High-efficiency combined type domestic garbage crusher

A technology of domestic waste and crusher, which is applied in the direction of grain processing, etc., can solve the problems of slow discharge speed, difficult feeding, insufficient processing capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

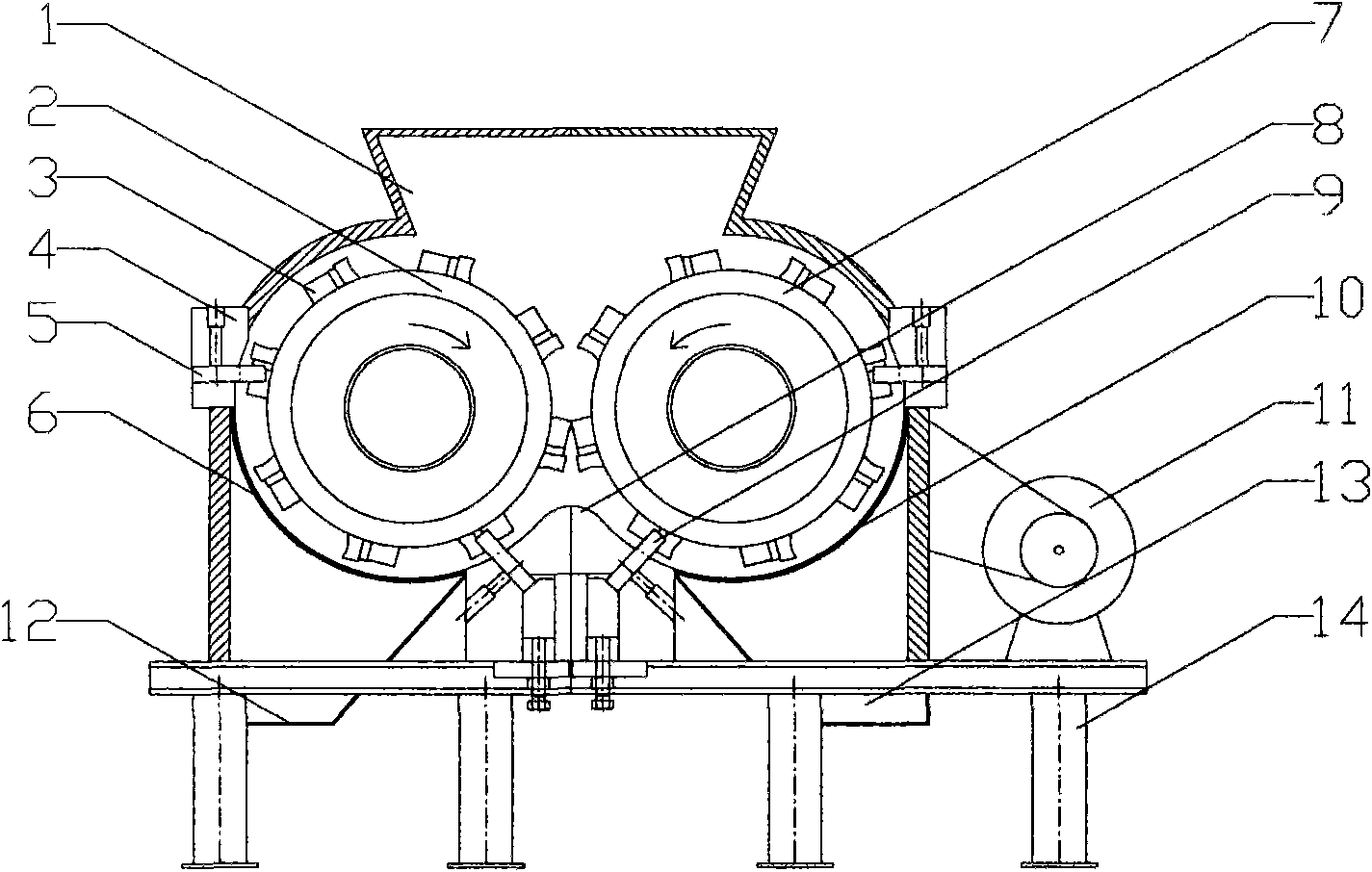

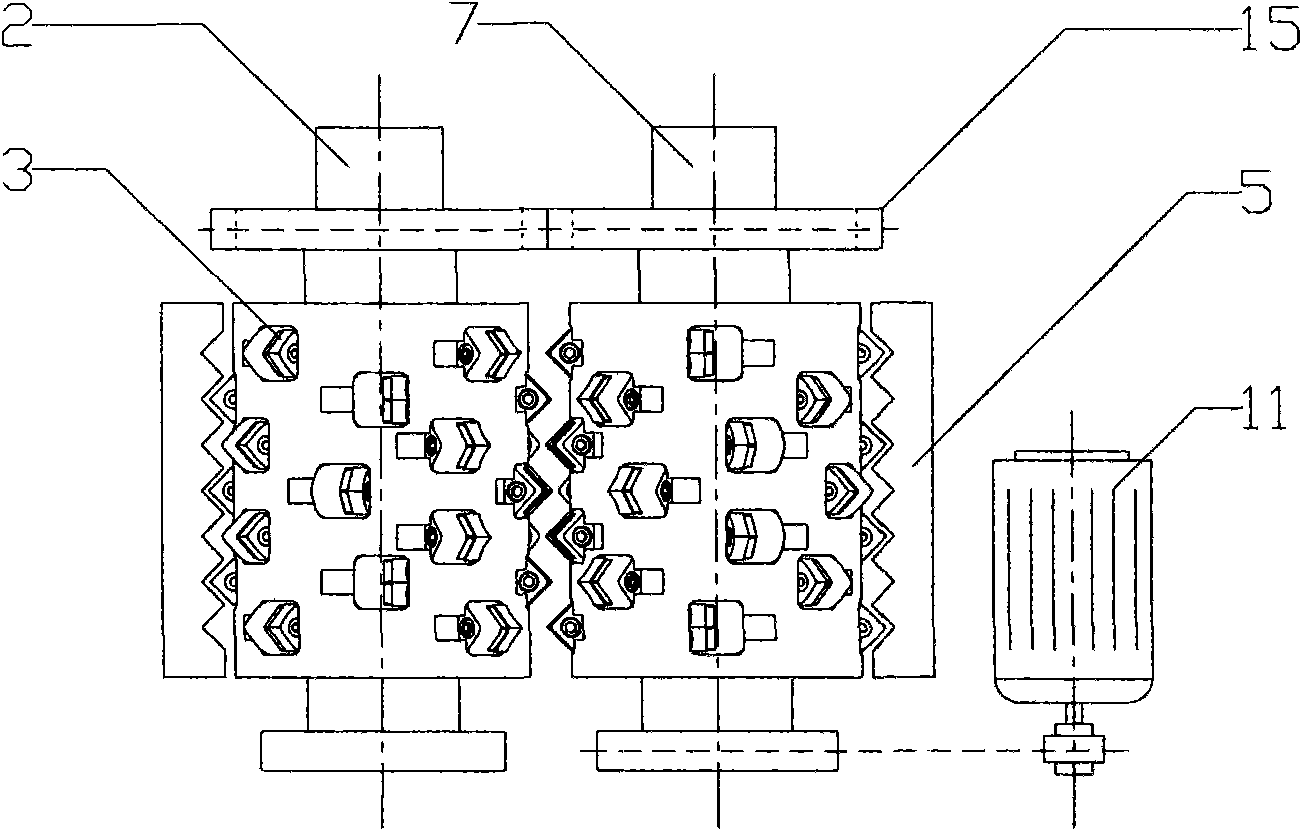

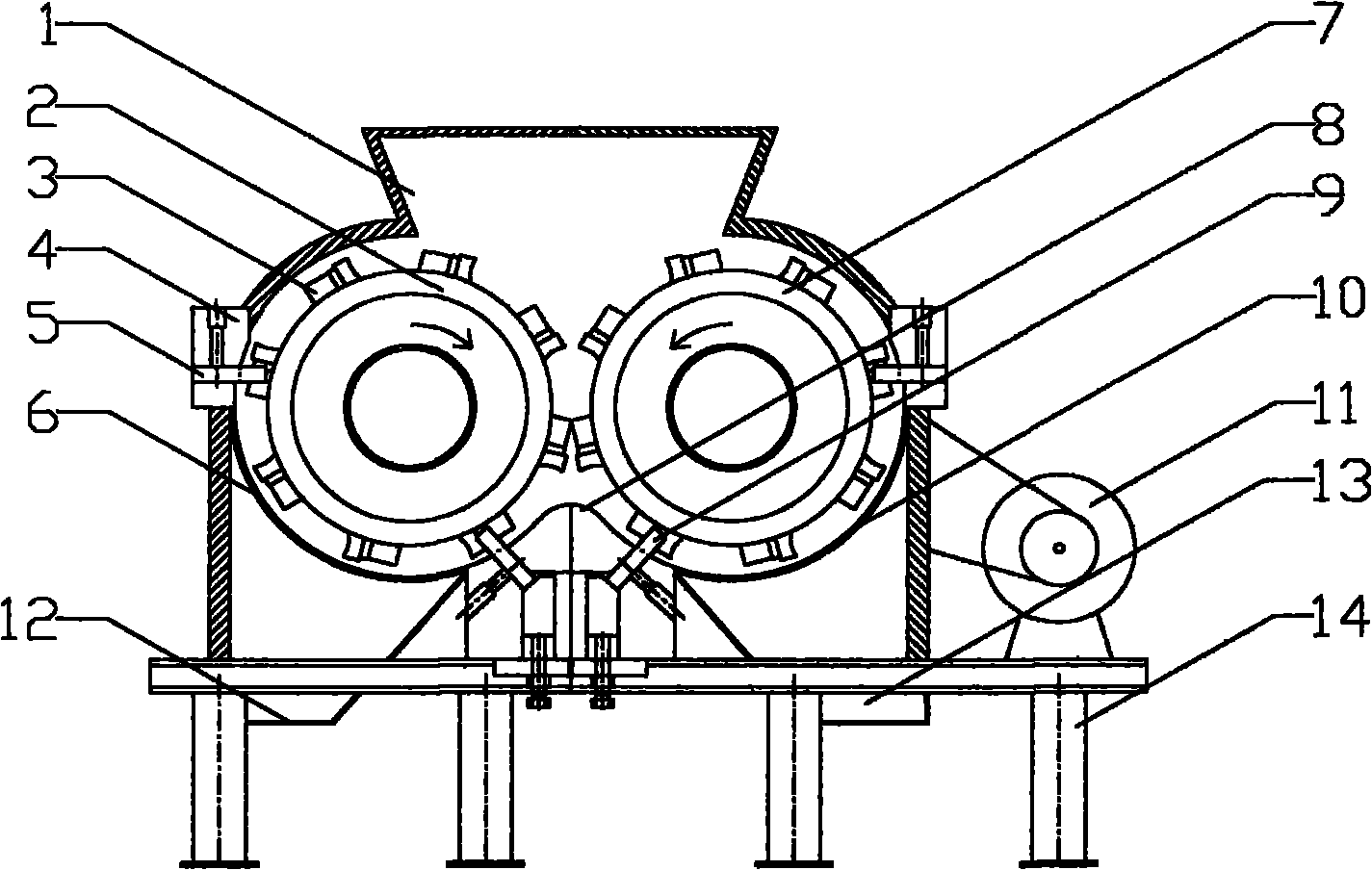

[0027] Figure 1~2 It is a specific embodiment of the present invention.

[0028] The present invention comprises material inlet 1, left knife roller 2, moving knife 3, side fixed knife adjusting device 4, side fixed knife 5, left screen 6, right knife roller 7, bottom block 8, bottom fixed knife 9, Right screen cloth 10, motor 11, left discharge port 12, right discharge port 13, frame 14 and synchronous gear set 15.

[0029] Such as figure 1 As shown, under the drive of the motor 11, through the synchronous gear set 15, the left knife roller 2 and the right knife roller 7 run oppositely and synchronously. The material is fed from the entrance 1. When the moving knife rotating on the left and right knife rollers is relatively close, it will pierce the material and shred the material. Driven by the moving knife, the material will be compressed to the space between the two knife rollers. gap and continue downward. When reaching the bottom block 8, the material is divided at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com