Fuel cell metal bipolar plate with surface coatings

A metal bipolar plate and fuel cell technology, applied in fuel cells, fuel cell parts, battery electrodes, etc., can solve the problem of stress concentration in the composite conductive layer, which is difficult to solve, mass production is not easy to accept, and the electroplating process is complicated and other problems, to achieve good application prospects, reduce weight and volume, uniform and dense coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

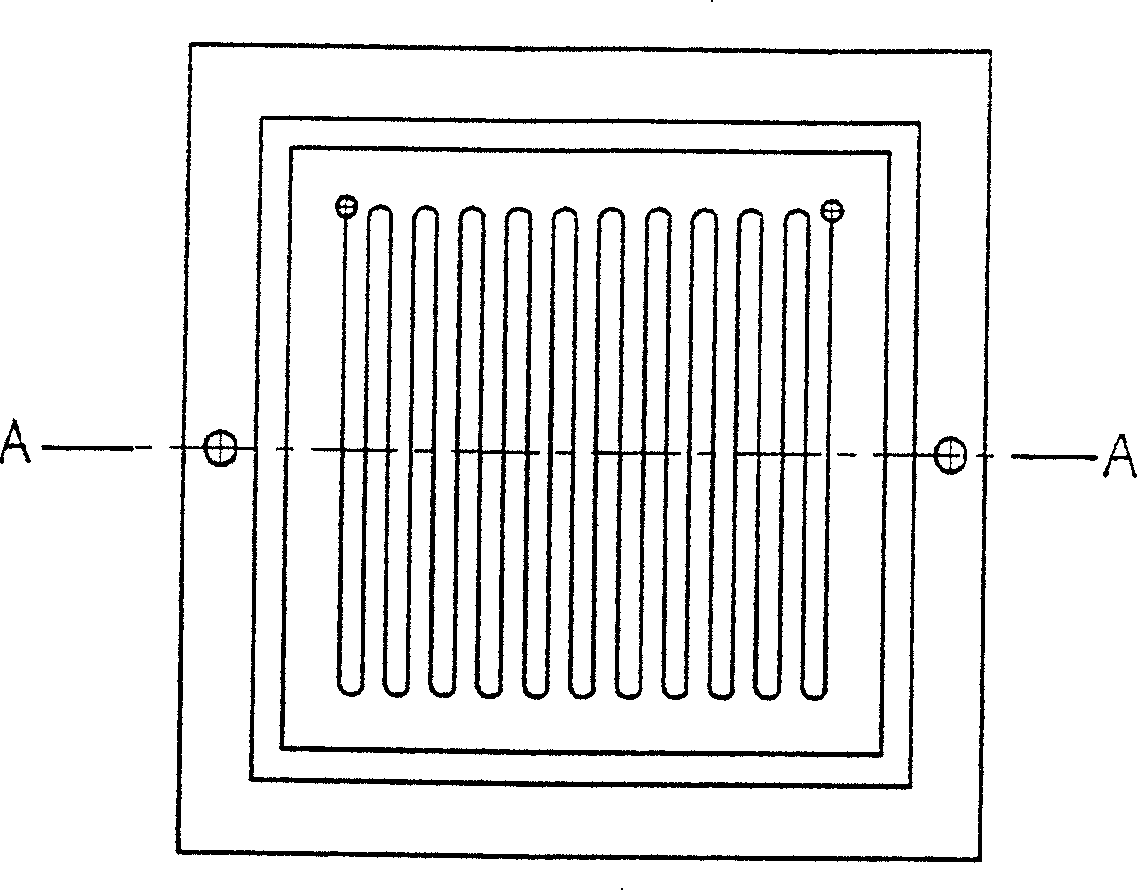

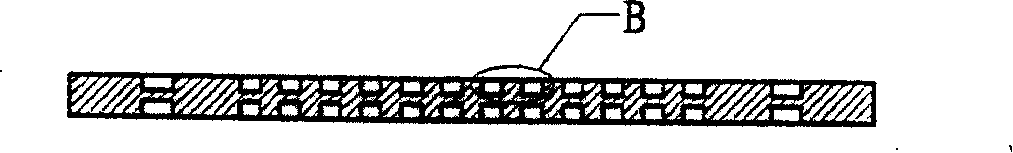

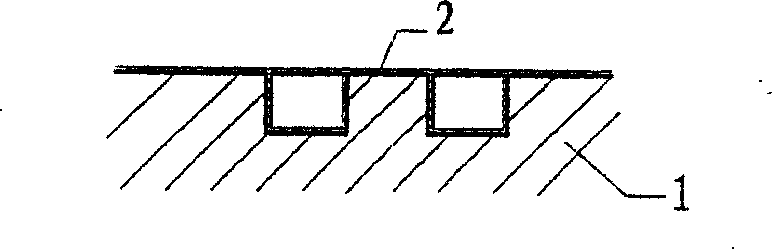

[0020] Refer to attached Figure 1-3 , take 321 stainless steel as the metal substrate 1 of the fuel cell bipolar plate, after polishing the surface of the metal substrate 1 with 800 mesh metallographic sandpaper, wash with distilled water and acetone to degrease the metal substrate 1; then clean the metal substrate 1 with distilled water; wash with water The final immersion formula of the metal substrate 1 is: sodium hydroxide 80g / L-100g / L, sodium carbonate 30g / L-60g / L, trisodium phosphate 20g / L-30g / L, and the temperature is 80°C-90°C. Remove oil in the solution; then immerse in a mixed solution with a formula of 800mL / L phosphoric acid, 100mL / L sulfuric acid, and 100g / L chromic anhydride at a temperature of 70°C to 80°C. 2 ~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com