Patents

Literature

45 results about "Titanium aluminium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium aluminium nitride (TiAlN) or aluminium titanium nitride (AlTiN; for aluminium contents higher than 50%) stands for a group of metastable hard coatings consisting of nitrogen and the metallic elements aluminium and titanium.

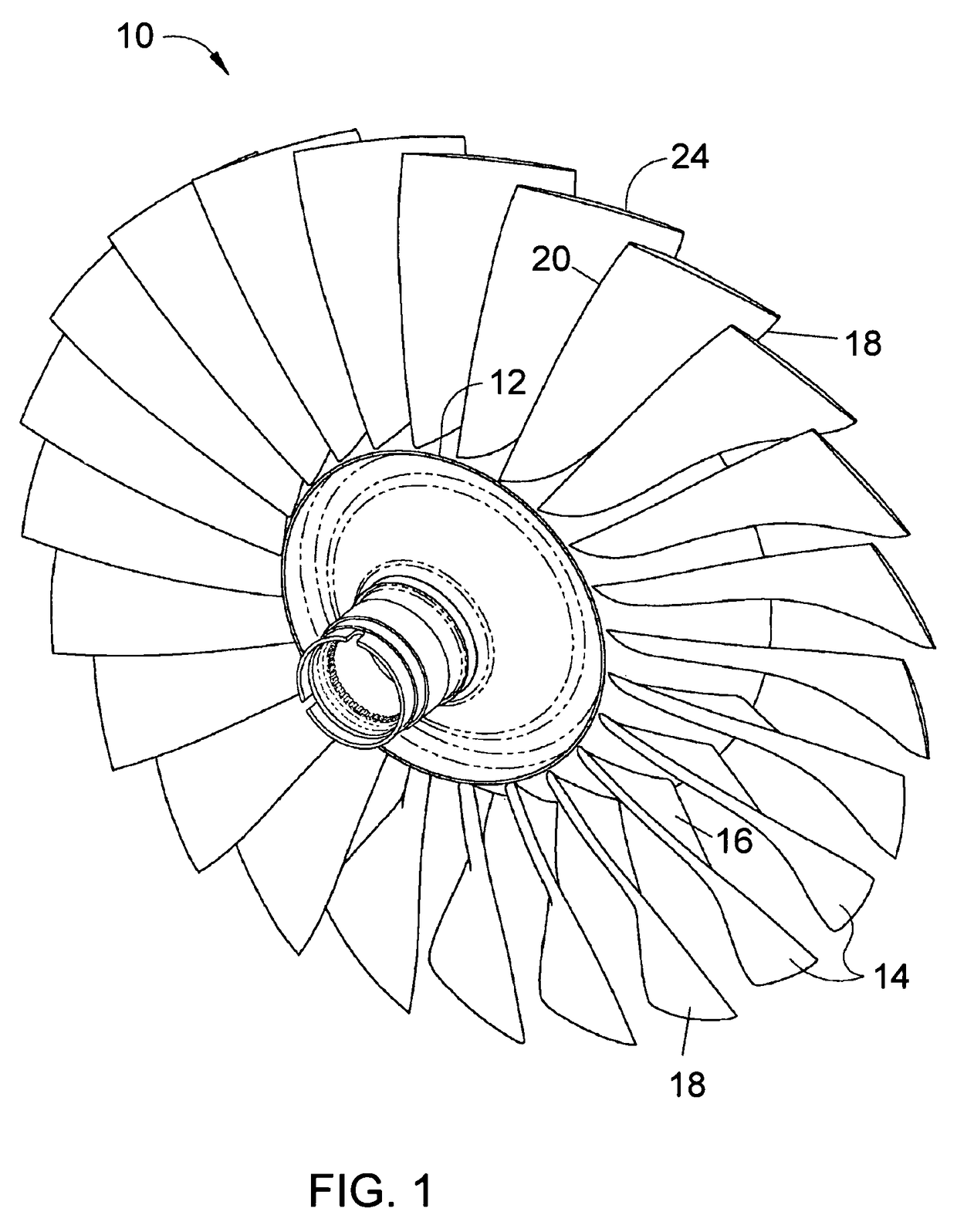

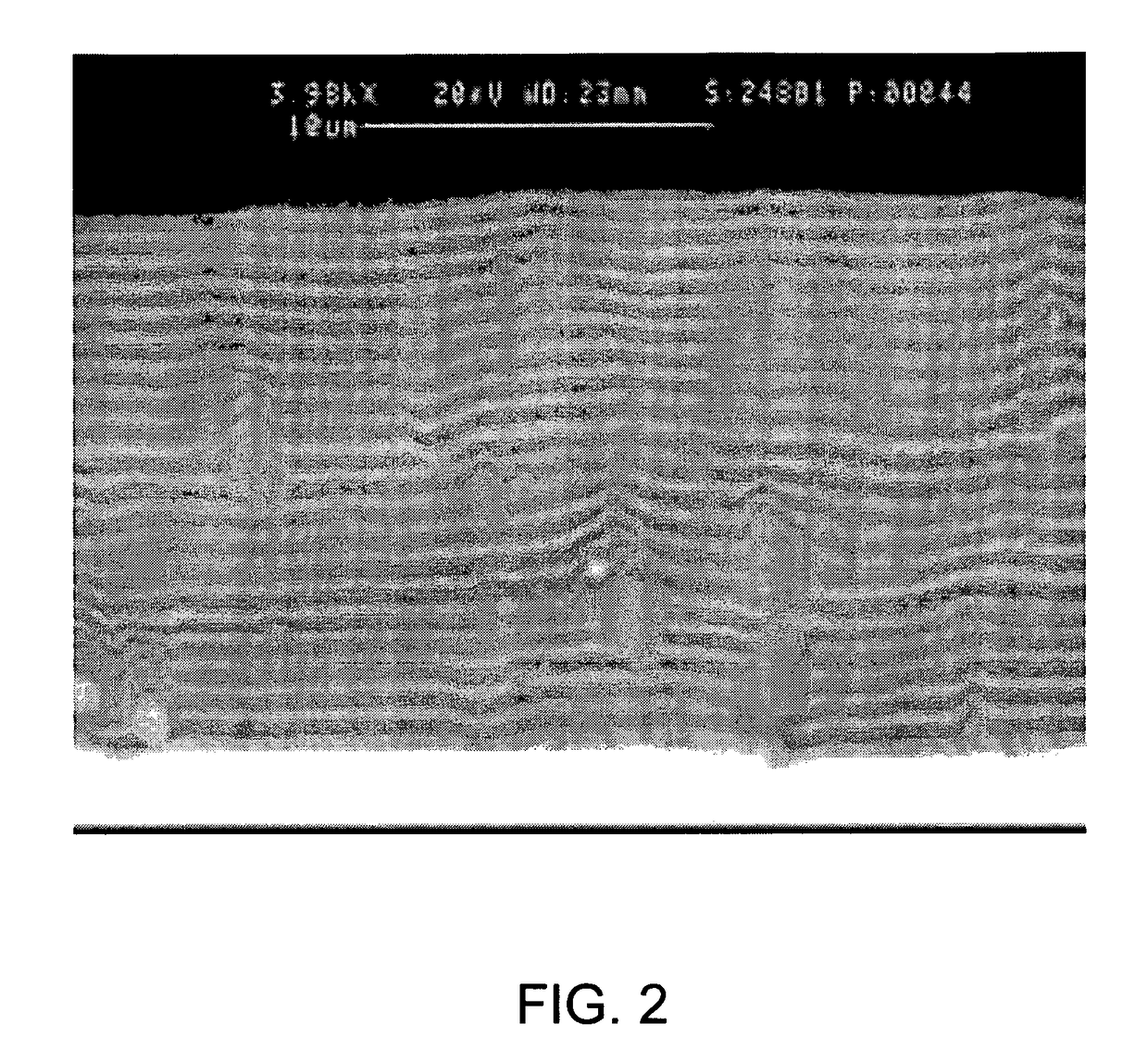

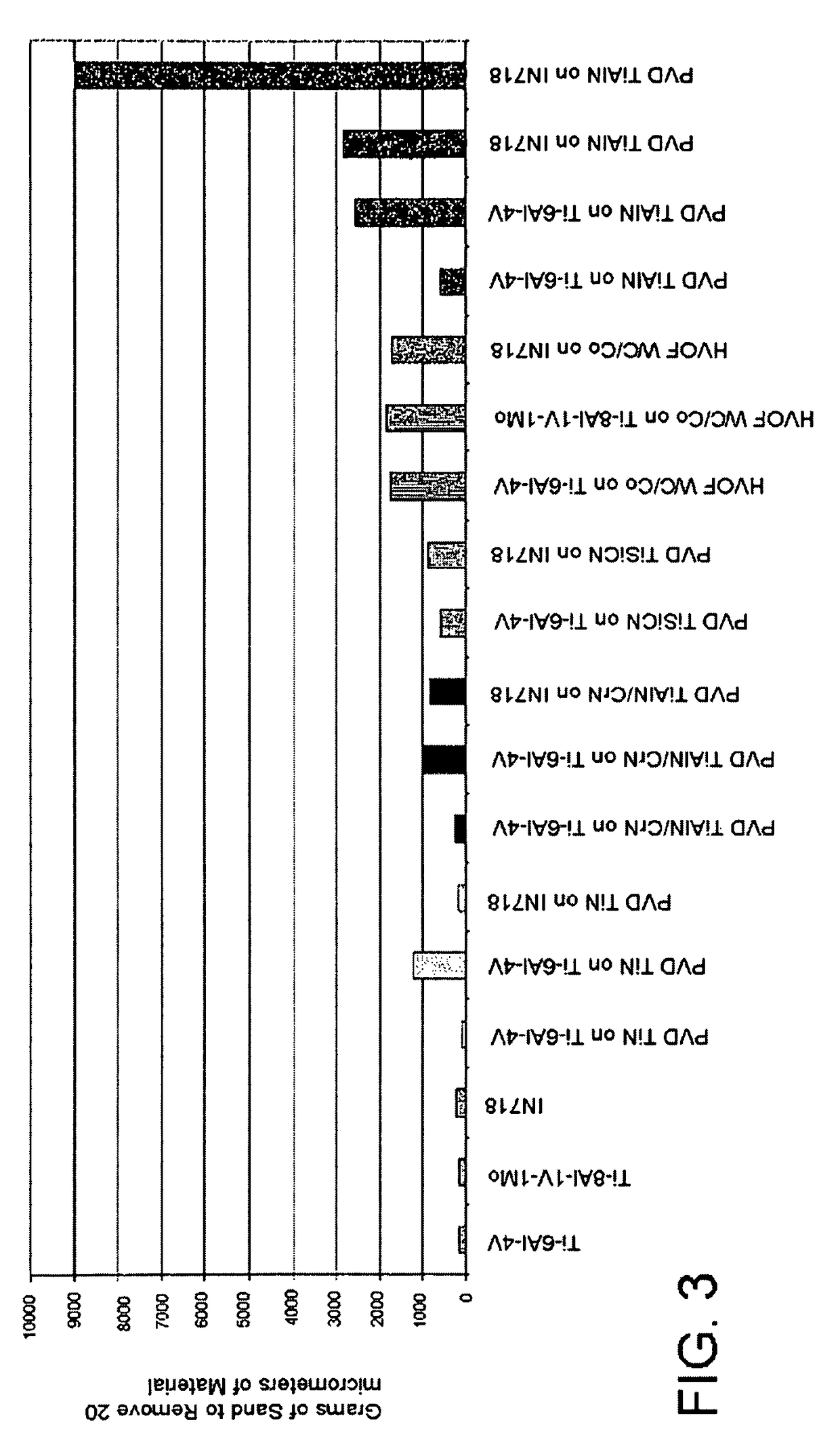

Erosion- and impact-resistant coatings

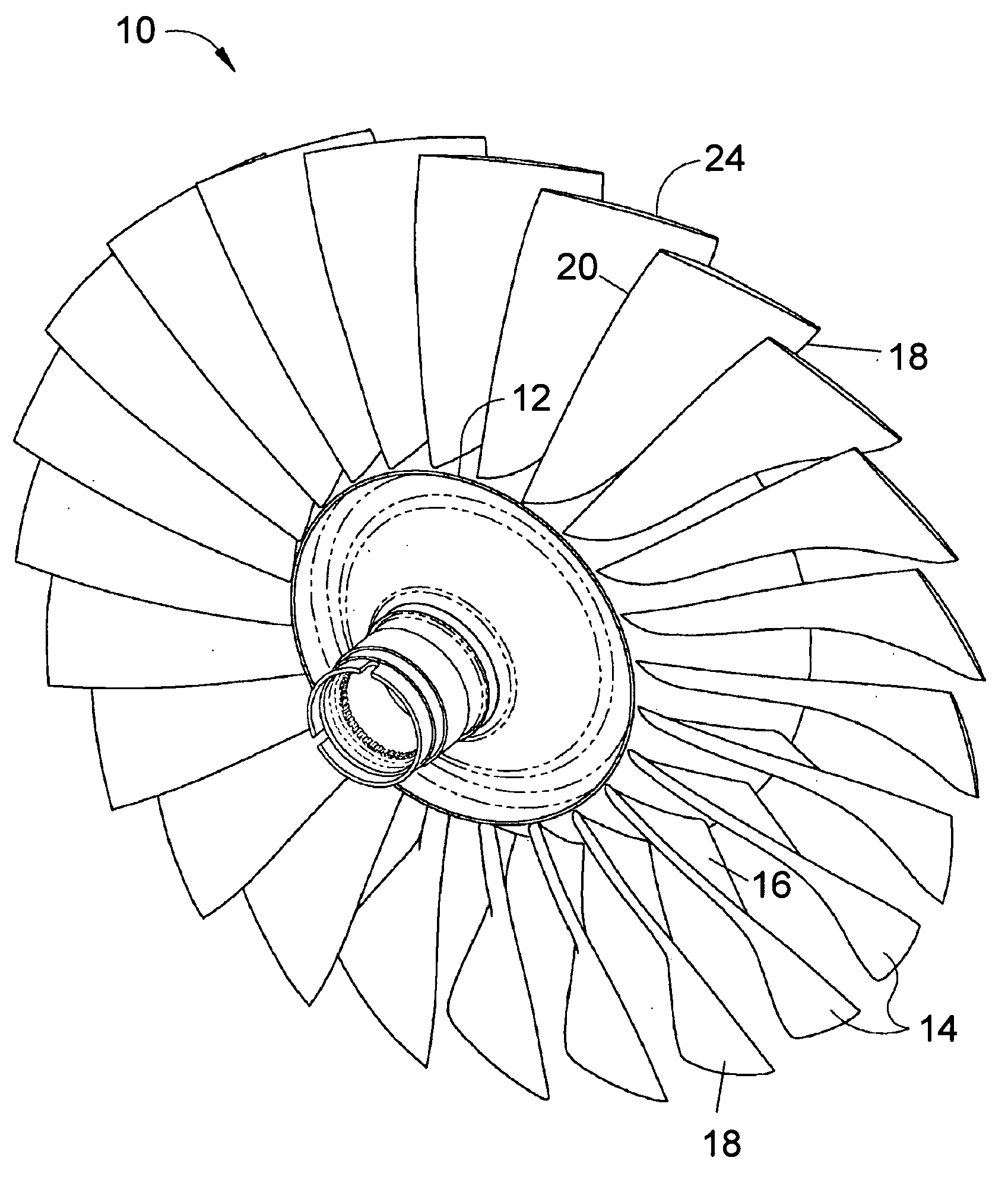

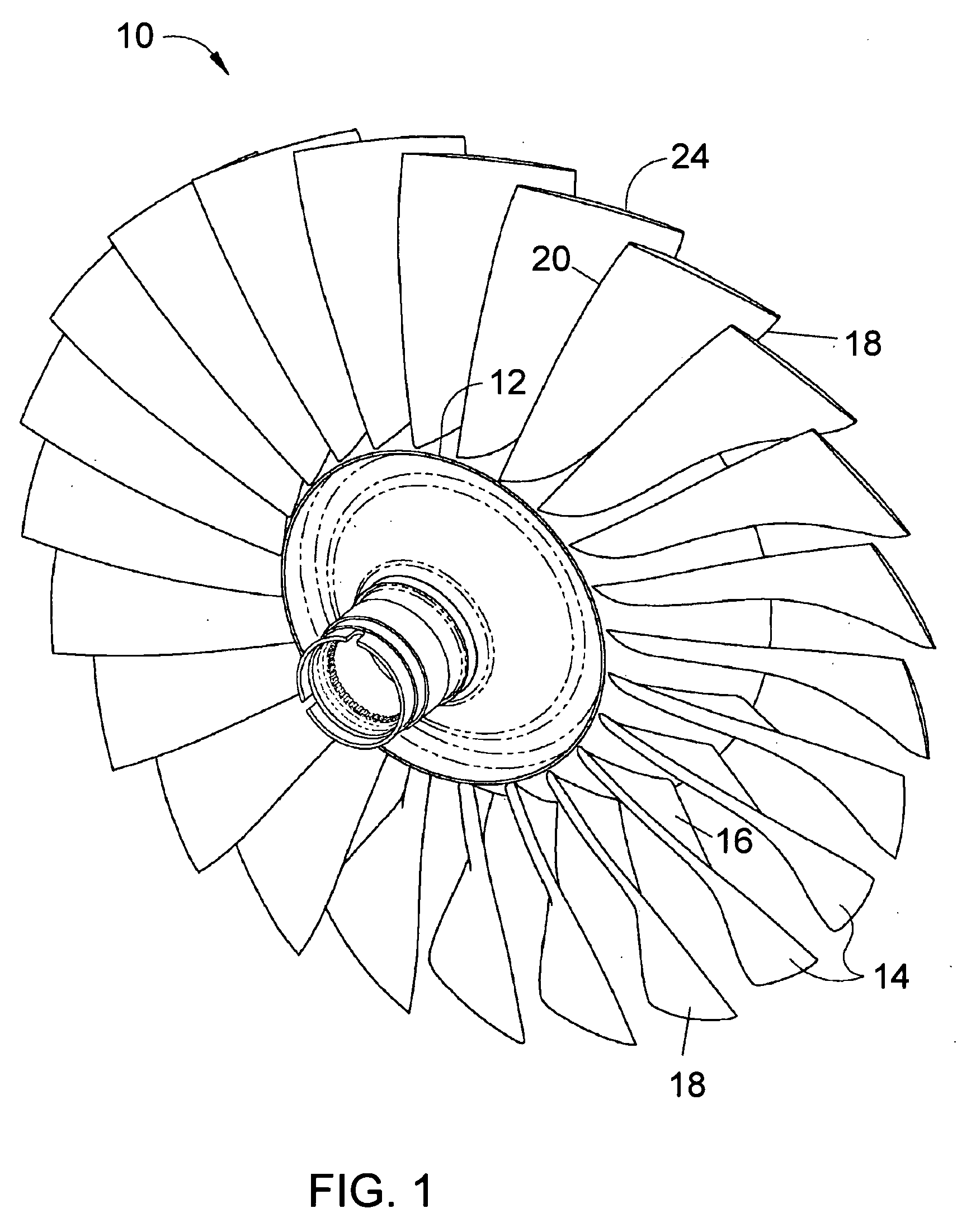

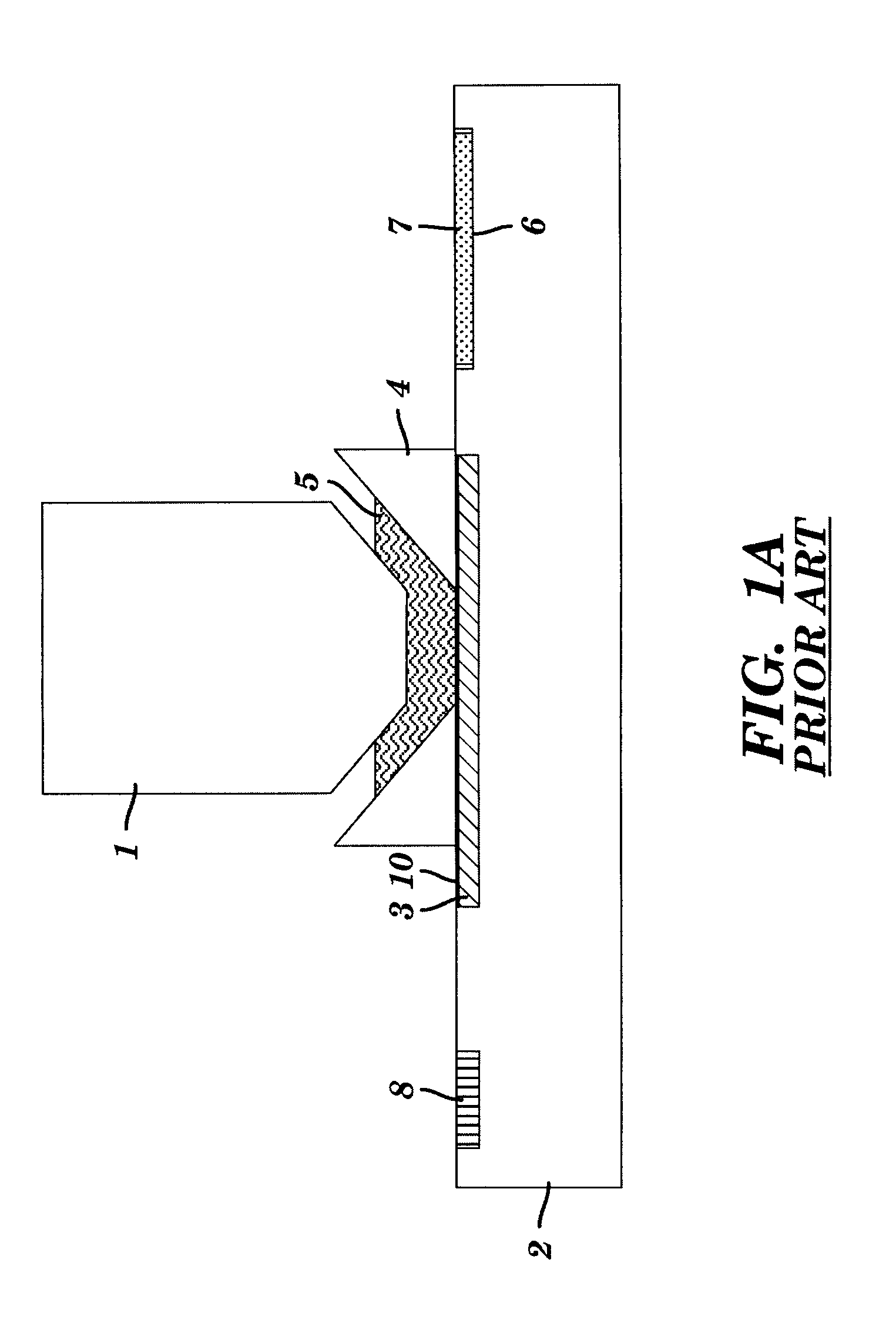

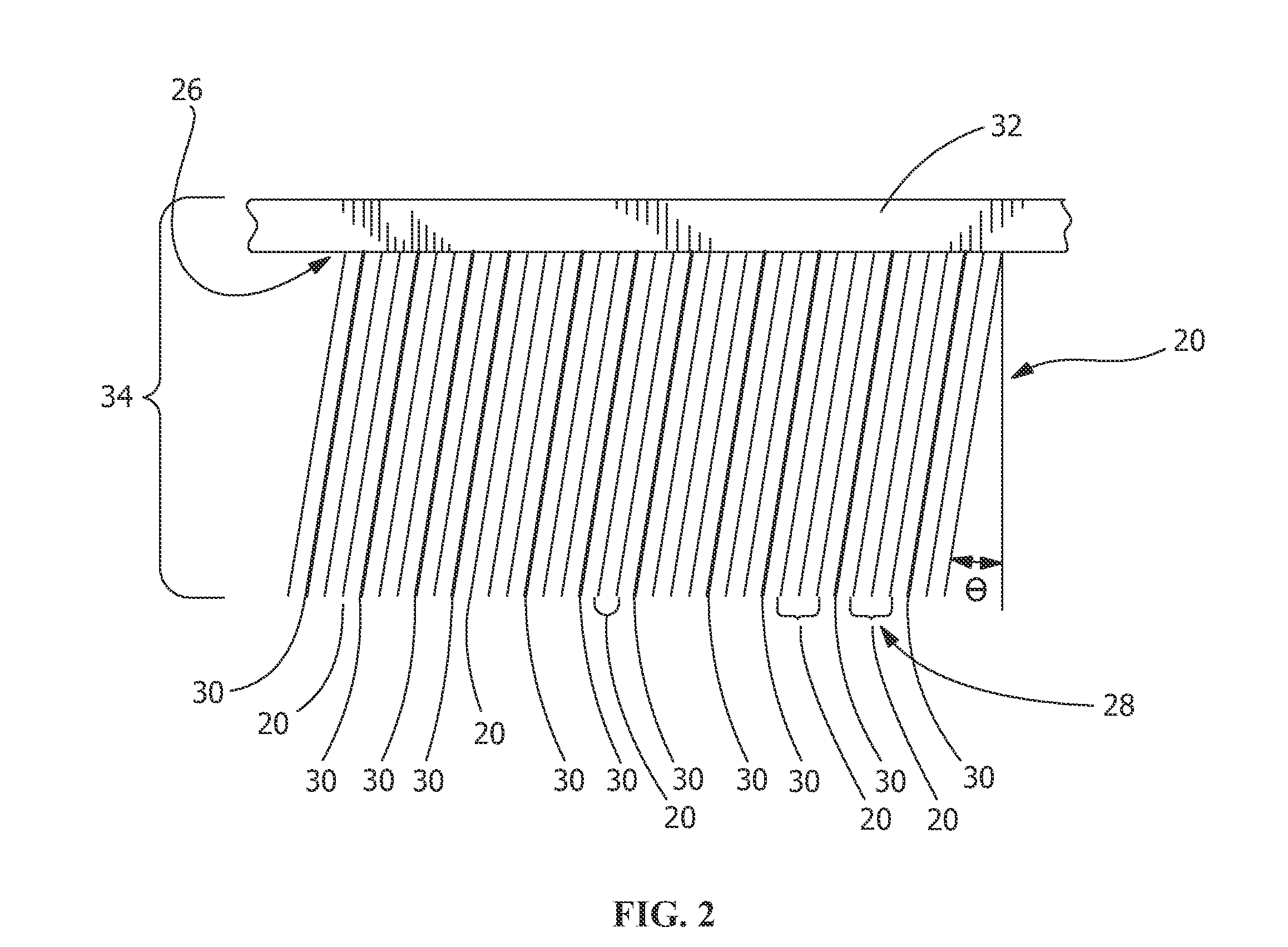

ActiveUS8118561B2Protect normal useSpecific fluid pumpsPropellersTitanium aluminium nitrideCeramic coating

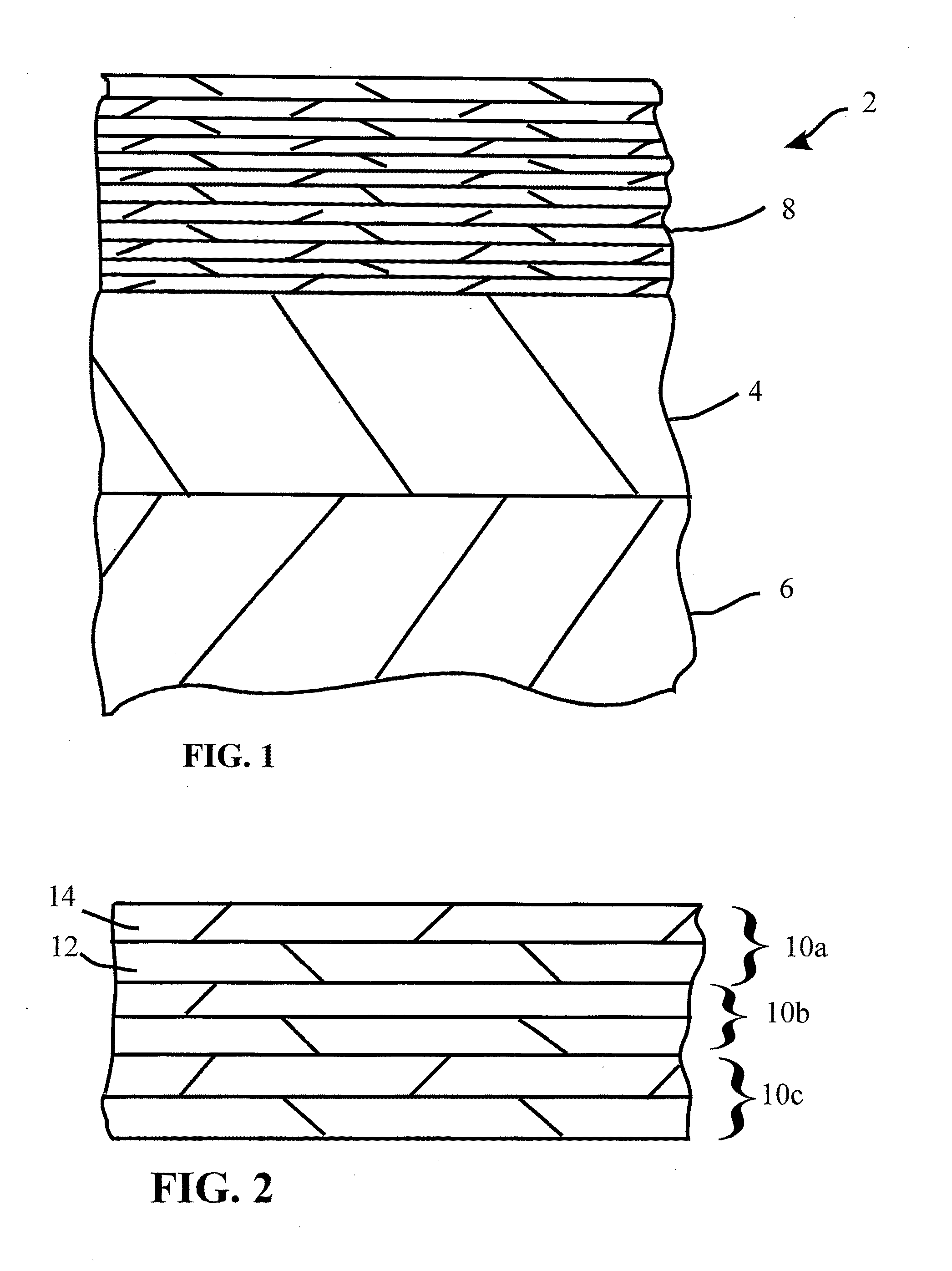

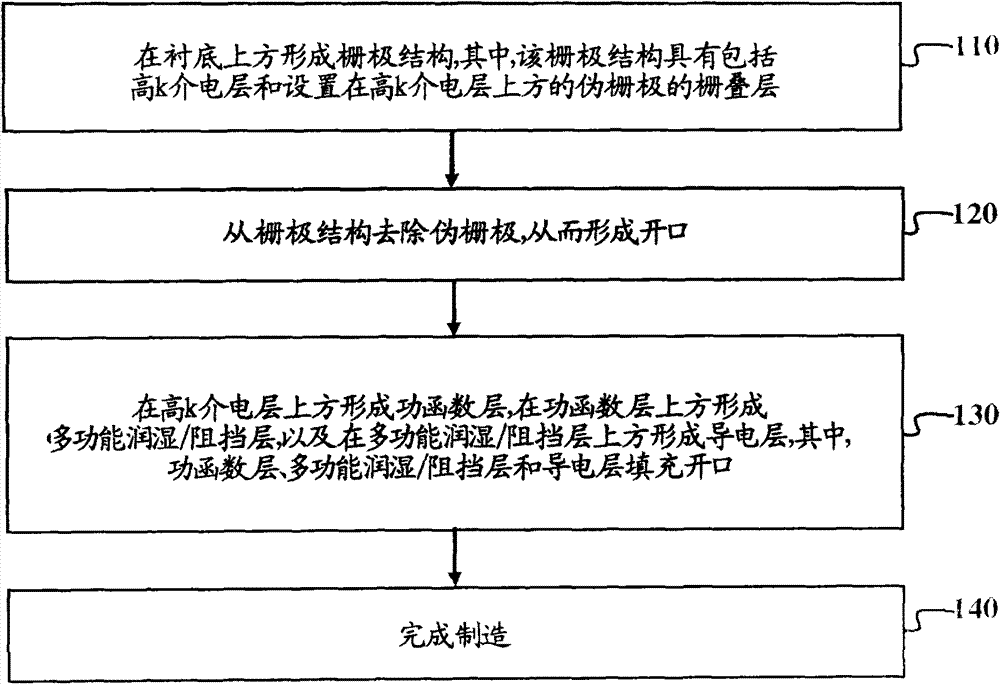

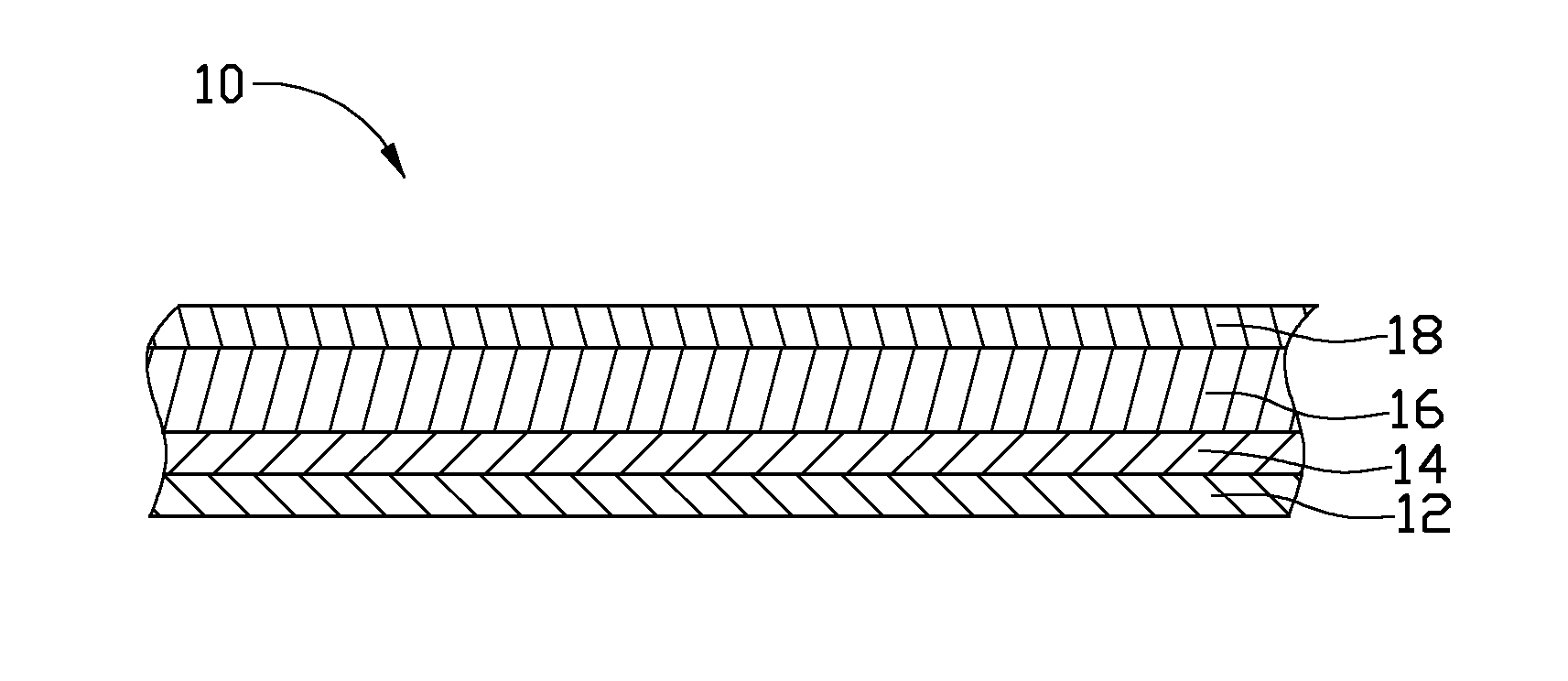

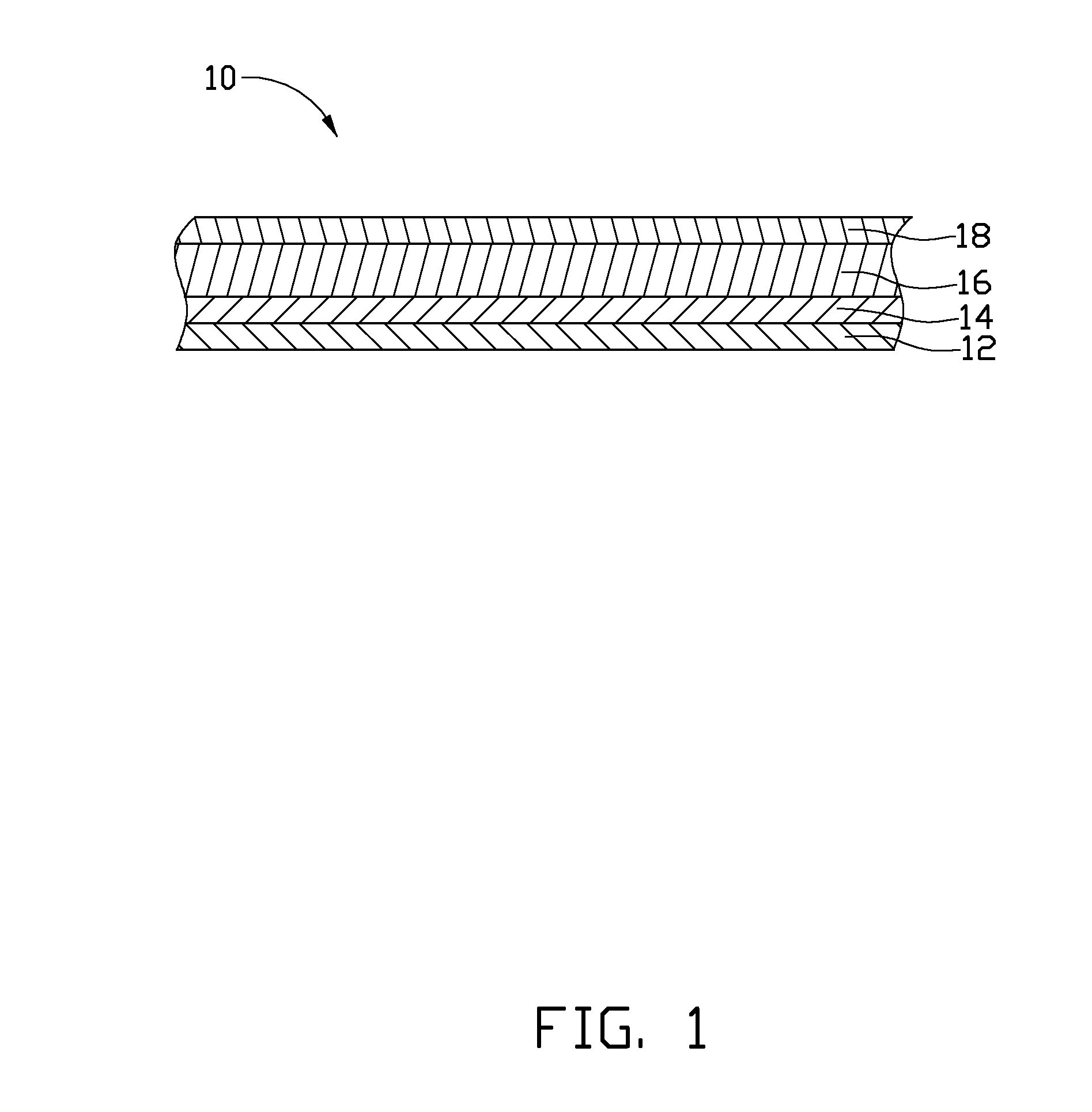

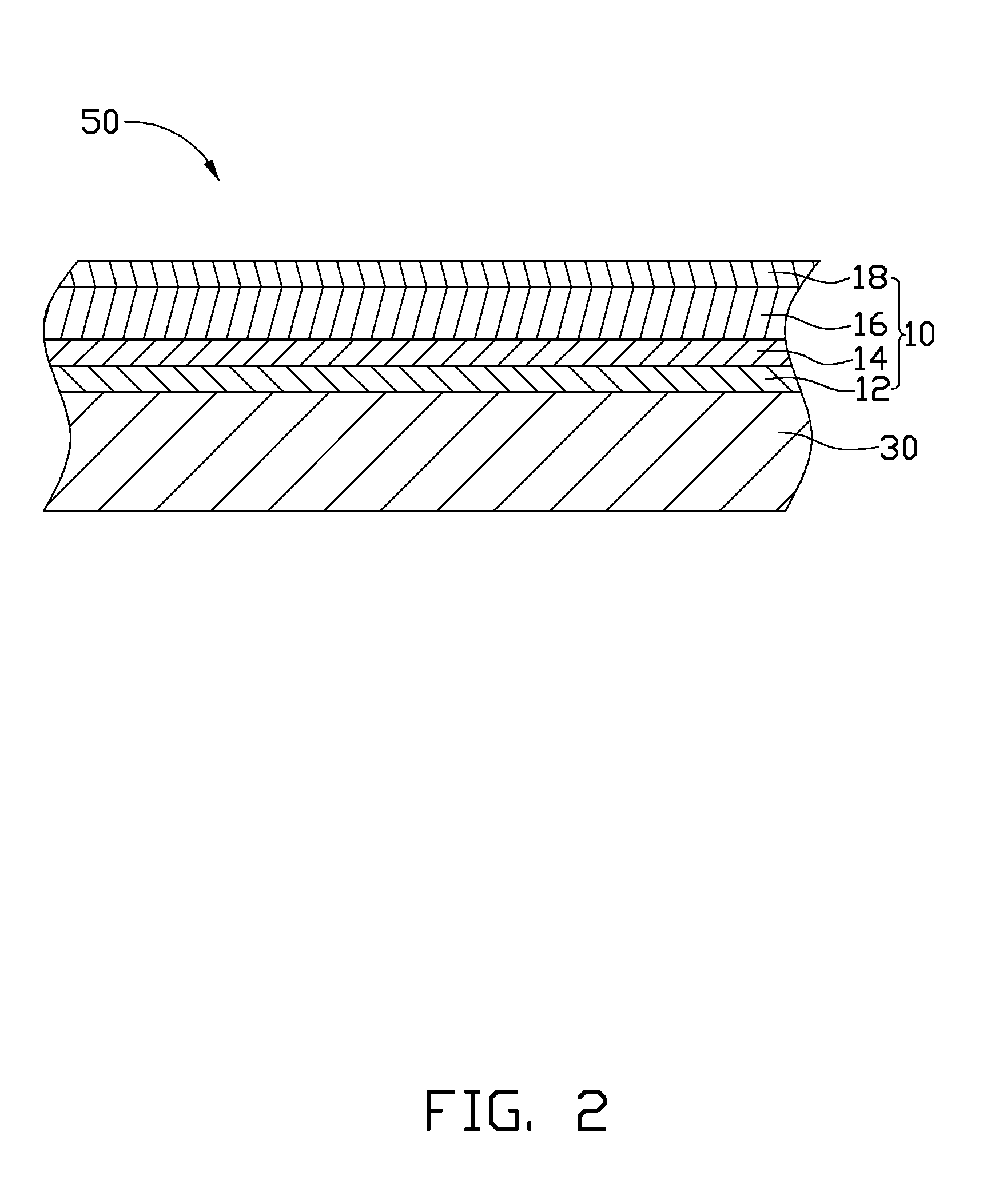

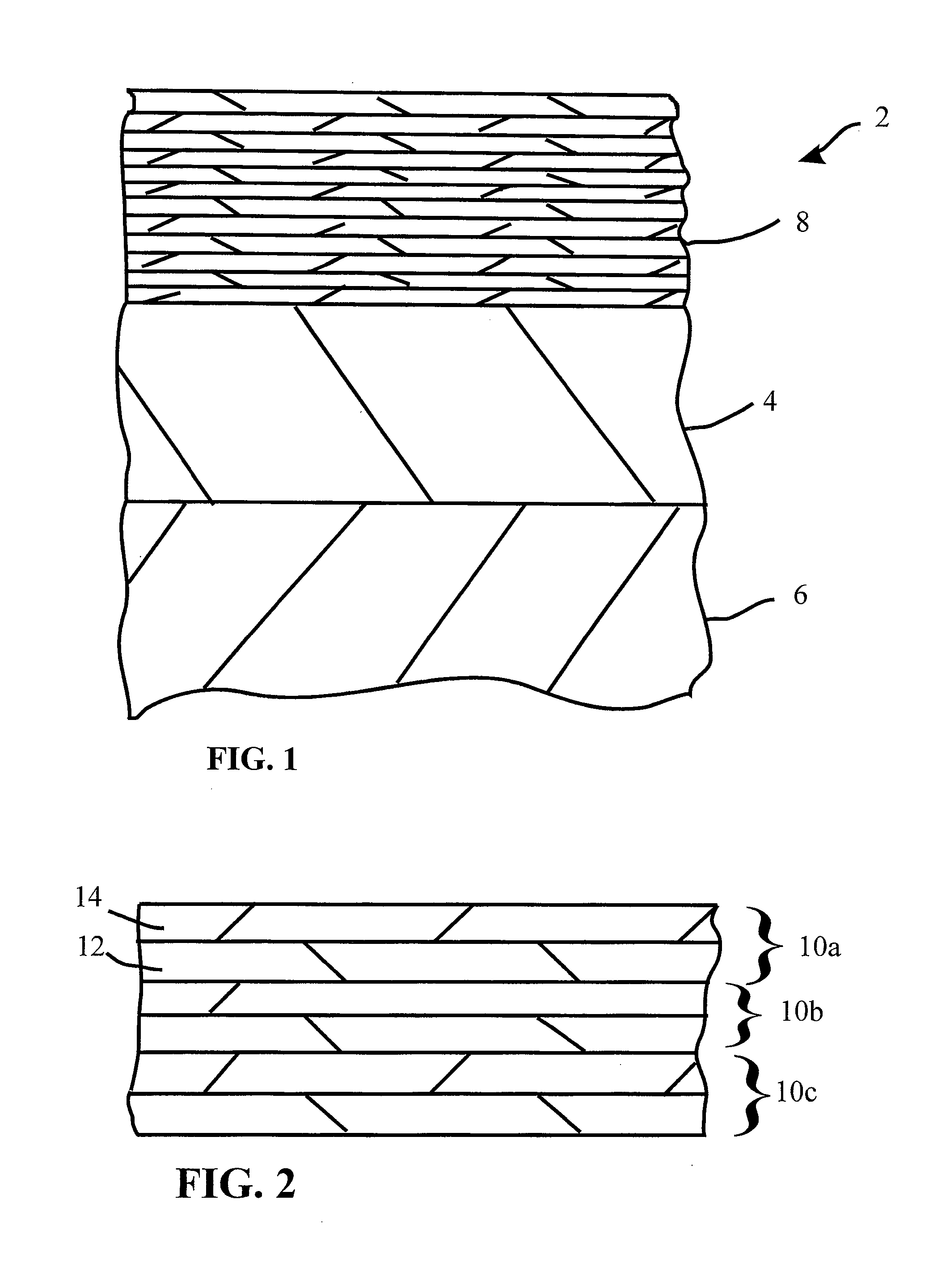

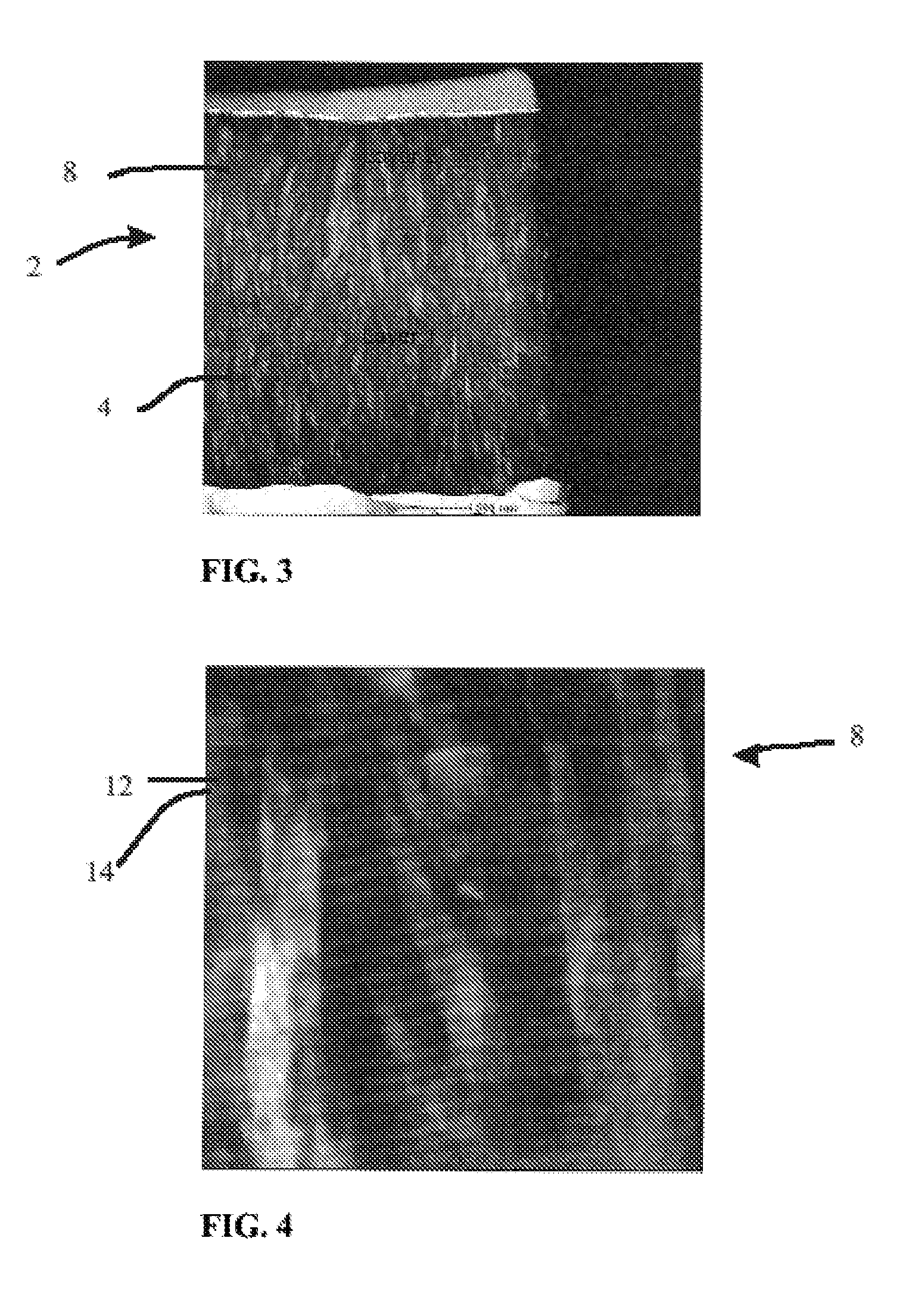

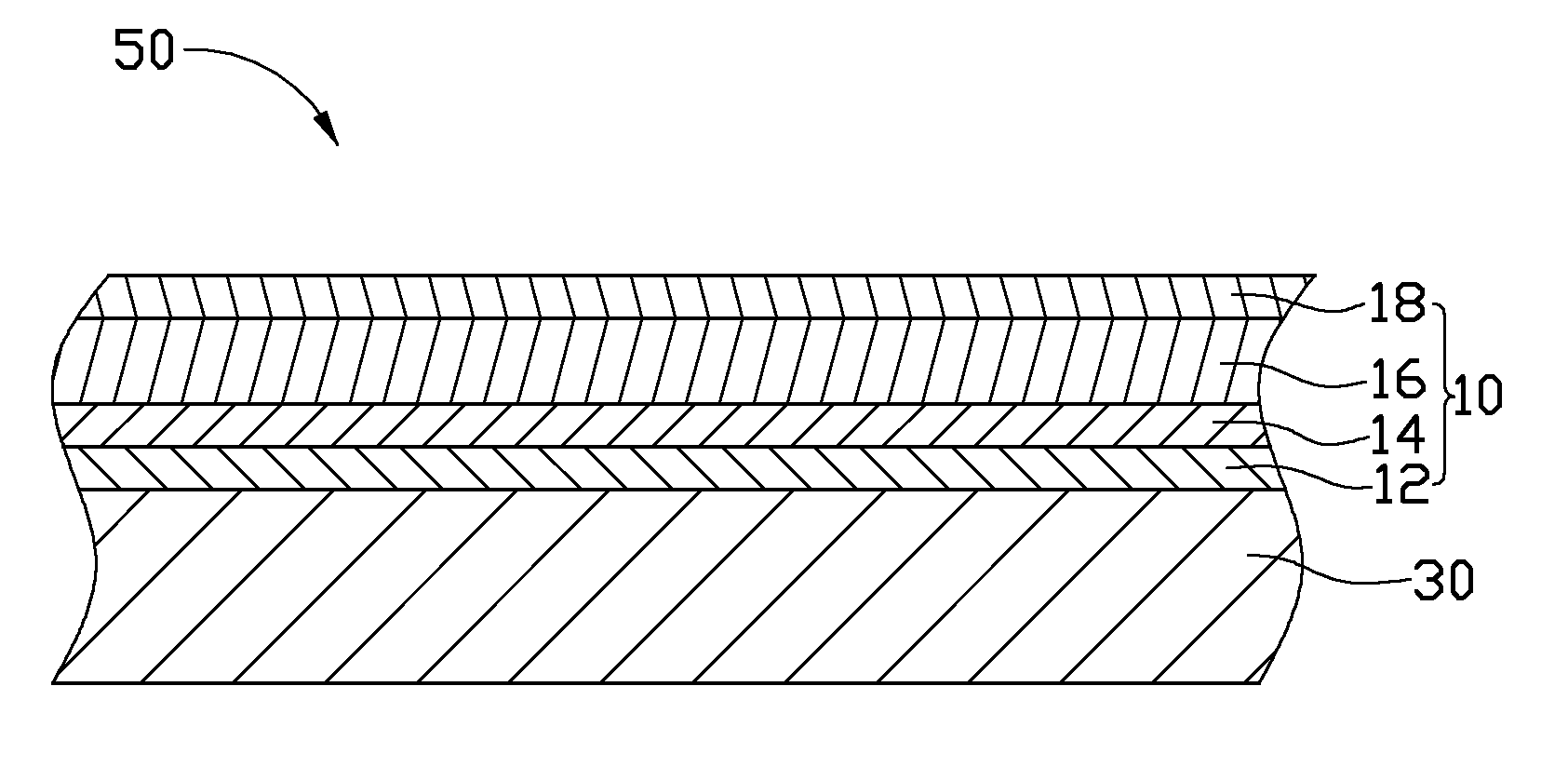

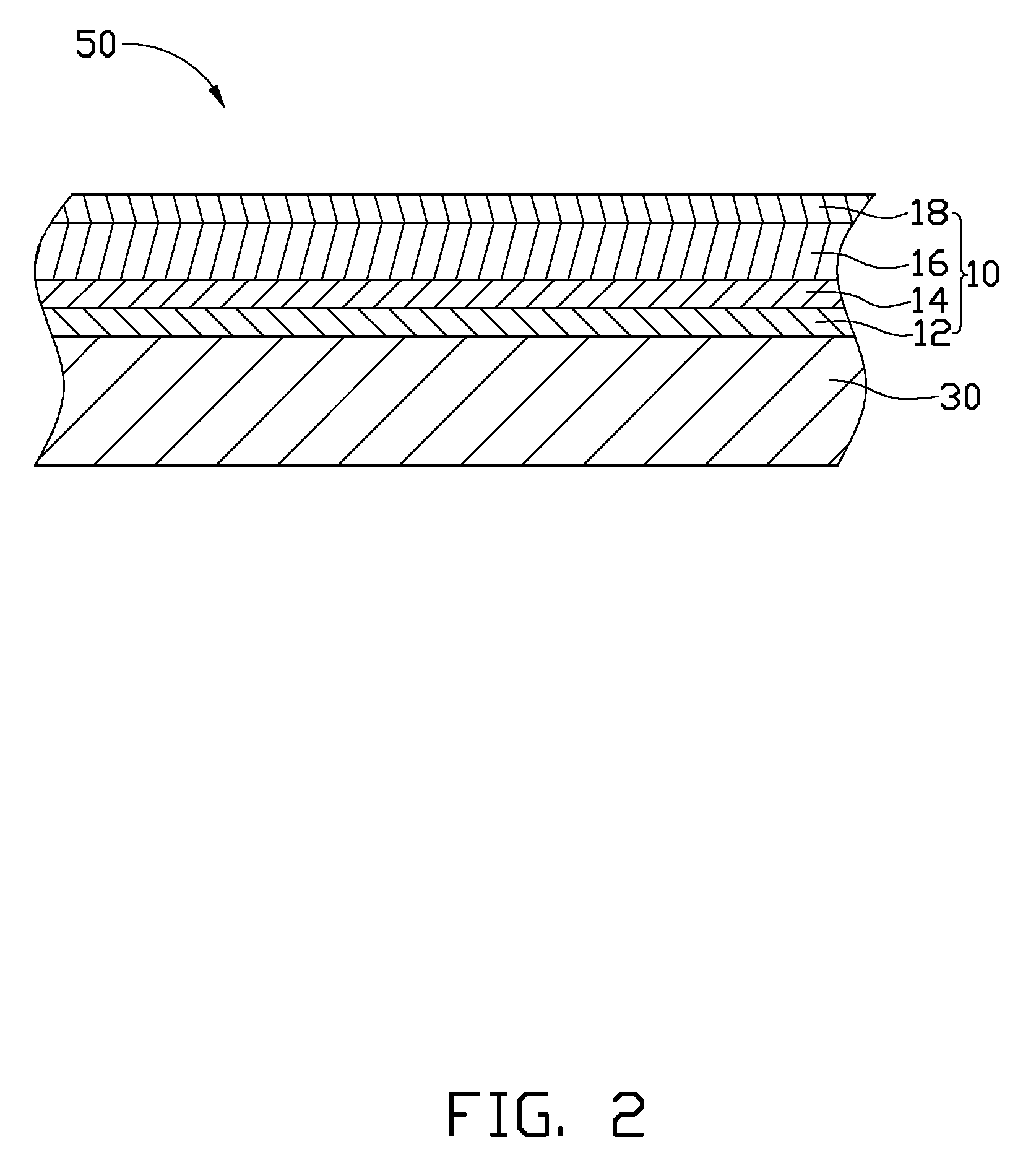

Erosion- and impact-resistant ceramic coatings suitable for protecting surfaces subjected to collisions with particles, including nominally round particles that typically inflict impact damage and more aggressive irregular-shaped particles that typically inflict erosion damage. The ceramic coating is formed to have one of three compositions: at least one layer of titanium aluminum nitride (TiAlN) having a thickness of about 25 to about 100 micrometers; multiple layers of chromium nitride (CrN) and TiAlN, each layer having a thickness of about 0.2 to about 1.0 micrometers to yield a total coating thickness of at least about 3 micrometers; and at least one layer of titanium silicon carbonitride (TiSiCN) having a thickness of about 15 to about 100 micrometers. The ceramic coating preferably has a total coating thickness of up to about 100 micrometers, and is deposited by a physical vapor deposition process to have a columnar and / or dense microstructure.

Owner:GENERAL ELECTRIC CO

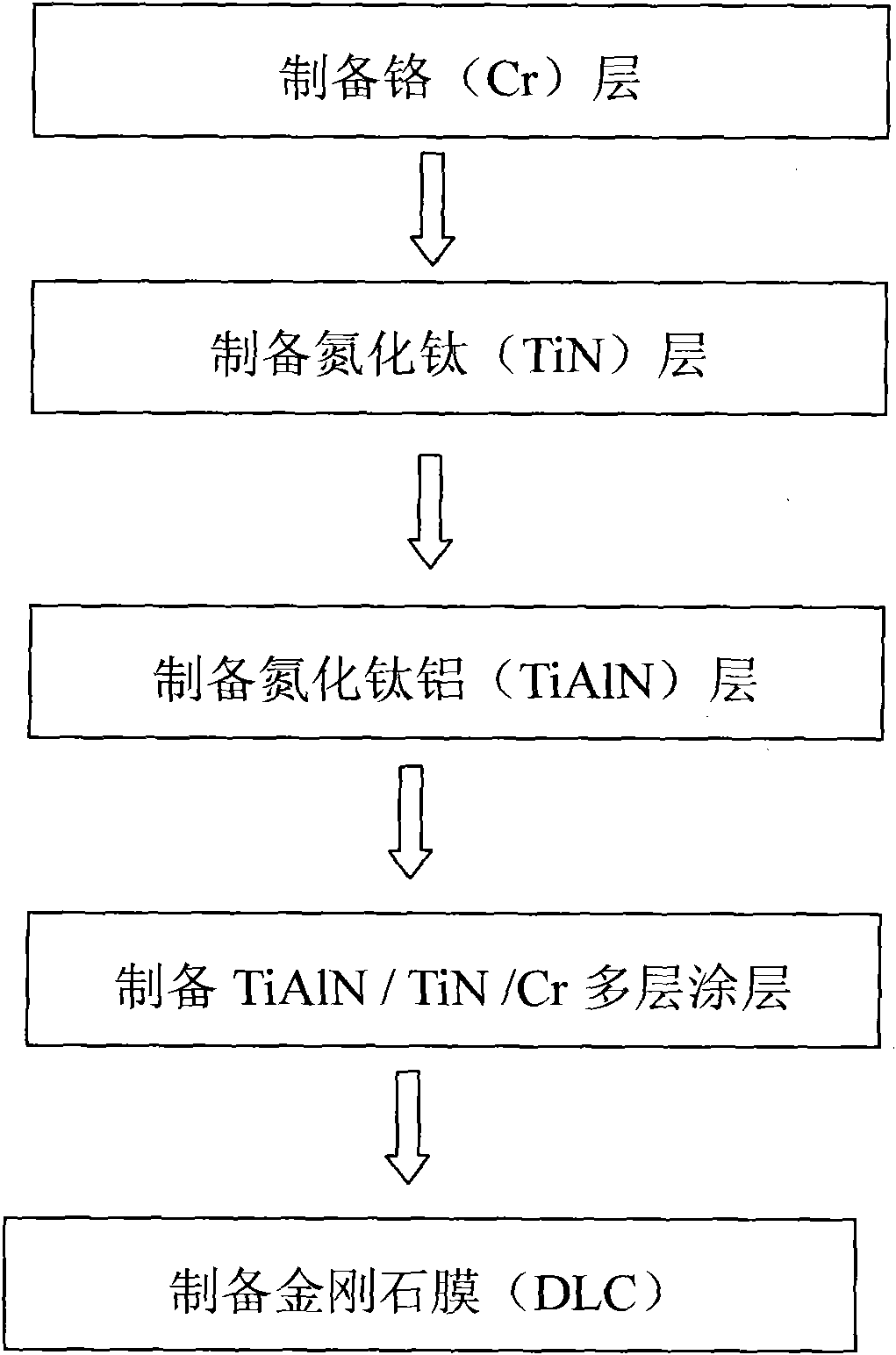

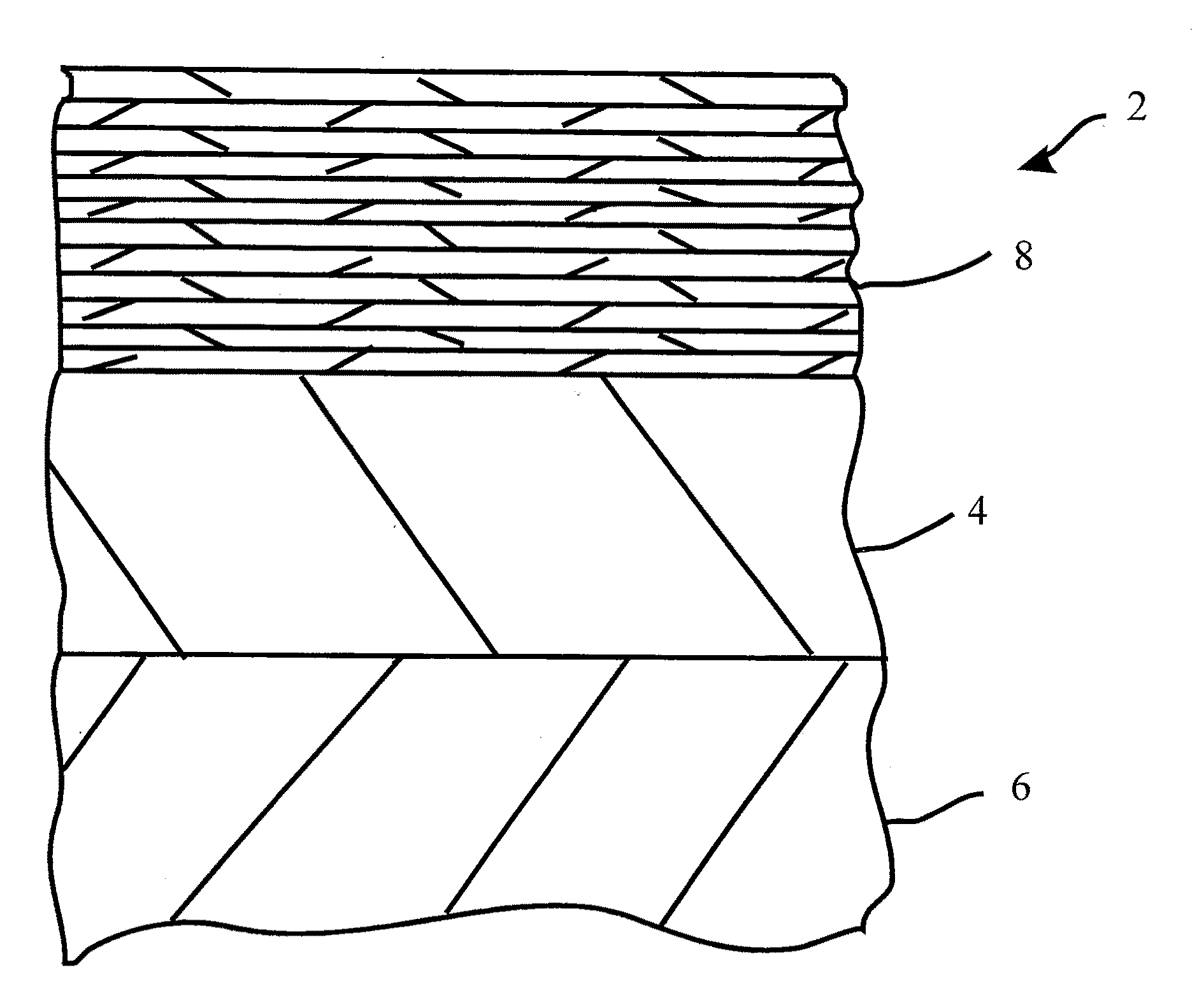

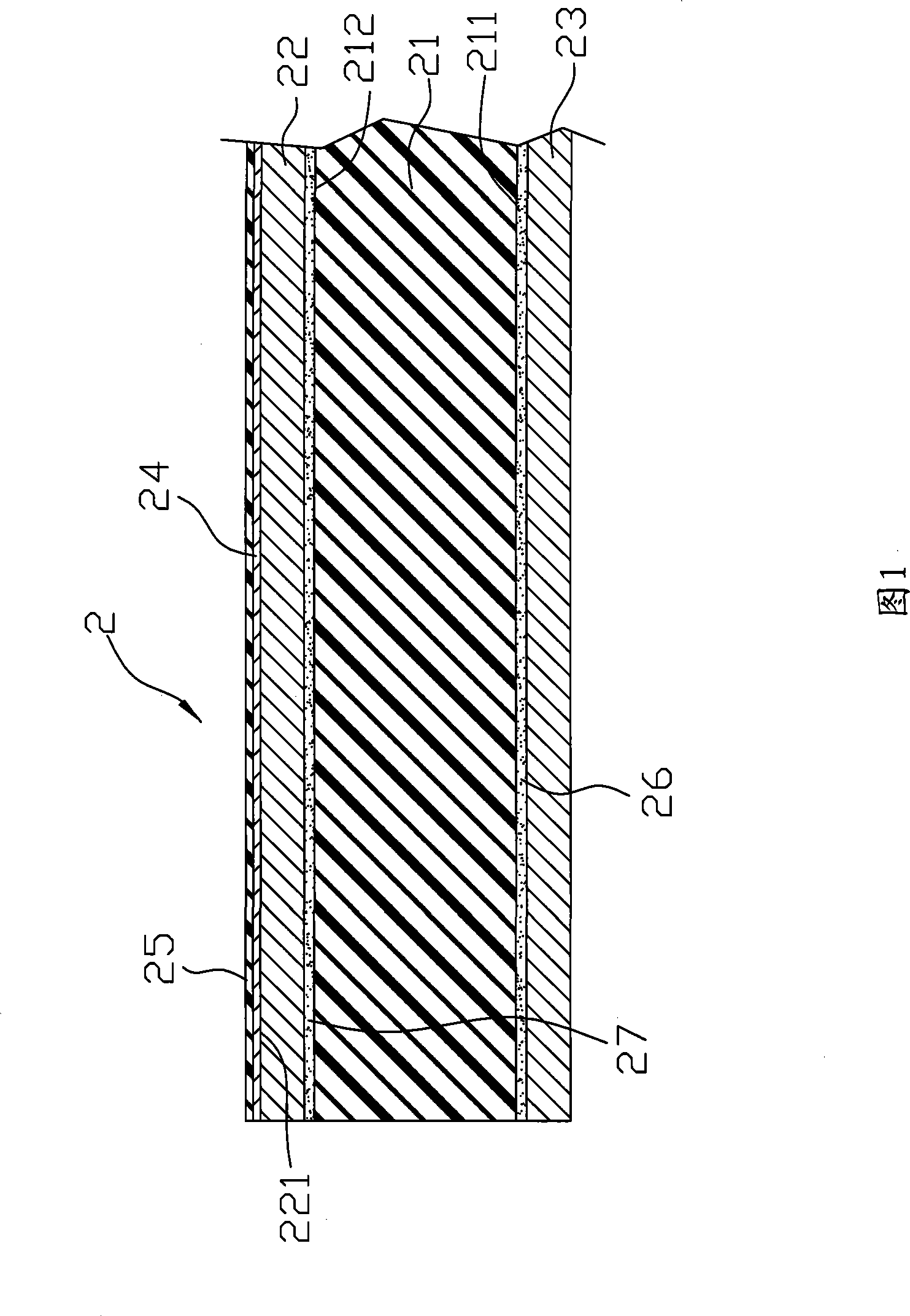

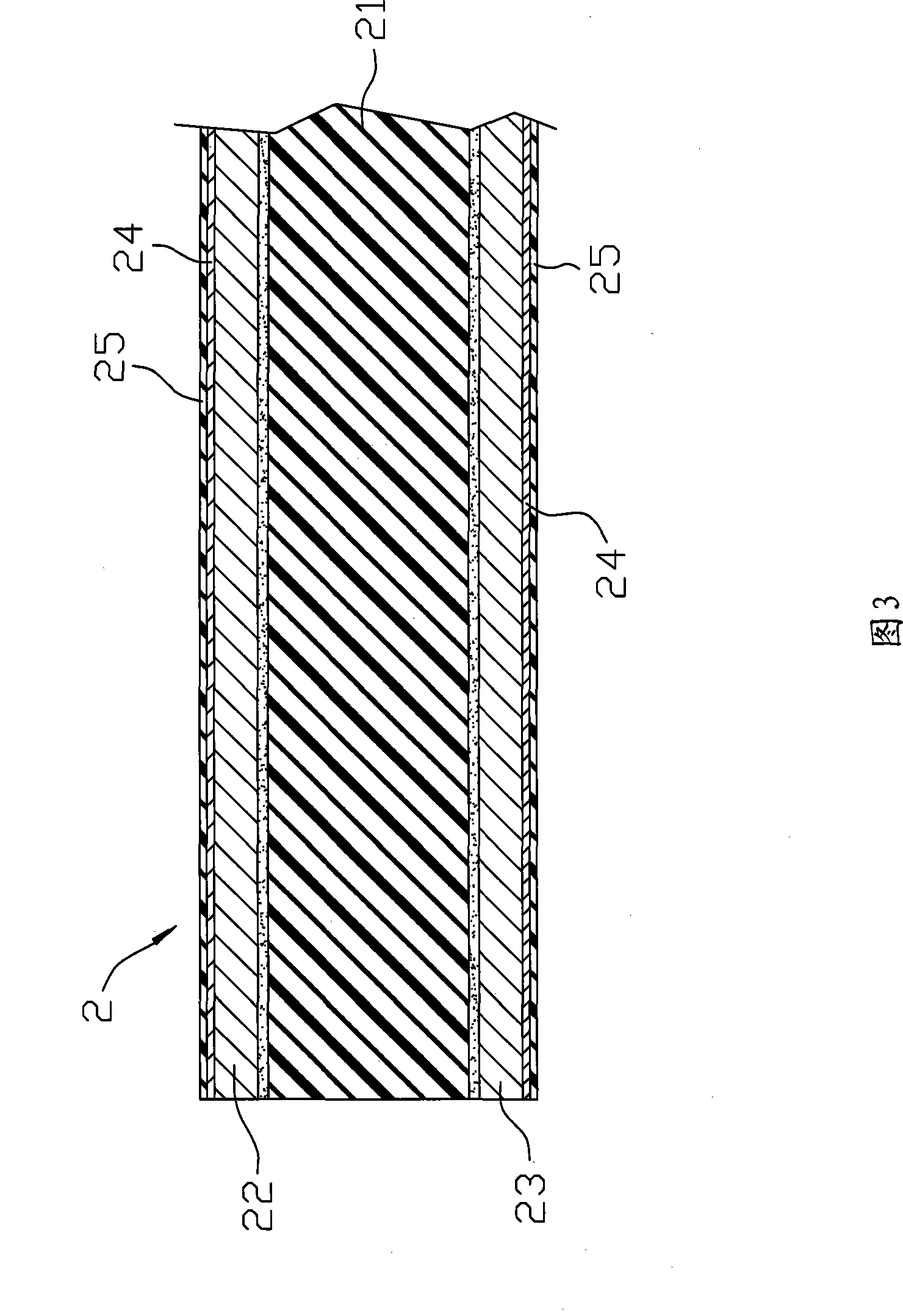

DLC (diamond-like carbon)/TiAlN (titanium aluminium nitride)/CrN (chromium nitride)/Cr (chromium) multilayer superhard film coating and preparation method thereof

InactiveCN102080207AImprove bindingImprove performanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideDiamond-like carbon

The invention discloses a DLC (diamond-like carbon) / TiAlN (titanium aluminium nitride) / CrN (chromium nitride) / Cr (chromium) multilayer superhard film coating for the surface treatment of piston rings of automobile engines, and the multilayer superhard film coating is prepared by adopting a multi-arc ion plating technology and a magnetron sputtering technology. The thickness of the prepared multilayer superhard film coating is between 5 mu m and 20 mu m (micrometer), and the hardness of the coating is greater than 40GPa.

Owner:SHENZHEN GUANGDA NANO ENG

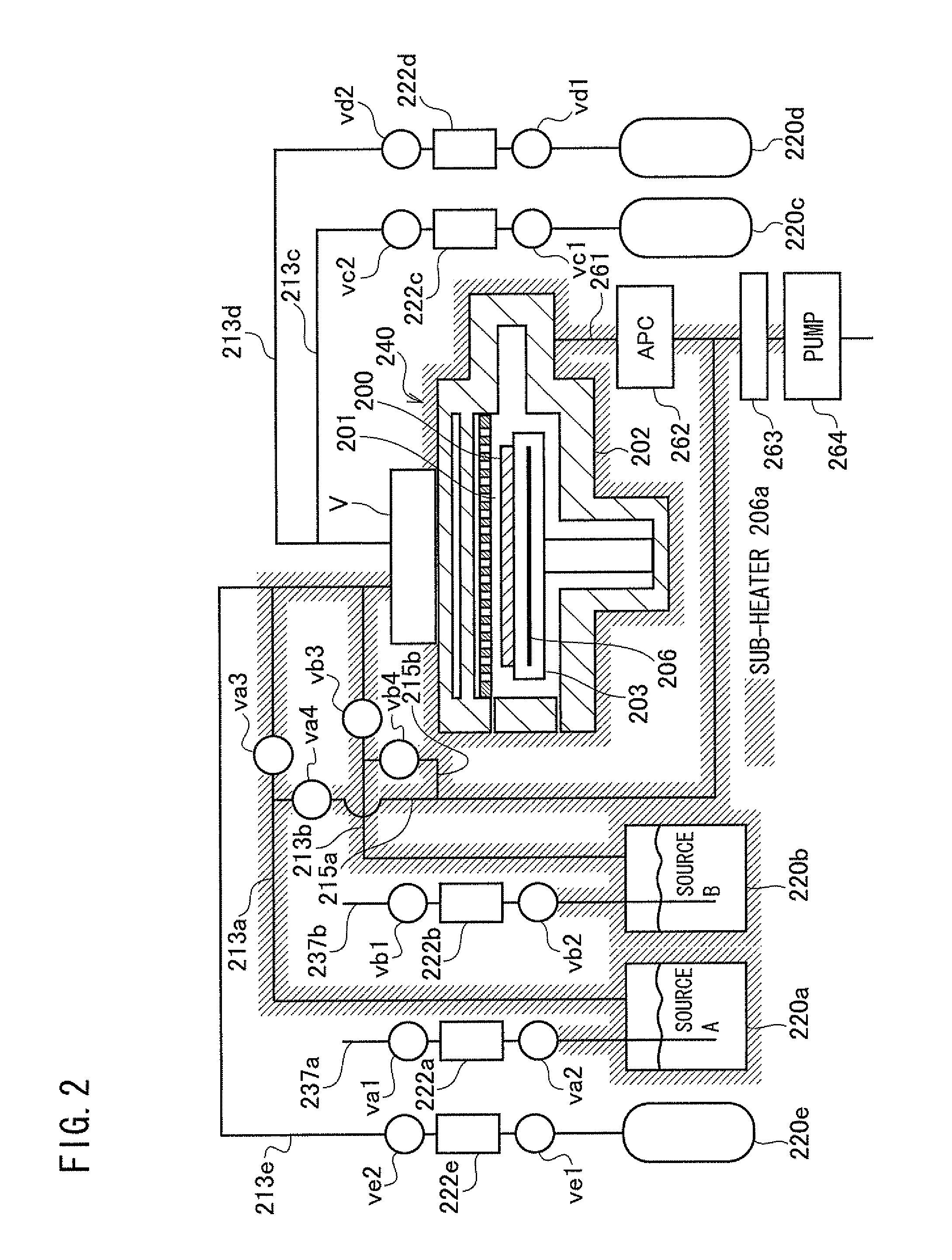

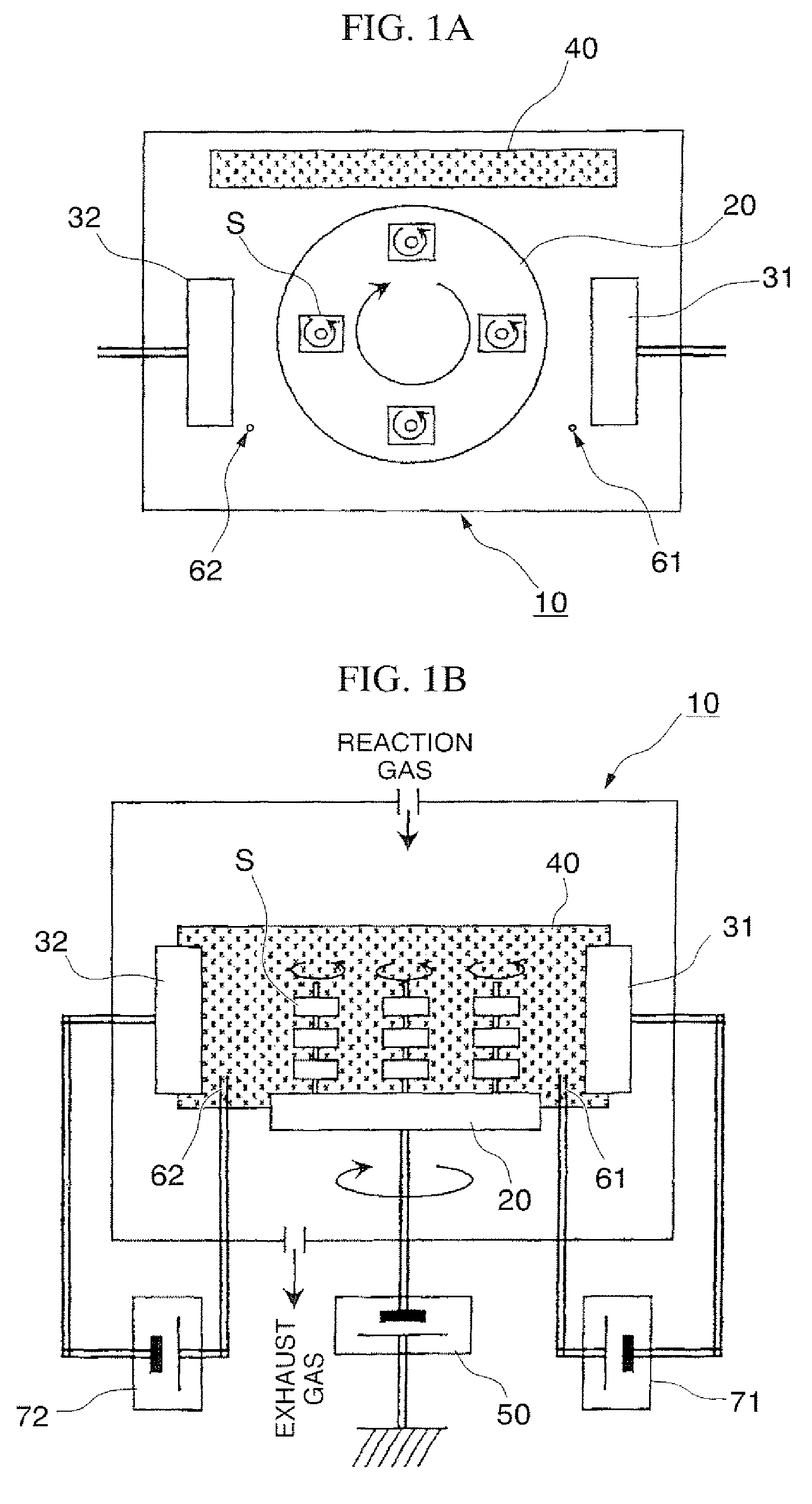

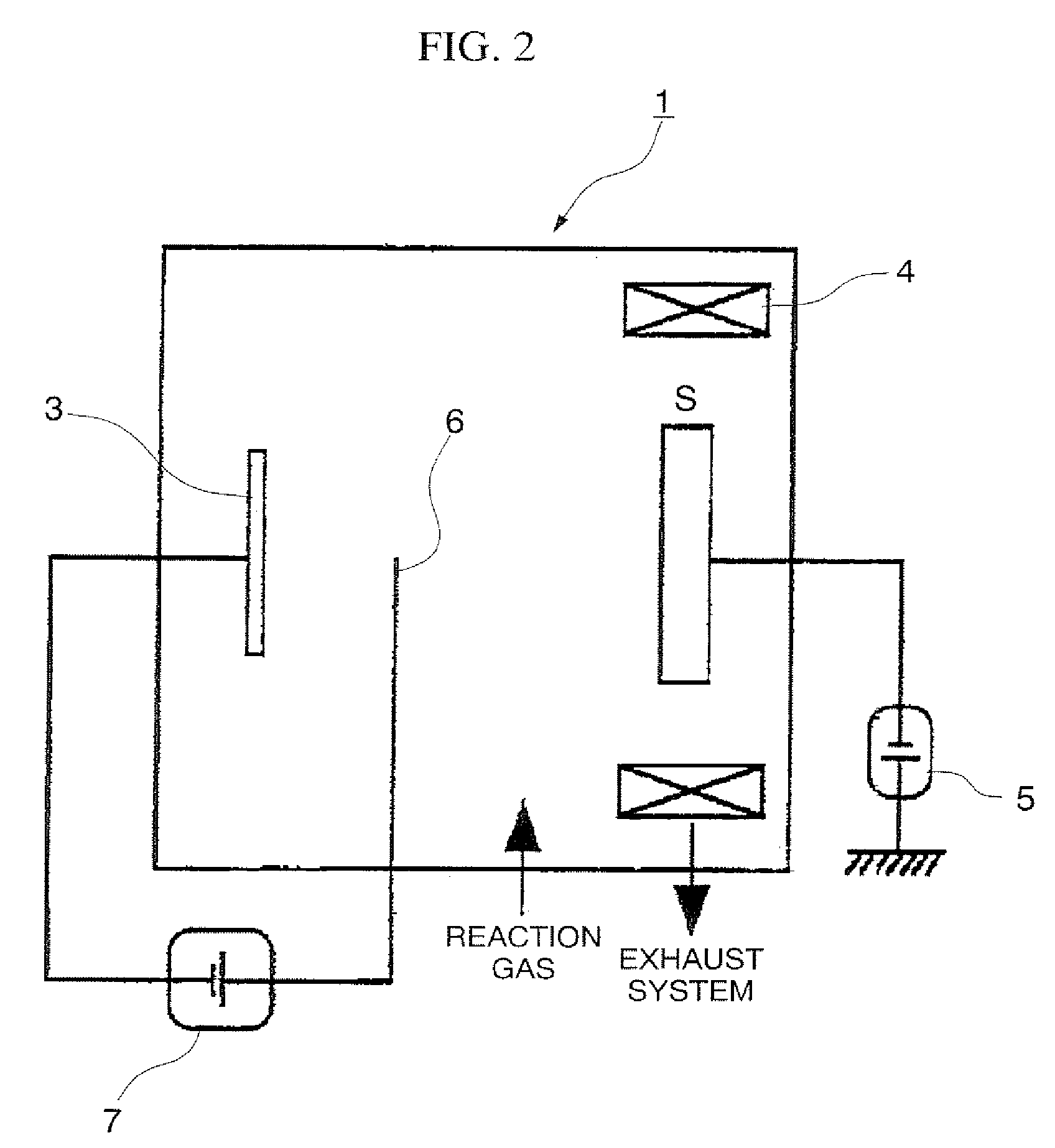

Method of manufacturing semiconductor device and substrate processing apparatus

ActiveUS20090325372A1Film formation rate of film can be moreImprove throughputLiquid surface applicatorsSemiconductor/solid-state device manufacturingTitanium aluminium nitrideSemiconductor

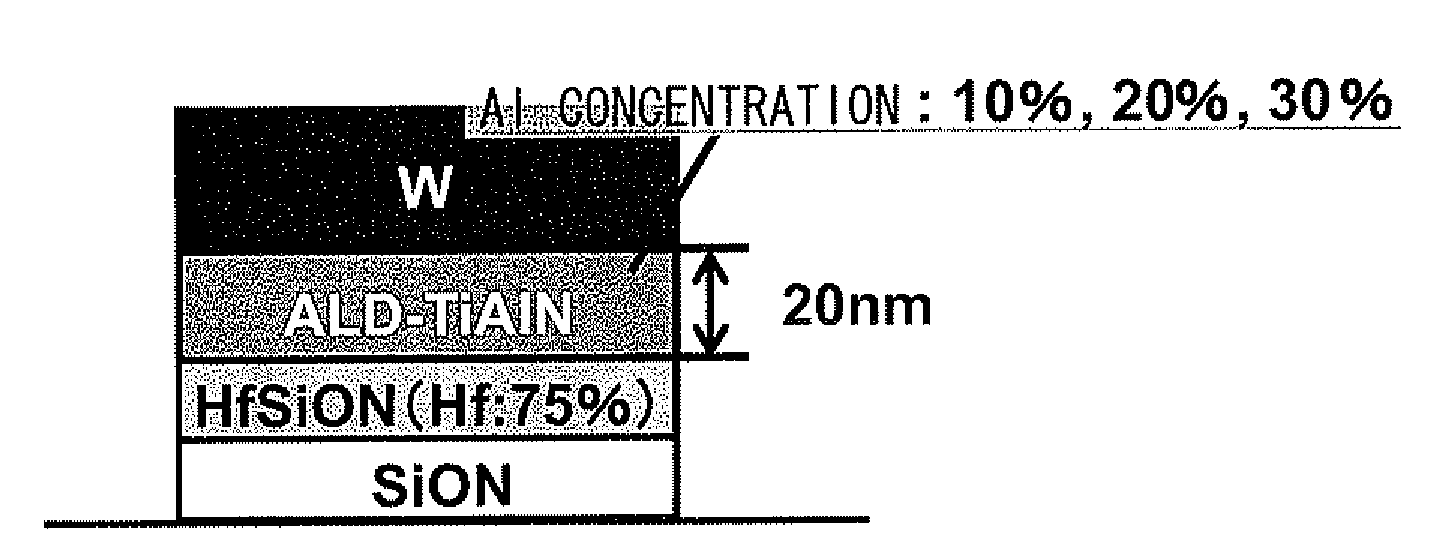

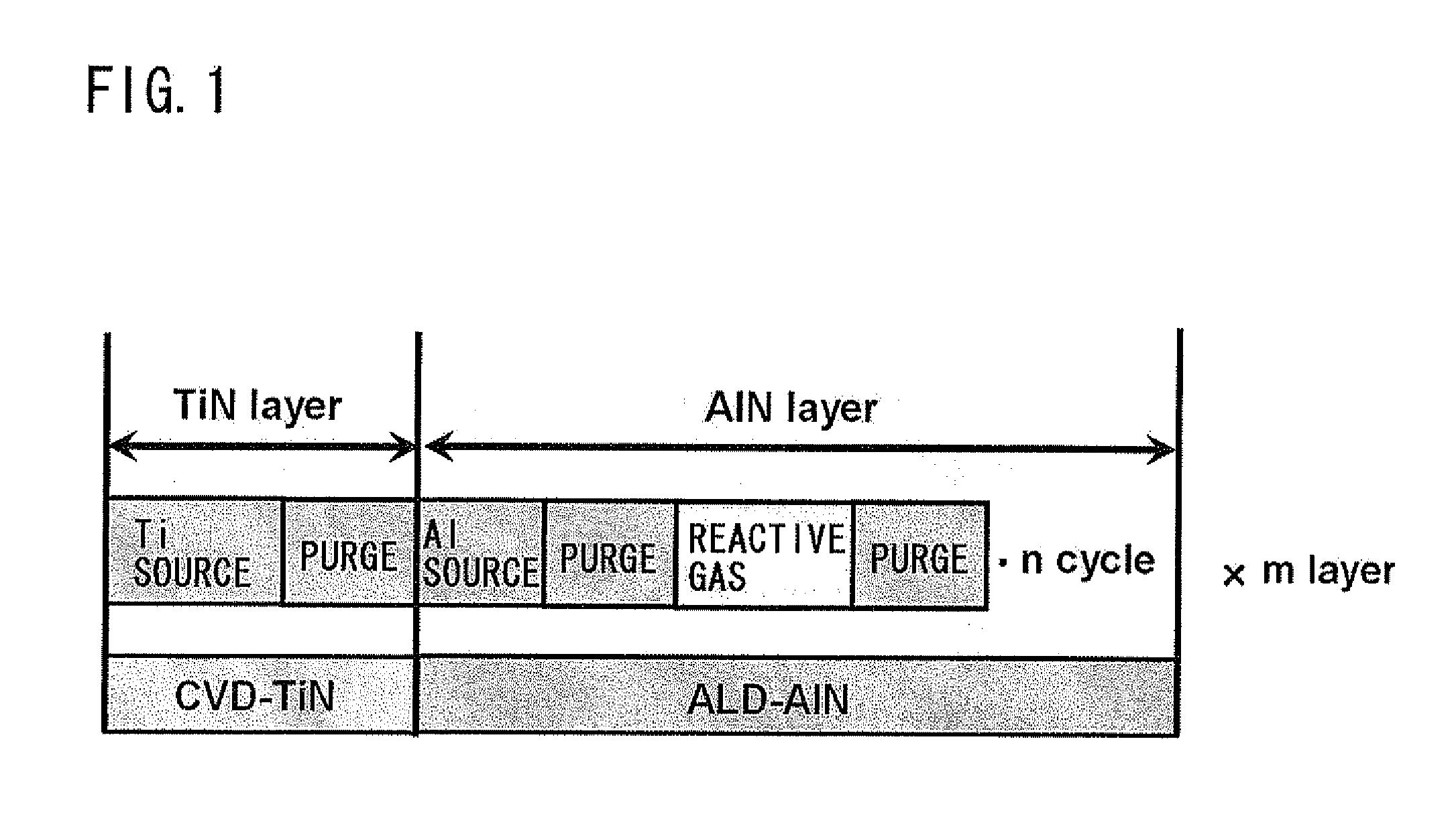

A manufacturing method of a semiconductor device of the present invention includes the step of forming an insulating film on a substrate, and the step of forming a high dielectric constant insulating film on the insulating film, and the step of forming a titanium aluminium nitride film on the high dielectric constant insulating film, wherein in the step of forming the titanium aluminum nitride film, formation of an aluminium nitride film and formation of a titanium nitride film are alternately repeated, and at that time, the aluminium nitride film is formed firstly and / or lastly.

Owner:KOKUSA ELECTRIC CO LTD

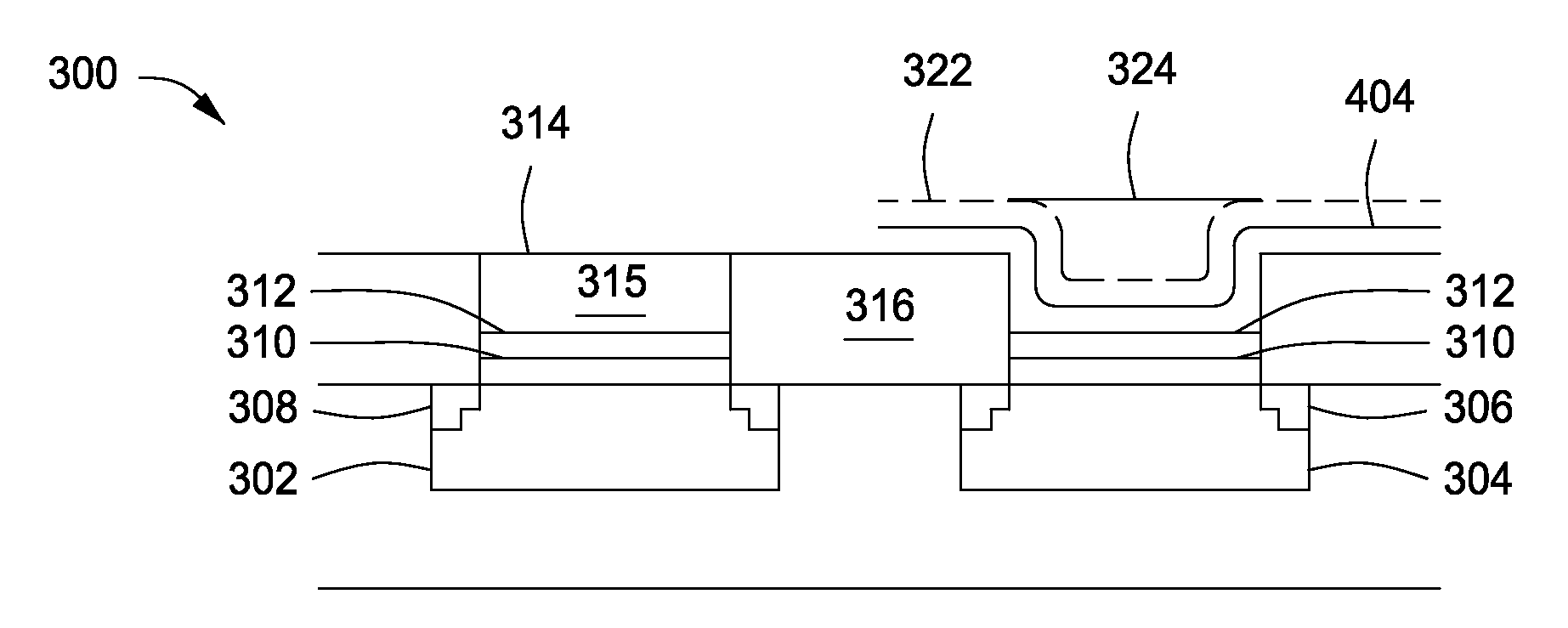

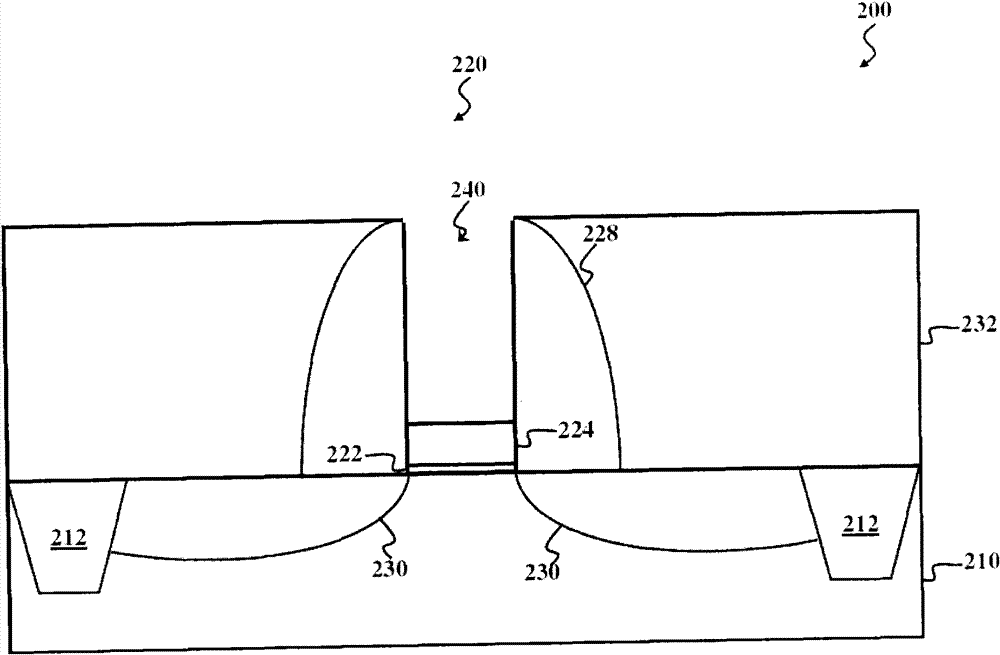

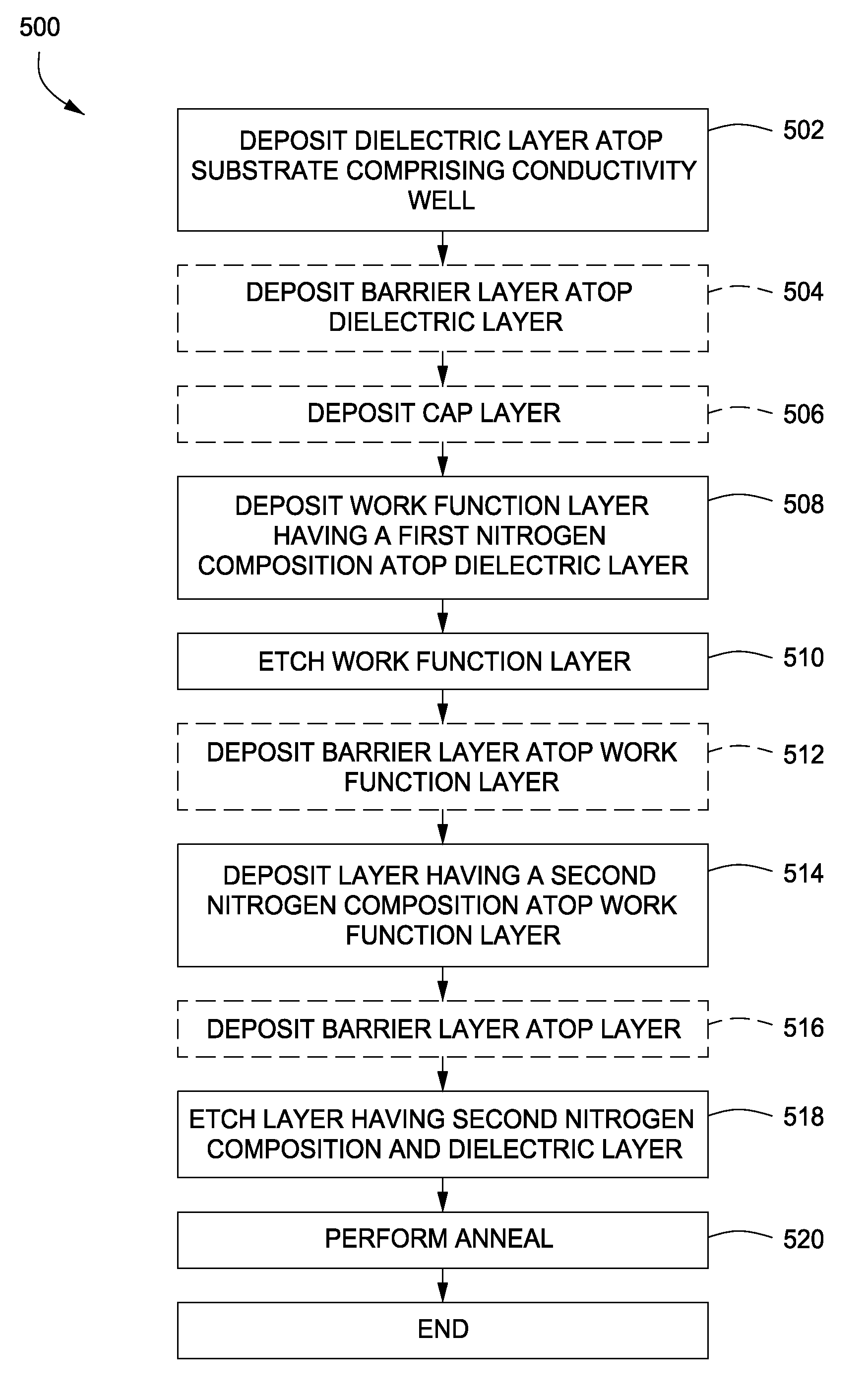

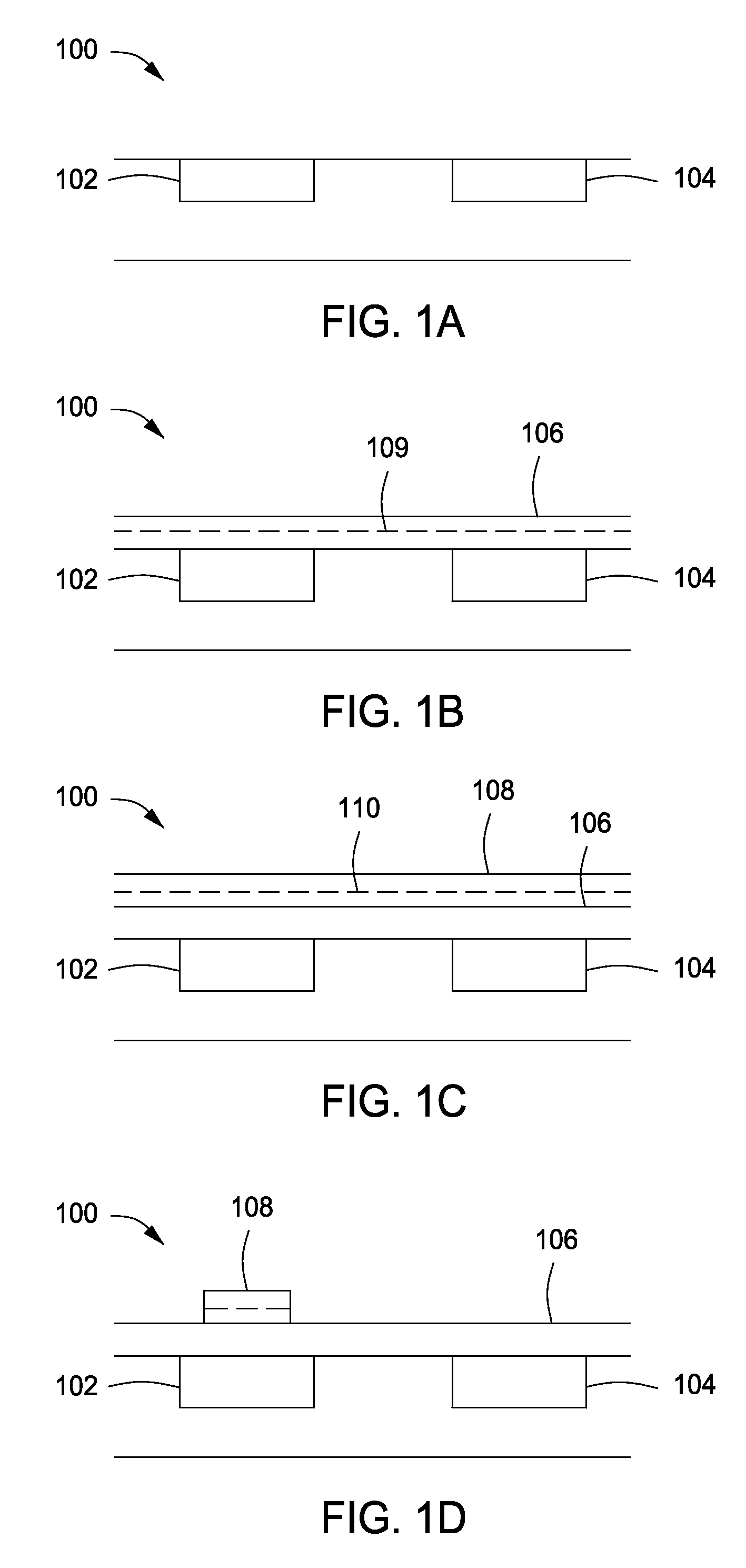

Substrate device having a tuned work function and methods of forming thereof

ActiveUS20110018073A1Semiconductor/solid-state device manufacturingSemiconductor devicesTitanium aluminium nitrideCelsius Degree

Substrate devices having tuned work functions and methods of forming thereof are provided. In some embodiments, forming devices on substrates may include depositing a dielectric layer atop a substrate having a conductivity well; depositing a work function layer comprising titanium aluminum or titanium aluminum nitride having a first nitrogen composition atop the dielectric layer; etching the work function layer to selectively remove at least a portion of the work function layer from atop the dielectric layer; depositing a layer comprising titanium aluminum or titanium aluminum nitride having a second nitrogen composition atop the work function layer and the substrate, wherein at least one of the work function layer or the layer comprises nitrogen; etching the layer and the dielectric layer to selectively remove a portion of the layer and the dielectric layer from atop the substrate; and annealing the substrate at a temperature less than about 1500 degrees Celsius.

Owner:APPLIED MATERIALS INC

Erosion- and impact-resistant coatings

ActiveUS20090011195A1Suitable protectionProtect normal useEngine manufactureLayered productsTitanium aluminium nitrideGas phase

Erosion- and impact-resistant ceramic coatings suitable for protecting surfaces subjected to collisions with particles, including nominally round particles that typically inflict impact damage and more aggressive irregular-shaped particles that typically inflict erosion damage. The ceramic coating is formed to have one of three compositions: at least one layer of titanium aluminum nitride (TiAlN) having a thickness of about 25 to about 100 micrometers; multiple layers of chromium nitride (CrN) and TiAlN, each layer having a thickness of about 0.2 to about 1.0 micrometers to yield a total coating thickness of at least about 3 micrometers; and at least one layer of titanium silicon carbonitride (TiSiCN) having a thickness of about 15 to about 100 micrometers. The ceramic coating preferably has a total coating thickness of up to about 100 micrometers, and is deposited by a physical vapor deposition process to have a columnar and / or dense microstructure.

Owner:GENERAL ELECTRIC CO

Cutting tool comprising multilayer coating

ActiveCN103201410AImprove wear resistanceExtended service lifeTurning toolsSuperimposed coating processTitanium aluminium nitrideTitanium

The invention relates to a cutting tool comprising a main part and a multilayer coating applied thereon. A first layer A made of a hard material is applied on the main part, said hard material being selected from titanium aluminum nitride (TiAIN), titanium aluminum silicon nitride (TiAISiN), chromium nitride (CrN), aluminum chromium nitride (AICrN), aluminum chromium silicon nitride (AICrSiN), and zirconium nitride (ZrN), and a second layer B made of silicon nitride (Si3N4) is applied directly over the first layer A.

Owner:WALTER AG

Method to reduce mechanical wear of immersion lithography apparatus

InactiveUS20080138631A1Defect minimizationMinimize mechanical wearPhotomechanical apparatusMetallic material coating processesTitanium aluminium nitrideDiamond-like carbon

A protective coating is provided for components of an immersion lithography tool, in which at least a portion of a component exposed to the immersion fluid is protected by a thin, hard protective coating, comprising materials such as silicon carbide, diamond, diamond-like carbon, boron nitride, boron carbide, tungsten carbide, aluminum oxide, sapphire, titanium nitride, titanium carbonitride, titanium aluminum nitride and titanium carbide. The protective coating may be formed by methods such as CVD, PECVD, APCVD, LPCVD, LECVD, PVD, thin-film evaporation, sputtering, and thermal annealing in the presence of a gas. The protective coating preferably has a hardness greater than a Knoop hardness of about 1000 and more preferably greater than about 2000, or a Moh hardness greater than about 7, more preferably greater than about 9. The protective coating minimizes defects due to mechanical wear of scanner components.

Owner:IBM CORP

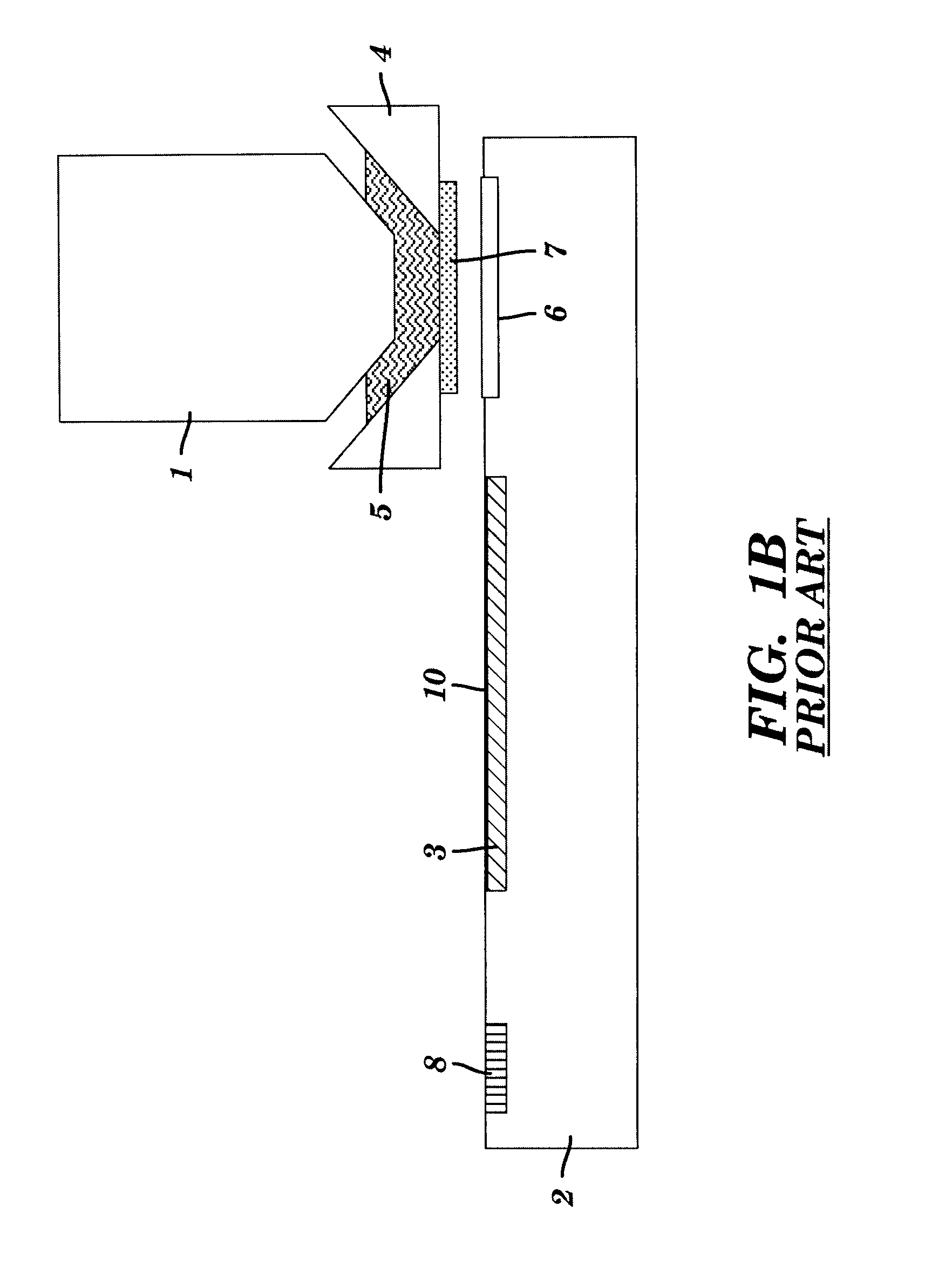

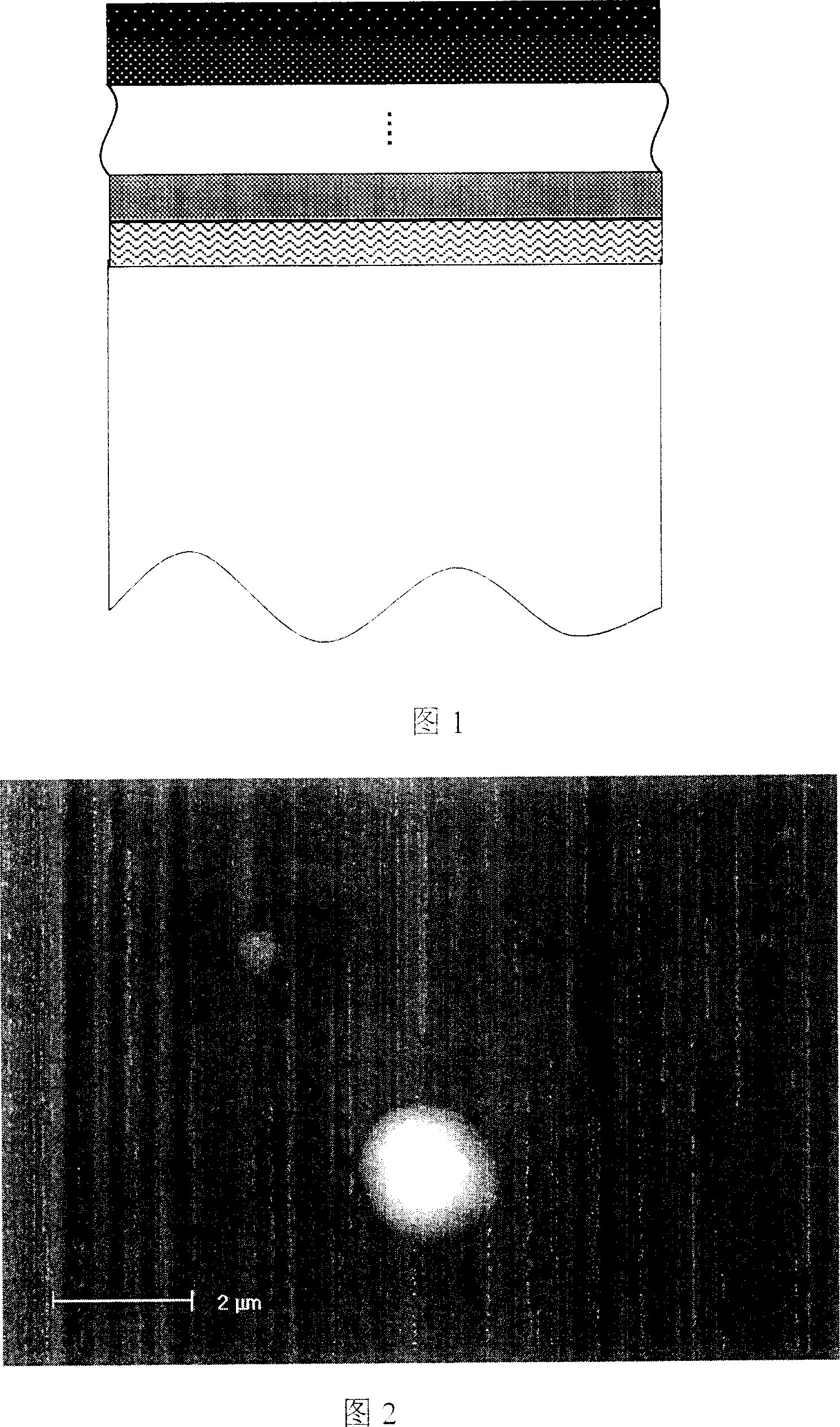

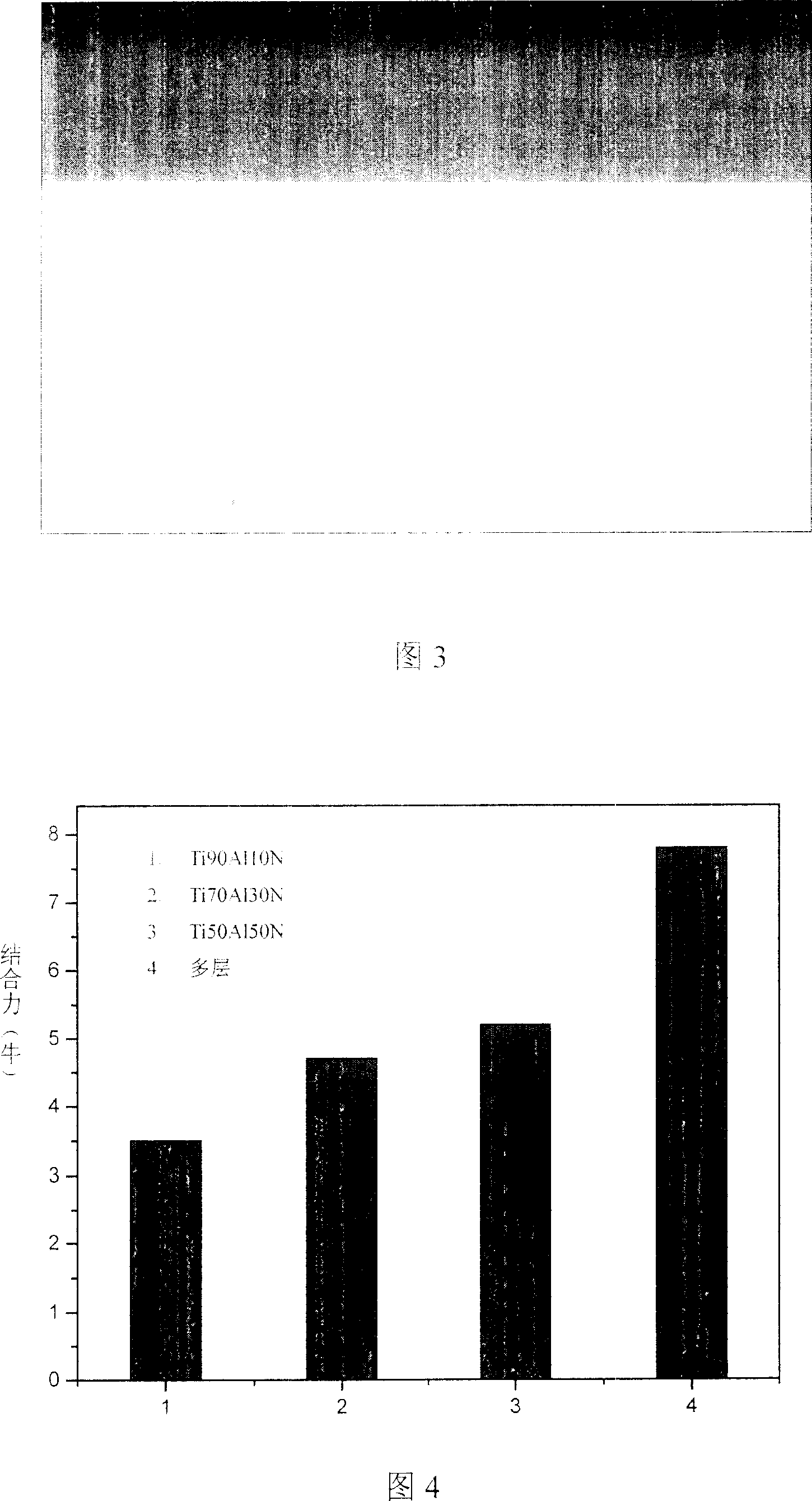

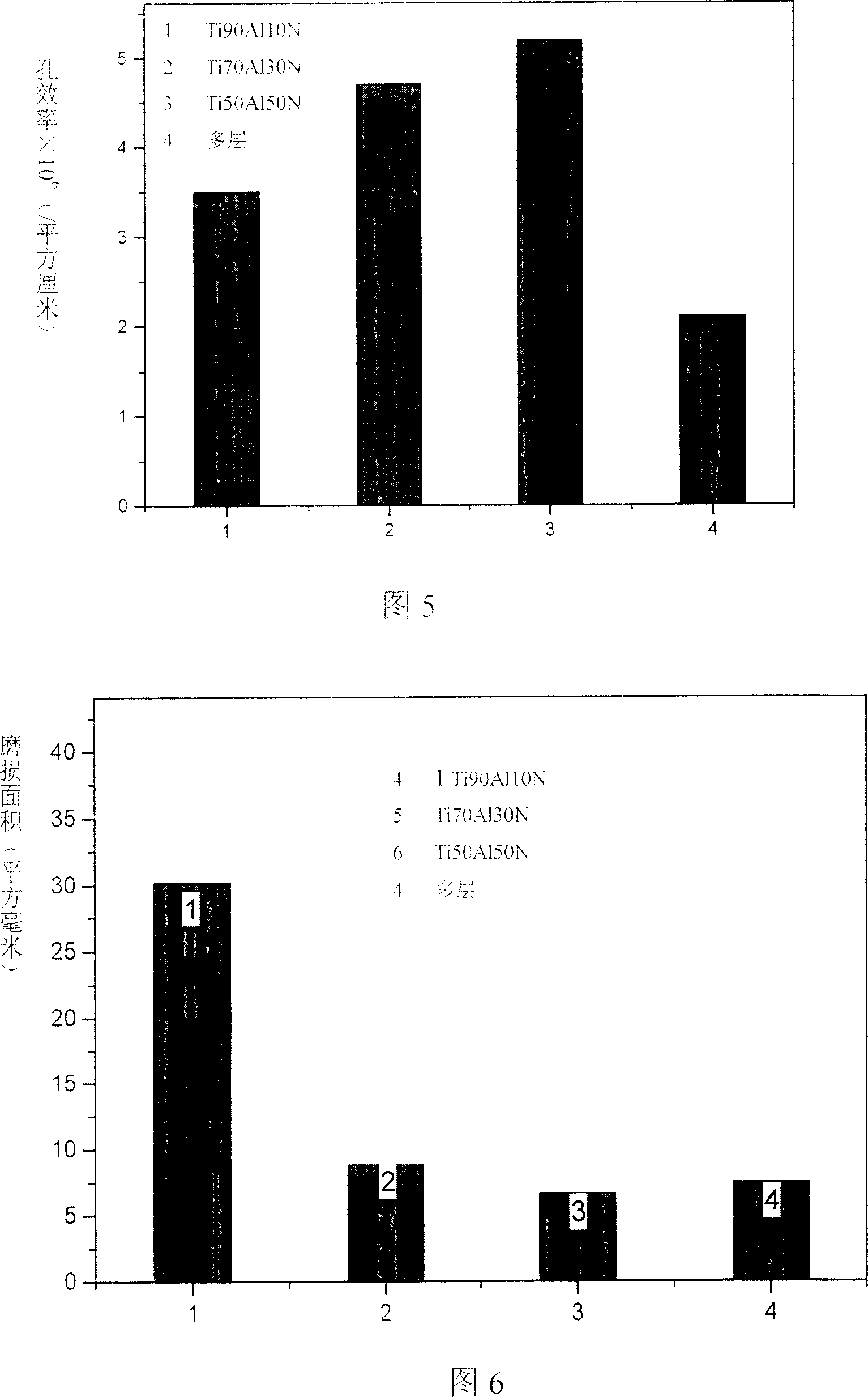

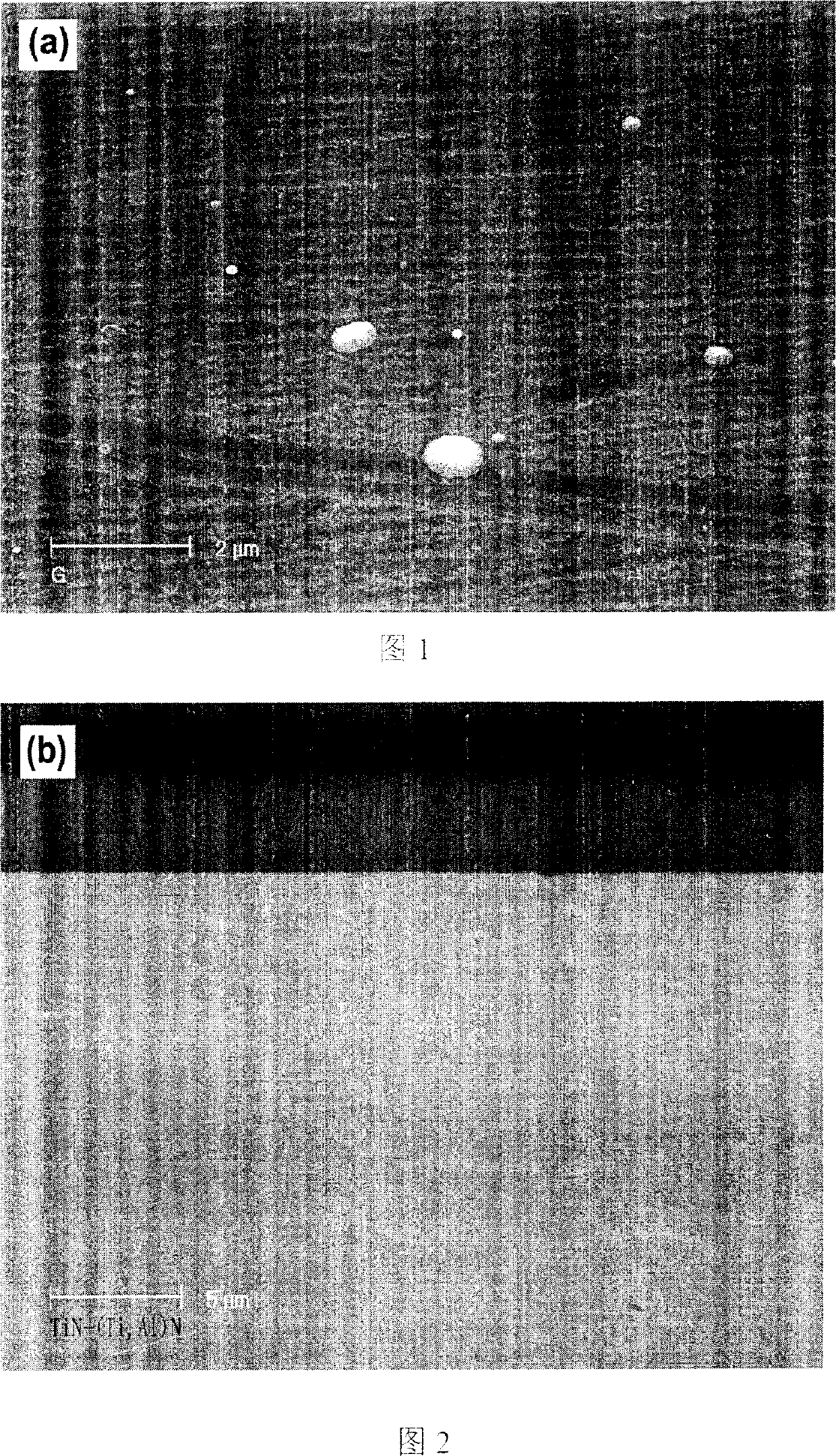

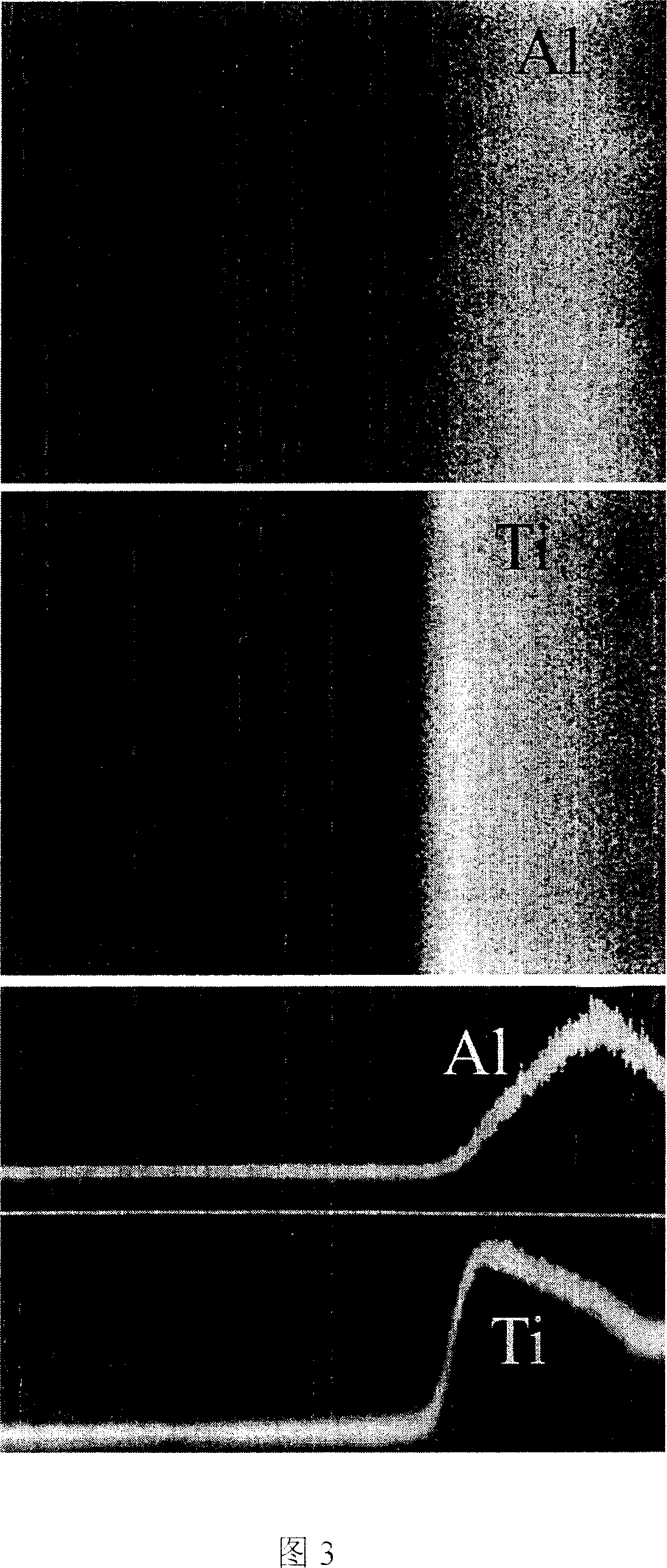

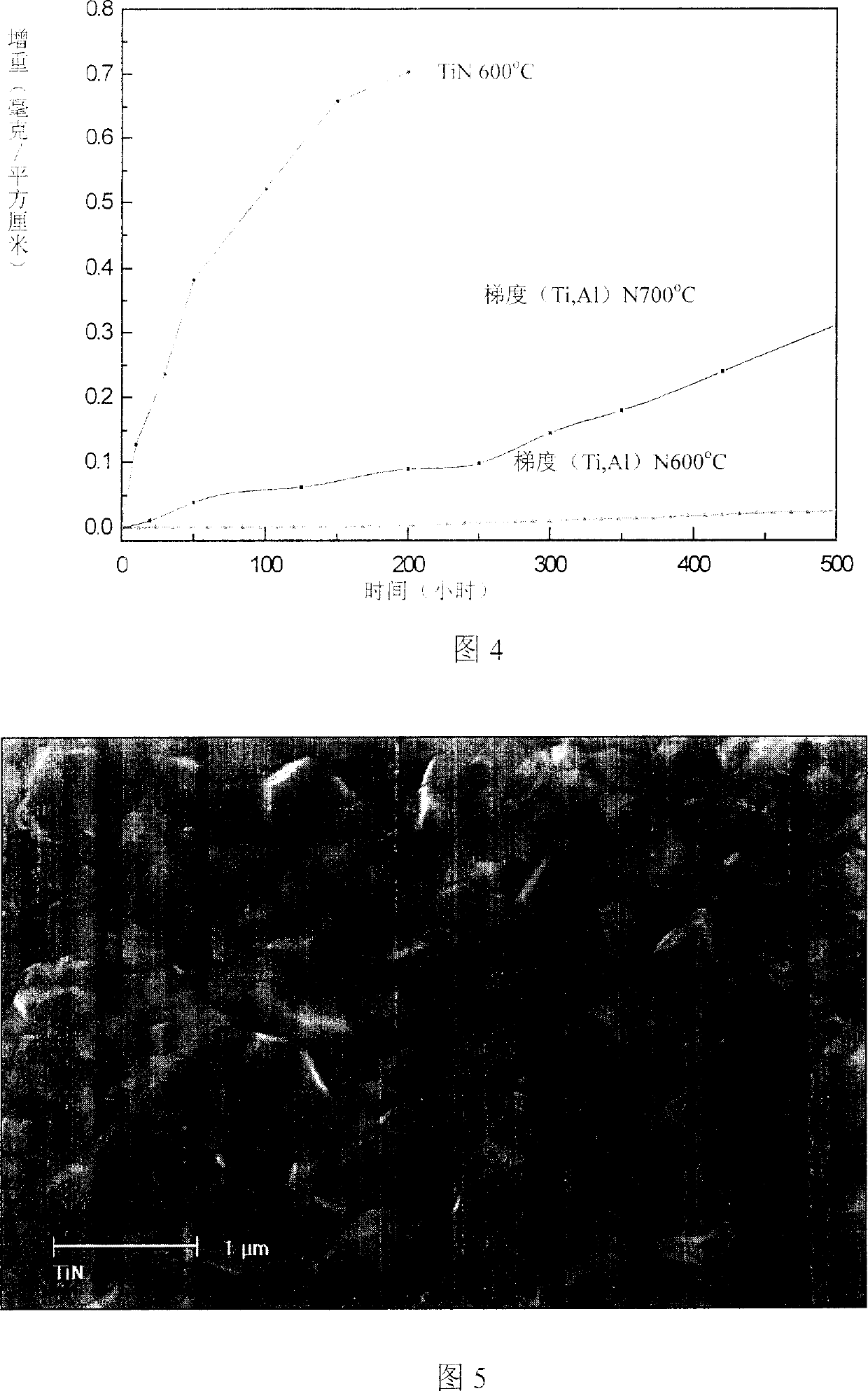

Metal materials protection method (2)

InactiveCN1962926AReduce pinholesReduce defects such as voidsVacuum evaporation coatingSputtering coatingStress concentrationAviation

The invention discloses a metal material protecting method, which is characterized by the following: coating hard film with multiple layers of titanium aluminium nitride coating on the surface of metal base; increasing aluminium content and reducing titanium content in the alloy; improving mating property between coating and base as well as combining strength; fitting for coating protection of blade, knife and mould of aviation generator.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Cutting tool made of surface-coated cubic boron nitride-based ultra-high-pressure sintered material

InactiveUS20070275268A1High surface finishImprove heat resistanceVacuum evaporation coatingSputtering coatingUltra high pressureTitanium nitride

A cutting tool made of a surface-coated cubic boron nitride-based ultra-high-pressure sintered material, comprising a cutting insert main body formed by ultra-high-pressure sintering of a compact composed of titanium nitride, aluminum and / or aluminum oxide, and boron nitride, and a hard coating layer vapor deposited on the main body. The main body has a texture containing cubic boron nitride, titanium nitride and reaction product. The hard coating layer has a lower layer of nitride having a composition of [Ti1-X-YAlXSiY]N, where X is in a range from 0.40 to 0.60 and Y is in a range from 0.02 to 0.10 in an atomic ratio, and the upper layer comprises a thin layer A having the composition of [Ti1-X-YAlXSiY]N, where X is in a range from 0.40 to 0.60 in an atomic ratio and Y is in a range from 0.02 to 0.10, and a thin layer B consisting of a Ti nitride (TiN). The upper layer consists of the thin layer A and a thin layer B layered alternately.

Owner:MITSUBISHI MATERIALS CORP

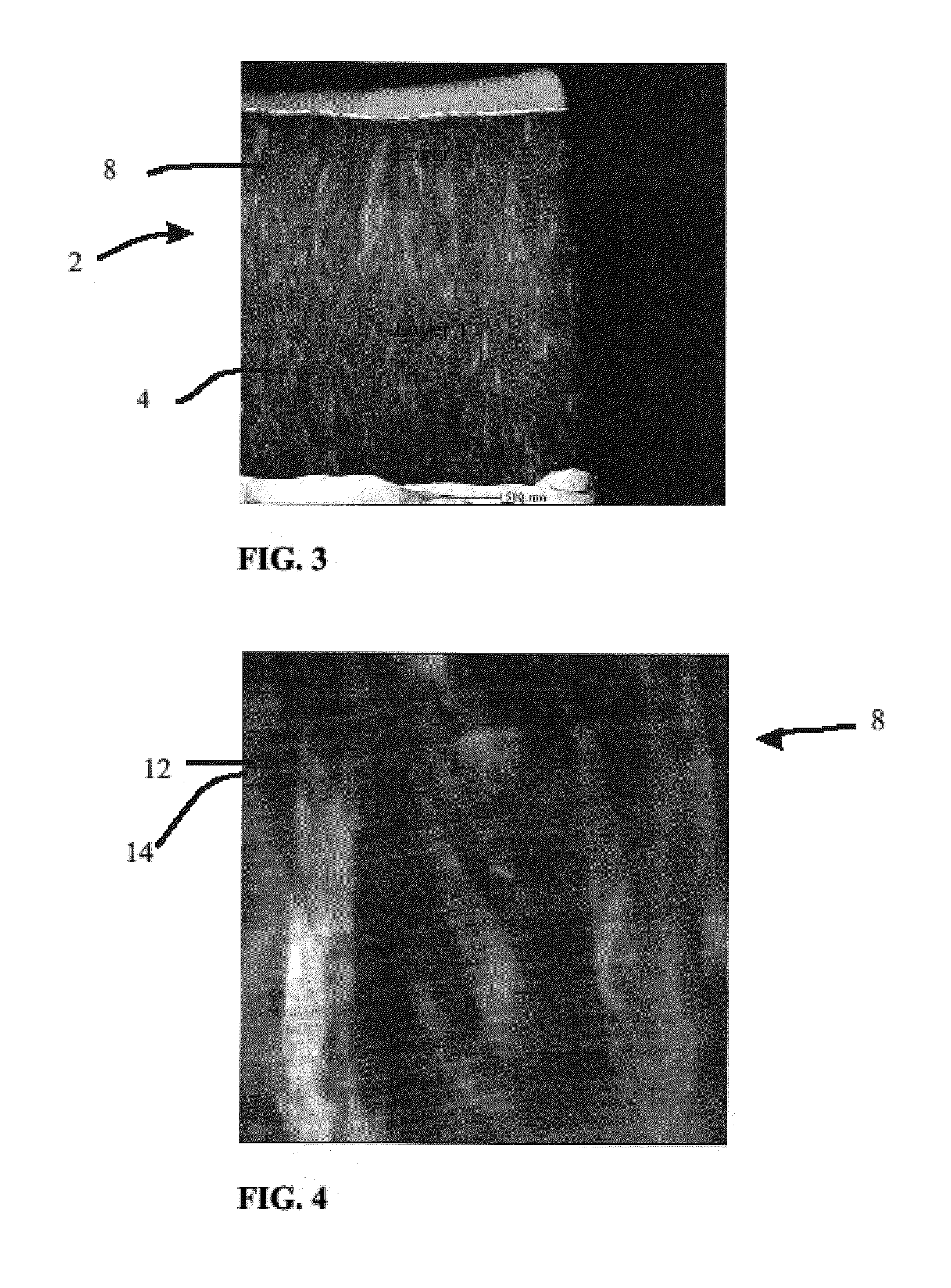

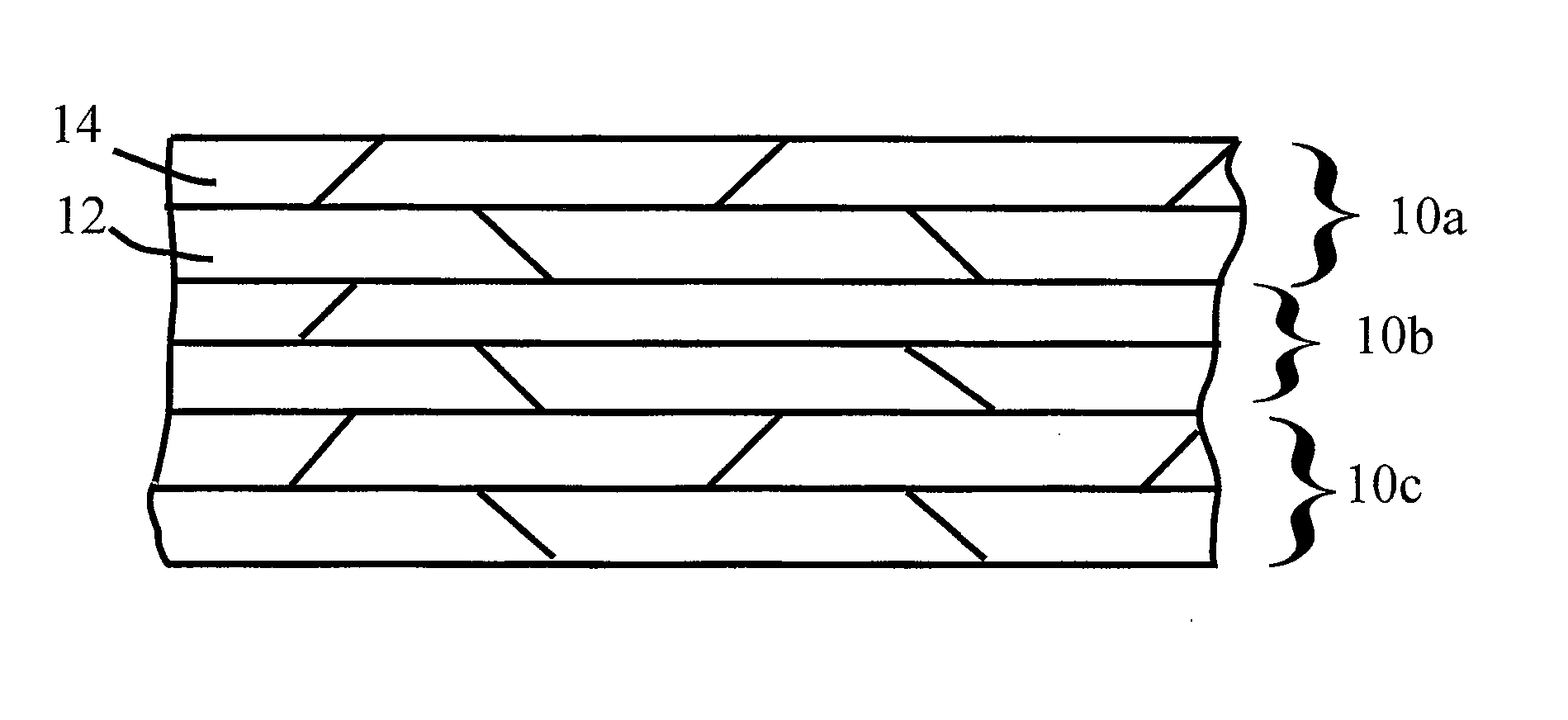

Multilayer Nitride Hard Coatings

ActiveUS20110293909A1Improve wear resistanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideWear resistant

A wear resistant multilayer nitride hard coating for substrates. The hard coating includes a first layer of titanium aluminum nitride and a second layer comprising a plurality of sublayer groups. Each sublayer group includes a first sublayer of titanium silicon nitride and a second sublayer of titanium aluminum nitride. The composition of the titanium aluminum nitride, both in the first layer and in the sublayer groups, is (TixAl1-x)N, wherein 0.4≦x≦0.6. The composition of the titanium silicon nitride sublayers is (TiySi1-y)N, wherein 0.85≦y≦0.98, and all of the silicon is in solid solution in the titanium silicon nitride such that no silicon phase or silicon nitride phase exists in this sublayer. The combined amount of aluminum and silicon present in the sublayer groups being narrowly controlled such that the sum of x and y is in the range of 1.38 to 1.46.

Owner:KENNAMETAL INC

Aluminum titanium carbonitride alloy grain refiner and preparation method thereof

The invention relates to an aluminum titanium carbonitride alloy grain refiner which contains 1%-10% of titanium carbonitride and 90%-99% of aluminum. A preparation method comprises the following steps: (1) dosing; (2) preparing an aluminum titanium carbonitride precast block; (3) smelting, putting aluminum into a heating furnace for preheating, heating under the inert gas protection or under the condition of adding covering agent, fully smelting aluminum to obtain molten aluminum, and then pressing the aluminum titanium carbonitride precast block into the molten aluminum at 800-1100 DEG C, after the aluminum titanium carbonitride precast block is fully smelted, adjusting the temperature of the molten aluminum to 800 DEG C and stirring for 5-30 min while keeping temperature, then adjusting the temperature of the molten aluminum to 700-720 DEG C, adding a refining agent being 0.4%-1.2% of the total mass into the molten aluminum, stirring and refining for 5-20 min, standing by and keeping temperature for 5-10 min, thereby obtaining an aluminum titanium carbonitride intermediate alloy solution; (4) pouring. The aluminum titanium carbonitride alloy grain refiner provided by the invention has excellent grain refining capacity and can further promote the comprehensive mechanical property of aluminum and aluminum alloy.

Owner:SICHUAN UNIV

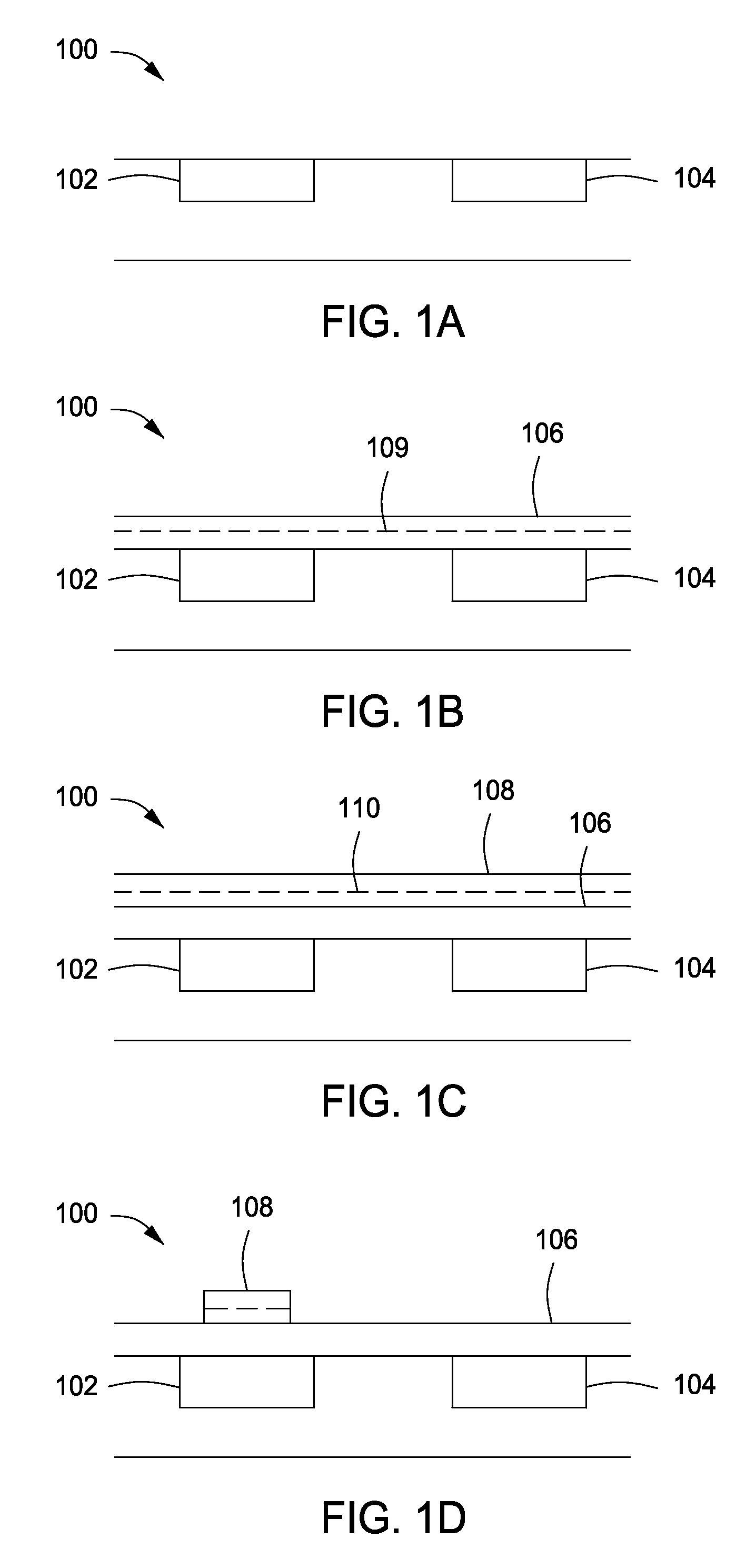

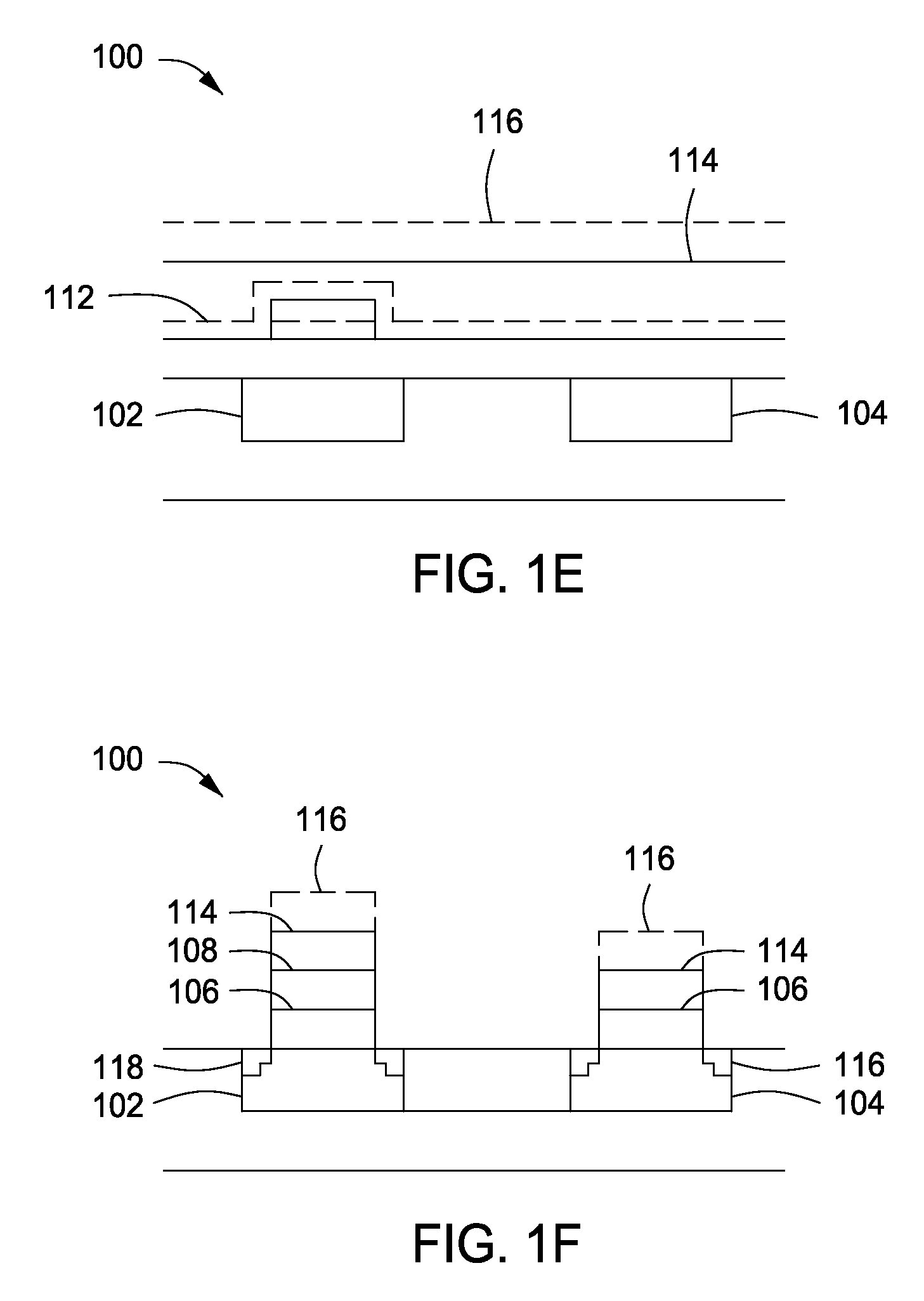

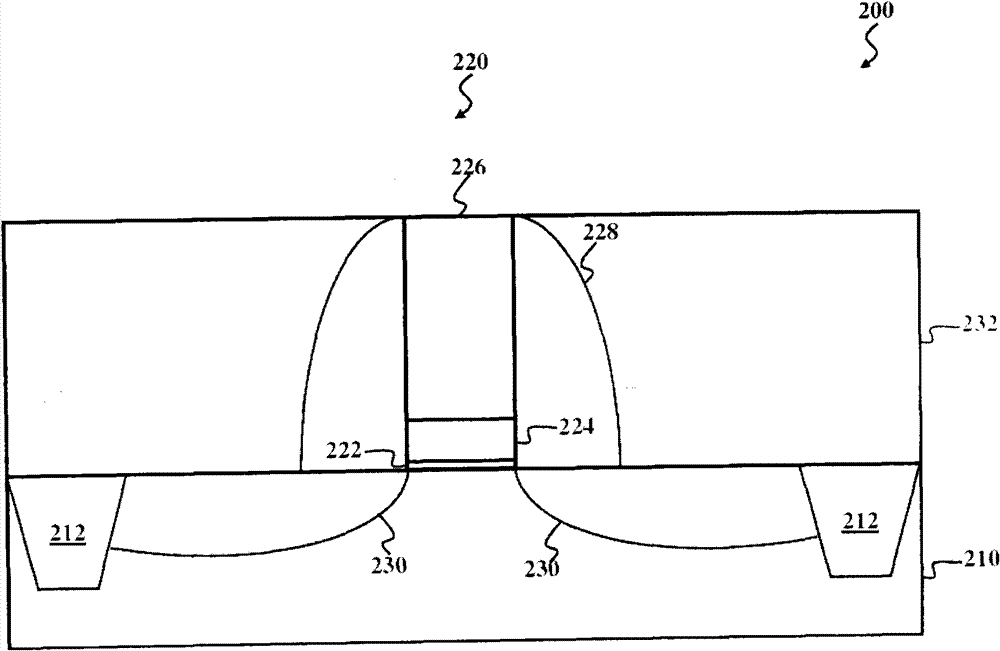

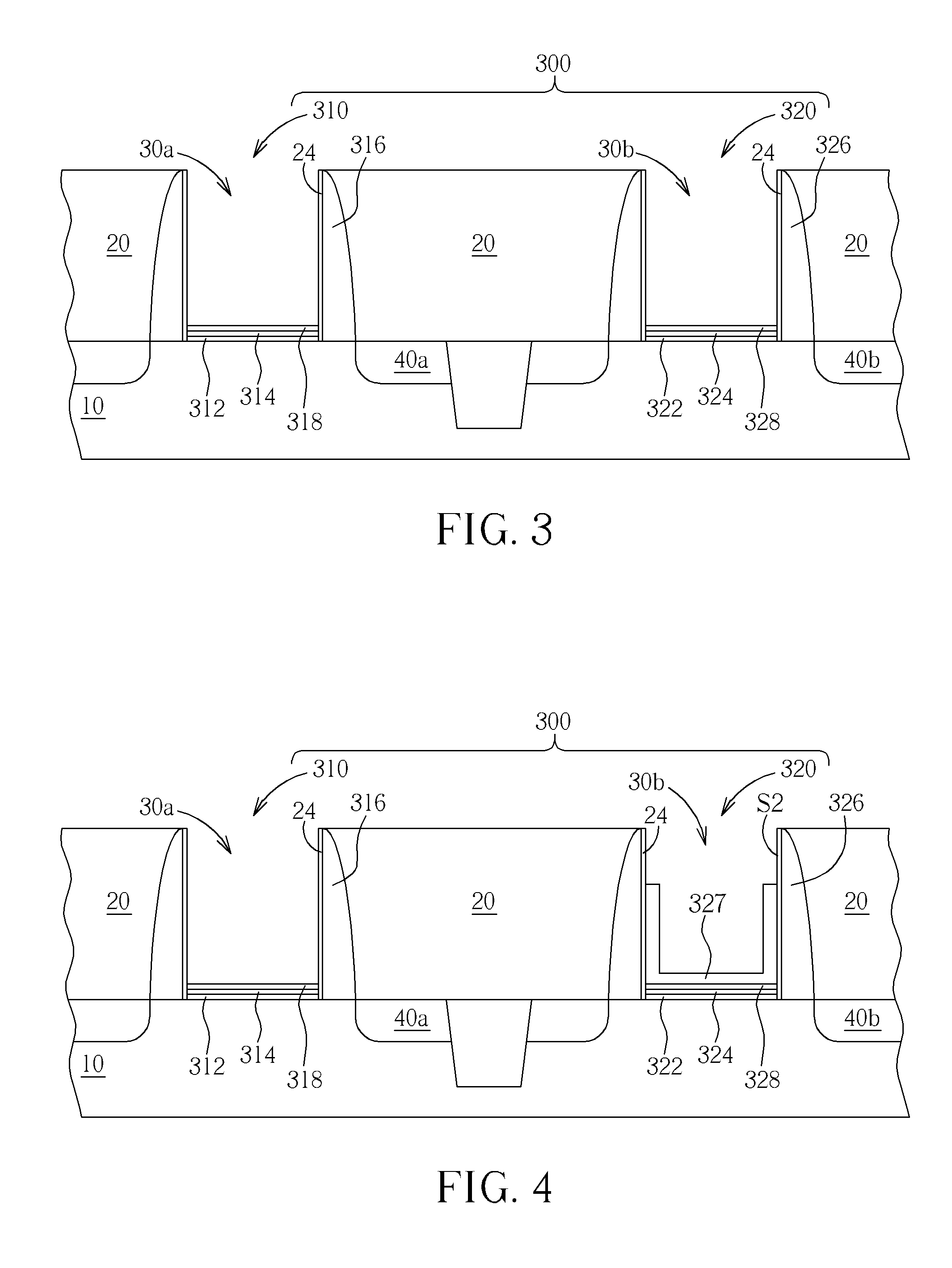

Metal gate stack having TIALN blocking/wetting layer

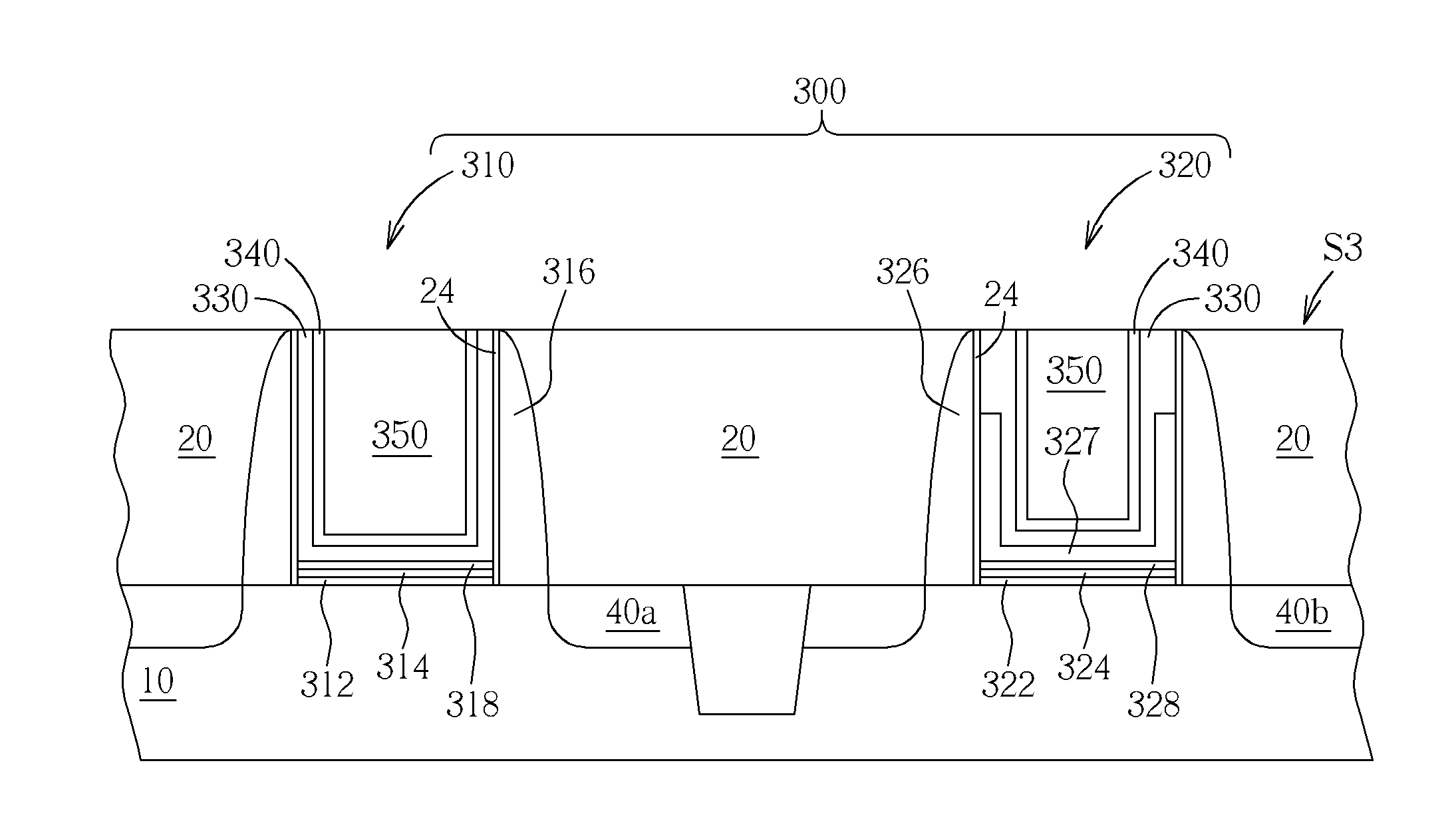

ActiveCN103022101ASemiconductor/solid-state device manufacturingSemiconductor devicesTitanium aluminium nitrideGate dielectric

A metal gate stack having a TiAlN blocking / wetting layer, and methods of manufacturing the same, are disclosed. In an embodiment, an integrated circuit device includes a semiconductor substrate and a gate stack disposed over the semiconductor substrate. The gate stack includes a gate dielectric layer disposed over the semiconductor substrate; a work function layer disposed over the gate dielectric layer; a multi-function wetting / blocking layer disposed over the work function layer, wherein the multi-function wetting / blocking layer is a titanium aluminum nitride layer; and a conductive layer disposed over the multi-function wetting / blocking layer.

Owner:TAIWAN SEMICON MFG CO LTD

Metal materials protection method (1)

InactiveCN1962947AAchieve depositionSimple structureVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideOxidation resistant

The invention discloses a metal material protecting method, which is characterized by the following: coating hard film with multiple layers of titanium aluminium nitride coating on the surface of metal base; increasing aluminium content and reducing titanium content in the alloy; fitting for high-speed steel, stainless steel, titanium alloy and high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

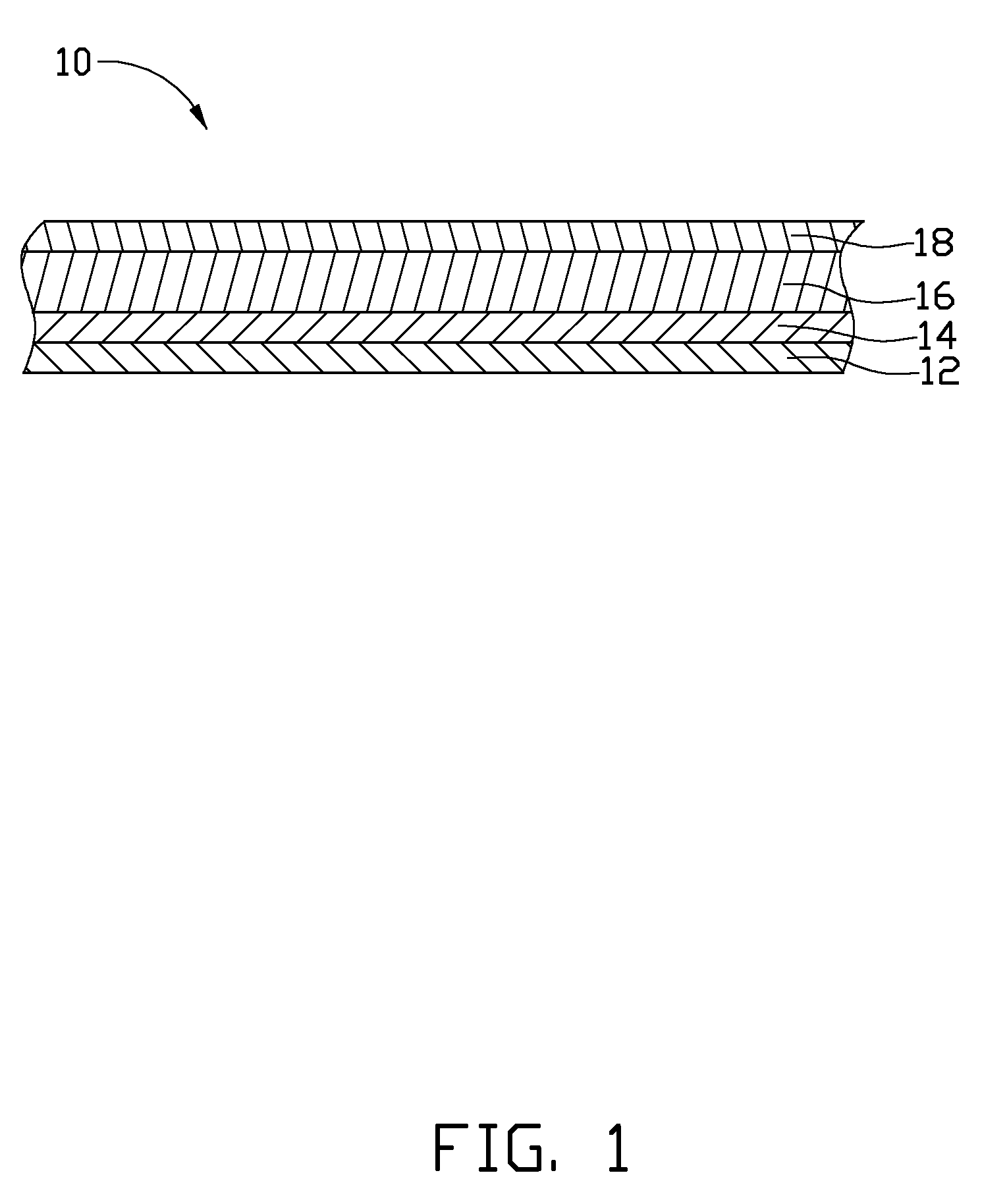

Coating, article coated with coating, and method for manufacturing article

InactiveUS20120052276A1Vacuum evaporation coatingSputtering coatingTitanium aluminium nitrideCarbon nitride

A coating includes a titanium aluminum layer; a titanium aluminum nitride layer deposited on the titanium aluminum layer; a titanium aluminum carbon-nitride layer deposited on the titanium aluminum nitride layer; and a silicon carbon-nitride layer deposited on the titanium aluminum carbon-nitride layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Multilayer nitride hard coatings

ActiveUS8409695B2Pigmenting treatmentOther chemical processesTitanium aluminium nitrideWear resistant

A wear resistant multilayer nitride hard coating for substrates. The hard coating includes a first layer of titanium aluminum nitride and a second layer comprising a plurality of sublayer groups. Each sublayer group includes a first sublayer of titanium silicon nitride and a second sublayer of titanium aluminum nitride. The composition of the titanium aluminum nitride, both in the first layer and in the sublayer groups, is (TixAl1-x)N, wherein 0.4≦x≦0.6. The composition of the titanium silicon nitride sublayers is (TiySi1-y)N, wherein 0.85≦y≦0.98, and all of the silicon is in solid solution in the titanium silicon nitride such that no silicon phase or silicon nitride phase exists in this sublayer. The combined amount of aluminum and silicon present in the sublayer groups being narrowly controlled such that the sum of x and y is in the range of 1.38 to 1.46.

Owner:KENNAMETAL INC

Preparation method for nitrogen oxygen titanium aluminum/titanium aluminum nitrogen and titanium aluminum composite film

InactiveCN103866243AImprove adhesionHigh hardnessLayered productsVacuum evaporation coatingTitanium aluminium nitrideAluminum composites

The invention discloses a preparation method for a nitrogen oxygen titanium aluminum / titanium aluminum nitrogen and titanium aluminum composite film. The preparation method sequentially comprises the following steps: 1, Determining a precipitation technology and target components; 2, selecting and pretreating a substrate workpiece; 3, determining the suspension position of the substrate workpiece; 4, performing vacuum heating treatment; 5, determining a pre-bombardment process; 6, determining a precipitation process. According to the preparation method, the adhesive force between the film and a substrate can be improved, the hardness of the film can be improved, and excellent stability and repeatability can be achieved.

Owner:SHENYANG UNIV

Self-lubricating brush seal assembly and method of reducing leakage

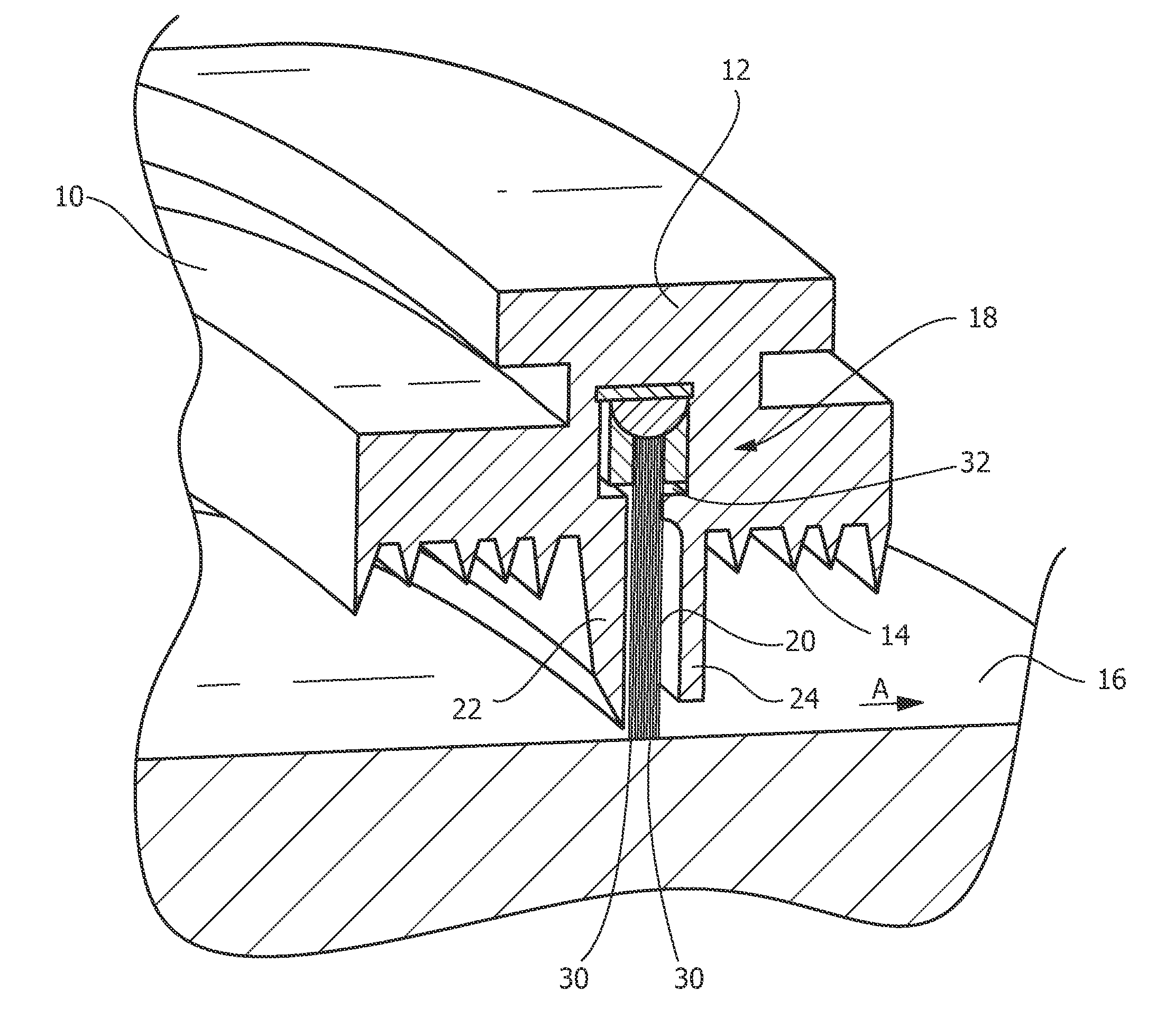

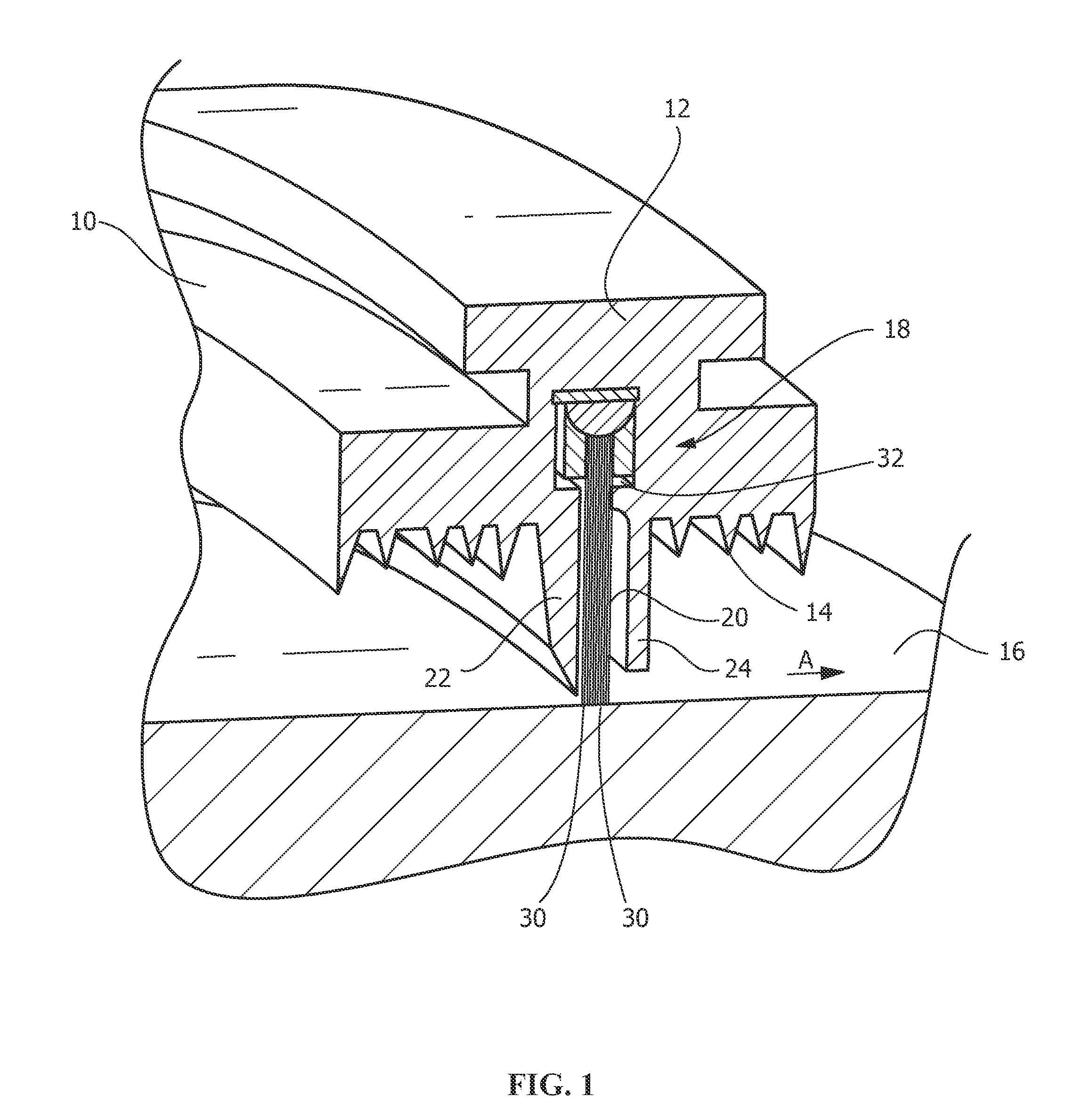

ActiveUS20130042456A1Reduce air leakageEngine sealsLeakage preventionTitanium aluminium nitrideBristle

A self-lubricating brush seal assembly, for a power generation system and method of reducing air leakage in a power generation system including a plurality of self-lubricating members is provided. The plurality of self-lubricating members include a plurality of self-lubricating bristles, a plurality of cores sheathed in a self-lubricating braid, a plurality of cores having an outer diameter coated with self-lubricating material and a solid lubricating pack. The lubricating material is selected from graphite, hexagonal-boron nitrite (hBN), molybdenum disulfide (MoS2), tungsten disulfide (WS2), titanium nitride (TiN), titanium aluminum nitride (TiAlN), titanium carbonitride (TiCN), and combinations thereof.

Owner:GENERAL ELECTRIC CO

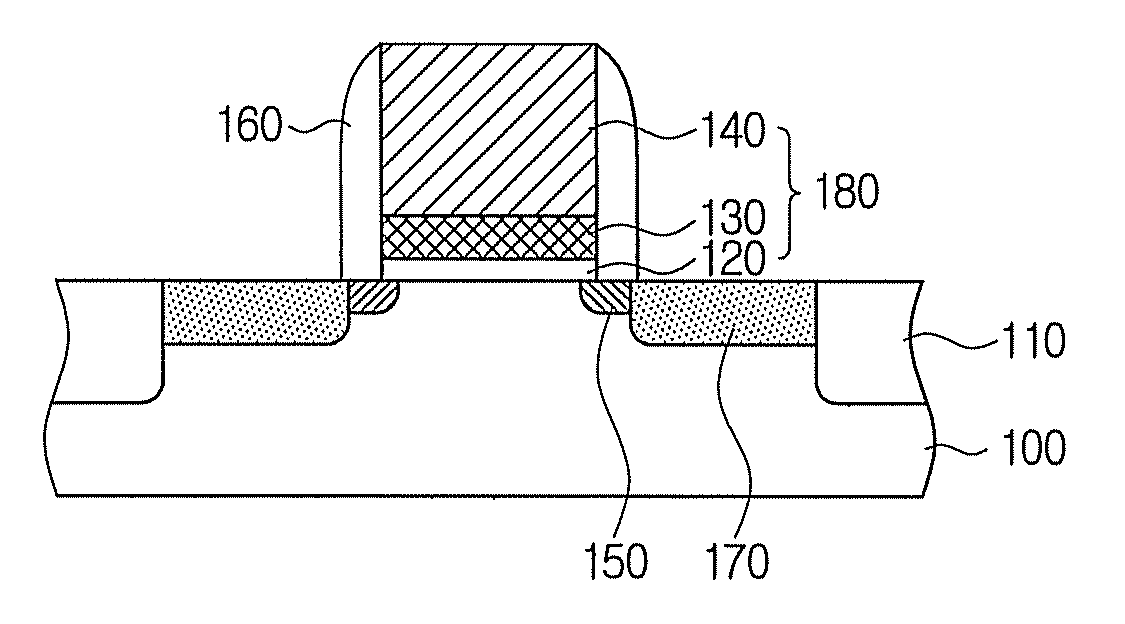

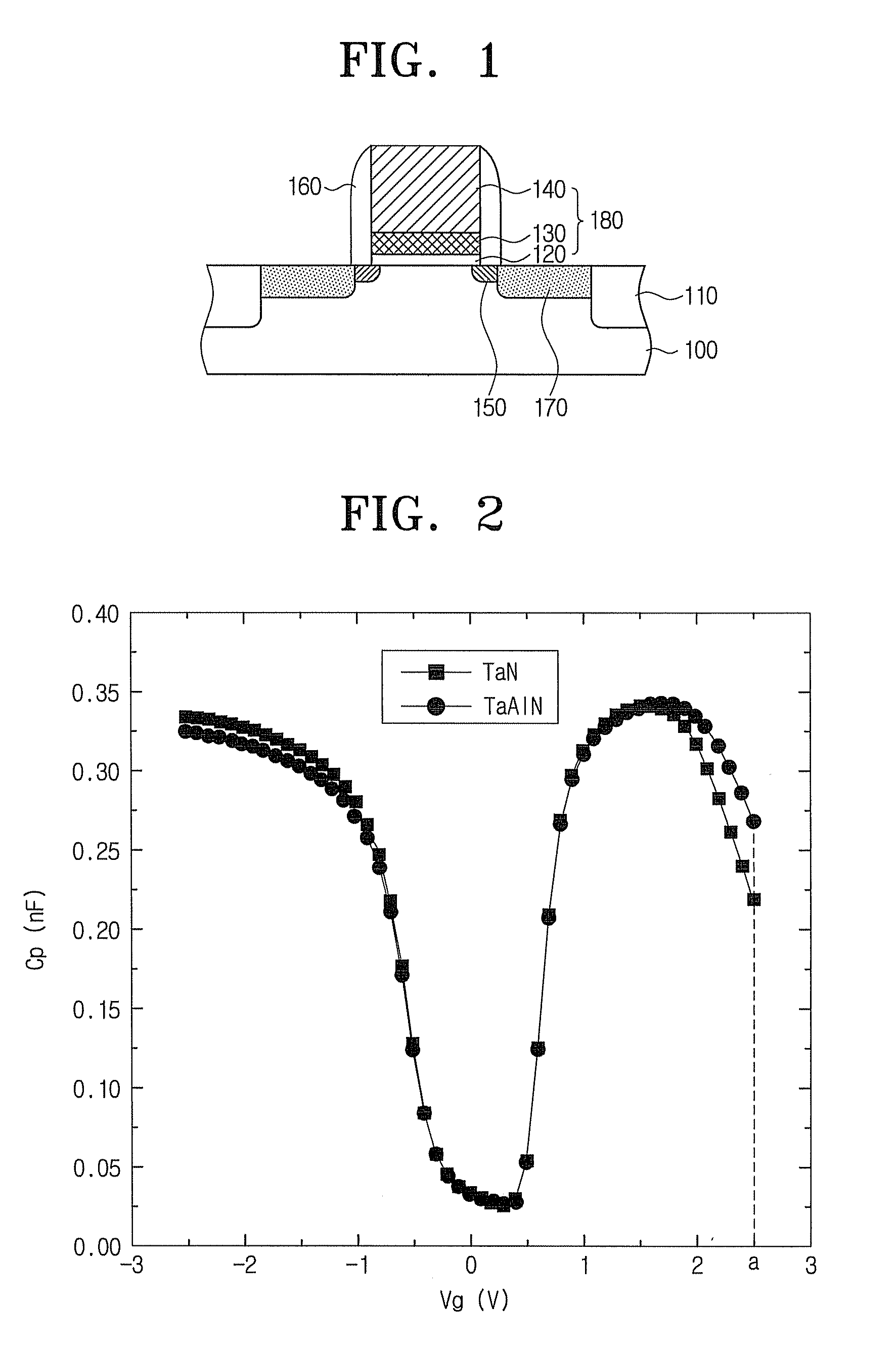

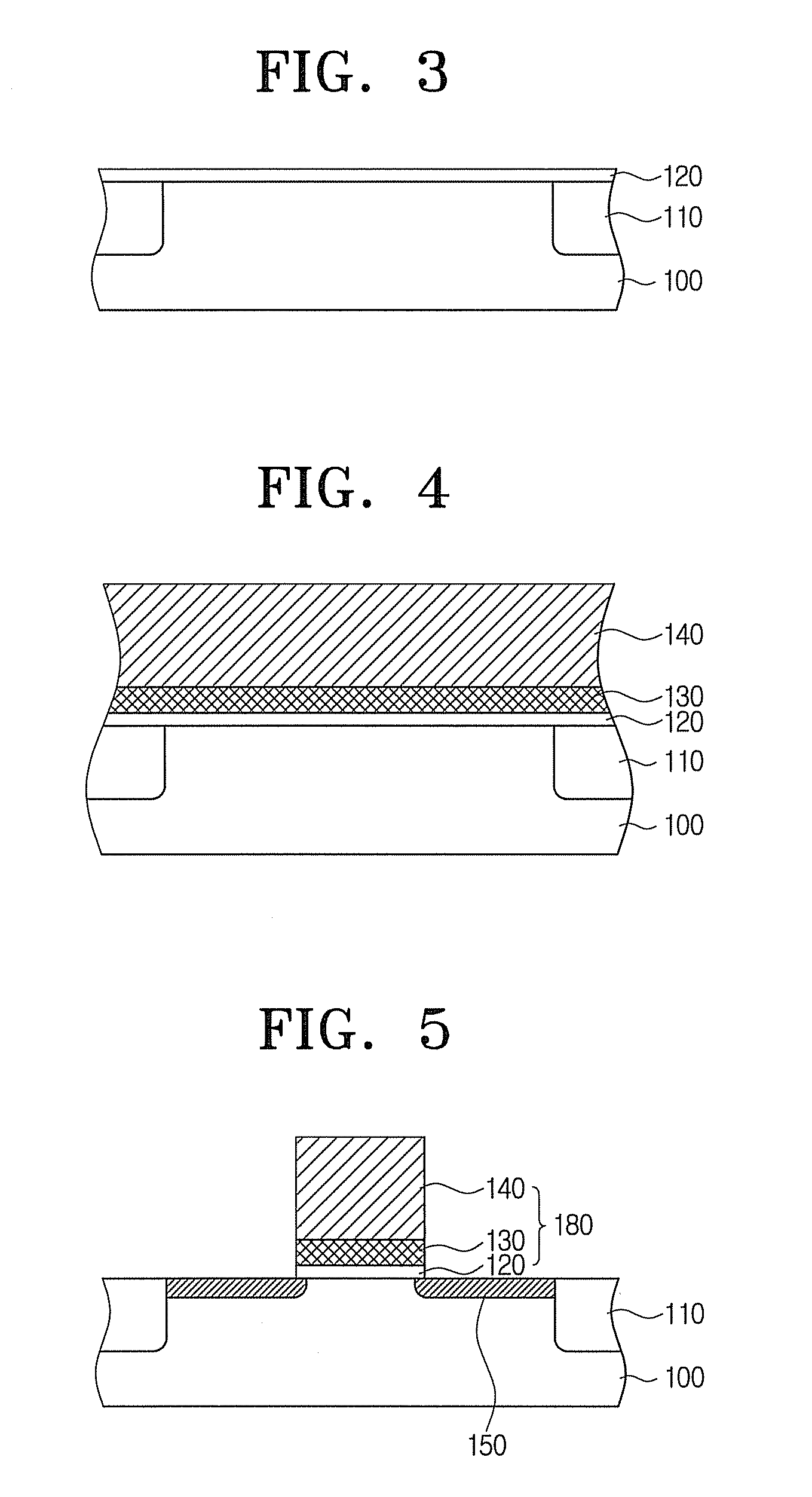

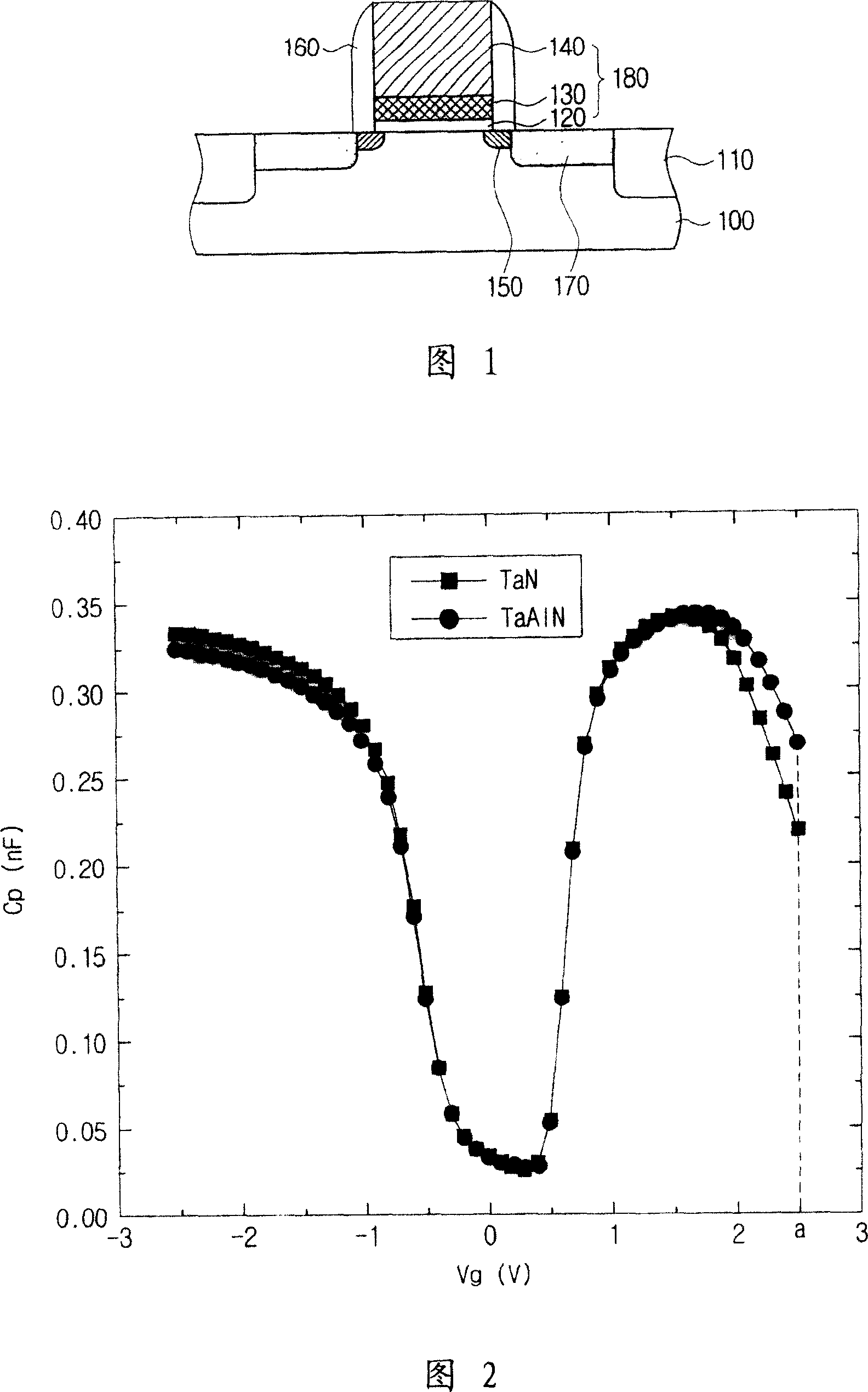

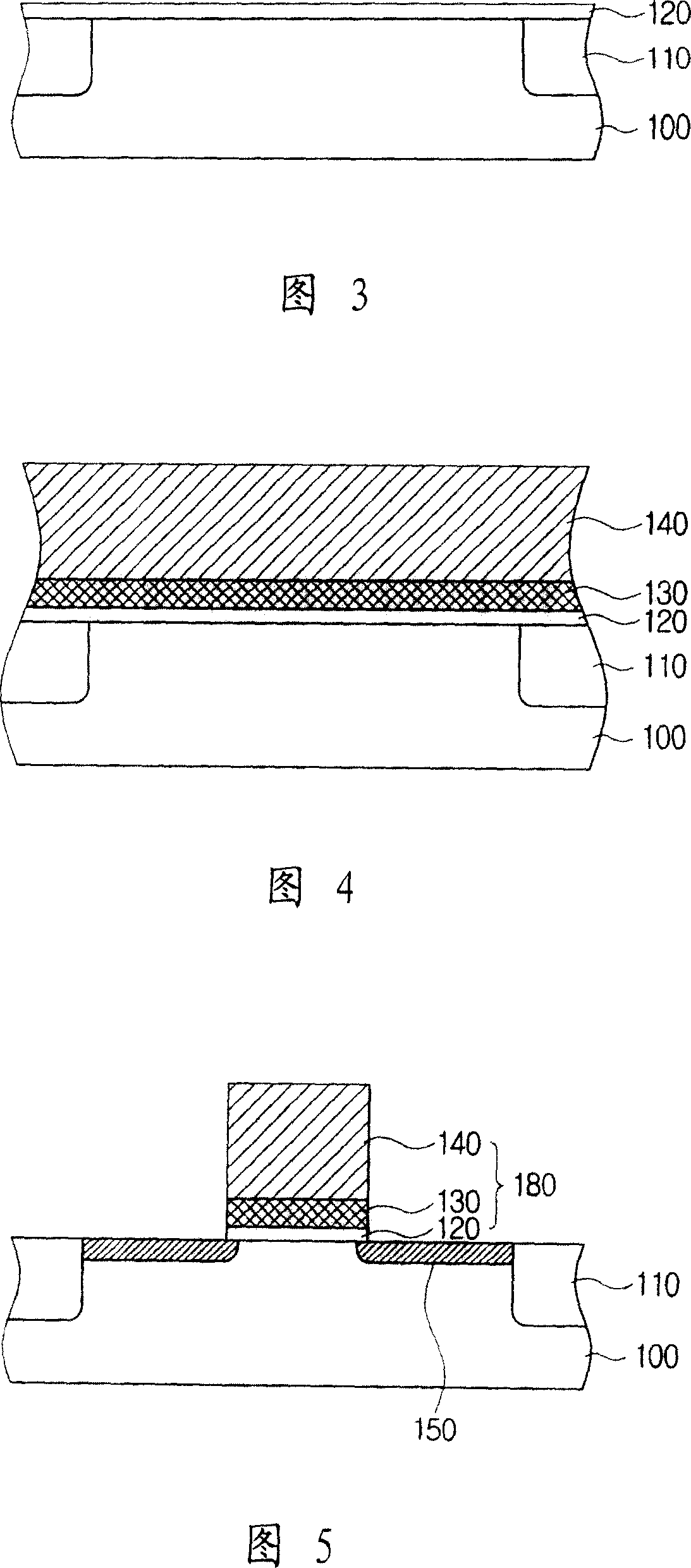

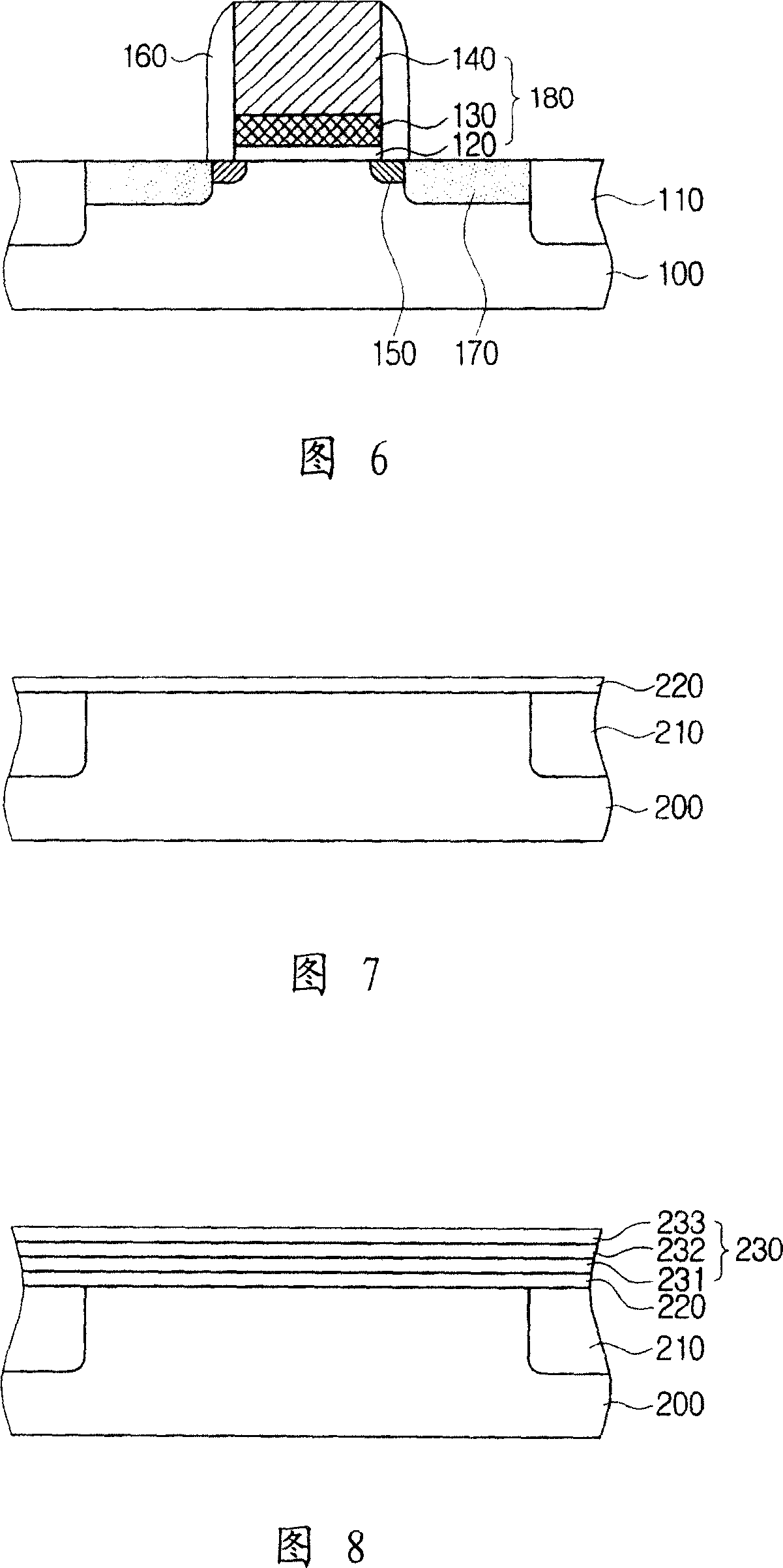

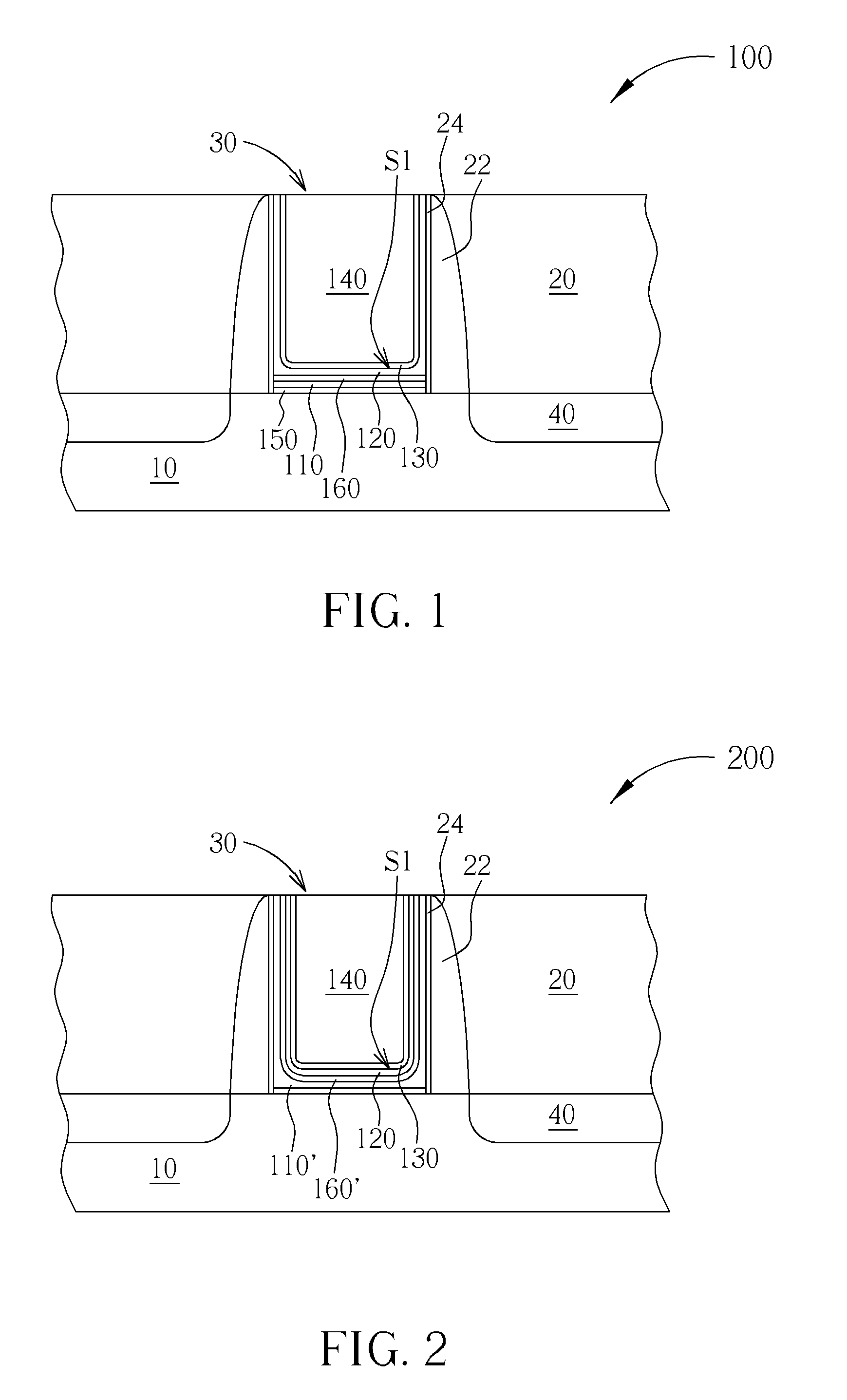

Semiconductor device and method of manufacturing the same

InactiveUS20070152283A1Inhibit deteriorationReduces and eliminates leakage currentTransistorSemiconductor/solid-state device manufacturingDielectricTitanium aluminium nitride

A semiconductor device and a manufacturing method thereof for preventing gate electrode degradation and gate current leakage. The semiconductor device includes a gate insulating layer including an H-k (high dielectric) material on a semiconductor substrate, a barrier metal layer including a metal alloy on the gate insulating layer, and a gate electrode layer formed on the barrier metal layer. Illustratively, the barrier metal layer includes at least one of TaAlN (tantalum aluminum nitride) or TiAlN (titanium aluminum nitride). The barrier metal layer can include an oxidation-resistant material so that oxidation of the barrier metal layer is prevented during a subsequent annealing of the semiconductor device in an oxygen atmosphere. Thus, degradation of a gate electrode is prevented, and gate current leakage due to degradation of the gate electrode is prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

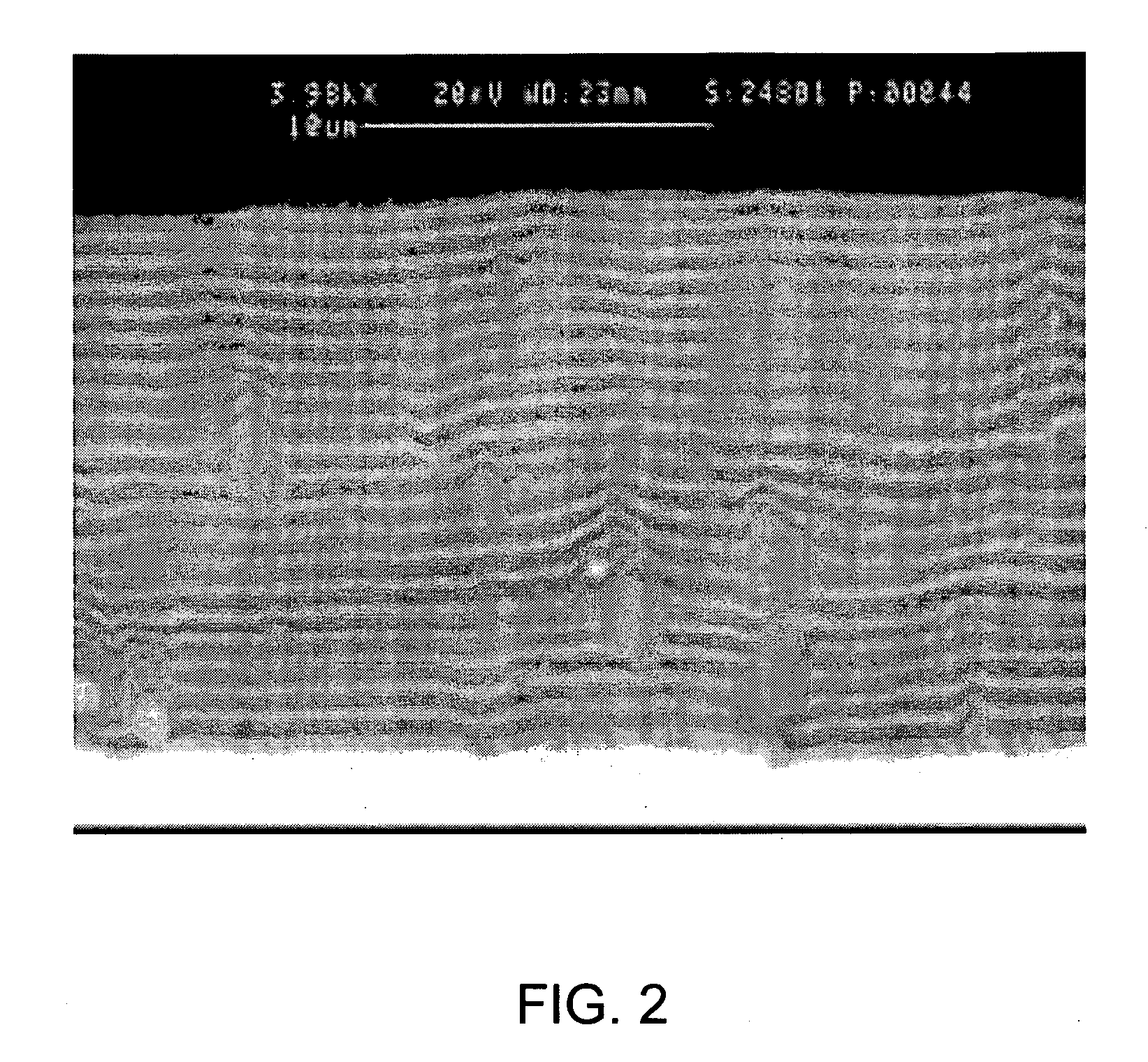

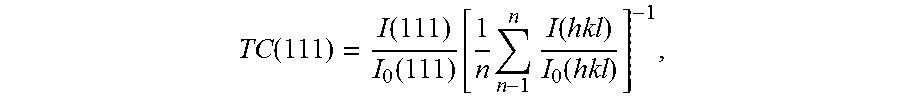

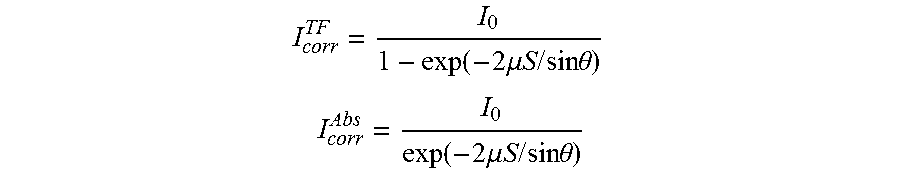

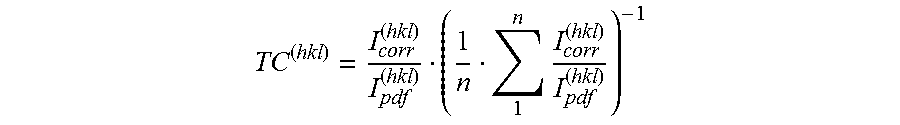

Coated Cutting Tool Insert with MT-CVD TiCN on TiAI(C,N)

ActiveUS20170275765A1Improve wear resistanceImprove thermal cracking resistanceWorkpiecesTurning toolsTitanium aluminium nitrideFiber

A coated cutting tool includes a substrate of cemented carbide, cermet, ceramics, steel or cubic boron nitride, a multi-layered wear resistant coating and at least two refractory coating layers deposited. The at least two refractory coating layers include a first coating layer and a second coating layer deposited on top of each other. The first coating layer is titanium aluminium nitride or carbonitride Ti1-uAluCvNw, with 0.2≦u≦1.0, 0≦v≦0.25 and 0.7≦w≦1.15 deposited by CVD. The second coating layer is titanium carbonitride TixCyN1-y, with 0.85≦x≦1.1 and 0.4≦y≦0.85, and is deposited on top of the first coating layer by MT-CVD. The second TixCyN1-y coating layer has a columnar grain morphology and the overall fiber texture of the TixCyN1-y coating layer is characterized by a texture coefficient TC (1 1 1)>2.

Owner:WALTER AG

Substrate device having a tuned work function and methods of forming thereof

ActiveUS8129280B2Semiconductor/solid-state device manufacturingSemiconductor devicesTitanium aluminium nitrideCelsius Degree

Substrate devices having tuned work functions and methods of forming thereof are provided. In some embodiments, forming devices on substrates may include depositing a dielectric layer atop a substrate having a conductivity well; depositing a work function layer comprising titanium aluminum or titanium aluminum nitride having a first nitrogen composition atop the dielectric layer; etching the work function layer to selectively remove at least a portion of the work function layer from atop the dielectric layer; depositing a layer comprising titanium aluminum or titanium aluminum nitride having a second nitrogen composition atop the work function layer and the substrate, wherein at least one of the work function layer or the layer comprises nitrogen; etching the layer and the dielectric layer to selectively remove a portion of the layer and the dielectric layer from atop the substrate; and annealing the substrate at a temperature less than about 1500 degrees Celsius.

Owner:APPLIED MATERIALS INC

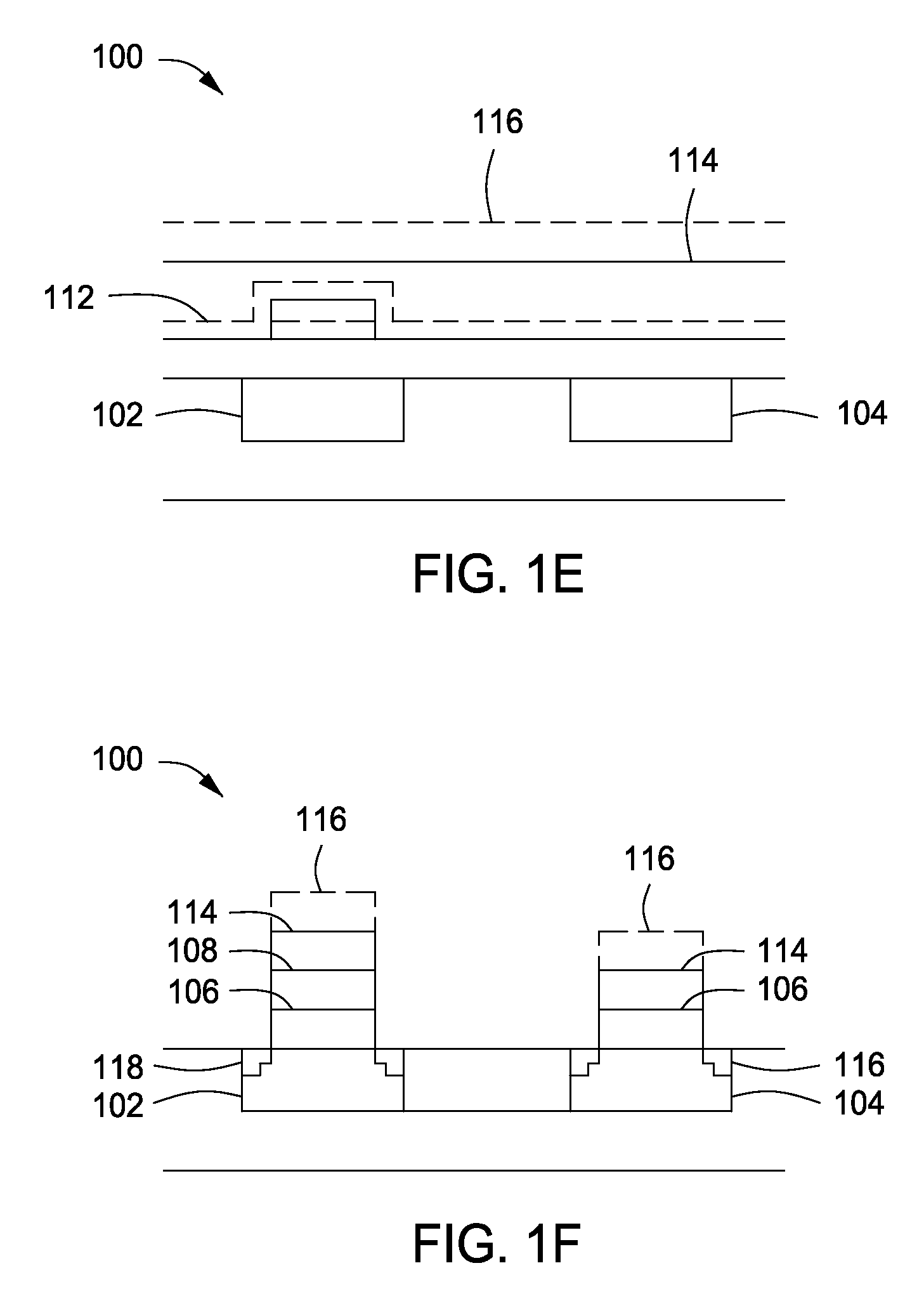

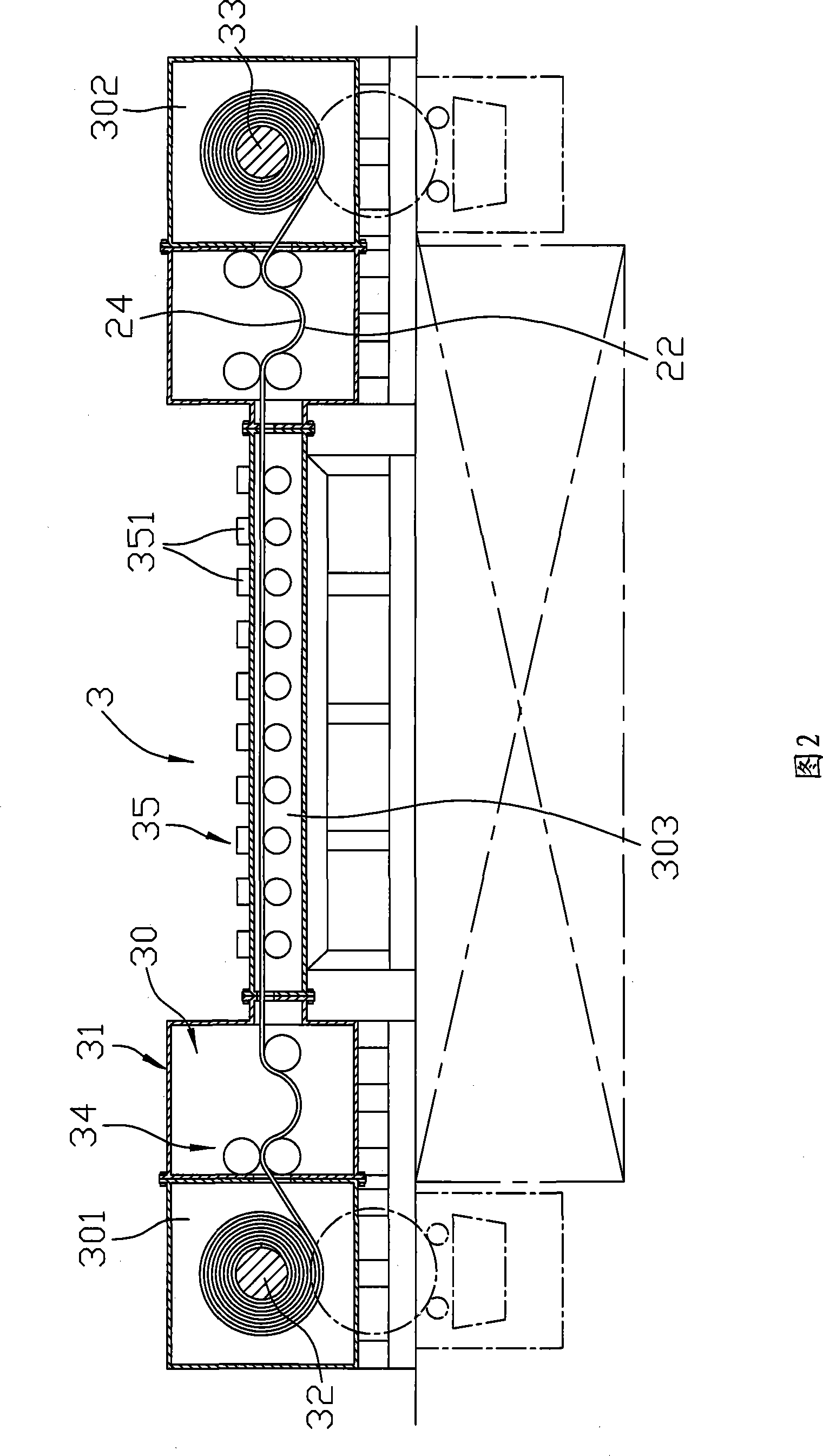

Method for manufacturing construction composite panel with sedimentary deposit

InactiveCN101428492AImprove wear resistanceGood temperature resistanceLamination ancillary operationsVacuum evaporation coatingTitanium aluminium nitrideGas phase

The invention relates to a production method of a construction composite board with a deposition layer and comprises the steps of preparing non-metal core layer, preparing two metal substrates, continuously forming deposition layer, combining the substrates to the core layer; the continuously forming of the deposition layer accords to the physical gas phrase deposition principle and a deposition layer of 0.3 to 10 Mum is formed on the surface of at least a substrate; and the deposition layer is chosen from at least one of the titanium, copper, chrome, zinc, aluminum, platinum, gold, silver, nickel, titanium nitride, aluminum nitride, titanium aluminum nitride, chromium nitride, silicon dioxide and titanium dioxide. The deposition layer formed though utilizing the physical gas phrase deposition principle not only has excellent wear resistance, temperature resistance and corrosion resistance, but also can naturally produce color change by utilizing physical phenomenon to light produced by the thickness of a coating without any additive solvent, dye and additive.

Owner:XXENTRIA TECH MATERIALS CO LTD

Preparation method of titanium nitride aluminum zirconium/titanium nitride aluminum zirconium chromium multi-element double-layer hard film

InactiveCN103484822AStrong membrane/substrate binding forceHigh hardnessVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideHeat resistance

The invention relates to a preparation method of a titanium nitride aluminum zirconium / titanium nitride aluminum zirconium chromium multi-element double-layer hard film. The preparation method comprises the steps: 1, determination of a deposition technology; 2, selection of target material components; 3, a workpiece selecting and preprocessing process; 4, a pre-bombarding process; 5, a deposition process; 6, a heating and cooling process; 7, a workpiece rotating process; 8, the titanium nitride aluminum zirconium / titanium nitride aluminum zirconium chromium multi-element double-layer hard film can be obtained according to the preparation method provided by the invention. According to the preparation method of the titanium nitride aluminum zirconium / titanium nitride aluminum zirconium chromium multi-element double-layer hard film, the binding force between the film and a matrix is enhanced, the heat resistance of the film is enhanced, in particular, the hardness and the wear resistance of the film are improved; the method is simple and easy to operate, the work efficiency is greatly improved, and the cost of film coating is reduced.

Owner:SHENYANG UNIV

Semiconductor device and method of manufacturing the same

InactiveCN1996614AInhibit deteriorationReduce or eliminate leakage currentTransistorSemiconductor/solid-state device manufacturingDielectricTitanium aluminium nitride

A semiconductor device and a manufacturing method thereof for preventing gate electrode degradation and gate current leakage. The semiconductor device includes a gate insulating layer including an H-k (high dielectric) material on a semiconductor substrate, a barrier metal layer including a metal alloy on the gate insulating layer, and a gate electrode layer formed on the barrier metal layer. Illustratively, the barrier metal layer includes at least one of TaAlN (tantalum aluminum nitride) or TiAlN (titanium aluminum nitride). The barrier metal layer can include an oxidation-resistant material so that oxidation of the barrier metal layer is prevented during a subsequent annealing of the semiconductor device in an oxygen atmosphere. Thus, degradation of a gate electrode is prevented, and gate current leakage due to degradation of the gate electrode is prevented.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of chromium nitride/titanium aluminum zirconium chromium nitride multiple double-layer hard film

InactiveCN103668059AStrong membrane/substrate binding forceHigh hardnessVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideHeat resistance

The invention discloses a preparation method of chromium nitride / titanium aluminum zirconium chromium nitride multiple double-layer hard film. The preparation method comprises the following steps: 1, determination of precipitation; 2, selection of target material components; 3, selection and pretreatment process of workpieces; 4, pre-bombardment process; 5, precipitation process; 6, heating and cooling process; 7, rotating process of the workpieces; 8, obtaining of the chromium nitride / titanium aluminum zirconium chromium nitride multiple double-layer hard film according to the preparation method provided by the invention. By adopting the preparation method, the high hardness and high film / substrate binding force of the film are guaranteed, the abrasion resistance of the film is improved, particularly, the heat resistance of the film is improved, the work efficiency is improved and the coating film cost is reduced; the method is simple and easy to operate.

Owner:SHENYANG UNIV

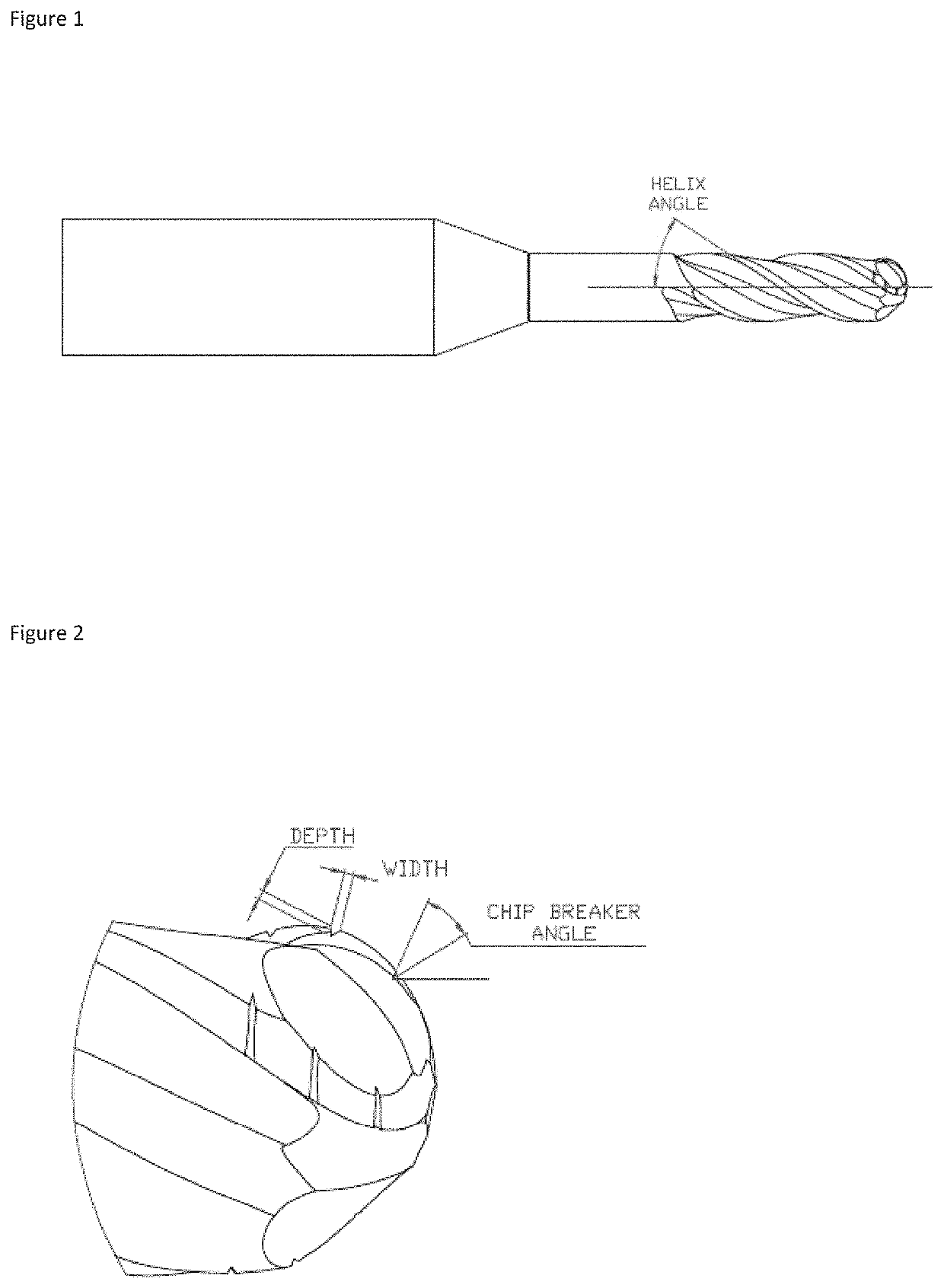

Dental Milling Tool

ActiveUS20190365502A1Improve tool lifeReduce cutting forceDental implantsMilling cuttersSuperhard materialTitanium aluminium nitride

The invention provides a dental milling tool for milling dental materials in the making of dental prostheses. The dental milling tool is a ball-nose end mill having three helical flutes, each flute being associated with a cutting edge, each cutting edge having chip breakers along the curved edges of the ball. The dental milling tool may be formed from a hard material such as carbide based material, ceramic, cermet, superhard materials including polycrystalline diamond (PCD) and cubic boron nitride (CBN), and diamond composite. Alternatively, the dental milling tool may be coated with a hard coating such as diamond coating, diamond-like-carbon (DLC), nitride based coating such as titanium aluminium nitride (TiAlN), aluminium titanium nitride, (AlTiN), and titanium nitride (TiN), and ceramic coating.

Owner:PRIMA DENTAL MFG

Coating, article coated with coating, and method for manufacturing article

InactiveUS8541101B2Vacuum evaporation coatingSputtering coatingTitanium aluminium nitrideCarbon nitride

A coating includes a titanium aluminum layer; a titanium aluminum nitride layer deposited on the titanium aluminum layer; a titanium aluminum carbon-nitride layer deposited on the titanium aluminum nitride layer; and a silicon carbon-nitride layer deposited on the titanium aluminum carbon-nitride layer.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Metal gate structure and fabrication method thereof

ActiveUS20150004780A1Reduce throughputReduce thicknessTransistorSemiconductor/solid-state device manufacturingTitanium aluminium nitrideGate dielectric

A metal gate structure located on a substrate includes a gate dielectric layer, a metal layer and a titanium aluminum nitride metal layer. The gate dielectric layer is located on the substrate. The metal layer is located on the gate dielectric layer. The titanium aluminum nitride metal layer is located on the metal layer.

Owner:MARLIN SEMICON LTD

Preparation method for niobium nitride/ titanium aluminum nitride zirconium-niobium quaternary double-layered nitride film

InactiveCN104726835AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideTitanium

A preparation method for a niobium nitride / titanium aluminum nitride zirconium-niobium quaternary double-layered nitride film comprises the following steps of (1) determinng a deposition technology; (2) using a target composition; (3) selecting and pre-treating workpieces; (4) performing pre-bombarding technology; (5) performing a deposition technology; (6) performing a heating and cooling-down technology; and (7) rotating the workpieces. By the preparation method for the niobium nitride / titanium aluminum nitride zirconium-niobium quaternary double-layered nitride film, high hardness and high film / base binding force of the film are guaranteed, the wear resistance of the film is improved, and the high-temperature-resistant oxidation performance of the film is greatly improved. Moreover, the preparation method is simple and is easy to operate, the work efficiency is greatly improved, and the film plating cost is reduced.

Owner:SHENYANG UNIV

Titanium nitride-aluminium-zirconium/titanium nitride-aluminium-zirconium-silicon quaternary double layer nitride film preparation method

InactiveCN104726824AImprove bindingImprove high temperature oxidation resistanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideTantalum nitride

A titanium nitride-aluminium-zirconium / titanium nitride-aluminium-zirconium-silicon quaternary double layer nitride film preparation method includes 1, deposition technology determination; 2, target composition selection; 3, workpiece selection and pre-processing process; 4, pre-bombardment process; 5, deposition process; 6, heating and cooling process; 7, workpiece rotation process. The method has the advantages that the combination force and high-temperature oxidation resistance of the film and substrate are increased and improved, and the hardness and wear resistance of the film are improved greatly; the method is simple and easy to operate, the working efficiency is improved greatly, and the coating cost is reduced.

Owner:SHENYANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com