Automobile hemming adhesive and preparation method thereof

A hemming glue, automotive technology, applied in the direction of adhesives, epoxy glue, adhesive types, etc., can solve the problems of short storage period, construction process influence, high viscosity, etc., and achieve good manufacturability and excellent dynamic mechanical properties , Good thixotropic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

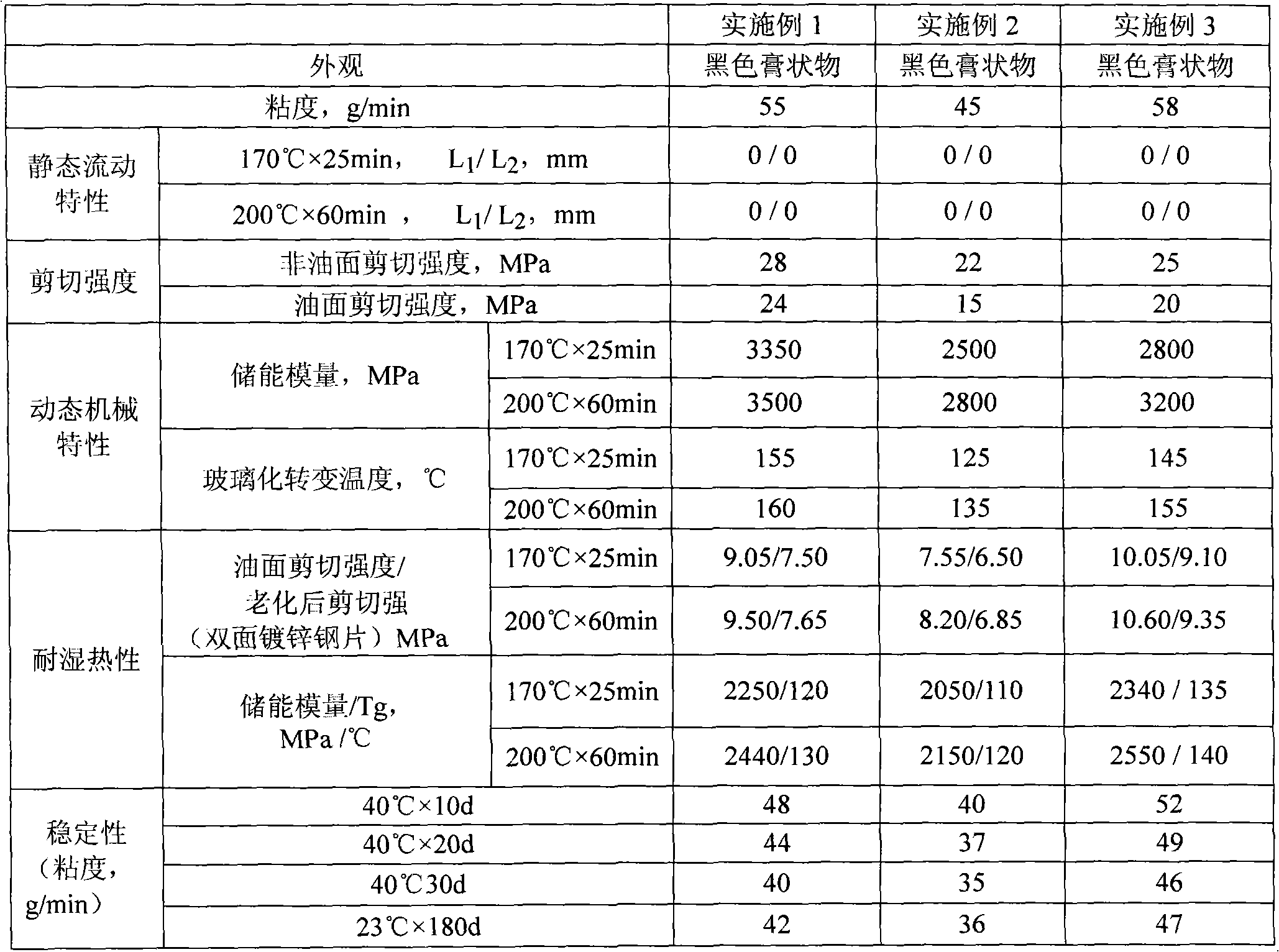

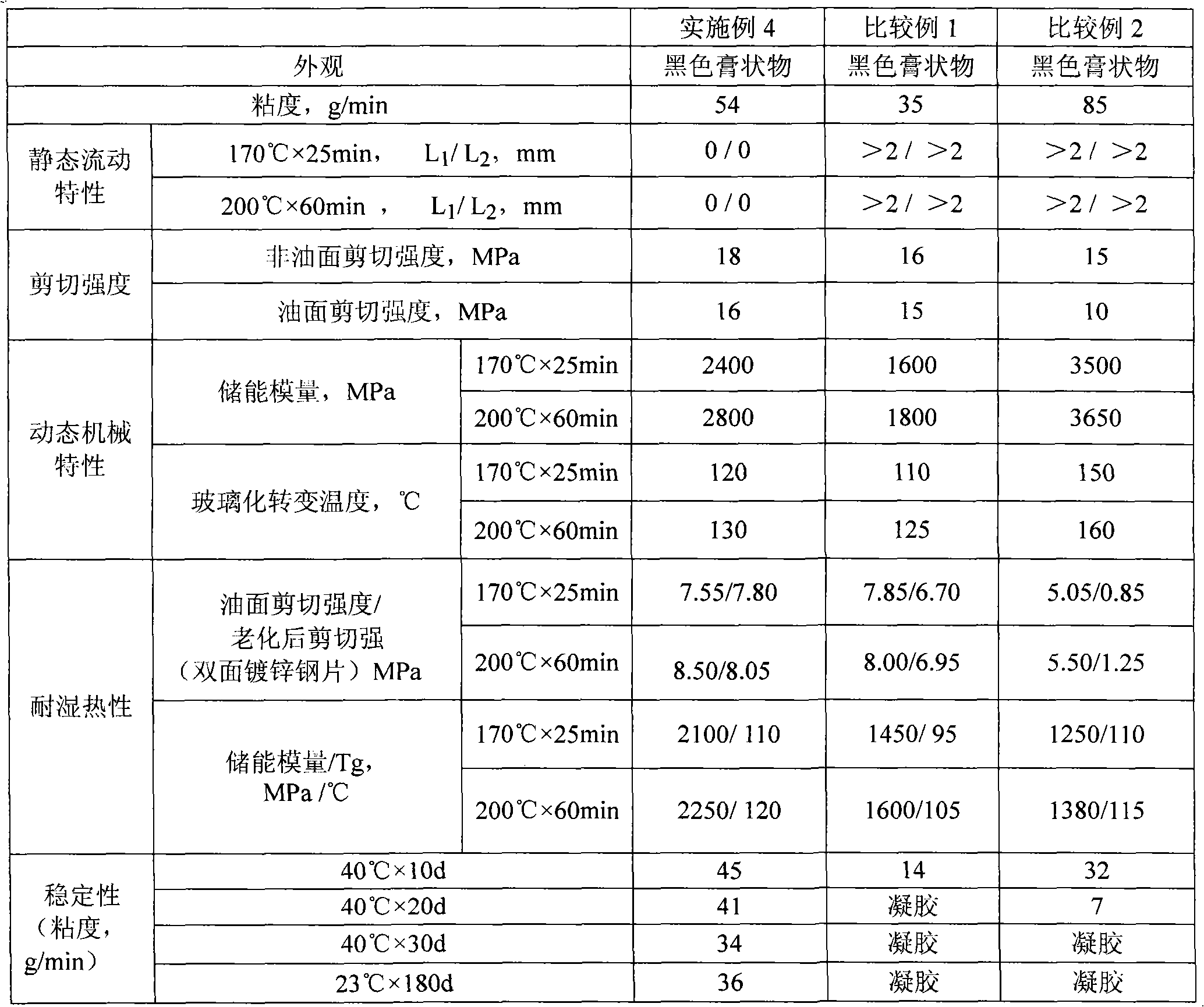

Examples

Embodiment 1

[0044] Proportion

[0045] Nano rubber modified epoxy resin (MX-125) 13%Wt

[0046] Epoxy Resin (E-51) 17%Wt

[0047] Qishi Toughening Agent (QS-BE) 5%Wt

[0048] 664 Reactive Diluent 5%Wt

[0049] PVC paste resin 10%Wt

[0050] Phenyl Alkyl Sulfonate 10%Wt

[0051] Calcium zinc composite stabilizer 1%Wt

[0052] Dicyandiamide 3%Wt

[0053] Clomerone 0.5%Wt

[0054] Titanate coupling agent (NDZ-101) 1%Wt

[0055] Microsilica 12.5%Wt

[0056] Nano calcium carbonate 20%Wt

[0057] Carbon Black 2%Wt

[0058] preparation:

[0059] (1) Stir the PVC paste resin fat and phenyl alkyl sulfonate at 5°C~35°C for 30mim~90min, until the solid material is completely dissolved and uniform, for subsequent use;

[0060] (2) Combine the above mixed liquid composition with nano-rubber modified epoxy resin (MX-125), 618 epoxy resin, Qishi toughening agent (QS-BE), 664 reactive diluent, calcium and zinc for compound stability Add in the dynamic mixer, dicyandiamide, clomeron, titanate...

Embodiment 2

[0092] Proportion

[0093] Carboxyl Liquid Nitrile Rubber Modified Epoxy Resin 12%Wt

[0094]Epoxy Resin (E-44) 18%Wt

[0095] Kishi Toughening Agent (QS-210B) 5%Wt

[0096] 5748 Reactive Diluent 5%Wt

[0097] PVC paste resin 10%Wt

[0098] Phenyl Alkyl Sulfonate 10%Wt

[0099] Calcium zinc composite stabilizer 1%Wt

[0100] Dicyandiamide 2%Wt

[0101] Sebacate dihydrazide 2%Wt

[0102] Titanate coupling agent (NDZ-102) 2%Wt

[0103] Microsilica 21%Wt

[0104] Fumed silica 10%Wt

[0105] Carbon Black 2%Wt

[0106] The preparation technology and the test method are the same as those in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0108] Proportion

[0109] Nano rubber modified epoxy resin (MX-257) 13%Wt

[0110] Epoxy Resin (E-51) 20%Wt

[0111] Liquid Nitrile Rubber 2%Wt

[0112] 5749 Reactive Diluent 5%Wt

[0113] PVC paste resin 10%Wt

[0114] Phenyl Alkyl Sulfonate 10%Wt

[0115] Calcium zinc composite stabilizer 1%Wt

[0116] Dicyandiamide 2%Wt

[0117] Sebacate dihydrazide 2%Wt

[0118] Titanate coupling agent (NDZ-101) 2%Wt

[0119] Nano Calcium Carbonate 25%Wt

[0120] Hollow glass beads 6%Wt

[0121] Carbon Black 2%Wt

[0122] The preparation technology and the test method are the same as those in Example 1, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com