Axial crushing and kneading machine

An axial and fan technology, applied in grain processing and other directions, can solve the problems of poor material crushing effect, high power consumption, and difficult control of material crushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

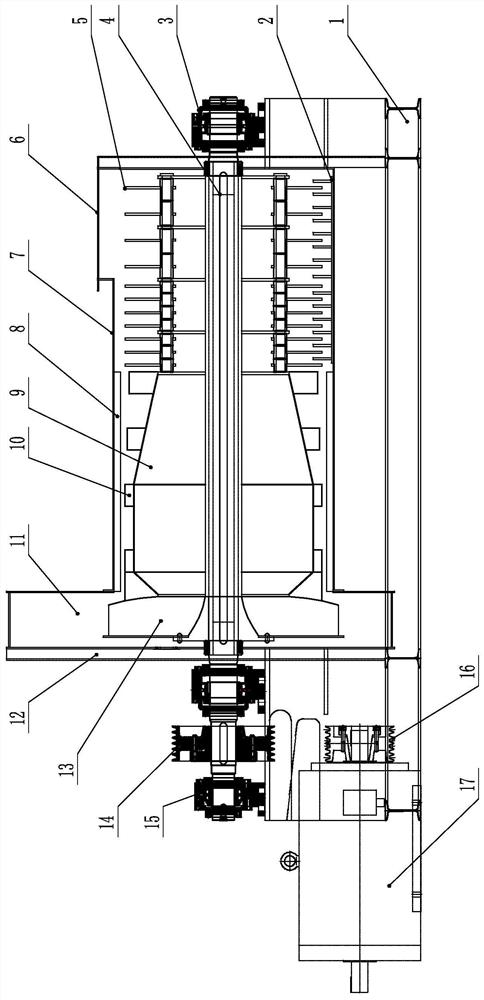

[0017] Specific implementation mode one: combine figure 1 Describe this embodiment, an axial crushing and kneading machine described in this embodiment includes a base 1, a fixed knife group 2, a rotor bearing 3, a crushing rotor 4, a moving knife 5, a kneading unit housing 7, a kneading plate 8, a closed Tube 9, kneading block 10, fan casing 11, fan blade 13, transmission pulley 14, support bearing 15, motor pulley 16 and motor 17;

[0018] The middle part of the upper surface of the base 1 is provided with a kneading unit housing 7, and the middle part of one end surface of the kneading unit housing 7 is provided with a through hole. The bearing 3 and one end of the crushing rotor 4 pass through the fan casing 11, the fan blade 13, the closed cylinder 9, the moving knife 5 and the kneading unit casing 7 in sequence, and are fixedly connected with the inner ring of the rotor bearing 3, and the moving knife 5 is fixed on the crushing On the circumferential surface of the roto...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the pulverizing and kneading machine described in the first specific embodiment. In the axial pulverizing and kneading machine described in this embodiment, the fan blades 13 are arranged on the fan housing 11 internal.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the crushing and kneading machine described in the first specific embodiment. In the axial crushing and kneading machine described in this embodiment, the blades of the fixed knife set 2 and the movable The blades of the knife 5 are arranged in a staggered manner;

[0022] In this specific embodiment, the blades of the fixed knife group 2 and the blades of the movable knife 5 are alternately arranged to improve the crushing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com