Automatic rolling ball grouping mechanism

An automatic grouping and ball rolling technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high manual labor intensity, error-prone, and large number of balls, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

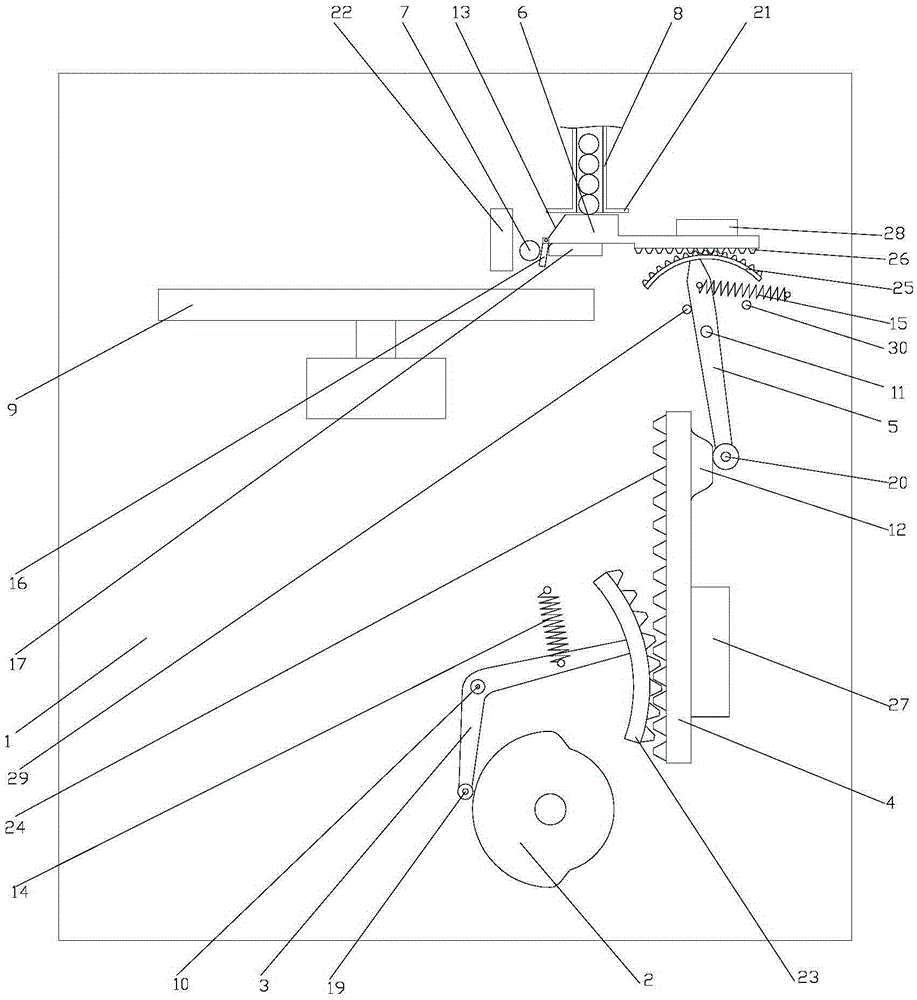

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

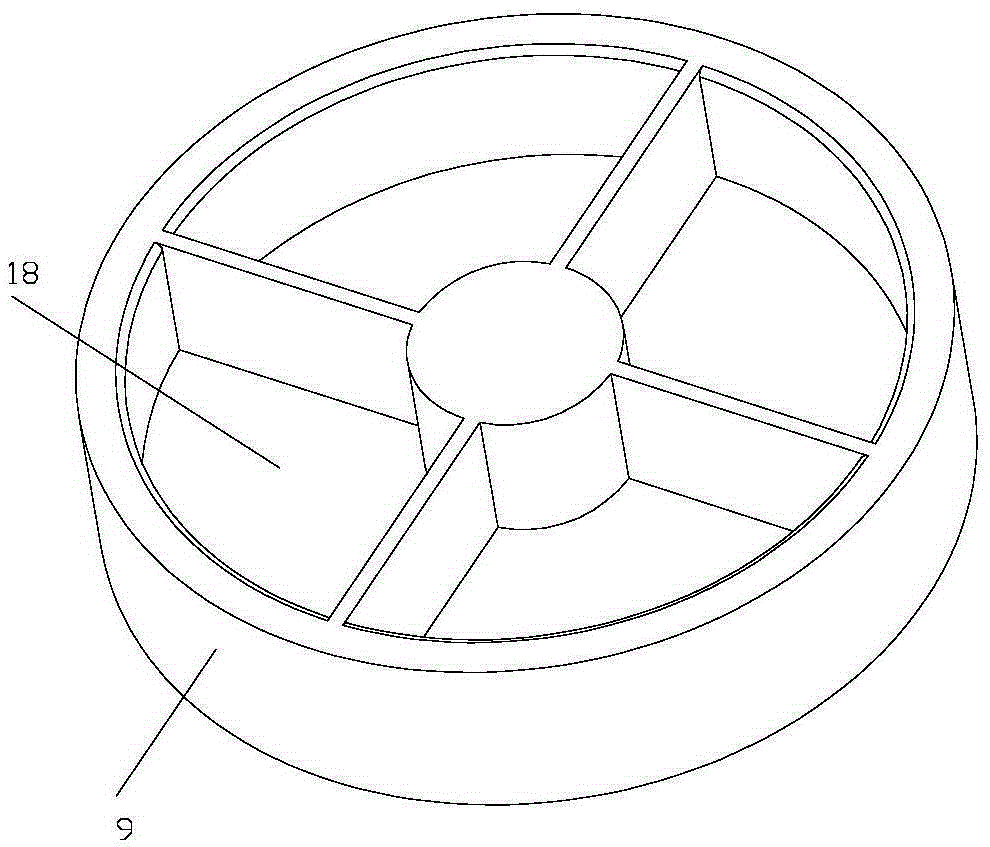

[0019] As shown in the figure, the working principle of the present invention: the first motor drives the cam to rotate continuously, and the rotation of the cam can drive the transmission rod to reciprocate clockwise and counterclockwise, and then drive the vertical plate to reciprocate up and down, and then through the bump and the swing rod The abutment of the lower end pushes the pendulum to reciprocate clockwise and counterclockwise, and finally drives the push block to reciprocate left and right; during each left and right movement of the push block, a ball can be pushed from the barrel to the turntable. In a groove; when a certain number of balls are placed in this groove on the turntable, the second motor can drive the turntable to rotate to align the next groove on the turntable with the position of the push block. Wherein, the swing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com