Patents

Literature

214 results about "Fatigue Intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Service life based high-temperature container creep fatigue strength design method

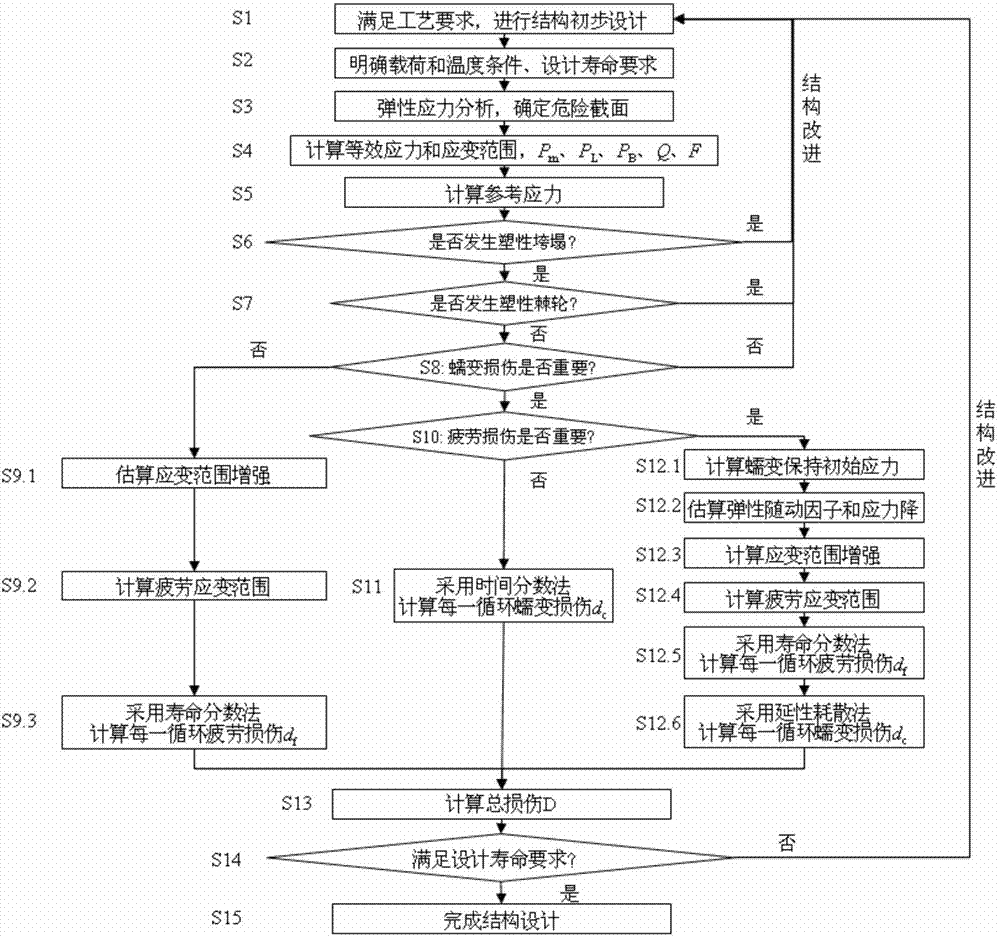

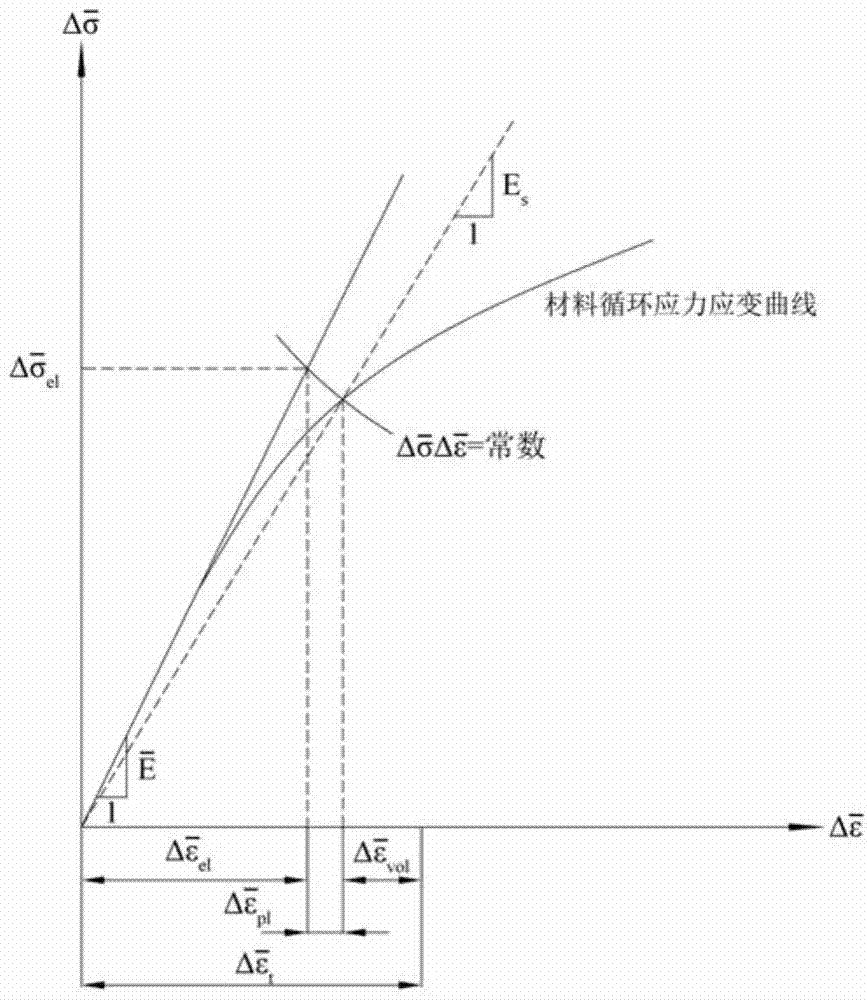

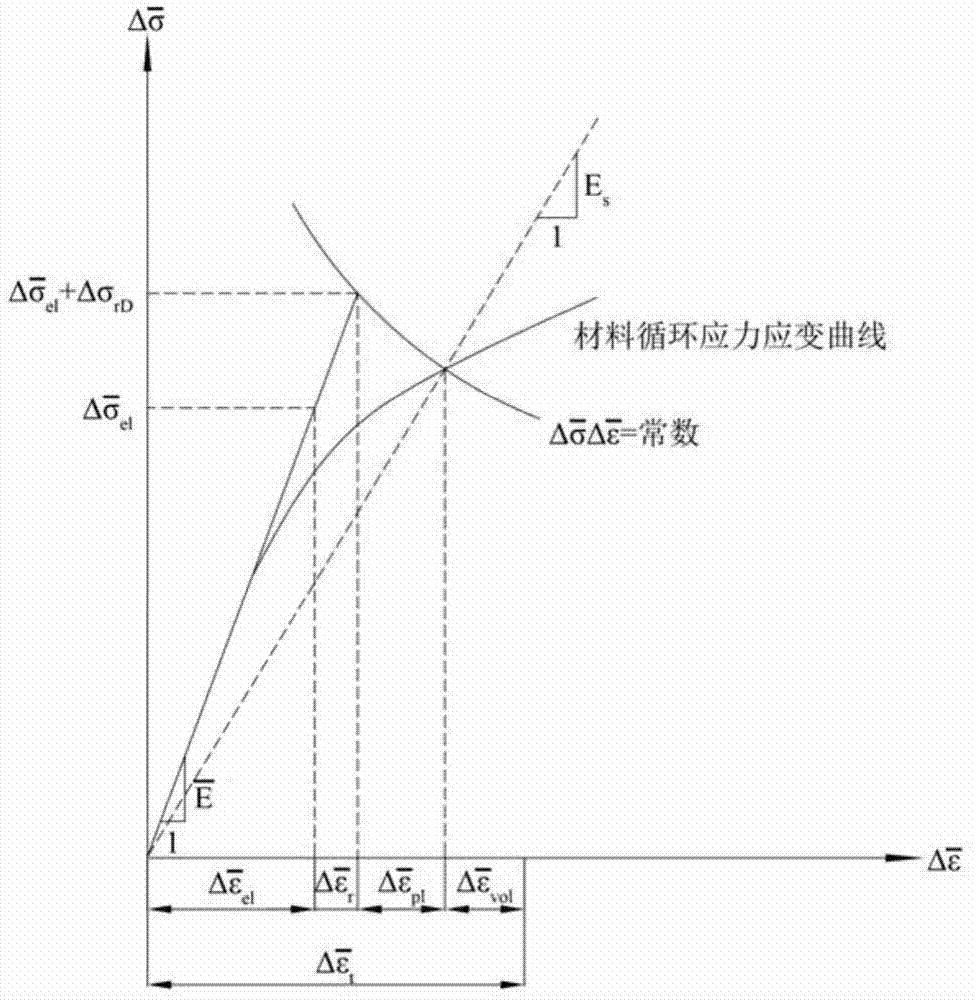

The invention discloses a service life based high-temperature container creep fatigue strength design method. The method comprises the steps of 1, performing structure preliminary design; 2 determining load and temperature conditions and the design service life requirement; 3, determining dangerous sections; 4, calculating the equivalent stress and strain range; 5, calculating reference stress; 6, determining whether plastic collapse occurs; 7 determining whether the plastic ratchet occur; 8, determining whether creep damage is important; 9, estimating fatigue damage of each cycle when the creep damage is not important; 10, determining whether the fatigue damage is important; 11, estimating the creep damage when the fatigue damage is not important; 12, estimating damage of each cycle when the creep damage and the fatigue damage are non-ignorable; 13, estimating creep-fatigue total damage; 14, performing result analysis and structural design improvement; 15, completing structural design. According to the method, the foundation is laid for national establishing of creep and fatigue failure mode based high-temperature pressure container design standards and achieving design and manufacture of high-temperature pressure containers according to the service life.

Owner:HEFEI GENERAL MACHINERY RES INST

Automobile transmission gear heat treatment method

ActiveCN104894506AAvoid early crackingAlleviate the problem of bulky carbidesSolid state diffusion coatingFatigue IntensityHigh carbon

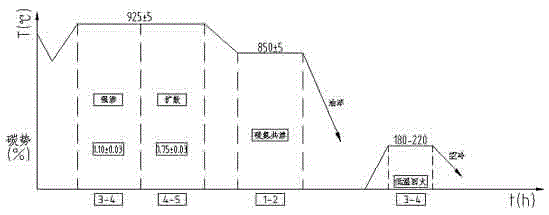

The invention discloses an automobile transmission gear heat treatment method. The method includes the steps of carburization, carbonitriding, quenching, cleaning, low temperature tempering and air cooling. The carburization technique is combined with the carbonitriding technique, abrasion resistance, fatigue strength and corrosive resistance are improved by a layer of highly hard nitride layer obtained on the carburized layer on the surface of a gear, and comprehensive performance of a product is good; meanwhile, the problems of massive carbide appearing under the high carbon potential state and network carbide appearing in the cooling process are avoided, and early-age cracking of the surface of the gear is avoided; moreover, by the method, the technological process is simplified, heating and cooling links and discharge links are reduced, carburization deformation and quenching deformation are reduced, generation of black structures is reduced as well, and anti-fatigue performance is guaranteed; finally, by the method, production cycle is shortened greatly, energy consumption is lowered, and production efficiency is improved highly.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

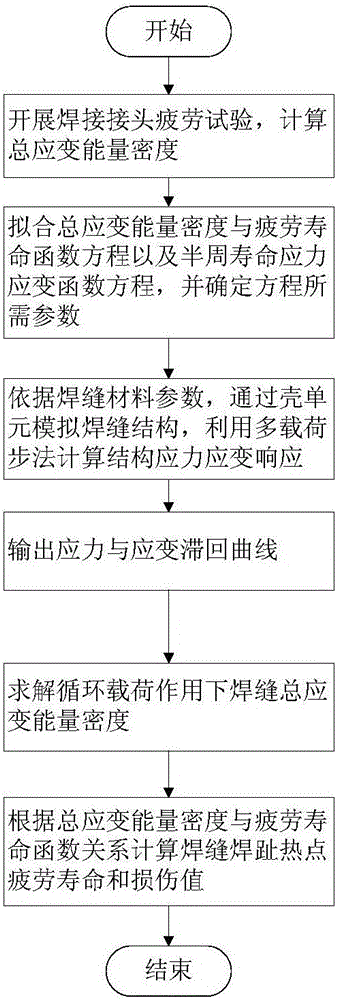

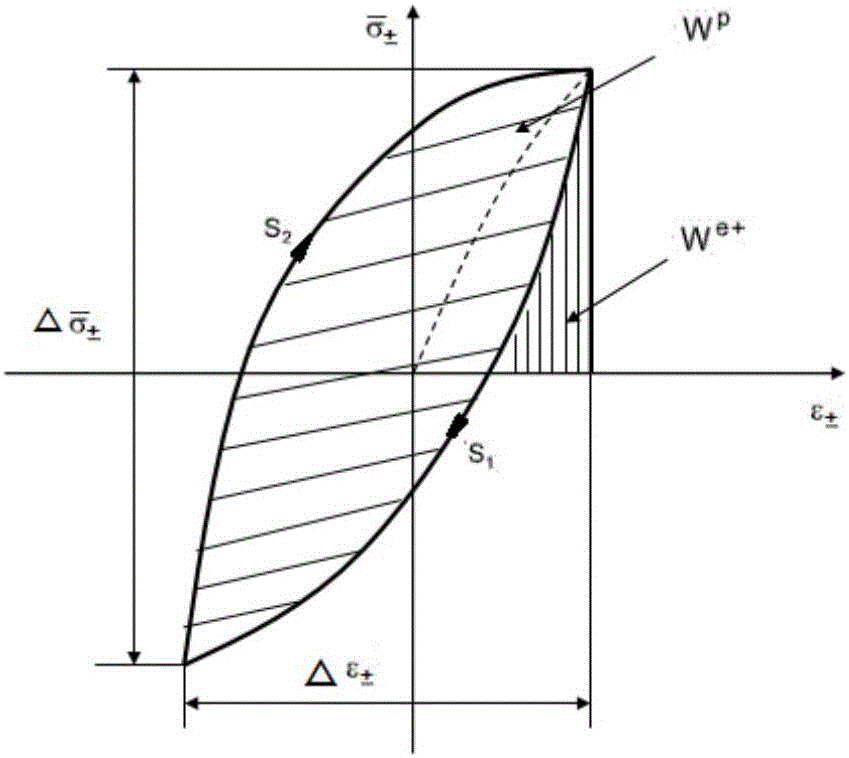

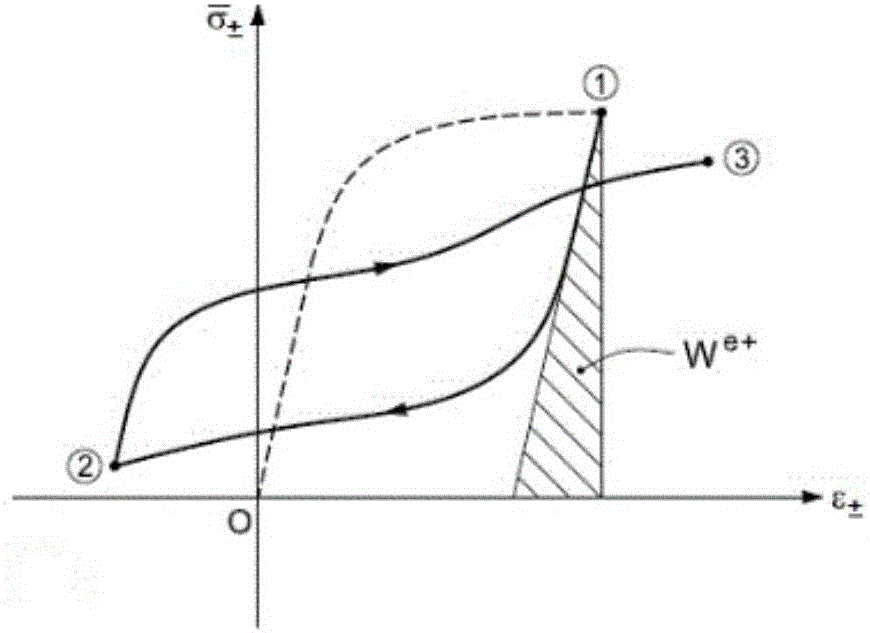

Weld seam fatigue life calculation method based on total strain energy density

ActiveCN106354898AImprove the accuracy of fatigue life calculationAvoid sureDesign optimisation/simulationSpecial data processing applicationsFatigue IntensityFatigue damage

The invention discloses a weld seam fatigue life calculation method based on total strain energy density. The method mainly comprises the steps that 1, the weld-seam total strain energy density, a life function equation and a fatigue strength coefficient, a fatigue strength index, a cyclic strengthening coefficient and a cyclic strain hardening index which are needed by half-cycle life stress and a strain function equation are acquired through a welded joint fatigue test; 2, the weld seam structure is simulated through a shell unit module, the stress-strain response of the weld seam structure under the cyclic load action is calculated through a multi-load step method, and a stress-strain hysteretic curve is output; 3, the total strain energy density is calculated according to the stress-strain response, and the hot point fatigue life and a damage value of a weld toe of the weld seam are calculated by combining the energy density with the life function equation. According to the method, contribution of elastic-plastic stress and strain to the fatigue damage is comprehensively taken into account, scalar quantities are taken as damage parameters, the position and direction problems related to vectors are effectively avoided, the calculation precision is improved, and the time is saved.

Owner:HUNAN UNIV OF TECH

Laser strengthening and toughening method for interface between ground-mass and coating

InactiveCN1504584AStable supportImprove toughnessHot-dipping/immersion processesVacuum evaporation coatingFatigue IntensityCeramic coating

The invention relates to a process for laser annealing of interface between a metal ground-mass and a coating layer, the coating is a metal or ceramic coating, and the process comprises proceeding micro-fusion discretization fabrication to the interface between the metal ground-mass and coating through laser rays, forming a discretization reinforcement layer on the interface, thus improving the material list tissue hardness, frictional wear performance, ablation property, fatigue performance and corrosion resistance under ambient temperature and hot environment.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Evaluation method of residual strength and service life under strengthening and damaging combined action

InactiveCN101718651AAccurately assess durabilitySolve the disadvantages of strength attenuationStrength propertiesFatigue IntensityResidual strength

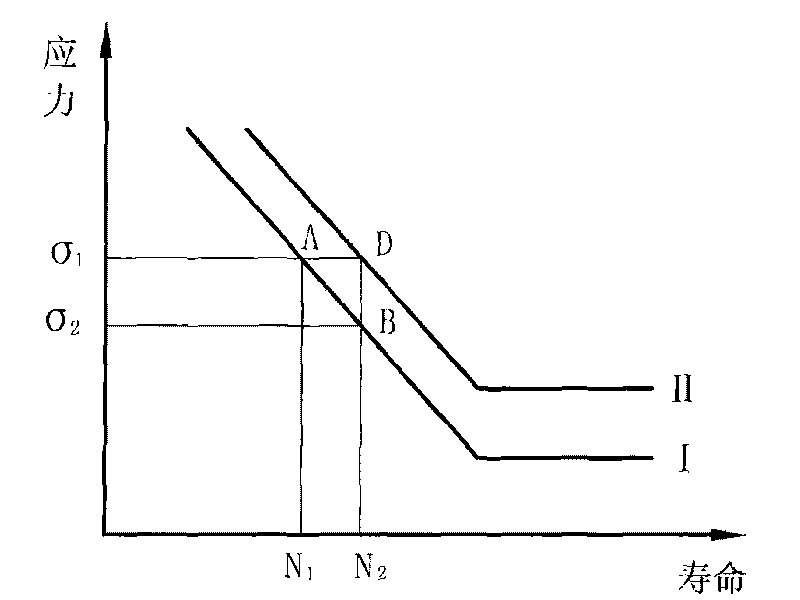

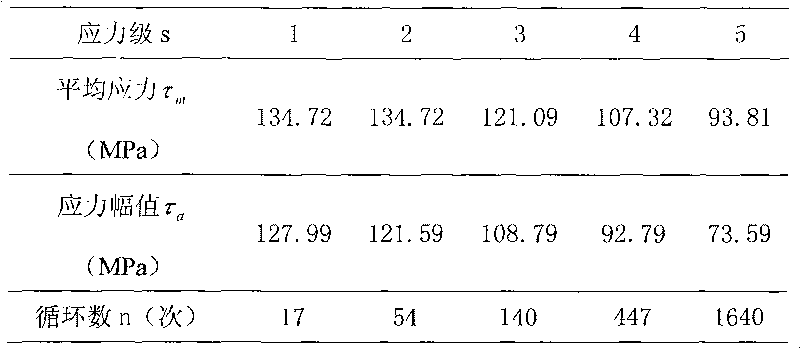

The invention relates to an evaluation method of residual strength and service life under strengthening and damaging combined action, which is characterized in that: (A) virtual stress-life curve of a material or a part is obtained by test or technical resources, and the fatigue strength and low amplitude loading range are determined; (B) the low-load strengthening general rule of the material or the part with different strength grades are built according to low-load strengthening performance data of low-strength and high-strength materials or parts by virtue of a numerical method of spline interpolation; (C) the fatigue strength changing rule is built according to the stress-life curve of the material or the part under the strengthening and damaging combined action; in addition, according to the loading grade and frequency of a loading spectrum, the instantaneous fatigue strength value, that is, the residual fatigue strength of the part with given using mileage is calculated; (D) according to the instantaneous stress-life curve, the life evaluation of the material or the part is carried out according to Miner linear damage theory. The invention provides a specific method for the service life of the part and the light-weight design.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

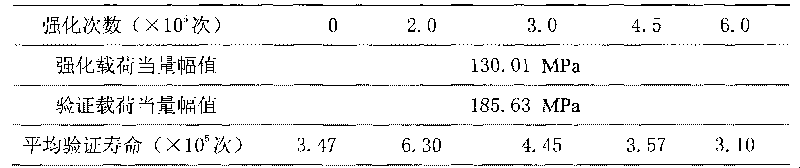

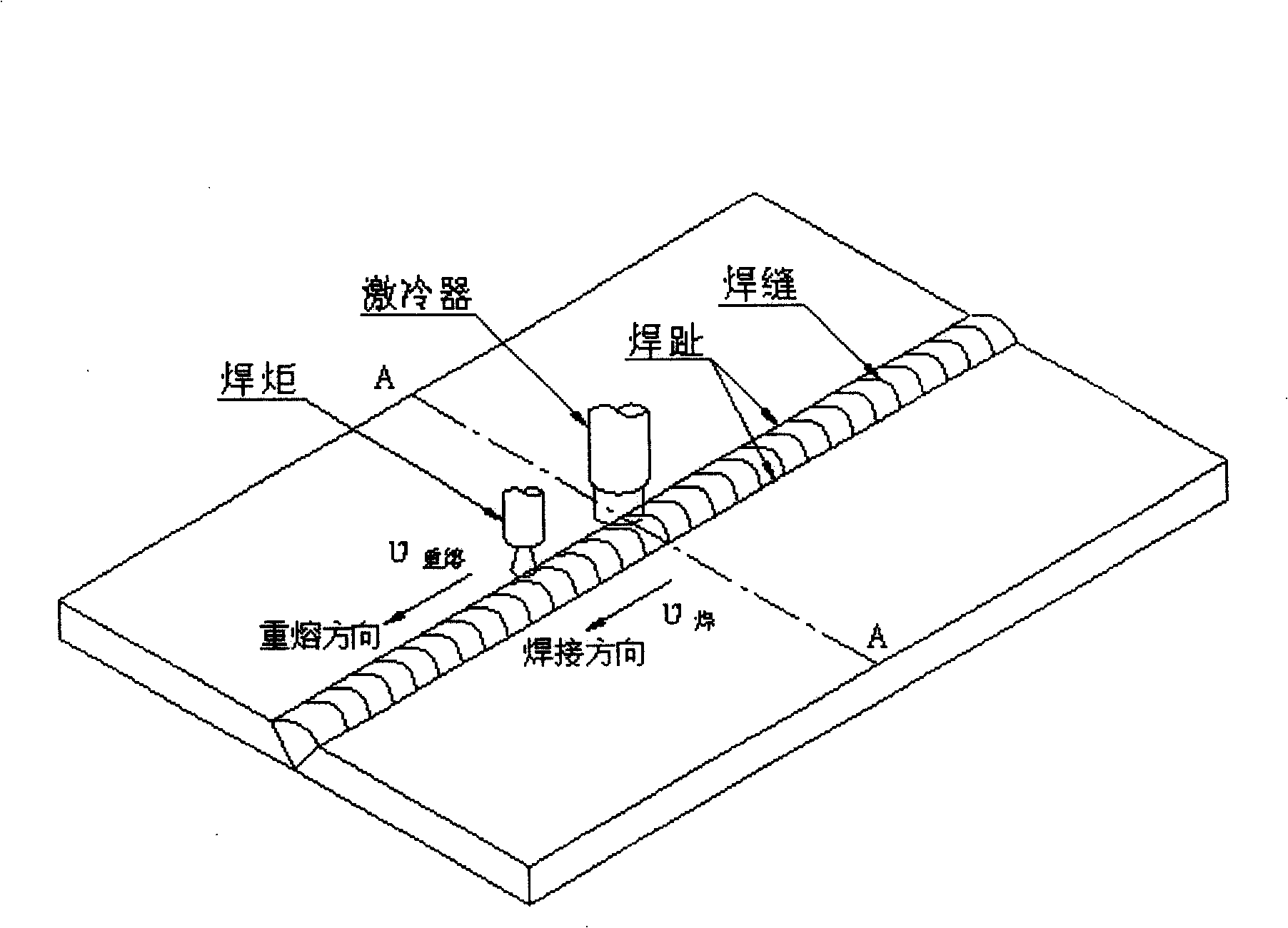

Method for improving welded joint fatigue strength following chilling treatment after weld toe TIG refusion

The invention discloses an after-welding processing method by using a welding joint after being remelted by a welding toe TIG to follow a spray chilling treatment to adjust the residual stress field of the weld toe to transfer the original residual tension stress field of the TIG remelting area into a compression stress field which is beneficial to improve the endurance strength of the joint. The method integrates both the advantages of improving the geometrical shape of the welding toe by TIG remelting and improving the residual stress state of the welding toe by the chilling treatment in the remelting area; besides, the method has the advantages of simple device, convenient operation, remarkable effect, easily checked and controlled quality, no noise, no environment pollution, etc. The method can be applied to the non-quenching steels like mild steel low alloyed steel, etc., as well as the welding structures of the metals like aluminum alloy and titanium alloy. The method can be popularized and applied in the industrial fields of shipping and ocean platforms, rolling stocks, railroad bridges, cranes, oil pipelines and chemical containers.

Owner:DALIAN JIAOTONG UNIVERSITY

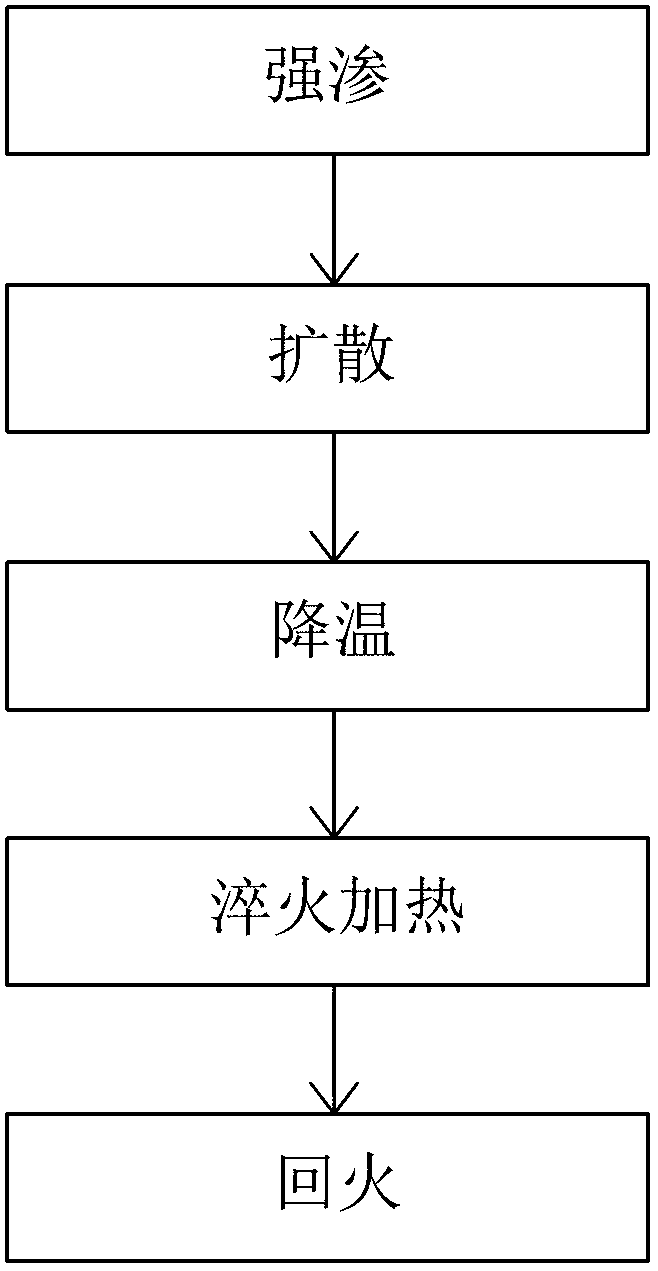

Combined carburizing and quenching process for improving gear performance

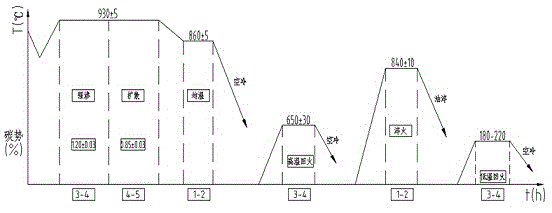

InactiveCN102703909AHigh surface hardnessImprove wear resistanceSolid state diffusion coatingFurnace typesFatigue IntensityHeavy duty

The invention relates to a combined carburizing and quenching process for improving gear performance, which comprises the steps of intensive carburization with carbon potential of 1.0-1.2% cp, diffusion with carbon potential of 0.8-1.0% cp, cooling after temperature decreases to 600-620 DEG C and is constant for 1-2 hours, quenching heating, and tempering, wherein quenching heating is divided into a first stage and a second stage, and the quenching temperature at the second stage is higher than that at the first stage. The combined carburizing and quenching process has the advantages that carburization, isothermality and quenching are combined, so that the process time is shortened, the energy consumption in heat treatment is reduced, the technology energy saving is optimized, and the technical indicators of carburizing heat treatment for heavy-duty gear, including surface hardness, abrasion resistance, fatigue strength, and strength and toughness of the core, are effectively enhanced.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

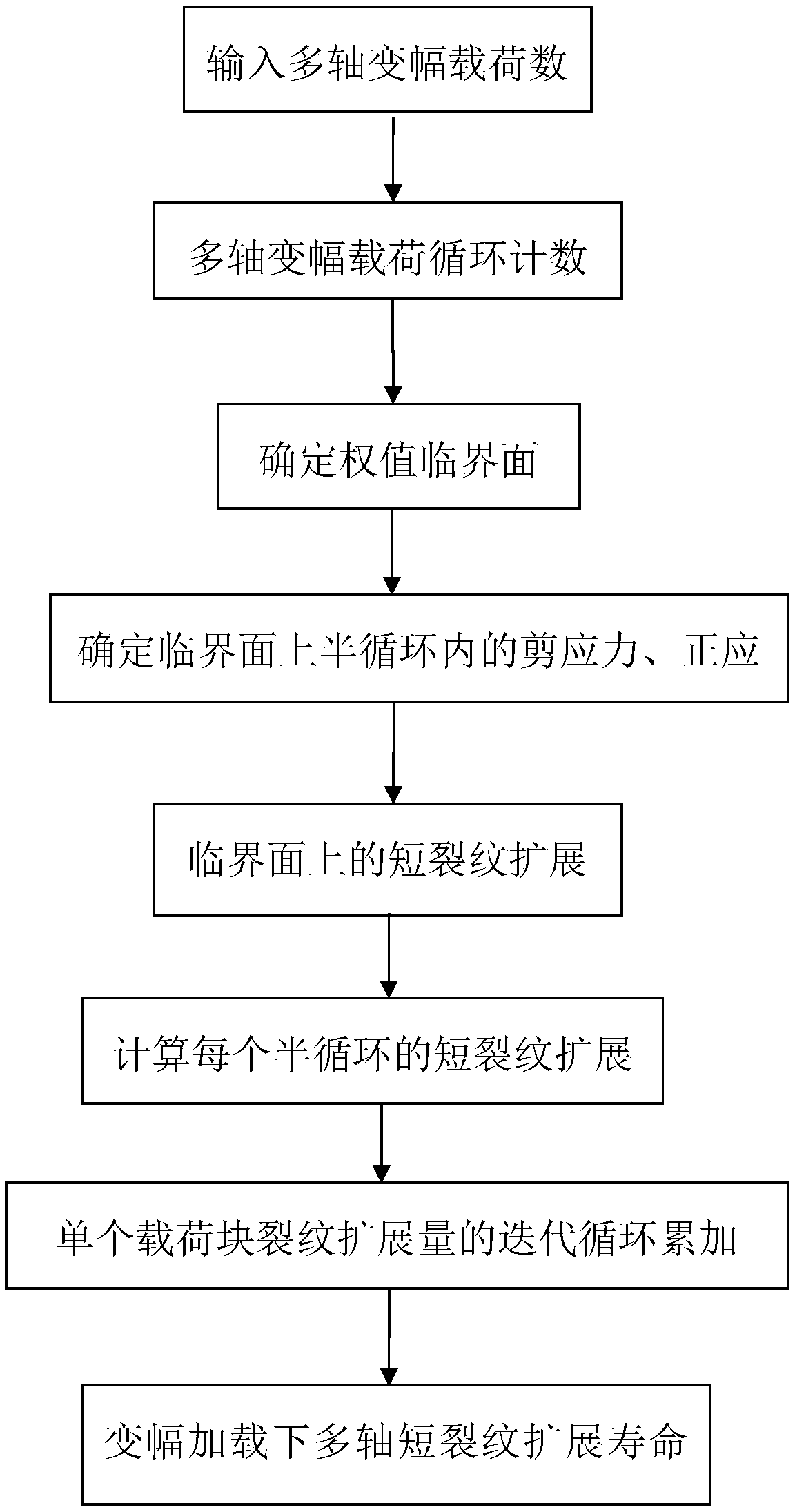

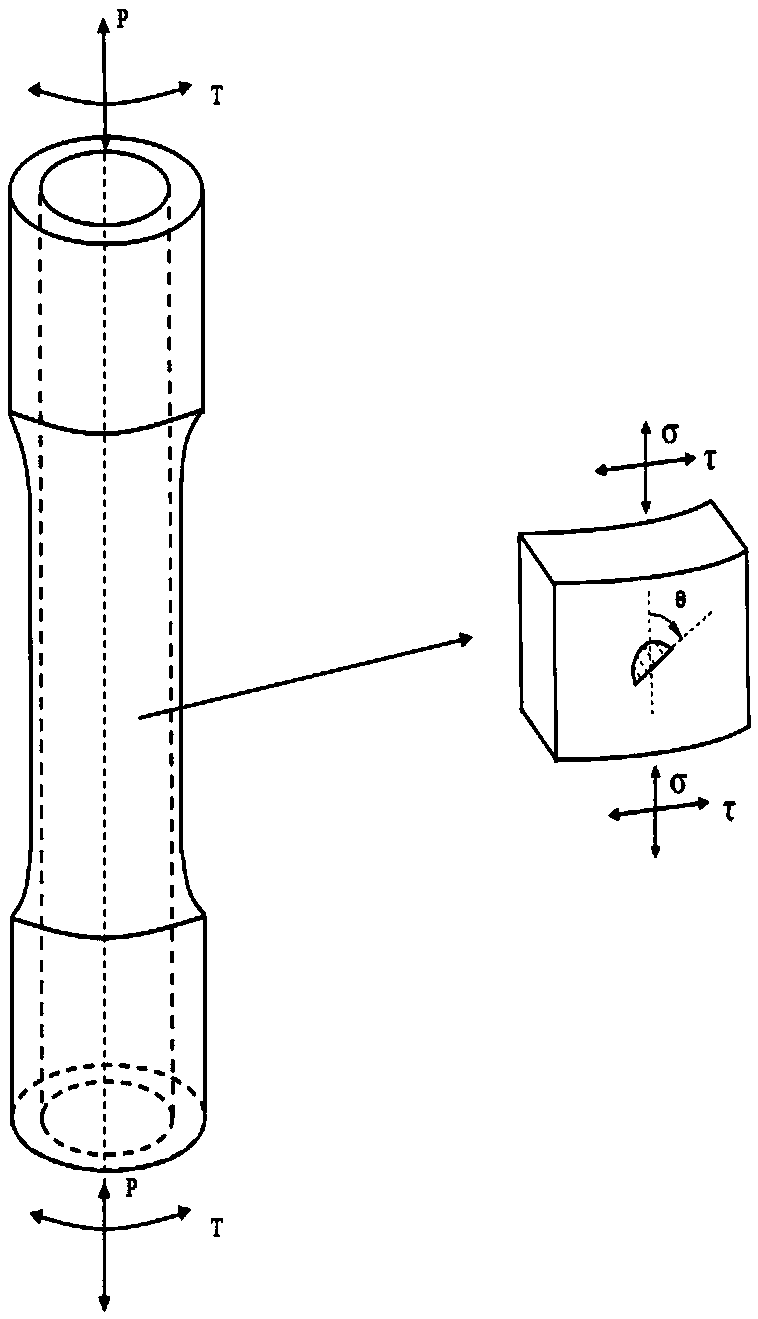

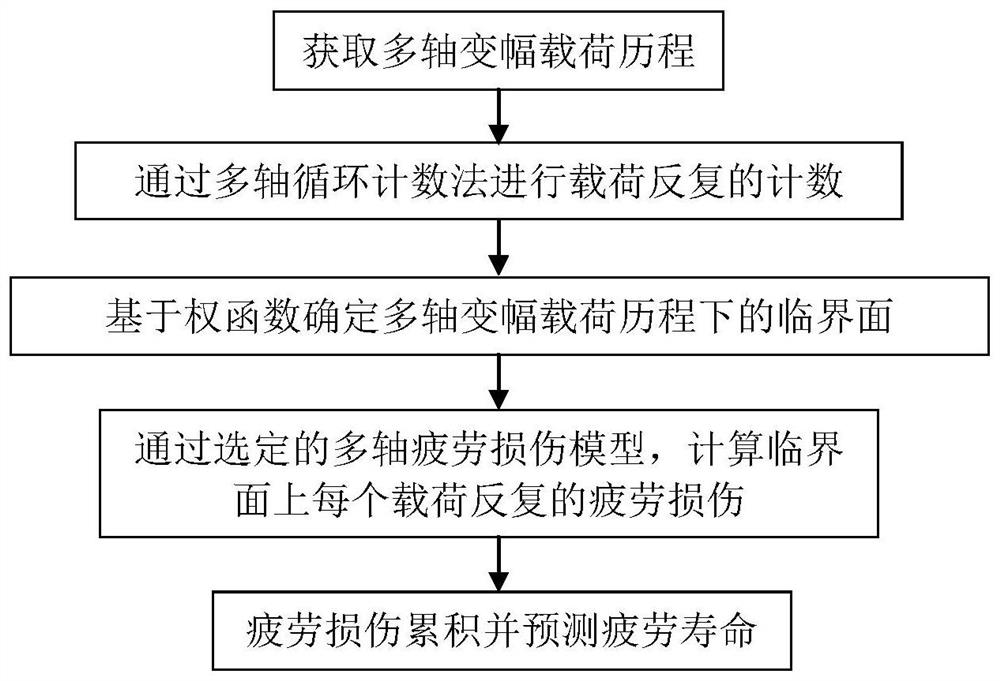

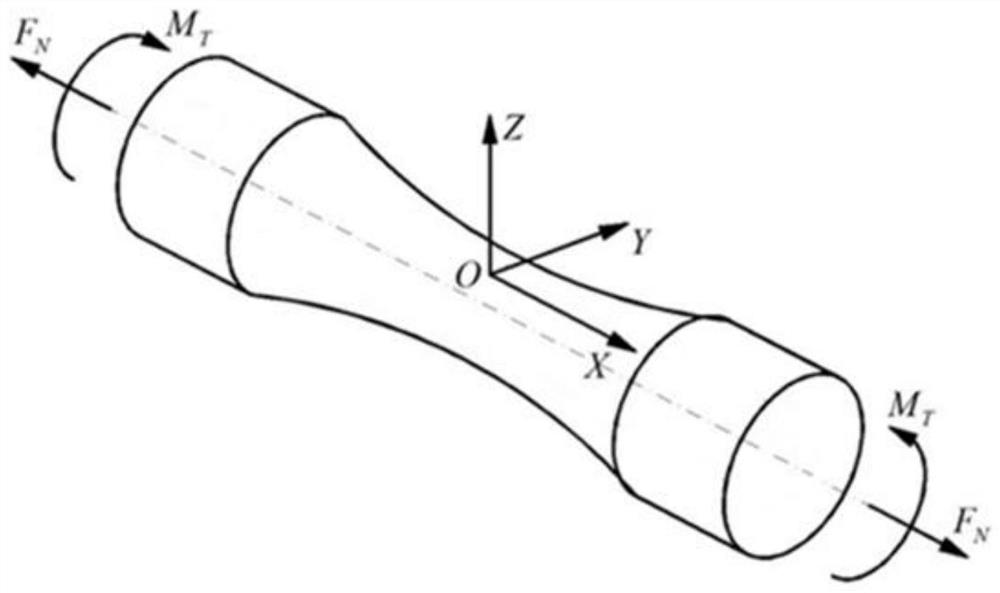

Fatigue short crack propagation life prediction method under multi-axis variable amplitude loading

ActiveCN108897900APromote engineering applicationNuclear energy generationDesign optimisation/simulationFatigue IntensityFracture mechanics

The invention discloses a fatigue short crack propagation life prediction method under multi-axis variable amplitude loading, and relates to the multi-axis fatigue strength theory field. The algorithmincludes the following steps: (1) using the Wang-Brown multi-axis cycle counting under stress loading to obtain a plurality of half cycles, and realizing multi-axis constant amplitude loading of eachhalf cycle; (2) using the weighted average maximum shear stress method to determine a weight critical surface for the characteristic that the critical surface is not fixed; (3) obtaining the crack propagation amount of a single variable amplitude load block by using a multi-axis fatigue short crack propagation model on the weight critical surface; and (4), performing plastic zone size correctionon crack tips, and calculating the short crack propagation life by the fracture mechanics method. The method can well describe the influence of multi-axis variable amplitude loading on crack propagation. The results show that the method can predict the short crack propagation life under multi-axis variable amplitude loading.

Owner:BEIJING UNIV OF TECH

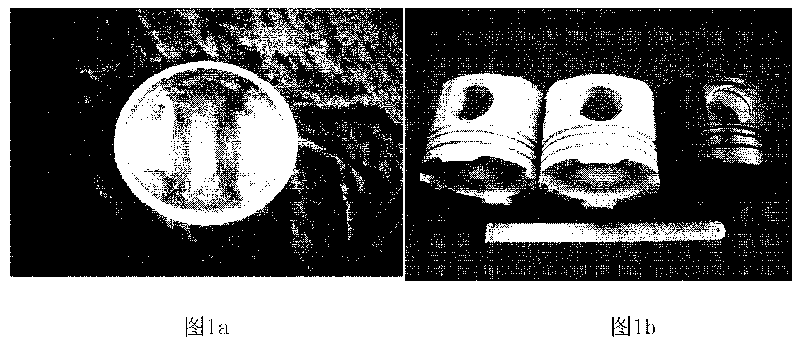

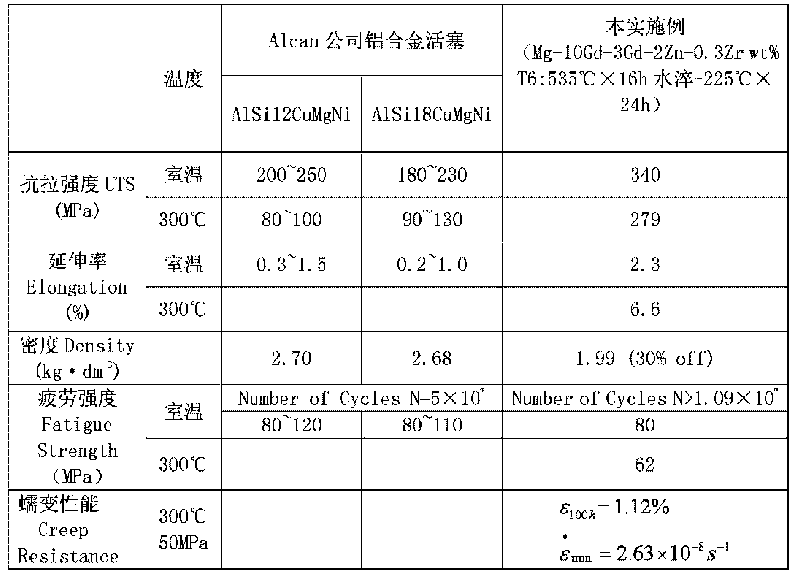

Method for heat resistant rare earth-magnesium alloy engine pistons through squeezing and casting

ActiveCN101693972AImprove performanceImprove creep resistanceMachines/enginesPistonsFatigue IntensityCold treatment

A method for heat resistant rare earth-magnesium alloy engine pistons through squeezing and casting comprises preparing master alloy Mg-Y, Mg-Gd, Mg-Zr, industrial pure magnesium and industrial pure zinc, smelting alloy, obtaining magnesium alloy fused mass, squeezing and casting the magnesium alloy fused mass, obtaining the primary blank of a magnesium alloy piston, and obtaining a heat resistant tare earth-magnesium alloy engine piston through orderly carrying out the solid solution treatment, the cold treatment and the aging treatment. The heat resistant rare earth-magnesium alloy engine pistons prepared by the invention have light weight, simple technology and receivable cost, and further have very excellent high-temperature intensity and creep resistance performance and good fatigue intensity, and can better satisfy the service requirements of engine pistons.

Owner:SHANGHAI JIAO TONG UNIV

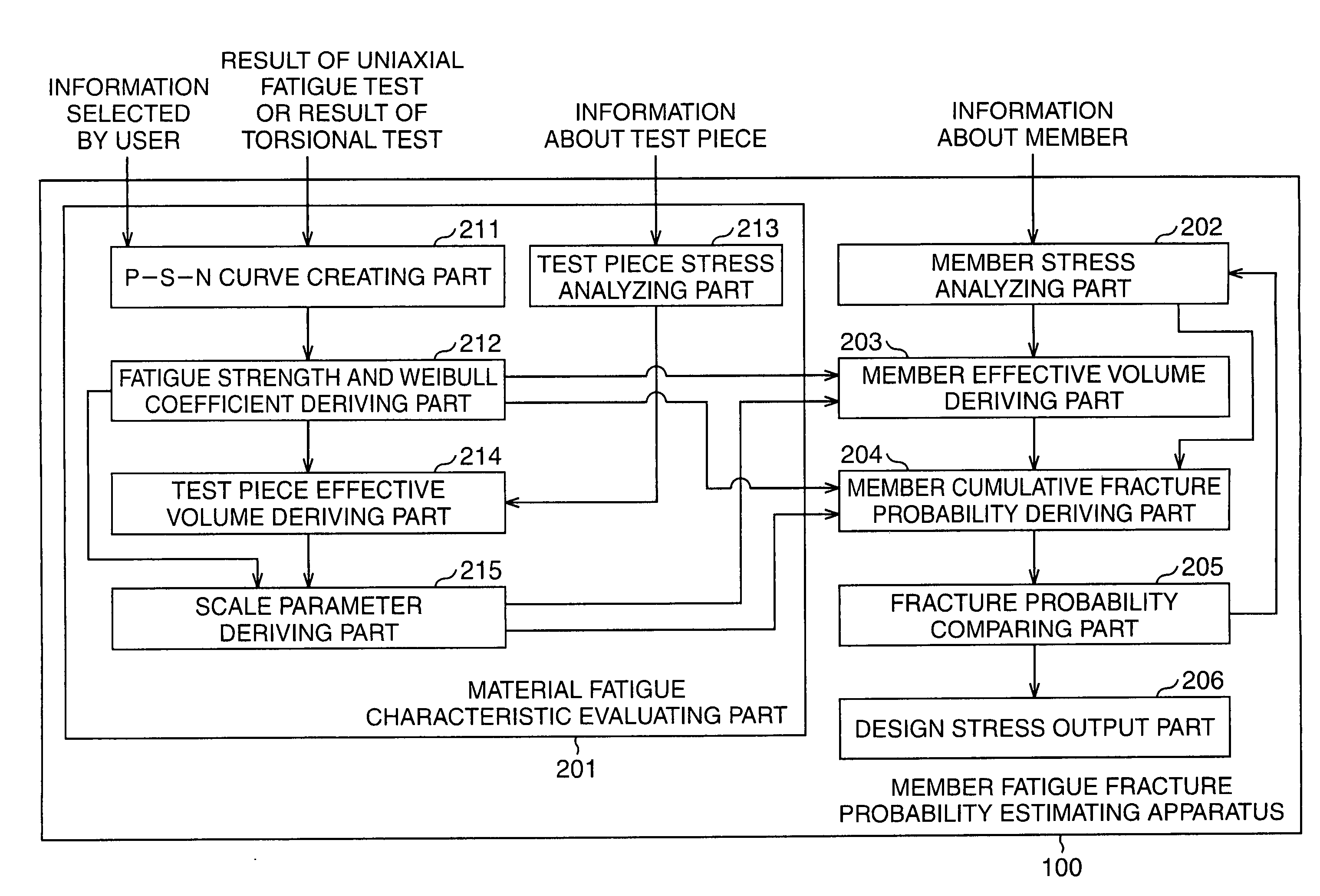

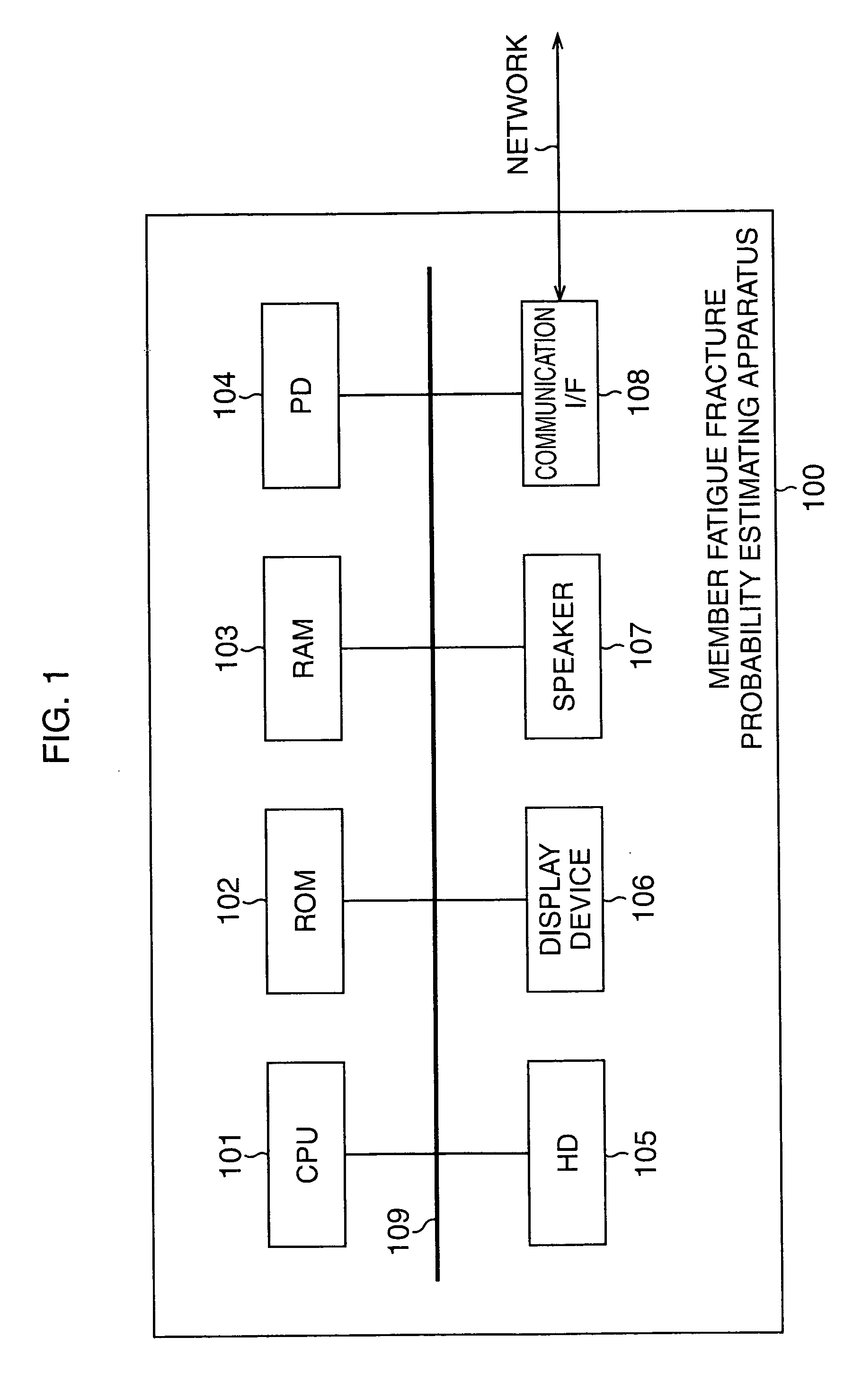

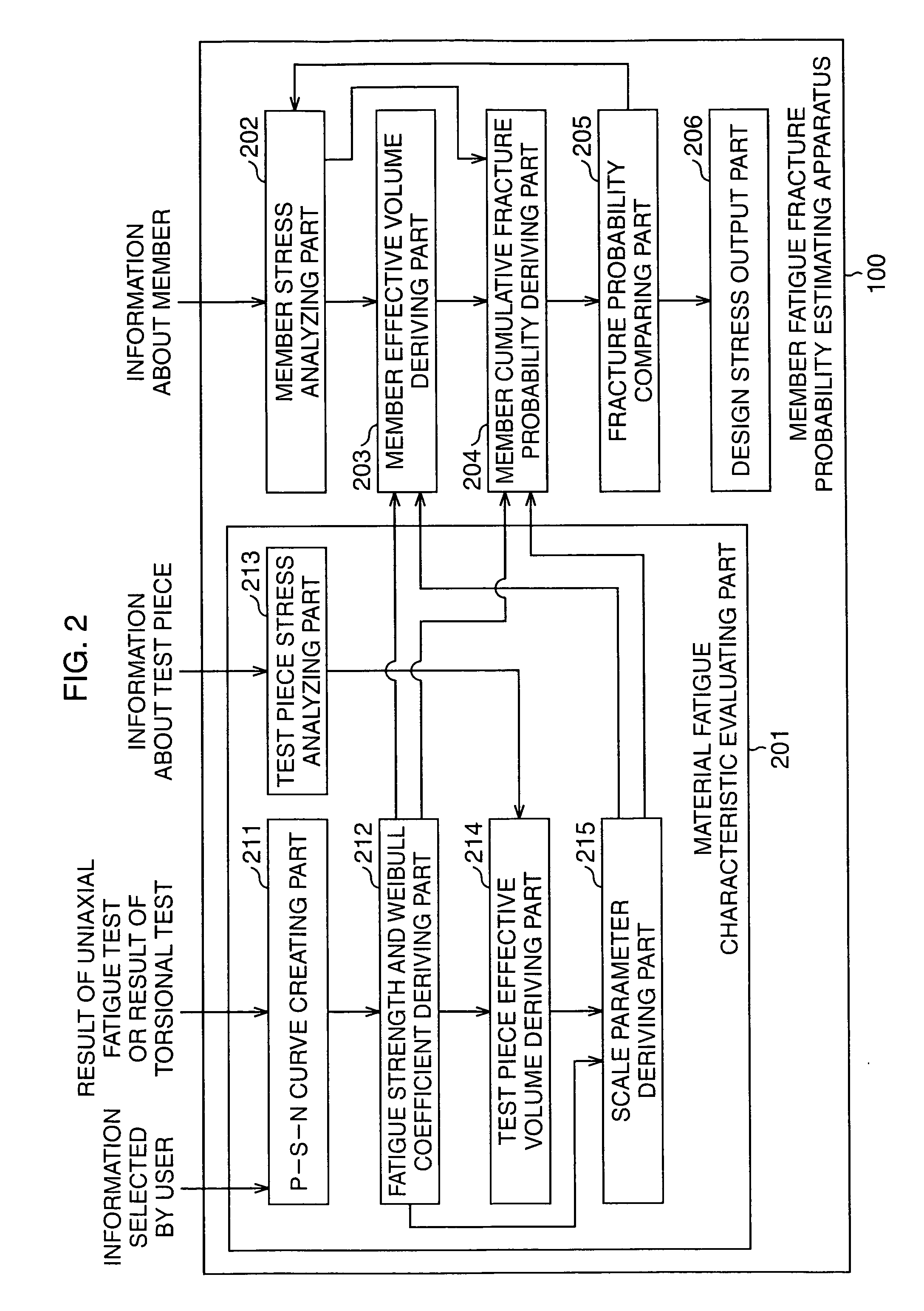

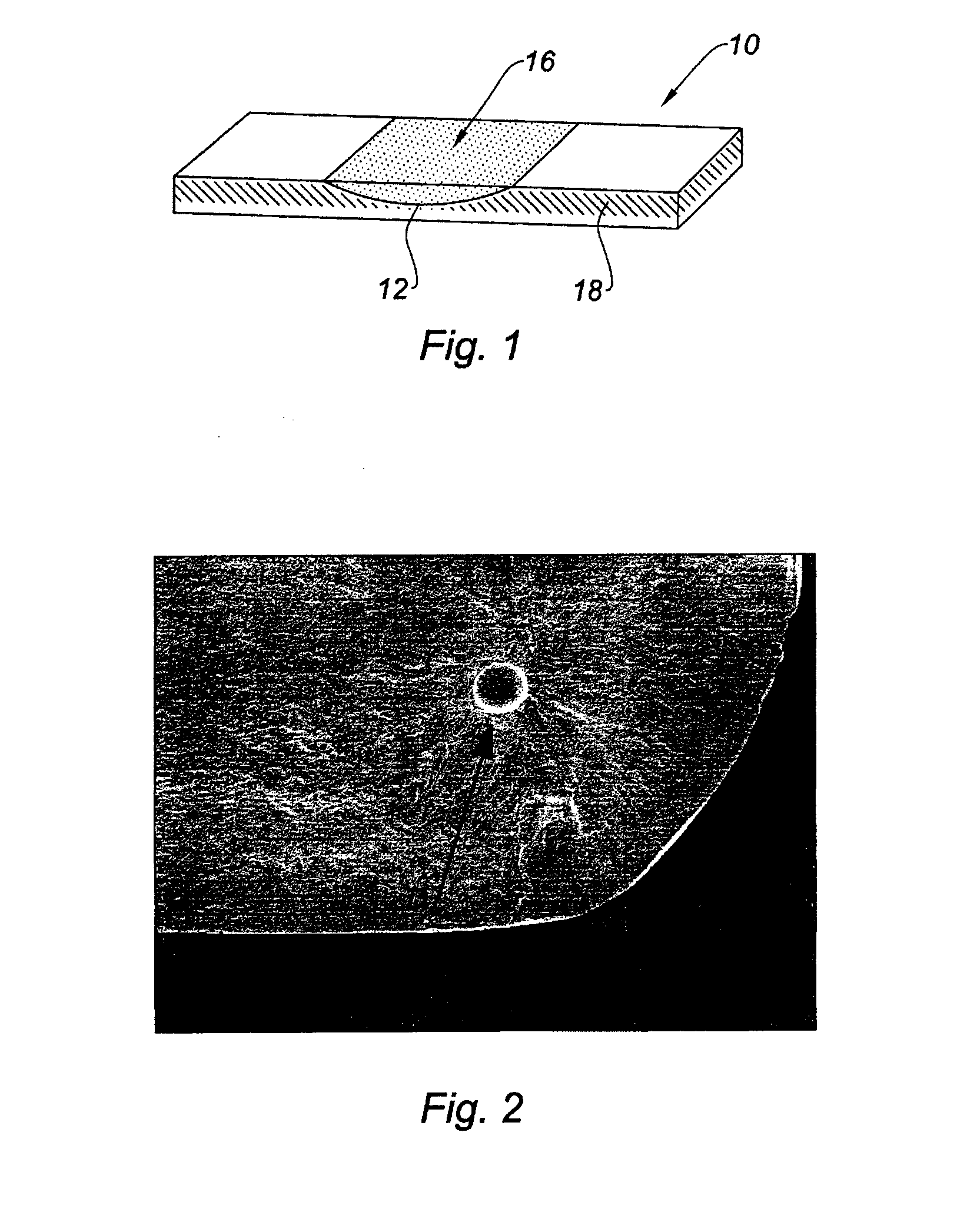

Member fatigue fracture probability estimating apparatus, member fatigue fracture probability estimating method, and computer readable medium

InactiveUS20120065934A1Accurate estimateDigital computer detailsMaterial strength using repeated/pulsating forcesFatigue fracturesMedicine

An effective volume Vep of a member is calculated with a stress correction amount σcorr added to an effective stress (stress amplitude) σip at each position of the member so that a fatigue strength of the member varying corresponding to an average stress varying depending on the position of the member is apparently constant at a value when the average stress on the member is 0 (zero) irrespective of the position of the member, and a cumulative fracture probability Pfp due to fatigue of the member is derived using the effective volume Vep of the member.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

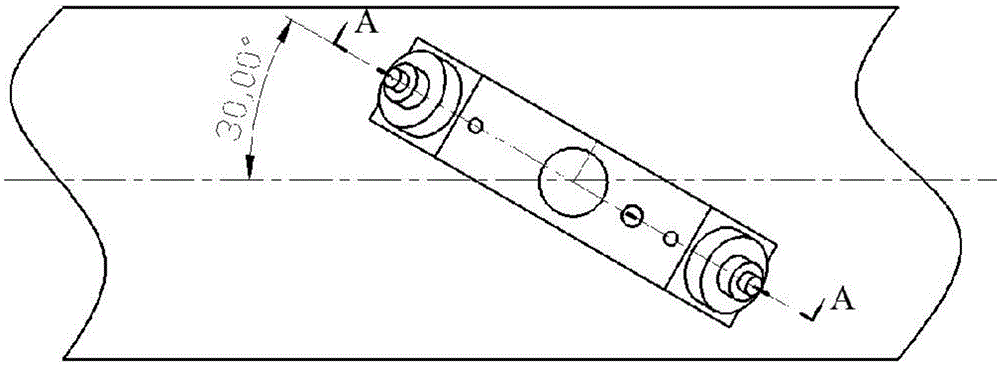

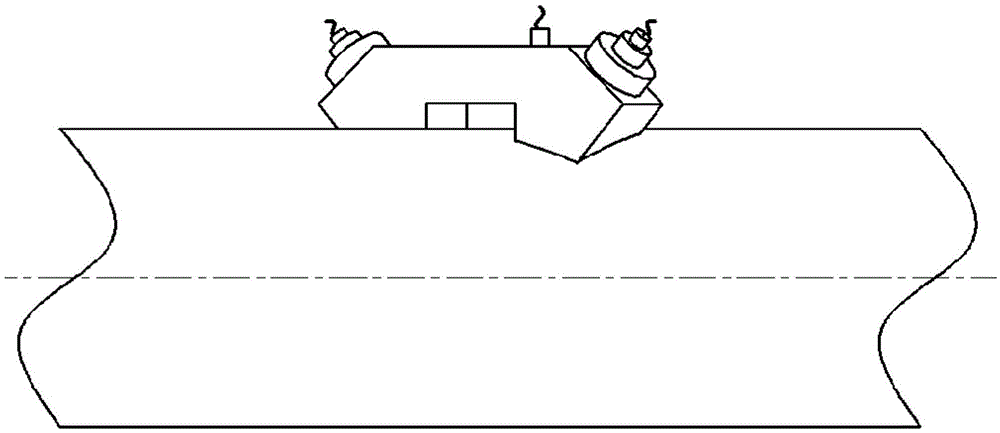

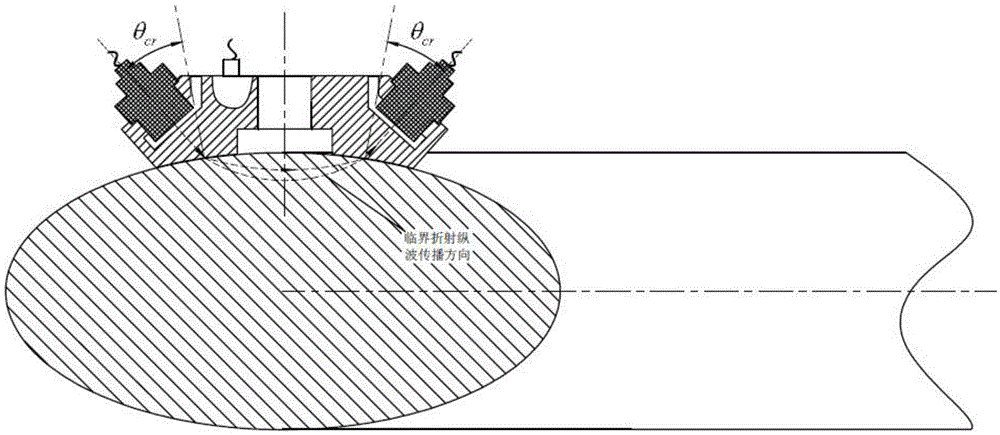

Torsion residual stress ultrasonic nondestructive test method

ActiveCN105424243ASolving Rapid NDT ProblemsRepeatableForce measurementFatigue IntensityStress distribution

The invention relates to a torsion residual stress ultrasonic nondestructive test method. Ultrasonic longitudinal waves form critical refraction longitudinal waves on a torsion surface of a shaft through waveform conversion once, time when the critical refraction longitudinal waves are spread in the shaft is tested, and corresponding torsion residual stress can be calculated through an acoustic elasticity theory. Through changing the frequency of the ultrasonic longitudinal waves, torsion residual stress at different depths on the same torsion surface can also be tested. The method provided by the invention can effectively solve the problem of distribution of the torsion residual stress on the torsion surface at different angles, helps to find a principle stress direction, can also perform fatigue strength analysis, is quite suitable for wide application in a production field and a maintenance repair field, is a novel method for detecting residual stress distribution through ultrasonic waves, and has quite bright application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

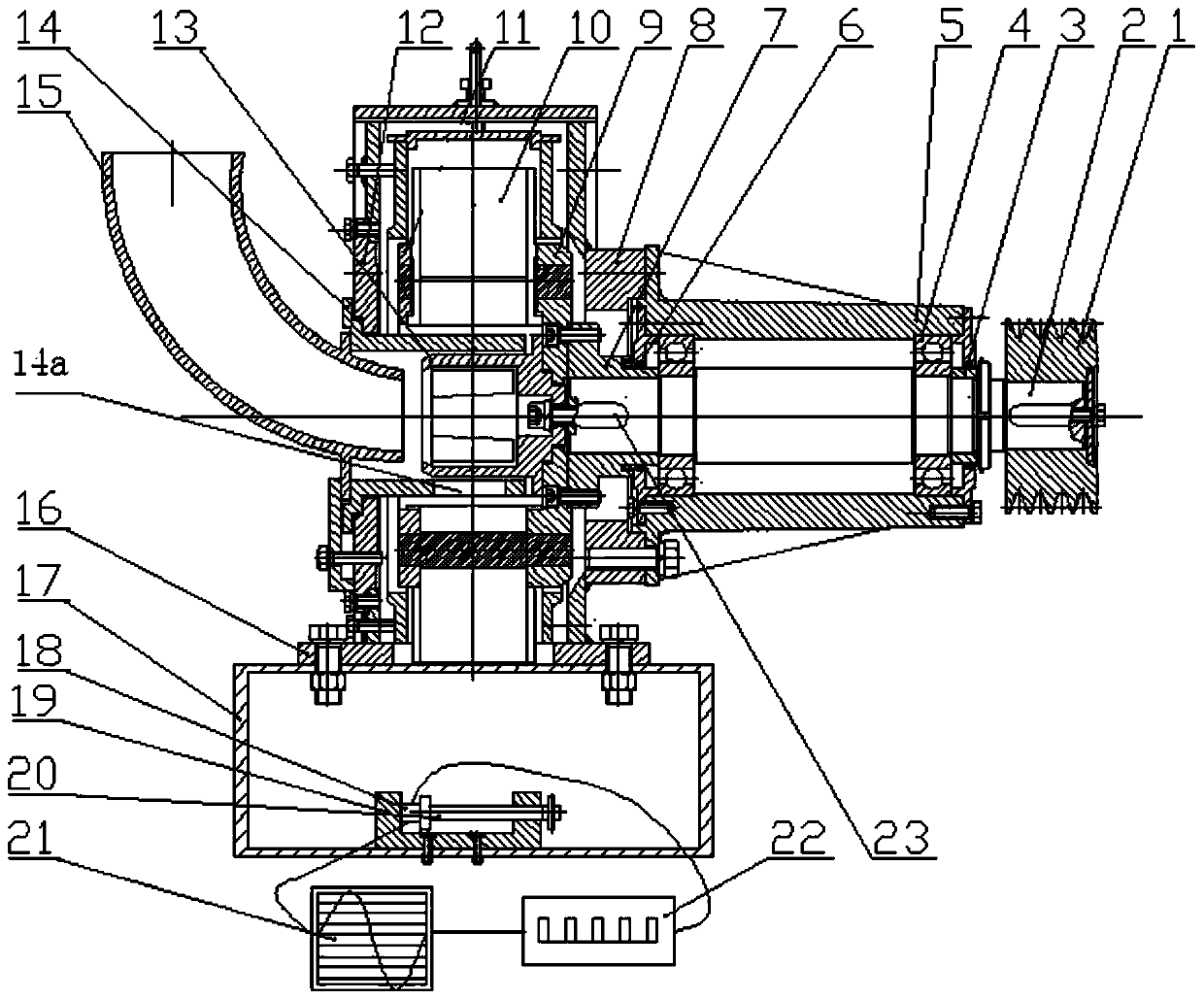

Method for testing high-frequency fatigue characteristic of material under microscale

InactiveCN103940685AMaterial strength using repeated/pulsating forcesFatigue IntensityFatigue damage

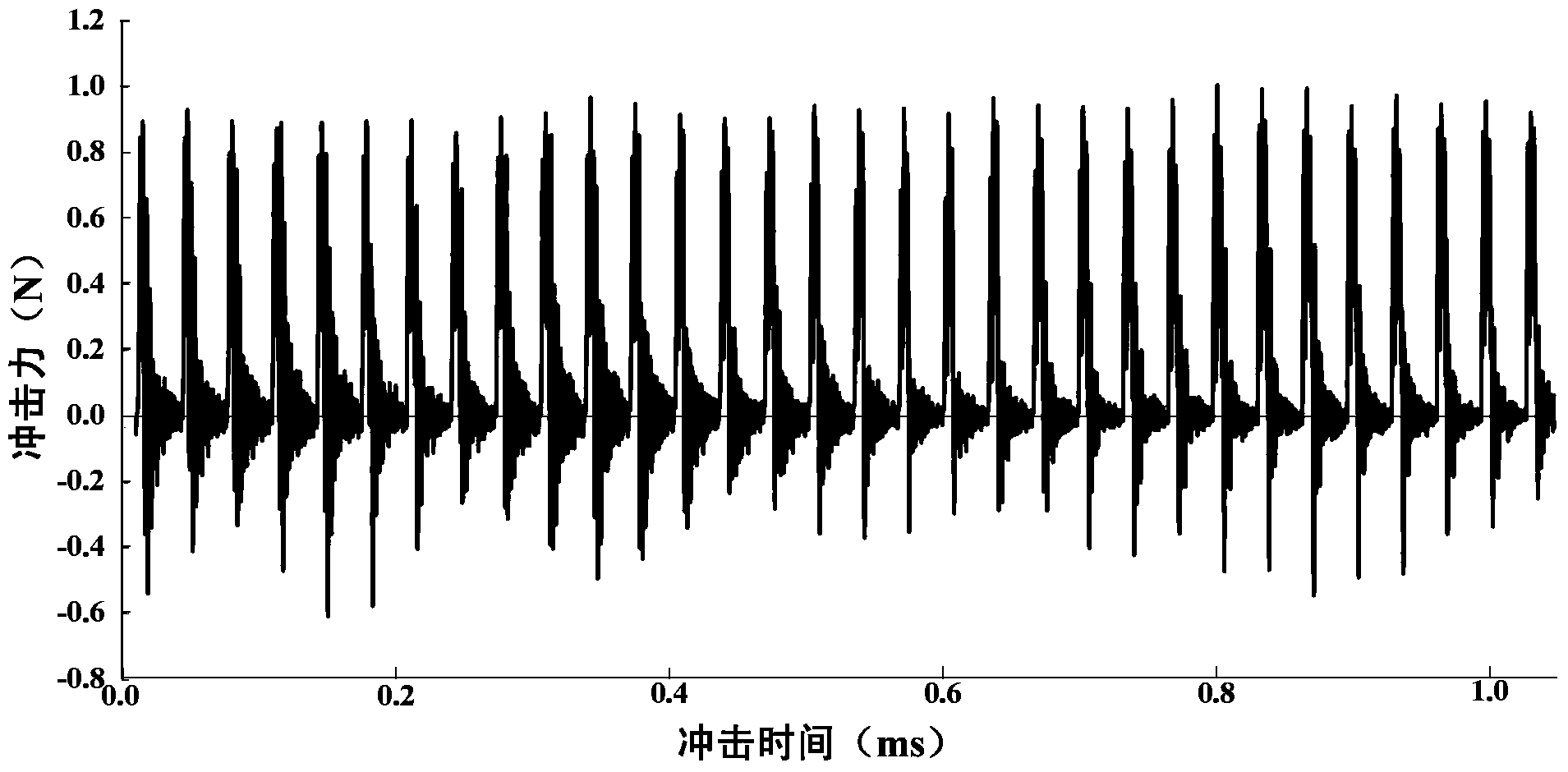

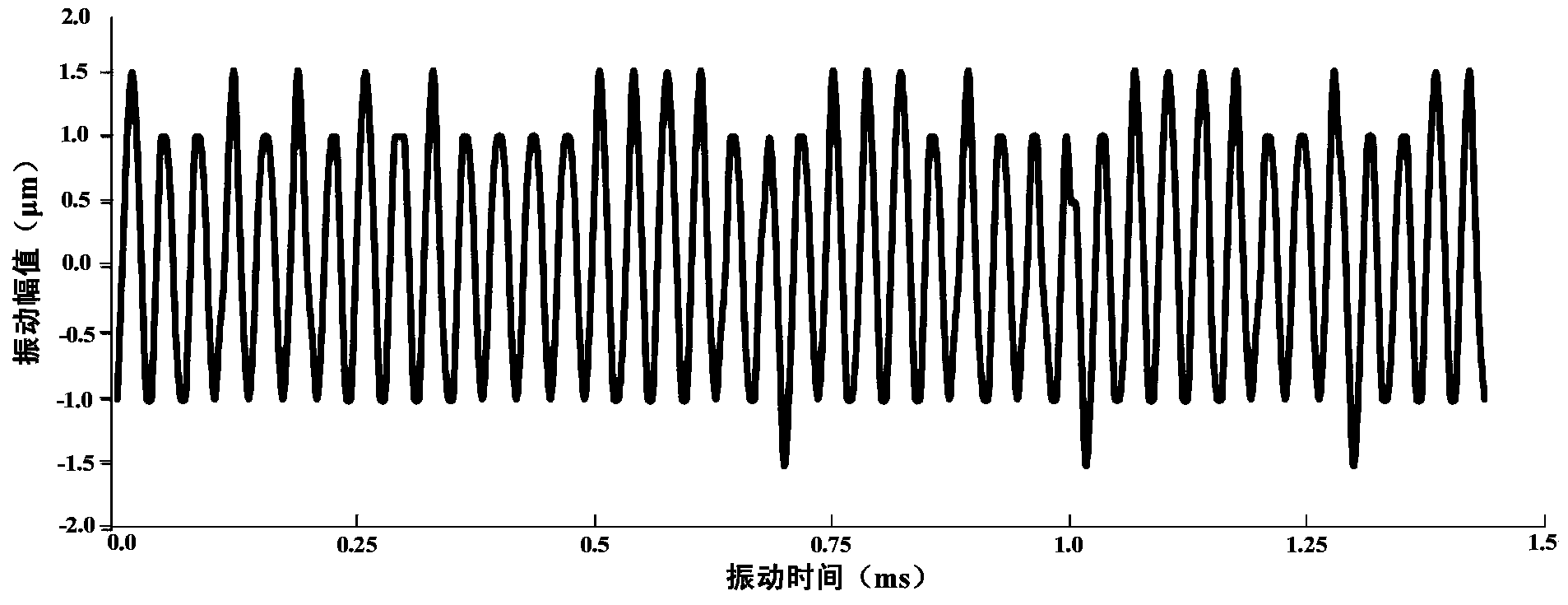

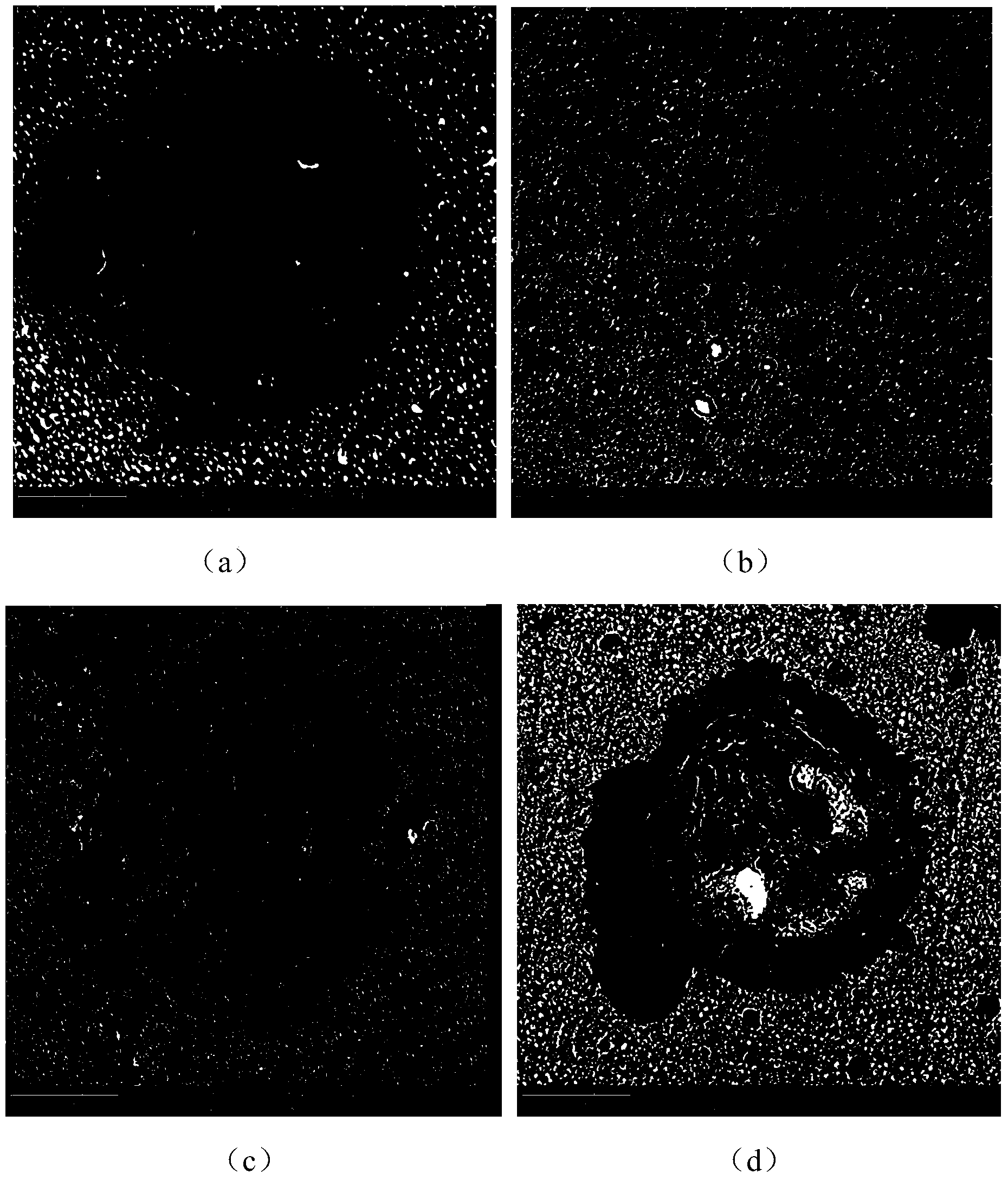

The invention discloses a method for testing a high-frequency fatigue characteristic of a material under microscale. The method comprises the following steps of (1) firmly connecting one end of a homogenous metal or non-metal test sample to an ultrasonic vibration generation device, and enabling the other end of the homogenous metal or non-metal test sample to be in contact with a diamond pressing head at a fixed position, wherein the diamond pressing head is connected with a high-precision force measurement system; (2) adjusting parameters of the ultrasonic vibration generation device to obtain vibration frequency f and amplitude A which need to be tested, generating ultrasonic vibration to enable the diamond pressing head to partially impact the homogenous metal or non-metal test sample so as to cause a high-frequency alternating load under a microscale; (3) measuring alternating impact force generated by vibration of the test sample through the high-precision force measurement system so as to calculate alternating stress on part of the test sample; (4) observing a fatigue damage condition of a region, which is in contact with the test sample, of the diamond pressing head at different times through a scanning electron microscope to obtain a fatigue intensity and alternating stress-circulating frequency curve of the material under microscale.

Owner:HUAQIAO UNIVERSITY

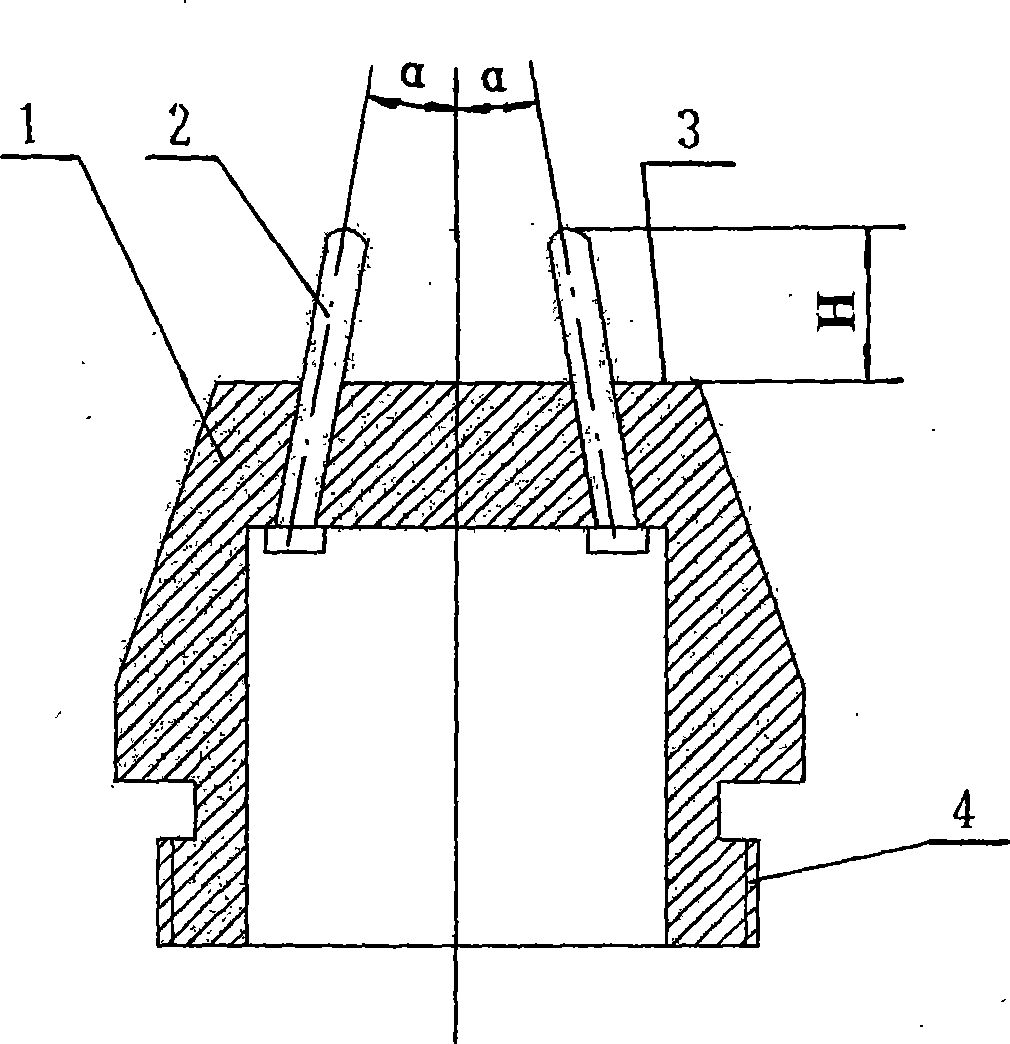

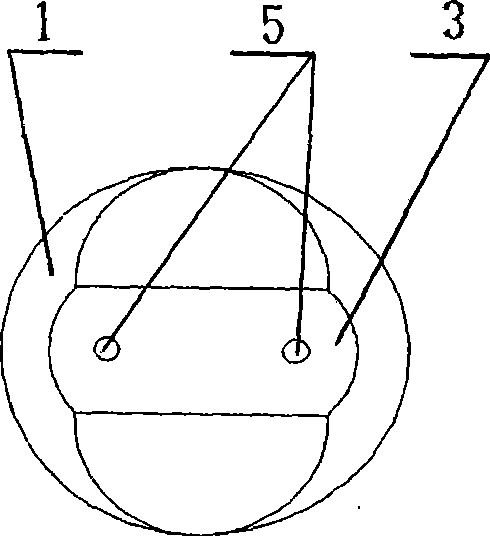

High-efficiency ultrasonic impact head for soldering joint stress release

InactiveCN101429588AImprove impact efficiencyIncrease impactNon-electric welding apparatusFatigue IntensityEconomic benefits

The invention relates to a high-efficient ultrasonic impact head for removing welding stress. The impact head comprises an impact head body and impact pins movably assembled in impact pinholes of the impact head body; two impact pins are symmetrically distributed on two side of a central axis, take the central axis as criteria and incline inwards to form an oblique angle alpha of between 2 and 5 degrees; each impact pin is of a cylindrical ball head shape; the diameter of each impact pin is between 5 and 8 mm; the length of each impact pin is between 30 and 35 mm; after each impact pin is arranged in the impact pin body, the length of the exposed part is required between 15 and 20 mm; and the lower part of the impact pin body is connected with an impact gun through screw thread. The impact head adopts two symmetric impact pins to simultaneously treat welding toes of two side of a weld joint, can remarkably improve the impact efficiency by 20 to 50 percent compared with a multi-pin impact head, improve the degree of the impact force, the impact strength, the removal of welding stress and the improvement of fatigue strength by more than 5 to 10 percent compared with the multi-pin impact head, has good impact effect, greatly improve the impact efficiency and stability in the treatment of a long aluminum alloy welding joint and has good economic benefit.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

Method of increasing strength of cold worked part by ultrasonic shock treatment, and metal product with high fracture toughness and fatigue strength

ActiveCN1714162AReduce residual stressImprove toughness and strengthFatigue IntensityUltrasonic impact treatment

The invention provides a method for improving the strength of a cold-worked part by ultrasonic impact treatment. By implementing ultrasonic impact treatment on the surface of the stretched side of the metal cold-bending process, the surface hardness can be made higher than that of the surface without ultrasonic impact treatment. The surface hardness is increased by more than 10%, and the tensile residual stress can be reduced, and the fracture toughness and fatigue strength can be improved.

Owner:NIPPON STEEL CORP

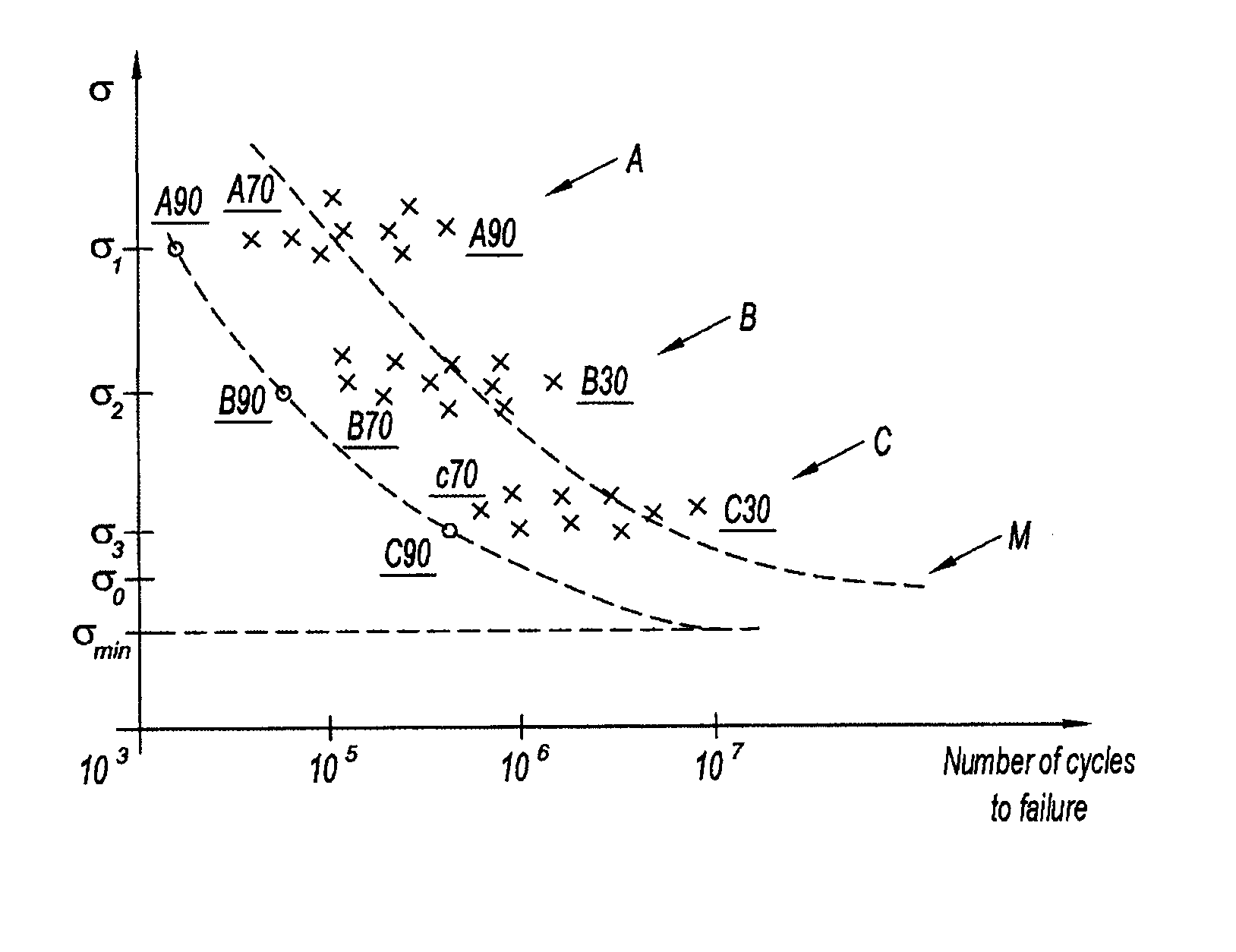

Method for evaluating the fatigue strength of welded joints

ActiveUS20080028866A1Long life-timeExpand accessMaterial strength using steady bending forcesWelding/soldering/cutting articlesFatigue IntensityFractography

Method for evaluating the fatigue strength of welded joints produced by melting an alloy using a specified welding technique, which method comprises the following steps:a statistically significant number N of specimens are produced with a welded joint using said welding technique;each of the specimens is subjected to cyclic fatigue tests, with an alternating stress a, until failure;the size of the relevant defect appearing in the fracture plane of the specimens is measured by fractography;a range of defect dimensions for which the probability of measuring by fractography a defect outside the range is less than a predetermined level of probability t is determined from the measured sizes; andthe lowest stress σmin liable to cause the specimen to fail with a level of probability t is determined from this range.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

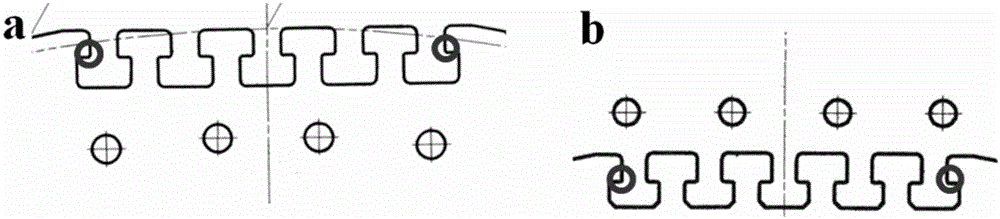

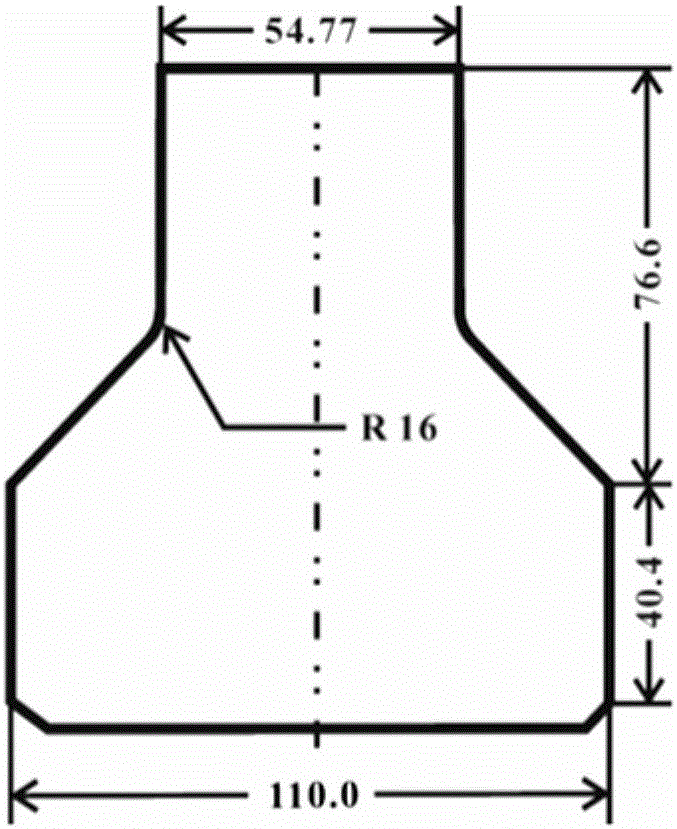

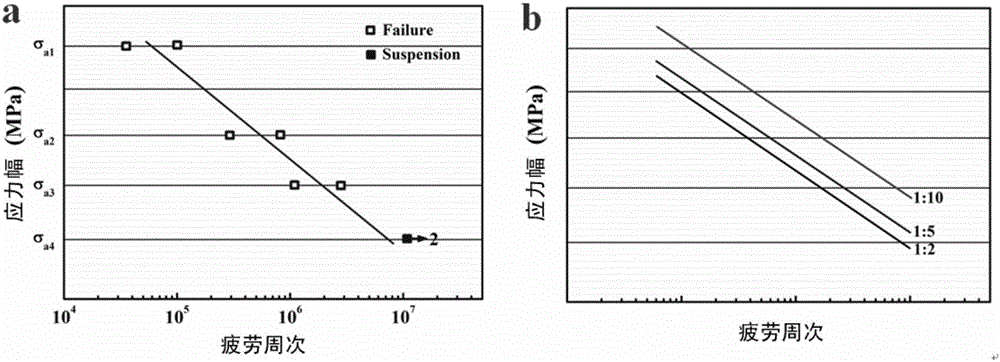

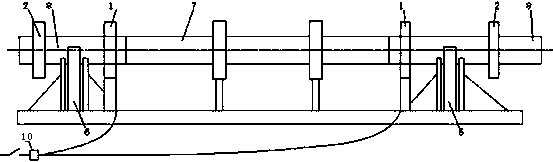

Large-scale dynamic load member fatigue performance testing method

InactiveCN106197967ASolve the difficulties that cannot be tested on conventional testing machinesLow costMachine part testingFatigue IntensityMagnetic poles

The invention discloses a large-scale dynamic load member fatigue performance testing method. The method comprises the steps: determining a most dangerous part of a magnet yoke of a magnetic pole, making the most dangerous part into a miniature member, reflecting the features of a key load, at different scales and a corresponding clamping tool; testing the stress fatigue performance of the miniature member on a fatigue machine, and searching the relation between the fatigue intensity, fatigue intensity index and fatigue intensity coefficient and the scales; and calculating the fatigue performance of a full-scale member. The invention solves a difficulty that a large-scale member cannot be tested on a conventional testing machine, and provides the large-scale dynamic load member fatigue performance testing method. The method can achieve the testing on the conventional testing machine through ingenious design, is lower in cost, is convenient to operate, and is suitable for other large-scale bearing dynamic load members.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

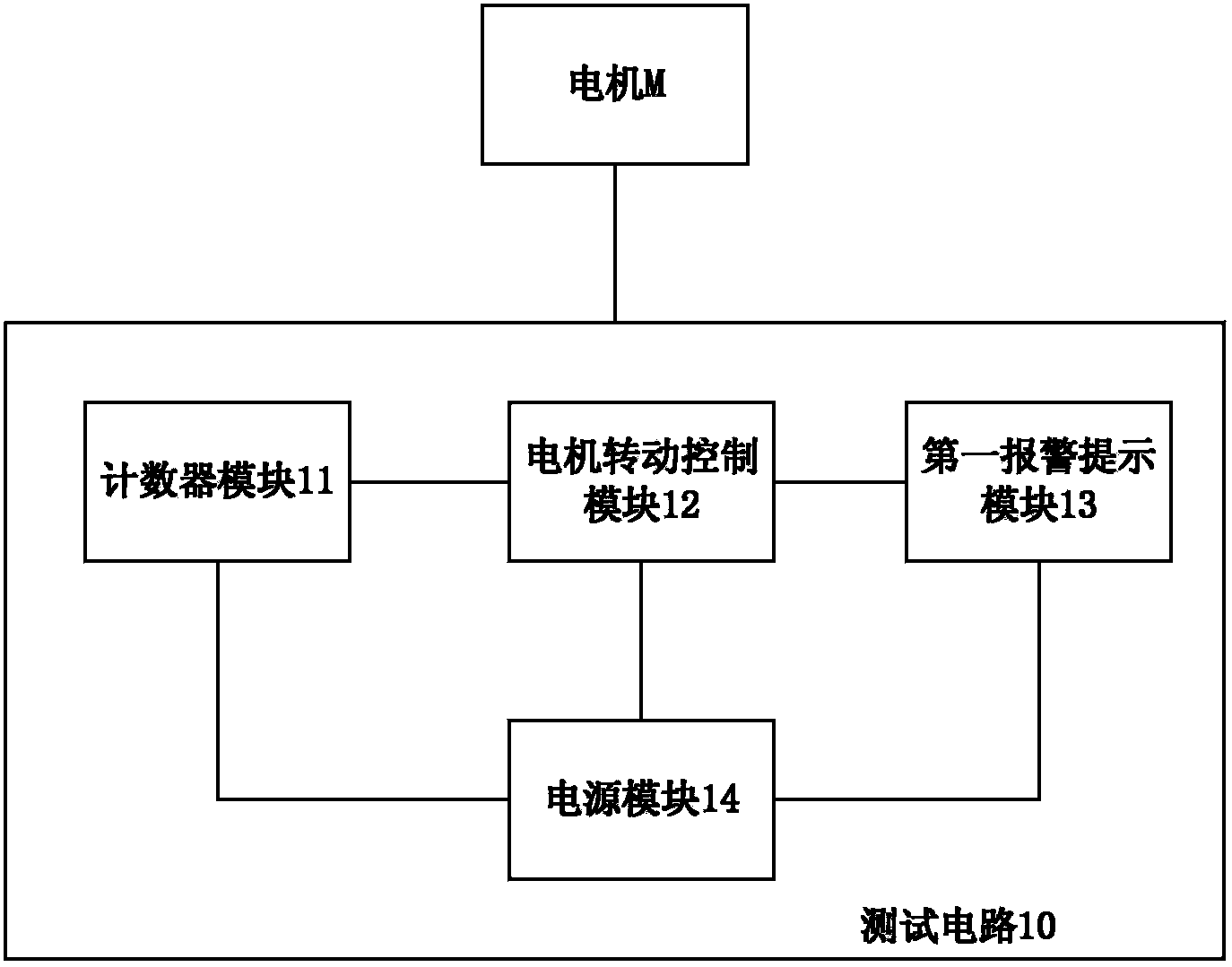

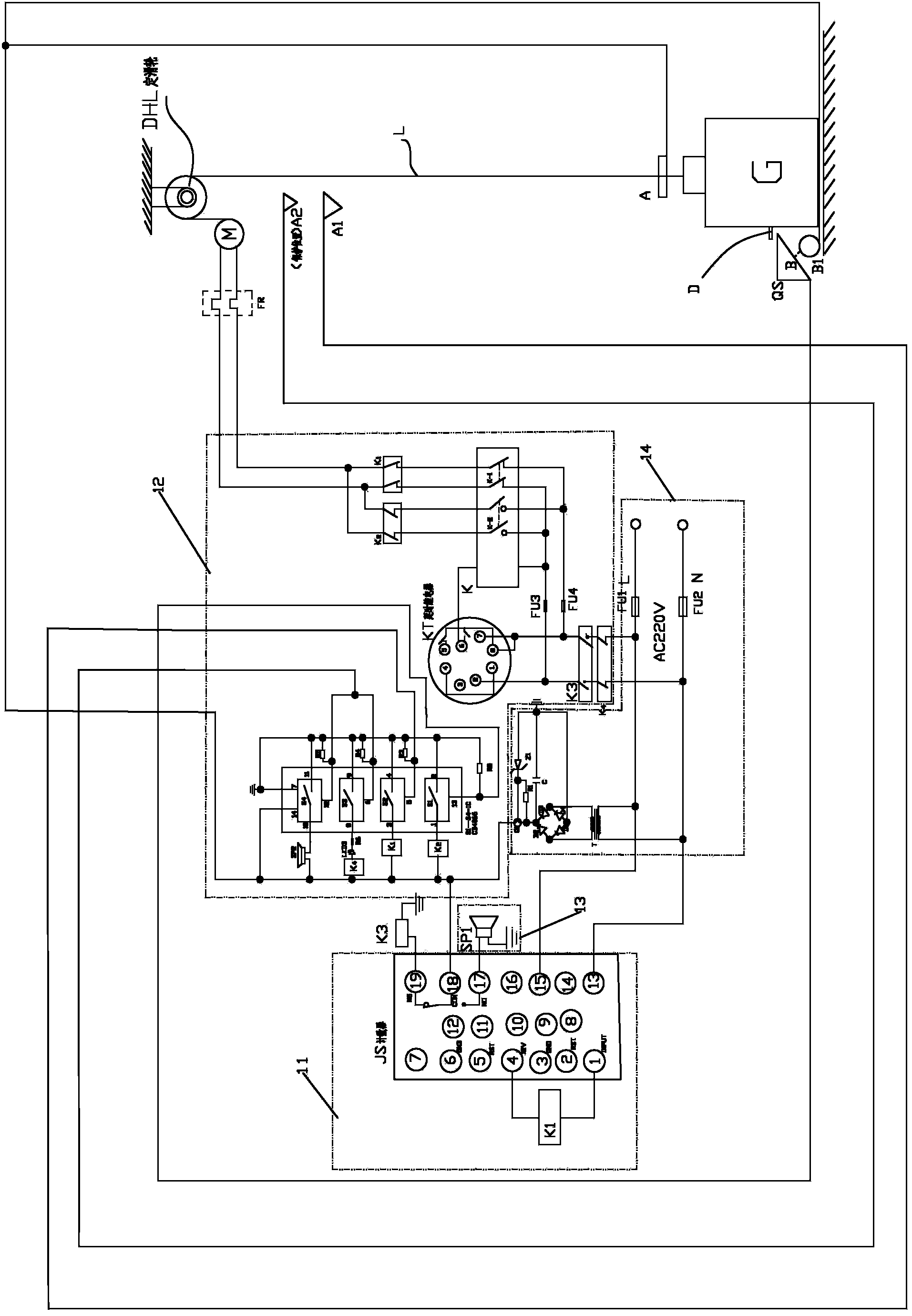

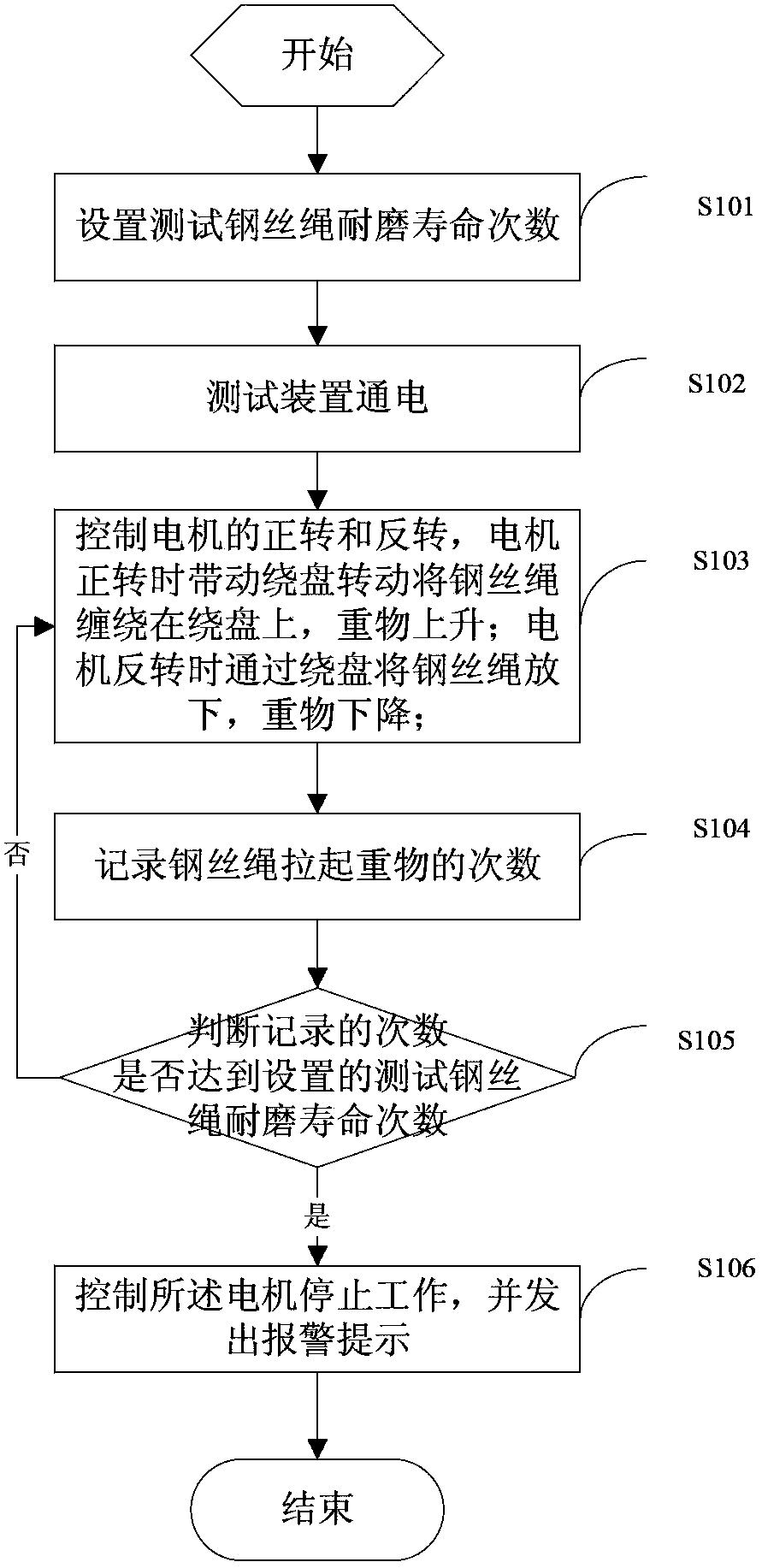

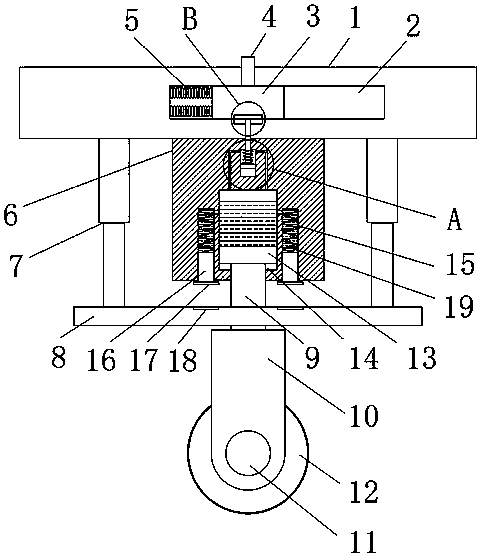

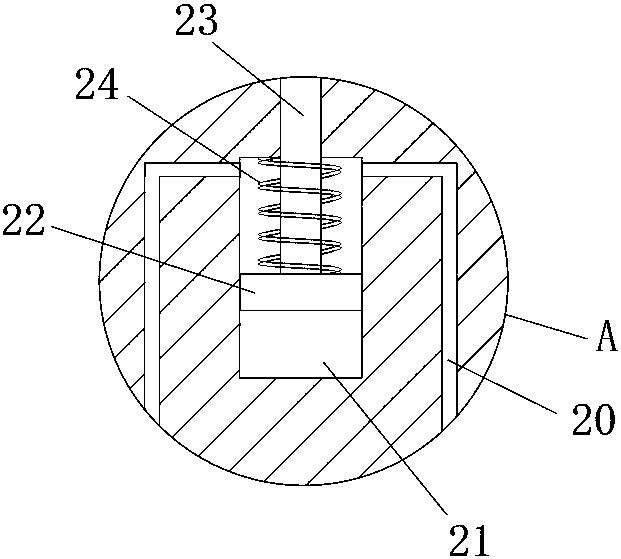

Device and method for testing wearing life of steel wire rope

ActiveCN103454171AReduce fatigue strengthImprove securityInvestigating abrasion/wear resistanceFatigue IntensityTest efficiency

The invention discloses a device and a method for testing the wearing life of a steel wire rope. The test device comprises a fixed pulley, a steel wire rope and a heavy object, and one end of the steel wire rope is suspendingly provided with the heavy object; the test device also comprises a motor, a winding disk and a test circuit, the winding disk is assembled on the motor, the other end of the steel wire rope passes through the fixed pulley and is fixed on the winding disk, and the test circuit is connected with the motor; the test circuit is used for controlling positive rotation and reverse rotation of the motor under a condition of a preset number of times for testing the wearing life of the steel wire rope, so as to driving the heavy object to rise and fall through the steel wire rope; when the preset number of times for testing the wearing life of the steel wire rope reaches, finishing of the test is reminded through the test circuit. The device and the method can allow testing personnel not to personally pull the steel wire rope to test and also not to always keep recording tensile times, and thereby reducing the fatigue intensity of the testing personnel; and the test device is simple, safe and reliable, and moreover, can improve the testing efficiency and safety.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Undercarriage damping structure for near space solar energy unmanned aerial vehicle

ActiveCN109502015AGuaranteed axial elastic deformationNo radial bendingAlighting gearFatigue IntensityEngineering

The invention discloses an undercarriage damping structure for a near space solar energy unmanned aerial vehicle. The undercarriage damping structure comprises a mounting plate, wherein a chute is formed in the mounting plate; a weighing sliding block is connected inside the chute in a sliding manner; an adjusting pin is fixedly connected with one side of the weighing sliding block; an elastic mechanism is arranged inside the chute; a fixing plate is connected with the mounting plate through two groups of first buffer mechanisms; a sealing base is fixedly connected with the bottom side of themounting plate; a piston rod is fixedly connected with the fixing plate; a walking device is arranged at one end of the piston rod; and a first sealing cavity is formed inside the sealing base. By reducing the distance between a first strong magnet and a second strong magnet, the repulsive force between the first strong magnet and the second strong magnet can be gradually increased, two-stage buffer damping is resulted by the repulsive force of the first strong magnet and the second strong magnet, and then due to cooperation with a buffer spring for damping, the fatigue intensity of the bufferspring can be shared while a buffer effect is improved.

Owner:浙江翔龙航空科技有限公司

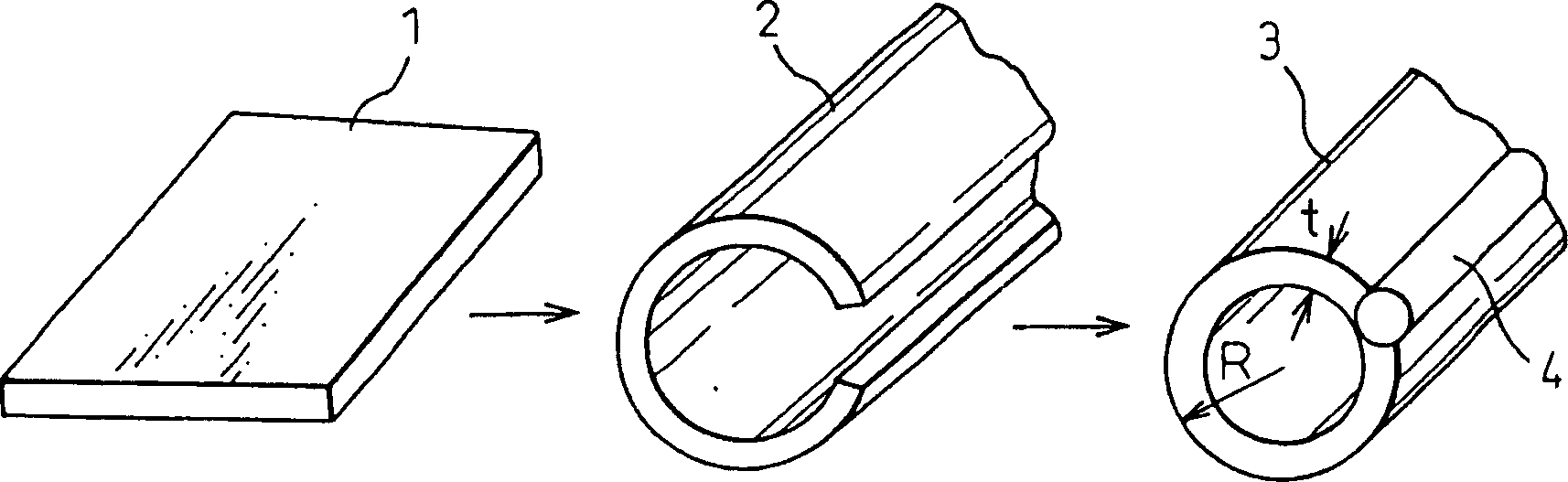

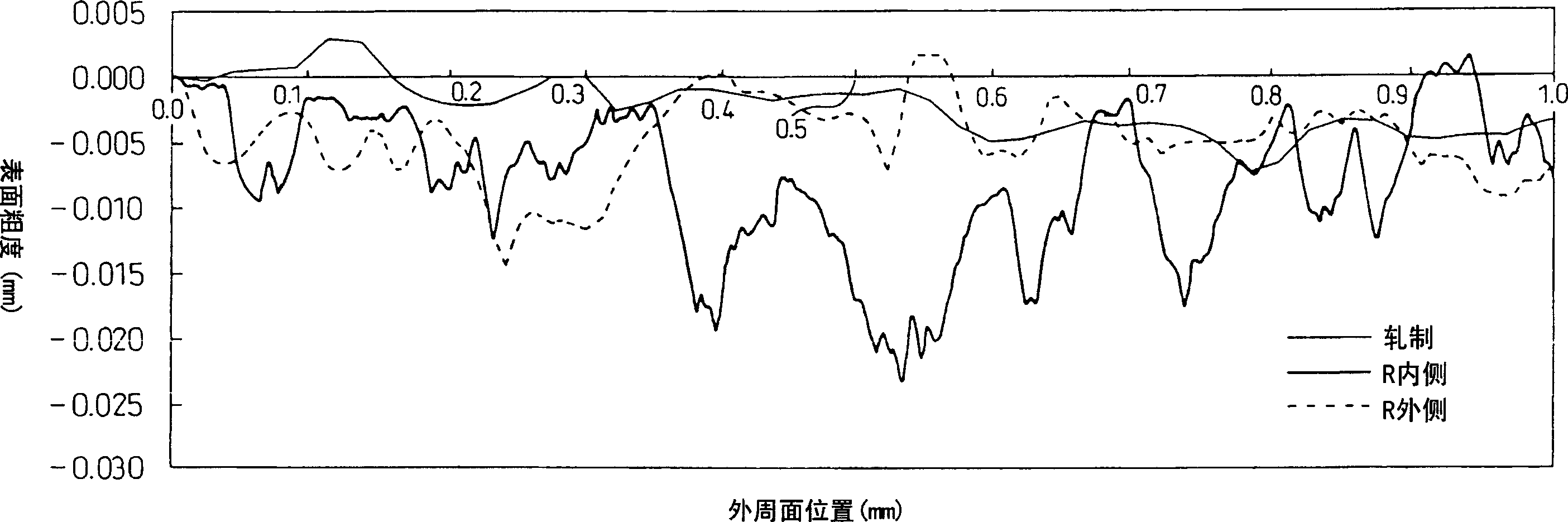

High strength machine parts and shaft excellent in fatigue characteristics, and method for improving fatigue characteristics thereof

High strength machine parts excellent in fatigue strength which contain 0.1 to 1.2 mass % of C, and have a notch having a radius of curvature of 25 mm or less, wherein the surface thereof has an HV hardness of 250 or more and a surface layer of the notch has a compression residual stress of -100 to -1500 MPa; and a method for improving the fatigue strength thereof. A shaft excellent in fatigue resistance characteristics which comprises a steel product having a chemical composition, in mass %, that C: 0.1 to 1.2 %, Si: 0.05 to 2.5 %, Mn: 0.2 to 3 %, Al: 0.005 to 0.1 %, N: 0.001 to 0.02 % and the blance: Fe and inevitable impurities, and exhibiting a tensile strength of 800 MPa or more, characterized in that the shaft has an oil hole, and the surface layer of the oil hole has a compression residual stress of 50 to 90 % of the tensile strength of the above steel product; and a method for improving the fatigue strength thereof.

Owner:NIPPON STEEL CORP

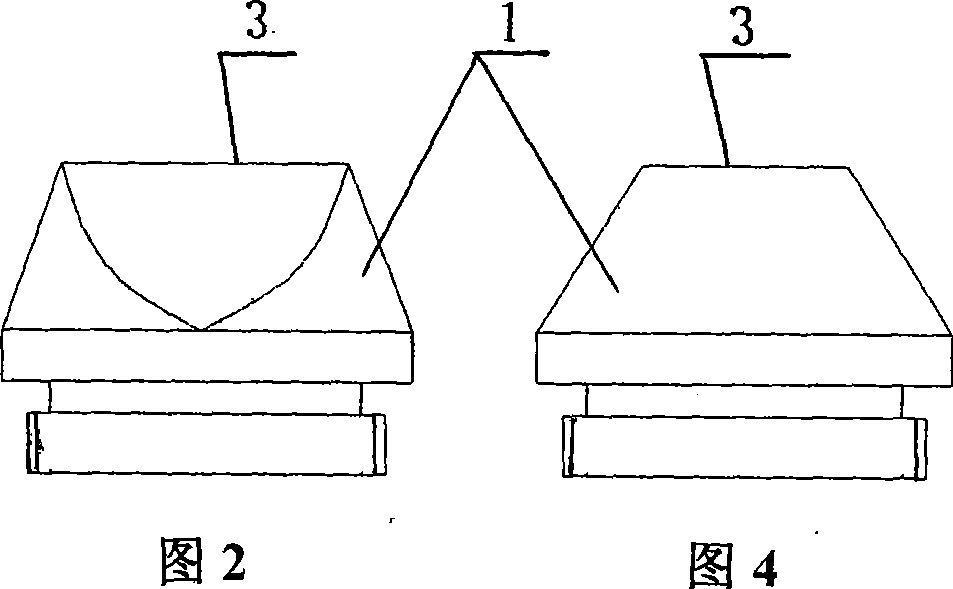

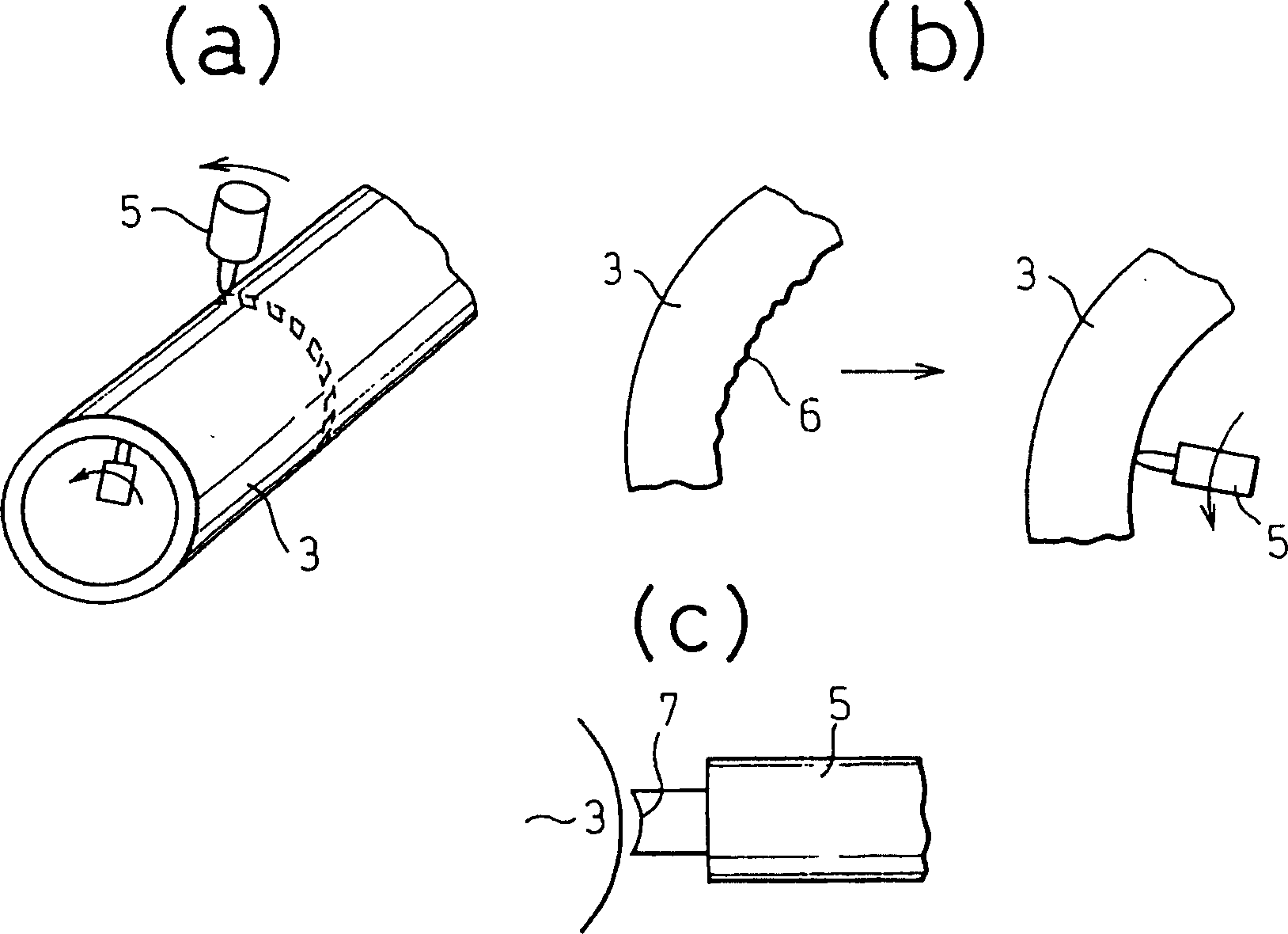

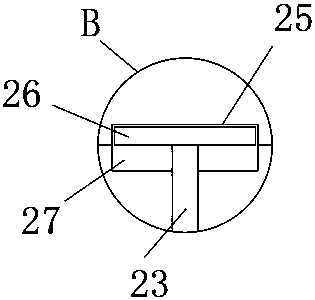

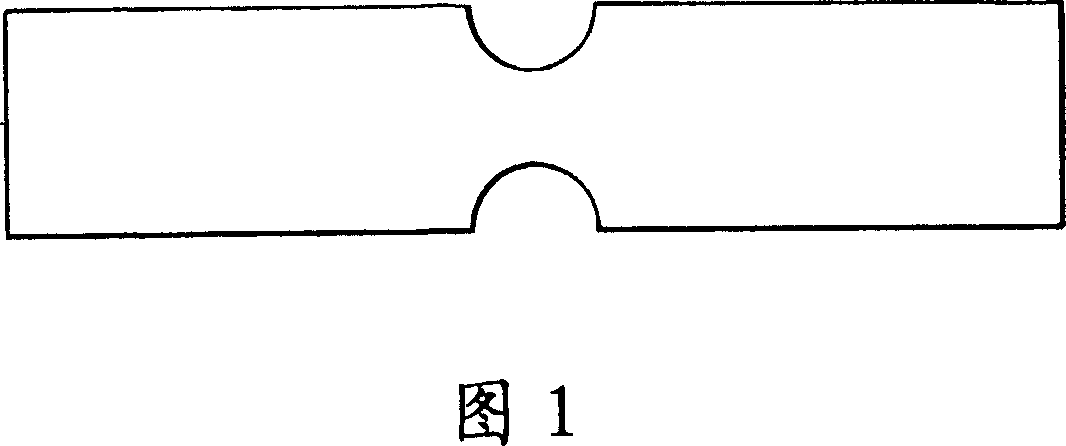

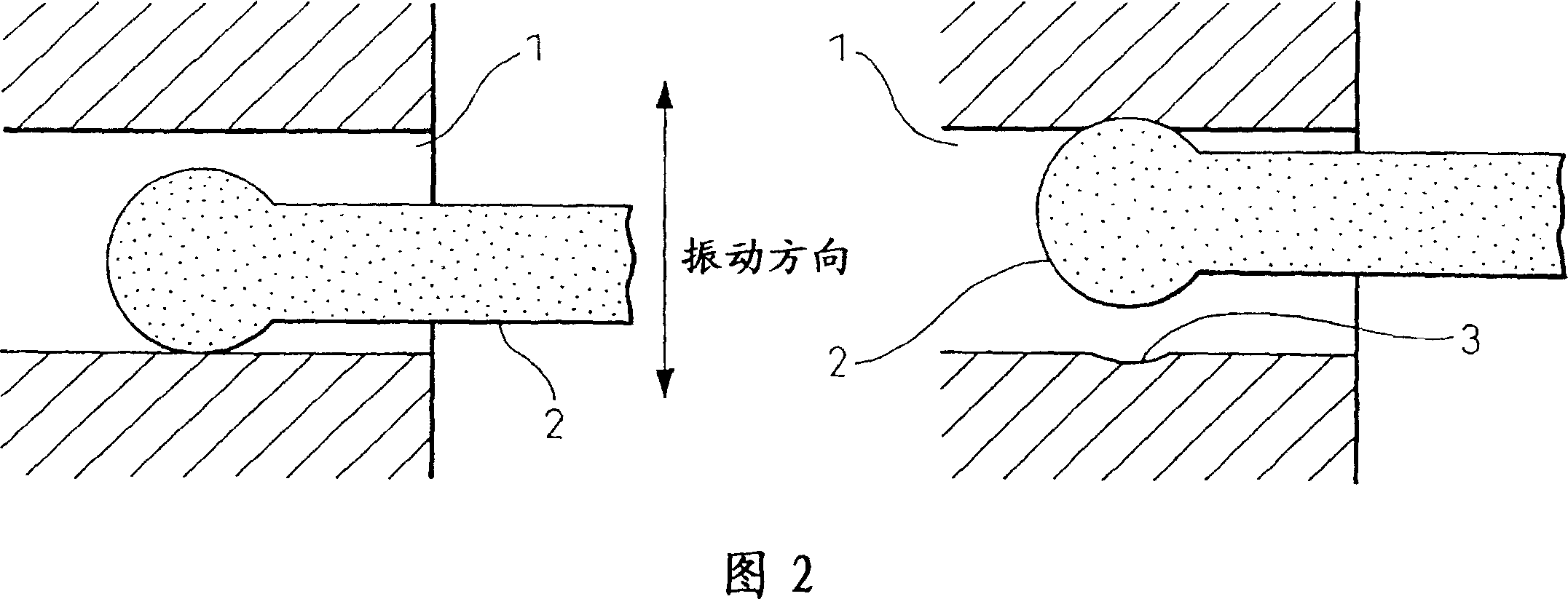

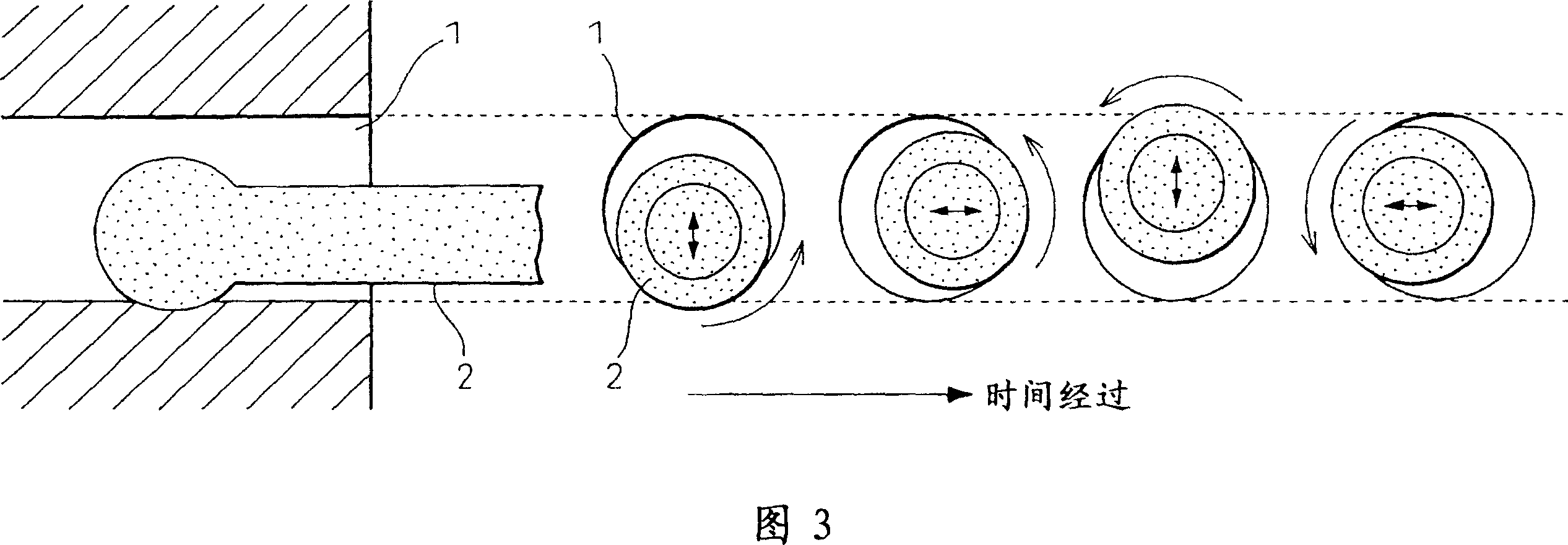

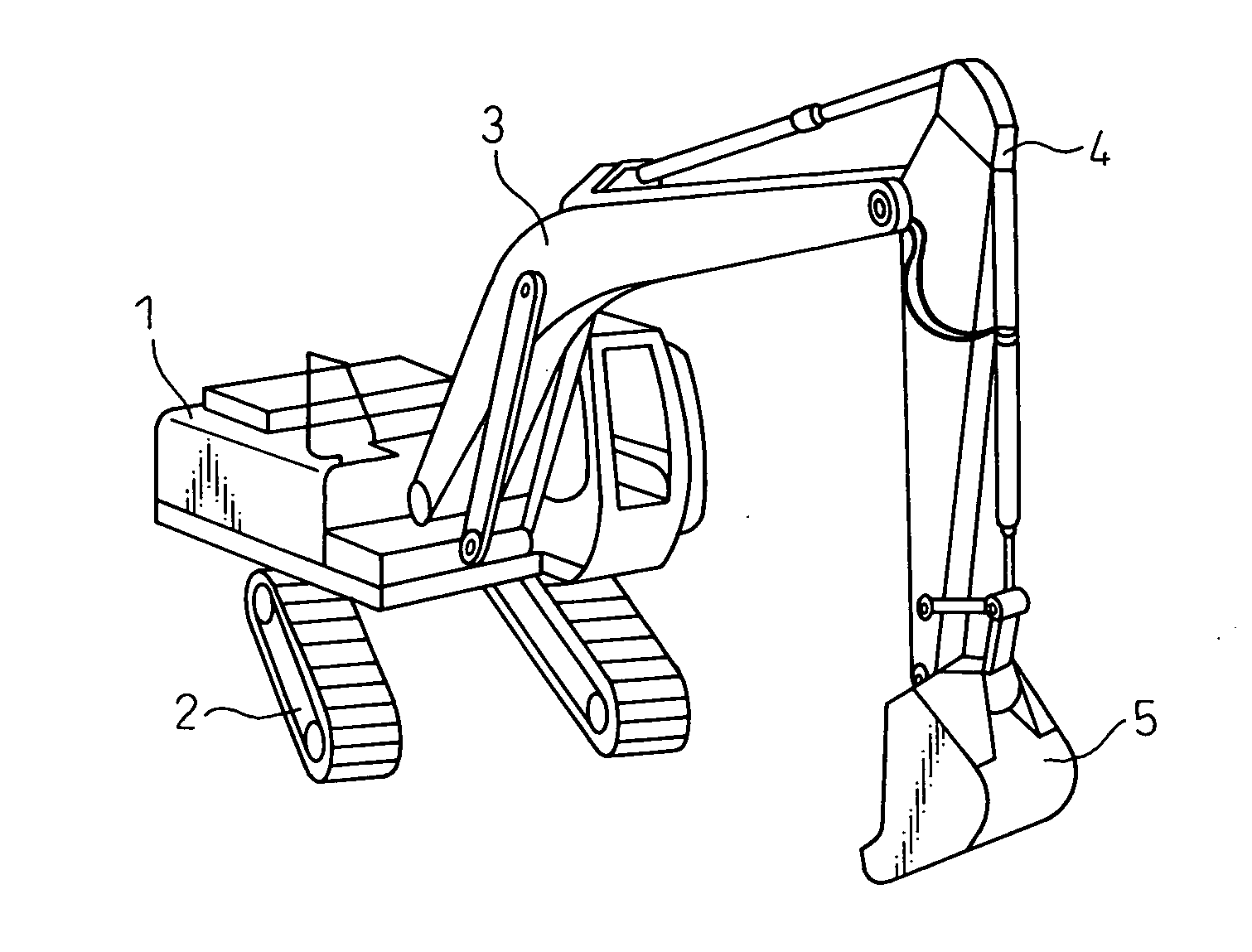

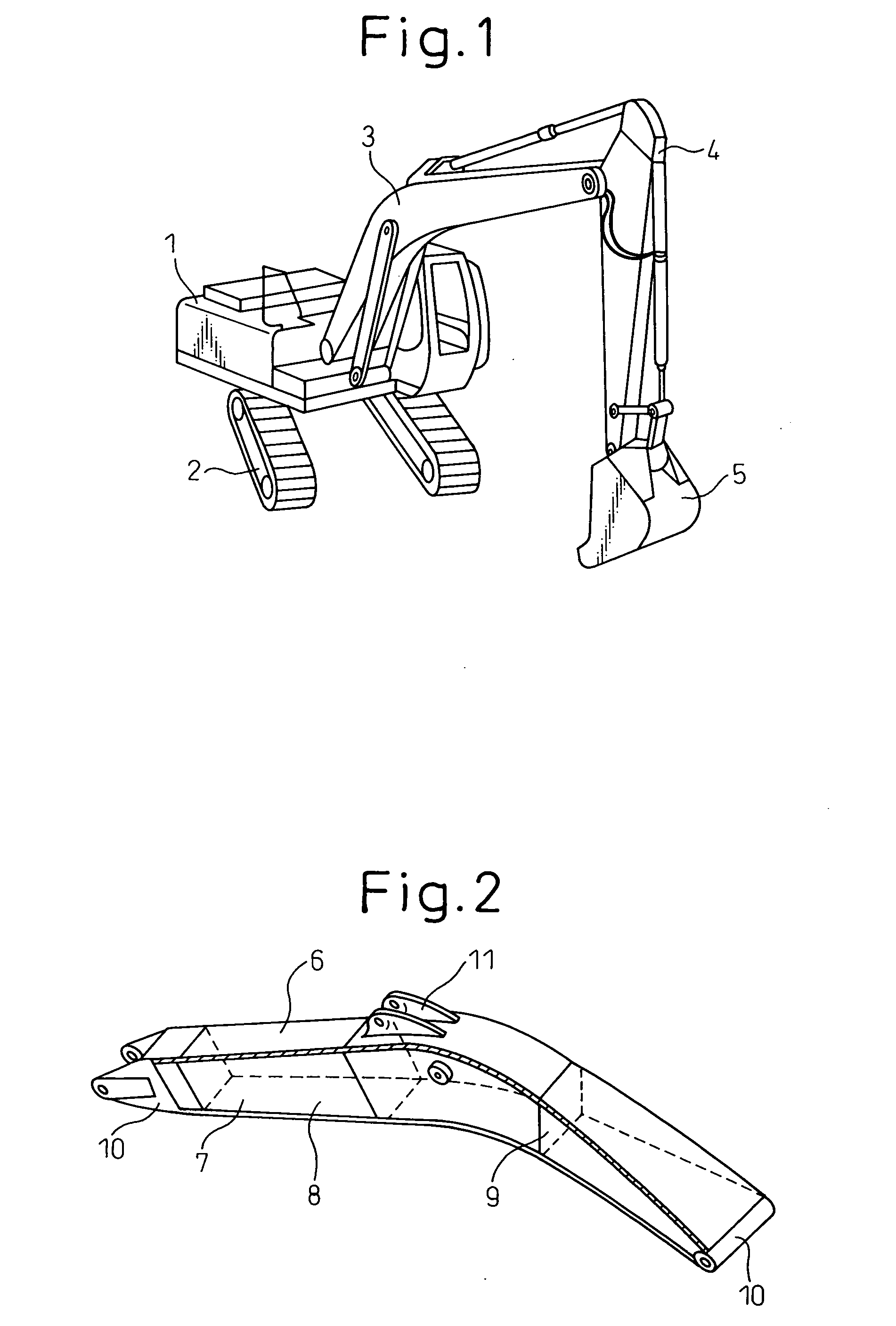

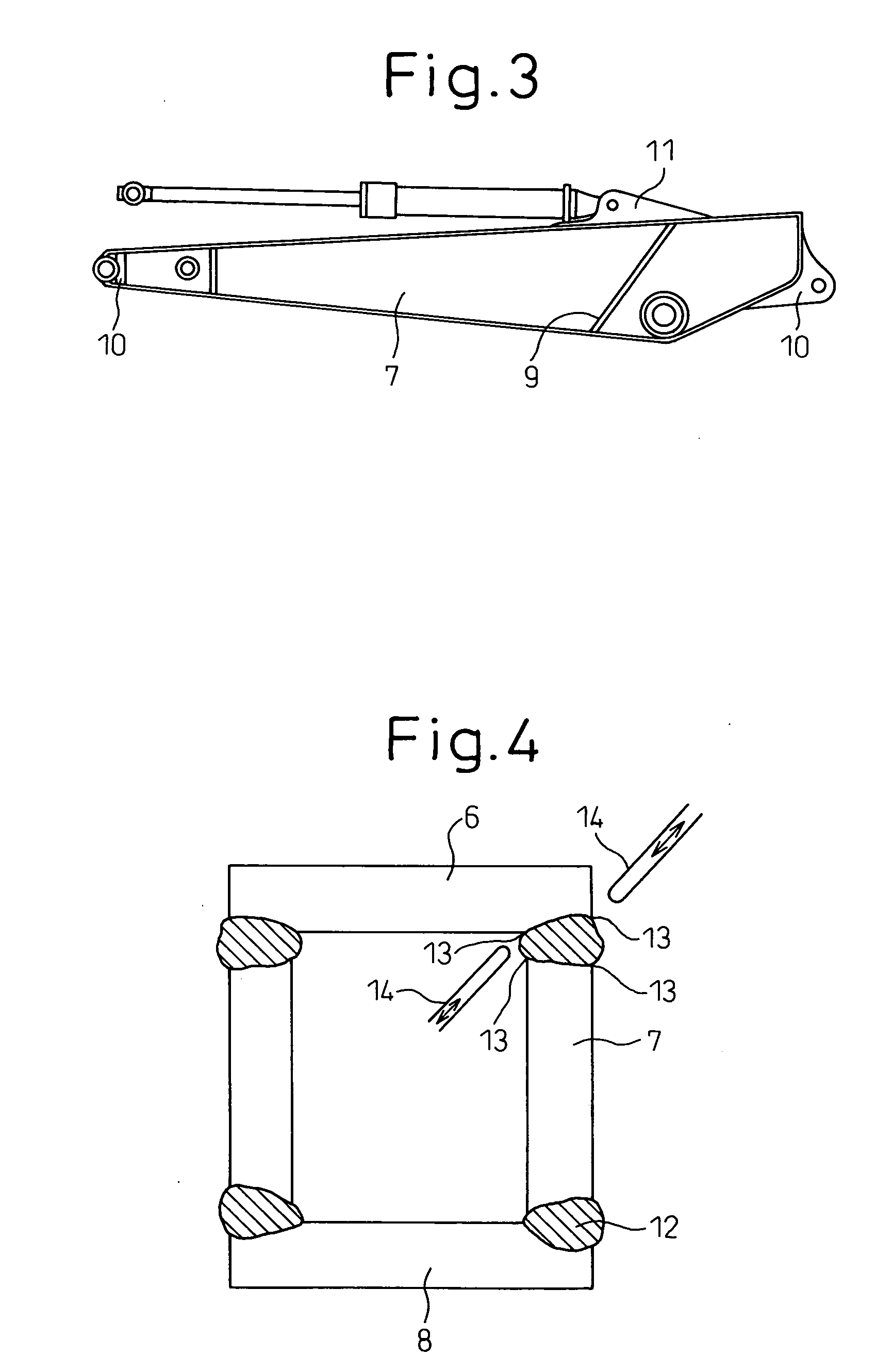

Boom and Arm Member of Construction Machine Excellent in Weld Zone Fatigue Strength and Method of Improvement of Its Fatigue Strength

ActiveUS20080292443A1Excellent in weld zone fatigue strengthImprove fatigue strengthMechanical machines/dredgersSoldering apparatusFatigue IntensityUltimate tensile strength

The present invention provides a boom and arm member of a construction machine excellent in weld zone fatigue strength and a method of improvement of its fatigue strength, that is, a boom and arm member of a construction machine superior in weld zone fatigue strength, the boom and arm member of a construction machine characterized in that toes of full penetrated weld zones of the boom and arm member have vibration strike marks, and a method of improvement of its fatigue strength. Preferably, the residual stress of the bottom surface of the vibration strike marks is a 10 MPa or higher compressive residual stress.

Owner:NIPPON STEEL CORP

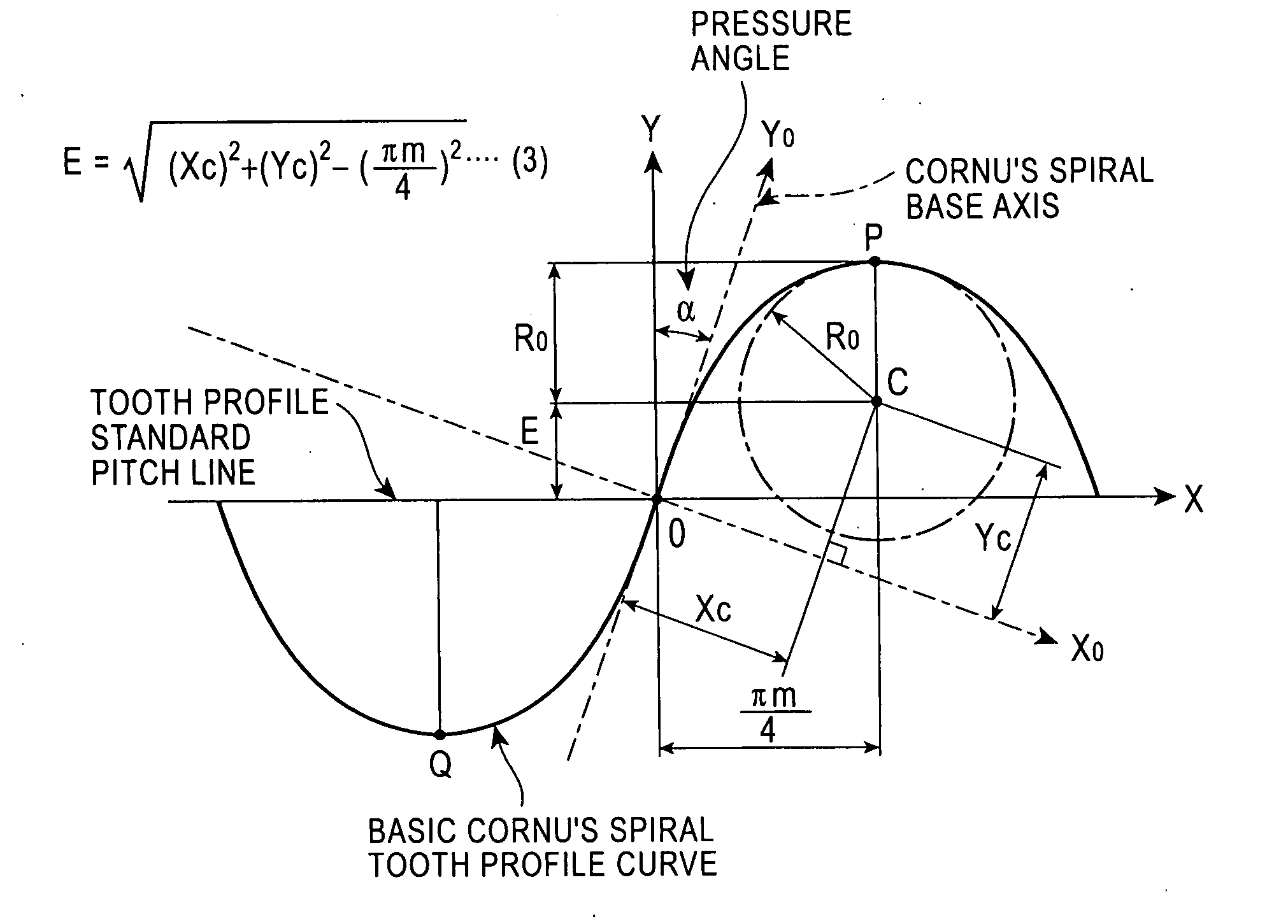

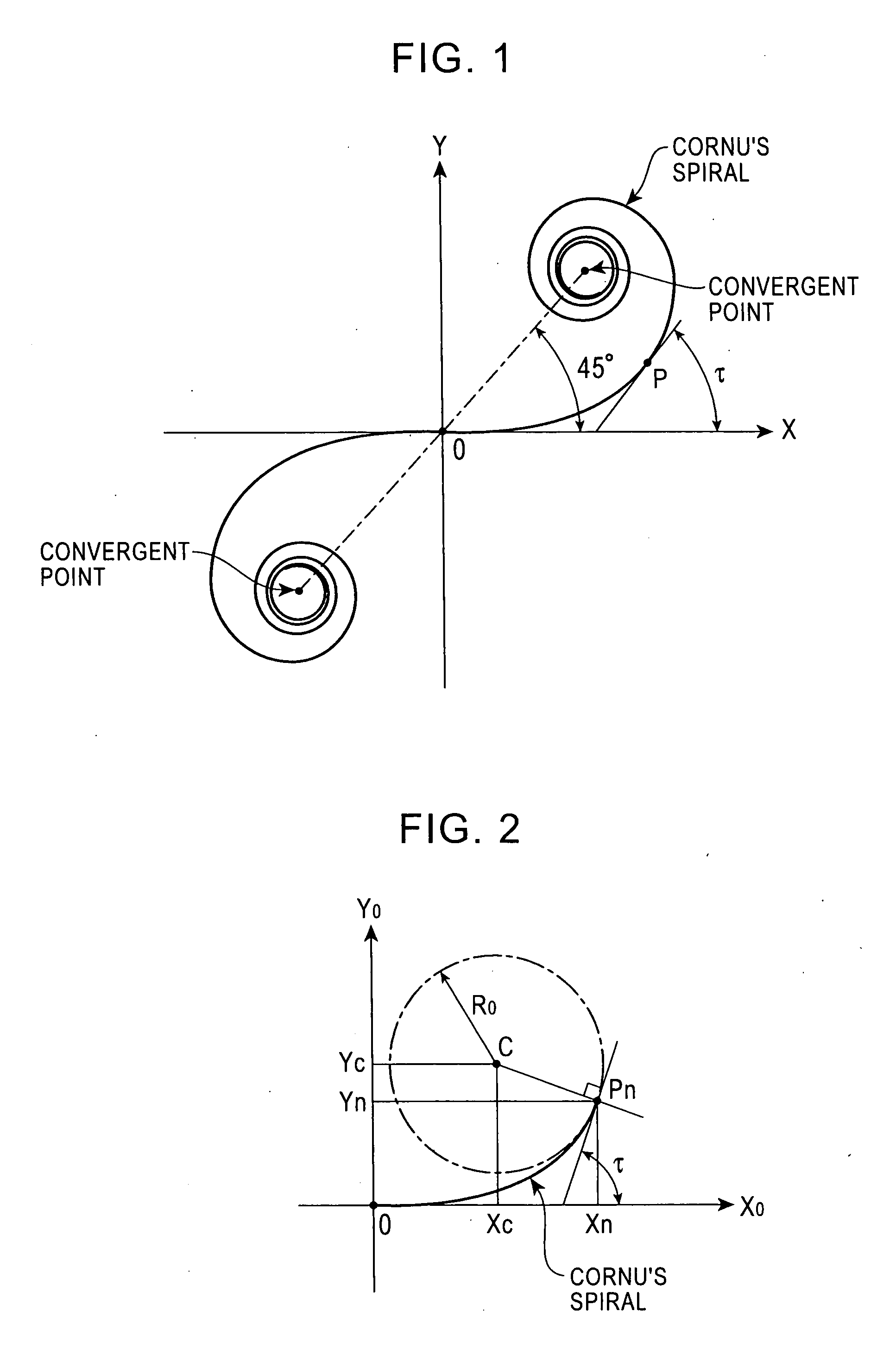

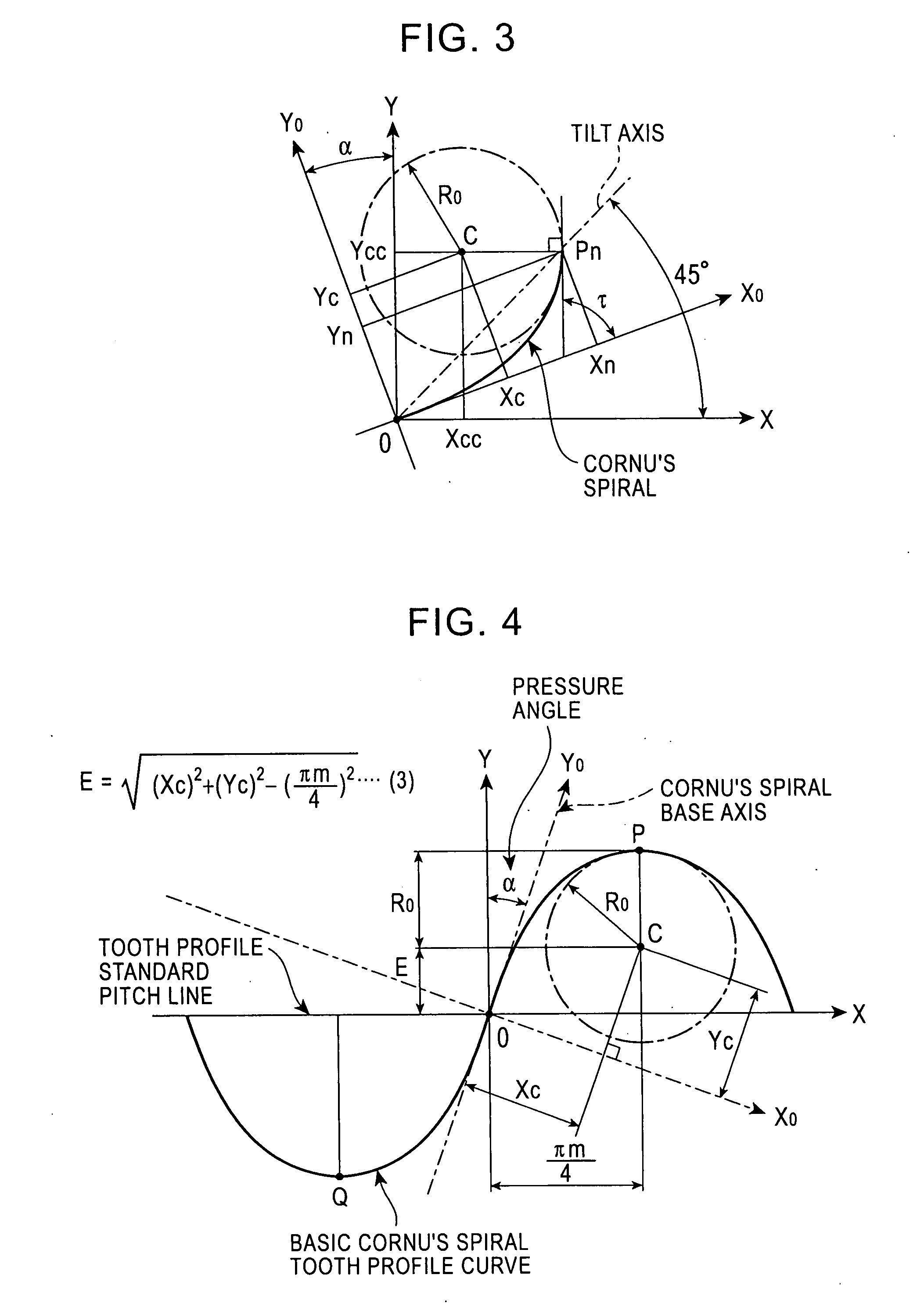

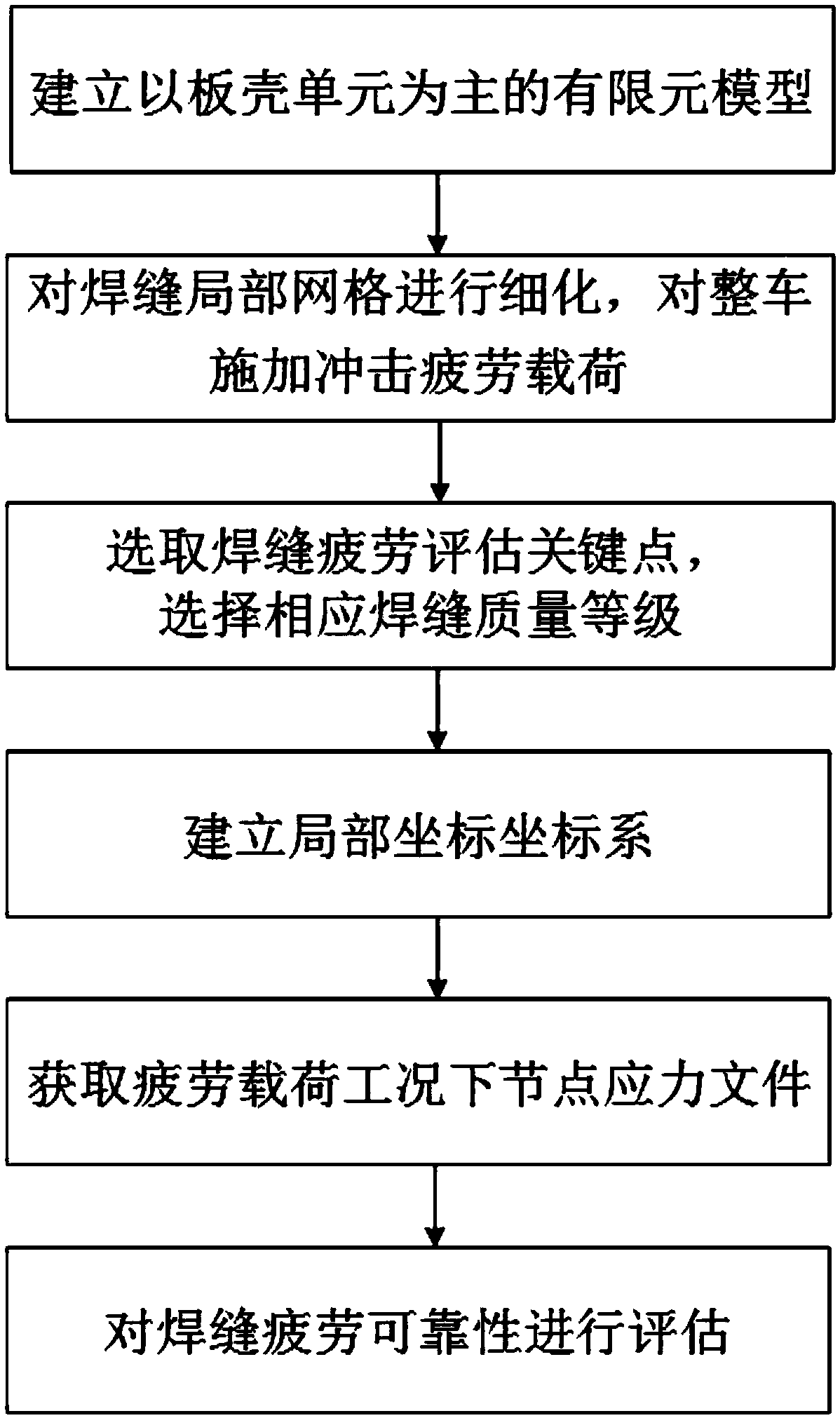

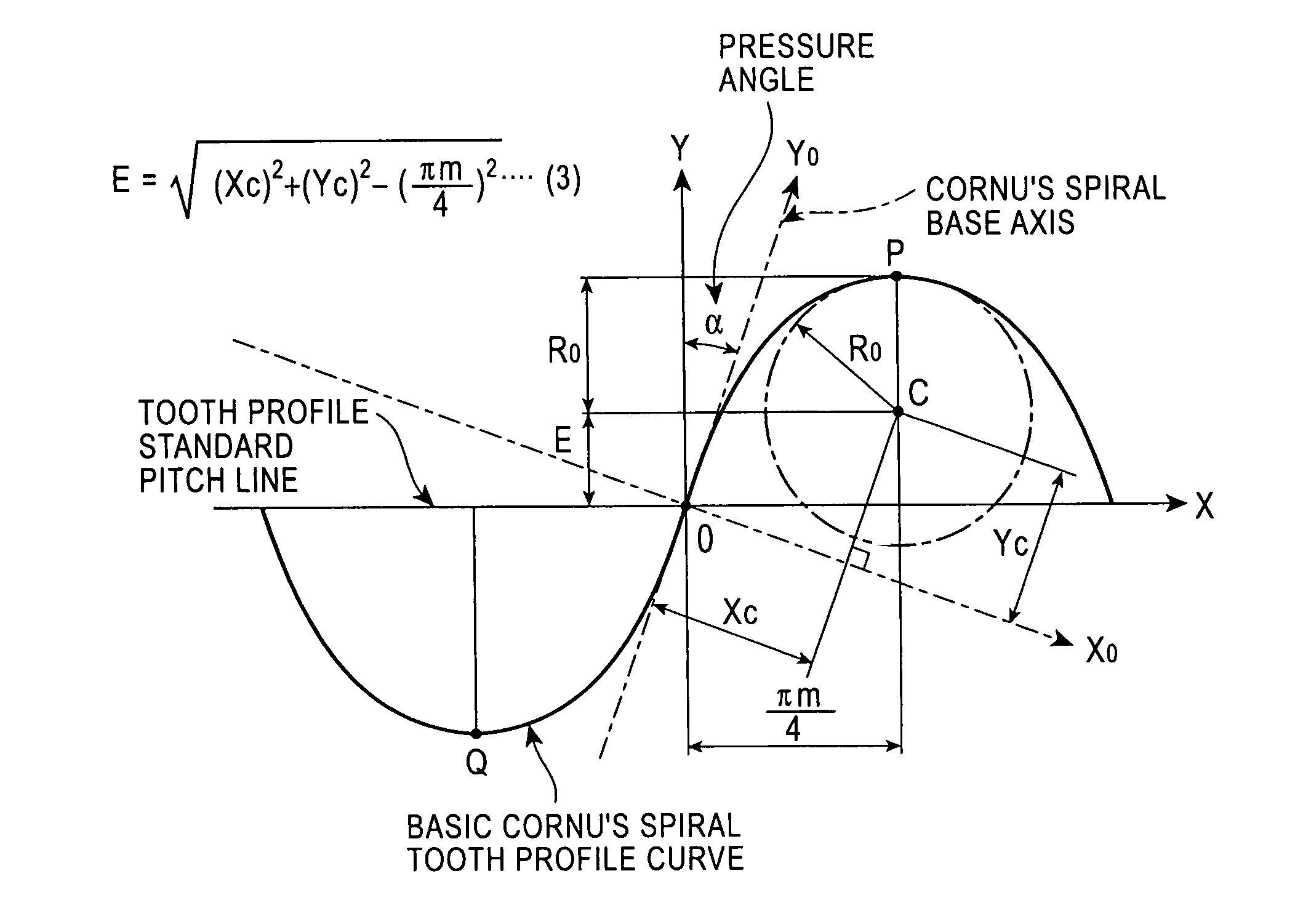

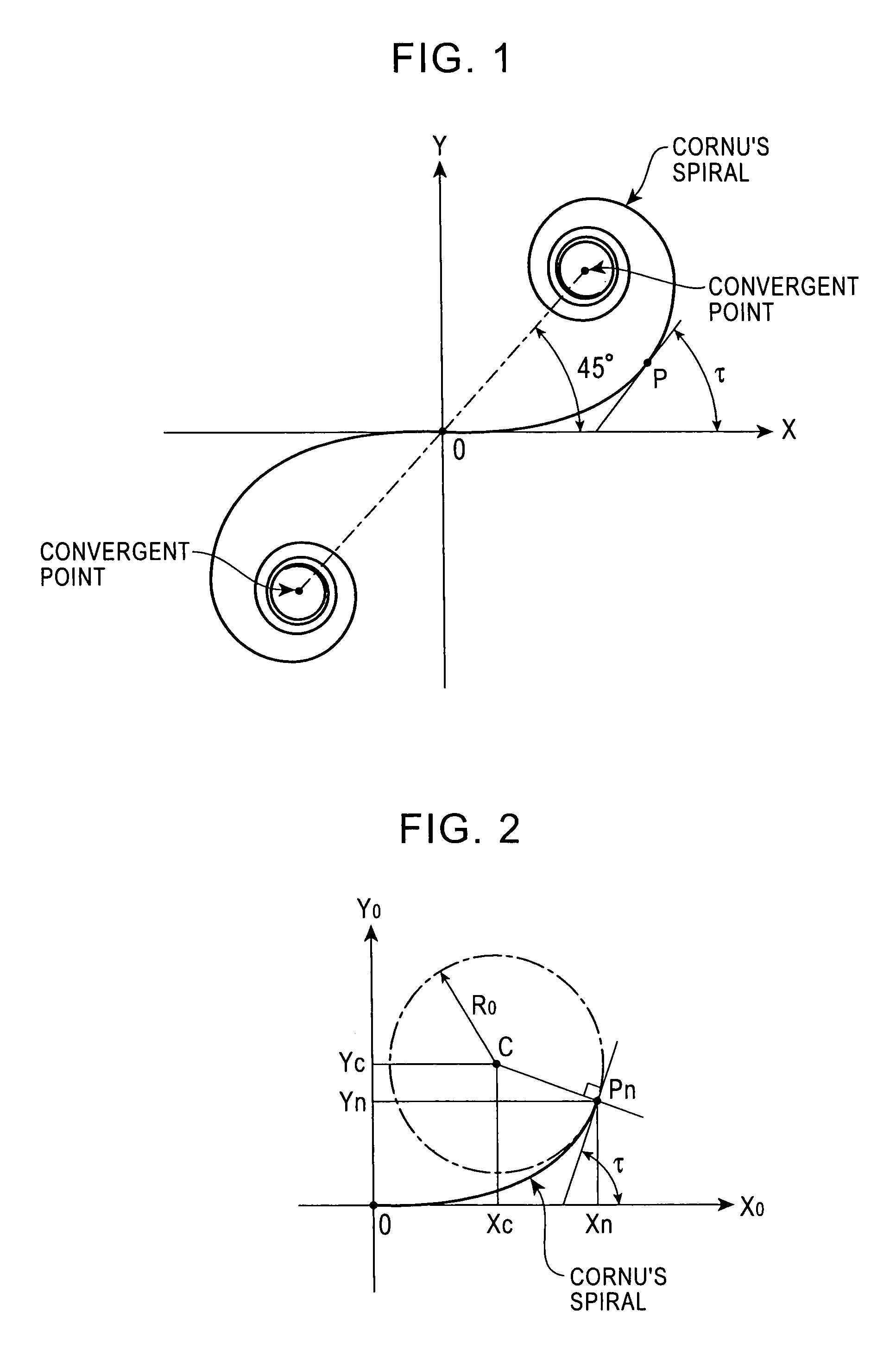

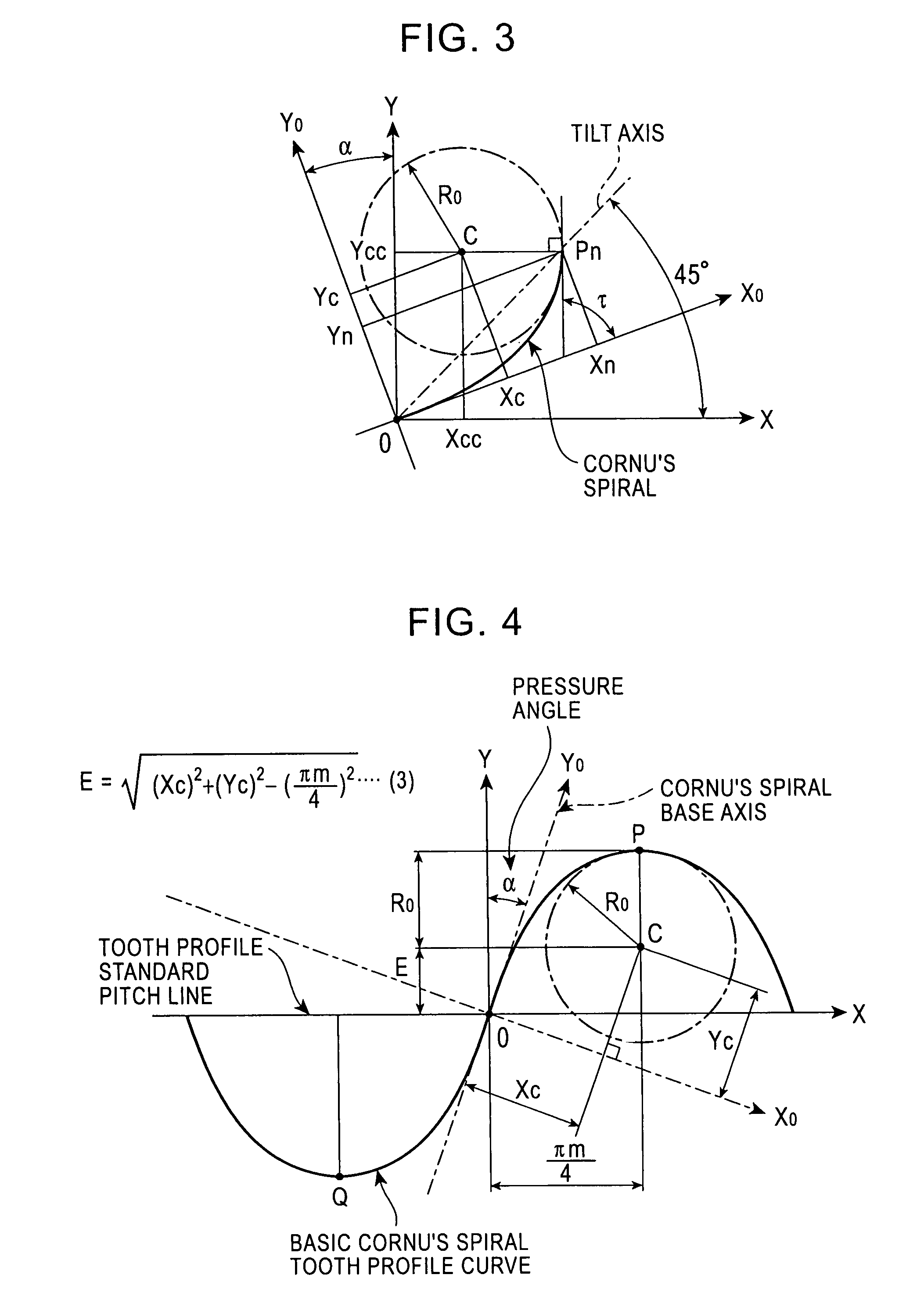

Cornu's Spiral Tooth Gear

ActiveUS20090049942A1Improve featuresSmooth and safe steering operationPortable liftingGearing elementsHelical lineSurface stress

A Cornu's spiral is applied to a tooth profile of a gear. In accordance with the application of the gear, the Cornu's spiral may be modified two-dimensionally by some constant proportion. Since Cornu's spirals have similarity are similar, when a pressure angle is determined, the tooth profile can be standardized by a module, so that it is highly versatile.By replacing the tip of a tooth and the bottom of a tooth by another curve, such as an arc, the range of application can be increased. Since working is always by flank contact between a protrusion and a recess, contact surface stress is low. In addition, the radius of curvature of a dedendum is large. Therefore, tooth bending stress is low, and fatigue strength is high. Even if the number of teeth is small, an undercut is not produced. Even if there is no backlash, a smooth working is achieved, so that the tooth profile is suitable for devices requiring precise alignment.

Owner:MIYAOKU TSUTOMU +2

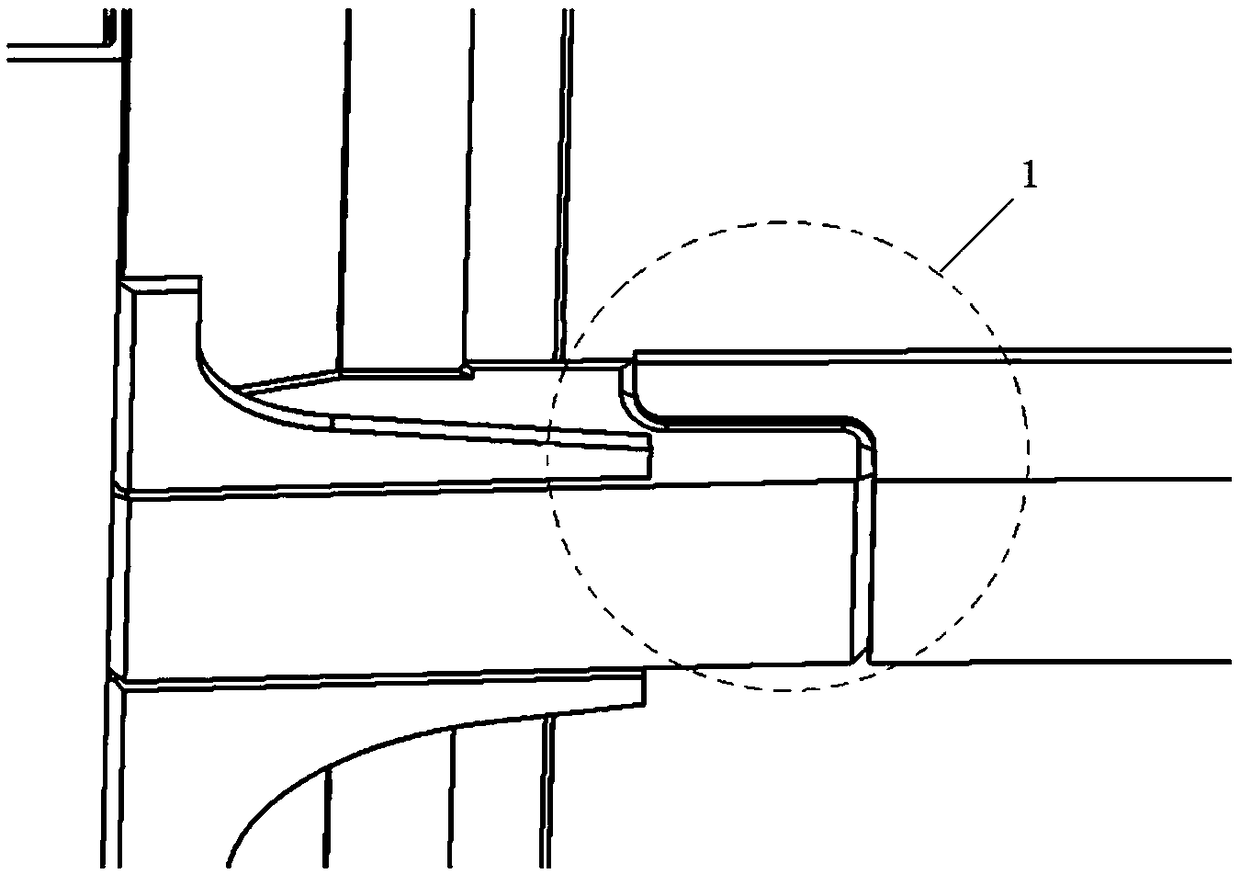

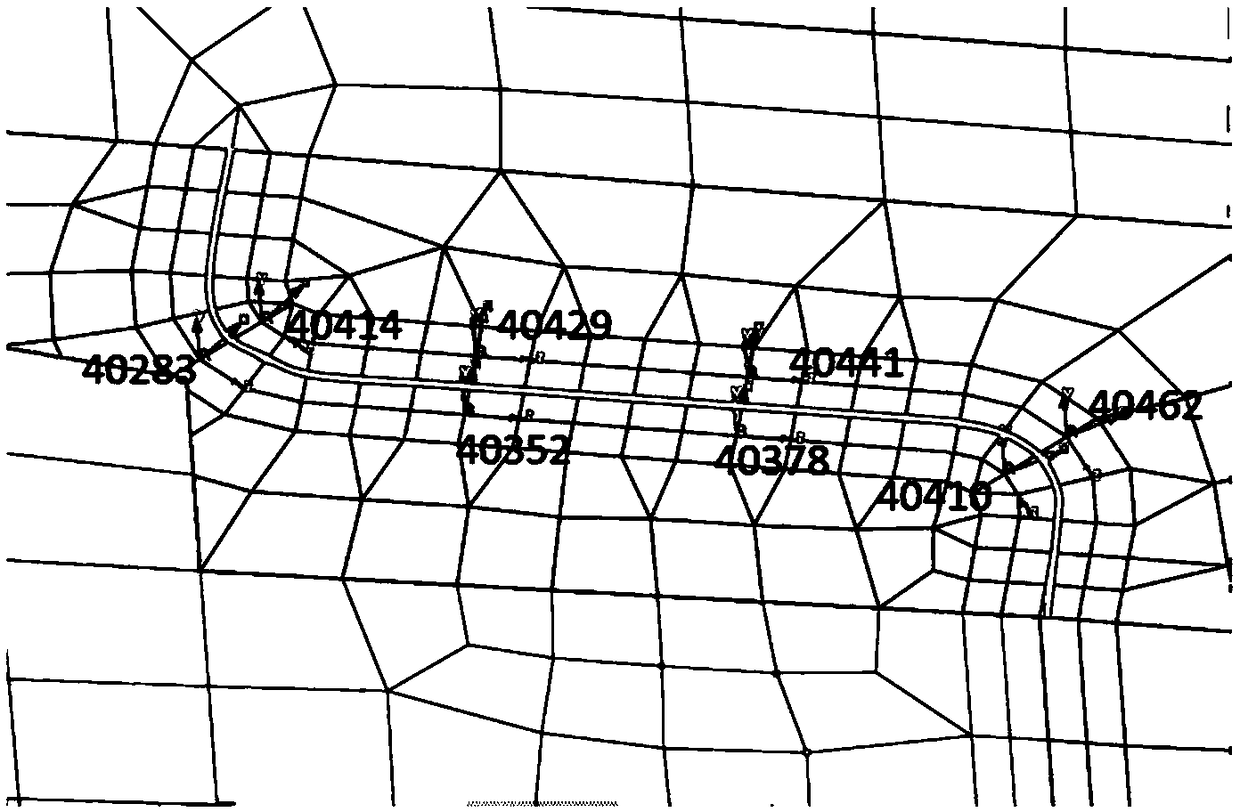

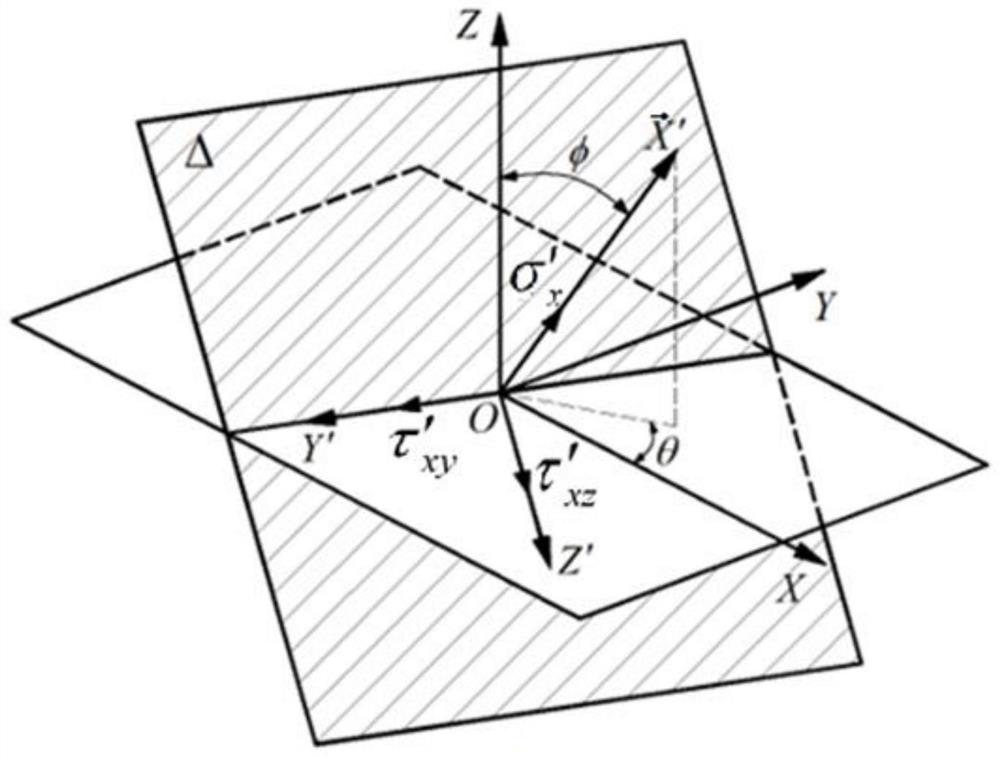

A method and a system for evaluating fatigue reliability of a weld seam of a rail vehicle body

PendingCN109190177AAvoid stressDesign optimisation/simulationSpecial data processing applicationsWeld seamSecondary development

The invention relates to a method and a system for evaluating fatigue reliability of a weld seam of a rail vehicle body. The invention applies a fatigue impact load to the rail vehicle body through afinite element method, directly calculates the stress of a weld coordinate system, obtains a node stress file, and evaluates the fatigue reliability of the weld of the vehicle body by combining the evaluation key point file and the node stress file. Compared with the prior art, the present invention solves the problem that the stress obtained by the prior finite element method is mostly under thefixed coordinate, which can not be directly applied to the multiaxial fatigue strength evaluation of the weld seam, and the coordinate system conversion in the post-processing or the stress result processing by the secondary development program are required.

Owner:TONGJI UNIV +1

Nuclear-radiation-resistant ageing-resistant rubber

InactiveCN102304253AImprove aging resistanceImprove radiation resistanceFatigue IntensityRubber material

The invention provides a nuclear-radiation-resistant ageing-resistant rubber and relates to a rubber material which can be used in the environments of gamma, beta and X rays and various charged particle lines. The rubber is high in strength and stable in processing property, and can resist heat and radiation. The rubber comprises the following components in parts by weight: 100 parts of ethylene propylene diene monomer rubber, 5-25 parts of bismuth oxide serving as a radiation-resistant auxiliary agent, 30-60 parts of high-wear-resistance carbon black serving as a reinforcing agent, 2-4 parts of 4,4'-diisopropyl diphenylamine and 1-3 parts of p-benzoquinone dioxime serving as thermal oxidative ageing resistant auxiliary agents, 1-5 parts of dicumyl peroxide serving as a vulcanizer, 4-8 parts of paraffin oil serving as a plasticizer and 1-6 parts of processing aid. The nuclear-radiation-resistant ageing-resistant rubber provided by the invention can meet production of membranes in a nuclear power station, a radioactive medical treatment department and the like; by using the rubber, the phenomena such as minute bubbles, air clog and the like can be reduced; and bismuth oxide in the rubber not only has the effect of radiation protection but also has an activation effect, so that a finished product can maintain extremely high fatigue-resisting strength for a long term in the radioactive environment and can be used for effectively preventing radioactive rays from penetrating. The rubber has the characteristics of high strength, yielding resistance, good hot tearing resistant property and large temperature application range.

Owner:JIANGSU YANGZHOU HELI RUBBER PROD

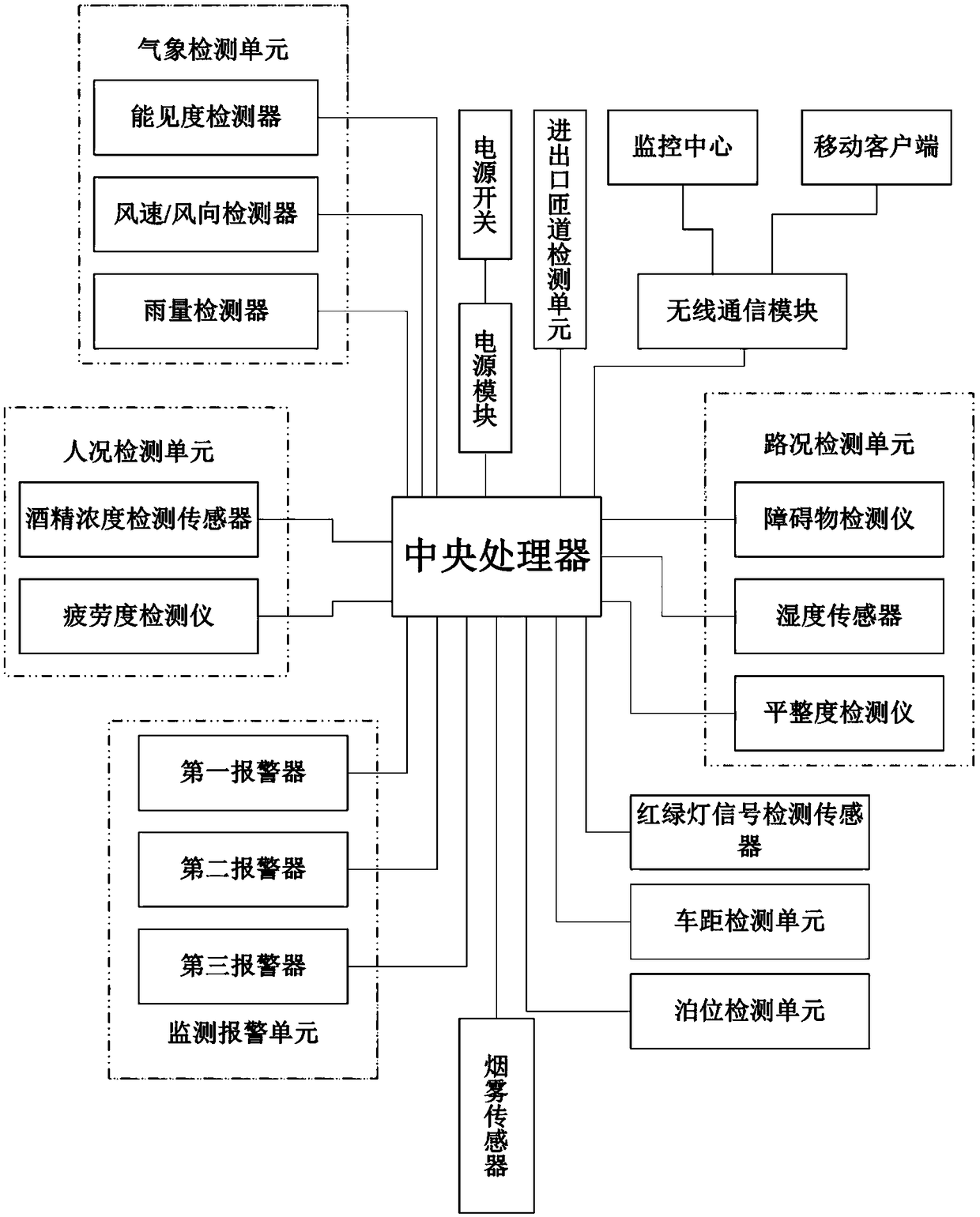

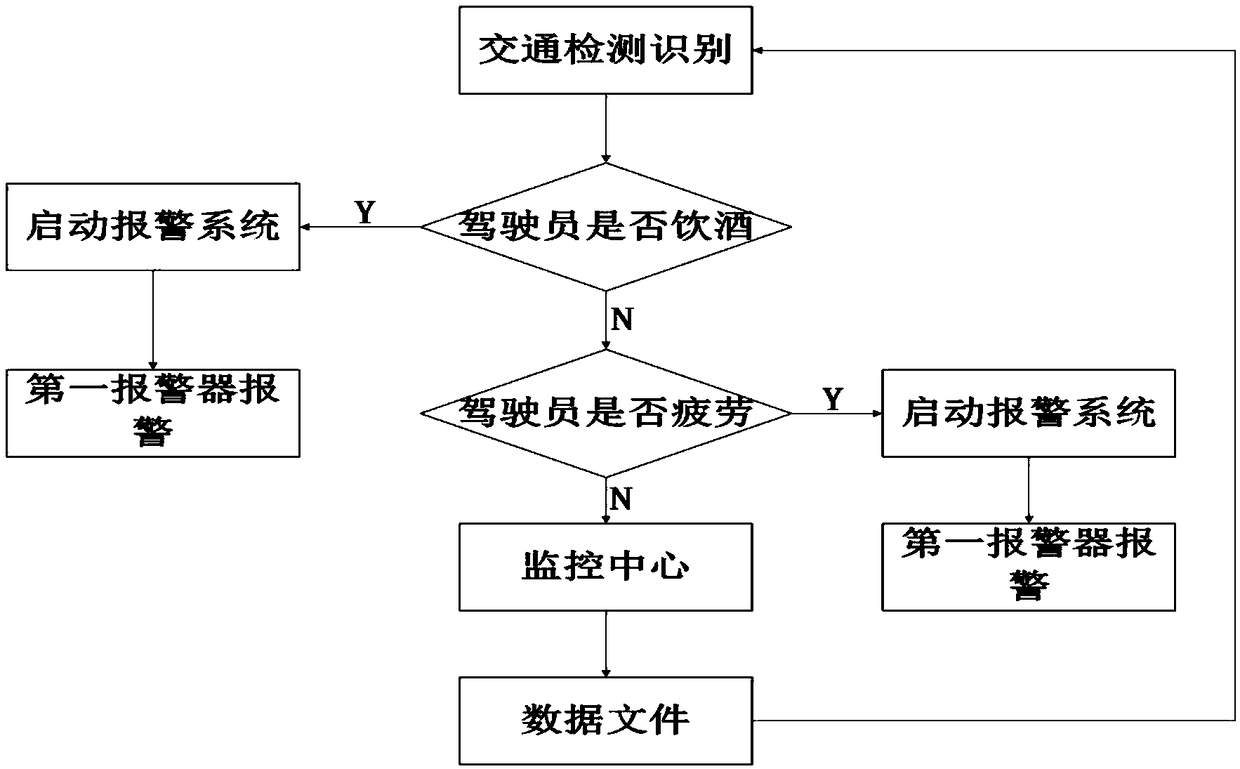

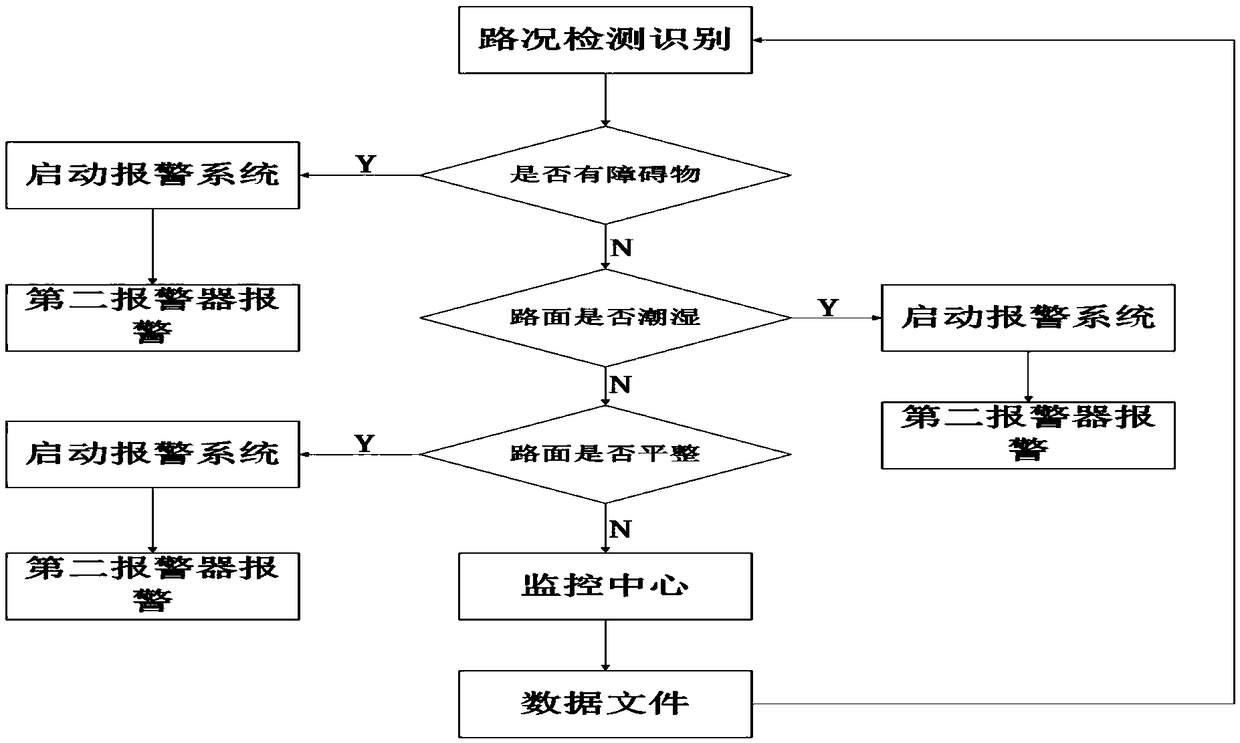

Smart traffic safety management system

InactiveCN108717785AImprove traffic safetyReduce traffic hazardsDetection of traffic movementIndication of parksing free spacesFatigue IntensitySafety management systems

The invention discloses a smart traffic safety management system. The smart traffic safety management system comprises a human condition detection unit, a road condition detection unit, a weather detection unit, a central processing unit, a monitoring alarm unit and a wireless communication module; the human condition detection unit is used for detecting the alcohol concentration and fatigue intensity of a driver in real time, the road condition detection unit is used for detecting obstacles on a traffic road surface, the road surface humidity and the road surface flatness in real time, and the weather detection unit is used for detecting the visibility, wind speed / wind direction and rainfall on the traffic road in real time. In the system, multiple module detection units are used for performing traffic safety detection, and thus the traffic safety is greatly improved; the traffic safety management system performs integrated processing on traffic safety status early warning index system of various traffic management units of a regional road network and determines the early warning level to generate intelligent early warning countermeasures, so that the pertinence, real-time performance and effectiveness of active traffic accident prevention measures of the highway traffic control department are improved.

Owner:CHANGAN UNIV

High-frequency pulse current assisted surface shot blasting reinforcement machining device and method

PendingCN110253449ASimple structureLow costAbrasive machine appurtenancesAbrasive blasting machinesFatigue IntensityAviation

The invention discloses a high-frequency pulse current assisted surface shot blasting reinforcement machining device. The device is characterized by consisting of a surface shot blasting reinforcement device and a pulse power supply device; the surface shot blasting reinforcement device comprises a shot blasting chamber, a shot blasting mechanism mounted on the shot blasting chamber and used for blasting shots into the shot blasting chamber, and a workpiece clamping mechanism arranged in the shot blasting chamber and used for fixing workpieces; and the pulse power supply device is connected to the workpieces during shot blasting to apply pulse current on the workpieces. The invention further discloses a high-frequency pulse current assisted surface shot blasting reinforcement machining method; the method uses an electroplastic effect of high-frequency pulse current to improve the surface plasticity of such aviation parts as titanium alloys and aluminum alloys, to reduce the hardness, to improve the surface shot blasting reinforcement effect of the parts and to improve the wear resistance and the fatigue intensity of the aviation parts.

Owner:HUNAN UNIV OF SCI & TECH

Thermal treatment method for high-strength thermal formation torsion beam of automobile

InactiveCN108504985AEliminate defects caused by decarburizationStress reliefSolid state diffusion coatingFurnace typesFatigue IntensityCarbonization

The invention discloses a thermal treatment method for a high-strength thermal formation torsion beam of an automobile. The high-strength thermal formation torsion beam is made of a material BR1500HS.The thermal treatment method comprises the following steps: performing pretreatment, namely putting the high-strength thermal formation torsion beam after stamping molding into a preheating furnace,placing vertically, heating to 500-540 DEG C at a speed of 100 DEG C / minute, and introducing nitrogen at a speed of 1m<3> / hour; performing carbonization treatment, namely treating for three sections;performing quenching treatment, namely soaking the high-strength thermal formation torsion beam into an oil tank to carry out quenching for 30 minutes at a vertical state, and adjusting the oil temperature to 75-85 DEG C; performing cleaning treatment, namely performing annealing treatment. By adopting the thermal treatment method for the high-strength thermal formation torsion beam of the automobile, the problem that the high-strength thermal formation torsion beam is low in fatigue strength because of steel surface decarburization in the formation process can be solved, meanwhile, the comprehensive mechanical properties of a material can be greatly improved, and defects caused by decarburization of a steel surface can be thoroughly eliminated in the thermal formation process of the high-strength thermal formation torsion beam.

Owner:永康市求精热处理厂

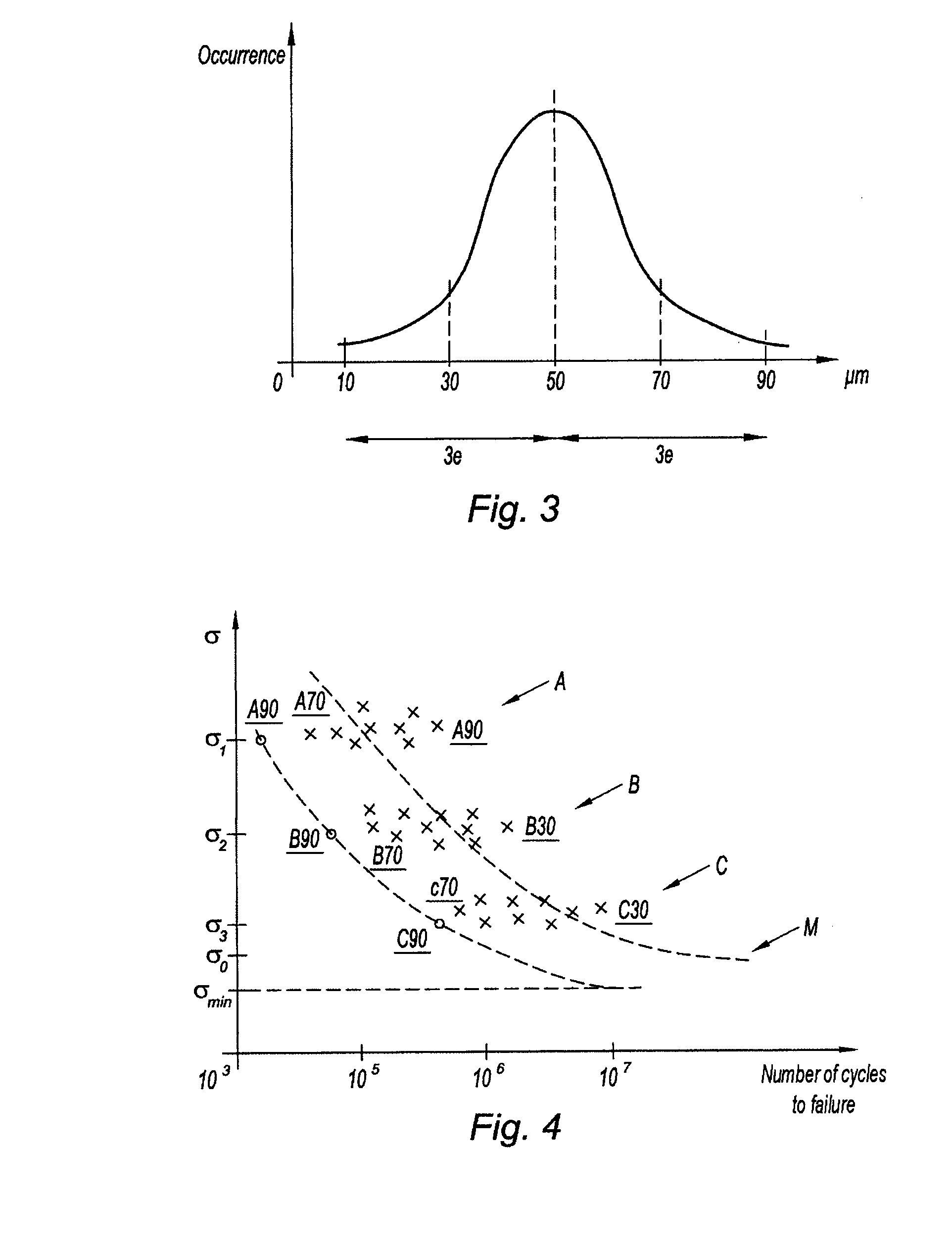

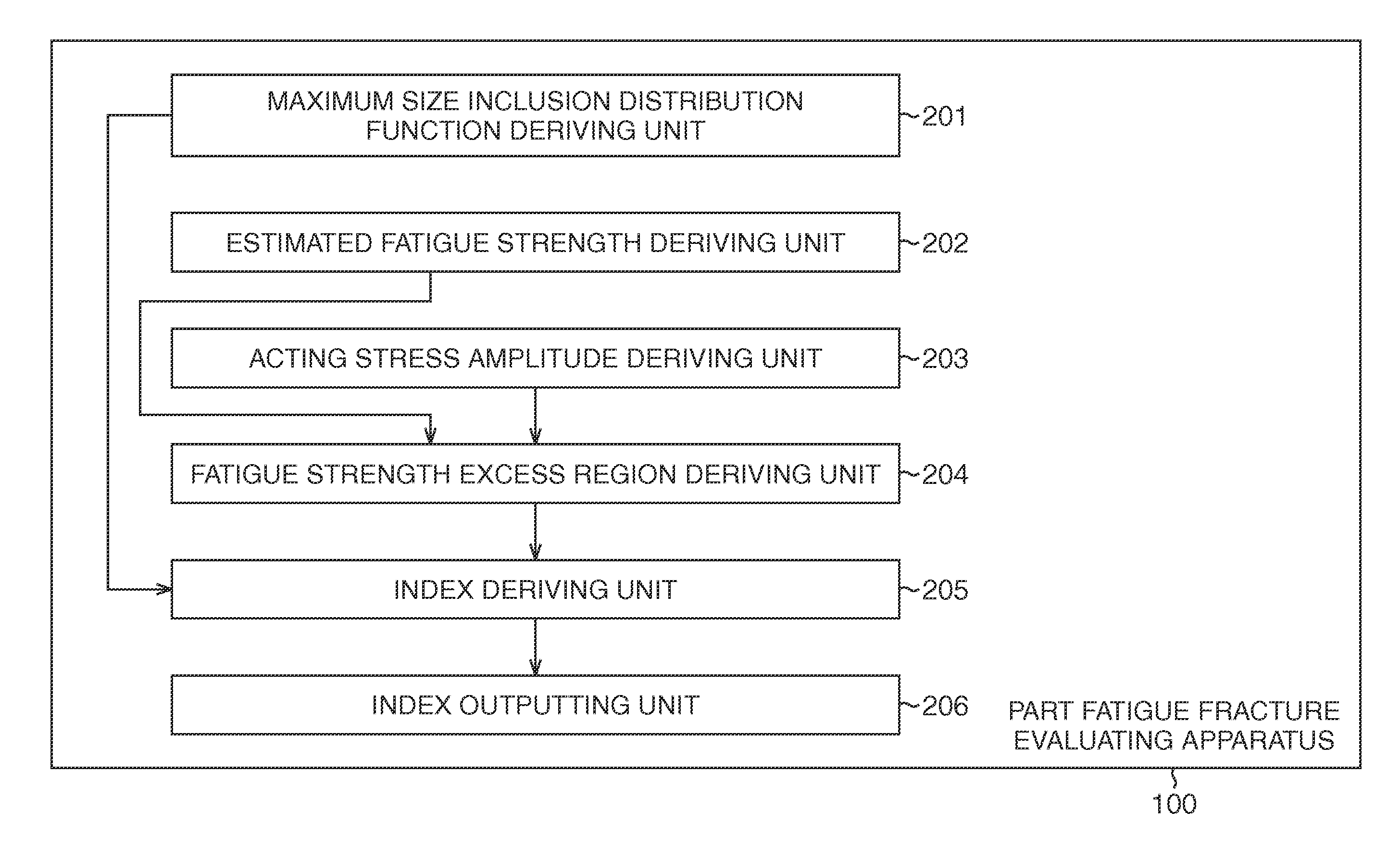

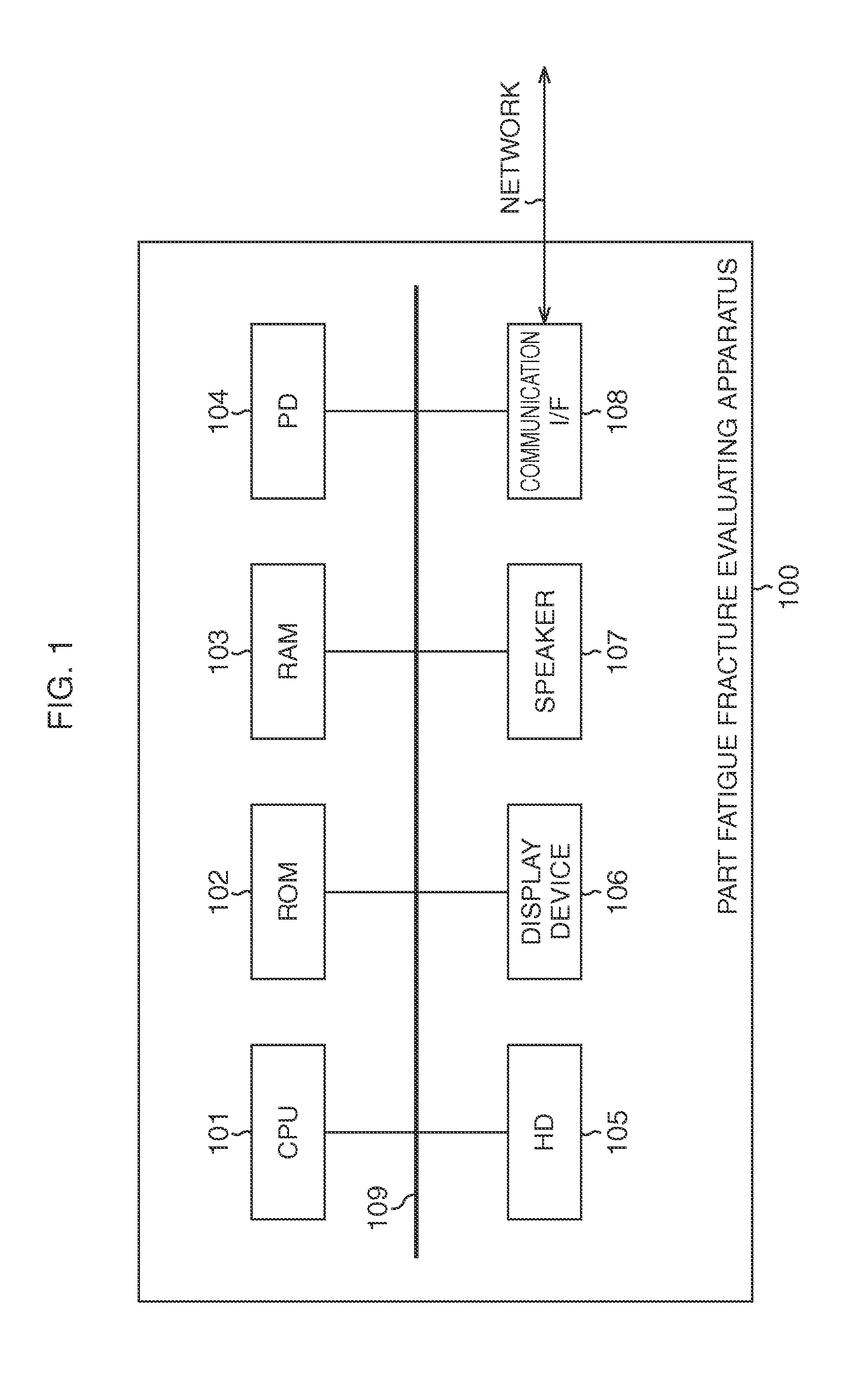

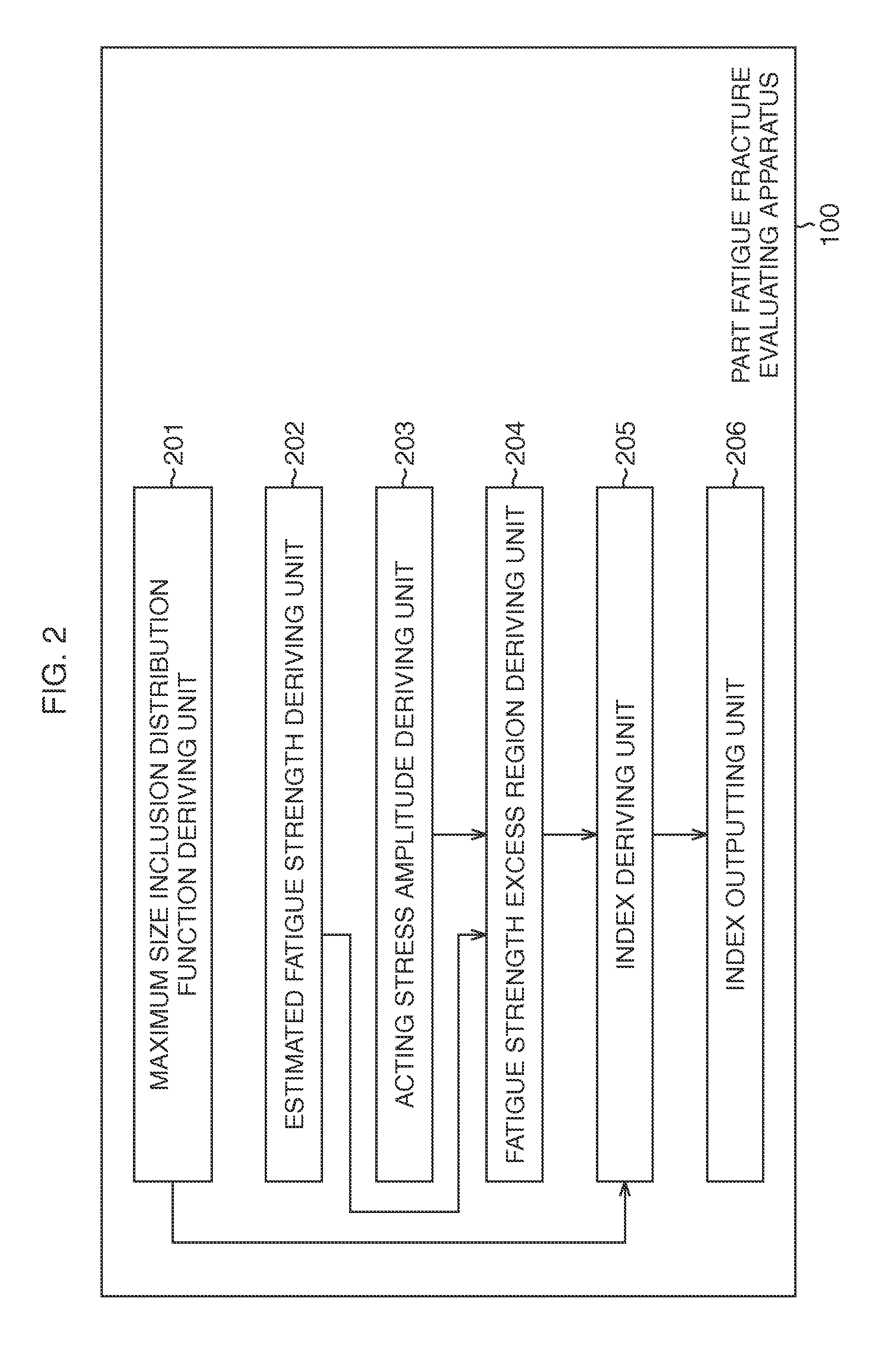

Part fatigue fracture evaluating apparatus, part fatigue fracture evaluating method, and computer program

InactiveUS20130298691A1Flow propertiesMaterial strength using repeated/pulsating forcesFatigue IntensityFatigue fractures

There is derived an index FS (P) obtained by integrating the product of a probability distribution function f (√{square root over ( )}areamax) of an inclusion size √{square root over ( )}areamax of a part and a “size S (P, √{square root over ( )}√{square root over ( )}areamax) of a region of the part” where a stress amplitude σ of an acting stress exceeds a stress amplitude σw of a fatigue strength at each location in the case of a load being applied under a loading condition P set previously by an operator over the inclusion size √{square root over ( )}√{square root over ( )}areamax of the part with the whole region of a range where a probability distribution of the inclusion size √{square root over ( )}areamax exists set as an integral range.

Owner:NIPPON STEEL CORP

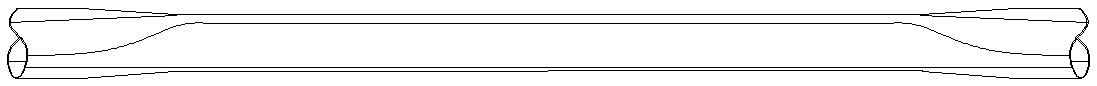

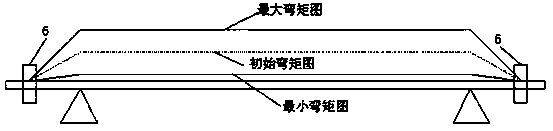

Device for testing bending fatigue of oil casing under complex load

ActiveCN103926154AReduce performance requirementsMaterial strength using steady bending forcesFatigue IntensityEngineering

The invention relates to a device for testing bending fatigue of an oil casing under a complex load. The conventional device has extremely high requirement on fatigue resistance of a test system, a sample often fails when not fatigued and existing bolts and other accessories of test equipment are fractured due to fatigue. The device for testing bending fatigue of the oil casing under the complex load comprises a loading part and a supporting part, wherein the loading part comprises a sample and two sample plugs positioned at two ends of the sample; the supporting part comprises two rubber supports positioned below the sample plugs; a bent loading weight is arranged at the end on the outer side of each sample plug. The device can simulate and evaluate fatigue strength of a drill stem under the rotating and bending action and also can simulate the strength and sealing reliability of the oil casing under the cyclic bending load action, an axial load can be applied to a pipe or a rotating shaft, and the bending fatigue life of a structural part in a complex stress state is simulated. Moreover, a sample is electromagnetically driven to rotate and bend, and the performance requirement of a test on a testing mechanical structure is met.

Owner:西安三维应力工程技术有限公司

Fatigue life prediction method and device based on weighted average maximum shear stress plane

ActiveCN111624116APredict fatigue lifePromote engineering applicationMachine part testingMaterial strength using steady shearing forcesFatigue damageFatigue Intensity

The invention provides a fatigue life prediction method and device based on a weighted average maximum shear stress plane. The method relates to the field of multi-axis fatigue strength theories, andcomprises the following steps: (1) synthesizing multi-axis variable-amplitude load processes into an equivalent stress process through a von Mises equivalent stress formula, and performing cyclic counting on the von Mises equivalent stress process through a Wang-Brown multi-axis cyclic counting method; (2) taking the proposed weighted average maximum shear stress plane as a critical plane under ahigh-cycle multi-axis variable-amplitude load; (3) calculating a fatigue damage parameter on the critical surface in each repeating by counting; (4) carrying out fatigue damage calculation by adoptinga Zhang-Shang model; and (5) accumulating damage calculated in each repeating by adopting a Miner linear accumulation rule, and finally calculating the fatigue life. The weight function proposed in the method can consider the main fatigue damage mechanism under multi-axis loading. The life prediction result shows that the life prediction method can better predict the fatigue life under multi-axisconstant amplitude and variable amplitude loading.

Owner:TSINGHUA UNIV +1

Cornu's spiral tooth gear

A Cornu's spiral is applied to a tooth profile of a gear. In accordance with the application of the gear, the Cornu's spiral may be modified two-dimensionally by some constant proportion. Since Cornu's spirals have similarity are similar, when a pressure angle is determined, the tooth profile can be standardized by a module, so that it is highly versatile.By replacing the tip of a tooth and the bottom of a tooth by another curve, such as an arc, the range of application can be increased. Since working is always by flank contact between a protrusion and a recess, contact surface stress is low. In addition, the radius of curvature of a dedendum is large. Therefore, tooth bending stress is low, and fatigue strength is high. Even if the number of teeth is small, an undercut is not produced. Even if there is no backlash, a smooth working is achieved, so that the tooth profile is suitable for devices requiring precise alignment.

Owner:MIYAOKU TSUTOMU +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com