Alloying element-saving hot rolled duplex stainless steel material, clad steel sheet having duplex stainless steel as mating material therefor, and production method for same

一种双相不锈钢、合金元素的技术,应用在金属轧制、制造工具、金属层状产品等方向,能够解决韧性下降等问题,达到廉价制造、能量少的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

[0067] Hereinafter, the unit "%" which shows content is mass %.

[0068] The first embodiment of the alloy element-saving duplex stainless steel hot-rolled steel material contains C, Si, Mn, P, S, Ni, Cr, N, and Al, and the balance contains Fe and unavoidable impurities.

[0069] In order to ensure the corrosion resistance of stainless steel, the C content is limited to less than 0.03%. If the C content exceeds 0.03%, Cr carbides are formed during hot rolling, deteriorating corrosion resistance and toughness.

[0070] Si is added in an amount of 0.05% or more for deoxidation. However, if the Si content exceeds 1.0%, the toughness deteriorates. Therefore, the upper limit of the Si content is limited to 1.0%. The Si content is preferably 0.2 to 0.7%.

[0071] Mn has the effect of increasing the austenite phase and improving toughness. In addition, it has the effect of lowering the chromium nitride precipitation temperature TN. Therefore, it is preferable to positively add ...

no. 2 Embodiment approach )

[0091] In the second embodiment of the alloy element-saving duplex stainless steel hot-rolled steel material, it contains C, Si, Mn, P, S, Ni, Cr, N, Al, and further contains one or more selected from V, Nb, and Ti. , and the balance contains Fe and unavoidable impurities.

[0092] The inventors of the present invention have found that steel containing one or more selected from V, Nb, and Ti exhibits a behavior different from conventional knowledge.

[0093] That is, it is general conventional knowledge that corrosion resistance deteriorates when the amount of chromium nitrides increases. However, when trace amounts of V, Nb, and Ti are contained, it is apparent that unexpectedly, even if the amount of chromium nitride precipitation increases to some extent, the corrosion resistance tends to improve.

[0094] As described above, when V, Nb, and Ti are contained in small amounts, the allowable amount of chromium nitrides increases. Therefore, for steel materials containing V,...

Embodiment 1)

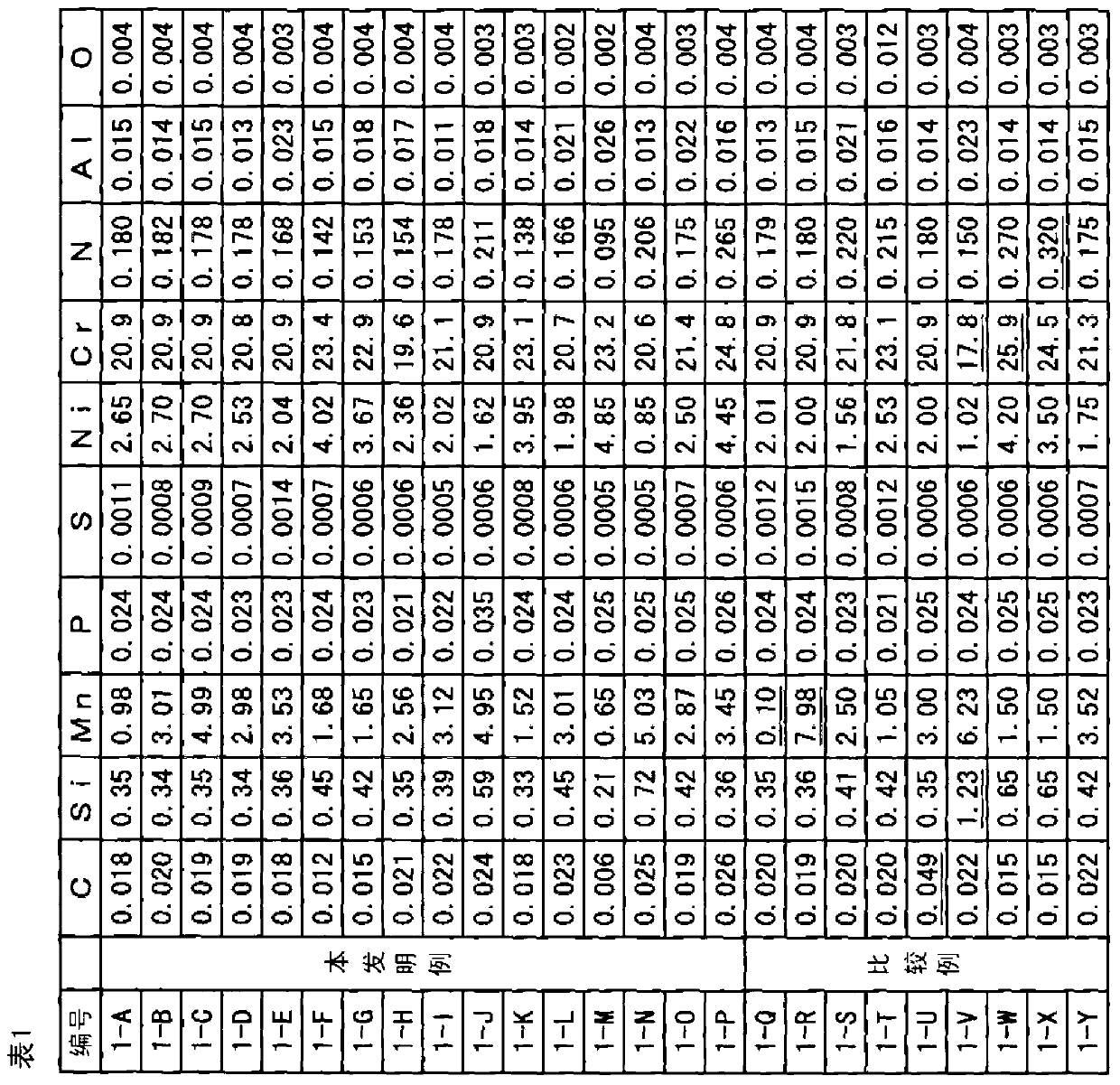

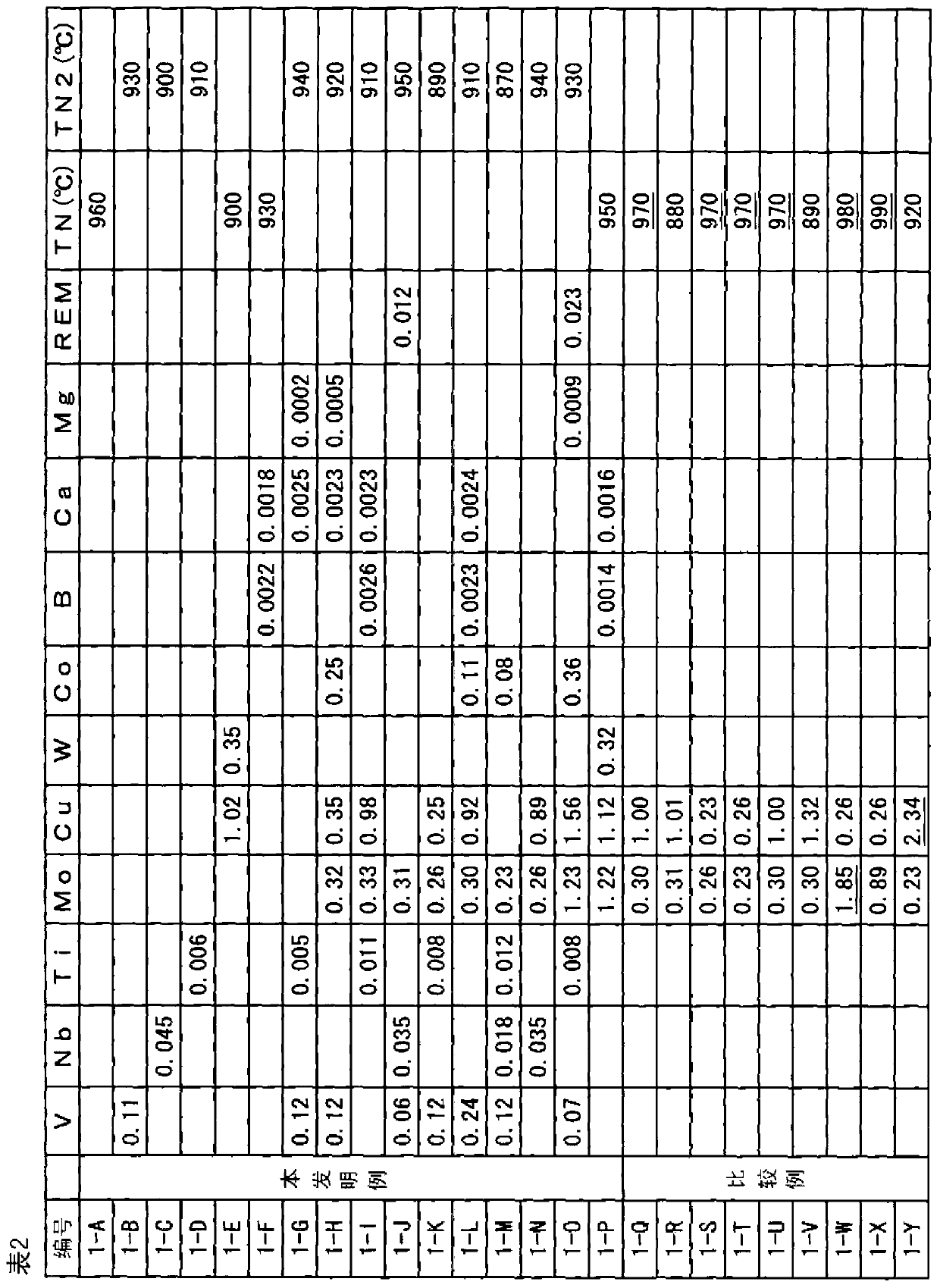

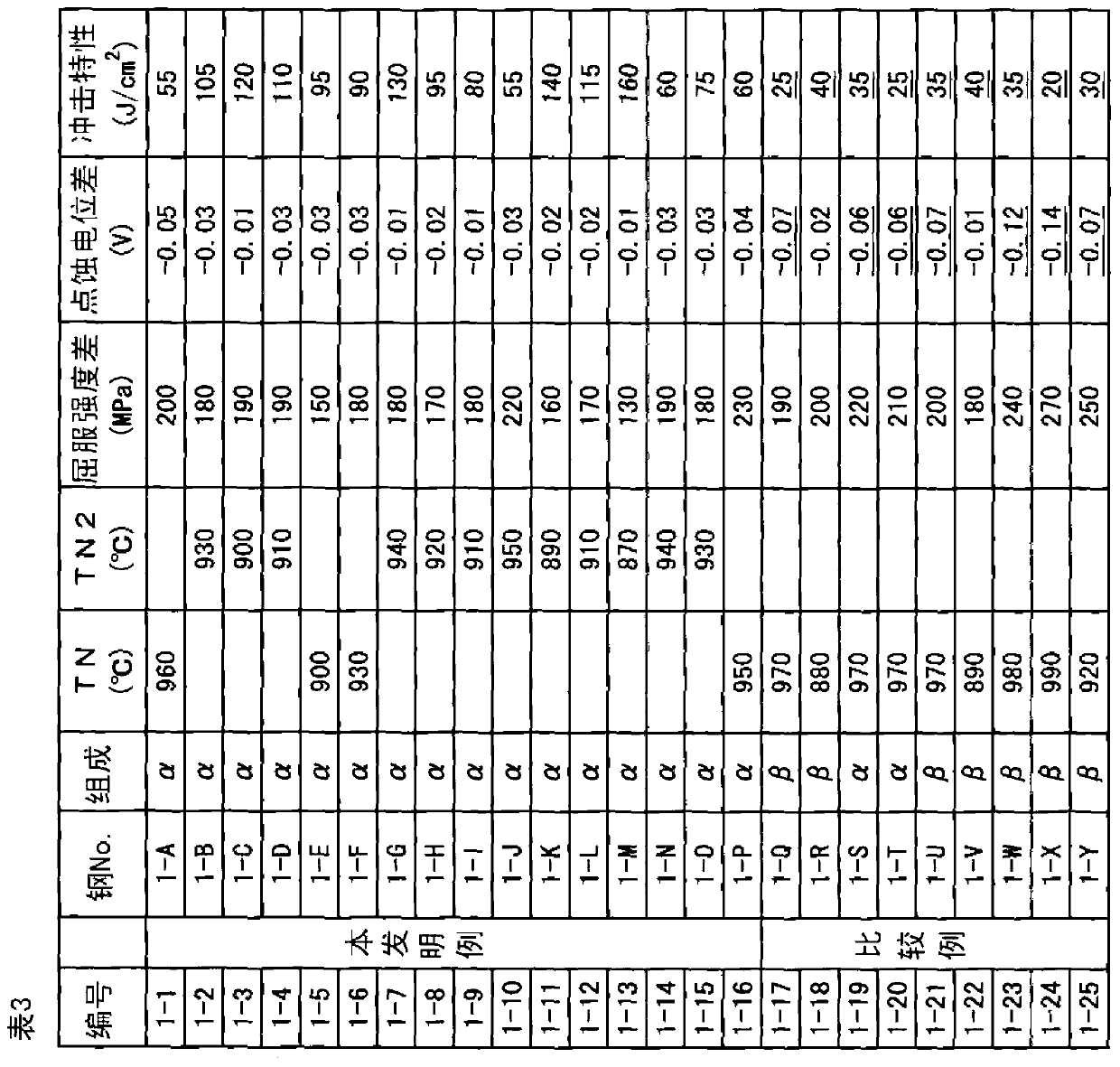

[0196] The chemical composition of the test steel is shown in Table 1 and Table 2 (continued from Table 1).

[0197] In addition, in the chemical composition shown in Table 1, 2, the balance is iron and unavoidable impurities. REM represents a lanthanoid rare earth element, and the content of REM is the total of these elements. In addition, O is an unavoidable impurity.

[0198] The chromium nitride precipitation temperatures TN and TN2 in the table were obtained by the following procedure.

[0199] (1) A test steel having a thickness of 10 mm was subjected to solution heat treatment under the conditions described later.

[0200] (2) After soaking at any temperature of 800 to 1000° C. for 20 minutes, water cooling is performed within 5 seconds.

[0201] (3) Wet-grind the surface layer of the cooled test steel with #500 sandpaper.

[0202] (4) Take 3g of the sample and conduct electrolysis (100mV constant voltage) in a non-aqueous solution (3% maleic acid + 1% tetramethylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com