Patents

Literature

2876 results about "Light absorbance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

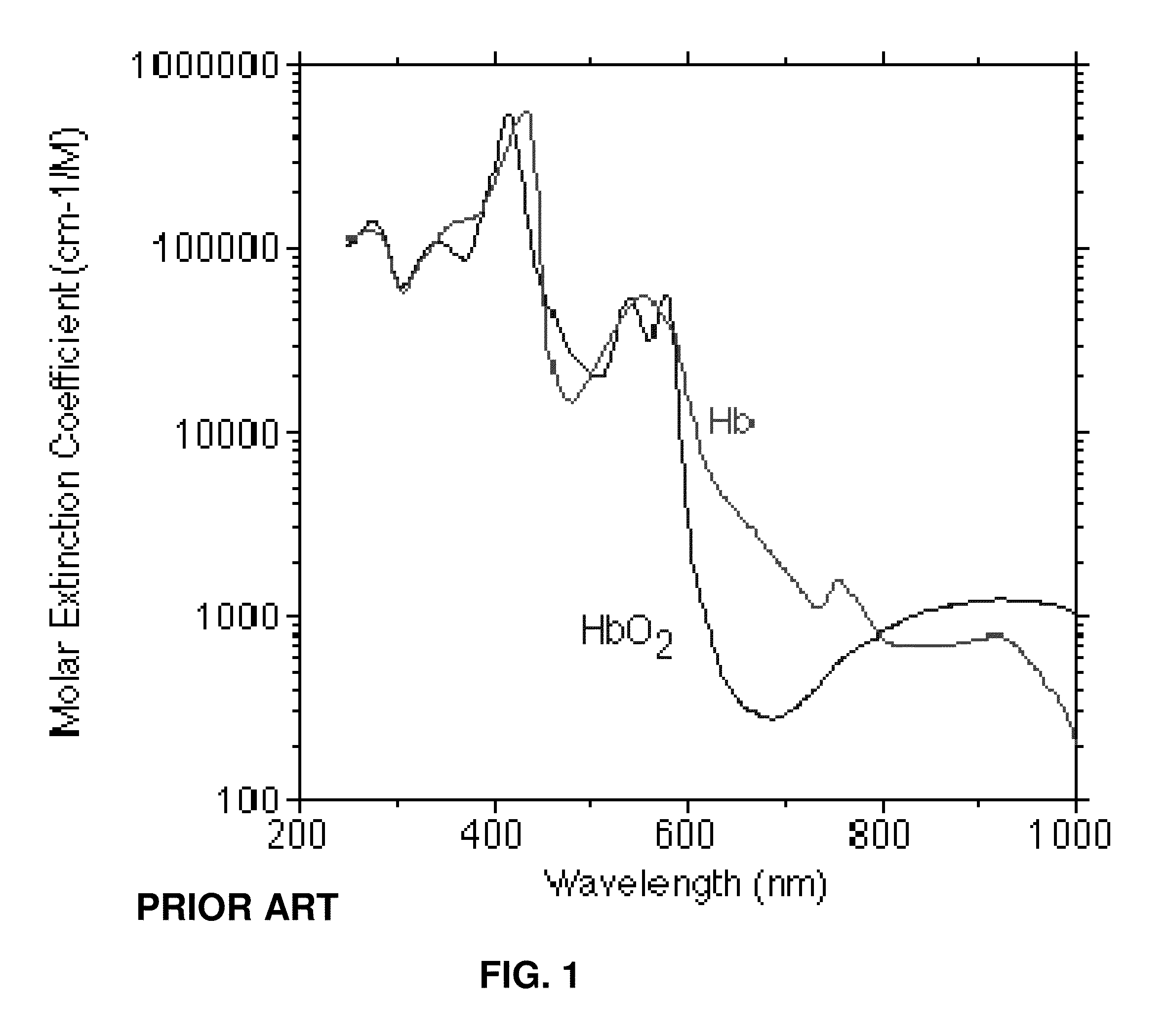

Absorbance is a measure of the amount of light with a specified wavelength that a given material prevents from passing through it. Absorbance does not necessarily measure the amount of light that the material absorbs. For example, absorbance would also include light that is dispersed by the sample material.

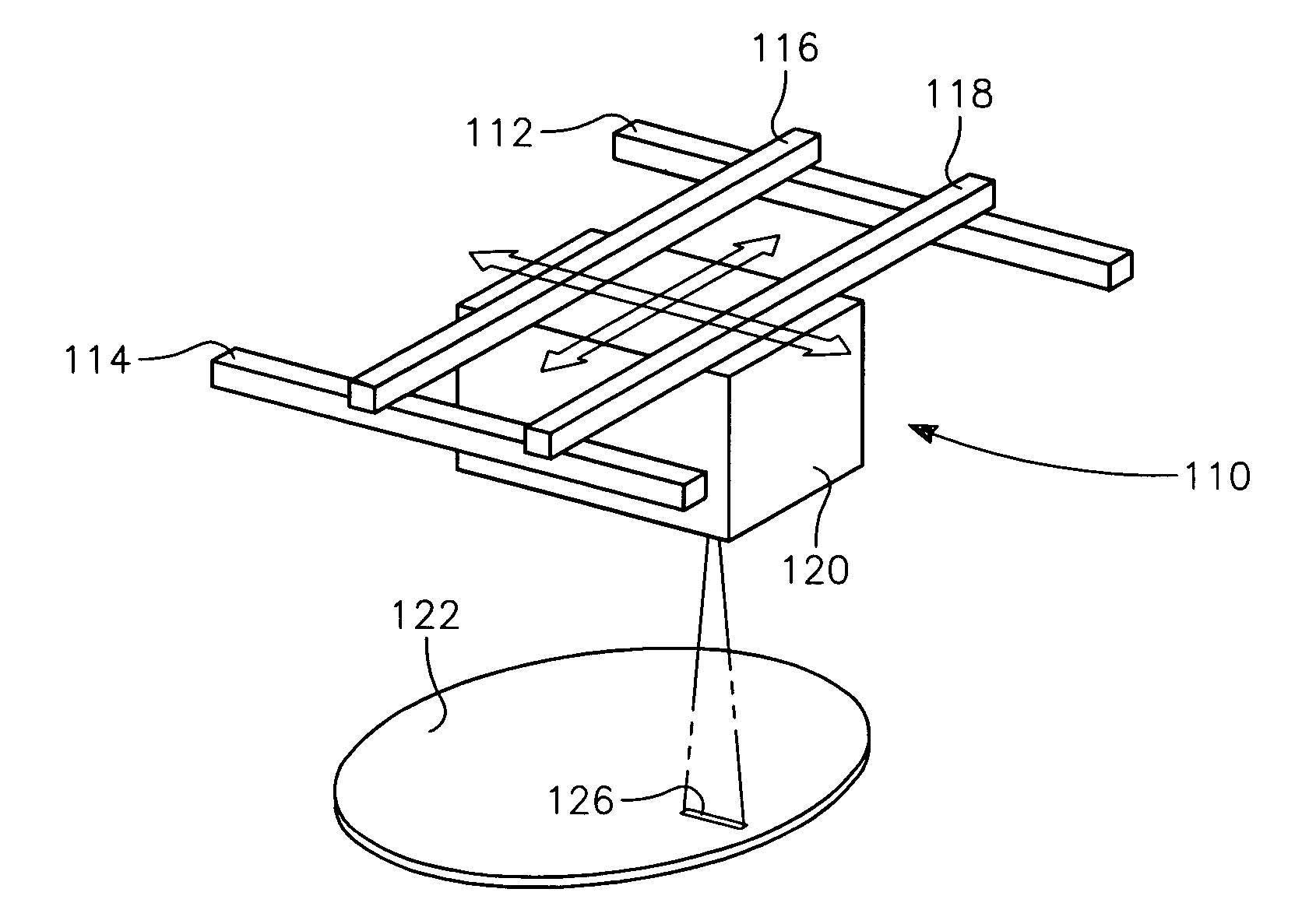

Copper conductor annealing process employing high speed optical annealing with a low temperature-deposited optical absorber layer

InactiveUS20070032095A1Semiconductor/solid-state device manufacturingWelding/soldering/cutting articlesCopper conductorEngineering

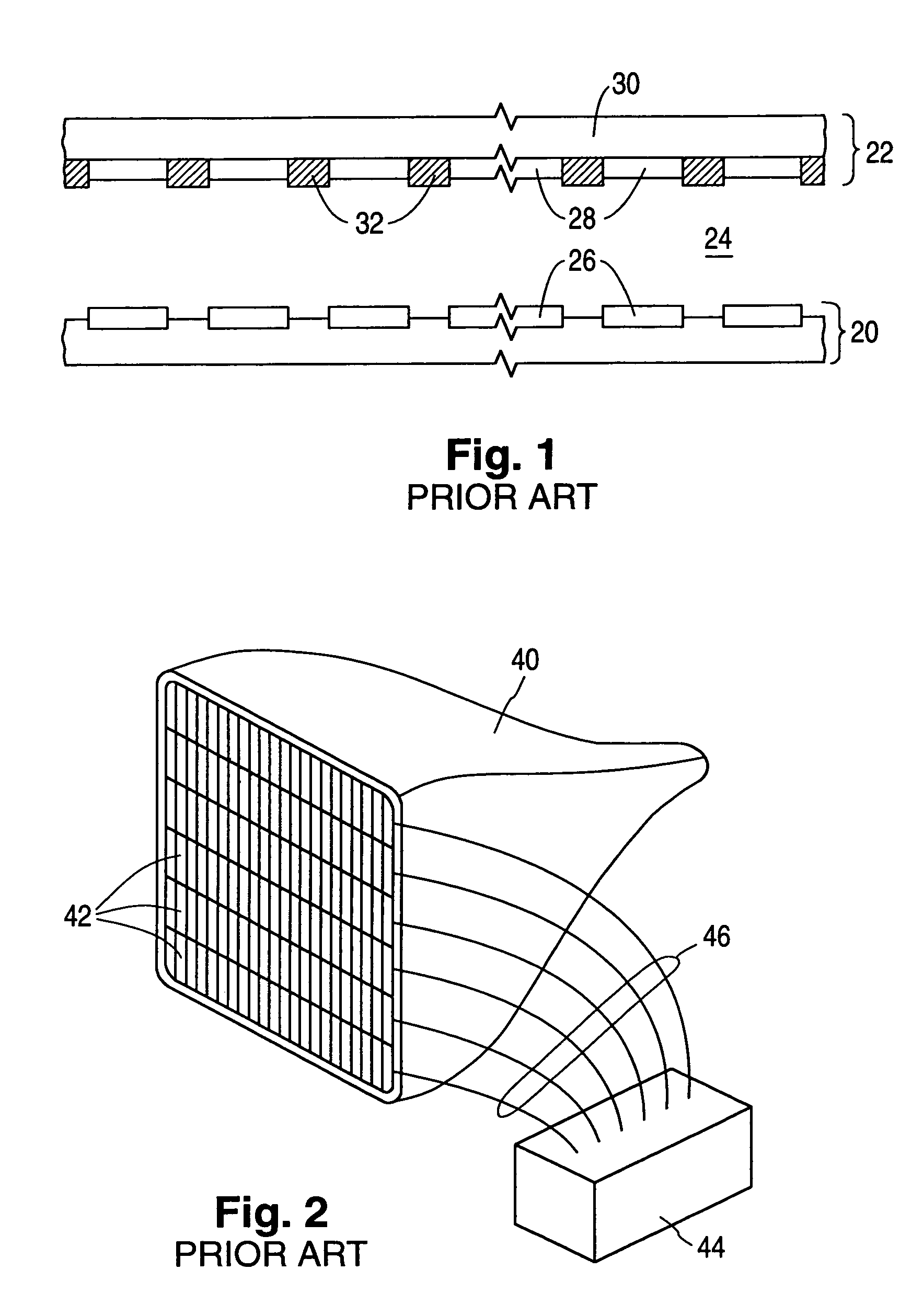

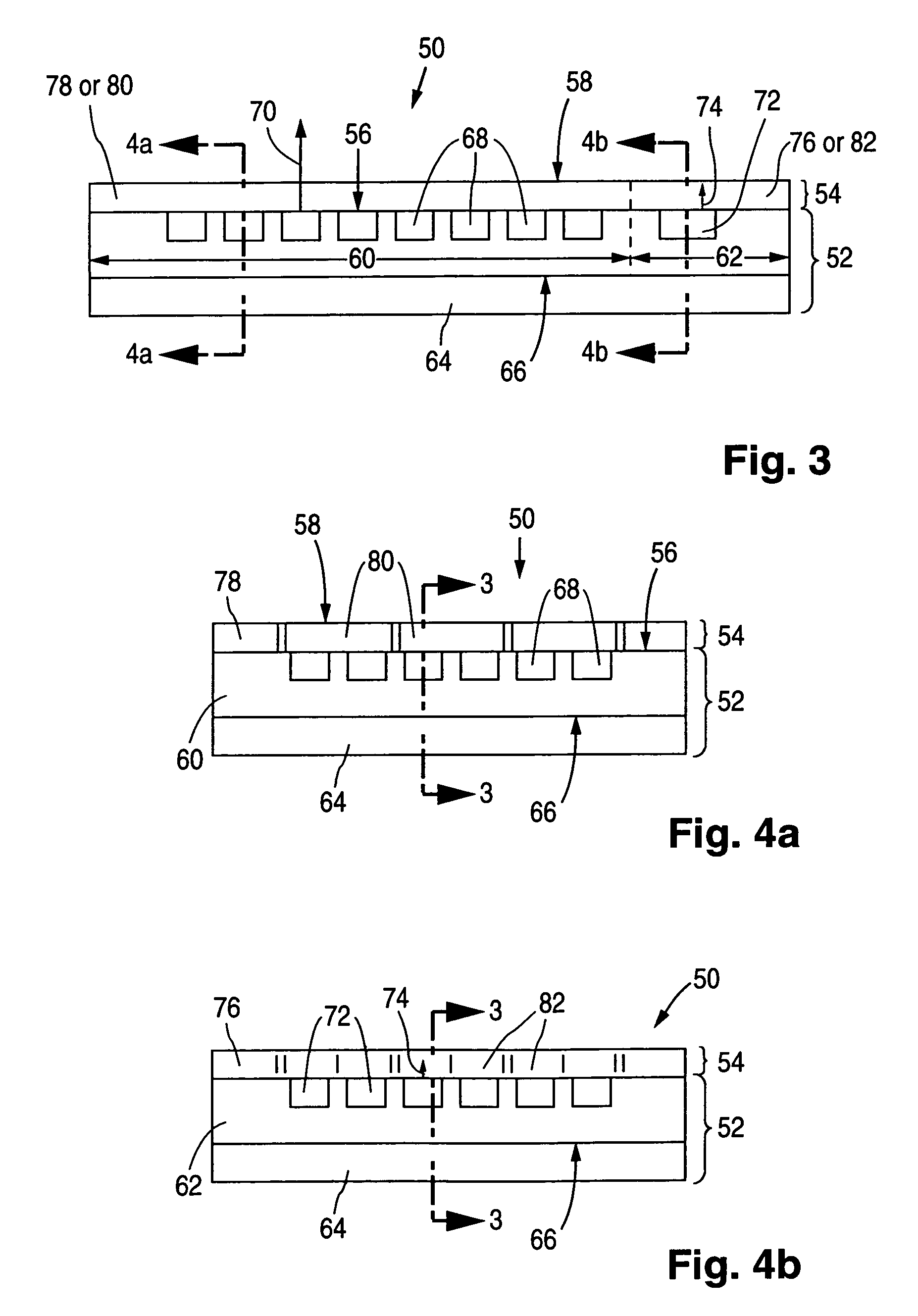

A method of forming a conductor in a thin film structure on a semiconductor substrate includes forming high aspect ratio openings in a base layer having vertical side walls, depositing a dielectric barrier layer comprising a dielectric compound of a barrier metal on the surfaces of the high aspect ratio openings including the vertical side walls, depositing a metal barrier layer comprising the barrier metal on the first barrier layer, depositing a main conductor species seed layer on the metal barrier layer and depositing a main conductor layer. The method further includes annealing the main conductor layer by (a) directing light from an array of continuous wave lasers into a line of light extending at least partially across the thin film structure, and (b) translating the line of light relative to the thin film structure in a direction transverse to the line of light. The method of Claim 1 further comprising, prior to the annealing step, depositing an amorphous carbon optical absorber layer on the main conductor layer. The step of depositing an amorphous carbon optical absorber layer includes introducing a carbon-containing process gas into a reactor chamber containing the substrate in a process zone of the reactor, applying RF source power to an external reentrant conduit of the reactor to generate a reentrant toroidal RF plasma current passing through the process zone and applying a bias voltage to the substrate.

Owner:APPLIED MATERIALS INC

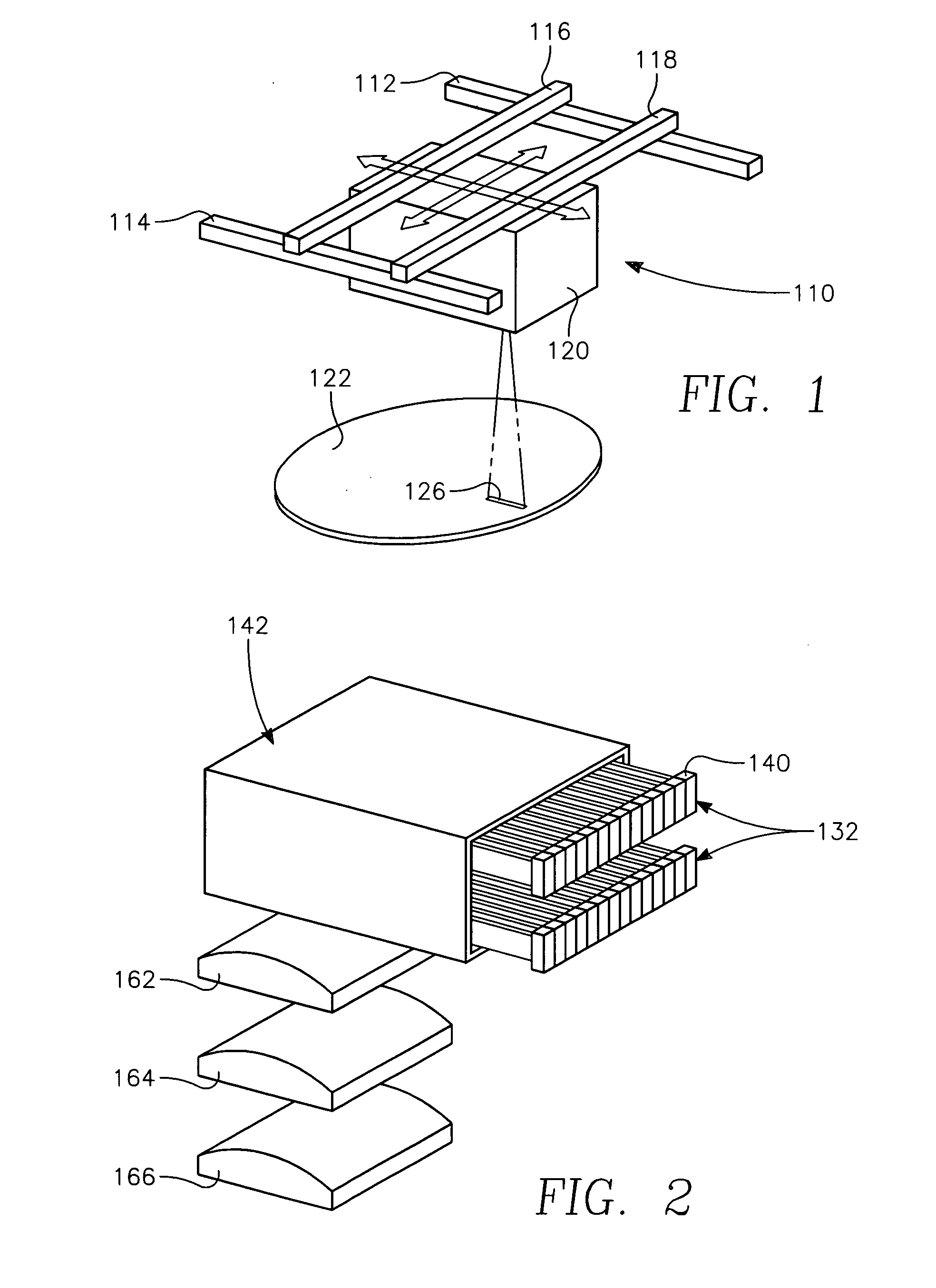

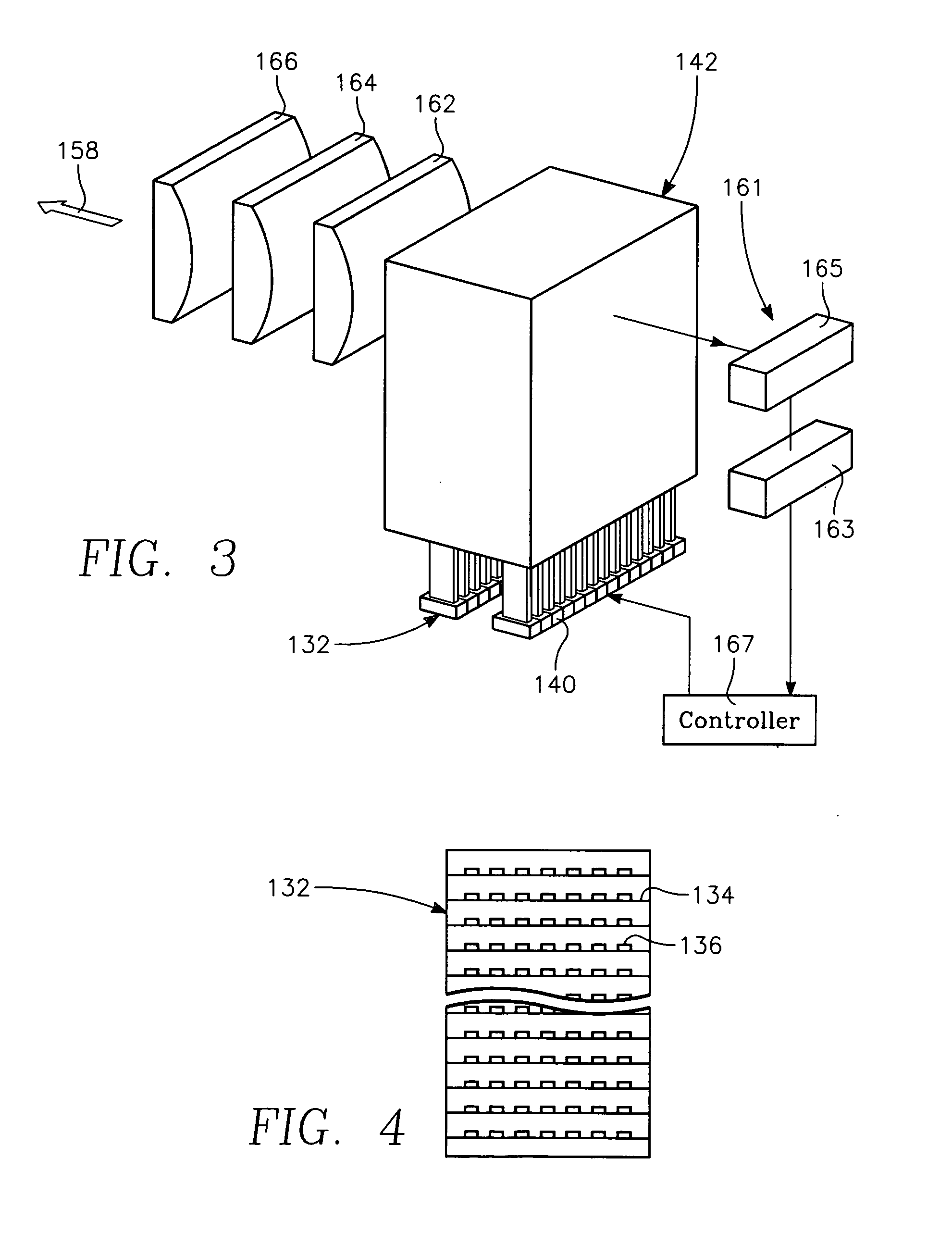

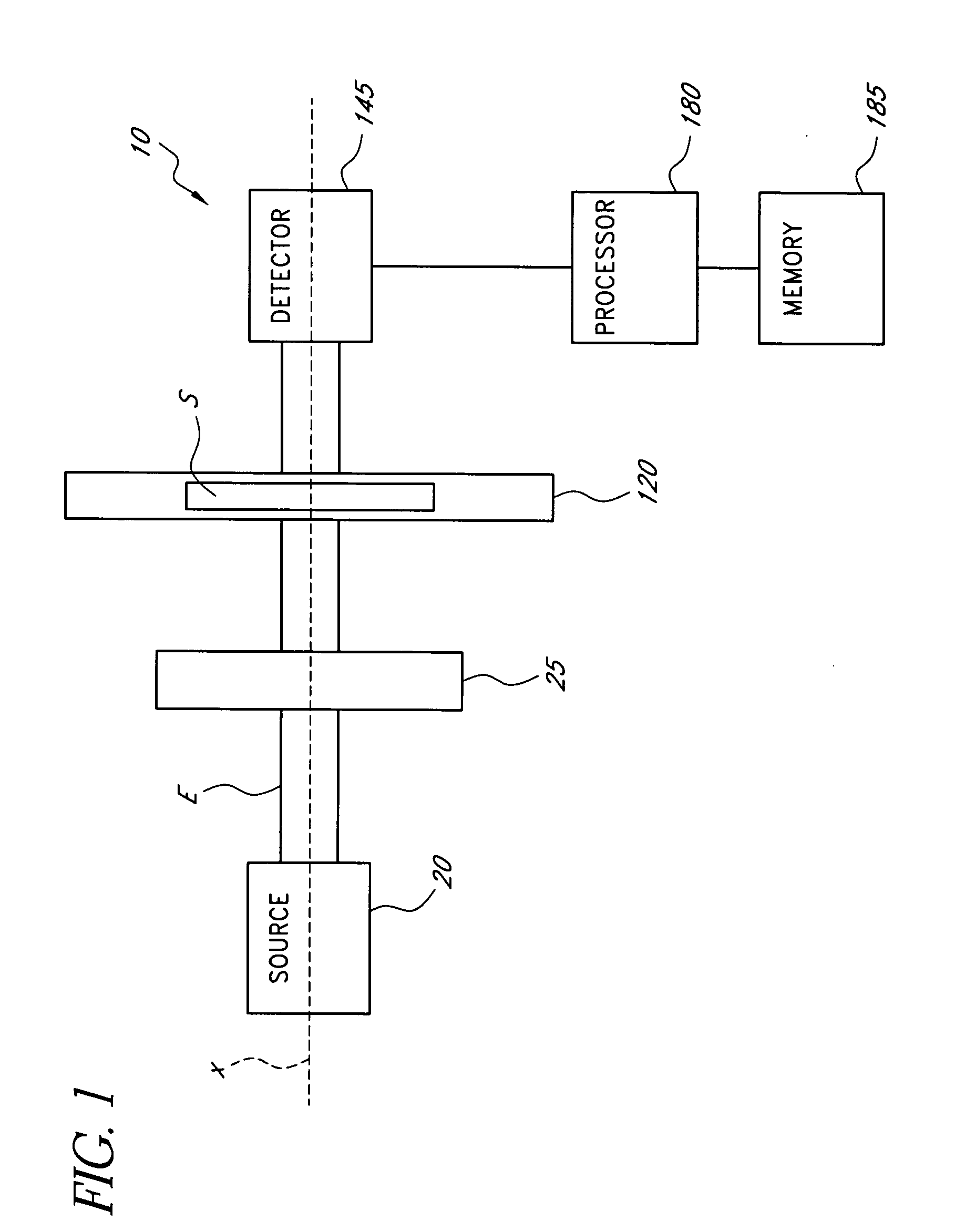

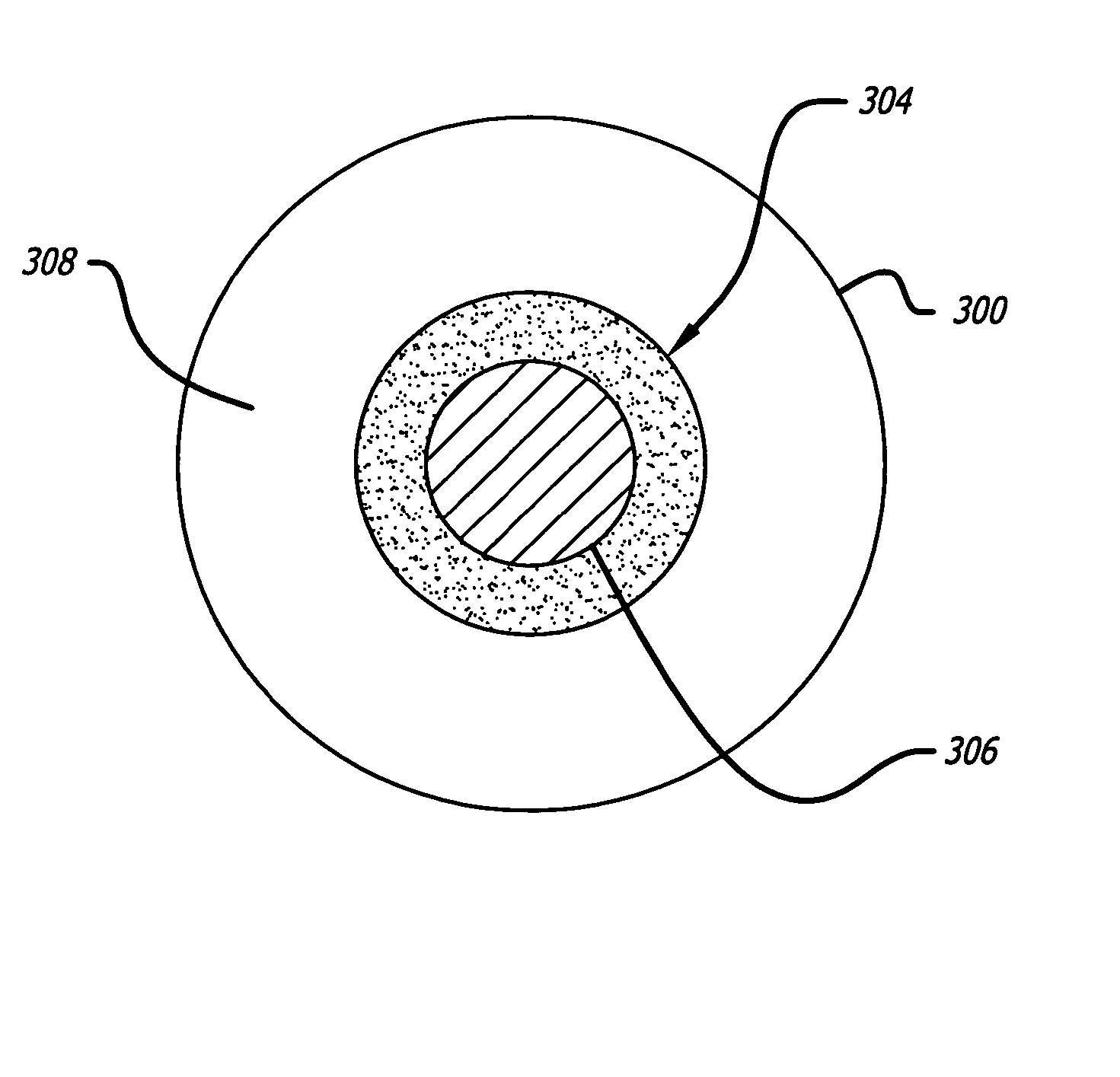

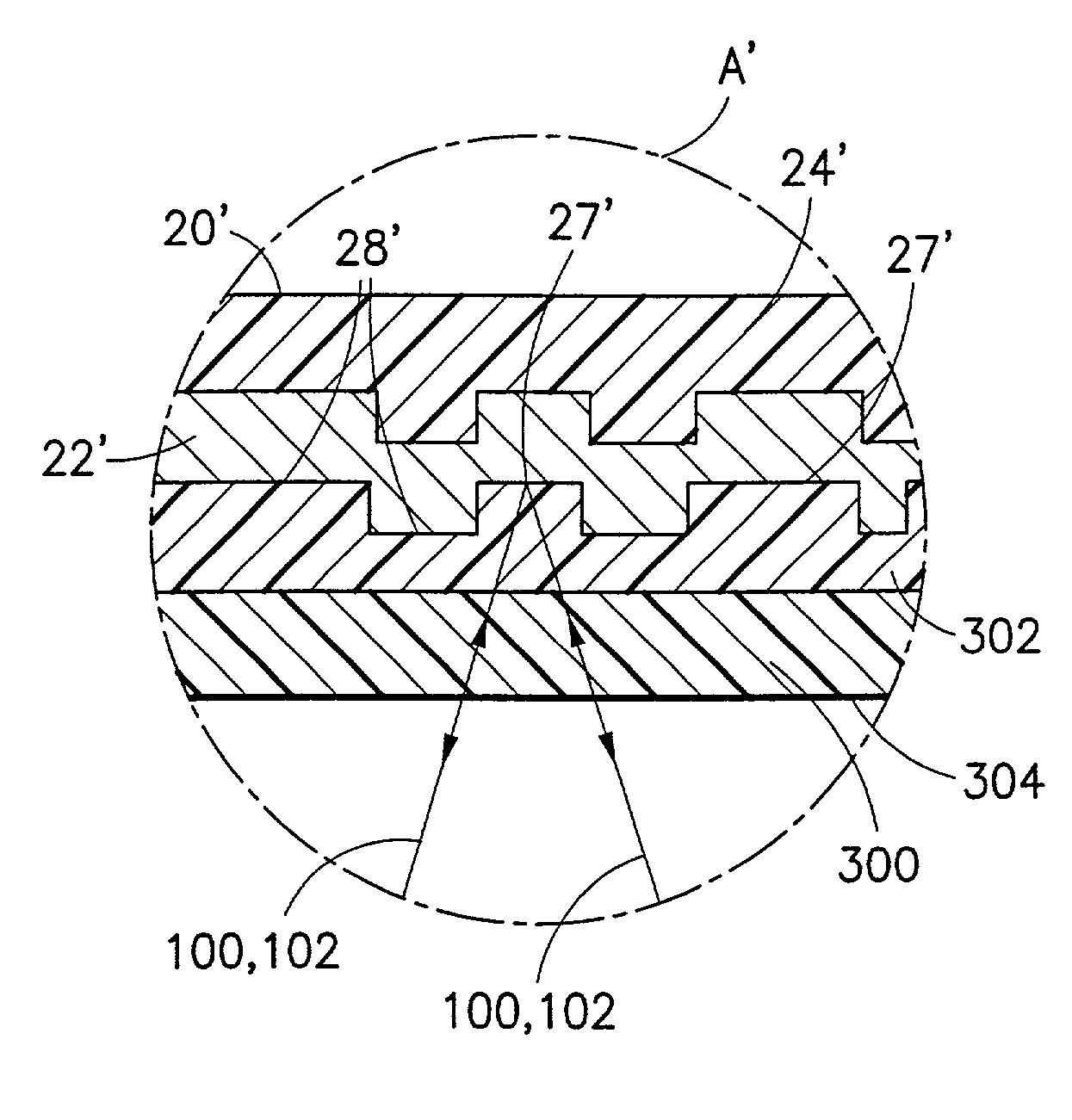

Sample element qualification

InactiveUS20050036146A1Withdrawing sample devicesInvestigating moving sheetsAnalyteElectromagnetic radiation

A sample element includes first and second substantially parallel faces separated by an intermediate member. The parallel faces and the intermediate member at least partially define a sample chamber configured to hold a volume of fluid. The sample element further includes an optical path extending through the parallel faces and the intermediate member, such that electromagnetic radiation can propagate through the sample chamber. The sample element further includes an identifying compound disposed within or on at least one of the parallel faces. The identifying compound has at least one indexed optical absorbance feature, such that spectral analysis of electromagnetic radiation propagated through the sample chamber yields the indexed optical absorbance feature. Detection of the indexed optical absorbance feature in electromagnetic radiation propagated through the sample chamber indicates to an analyte detection system whether the sample element is configured for use with the analyte detection system.

Owner:OPTISCAN BIOMEDICAL

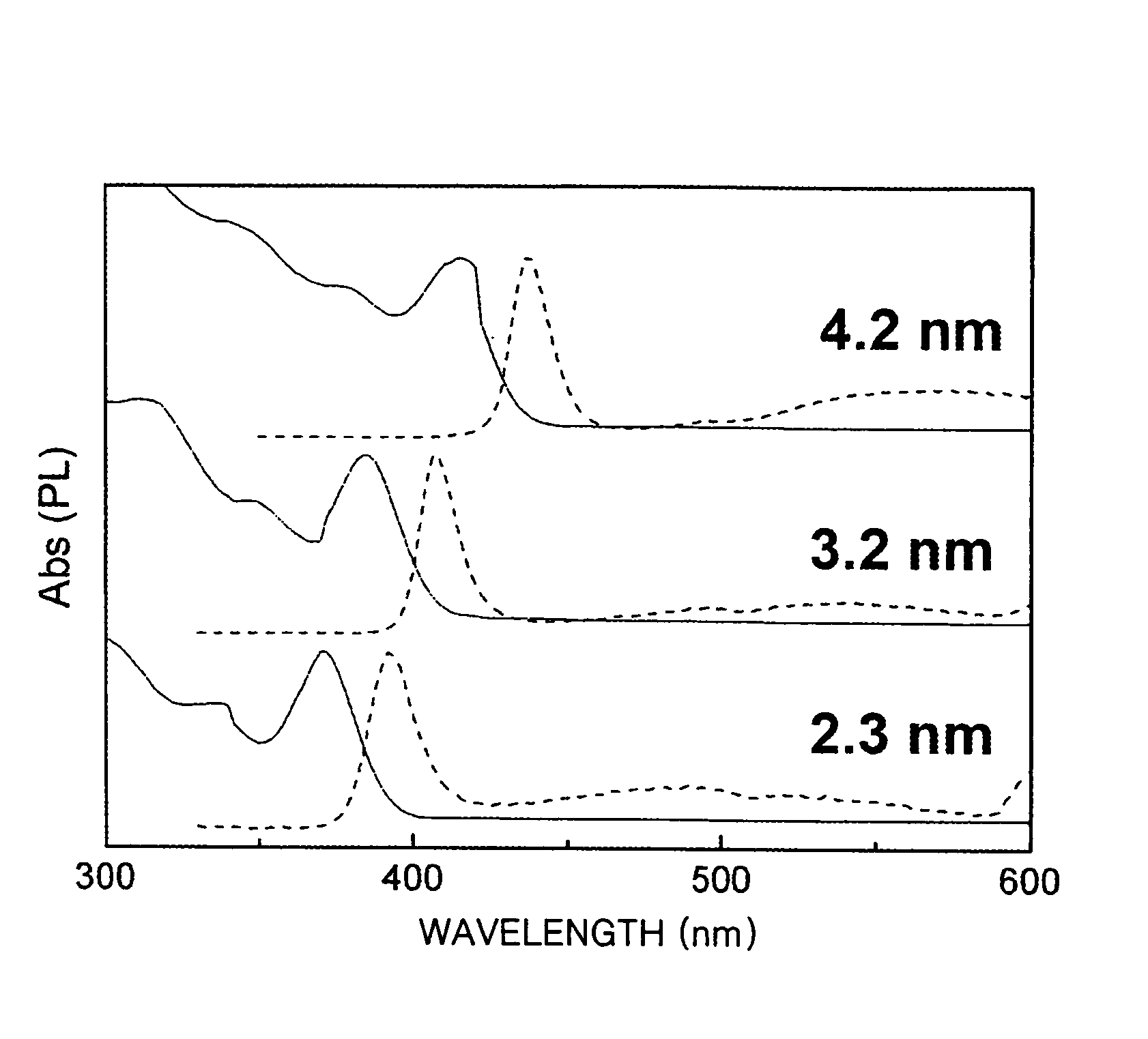

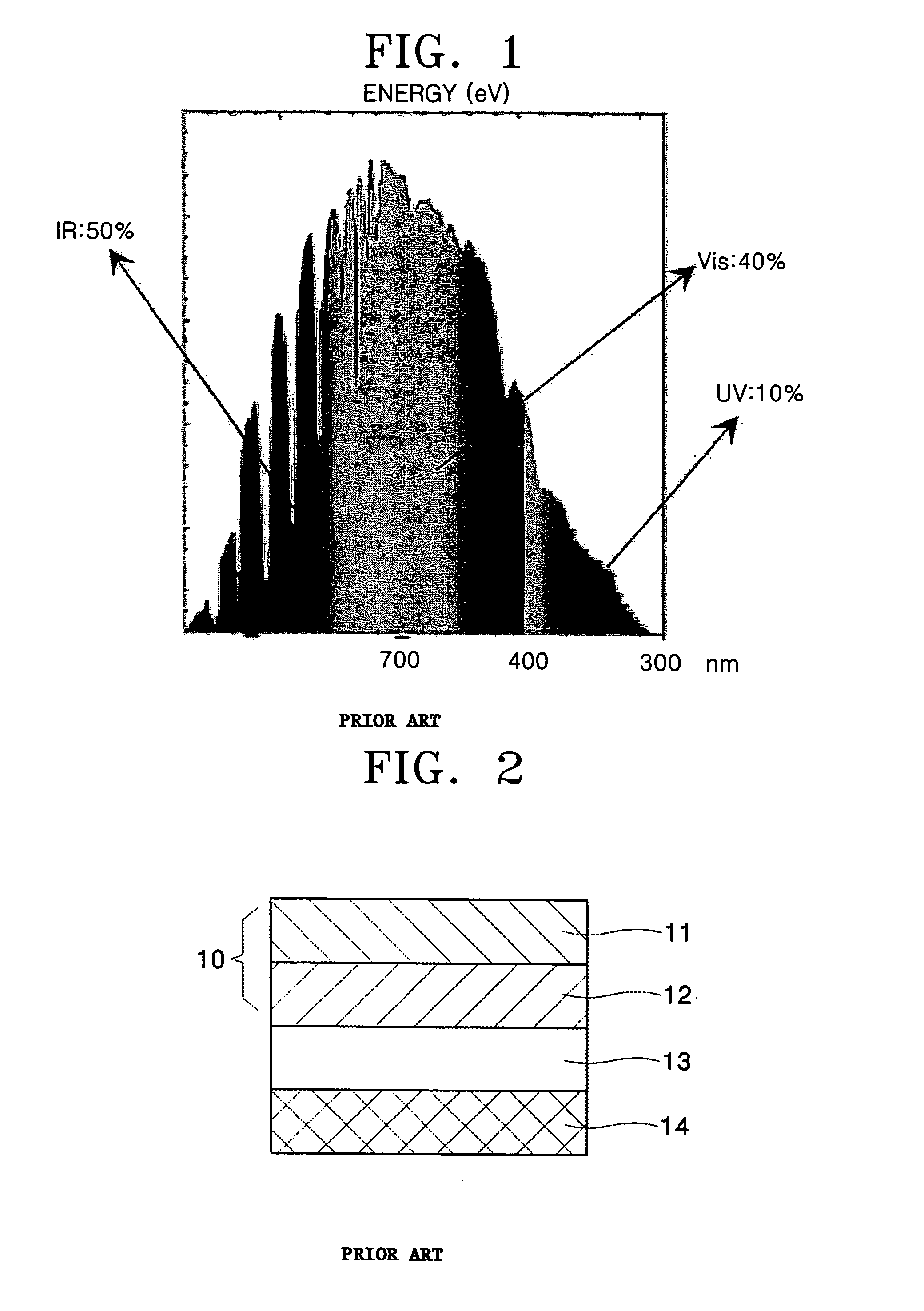

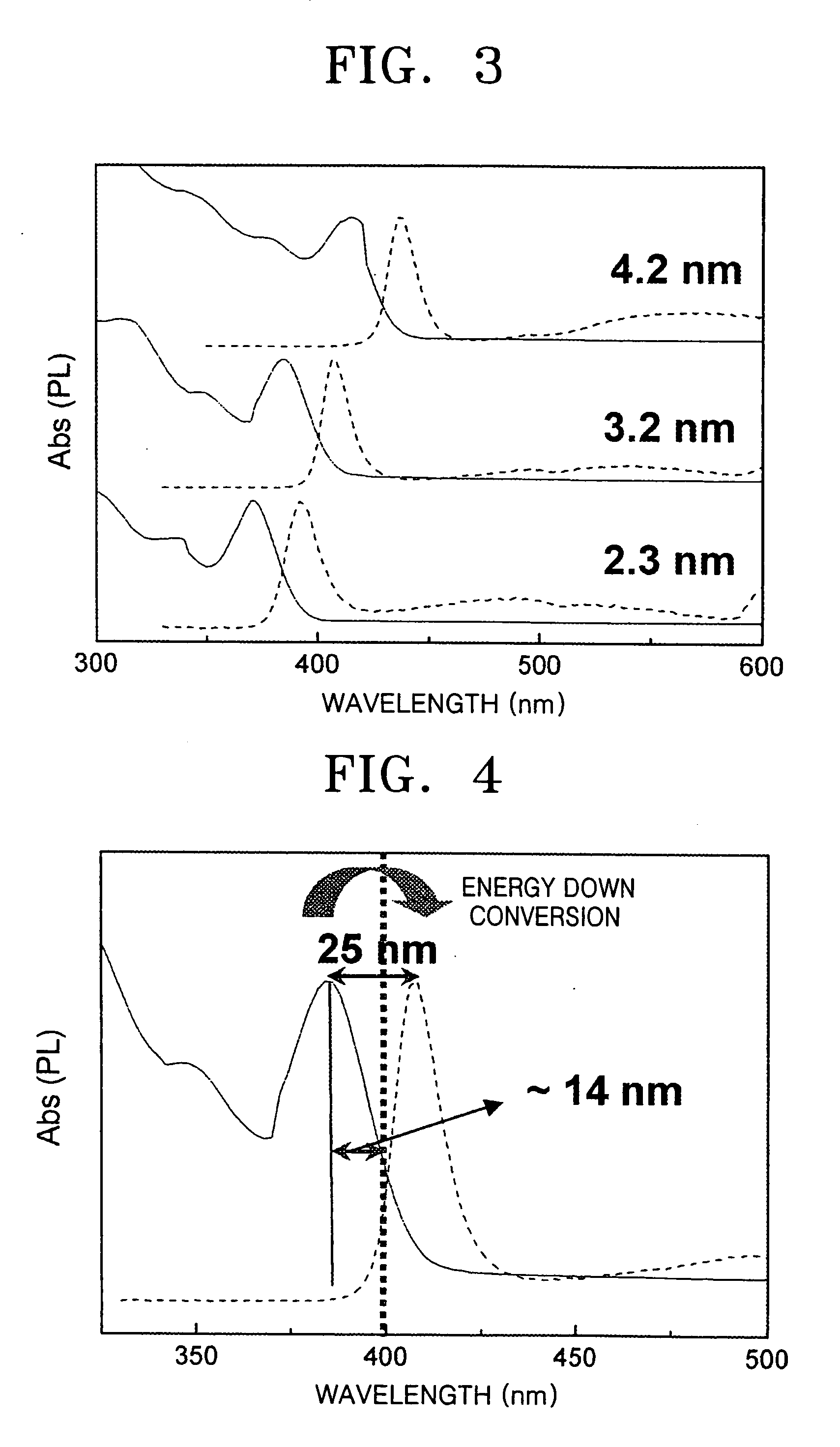

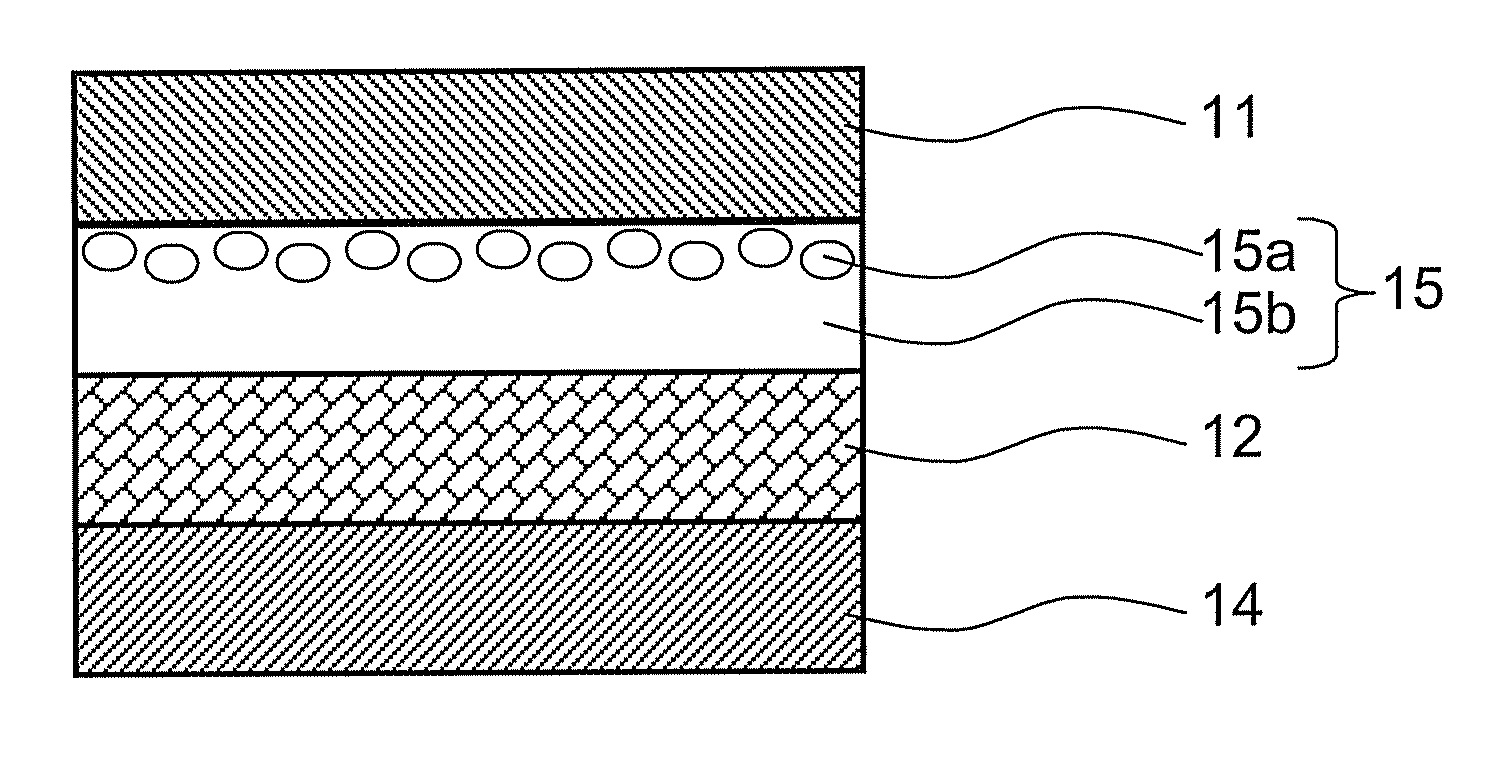

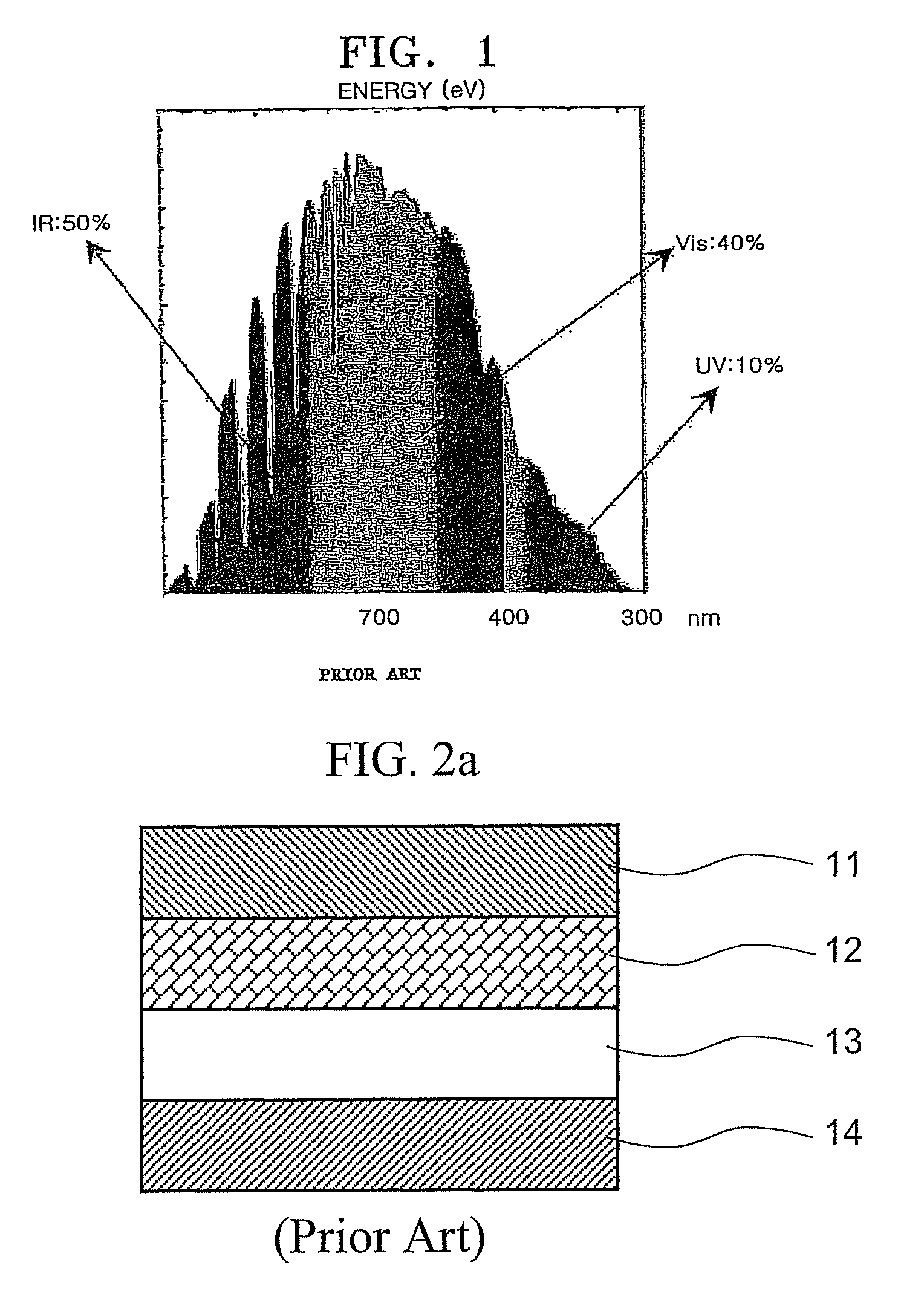

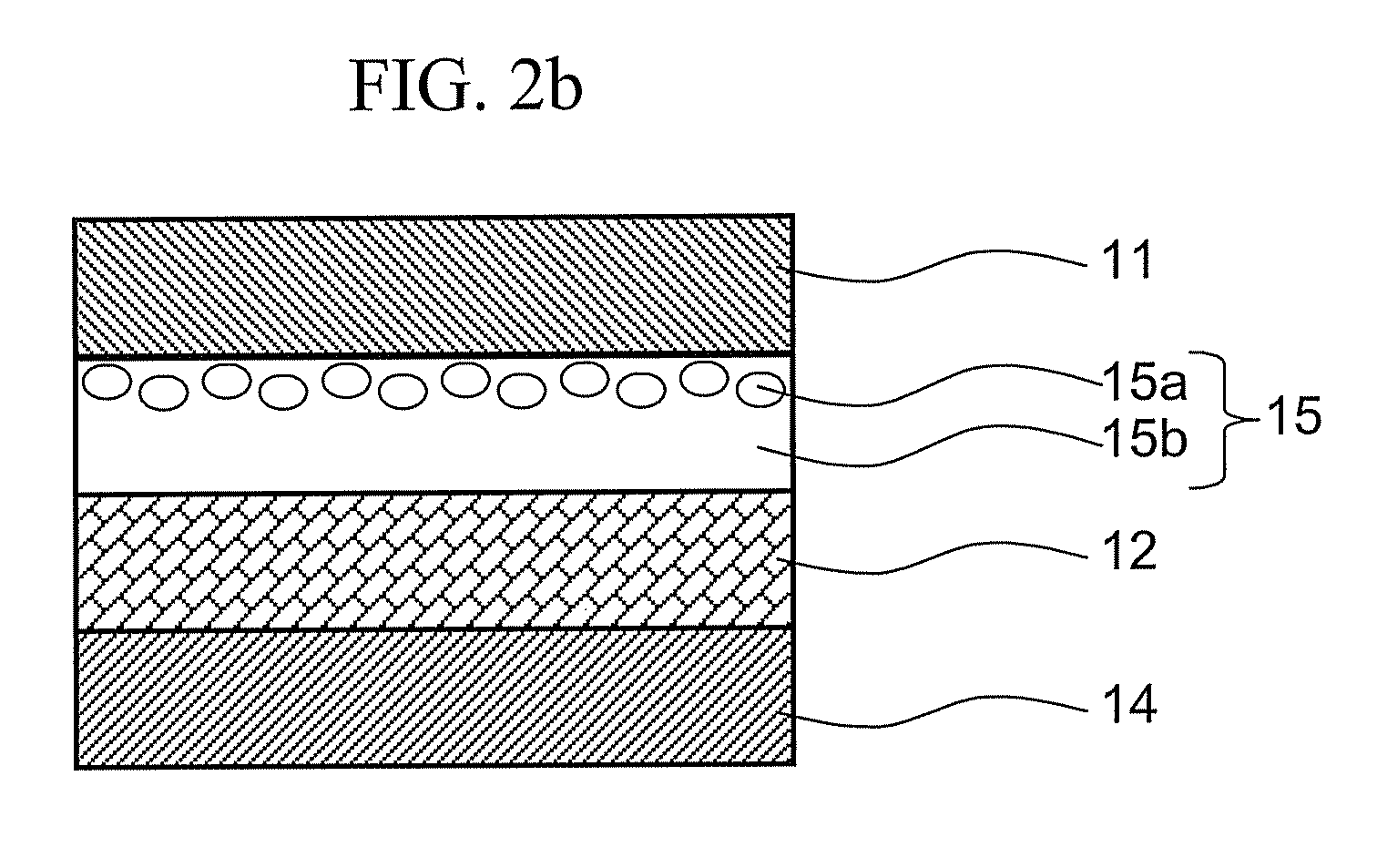

Energy conversion film and quantum dot film comprising quantum dot compound, energy conversion layer including the quantum dot film, and solar cell including the energy conversion layer

ActiveUS20060169971A1Improve energy efficiencyHigh solar efficiencyElectrolytic capacitorsFinal product manufactureHigh energySolar cell

An energy conversion film and a quantum dot film which contain a quantum dot compound, an energy conversion layer including the quantum dot film, and a solar cell including the energy conversion layer. The films act as cut-off filters blocking light of a particular energy level using the light absorption and emission effects of quantum dots and can convert high energy light to low energy light. The efficiency of a solar cell may be improved by providing the cell with a film that converts light above the spectrum-responsive region to light in the cell's spectrum-responsive region. The absorption wavelength region of the films can be broadened by providing the quantum dot compound in a variety of average particle sizes, for example, by providing a mixture of a first quantum dot compound having a first average particle size and a first quantum dot compound having a second average particle size.

Owner:SAMSUNG ELECTRONICS CO LTD

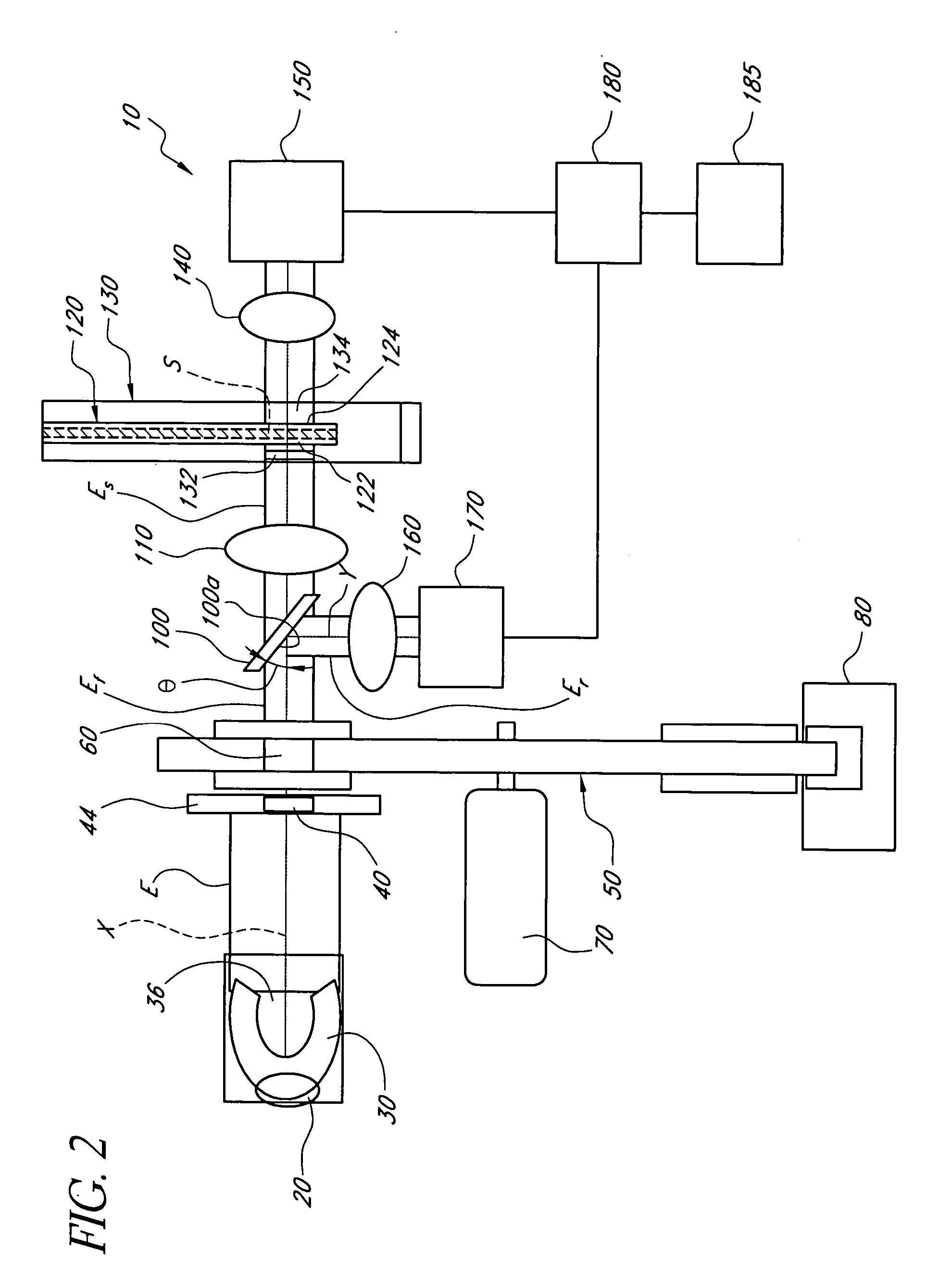

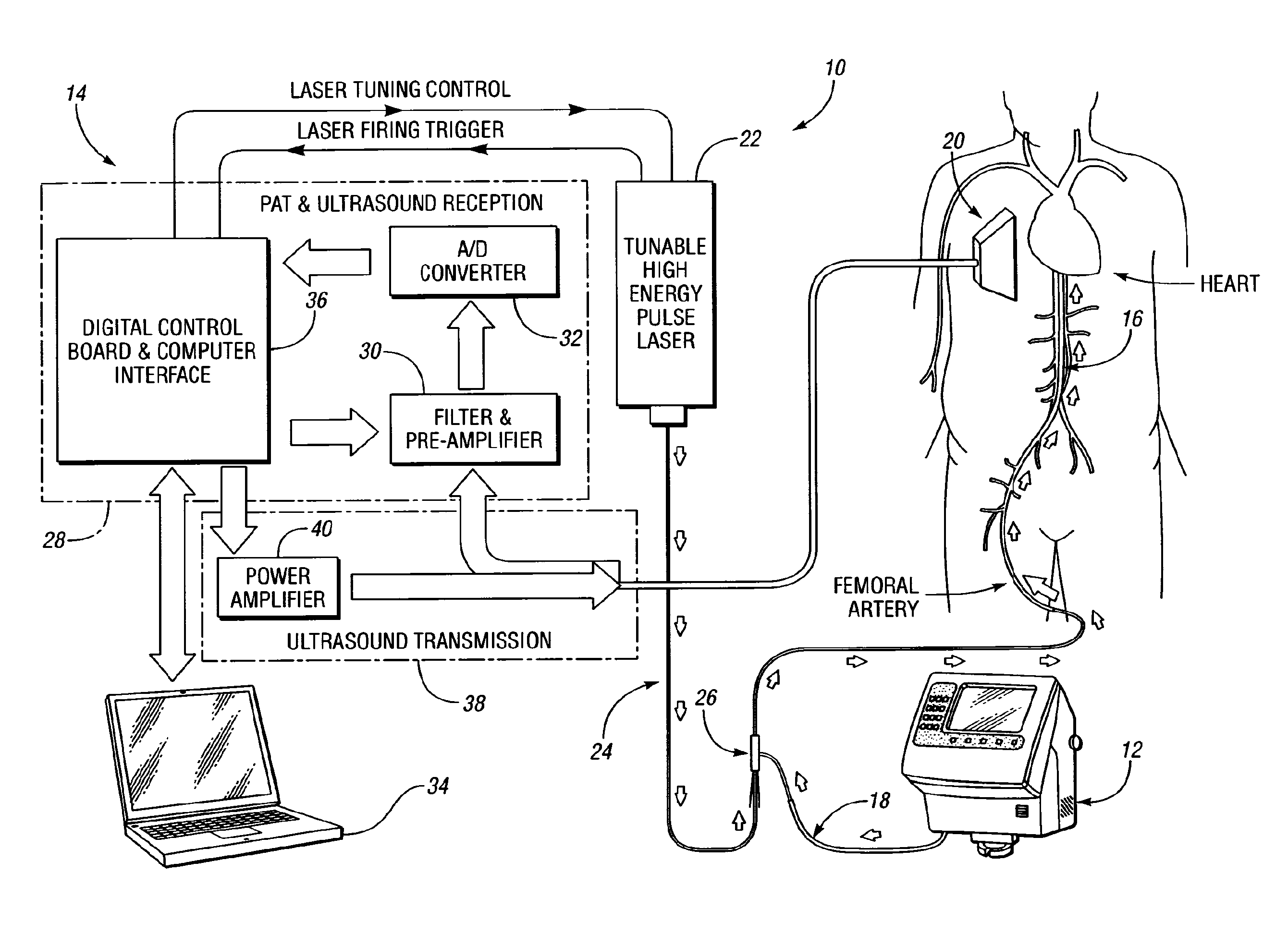

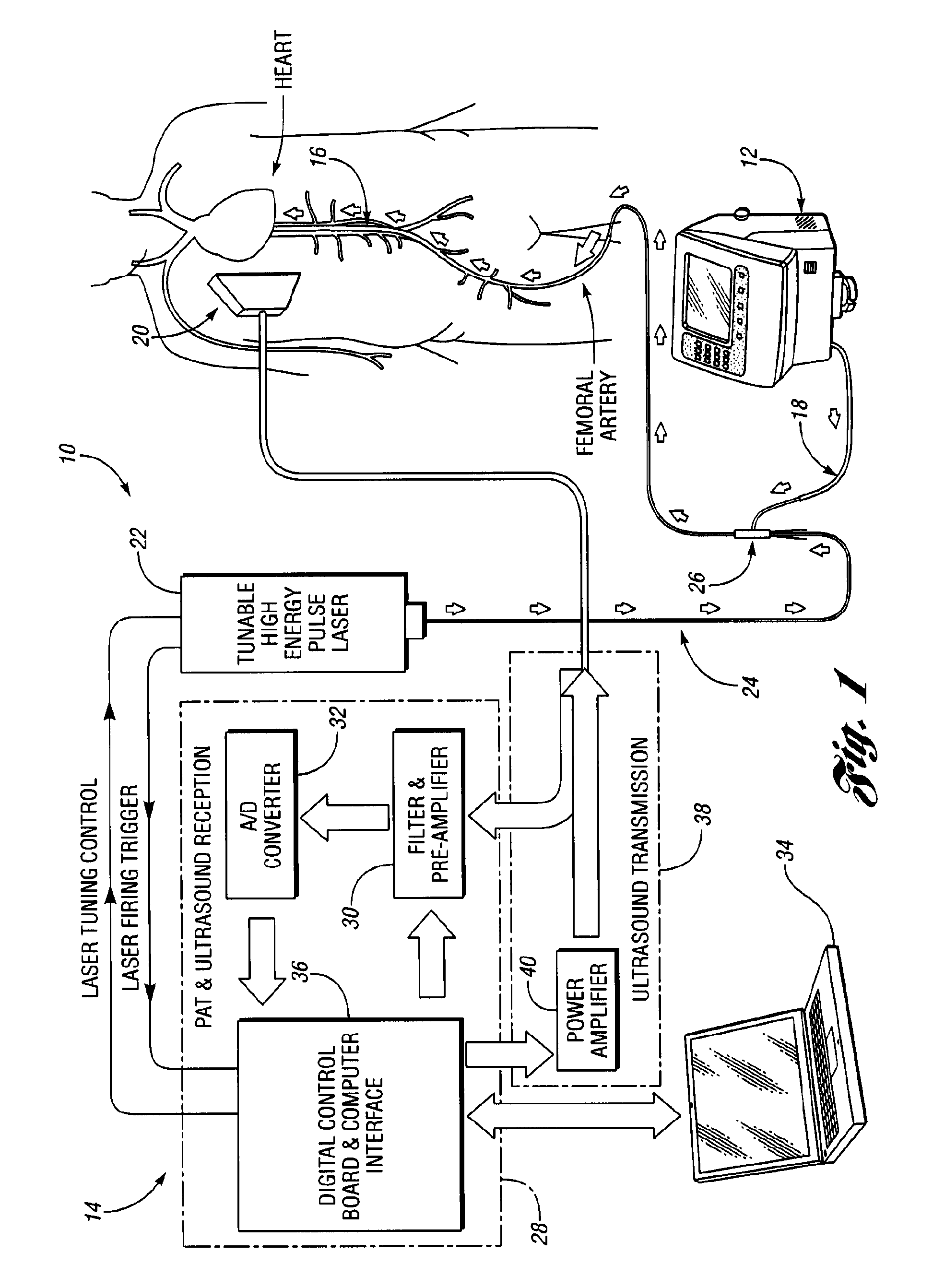

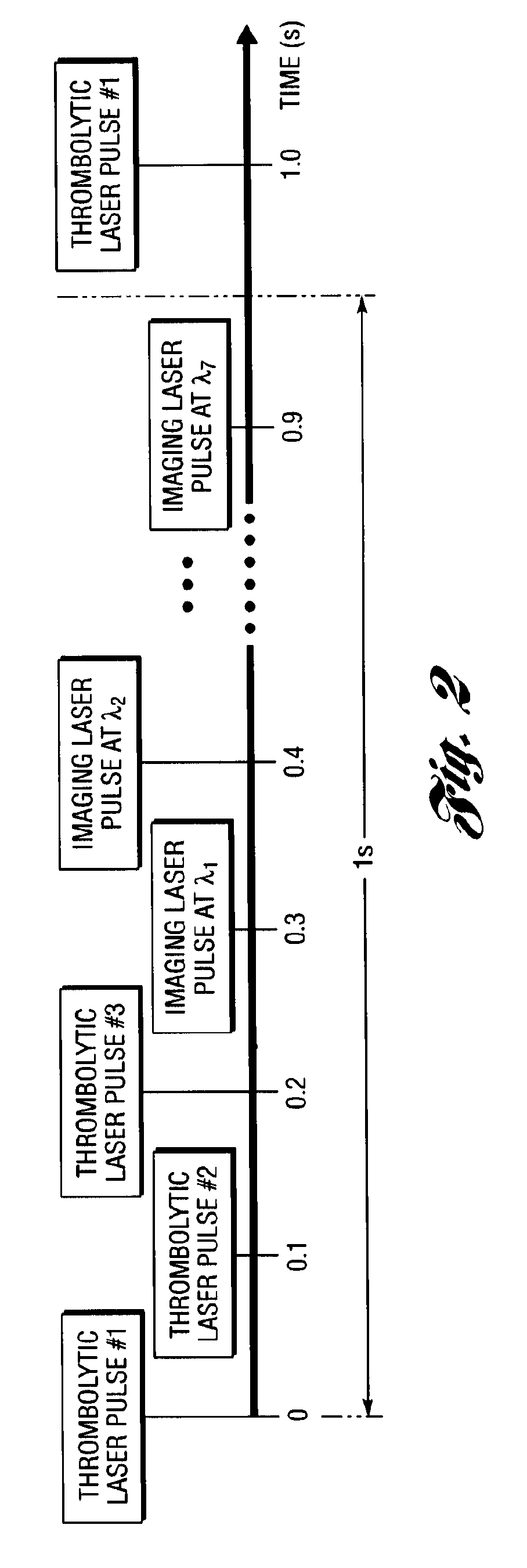

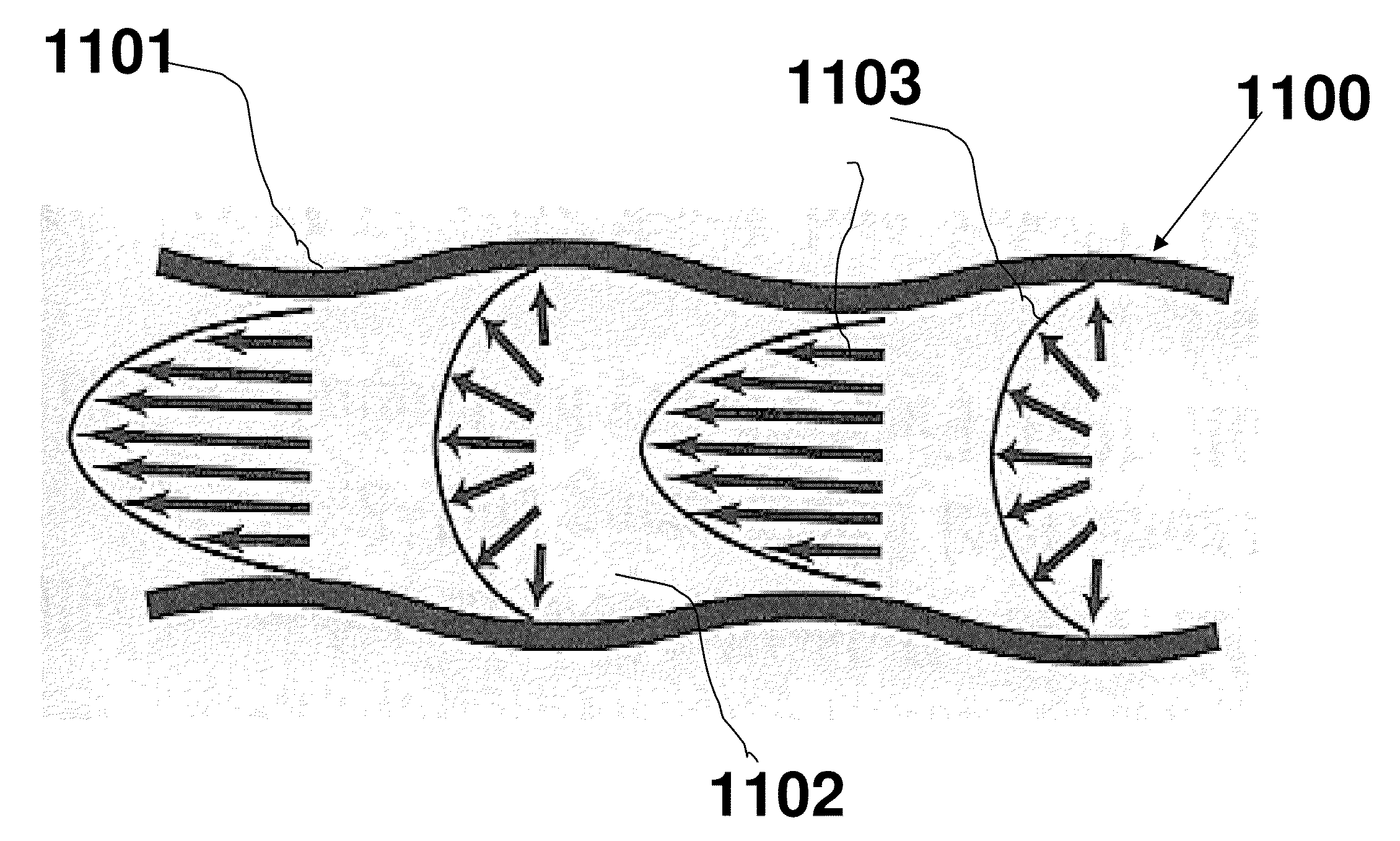

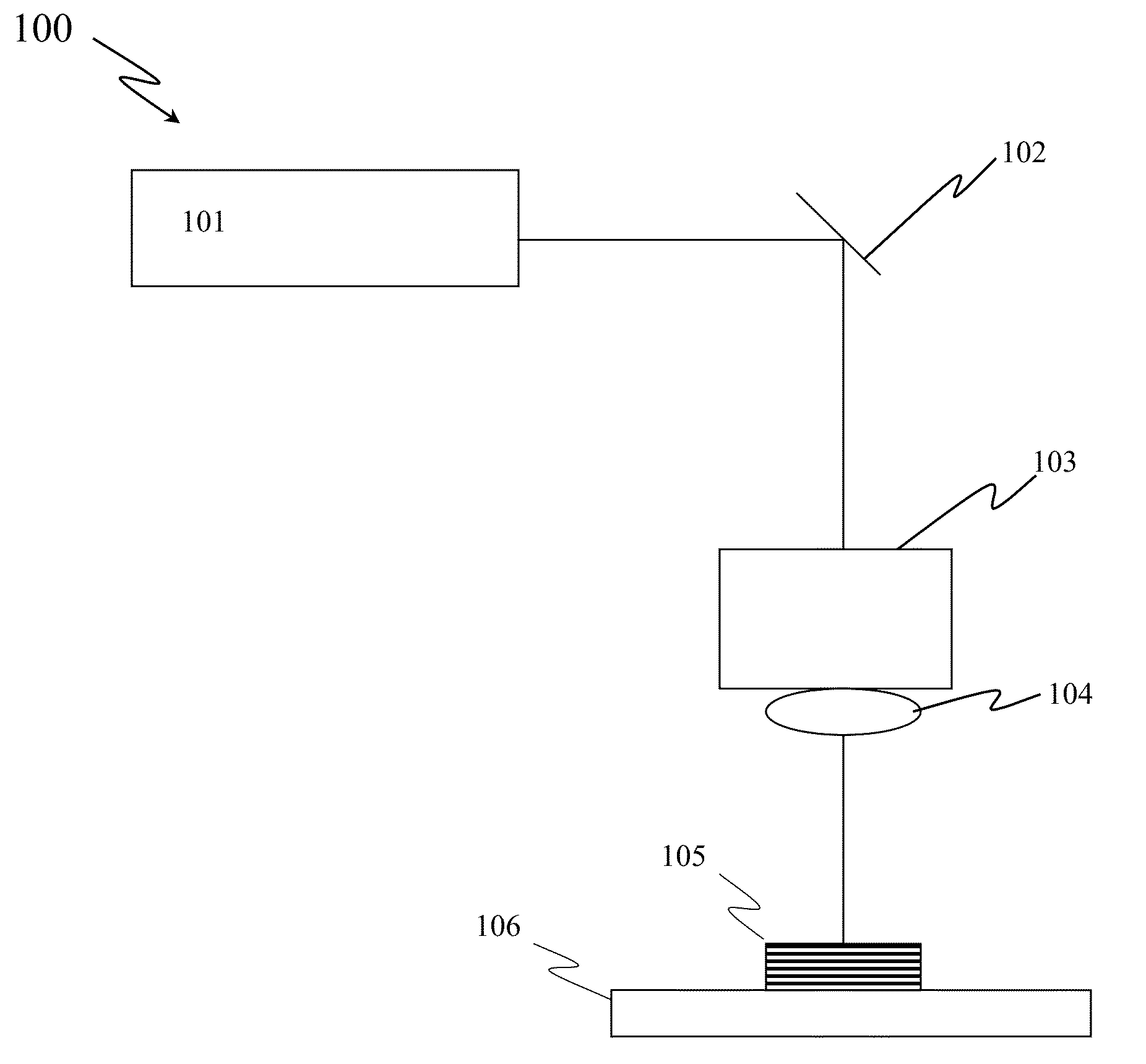

System and method for photoacoustic imaging and monitoring of laser therapy

InactiveUS20090227997A1Control damageEasy to controlUltrasonic/sonic/infrasonic diagnosticsCatheterTherapy controlTomographic image

A system and method for monitoring laser therapy of a target tissue include a therapeutic control unit having a first light source configured to deliver light to the target tissue for therapy, an ultrasonic transducer for receiving photoacoustic signals generated due to optical absorption of light energy by the target tissue, and a monitoring control unit in communication with the ultrasonic transducer for reconstructing photoacoustic tomographic images from the received photoacoustic signals to provide an optical energy deposition map of the target tissue. A second light source utilized for imaging may also be provided.

Owner:THE RGT OF THE UNIV OF MICHIGAN

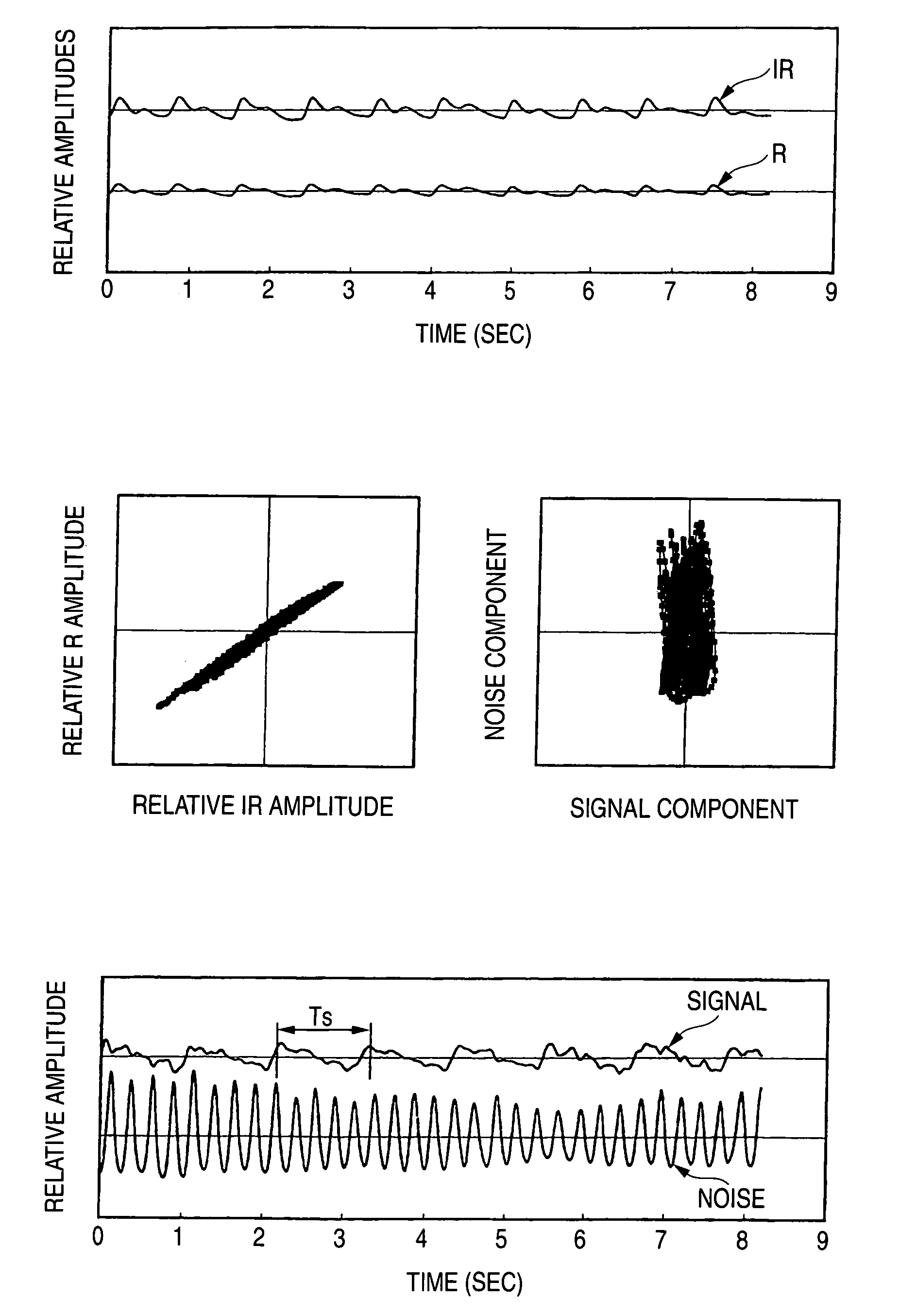

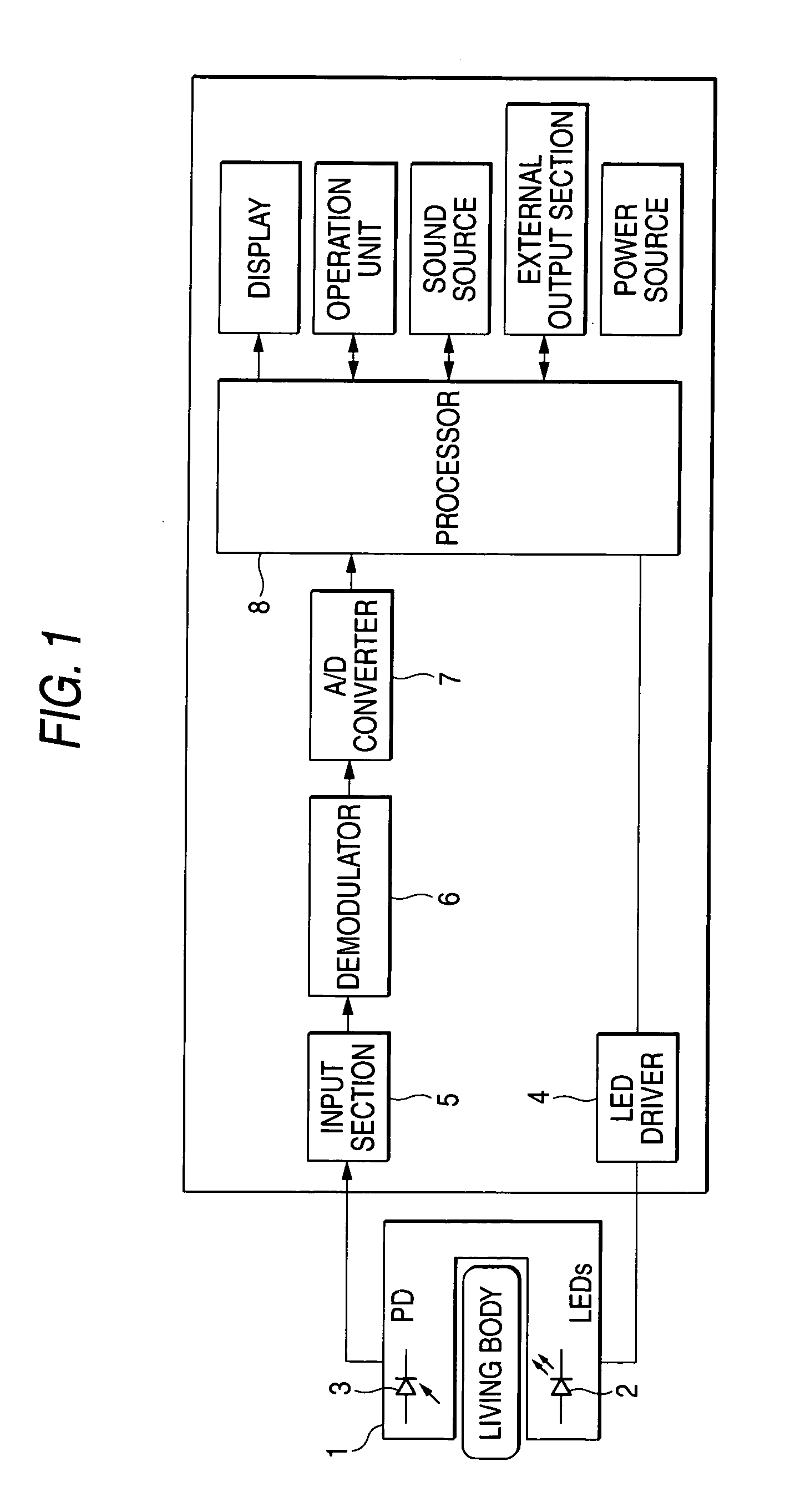

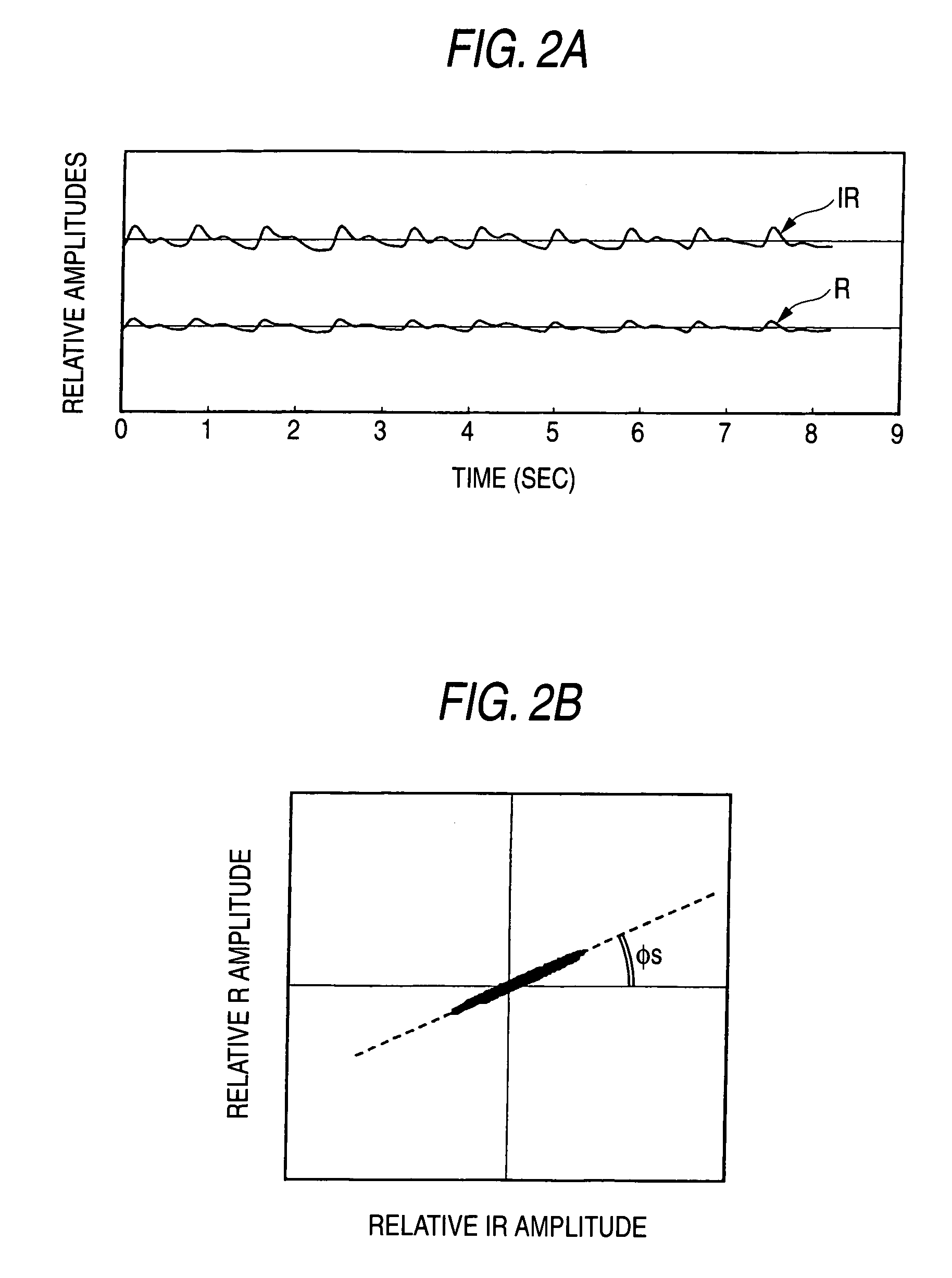

Method for reducing noise, and pulse photometer using the method

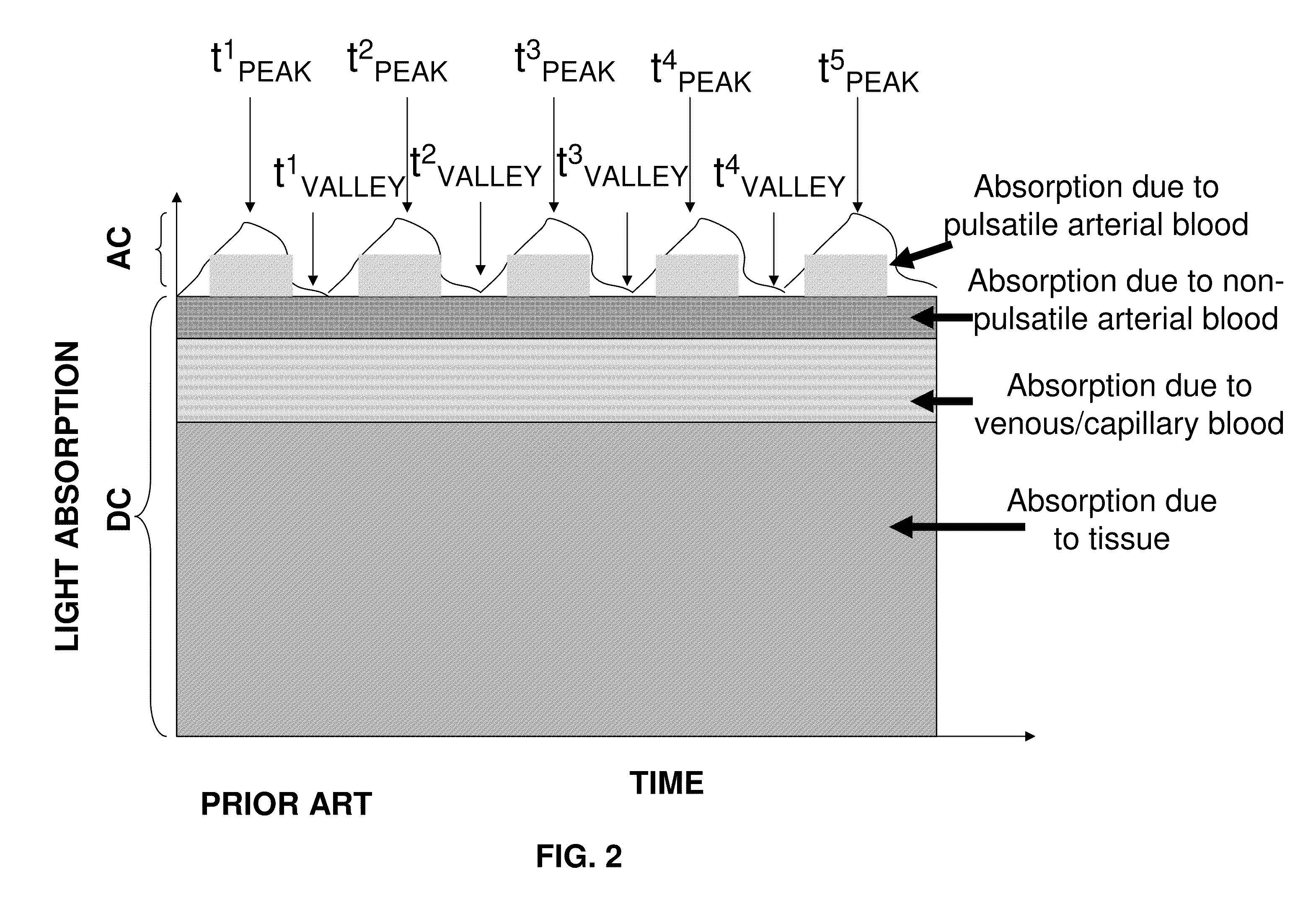

A living body is irradiated with a first light beam having a first wavelength and a second light beam having a second wavelength which is different from the first wavelength. The first light beam and the second light beam, which have been reflected or transmitted from the living body, are converted into a first electric signal corresponding to the first wavelength and a second electric signal corresponding to the second wavelength, as the observed pulse data. A light absorbance ratio obtained from the first electric signal and the second electric signal is computed, for each one of frequency ranges dividing an observed frequency band. It is determined that noise is not mixed into the observed pulse wave data in a case where a substantial match exists among light absorbance ratios computed for the respective frequency ranges.

Owner:NIHON KOHDEN CORP

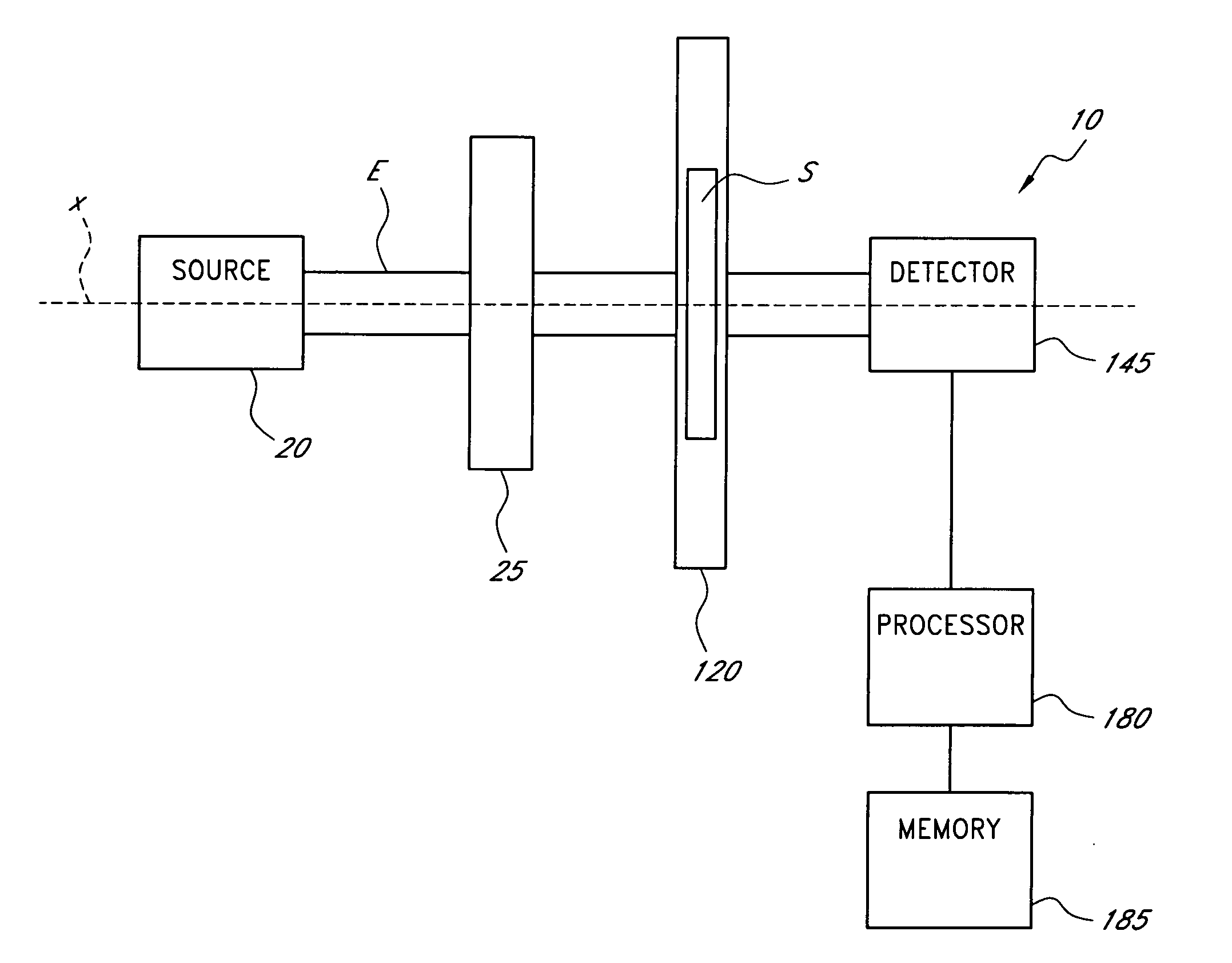

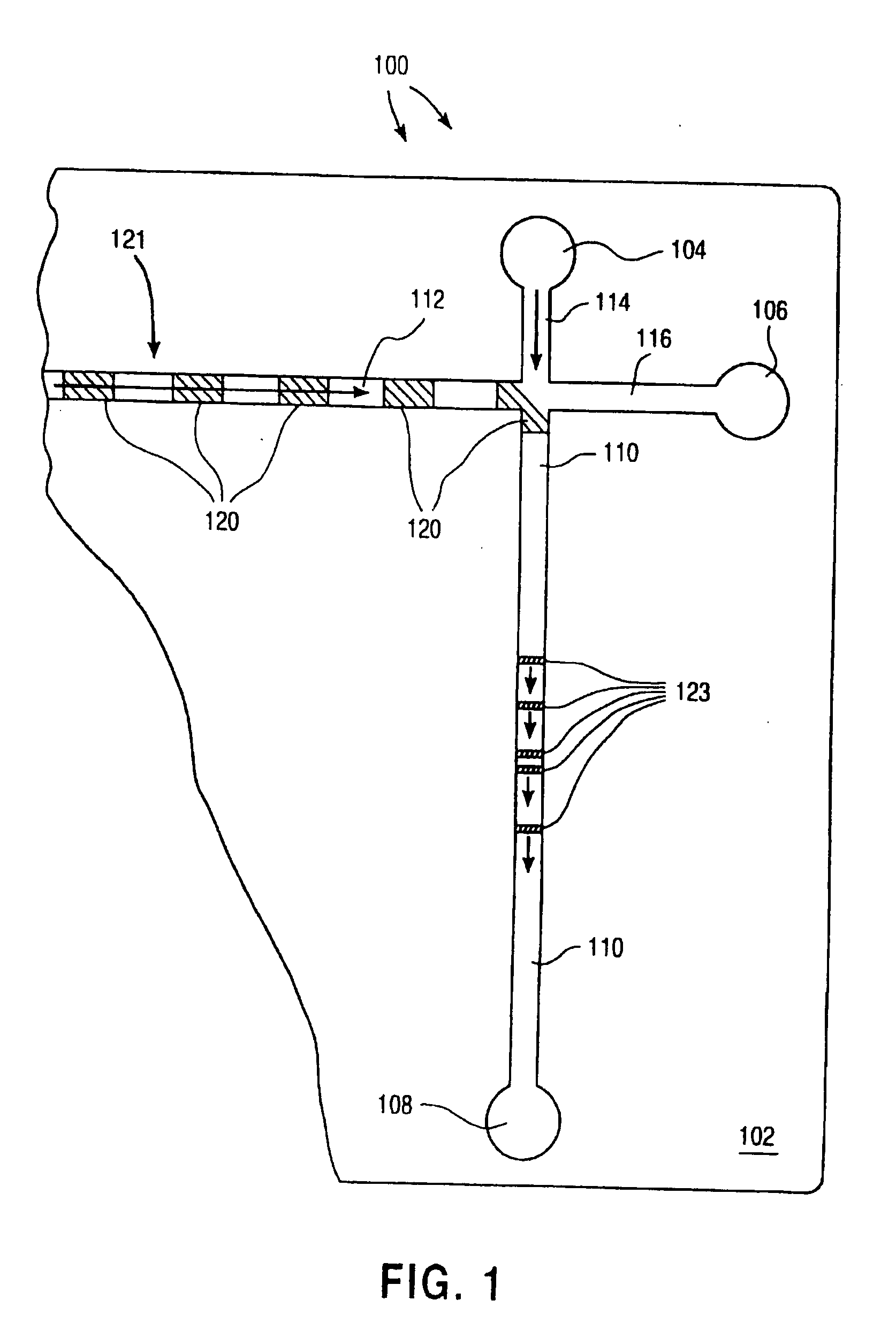

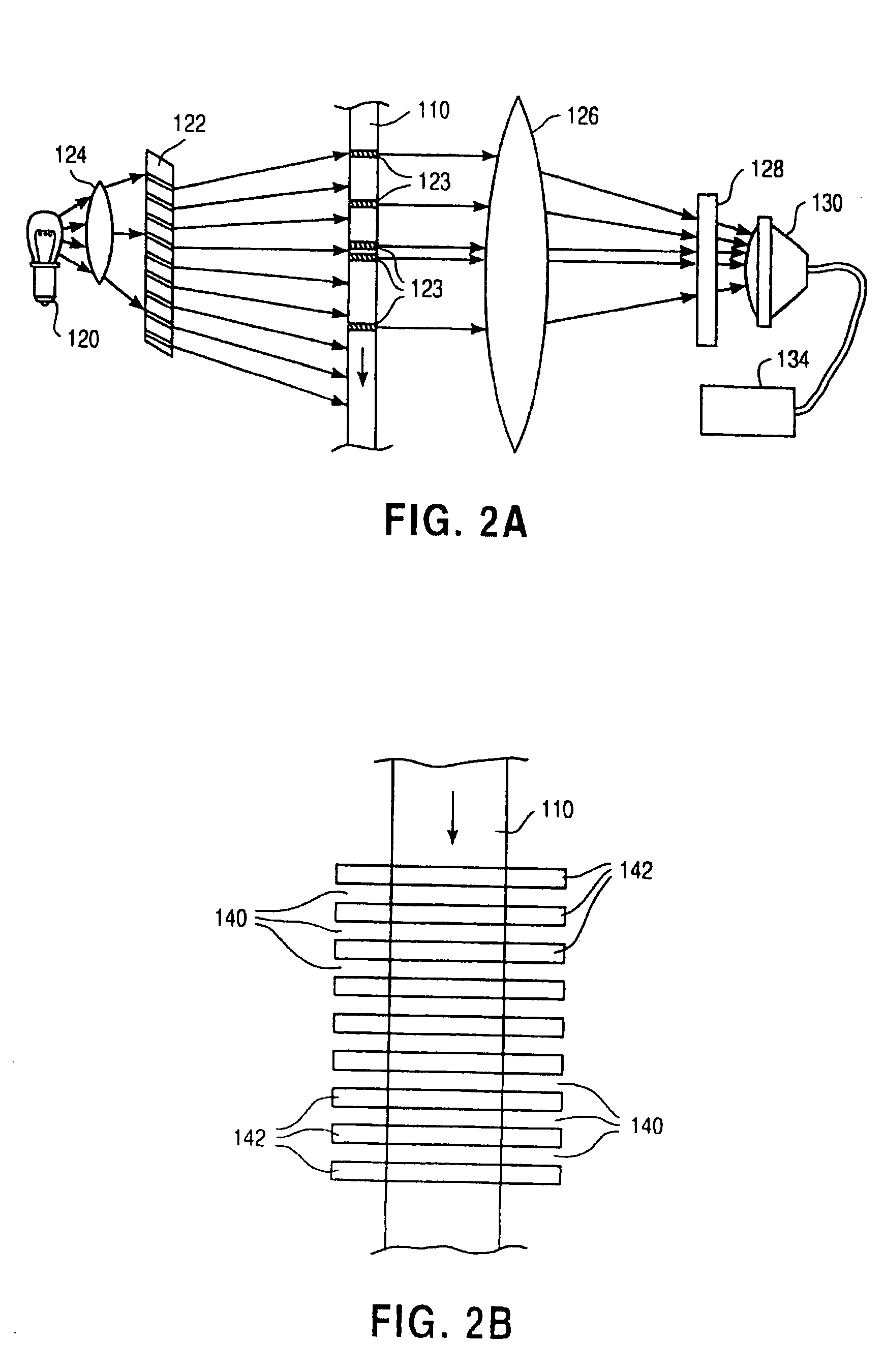

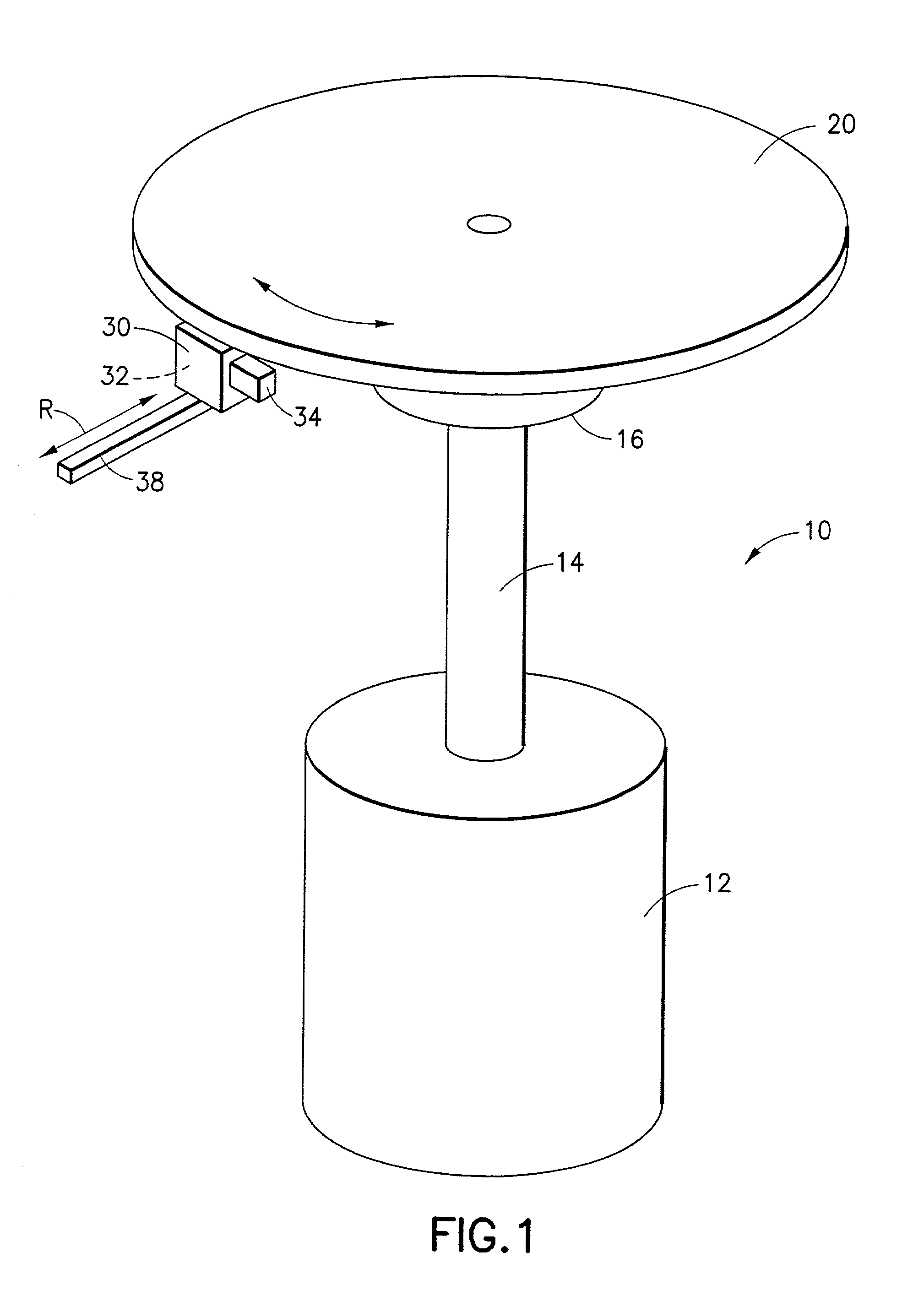

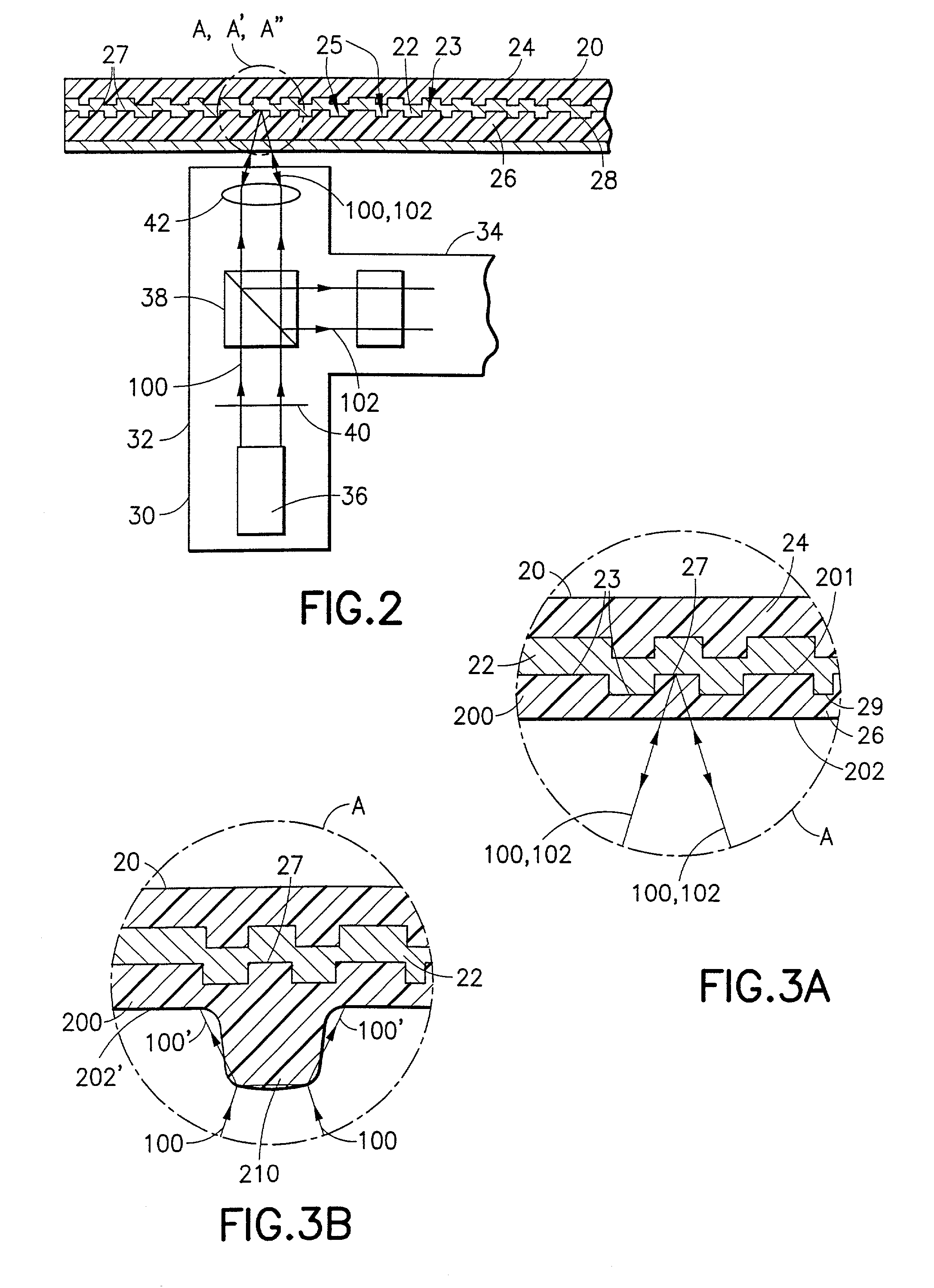

Microfluidic devices for electrophoretic analysis of materials

InactiveUS20070177147A1High-speed analysisOther chemical processesMaterial analysis by optical meansPhotovoltaic detectorsPhotodetector

The present invention provides a microfluidic system for electrophoretic analysis of materials in the fields of chemistry, biochemistry, biotechnology, molecular biology and numerous other fields. Light absorbance signals are received by a photodetector from periodically spaced regions along a channel in the microfluidic system. The signals received by the photodetector are modulated by the movement of species bands through the channel under electrophoretic forces. By Fourier analysis, the velocity of each species band is determined, and identification of the species is made based on its electrophoretic mobility in the channel.

Owner:CAPLIPER LIFE SCI INC

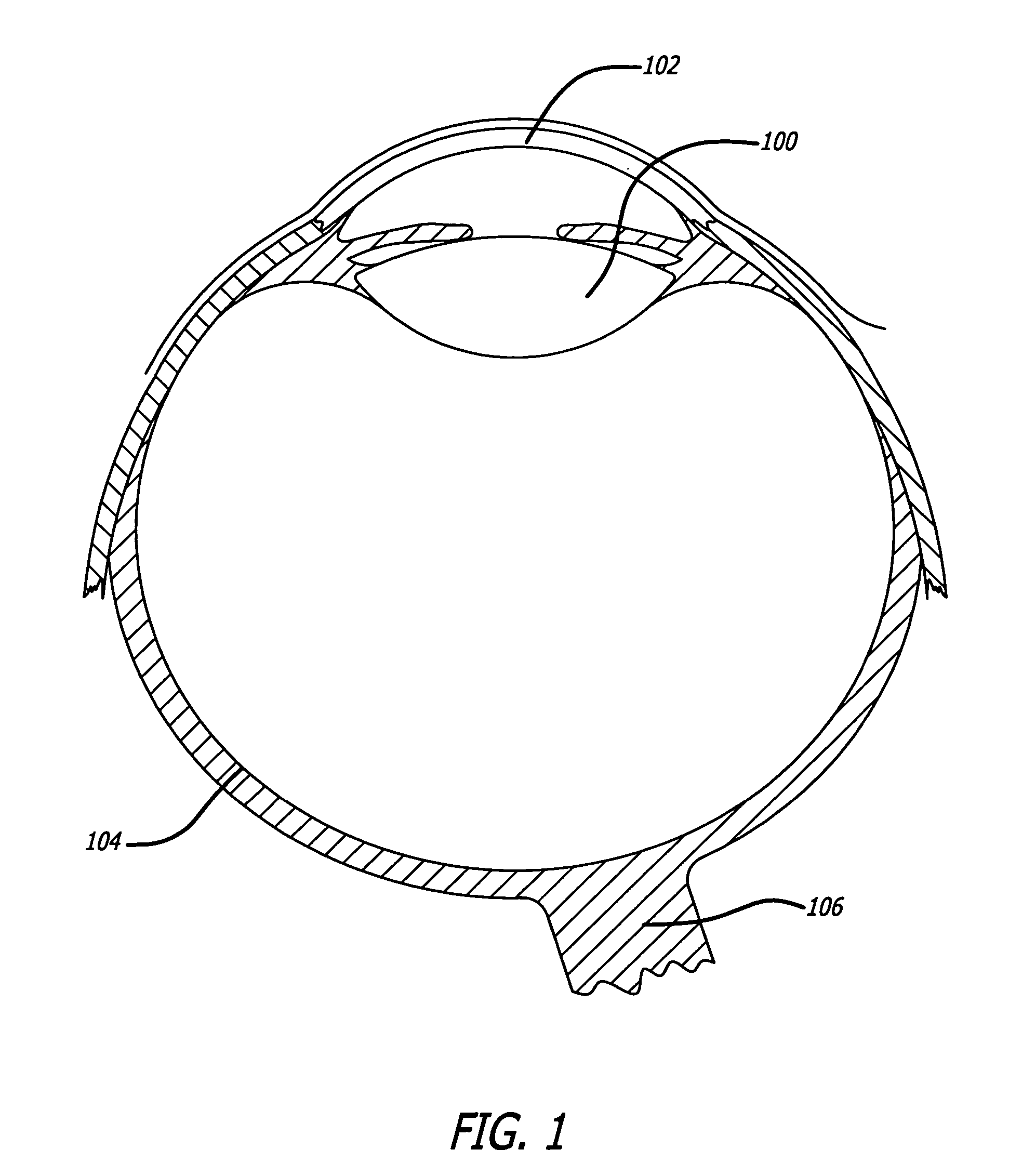

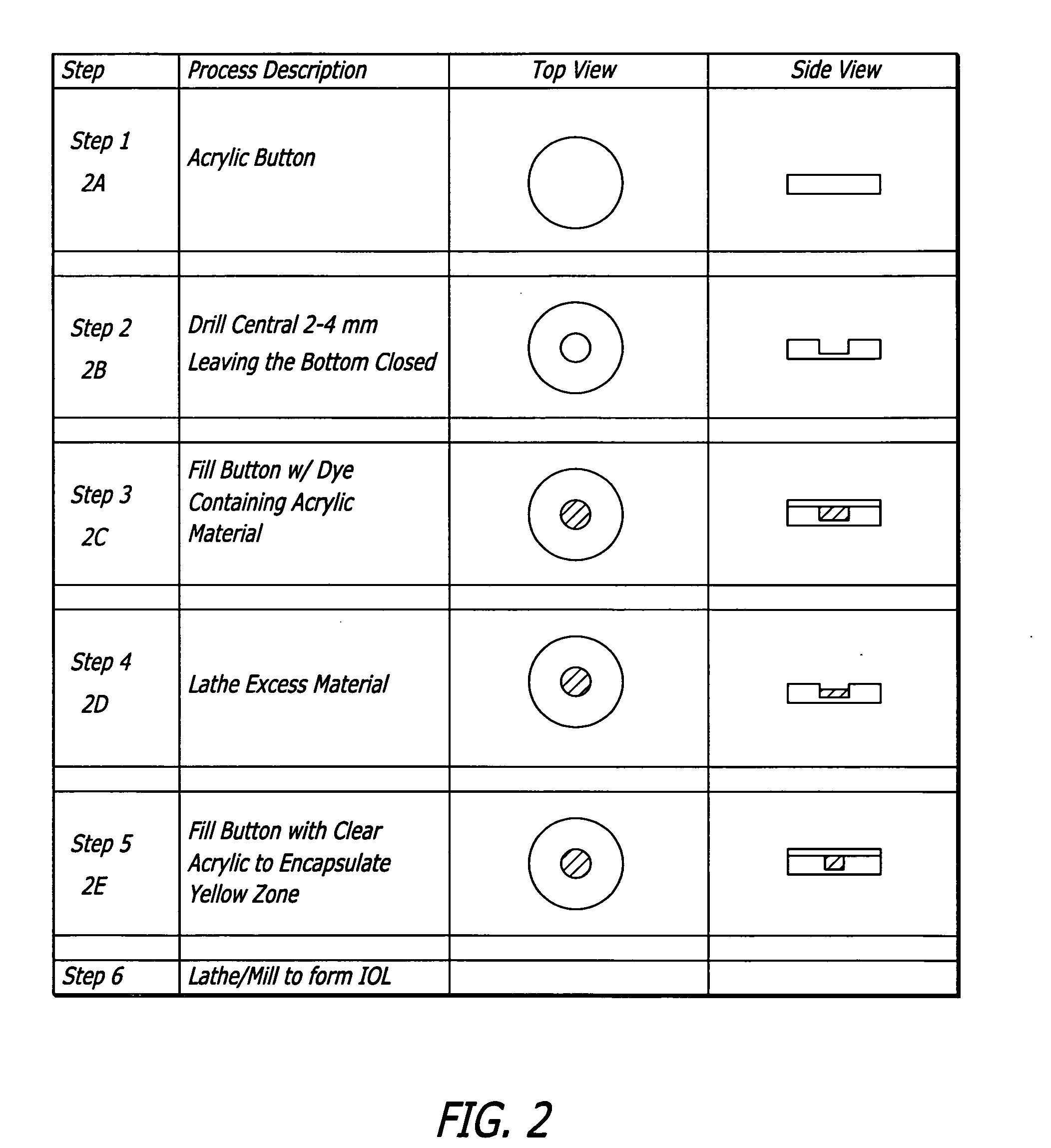

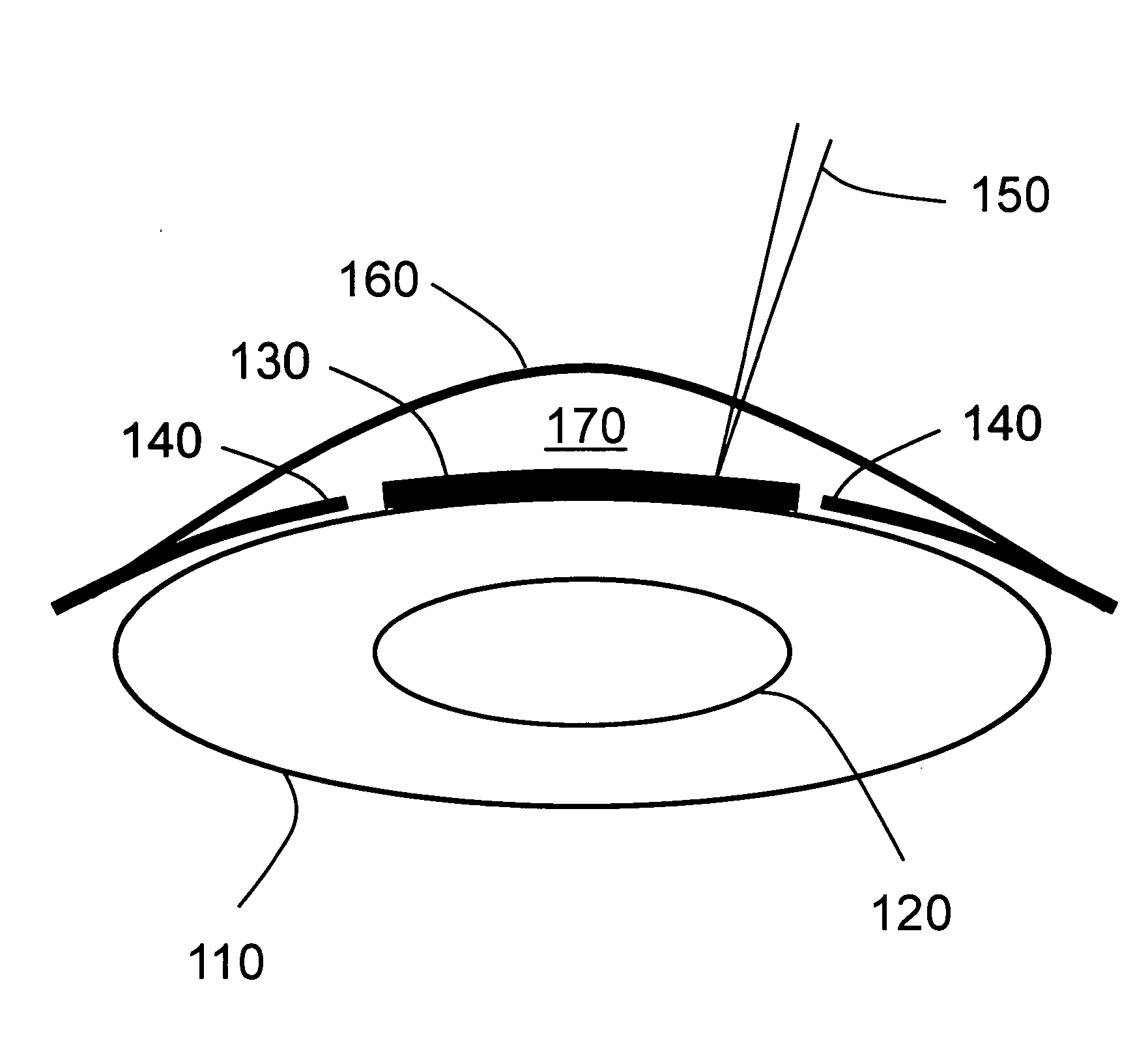

Intraocular lenses having a visible light-selective-transmissive-region

ActiveUS20050143812A1Maximum protectionImprove eyesightOptical articlesIntraocular lensBlue lightVisible spectrum

Intraocular lenses are provided having a visible-light selective transmissive zone defined therein. The visible light-selective transmissive zone can be located near the lens center and designed to reduce the transmission of any wave-length of visible light specifically light in the blue light region having wavelength between approximately 400 λ to 550 λ. In one embodiment he IOLs are made from acrylates and the light absorbing compound is a yellow dye.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

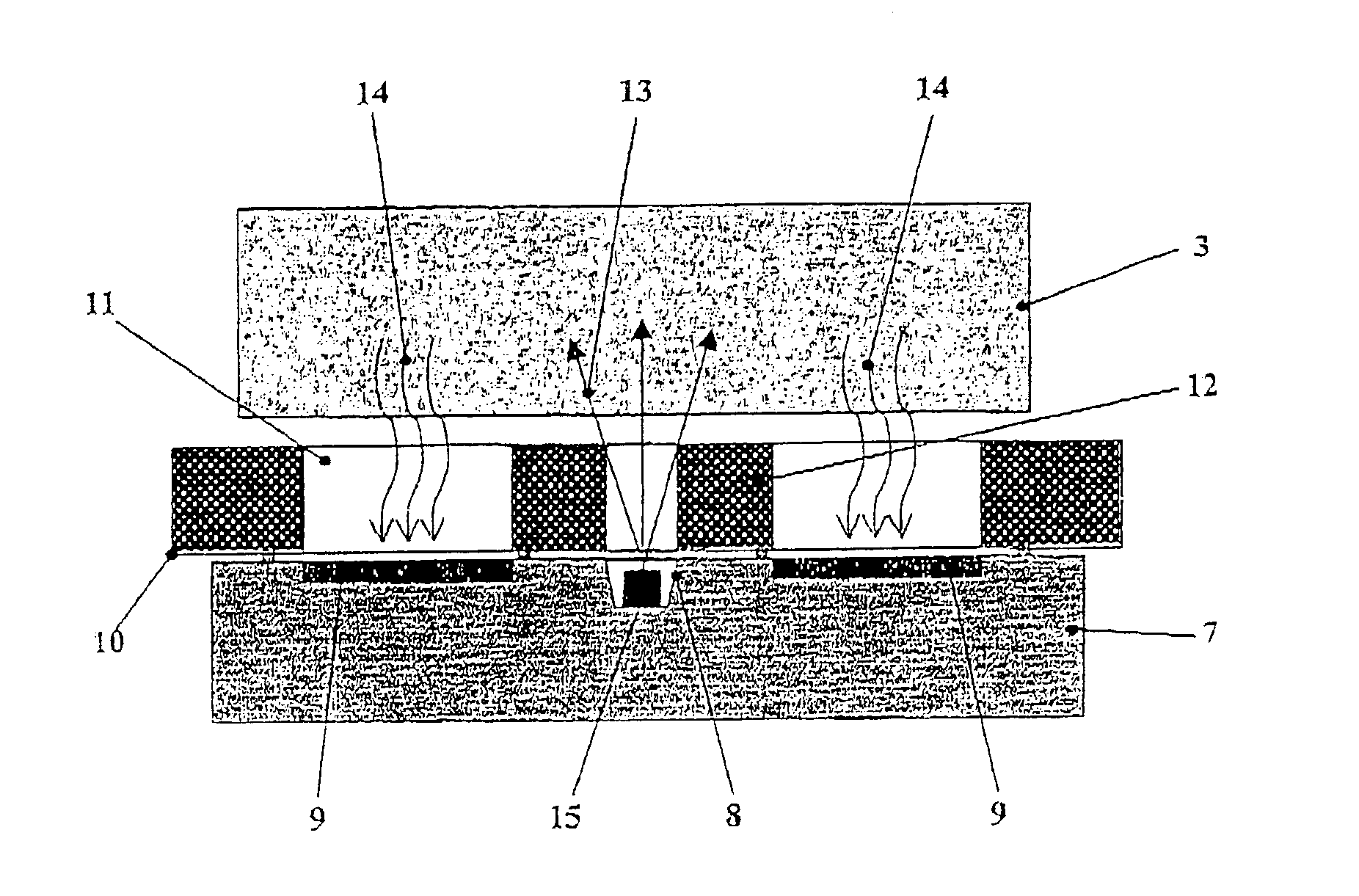

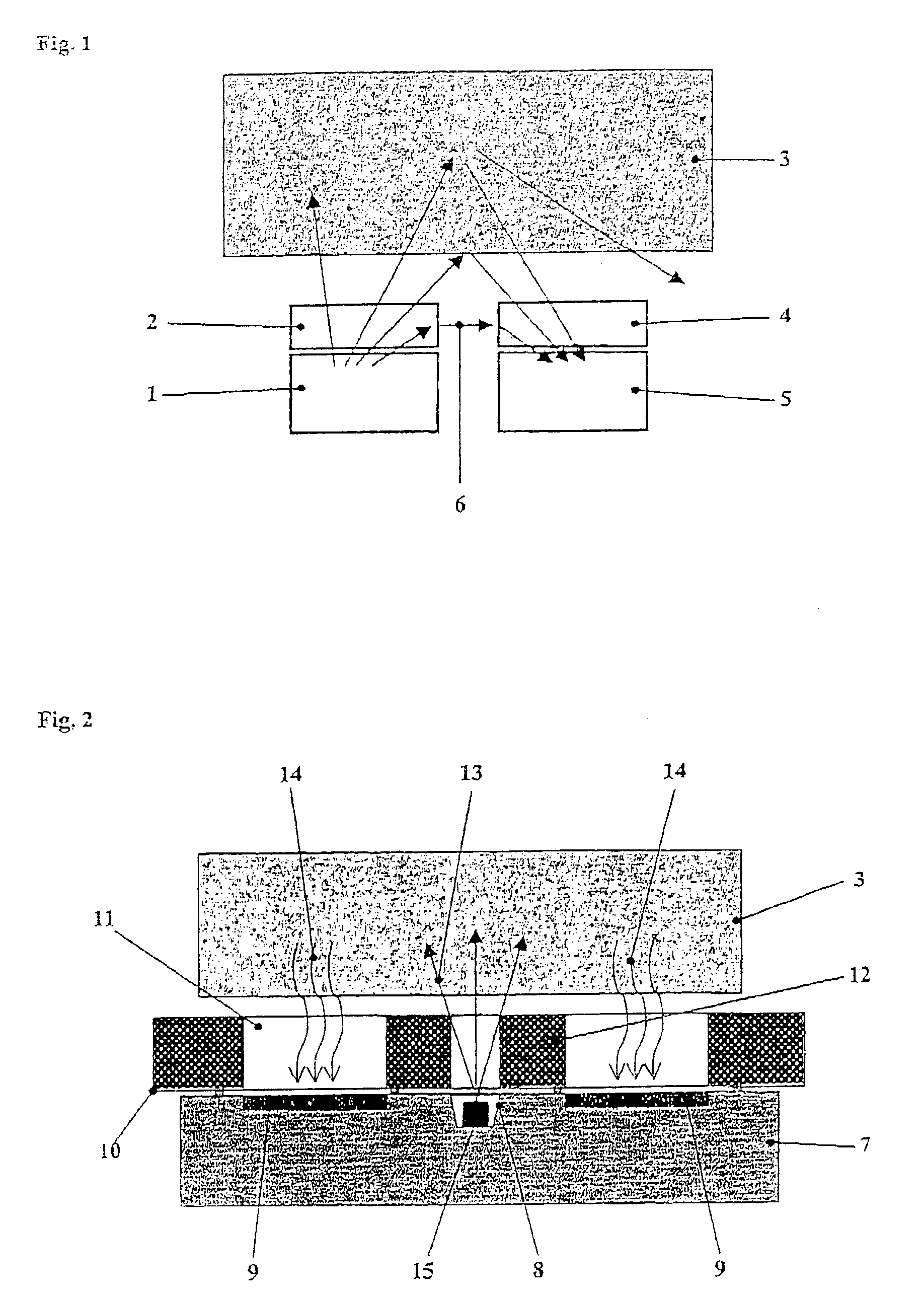

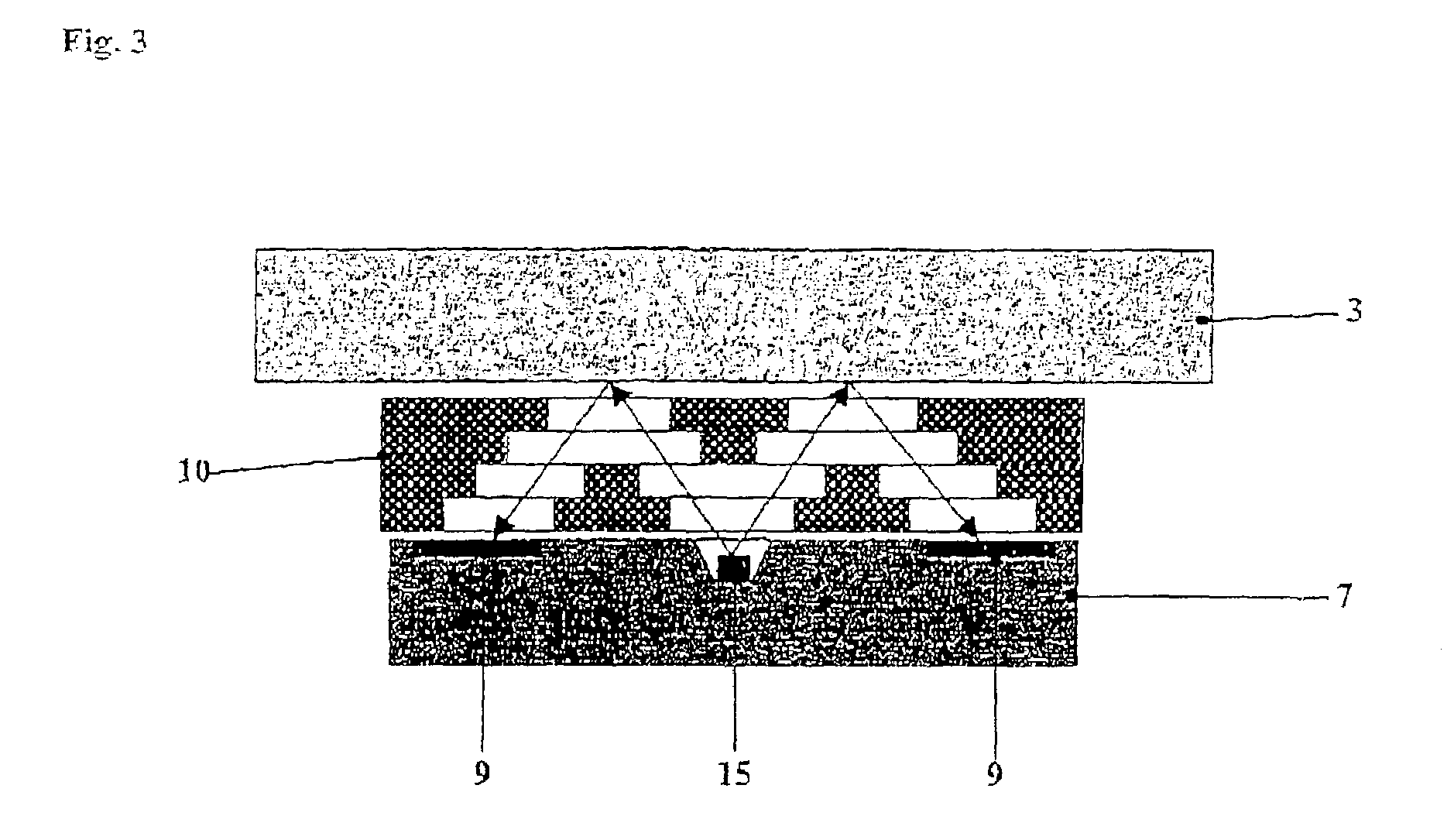

Sensor detecting reflected light and method for its manufacture

ActiveUS7030359B2Simply and effectively accomplishedSuppressing optical “ crosstalk ”Beam/ray focussing/reflecting arrangementsSolid-state devicesLight emitterRadiation

A reflected-light sensor includes a light emitter for emitting radiation onto an object to be measured and an optical receiver for receiving the reflected radiation from the object. The sensor includes a carrier for the light emitter and the optical receiver and a glass layer arranged on the carrier. The glass layer has transparent areas arranged above the light emitter and the optical receiver and light absorbing areas located in between.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

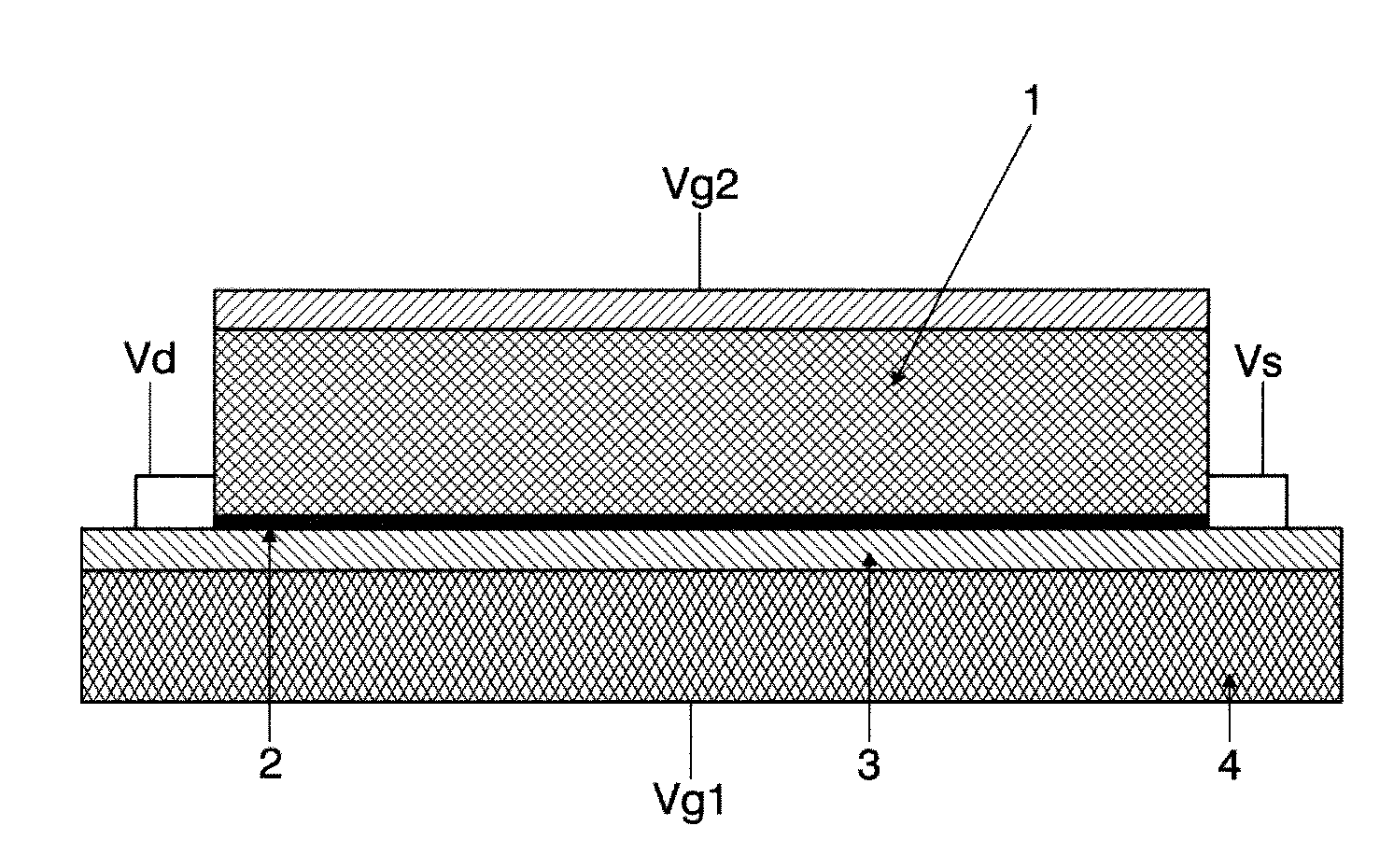

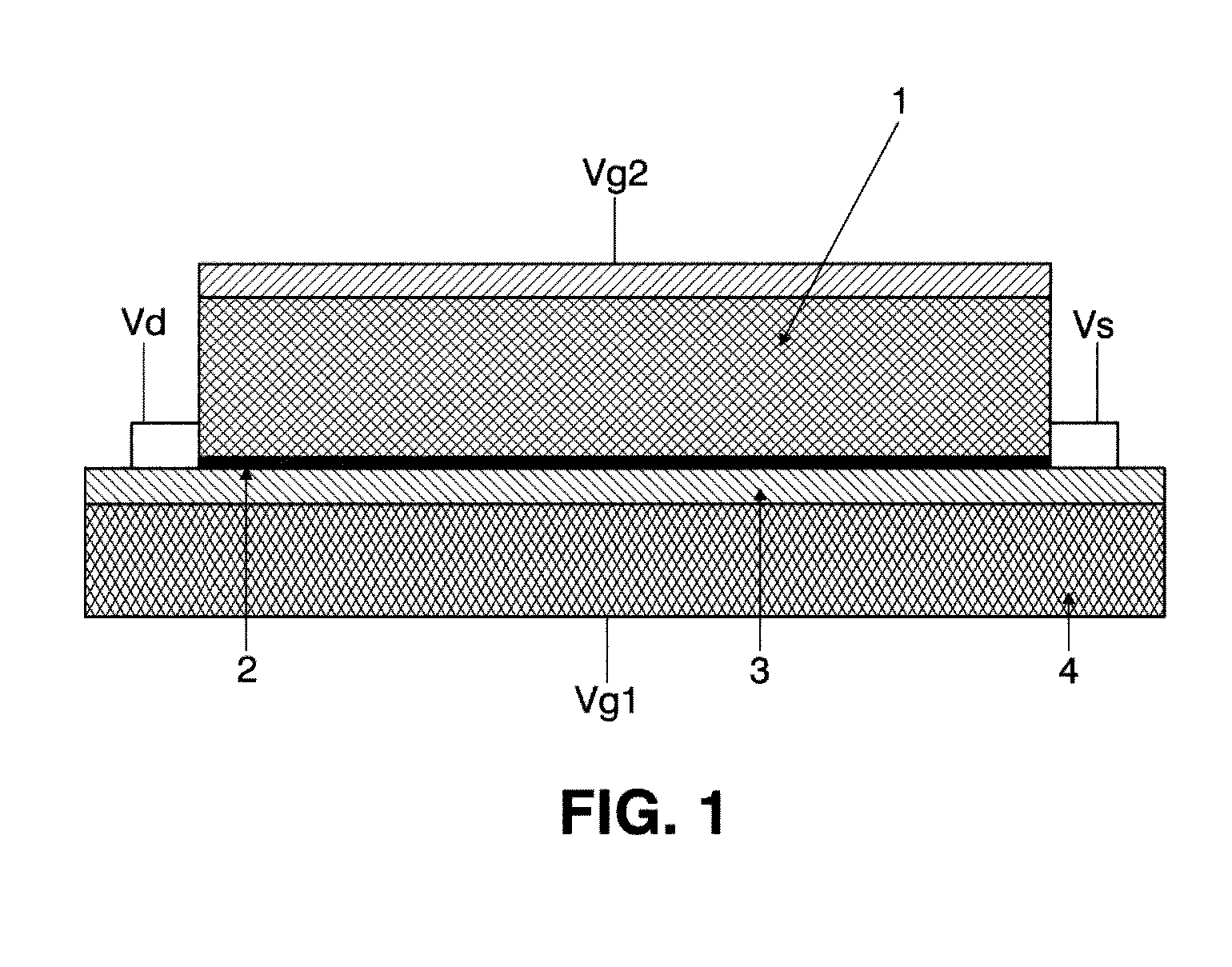

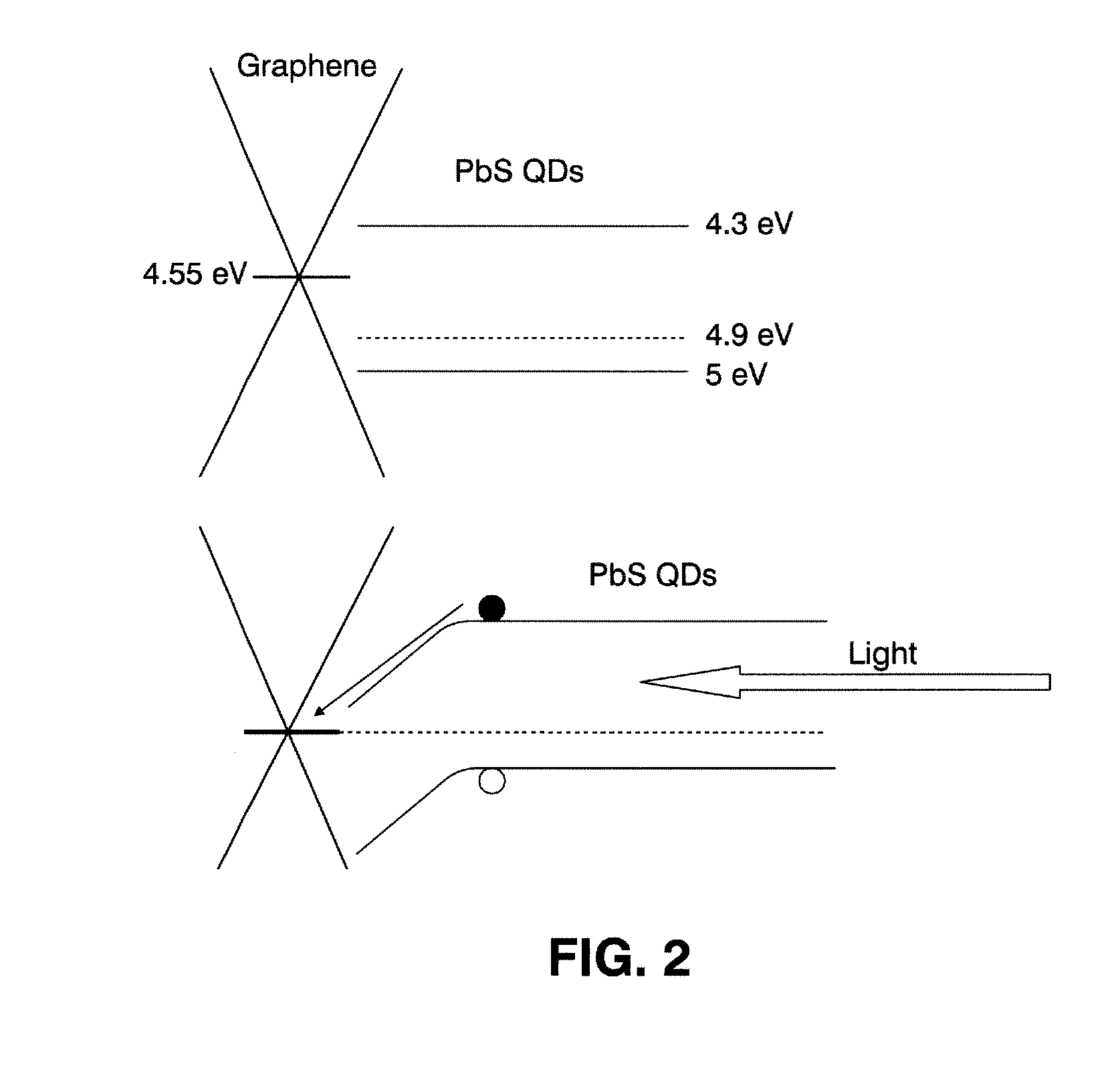

Optoelectronic platform with carbon based conductor and quantum dots and transistor comprising such a platform

The invention comprises an optoelectronic platform with a carbon-based conduction layer and a layer of colloidal quantum dots on top as light absorbing material. Photoconductive gain on the order of 106 is possible, while maintaining de operating voltage low. The platform can be used as a transistor.

Owner:FUNDACIO INST DE CIENCIES FOT NIQUES

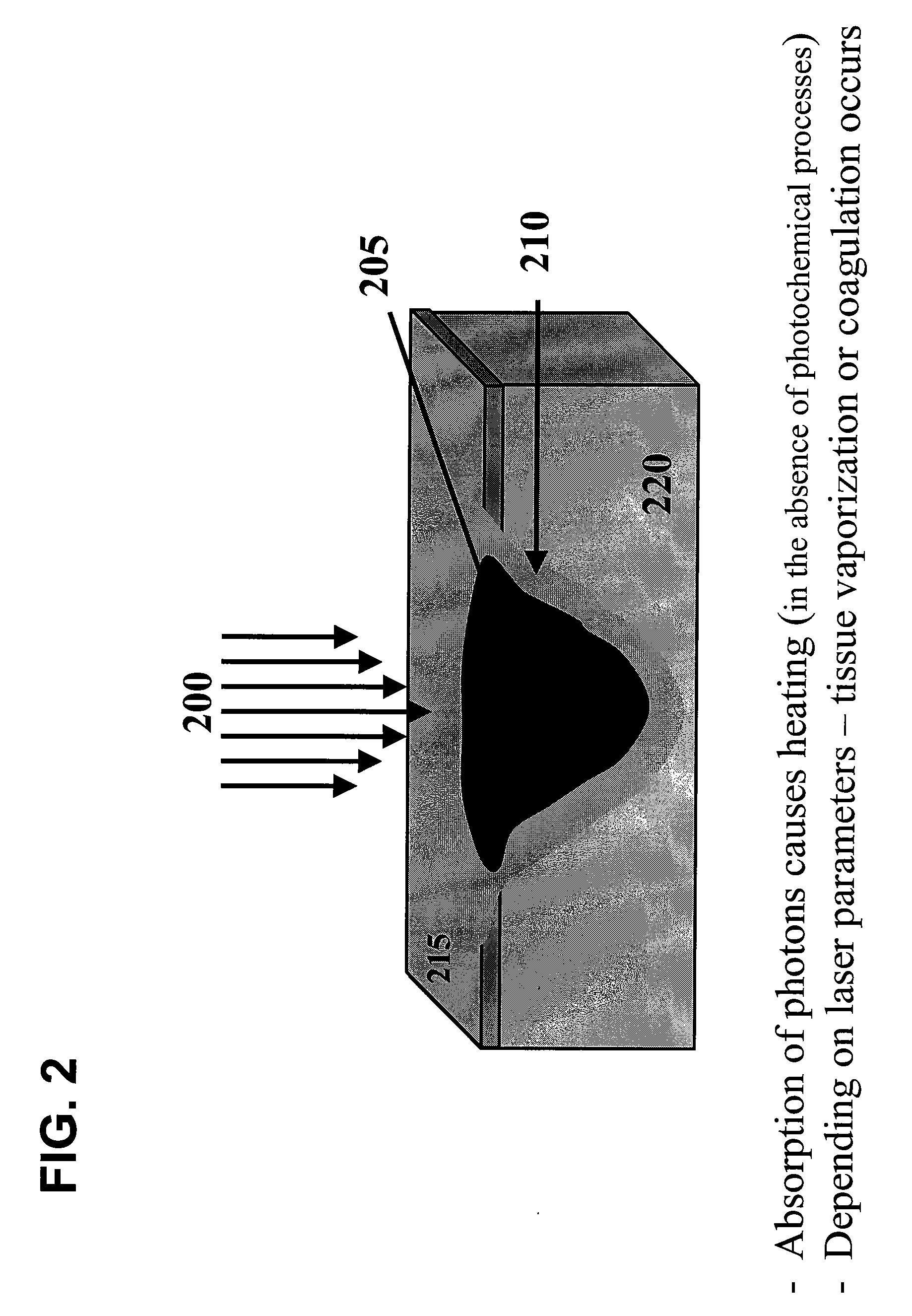

Laser-assisted thermal separation of tissue

A laser-assisted method for fully or partially separating tissue such as collagen-containing tissue is provided. In one embodiment, the method pertains to a capsolurorhexis whereby the laser-assisted method is applied to the lens capsule. A light-absorbing agent is added into or onto the tissue. A light beam with a wavelength capable of being absorbed by the light absorbing agent is then directed at the tissue to cause a thermal effect at the tissue following a predetermined closed curve with the goal to avoid irregularity or potential tears in the resulting rim of the tissue.

Owner:EXCEL LENS INC

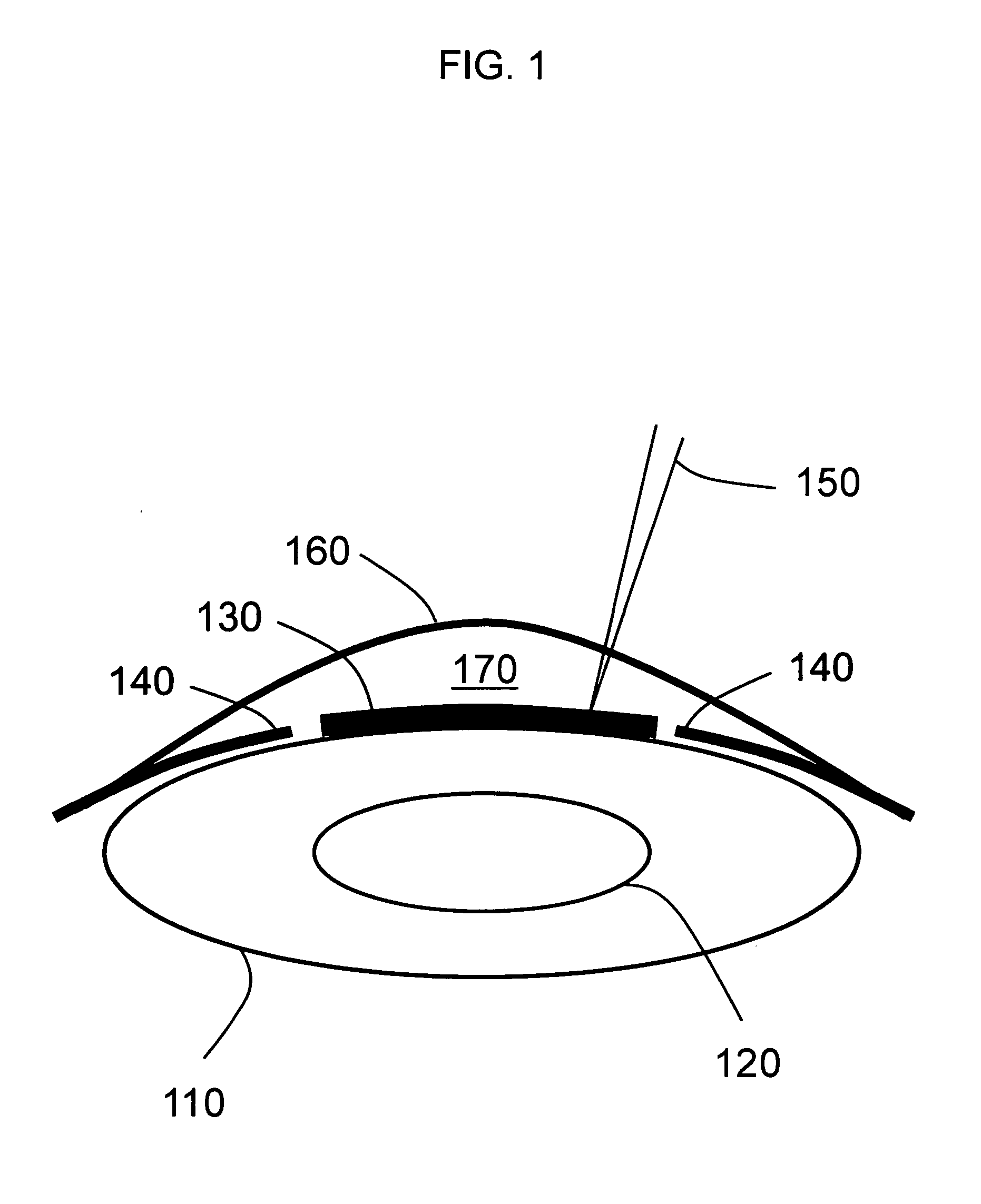

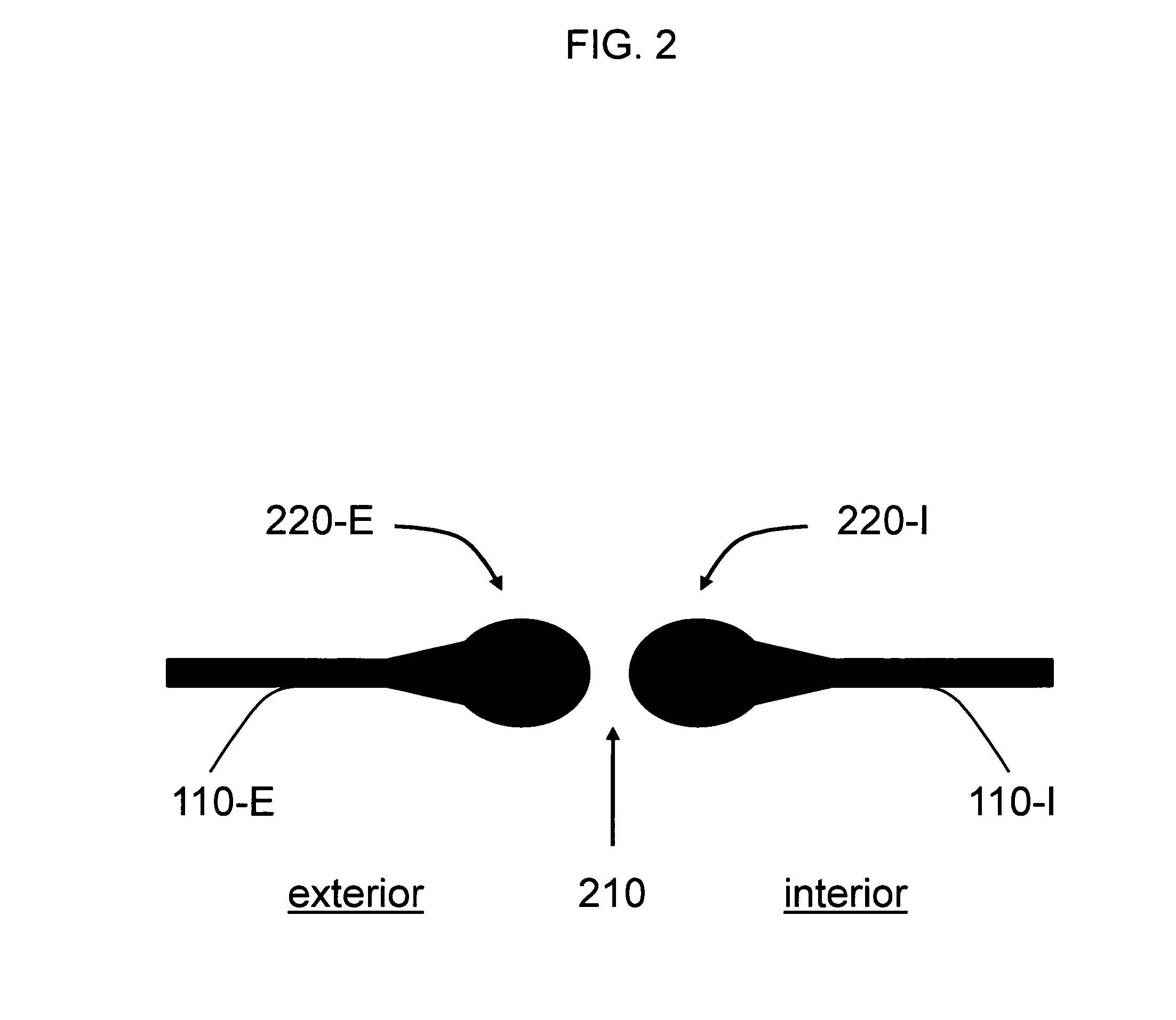

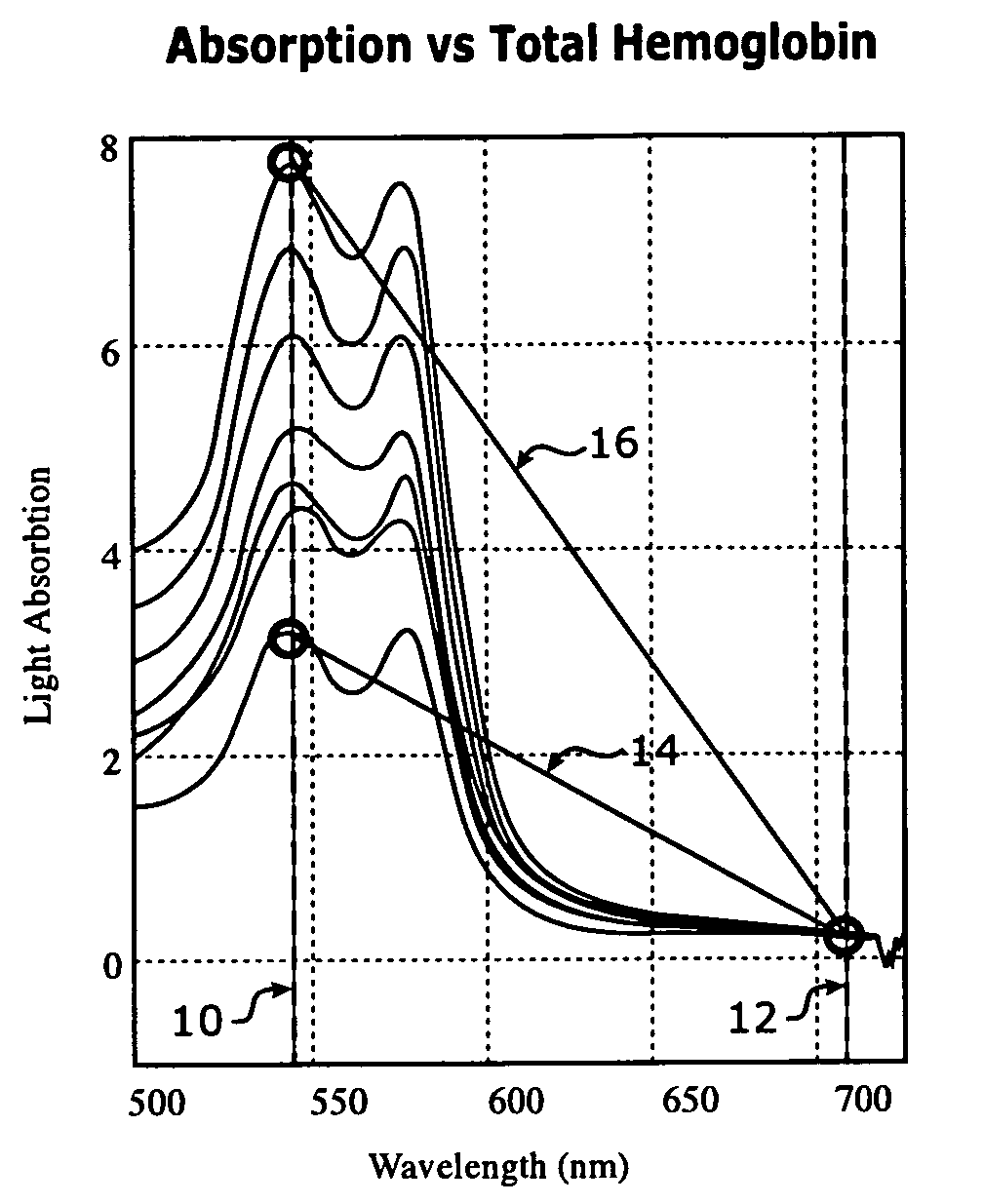

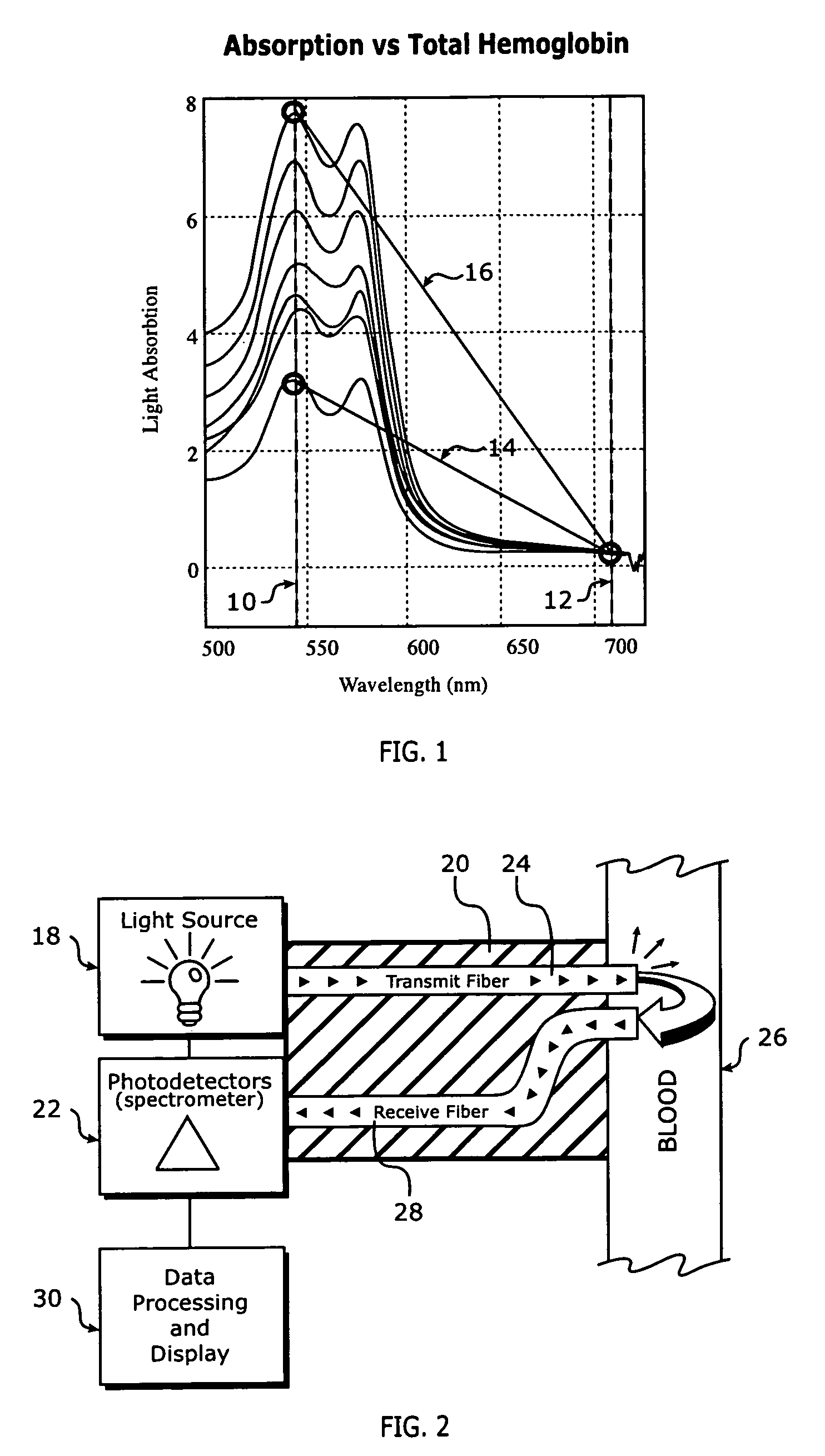

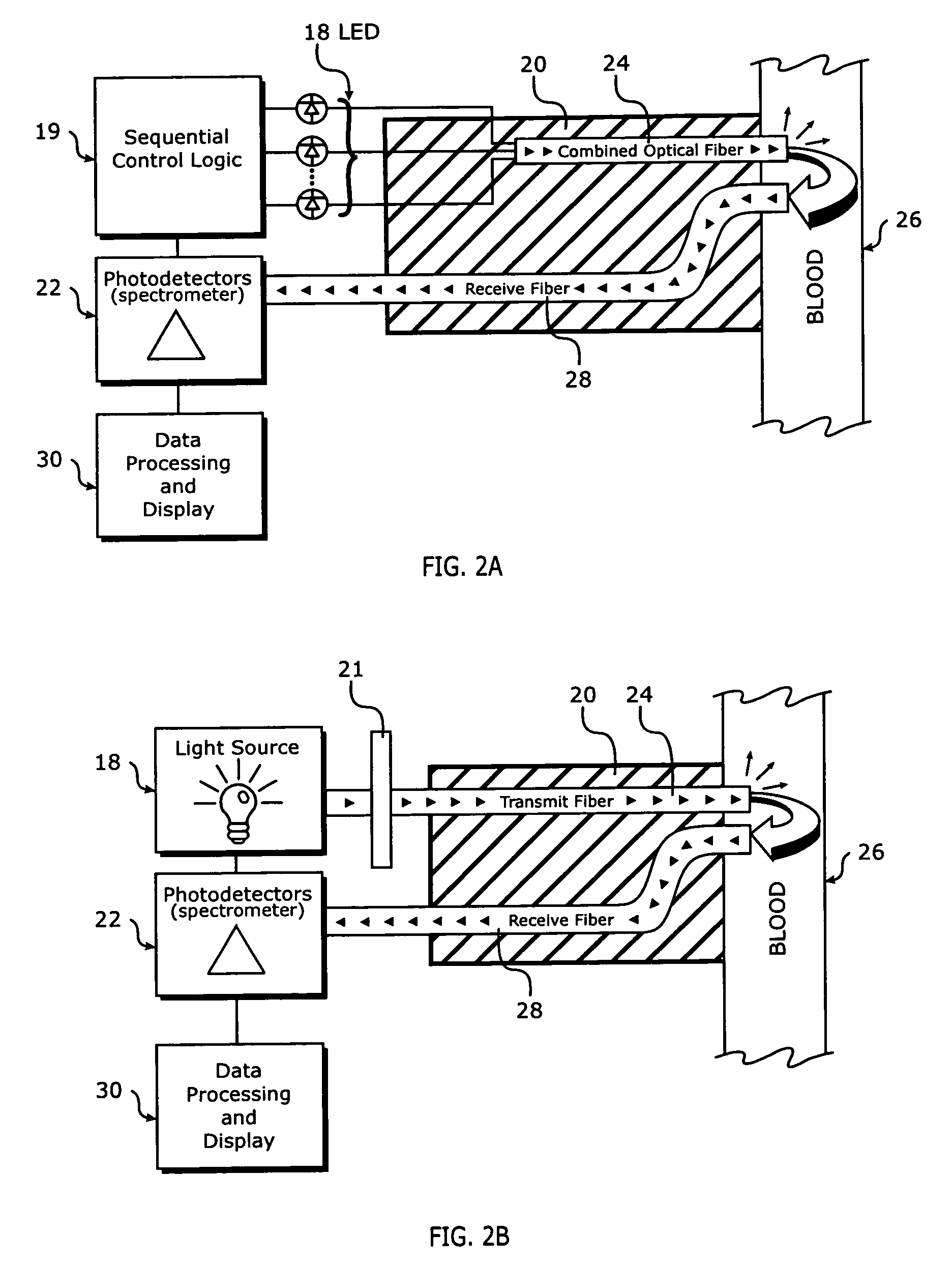

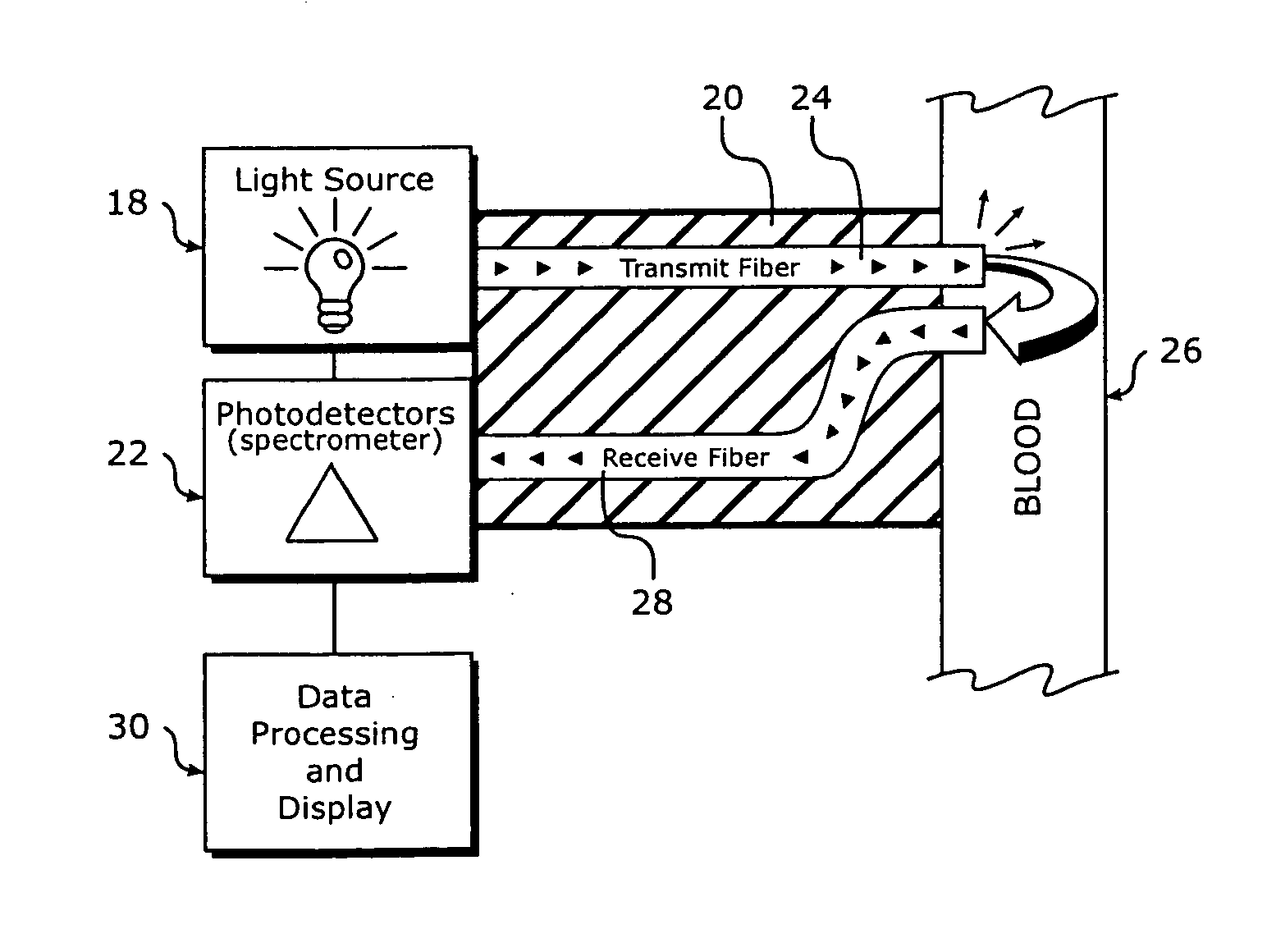

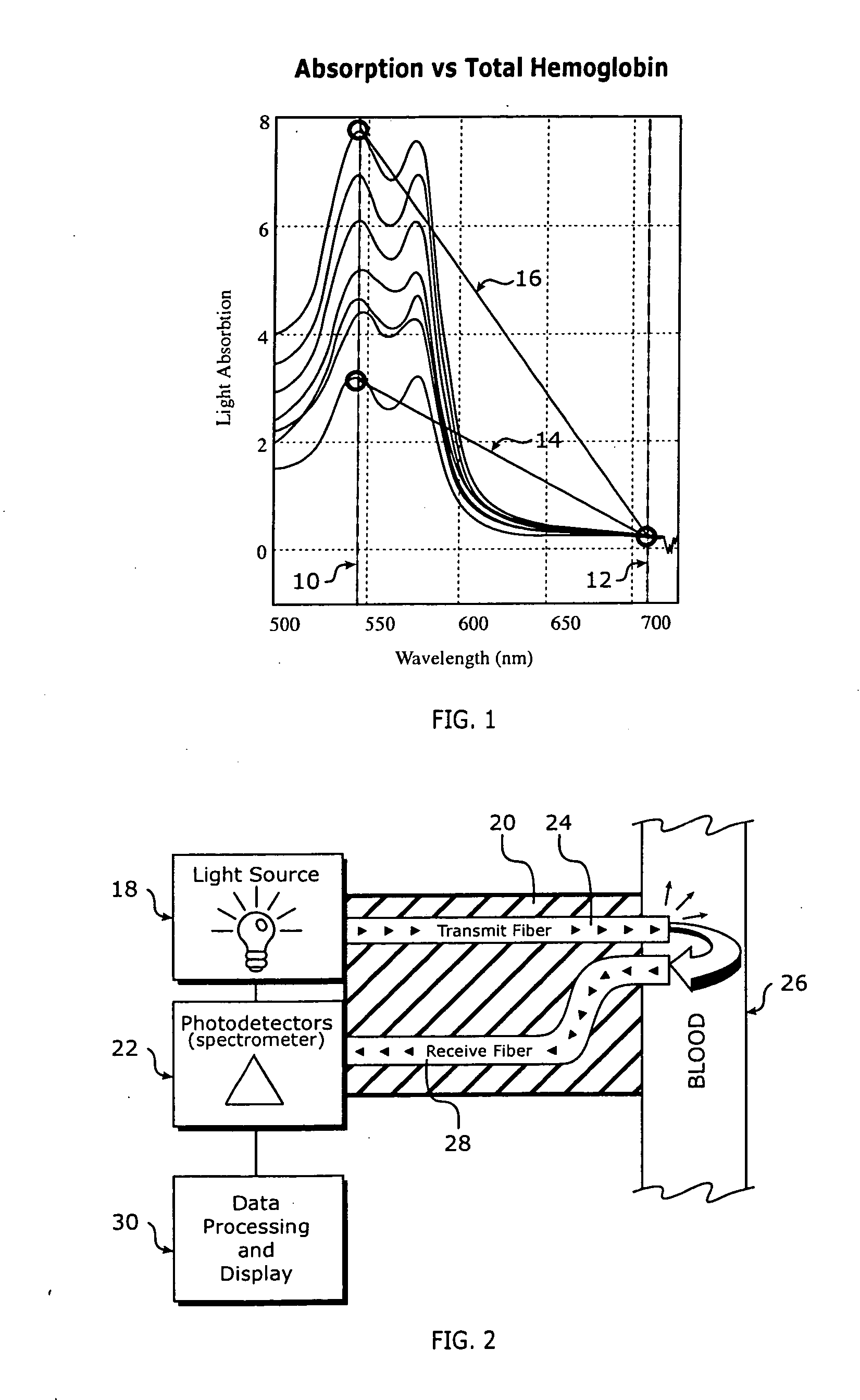

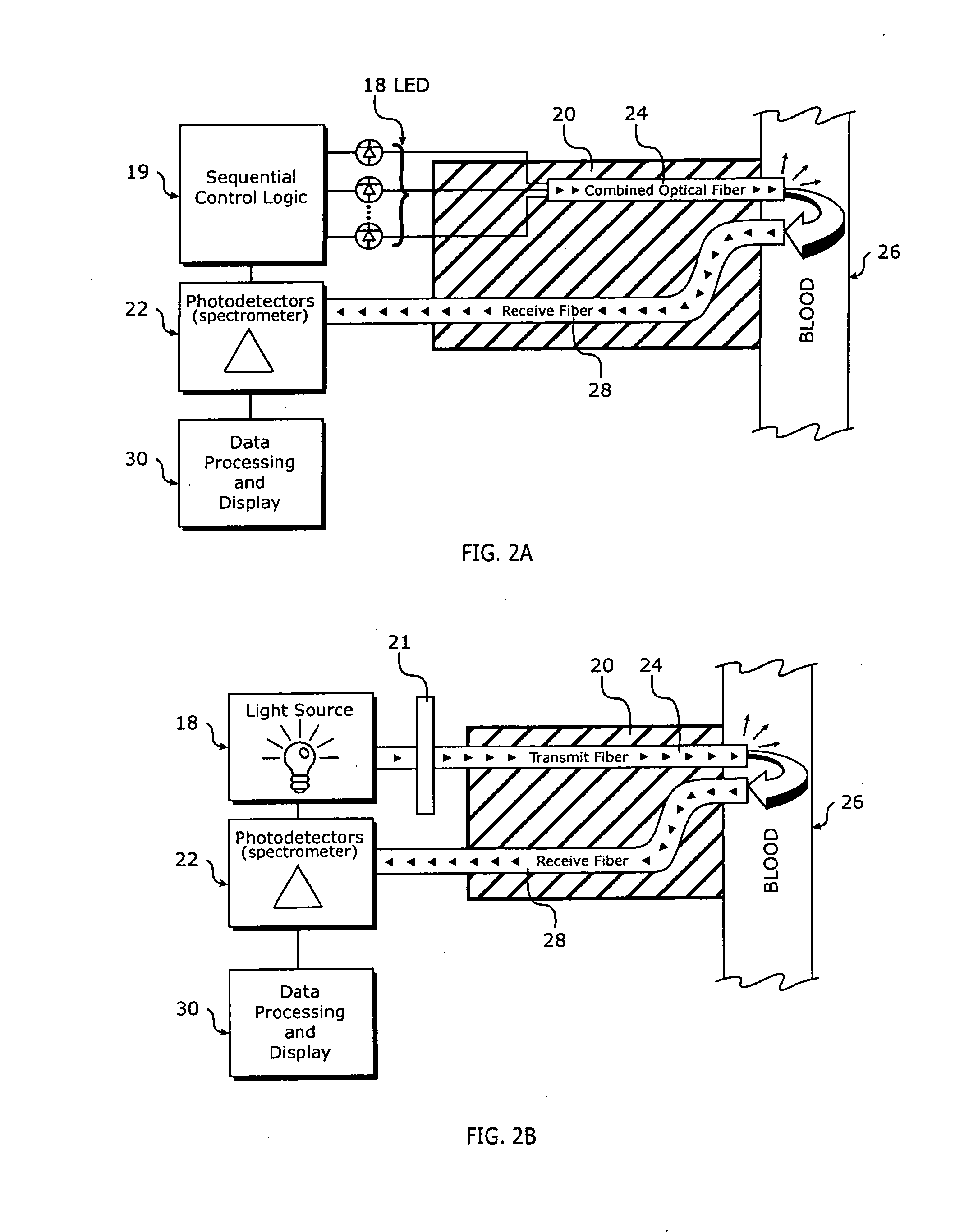

Continuous spectroscopic measurement of total hemoglobin

ActiveUS7319894B2Fast informationEasy to readDiagnostics using spectroscopyCatheterPhotodetectorTotal hemoglobin

Methods for measuring the total hemoglobin of whole blood include measuring reflective light at multiple wavelengths within the visible spectrum, calculating light absorbance at each of the multiple wavelengths, performing a comparison in a change in like absorbance between the multiple wavelengths, and / or relating the comparison to total hemoglobin. A system for measuring total hemoglobin of whole blood may include at least one light source, a catheter, optical fibers, at least one photodetector, data processing circuitry, and / or a display unit.

Owner:EDWARDS LIFESCIENCES CORP

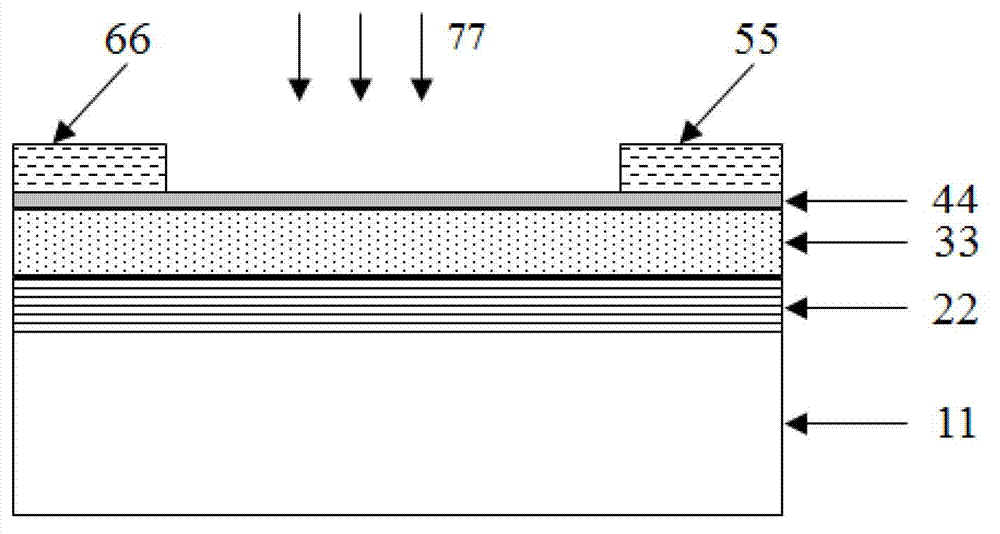

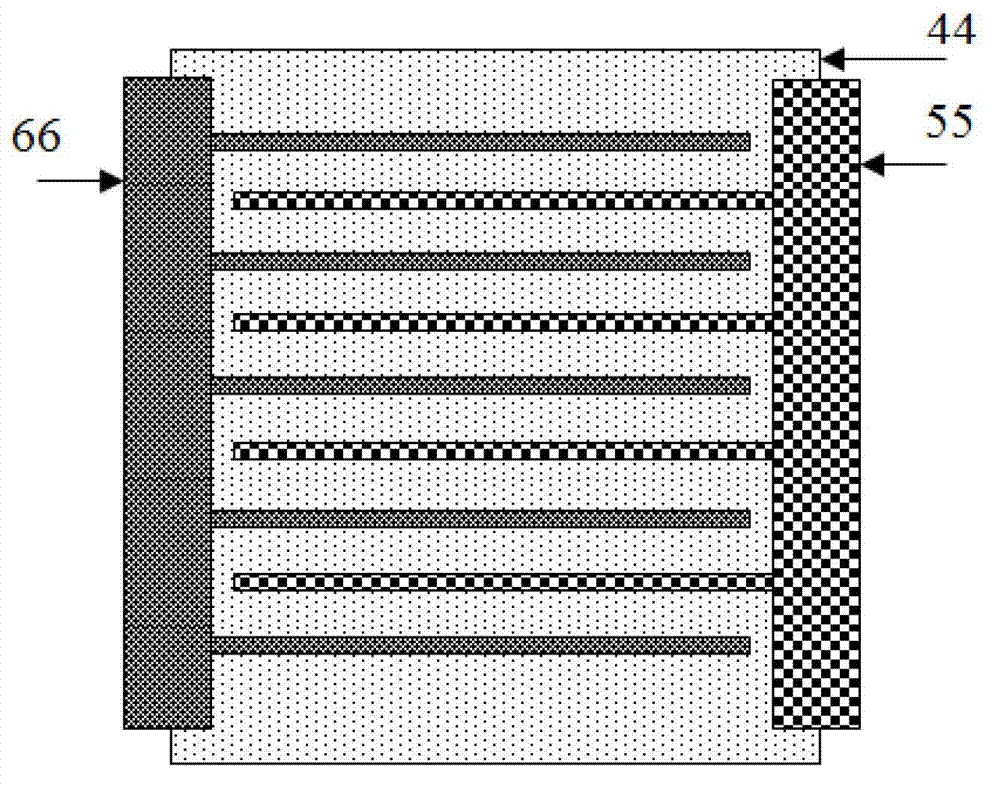

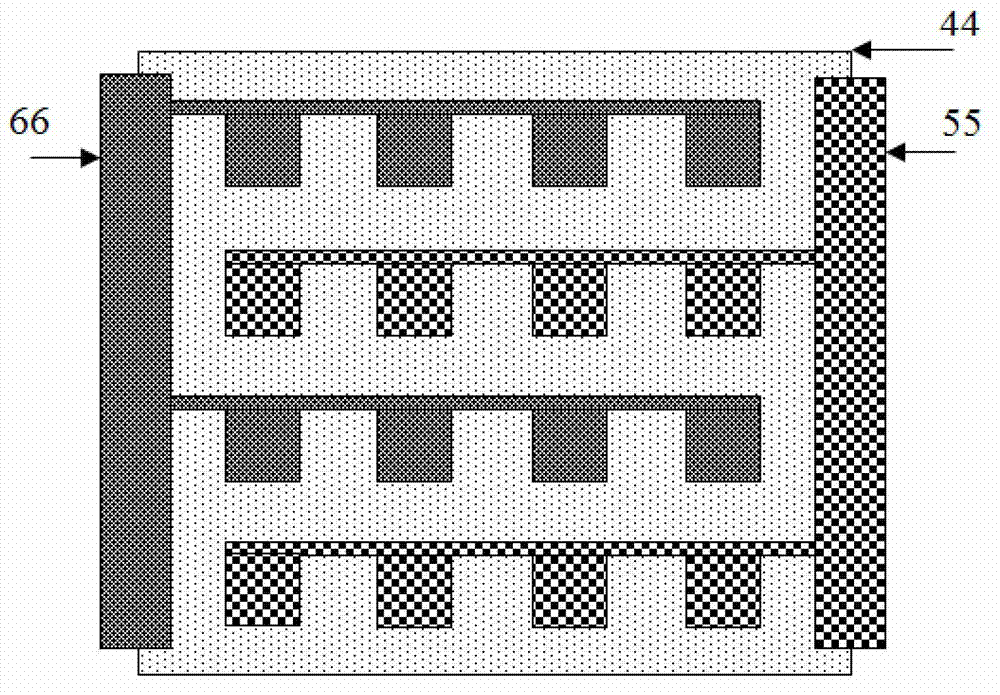

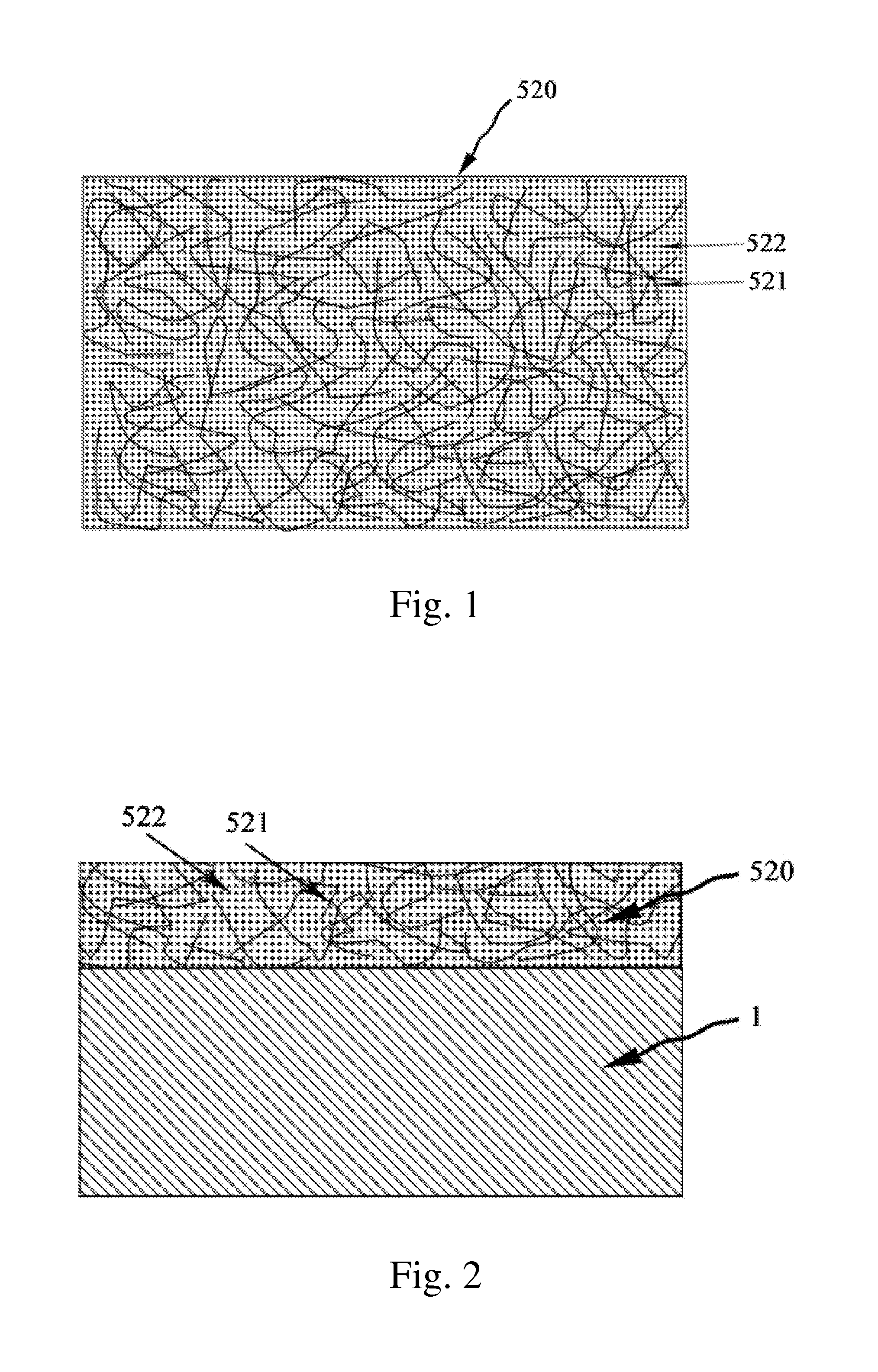

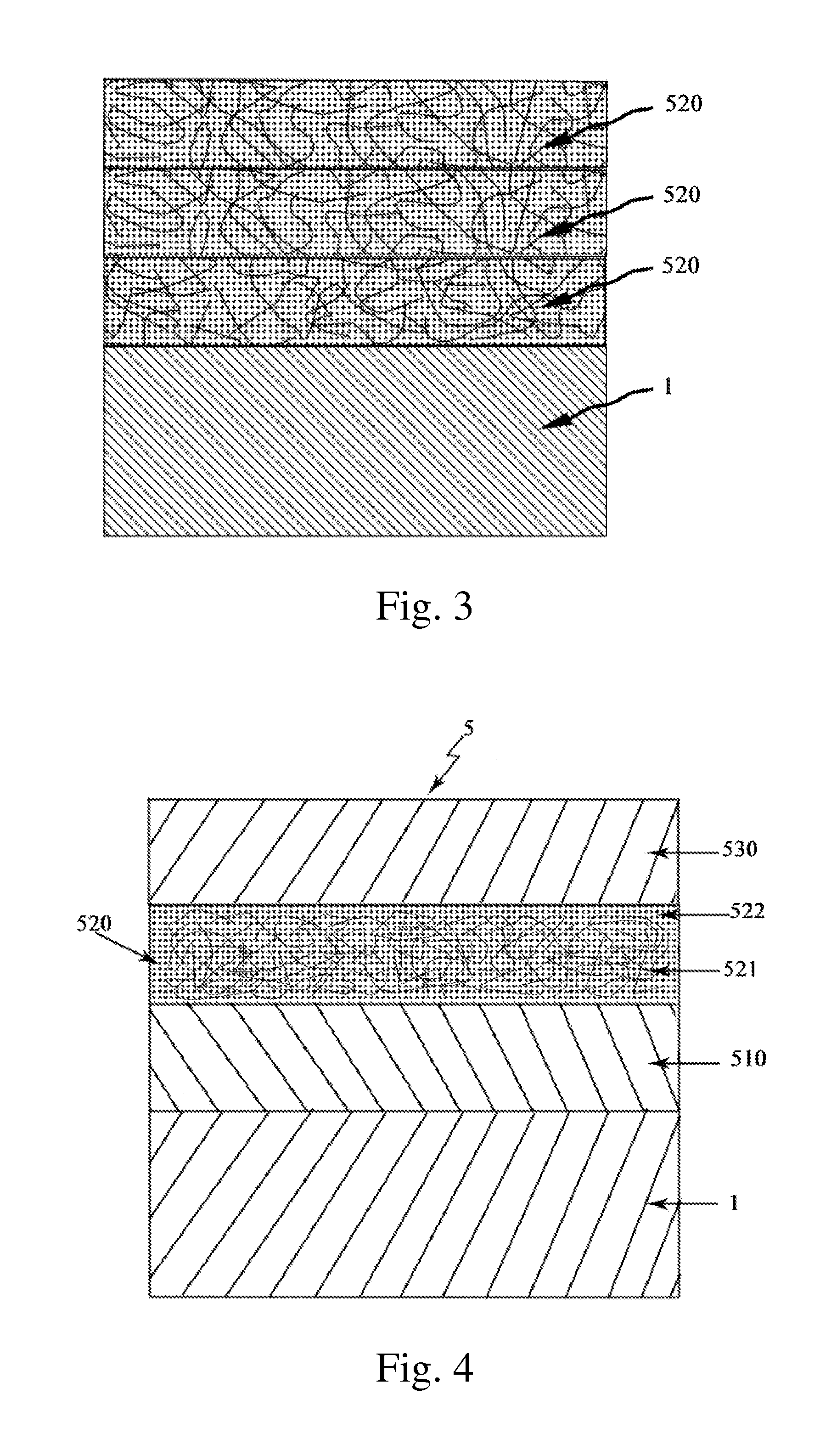

Graphene transistor based on metamaterial structure, optical sensor based on metamaterial structure, and application of graphene transistor

ActiveCN103117316APromote absorptionAdjustableRadiation pyrometrySpectrum investigationMicro nanoUltra-wideband

Disclosed are a graphene transistor based on a metamaterial structure, an optical sensor based on a metamaterial structure, and application of the graphene transistor. The graphene transistor sequentially comprises a liner, a grid metal layer, a grid medium layer, a grapheme layer and a source and drain metal layer from bottom to top. At least local area of the source and drain metal layer is provided with a periodicity micro-nano structure. The periodicity micro-nano structure, the grid metal layer and the grid medium layer match to form the metamaterial structure with the feature of complete absorption. By changing refractive index, thickness and the like of the periodicity micro-nano structure and the grid medium layer material, optical absorption frequency range of the metamaterial structure can be adjusted. Due to the feature of perfect wavelength selectivity absorption, higher flexibility and narrow-band response of the metamaterial structure, the graphene transistor can work under visible light to infrared even longer wave bands by selecting different metamaterial structures. By integrating optical sensor working in different wave bands, image sensors, spectrum detecting analyzing device and the like which can work in ultra-wide bands can be formed.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Energy conversion film and quantum dot film comprising quantum dot compound, energy conversion layer including the quantum dot film, and solar cell including the energy conversion layer

ActiveUS7791157B2Improve energy efficiencyHigh solar efficiencyElectrolytic capacitorsFinal product manufactureHigh energySpectral responsivity

An energy conversion film and a quantum dot film which contain a quantum dot compound, an energy conversion layer including the quantum dot film, and a solar cell including the energy conversion layer. The films act as cut-off filters blocking light of a particular energy level using the light absorption and emission effects of quantum dots and can convert high energy light to low energy light. The efficiency of a solar cell may be improved by providing the cell with a film that converts light above the spectrum-responsive region to light in the cell's spectrum-responsive region. The absorption wavelength region of the films can be broadened by providing the quantum dot compound in a variety of average particle sizes, for example, by providing a mixture of a first quantum dot compound having a first average particle size and a first quantum dot compound having a second average particle size.

Owner:SAMSUNG ELECTRONICS CO LTD

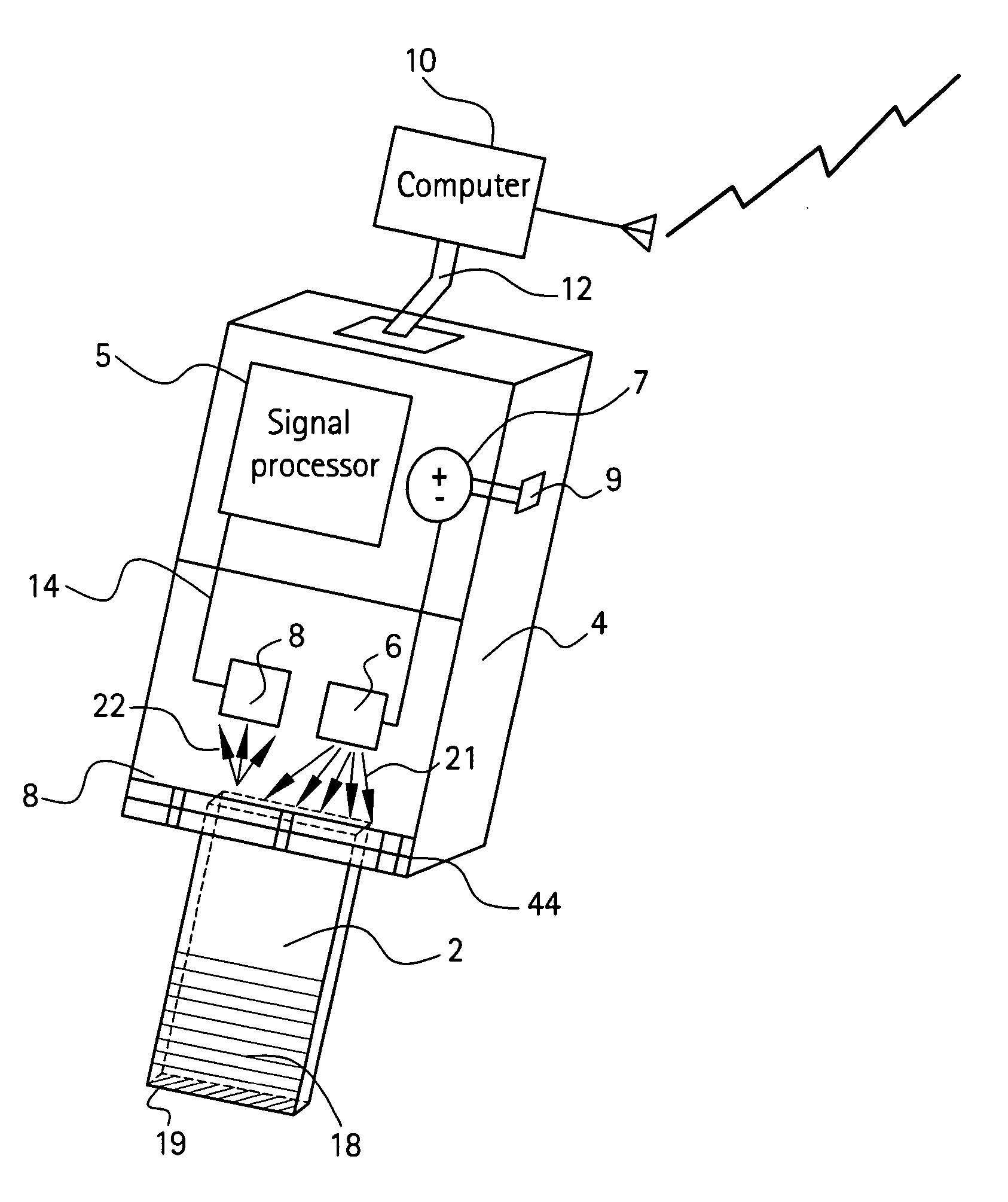

Photoplethysmography device and method

InactiveUS20110082355A1Accurate descriptionDiagnostic recording/measuringSensorsAnalytePulse parameter

A system and method for measuring one or more light-absorption related blood analyte concentration parameters of a mammalian subject, is disclosed. In some embodiments, the system comprises: a) a photoplethysmography (PPG) device configured to effect a PPG measurement by illuminating skin of the subject with at least two distinct wavelengths of light and determining relative absorbance at each of the wavelengths; b) a dynamic light scattering measurement (DLS) device configured to effect a DLS measurement of the subject to rheologically measure a pulse parameter of the subject; and c) electronic circuitry configured to: i) temporally correlating the results of the PPG and DLS measurements; and ii) accordance with the temporal correlation between the PPG and DLS measurements, assessing value(s) of the one or more light-absorption related blood analyte concentration parameter(s).

Owner:OXITONE MEDICAL

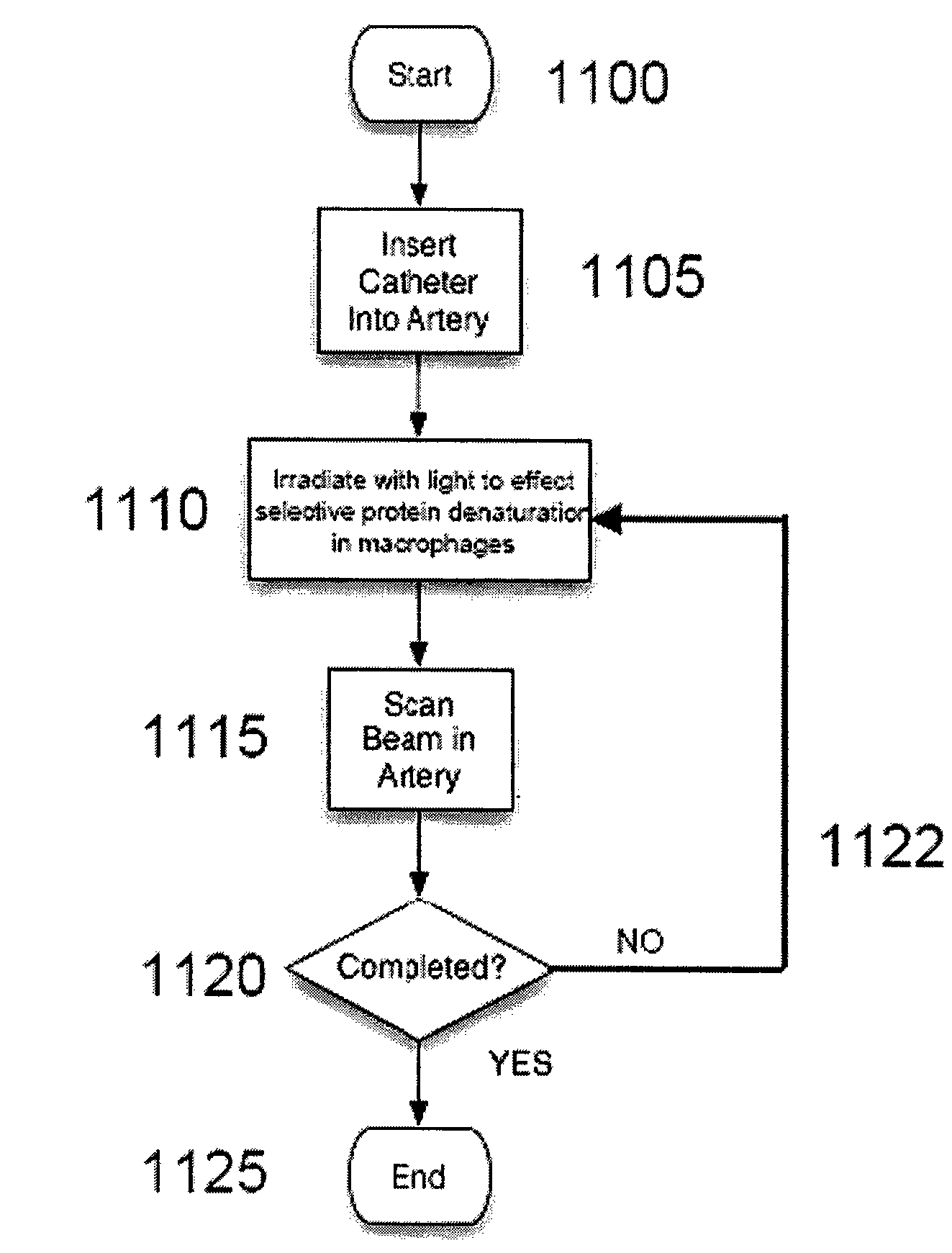

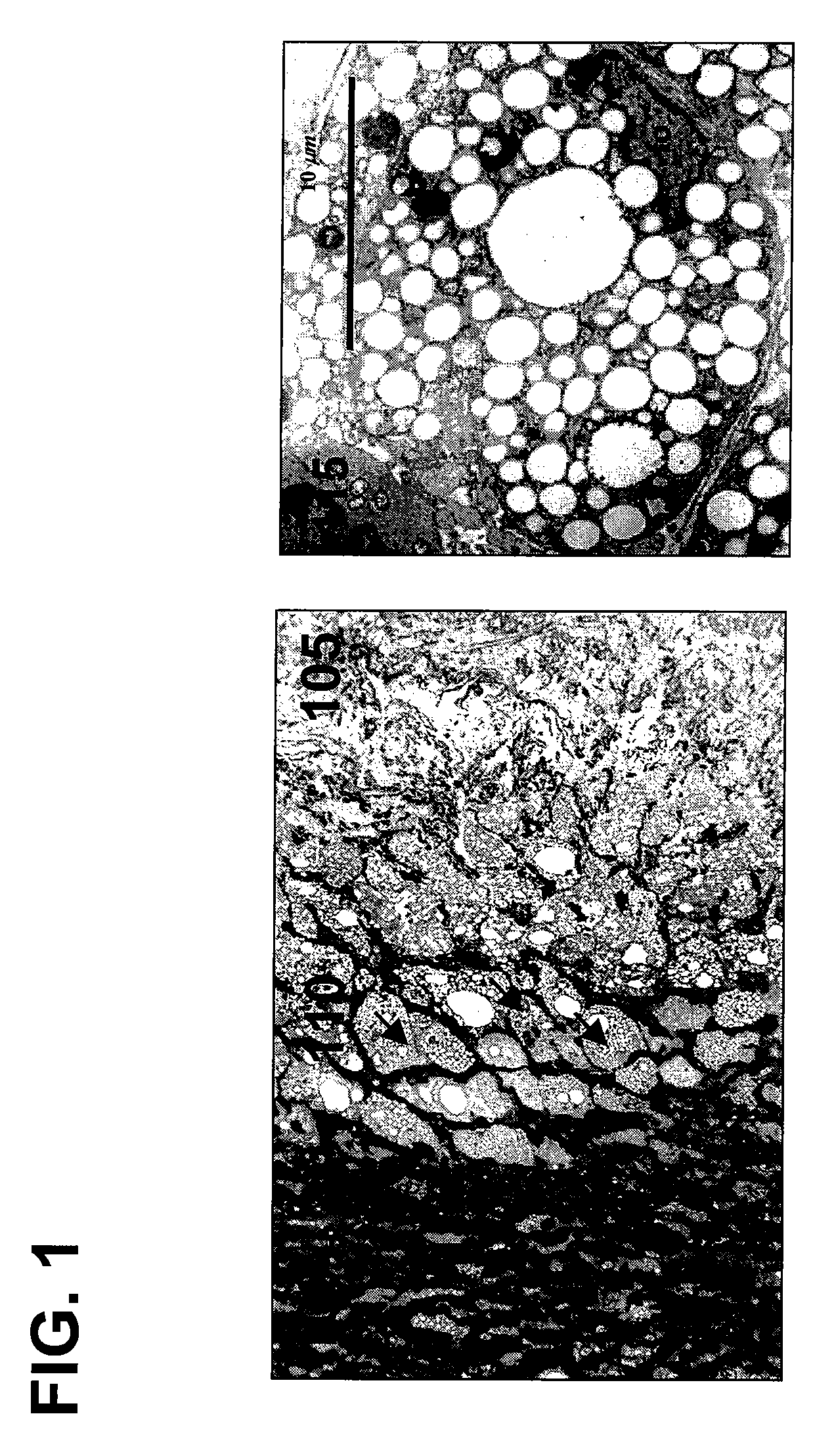

System and method for providing cell specific laser therapy of atherosclerotic plaques by targeting light absorbers in macrophages

An apparatus and method according to the present invention can be provided, e.g., for a cell specific laser therapy of atherosclerotic plaques, particularly to systems and methods for targeting endogenous light absorbers present within plaque macrophages and exogenous nanoparticle targeting. In one exemplary embodiment, an electro-magnetic radiation can be forwarded to an anatomical structure. The electromagnetic radiation may have at least one property configured to (a) modify at least one characteristic of at least one first cell, and (b) minimize any modification of and / or modify at least one characteristic of at least second cell. The first and second cells may be different from one another, the characteristics of the first and second cells can be different from one another, and the first cell and / or the second cell may have at least one macrophage feature, and the characteristic of the at least one first cell and / or the at least one second cell can be temperature. According to still another exemplary embodiment, a location associated with the first cell and the second cell can be determined. For example, the electromagnetic radiation can be forwarded in a vicinity of the location.

Owner:THE GENERAL HOSPITAL CORP

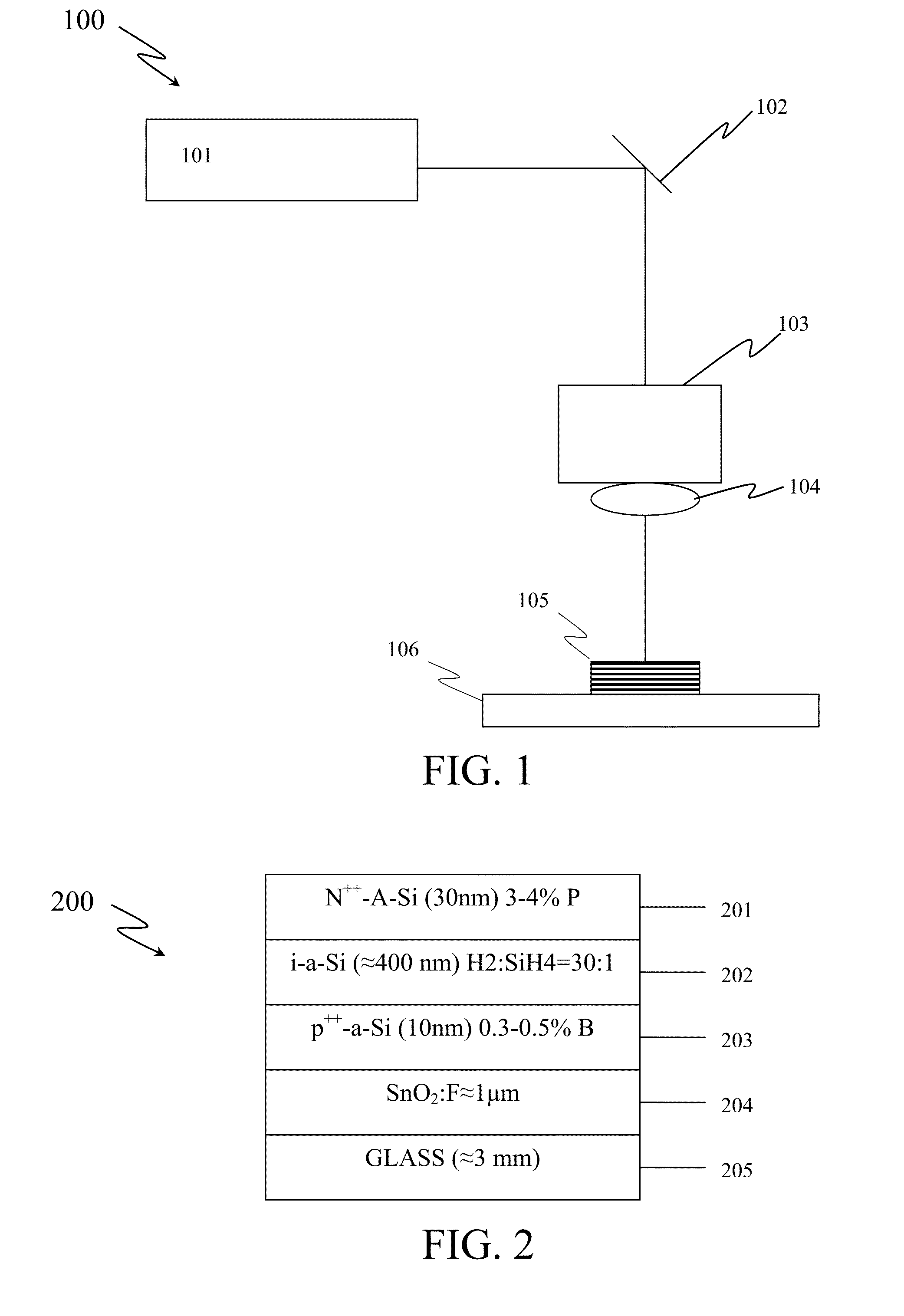

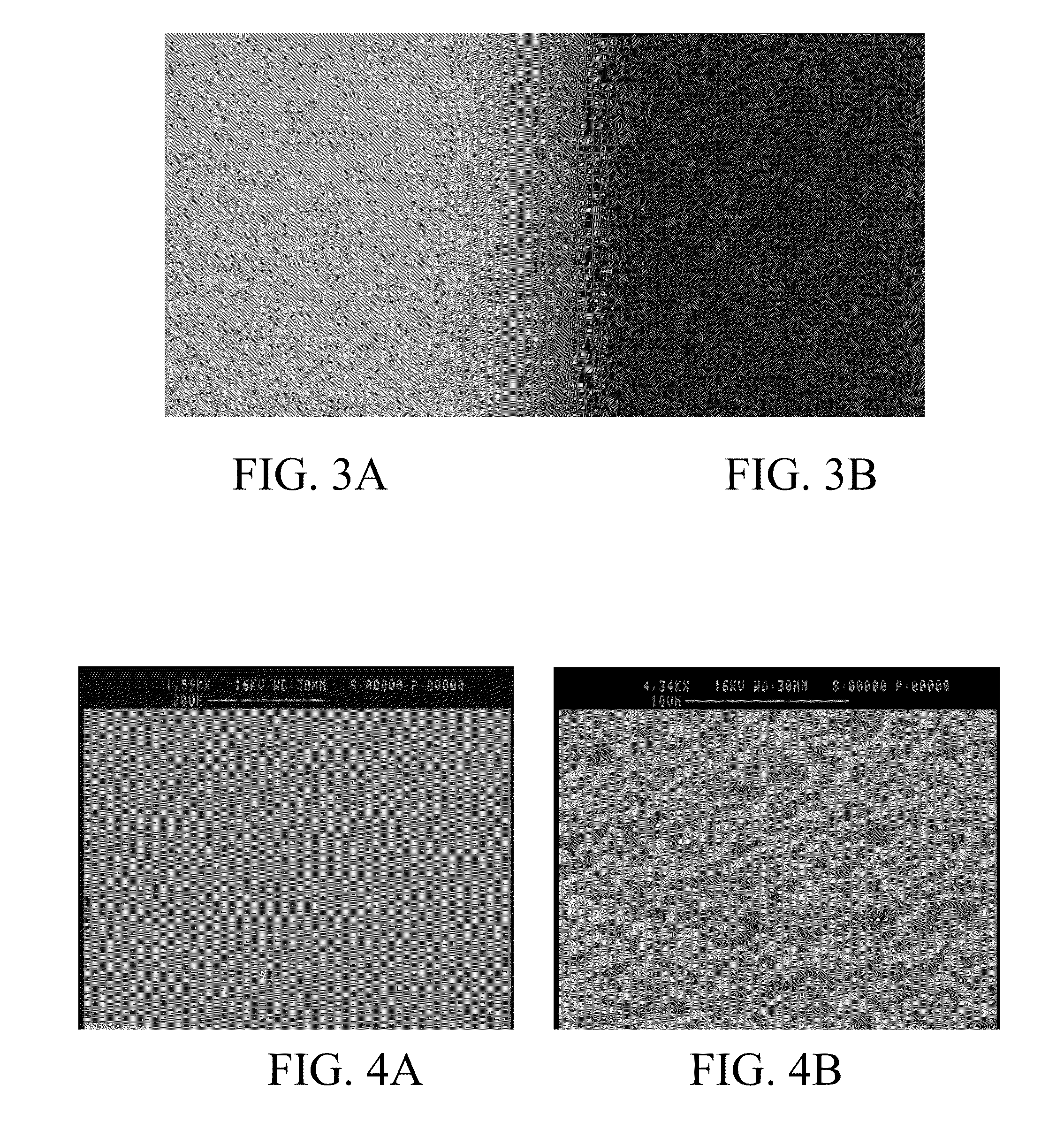

Systems and methods of laser texturing of material surfaces and their applications

ActiveUS20130020297A1Enhance light absorptionImprove conductivityNanotechLaser beam welding apparatusAlloyElectron

The surface of a material is textured and by exposing the surface to pulses from an ultrafast laser. The laser treatment causes pillars to form on the treated surface. These pillars provide for greater light absorption. Texturing and crystallization can be carried out as a single step process. The crystallization of the material provides for higher electric conductivity and changes in optical and electronic properties of the material. The method may be performed in vacuum or a gaseous environment. The gaseous environment may aid in texturing and / or modifying physical and chemical properties of the surfaces. This method may be used on various material surfaces, such as semiconductors, metals and their alloys, ceramics, polymers, glasses, composites, as well as crystalline, nanocrystalline, polycrystalline, microcrystalline, and amorphous phases.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

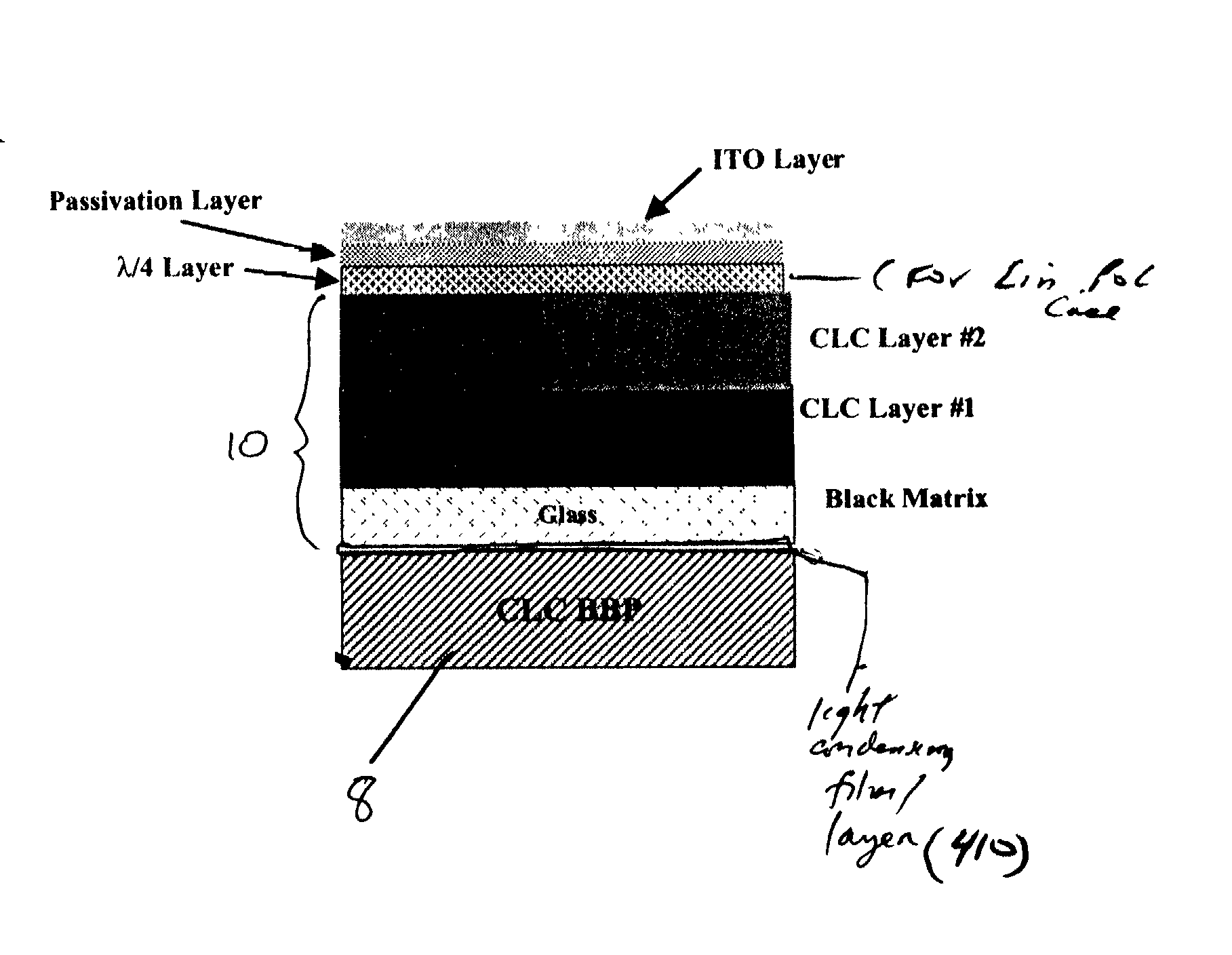

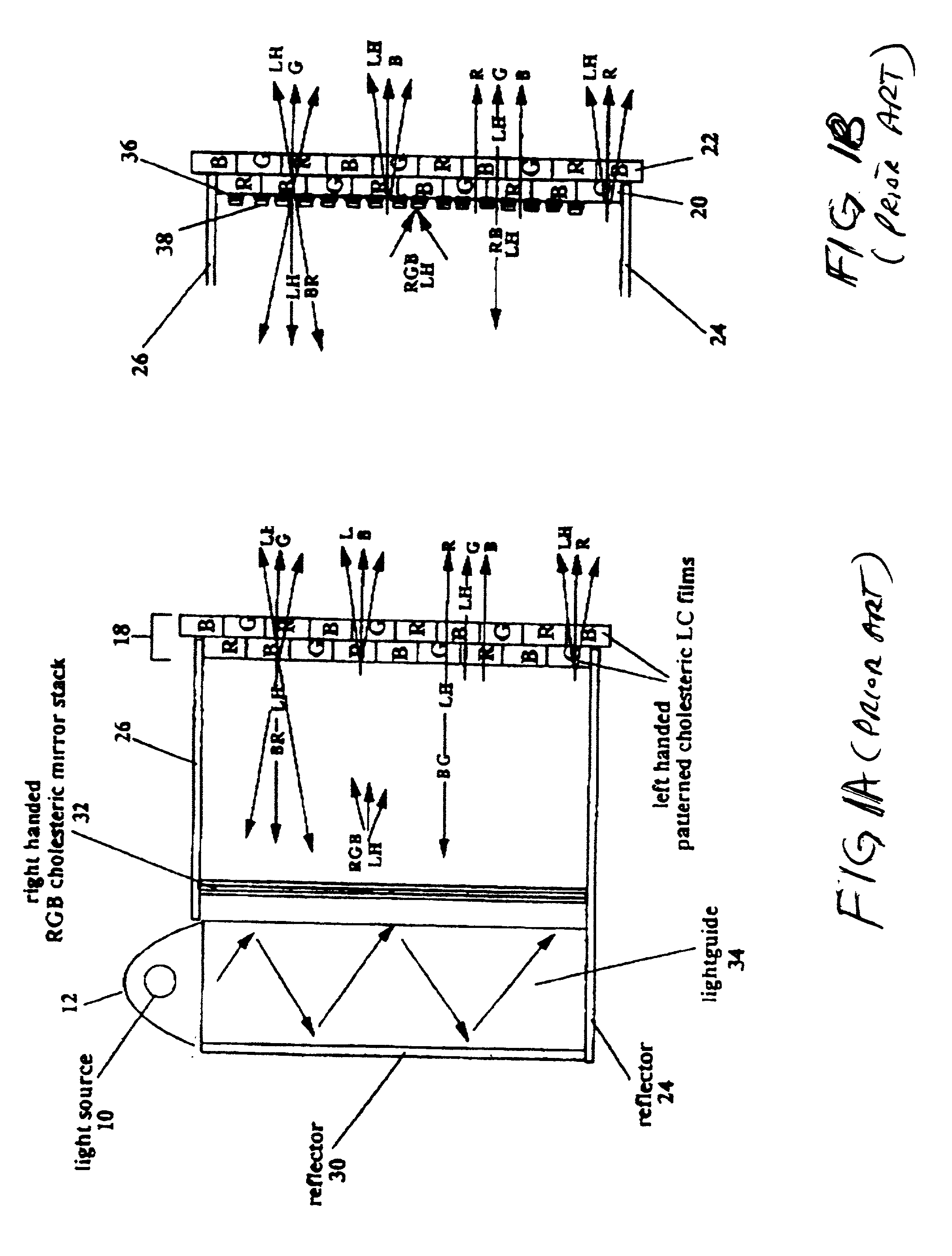

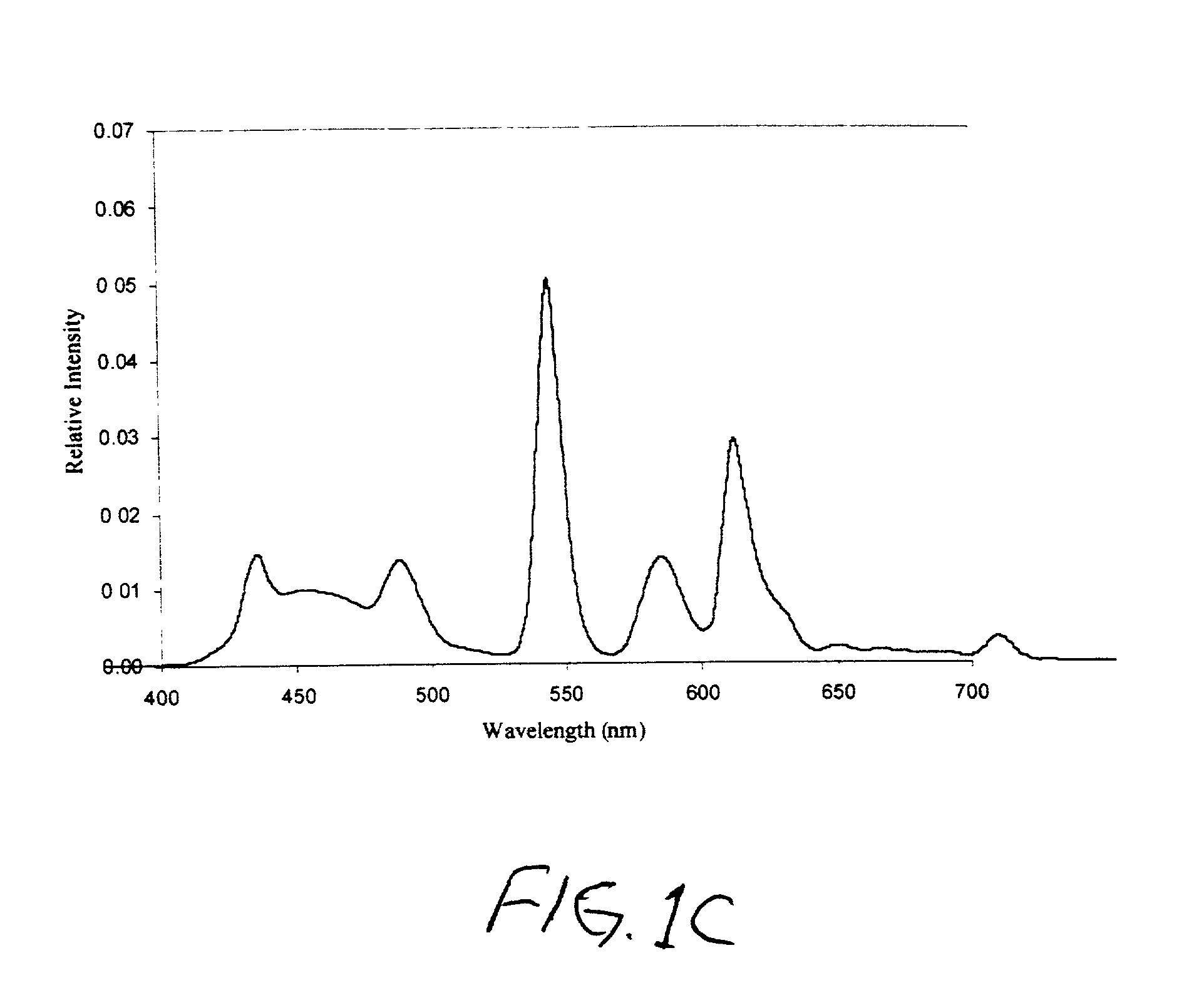

High-brightnesss color liquid crystal display panel employing light recycling therein

InactiveUS20020113921A1Good colorAvoiding shortcoming and drawbackLiquid crystal compositionsSolar heating energyDisplay devicePolarizer

Reflective color filters using layers of cholesteric liquid crystals with two different center wavelengths and bandwidths per layer are stacked in two layers to provide colored light for displays. With a two layer stack circularly polarized light of one handedness can be provided. With a four layer stack unpolarized colored light can be provided. With a broadband polarizing filter overlapping other filters in the stack a black matrix can be provided by reflecting all colors and transmitting no light in the overlapping areas. When broadband reflective cholesteric liquid crystals are used two primary colors can be reflected in the same pixel of a display making reflective layers with two reflective portions per layer possible. Color displays having three linear sub-pixels with three primary colors or with four sub-pixels of white, blue, green, and red in a pixel with two colors in a top row and two colors on a bottom row can are made with two colors per layer in two layer stacks. The pixels in the display are arranged such that multiple adjacent sub-pixels in a layer, or row in a layer, with the same color makes the color filters easier to manufacture. Displays using these reflective color filters may have a reflective polarizer for viewing the display at wide angles without color distortion. A method of producing cholesteric liquid crystal color filters by polymerizing different portions of cholesteric liquid crystal mixtures at different temperatures and radiations to obtain different central wavelengths and bandwidths of reflection. By masking parts of a layer several portions with different colors are polymerized in a single layer. Further, with radiation which is attenuated in the cholesteric liquid crystal material stacks of different portions reflecting different colors in the same layer are made. Further the cholesteric liquid crystals are polymerized to have other optical properties in the stack such as quarter wave plates and broad band polarizers such that entire optical devices can be made in one layer of cholesteric liquid crystal material making the devices smaller, lighter, more robust, reliable, and easier to make by eliminating gluing and alignment problems. With overlapping reflective cholesteric liquid crystal which together reflect all light stacks with automatic black matrixes built into the layer are made saving light from being blocked by conventional black matrix light absorbing layers in display devices.

Owner:REVEO

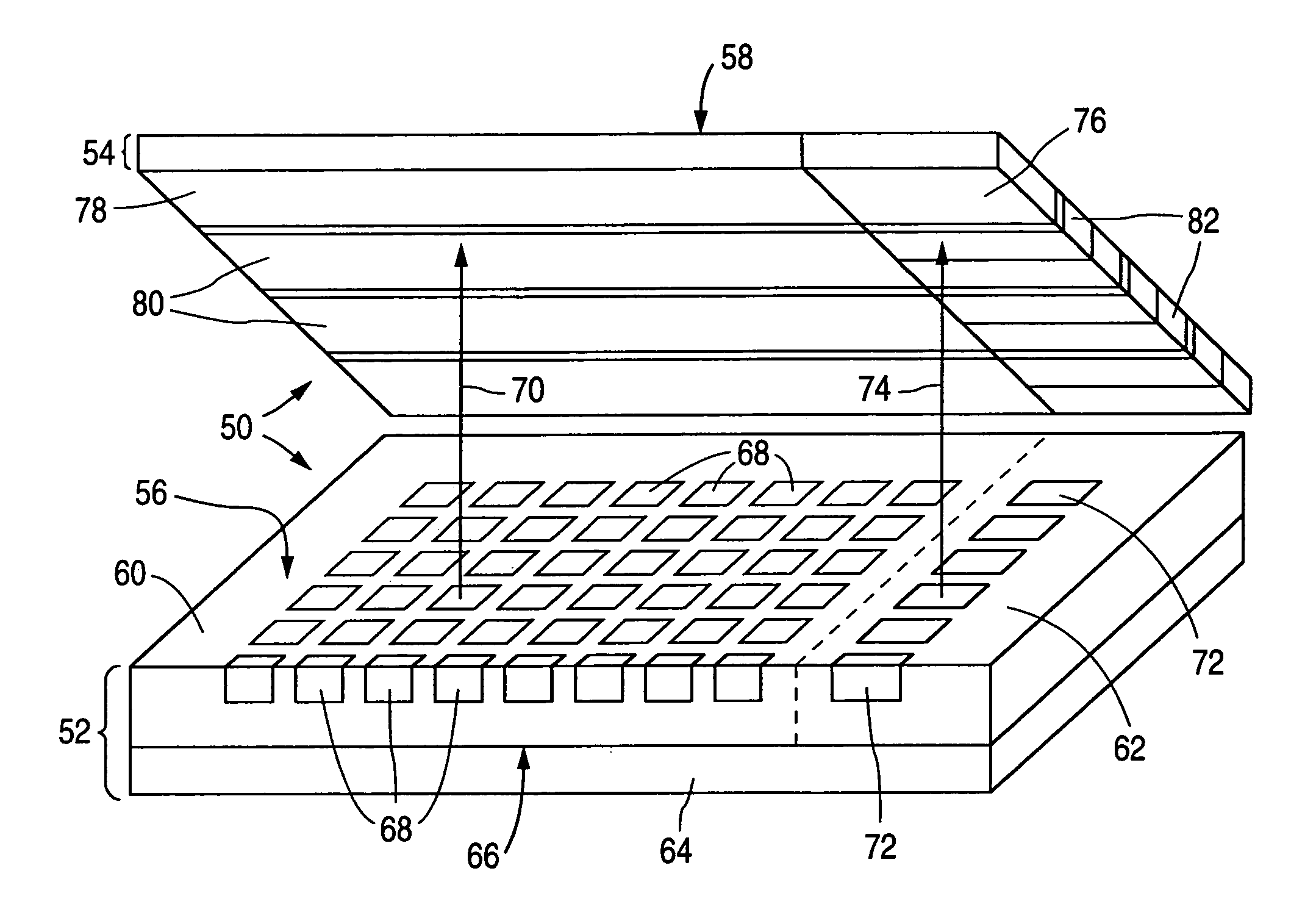

Display with active contrast enhancement

InactiveUS7071907B1Less reliability concernImprove image contrastCathode-ray/electron-beam tube vessels/containersSolid-state devicesLiquid-crystal displayImage contrast

A display (50) with enhanced image contrast contains an image-producing component (60) and a set of shutter strips (80). The image-producing component, typically a flat-panel device, has multiple imaging lines that provide light to produce an image. Each shutter strip is situated in front of one or more associated imaging lines. By appropriately switching the shutter strips between light-absorptive and light-transmissive states, the image contrast is enhanced. The shutter strips are typically implemented with a liquid-crystal display structure. The switching of the shutter strips is typically performed with a control component (52 / 76) which utilizes light to control the shutter switching and which is synchronized to signals (90 or / and 100) that control the imaging lines.

Owner:CANON KK

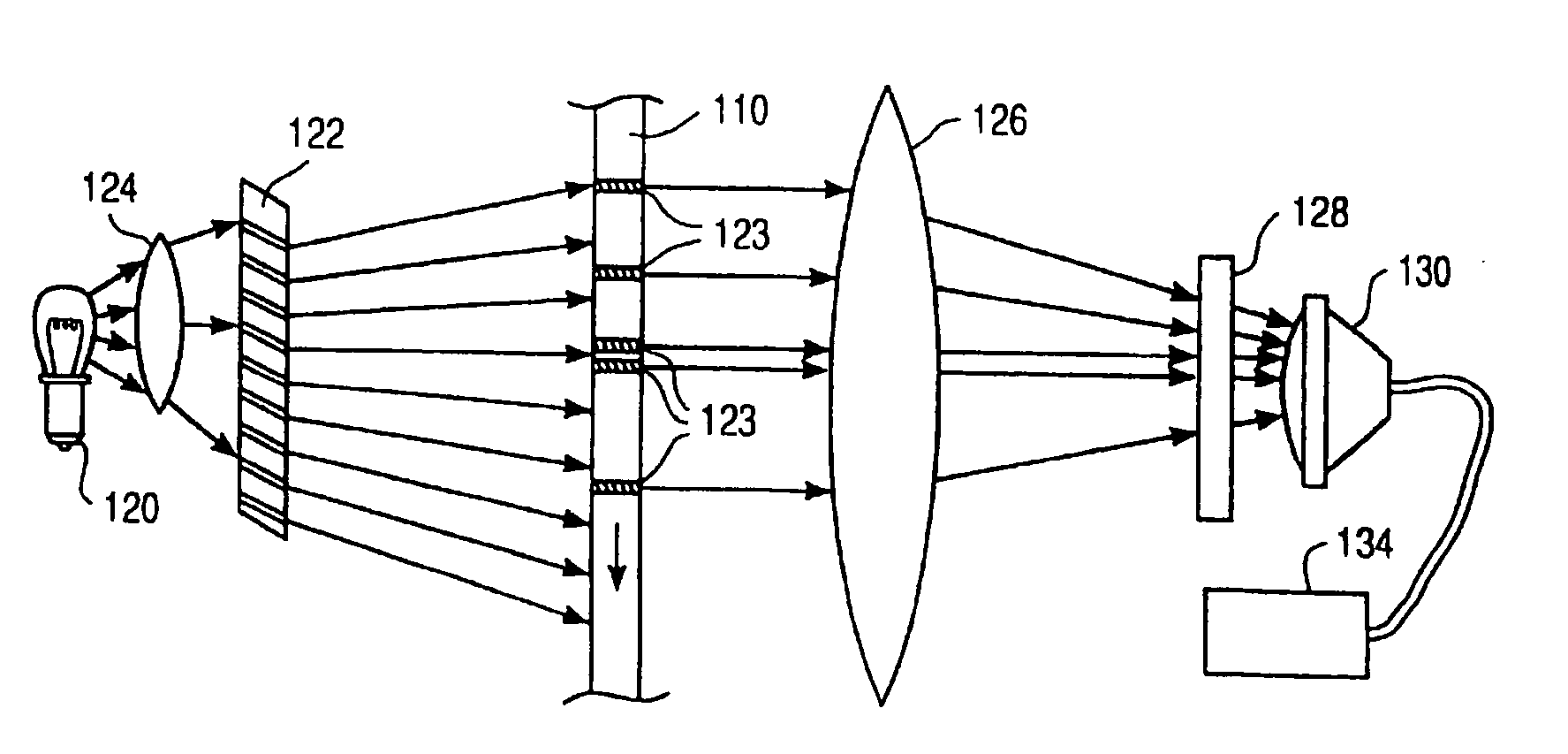

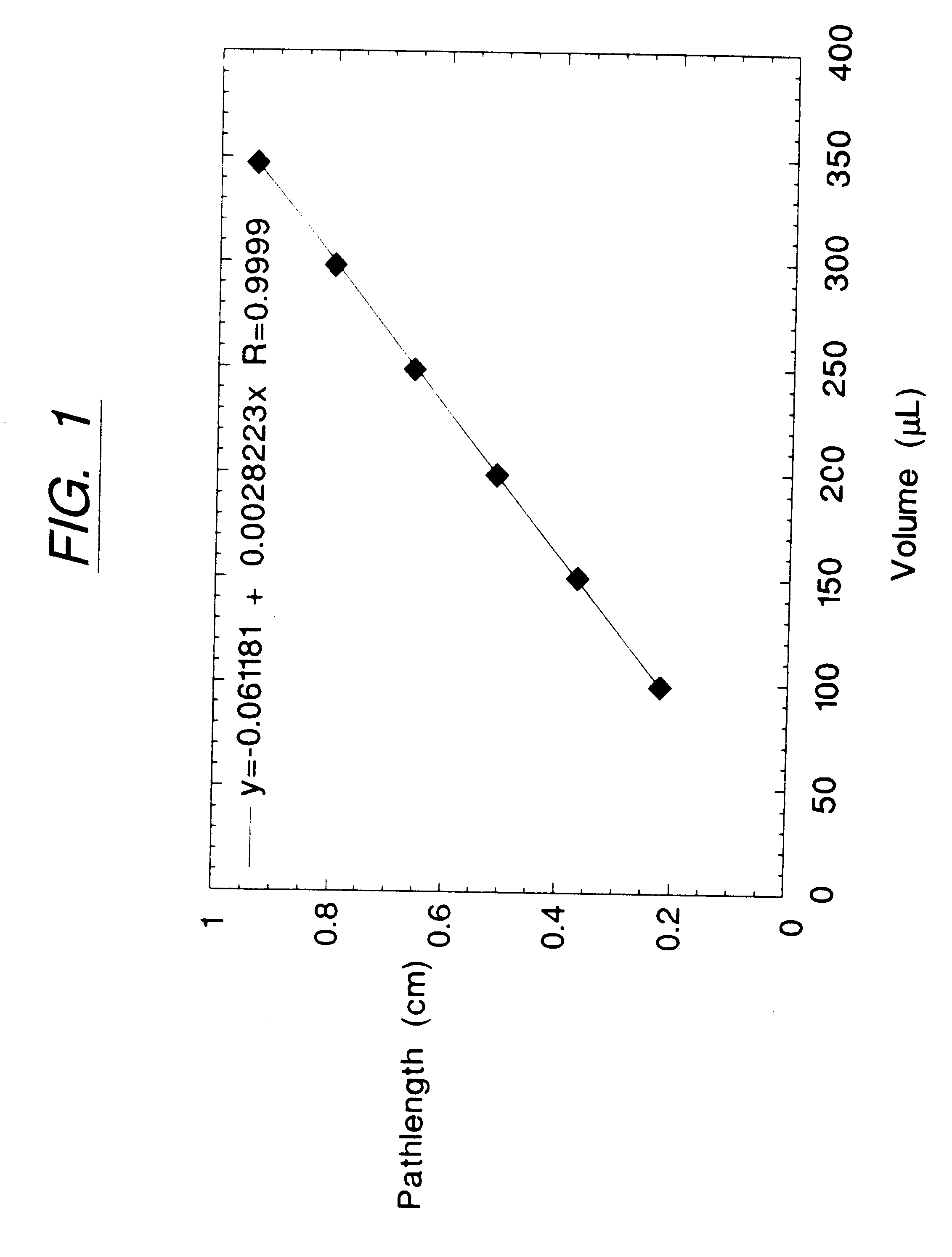

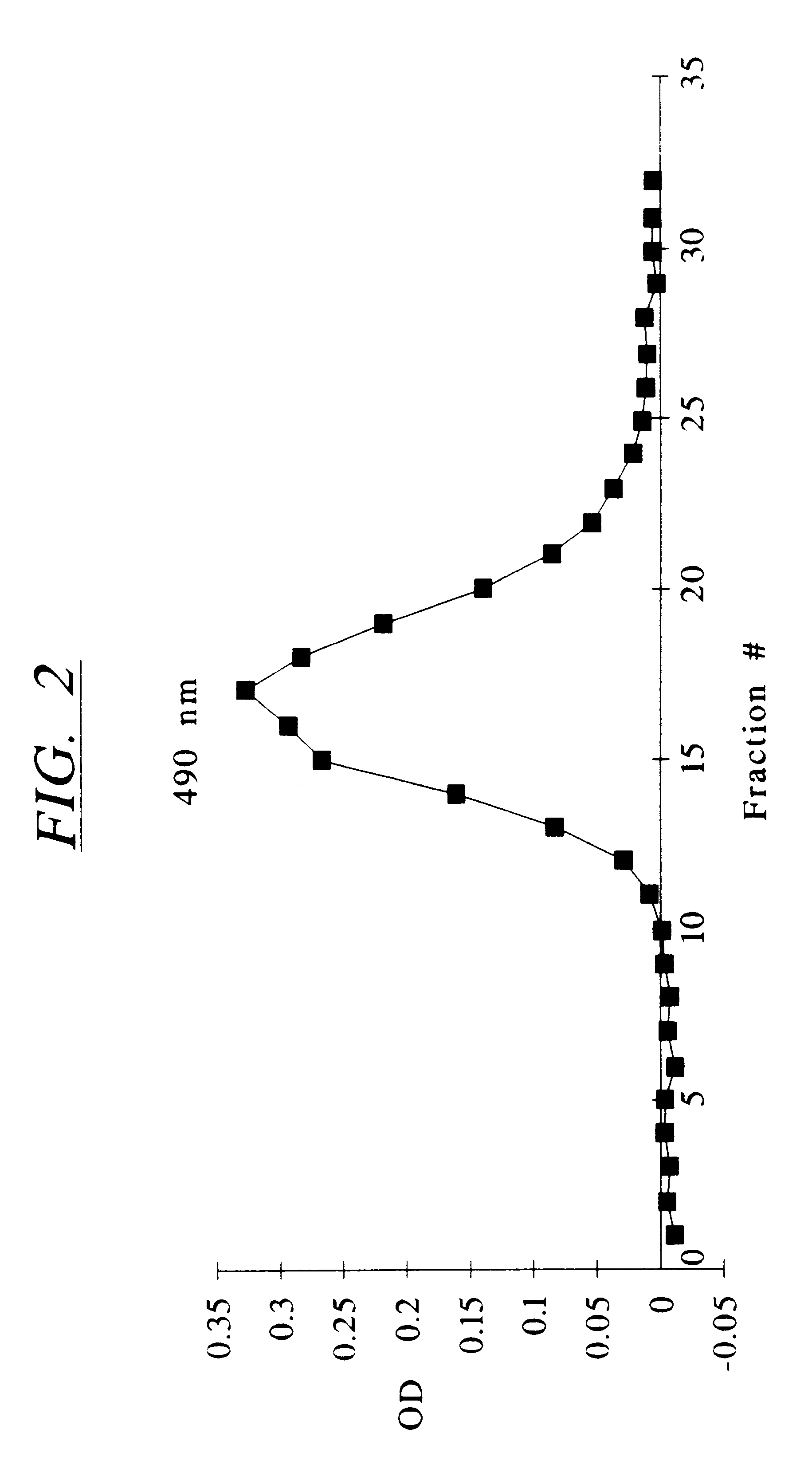

Determination of light absorption pathlength in a vertical-beam photometer

InactiveUS6188476B1Volume measurement apparatus/methodsColor/spectral properties measurementsAnalyteLight beam

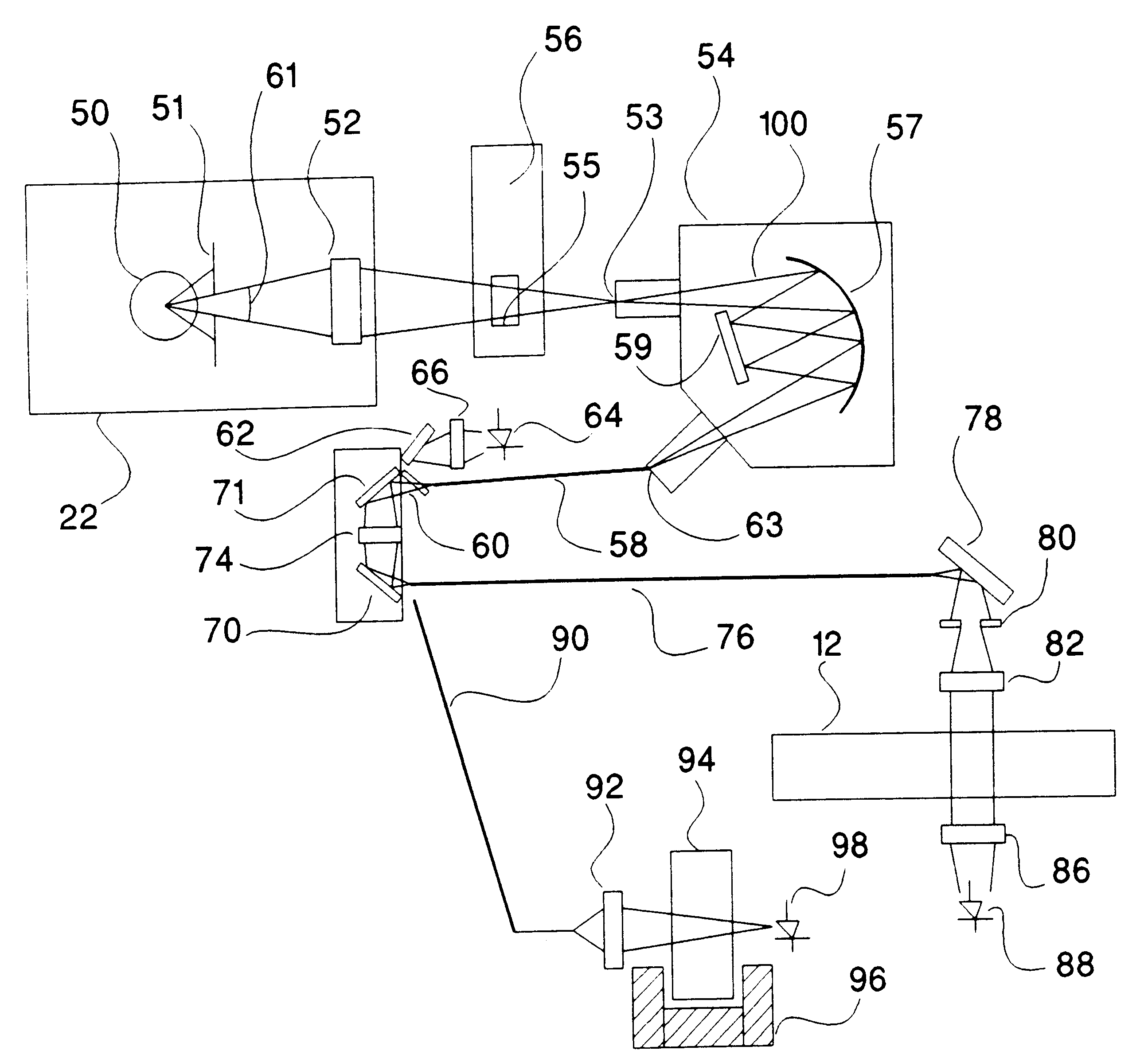

Disclosed are photometric methods and devices for determining optical pathlength of liquid samples containing analytes dissolved or suspended in a solvent. The methods and devices rely on determining a relationship between the light absorption properties of the solvent and the optical pathlength of liquid samples containing the solvent. This relationship is used to establish the optical pathlength for samples containing an unknown concentration of analyte but having similar solvent composition. Further disclosed are methods and devices for determining the concentration of analyte in such samples where both the optical pathlength and the concentration of analyte are unknown. The methods and devices rely on separately determining, at different wavelengths of light, light absorption by the solvent and light absorption by the analyte. Light absorption by the analyte, together with the optical pathlength so determined, is used to calculate the concentration of the analyte. Devices for carrying out the methods particularly advantageously include vertical-beam photometers containing samples disposed within the wells of multi-assay plates, wherein the photometer is able to monitor light absorption of each sample at multiple wavelengths, including in the visible or UV-visible region of the spectrum, as well as in the near-infrared region of the electromagnetic spectrum. Novel photometer devices are described which automatically determine the concentration of analytes in such multi-assay plates directly without employing a standard curve.

Owner:MOLECULAR DEVICES

Methods and apparatus for rendering an optically encoded medium unreadable

InactiveUS20020076647A1Increase scatteringReduce the ratioPhotography auxillary processesPhotosensitive materialsOptical radiationSinglet oxygen

Methods and apparatus are provided for making an optically readable media unreadable. The method includes steps of (a) providing the media with an optically activated mechanism that degrades the reflectivity of a surface wherein information is encoded; (b) exposing the media to optical radiation for reading out the information; and, during the step of exposing, (c) initiating the operation of the optically activated mechanism. In this embodiment the step of initiating includes steps of (d) generating singlet oxygen in a layer disposed on the media; and (e) reacting the singlet oxygen with a metal-containing layer for oxidizing the surface of the metal-containing layer, thereby degrading the reflectivity of the surface. In a further aspect the optically activated mechanism causes a defocusing of a readout beam, thereby degrading reflection of the readout beam from a surface wherein information is encoded. In another embodiment the method deforms a surface of the layer resulting in readout beam aberration or in an inability to correctly stay on track. In another embodiment a portion of the surface is removed to the atmosphere, such as by evaporation of sublimation. In this embodiment a layer of the media is comprised of a volatile component and at least one other component. Removing at least some of volatile component by evaporation or sublimation causes an increase in at least one of photoabsorption or scattering or surface roughness with the remaining component, thereby rendering at least a portion of encoded information of the media unreadable, or affecting the tracking operation.

Owner:FLEXPLAY TECH INC

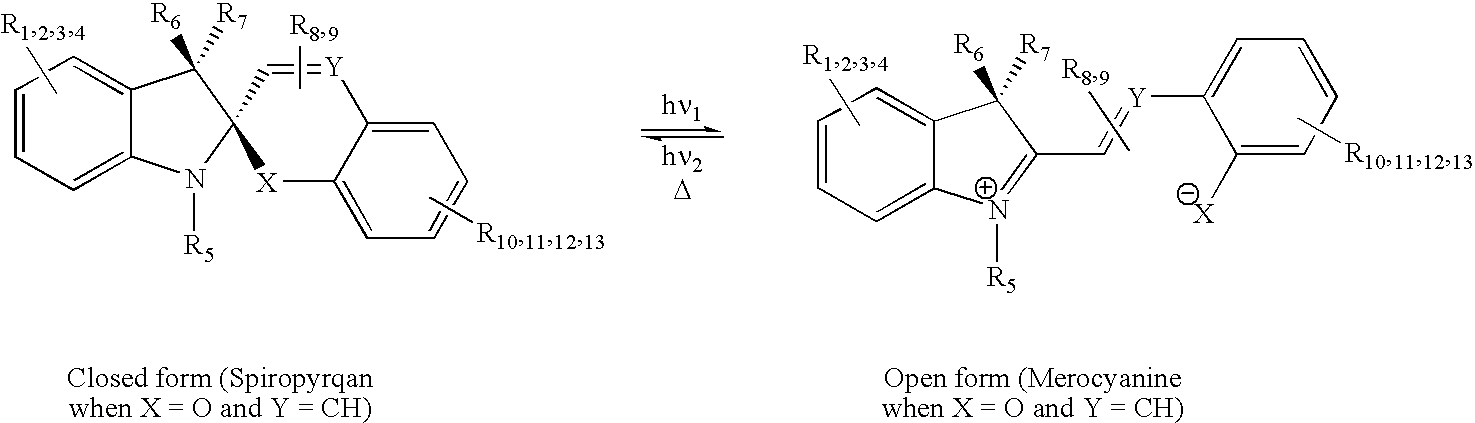

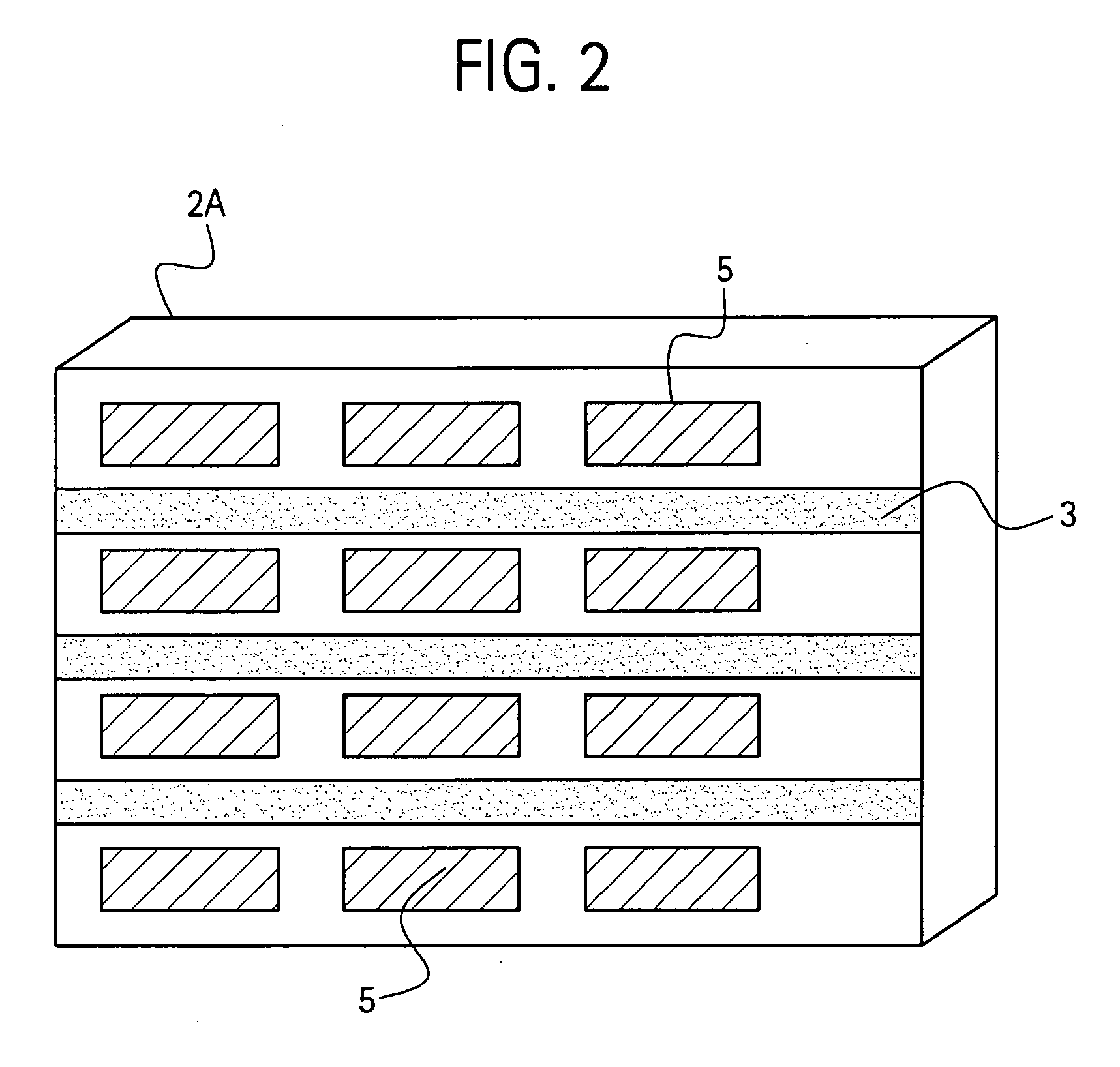

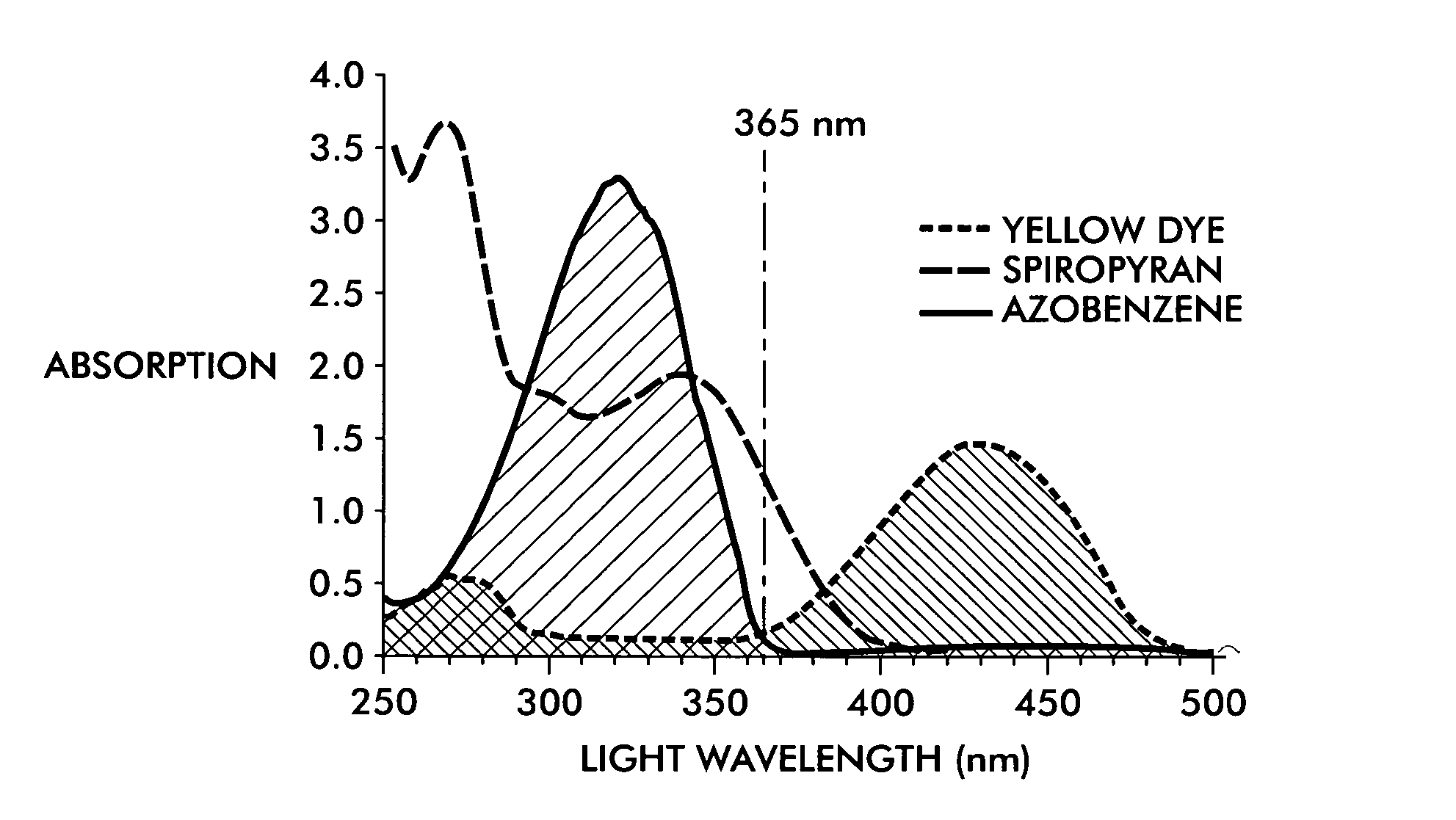

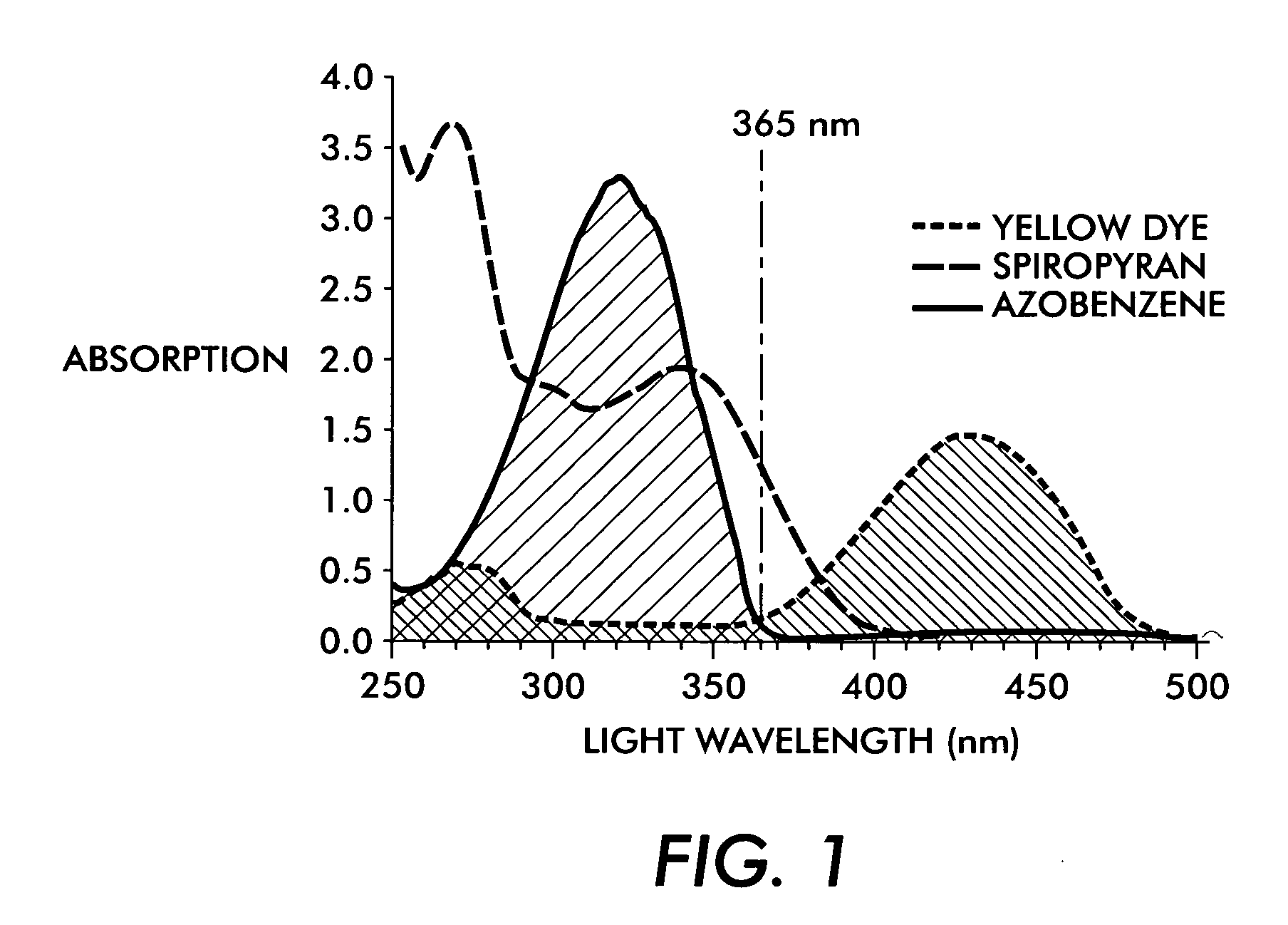

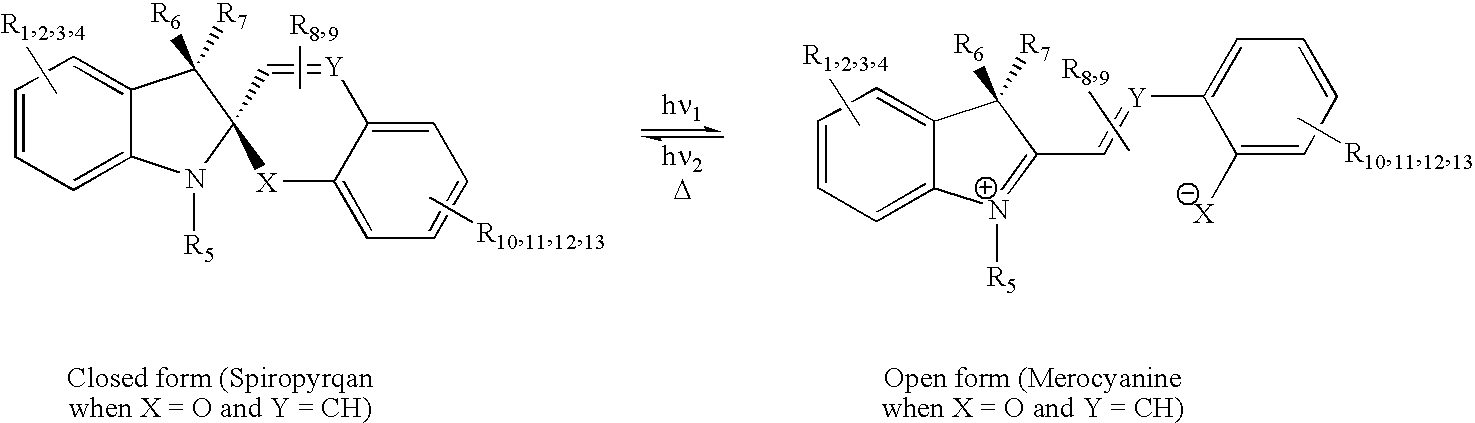

Reimageable medium with light absorbing material

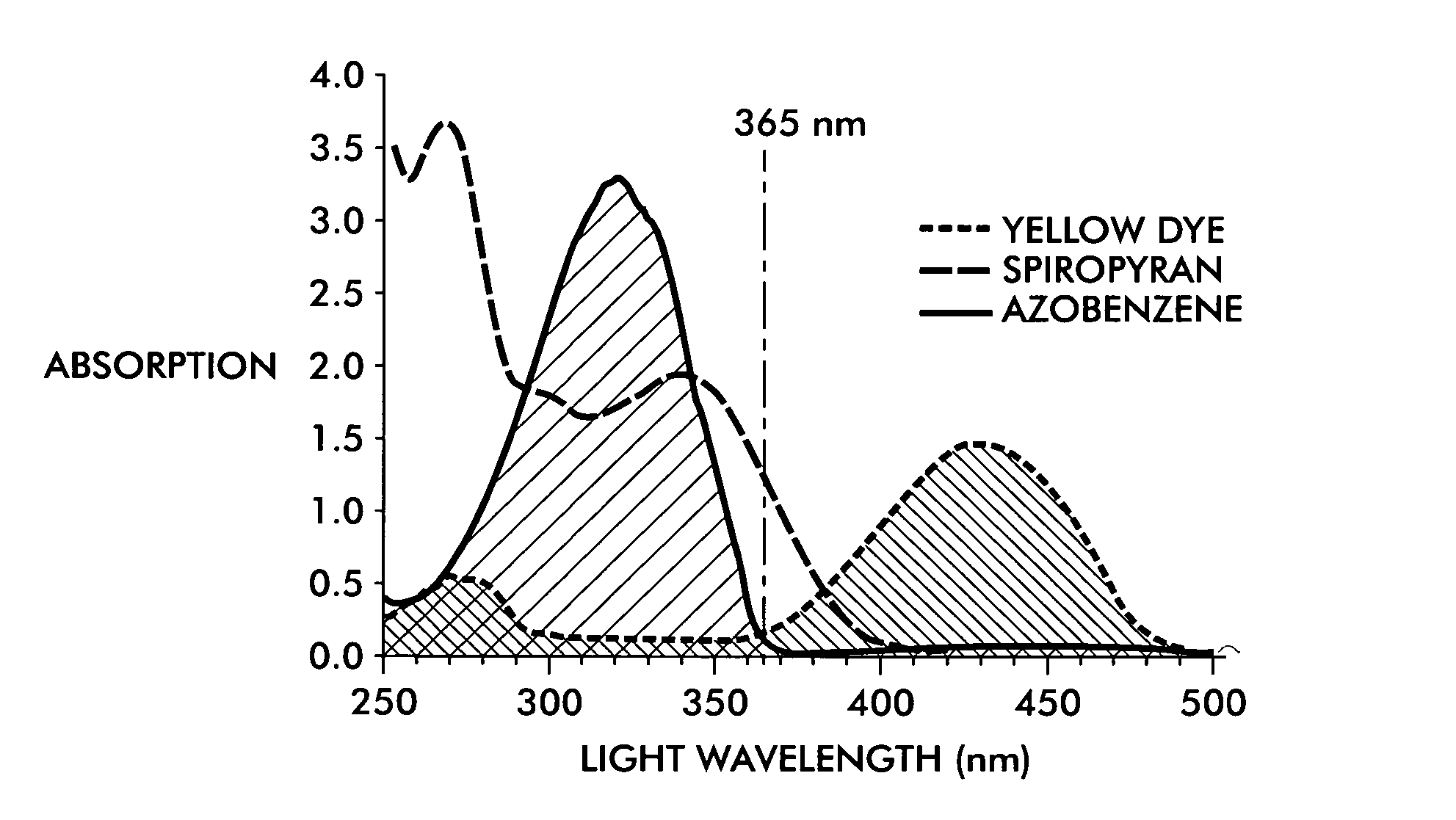

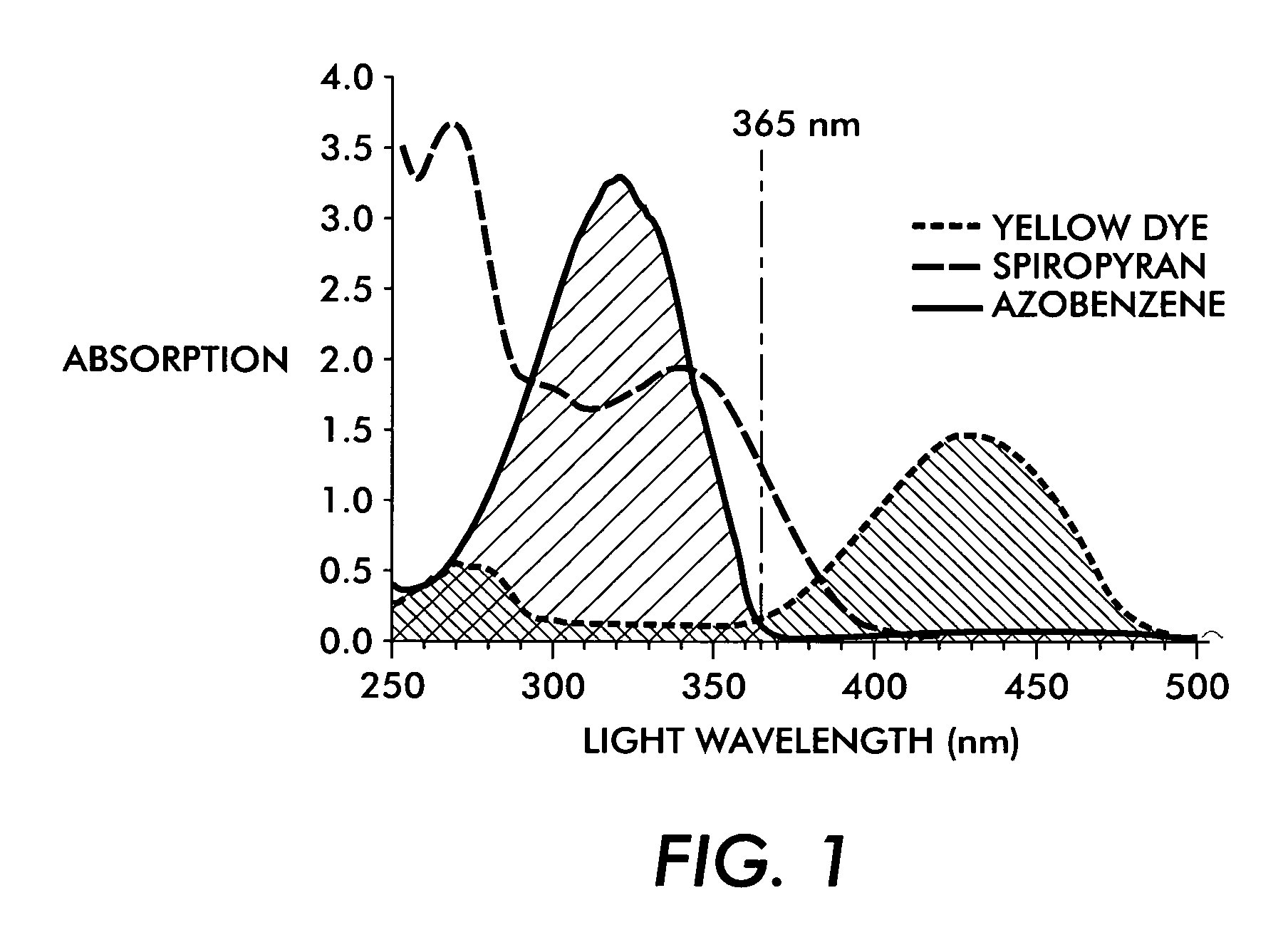

InactiveUS7205088B2Photography auxillary processesRadiation applicationsAbsorbance spectraPhotochromism

A reimageable medium for receiving an imaging light having a predetermined wavelength scope, the medium composed of: a substrate; a photochromic material capable of reversibly converting among a number of different forms, wherein one form has an absorption spectrum that overlaps with the predetermined wavelength scope; and a light absorbing material exhibiting a light absorption band with an absorption peak, wherein the light absorption band overlaps with the absorption spectrum of the one form.

Owner:XEROX CORP

Microbolometer for infrared detector or Terahertz detector and method for manufacturing the same

InactiveUS20110315981A1Improve business performanceLow costSemiconductor/solid-state device manufacturingPyrometry using electric radation detectorsComposite filmMicrobolometer

A microbolometer includes a micro-bridge structure for uncooling infrared or terahertz detectors. The thermistor and light absorbing materials of the micro-bridge structure are the vanadium oxide-carbon nanotube composite film formed by one-dimensional carbon nanotubes and two-dimensional vanadium oxide film. The micro-bridge is a three-layer sandwich structure consisting of a layer of amorphous silicon nitride base film as the supporting and insulating layer of the micro-bridge, a layer or multi-layer of vanadium oxide-carbon nanotube composite film in the middle of the micro-bridge as the heat sensitive and light absorbing layer of the microbolometer, and a layer of amorphous silicon nitride top film as the stress control layer and passivation of the heat sensitive film. The microbolometer and method for manufacturing the same can overcome the shortcomings of the prior art, improve the performance of the device, reduce the cost of raw materials and is suitable for large-scale industrial production.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

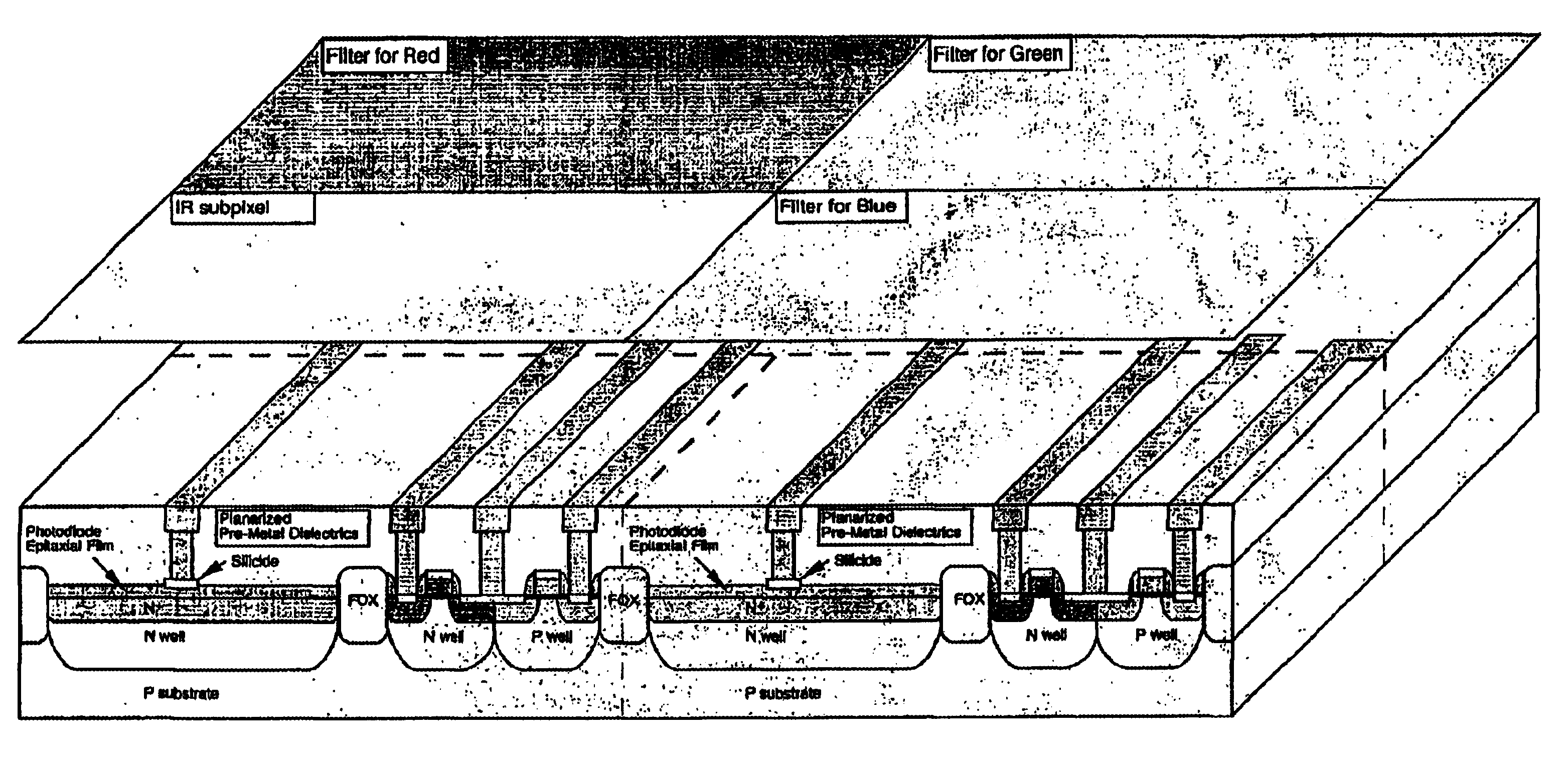

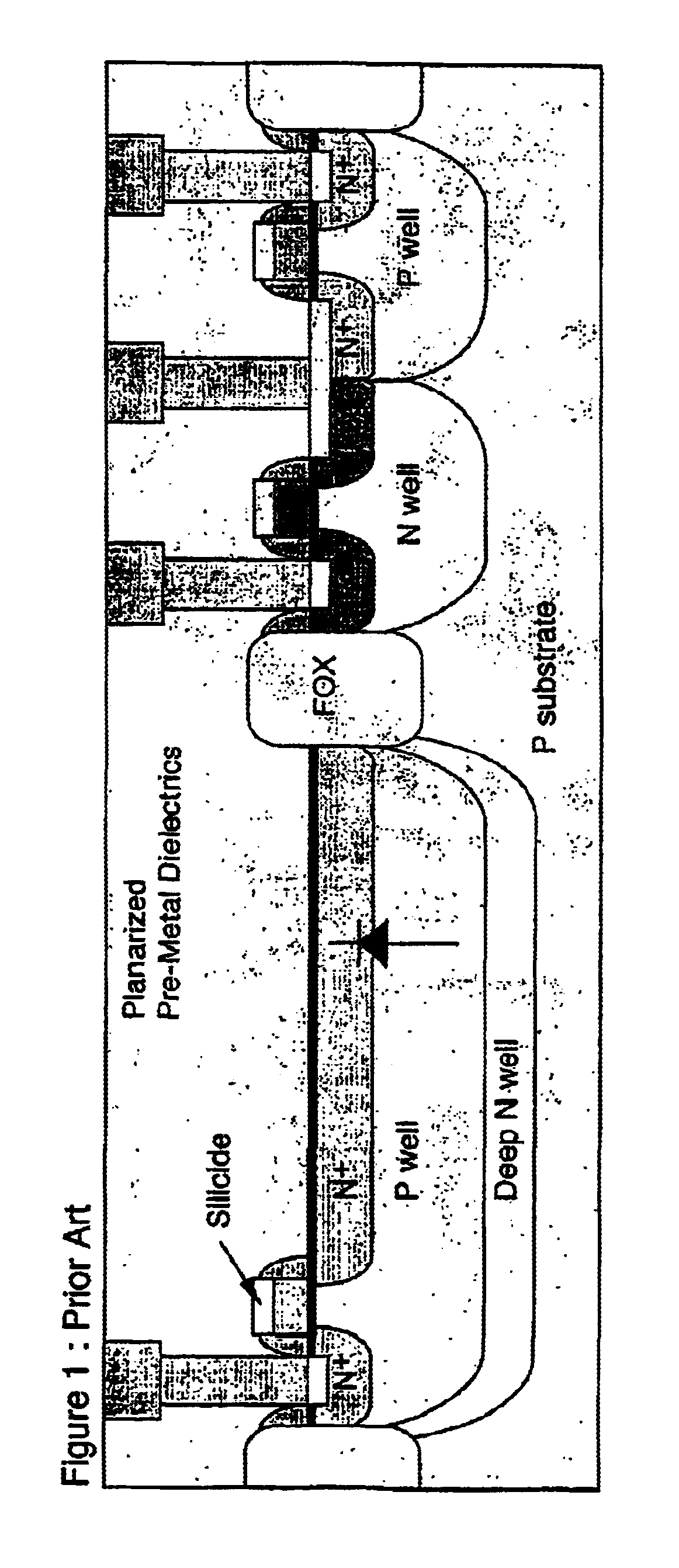

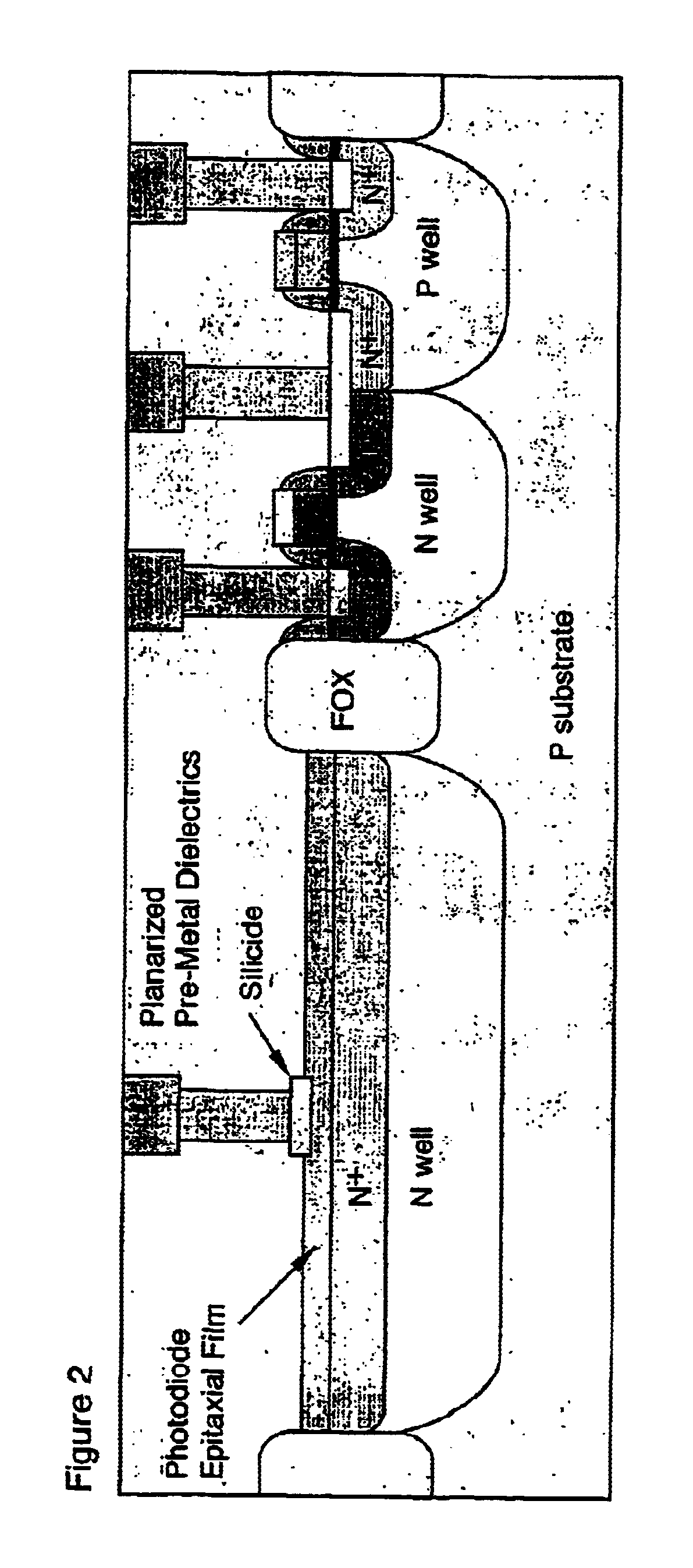

Method of fabricating heterojunction photodiodes integrated with CMOS

Owner:QUANTUM SEMICON

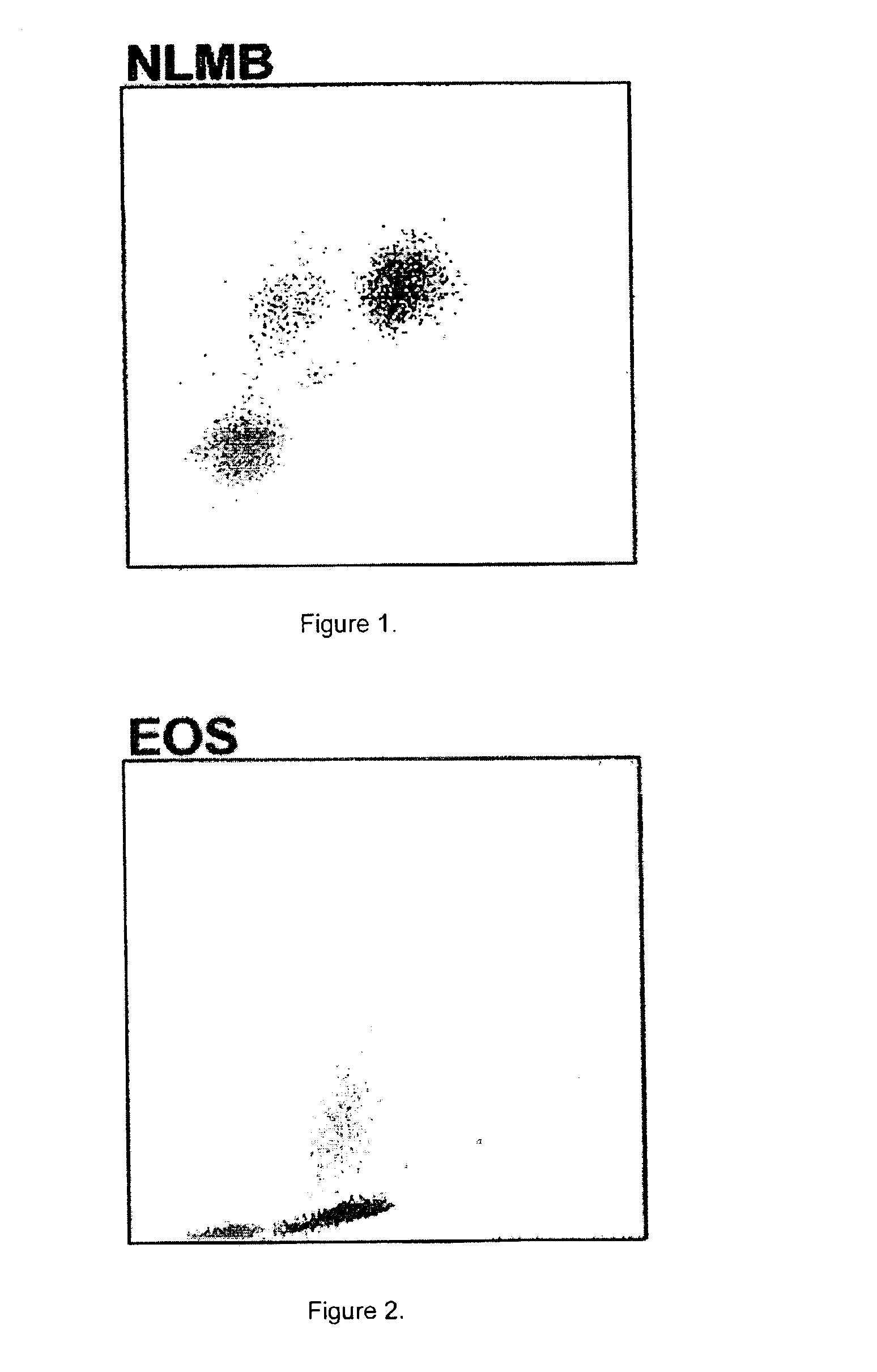

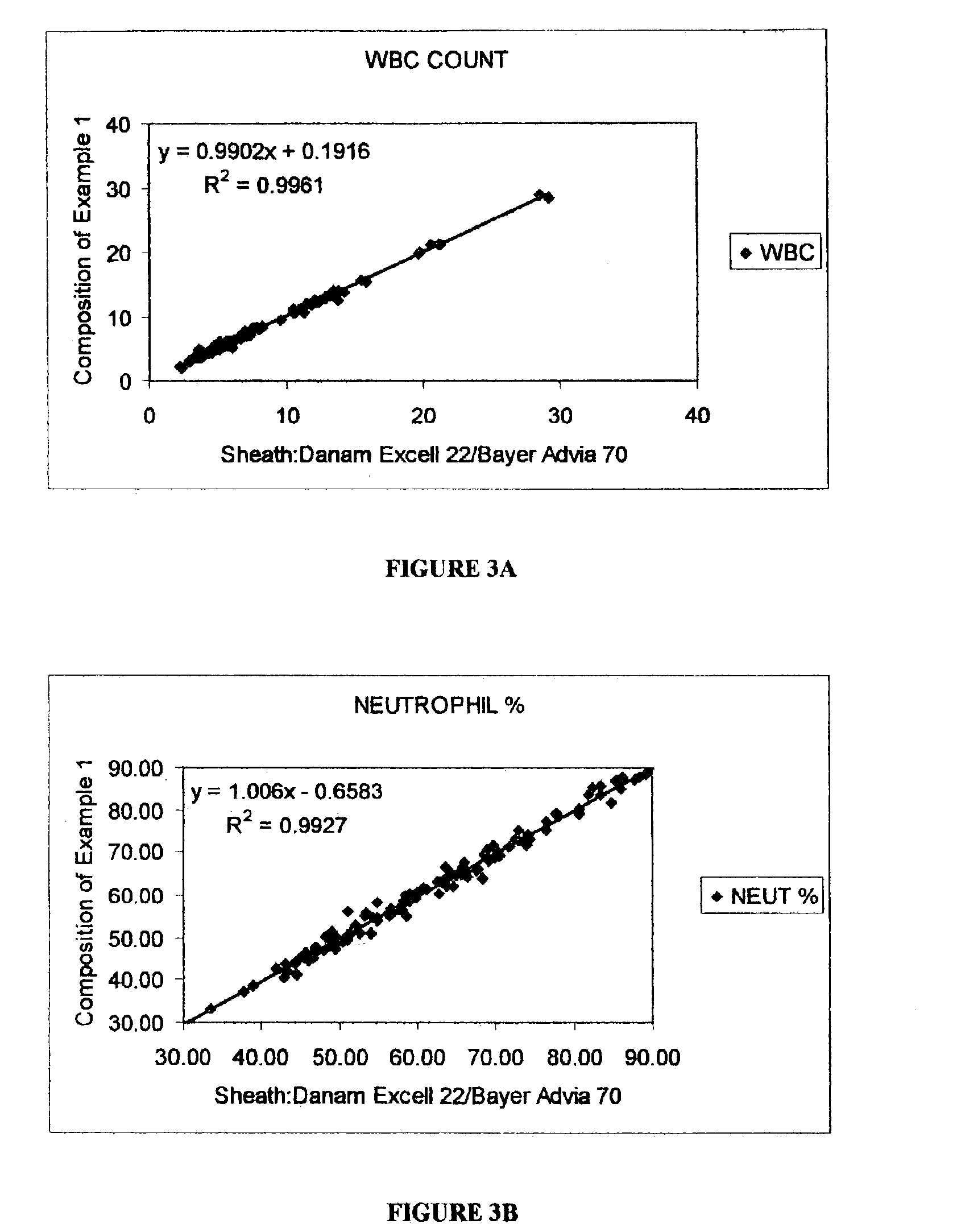

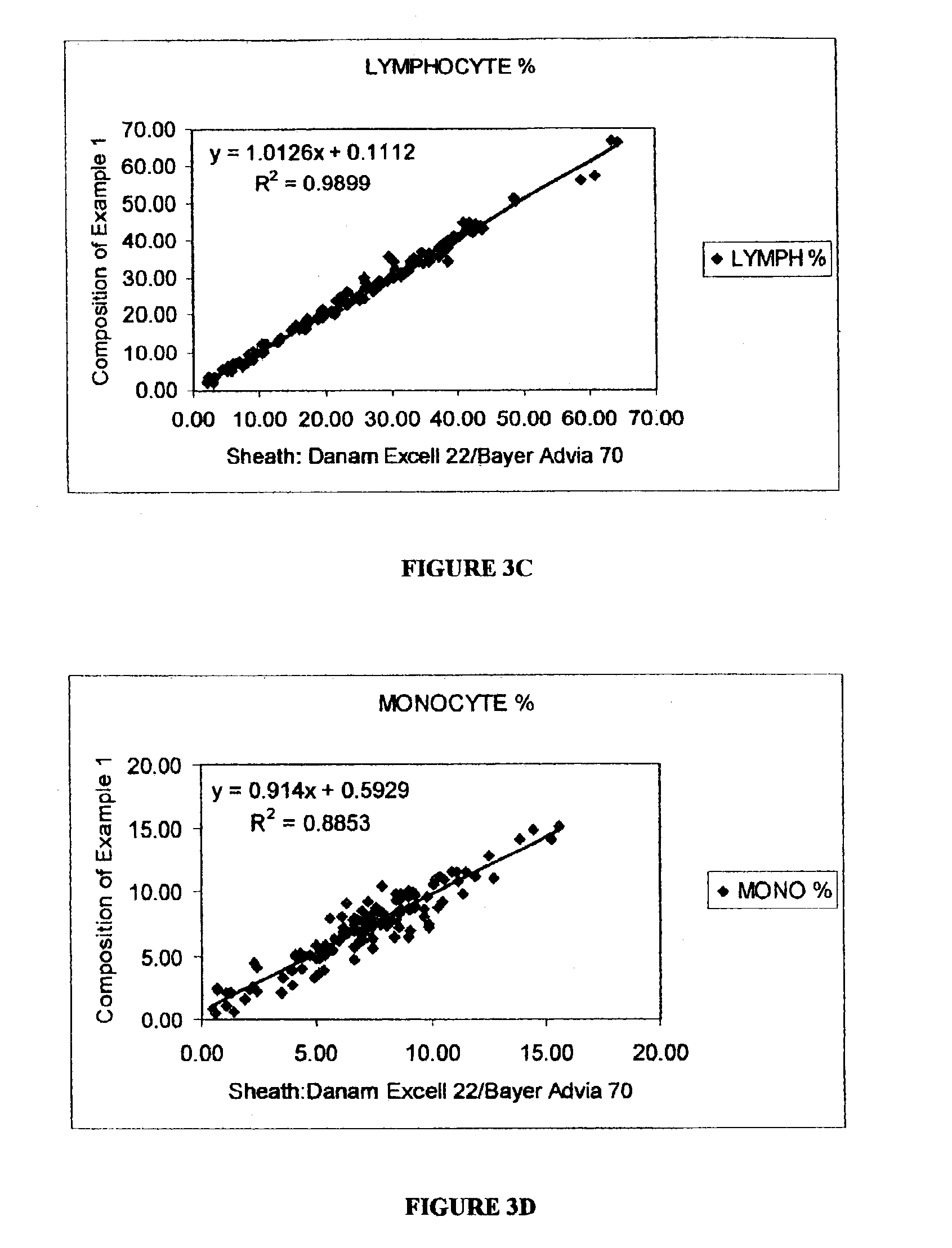

Lytic reagent composition for leukocyte differential analysis

InactiveUS6869798B2Effect counting accuracyLow rangeMicrobiological testing/measurementDead animal preservation2-propoxyethanolWhite blood cell

A lytic reagent composition and the method of use for differential analysis of leukocytes using flow cytometry are disclosed. The lytic reagent composition includes a short chain alkyl oxyethanol, such as 2-methoxyethanol, 2-ethoxyethanol, 2-propoxyethanol, or 2-isopropoxyethanol, in a sufficient amount to preserve leukocytes; a non-lysing nonionic surfactant as a debris solublizer; and an inorganic buffer to maintain pH of the lytic reagent composition in a range from 9.1 to 10.7. The lytic reagent composition is used to lyse red blood cells and preserve leukocytes, as well as used as the sheath reagent for the focus flow measurement. The lytic reagent composition, when used on a flow cytometric analyzer with multiple angle light scatter and light absorbance measurements, enables differentiation of leukocytes into five subpopulations.

Owner:CLINICAL DIAGNOSTICS SOLUTIONS

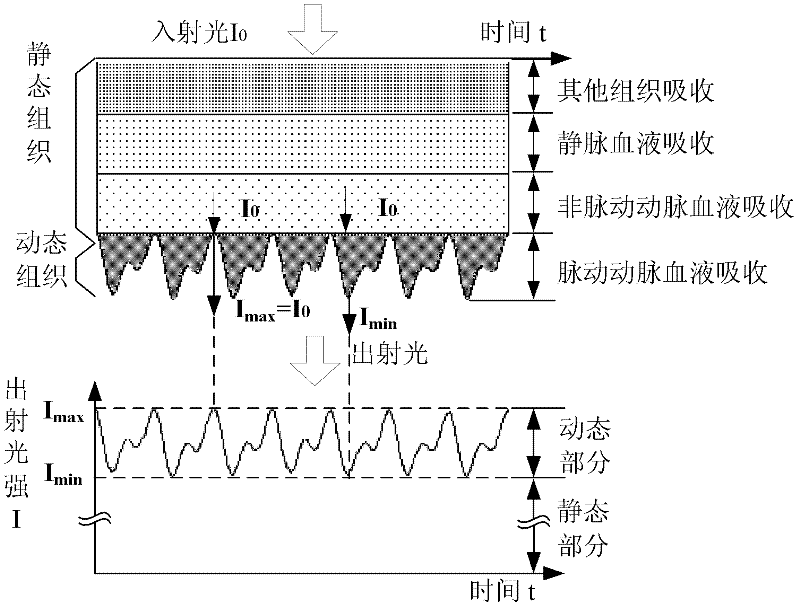

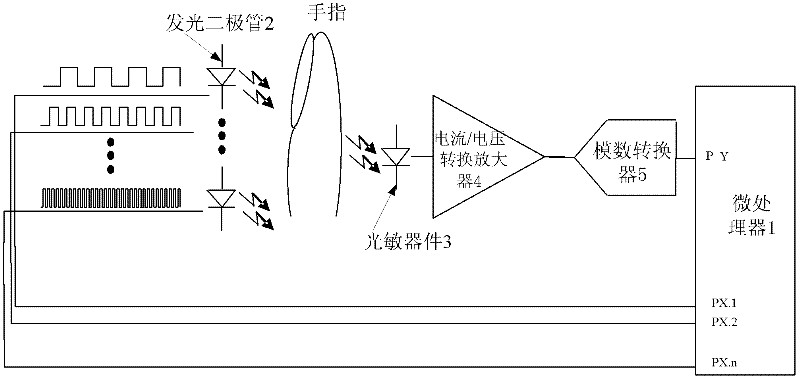

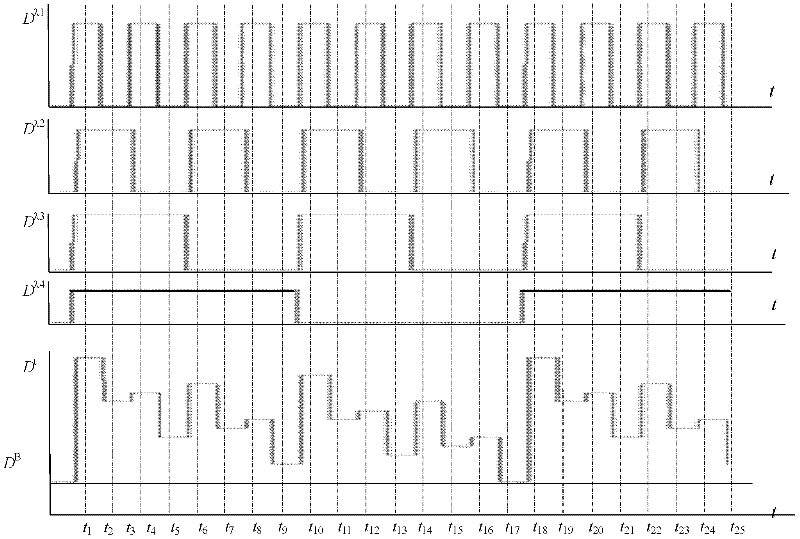

Device and method for measuring square wave modulated photoelectric volume pulse wave

ActiveCN102389313AAccurate measurementNo need to debugCatheterDiagnostic recording/measuringMeasurement devicePeak value

The invention discloses a device and a method for measuring square wave modulated photoelectric volume pulse wave. A microprocessor outputs square waves which have different frequencies and form a double ratio relationship; the square waves drive at least two light-emitting diodes; the light from the light-emitting diodes are received by a photosensitive device after passing through tested finger; the photosensitive device converts the light into a voltage signal; the voltage signal is converted into a predefined amplitude value voltage signal by a current / voltage conversion amplifier; an analogue-to-digital converter converts the predefined amplitude value voltage signal into a digital signal; the microprocessor processes the digital signal to obtain photoelectric volume pulse wave and valley value and peak value thereof, and gets spectrum value by the valley value and the peak value. The measurement method comprises the following steps of: separating the digital signal to obtain the photoelectric volume pulse wave and removing interference of background light by the microprocessor; getting the valley value and the peak value according to the photoelectric volume pulse wave; and calculating the valley value and the peak value to obtain light absorbance difference, and obtaining the spectrum value by the light absorbance difference. The accurate measurement, simple circuit and low cost are realized.

Owner:TIANJIN UNIV

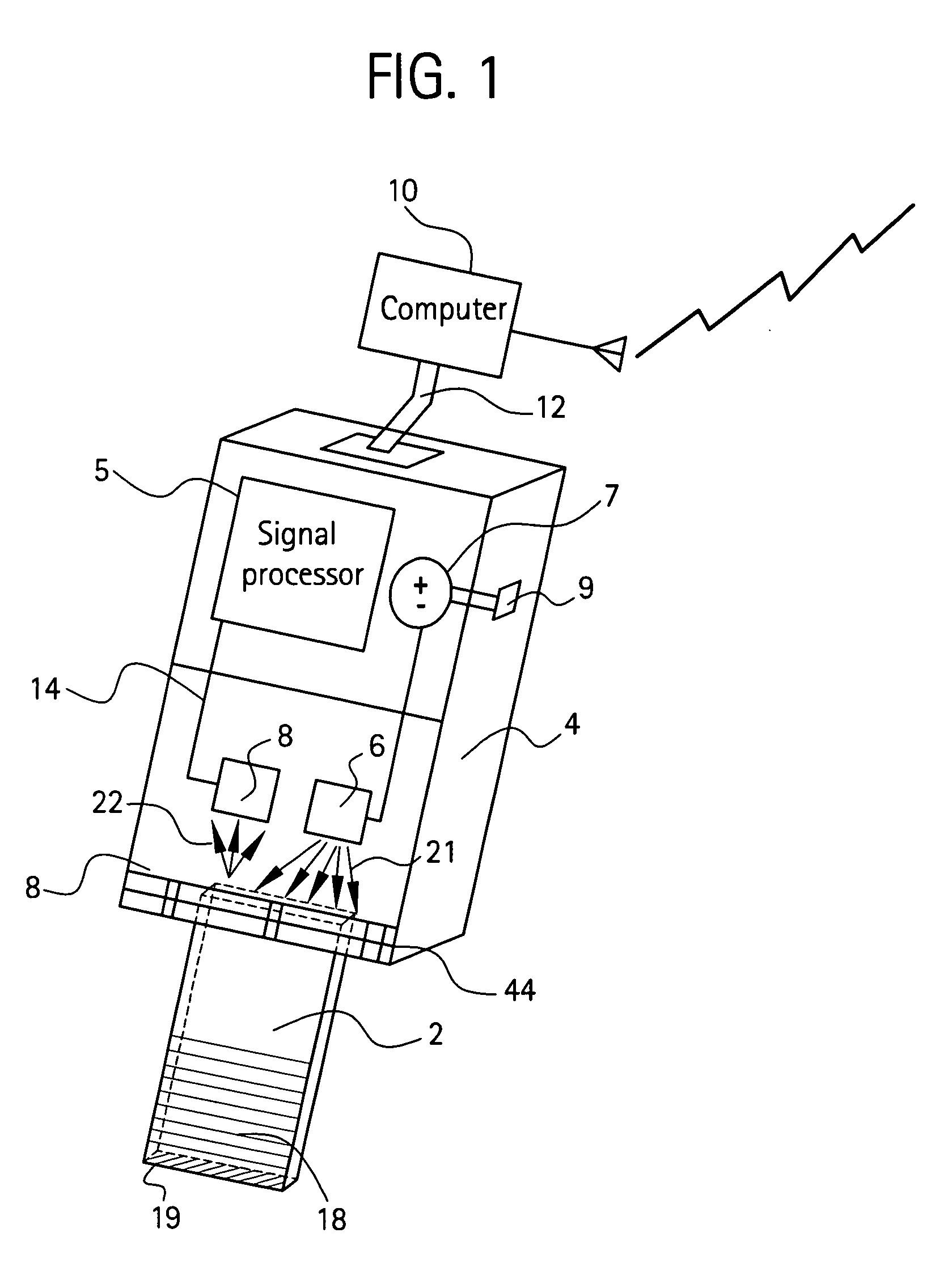

Handheld device with a disposable element for chemical analysis of multiple analytes

ActiveUS20050157304A1Easy to carryImprove responseMaterial analysis by observing effect on chemical indicatorInvestigating moving sheetsInformation processingAnalysis data

A portable system and method for measuring the concentration of multiple chemical or biological substances where an onsite analysis of such substances is needed. The new and original handheld sensor system uses a disposable optical test element and a spectroscopic detector that measures the test element response to specific analytes through a change in light absorbance, luminescence, and other forms of light-based response. In this way, reflection light intensities indicative of the test element response can be used to measure the concentration of the target analytes. The sensor system is also capable of being interfaced to an information processing unit or computer so that analytical data can be manipulated or stored electronically.

Owner:BL TECH INC

Method and apparatus for determining the calorific value of a natural gas optically and in real time

InactiveUS6157455ALow costAccurate measurementRadiation pyrometryColor/spectral properties measurementsLight beamProduct gas

Natural gas whose calorific value is to be determined is illuminated with a light beam that is applied by a measurement head and that defines three measurement bands with different wavelength ranges each having a bandwidth of 10 nm to 20 nm and all situated in the near infrared. The intensity of each light beam is measured after it has passed through the gas, and the calorific value of the natural gas is computed in situ and in real time on the basis of the optical absorption values obtained by measuring the intensities of the light beam after it has passed through the gas.

Owner:GAZ DE FRANCE

Reimageable medium with light absorbing material

InactiveUS20050244742A1Photography auxillary processesRadiation applicationsLength wavePhotochromism

A reimageable medium for receiving an imaging light having a predetermined wavelength scope, the medium composed of: a substrate; a photochromic material capable of reversibly converting among a number of different forms, wherein one form has an absorption spectrum that overlaps with the predetermined wavelength scope; and a light absorbing material exhibiting a light absorption band with an absorption peak, wherein the light absorption band overlaps with the absorption spectrum of the one form.

Owner:XEROX CORP

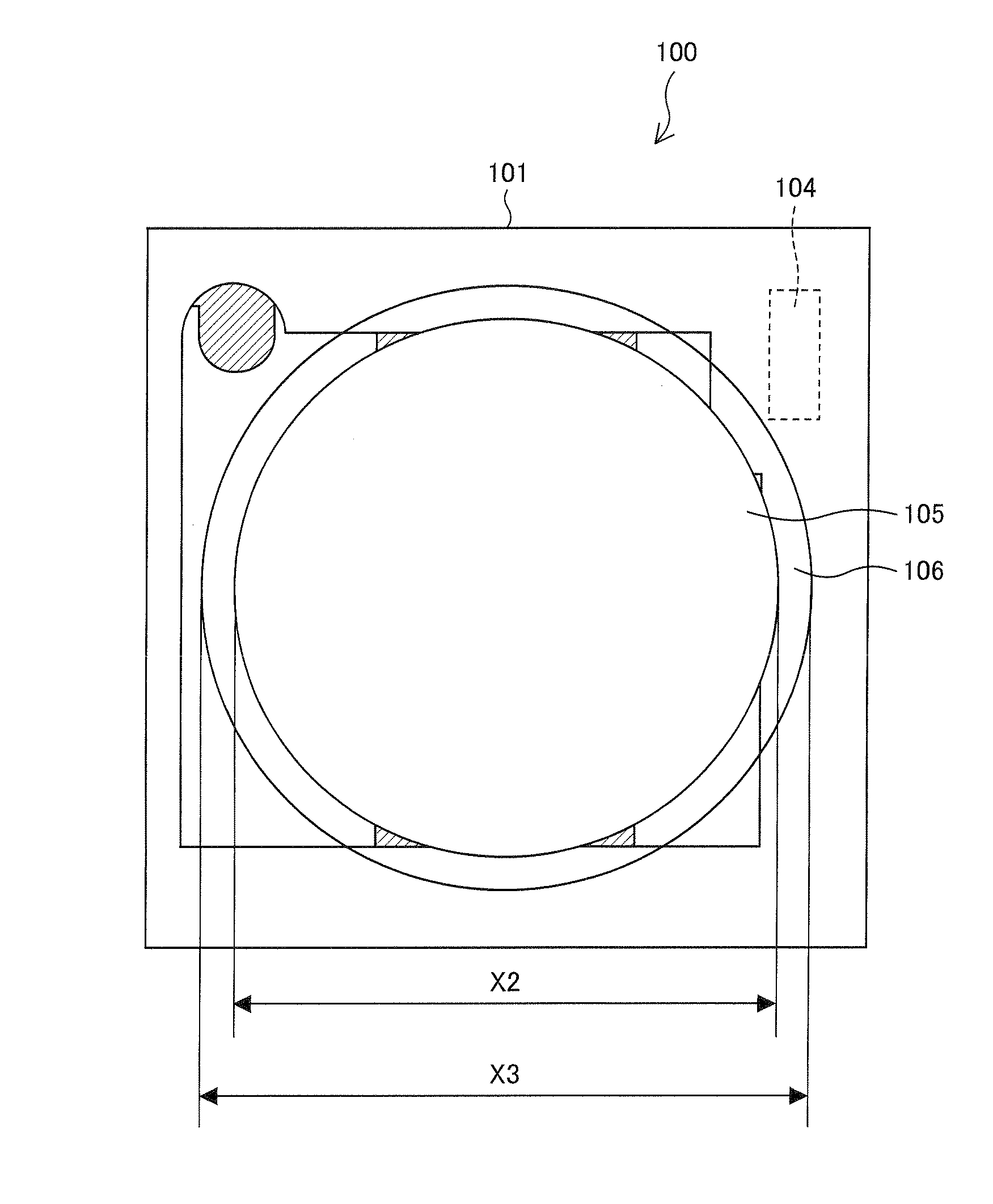

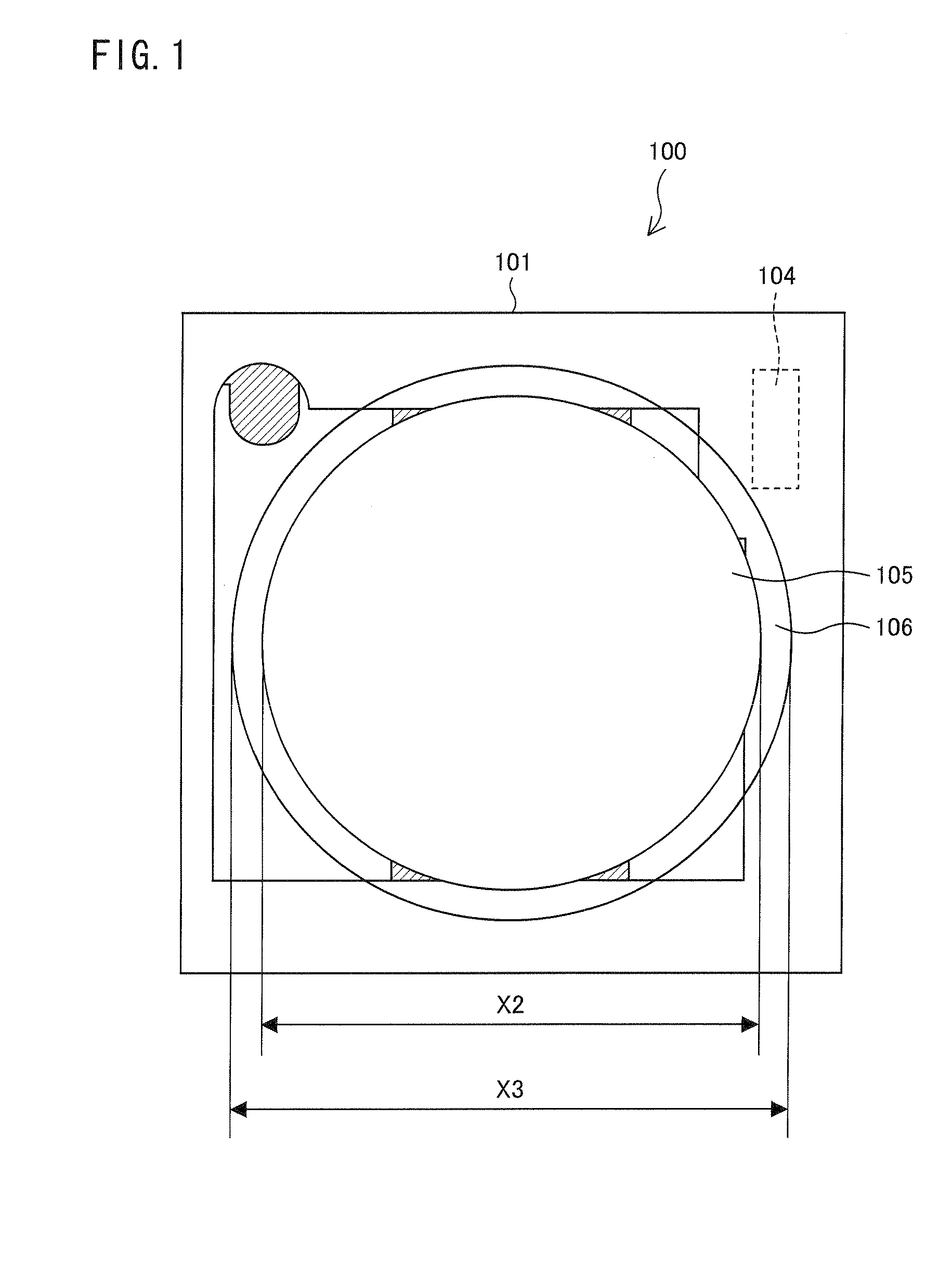

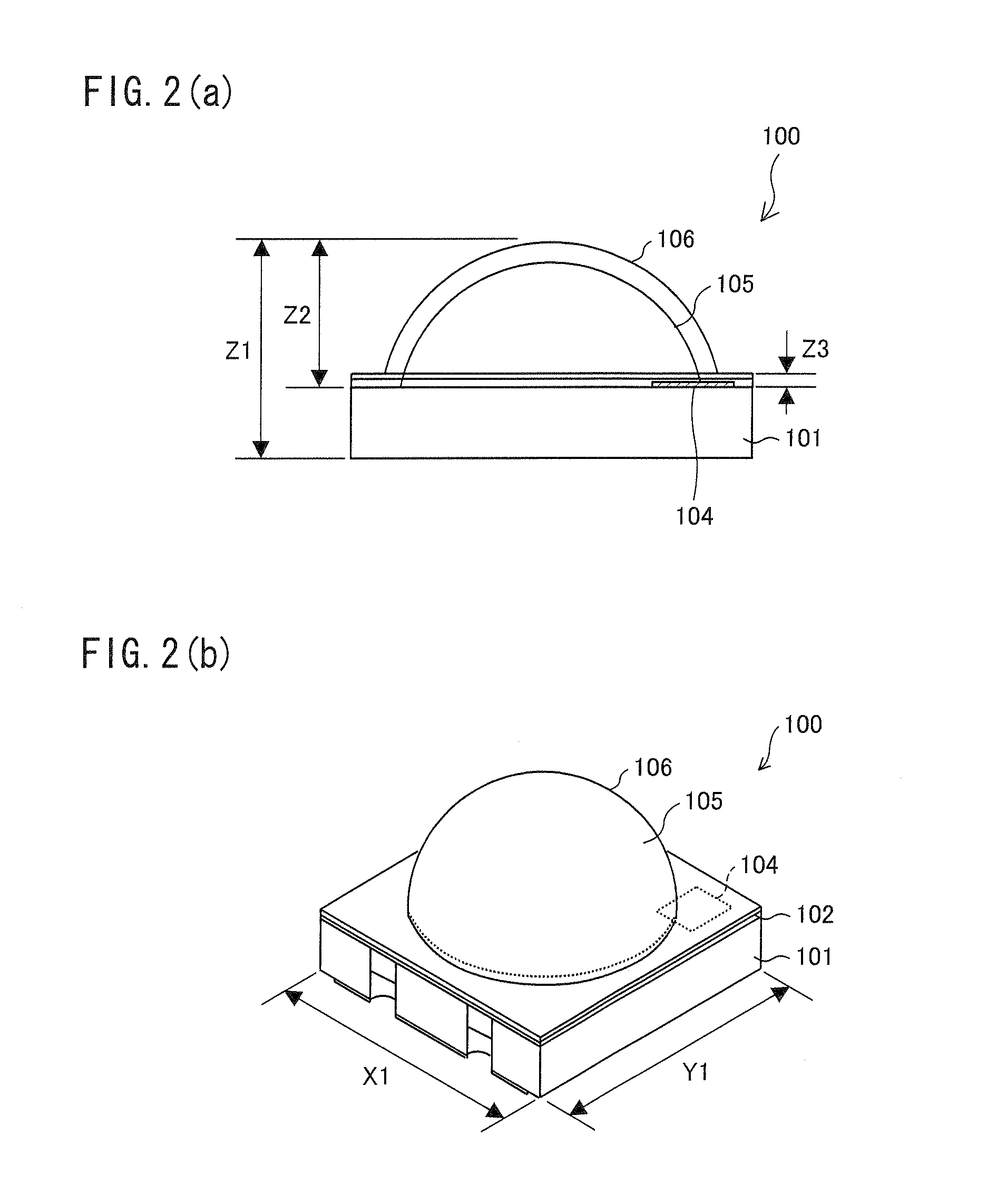

Light emitting device and method for manufacturing same

ActiveUS20110001156A1Reduction in optical outputReduce outputSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceResistor

A light emitting device includes: a substrate; an LED chip provided on a main surface of the substrate; and a printed resistor element connected in parallel with the LED chip, the printed resistor element being provided in at least one of regions (i) on the main surface of the substrate, (ii) on a back surface of the substrate, and (iii) inside the substrate. According to the arrangement, it is possible to provide: a light emitting device which can emit light having preferable luminance without a reduction in optical output by suppressing light shielding and light absorption of light emitted from the LED toward the outside; and a method for manufacturing the light emitting device.

Owner:HEAVY DUTY LIGHTING LLC

Continuous spectroscopic measurement of total hemoglobin

ActiveUS20070060809A1Fast informationEasy to readDiagnostics using spectroscopyCatheterPhotodetectorTotal hemoglobin

Methods for measuring the total hemoglobin of whole blood include measuring reflective light at multiple wavelengths within the visible spectrum, calculating light absorbance at each of the multiple wavelengths, performing a comparison in a change in like absorbance between the multiple wavelengths, and / or relating the comparison to total hemoglobin. A system for measuring total hemoglobin of whole blood may include at least one light source, a catheter, optical fibers, at least one photodetector, data processing circuitry, and / or a display unit.

Owner:EDWARDS LIFESCIENCES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com