Cold-heat circulation aging treatment method for increasing magnetic stability of permanent magnets

A technology of cooling and heating cycle and aging treatment, applied in the direction of permanent magnet, inductor/transformer/magnet manufacturing, electrical components, etc., can solve insufficient problems, achieve convenient operation, improve radiation resistance magnetic stability, and improve magnetic stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

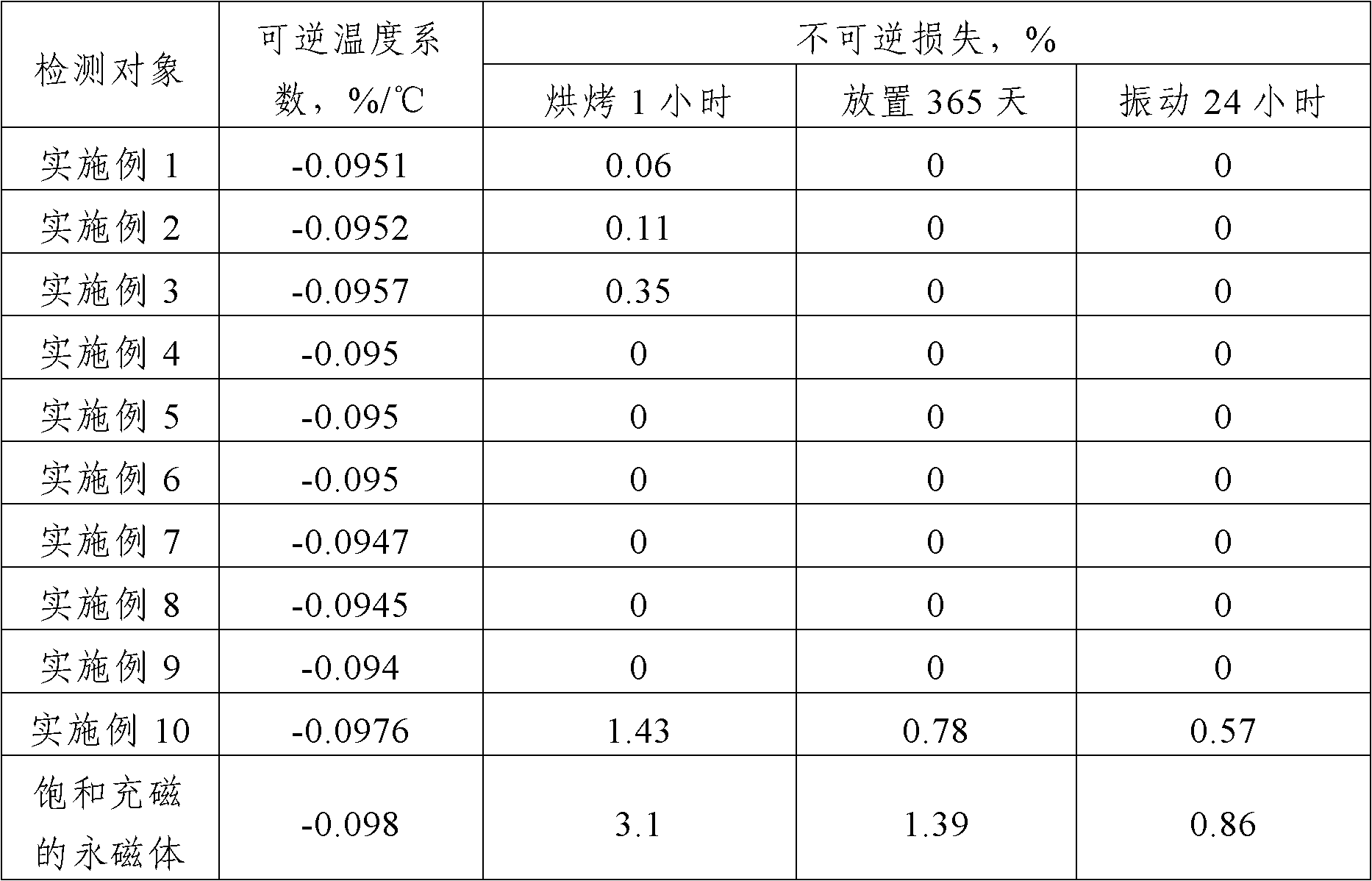

Embodiment 1

[0025] Aging treatment of N35SH permanent magnets with a temperature of -60°C to 140°C:

[0026] Saturation magnetize 50 D4mm×20mm axially magnetized iron-boron N35SH permanent magnets, place the saturated magnets on a non-magnetic copper, aluminum or austenitic stainless steel bottom plate, and keep two adjacent The interval between the permanent magnets is 5 times the length of the magnetization direction of the permanent magnets, and the specific interval is 100mm. Then put the permanent magnets and the non-magnetic bottom plate together in a high and low temperature box, and freeze them at -70°C for 60 minutes. Then heat the temperature of the high and low temperature box to 150°C at a heating rate of 5°C / min, keep it warm for 60 minutes, and finally cool down to room temperature naturally, complete a cooling and heating cycle aging treatment, and take out the permanent magnet.

Embodiment 2

[0028] Aging treatment of N35EH permanent magnets at temperatures between -60°C and 200°C:

[0029] Saturation magnetize 20 cylindrical NdFeB N35EH permanent magnets magnetized along the diameter direction of D4mm×20mm, place the saturated magnetization on a non-magnetic copper, aluminum or austenitic stainless steel bottom plate, and keep The interval between two adjacent permanent magnets is 10 times the length of the magnetization direction of the permanent magnets, and the specific interval is 200mm. Then put the permanent magnets and the non-magnetic bottom plate into the high and low temperature box together, under the condition of -60℃ Freeze for 30 minutes, then heat the temperature of the high and low temperature box to 250 ° C at a temperature increase rate of 10 ° C / min and keep it warm for 30 minutes. gas) so that the mass concentration of oxygen in the high and low temperature box is not higher than 2%, and finally naturally cool to room temperature, complete a ...

Embodiment 3

[0031] Aging treatment of N35 permanent magnets with a temperature of -10°C to 50°C:

[0032] Saturation magnetize 15 cylindrical NdFeB N35 permanent magnets with L / D=0.7, place the saturated magnets on non-magnetic copper, aluminum or austenitic stainless steel bottom plate, and keep them adjacent The distance between the two permanent magnets is 8 times the length of the magnetization direction of the permanent magnets. Then put the permanent magnets and the non-magnetic bottom plate together in a high-low temperature box, and freeze them for 120 minutes at a temperature of -20°C. The heating rate of ℃ / min is to heat the temperature of the high and low temperature box to 60 ℃, and keep it warm for 240 minutes. Thermal cycle aging treatment, take out the permanent magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com