Patents

Literature

5198results about How to "Good workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

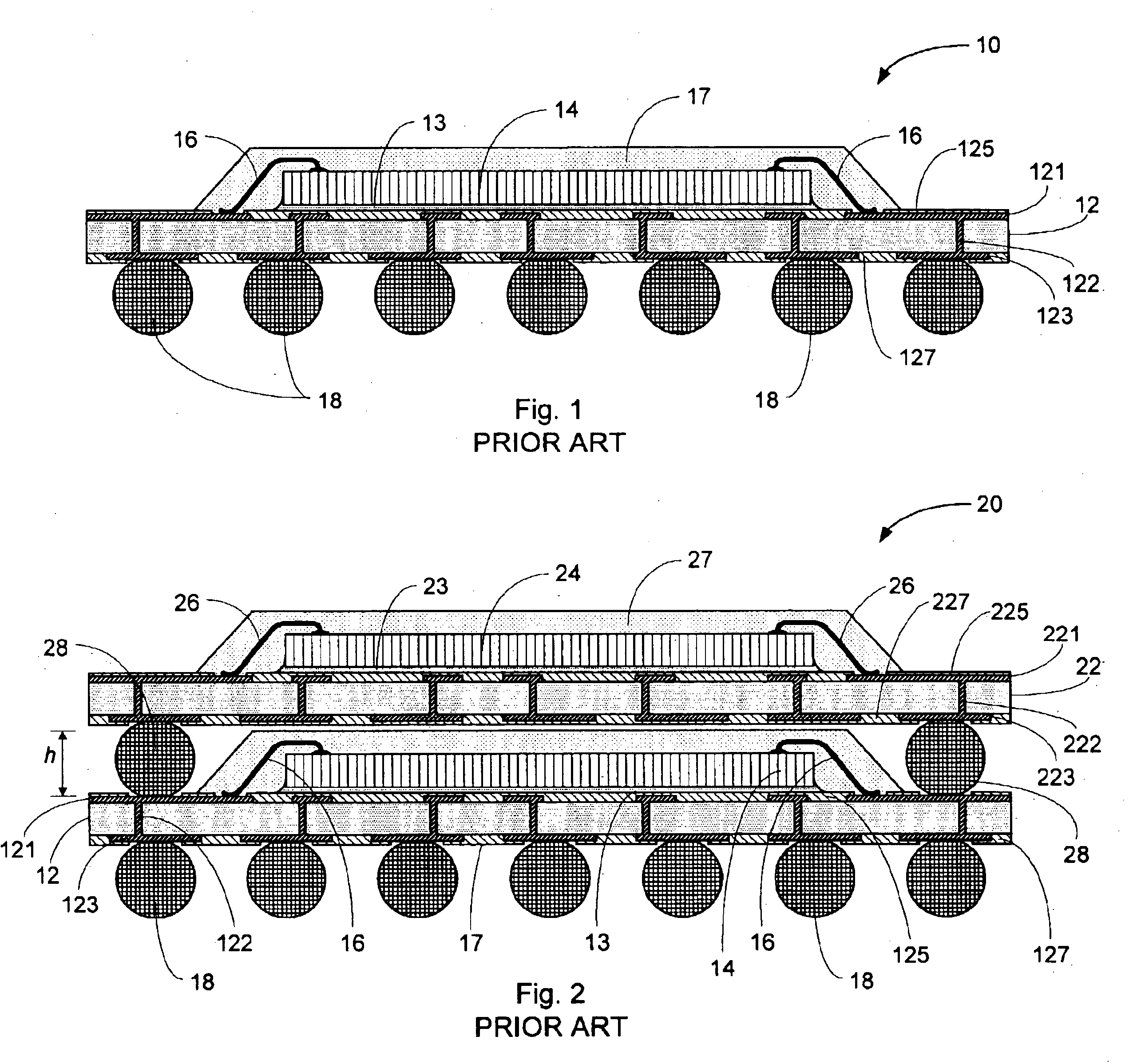

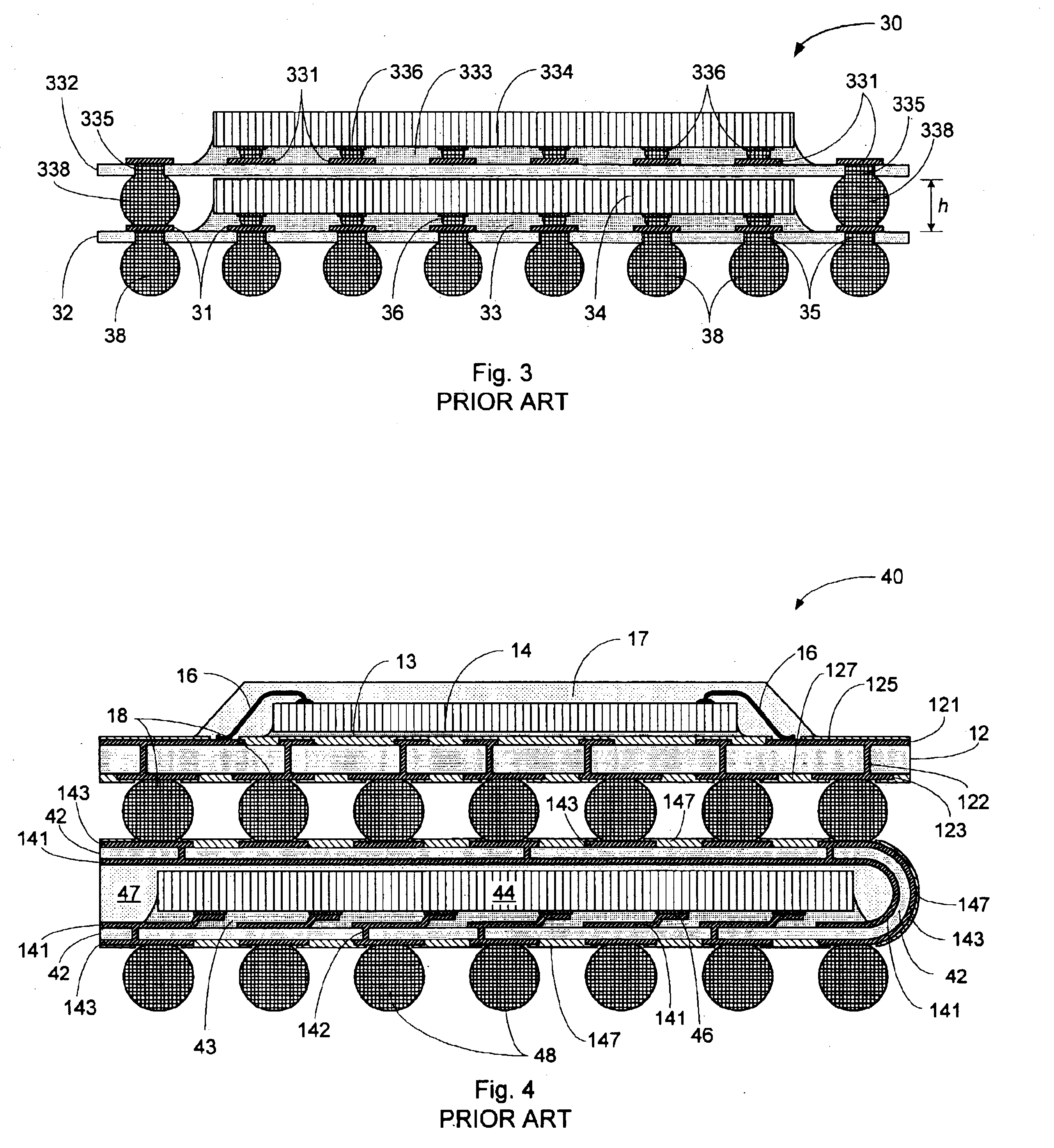

Semiconductor multi-package module having wire bond interconnect between stacked packages and having electrical shield

ActiveUS6838761B2Low production costOverall design flexibilitySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

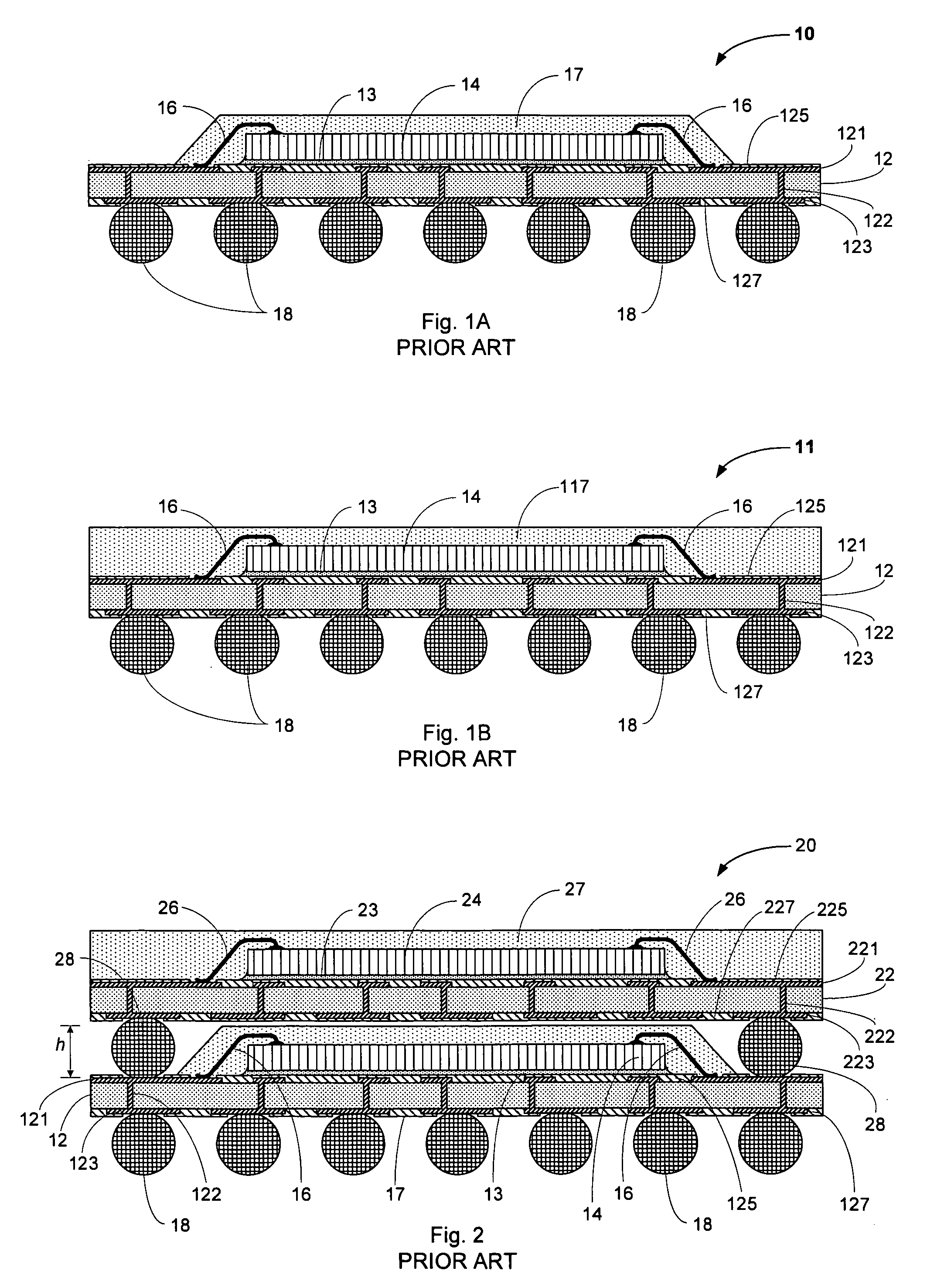

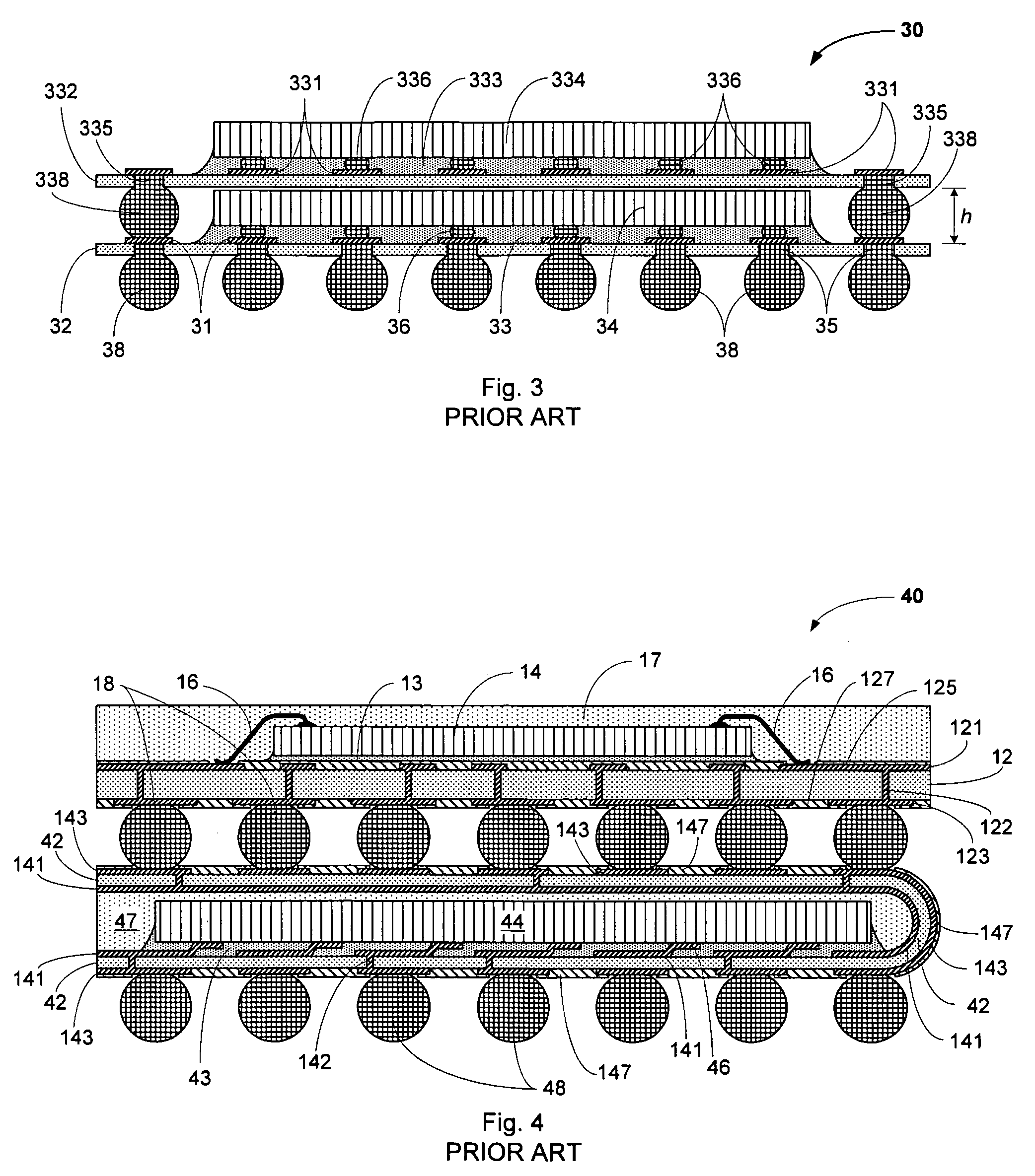

A semiconductor multi-package module having stacked lower and upper packages, each package including a die attached to a substrate, in which the upper and lower substrates are interconnected by wire bonding. Also, a method for making a semiconductor multi-package module, by providing a lower molded package including a lower substrate and a die, affixing an upper molded package including an upper substrate onto the upper surface of the lower package, and forming wire bond z-interconnects between the upper and lower substrates.

Owner:STATS CHIPPAC LTD

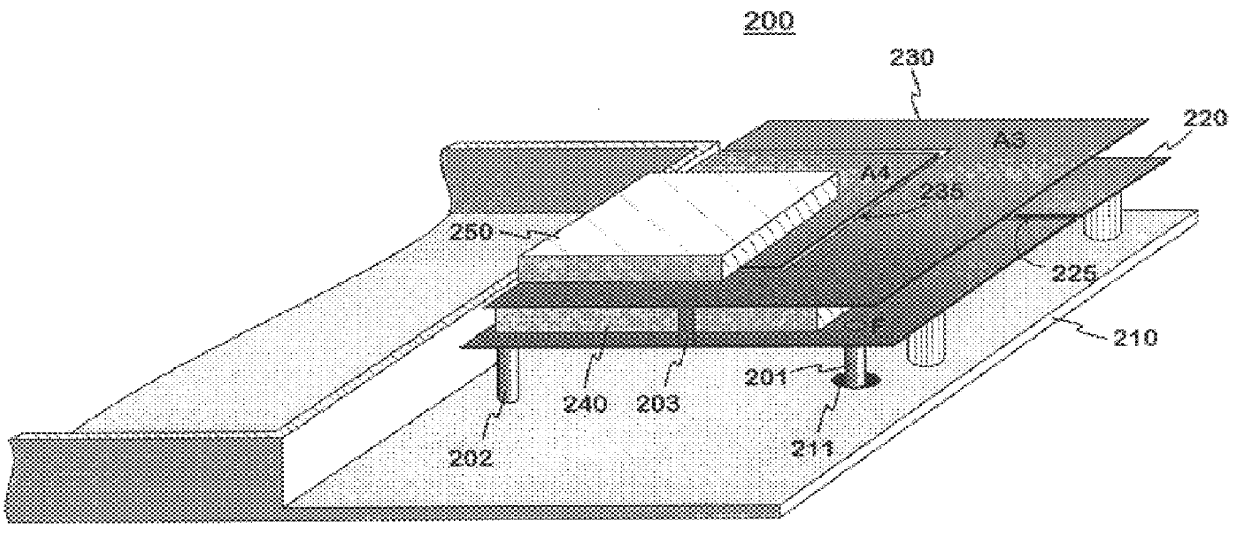

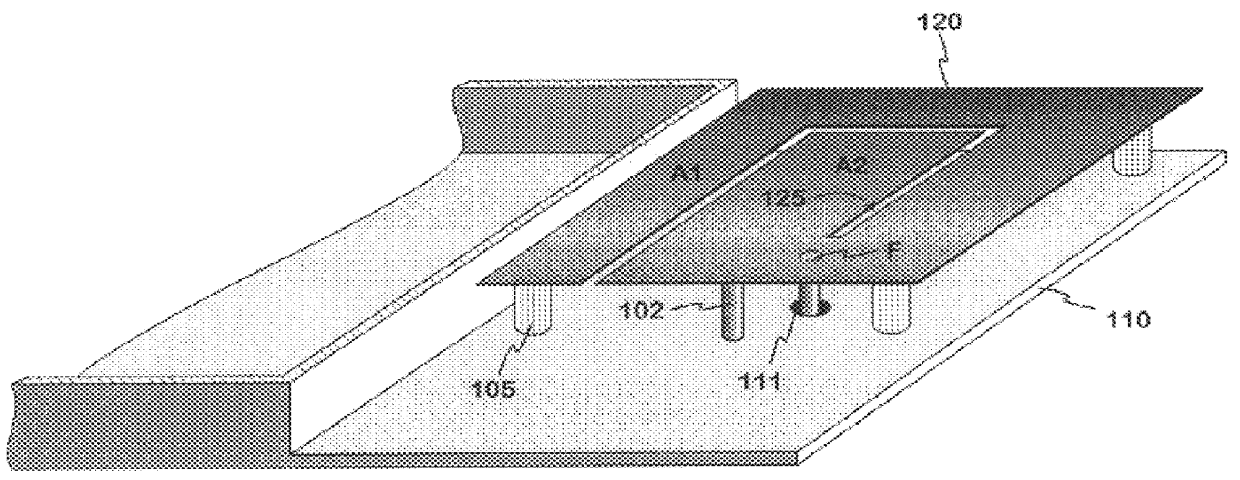

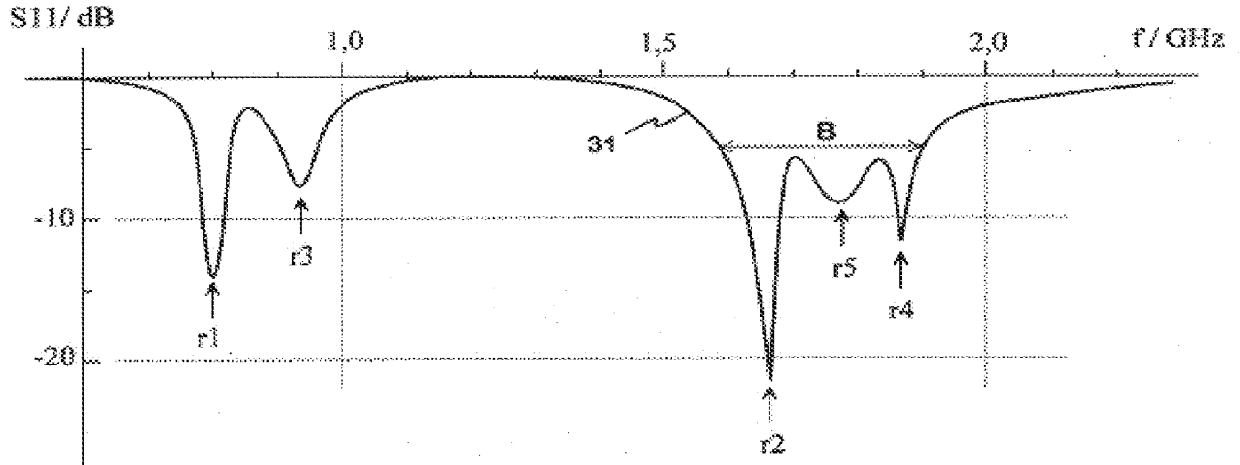

Internal antenna for an apparatus

InactiveUS6348892B1High bandwidthGood workmanshipSimultaneous aerial operationsAntenna supports/mountingsAntenna bandwidthResonance

The invention relates to an antenna structure to be installed inside small-sized radio apparatus. A conventional PIFA-type structure is extended such that on top of the ground plane (210) there will be instead of one at least two radiating planes (220, 230) on top of each other. There is between them dielectric material (240) to reduce the size of the lower radiator and to improve the band characteristics. Likewise, there is dielectric material (250) on top of the uppermost radiating plane so as to bring one resonance frequency of the antenna relatively close to another resonance frequency in order to widen the band. Advantageously the radiating planes are in galvanic contact (203) with each other. The invention accomplishes a greater increase in the antenna bandwidth as compared to that achieved by placing the only radiating plane at a distance from the ground plane equal to that of the upper radiating plane according to the invention.

Owner:PULSE FINLAND

UV-light solidifying paint having decorative effect and preparation method thereof

The invention relates to a UV-light solidifying paint having decorative effect and preparation method thereof, in particular to a light solidifying paint containing mica coated with metallic oxides as a paint. The paint is composed of the followings in proportions: the content of low polymer is 30-70wt%; the content of reactive diluent is 25-65wt%; the content of light trigger is 0.5-10wt%; the content of pearlescent pigment is 3-30wt%; the content of accessory ingredient is 0.2-8wt%; the content of solvent is 0-50wt%. As added pearlescent pigment has strong metallic performance, the prepared light solidifying paint has the character of strong pearl effect and also has very good water resisting property, higher rigidity and abrasive resistance. The paint can be applied to decoration on the surfaces of motor vehicles, electric appliance, furniture, articles for daily use, toys, walls, leather products, etc.

Owner:SICHUAN UNIV

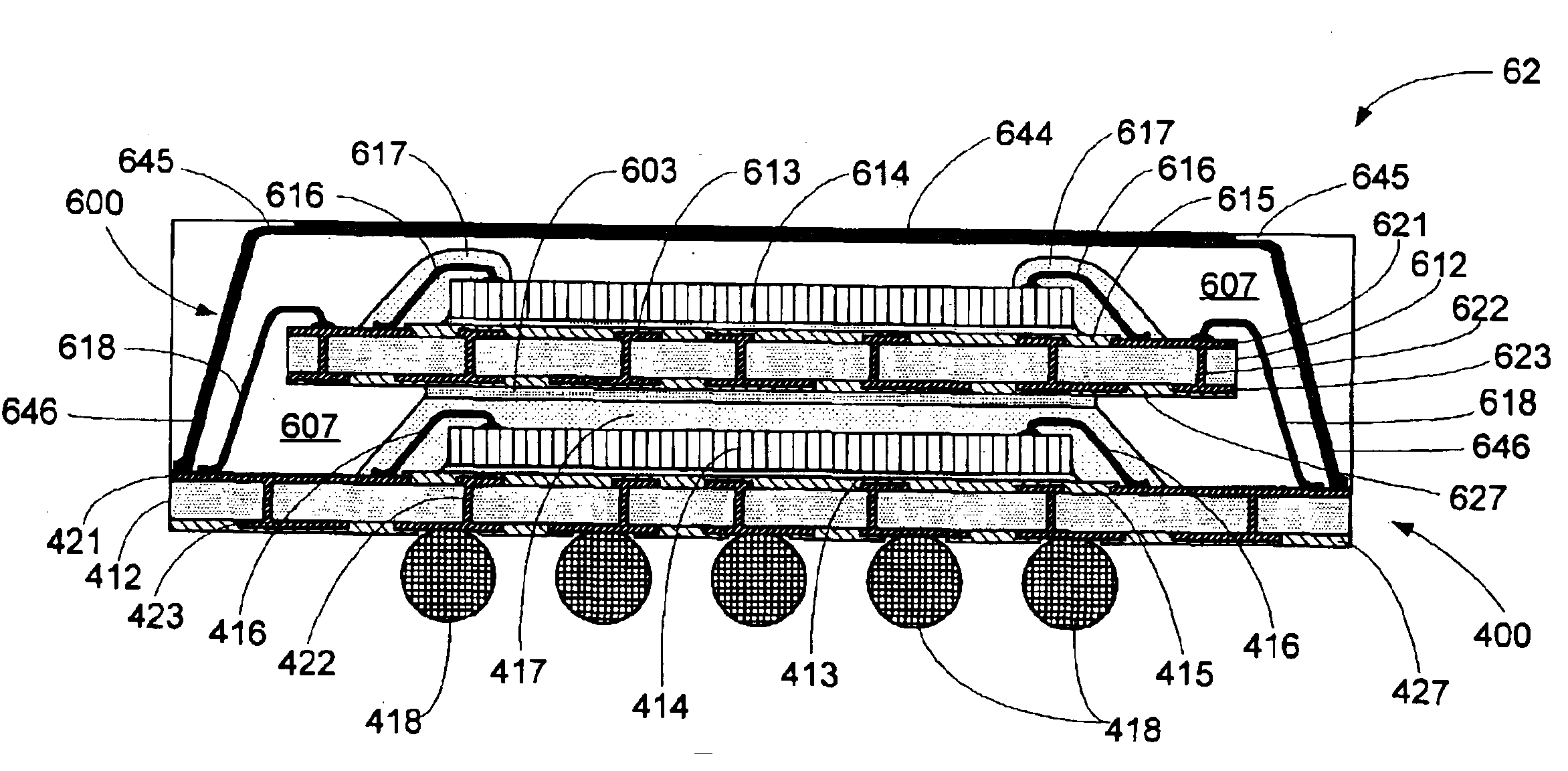

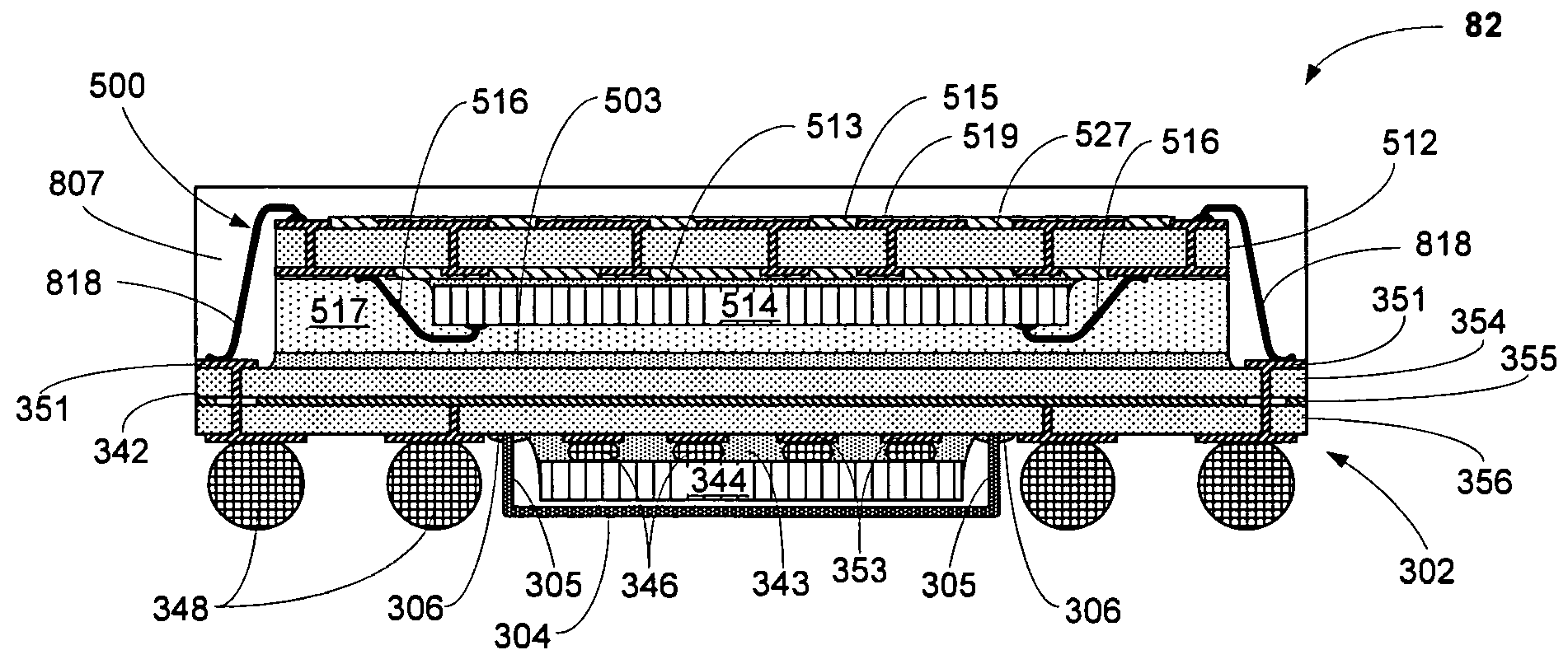

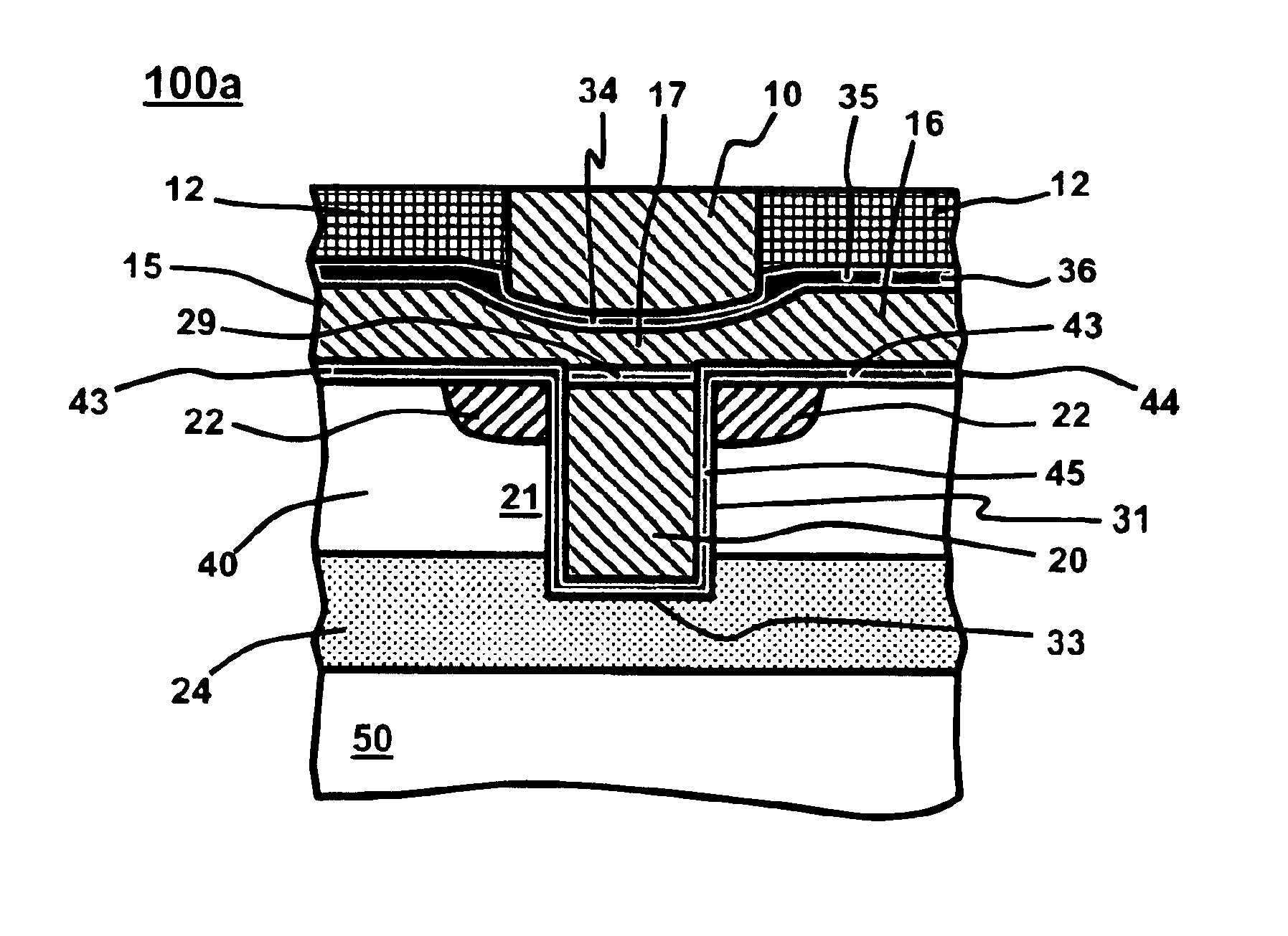

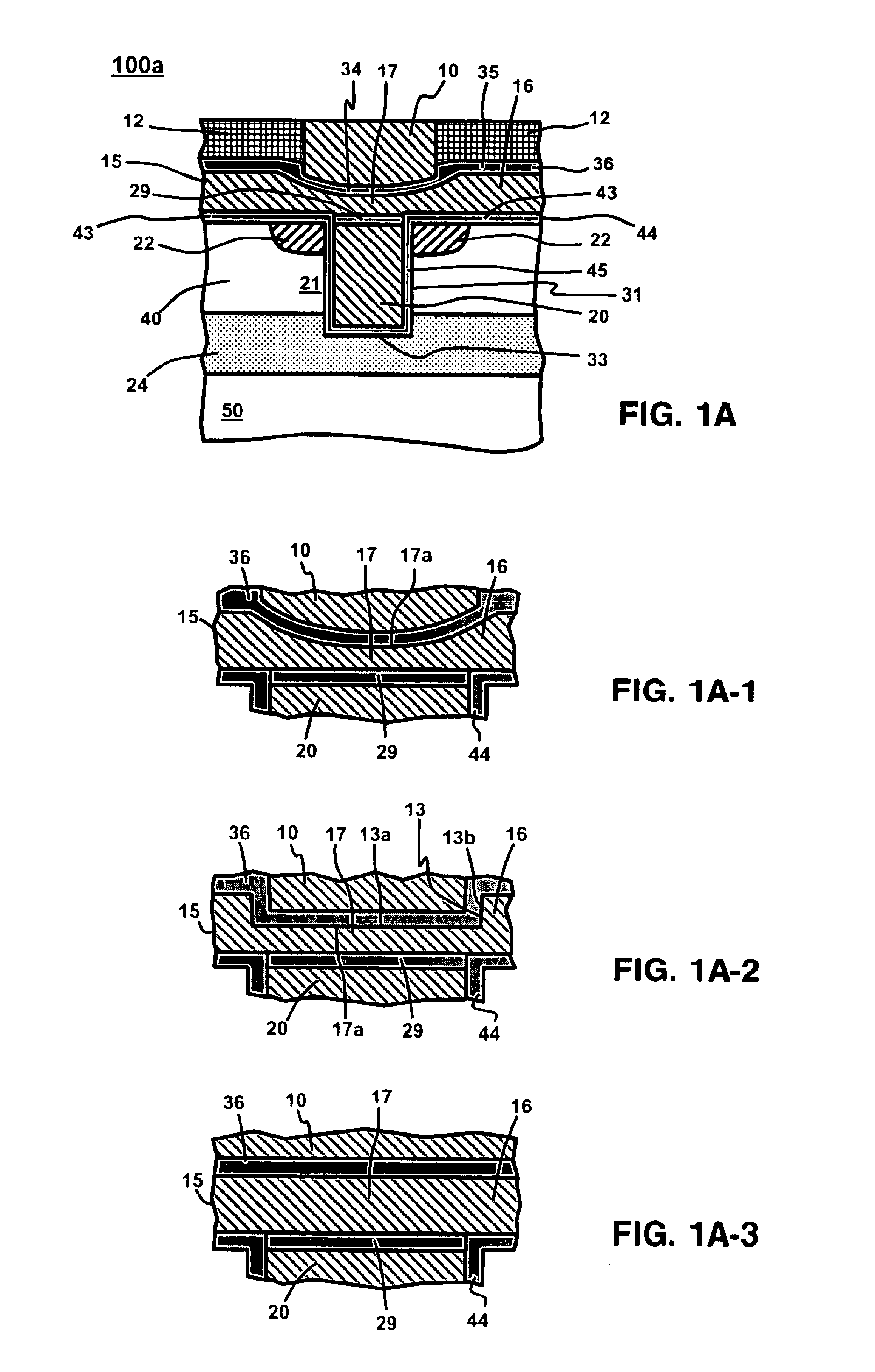

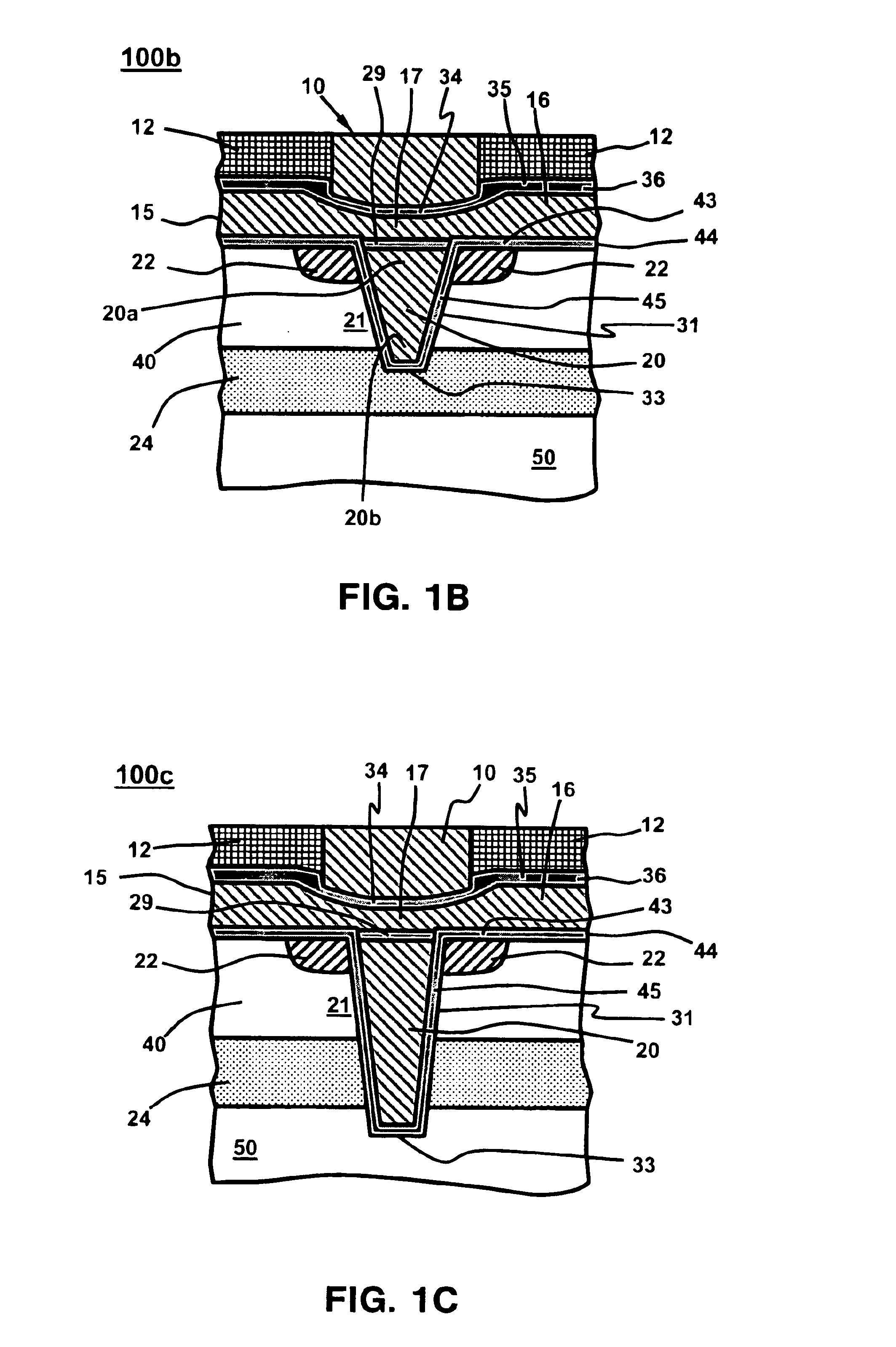

Semiconductor multi-package module having inverted second package stacked over die-up flip-chip ball grid array (BGA) package

ActiveUS7101731B2Low production costOverall design flexibilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor multi-package module has stacked lower and upper packages, each of which includes a die attached to a substrate, in which the second package is inverted, and in which the first and second substrates are interconnected by wire bonding, and in which the first package includes a flip-chip ball grid array package having a flip-chip in a die-down configuration. Also, a method for making a semiconductor multi-package module, by providing a lower molded package including a lower substrate and a flip-chip in a die-down configuration, affixing an upper molded package including an upper substrate in inverted orientation onto the upper surface of the lower package, and forming z-interconnects between the upper and lower substrates.

Owner:STATS CHIPPAC LTD

Epoxy resin adhesive modified by unsaturated polyimide and preparation method thereof

InactiveCN102181251AModerate viscosityGood workmanshipEpoxynovolac adhesivesMicroelectronicsChemistry

The invention relates to an epoxy resin adhesive modified by unsaturated polyimide and a preparation method thereof. A formula of the adhesive contains 80-85% of epoxy resin, 8-10% of unsaturated polyimide resin and 7-10% of curing agent in percentage by mass. By using the invention, the strength of the adhesive is effectively increased, the tensile shear strength at room temperature reaches up to 17.3 MPa and the brittleness of condensate is reduced; the epoxy resin adhesive provided by the invention is of very high practical value to the development of the adhesive industry, is favorable for realizing industrial production and has the advantages of simple preparation process and low cost. Broad application prospects are obtained in the fields of electronics, microelectronics, flexible copper clad laminates, flexible printed circuit boards, hard copper clad laminates, motors, aerospace and the like.

Owner:DONGHUA UNIV +1

Floating-gate memory cell having trench structure with ballistic-charge injector, and the array of memory cells

Owner:MARVELL ASIA PTE LTD

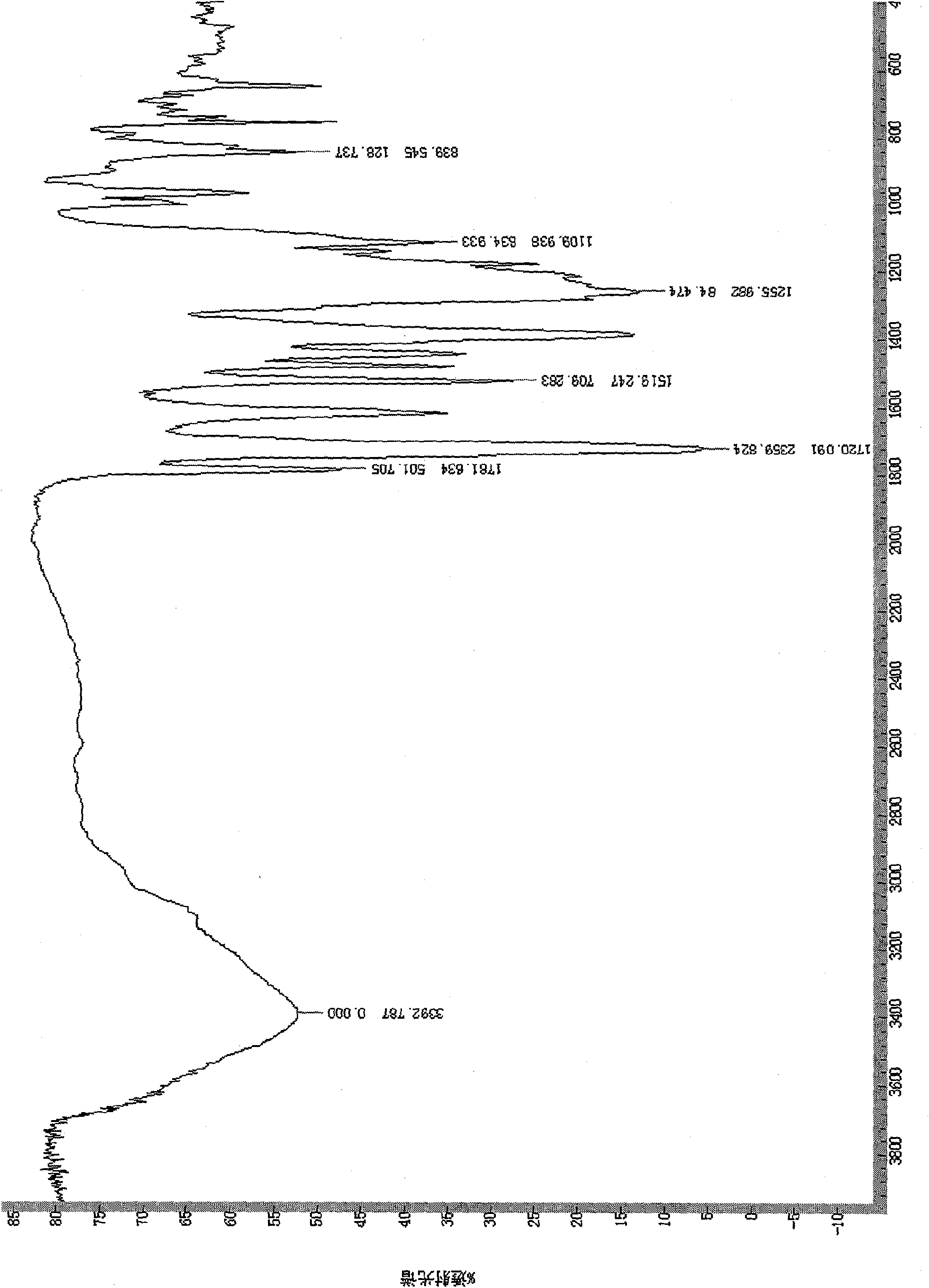

Preparation method of high temperature resistant single-component solventless epoxy adhesive

InactiveCN101649174AConvenient sourceSimple preparation processEpoxy resin adhesivesSolventThermoplastic polyimide

The invention relates to a preparation method of high temperature resistant single-component solventless epoxy adhesive. The method comprises the following steps: adding aromatic binary primary amine and strongly polar non-proton organic solvent in a reaction tank, stirring at room temperature to dissolve, adding aromatic binary acid anhydride to perform refluxing and water-segregating reaction at 120-150 DEG C for 6-12h, cooling, adding the reaction solution in a stamp tank with precipitant to precipitate solid powder, namely white thermoplastic polyimide powder, adding white thermoplastic polyimide powder and tertiary amine compound or imidazole compound in epoxy resin to react for 1-2h, adding active diluent and latent curing agent to stir evenly and obtaining the product. The production process is easy and the cost is low so as to realize industrialized production; the tensile shear intensions of the epoxy adhesive at room temperature and 120 DEG C are respectively up to 28Mpa and26Mpa and the epoxy adhesive has broad application prospect in fields such as electronics and microelectronics, electrical motors, aviation and aerospace and the like.

Owner:DONGHUA UNIV

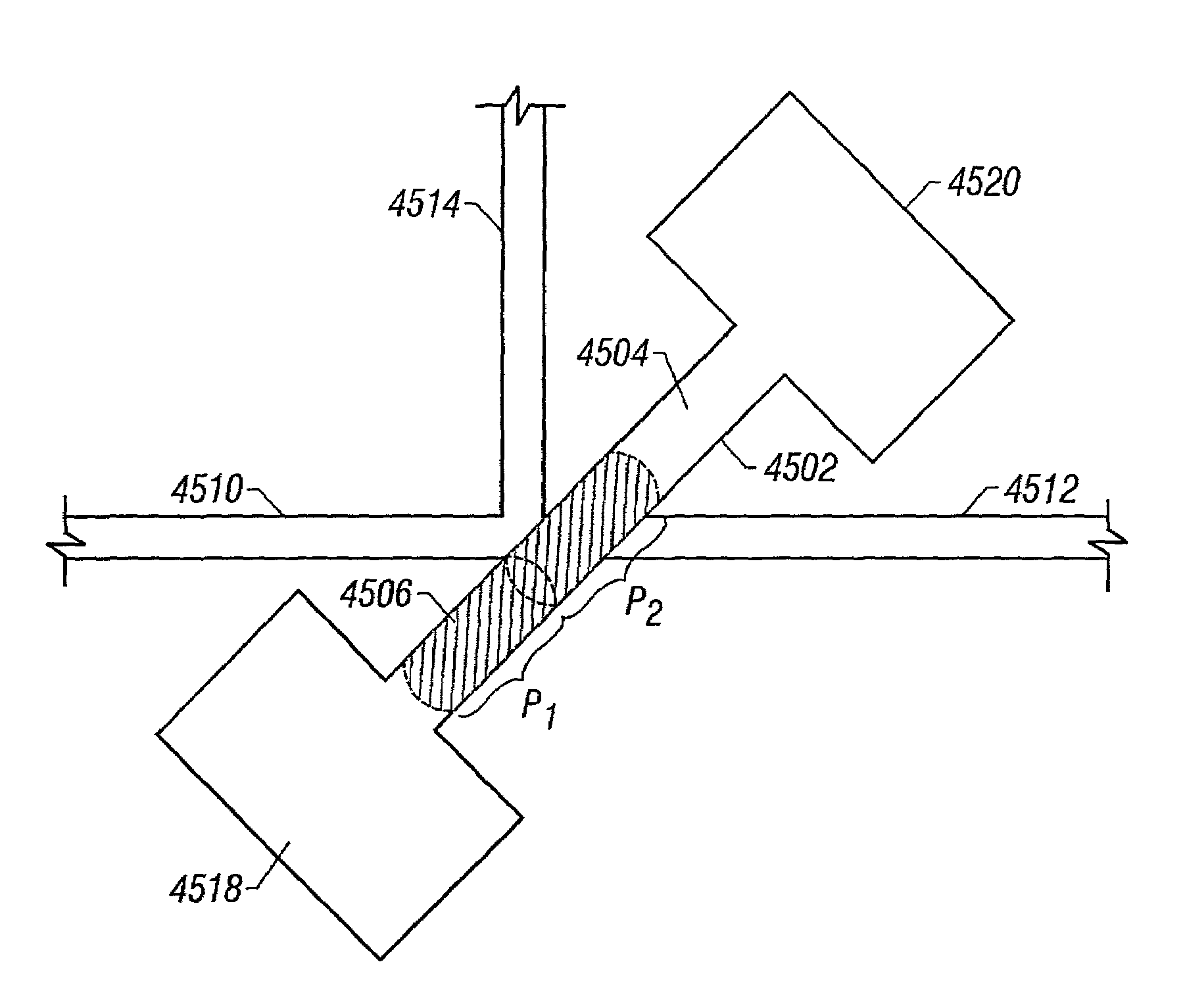

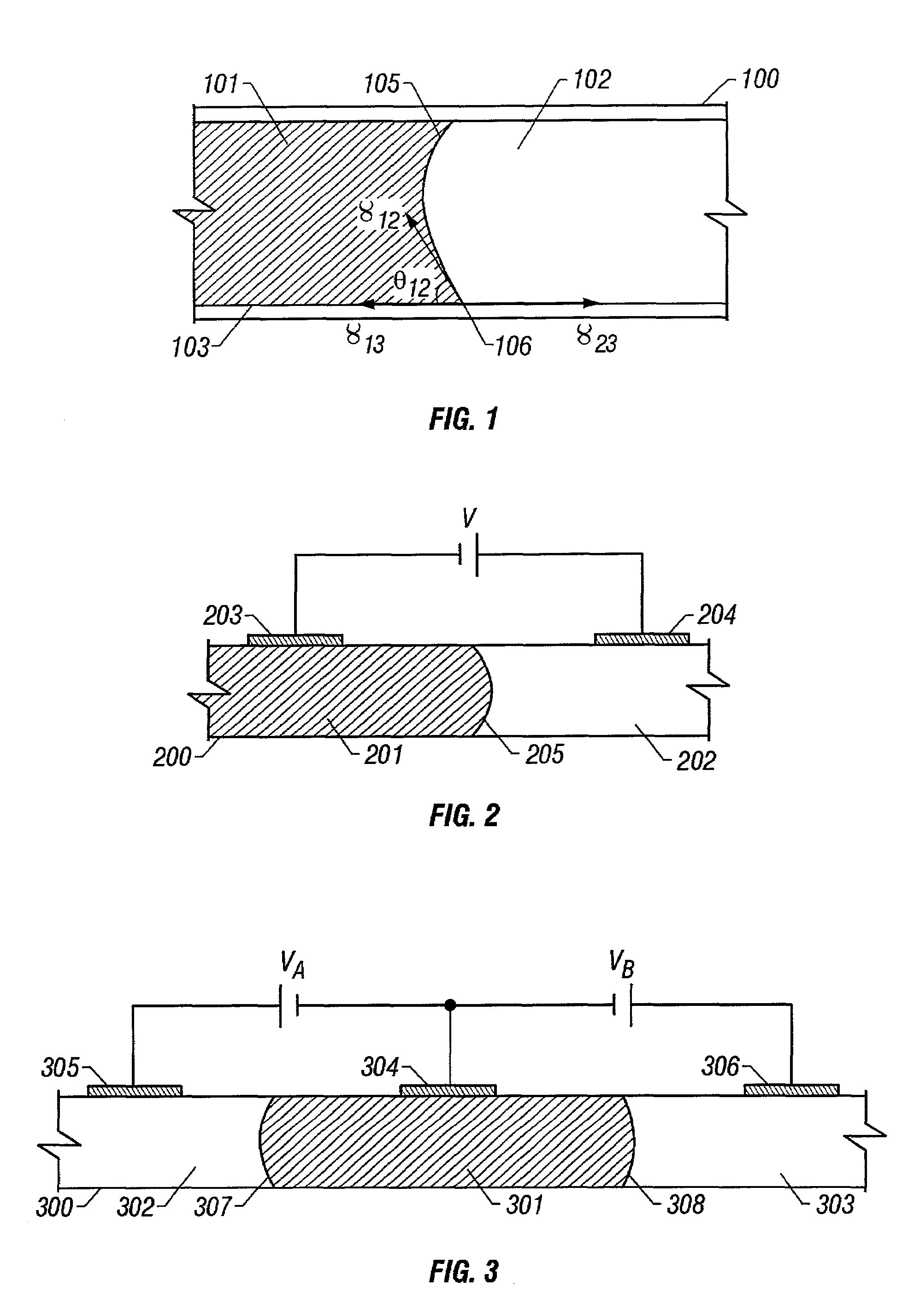

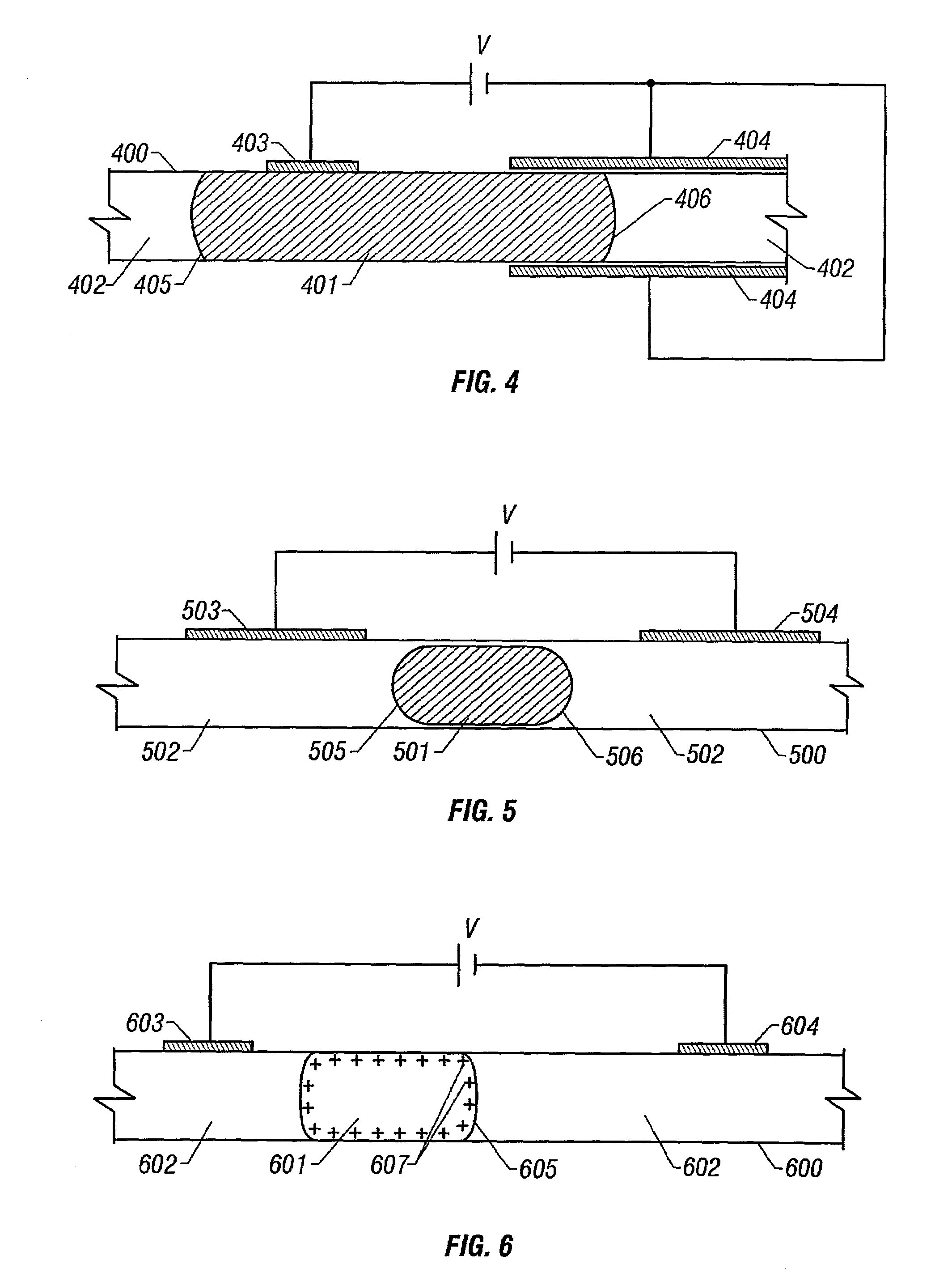

Microfluidic control for waveguide optical switches, variable attenuators, and other optical devices

InactiveUS7016560B2Reduce power consumptionGood workmanshipTransportation and packagingMixersDifferential pressureThermal expansion

Devices utilize elements carried by a fluid in a microchannel toswitch, attenuate, shutter, filter, or phase shift optical signals. In certain embodiments, a microchannel carries a gaseous or liquid slug that interacts with at least a portion of the optical power of an optical signal traveling through a waveguide. The microchannel may form part of the cladding of the waveguide, part of the core and the cladding, or part of the core only. The microchannel may also have ends or may be configured as a loop or continuous channel. The fluid devices may be self-latching or may be semi-latching. The fluid in the microchannel is moved using e.g., e.g., electrocapillarity, differential-pressure electrocapillarity, electrowetting, continuous electrowetting, electrophoresis, electroosmosis, dielectrophoresis, electro-hydrodynamic electrohydrodynamic pumping, magneto-hydrodynamic magnetohydrodynamic pumping, thermocapillarity, thermal expansion, dielectric pumping, and / or variable dielectric pumping.

Owner:NEOPHOTONICS CORP

Environment protection type silicon solar cell back electric field aluminum pulp and producing method thereof

InactiveCN101425545AImproved chemical stability and electrical performanceImprove uniformityFinal product manufactureNon-conductive material with dispersed conductive materialSolventElectric field

The invention relates to a manufacturing method of environment-friendly aluminum paste for a silicon solar battery back electric field. The aluminum paste comprises the following components and contents (weight percentage): 50 to 80 percent of aluminum conducting powder, 1 to 10 percent of crown glass binding agent, 0.05 to 5 percent of trivalent metal organic compound, 2 to 15 percent of organic resin, 10 to 25 percent of solvent and 2 to 10 percent of additive. The manufacturing method of the environment-friendly aluminum paste comprises the preparation of a glass binding agent, the preparation of an organic carrier, the formulation of aluminum paste stock and the processing technique of paste stock. The paste stock researched by the invention can not increase or generate substances which are harmful to human bodies and pollute the environment during the production and processing; the lead content of the paste stock is less than 100 ppm; and the contents of other hazardous substances such as Hg, Cd and the like can satisfy the environmental protection requirements. The aluminum past is applied to electrodes in the silicon solar battery back electric field; and the aluminum past has strong adhesion, good ohmic contact, and high conversion efficiency of a battery through the quick heat treatment in a continuous tunnel furnace.

Owner:WUHAN SUPERNANO OPTOELEC TECH CO LTD

Iron-based alloy powder for high strength and toughness laser deposited coating

InactiveCN101974724AGood workmanshipMetallic material coating processesLaser beam welding apparatusHardnessAlloy coating

The invention discloses iron-based alloy powder for a high strength and toughness laser deposited coating in the technical field of alloy materials. The iron-based alloy powder comprises the following components: 0.60 to 1.00 percent of C, 0.35 to 0.70 percent of Si, 0.30 to 0.60 percent of Mn, 5.00 to 7.00 percent of Cr, 2.50 to 4.00 percent of Ni, 1.50 to 2.50 percent of Mo, 1.00 to 1.50 percent of W, 0.70 to 1.00 percent of V, 0.20 to 0.40 percent of Ti, 0.50 to 0.70 percent of B, 0.20 to 0.40 percent of Nb, 0.10 to 0.30 percent of Ce and the balance of Fe. The iron-based laser deposited alloy coating without cracks in large area can be obtained without pre-heating and post thermal treatment, the deposited alloy coating has high hardness which reaches 62 to 67HRC, and the yield strength reaches 1,700 to 2,000MPa.

Owner:SHANGHAI JIAO TONG UNIV

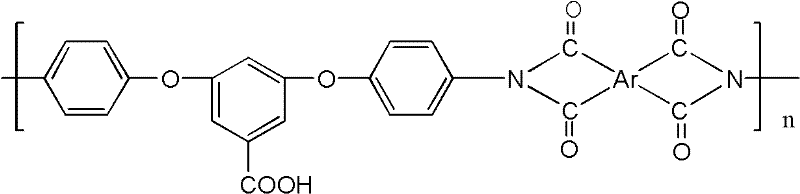

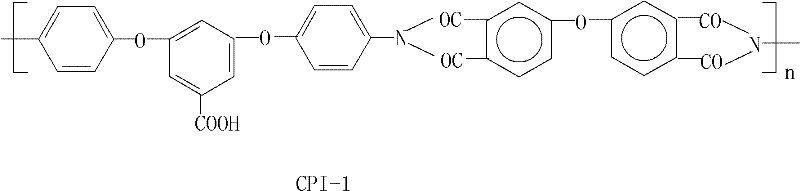

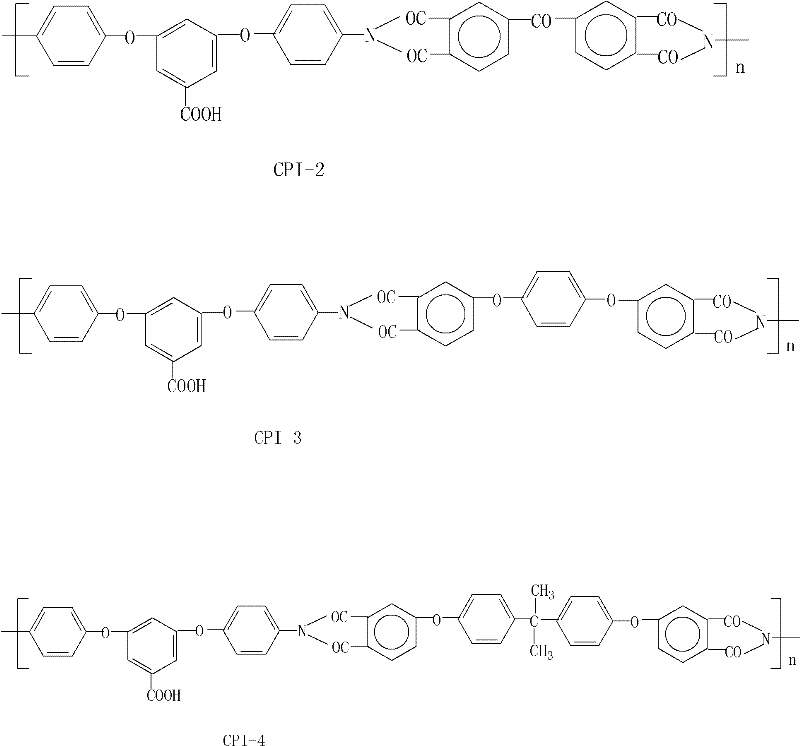

A kind of high temperature resistant modified epoxy resin adhesive and preparation method thereof

InactiveCN102260480AModerate viscosityGood workmanshipCarboxyl rubber adhesivesEpoxy resin adhesivesMicroelectronicsChemistry

The invention relates to a high-temperature-resistant modified epoxy resin adhesive and a preparation method thereof. The high-temperature-resistant modified epoxy resin adhesive comprises the following formula components by weight percent: 55%-58% of epoxy resin, 1%-6% of carboxyl-containing polyimide powder, 3.8%-4% of curing agent, 28.7%-30.5% of diluent and 6.3%-6.8% of terminal carboxyl nitrile rubber. The formula components are mixed evenly to obtain the adhesive. According to the preparation method, carboxyl-containing polyimide is added in an epoxy resin substrate, thereby effectivelyimproving the strength of the adhesive and reducing the brittleness of the cured material of the adhesive; the preparation method has the advantages of simple process and low cost, and is convenient for operation; and the preparation method has a high practicable value for the development of the adhesive industry and has a wide application prospect in multiple fields, such as electronics, microelectronics and the like.

Owner:DONGHUA UNIV +1

Alloy powder special for laser-remelted high hardness crackless iron-base alloy

InactiveCN101381869AHigh strengthHigh hardnessMetallic material coating processesThermal sprayingNiobium

The invention belongs to the technical field of alloy material, and relates to an improvement on the prior art, in particular to special alloy powder for laser cladding of high-hardness crack-free iron-based alloy. The formula of the alloy powder comprises the following compositions in weight percentage: 0.3 to 0.5 of C, 1.2 to 2.0 of Si, 0.4 to 1.0 of B, 1.5 to 2.5 of Ni, 1.0 to 1.5 of Cr, 1.0 to 1.5 of Mn, 1.5 to 2.5 of Mo, 0.15 to 0.7 of V, and 0.15 to 0.7 of Nb, the balance being Fe; and the total weight of the compositions is 100 percent. The special alloy powder can obtain the iron-based alloy with large area, large thickness and no crakes for laser cladding without preheating and subsequent heat treatment, has high strength, hardness and wear resistance and good plastic toughness of a cladding layer, and has lower cost compared with most of hot spraying self melting alloy powder and the prior laser cladding special iron-based alloy powder.

Owner:东莞市豪恩新材料技术有限公司

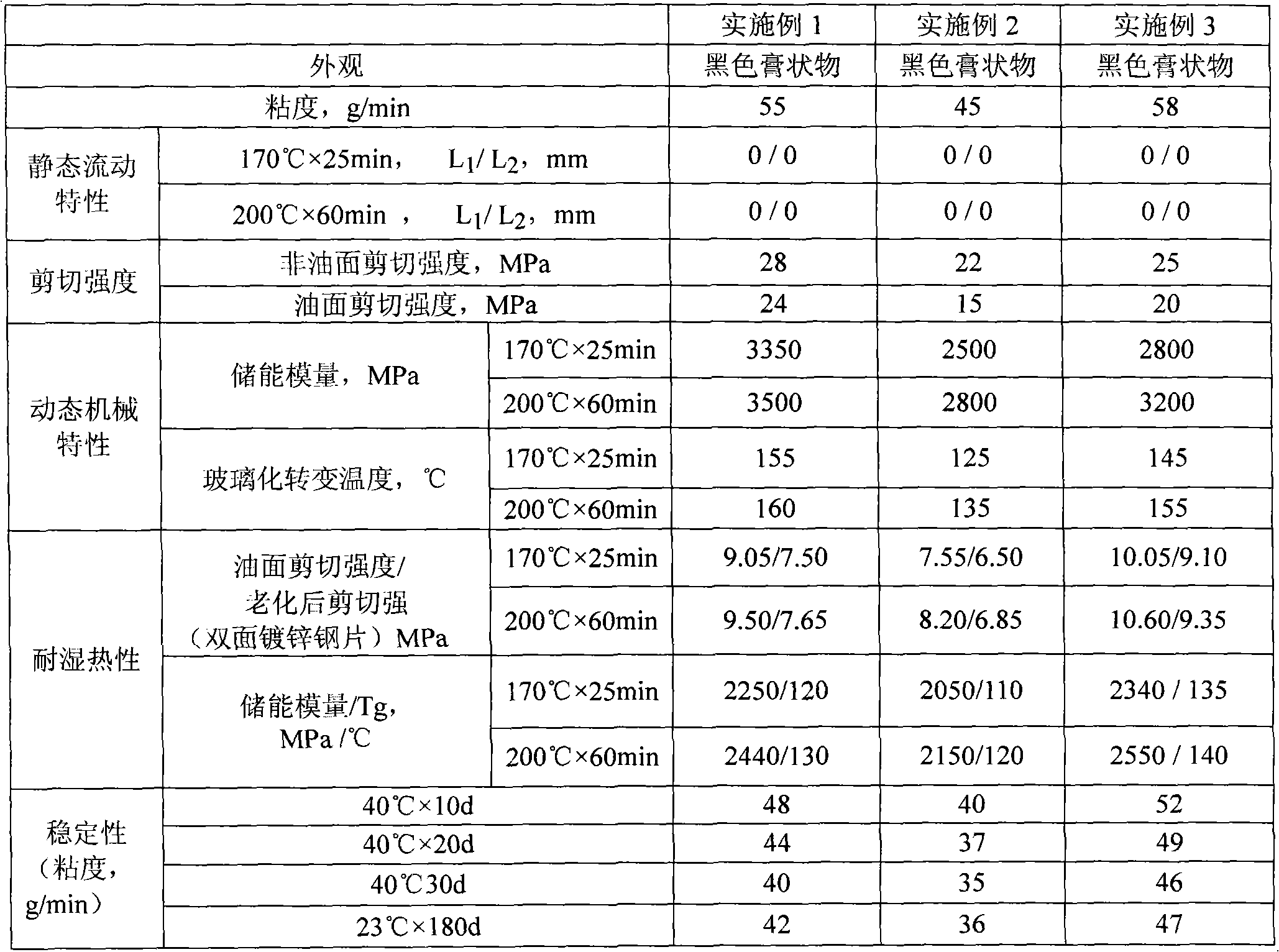

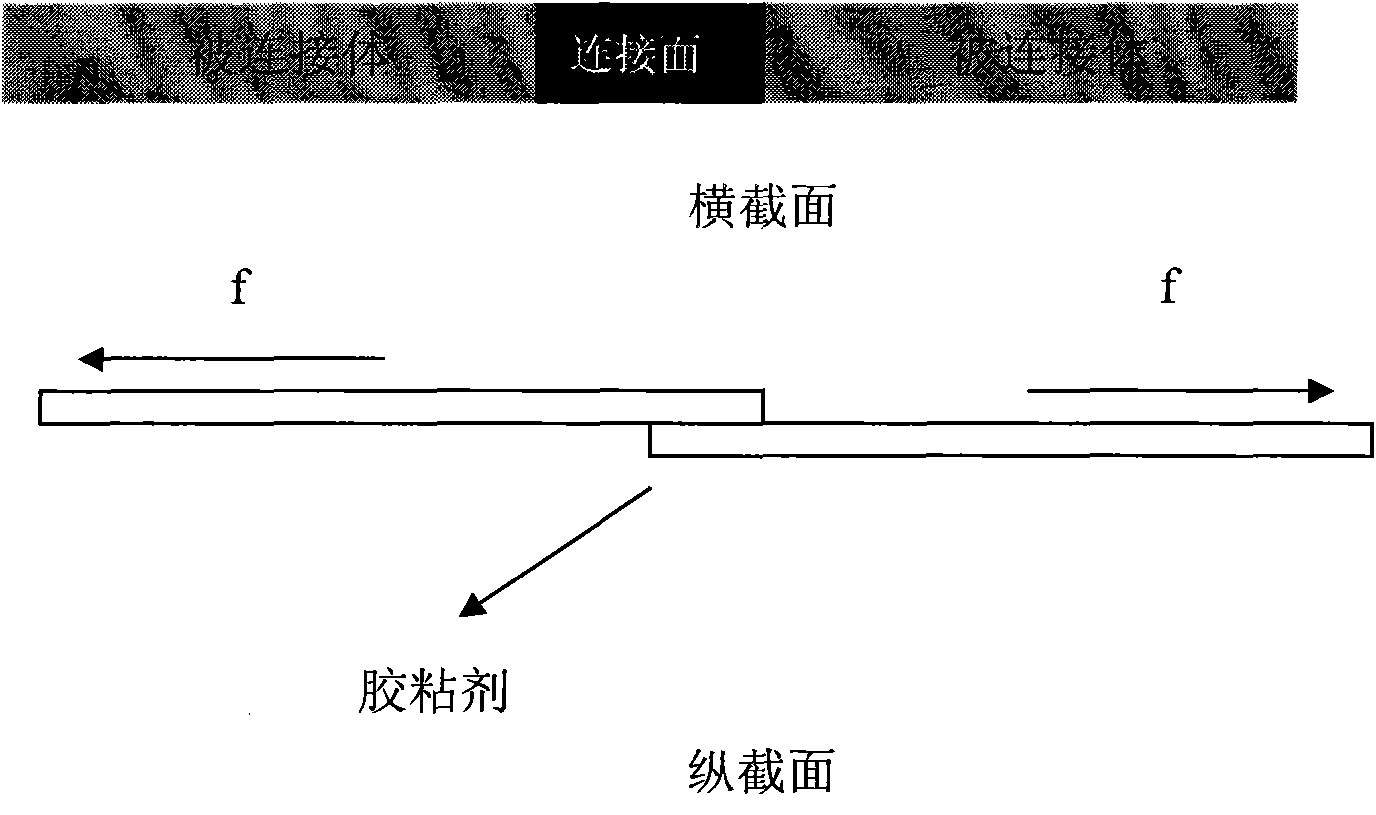

Automobile hemming adhesive and preparation method thereof

ActiveCN102115654AGood workmanshipImprove thixotropyNon-macromolecular adhesive additivesEpoxy resin adhesivesPlasticizerHeat resistance

The invention relates to an automobile hemming adhesive and a preparation method thereof, belonging to the technical field of single-component epoxy adhesives. The automobile hemming adhesive is mainly used for bonding an automobile hemming part. The automobile hemming adhesive is mainly characterized by comprising (A) epoxy resin, (B) modified epoxy resin, (C) toughener, (D) epoxy diluter, (E) thermoplastic resin, (F) plasticizer, (G) thermal stabilizer, (H) latent curing agent, (I) coupling agent, (J) filler and (K) pigment. The preparation method comprises the following steps: (1) evenly stirring (E) and (F) at 5-35 DEG C; (2) adding the mixed liquid composition in the step (1), and (A), (B), (C), (D), (G), (H), (I), (J) and (K) into a movable mixer, and evenly stirring at 5-35 DEG C; (3) passing the mixture in the step (2) through a three-roller machine once or twice; and (4) vacuumizing the movable mixer, stirring, defoaming, and discharging for later use. The invention mainly solves the problems of low environmental-protection index, poor technical properties of sizing, short storage period, low modulus, poor moisture and heat resistance and the like in the existing hemming adhesive.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD

Production method for reducing and fining the high-carbon chromium bearing steel D-type impurity

ActiveCN1621538AGood workmanshipMeet production needsProcess efficiency improvementElectric furnaceAlkalinityHigh carbon

The production process with reduced and fined type-D inclusion in high-carbon chromium bearing steel features the four-step metallurgical process including initial smelting of steel liquid in electric furnace, refining in bottom blowing Ar LF ladle furnace, deairing in VD vacuum furnace, and die casting or continuous casting. By means of the comprehensive deoxidation process including pre-deoxidation of aluminum deposition of the steel from electric furnace, deoxidation with Fe-Si powder diffusion slag in LF site and vacuum carbon deoxidation in VD site; and the new refining process including high alkalinity slag desulfurization in LF site, adoption of low alkalinity slag in the VD site and reducing free CaO inside slag, the present invention reaches the aims of reducing and fining type-D inclusion.

Owner:宝武特种冶金有限公司

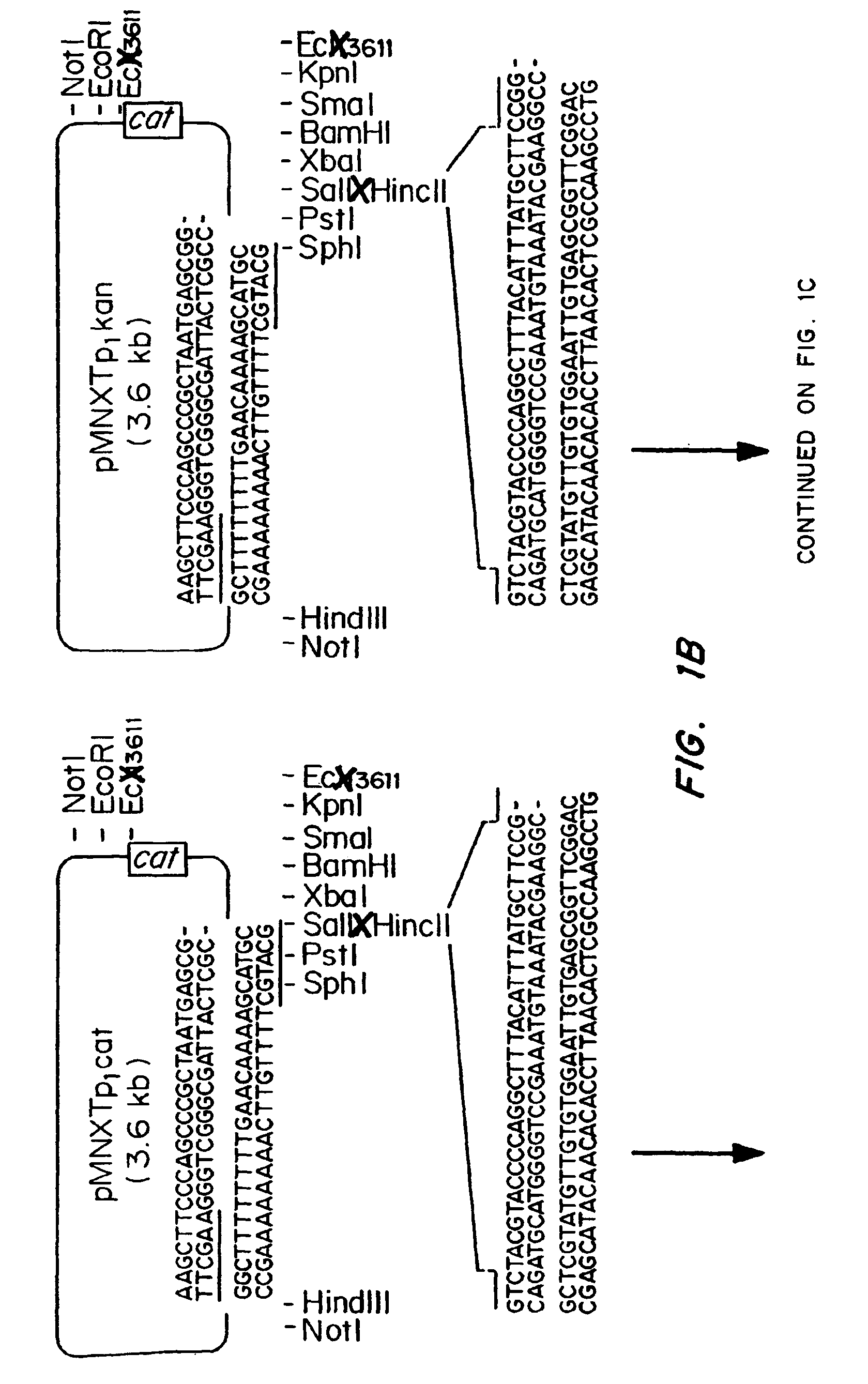

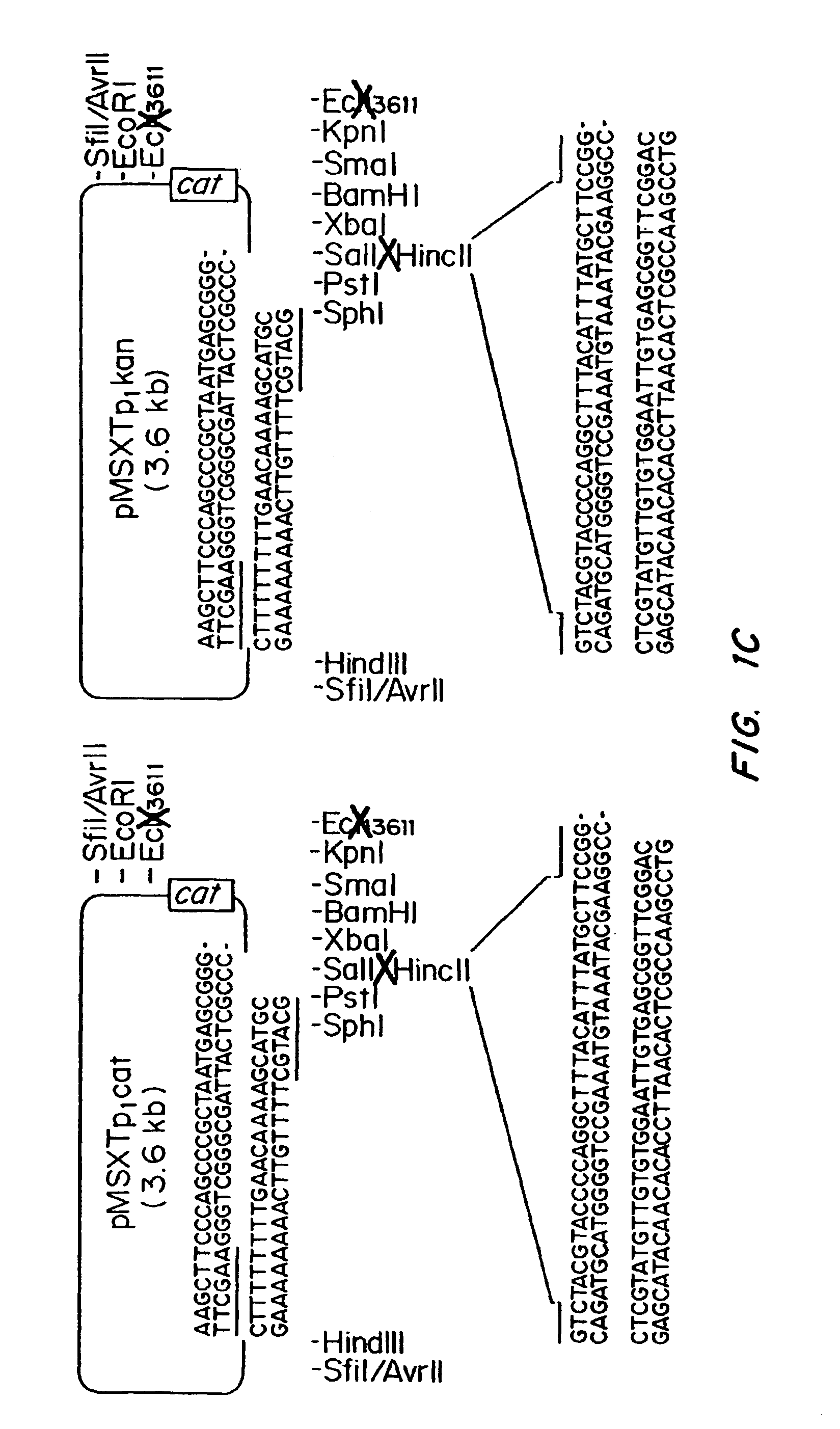

Transgenic microbial polyhydroxyalkanoate producers

InactiveUS6913911B2Simple production processInduce expressionSugar derivativesBacteriaBiotechnologyTransposon mutagenesis

Transgenic microbial strains are provided which contain the genes required for PHA formation integrated on the chromosome. The strains are advantageous in PHA production processes, because (1) no plasmids need to be maintained, generally obviating the required use of antibiotics or other stabilizing pressures, and (2) no plasmid loss occurs, thereby stabilizing the number of gene copies per cell throughout the fermentation process, resulting in homogeneous PHA product formation throughout the production process. Genes are integrated using standard techniques, preferably transposon mutagenesis. In a preferred embodiment wherein mutiple genes are incorporated, these are incorporated as an operon. Sequences are used to stabilize mRNA, to induce expression as a function of culture conditions (such as phosphate concentration), temperature, and stress, and to aid in selection, through the incorporation of selection markers such as markers conferring antibiotic resistance.

Owner:CJ CHEILJEDANG CORP

Method for manufacturing high-strength 7055 aluminum alloy forge piece formed by spraying

The invention belongs to a manufacturing technology of aluminum alloy and relates to a method for manufacturing a high-strength 7055 aluminum alloy forge piece formed by spraying. The method sequentially comprises the following steps: (a) melting components of 7055 alloy in an intermediate frequency furnace; (b) degassing, deslagging, refining and filtering an aluminum alloy fusant; (c) forming the filtered fusant by spraying to obtain a columnar aluminum alloy ingot blank; (e) carrying out hot extrusion on the aluminum alloy ingot blank formed by spraying; (f) constantly cutting the extrusion ingot as required and then carrying out free forging; (g) carrying out blocker-type forging and / or stamp forging on the blank after the free forging to obtain a stamp forging piece; and (h) carrying out T6 heat treatment on the stamp forging piece. A large-specification and high-property 7055 product can be obtained by using the method which is suitable for industrial production.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

Multi-piece solid golf ball

A multi-piece solid golf ball has a solid core obtained by molding and vulcanizing a rubber composition which includes (A) a base rubber containing a polybutadiene synthesized using a rare-earth catalyst, (B) an unsaturated carboxylic acid and / or a metal salt thereof, (C) an organic sulfur compound, (D) an inorganic filler and (E) an organic peroxide. The core is enclosed within a mantle of one or more layer which is made primarily of a thermoplastic resin and has a Durometer D hardness of 30 to 70. The mantle is enclosed within a cover which is made primarily of a thermoplastic polyurethane and which has a Durometer D hardness of 40 to 60 that is lower than the Durometer D hardness of the outermost layer of the mantle. This construction provides the golf ball with an outstanding rebound.

Owner:BRIDGESTONE SPORTS

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

Powdery paint for lost foam casting of cast iron

The invention discloses a special coating for pulverous expendable pattern casting and casting iron, and the special coating comprises 60-70 percent of 180-200 mesh refractory materials, 2.0-3.0 percent of suspending agent, 1.5-2.5 percent of adhesive, 0.3-0.6 percent of organosilicon defoamer, 0.01-0.03 percent of preservative agent and 180-200 mesh residual mica powder in balancing amount. When the special coating is prepared, various pulverous materials are weighed according to the required proportion, interposed into the powder stirrer in sequence to stir for 20 to 40 minutes at a low speed and then discharged and packed. When the coating is used, appropriate water is interposed into the stirred vessel by the powder-to-water ratio of 1 to (1.1-1.4). After the stirred vessel is turned on, the powder coating weighed is interposed in batches. The coating is utilized after preparing into slurry; therefore, the special coating has the advantages of good suspension property, high intensity, uniform coating, good thixotropy, good leveling property, glabrous surface, no bubbles, no cracks and the like. Moreover, the user can adopts the dip-coating method, the hang-coating method and the brush-coating method, the viscosity change of coating materials can be decided upon the demands of the user, and different viscosities can realize different coating thicknesses.

Owner:HUAZHONG UNIV OF SCI & TECH

High ductility buried arc welding wire for low-alloy super-strength steel

InactiveCN1919524ALow costGood workmanshipArc welding apparatusWelding/cutting media/materialsAlloyWeld seam

The invention discloses a low-alloy super-strength steel high-flexible buried arc solder wire, which comprises the following parts: 0.06-0.12% C, 0.03-0.20% Si, 1.50-2.00% Mn, 0.20-0.60% Cr, 1.40-2.60% Ni, 0.10-0.50% Mo, 0.10-0.60% Cu, 0.06-0.20% Ti, 0.002-0.010% B and Fe and impurity. The solder wire mates the alkaline sintered welding agent with tensile strength of welding seam not less than 800Mpa, which possesses impacting flexibility AKV not less than 47J at -40 deg.c.

Owner:武钢集团有限公司

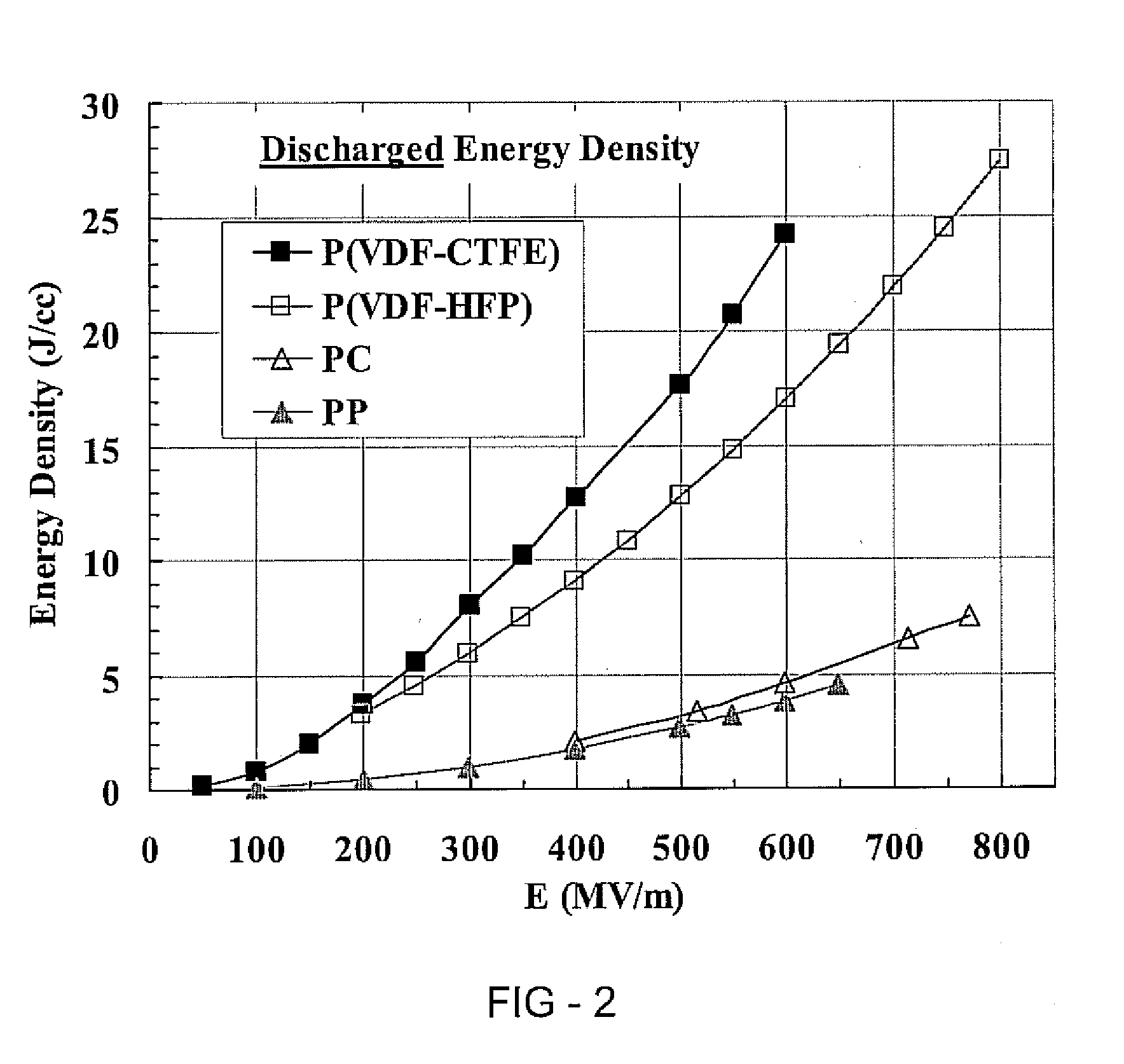

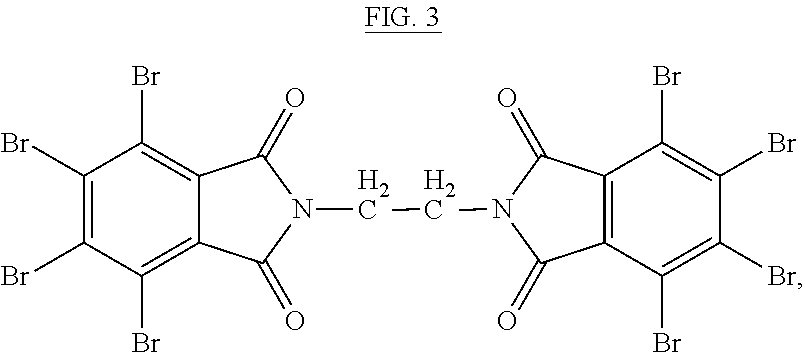

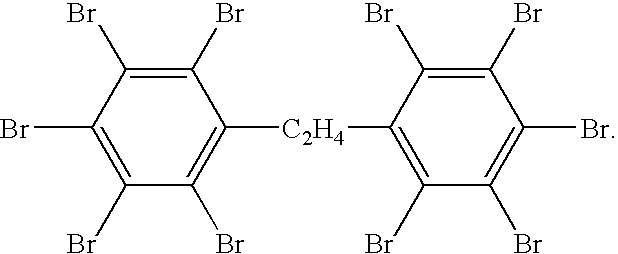

High electric energy density polymeric compositions, methods of the manufacture therefor, and articles comprising the same

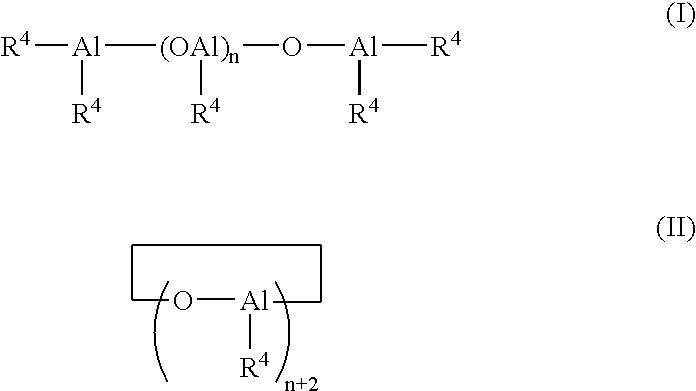

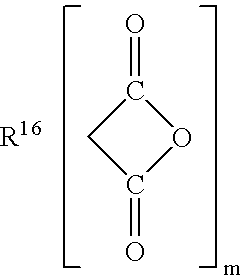

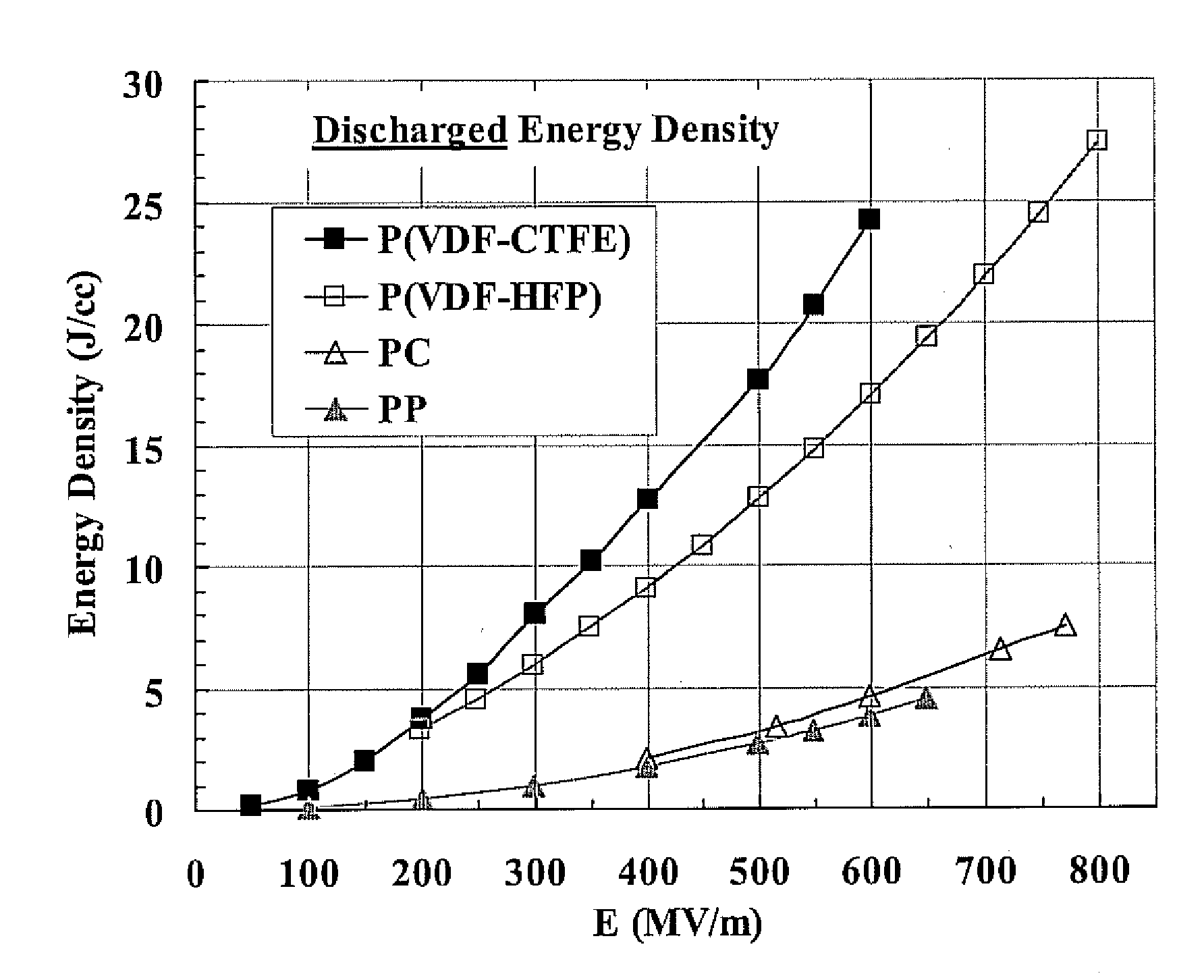

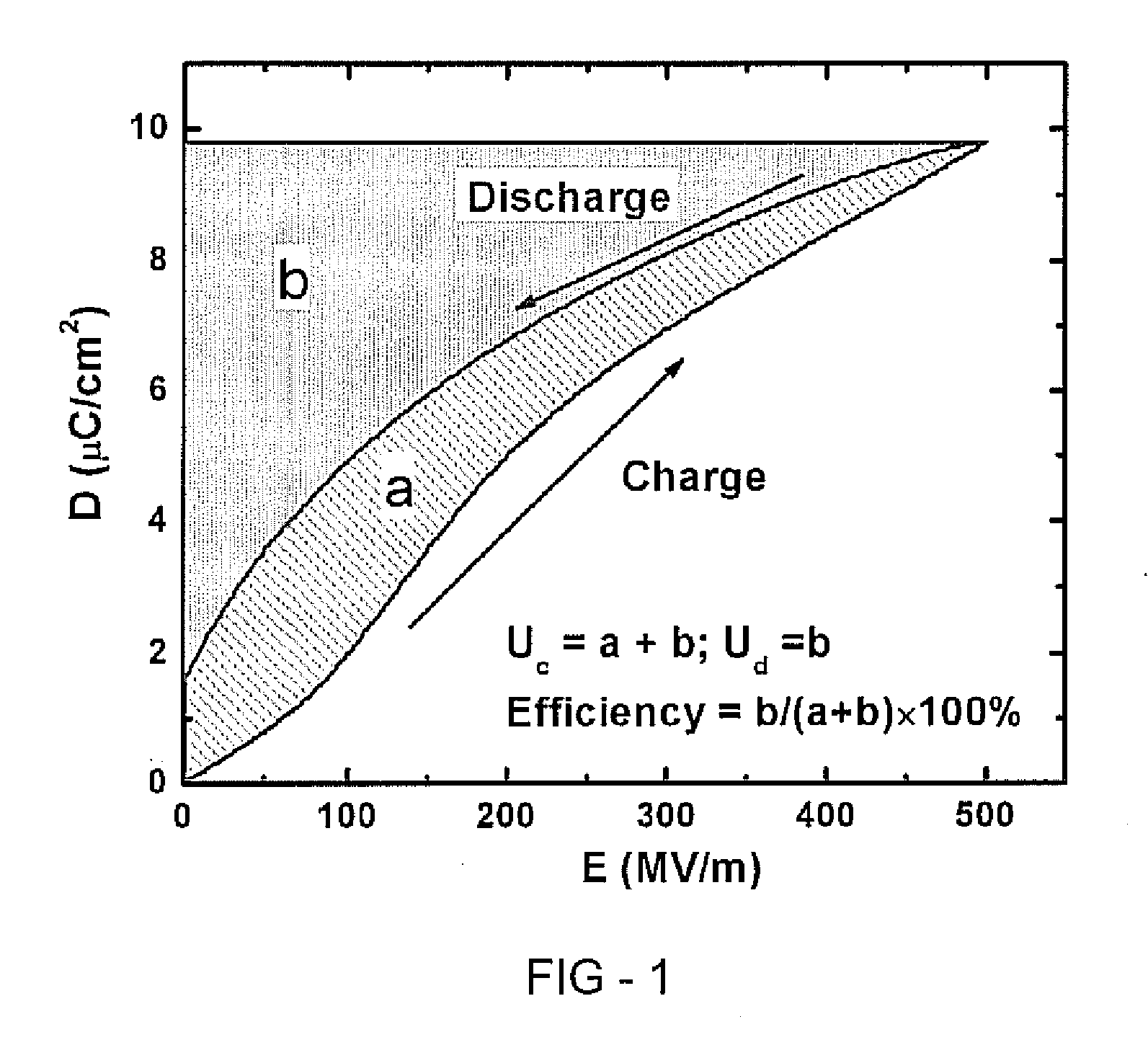

InactiveUS20100067172A1Improve efficiencyFast dischargeFixed capacitor dielectricVehicular energy storagePolymer capacitorPolymer science

Examples of the present invention relate generally to high electric energy density polymer film capacitors with high charge-discharge efficiency and fast discharge speed. For example, a high energy density polymer capacitor may be fabricated using a polymer blend comprising one or more high dielectric constant PVDF-based polymers (including homopolymers, copolymers and / or terpolymers) and one or more other polymer with low dielectric loss and high volume resistivity compared to the one or more PVDF-based polymers. An example film capacitor may comprise a high temperature fluoropolymer with dielectric loss lower than 0.2% and good film manufacturability. Polymer films can be stretched and orientated at least in one direction to make thinner films with improved performance. Film capacitors can be made by winding metallized films, plain films with metal foils, or using a hybrid construction where the dielectric films comprise the new compositions. Capacitors can also have a multilayer construction where the films are metallized.

Owner:NOVASENTIS

Thermosetting resin composition and use thereof

The present invention discloses a thermosetting resin composition comprising: a bifunctional or multifunctional epoxy resin, a styrene-maleic anhydride (SMA) copolymer with a styrene / maleic anhydride molar ratio of 5-12:1 as a curing agent, a BPA epoxy resin with a low or high bromine content or tetrabromobisphenol A as a flame retardant agent, an accelerator and a solvent. The cured resin composition of the invention has a very low dielectric property, improved thermal reliability and better toughness. A copper clad laminate made of the resin composition and a reinforced material such as glass fiber cloth has a very low dielectric constant and dissipation factor, high Td, better toughness and PCB manufacturability, and thus very suitable to be used as a copper clad laminate and a prepreg for manufacturing PCBs and also applied to the common use of epoxy resins, such as molding resins, and composite materials for construction, automobiles and aviation.

Owner:ITEQ DONGGUAN +1

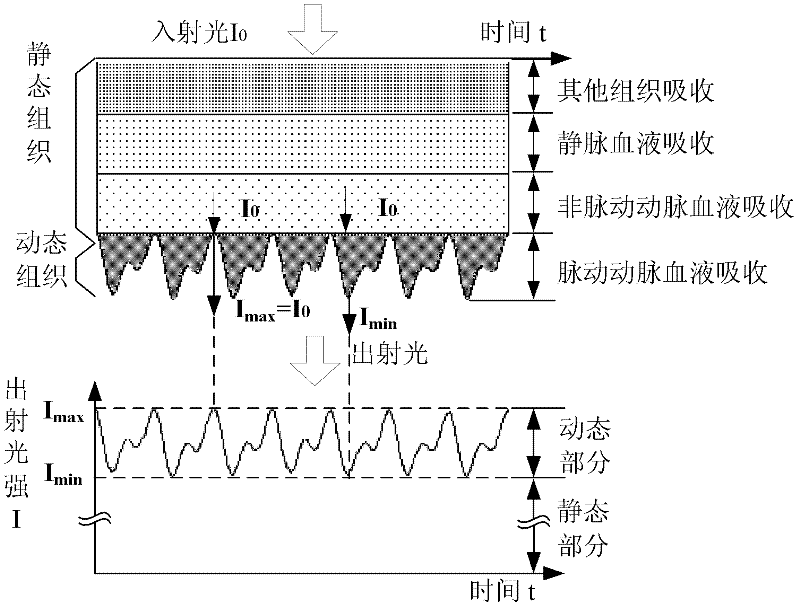

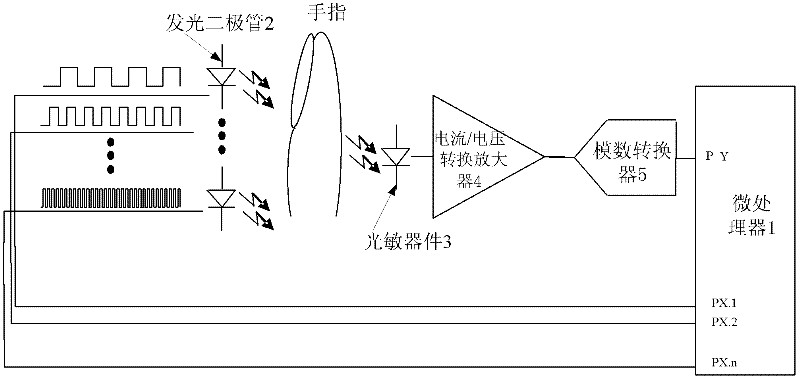

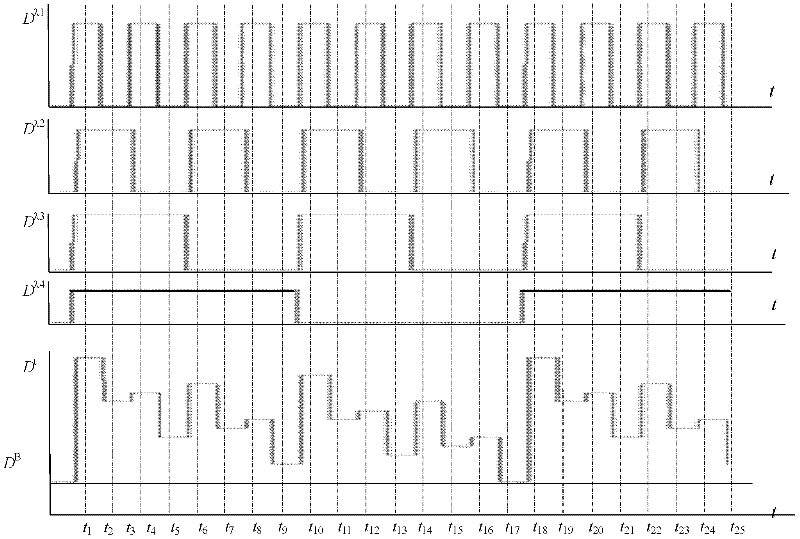

Device and method for measuring square wave modulated photoelectric volume pulse wave

ActiveCN102389313AAccurate measurementNo need to debugCatheterDiagnostic recording/measuringMeasurement devicePeak value

The invention discloses a device and a method for measuring square wave modulated photoelectric volume pulse wave. A microprocessor outputs square waves which have different frequencies and form a double ratio relationship; the square waves drive at least two light-emitting diodes; the light from the light-emitting diodes are received by a photosensitive device after passing through tested finger; the photosensitive device converts the light into a voltage signal; the voltage signal is converted into a predefined amplitude value voltage signal by a current / voltage conversion amplifier; an analogue-to-digital converter converts the predefined amplitude value voltage signal into a digital signal; the microprocessor processes the digital signal to obtain photoelectric volume pulse wave and valley value and peak value thereof, and gets spectrum value by the valley value and the peak value. The measurement method comprises the following steps of: separating the digital signal to obtain the photoelectric volume pulse wave and removing interference of background light by the microprocessor; getting the valley value and the peak value according to the photoelectric volume pulse wave; and calculating the valley value and the peak value to obtain light absorbance difference, and obtaining the spectrum value by the light absorbance difference. The accurate measurement, simple circuit and low cost are realized.

Owner:TIANJIN UNIV

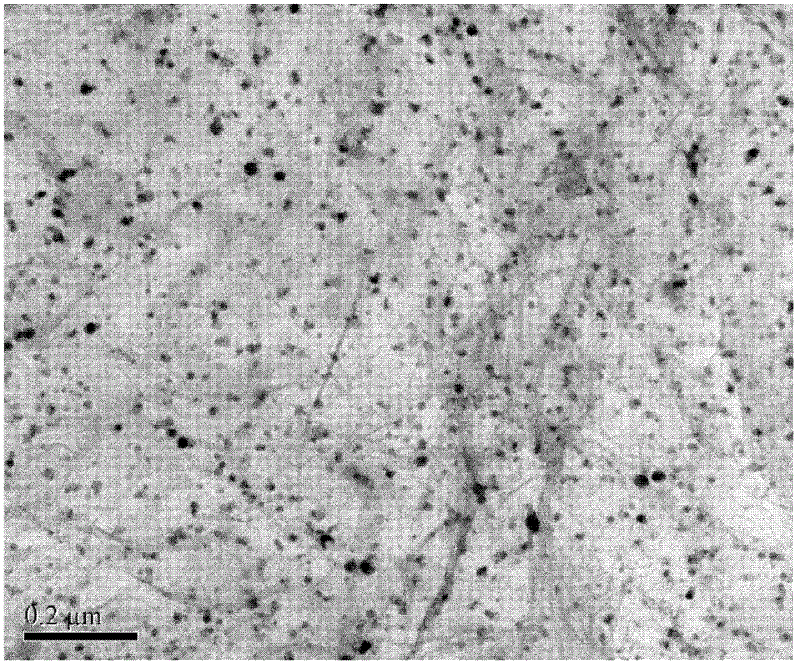

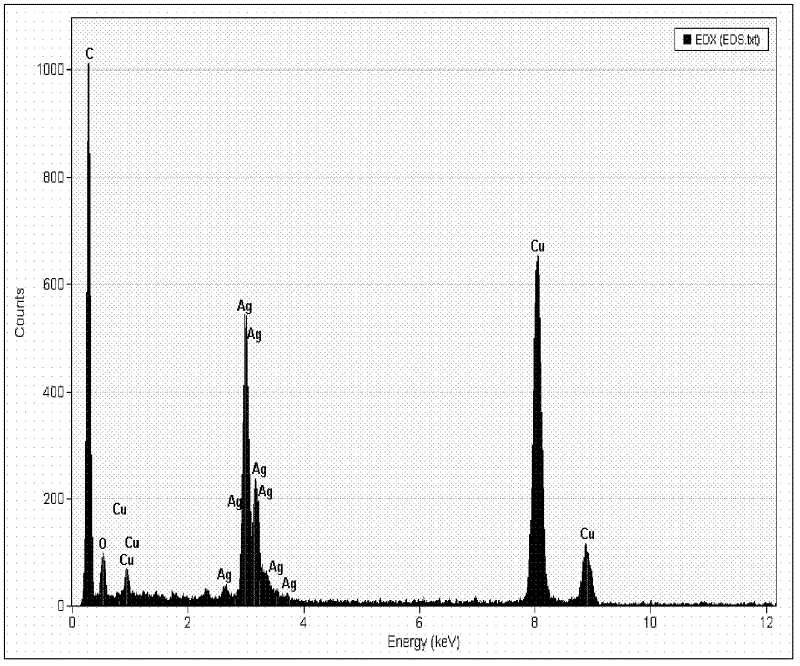

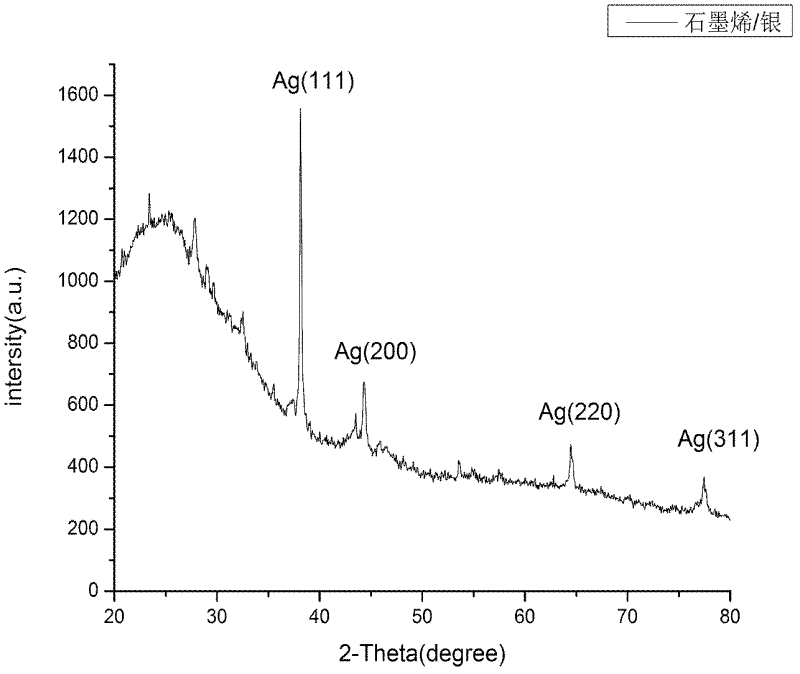

Method for preparing grapheme/silver nanoparticles composite material by using liquid phase method

ActiveCN102614871ALow impurity contentHigh bonding strengthMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsBond strengthElectron

The invention discloses a method for preparing a grapheme / silver nanoparticles composite material by using a liquid phase method. N and N-dimethyl formamide (DMF) serve as a reducing agent, grapheme powder with purity as high as 99% serves as a carrier, and silver forms a core and grows on a grapheme layer under a soft reaction condition to obtain the grapheme / silver nanoparticles composite material. The preparation method has the advantages of being simple, convenient, rapid and high-efficient in process, the grapheme / silver nanoparticles composite material prepared by using the method is high in purity and less in impurity content, and silver nanoparticles generated on the surface layer of the grapheme are small in particle size, uniform in distribution and high in bond strength with the grapheme. The silver nanoparticles are closely absorbed on the grapheme layer, aggregation of the grapheme is effectively avoided, and application of the grapheme / silver nanoparticles composite material in the fields of electron, catalysis, antibiosis and the like can be enlarged.

Owner:TIANJIN UNIV

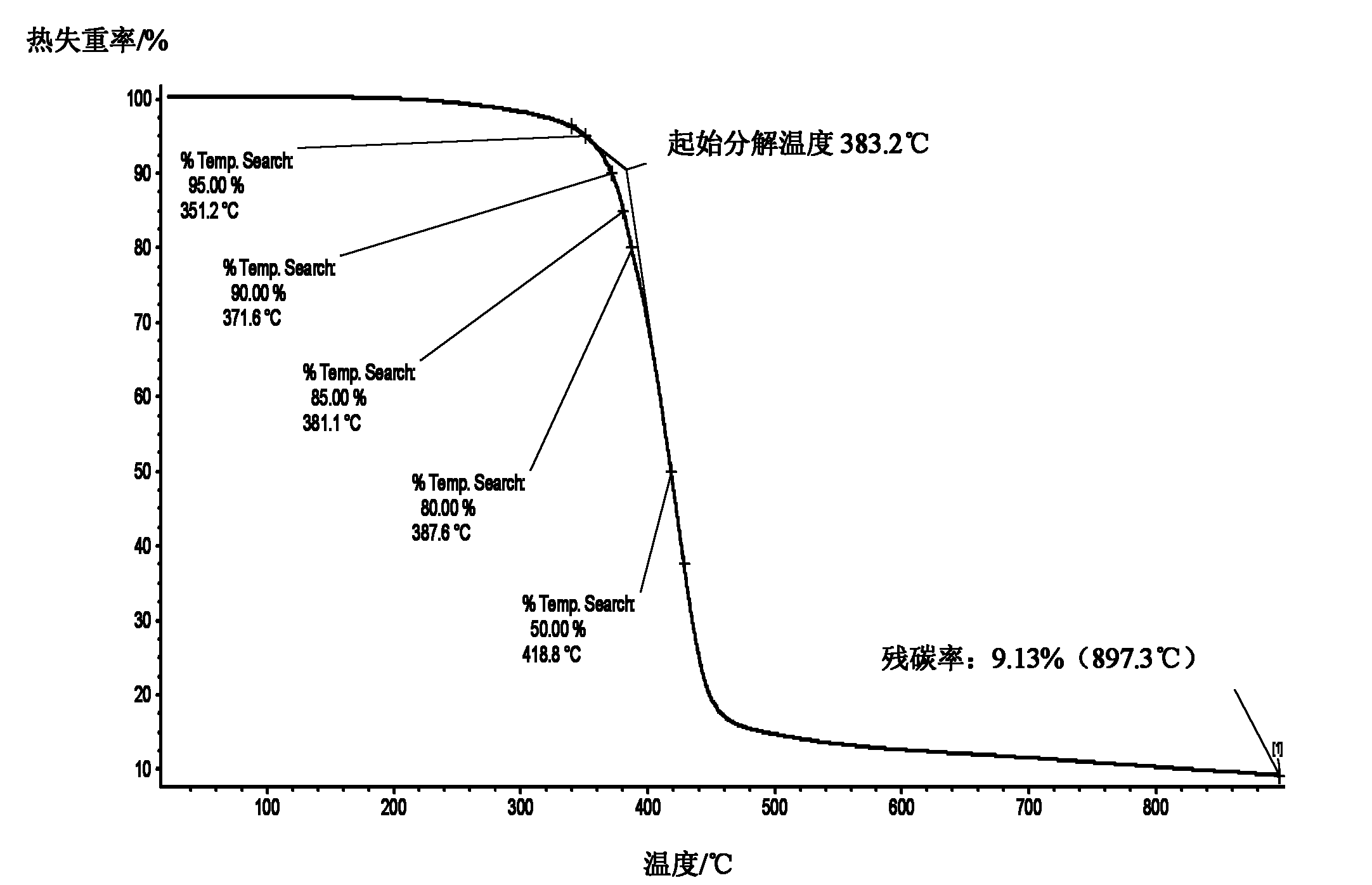

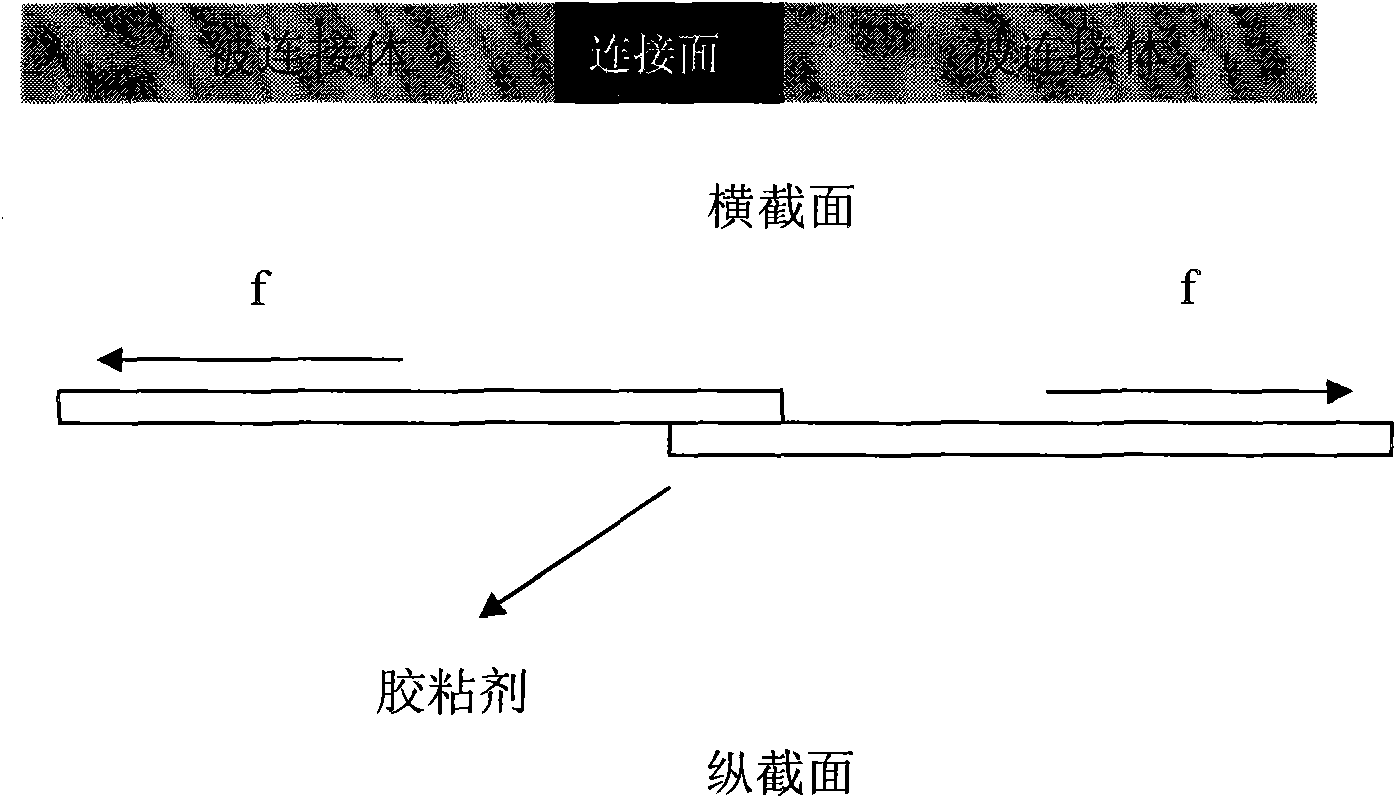

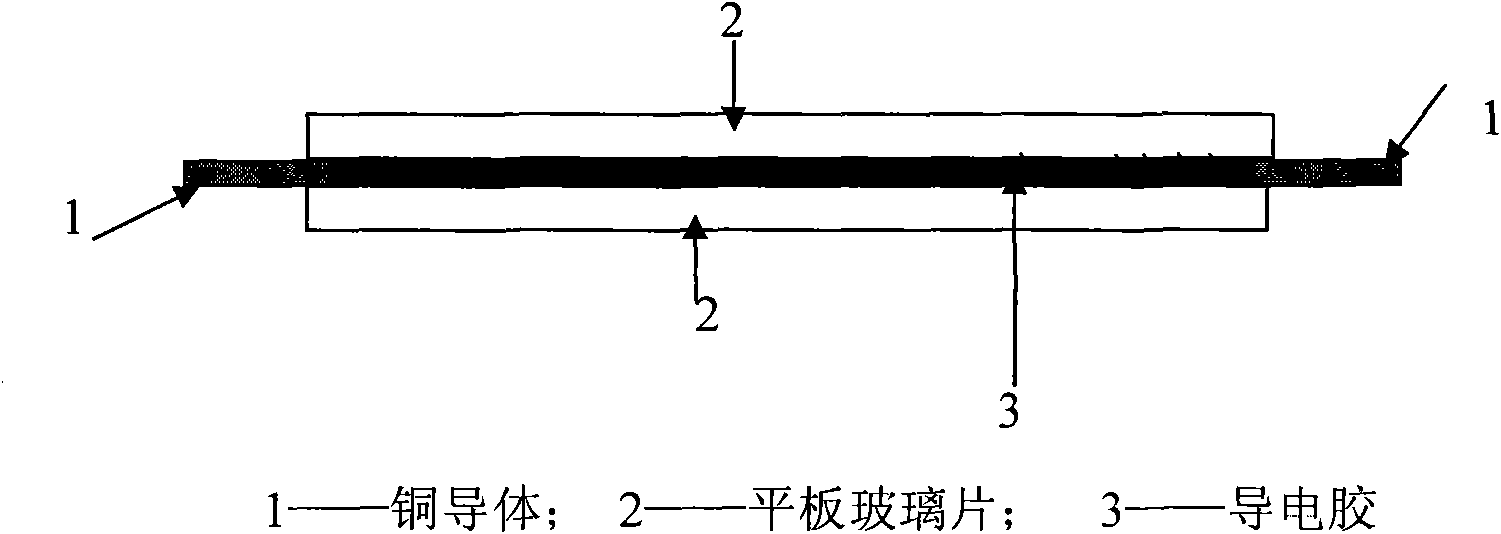

High-performance conducting resin and preparation method thereof

InactiveCN101781540AConvenient sourceSimple preparation processNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyRoom temperature

The invention relates to a high-performance conducting resin, comprising the following components: epoxy, latent curing agent, active toughener and conducting particles. The preparation method comprises the following steps: adding the epoxy and the active toughener in a reaction bulb to react, then adding the latent curing agent, uniformly stirring, adding the surface-treated conducting particles, uniformly stirring, and defoaming in vacuum to obtain the high-performance conducting resin. The conducting resin in characterized in that the bonding strength reaches up to 24.1 MPa; the volume resistivity is 4.30*10<-5>-2.12*10<-4> ohm.cm; the Tonset thermal decomposition temperature reaches up to 398.7 DEG C; the water absorption is only 0.2%; and storage life at the room-temperature is as long as more than 3 months. The invention has the advantages of simple preparation process, low cost, convenient operation and convenient reaction material source, can complete the preparation process in universal devices, is beneficial to realizing industrial production, and has wide application prospects in the fields of electronic components, resonators, relays, electronic capacitors and the like.

Owner:DONGHUA UNIV +1

Leadless platinum electrode slurry and manufacturing method thereof

InactiveCN101168472AImprove liquidityPromote wettingMaterial analysis by electric/magnetic meansElectrically-conductive paintsPlatinumAdhesive

The invention relates to a leadless platinum electrode slurry and process for preparation, wherein the platinum electrode slurry is prepared from 2-10mass% leadless glass adhesive, 2-10mass% metal oxide, 10-20mass% organic adhesive, and ultra-fine platinum powder at left amount. The production comprises leadless glass adhesive preparation, organic adhesive preparation, leadless platinum electrode slurry formulation, and slurry treatment. The invention can produce leadless platinum electrode slurry which lead content is lower than 100ppm, while the slurry applied in the electrode of zirconium oxide oxygen sensor can sinter at 1200DEG C, and via the formula adjustment of the leadless glass adhesive, the invention can produce platinum electrode slurry which can sinter at 800-1500DEG C. The electrode has the advantages of strong zirconium oxide substrate adhesive force, high conductivity, and stable electrical property.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

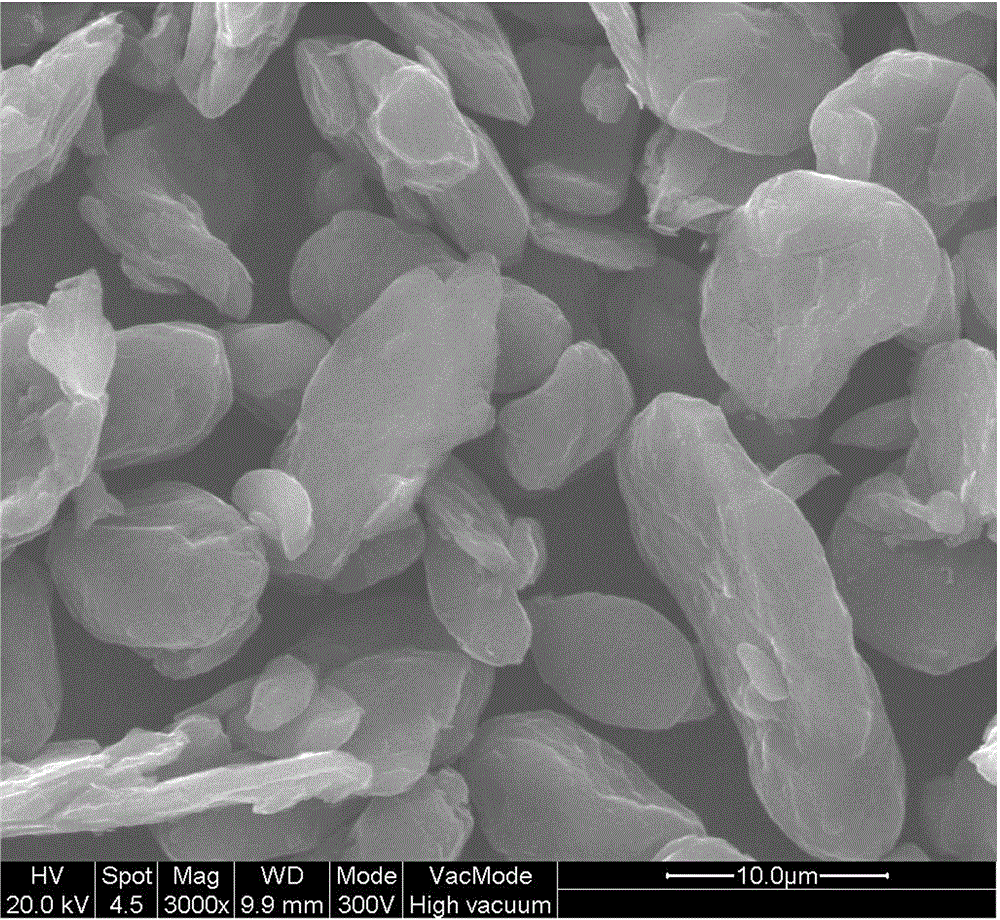

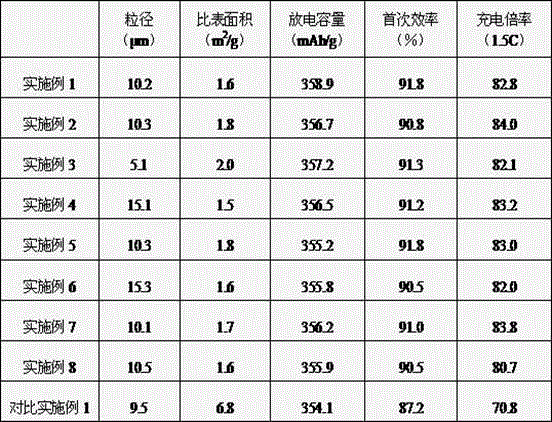

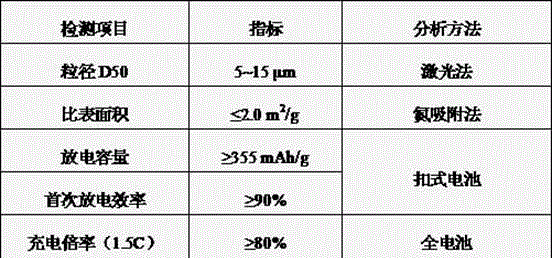

Negative electrode material for quickly rechargeable graphite lithium-ion battery and preparation method of negative electrode material

InactiveCN105024075ASmall specific surface areaIncrease charging rateCell electrodesSecondary cellsDischarge efficiencyElectrical battery

The invention discloses a negative electrode material for a quickly rechargeable graphite lithium-ion battery and a preparation method of the negative electrode material. The preparation method of the negative electrode material for the quickly rechargeable graphite lithium-ion battery comprises the following steps: (1) mixing a mixture containing a graphite precursor and bitumen and heating the mixture for kneading and crushing, wherein the mean grain size D50 of the graphite precursor ranges from 5 to 10 microns, and the mass ratio of the graphite precursor to the bitumen ranges from 50:50 to 90:10; (2) performing heat treatment at a temperature within the range of 300-700 DEG C under the protection of an inert gas; and (3) carrying out graphitizing. The mean grain size D50 of the negative electrode material prepared by use of the preparation method for the quickly rechargeable graphite lithium-ion battery is within the range of 5-15 microns and the specific surface area of the negative electrode material is below 2.0m2 / g; the first discharge capacity of a negative electrode, manufactured by use of the negative electrode material for the quickly rechargeable graphite lithium-ion battery, is more than 355mAh / g, and the initial charge-discharge efficiency of the battery is above 90%; if the battery is quickly charged (1.5C) for 45 minutes, the capacity of the battery can be above 80%; in short, the product is high in discharge capacity and charge / discharge efficiency, and good in rate capability. The invention also relates to a battery comprising the negative electrode material for the quickly rechargeable graphite lithium-ion battery.

Owner:SHANGHAI SHANSHAN TECH CO LTD

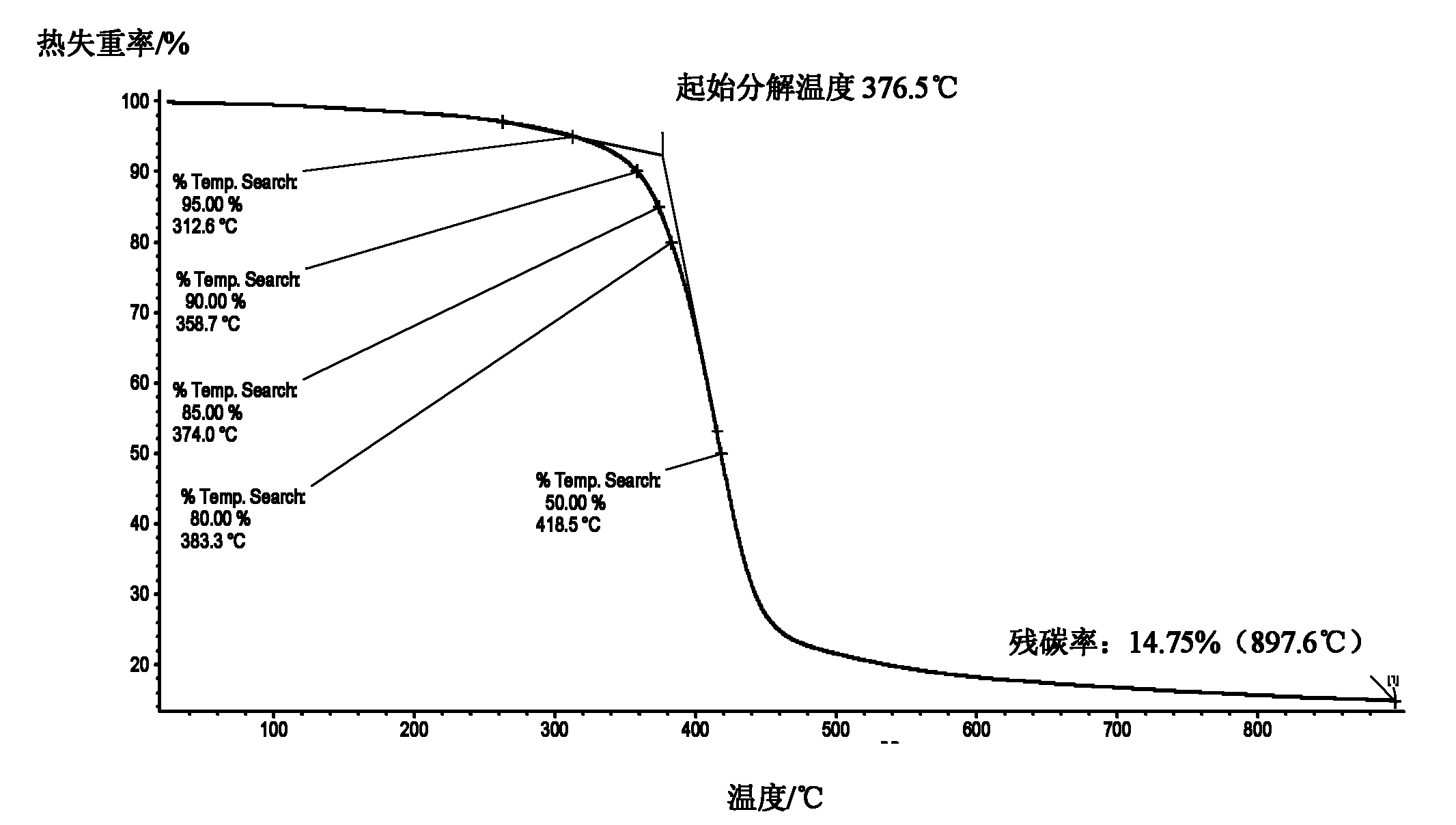

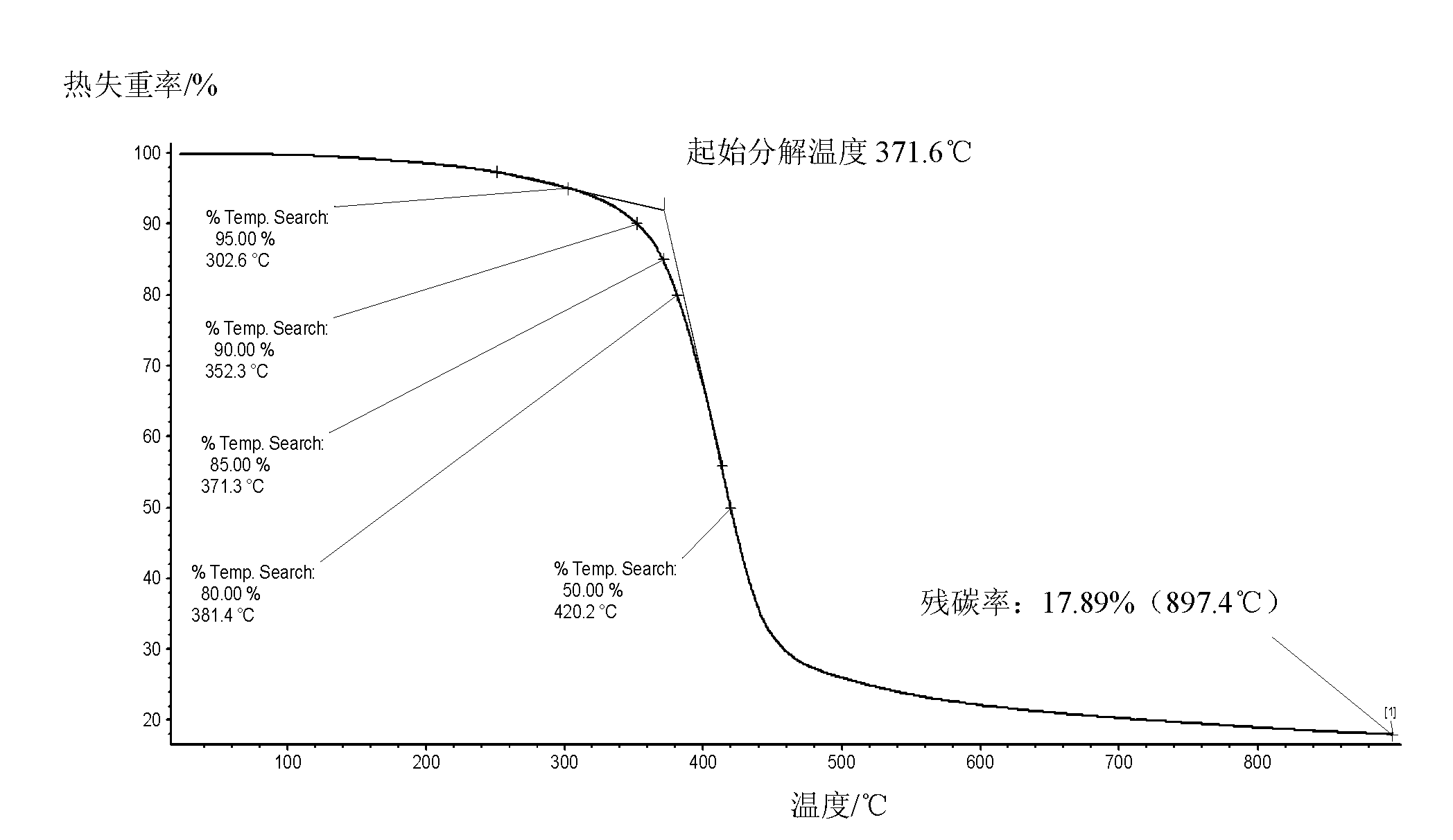

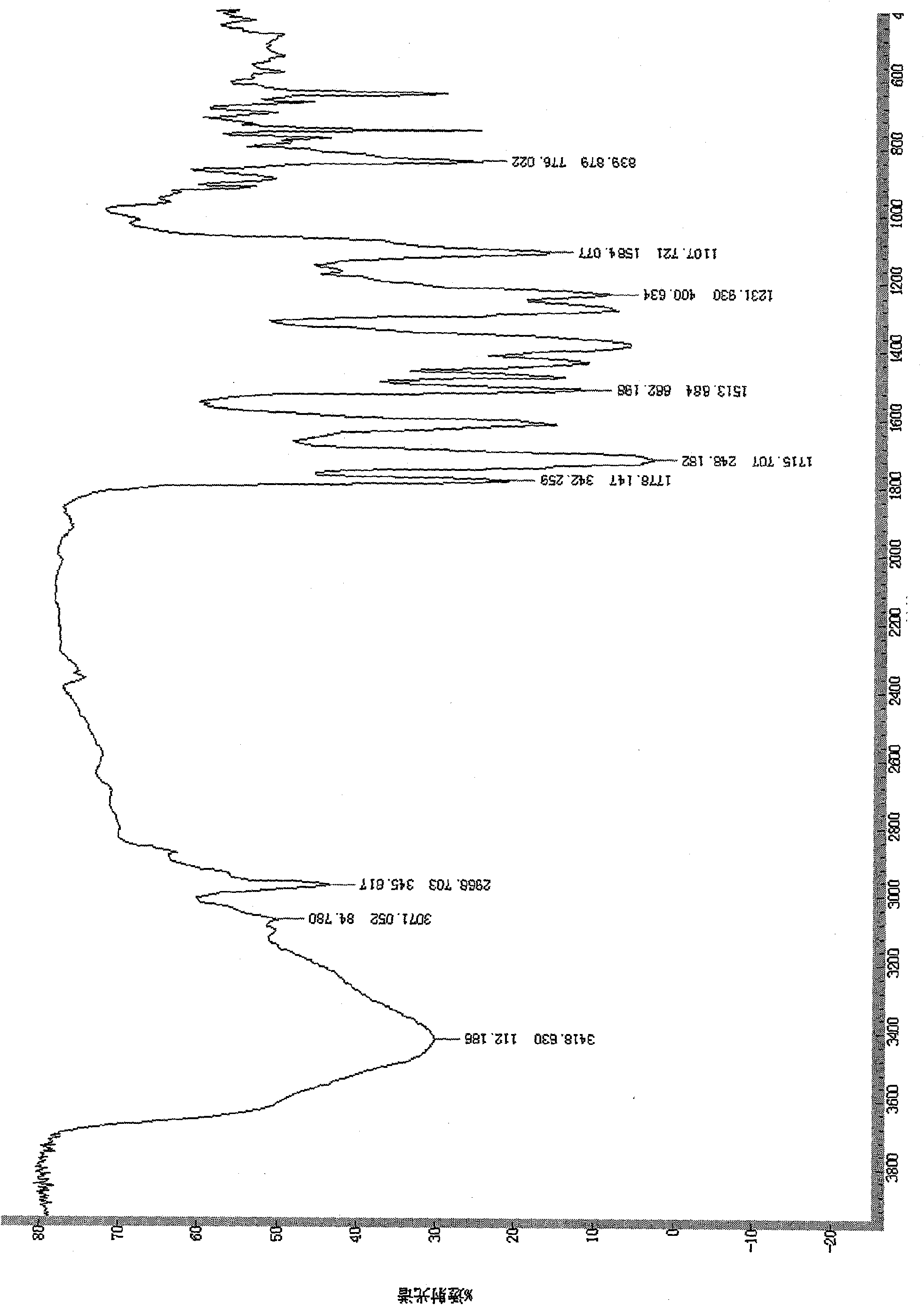

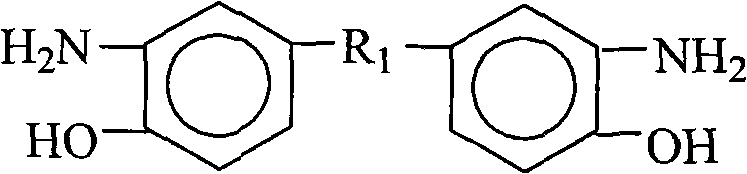

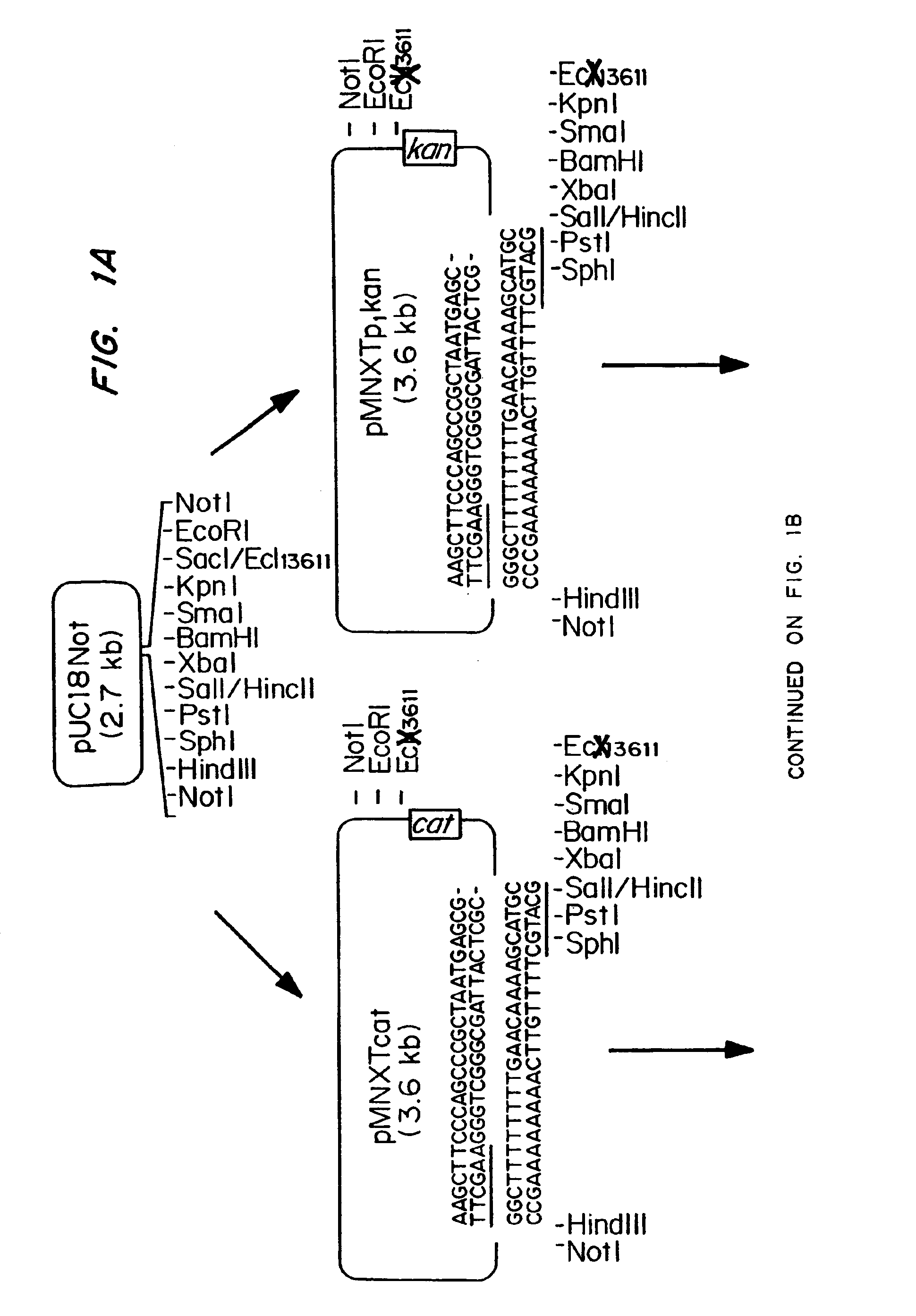

2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof

InactiveCN103146330AGood adhesionGood viscosity controllabilityMacromolecular adhesive additivesEpoxynovolac adhesivesResin-Based CompositePhenyl group

The invention relates to a 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and a preparation method thereof. The 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive is composed of a component A and a component B, wherein the component A is a copolymer prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and epoxy resin; and the component B is a homogeneous transparent solution with the solid content of 15-30%, which is prepared by reacting 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane and aromatic dibasic acid anhydride in a strong-polarity non-proton organic solvent and toluene. The preparation method comprises the following step: evenly mixing the component A and the component B in a mass ratio of 1:(1-2) at room temperature. The preparation technique is simple; and the adhesive has excellent comprehensive properties, can be widely used for bonding steel, copper, aluminum or any other metal with ceramic, glass, resin-base composite material or any other substrate, and has favorable industrialization prospects.

Owner:DONGHUA UNIV +1

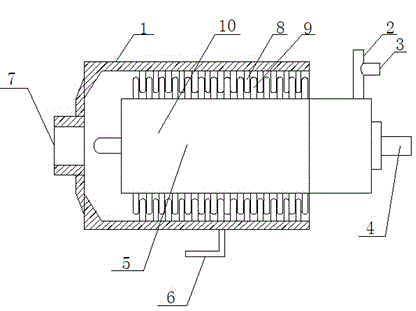

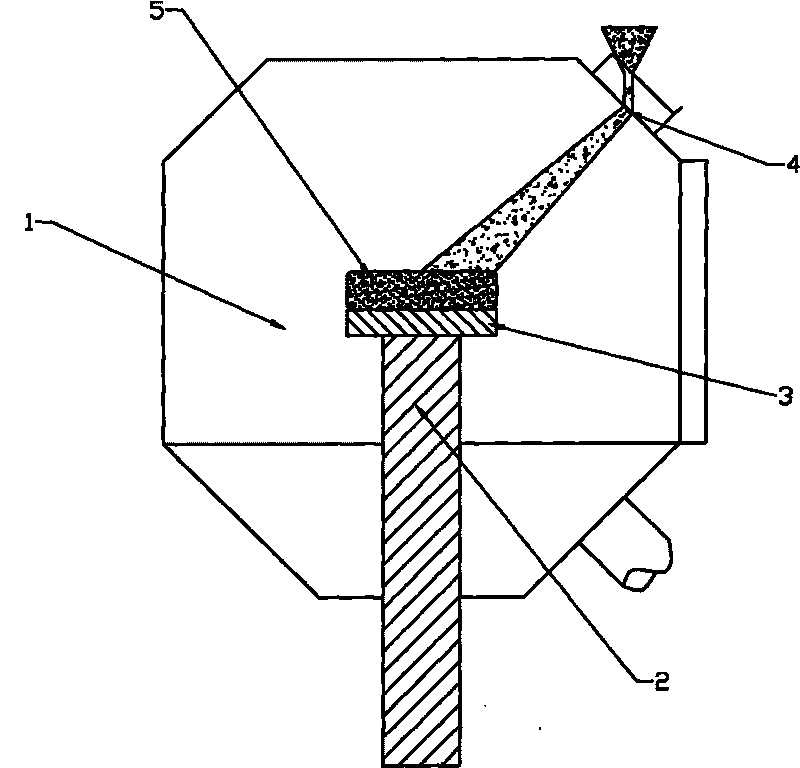

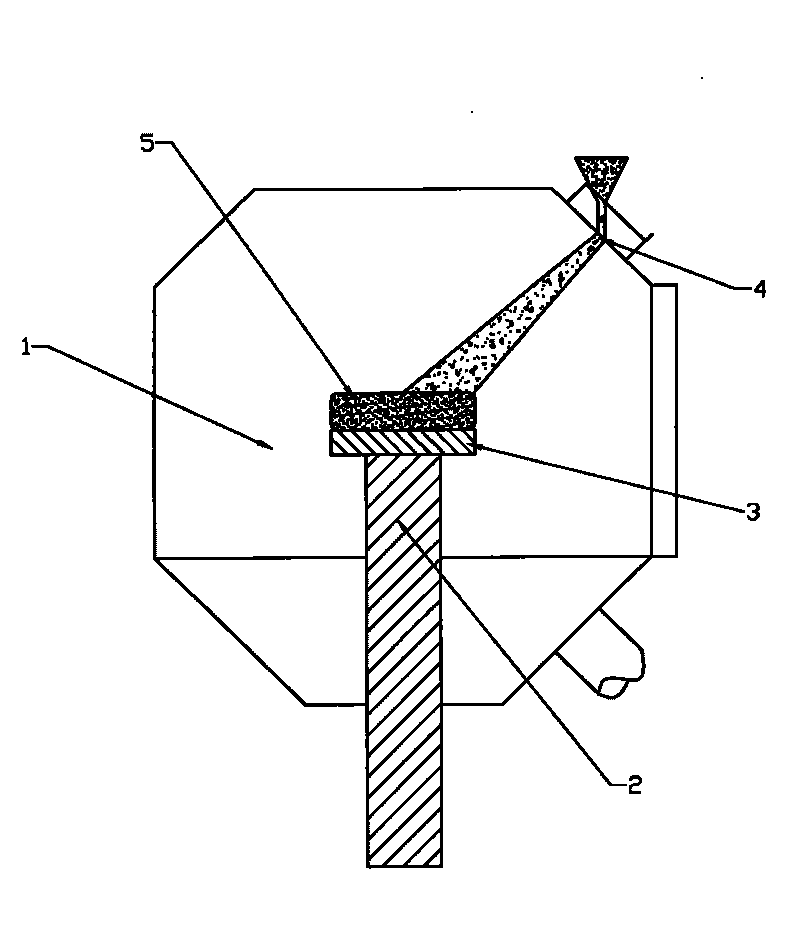

Micro-nano bubble generating device

InactiveCN104803467AReduce energy consumptionSimple structureWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processMicro nanoMicro bubble

The invention provides a medical cleaning device, and relates to a micro-nano ozone bubble device, in particular to a micro-nano bubble generating device. The micro-nano bubble generating device comprises a foam maker and an ozone generator, wherein the foam maker is connected with the ozone generator through a pipeline; the foam maker comprises an inlet end, an outlet end, a power output device and a rotary stirring device; the inlet end is arranged at one end of the foam maker, and the outlet end is arranged at the other end, opposite to the inlet end, of the foam maker; the power output device is connected with the rotary stirring device and arranged outside the foam maker; the rotary stirring device is arranged inside the foam maker. The micro-nano bubble generating device is low in energy consumption, and can generate lots of micro bubbles; under the condition that the water pump power and the water flow pressure are not increased, more micro bubbles can be generated, and can reach micro-nanoscale. The device is simple in structure, excellent in processing and assembly performance, and simple and convenient to use and operate.

Owner:刘芮萌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof 2,2-bis[4-(2,4-diamidophenoxy)phenyl]hexafluoropropane high-temperature-resistant epoxy adhesive and preparation method thereof](https://images-eureka.patsnap.com/patent_img/c3dc5c5a-1b77-468c-bc0c-b8ed519f1fb6/BDA00002903323100091.PNG)