Patents

Literature

510 results about "Chromium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromium nitride is a chemical compound of chromium and nitrogen with the formula CrN. It is very hard, and is extremely resistant to corrosion. It is an interstitial compound, with nitrogen atoms occupying the octahedral holes in the chromium lattice: as such, it is not strictly a chromium(III) compound nor does it contain nitride ions (N³⁻). Chromium forms a second interstitial nitride, dichromium nitride, Cr₂N.

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

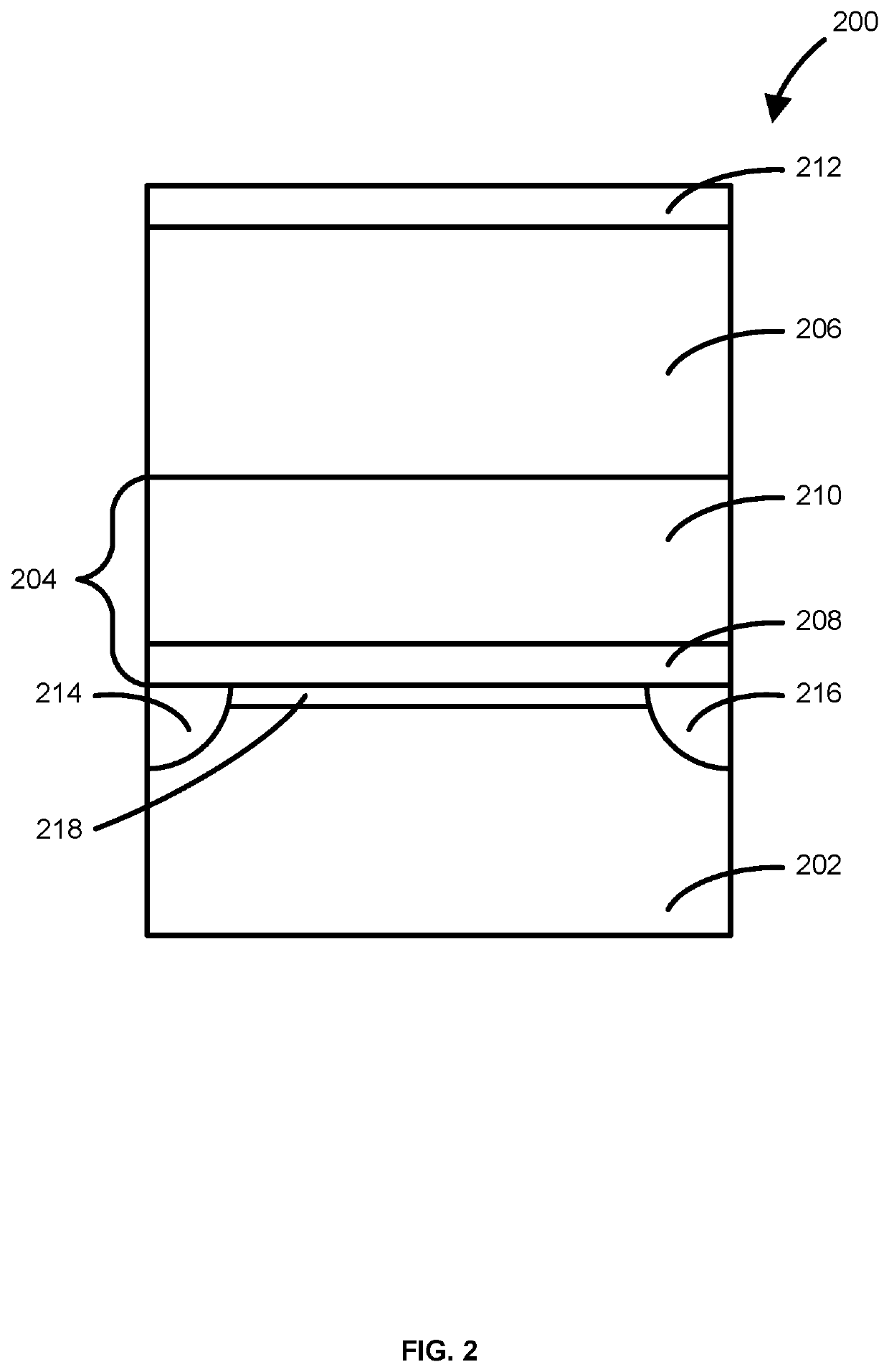

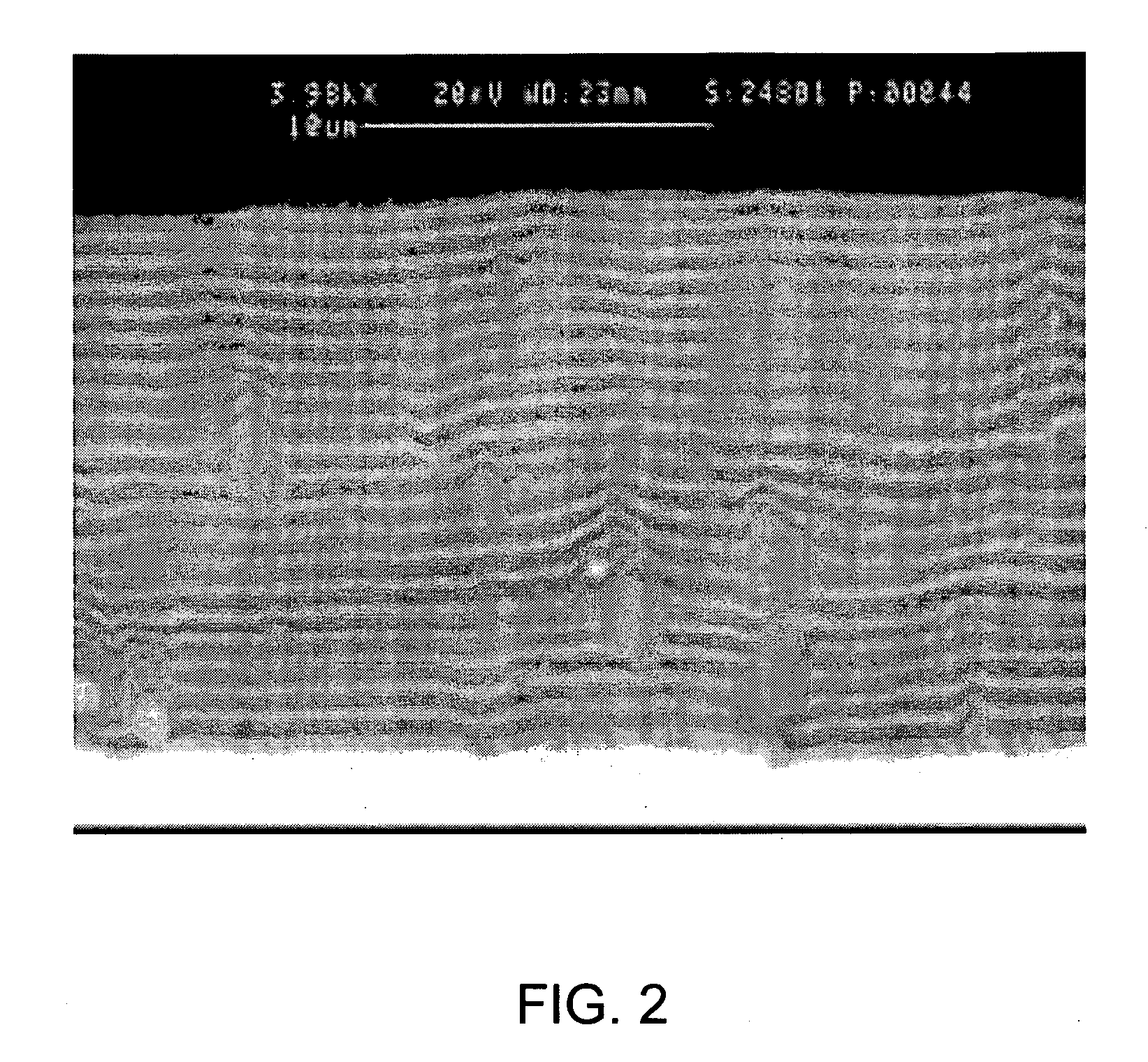

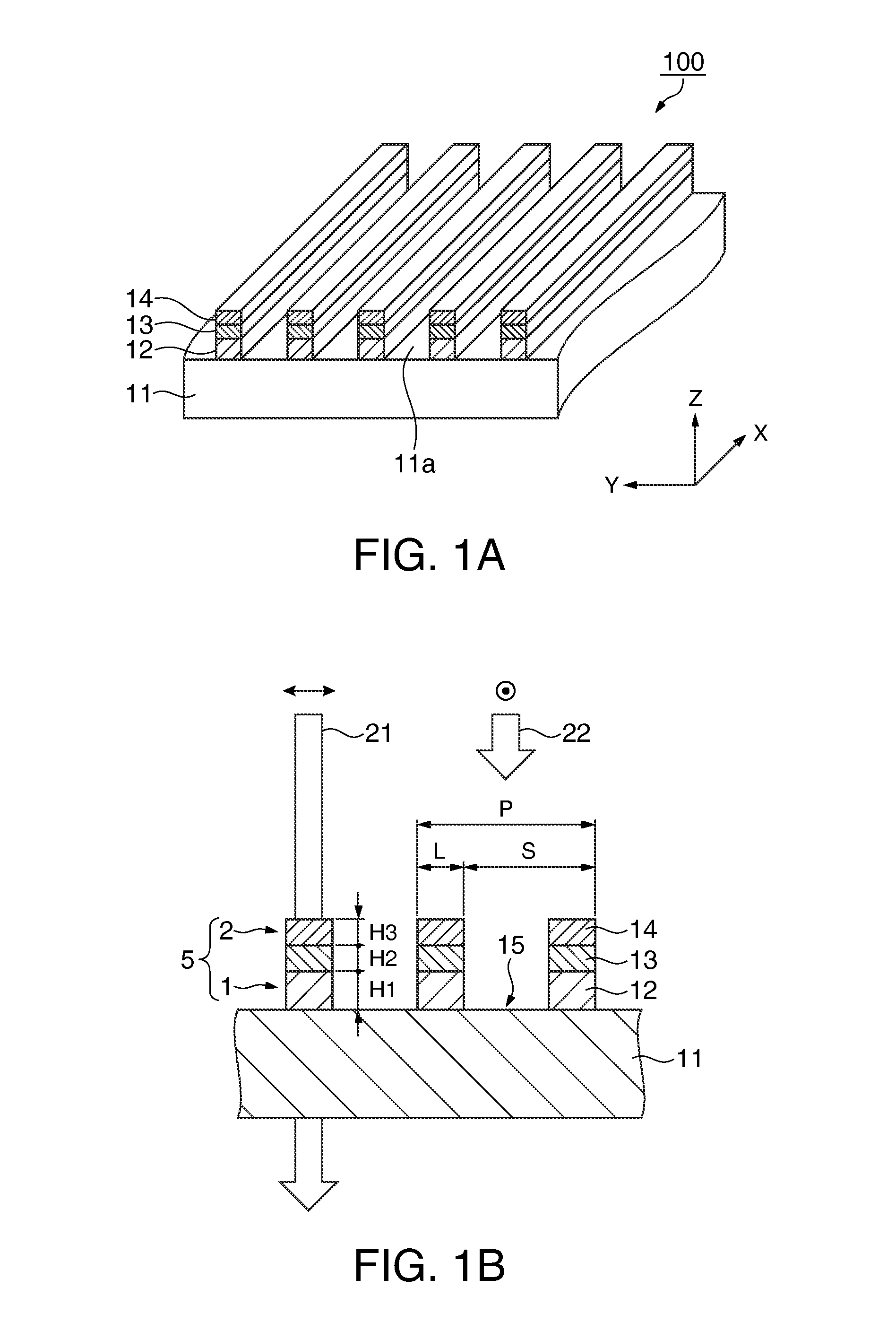

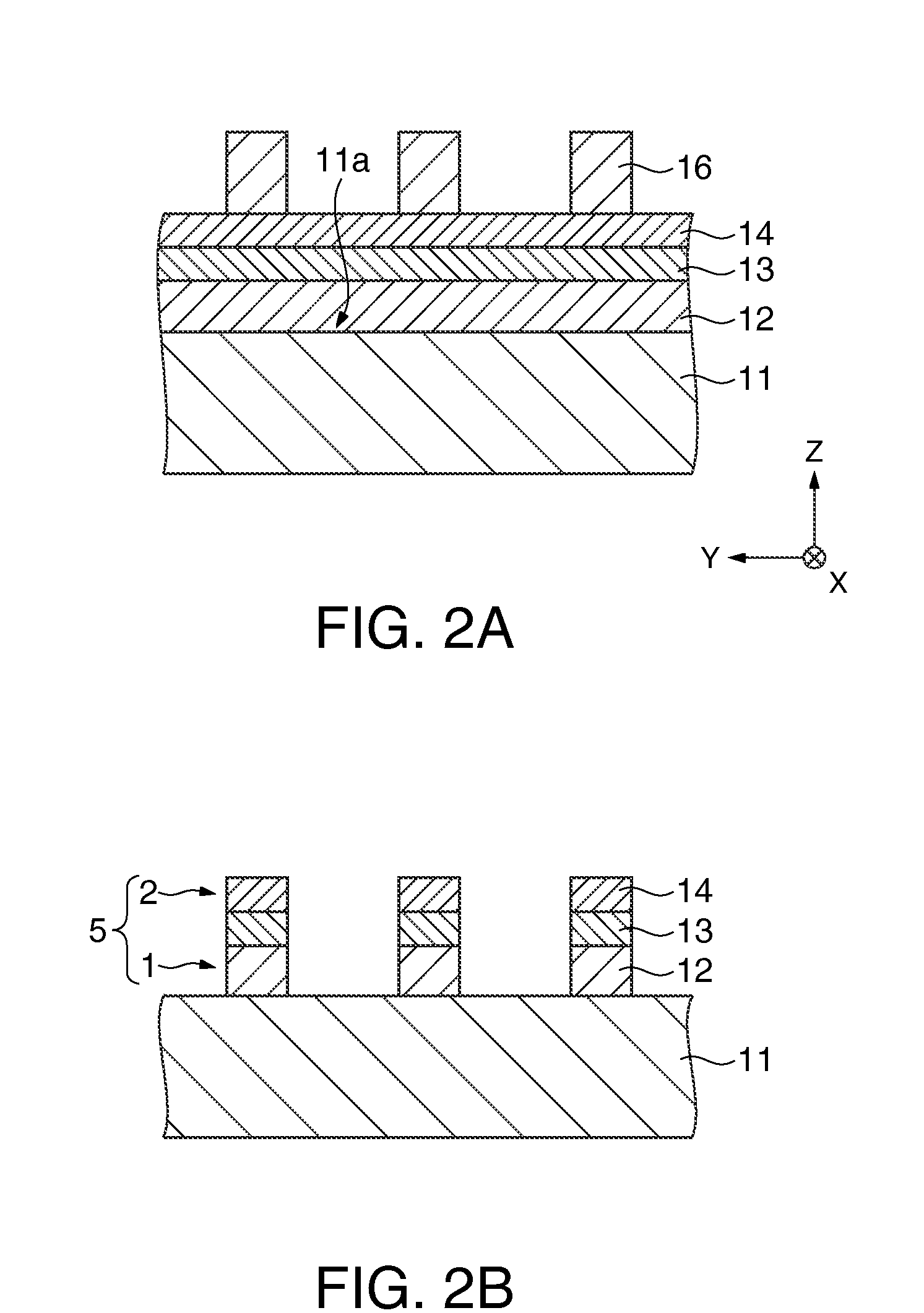

Method of forming chromium nitride layer and structure including the chromium nitride layer

PendingUS20210327715A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChromium nitrideDeposition process

Methods and systems for depositing chromium nitride layers onto a surface of the substrate and structures and devices formed using the methods are disclosed. An exemplary method includes using a deposition process, depositing a chromium nitride layer onto a surface of the substrate. The deposition process can include providing a chromium precursor to the reaction chamber and separately providing a nitrogen reactant to the reaction chamber. The deposition process may be a thermal cyclical deposition process.

Owner:ASM IP HLDG BV

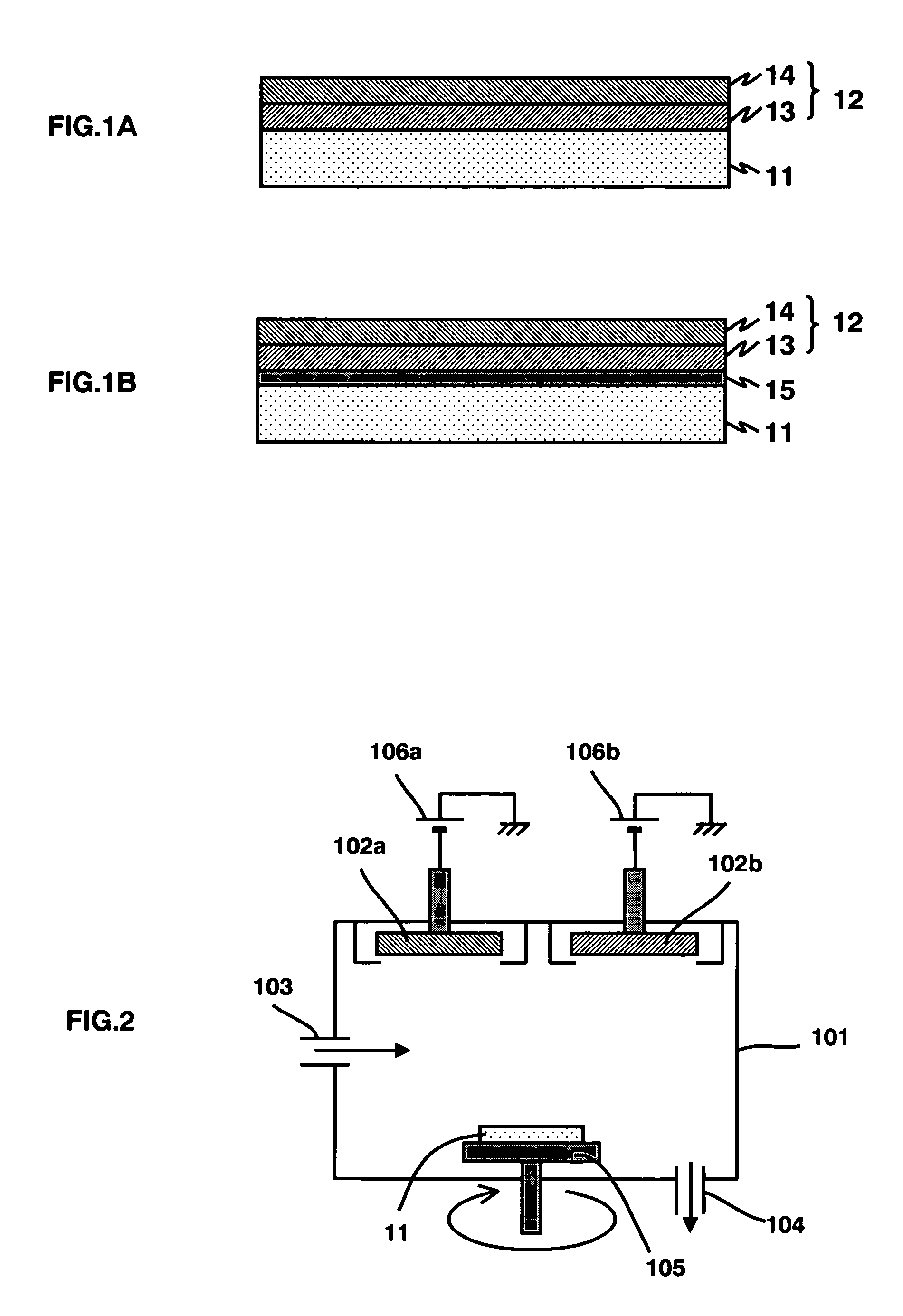

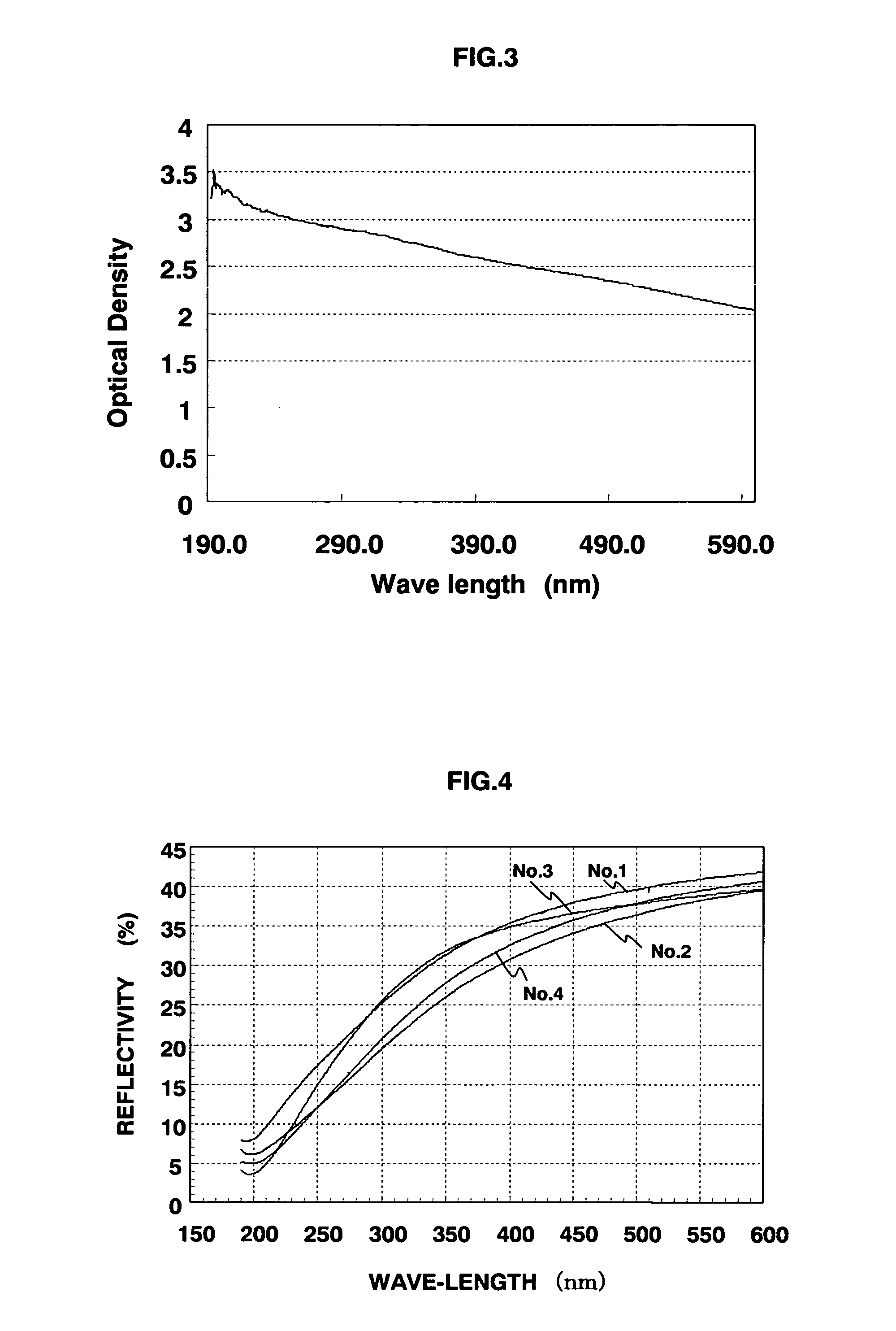

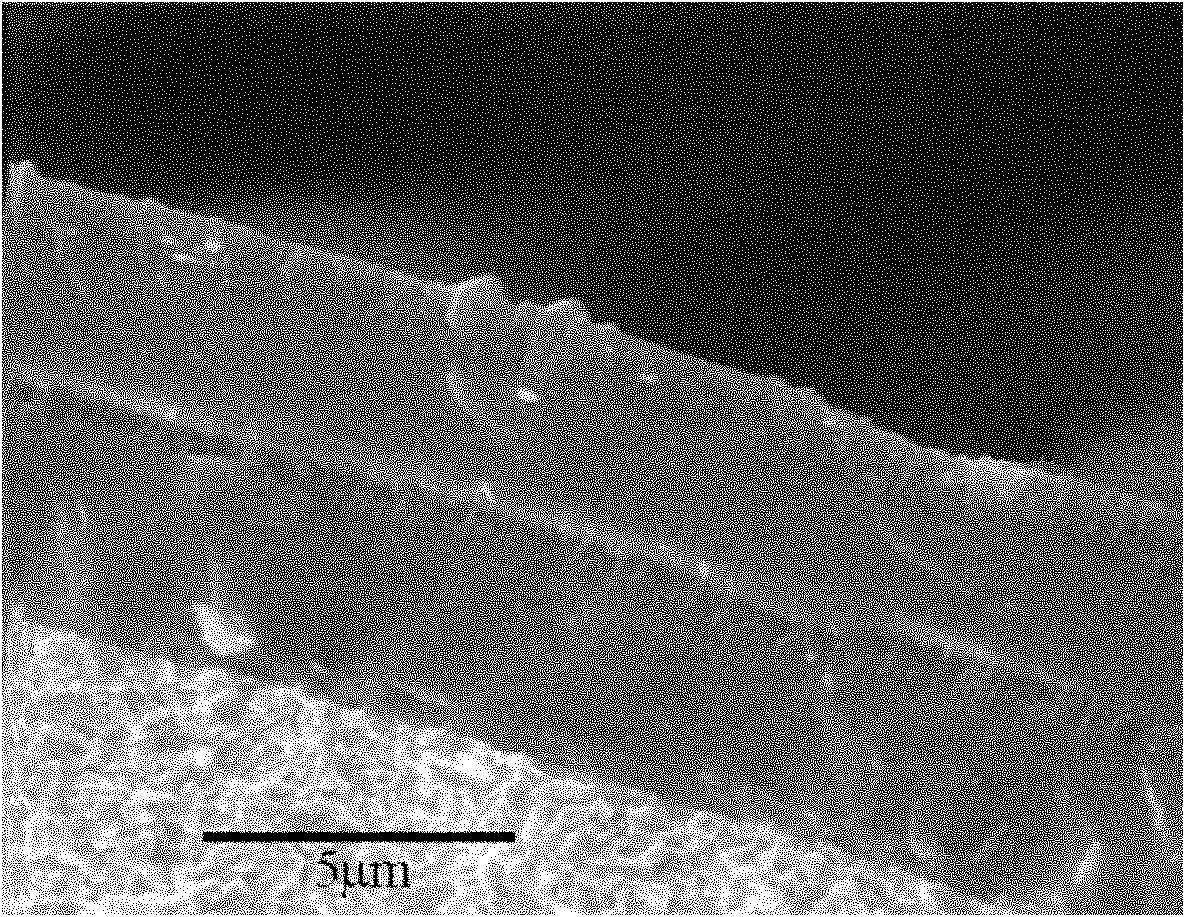

Photomask blank, photomask and fabrication method thereof

ActiveUS20060088774A1Reduce the burden onImprove accuracyDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxideChromium nitride

Owner:TOPPAN PHOTOMASK CO LTD +1

Chromium nitride aluminum-titanium composite coating, cutter deposited with same, and preparation method

InactiveCN102166849AHigh hardnessStrong adhesionVacuum evaporation coatingSputtering coatingOxidation resistantHigh surface

The invention discloses a chromium nitride aluminum-titanium composite coating, a cutter deposited with the same, and a preparation method. A Cr bonding layer, a CrN supporting layer and a main wear-resistant layer are sequentially deposited on a cutter substrate, wherein the main wear-resistant layer is a multi-layer composite coating composed of a TiAlN layer in a nanocrystalline structure and a CrTiAlN layer in a superlattice structure in an alternate mode, thereby obtaining the cutter with the chromium nitride aluminum-titanium composite coating. The chromium nitride aluminum-titanium composite coating provided by the invention combines the advantages of high hardness, low friction coefficient, strong adhesive force and high oxidation resistance temperature of the superlattice structure and nanocrystalline structure. The obtained cutter has high surface hardness, relatively strong film-base adhesive force, good wear resistance and good high temperature resistance.

Owner:YICHANG HOUHUANG VACUUM TECH

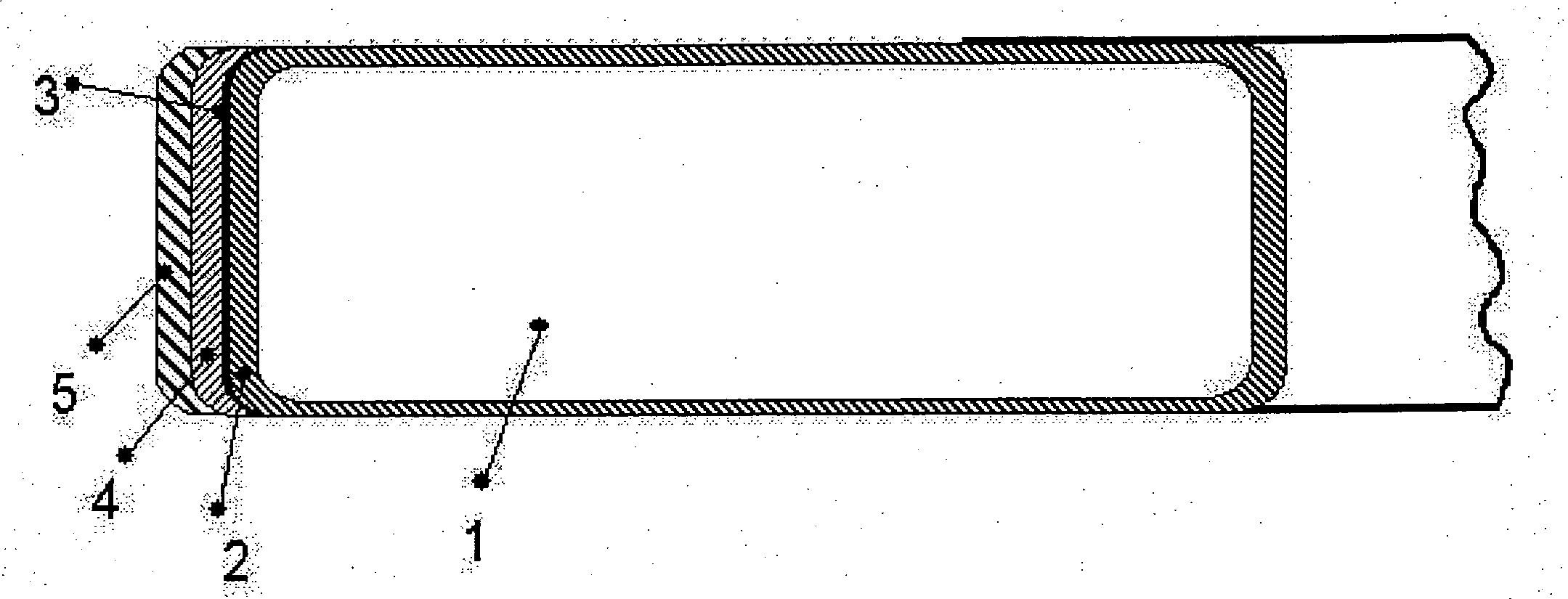

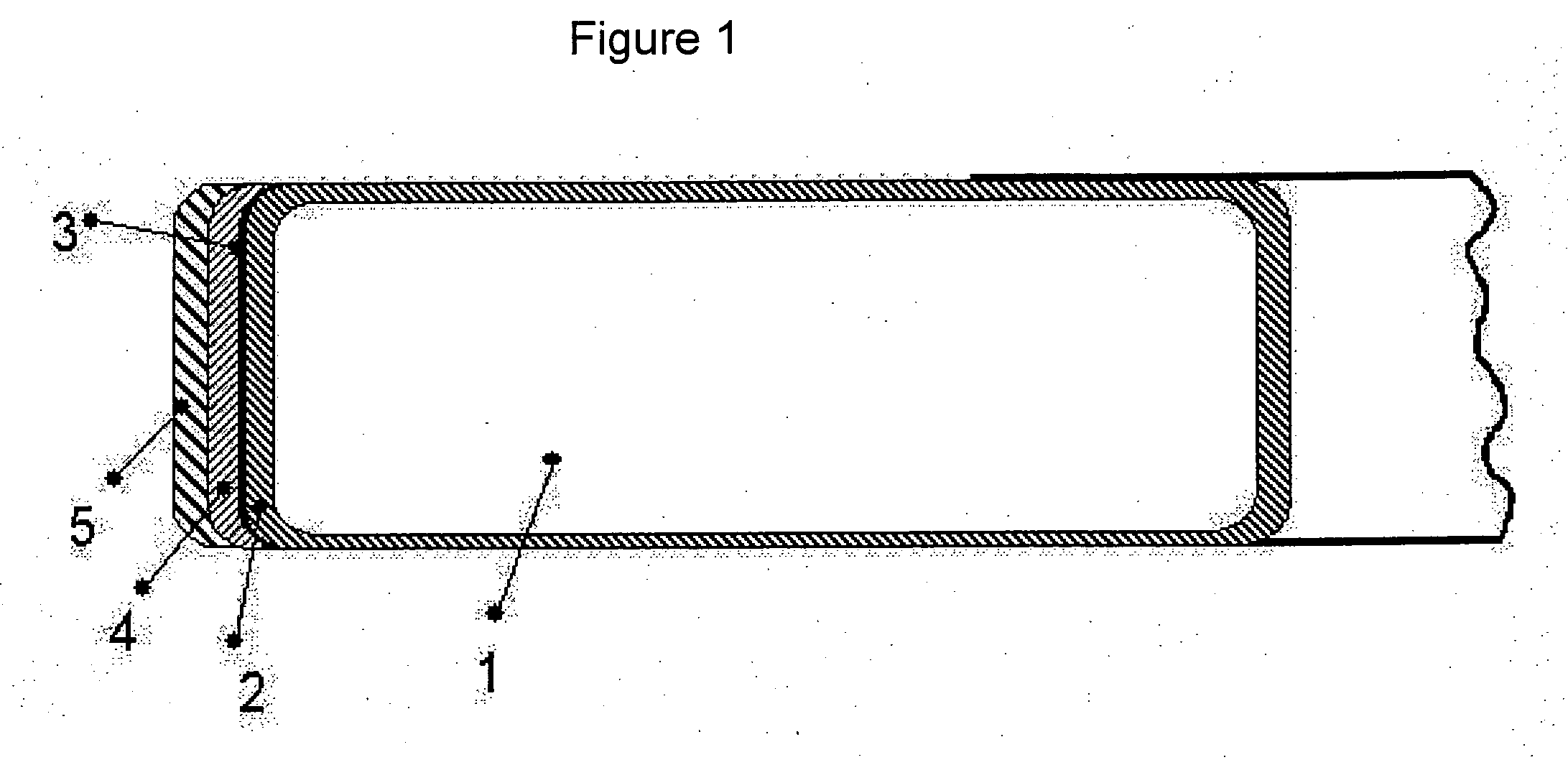

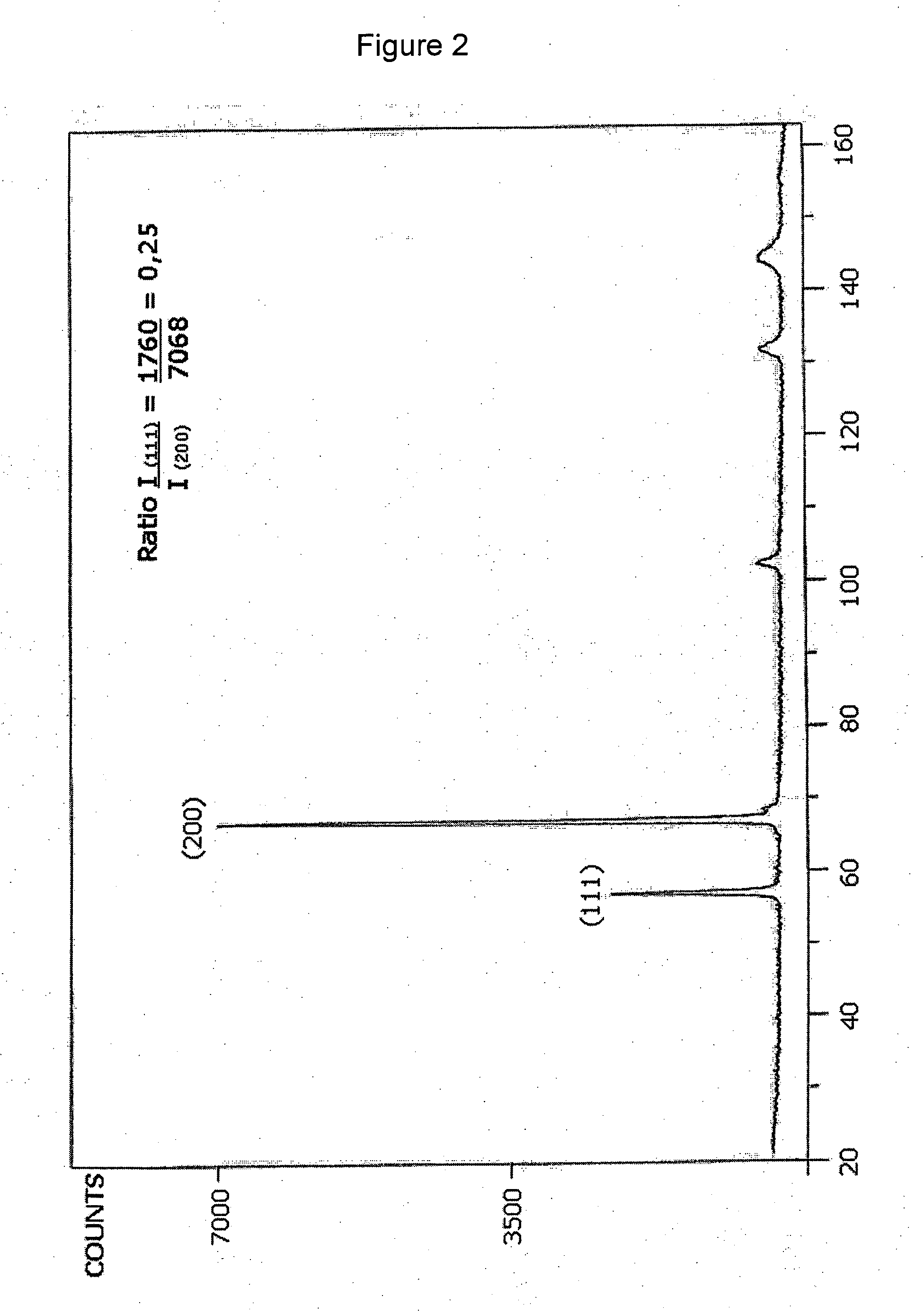

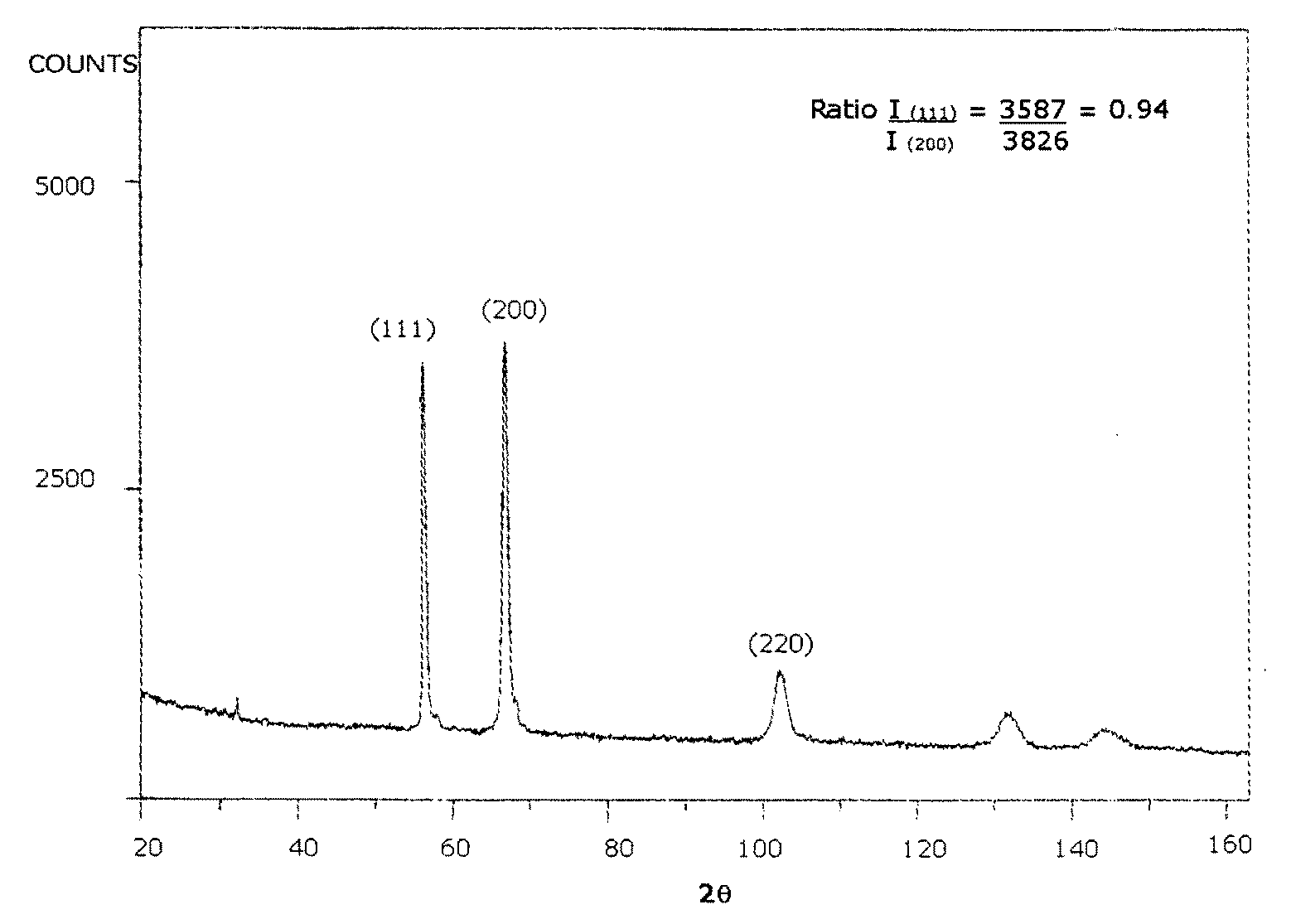

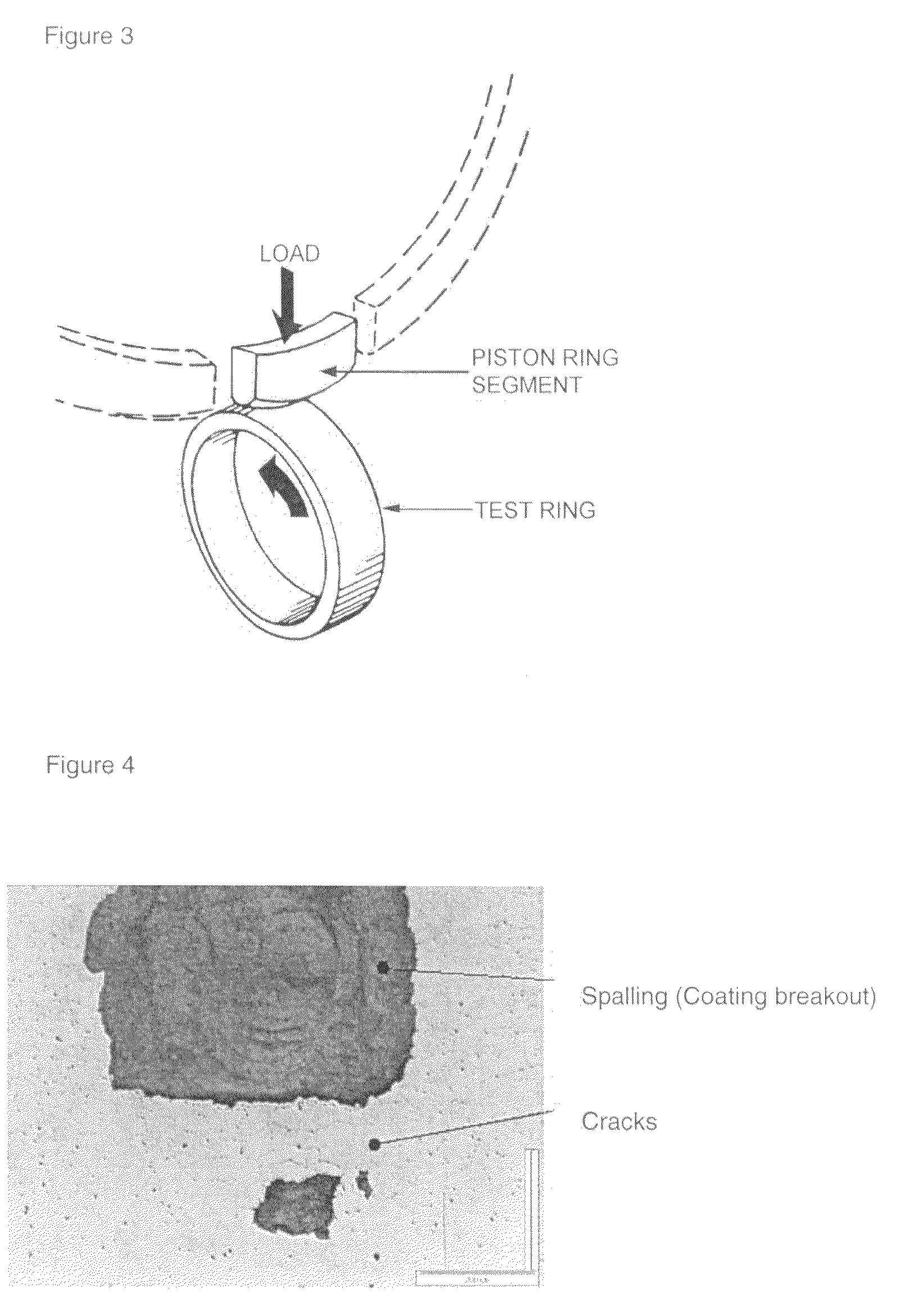

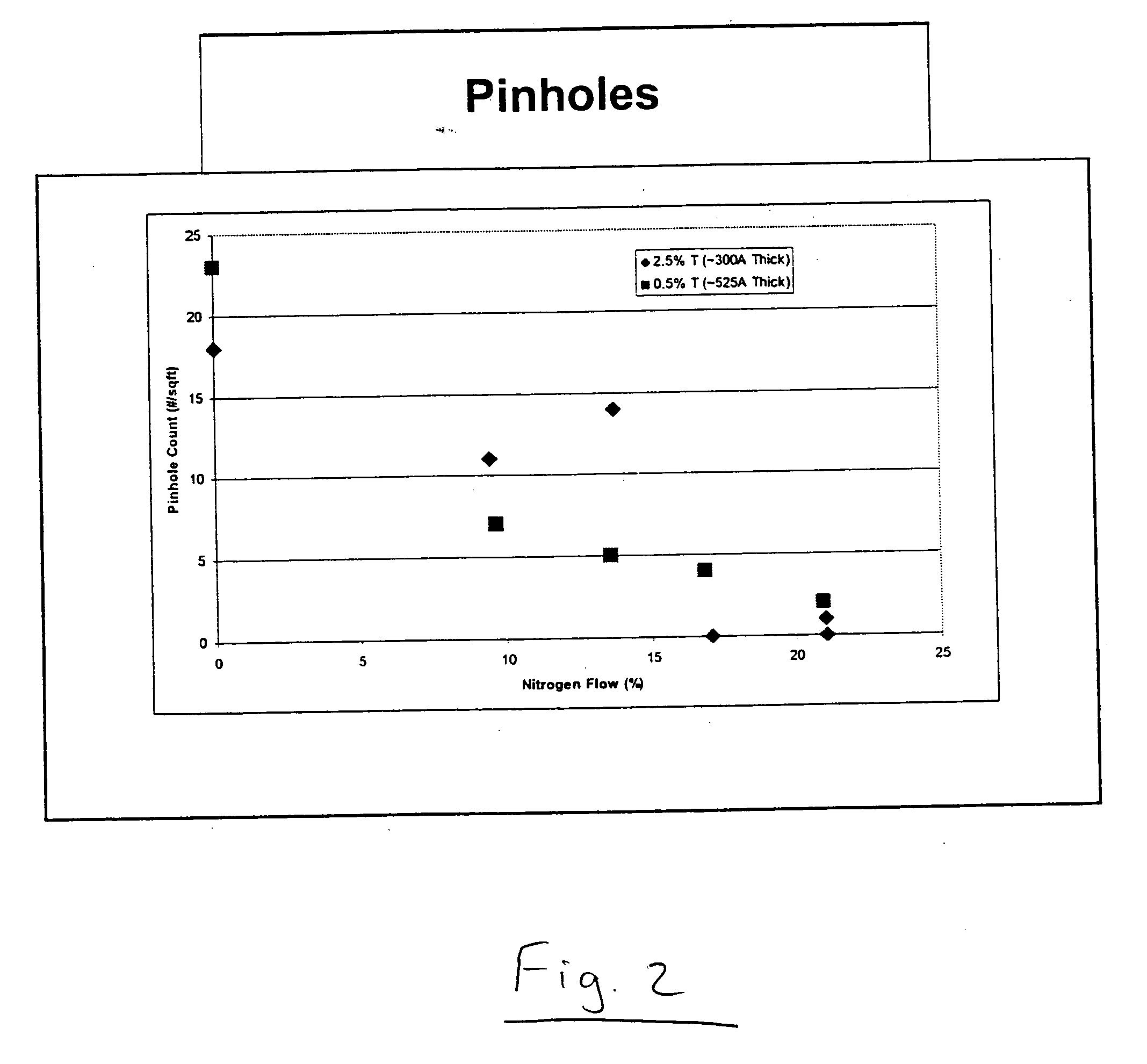

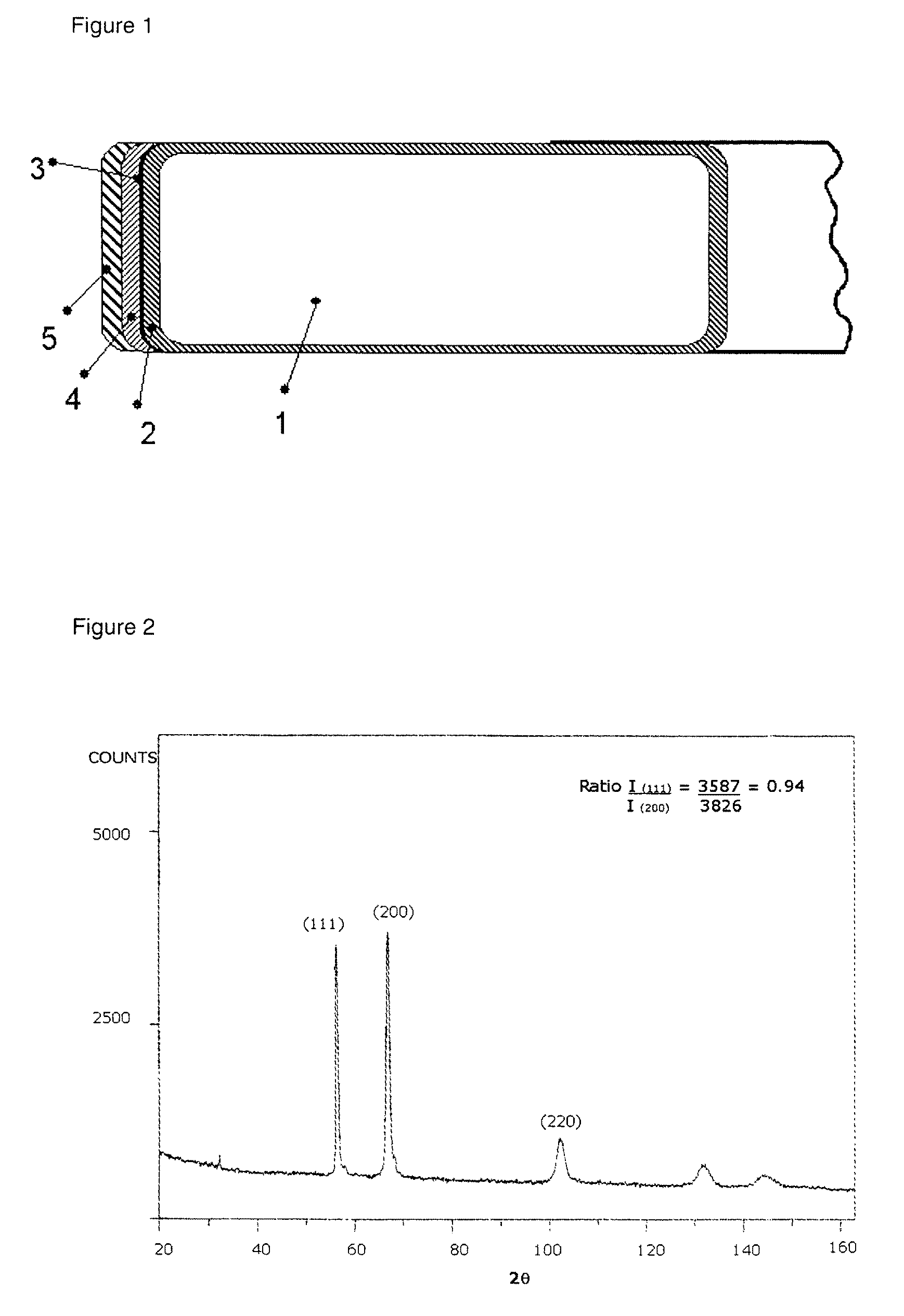

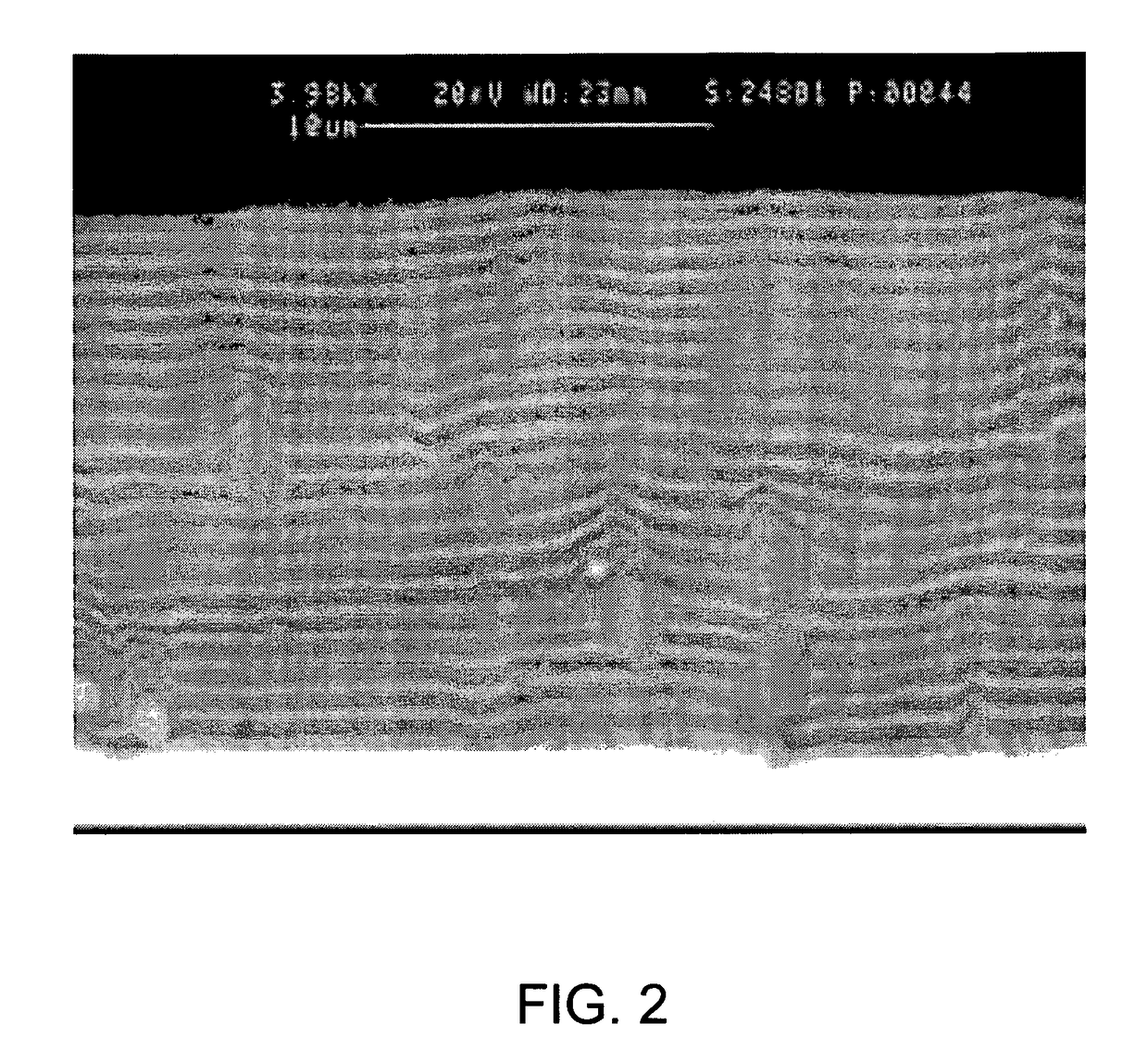

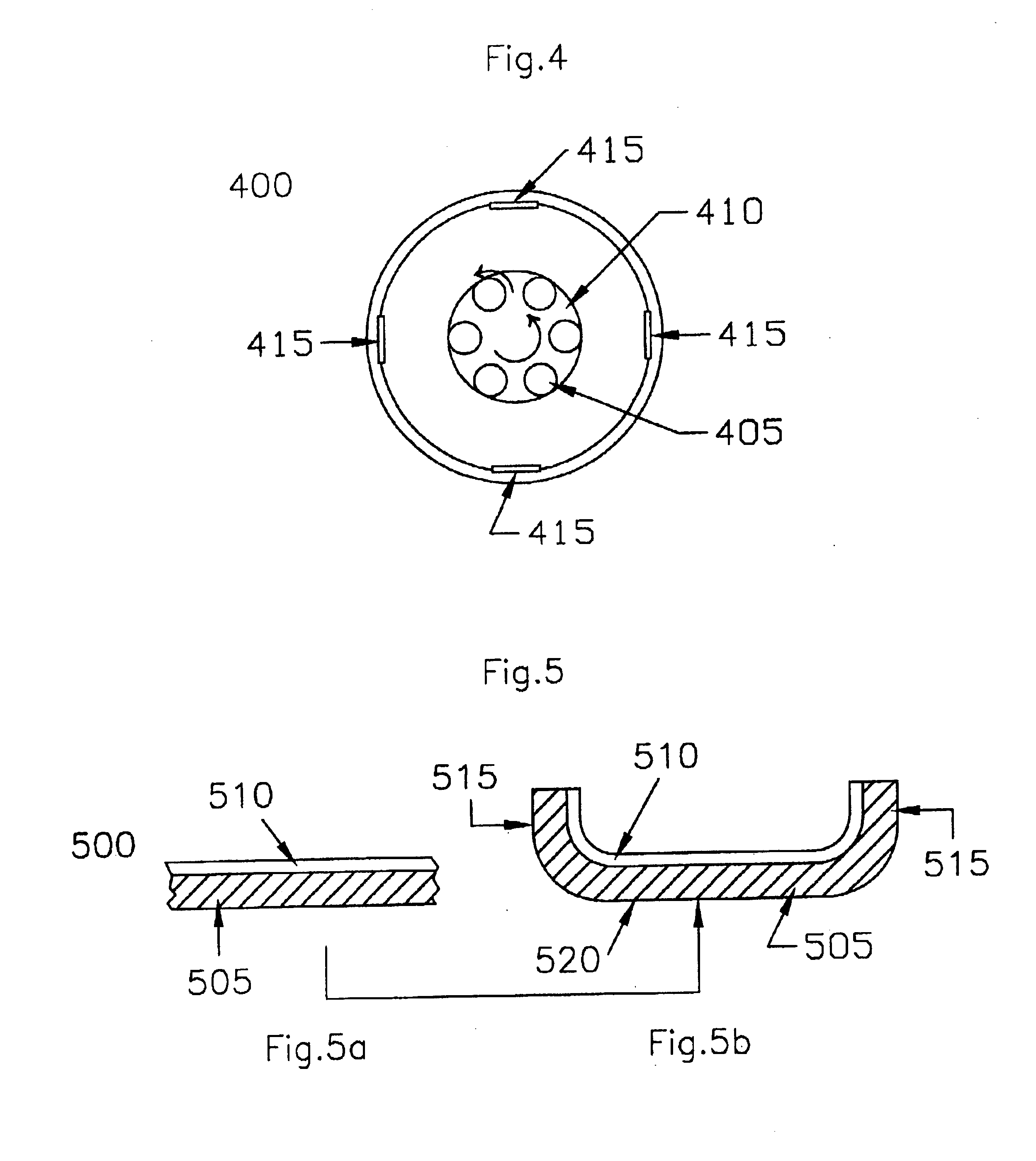

Piston ring for internal combustion engines

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

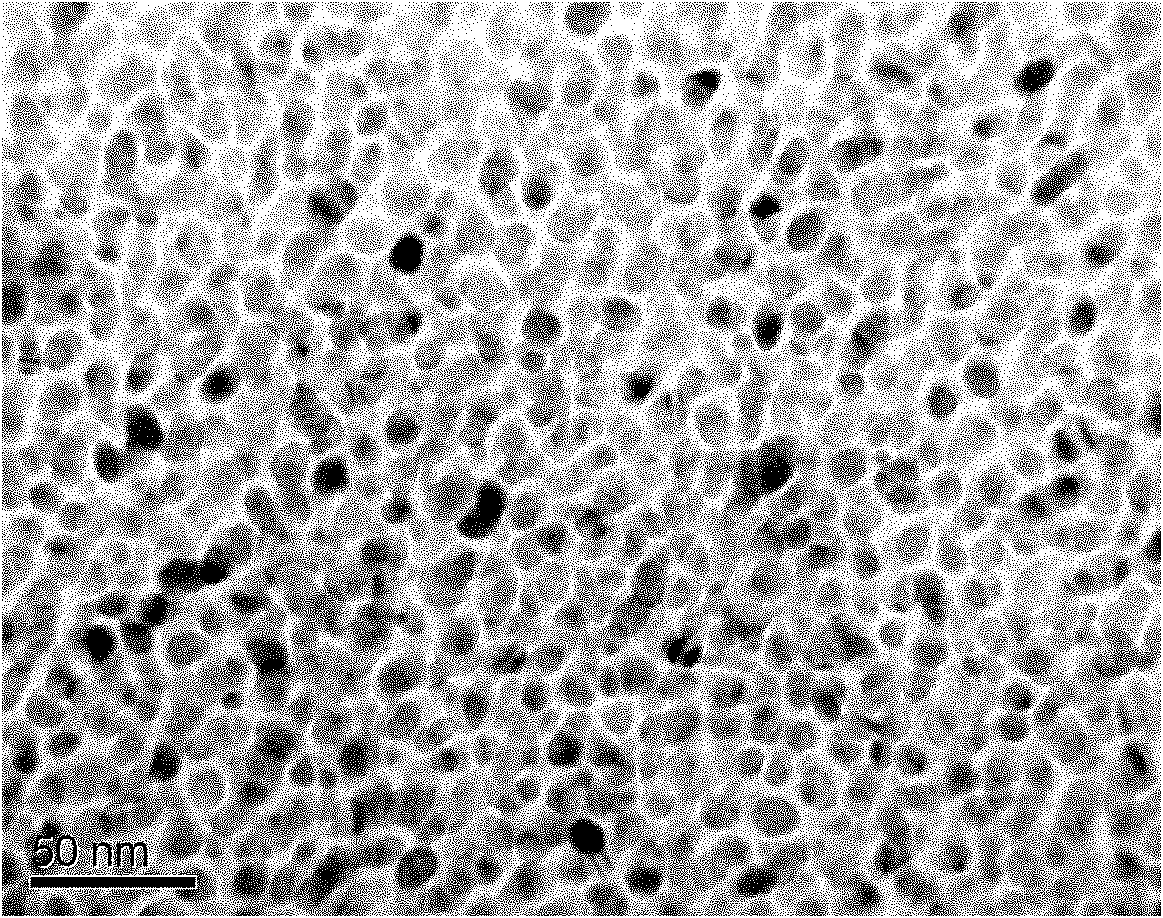

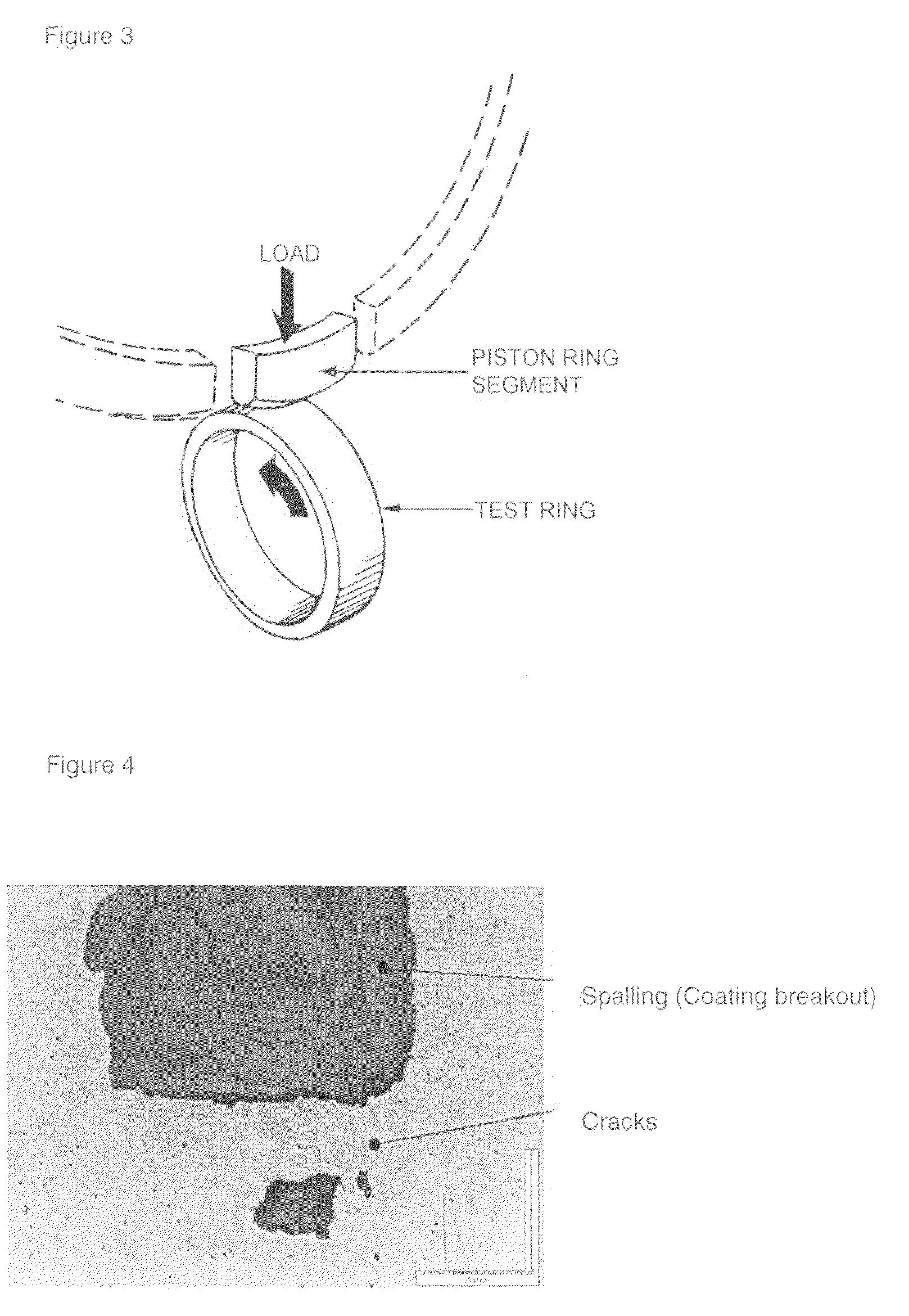

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

Preparation method of wear-resistant high-chromium cast iron

The invention discloses a preparation method of wear-resistant high-chromium cast iron and belongs to the technical field of metal materials. According to the preparation method, common scrap steel, carburant, ferrochromium, ferromolybdenum, copper plates, ferrochromium nitride, ferrosilicon, ferromanganese, ferroboron and aluminum are smelted in an electric furnace so as to form the wear-resistant high-chromium cast iron. The molten wear-resistant high-chromium cast iron comprises the following chemical components in percentage by mass: 3.0-3.5% of C, 18-25% of Cr, 0.3-0.5% of Mn, 0.3-0.5% of Si, 0.18-0.25% of N, 0.5-0.8% of Mo, 0.2-0.4% of B, 0.08-0.12% of Al, 0.5-1.0% of Cu, less than 0.05% of S, less than 0.05% P and the balance of Fe. Molten iron is treated with an inoculator when taken out from the electric furnace, and is treated with a suspending agent when poured, so as to obtain fine solidification structures. Therefore, the wear-resistant high-chromium cast iron has excellent properties.

Owner:BEIJING UNIV OF TECH

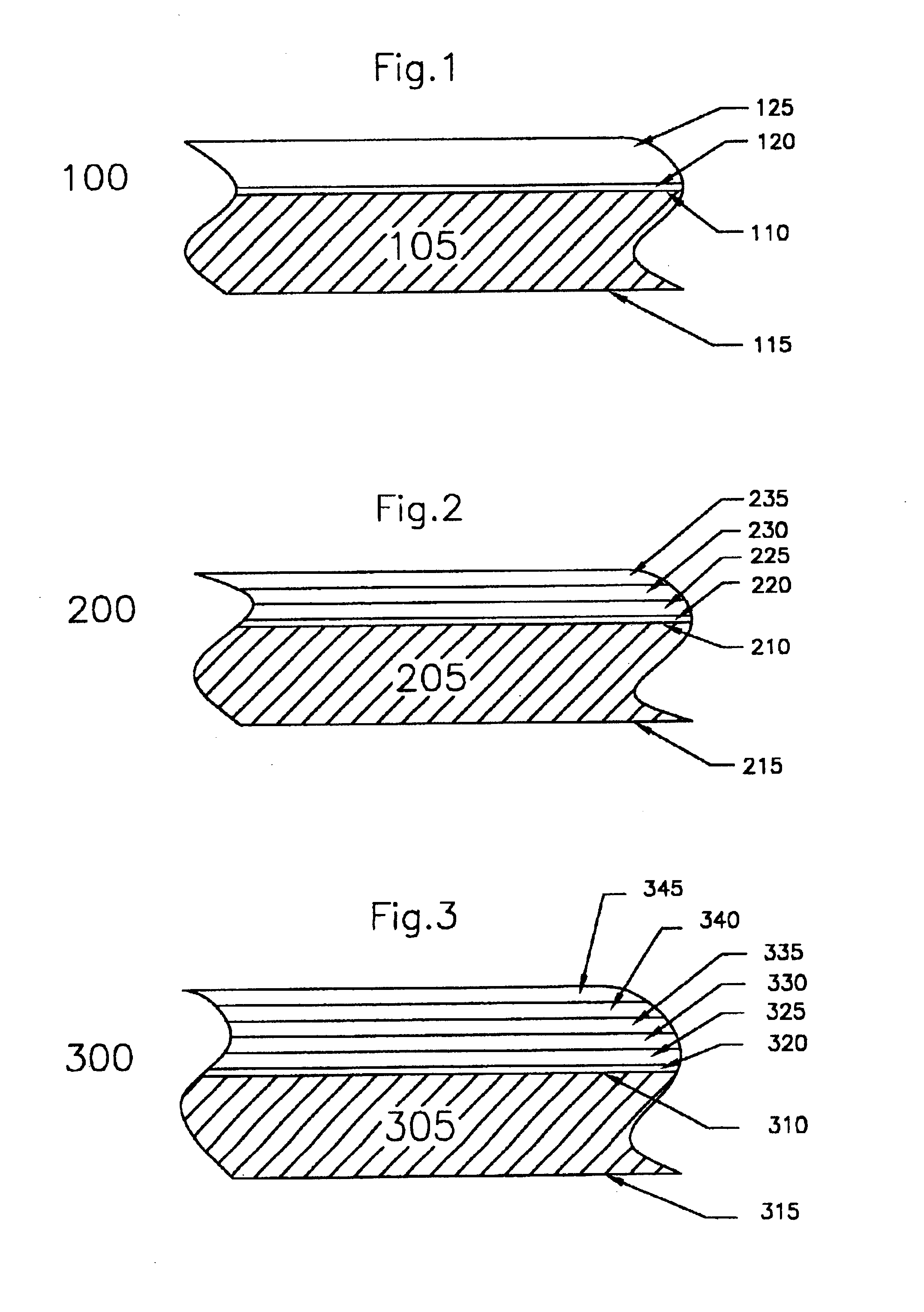

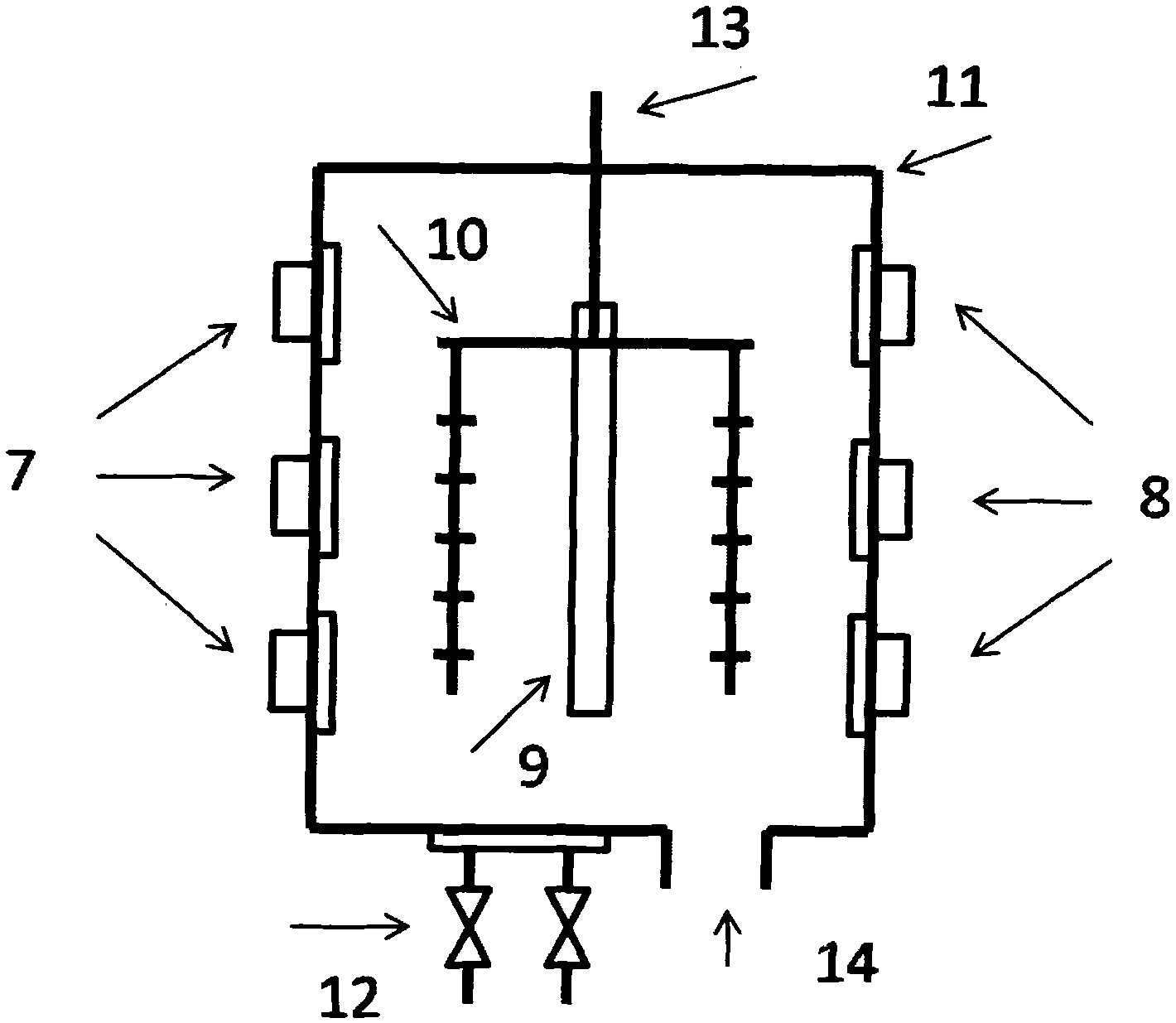

Corrosion resistant metallic bipolar plate

InactiveUS20030190515A1Improve corrosion resistanceHigh efficiency and low costActive material electrodesSolid state diffusion coatingFuel cellsChromium nitride

A corrosion resistant, electrically conductive component such as a bipolar plate for a PEM fuel cell includes 20-55% Cr, balance base metal such as Ni, Fe, or Co, the component having thereon a substantially external, continuous layer of chromium nitride.

Owner:UT BATTELLE LLC

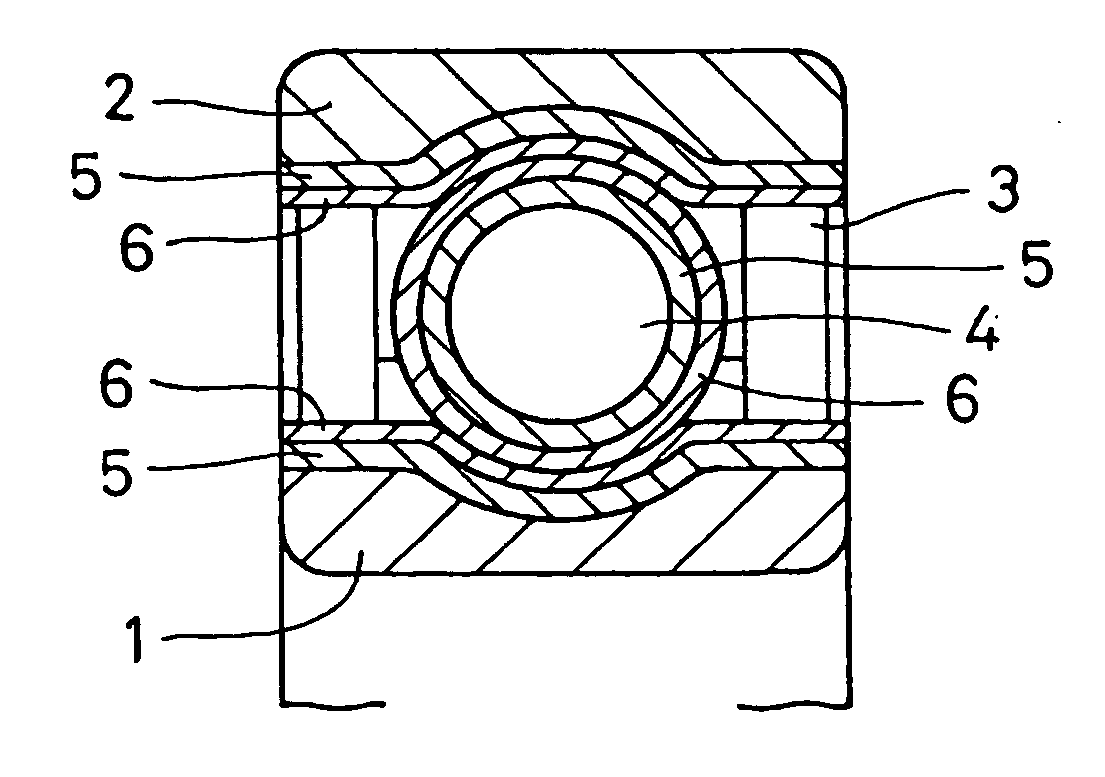

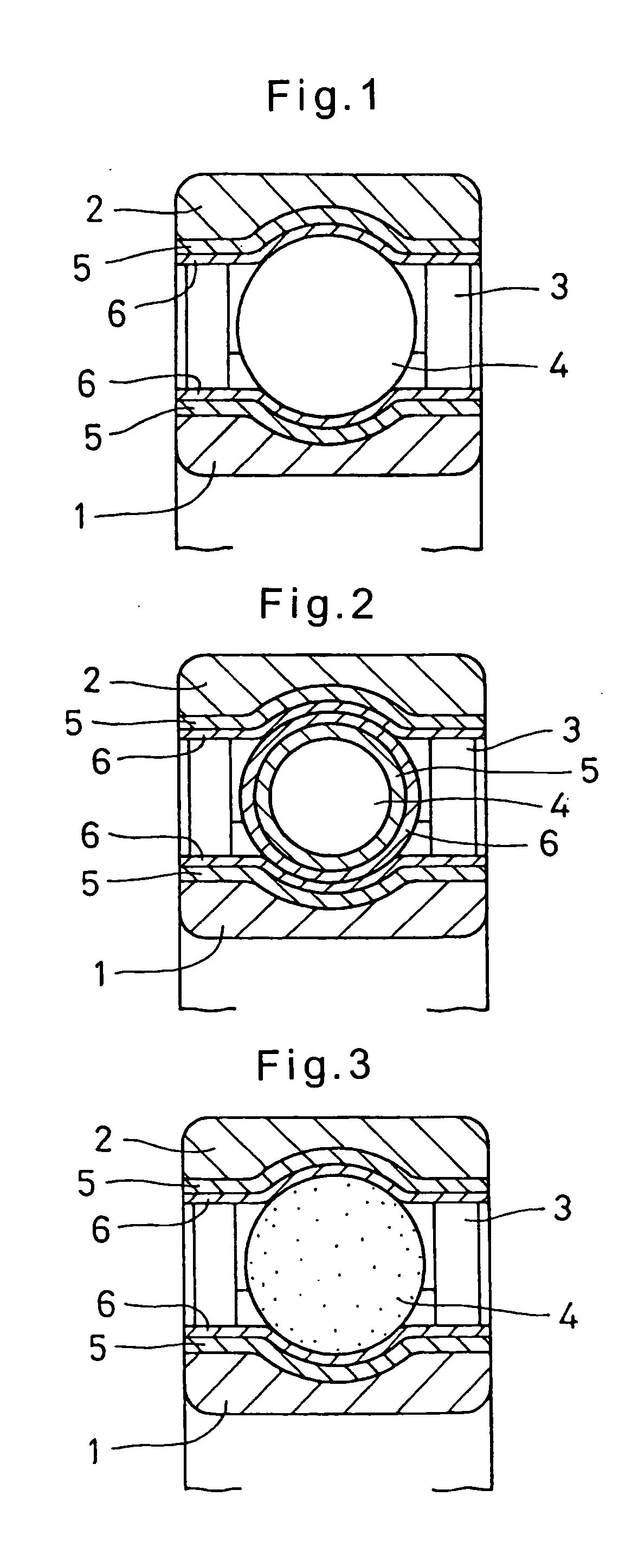

Rolling bearing

InactiveUS20050047694A1Avoid smearingExtended roll lifeBearing componentsMachines/enginesBall bearingRolling-element bearing

A ball bearing for use in a high-temperature, high-speed, light-load environment is proposed which includes inner and outer rings formed of heat-resistant bearing steel M50. A nitrided layer which is formed of a diffusion layer only is formed on each of the surfaces of the inner and outer rings where the raceways are formed. A chromium nitride film is further formed on the nitrided layer. The layer and film serves to prevent surface-starting peeling and smearing, thus prolonging the life of the bearing.

Owner:NTN CORP

Piston ring with chromium nitride coating for internal combustion engines

ActiveUS20090278320A1Improve the immunityHigher absorption of internal compressive stressesPiston ringsBraking action transmissionGas phaseX-ray

The invention relates to a piston ring for internal combustion engines, the piston ring comprises a steel or cast iron base material with a coating of chromium nitride deposited by a physical vapor deposition process on a sliding surface of the piston ring, wherein the coating is composed of a columnar crystal structure of CrN with the following features:(a) an oxygen content in solid solution of 0.5 to 2.5 wt %;(b) a content of uniformly dispersed micro-pores of less than 10% in volume of the coating; and(c) an X-ray diffraction intensity ratio of (111) planes to (200) planes parallel to the surface in the range of 0.80 to 1.20.

Owner:MAHLE INT GMBH +1

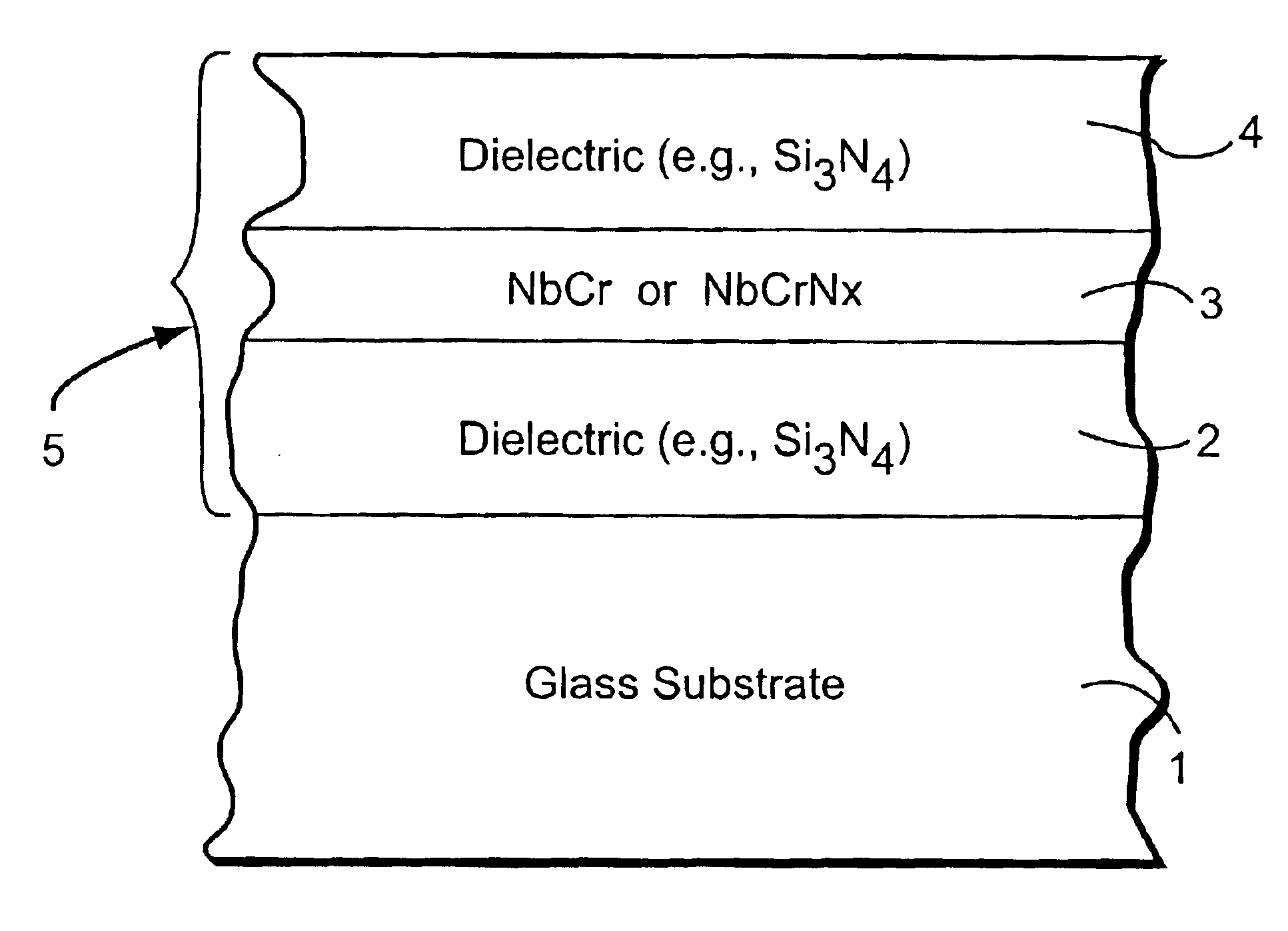

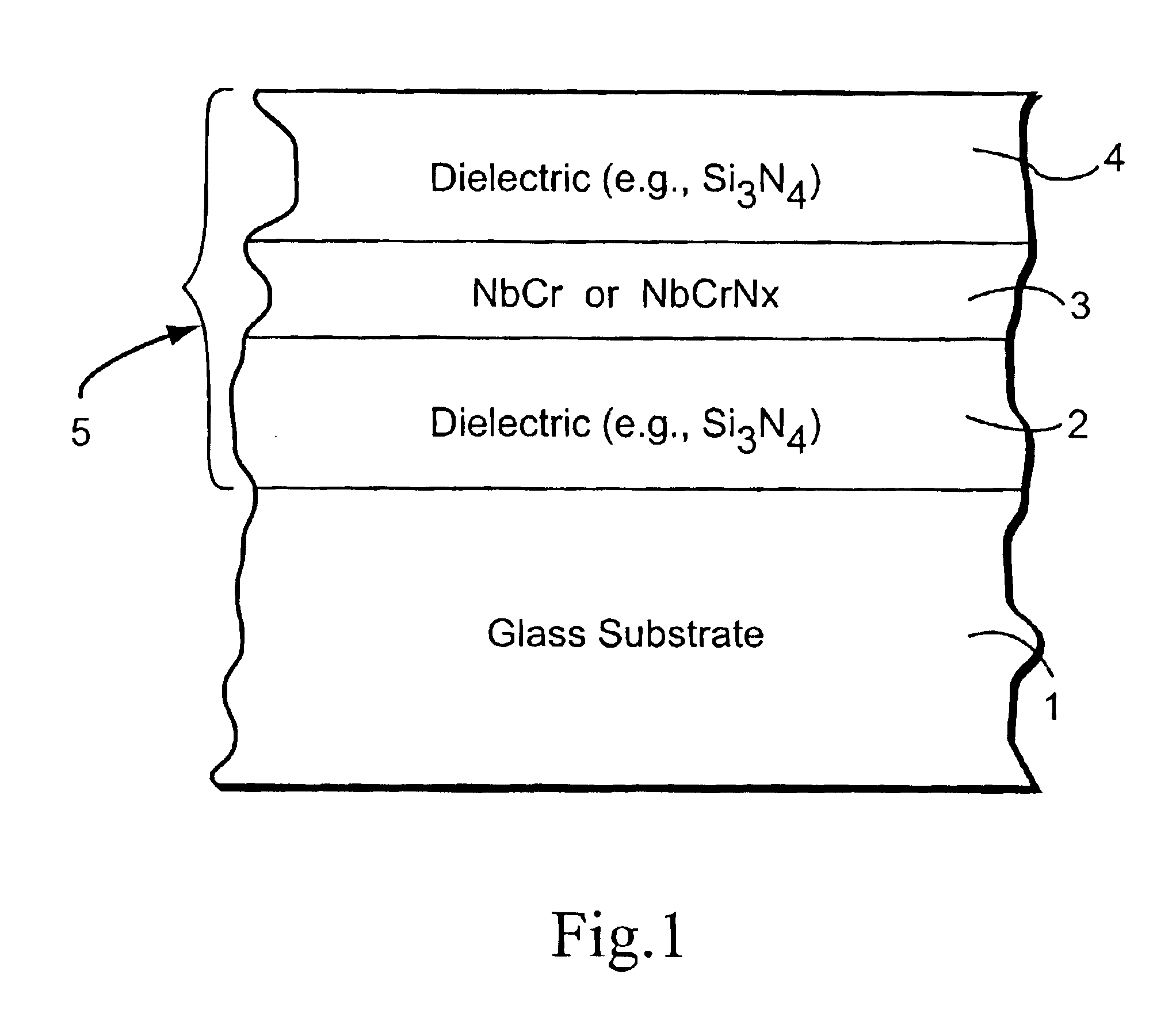

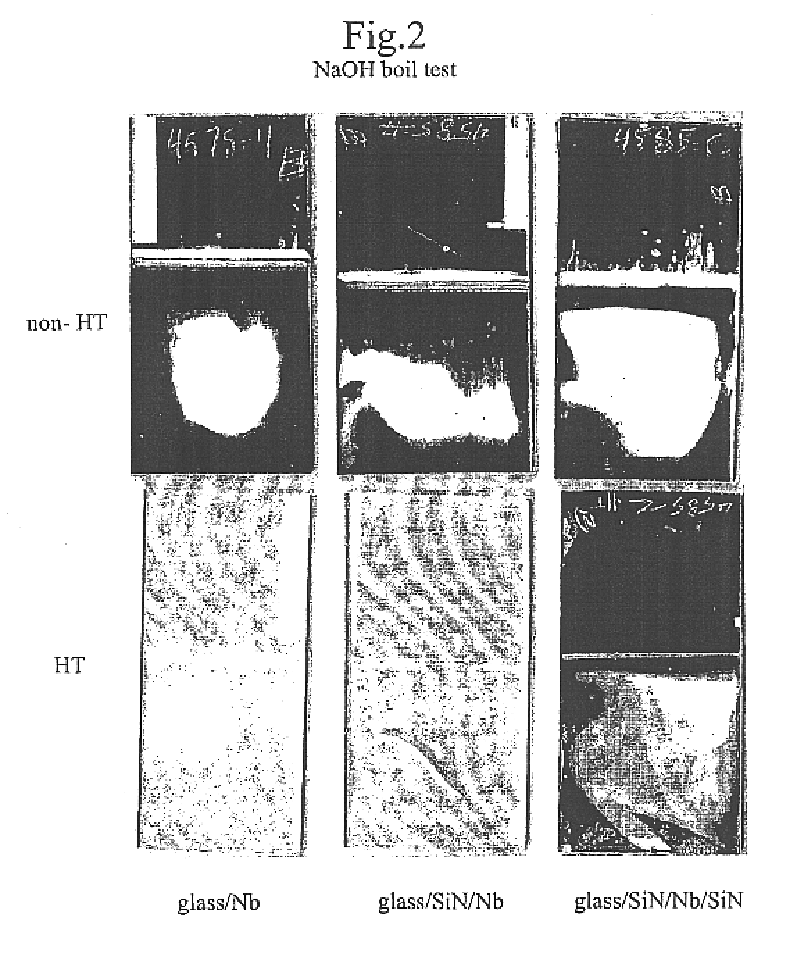

Heat treatable coated article with niobium chromium nitride IR reflecting layer and method of making same

InactiveUS6852419B2Improve corrosion resistanceImproved color stabilityDoors/windowsGlass/slag layered productsNiobiumChromium nitride

A coated article is provided so as to include a solar control coating having an infrared (IR) reflecting layer sandwiched between at least a pair of dielectric layers. The IR reflecting layer includes NbCr and / or NbCrNx in certain embodiments of this invention. The use of such materials as an IR reflecting layer(s) enables the coated article to have good corrosion resistance to alkaline solutions, good mechanical performance such as scratch resistance, and / or good color stability (i.e., a low ΔE* value(s)) upon heat treatment (HT). The coated article may be heat treated (e.g., thermally tempered) in certain example embodiments of the invention.

Owner:GUARDIAN GLASS LLC

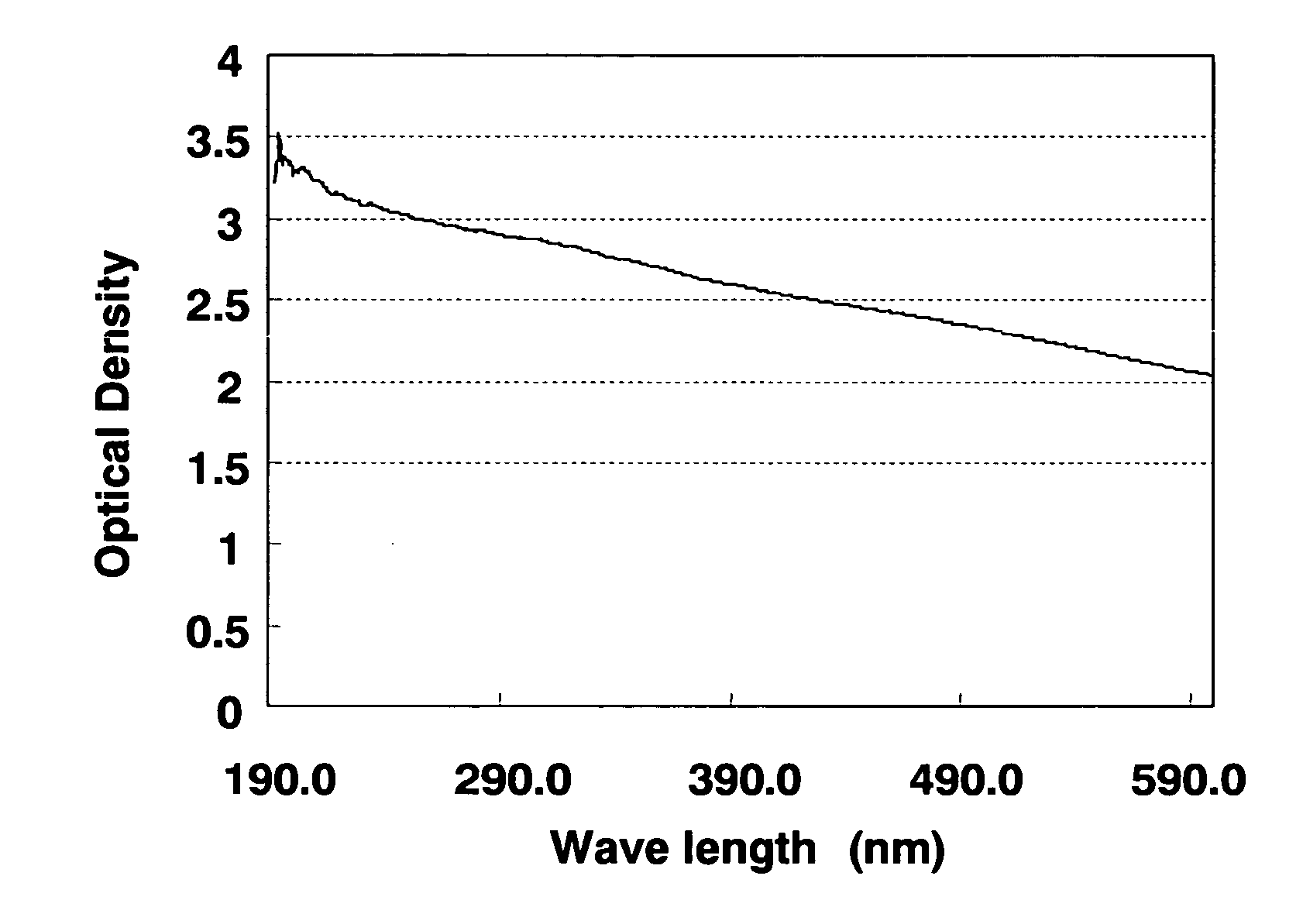

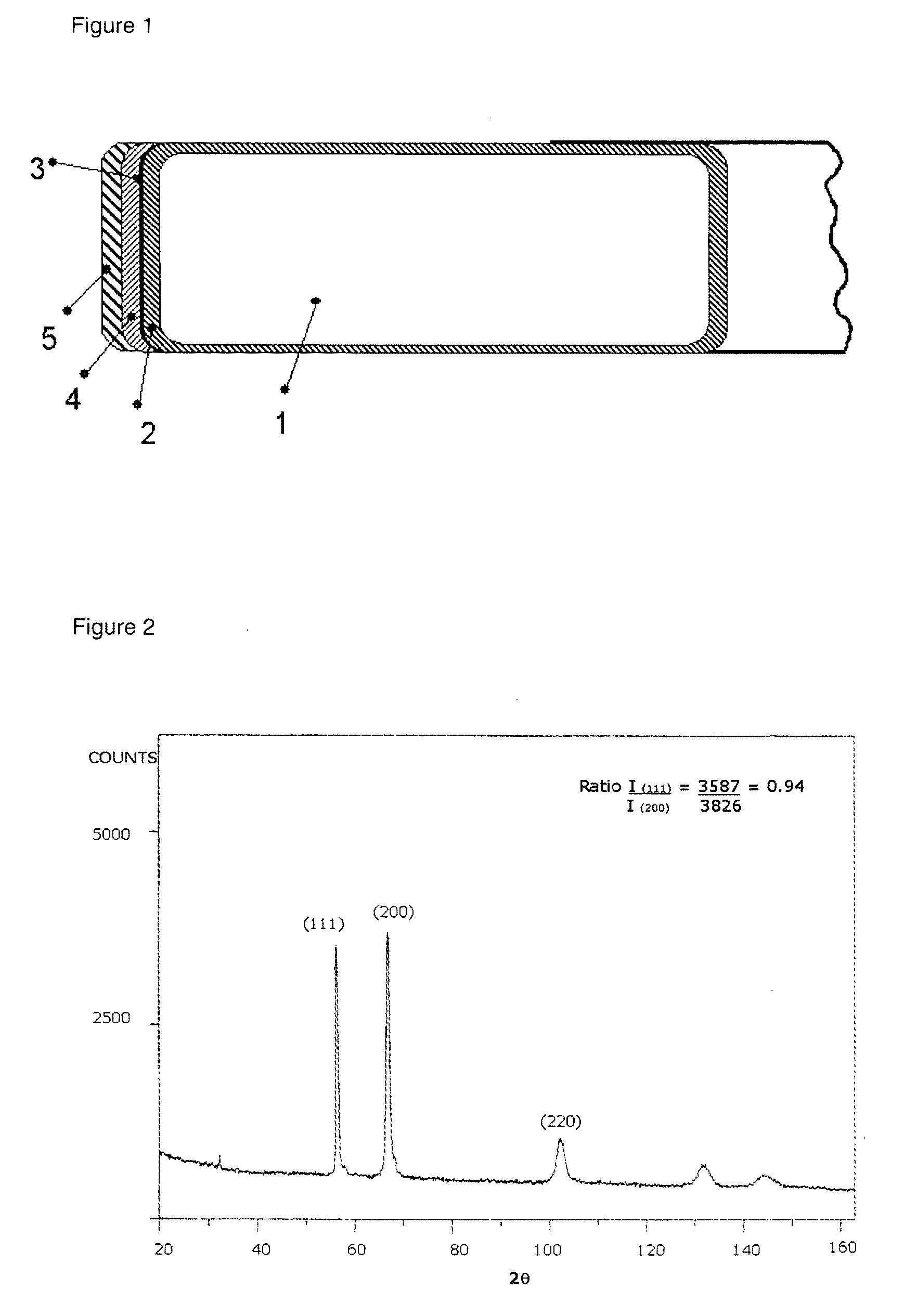

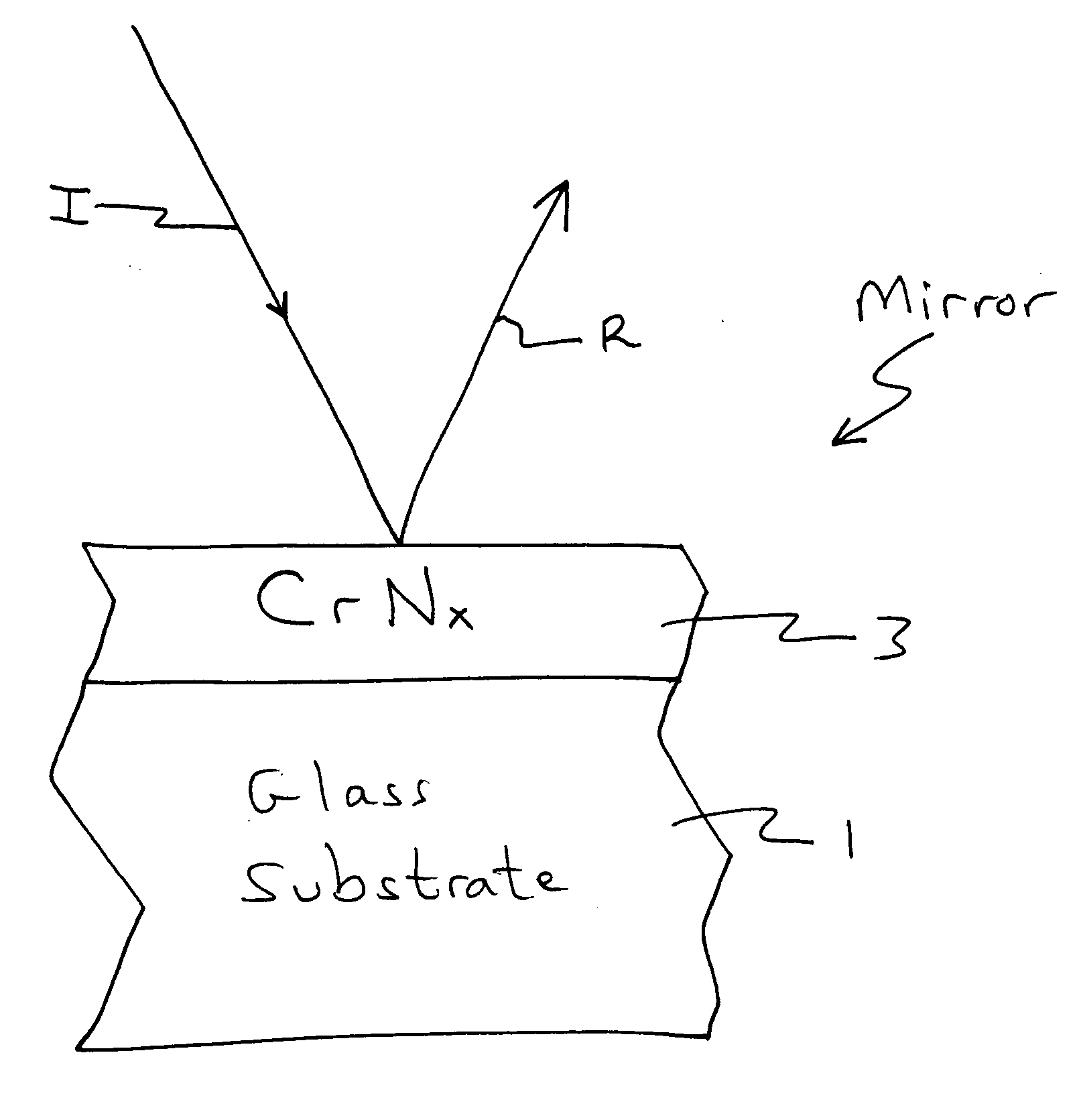

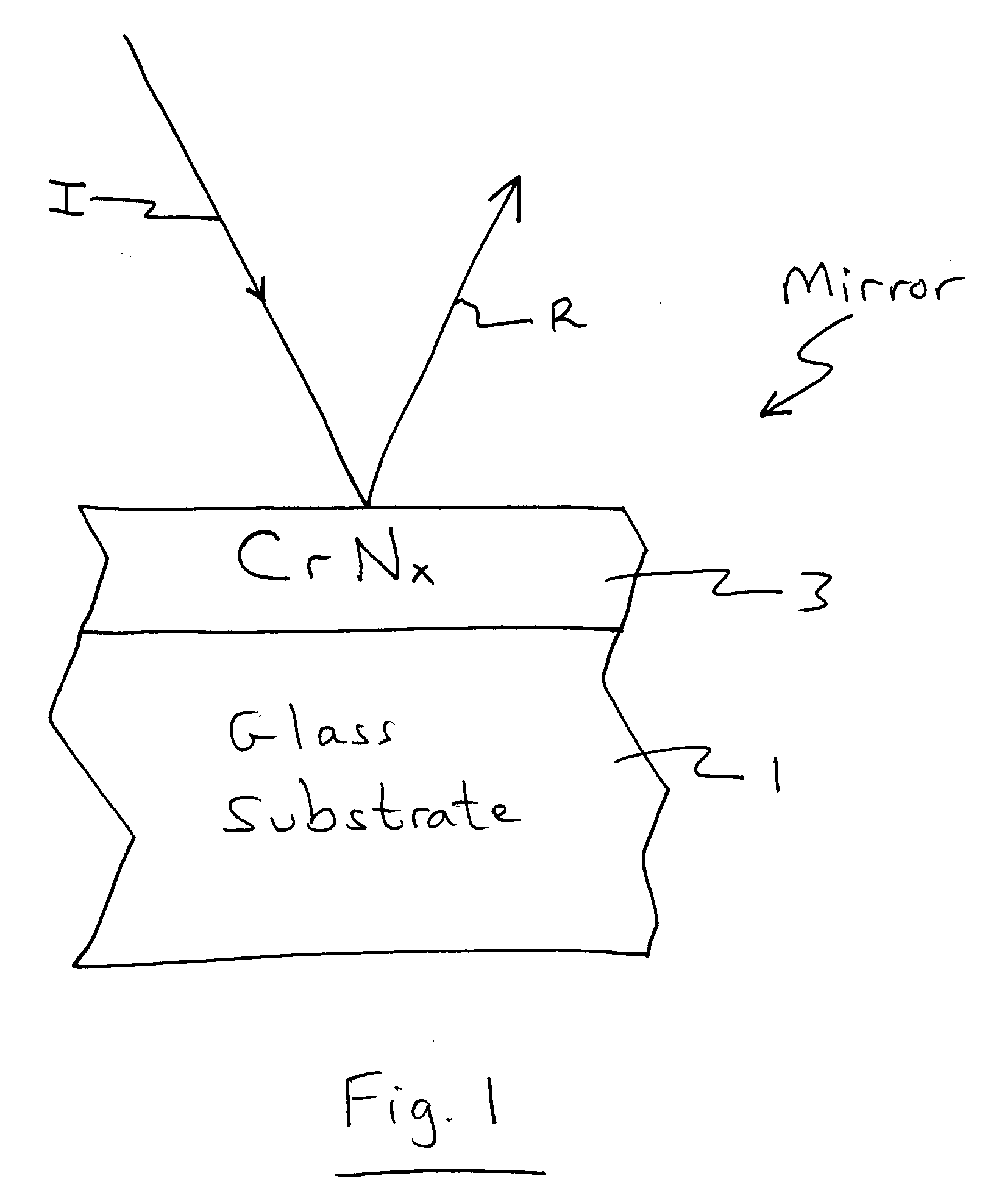

First surface mirror with chromium nitride layer

A mirror (e.g., first surface mirror) is provided with a layer of or including chromium nitride (CrNx). In certain example embodiments, the CrNx layer may be the primary reflective layer of the mirror. Surprisingly and unexpectedly, it has been found the addition of nitrogen to the chromium to form CrNx reduces pinhole formations in the resulting layer. In certain example embodiments, the more nitrogen which is introduced into the layer, the smaller the number and / or size of pinholes in the Cr inclusive layer. In certain example embodiments, it has also been found that the addition of nitrogen to Cr may improve durability.

Owner:GUARDIAN EURO S A R L +1

Piston ring with chromium nitride coating for internal combustion engines

ActiveUS7891669B2Improve the immunityPiston ringsBraking action transmissionExternal combustion engineGas phase

The invention relates to a piston ring for internal combustion engines, the piston ring comprises a steel or cast iron base material with a coating of chromium nitride deposited by a physical vapor deposition process on a sliding surface of the piston ring, wherein the coating is composed of a columnar crystal structure of CrN with the following features:(a) an oxygen content in solid solution of 0.5 to 2.5 wt %;(b) a content of uniformly dispersed micro-pores of less than 10% in volume of the coating; and(c) an X-ray diffraction intensity ratio of (111) planes to (200) planes parallel to the surface in the range of 0.80 to 1.20.

Owner:MAHLE INT GMBH +1

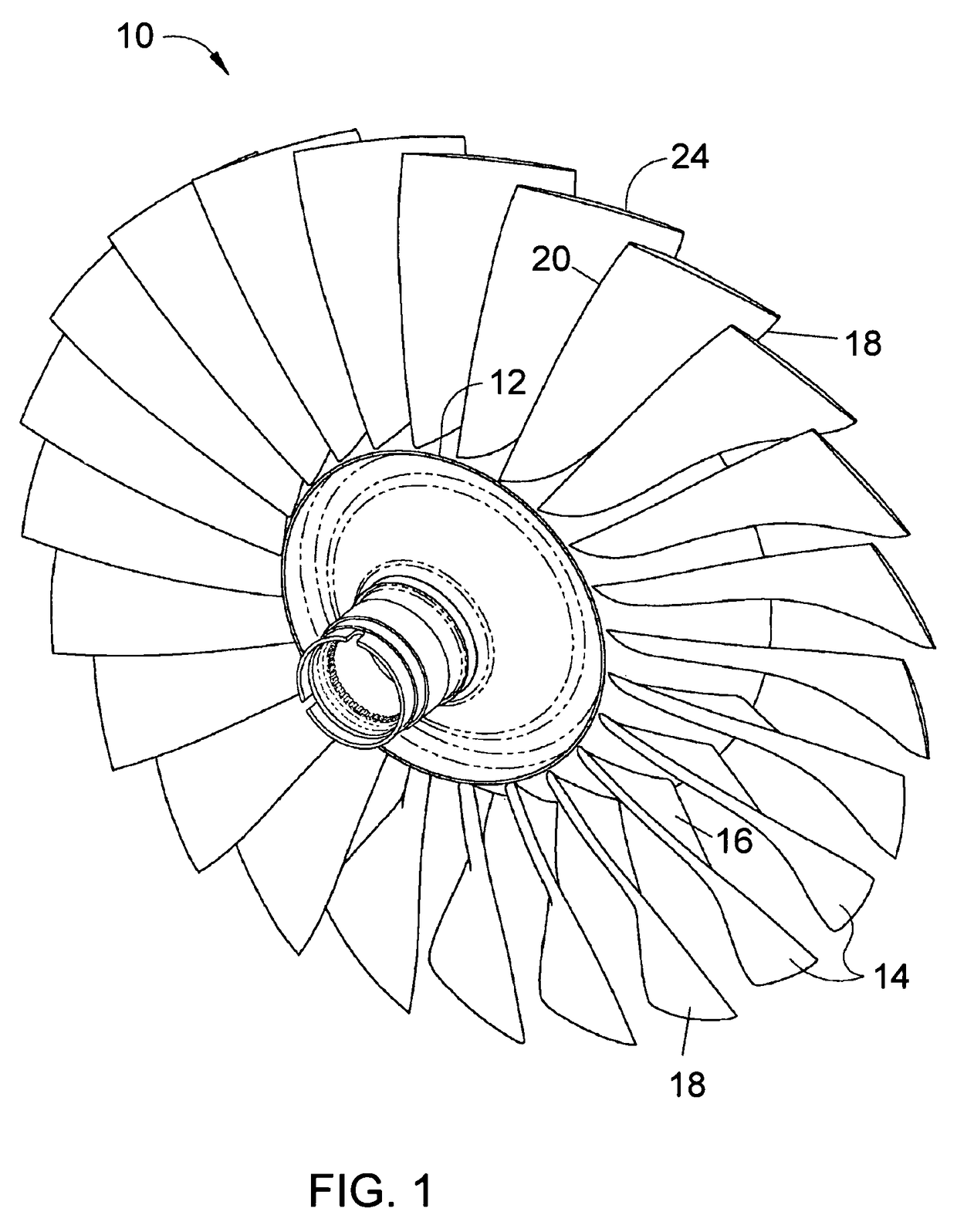

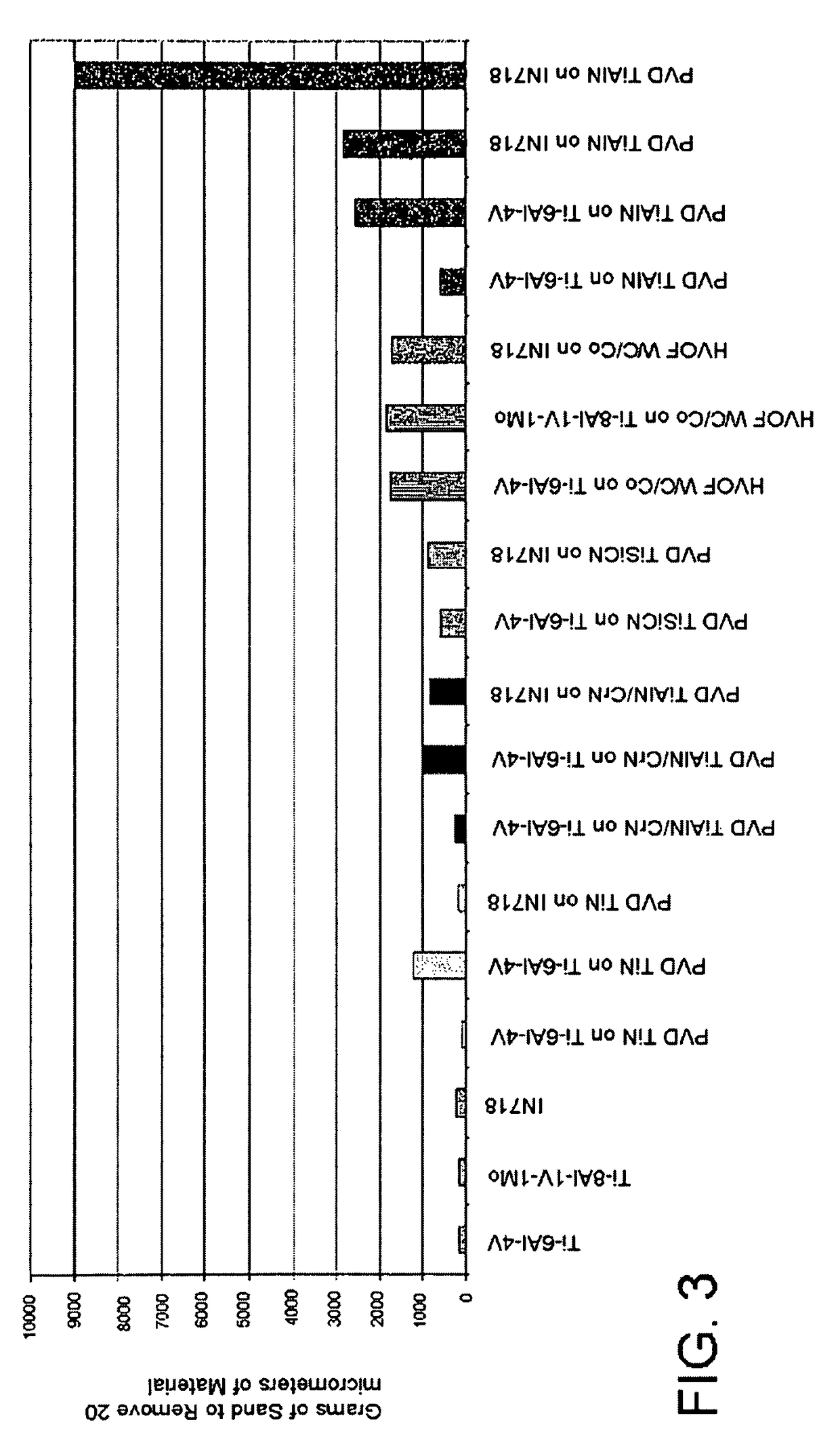

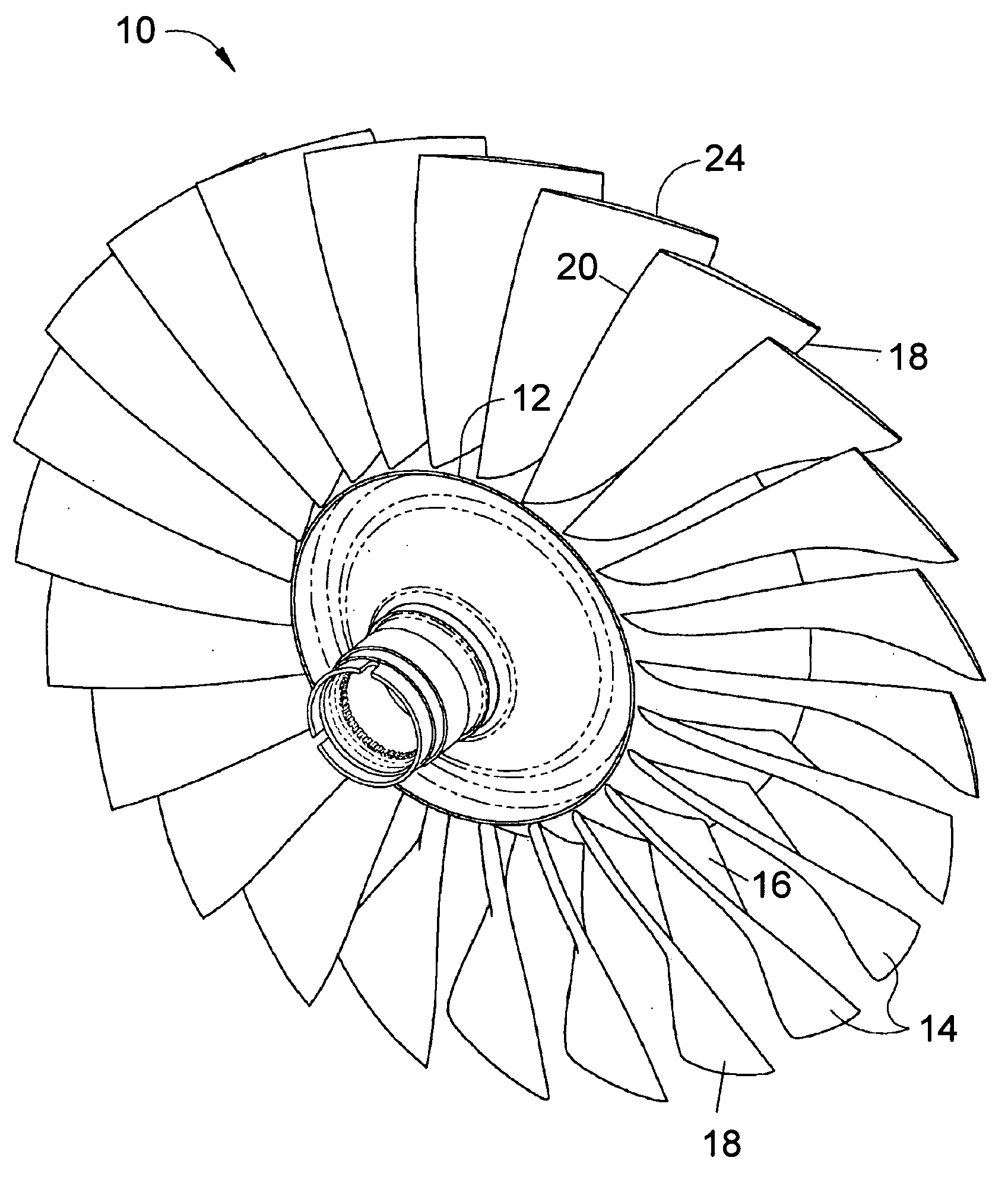

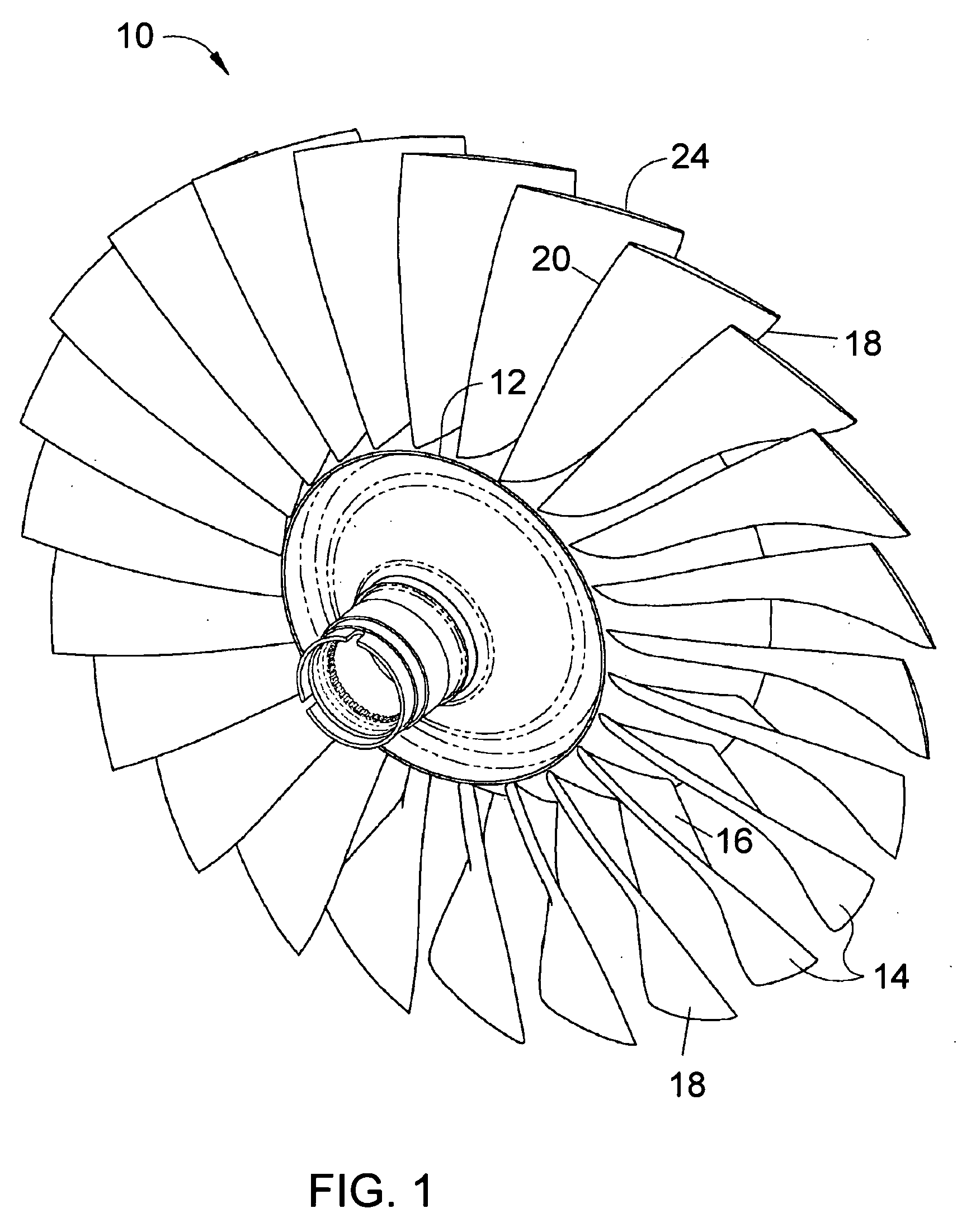

Erosion- and impact-resistant coatings

ActiveUS8118561B2Protect normal useSpecific fluid pumpsPropellersTitanium aluminium nitrideCeramic coating

Erosion- and impact-resistant ceramic coatings suitable for protecting surfaces subjected to collisions with particles, including nominally round particles that typically inflict impact damage and more aggressive irregular-shaped particles that typically inflict erosion damage. The ceramic coating is formed to have one of three compositions: at least one layer of titanium aluminum nitride (TiAlN) having a thickness of about 25 to about 100 micrometers; multiple layers of chromium nitride (CrN) and TiAlN, each layer having a thickness of about 0.2 to about 1.0 micrometers to yield a total coating thickness of at least about 3 micrometers; and at least one layer of titanium silicon carbonitride (TiSiCN) having a thickness of about 15 to about 100 micrometers. The ceramic coating preferably has a total coating thickness of up to about 100 micrometers, and is deposited by a physical vapor deposition process to have a columnar and / or dense microstructure.

Owner:GENERAL ELECTRIC CO

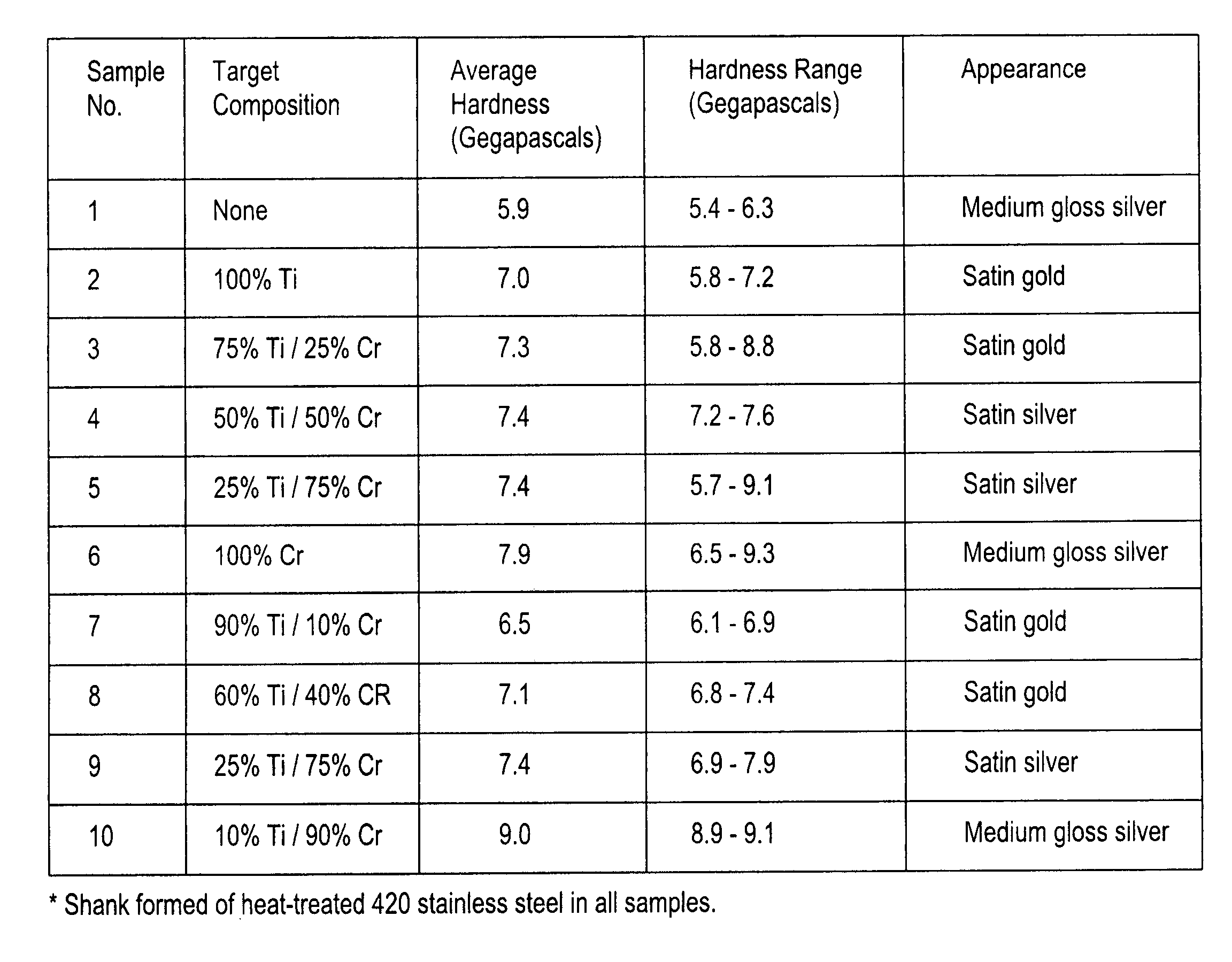

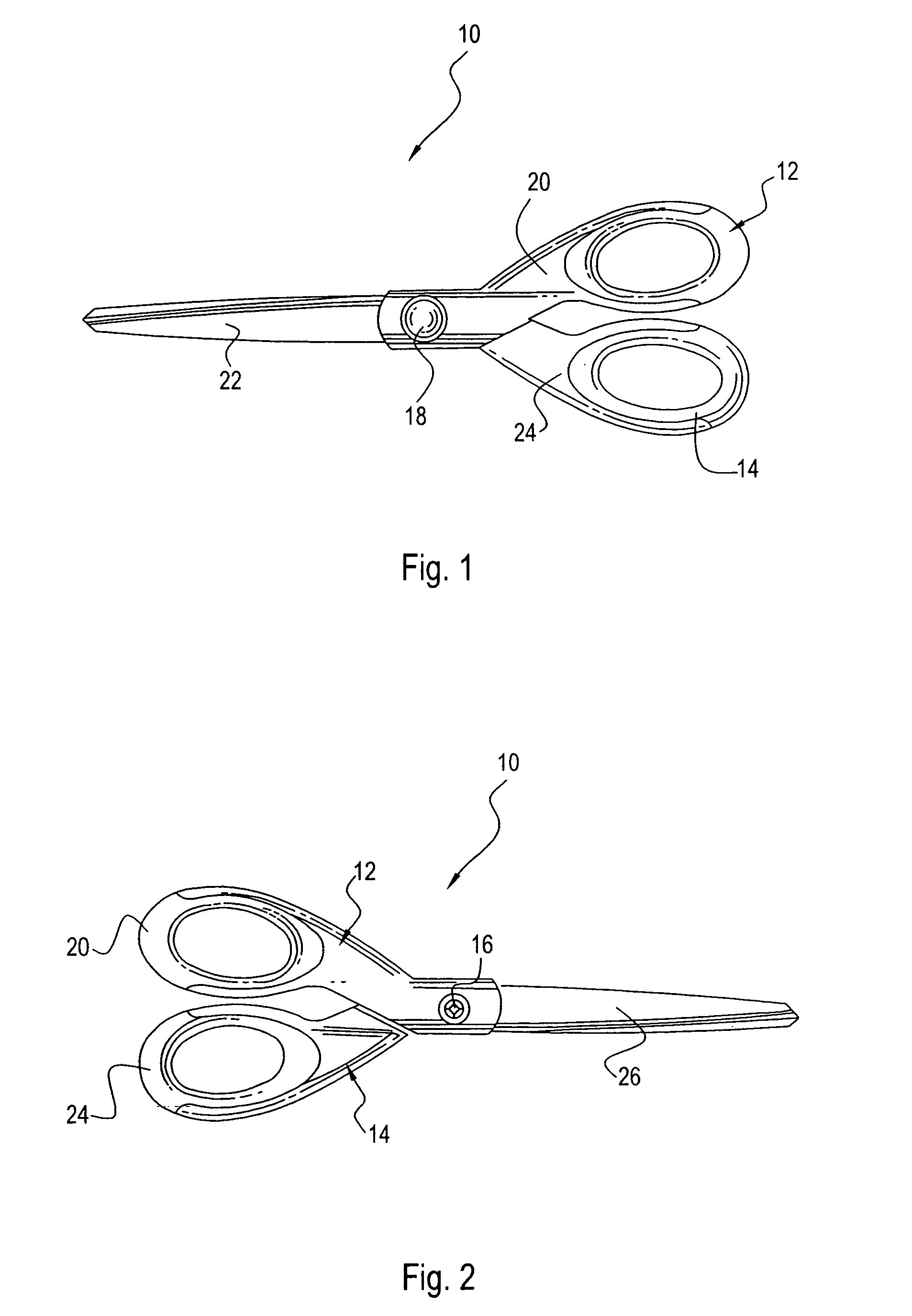

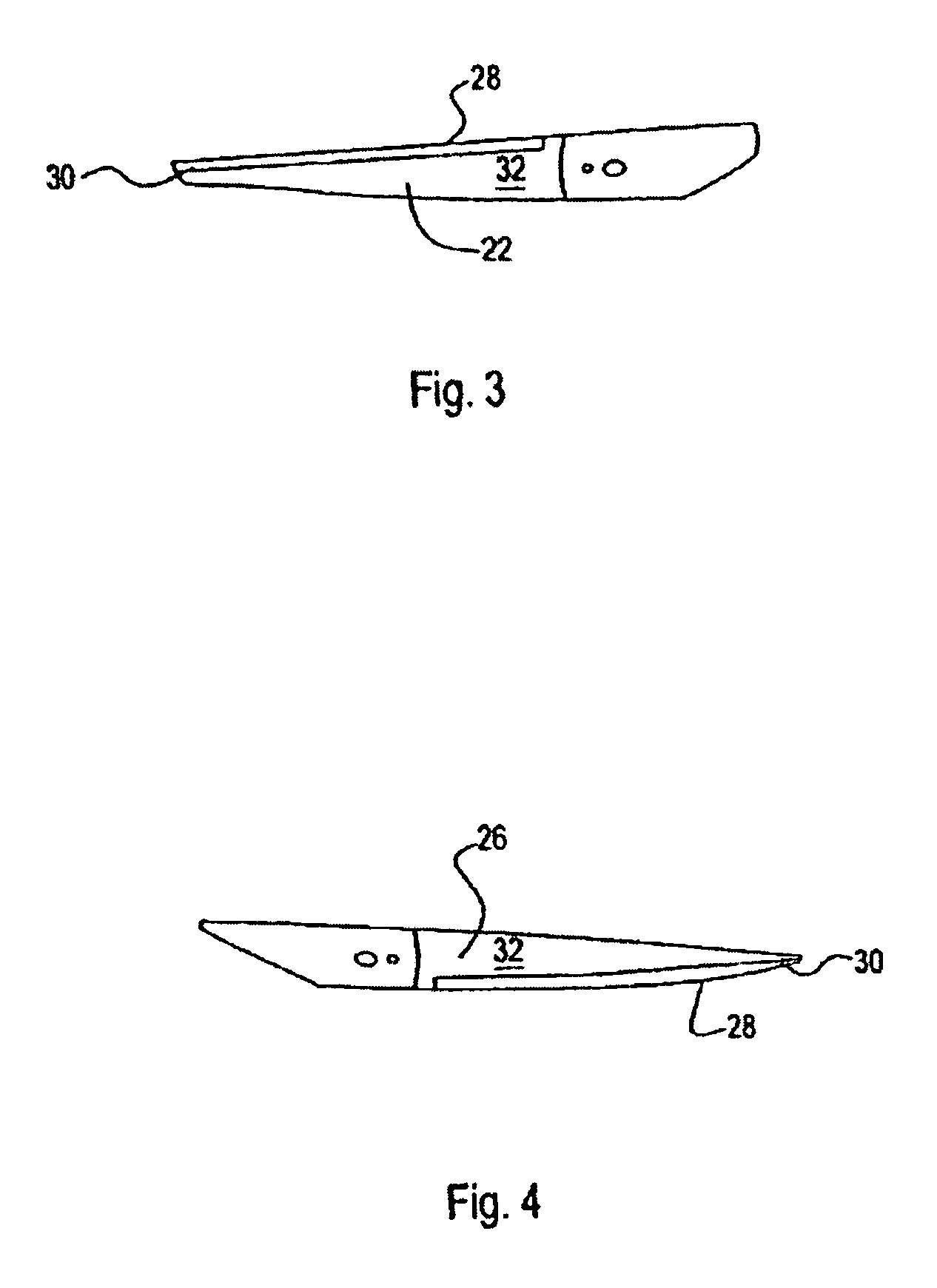

Coating for cutting implements

InactiveUS6988318B2Improve wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingSurface roughnessTitanium

A cutting implement having a pair of cutting blades and a coating is provided. The coating has titanium chromium nitride and provides the cutting blades with a satin silver appearance. In some embodiments, the titanium chromium nitride coating has a thickness in a range between about 0.3 microns and 0.5 microns, a surface roughness in a range of about 15 to 25 10−6 inch / inch, and a hardness in a range of about 5.7 to about 9.1 gegapascals.

Owner:ACME UNITED CORPORATION

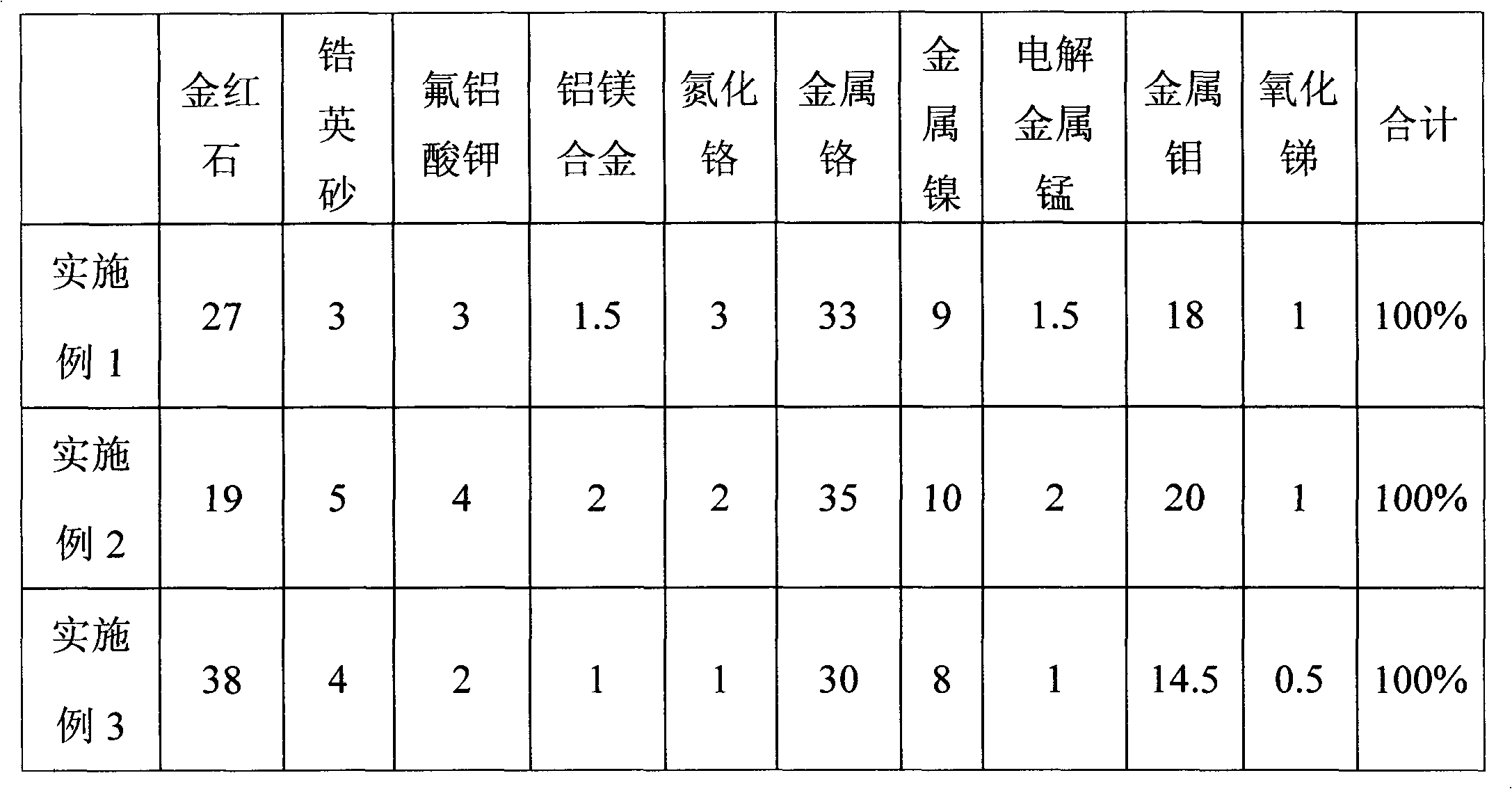

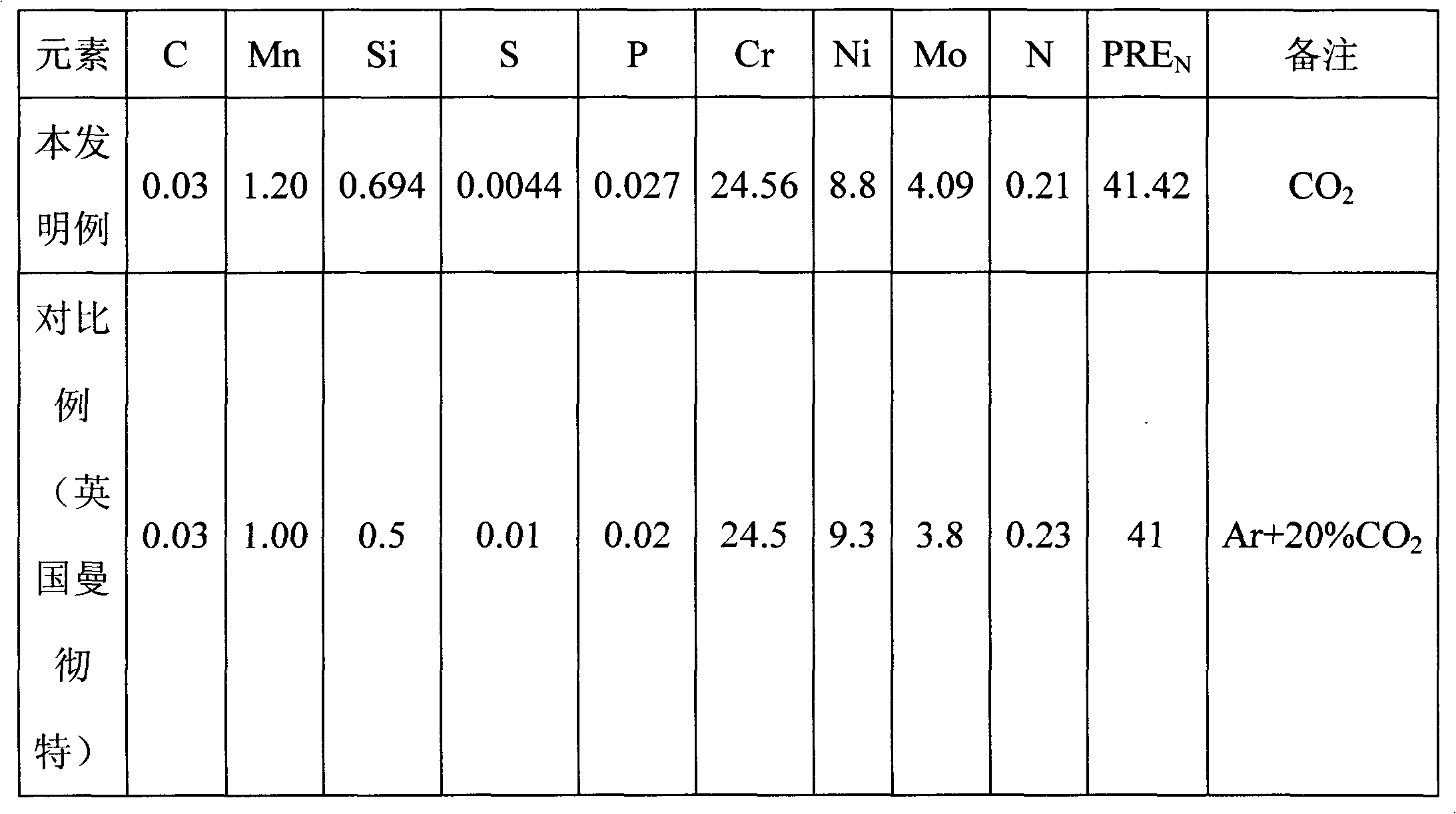

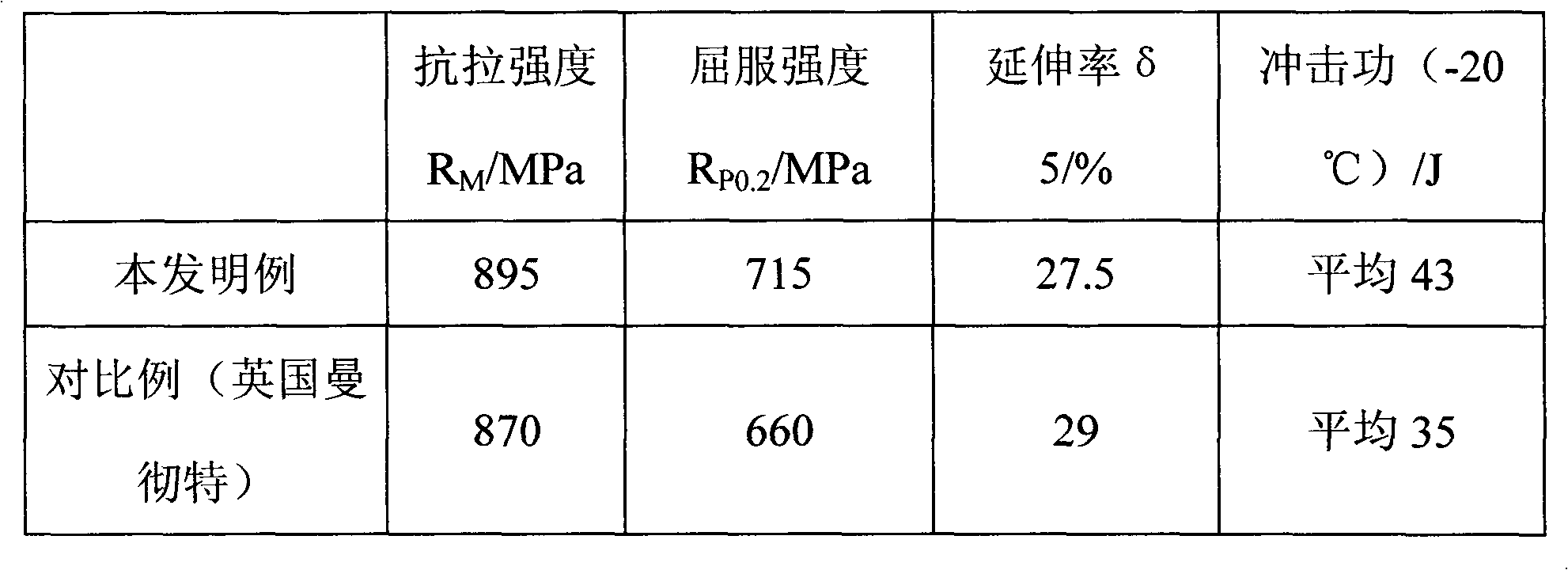

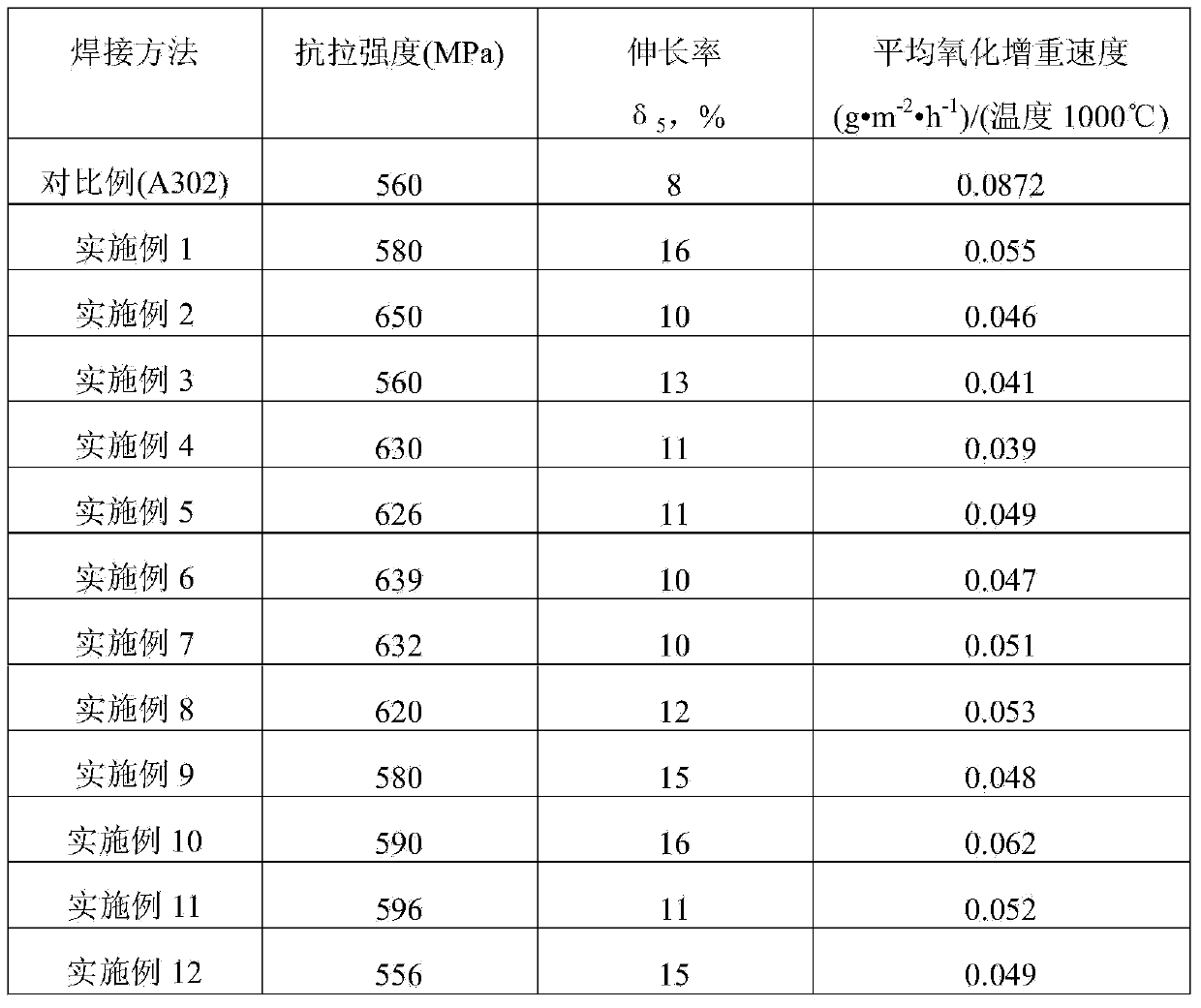

Chemical powder components of 2507 type super double-phase stainless steel flux-cored wire

InactiveCN101966628AGood performance in welding operationBeautiful weld shapeWelding/cutting media/materialsSoldering mediaElectrolysisDouble phase

The invention belongs to the field of welding materials and discloses chemical powder components of a 2507 type super double-phase stainless steel flux-cored wire. A common 304L stainless steel metal strip is used as an outer skin; the chemical powder components are filled inside the common 304L stainless steel metal strip to be rolled into a flux-cored wire. The chemical powder components of the 2507 type super double-phase stainless steel flux-cored wire are characterized by comprising the following components in percent by mass: 19 percent-38 percent of rutile, 3 percent-5 percent of zircon sand, 2 percent-4 percent of potassium fluoroaluminate, 1 percent-2 percent of aluminium magnesium alloy, 1 percent-3 percent of chromium nitride, 30 percent-35 percent of metallic chrome, 8 percent-10 percent of metallic nickel, 1 percent-2 percent of electrolytic manganese metal, 14.5 percent-20 percent of metallic molybdenum and 0.5 percent-1 percent of antimony oxide. In the invention, the steel pipe made from the 304L stainless steel strip (with the specification of 10*0.4mm) filled with the chemical powder is manufactured into the super double-phase stainless steel flux-cored wire according to the general production process. CO2 is used as welding protection gas for the flux-cored wire, and the flux-cored wire has the characteristics of good welding operation process performance, attractive welding line moulding, excellent welding process performance, favorable balance of welding tissue austenite and ferrite and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

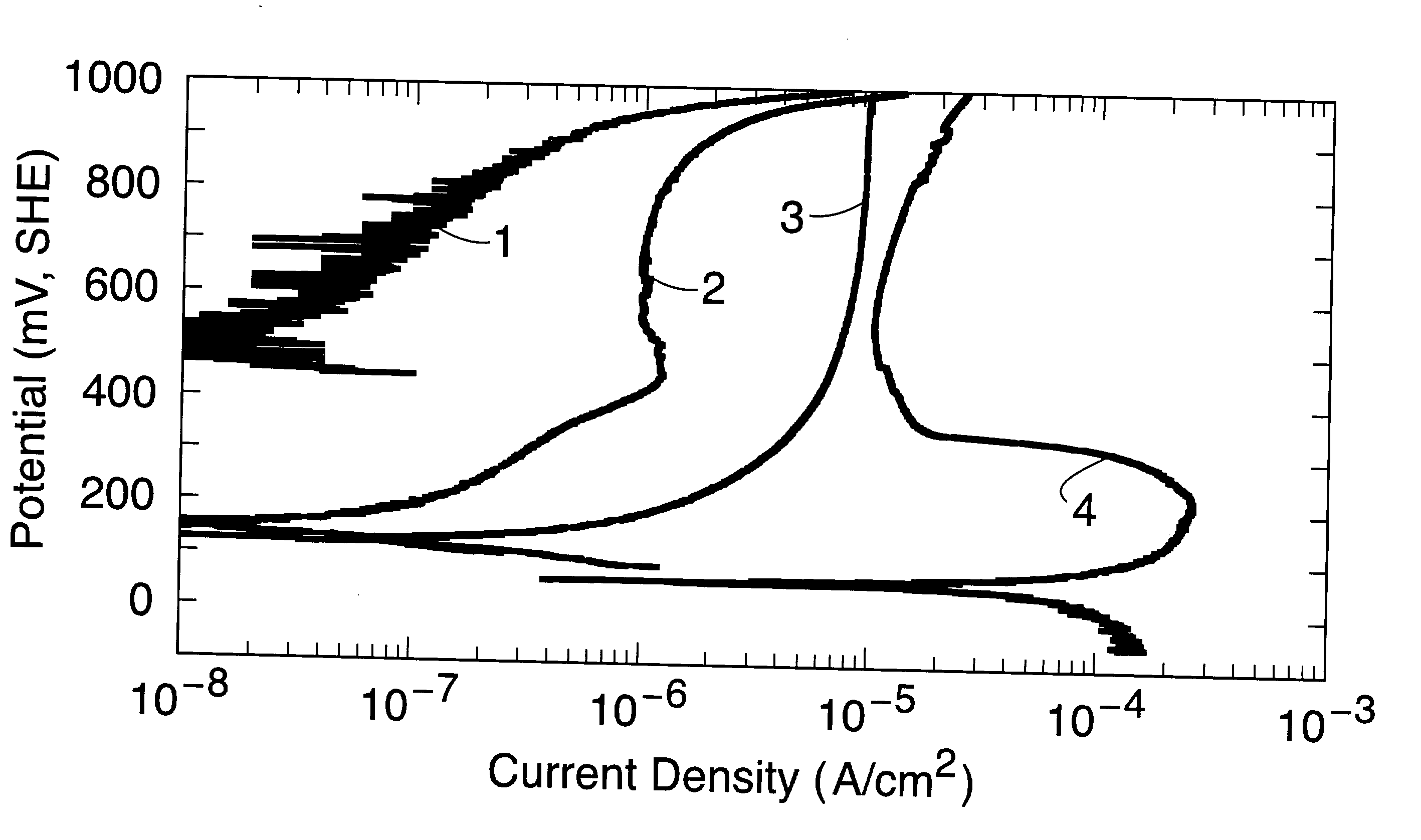

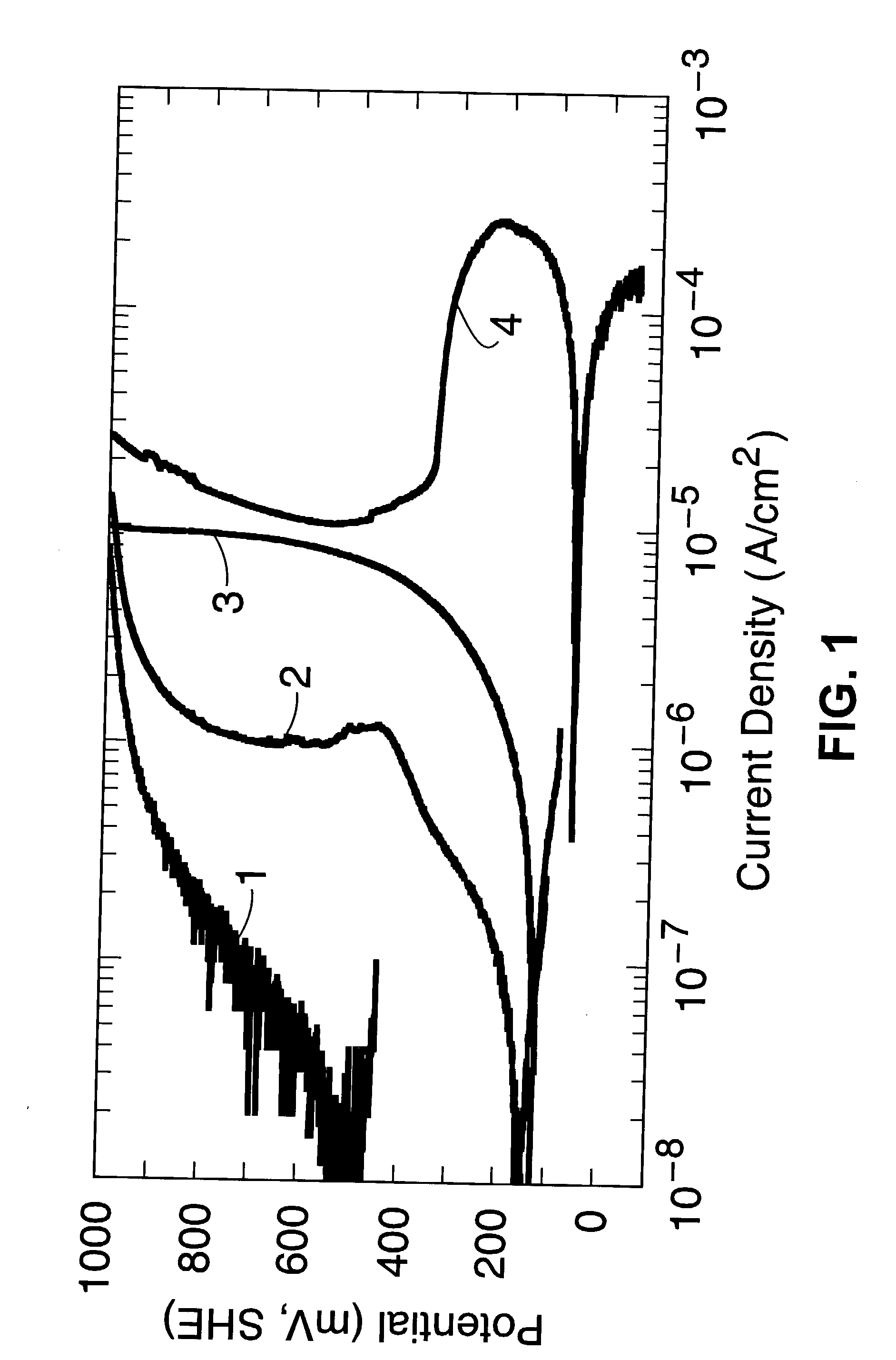

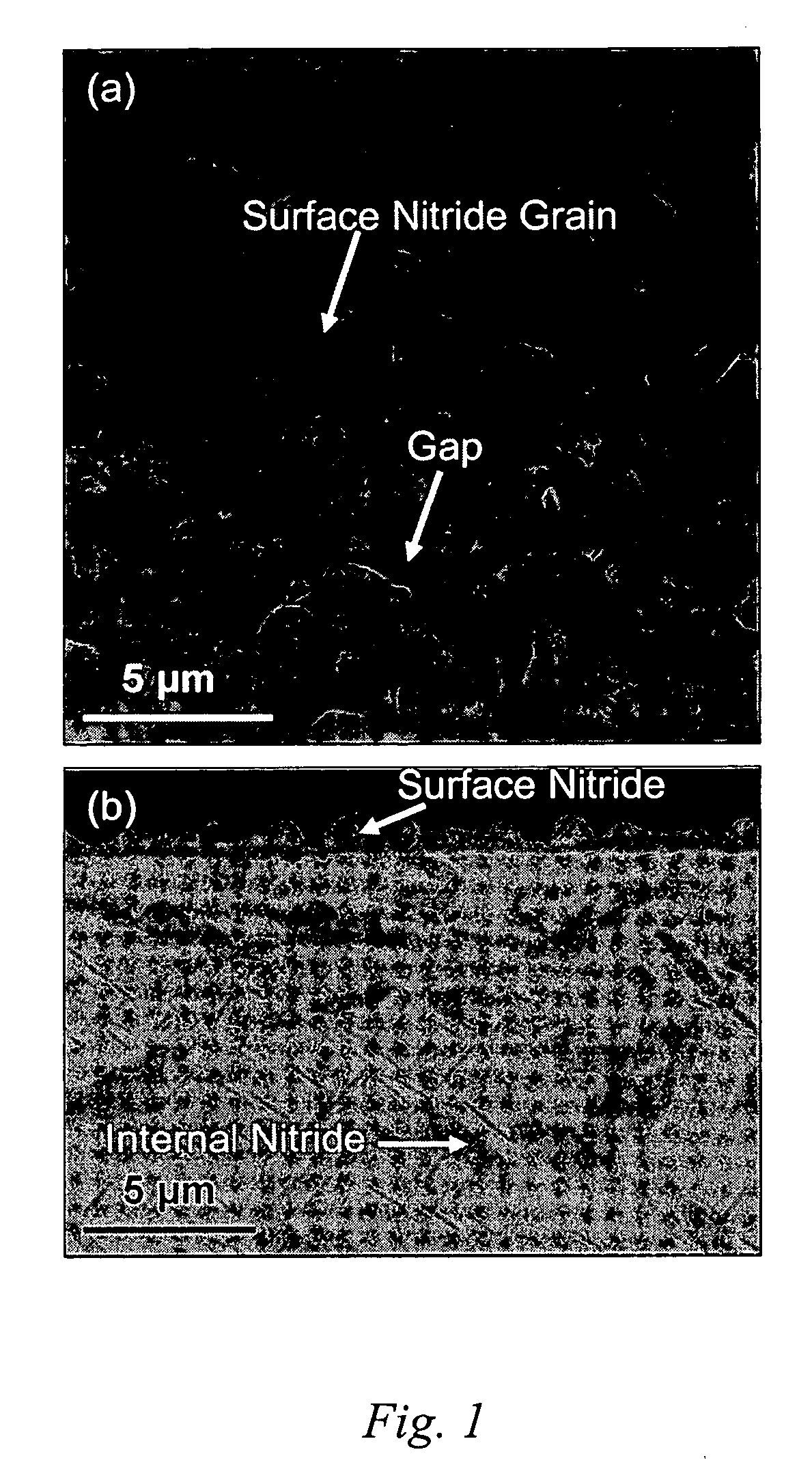

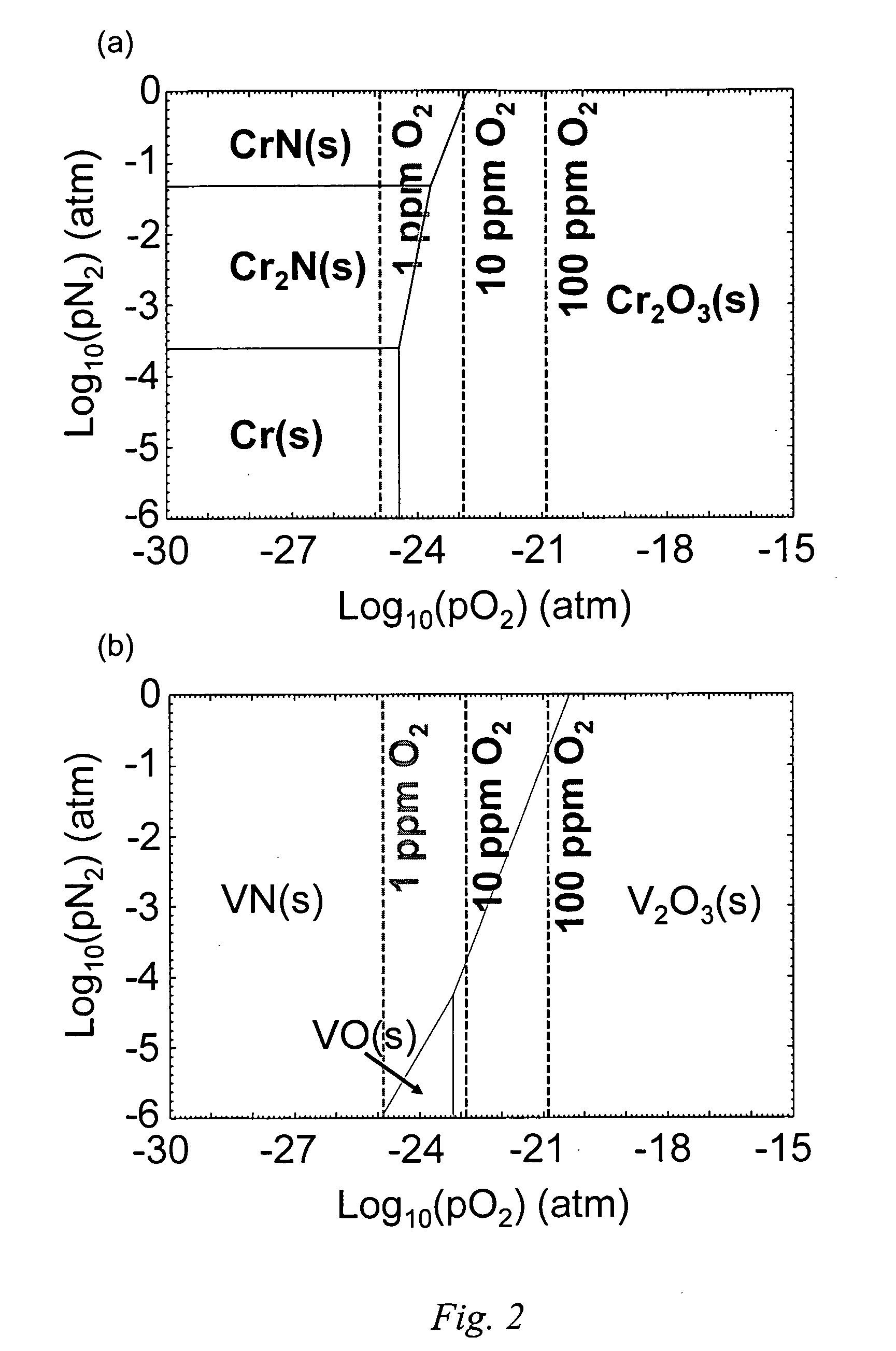

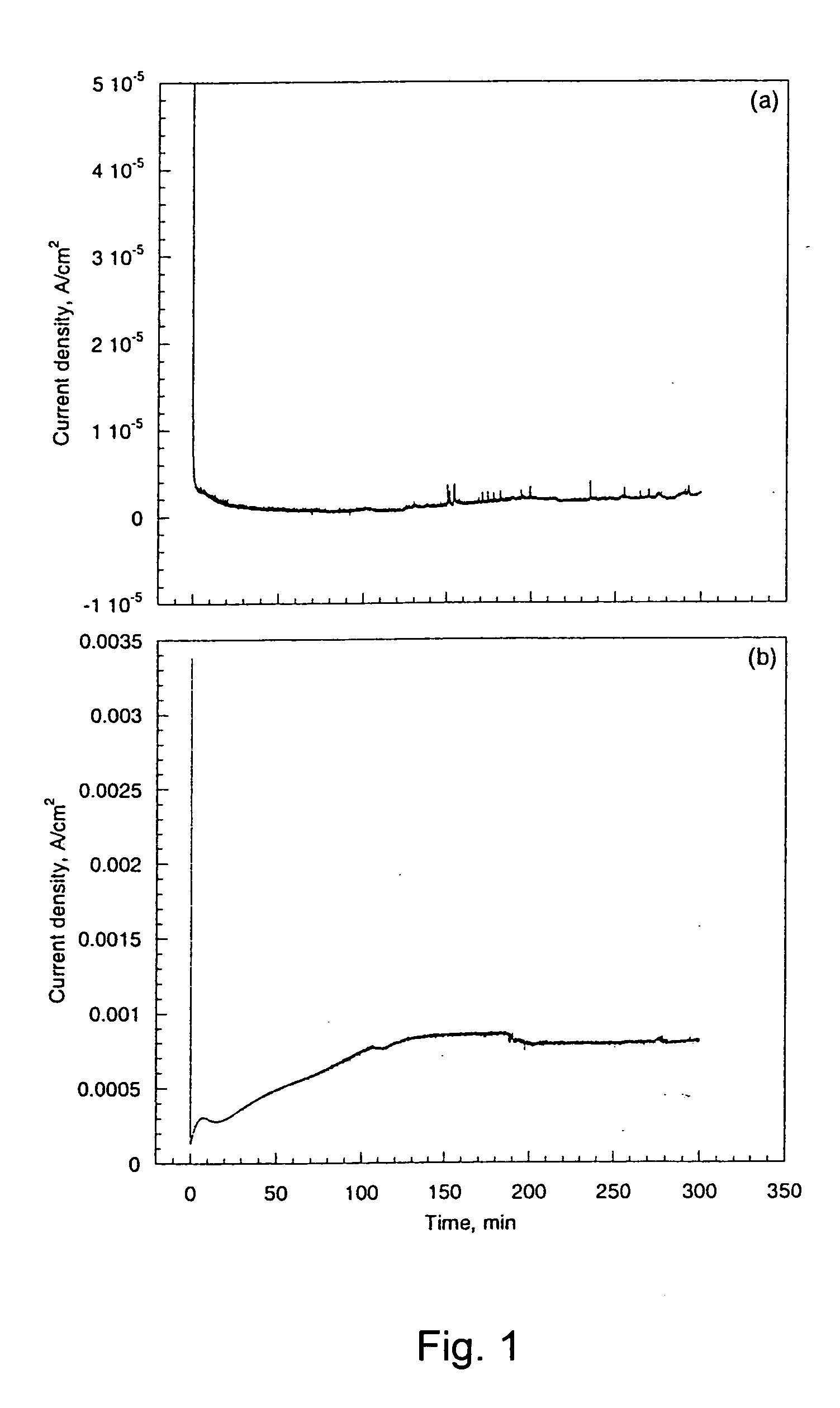

Iron-based alloy and nitridation treatment for PEM fuel cell bipolar plates

A corrosion resistant electrically conductive component that can be used as a bipolar plate in a PEM fuel cell application is composed of an alloy substrate which has 10-30 wt. % Cr, 0.5 to 7 wt. % V, and base metal being Fe, and a continuous surface layer of chromium nitride and vanadium nitride essentially free of base metal. A oxide layer of chromium vanadium oxide can be disposed between the alloy substrate and the continuous surface nitride layer. A method to prepare the corrosion resistant electrically conductive component involves a two-step nitridization sequence by exposing the alloy to a oxygen containing gas at an elevated temperature, and subsequently exposing the alloy to an oxygen free nitrogen containing gas at an elevated temperature to yield a component where a continuous chromium nitride layer free of iron has formed at the surface.

Owner:UT BATTELLE LLC

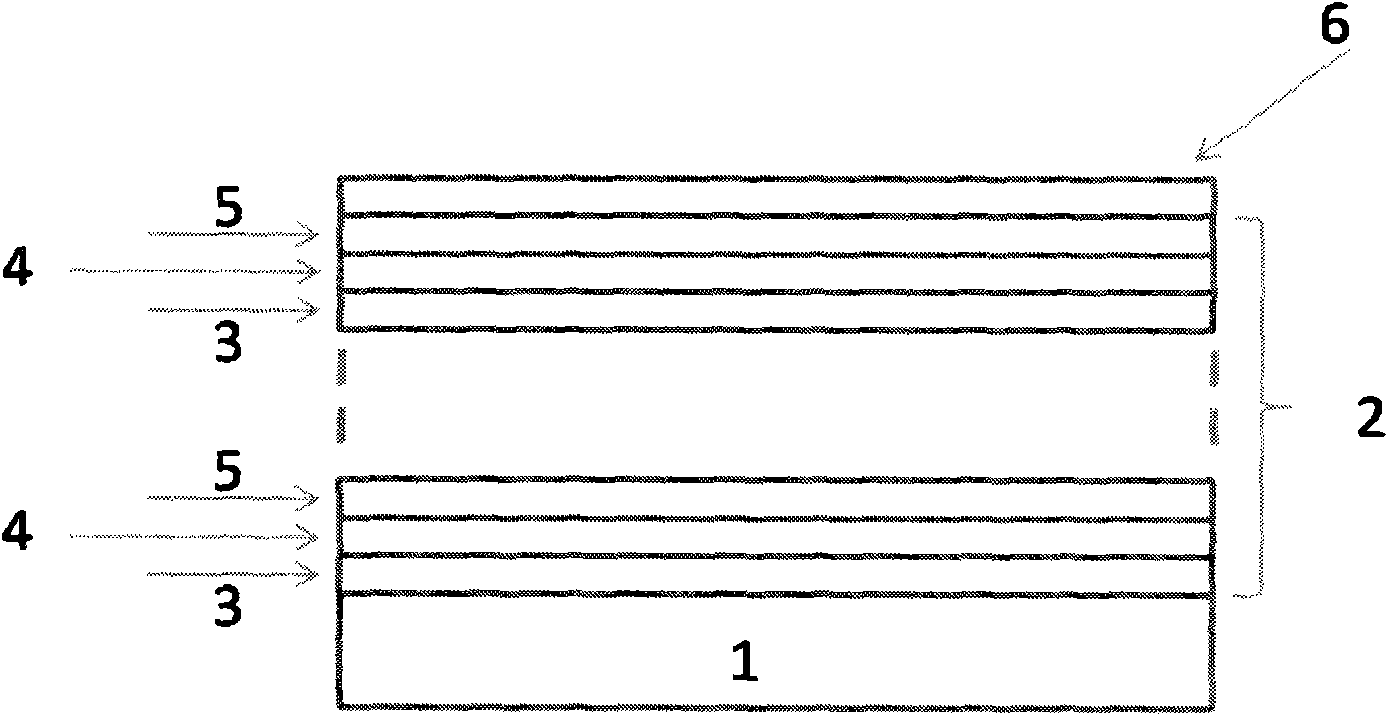

Foodware with multilayer stick resistant ceramic coating and method of making

A foodware article having a multilayer, stick resistant, ceramic coating. The foodware article of the present invention includes a metal foodware article having an inner food-contacting surface and an outer surface; a bonding layer deposited on the food-contacting surface; and a first layer of (Ti,Al,Cr)N deposited adjacent to the bonding layer. There is optionally a layer of chromium nitride deposited adjacent to the first (Ti,Al,Cr)N layer, and a second layer of (Ti,Al,Cr)N deposited on the chromium nitride layer. These layers can be repeated as many times as desired. The (Ti, Al, Cr)N layer is generally the top layer of the multiplayer coating. The coating is stick resistant, scratch resistant, thermally stable, corrosion resistant, and color stable. The foodware is suitable for use with both salty-based and acidic-based foods. A method of making such a foodware article is also disclosed.

Owner:MEYER INTPROP

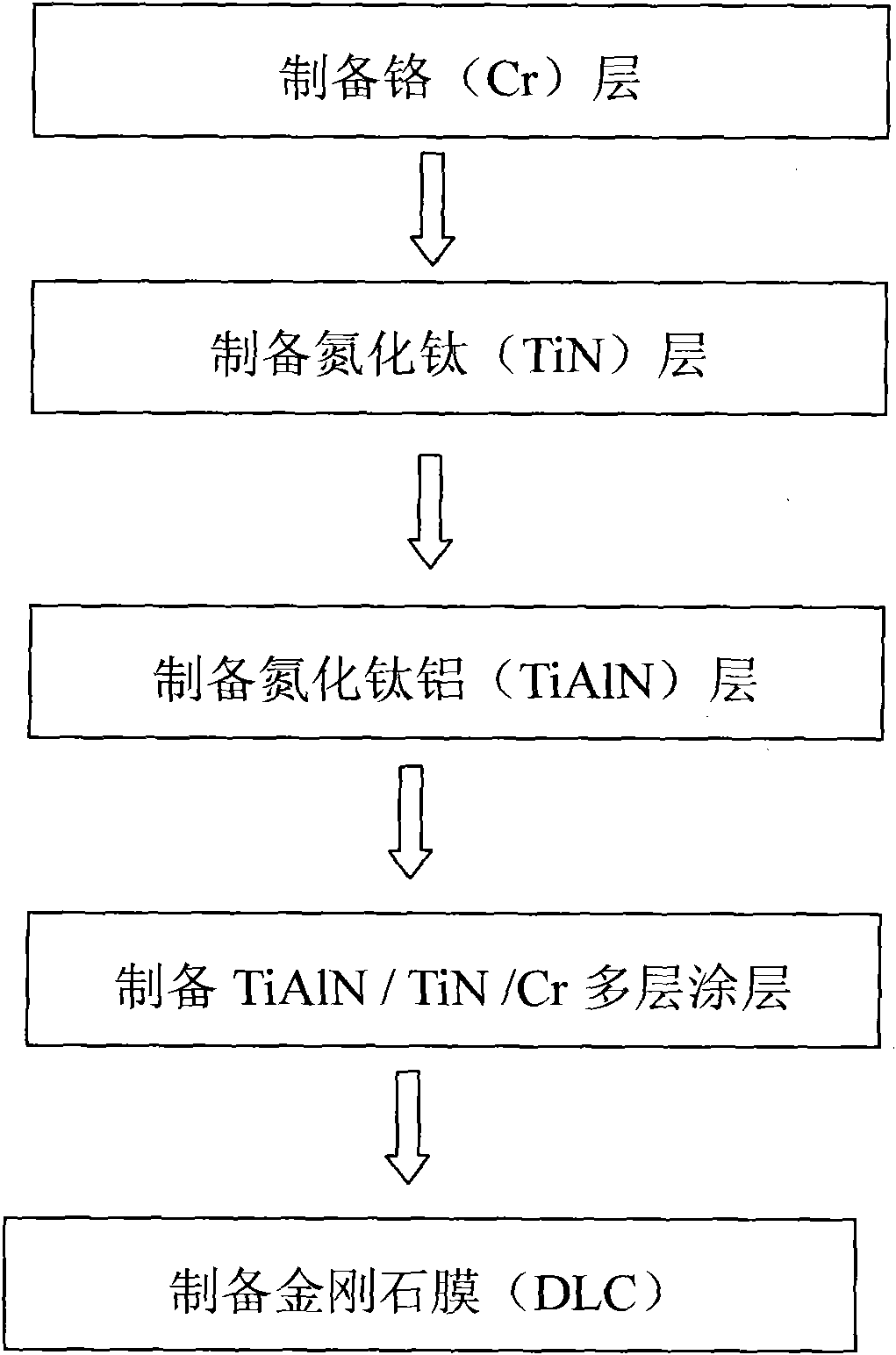

DLC (diamond-like carbon)/TiAlN (titanium aluminium nitride)/CrN (chromium nitride)/Cr (chromium) multilayer superhard film coating and preparation method thereof

InactiveCN102080207AImprove bindingImprove performanceVacuum evaporation coatingSputtering coatingTitanium aluminium nitrideDiamond-like carbon

The invention discloses a DLC (diamond-like carbon) / TiAlN (titanium aluminium nitride) / CrN (chromium nitride) / Cr (chromium) multilayer superhard film coating for the surface treatment of piston rings of automobile engines, and the multilayer superhard film coating is prepared by adopting a multi-arc ion plating technology and a magnetron sputtering technology. The thickness of the prepared multilayer superhard film coating is between 5 mu m and 20 mu m (micrometer), and the hardness of the coating is greater than 40GPa.

Owner:SHENZHEN GUANGDA NANO ENG

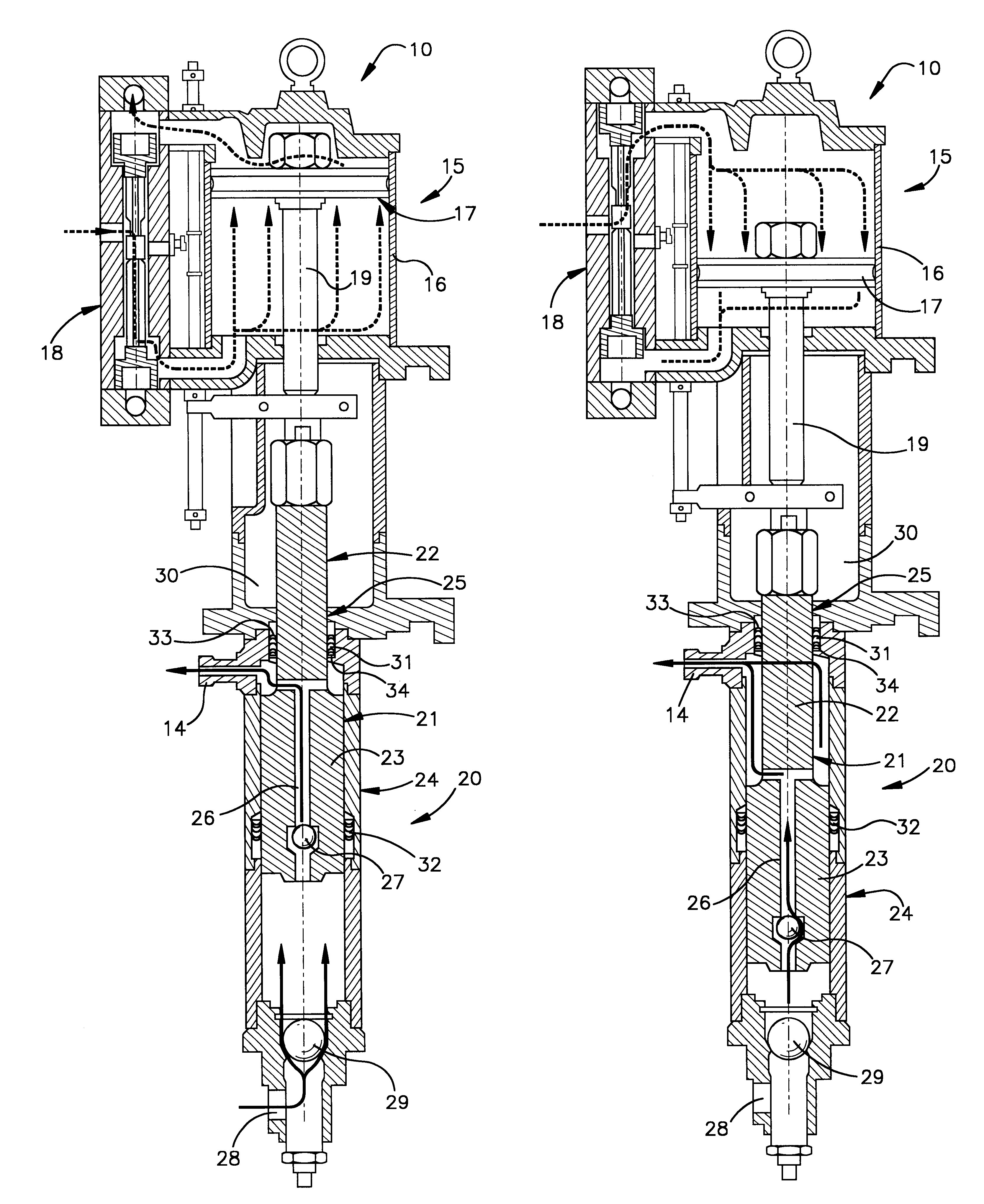

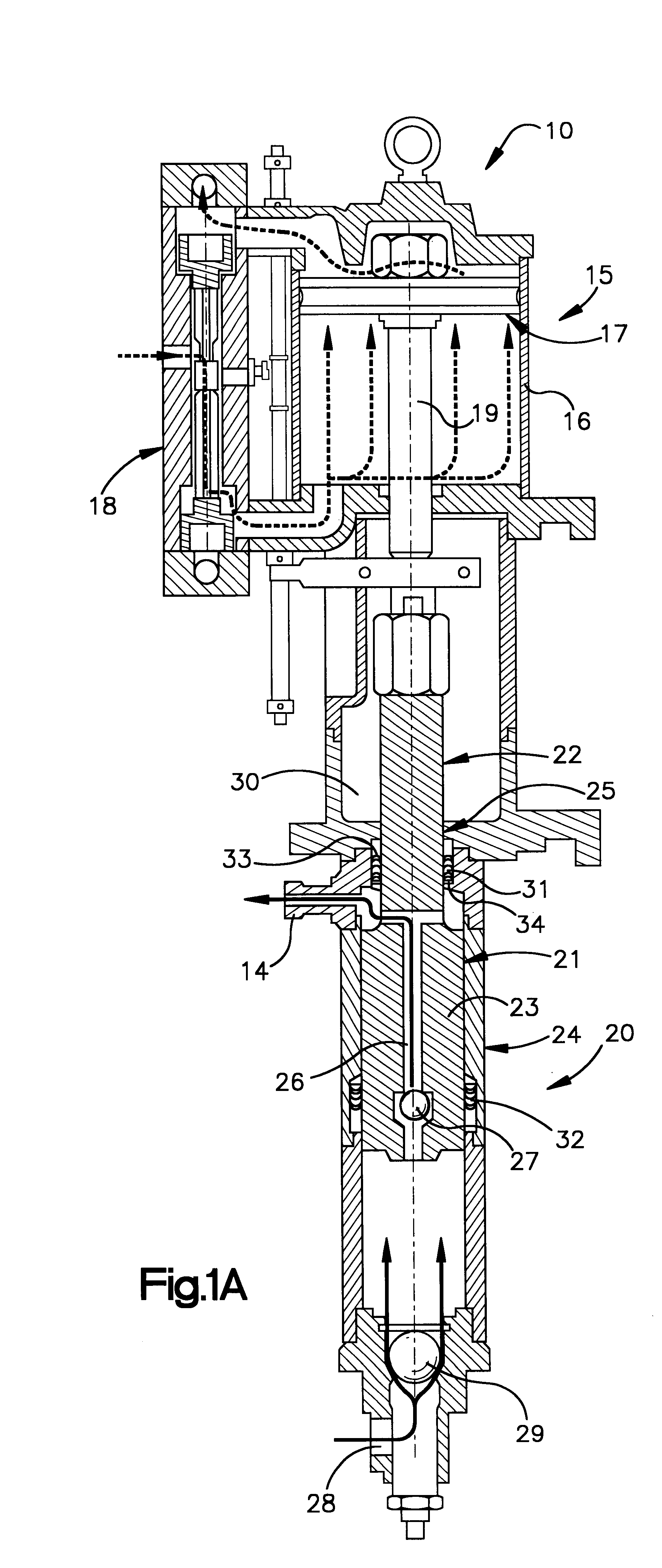

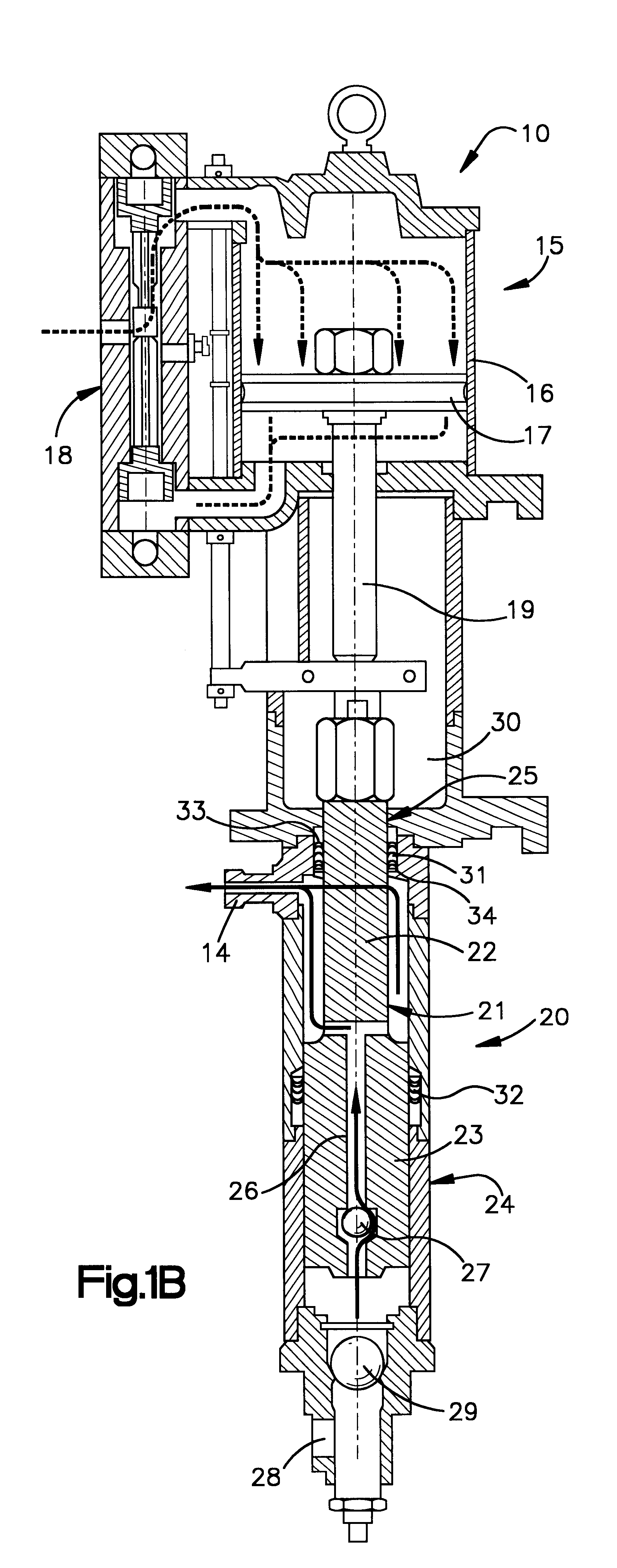

Reciprocating fluid pumps with chromium nitride coated components in contact with non-metallic packing and gasket materials for increased seal life

InactiveUS6212997B1Extend your lifeEngine sealsPositive displacement pump componentsEngineeringChromium nitride

Chromium nitride coating of machine components such as reciprocating pump plungers for continuous sliding contact with non-metallic packing and gasket materials greatly increases the performance life of fluid seals. In an air driven reciprocating constant pressure pump, exterior surfaces of the pump plunger are coated with chromium nitride to a thickness of seven to ten microns. The coating resists failure from repeated sliding contact against non-metallic packing and gasket materials for at least four million pump cycles, with no evidence of cracking or release of metallic particles which would embed in the packing or gasket material and score the plunger. In lower pressure pumps, interior walls of a housing against which a sliding gasket bears, when coated with chromium nitride, greatly increase the seal life of the sliding gasket.

Owner:NORDSON CORP

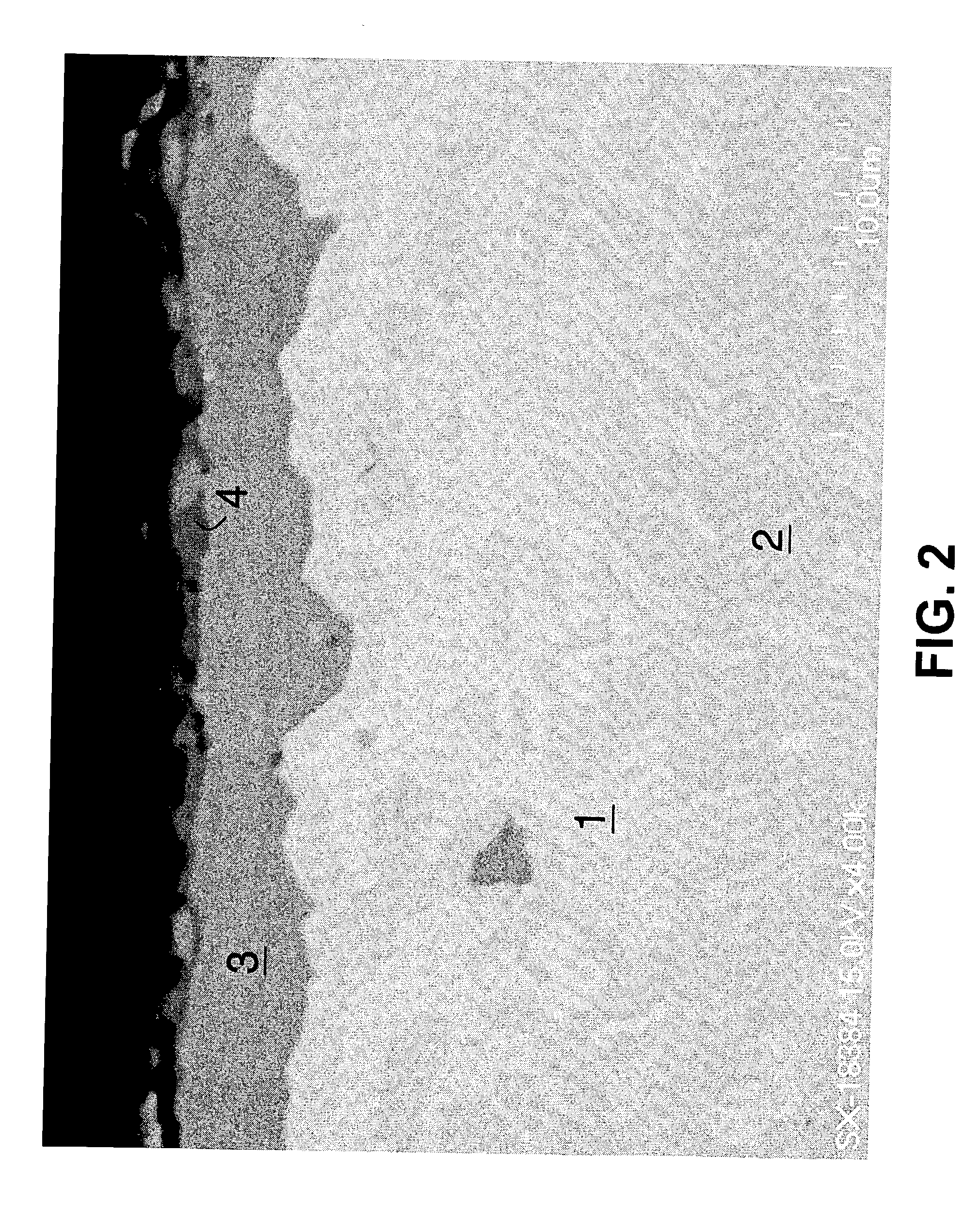

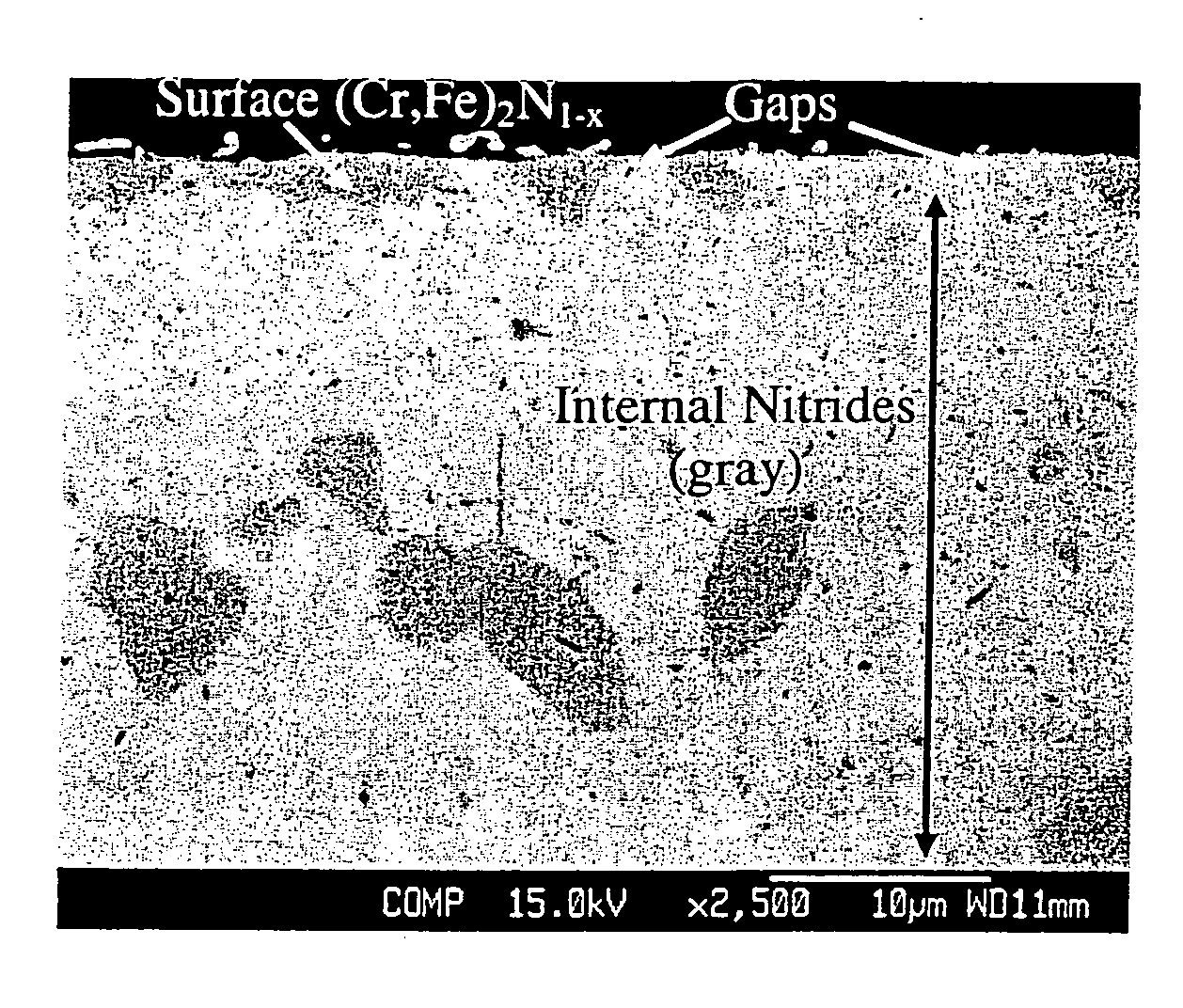

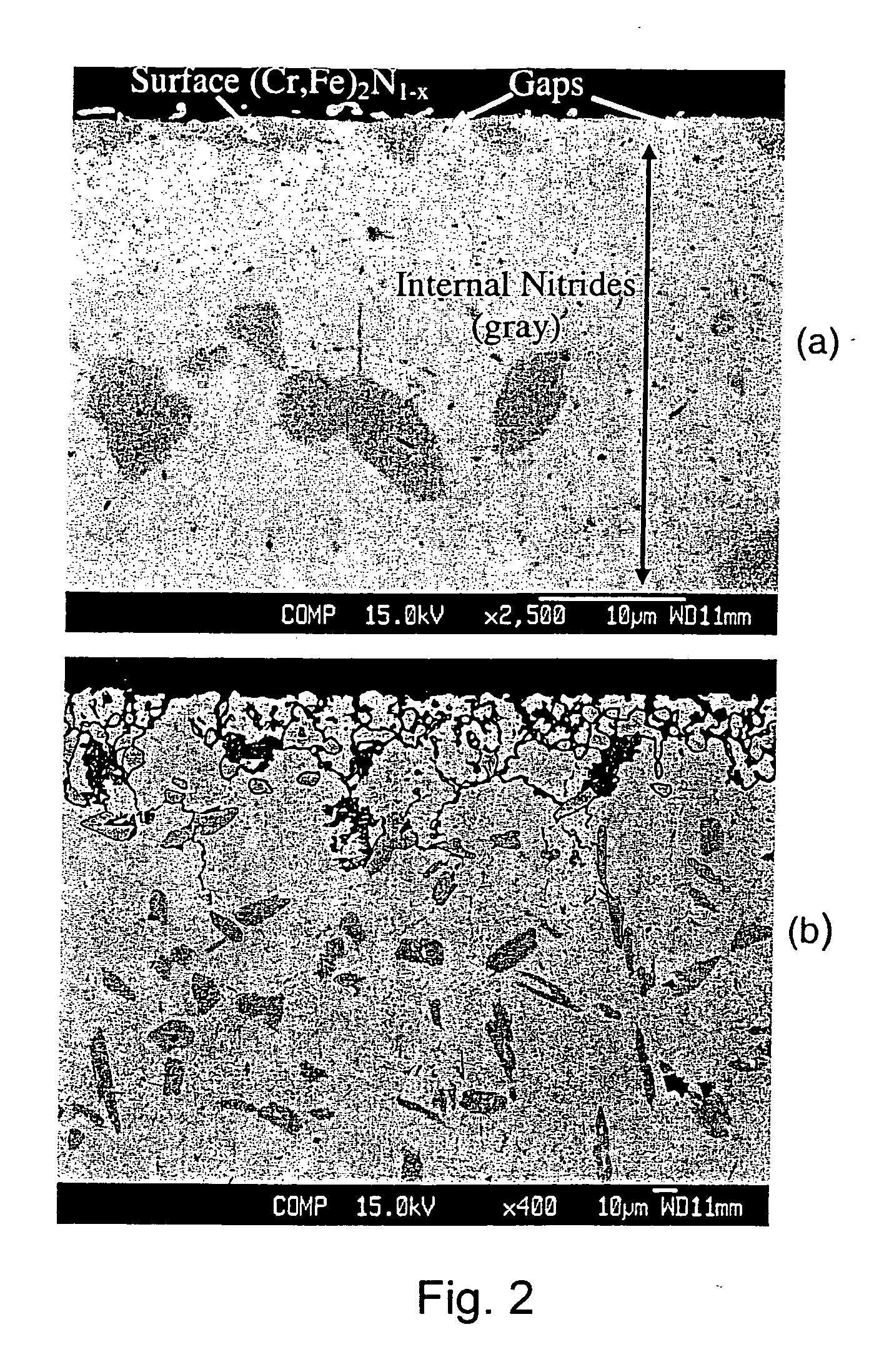

Surface modified stainless steels for PEM fuel cell bipolar plates

ActiveUS20050238873A1Improve corrosion resistanceReduce interface contact resistanceElectrode carriers/collectorsRecord information storageSurface layerTitanium nitride

A nitridation treated stainless steel article (such as a bipolar plate for a proton exchange membrane fuel cell) having lower interfacial contact electrical resistance and better corrosion resistance than an untreated stainless steel article is disclosed. The treated stainless steel article has a surface layer including nitrogen-modified chromium-base oxide and precipitates of chromium nitride formed during nitridation wherein oxygen is present in the surface layer at a greater concentration than nitrogen. The surface layer may further include precipitates of titanium nitride and / or aluminum oxide. The surface layer in the treated article is chemically heterogeneous surface rather than a uniform or semi-uniform surface layer exclusively rich in chromium, titanium or aluminum. The precipitates of titanium nitride and / or aluminum oxide are formed by the nitriding treatment wherein titanium and / or aluminum in the stainless steel are segregated to the surface layer in forms that exhibit a low contact resistance and good corrosion resistance.

Owner:UT BATTELLE LLC +1

Soldering wire material containing nitrogen alloyed alloy core in form of hard surface

InactiveCN1562552AGuaranteed performanceIncrease productivityWelding/cutting media/materialsSoldering mediaHigh carbonNitrogen

A nitrogen alloyed welding wire with hard surface and alloy core for repairing on manufacturing rolling roller, mine machinery and large digger features that its core powder is prepared from alloy powder and mineral powder through mixing, and contains rutile, high-carbon ferrochromium, low-carbon ferrochromium, Si Al-Mg alloy, Mn, ferromolybdenum, ferrovanadium, ferrotictanium, Ni, chromium nitride and Fe. The nitrogen is used to replace part of carbon for alloying, so improving anticracking performance.

Owner:HUAZHONG UNIV OF SCI & TECH

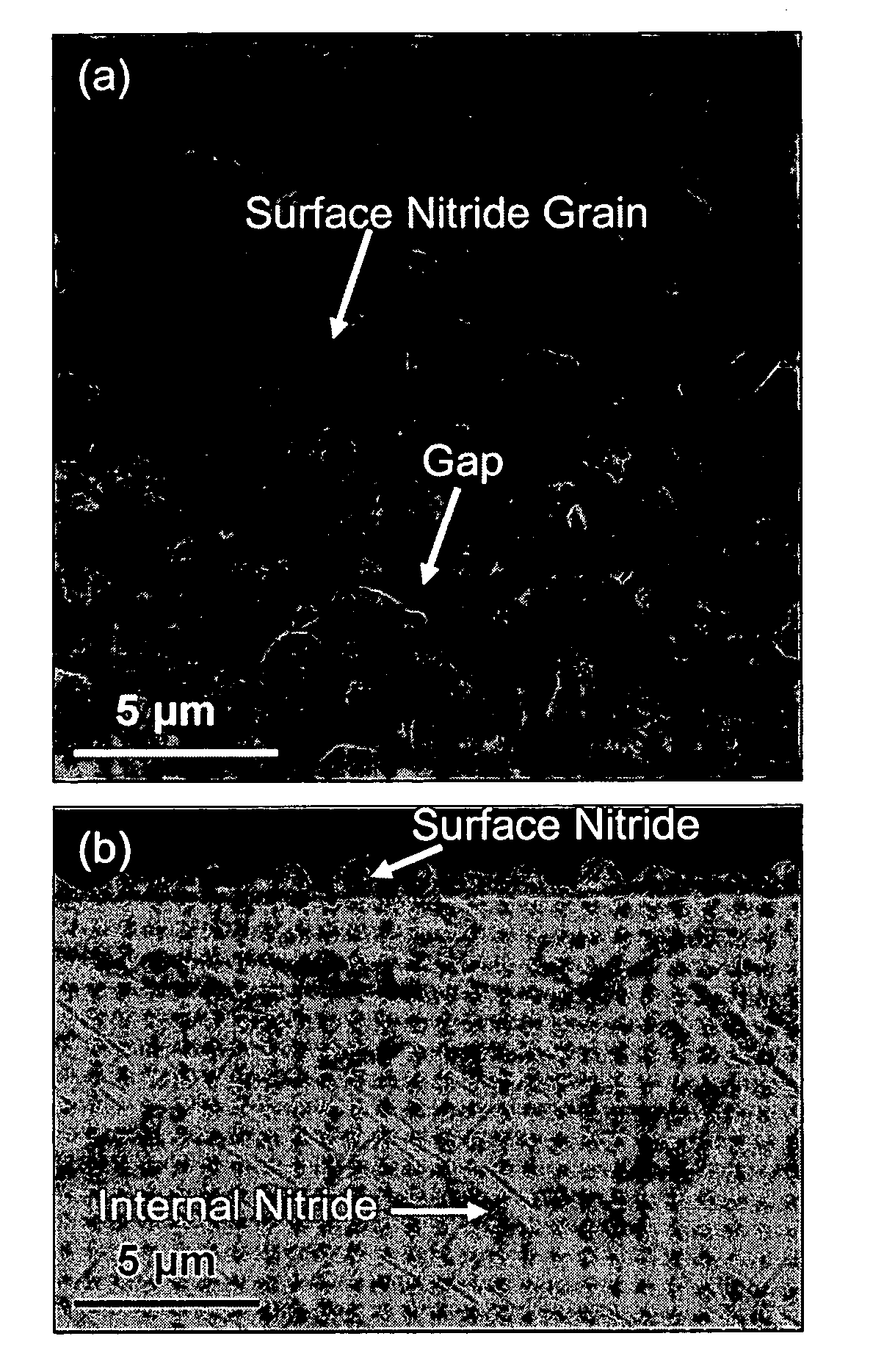

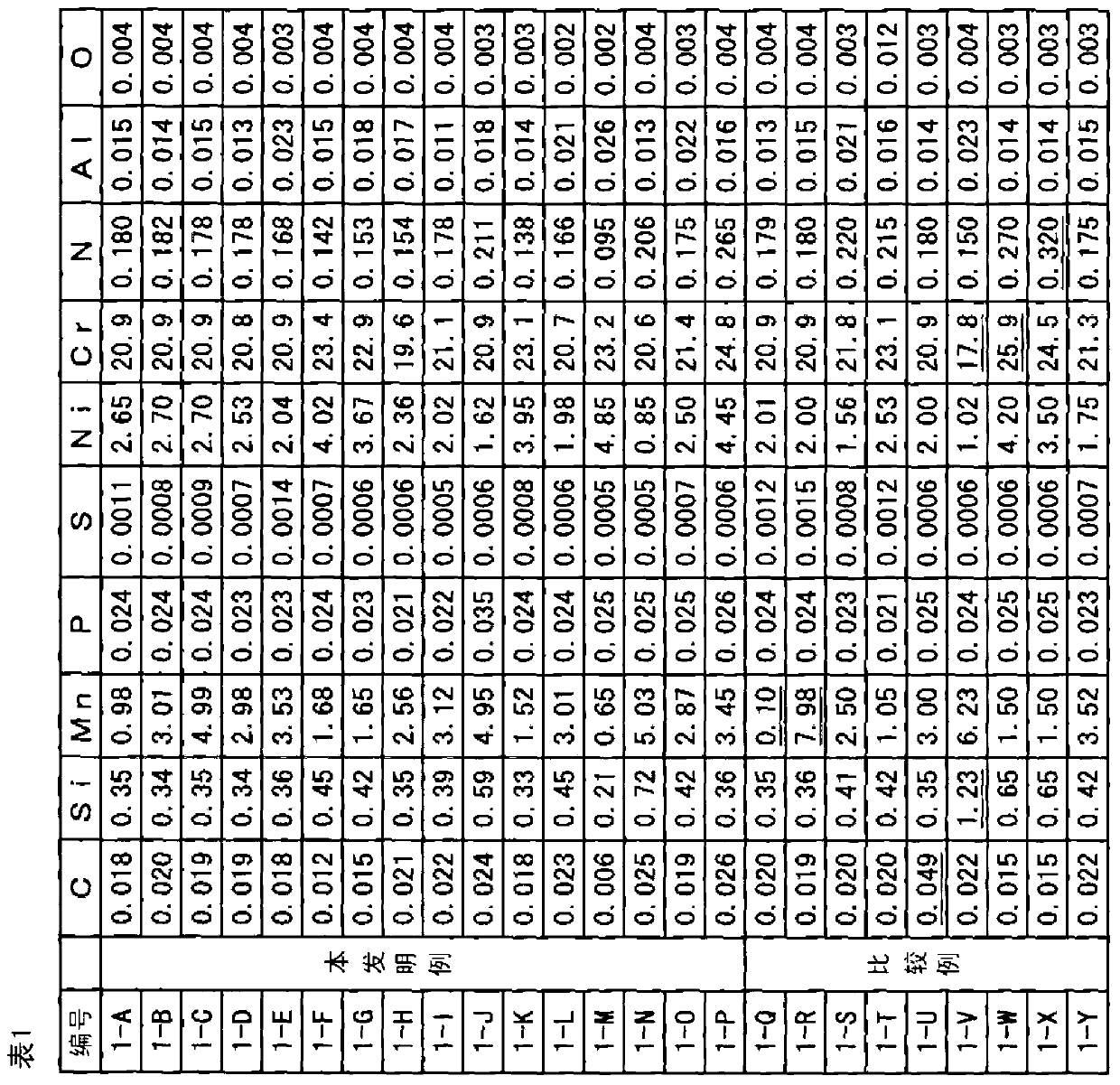

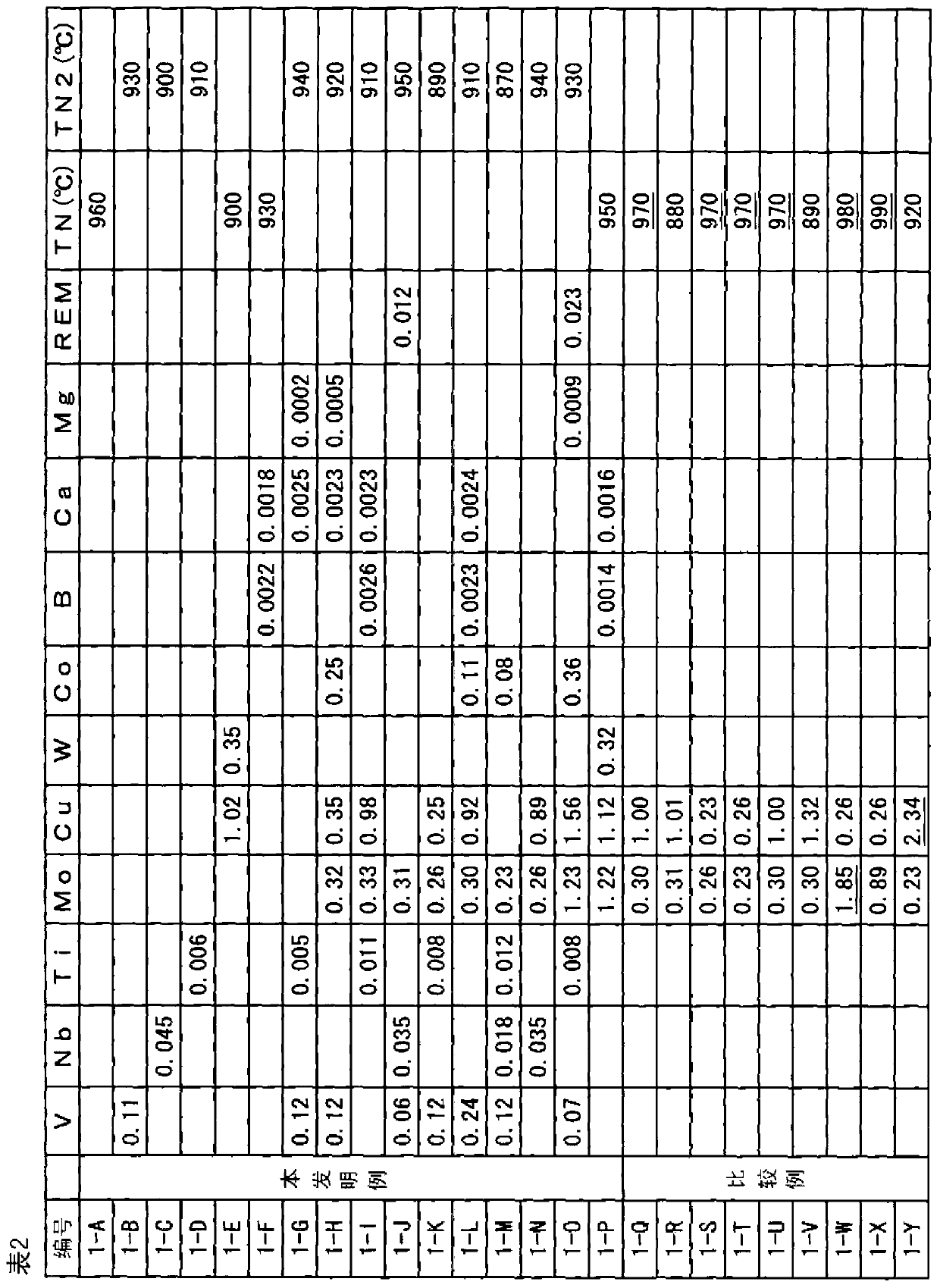

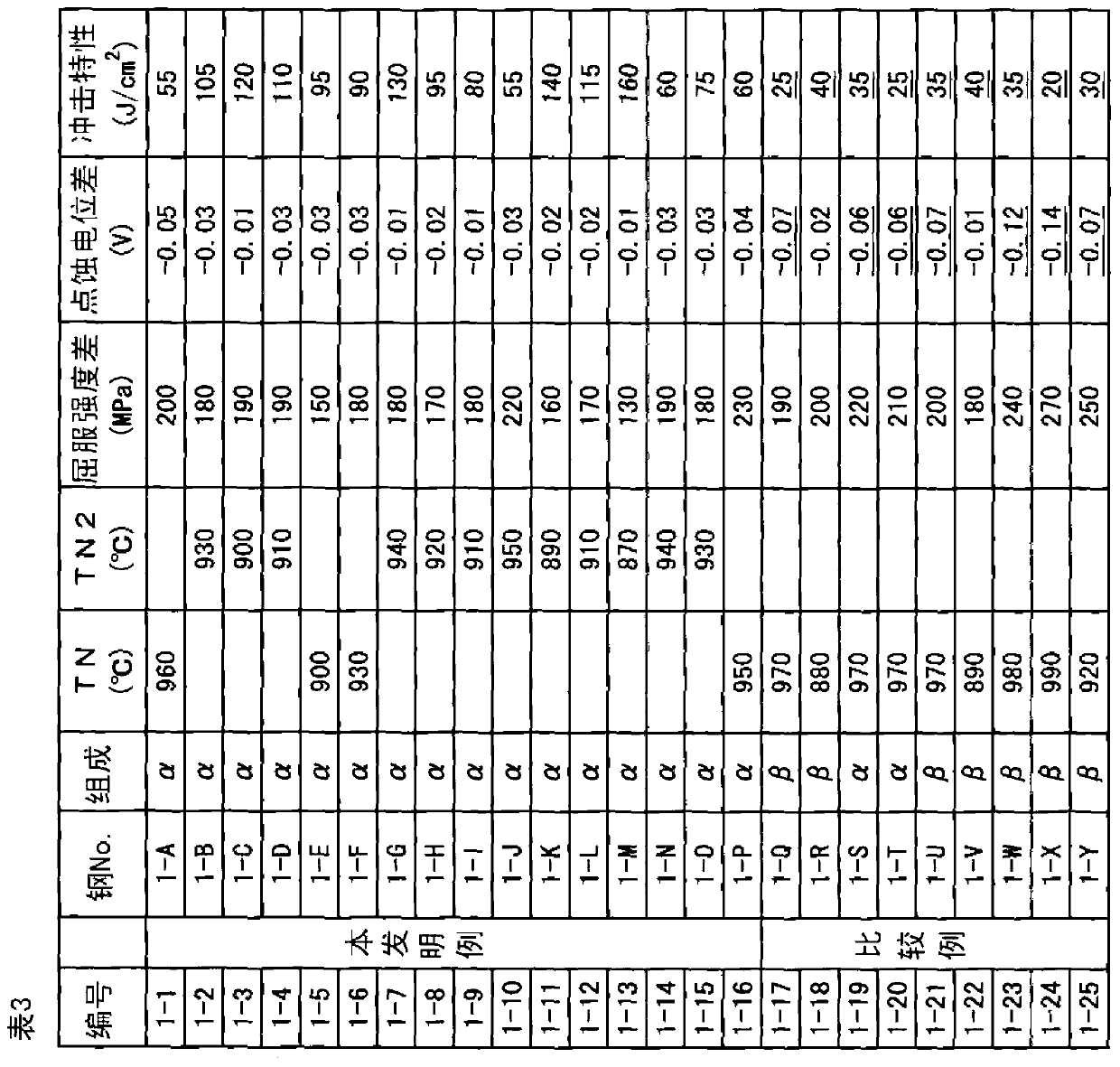

Alloying element-saving hot rolled duplex stainless steel material, clad steel sheet having duplex stainless steel as mating material therefor, and production method for same

ActiveCN103298965ACheap manufacturingSave energyWelding/soldering/cutting articlesThin material handlingDeposition temperatureSheet steel

An alloying element-saving hot rolled duplex stainless steel material comprising, in % by mass, 0.03% max. of C, 0.05%-1.0% of Si, 0.5%-7.0% of Mn, 0.05% max. of P, 0.010% max. of S, 0.1%-5.0% of Ni, 18.0%-25.0% of Cr, 0.05%-0.30% of N, and 0.001%-0.05% of Al, with the remainder comprising Fe and unavoidable impurities. Said material is produced by hot rolling, has a chromium nitride deposition temperature (TN) of 960 DEG C max., has a yield strength 50 MPa min. greater than that of solution heat-treated hot rolled steel material, has not received treatment after hot rolling, and has not been solution heat treated. The clad steel sheet comprises a duplex stainless steel as the mating material therefor. Said duplex stainless steel has the above composition and the chromium nitride deposition temperature (TN) thereof is 800-970 DEG C.

Owner:NIPPON STEEL STAINLESS STEEL CORP

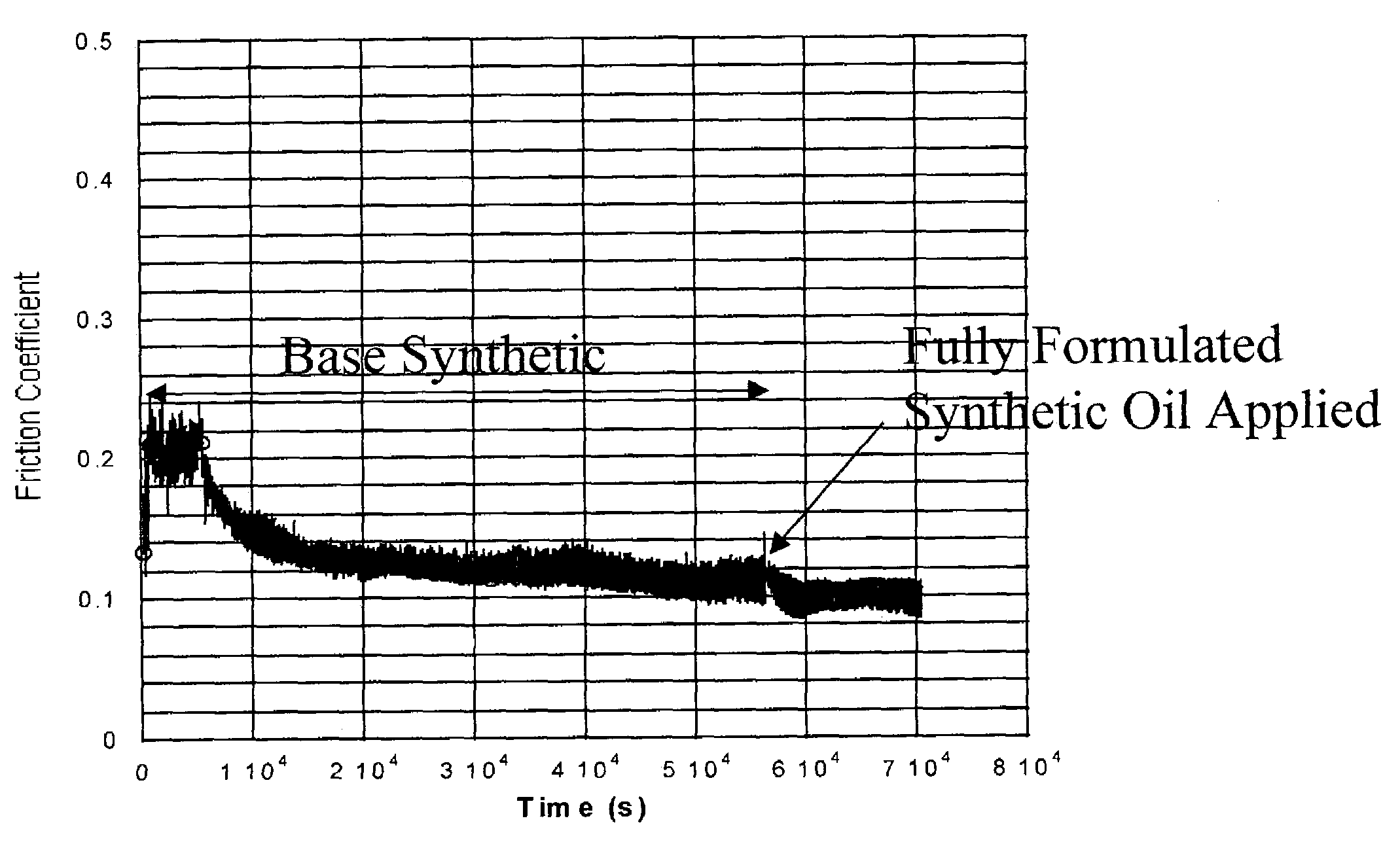

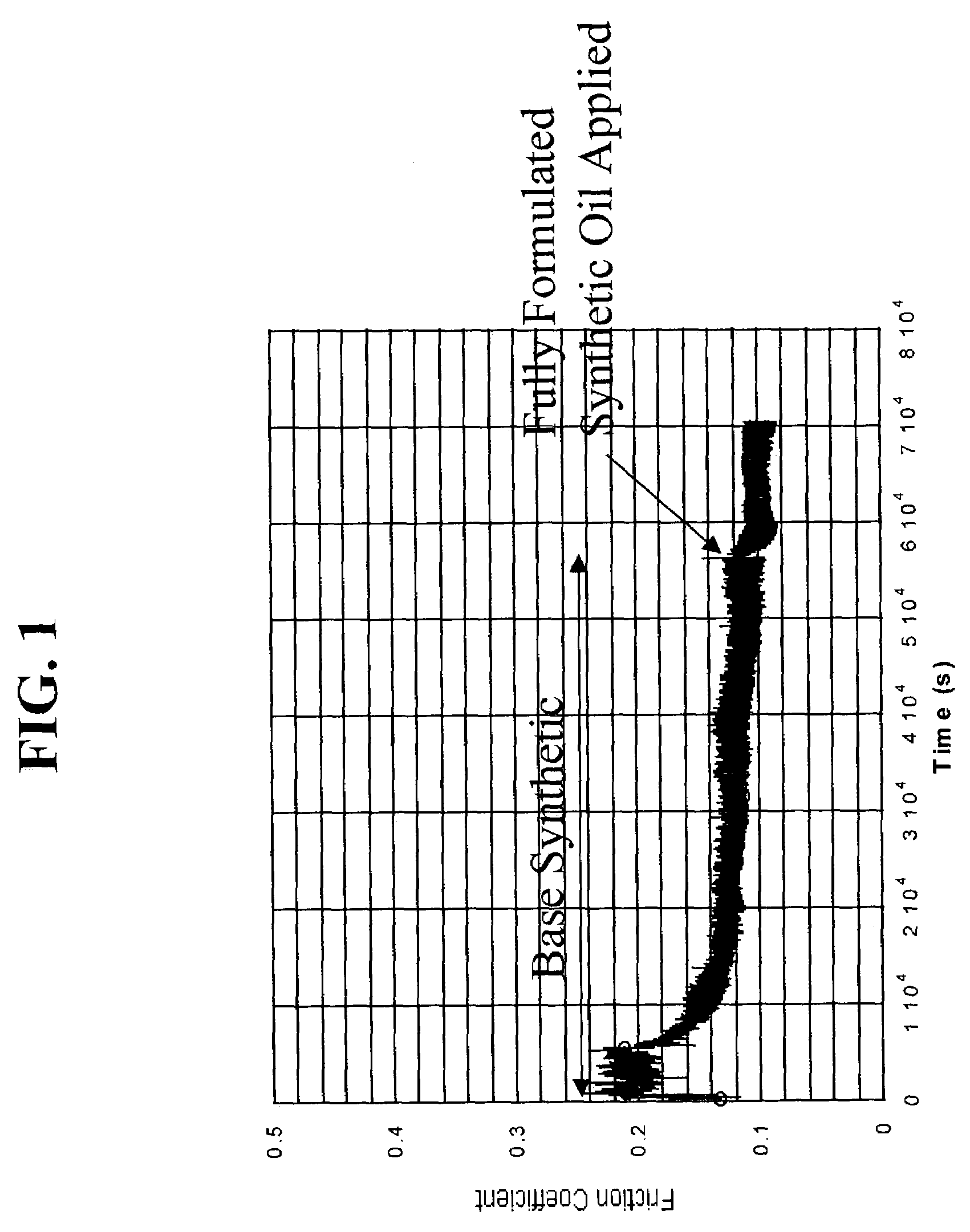

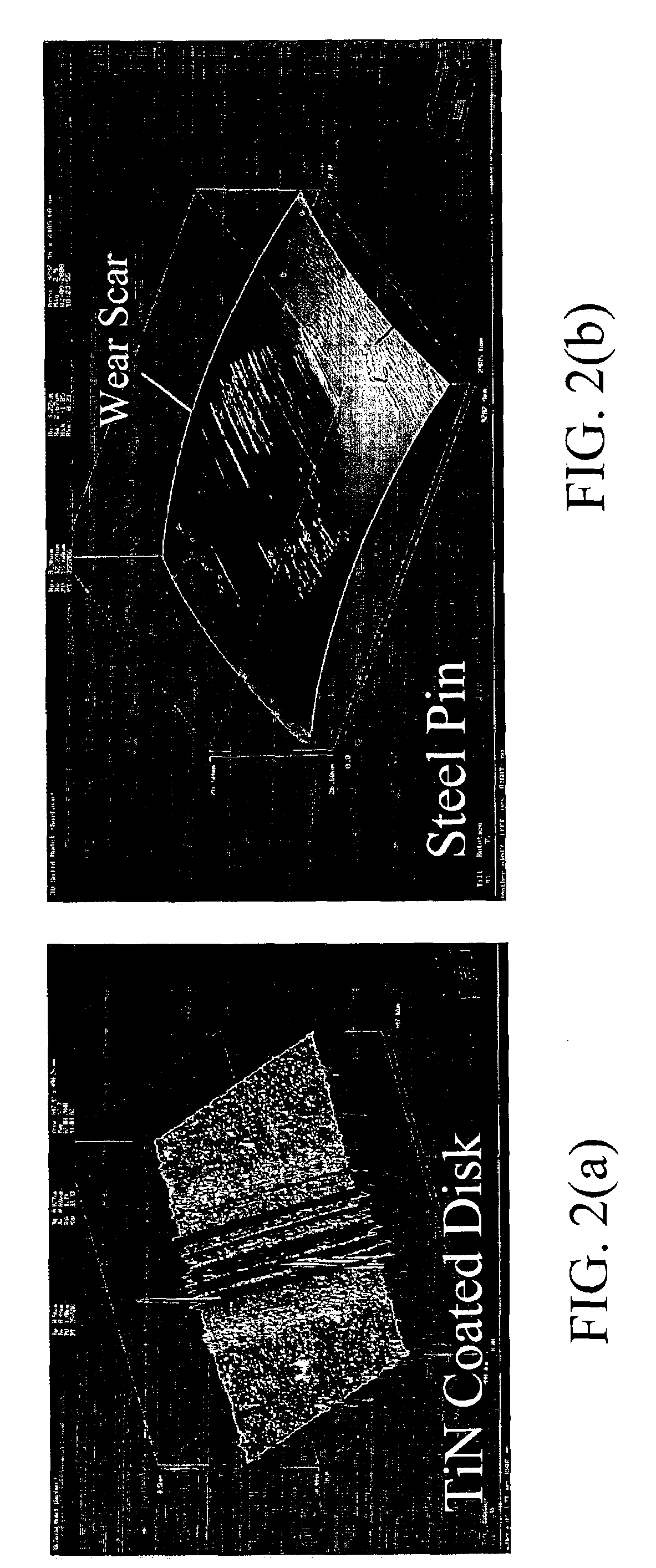

Hard and low friction nitride coatings and methods for forming the same

InactiveUS7211323B2High hardnessLow in its friction propertyVacuum evaporation coatingSputtering coatingTitanium nitrideHardness

An improved coating material possessing super-hard and low friction properties and a method for forming the same. The improved coating material includes the use of a noble metal or soft metal homogeneously distributed within a hard nitride material. The addition of small amounts of such metals into nitrides such as molybdenum nitride, titanium nitride, and chromium nitride results in as much as increasing of the hardness of the material as well as decreasing the friction coefficient and increasing the oxidation resistance.

Owner:UCHICAGO ARGONNE LLC +1

Special-purpose welding rod for built-up welding of hot work die restoration

ActiveCN105033507AImprove toughnessImprove crack resistanceWelding/cutting media/materialsSoldering mediaWear resistantOxidation resistant

The invention provides a special-purpose welding rod for built-up welding of hot work die restoration. The special-purpose welding rod comprises a coating and a welding core. Nanometer chromium-nitride powder is added into alloy powder and a fine nitride interstitial phase is formed in deposited metal, so that the deposited metal has excellent toughness and crack-resistant performances. Meanwhile, yttrium oxide is added into the alloy powder, so that the deposited metal can be purified, occluded foreign substances can be spheroidized, formation of the nitride strengthening phase can be promoted, and the anti-fatigue performance of the deposited metal is improved. When the welding rod is used for restoring the hot work die, the obtained deposited metal has the excellent high-temperature anti-oxidation performance, wear-resistant performance, cleanliness and anti-fatigue performance.

Owner:SHANDONG UNIV

Special flux-cored wire for hot-working die repairing surfacing

ActiveCN105057926AGood workmanshipSuitable for automatic weldingArc welding apparatusWelding/cutting media/materialsSlagGas metal arc welding

The invention provides a special flux-cored wire for hot-working die repairing surfacing. The special flux-cored wire comprises the wire tube wall and powder covered by the wire tube wall, wherein the powder comprises a deoxidation alloying agent and a slag former; by adding nanometer chromium nitride powder into iron-base alloy powder, a thin nitride interstitial phase is formed in the deposited metal, so that the deposited metal has good tenacity and anti-cracking capacity; meanwhile, yttria is added into the alloy powder, so that the deposited metal is purified, the occluded foreign substances are nodulized, the nitride strengthening phase is formed, and the anti-fatigue performance of the deposited metal is improved; by adopting the gas metal arc welding technology combining flux-cored wire and argon-rich gas protection to repair the hot-working die, the obtained deposited metal has excellent high-temperature oxidation resistance, excellent abrasive resistance, excellent cleanliness and good anti-fatigue performance.

Owner:SHANDONG UNIV

Erosion- and impact-resistant coatings

ActiveUS20090011195A1Suitable protectionProtect normal useEngine manufactureLayered productsTitanium aluminium nitrideGas phase

Erosion- and impact-resistant ceramic coatings suitable for protecting surfaces subjected to collisions with particles, including nominally round particles that typically inflict impact damage and more aggressive irregular-shaped particles that typically inflict erosion damage. The ceramic coating is formed to have one of three compositions: at least one layer of titanium aluminum nitride (TiAlN) having a thickness of about 25 to about 100 micrometers; multiple layers of chromium nitride (CrN) and TiAlN, each layer having a thickness of about 0.2 to about 1.0 micrometers to yield a total coating thickness of at least about 3 micrometers; and at least one layer of titanium silicon carbonitride (TiSiCN) having a thickness of about 15 to about 100 micrometers. The ceramic coating preferably has a total coating thickness of up to about 100 micrometers, and is deposited by a physical vapor deposition process to have a columnar and / or dense microstructure.

Owner:GENERAL ELECTRIC CO

Double-phase stainless steel electric welding bar

InactiveCN101817123AHigh strengthGood formabilityWelding/cutting media/materialsSoldering mediaArc stabilityElectrolysis

The invention discloses a double-phase stainless steel electric welding bar, and relates to the stainless steel electric welding field of electric arc welding. The invention provides a novel titanium-calcium type double-phase stainless steel electric welding bar, which has good welding performance such as little splash, low cost, good slag removal performance and the like. The electric welding bar is characterized in that: according to the coating formula, the electric welding bar comprises the following components in part by weight: 35 to 38 parts of rutile, 8 to 10 parts of natural mica, 1 to 2 parts of potassium titanate, 5 to 7 parts of marble, 10 to 12 parts of iron powder, 1 to 2 parts of bentonite, 2 to 3 parts of electrolytic manganese, 3 to 5 parts of fluorite, 1 to 2 parts of potassium feldspar, 1 to 2 parts of sodium alginate, 2 to 3 parts of chromium nitride, 20 to 24 parts of chromium metal, 8 to 10 parts of ferromolybdenum, 2 to 4 parts of magnesite, 2 to 4 parts of nickel powder and 1 part of Teflon. The welding process performance of the stainless steel welding bar is improved, and particularly the application range of the stainless steel welding bar is enlarged during welding, so the double-phase stainless steel electric welding bar has good welding performance such as good electric arc stability, little splash, low cost, good slag removal performance and the like.

Owner:SHANGHAI ATLANTIC WELDING CONSUMABLES

Polarizer, polarizer producing process, projector, liquid crystal device, and electronic device

ActiveUS20130120672A1Nitrogen-metal/silicon/boron binary compoundsPolarising elementsGratingTantalum nitride

Owner:SEIKO EPSON CORP

Stainless heat-proof self-protecting flux-cored wire for magnesium smelting reduction tank

ActiveCN104259690AQuality improvementHigh welding currentWelding/cutting media/materialsSoldering mediaMisch metalVulcanization

A stainless heat-proof self-protecting flux-cored wire for a magnesium smelting reduction tank belongs to the technical field of materials processing engineering. A normal stainless steel band 304L or common carbon steel serves as a coating layer, and alloys in a powder core are rutile, sodium carbonate, feldspar, compound fluorides, chromium, nickel, manganese, molybdenum, chromium nitride, aluminium-magnesium alloy, misch metal and iron power. Compared with a conventional stainless steel welding rod, the stainless heat-proof self-protecting flux-cored wire has the advantages that higher welding current can be used; higher welding speed can be realized; the production efficiency is improved; and the labor intensity is lowered; c. Compared with a conventional stainless steel submerged-arc welding solid wire, the stainless heat-proof self-protecting flux-cored wire has the advantages that all-position welding can be realized; the heat input is small; the slag detachability is good; and the manufacturing technique is simpler. A welded joint formed by using the stainless heat-proof self-protecting flux-cored wire provided by the invention has favorable heat resistance, oxidation resistance, vulcanization and corrosion resistance and high-temperature creep resistance compared with welded joints formed by welding the stainless steel welding rod and the stainless steel solid wire.

Owner:BEIJING UNIV OF TECH

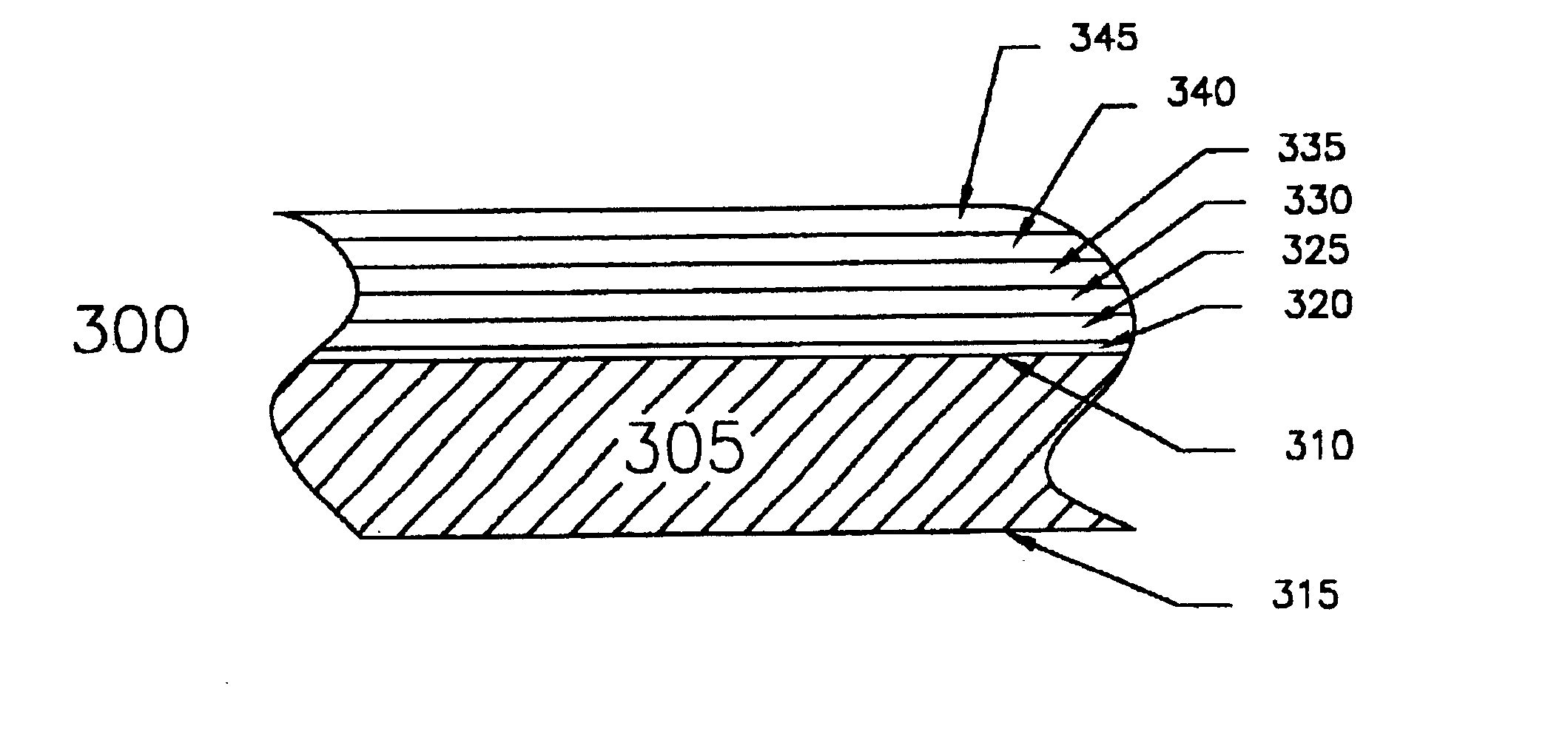

Fuel cell metal bipolar plate with surface coatings

InactiveCN101192670AImprove conductivityImprove corrosion resistanceCell electrodesFuel cell detailsOxidation resistantChromium nitride

The invention belongs to a fuel battery metal bipolar plate with a surface coat, which comprises a metal base and is characterized in that: a chromium nitride coat is arranged on the surface of the metal base; the thickness of the chromium nitride coat is 0. 5 to 10 micrometers; the chromium nitride coat is a membrane of compaction without any pinhole. The metal bipolar plate is characterized by excellent electric conduction, corrosion resistance, anti-oxidation and high temperature resistance. A layer of membrane is formed on the surface of the base by adopting a technique of ion beam surface modification so as to keep the shape and precision of the base entirely; the bipolar plate has a long-term stability and good mechanical property in the range of working electric potential on the fuel battery since the binding power between the coat and the base is high, and the coat is even and compact; the ultra-thin metal bipolar plate can be made to reduce the weight and volume of the battery pile and increase the specific power and specific energy of the battery pile. Therefore, the invention has a good application prospect.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com