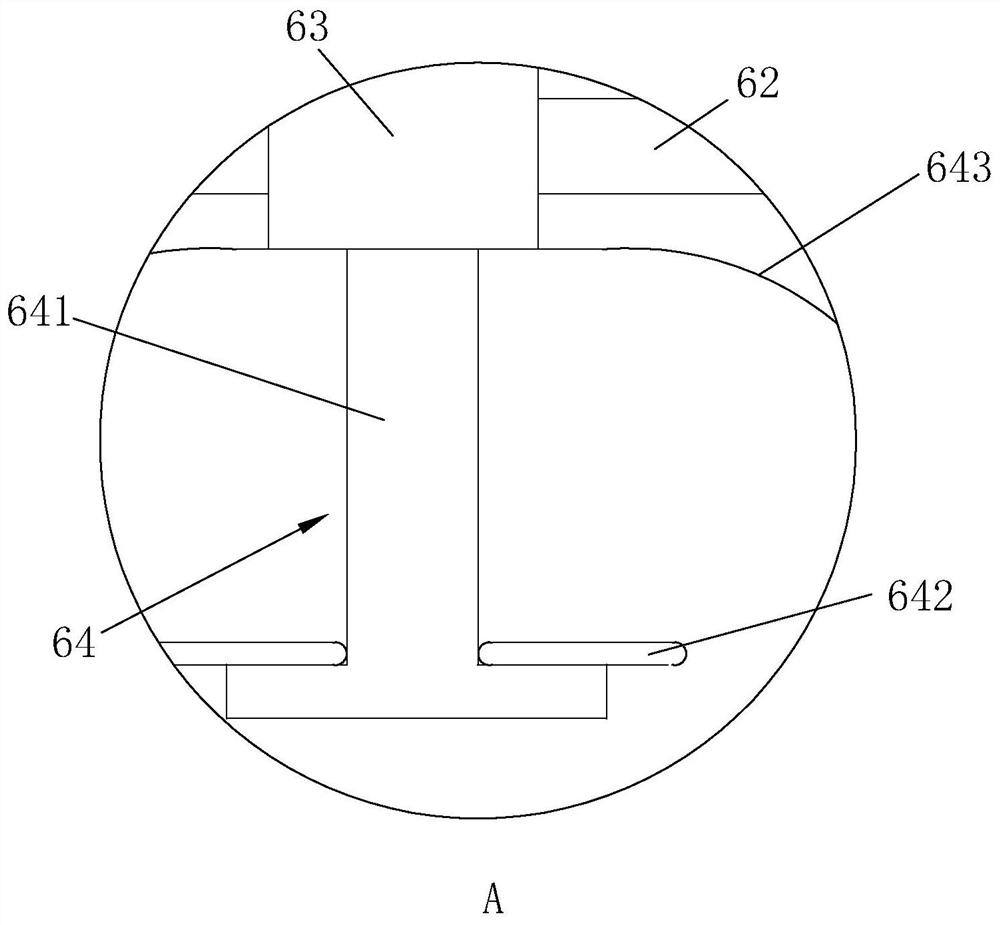

Activated carbon drying device

InactiveCN112432467AFully contactedImprove drying effectSievingDrying solid materials with heatActivated carbonElectric machine

The invention relates to an activated carbon drying device. The activated carbon drying device comprises a drying box, wherein a feeding hole is formed in the drying box, a funnel is arranged on the feeding hole, and an air outlet pipe is arranged on one side of the feeding hole; a first vibrating plate and a second vibrating plate are arranged in the drying box, one end of the first vibrating plate and one end of the second vibrating plate are connected with a vibrating motor, a plurality of first heat dissipation holes and a plurality of second heat dissipation holes are uniformly formed inthe first vibrating plate and the second vibrating plate respectively, and the hole diameters of the first heat dissipation holes are larger than the hole diameters of the second heat dissipation holes; and a heating plate is fixed at the bottom in the drying box, the bottom of the drying box is connected with an air inlet pipe, an air heater is arranged in the air inlet pipe, and a movable heating mechanism is arranged in the drying box. According to the activated carbon drying device, a vibrating mechanism is arranged in a drying mechanism, so that activated carbon is irregularly vibrated during drying, uniform heating is guaranteed, and the drying effect of the activated carbon is improved.

Owner:JIANGSU SHANGLV TECH

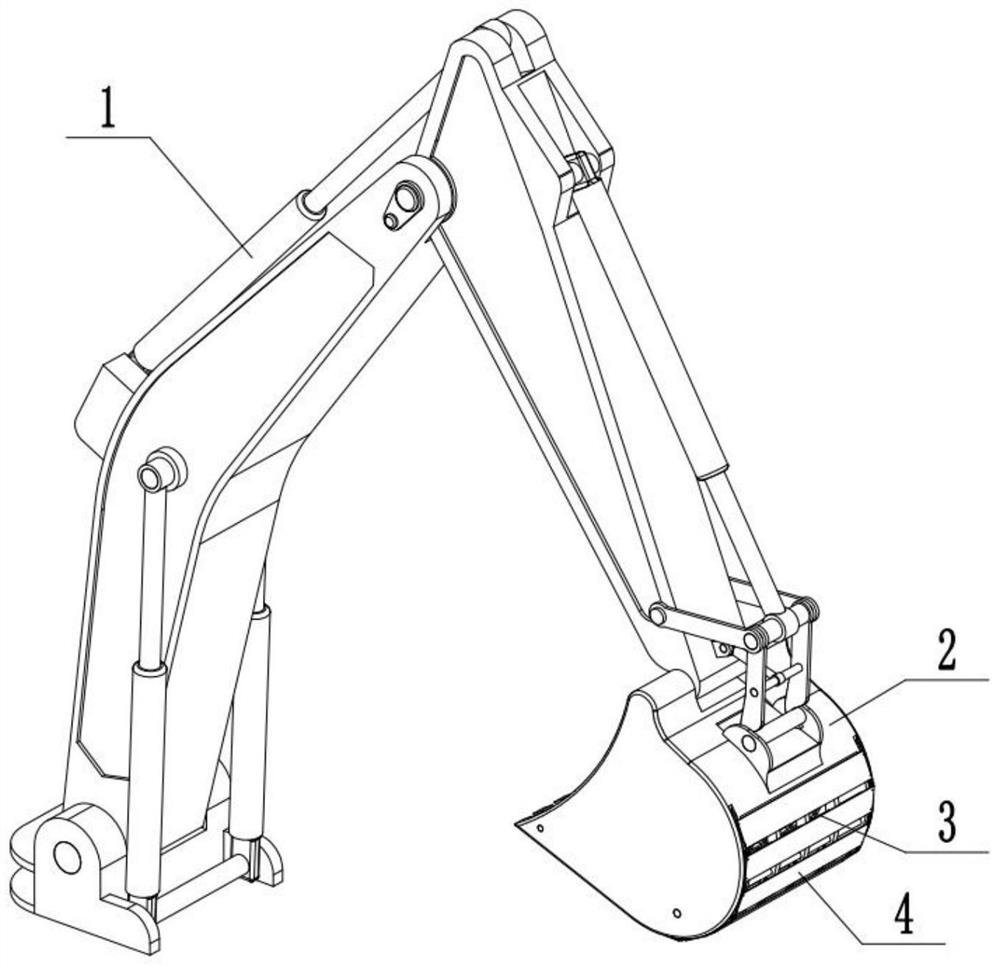

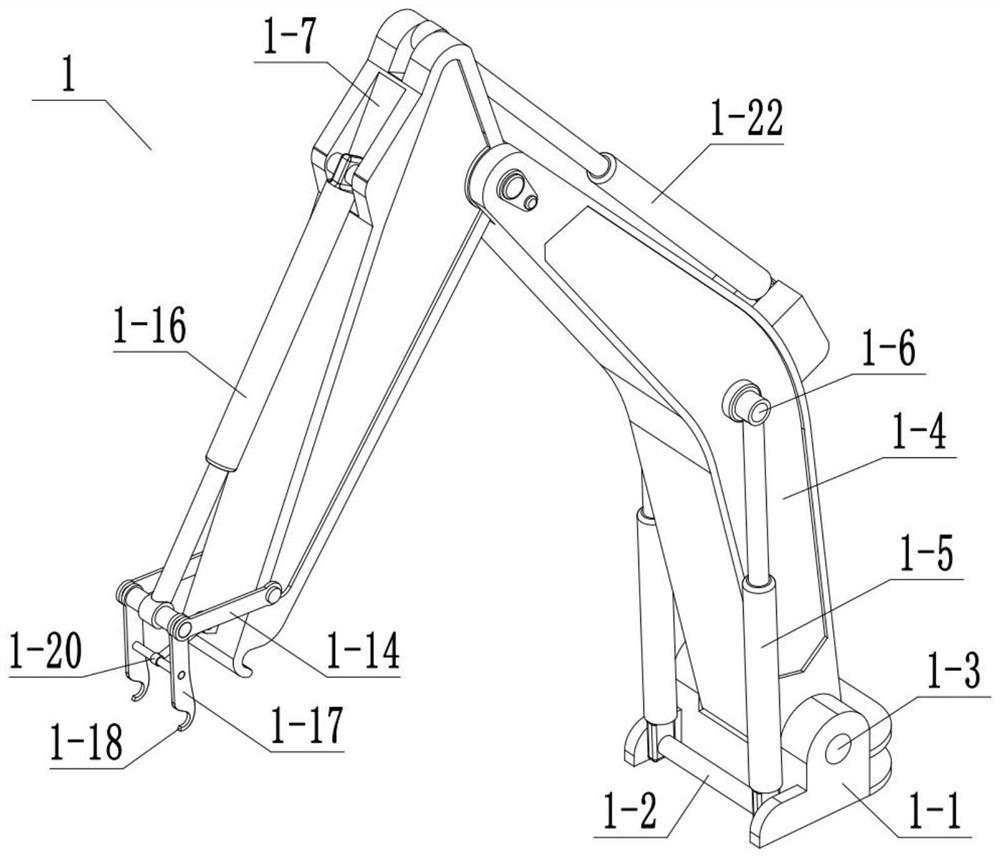

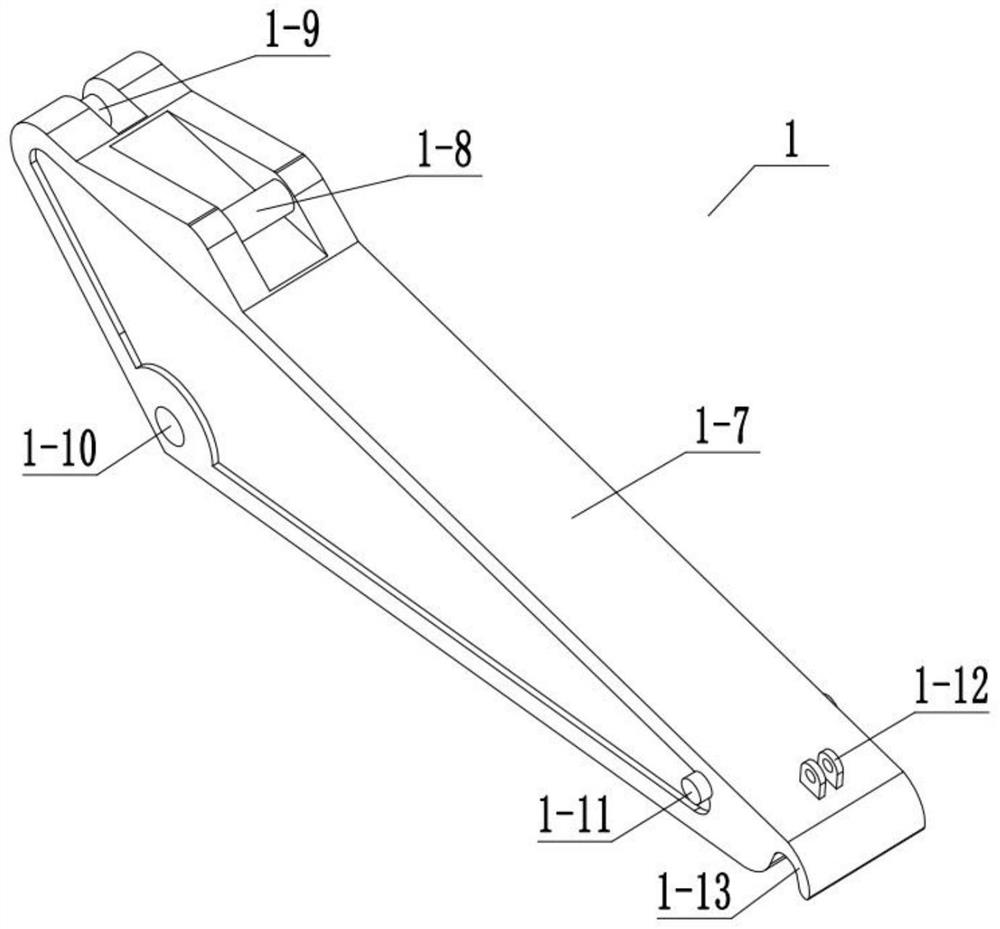

Screening bucket of excavator

InactiveCN113235680APlay the role of cleaning and dust removalPlay a screening roleSievingMechanical machines/dredgersReciprocating motionElectric machinery

The invention relates to engineering machinery, in particular to a screening bucket of an excavator. The bucket can be automatically installed through cooperative work of oil cylinders, primary screening can be carried out through a screening bucket assembly, secondary screening can be carried out through the excavator bucket, and tertiary screening can be carried out through an adjustable screening plate assembly. When the bucket is installed, a first arc hook hooks a pin shaft on the bucket, the second arc hook hooks the pin shaft on the bucket, and installation is automatically completed. During use, screening holes in the screening bucket play a role in primary screening, a motor drives a crankshaft to move, and the radial movement of a crankshaft connecting rod is converted into the reciprocating movement of the screening bucket around a sixth rotating shaft in a bucket body; the bucket body plays a role in secondary screening, and water is sprayed outwards from a spray head to achieve the effects of cleaning and dust removal; and the motor drives a one-way clutch and a sleeve to only rotate in one direction, so that all connecting rods of the screening plate assembly can be straightened, screening plates are fixed to all the connecting rods, and every two adjacent screening plates play a role in tertiary screening.

Owner:张桂莲

Tree leaf collecting device

InactiveCN109989377AComprehensive collectionReduce sizeRoad cleaningPulp and paper industryExhaust pipe

The invention provides a tree leaf collecting device. The tree leaf collecting device comprises a vehicle body, wherein the upper surface of the vehicle body comprises a push handle, a material collecting barrel, a material collecting mechanism, a crushing mechanism, a partition plate, a material outlet, a discharging door, a vent hole, a storage battery and a control panel; the bottom of the pushhandle is fixedly connected with the left side of the upper surface of the vehicle body, the middle of the upper surface of the vehicle body is fixedly connected with the bottom of the material collecting barrel, and the inner wall of the vehicle body is fixedly connected with the surface of the material collecting mechanism. According to the tree leaf collecting device, an exhaust fan and a speed reducing motor are controlled to be started through the cooperation of the material collecting mechanism and the crushing mechanism, the exhaust fan can drive an exhaust pipe to draw scattered leaves below the vehicle body into the material collecting barrel, then the leaves inside the material collecting cylinder are conveyed to the interior of the exhaust pipe, meanwhile, the leaves are crushed through a blade, then the size of the leaves can be reduced, and therefore more leaves can be collected in the material collecting barrel.

Owner:XUZHOU NORMAL UNIVERSITY

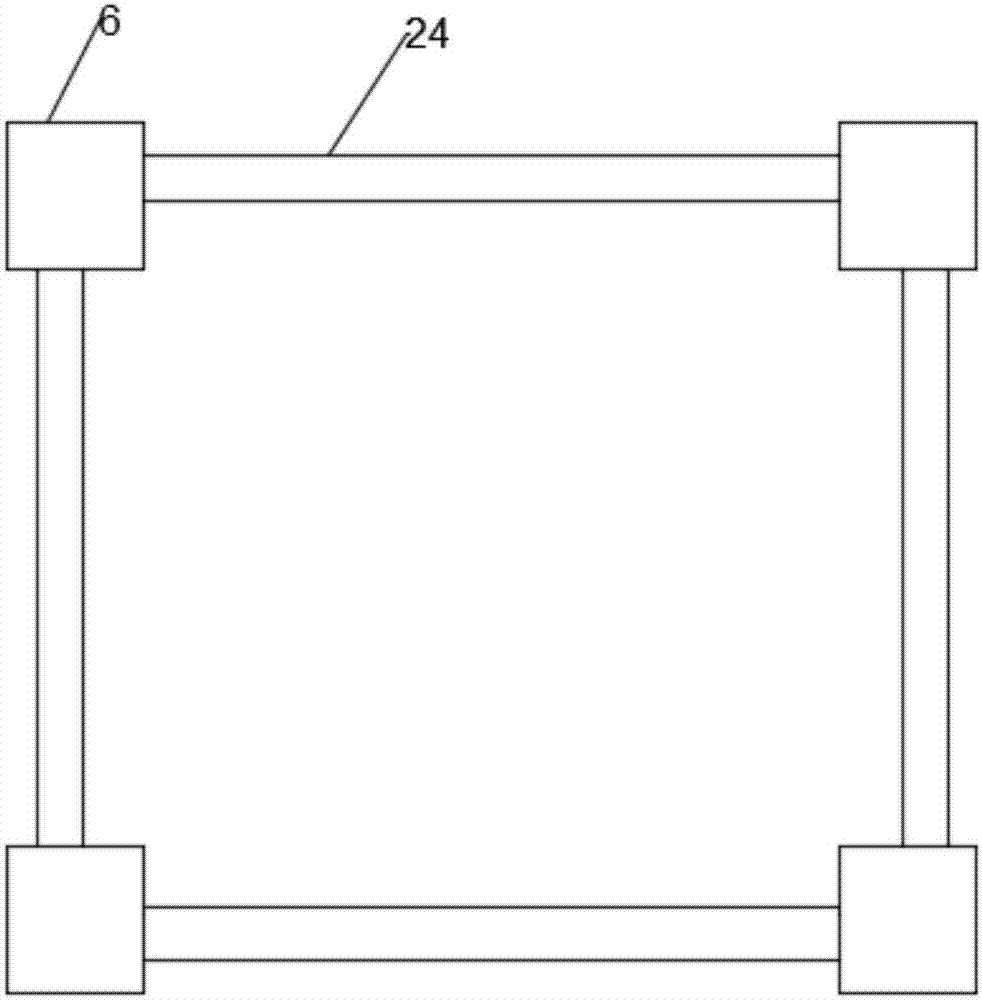

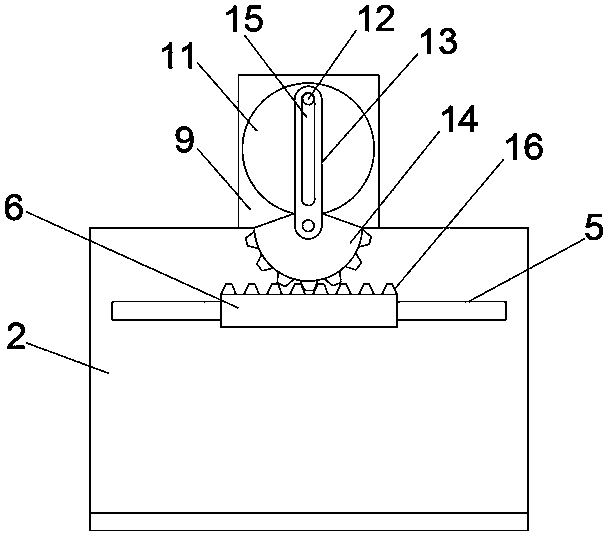

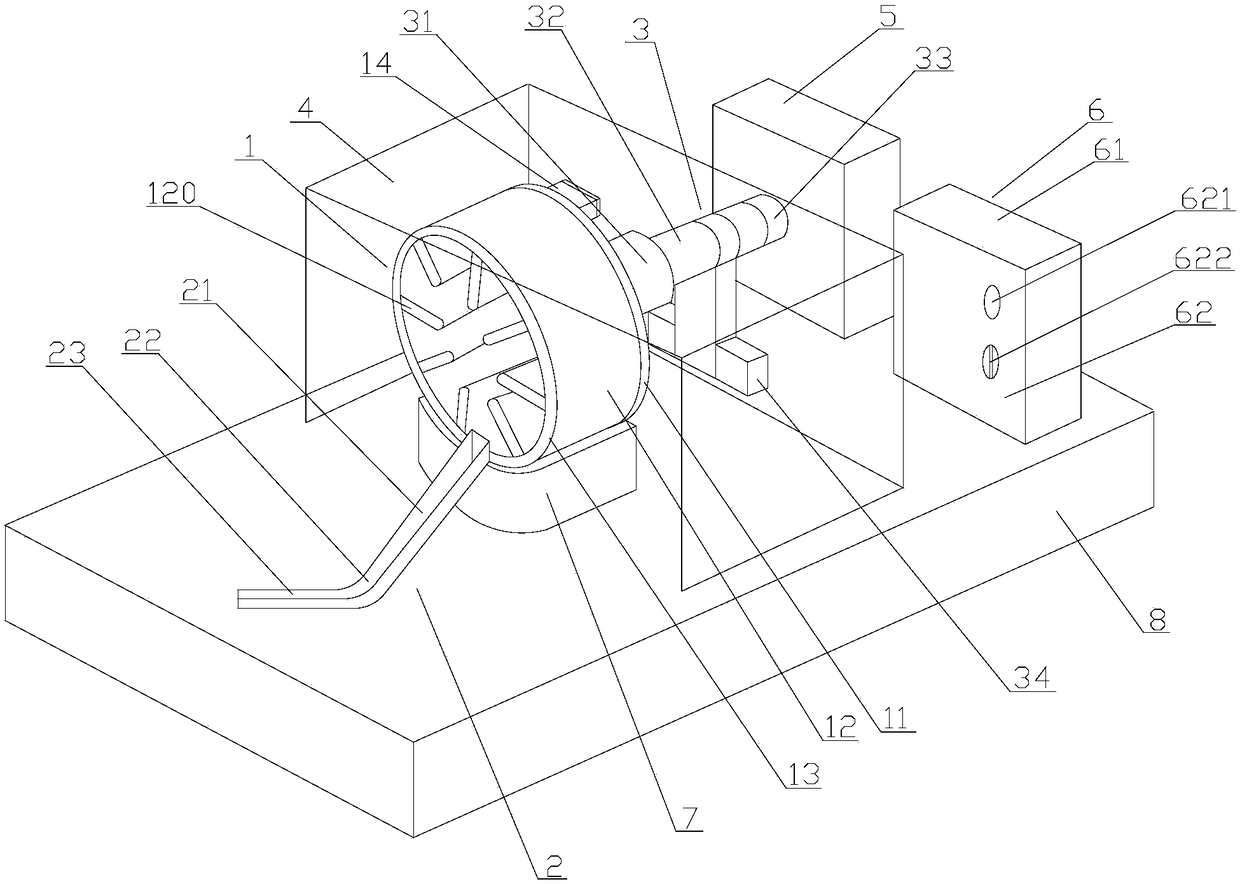

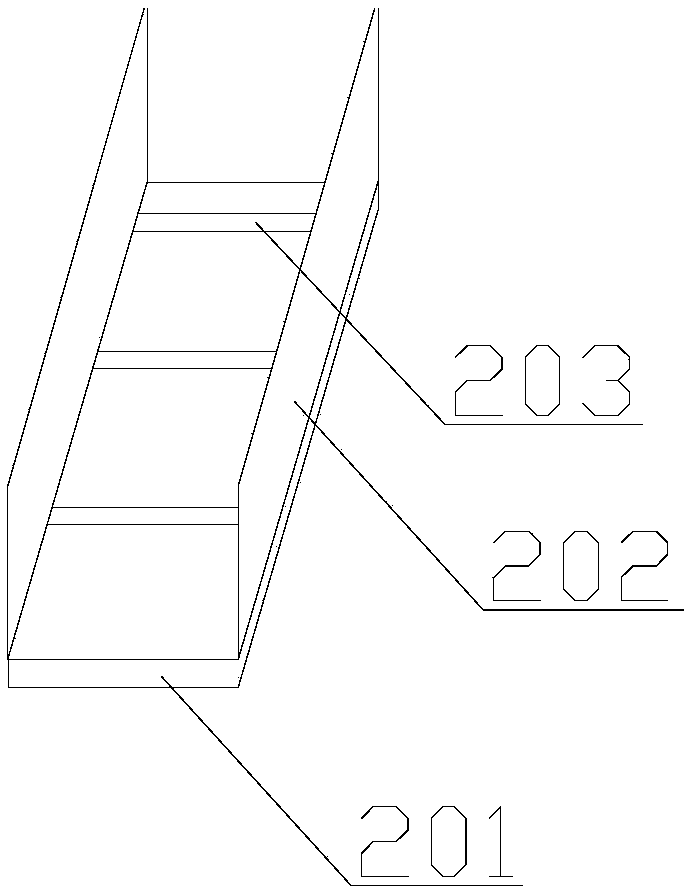

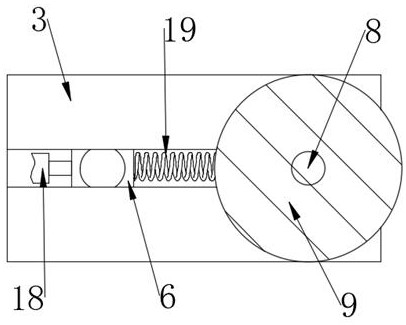

Grain processing and deroughening machine

The invention discloses a grain processing and deroughening machine. The machine comprises a base, a deroughening sieve and a deroughening device, two supporting plates are symmetrically fixed at thetop of the base, sliding assemblies are symmetrically fixed on the inner sides of the two supporting plates, the sliding assemblies comprises fixing blocks, sliding rods and sleeves; the two ends of the sliding rods are fixed with the supporting plates through the fixing blocks; the sleeves are connected to the outer side of the sliding rods in a sliding mode, the two sides of the deroughening sieve are respectively fixed with the sleeves, the deroughening device is fixed on the supporting plate on one side of the top of the base, the deroughening device comprises mounting plates, a driving assembly, a rotating disc, a driving shaft, a connecting rod and a transmission gear, the mounting plates are fixed at the top of the supporting plates, the driving assembly is fixed on the mounting plate, the output end of the driving assembly is fixed with the turntable, the driving shaft is fixed on one side, far away from the driving assembly, of the rotating disc. According to the grain processing and deroughening machine, the deroughening sieve can be driven to move in a reciprocating mode through the deroughening device, so that the screening speed of the deroughening sieve is increased,and the deroughening quality of the grain is higher.

Owner:HUAIAN YUETA RICE IND CO LTD

Axial crushing and kneading machine

PendingCN112774819AImprove crushing effectPlay a screening roleGrain treatmentsStructural engineeringCrusher

The invention discloses an axial crushing and kneading machine and relates to the field of crushers. The problems that an existing crusher is low in crushing efficiency, poor in material crushing effect and large in power consumption, and the material crushing effect is not easy to control are solved. The number of fixed cutter sets at one end of the inner bottom face of a rubbing unit shell is increased, so that the crushing effect is improved, meanwhile, the screening effect is achieved, materials with too large sizes continue to be crushed, the materials become slender and soft under the interaction of rubbing blocks and rubbing plates, discharging can be smoother and more uniform under the negative pressure effect of a discharging fan, the power consumption is correspondingly reduced, the production cost is reduced, and the crushing effect is convenient to control, so that the crushing efficiency of a crusher is improved. The invention is applicable to the field of crushers.

Owner:HEGANG TIANFENG AGRI MACHINERY MFG

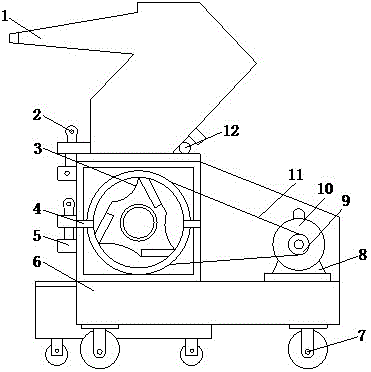

Novel plastic pulverizer

InactiveCN106334618AReduce pollutionSmooth inside and outsidePlastic recyclingGrain treatmentsEngineeringMaterial storage

The invention discloses a novel plastic pulverizer which comprises a feeding hopper, an electric motor, a box body, a starting switch, a screen, a material storage hopper, a belt wheel and a rotary shaft, wherein a hinge is arranged on a bottom edge of the feeding hopper; a movable cutter is arranged inside the box body; the movable cutter is mounted on the rotary shaft; an insertion pin hole is formed in the rotary shaft; the two sides of the movable cutter are fixed through movable cutter fixing devices; the rotary shaft is fixedly mounted inside the box body; the two ends of the rotary shaft penetrate through the box body; and one end of the rotary shaft is equipped with the belt wheel. According to the novel plastic pulverizer disclosed by the invention, inner and outer surfaces are flat, and contact parts between inner and outer surfaces and materials are polished, so that cleaning operation burden is relieved; in a pulverizing process, the novel plastic pulverizer is totally sealed without dust overflow, so that operation environment is sufficiently improved, and environmental pollution is reduced; and a mechanical and electronic integration technology is adopted, so that high performance and high level of equipment are realized, labor usage is reduced, and pollution degree of products is small, and therefore, product quality is improved.

Owner:无锡市富能金属制品有限公司

Fertilizer conveying device

A fertilizer conveying device comprises a feeding conveyor belt; a sieve plate inclined downwards is arranged on the lower portion of the tail end of the feeding conveyor belt; the tail end of the sieve plate is arranged above an ascending conveyor belt; the sieve plate is provided with a plurality of through holes; and a starting conveyor is arranged under the sieve plate. According to the fertilizer conveying device, the conveyor belts and a pneumatic conveying device are adopted for conveying fertilizer to a high place, different conveying modes can be selected according to the size of thechemical fertilizer, the sieve plate can screen the chemical fertilizer, materials with small size fall from the sieve plate and are conveyed through the pneumatic conveying device, and materials withlarge size slide from the sieve plate to the ascending conveyor belt and are conveyed to a high place through the conveyor belt.

Owner:湖北香青化肥有限公司

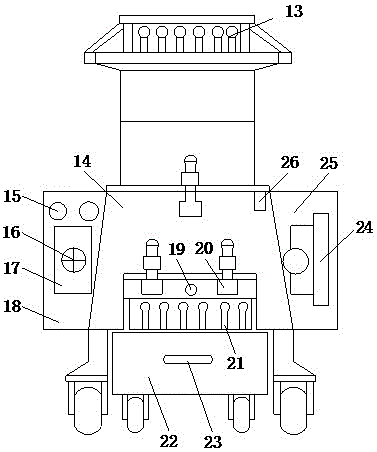

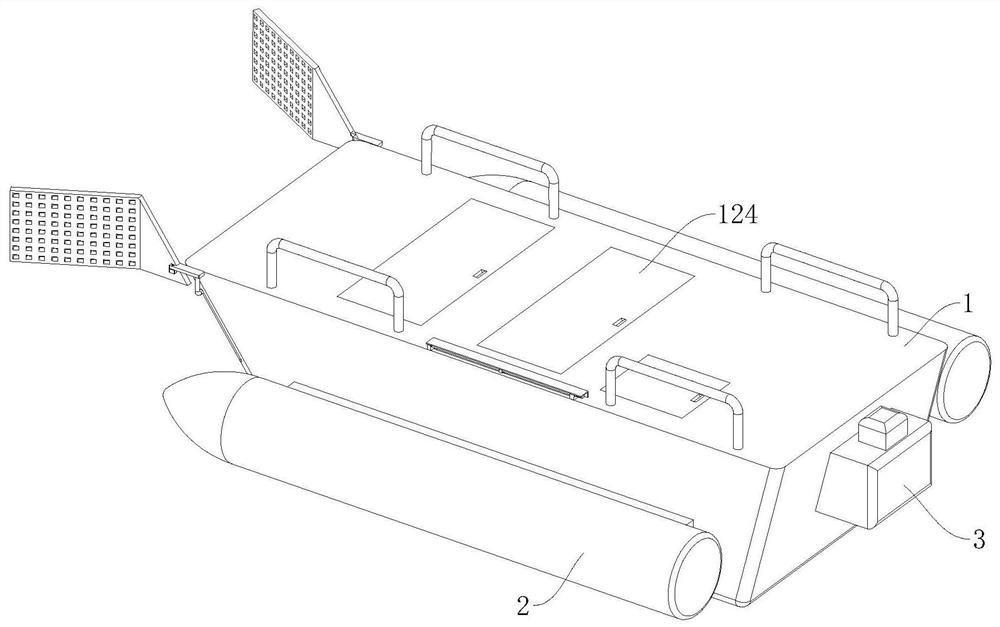

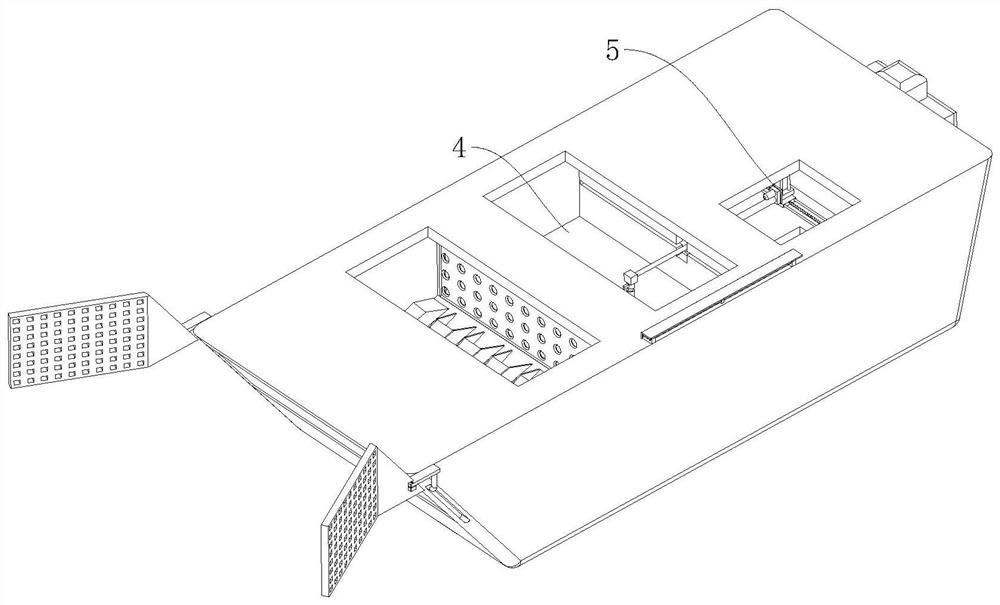

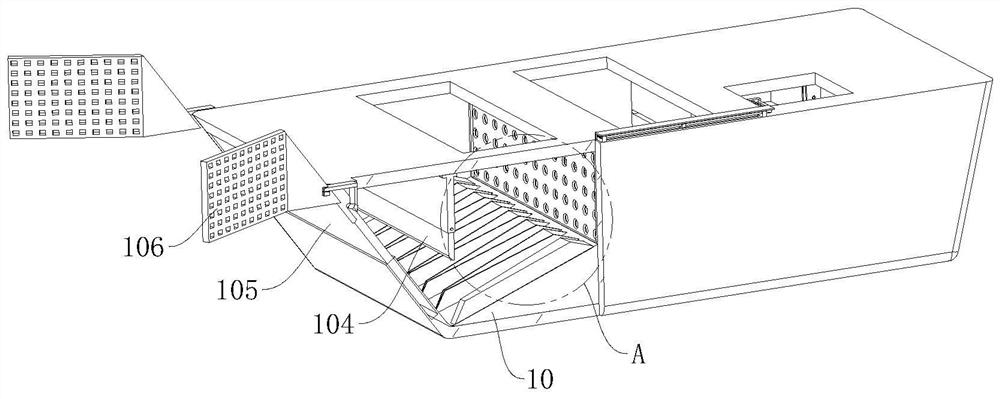

Lake surface poultry feed identifying and collecting device and method

InactiveCN111891304AEasy to grabEasy Grab Component CaptureSievingHull interior subdivisionShrimpEngineering

The invention relates to the technical field of garbage cleaning, and particularly relates to a lake surface poultry feed identifying and collecting device and method. The ship comprises a ship body and two supporting air bags. The device further comprises a control box, an adsorption mechanism and a catching mechanism. A controller is mounted in the control box; a first storage cabin, a second storage cabin and a third storage cabin are integrally formed in the ship body; a sealed cabin is arranged at the bottom of the second storage cabin; the top of the third storage cabin is communicated with an isolation cabin; the adsorption mechanism comprises a sealing plate and a drainage assembly; the catching mechanism is arranged in the isolation cabin and is used for catching fishes and shrimps; the catching mechanism comprises an elastic rod, a sliding assembly and a grabbing assembly. According to the lake surface poultry feed recognizing and collecting device and method, lake surface garbage and living things can be distinguished, mixing of the lake surface garbage and the living things is prevented, poultry breeding is facilitated, meanwhile, the loading space can be effectively saved, and the garbage treatment efficiency is improved.

Owner:芜湖星之原工业设计有限公司

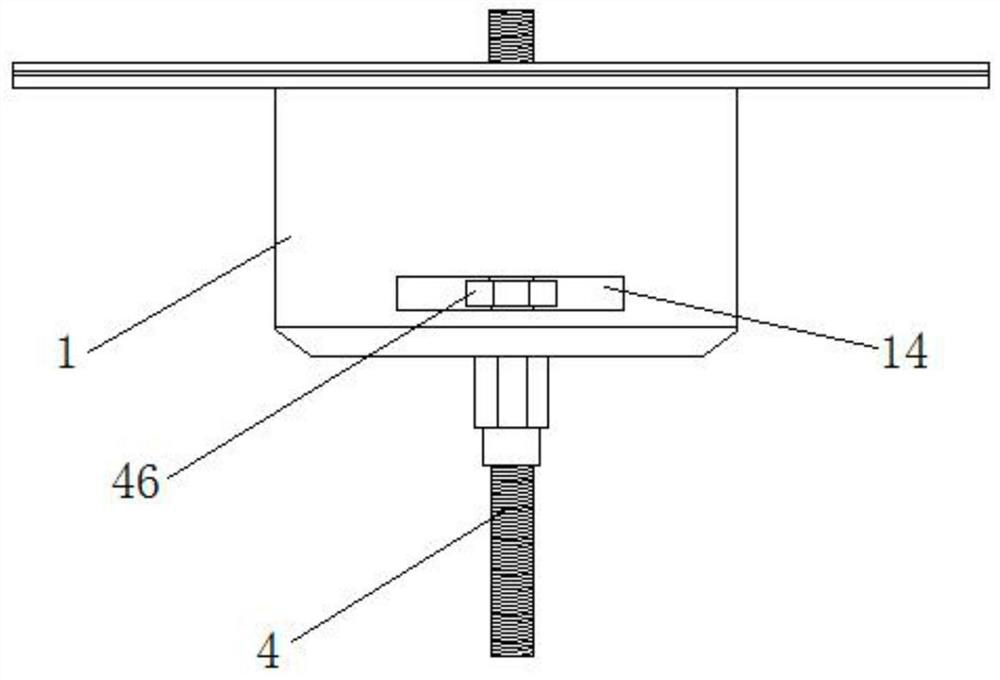

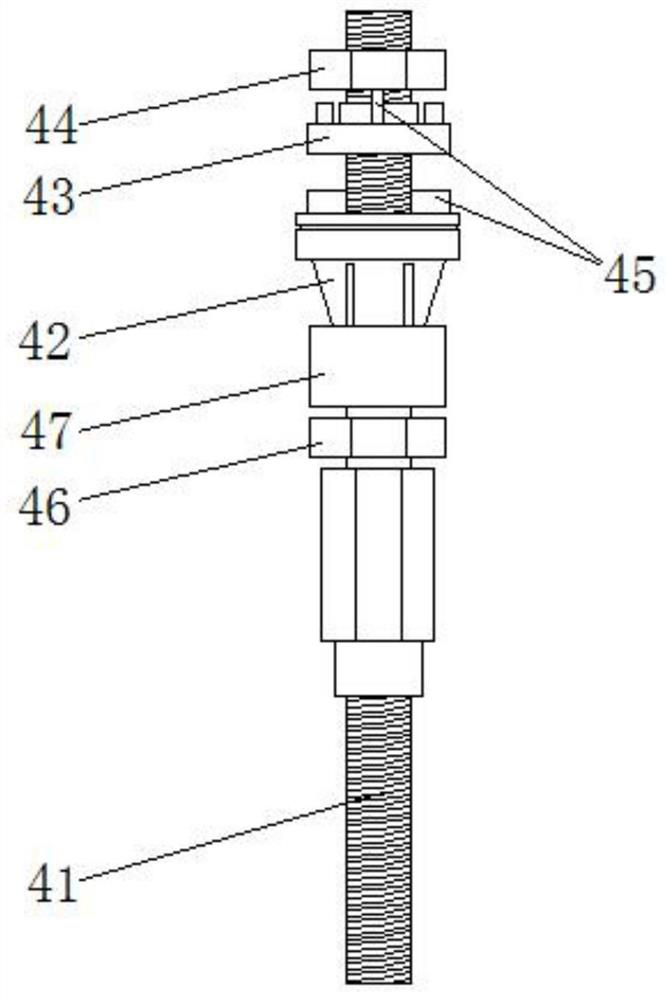

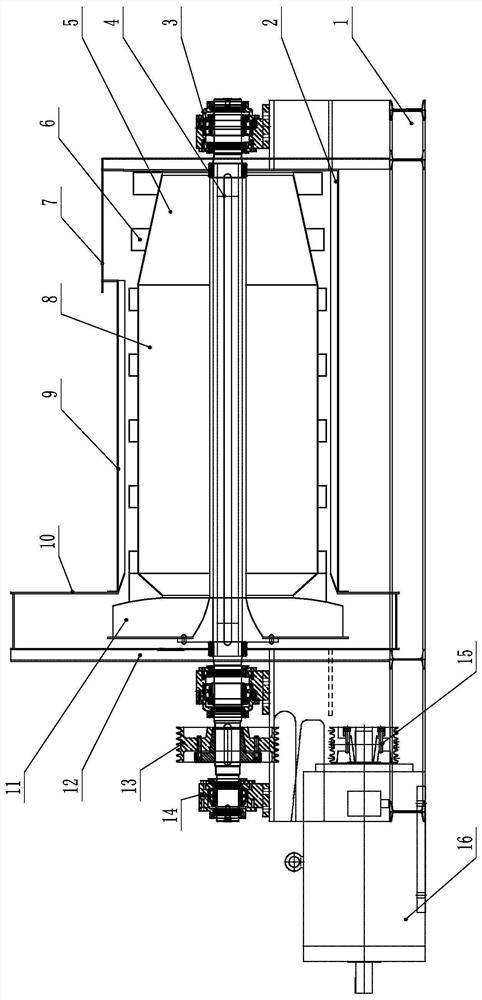

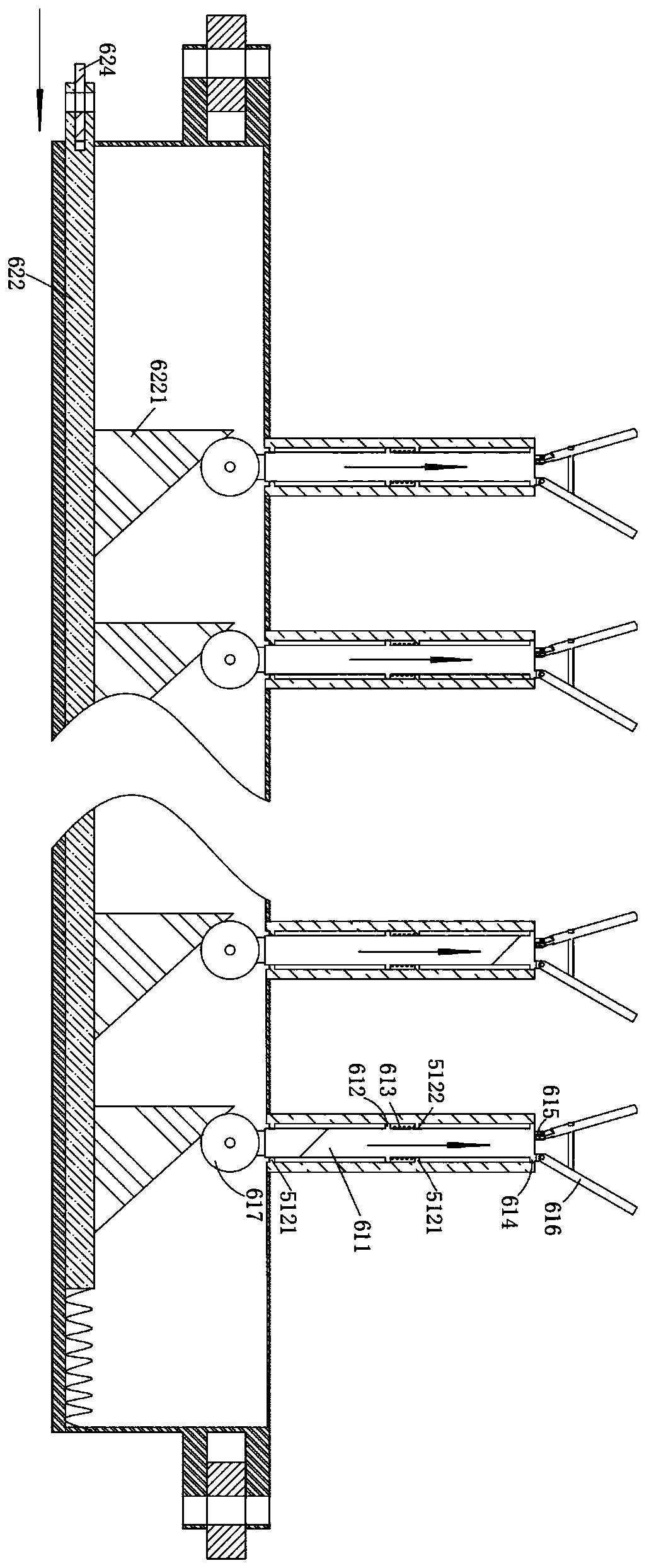

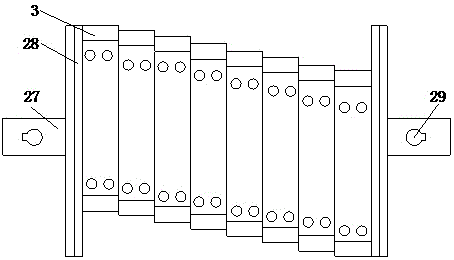

Rotary bearing feeding device

Owner:新昌县博源科技有限公司

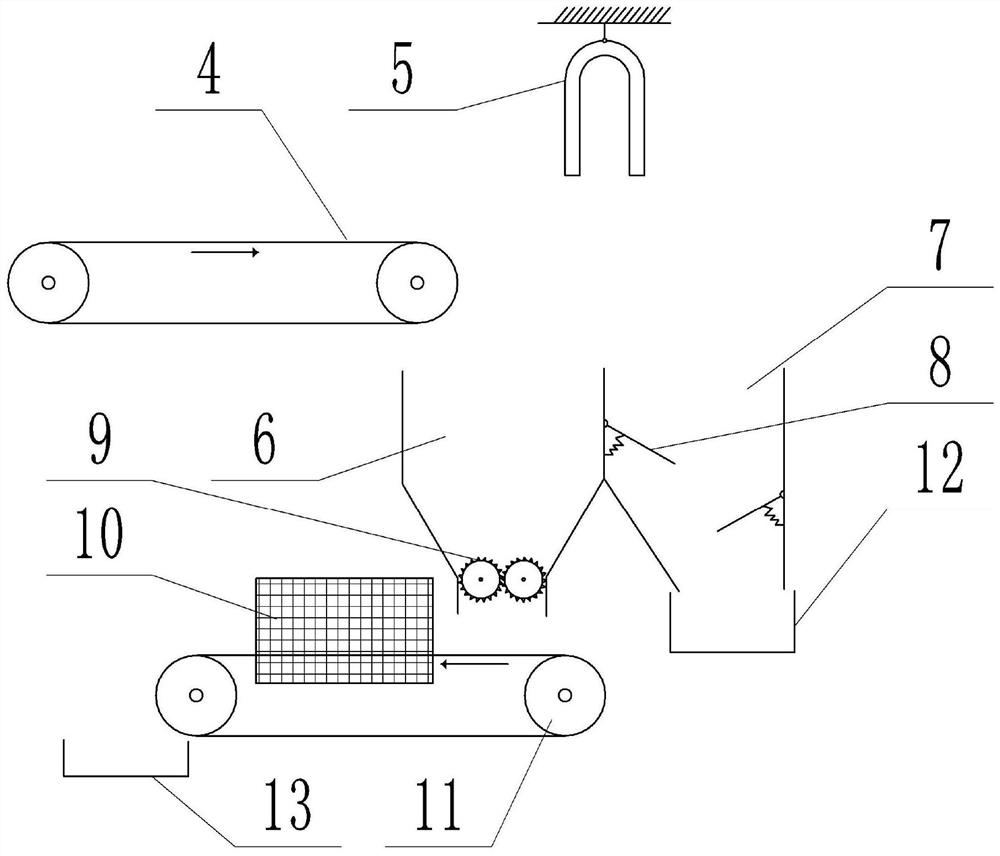

Environment-friendly household garbage treatment device

PendingCN112828022APlay a screening roleGas current separationSolid waste disposalRefuse DisposalsMechanical engineering

The invention discloses an environment-friendly household garbage treatment device which comprises a hollow box body and a feeding hopper located on the upper side of the box body. A first conveying belt located below the feeding hopper, a front screening channel located below the tail of the first conveying belt, a rear screening channel and a second conveying belt located below the front screening channel are arranged in the box body. A permanent magnet is arranged above the tail of the first conveying belt. The front screening channel is located between the rear screening channel and the first conveying belt. A roller pair is arranged at the bottom of the front screening channel, and smashing teeth are evenly distributed on the roller pair. An air blower located on the side face of the second conveying belt is further arranged in the box body. The environment-friendly household garbage treatment device integrates the functions of garbage classification, crushing, treatment and the like, and household garbage treatment is conveniently and rapidly achieved.

Owner:周海传

Pineapple dicing device

InactiveCN105345864APlay a screening roleEasy to processMetal working apparatusGear wheelElectric machinery

The invention belongs to the field of fruit dicing devices and particularly discloses a pineapple dicing device comprising a rack, two sets of cutters, a hopper and a collecting barrel. The first set of cutter comprises two circular blades, a base, a driving gear, a driven gear and a motor; the motor is fixed on the rack, the two blades are horizontally arranged and are hinged to the bottom of the hopper side by side, notches matched with the blades are formed in the bottom of the hopper, the two blades are respectively provided with a driven belt pulley, the driving gear is fixed on the rotating shaft of the motor, the driven gear is hinged to the rack, and the driving gear is meshed with the driven gear; the driving gear and the driven gear are respectively provided with a driving belt pulley, and a belt is arranged between the driving belt pulley and the driven belt pulley; the structure of the second set of cutter is the same as that of the first set of cutter, the blades of the second sets of cutter are vertical to the blades of the first set of cuter; and the collecting barrel is fixed below the hopper. The invention aims at providing the pineapple dicing device which cannot cause pineapple jamming and is high in dicing efficiency.

Owner:CHONGQING FENGTANGMEI AGRI DEV CO LTD

Axial crusher

PendingCN112774820AReduce crushing efficiencyReduce power consumptionGrain treatmentsClassical mechanicsStructural engineering

The invention discloses an axial crusher, relates to the field of crushers, and aims to solve the problems that an existing crusher is low in crushing efficiency, poor in material crushing effect, large in power consumption and not easy to control in the material crushing effect. A shell is arranged in the middle of the upper surface of a base, and a through hole is formed in the middle of one end face of the shell; and the other end of the shell communicates with a fan shell, rotor bearings are arranged at the two ends of the upper surface of the base, a crushing rotor is arranged in the shell and the fan shell, and each end of the crushing rotor is connected with one rotor bearing. A plurality of movable cutter groups and fan blades are arranged outside the crushing rotor; the fan blades are arranged in the fan shell; the plurality of movable cutter groups are arranged in the shell; a plurality of fixed cutter groups are arranged at one end of the shell in a surrounding manner along the inner wall of the shell; a rubbing plate is arranged at the other end of the shell along the inner wall of the shell in a surrounding manner; a feeding hole is formed at the top of one end of the shell; and the crushing effect is improved, meanwhile, the screening effect is achieved, discharging is smoother and more uniform, and the production cost is reduced.

Owner:HEGANG TIANFENG AGRI MACHINERY MFG

Oat treatment device used for producing oat yogurt and using method thereof

InactiveCN112060652AAdjustable distanceDoes not affect rotationSievingScreeningBiotechnologyEngineering

The invention discloses an oat treatment device used for producing oat yogurt and a using method thereof, and relates to the field of oat treatment devices. The oat treatment device is simple in structure, is convenient in use, can adjust a distance between two extrusion roller columns, is more convenient in use, and is more stable in working process. A droop curtain structure is arranged for reinforcing and shielding such that rotation of the extrusion roller columns is not affected; a blocking strip is arranged to achieve certain shielding effect to avoid the problem that oat directly flowsto the other end as conveying for relatively great flow of oat by a conveying structure is not timely; the conveying structure is hollow structure and a collecting box body is arranged below the conveying structure; the collecting box body can achieve the screening effect to prevent dust particles and the like from being mixed into oat; a vibrating mechanism further can be arranged to make the conveying structure vibrate for reinforcing the screening effect; and meanwhile, the vibrating mechanism also can avoid the problem that oat shells are covered and cannot be blown out while accumulated on the oat conveying structure.

Owner:QINGHAI JINQILIAN DAIRY LLC

Current Density Imaging Method of Biological Tissue Based on Acoustoelectric Effect

InactiveCN103156605BHigh precisionHigh resolutionOrgan movement/changes detectionDiagnostic recording/measuringDensity basedMedical diagnosis

The invention discloses an imaging method of the biological tissue electric current density based on the acoustoelectric effect. The imaging method of the biological tissue electric current density based on the acoustoelectric effect comprises the following steps: (1) adopting an ultrasound excitation source to generate ultrasonic wave, driving and focusing the ultrasonic wave at the inner portion of biological tissue by the ultrasound; (2) continuously positioning the ultrasonic wave which is focused at the inner portion of the biological tissue, and finishing scanning of the whole or the local of the biological tissue; (3) collecting signals, focusing and positioning in a certain spatial position by the ultrasonic wave, generating a high frequency electrical signal which corresponds to the electric current density in the spatial position, and obtaining a set of signals of the whole or the local of the biological tissue; and (4) calculating and rebuilding the electric current density at the inner portion of the biological tissue according to the signals obtained after the scanning of the whole or the local of the biological tissue. The imaging method of the biological tissue electric current density based on the acoustoelectric effect is dynamic imaging, can intuitively reflect internal activities in the biological tissue, can obtain an electric current density image which is high in precision and resolution, and can facilitate medical diagnosis.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com