Thermal treatment method for high-strength thermal formation torsion beam of automobile

A heat treatment method and thermoforming technology, applied in the field of heat treatment, can solve the problems of low fatigue strength and achieve the effects of improving product performance, eliminating stress and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

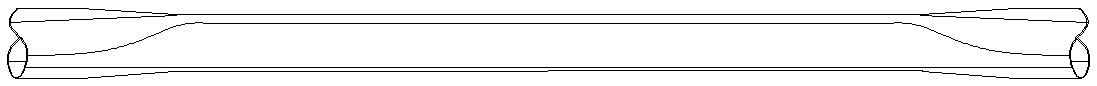

Image

Examples

Embodiment 1

[0042] The present invention is a heat treatment method for high-strength thermoformed torsion beams for automobiles. The material of the high-strength thermoformed torsion beams shown is BR1500HS, and the steps are as follows:

[0043] A: Preprocessing

[0044] Put the high-strength thermoformed torsion beam into the preheating furnace after stamping, use tooling to place the high-strength thermoformed torsion beam vertically, raise the temperature to 500°C at a speed of 10°C / min, and inject nitrogen at a rate of 1m³ / h , so that the furnace is a non-oxidizing atmosphere, keep warm for 100min;

[0045] B: carburizing treatment

[0046] Transfer the high-strength thermoformed torsion beam pretreated in step A to the carburizing furnace, use tooling to place the pipe vertically, and process it in three stages:

[0047] (1) Stage 1: heat up to 885°C at a rate of 10°C / min, and feed N at 4m³ / h 2 , drop methanol CH3OH at 3.5L / h, feed propane C3H8 gas at 0.6m³ / h, make the mass per...

Embodiment 2

[0068] The present invention is a heat treatment method for high-strength thermoformed torsion beams for automobiles. The material of the high-strength thermoformed torsion beams shown is BR1500HS, and the steps are as follows:

[0069] A: Preprocessing

[0070] Put the high-strength thermoformed torsion beam into the preheating furnace after stamping, use tooling to place the high-strength thermoformed torsion beam vertically, raise the temperature to 520°C at a speed of 10°C / min, and inject nitrogen at a rate of 1m³ / h , so that the furnace is a non-oxidizing atmosphere, keep warm for 120min;

[0071] B: carburizing treatment

[0072] Transfer the high-strength thermoformed torsion beam pretreated in step A to the carburizing furnace, and process it in three stages:

[0073] (1) Stage 1: heat up to 900°C at a rate of 10°C / min, and feed N at 4m³ / h 2 , drop methanol CH3OH at 3.5L / h, feed propane C3H8 gas at 0.6m³ / h, make the mass percentage of C in the non-oxidizing atmosphe...

Embodiment 3

[0094] The present invention is 1. a heat treatment method of a high-strength thermoformed torsion beam for automobiles, the material of the high-intensity thermoformed torsion beam shown is BR1500HS, and its steps are as follows:

[0095] A: Preprocessing

[0096] Put the high-strength thermoformed torsion beam into the preheating furnace after stamping, use tooling to place the high-strength thermoformed torsion beam vertically, raise the temperature to 540°C at a speed of 10°C / min, and inject nitrogen at a rate of 1m³ / h , so that the furnace is a non-oxidizing atmosphere, keep warm for 140min;

[0097] B: carburizing treatment

[0098] Transfer the high-strength thermoformed torsion beam pretreated in step A to the carburizing furnace, and process it in three stages:

[0099] (1) Stage 1: heat up to 895°C at a rate of 10°C / min, and feed N at 4m³ / h 2 , drop methanol CH3OH at 3.5L / h, feed propane C3H8 gas at 0.6m³ / h, make the mass percentage of C in the non-oxidizing atmos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com